Patents

Literature

83results about How to "Increase cycle ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-density pressurized fluidized bed coal gasification apparatus and method

ActiveCN101372635AGood amplification performance of flow dynamic characteristicsImprove carbon conversionCombined combustion mitigationGranular/pulverulent flues gasificationProcess engineeringTransformation ratio

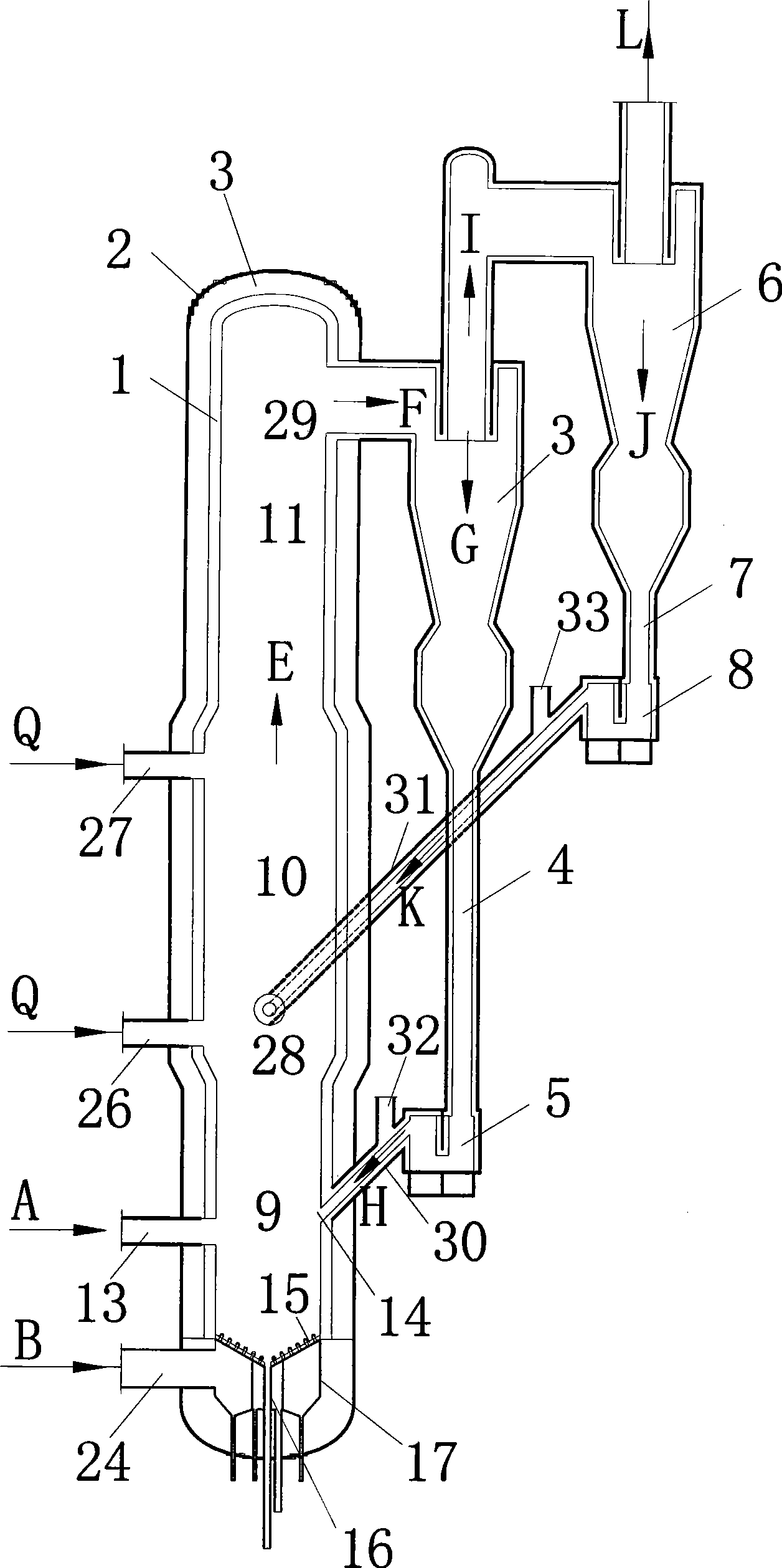

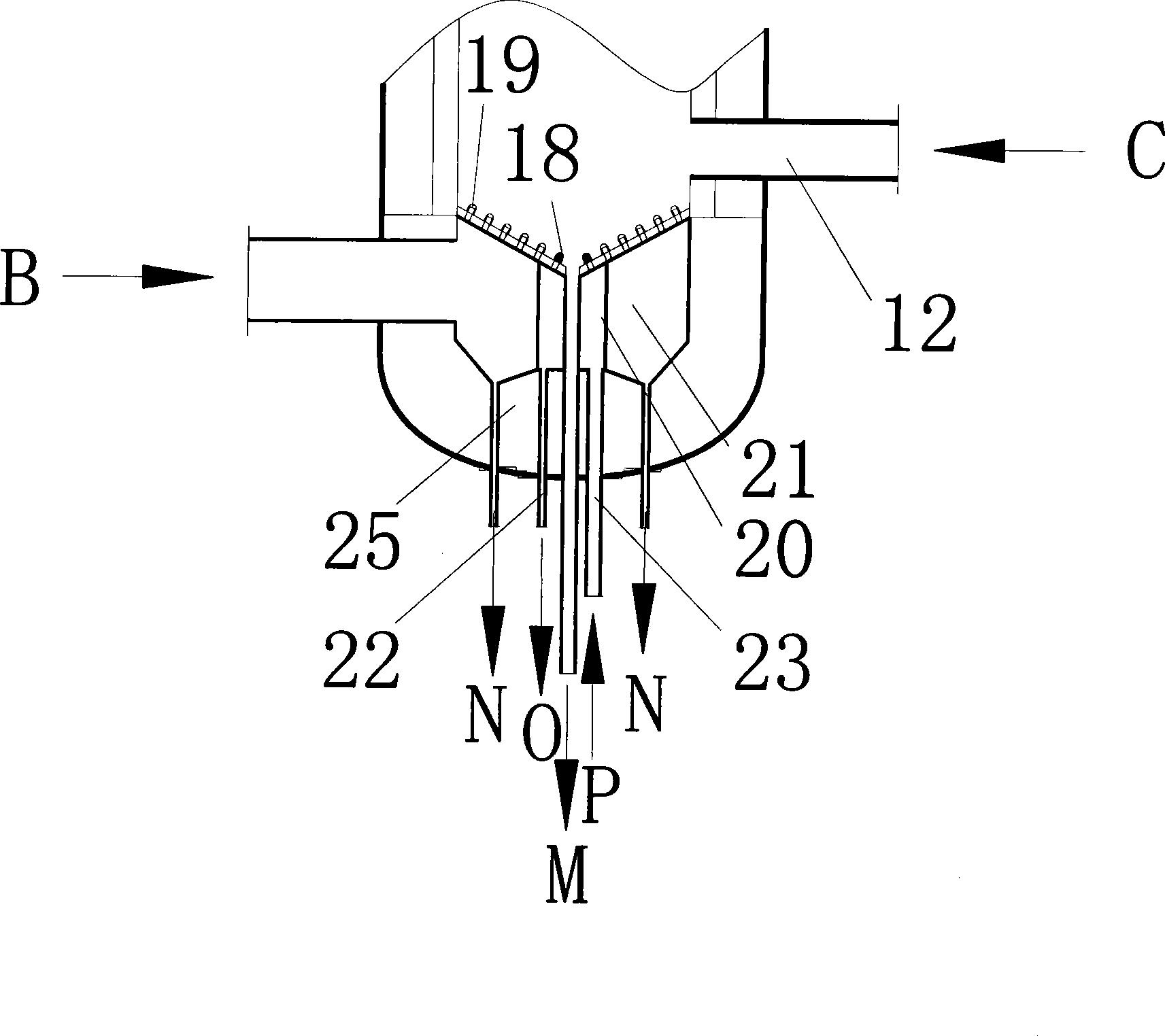

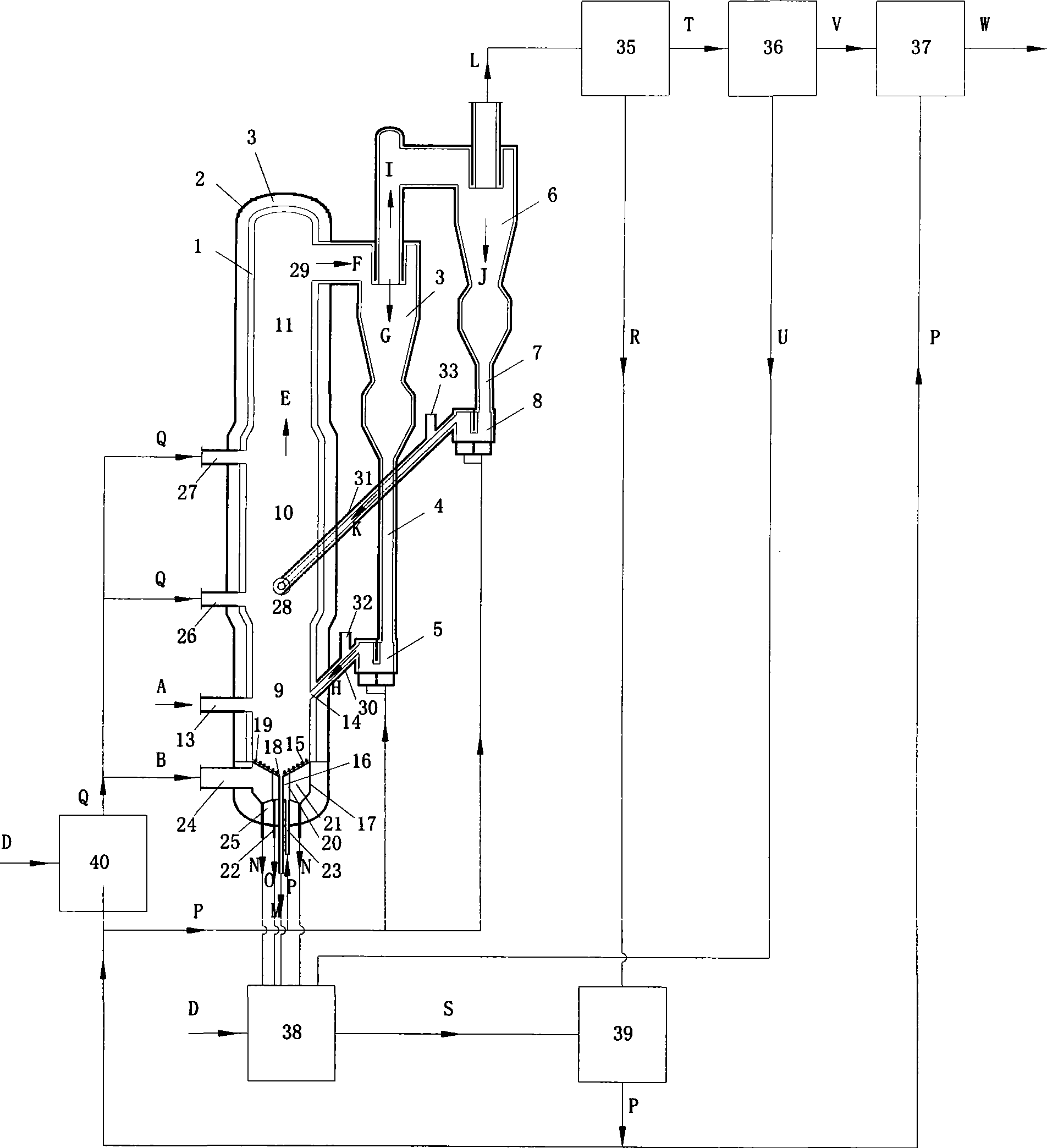

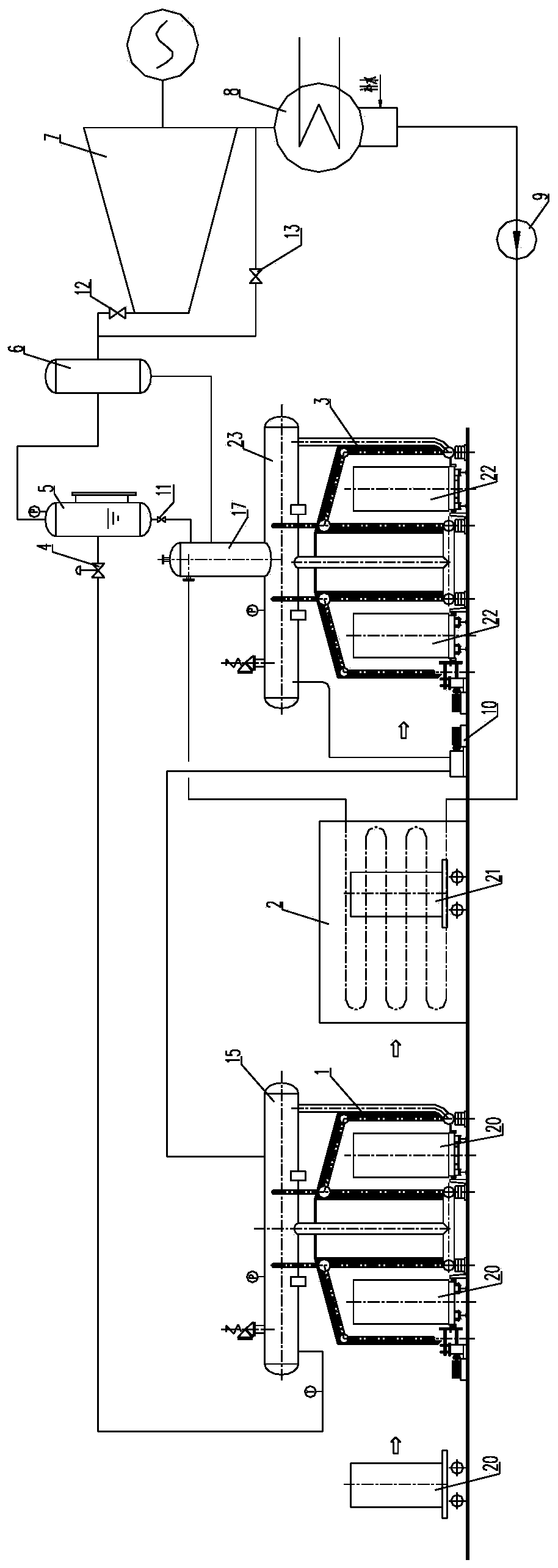

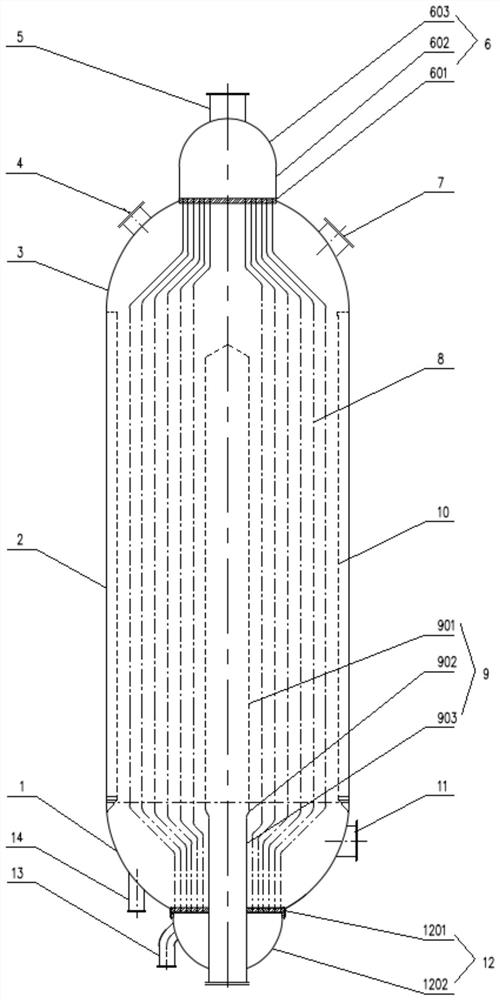

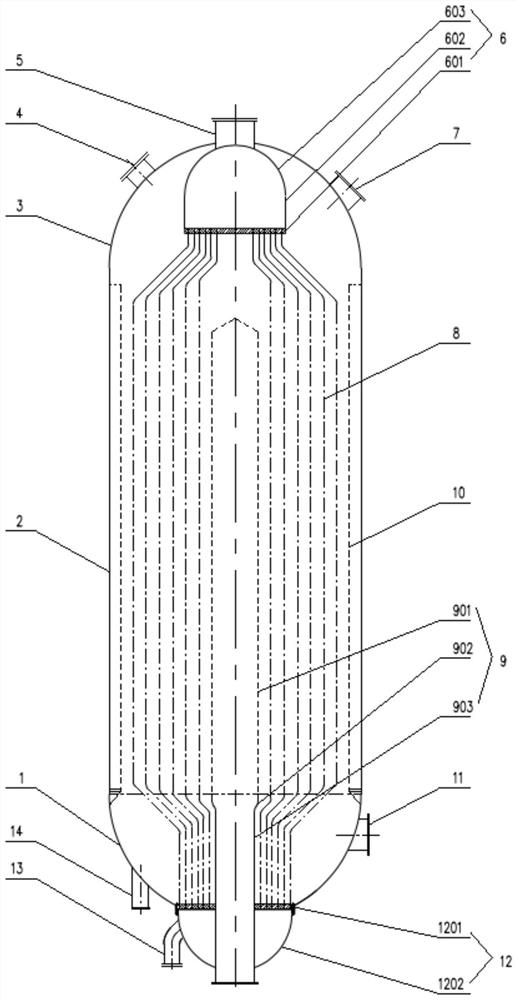

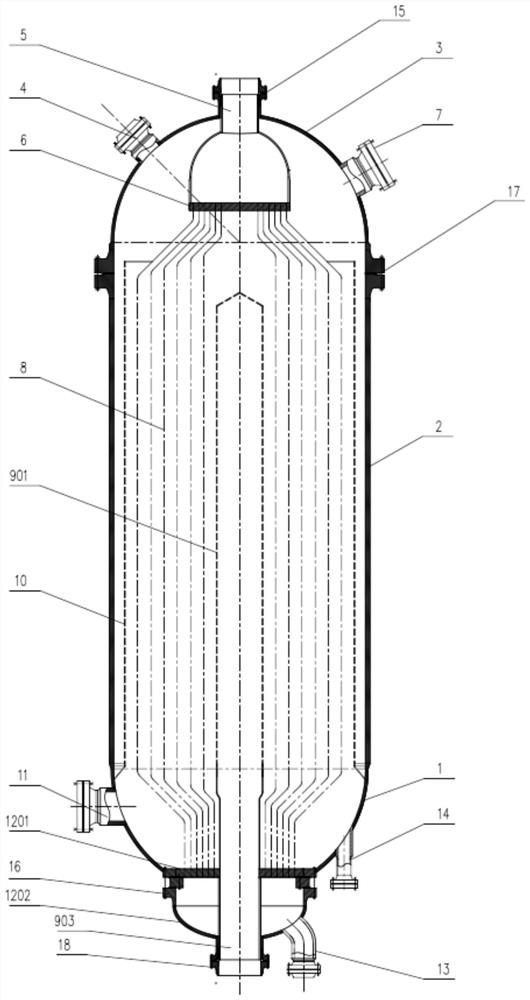

A high-density pressurized fluid bed coal gasification device and a method relate to a gasification device and a method which are especially suitable for the efficient treatment of the high-sulfur, high-ash and high ash fusion point coal with high reserve volume in China and have the advantages of broad coal type adaptability, high carbon transformation ratio in the gasification process, high heat value of coal gas, low investment and excellent environment-friendly performance. A gasification reactor (1) is arranged in a pressure shell (2) and is divided into a dense-phase turbulent flow fluidizing section (9), a high-density core-annulus flow section (10) and a density rapid flow section (11) from bottom to top, and according to the gasification character of the goal with high sulfur, high ash and high ash fusion point, flow states with different features are adopted for pressurizing and sectionalized gasification from bottom to top and the pressure for gasification is 1.0-2.5MPa.

