Patents

Literature

909results about How to "Realize harmless treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Centralized kitchen waste treatment method

ActiveCN101837366ARealize harmless treatmentRecycling is possibleFatty oils/acids recovery from wasteBio-organic fraction processingResource utilizationOil water

The invention relates to a centralized kitchen waste treatment method which comprises the following steps of: (A) sorting kitchen waste; (B) separating oil from water; (C) treating oil; (D) treating sewage; and (E) treating odor. Compared with a traditional kitchen waste burying method, by using the centralized kitchen waste treatment method, a great amount of soil is saved and an available methane resource is generated, kitchen waste reaches 100 percent of harmlessness, more than 95 percent of resource utilization and more than 95 percent of quantitative reduction, and the harmless treatmentof waste and the recycle of resources are truly realized.

Owner:北京昊业怡生科技有限公司

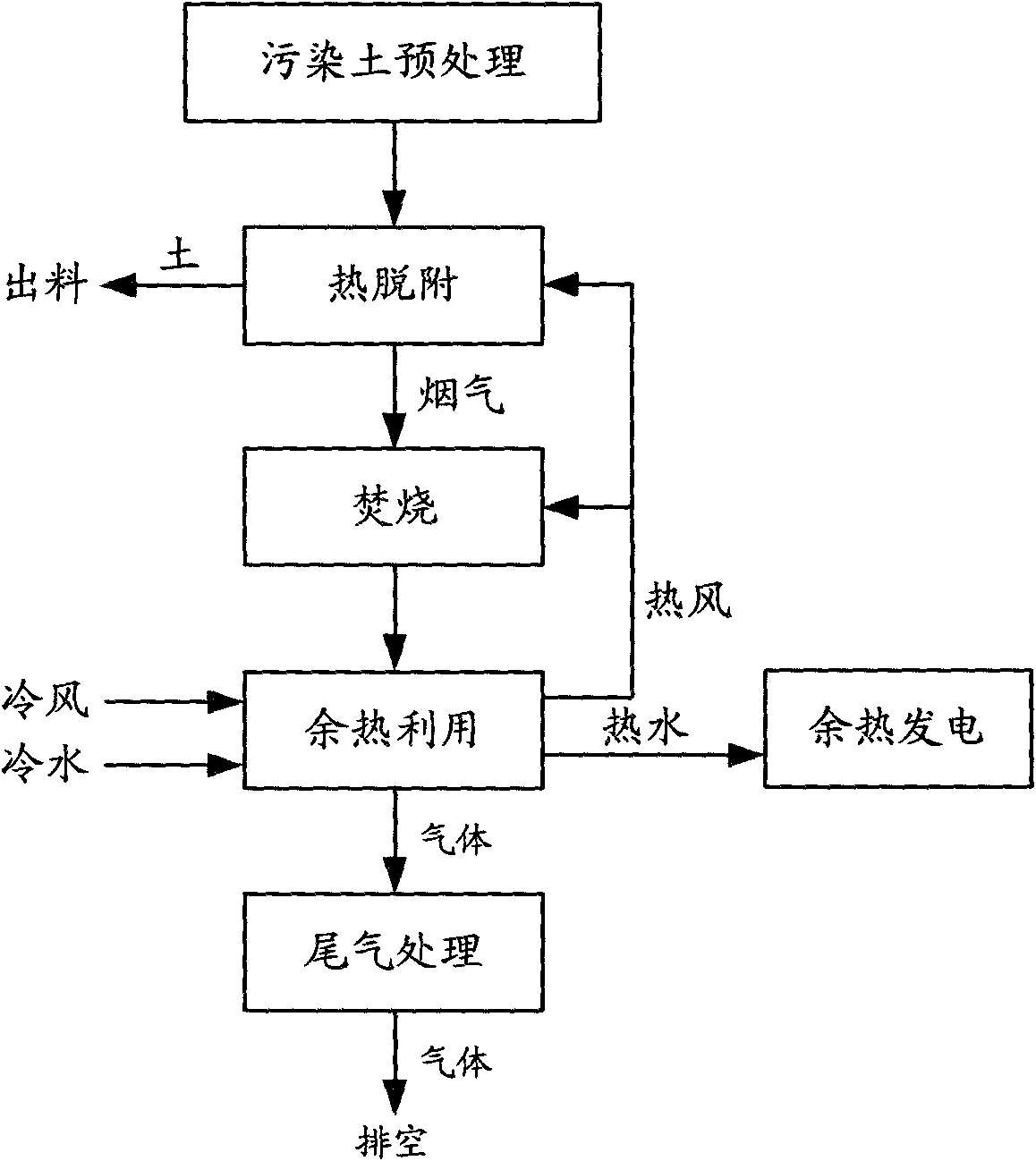

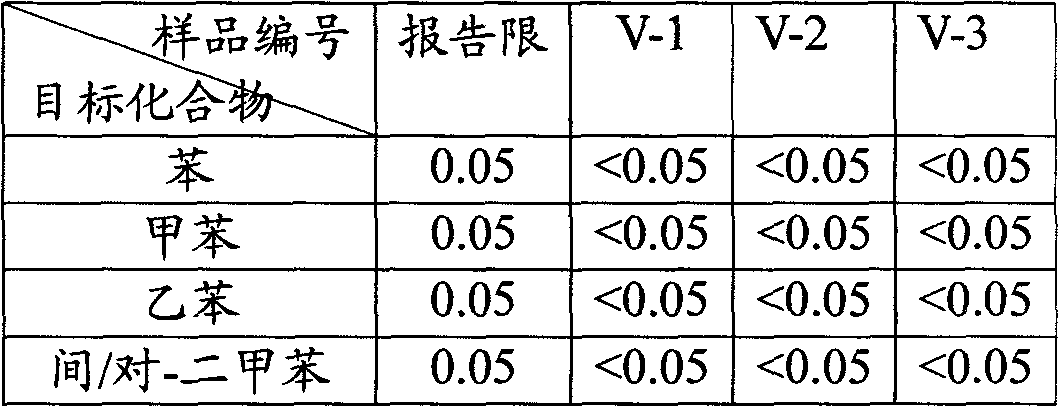

Thermal desorption method for contaminated soil

ActiveCN102218446AAvoid secondary pollutionKeep the inherent characteristicsContaminated soil reclamationIncinerator apparatusThermal desorption spectroscopyFlue gas

The invention discloses a thermal desorption method for contaminated soil, which comprises the following steps of: performing thermal desorption on the contaminated soil at the temperature of between 400 and 650 DEG C; incinerating gaseous contaminant-containing flue gas which is discharged by the thermal desorption step at the temperature of between 750 and 1,200DEG C; and performing afterheat utilization and tail gas treatment on the incinerated flue gas. When the thermal desorption method is used for treating the contaminated soil, the destruction and removal efficiency for the organic contaminants in the contaminated soil is over 99 percent, the tail gas meets the emission standard, and the possible secondary pollution in the process of treating the contaminated soil is stopped, so that the effective innocent treatment is realized and the original reutilization property of the soil is maintained.

