Circulating fluidized bed type high temperature hot blast stove system

A technology of circulating fluidized bed and high-temperature hot blast stove, which is applied in the direction of fluidized bed combustion equipment, fluid heater, combustion type, etc. It can solve the problems of small load adjustment range, dew point corrosion, unstable operation, etc., and save alloy steel , increase the degree of turbulence, and ensure the effect of air velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

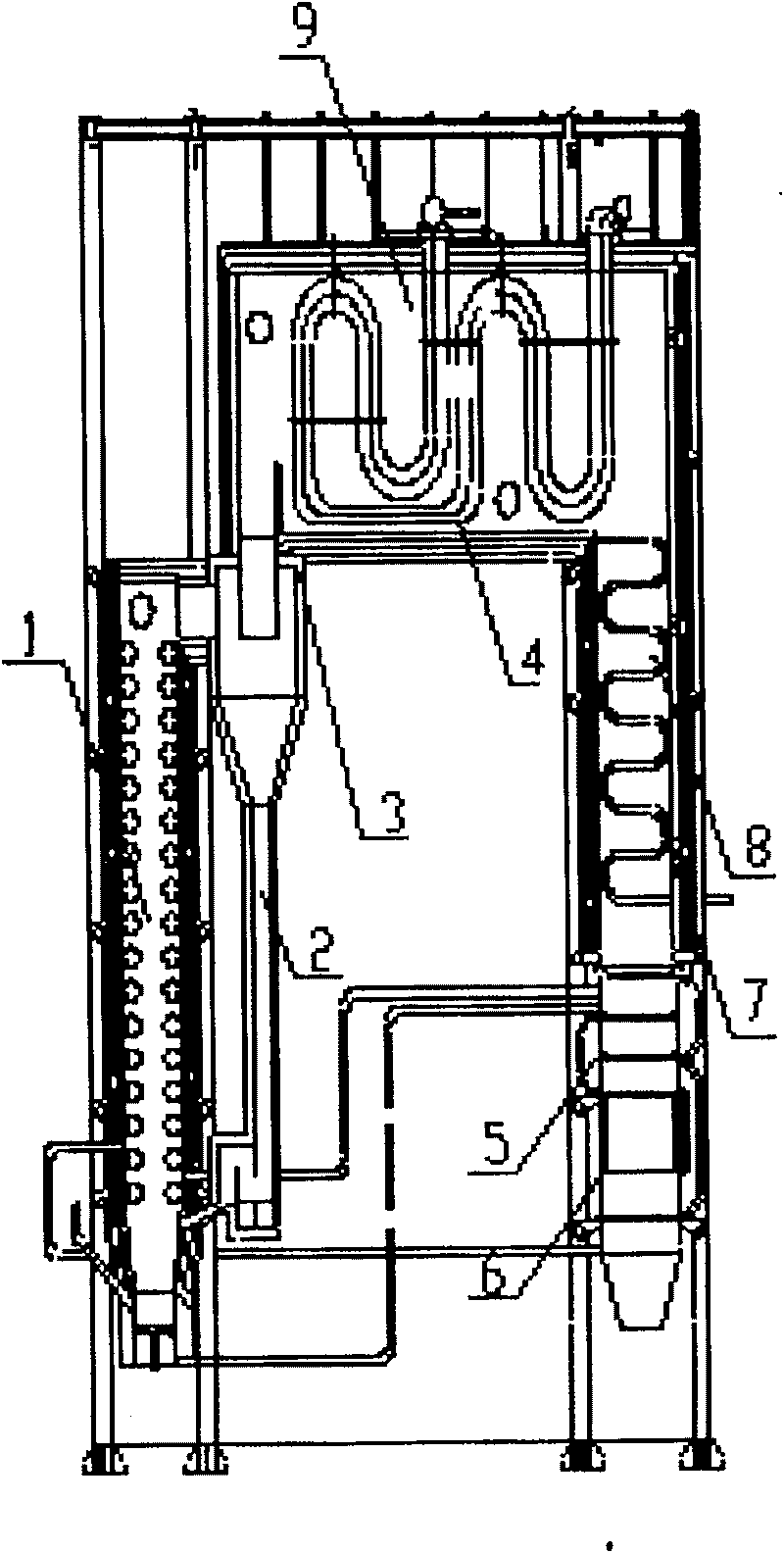

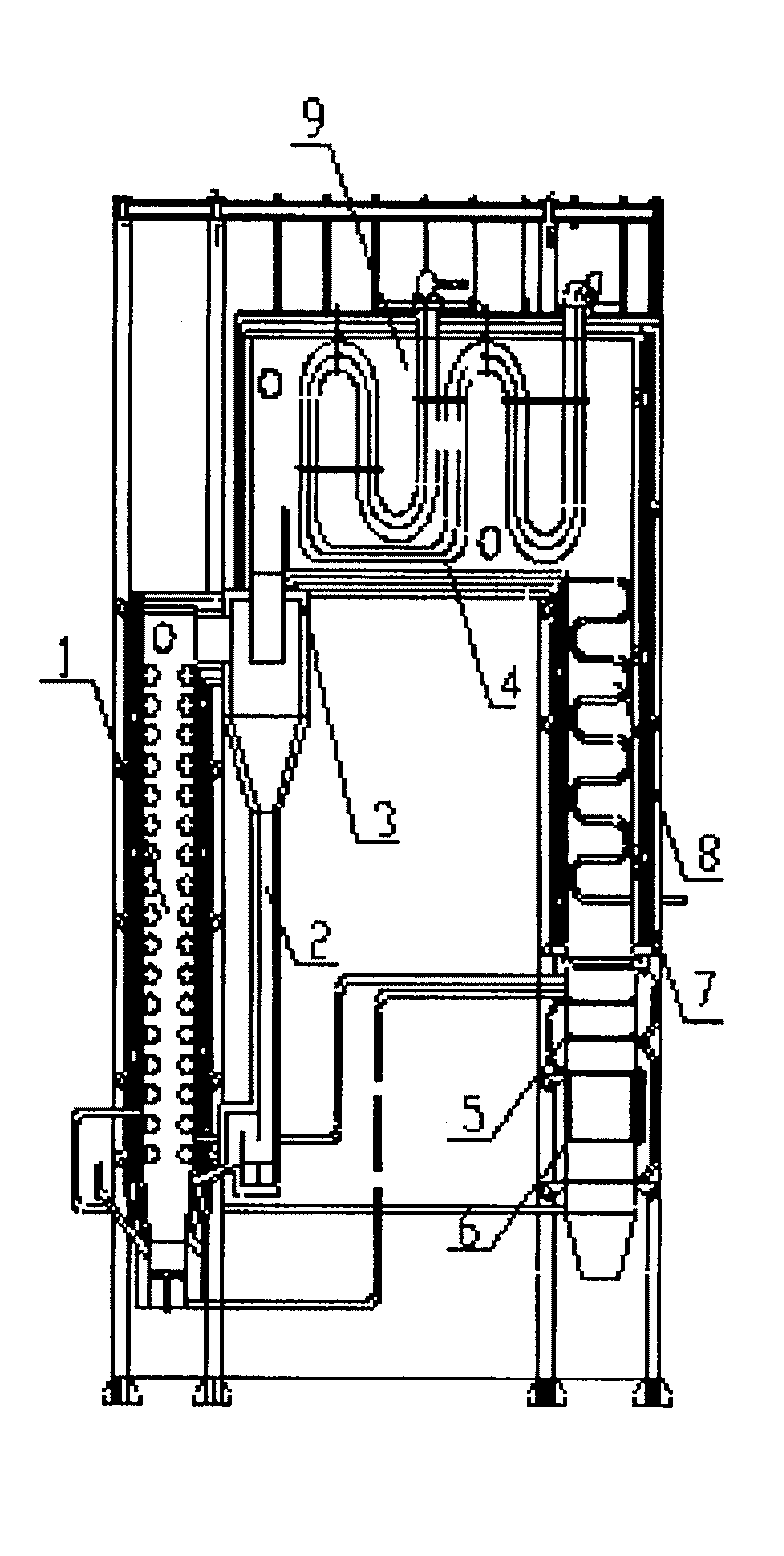

[0018] Referring to the accompanying drawings, a cyclone separator 3 is provided at the outlet of the circulating fluidized bed furnace 1 of the present invention, the bottom of the cyclone separator 3 is connected to the standpipe 2, and the top is connected to the horizontal flue 9, and a high-temperature flue is arranged in the horizontal flue 9. The heat exchanger 4, the end of the horizontal flue 9 is connected to the vertical tail flue 8, and the tail flue 8 is arranged in sequence from top to bottom with a low-temperature heat exchanger 7, a high-temperature air preheater 5, and a low-temperature air preheater 6 . The air distribution device adopts a hood-type air distribution plate to support the static fuel layer, maintain the stability of the fluidized bed layer, and increase the airflow resistance. The feeder adopts a flow sealing valve, which can ensure stable material flow, no gas backflow and controllable material flow, and can adapt to changes in boiler operatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com