Owner:SOUTHEAST UNIV

Fine coal pressurization dense phase transporting bed gasification method and device

ActiveCN101240196AIncrease speedGuaranteed to loop multiple timesCombined combustion mitigationGranular/pulverulent flues gasificationHigh rateHigh flux

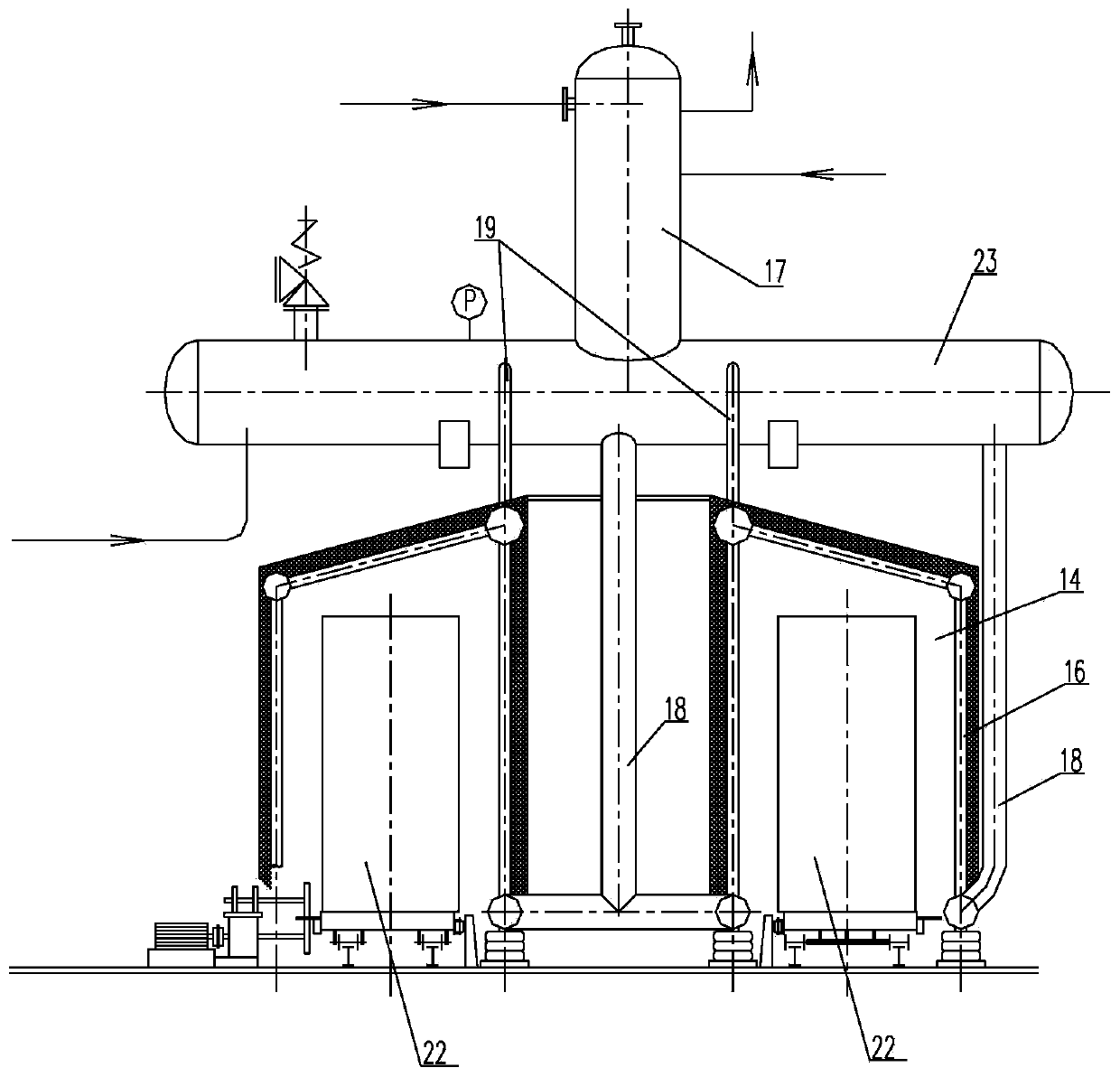

A pulverized coal pressure dense transport bed gasification method and installation of the invention relates to gasification technology and employs in-furnace desulfurization craft. Pulverized coal and desulfurizer are sent into gasification furnace through the middle and lower part of gasification furnace by a feeder, and then react with a gasifying agent. Reaction mass flow upward from the bottom of the gasification furnace, and enter into a multistage gas-solid separator from an export on the top of the gasification furnace. Most solids are separated in the gas-solid separator and enter into the low part of the gasification furnace by a high flux return feeder to continue to participate in reaction. Gas products with a small amount of solid enter into a gas cooler which can recover gas manifested heat to generate steam. The enter modes of the gasifying agent are bottom once wind and cyclone twice wind, otherwise, the reactor can also be use to burn. Because of the high-rate cycle, high solid content and high gas-solid mixing in the gasification furnace of the invention, the gasification strength and gasification rate of the gasification furnace can be improved and higher gasification efficiency and carbon conversion rate can be obtained.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

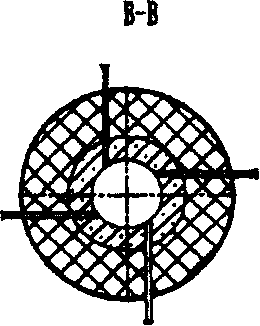

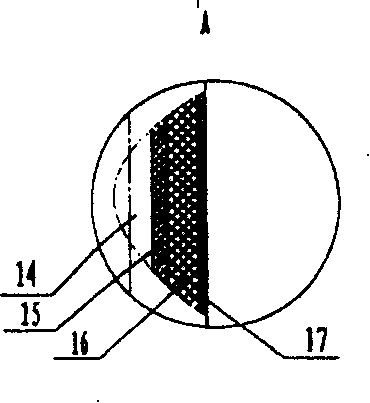

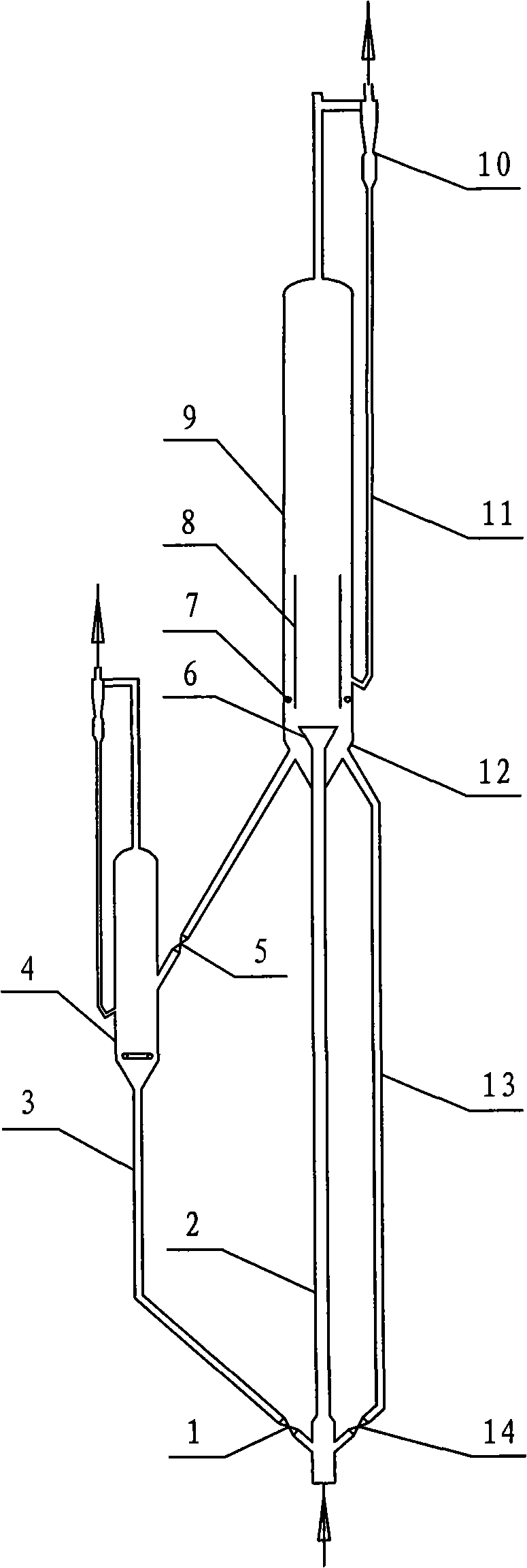

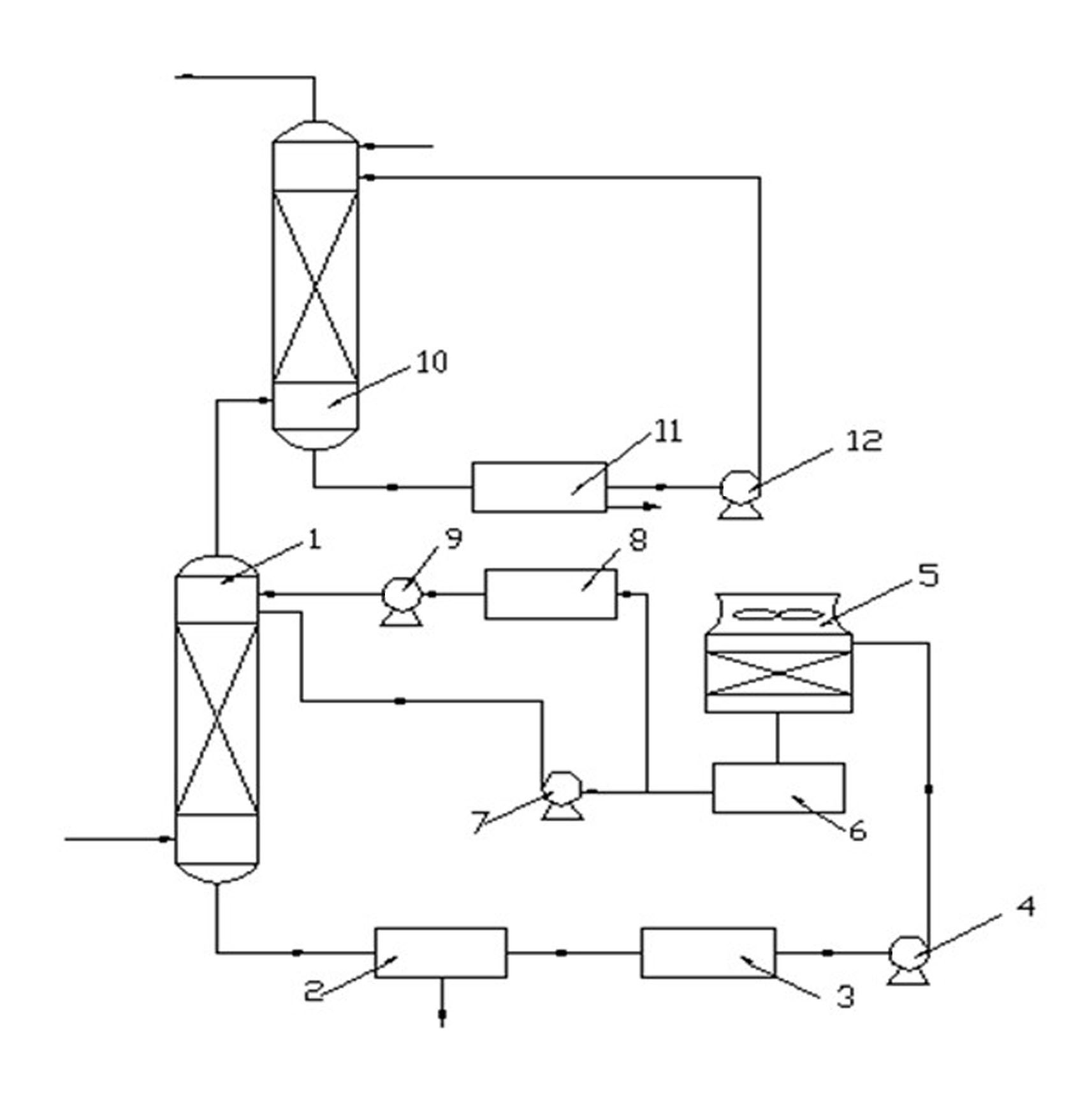

Dense-phase conveying-bed coal pressurizing gasifying apparatus and method

ActiveCN101024782AExtended stayEfficient mixingCombined combustion mitigationGranular/pulverulent flues gasificationCycloneProcess engineering

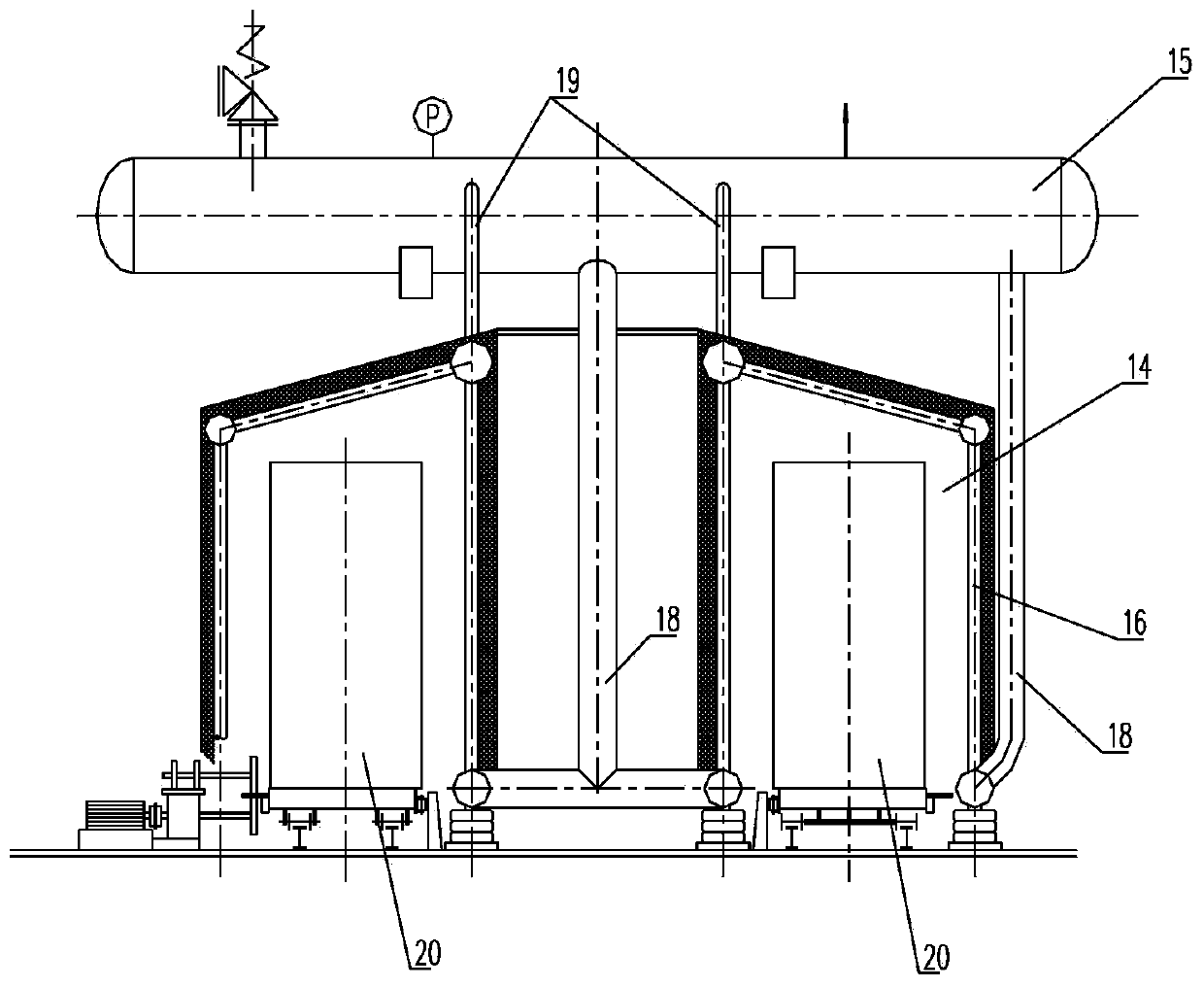

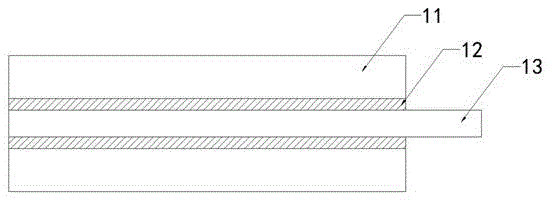

The invention relates to a dense phase conveying bed coal preesurized gasification device and a gasification method. The gasification reactor includes pressure case, mixing section, lifting section, and conveying section. The mixing section adopts low flow speed, and has inlet for coal limestone, assistant gasification agent, and has grid plate, scum pipe, air chamber and main gasification agent inlet. The lifting section has assistant air or oxygen inlet and adopts high flow velocity mode. The convey section adopts middle velocity mode, and the outlet of convey section has two high efficiency cyclone separator. The material return mouth of material return section is inserting into gasification reactor.

Owner:SOUTHEAST UNIV

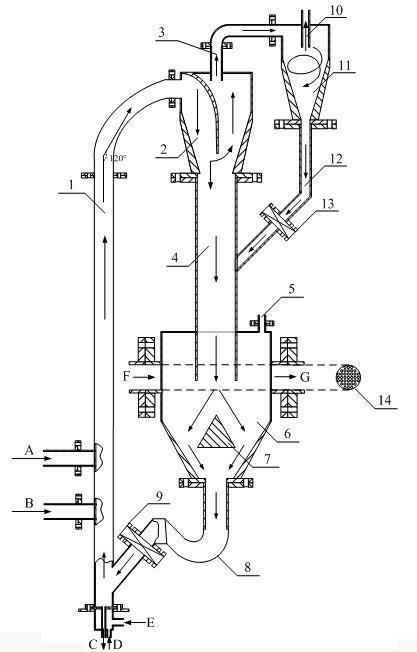

Device for improving pipe and gas-solid circumfluence bed coupling reaction

ActiveCN101259398AExtended reaction timeReduce resistanceFluidized bed combustionChemical/physical processesChemical industryGas solid

The invention provides a lift pipe and air-solid circulation bed coupling reaction device which at least includes a lift pipe, a shower head distributor, a guide cylinder, an annular space air distribution ring, an outer cylinder, an inner circulation pipe, an outer circulation fluidized bed, an outer circulation pipe and an air-solid separating system. Particles and air are transmitted upwards along the lift pipe, pass through the shower head distributor and enter the upper annular fluidized bed to form a central air lifting type circumfluence between the guide cylinder and the annular space. Part of the particles below the outer cylinder enters the lift pipe through the inner circulation pipe and another part enters the outer circulation fluidized bed to be mixed with the original particles in the outer circulation fluidized bed; the mixed particles enter the lift pipe through the outer circulation pipe; the positions where the inner circulation pipe and the outer circulation pipe enter the lift pipe can be flexibly arranged; the lift pipe and air-solid circulation bed coupling reaction device overcomes the limitations of system pressure balance and short reaction time and has the advantages that each area is flexible to be operated and controlled, the air-solid contact efficiency of the annular fluidized bed is high and the resistance above the distributor is small, etc. The device can be broadly applied to the fields of energy supply, chemical industries and particle combustion, etc.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

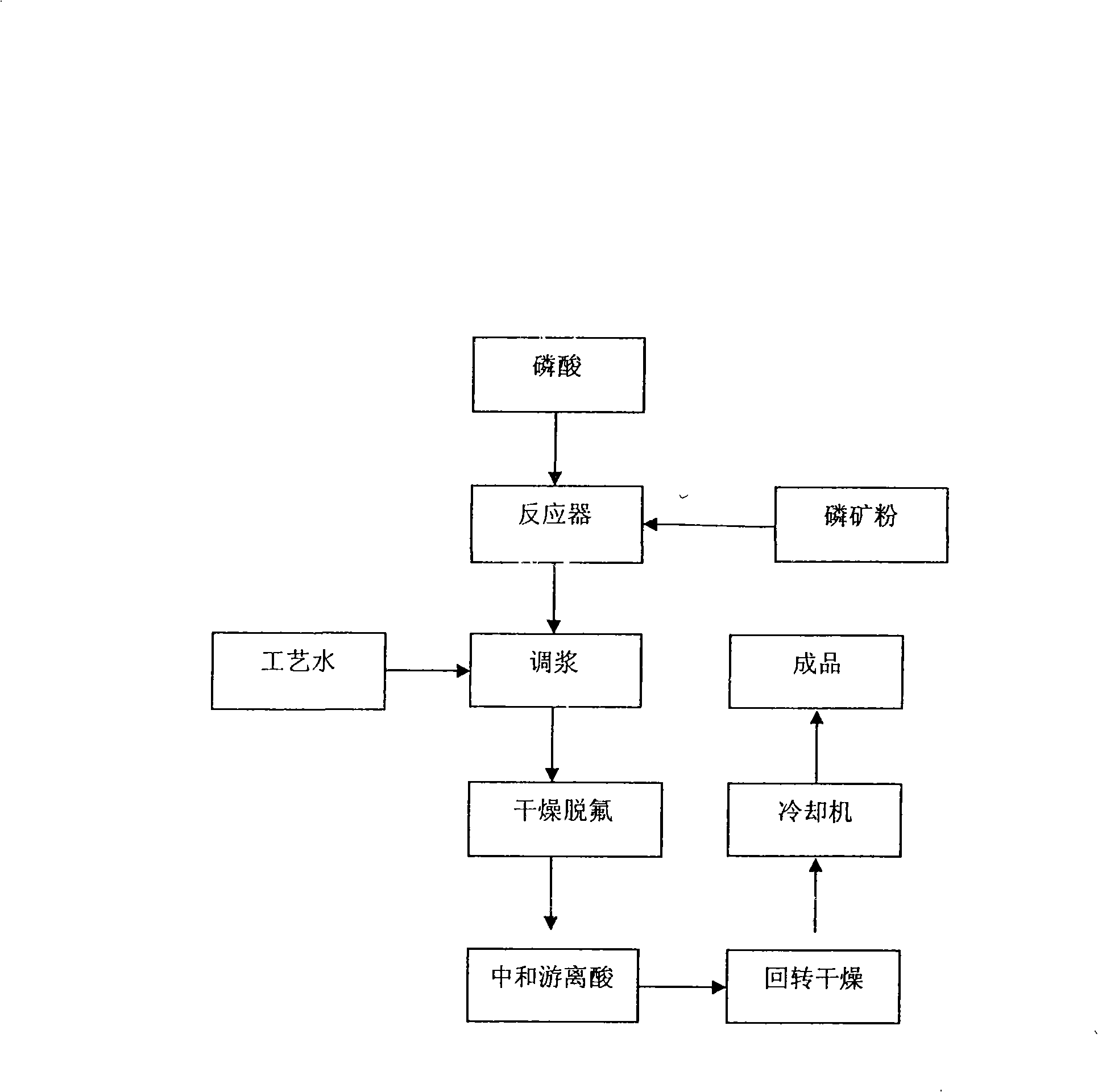

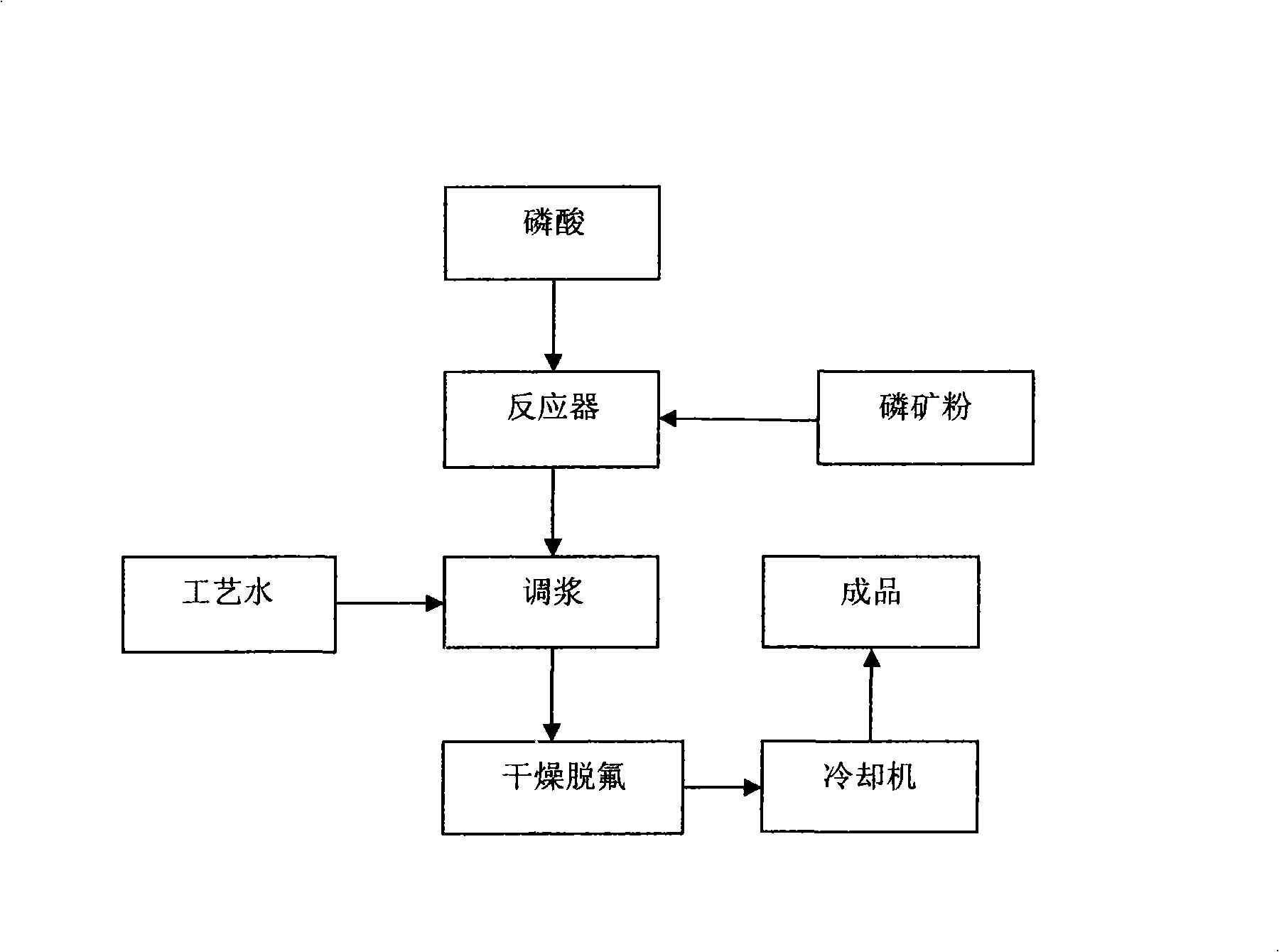

Method for producing feed-grade calcium phosphate

ActiveCN101264873AReduce acidityIncrease cycle ratioPhosphorus compoundsCalcium biphosphatePhosphate

The invention discloses a forage level calcium phosphate production method, comprising that excess phosphoric acid and rock phosphate are added into a reactor to react mixedly; the calcium dihydrogen phosphate material containing fluorine and phosphoric acid; the material is added into a drier to be dried and defluorinated, and the forage level calcium phosphate is made. The forage level calcium phosphate production method has the advantages of fast defluorination, high efficiency, resource saving, low cost, friendly environment, energy saving and emission reducing, which brings the industrial revolution of forge phosphate.