Owner:BEIJING ECO ISLAND SCI & TECH +1

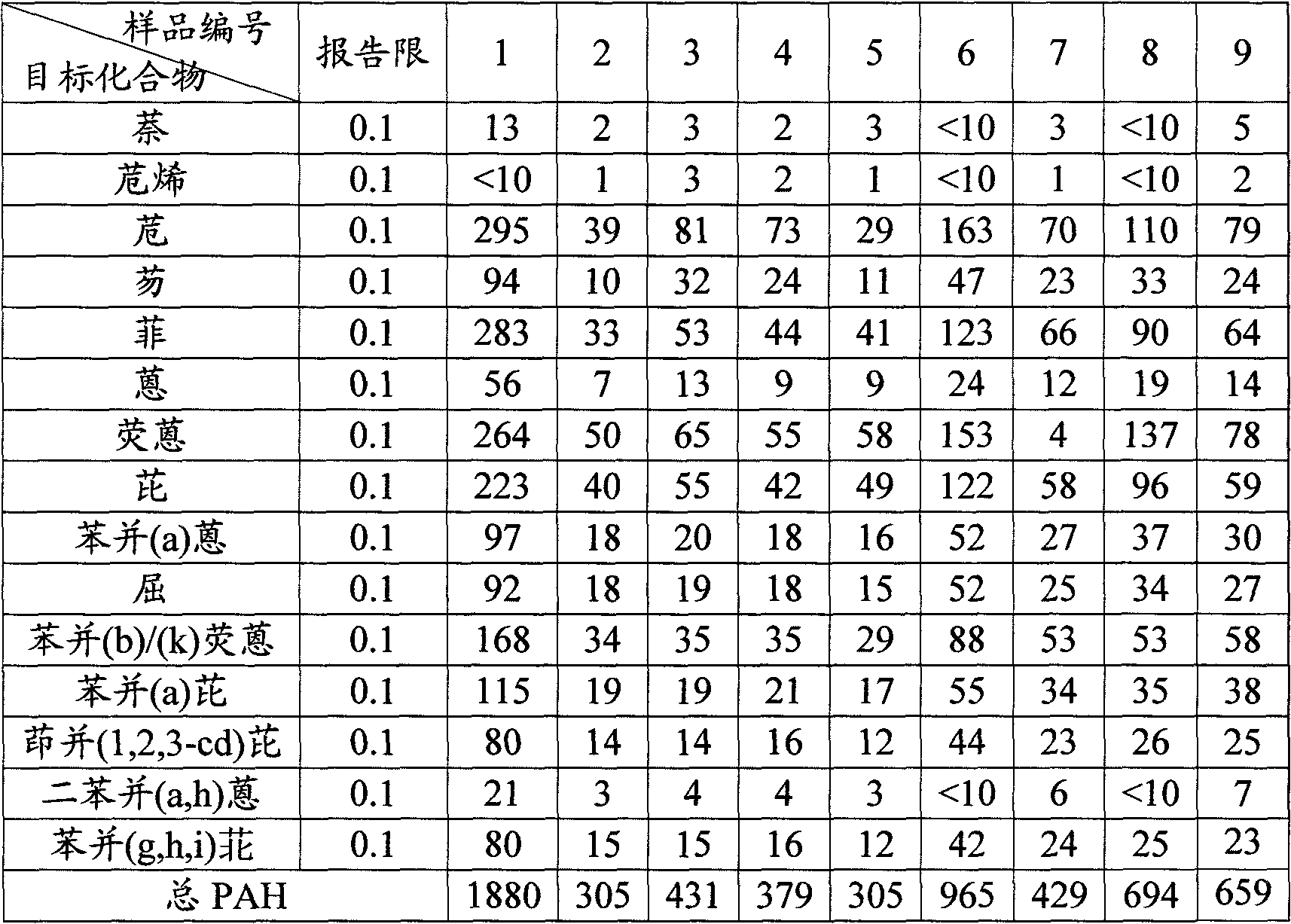

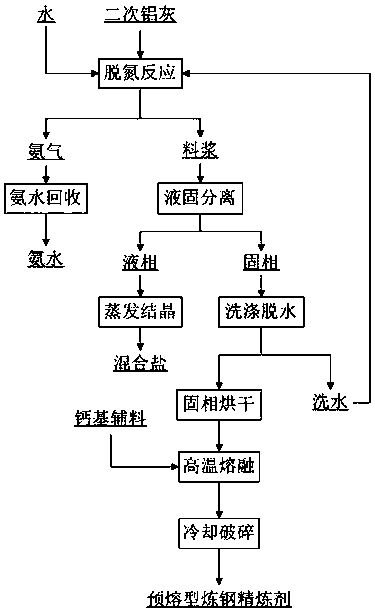

Harmless and comprehensive utilization method of secondary aluminum dross

InactiveCN107555447ARealize harmless treatmentTo achieve the purpose of "zero emission" utilizationChloride preparationFluoride preparationSlurryLiquid solid

The invention provides a harmless and comprehensive utilization method of secondary aluminum dross and relates to a harmless and comprehensive utilization method of secondary aluminum dross produced in an aluminum dross treating process. The harmless and comprehensive utilization method is characterized in that slurry is prepared from the secondary aluminum dross produced in the aluminum dross treating process and water, a stirring deamination reaction is performed, and ammonia gas formed through the reaction is condensed or absorbed by water; slurry after the reaction is subjected to liquid-solid separation, separated liquid phase is subjected to evaporative crystallization, and a chlorate and fluoride salt mixture is obtained; separated solid phase is used for producing a calcium aluminate material. With adoption of the method, the aluminum dross can be treated harmlessly, useful components in the aluminum dross are recovered efficiently, the harmless secondary aluminum dross can replace high-alumina bauxite for preparing a calcium aluminate product, production cost is reduced greatly, zero-release utilization of the aluminum dross is realized, the process is simple, the operation is convenient, the cost is low, environmental protection is realized, and the method has wide applicability.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

