Coal slime treatment method

A treatment method and technology of coal slime, which is applied in the field of harmless treatment and resource utilization of coal slime, can solve the problems of low combustion efficiency and thermal efficiency, and achieve the effects of high thermal efficiency, stability, sufficient oxidation and good thermal stability of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

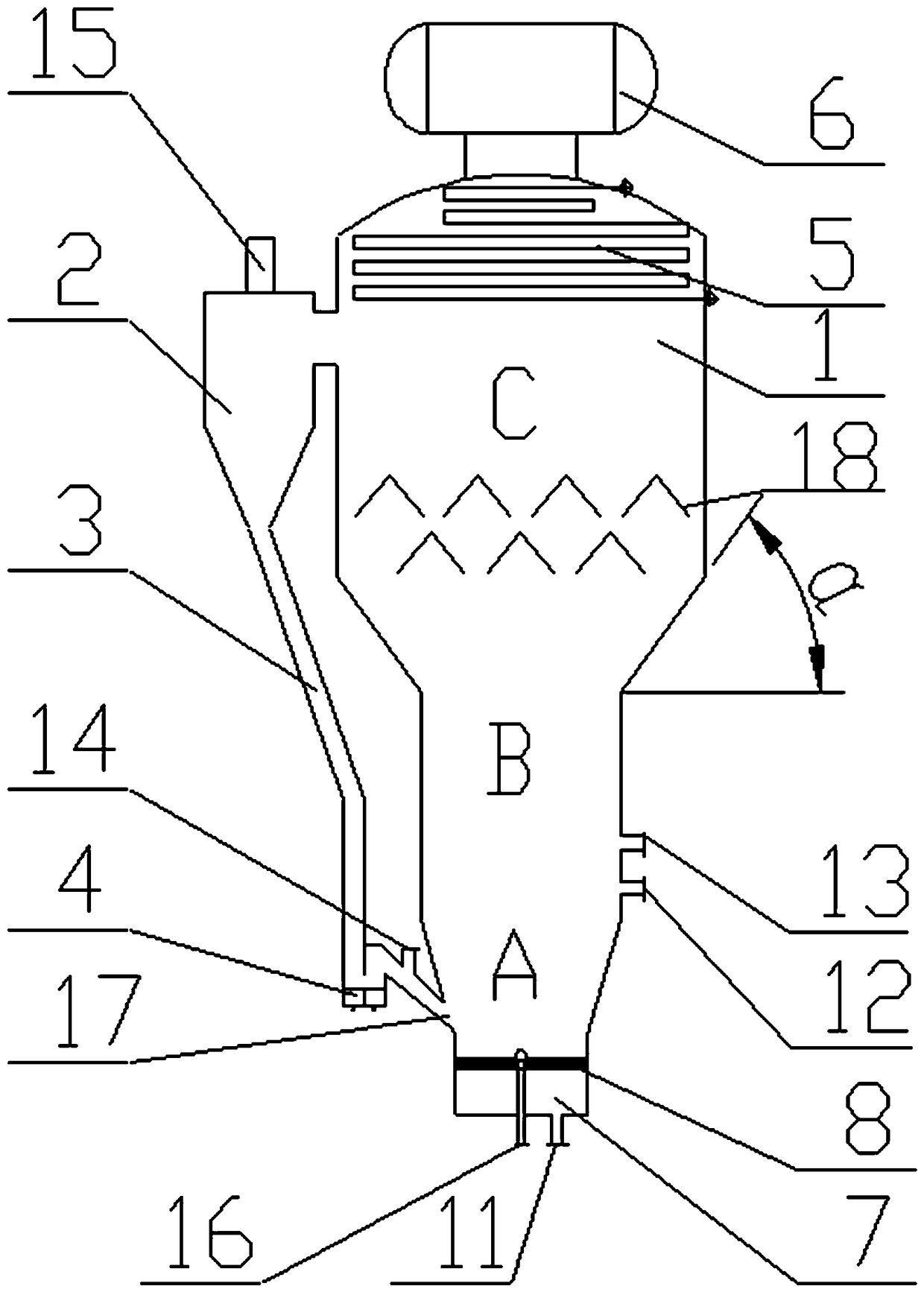

Image

Examples

Embodiment 1

[0055] The initial water content of coal washing slime in a mining area is about 70wt%, and the industrial analysis and elemental analysis data of coal slime are as follows:

[0056] Table 1 Basic data of coal slime

[0057] War

Aar

Var

car

Har

Oar

Nar

Sar

Qnet.ar

%

%

%

%

%

%

%

%

MJ / kg

15

48.71

17.65

25.38

2.07

8.00

0.61

0.23

9700

[0058] The operating conditions and processing effects during the processing are as follows:

[0059] The temperature-regulating medium preparation process in the present embodiment 1 is as follows:

[0060] 1) Take high-quality high-alumina bauxite. The main components of high-alumina bauxite are as follows: Al 2 o 3 =71.22%, SiO 2 =22.53%, Fe 2 o 3 =2.48%, TiO 2 =0.58%, CaO=0.7%, MgO=1.06%, K 2 O=0.61%, Na 2 O=0.82%, crush the high alumina bauxite into powder, the mesh number is 200; take the industrial alumina powder with a purit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com