Owner:GUIZHOU CHANHEN CHEM CO LTD

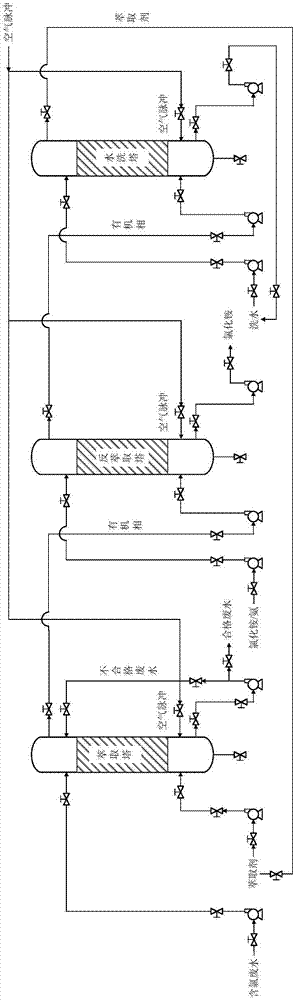

Coal gas washing, dedusting and purifying process

ActiveCN102010760ANo purification effectTo achieve the purification effectGas dust removalSaline waterWastewater

The invention relates to a coal gas washing process, in particular to a coal gas washing, dedusting and purifying process. The process can solve the problems of non-complete dedusting and non-complete purification of the traditional coal gas washing process. The coal gas washing, dedusting and purifying process is realized by adopting the following steps: a) introducing coal gas containing dust into a dedusting and washing tower; b) leading waste water after dedusting and washing to flow into a sedimentation tank for sedimentation via the tower bottom of the dedusting and washing tower; c) leading the coal gas after washing to enter into a purifying and washing tower, thereby being in countercurrent contact with circulating water at the upper part of the purifying and washing tower for washing and then further being in countercurrent contact with desalted water at the tower top of the purifying and washing tower for further washing and purifying; and d) leading the water after purifying and washing to flow into a circulating tank via the tower bottom of the purifying and washing tower and then leading the water to be divided into two lines. The coal gas washing, dedusting and purifying process can effectively solve the problems of non-complete dedusting and non-complete purification of the traditional coal gas washing process and is suitable for coal gas washing during the coal gas making process.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

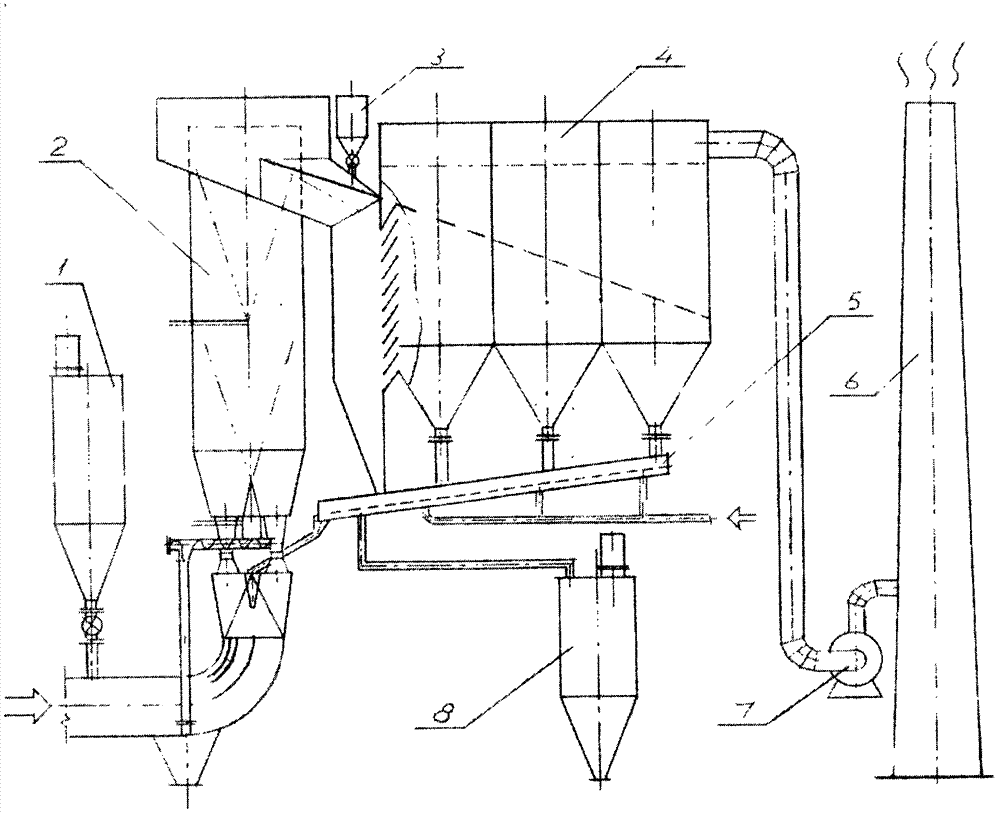

Low-nitrogen combustion technique based on circulating fluidized bed boiler

ActiveCN106051749ASolve the reduction of NOx emissionsSolve the high carbon content of fly ashFluidized bed combustionFluegas recirculationBurning outCirculating fluidized bed boiler

The invention discloses a low-nitrogen combustion technique based on circulating fluidized bed boiler. The circulating fluidized bed boiler comprises a boiler body, a cyclone separator, a deduster, an induced draft fan, a primary air supply system and a secondary air supply system which are connected in sequence. A smoke recirculation pipe is drawn out behind the induced draft fan. The primary air supply system and the secondary air supply system are connected to the smoke recirculation pipe in parallel. A burn-out chamber is arranged at an outlet of the cyclone separator. The low-nitrogen combustion technique based on the circulating fluidized bed boiler comprises the following steps that pulverized coal enters the boiler body under the action of primary air, specifically, the amount of smoke recirculation air in the primary air accounts for 8-10% the total air amount of the primary amount, and the amount of the primary air accounts for 40-45% of the total air amount; secondary air is introduced into the boiler body through the secondary air supply system, specifically, the amount of smoke recirculation air in the secondary air accounts for 12-14% the total air amount of the secondary air; fine flying ash enters the burn-out chamber; and over fire air is introduced into the burn-out chamber. According to the low-nitrogen combustion technique based on the circulating fluidized bed boiler, the burn-out chamber is arranged at the outlet of the separator, and part of smoke is mixed into the primary air and the secondary air, so that generation of NOx is reduced.

Owner:QINGDAO JINTIAN THERMAL POWER CO LTD

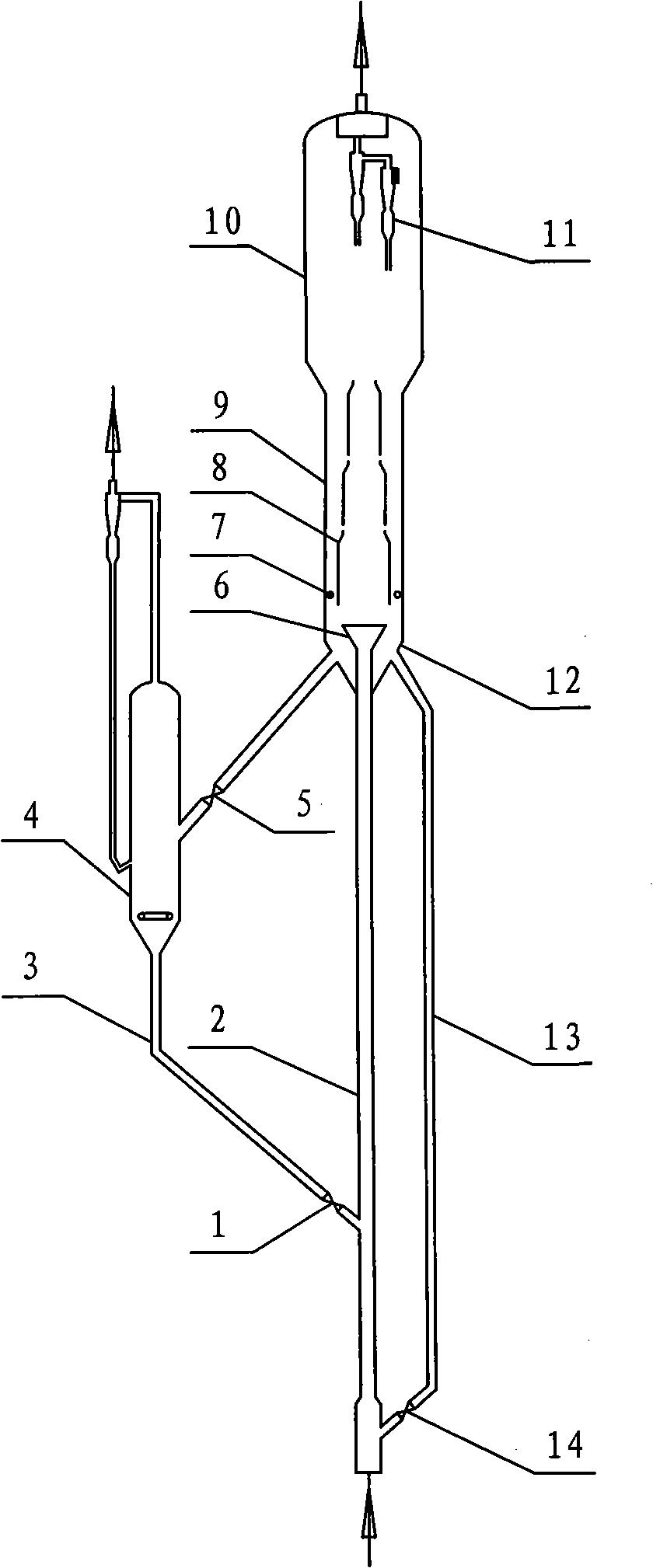

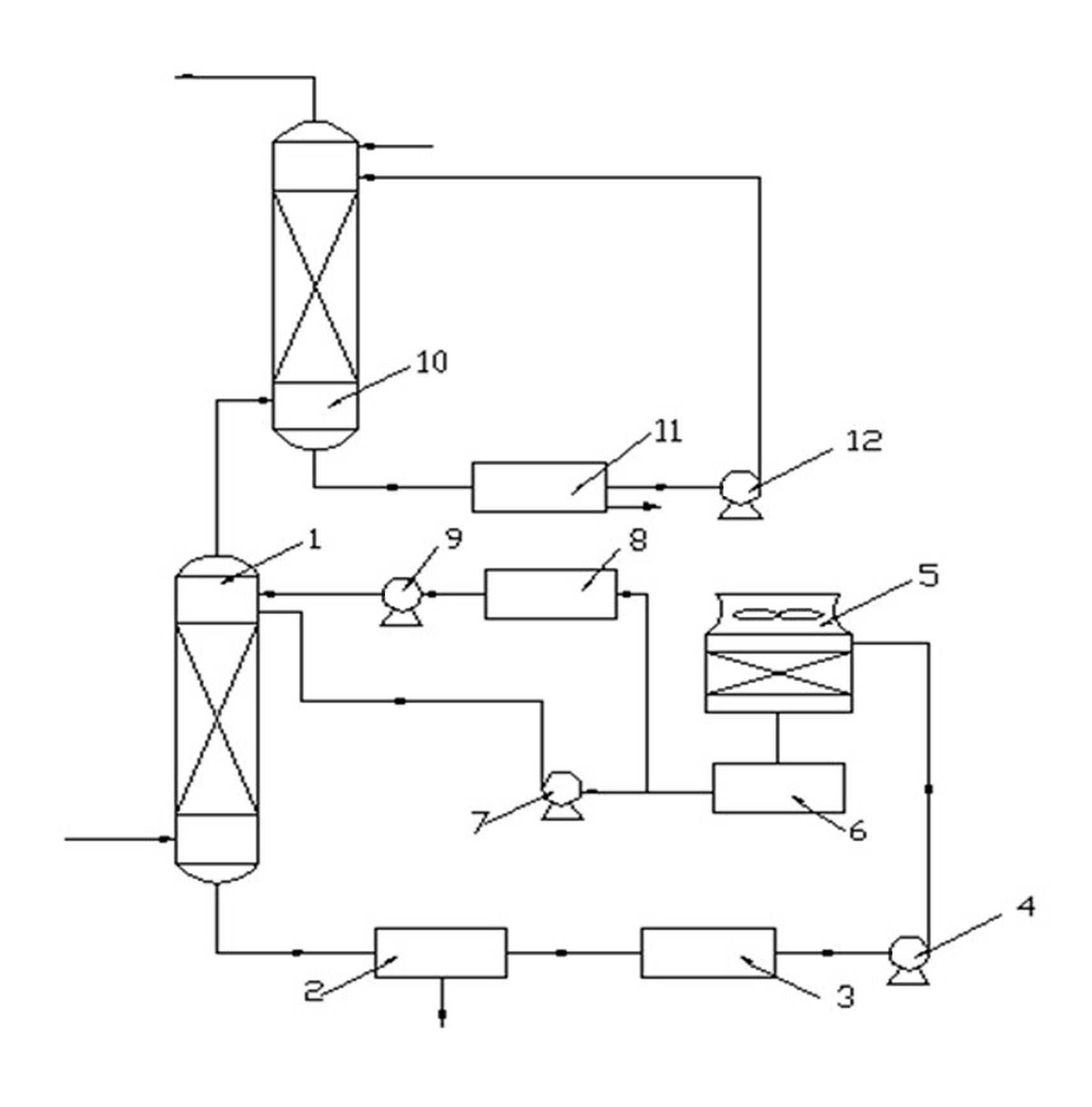

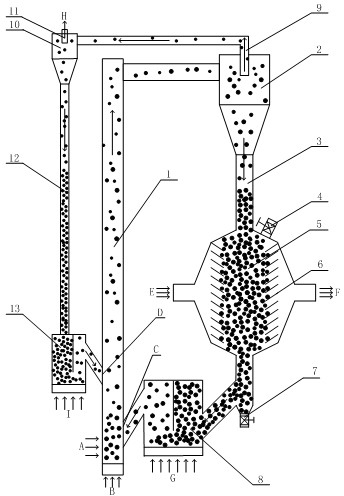

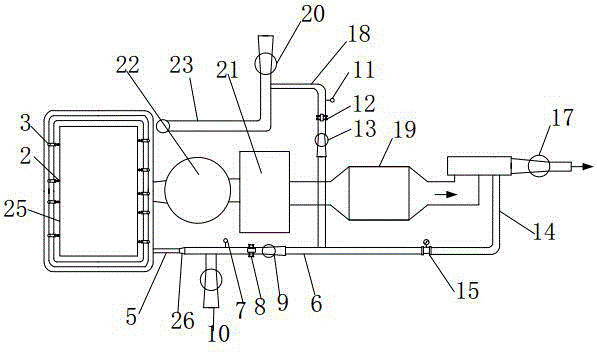

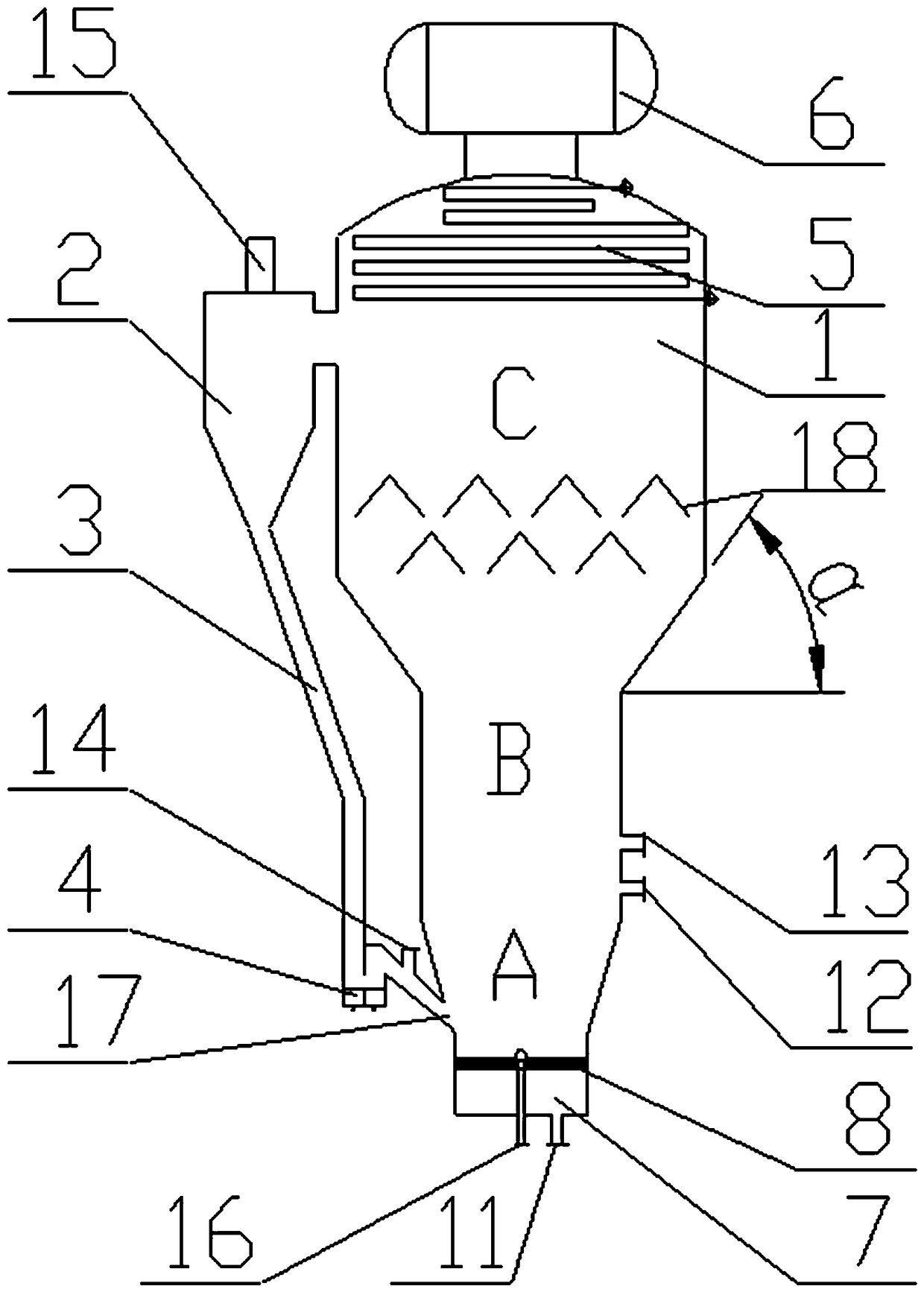

Method for separating CO2 through chemical looping combustion in coal pressure high-density circulating fluidized bed

ActiveCN102183014AIncrease the combustion reaction rateSolving the Response Matching ProblemFluidized bed combustionIndirect carbon-dioxide mitigationCycloneHigh density

The invention provides a method for separating CO2 through chemical looping combustion in a coal pressure high-density circulating fluidized bed, which comprises the following steps: coal particles and a gasifying agent are subjected to gasification reaction in a fuel reactor 1 of the coal pressure high-density circulating fluidized bed, and gasified products and oxygen carriers which return to the fuel reactor are subjected to combustion reaction to produce CO2 and H2O; smoke which is produced during the reaction and carries oxygen-lost oxygen carriers and carbon-containing coal ash enters a primary cyclone separator 2 for separation, and separated oxygen-lost oxygen carriers are in contact with transversely passing air for reaction in an air reactor 5 of a cross flow moving bed to be regenerated and are turned to the combustion reactor through a primary material returning device 8 to continuously participate in the combustion reaction; and separated smoke in the primary cyclone separator 2 further enters a secondary cyclone separator 10 for separation, solid particles secondarily separated are returned to the fuel reactor 1 through a secondary material returning device 13 to continuously participate in the combustion reaction, and H2O is removed from the separated gases through condensation to obtain high-purity CO2.