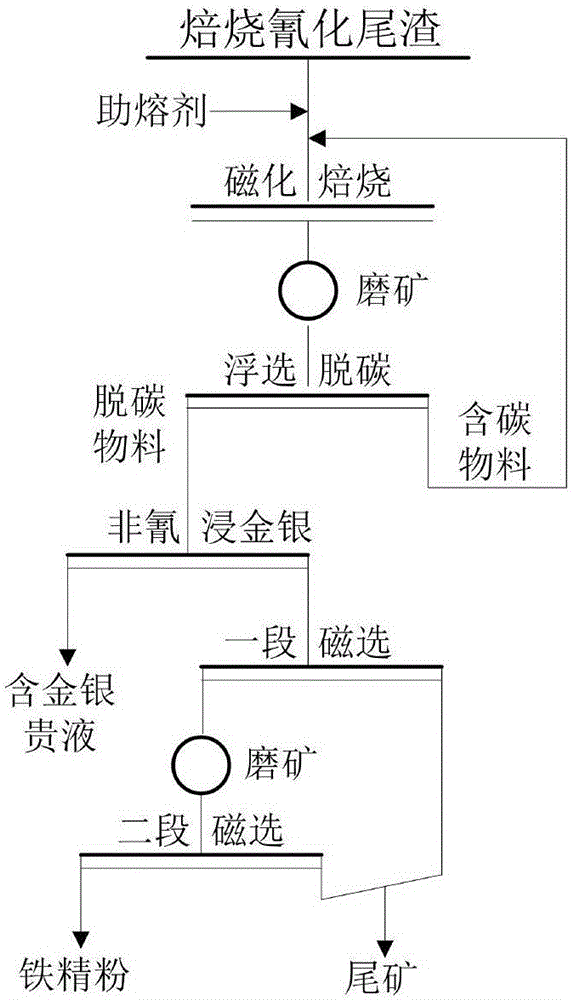

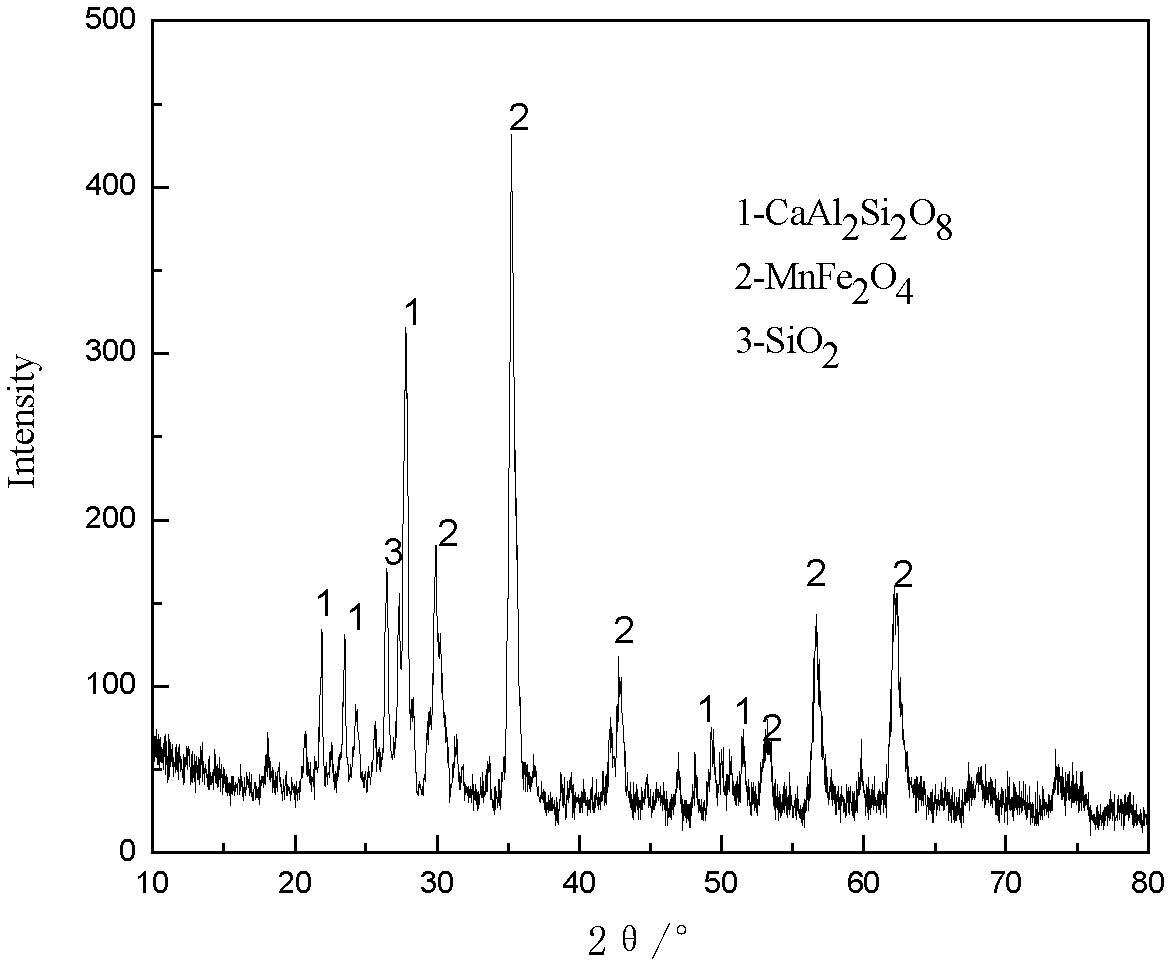

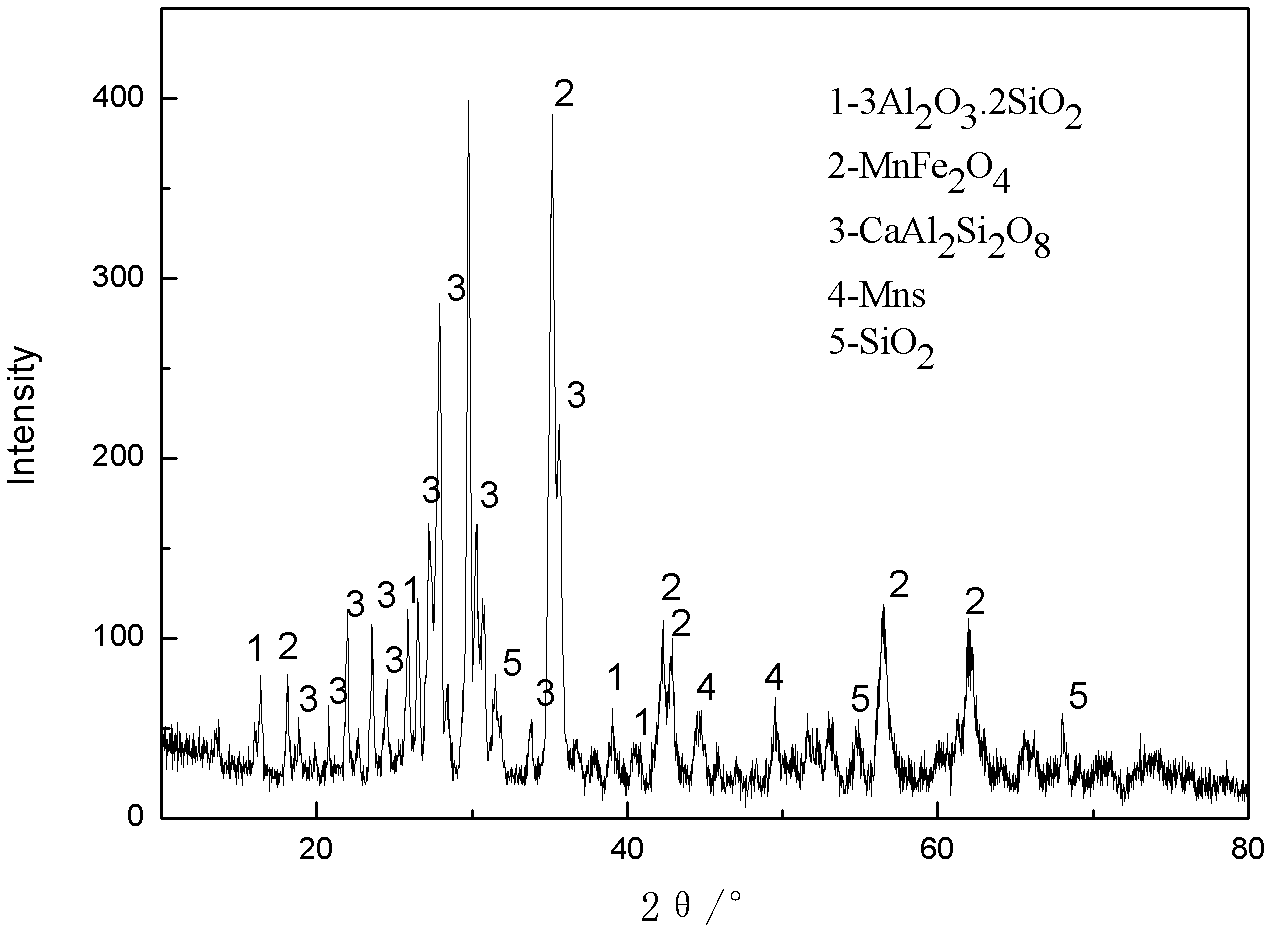

Method for recycling and synchronous harmless treatment of gold, silver and iron in roasting-cyanidation tailings

ActiveCN106498177ARealize harmless treatmentLow toxicityProcess efficiency improvementSilicate mineralsGold leaching

The invention provides a method for recycling and synchronous harmless treatment of gold, silver and iron in roasting-cyanidation tailings, and belongs to the technical field of metallurgical waste residue utilization. The method comprises the following steps: mixing dried roasting-cyanidation tailings with a fluxing agent and a reducing agent; carrying out roasting at 750 to 900 DEG C for 3 to 5 hours; conducting water quenching on hot roasted sand for cooling; carrying out ore grinding and flotation to remove residual carbon; leaching gold and silver with an environment-friendly gold leaching agent; and conducting magnetic separation on the leaching residue to obtain fine iron powder. Containing no highly toxic cyanide, the rejects belong to general industry solid waste. As the fluxing agent is added for magnetic roasting, not only can gold and silver coated with an iron mineral be exposed, but also the fluxing agent can perform a solid-phase reaction with a silicate mineral to generate a dissoluble silicate, and gold and silver coated with the dissoluble silicate can also be exposed after ore grinding. According to the method, gold, silver and iron in the roasting-cyanidation tailings are recycled, harmless treatment is realized synchronously, and the purpose of clean production is realized.

Owner:UNIV OF SCI & TECH BEIJING

Liquid crystal display panel resource processing method

InactiveCN1900770ARealize harmless treatmentAchieve sustainable useNon-linear opticsEpoxyLiquid-crystal display

The method includes following steps: using manual work or dipping LCD faceplate in solvent to remove polarized light film; using cutting method or dipping faceplate in acid liquor to remove sealing epoxy resin to open up two pieces of base plate of LCD faceplate in glass; dipping faceplate in organic solvent to remove liquid crystal; after cleaning glass base plate, and dipping the base plate to acid leach liquor to remove metallized plating film so as to obtain clean glass base plate; picking up and refining indium from acid leach liquor. The invention carries out innocent treatment for worn-out LCD faceplates, and recovers resources.

