Fine coal pressurization dense phase transporting bed gasification method and device

A gasification device and transport bed technology, applied in the field of gasification, can solve the problems of reduced efficiency and economy, high oxygen consumption, and large investment, so as to improve the overall carbon utilization rate, high gasification efficiency, and reduce the overall investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

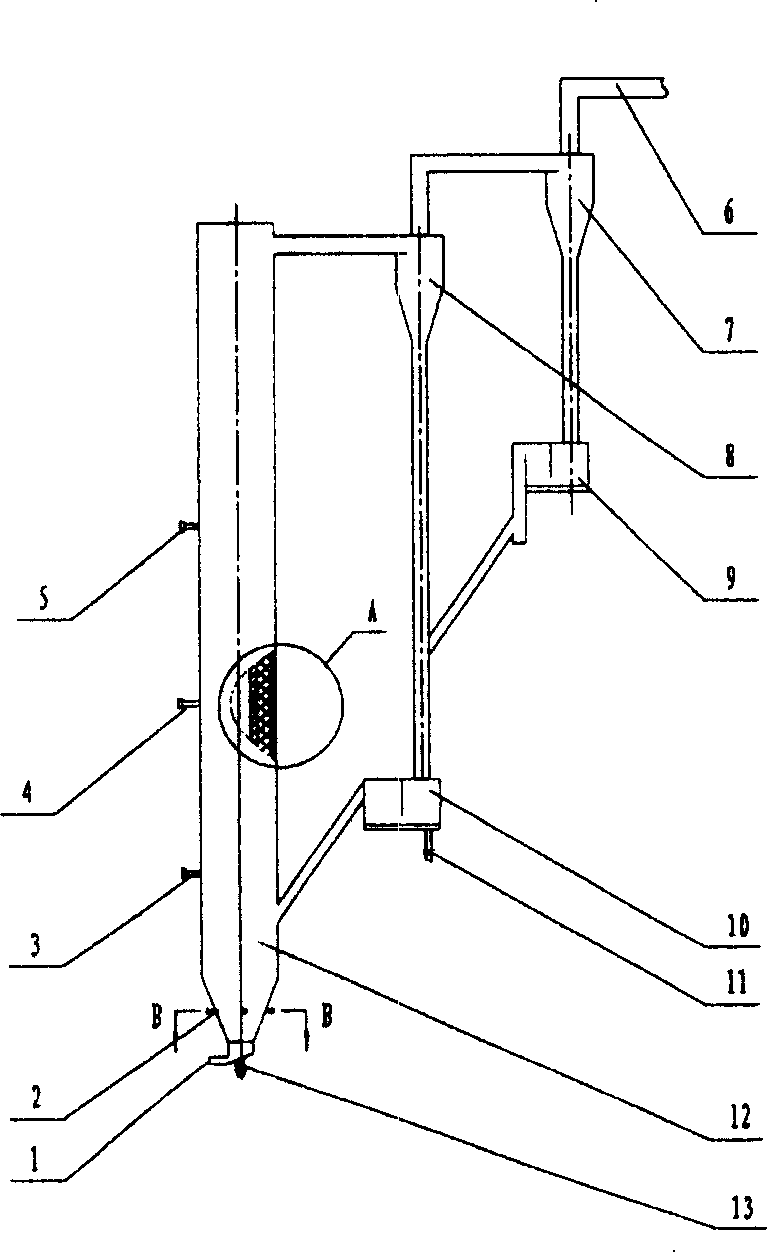

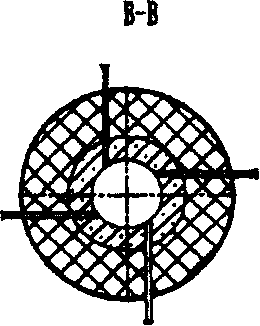

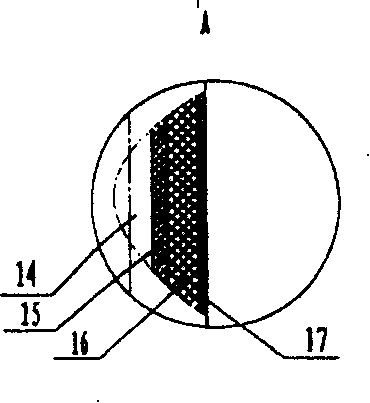

[0033] Combined with Figure 1(a), Figure 1(b), Figure 1(c), figure 2 , one example of which is as follows:

[0034] The pulverized coal pressurized dense-phase transport bed gasification device of the present invention is a device for producing synthetic raw material gas or fuel gas from coal gasification. The air distribution of the gasifier adopts the primary air intake at the bottom and the secondary lateral swirling air intake. way; the device can also be used for coal or other solid fuel combustion.

[0035] In the pulverized coal pressurized dense-phase transport bed gasification method of the present invention, the pulverized coal and gasification agent (air / enriched oxygen / pure oxygen+water vapor) move from bottom to top in the gasifier.

[0036] The gasification raw materials (including coal and desulfurizer) prepared from the raw materials enter the lower part of the gasification furnace through the feeding port 3 through the conveying device, and the feeding method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com