Owner:SOUTHEAST UNIV

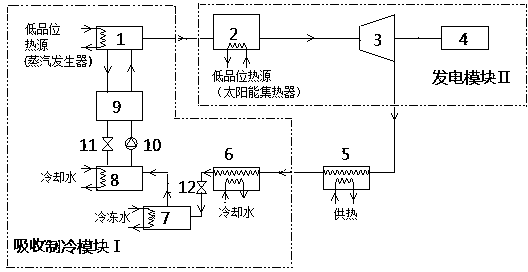

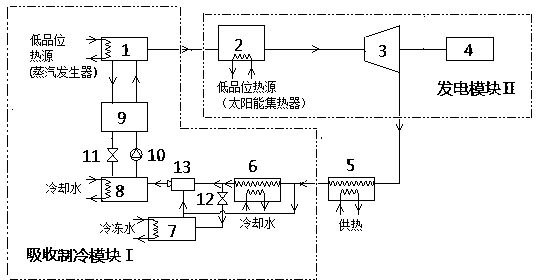

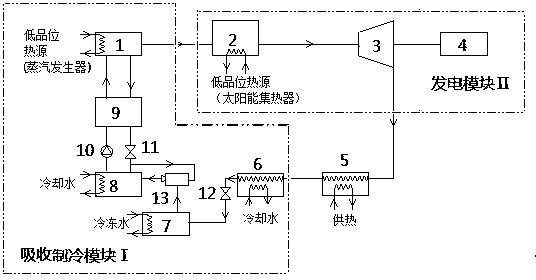

Low-grade energy driving CO2 absorption type combined cooling heating and power system

InactiveCN103868278AReduce outlet steam pressureImprove net power generation efficiencyClimate change adaptationEnergy efficient heating/coolingCo2 absorptionProcess engineering

The invention discloses a low-grade energy driving CO2 absorption type combined cooling heating and power system, which consists of a low-grade energy driving absorption refrigeration module, a power generating module, an afterheat recoverer and an ejector. The low-grade energy driving CO2 absorption type combined cooling heating and power system has the advantages that the refrigeration efficiency, the heat conversion efficiency and the system net power generating efficiency of the low-grade energy driving CO2 absorption type combined cooling heating and power system are improved, peripheral equipment of the low-grade energy driving CO2 absorption type combined cooling heating and power system is simplified, the stability and the reliability of the low-grade energy driving CO2 absorption type combined cooling heating and power system are improved, the efficient utilization of unstable and discontinuous low-grade energy is realized, and the foundation is laid in the efficient utilization of the low-grade energy in the absorption type combined cooling heating and power system.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