Owner:NANJING UNIV

Method for recovering copper and nickel from electroplating sludge

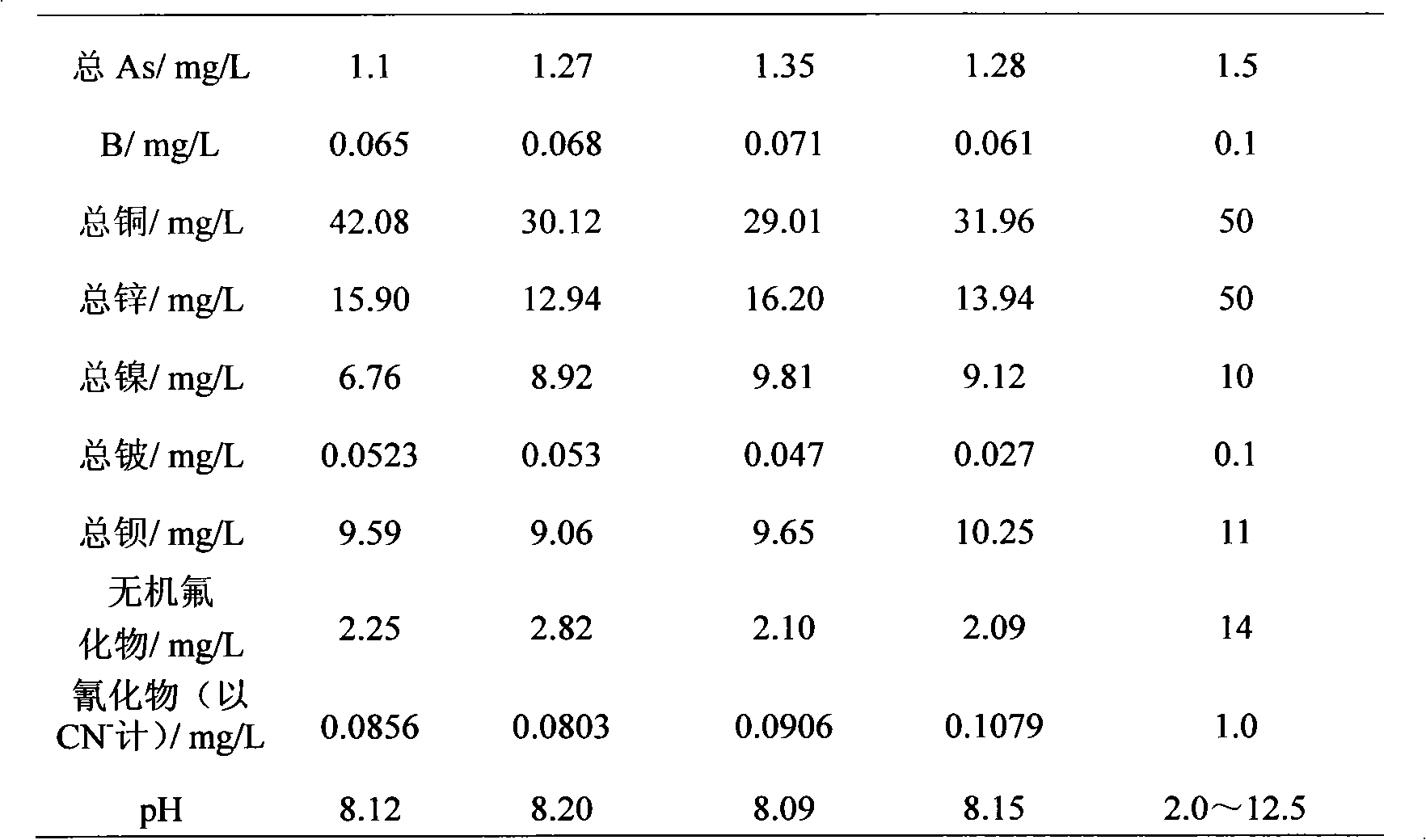

ActiveCN103290222ARealize harmless treatmentSimple processProcess efficiency improvementMagnesiumCalcium

The invention relates to a treatment method for electroplating sludge, especially to a method for recovering copper and nickel from electroplating sludge. The method comprises the following steps: (1) acid leaching; (2) separation of copper from nickel: a step of adding a sulfide into a leachate of acid leaching obtained in the previous step so as to obtain a copper sulphide precipitate; (3) filtration to separate copper sulphide and a precipitate mother liquor; (4) removal of impurities; (5) filtration to separate a filter residue containing iron, chromium, calcium and magnesium and mother liquor containing nickel; and (6) evaporation and crystallization of nickel sulfate: a step of adding a sodium carbonate solution while stirring the mother liquor containing nickel until a supernatant becomes clear, controlling the pH value of a solution to be 7.5 to 9.0, carrying out standing, filtering and washing, then dissolving a sediment with sulfuric acid, controlling the pH value at an end point to be 3 to 6 and carrying out evaporation and crystallization so as to obtain a nickel sulfate product. According to the invention, the recovery rate of copper is more than 90%, the recovery rate of nickel is more than 80%, and waste water produced in the method reaches an emission standard.

Owner:HUIZHOU UNIV

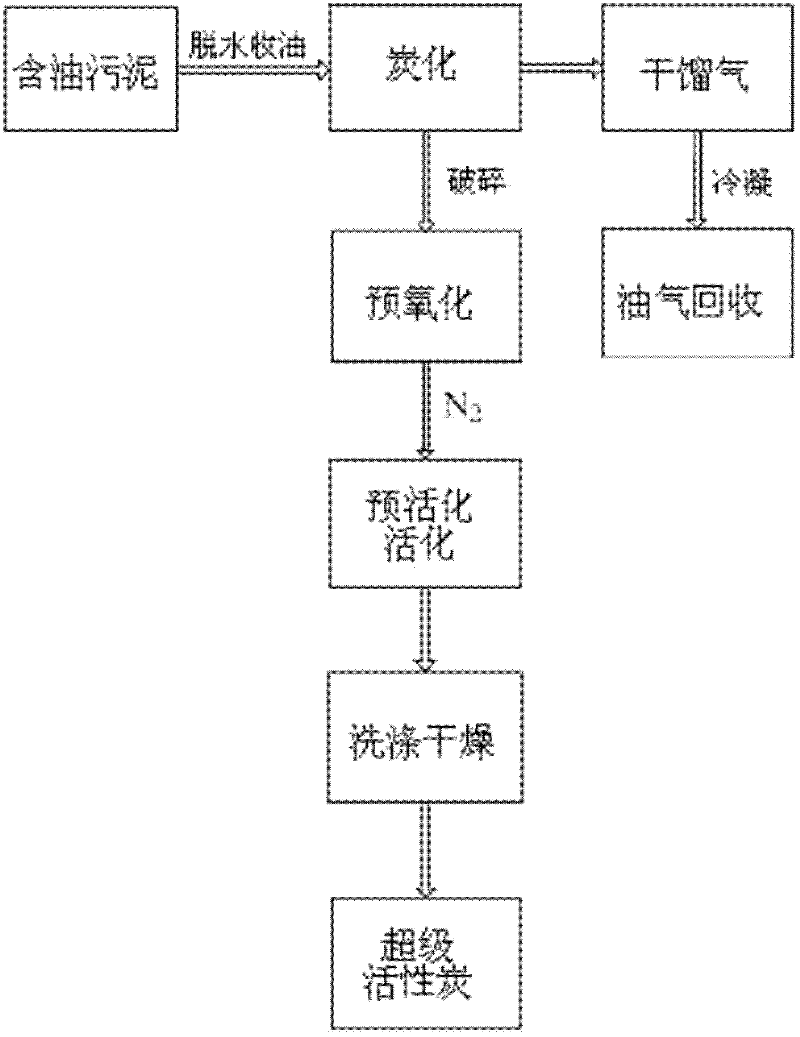

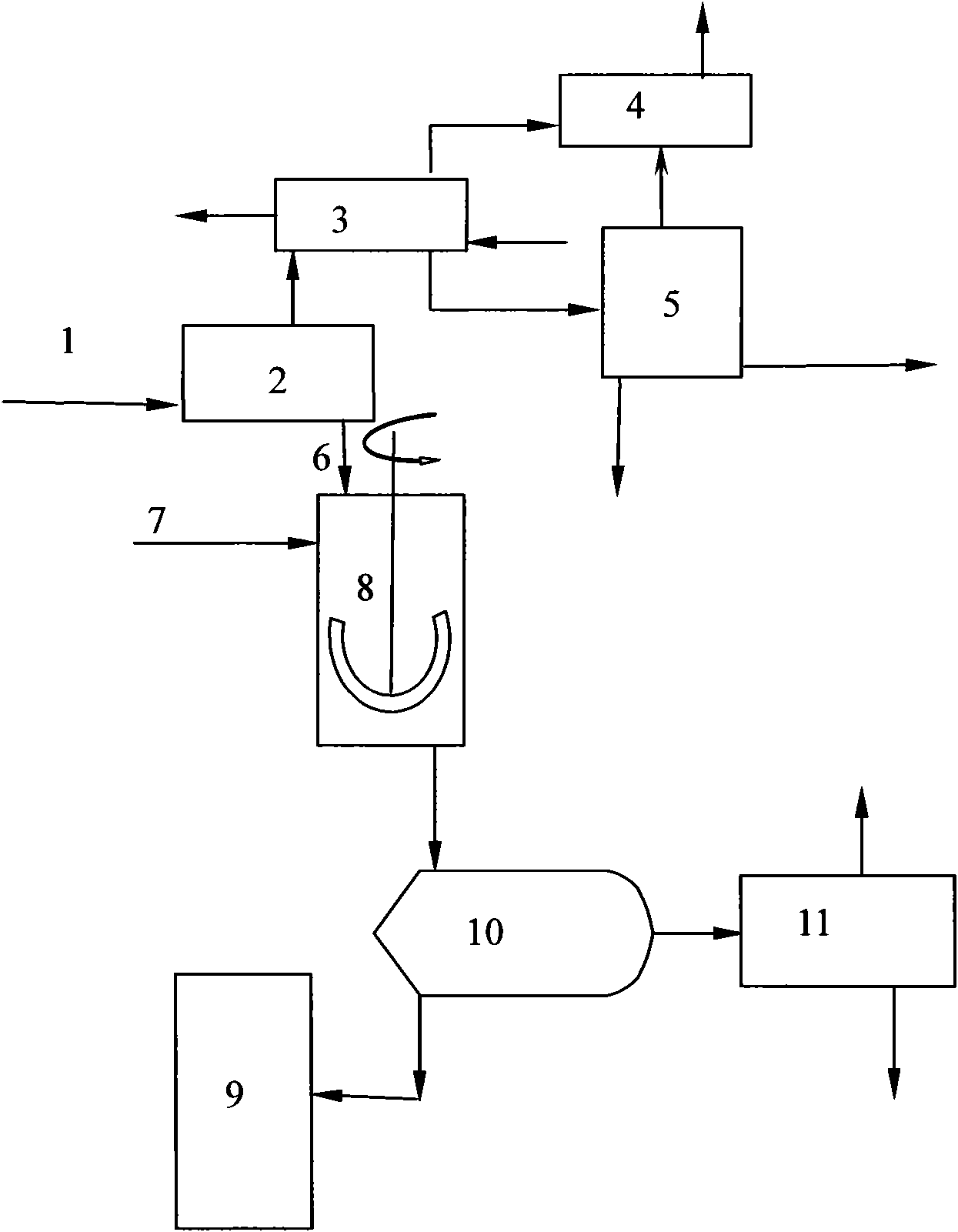

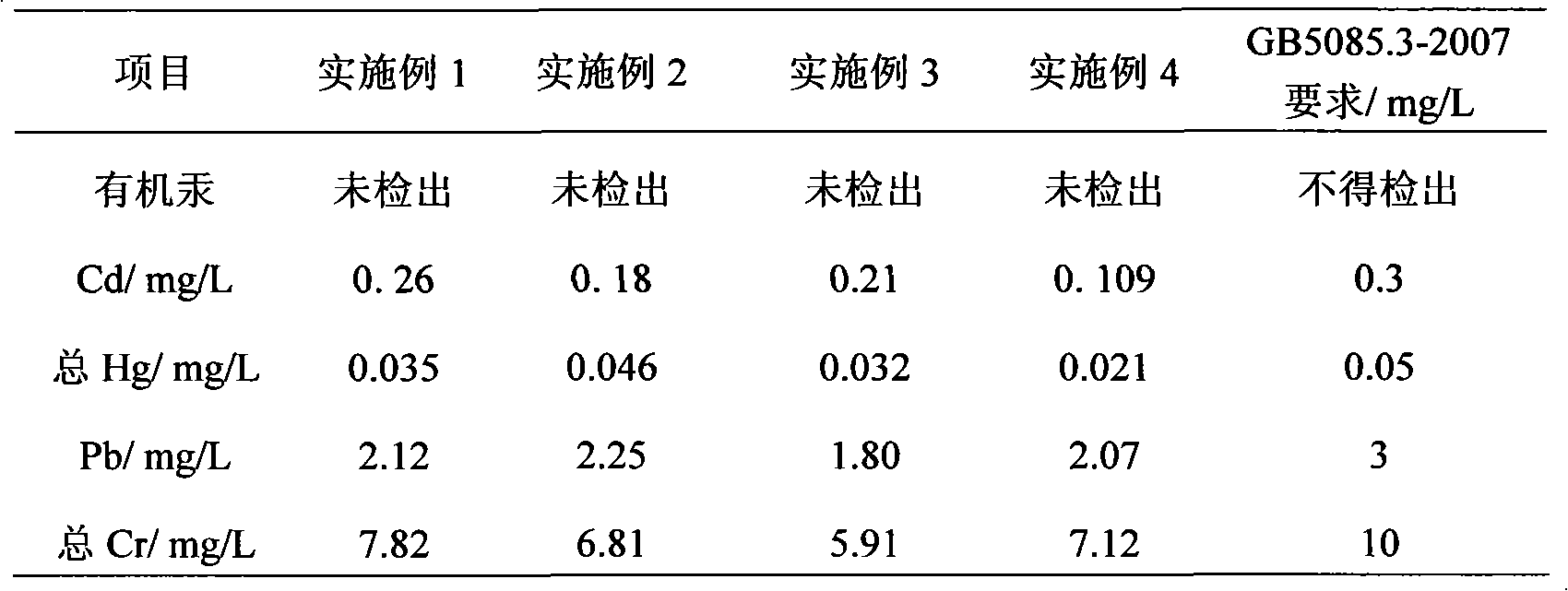

A method for preparing super activated carbon from oily sludge

The invention provides a method for preparing super activated charcoal from oily sludge, and the method is applied to recycling of oily solid wastes in petroleum and petrochemical enterprises. The method comprises the following steps: adding a modifying treatment agent into the oily sludge for dewatering and oil collection treatment; then heating the dewatered oily sludge in the absence of air toa certain temperature at a rate of 2-20 DEG C / min for charring; after crushing the charred product to a set size, carrying out pre-oxidation; uniformly mixing the pre-oxidized charred product with compound activator powder at a certain mass ratio, and heating the mixture to a specified temperature in an inert atmosphere at a rate of 2-20 DEG C / min for pre-activation and activation; and soaking the cooled charred product in an acid solution, rinsing with distilled water to be neutral and then drying to obtain an activated charcoal product. By virtue of modifying, charring, oxidation, activation, washing and drying steps, the resulting activated charcoal has the advantages of strong adsorption performance and high specific surface area; and the iodine adsorption value and specific surface area of the obtained activated charcoal are higher than those of ordinary activated charcoal.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

A treating method of waste cathode charcoal blocks

InactiveCN106166560ARealize harmless treatmentEliminate pollutionSolid waste disposalSolid fuelsElectrolysisSlag