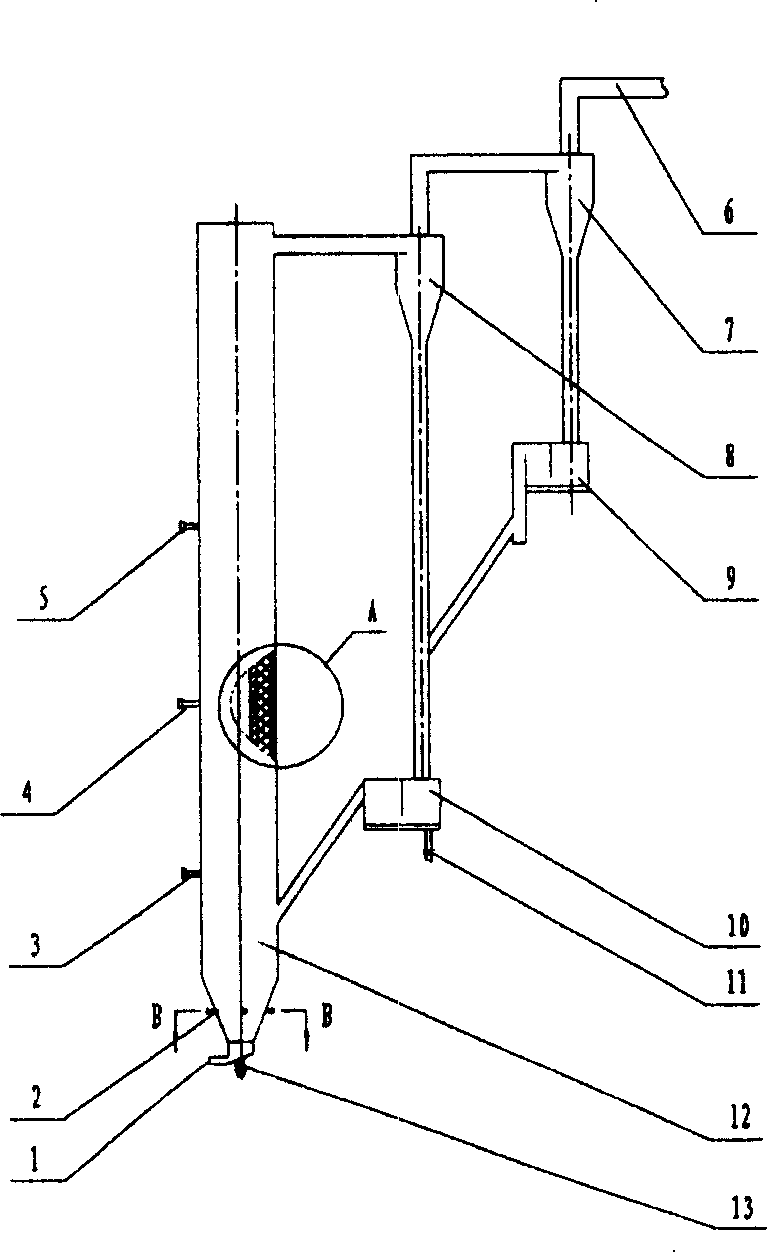

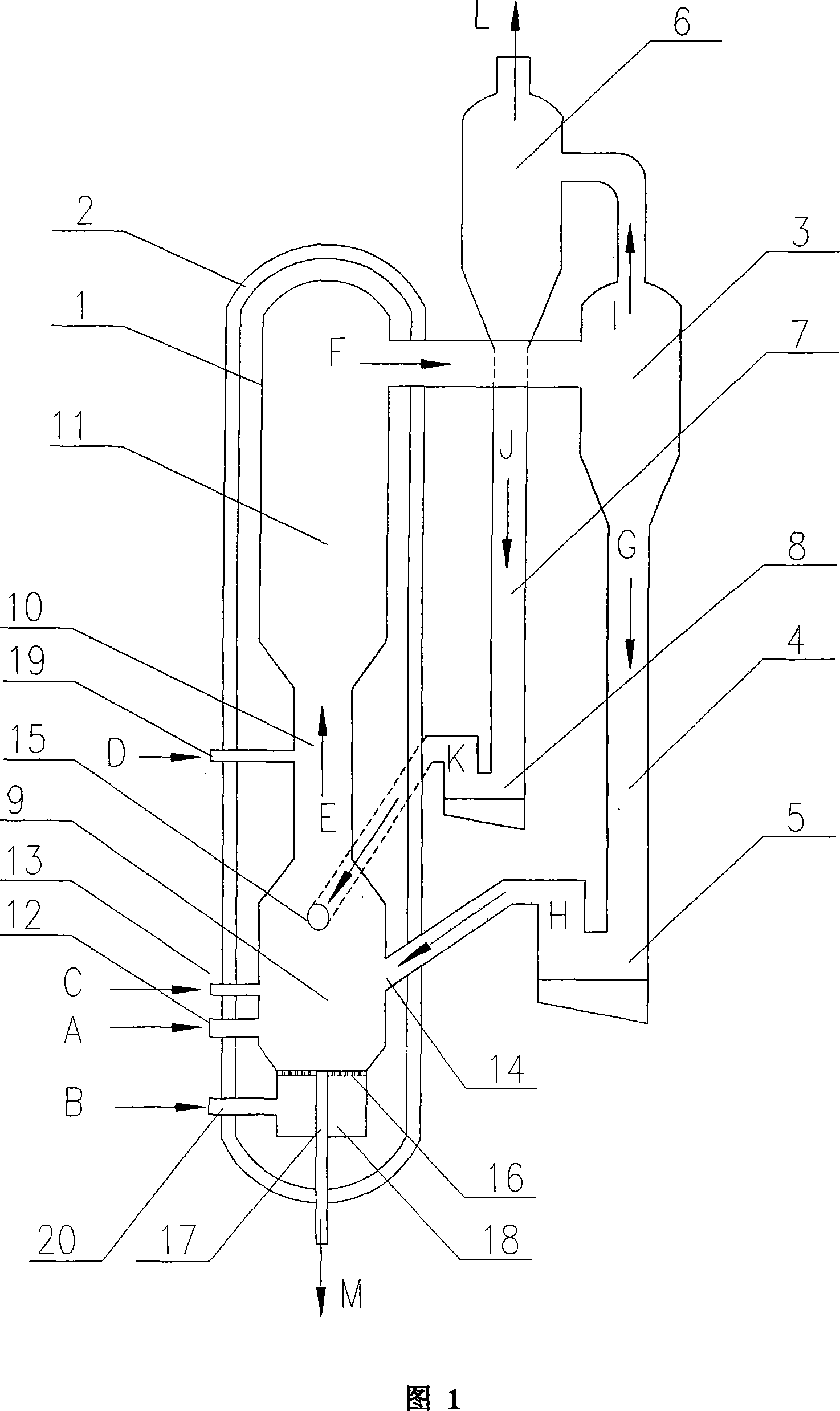

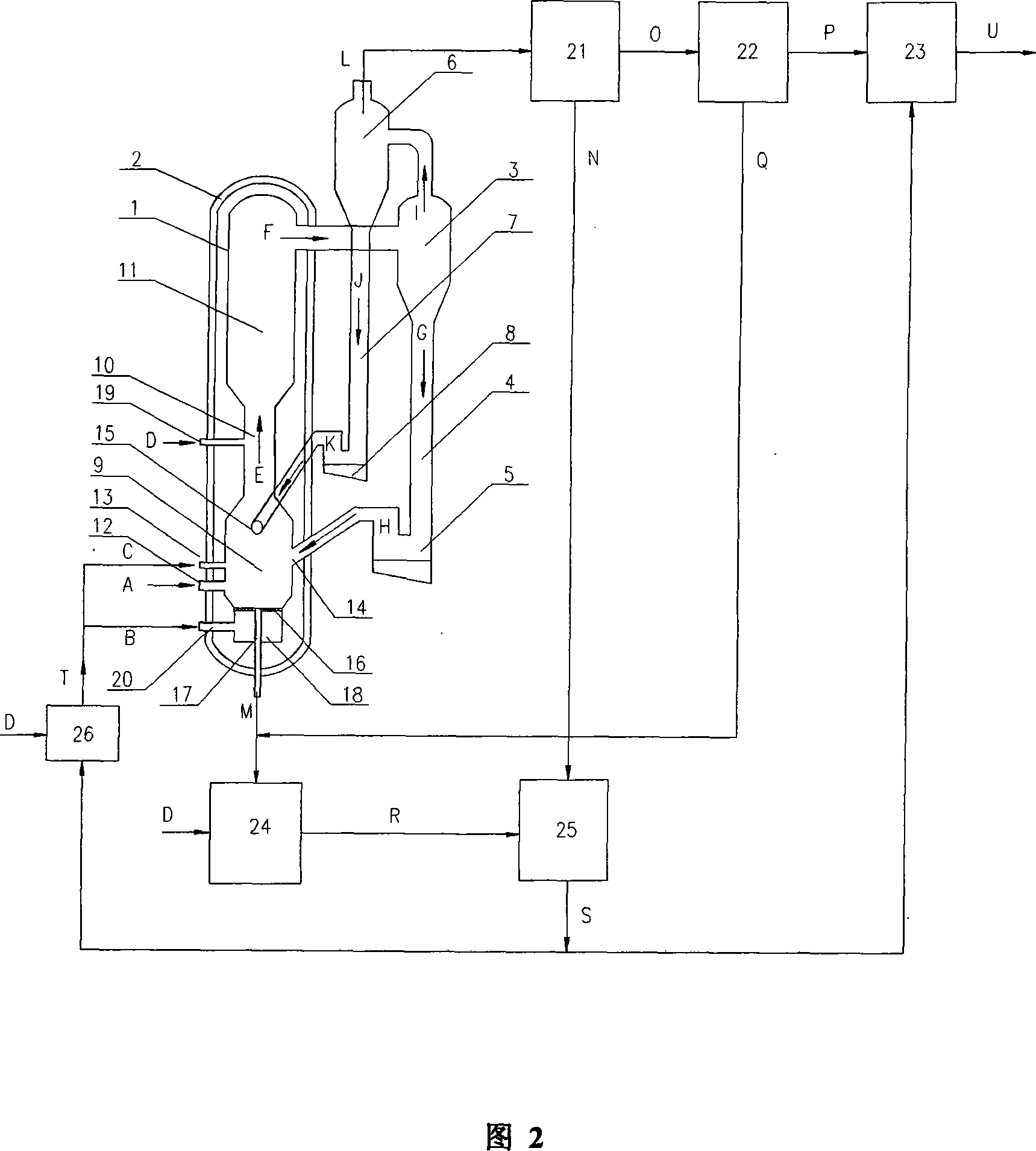

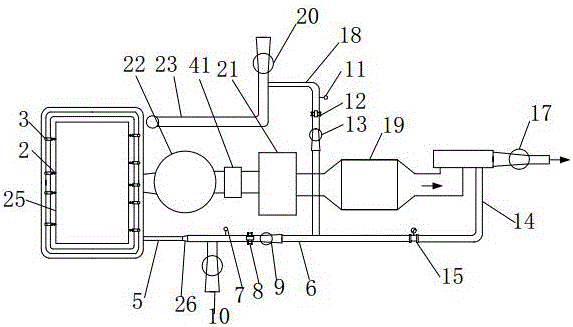

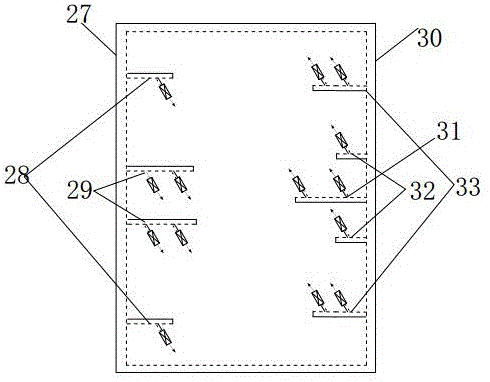

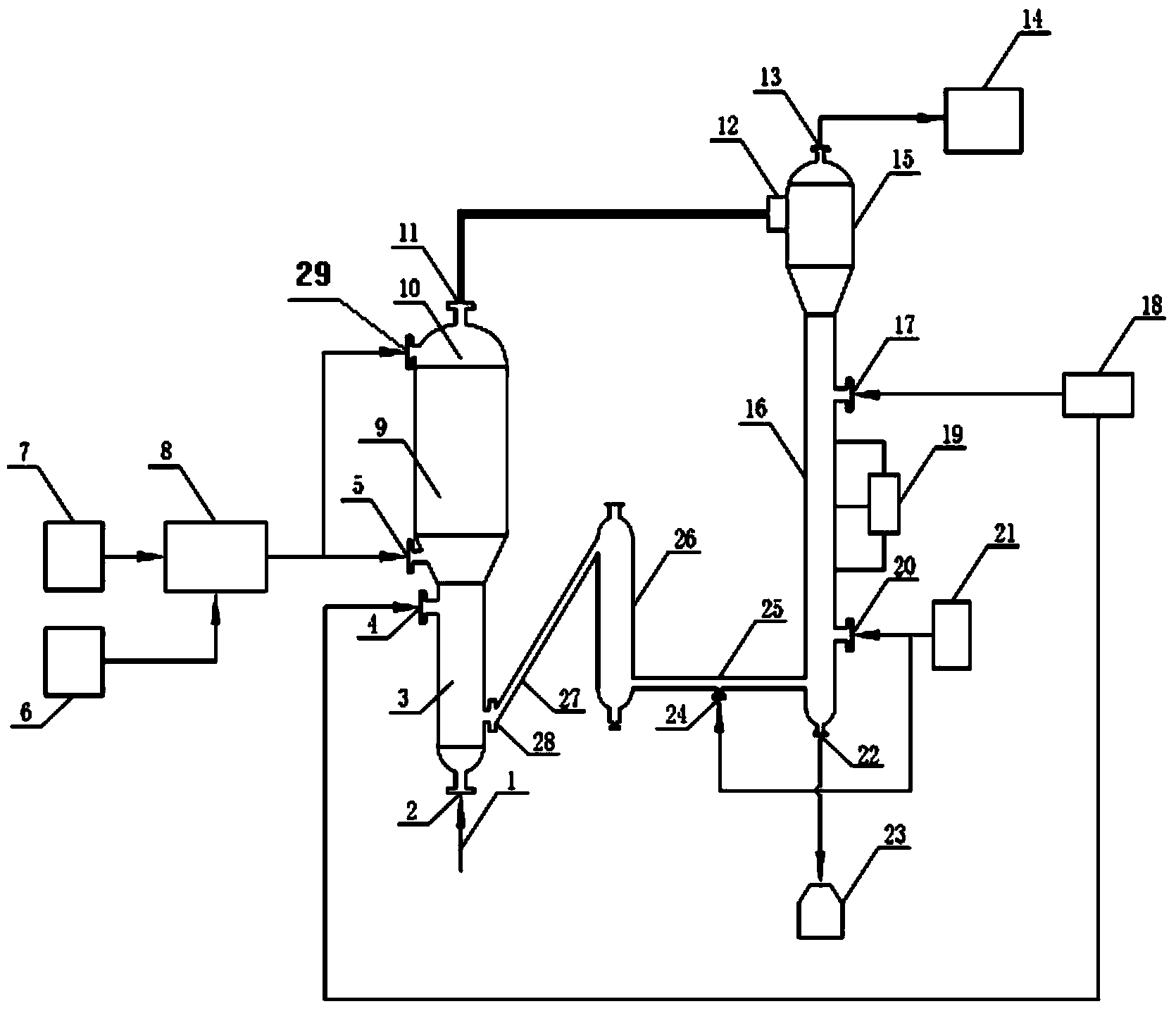

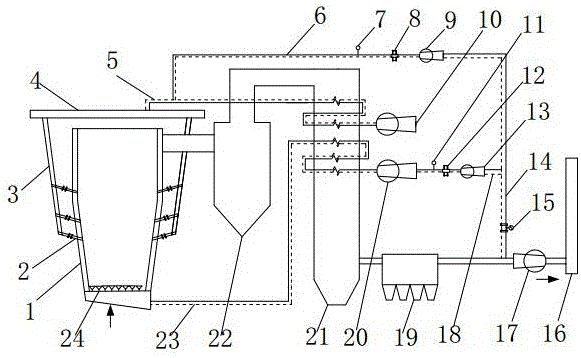

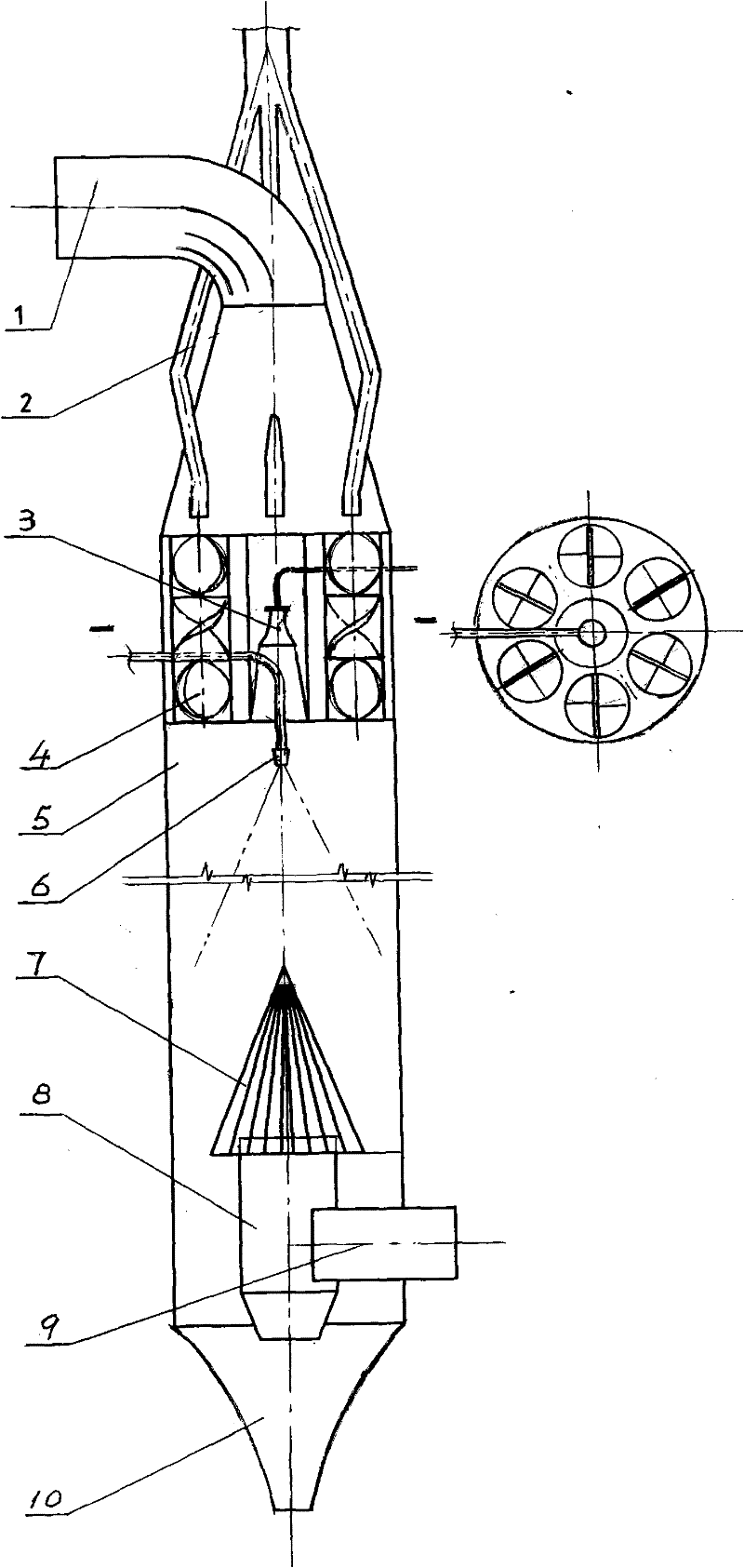

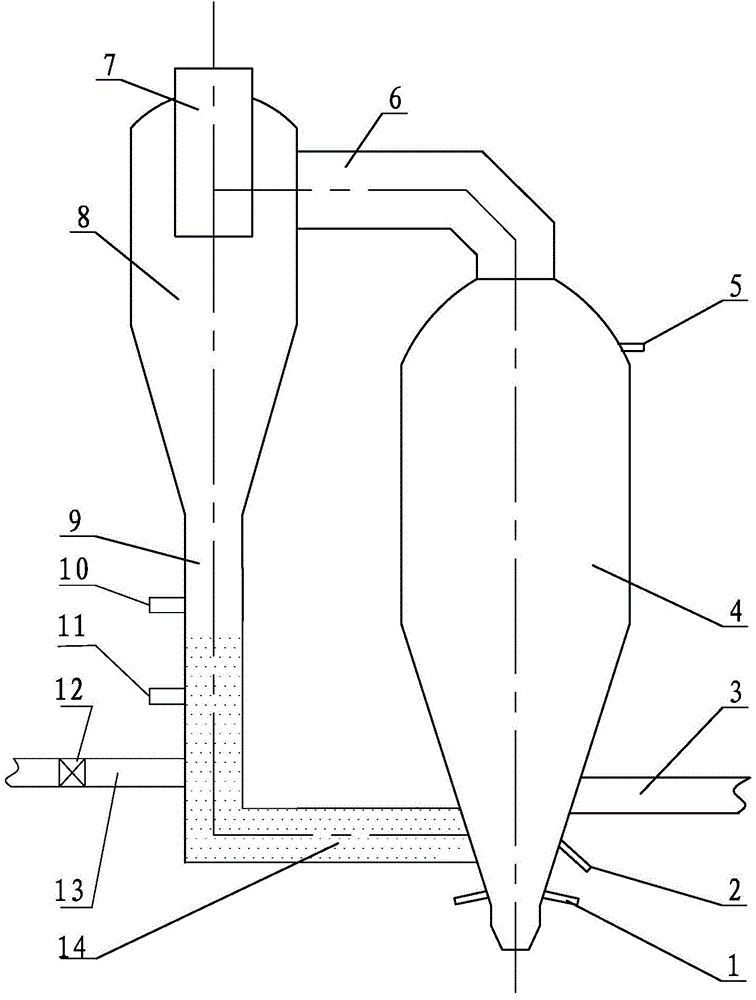

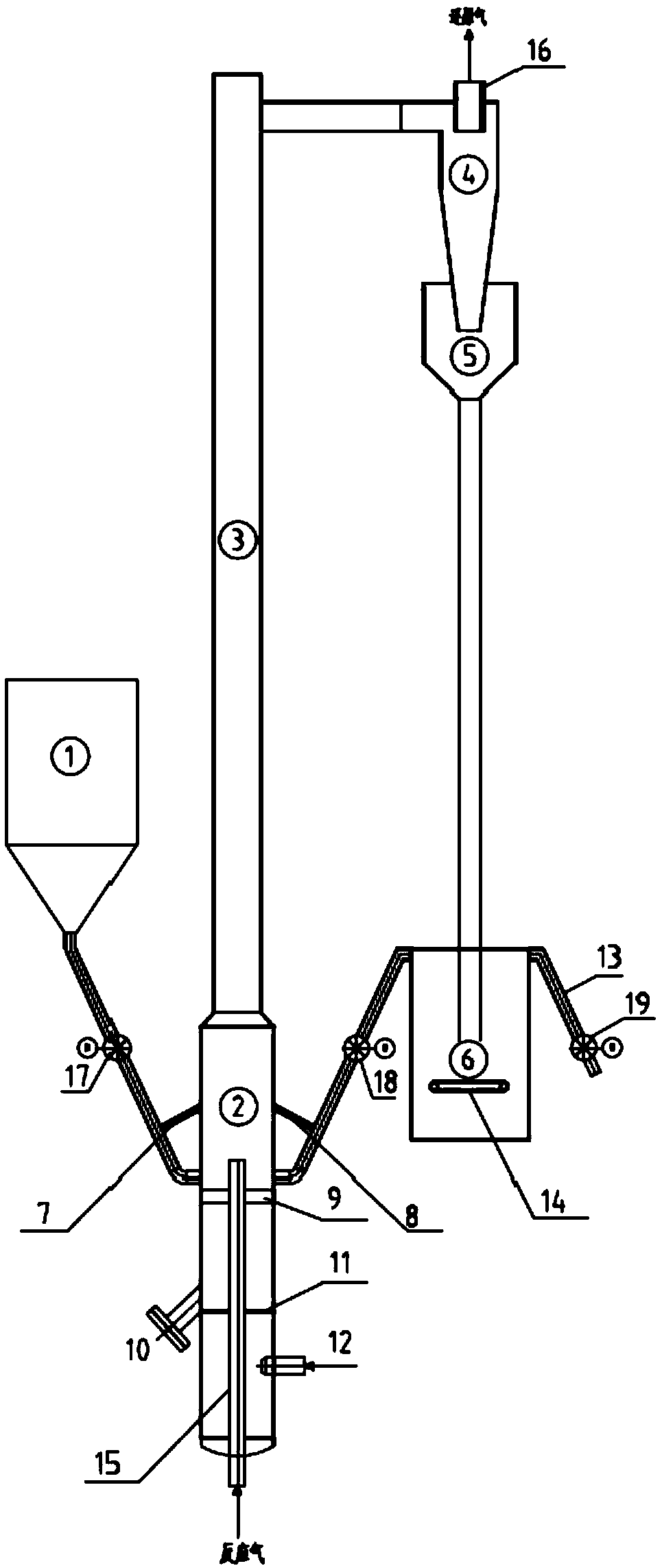

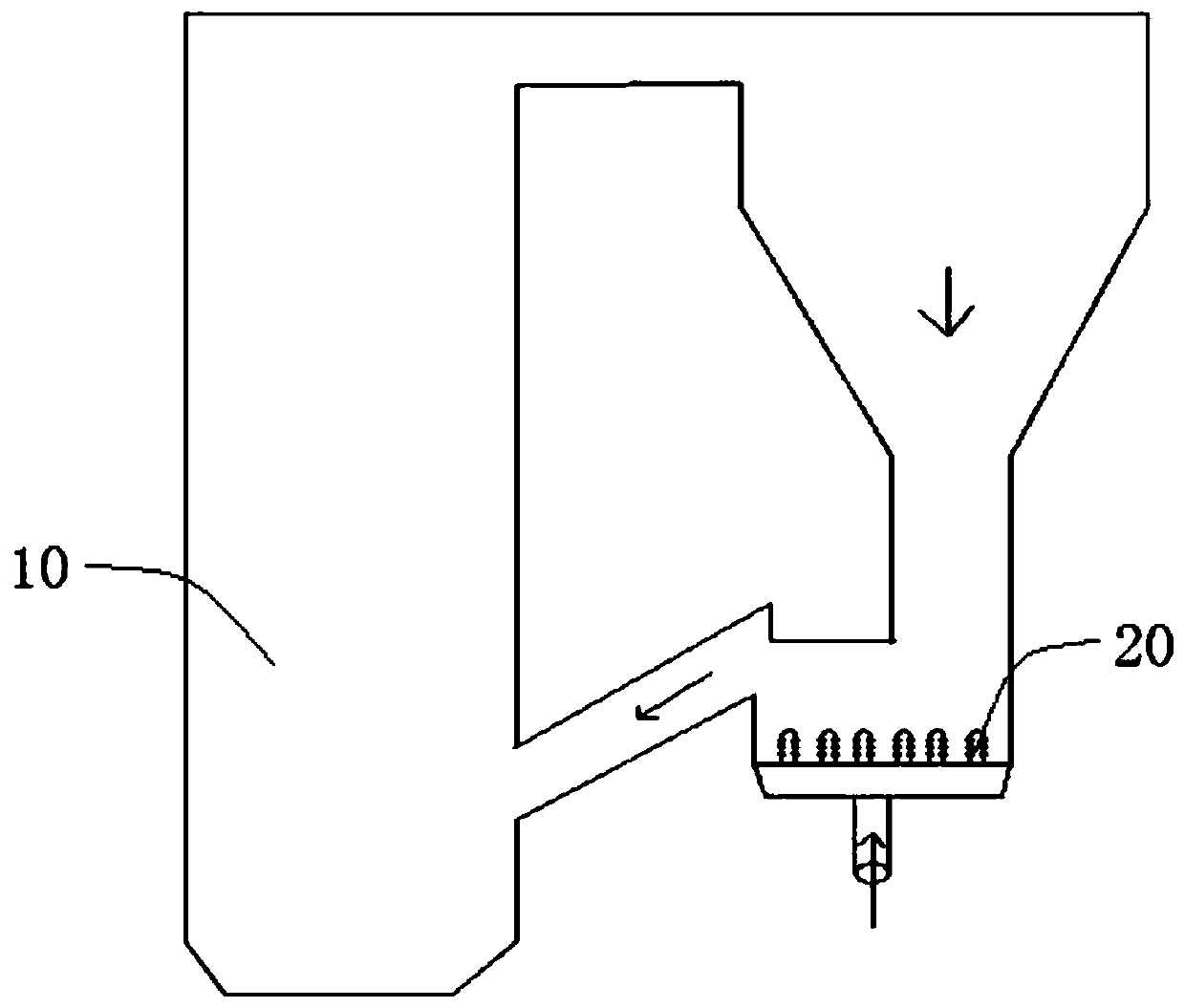

Apparatus for converting tar component and carbonaceous particles in raw gas, and method thereof

ActiveCN103820170AIncrease cycle ratioIncrease heating capacityHydrogenCombustible gas purificationGas solidShunt Device

The invention relates to an apparatus for converting a tar component and carbonaceous particles in raw gas, and a method thereof. The conversion apparatus comprises a conversion system, a material return system and a material sealing system. The conversion system is mainly composed of a solid particle distribution zone, a partial oxidation zone and an advanced treatment zone. The material return system is composed of a gas-solid shunting device, a solid particle trapping device and a vertical dipleg. The material sealing system is composed of a seal level control device, an annular seal and a material return inclined tube. A partial oxidation reduction reaction of a gasification agent, and the tar component and carbonaceous particles carried in the raw gas is carried out to convert the tar component and the carbonaceous particles into gas, so the advanced conversion treatment of the tar component and the carbonaceous particles in the raw gas is realized, and the energy conversion efficiency is greatly improved. The apparatus and the method have the technical advantages of simple operation process, low apparatus investment and running cost, high conversion rate and the like.

Owner:陕西延长石油(集团)有限责任公司碳氢高效利用技术研究中心

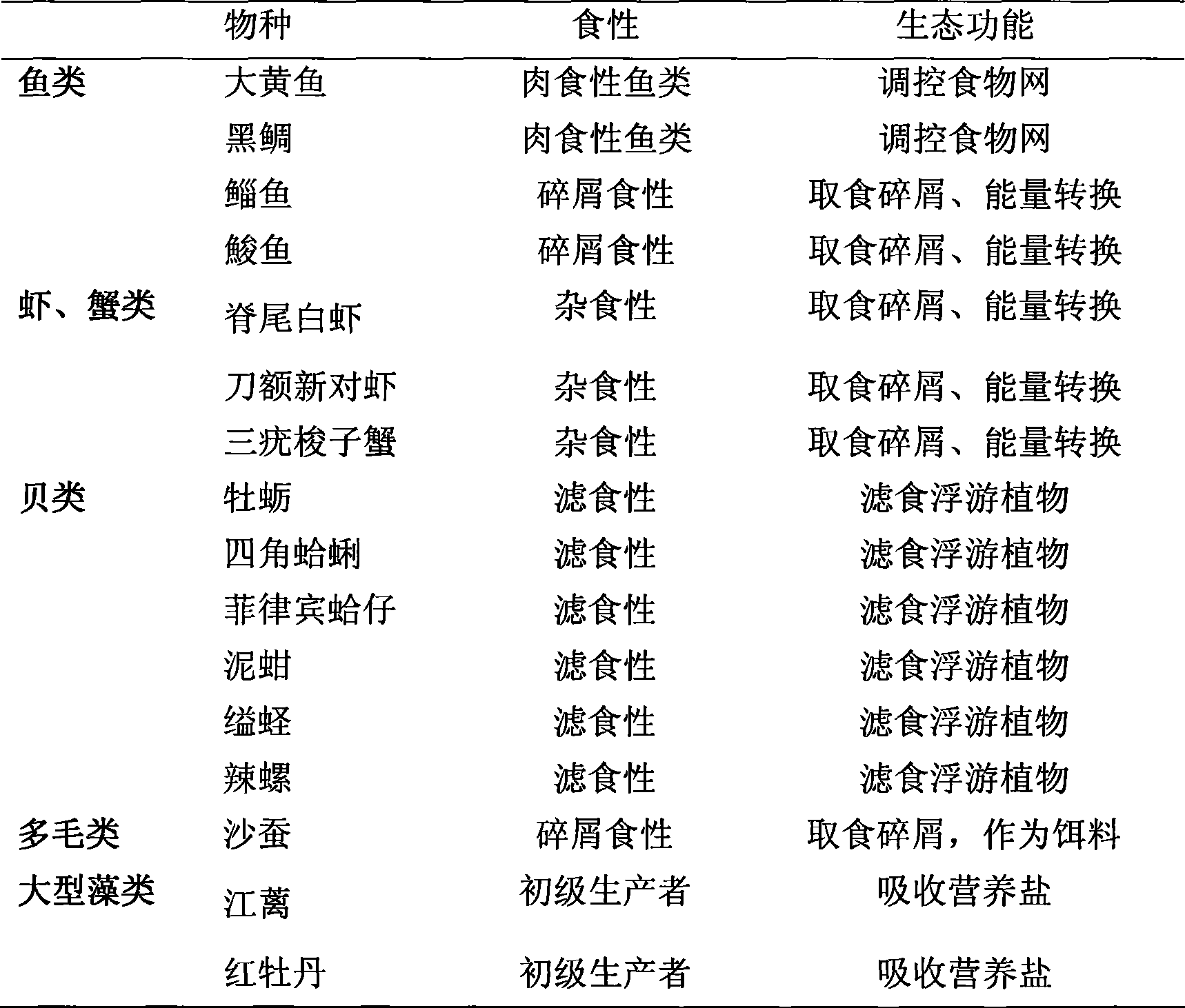

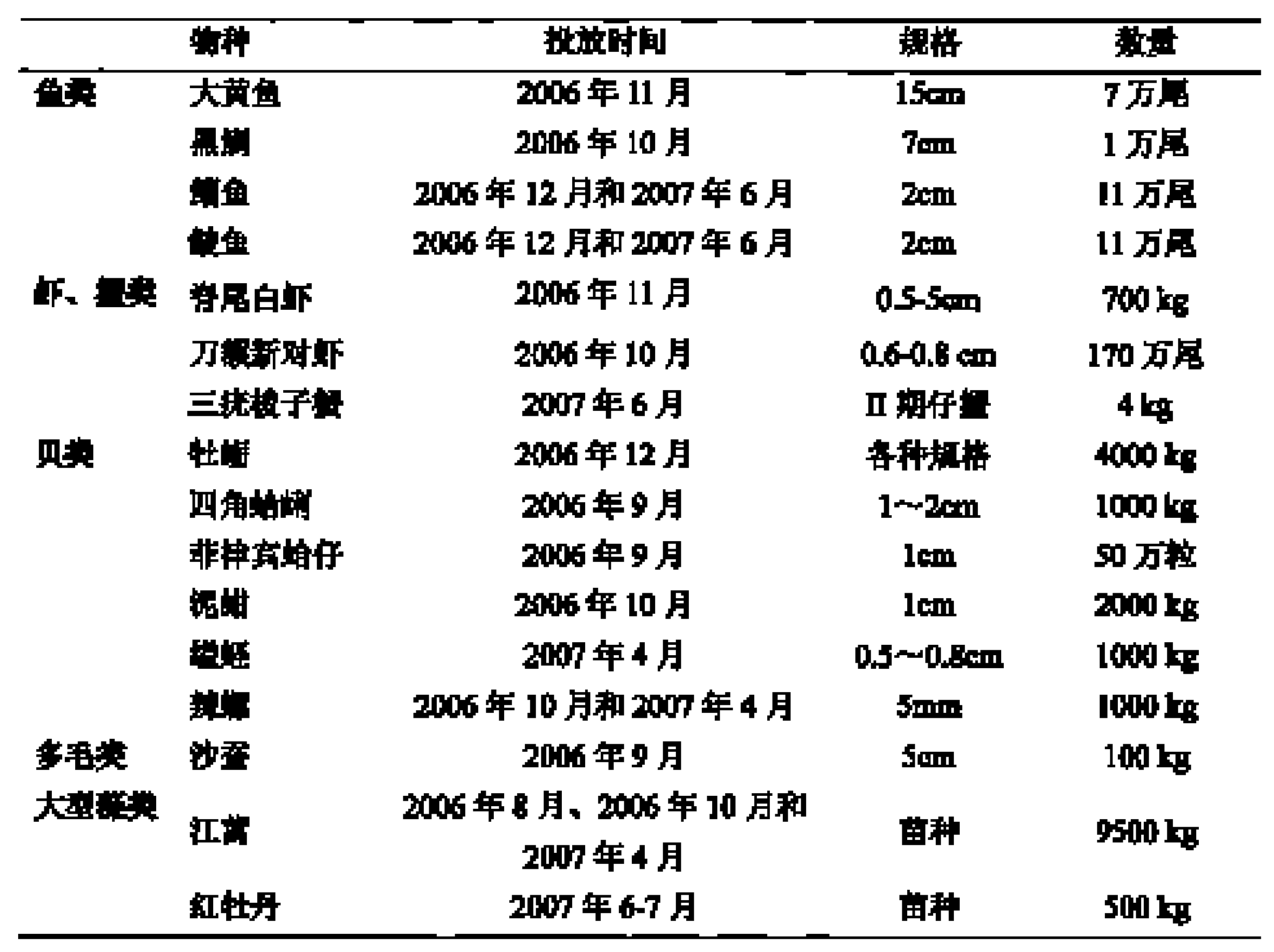

Control method of 'artificial lagoon' water body eutrophication in Jin shan urban beach

InactiveCN101381165AGrowth inhibitionEasy to controlBiological water/sewage treatmentAquatic ecosystemEutrophication

The present invention discloses a method for controlling water eutrophication of the 'artificial lagoon' of the Jinshan city beach, which comprises the following steps: firstly, according to the theory of trophodynamics, aquatic organisms are put into the water of the 'artificial lagoon'of the Jinshan city beach so as to adjust and control the aquatic ecosystem structure, and alga, polychetes, conches, shrimps, crabs and fishes are put into the water sequentially; and secondly, the water quality is detected and the aquatic ecology effect is evaluated. The method restrains the growth of microscopic algae, improves the water quality, improves the circulation rate of nitrogen and phosphorus elements in the ecosystem, enables more nutritive salt to be deposited in the consumers of each trophic level, and controls the growth of the phytoplankton in terms of the aspect of bottom-up effect (nutritive salt) and the aspect of the up-bottom effect (food chain), thereby achieving the aim of controlling the water eutrophication of the 'artificial lagoon' of the Jinshan city beach.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Circulating fluidized bed boiler system for achieving low nitrogen oxide discharge

InactiveCN105805730AImprove fluidization characteristicsWell mixedFluidized bed combustionStaged combustionFlue gasEngineering

The invention discloses a circulating fluidized bed boiler system for achieving low nitrogen oxide discharge. The circulating fluidized bed boiler system comprises a boiler, a cyclone separator, a dust remover and an induced draft fan which are sequentially connected. The circulating fluidized bed boiler system further comprises a primary air supply system and a secondary air supply system. A flue gas recirculation pipe is guided out of the rear portion of the induced draft fan and connected with the primary air supply system and the secondary air supply system in parallel. The secondary air supply system comprises a secondary air fan, a secondary air pipe, a plurality of secondary air vertical pipes arranged on the outer sides of a front wall and a rear wall of the boiler and secondary air nozzles, wherein the secondary air nozzles are arranged on a water cooling wall, connected with the secondary air vertical pipes and arranged in a dilute phase area of the boiler in a layered manner. According to the circulating fluidized bed boiler system, part of flue gas is mixed into primary air, the fluidization characteristic of a dense phase area during low-load running is improved, part of flue gas is mixed into secondary air, the air speed of the secondary air nozzles can be increased easily, a local high-temperature area is avoided, and generated NOx is reduced. By means of the secondary air arrangement manner of the system, the disturbance function of the flue gas in a hearth is increased, fuel is combusted fully, and the generated NOx is reduced.

Owner:QINGDAO JINTIAN THERMAL POWER CO LTD

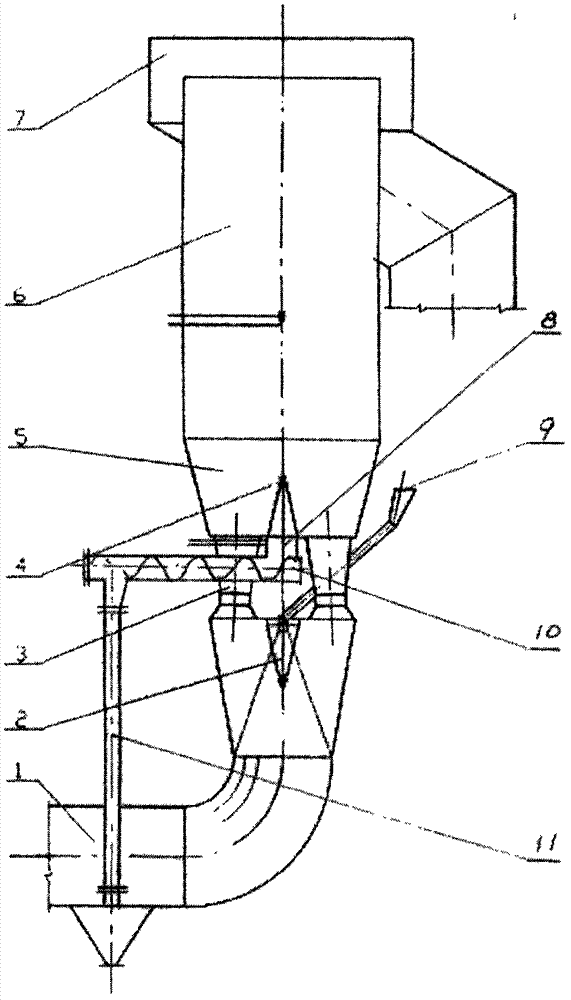

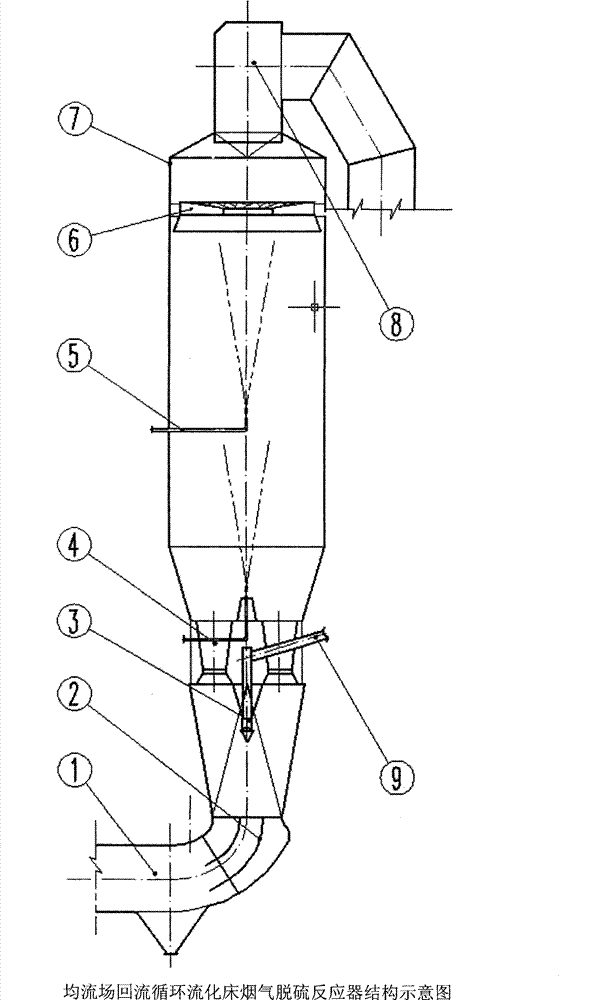

Homogeneous flow-field circulating fluidized bed flue gas desulfurization technology

InactiveCN102784556AGood effectWell mixedLighting and heating apparatusDispersed particle separationBiological activationDistributor

The invention relates to a homogeneous flow-field circulating fluidized bed flue gas desulfurization technology. A homogeneous flow-field circulating fluidized bed flue gas desulfurization reactor adopted by the homogeneous flow-field circulating fluidized bed flue gas desulfurization technology comprises a linear stream line-type flue gas inlet channel, a central built-in (center-explosion type) absorbent distributor, a flue gas accelerator, a humidifying activation nozzle, an annular flue gas outlet channel, an inner reflux circulating ash bin, a screw conveyer and an inner reflux circulating ash downcomer. The homogeneous flow-field circulating fluidized bed flue gas desulfurization technology has the advantages that a design is reasonable so that flue gas in the homogeneous flow-field circulating fluidized bed flue gas desulfurization reactor is acted upon by a homogeneous flow field, a homogeneous pressure field and a homogeneous temperature field; an absorbent has a high circulating ratio and a high utilization rate; a two-stage humidifying process can effectively improve reactivity of an absorbent; the humidifying activation nozzle is located in the center of a homogeneous flue gas flow field and a homogeneous absorbent flow field so that wall wetting, scaling and bed collapse are avoided effectively and flue gas desulfurization efficiency is improved effectively; the annular flue gas outlet channel is conducive to homogenization of a flow field in the homogeneous flow-field circulating fluidized bed flue gas desulfurization reactor and reduces a pressure drop and loads of a bag-type duster; and an inner reflux circulating conveying system can effectively prevent bed collapse and tower blocking so that safety, stability and a long running period of equipment are guaranteed.