A treating method of waste cathode charcoal blocks is provided. The waste cathode charcoal blocks are from electrolytic tank heavy maintenance slag of an electrolytic aluminium factory. The method includes treating the electrolytic tank heavy maintenance slag to obtain powdered waste cathode charcoal blocks, subjecting the powdered waste cathode charcoal blocks to water leaching to obtain a leachate and cathode charcoal blocks after leaching, performing solid liquid separation after the leachate and a fluorine removal agent are subjected to a curing reaction, returning the filtrate to the leaching step for circulated use, and stacking filter cakes or adopting the filter cakes as a raw material for preparing calcium fluoride. The method adopts a manner of a plurality of times of leaching, thus achieving innocent treatment of the waste cathode charcoal blocks. The filtrate and the filter cakes after leachate treatment can be reused, and the cathode charcoal blocks after leaching can be adopted as fuel for producing alumina. The method overcomes a series of problems caused by stacking of a large amount of the waste cathode charcoal blocks, achieves efficient utilization of the waste cathode charcoal blocks, and is obvious in economic benefit and suitable for industrial production.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Treatment method of oily sludge

ActiveCN102050556AReduce volumeReduce quality problemsThermal non-catalytic crackingSludge treatment by de-watering/drying/thickeningTherapeutic effectOil sludge

The invention relates to a treatment method of oily sludge, which is particularly suitable for oily sludge generated during the sewage treatment process of a refinery plant. The method comprises the following steps: after centrifugal dewatering, the oily sludge is dehydrated through rotary dehydration equipment under the control of a certain negative pressure and a certain temperature, so as to destroy the water, oil and solid stable system in the oily sludge; parts of oil and water in the oily sludge are distilled out; the coke generated after dehydration is extracted with a solvent; after extraction, the material undergoes the solid-liquid separation; the separated liquid phase is delivered to a delayed coking device; the separated solid phase is dehydrated to form the residues that meet the discharge standards for solids; and the wastewater generated during the process is biochemically treated and then discharged after reaching the discharge standards. The invention is mainly characterized in that the sludge treatment process is short, the speeds and the efficiencies of sludge dehydration and extraction are high, the effect is good, the operational condition is moderate, the energy consumption is reduced, the oily sludge treatment effect is good, and the operating maintenance of the equipment is simple.

Owner:PETROCHINA CO LTD

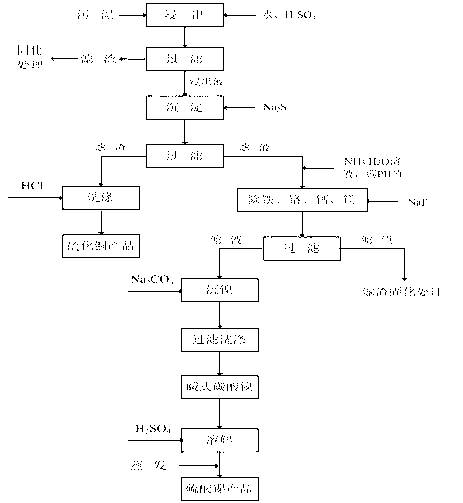

Chromic slag wet method detoxifcation and resource comprehensive utilization new technique

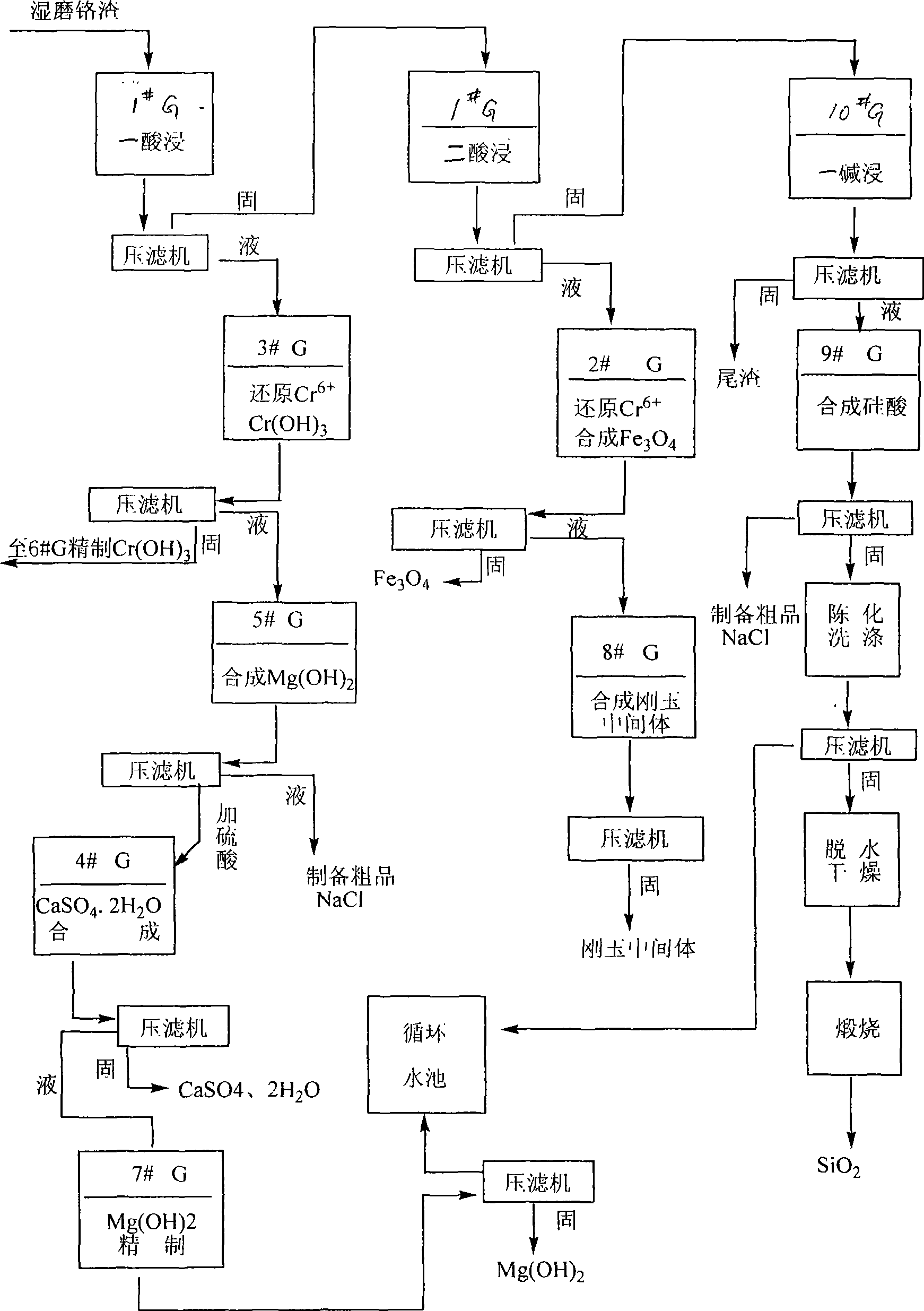

InactiveCN101380510ADetoxify thoroughlyAchieve detoxificationCalcium/strontium/barium sulfatesFerroso-ferric oxidesAmmonium hydroxideHexavalent chromium