Owner:北京博朗环境工程技术股份有限公司 +2

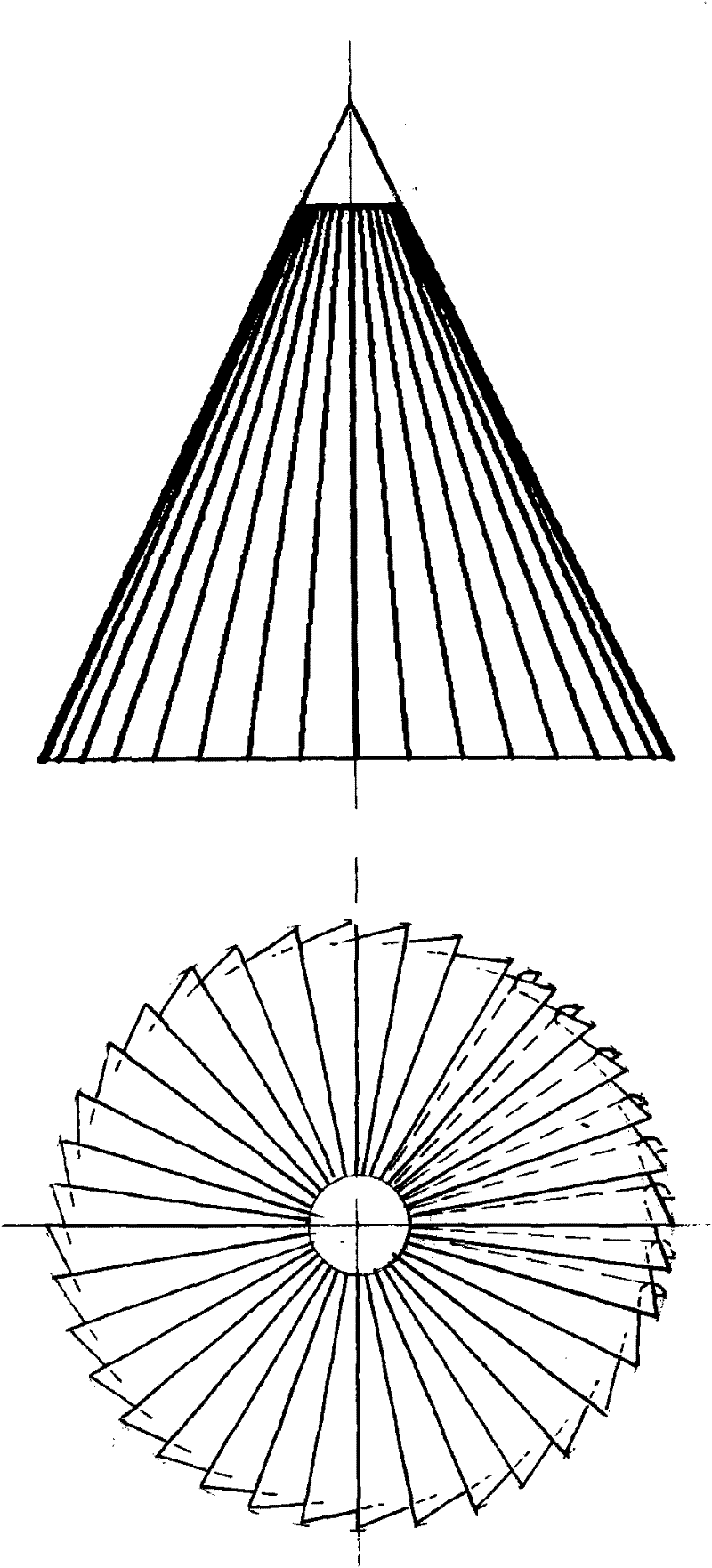

Flue gas desulfurization reactor of return current circulating fluidized bed in flow equalizing field

InactiveCN101402019BGood effectIncrease cycle ratioGas treatmentDispersed particle separationRefluxReturn current

The invention relates to a flue gas desulfurization technology for a uniform flow field internal reflux circulating fluidized bed. Core equipment, namely a reactor, of the flue gas desulfurization technology comprises a direct-current streamline bottom air inlet, a guide plate, a central built-in absorbent distributor, a flue gas accelerator, a humidified activated nozzle, a rotating-stream tray gas-solid separator and a central outlet flue on the upper part of a cylinder body of the reactor form the bottom up in turn, wherein the inside of an inlet flue of the reactor is provided with a dual-chip circular uniform flue gas distribution guide plate; and the inside of the reactor is provided with the central built-in absorbent distributor, the 'Laval nozzle' - type flue gas accelerator, the two-stage double-fluid humidified activated nozzle and the rotating-stream tray gas-solid separator. The flue gas desulfurization technology is reasonable in configuration; flue gas in the reactor obtains ideal and stable uniform fluid field and temperature field; an absorbent obtains high circulation ratio and high utilization rate; and two-stage humidification can effectively improve the reaction activity of the absorbent, and can also effectively avoid wetted wall, fouling and collapsed bed. Moreover, the flue gas desulfurization technology guarantees the desulfurization efficiency, obviously reduces the dust content of the outlet flue, greatly lightens the load of a rear bag-type duster, and solves the technical problems in a flue gas desulfurization technology for a semi-dry circulating fluidized bed.

Owner:北京联合拓展科技有限公司

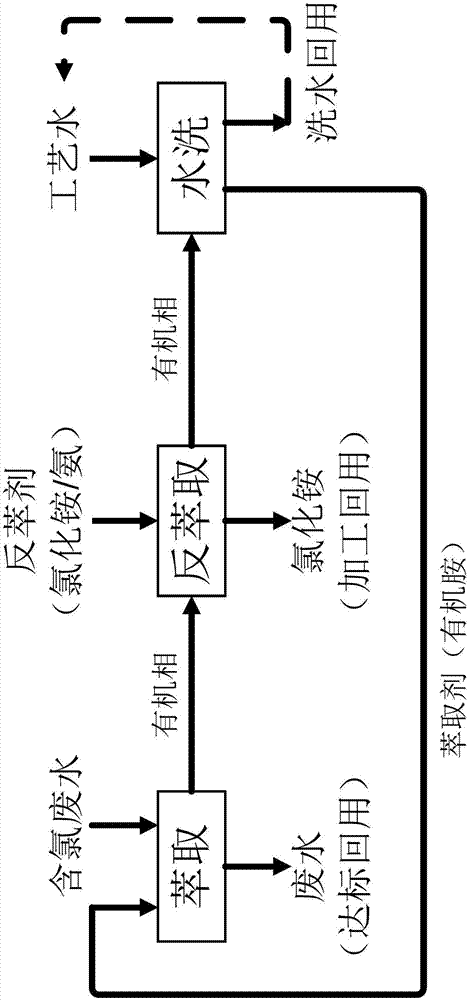

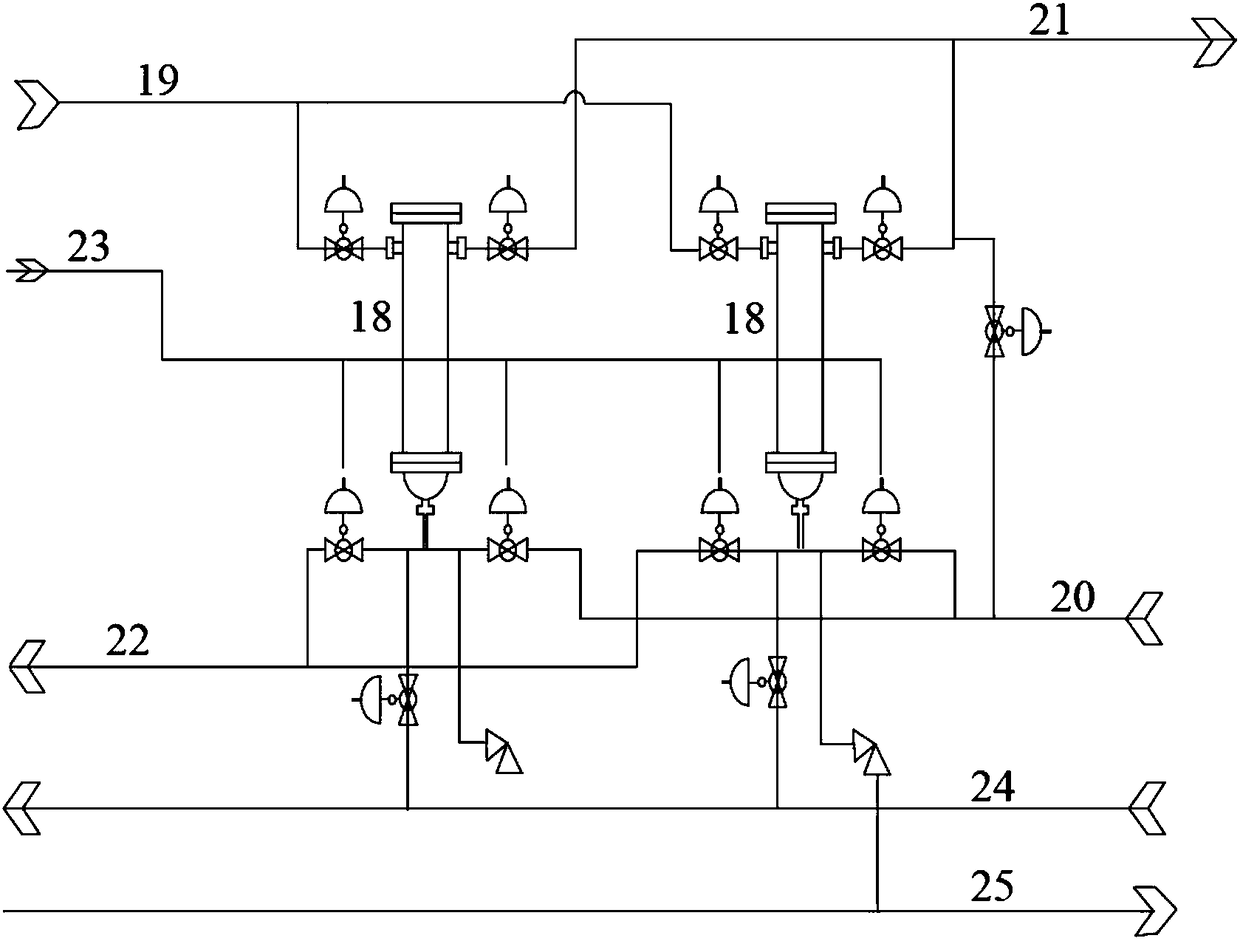

Method for recycling chloride ions in wastewater

ActiveCN106882884AIncrease cycle ratioEmission reductionWater contaminantsMultistage water/sewage treatmentReflux extractionEmission standard

The invention provides a method for recycling chloride ions in wastewater and relates to the technical field of industrial water treatment and comprehensive utilization of resources. The method provided by the invention comprises the following steps: pre-treating chloride-containing wastewater to remove suspension matters; conveying the wastewater into an extracting tower; taking an organic amine as an extracting agent, and carrying out countercurrent extraction and desulfurization to remove the chloride ions in the wastewater; discharging raffinate from an extracting system; when the content of the chloride ions in the raffinate does not reach circulating utilization or emission standards, carrying out reflux extraction; enabling an extracting solution to enter a back extraction tower; carrying out countercurrent back extraction on an ammonium chloride solution containing ammonia to generate ammonium chloride; separating by a water washing tower, cooling and crystallizing to obtain an ammonium chloride product; returning organic amine back into the extracting tower for recycling and returning a washing solution back to the water washing tower for recycling.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

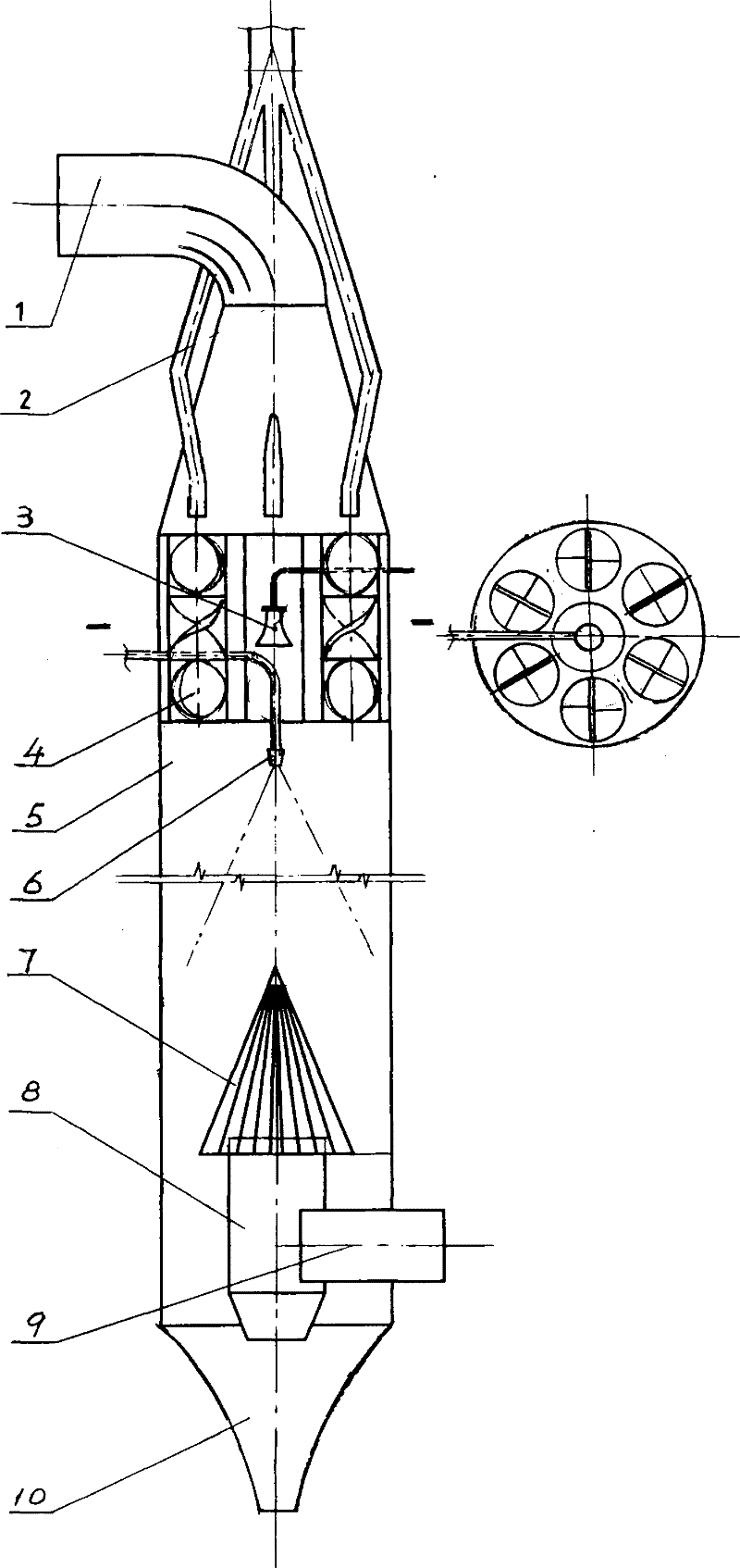

Flue gas desulfurization reactor for descending circulating fluidized bed

InactiveCN102441324AGood effectFull collisionGas treatmentDispersed particle separationNuclear engineeringFlue gas

The invention relates to a flue gas desulfurization technique for a descending circulating fluidized bed. The core equipment of the reactor is a reactor structure, which comprises a straight-flow streamline inlet flue, an absorbent distributor, a sound-wave soot blower, a static mixer, a reaction shell, a humidifying and activating nozzle, a tapered swirl-board gas-solid separator, a gas-solid separation guide cylinder, a desulphurized-gas outlet flue and a hyperbolic ash hopper. The reactor has a rational configuration which enables the smoke in the reactor to be fully collided and mixed with the absorbent so as to obtain a stable and even flow field, a temperature field and a pressure field. Besides, the reactor enables the absorbent to obtain with higher circulation ratio and use ratio. The invention is out of any problems such as sticking wall, scaling and bed collapsing; meanwhile, the reactor reduces the dust load of the exit flue gas obviously and also lowers the load of the bag-type dust remover at the back part greatly, thereby guaranteeing the safe, reliable and long-term operation and solving the technical problem in the semidry method flue gas desulfurization effectively.

Owner:北京博朗环境工程技术股份有限公司 +2

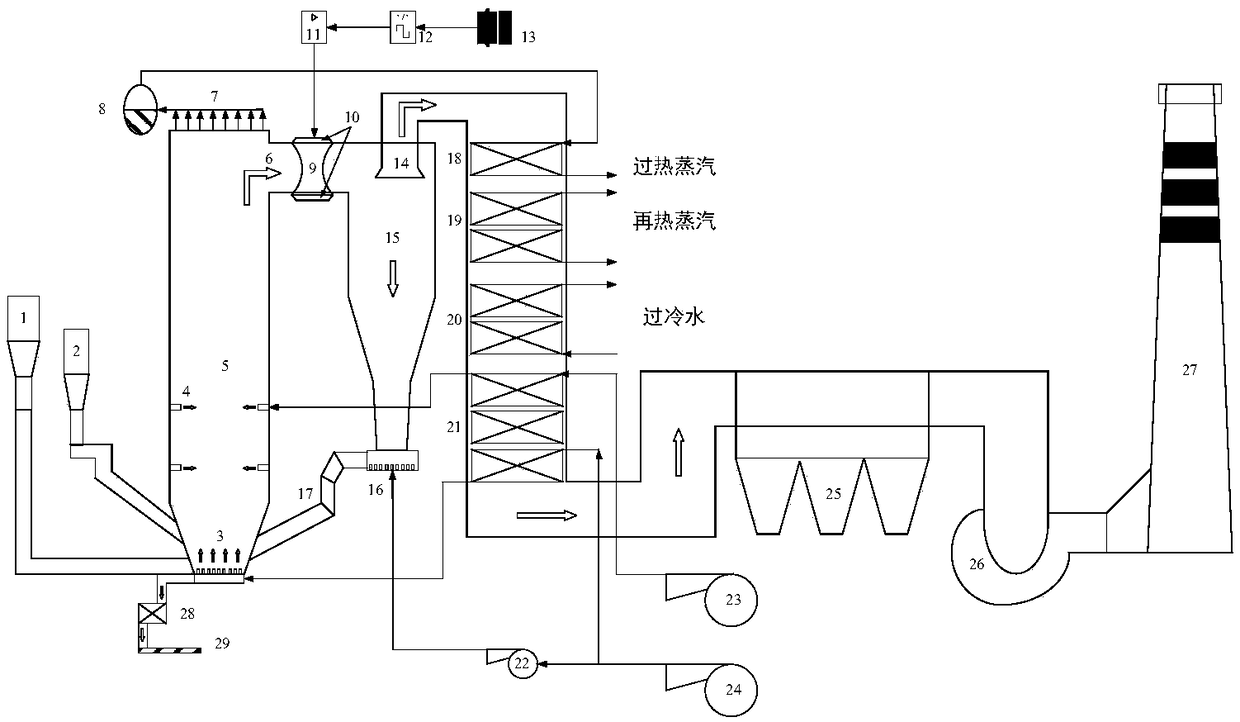

System and method for achieving flexible operation of circulating fluidized bed boiler based on acoustic wave technology

PendingCN109442395AIncrease flexibilityImprove combustion efficiencyFluidized bed combustionApparatus for fluidised bed combustionLow nitrogenEngineering

The invention provides a system and method for achieving flexible operation of a circulating fluidized bed boiler based on the acoustic wave technology. The system comprises the circulating fluidizedbed boiler and an acoustic wave emission device, wherein the circulating fluidized bed boiler comprises a limestone powder feeding device, a coal feeding device, a furnace, a horizontal flue, a central cylinder, a separator, a return feeder and a tail flue; and the acoustic wave emission device comprises a loudspeaker, a compression drive device and a remote control device. By means of the systemand method for achieving flexible operation of the circulating fluidized bed boiler based on the acoustic wave technology, the particle size distribution of flue gas and dust can be flexibly changed,and the circulation ratio of materials is increased through acoustic wave agglomeration effect, so that the system and the method are directly beneficial to improving the combustion efficiency of theboiler and reducing the combustible index of fly ash, and economic benefits are generated; and the system and the method are indirectly beneficial to low nitrogen combustion and reducing the emissionconcentration of SO2, NOX and other pollution gases in the boiler, so that environmental benefits are generated.

Owner:HUANENG CLEAN ENERGY RES INST

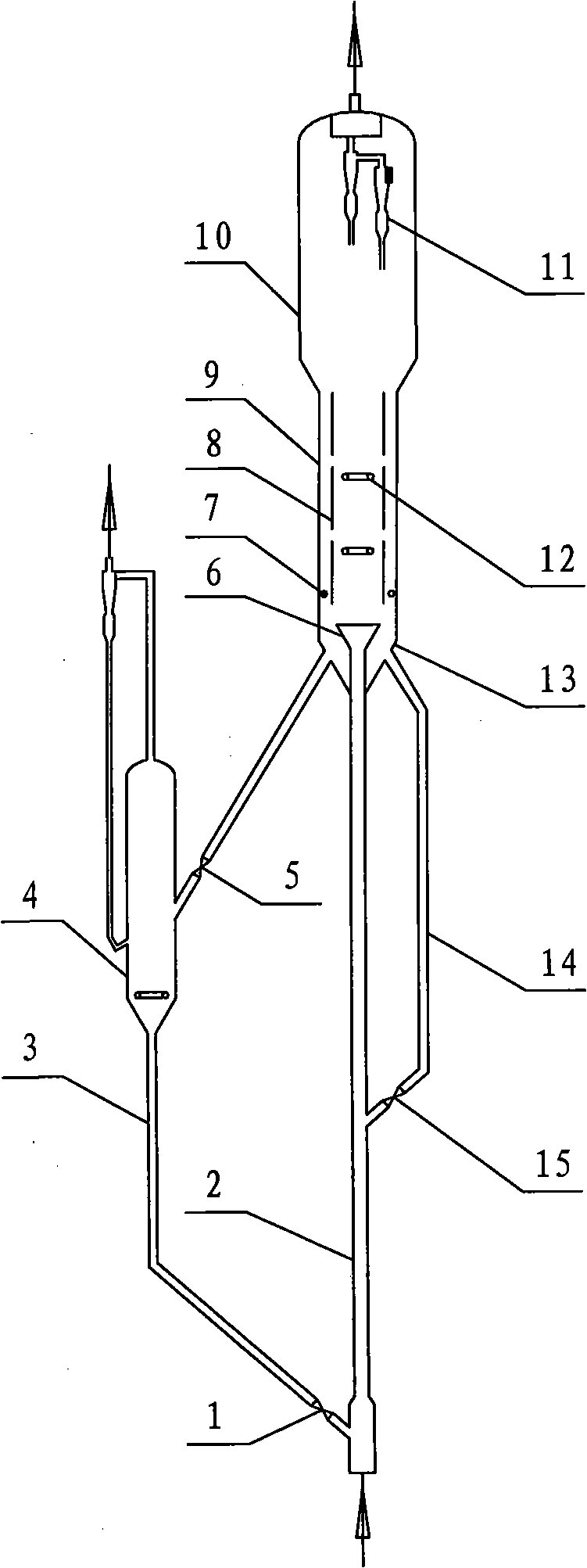

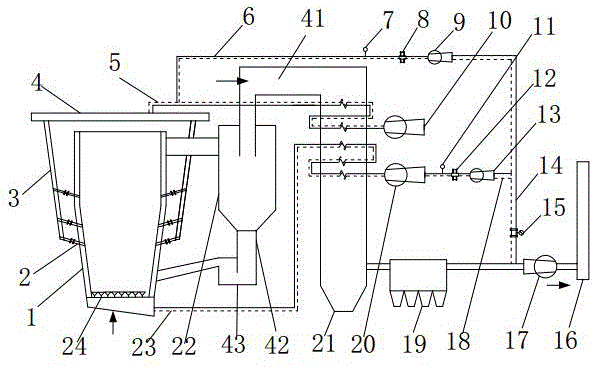

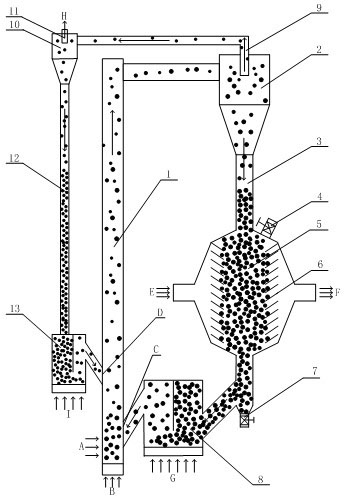

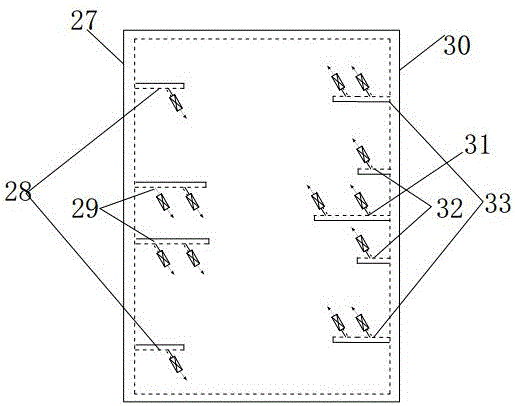

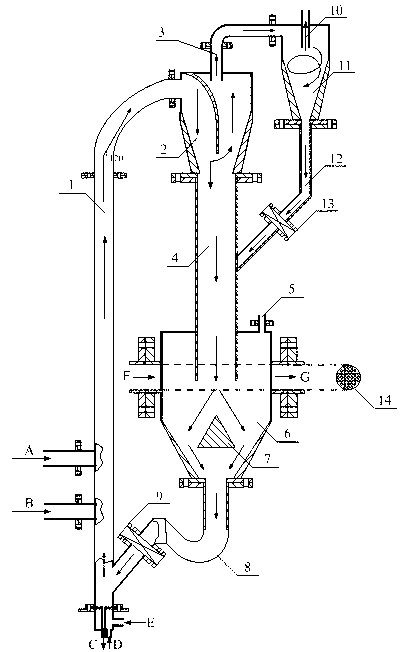

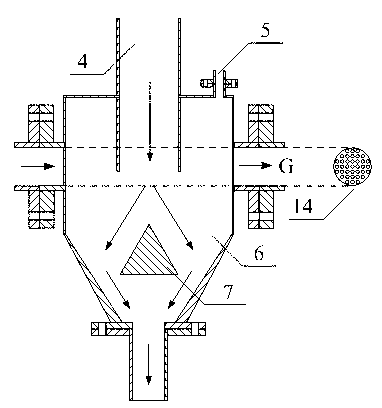

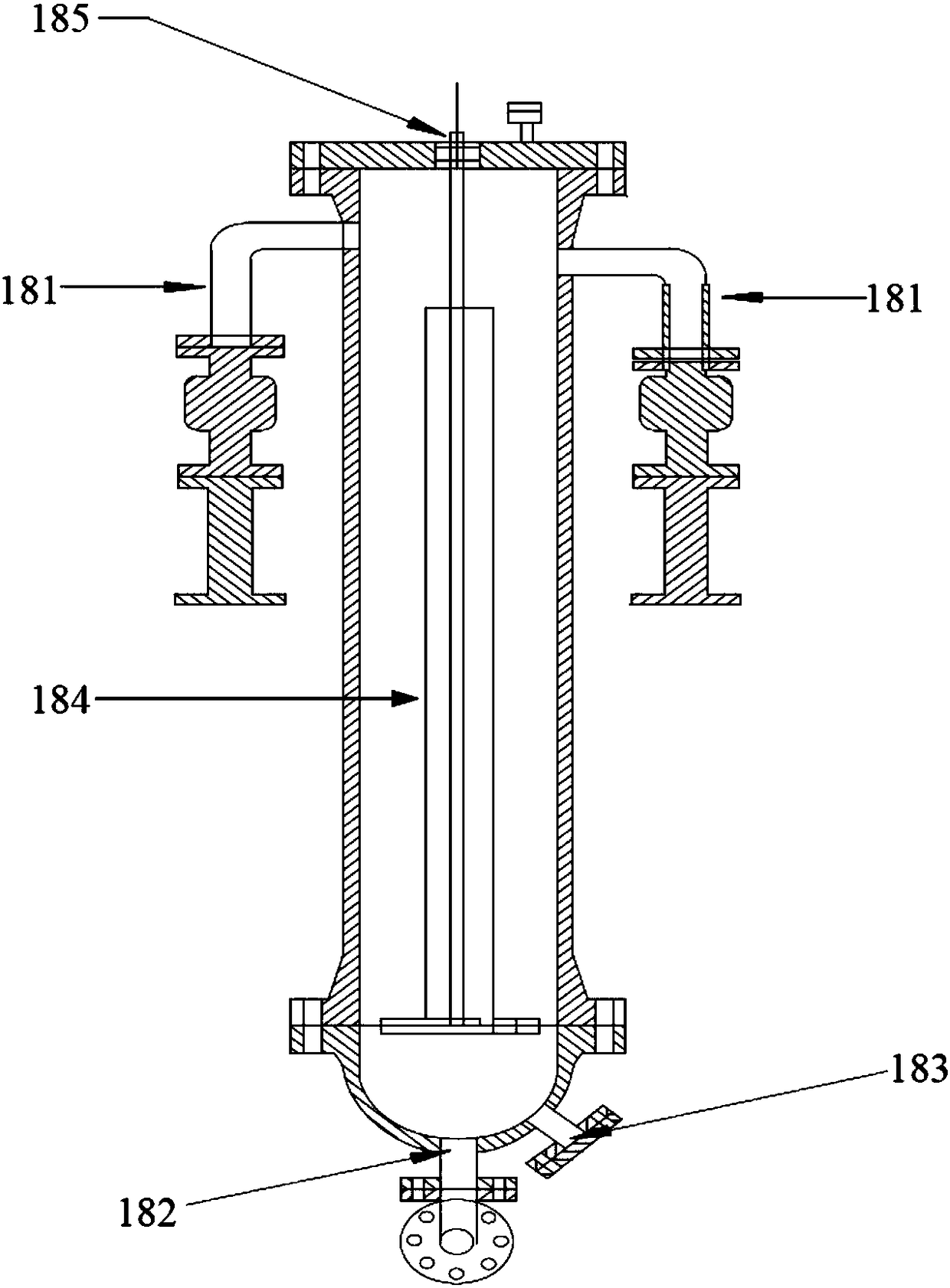

Device and method for separating CO2 by circulating fluidized bed chemical looping-combustion of coal and combustible solid waste

InactiveCN102705822ASolving the Response Matching ProblemIncrease cycle ratioFluidized bed combustionIndirect carbon-dioxide mitigationProcess engineeringCoal

The invention discloses a device and a method for separating CO2 by circulating fluidized bed chemical looping-combustion of coal and combustible solid waste; the device mainly comprises three portions including a burning reaction system, a separation system and an oxygen carrying reaction system, wherein the burning reaction system is a circulating fluidized bed fuel reactor (1); the separation system comprises a one-stage inertial separator (2), a one-stage inertial separator outlet (3), a one-stage dipleg (4), a two-stage cyclone separator (11), a two-stage cyclone separator outlet (10) and a two-stage dipleg (12); the oxygen carrying reaction system comprises a cross-flow moving bed air reactor (6), a fresh oxygen carrier particle feeder (5), a J-shaped material returning valve (8) and an inactive oxygen carrier particle discharger (C); the method can enable the speed of combustion reaction of coal / combustible solid waste and oxygen carrier to be matched with the speed of oxygen carrying reaction of the oxygen carrier so as to achieve the effects that burning efficiency is high, oxygen carrying capability of the oxygen carriers is strong, concentration of separated CO2 is high, and final CO2 capturing rate is high.

Owner:SOUTHEAST UNIV

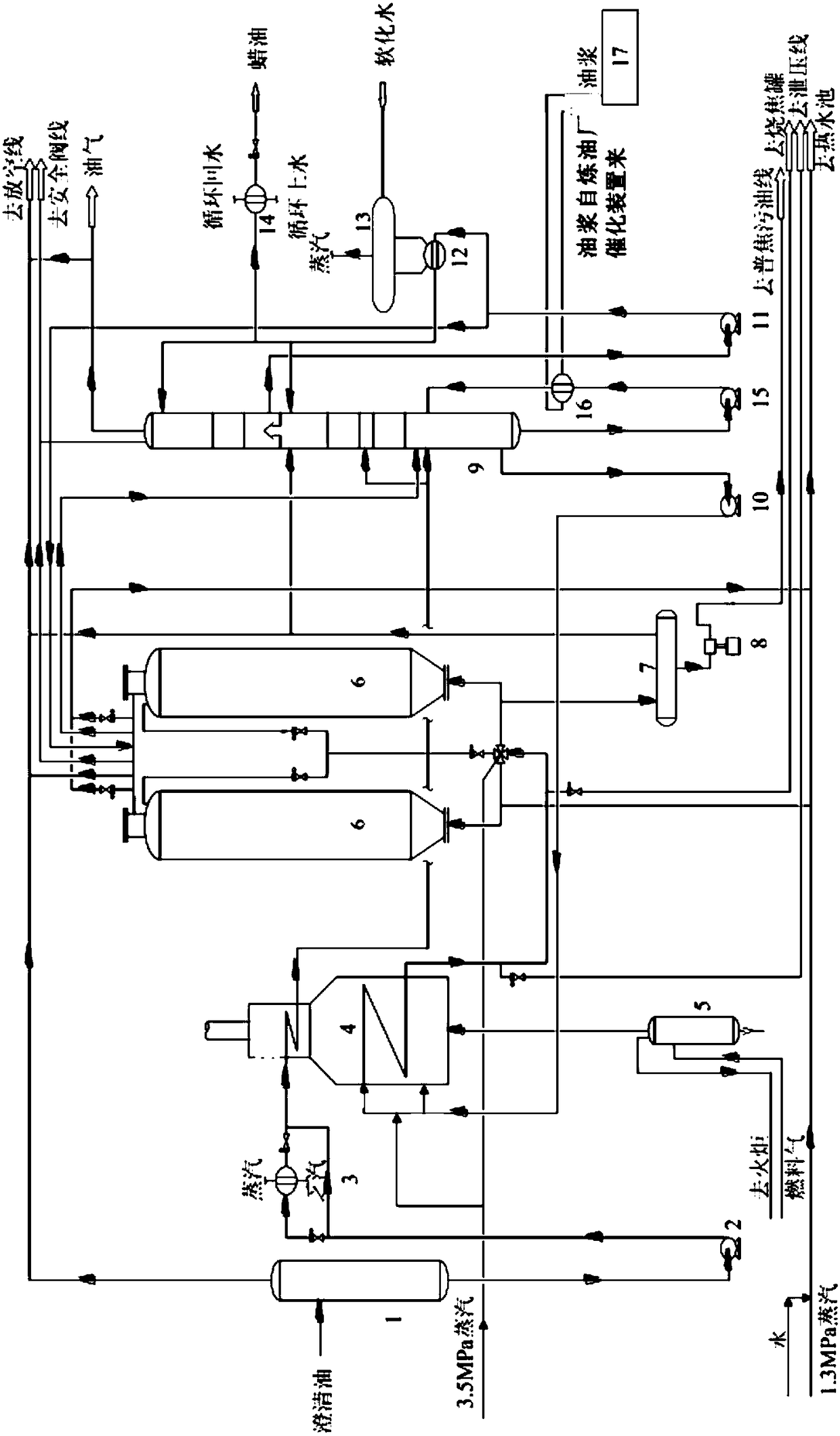

Production method and device of needle coke

PendingCN108219839ALow costSolve the long-term problems that have plagued needle coke production technologyHydrocarbon oils treatmentWaxFour-way valve

The invention provides a production method and device of needle coke. The production method comprises the following steps: clarified oil enters an evaporation section of a heat exchange condensation tower through a convection chamber of a heating furnace, oil and gas overflowing from the top of coke towers enters the evaporation section of the heat exchange condensation tower, the clarified oil exchanges heat with the oil and gas from the coke tower, components below wax oil in the clarified oil and circulating oil condensed from the oil and gas form combined oil; the combined oil enters one coke tower for coke generation through a four-way valve after being heated by a radiation chamber of the heating furnace, and the two coke towers are used for coke generation in turn; wax oil circulation is established in the heat exchange condensation tower, and part of the wax oil is pumped out. The device at least comprises a clarifying oil buffer tank, a raw material pump, the heating furnace,the coke towers, the heat exchange condensation tower, a radiation feeding pump, a wax oil pump, a wax oil evaporator and a wax oil cooler. The provided production method and device of the needle cokecan produce the high-quality needle coke, and have the advantages that process flow is simple, operability is high, industrial production is facilitated and the like.

Owner:亚通石化集团有限公司

Fused magnesium molten lump waste heat utilizing method and system

The invention relates to fused magnesium molten lump waste heat utilizing method and system. Molten fused magnesium molten lumps are sequentially sent into a magnesium molten lump waste heat recyclingchamber, a cracked magnesium molten lump waste heat recycling chamber and an automatic-deoxidizing magnesium molten lump waste heat recycling chamber so that waste heat can be recycled respectively.Turbine condensed water exchanges heat with the cracking fused magnesium molten lumps and then is sent to the automatic-deoxidizing magnesium molten lump waste heat recycling chamber to exchange heatwith the cracked fused magnesium molten lumps so that saturated water can be generated. The saturated water exchanges heat with the fused magnesium molten lumps which are just molten and then enters aflash tank so that saturated vapor can be generated and enter a turbine to be used for power generation. According to the method and the system, the fused magnesium molten lumps sequentially enter the three waste heat recycling devices so that waste heat can be recycled in stages, the finally generated saturated vapor is used for driving the turbine to generate power, the output of a system heatsource is table, the heat conversion rate is high, and the waste heat recycling efficiency is high.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

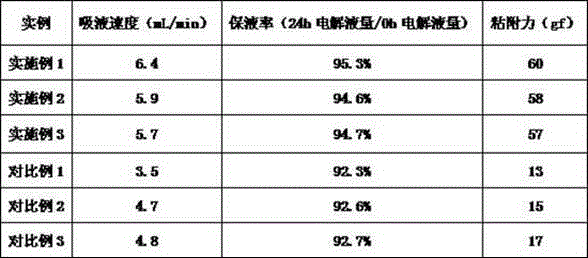

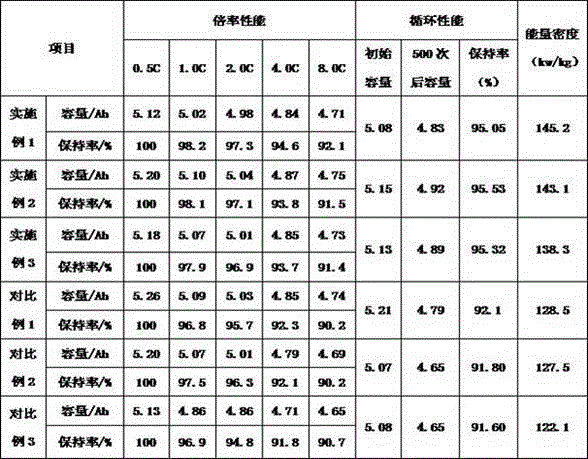

Preparation method of positive pole piece of high-rate lithium-ion battery

InactiveCN105633353AImprove permeabilityEvenly distributedElectrode carriers/collectorsSecondary cellsHigh rateElectrical battery

The invention provides a preparation method of a positive pole piece of a high-rate lithium-ion battery. The method is characterized by comprising the following steps: firstly, preparing a composite primer liquid; coating the surface of a nickel foam cathode current collector with the composite primer liquid by a gravure printing or spraying technology and drying the nickel foam cathode current collector to obtain a cathode primed piece; and coating the surface with cathode lithium iron phosphate slurry, and carrying out drying and roll-cutting procedures to prepare the positive pole piece. The prepared positive pole piece develops the advantages of high conductivity, high adhesive force and corrosion resistance of a priming coat and the advantage of low volume energy density of a mesh current collector; the cycle performance and the rate capability of the pole piece in the lithium-ion battery are greatly improved; meanwhile, the energy density of the battery is also improved; and the lithium-ion battery prepared from the pole piece is especially suitable for application in a hybrid electric vehicle.

Owner:JIANGSU LENENG BATTERY INC

Production method of feed grade calcium phosphate acidity agent

ActiveCN101288440AThe material is dry and does not stickShort defluorination timeAnimal feeding stuffAccessory food factorsCalcium biphosphatePhosphorite

The invention discloses a production method for a feed-grade calcium phosphate acidity agent; the production method includes that: excessive phosphoric acid and ground phosphorite are added in a reactor for hybrid reaction to prepare calcium dihydrogen phosphate material containing fluorine and phosphoric acid, the material is added into a dryer for drying and defluorination to prepare the defluorinated calcium phosphate acidity agent containing free phosphoric acid. The production method has the main technical advantages of quick defluorination, extremely high efficiency, resource saving, extremely low cost, environmental-friendly property, energy saving and emission reduction; the technique inevitably brings about the revolution of feed calcium phosphate acidity agent industry.

Owner:GUIZHOU CHANHEN CHEM CO LTD

Undok pulverized coal gasification furnace with nitrogen, water vapor and synthesis gas-driven material return mechanism

InactiveCN104593086ALow calorific valueGuaranteed uptimeGranular/pulverulent flues gasificationSyngasWater vapor

Owner:HARBIN INST OF TECH

Fixed bed reactor

PendingCN112934122AReduce resistanceReduce the cycle rateHydrogenChemical/physical processesThermodynamicsPtru catalyst

The present invention discloses a fixed bed reactor. The fixed bed reactor comprises a shell, the shell comprises: a straight cylinder (2), a lower sealing head (1) and an upper sealing head (3), wherein the upper sealing head is provided with a reaction gas inlet (4) and a charging port (7), and the lower sealing head is provided with a manhole (11) and a discharging port (14); a lower pipe box (12) which is connected with one end, far away from the straight cylinder, of the lower sealing head and is provided with a hot water inlet connecting pipe (13); an upper tube box (6) which is connected with one end, far away from the straight cylinder, of the upper sealing head and is provided with a steam-water mixture outlet connecting tube (5); a heat exchange tube bundle (8), wherein heat exchange tubes of the heat exchange tube bundle (8) are fixed and communicated with the tube plates of the upper tube box, and the lower tube box, and the diameter of the tube plate of the upper tube box and the diameter of the tube plate of the lower tube box are smaller than the diameter of the shell; a central pipe which is used for collecting and discharging reacted gas; and a catalyst frame. According to the reactor disclosed by the invention, the heat exchange tubes can be checked and plugged without taking out internal parts, and loading and unloading of a catalyst are not hindered; and the large-angle arched heat exchange pipe is small in water circulation resistance, and reaction heat can be quickly removed.

Owner:张晓艳

Coal slime treatment method

InactiveCN109000221AImprove thermal efficiencyStable oxidation temperatureFluidized bed combustionApparatus for fluidised bed combustionResource utilizationFlue gas

The invention discloses a coal slime treatment method. The treatment method comprises the following steps: enabling coal slime to enter a reactor and be in contact with temperature-regulating medium particles in the reactor, carrying out a reaction under the effect of fluidizing air, performing separating treatment on the reacted flue gas, separating the large-size temperature-regulating medium particles taken out by the flue gas, returning to the reactor, and performing subsequent treatment on ground fine powder of small-particle coal slime and temperature-regulating medium particles in a flyash form along with the flue gas. According to the coal slime treatment method disclosed by the invention, due to use of the temperature-regulating medium particles in the reactor, a stable coal slime temperature is provided, coal slime reduction, innocent treatment and high-efficiency resource utilization can be realized, oxidation burning can be performed by taking pure coal slime as the raw material for recovering the heat, and the coal slime oxidation efficiency and thermal efficiency of the device are high.

Owner:DALIAN EAST REFRIGERATION EQUIP +1

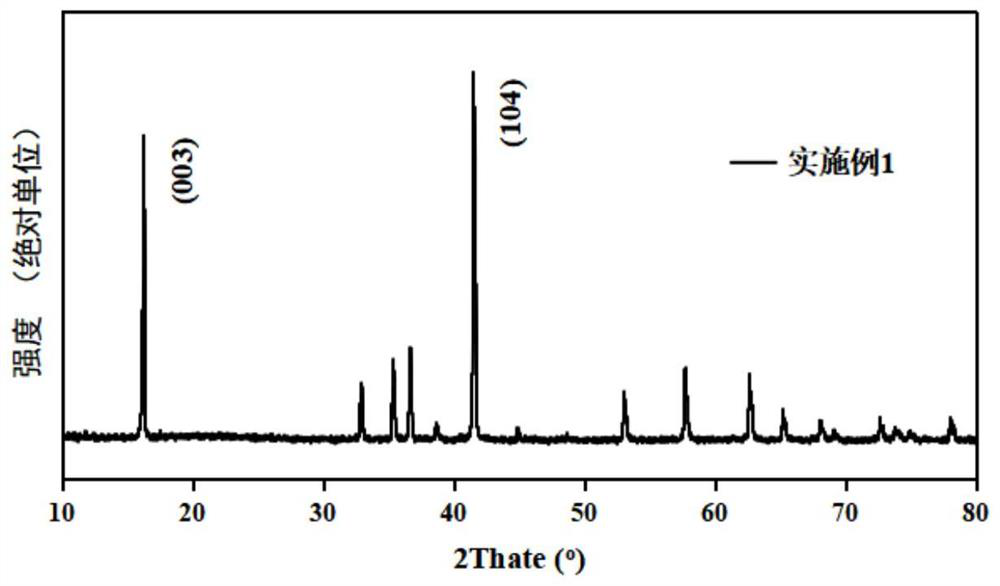

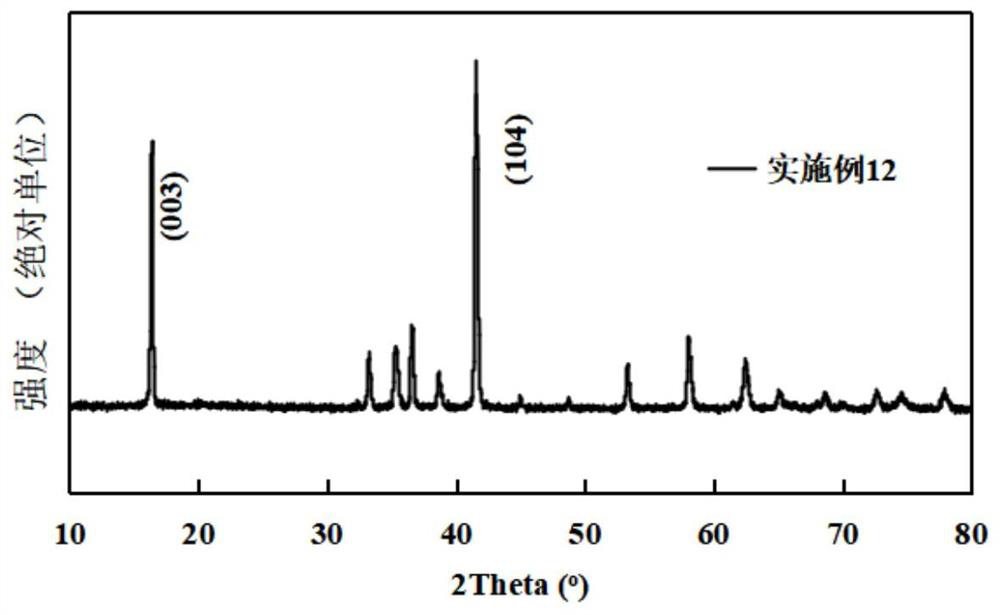

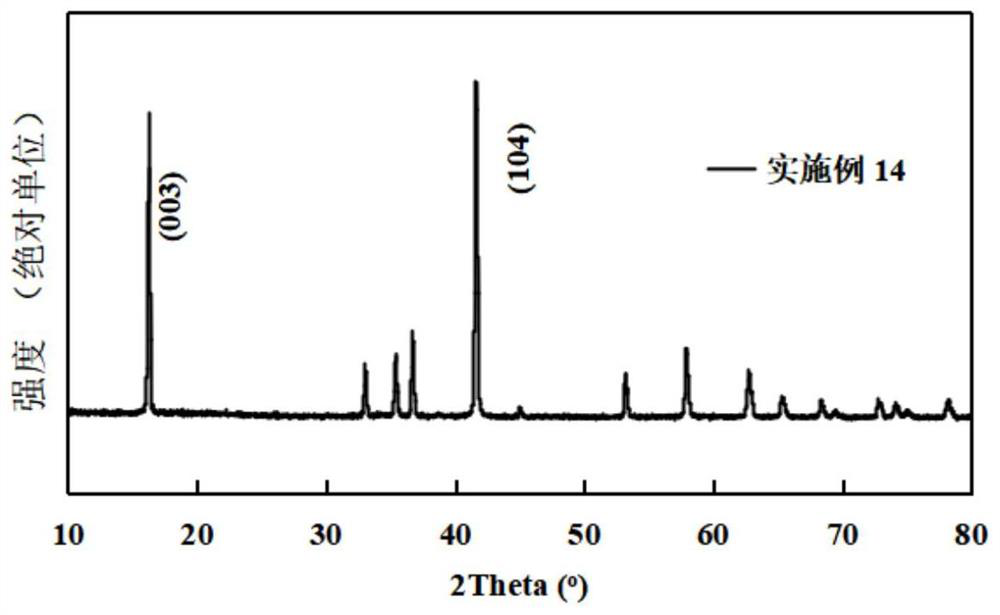

Sodium-containing oxide positive electrode material, preparation method and application thereof, positive plate and application thereof

ActiveCN114843498AIncrease capacityReduce capacityRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsSecondary cellsPhysical chemistrySodium-ion battery

The invention relates to the technical field of sodium ion batteries, and discloses a sodium-containing oxide positive electrode material, a preparation method and application thereof, a positive plate and application thereof. The content of soluble alkali on the surface of the positive electrode material meets the following conditions: (1) m (Na2CO3) + m (NaOH) is less than or equal to 15000ppm; (2) 0.1 < = m (Na2CO3) / m (NaOH) < = 1. The surface of the sodium-containing metal oxide positive electrode material has low soluble alkali content, and when the positive electrode material is applied to a sodium ion battery, the battery can have high capacity, high rate and high safety, and sodium ion deintercalation / intercalation reaction can be continuously performed without obviously causing reduction of the battery capacity.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

Device and method for preparing sulfur by means of carbothermic reduction of SO2

ActiveCN108640090ARelieve pressureAvoid cloggingSulfur preparation/purificationGas solidHigh concentration

The invention relates to a device and method for preparing sulfur by means of carbothermic reduction of SO2 and belongs to the technical field of sulfur recovery. The device includes a material chamber,a gas-solid mixing chamber,a carbothermic reduction tower,a high-temperature gas-solid separator,an ash hopper and a carbon-based reducing agent buffering tank. The carbothermic reduction tower includes a reaction segment and the gas-solid mixing chamber from top to bottom,the material chamber is connected to a material inlet of the gas-solid mixing chamber,a reducing gas outlet is formed in thetop of the reaction segment and connected to the high-temperature gas-solid separator,the ash hopper and the carbon-based reducing agent buffering tank in sequence,and the carbon-based reducing agentbuffering tank is connected to a material returning port of the gas-solid mixing chamber; the gas-solid mixing chamber is internally provided with a bracket,a distribution plate and a supplemented gas inlet from top to bottom in sequence. A reaction gas inlet pipe enters the gas-solid mixing chamber from the bottom of the gas-solid mixing chamber,the bracket is positioned on the lower sides of the material inlet and material returning port,one end of the reaction air inlet pipe is positioned above the bracket,and SO2 flue gas with high concentration is subjected to preliminary desulfurization; sulfur is recovered,blockage caused by accumulation of materials is avoided,and the materials are fully utilized.

Owner:SHANDONG UNIV

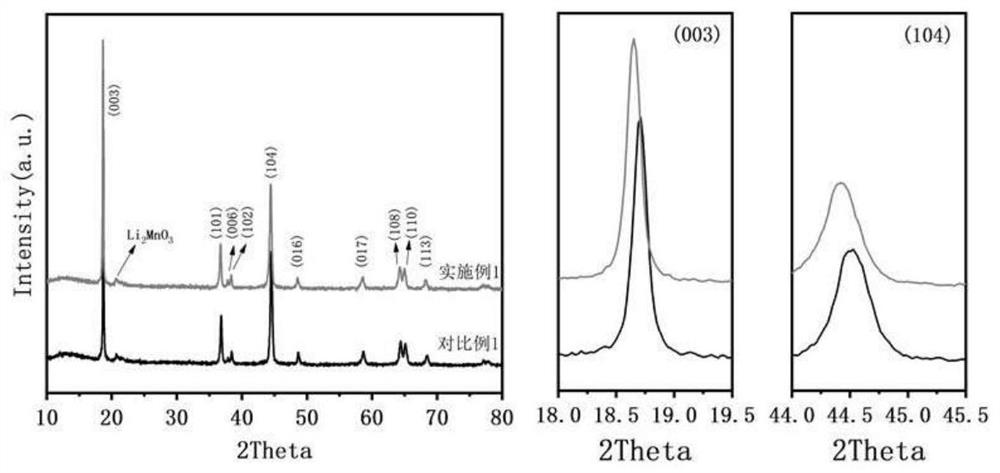

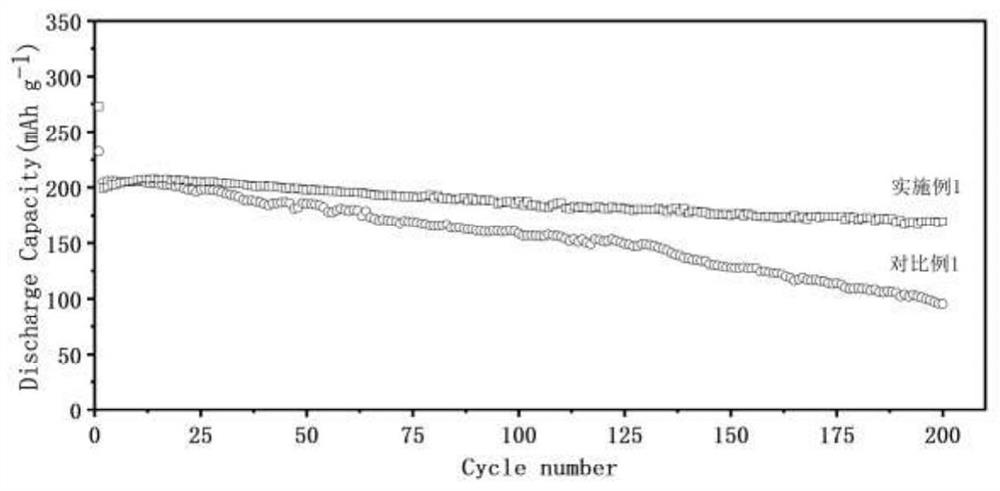

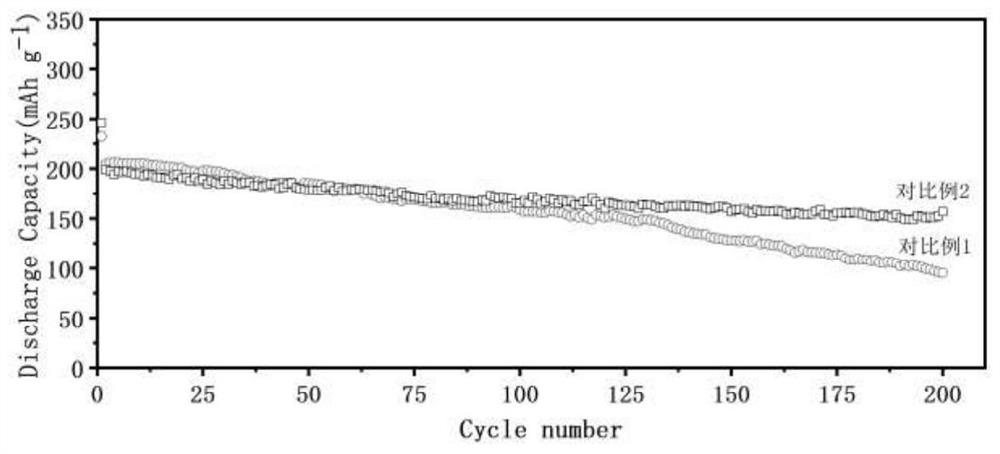

Anion-cation co-doped lithium-rich manganese-based positive electrode material as well as preparation method and application thereof

PendingCN112072114AIncrease the lattice constantReduce polarizationSecondary cellsPositive electrodesManganesePhysical chemistry

The invention provides a preparation method and application of an anion-cation co-doped lithium-rich manganese-based positive electrode material, which comprises the following steps: uniformly mixingprecursor powder, lithium-containing compound powder, a certain amount of alkali metal M1-containing compound powder and a certain amount of negative valence M2-containing compound powder, carrying out heat treatment at 300-600 DEG C for 3-7 hours, heating to 700-1000 DEG C, and carrying out heat treatment for 8-20 hours. The element M1 replaces Li to inhibit migration of transition metal ions tothe lithium layer so as to stabilize the structure; the element M2 replaces O, so that the release of oxygen can be inhibited. According to the anion-cation co-doped lithium-rich manganese-based positive electrode material, the interlayer spacing is enlarged, the lithium ion migration rate is increased, the structure is stable, the average working voltage is relatively high, and the rate capability and the cycle performance are good.

Owner:CENT SOUTH UNIV

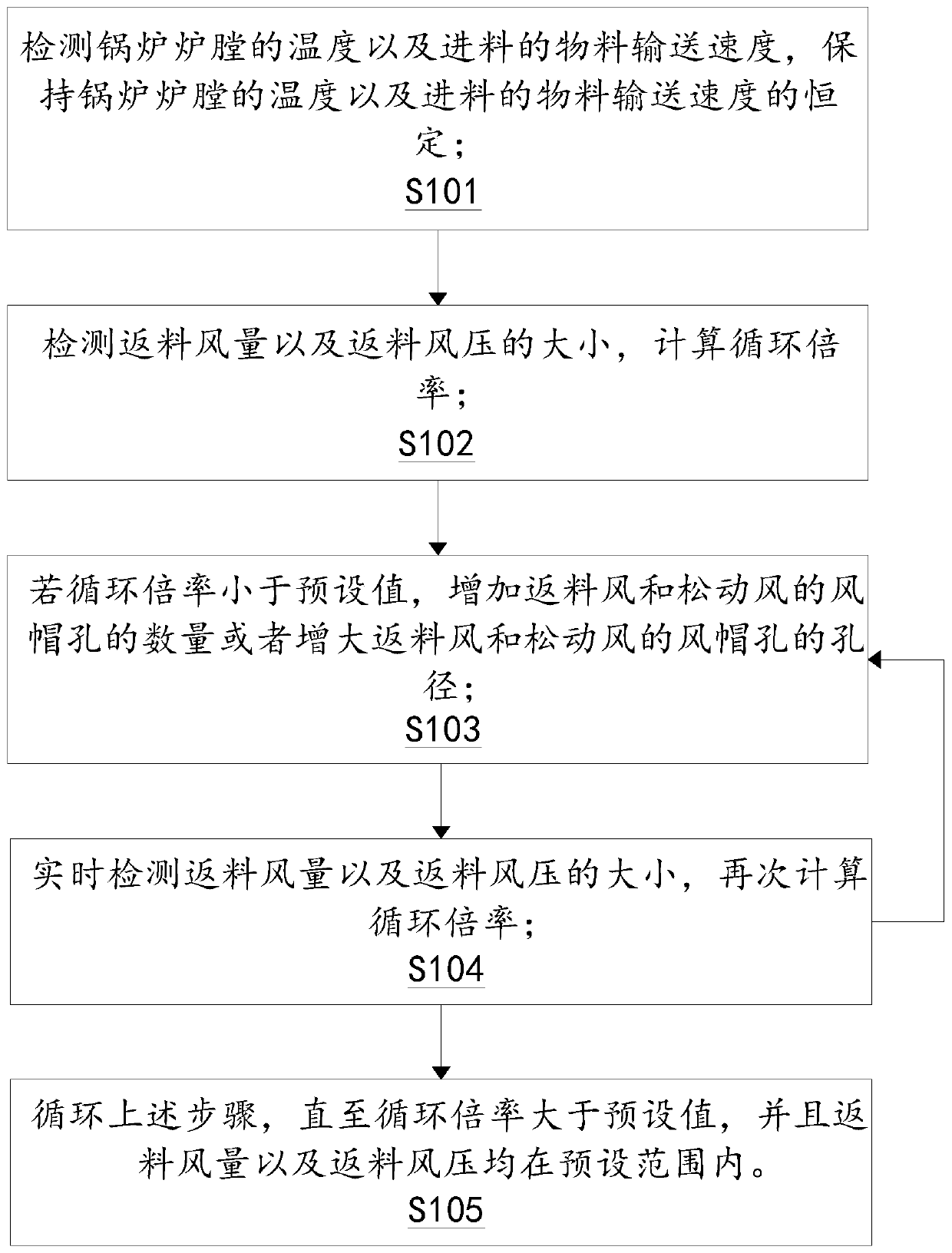

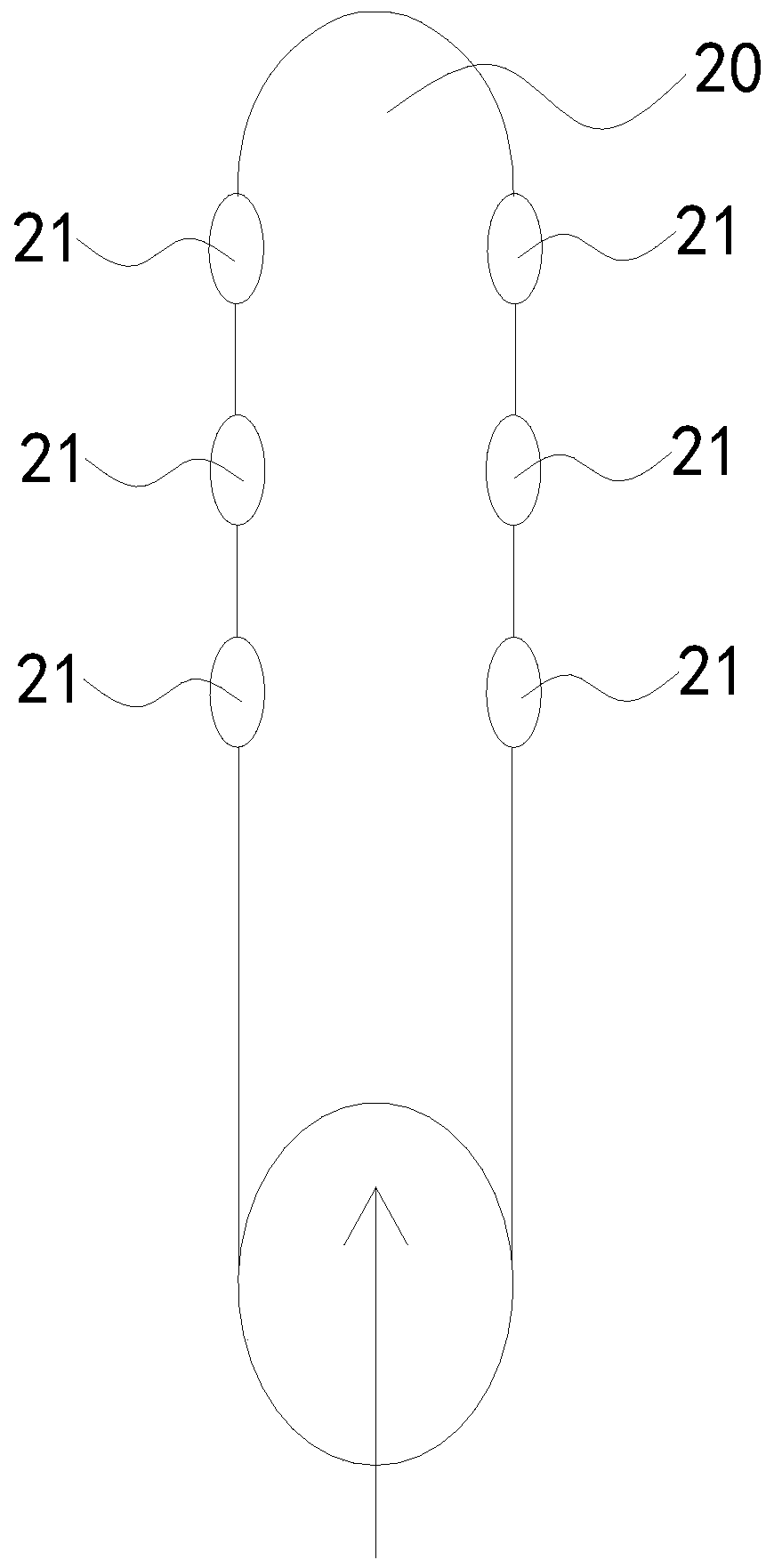

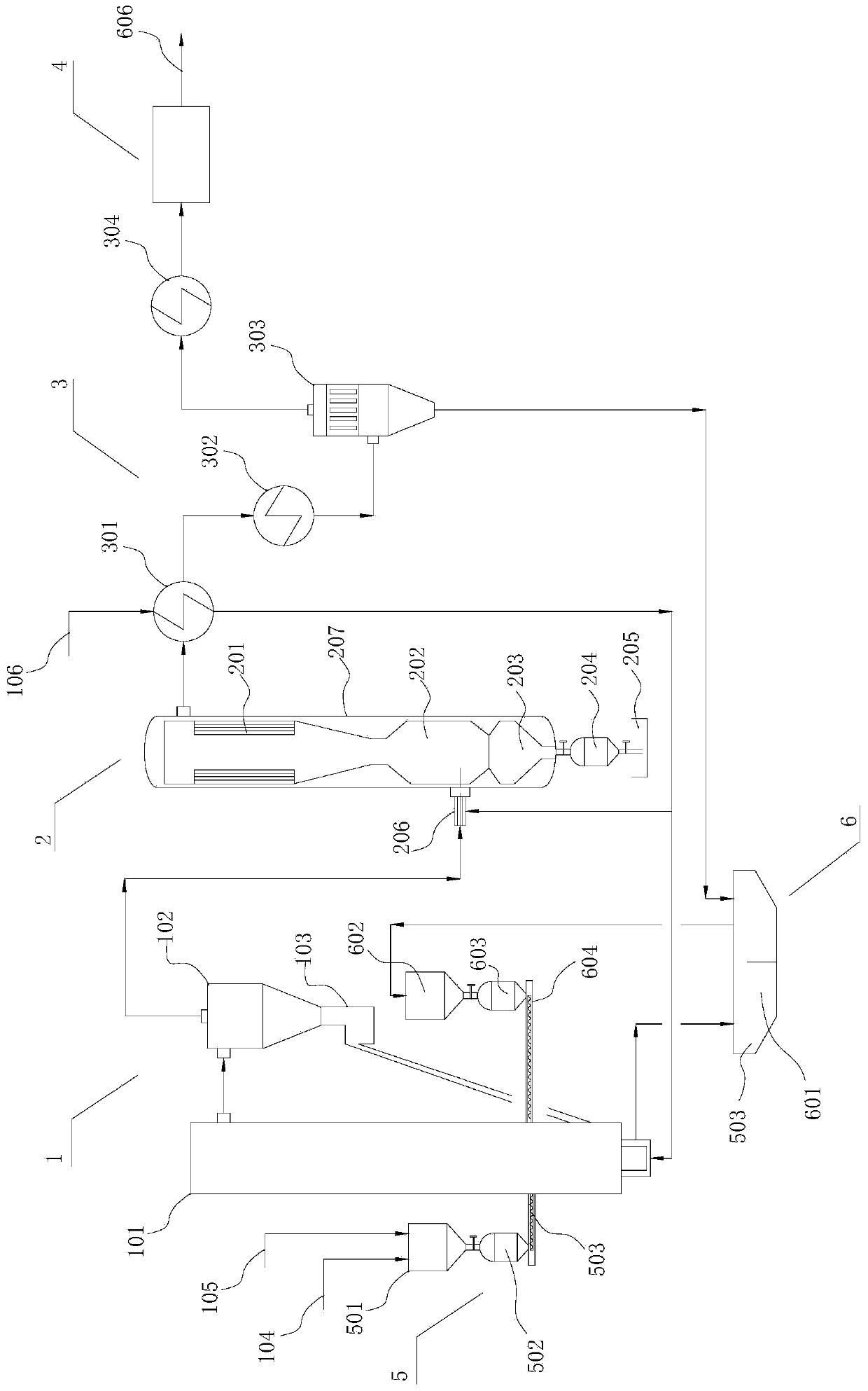

Method for improving circulation of materials in paper mill boiler furnace

ActiveCN110107891AIncrease the number ofLarge apertureFluidized bed combustionApparatus for fluidised bed combustionAir volumeBoiler furnace

The invention relates to a method for improving the circulation of materials in a paper mill boiler furnace. The method for improving the circulation of the materials in the paper mill boiler furnacecomprises the following steps that the temperature of the boiler furnace and the material conveying speed of feeding are detected, and the temperature of the boiler furnace and the material conveyingspeed of the feeding are kept constant; the returning air volume and the returning air pressure are detected, and the circulating ratio is calculated; if the circulating ratio is less than a preset value, the number of air cap holes of returning air and aeration air or the bore diameters of the air cap holes of the returning air and the aeration air are increased; the returning air volume and thereturning air pressure are detected in real time, and the circulating ratio is calculated again; and the steps are cycled until the circulating ratio is greater than the preset value and the returningair volume and the returning air pressure are within a preset range. Different from the prior art, according to the method for improving the circulation of the materials in the paper mill boiler furnace, by increasing the returning air volume and decreasing the returning air pressure slightly, the circulation ratio between the materials is effectively increased, the heat load rate of a boiler isevidently accelerated, and the thermal efficiency of the boiler is promoted.

Owner:LIANSHENG PAPER IND LONGHAI

System and method for gasifying and melting solid wastes

PendingCN110205166AImprove gasification efficiencyRaise the reaction temperatureEnergy inputGranular/pulverulent flues gasificationSlagHigh energy

The invention discloses a system and a method for gasifying and melting solid wastes, and belongs to the technical field of environmental protection. The system comprises a solid waste feeding unit, acirculating fluidized bed gasifying unit, an entrained flow bed gasifying and melting unit, a waste heat recovery and dust removal unit and a gasified gas purification unit which are sequentially connected, the waste heat recovery and dust removal unit comprises a gasification agent preheater, a waste heat boiler, a dust remover and a gas cooler which are connected in sequence, a fly ash circulation pipeline is connected to the bottom of the dust remover, the fly ash circulation pipeline is provided with a returning unit, the circulating fluidized bed gasifying unit comprises a circulating fluidized bed gasifying furnace and a circulating fluidized bed gas-solid separator, and the returning unit is connected with the returning port of the circulating fluidized bed gas gasifying furnace. The system and the method can realize the large-scale industrial processing scale of solid wastes, and solve the problems of high energy consumption, low thermal efficiency, low gasification efficiency, poor adaptability of raw materials, incomplete harmless treatment of ash and slag, and easy entrainment of harmful substances in the smoke in existing solid waste treatment methods.

Owner:陕西德信祥能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com