A new harmless comprehensive utilization technique for wet processing chromic slag comprises steps as follows: ball milling chromic slag to 80-200 meshes, adding water to prepare slurry, immersing the slurry in hydrochloric acid solution, regulating the pH to 5-6, performing solid-liquid separation with filter press, in the immersion liquid after separation, the hexavalent chrome is reduced to trivalent chromium, adding sodium hudroxide aqueous solution, regulating the pH to 4-6, roughly preparing chromic hydroxide, adding sulfuric acid into filtrate, regulating the pH to 5-6, removing the calcium coprecipitated with magnesium in the rest filtrate, preparing the 2-water calcium sulphate whisker, adding alkali to the filtrate after filter-pressing to regulate the pH to 9-12 to synthesize super-fine magnesium hydroxide powder; the solution after filter-pressing is concentrated to prepare sodium chloride. The main contents of extracts within the chromic slag treated by wet processing all can meet primary, secondary or even accredited national or ministerial standard. The technique can thoroughly detoxicate Cr<6+> in chromic slag and can prepare nine products, includiing chromic hydroxide, magnesium hydroxide, ammonium hydroxide, silicon dioxide, magnetic ferrous ferricoxide, 2-water calcium sulphate, corundum intermediate, sodium chloride, and tailings-chromite; and the extracts after processing chromic slag have high quality.

Owner:杨恩清 +1

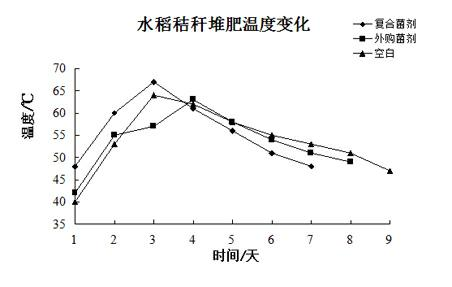

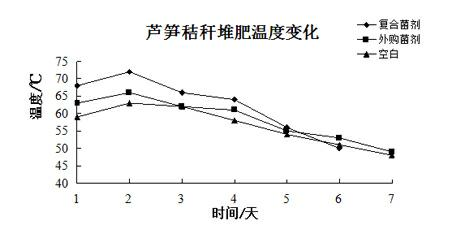

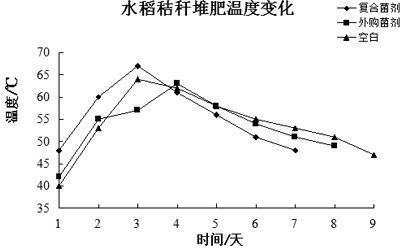

Efficient straw degrading composite fungicide and organic fertilizer preparing method thereof

ActiveCN102676492AFully degradedIncrease productivityBio-organic fraction processingMicroorganism based processesInsect pestFermentation

The invention relates to an efficient straw degrading composite fungicide (JFB-1) and an organic fertilizer preparing method thereof. The composite fungicide comprises composite bacteria and a carrier, wherein the carrier is wheat bran, and the composite bacteria include composite bacteria I, composite bacteria II, composite bacteria III and auxiliary bacteria. The composite bacteria I, II and III account for 1-1.5% of the weight of straws, wherein the composite bacteria I account for 20-25%, the composite bacteria II account for 45-50%, the composite bacteria III account for 30-35%, and the composite bacteria are added uniformly in compost fermentation so as to effectively improve the maturation speed and the quality of an organic fertilizer. The fungicide is fully mixed with straws of rice, asparagus and other crops to carry out compost fermentation, the straws can be degraded rapidly through the synergistic effect of the bacteria, the degradation efficiency is improved, the degradation time is shortened, and insect pests are effectively killed and are rapidly transformed into the organic fertilizer for improving soil. The efficient straw degrading composite fungicide can be used for effectively solving the problem of land occupation caused by landfill, or the problems of fire, traffic dangers, environment pollution and the like caused by burning.

Owner:SHANGHAI JIAO TONG UNIV

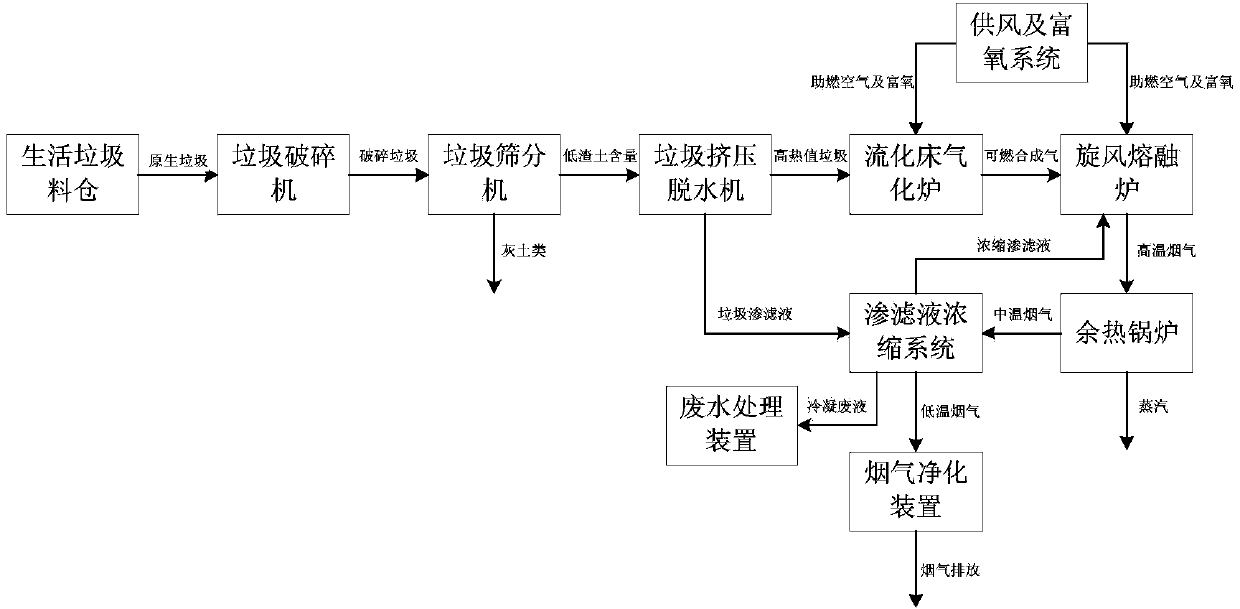

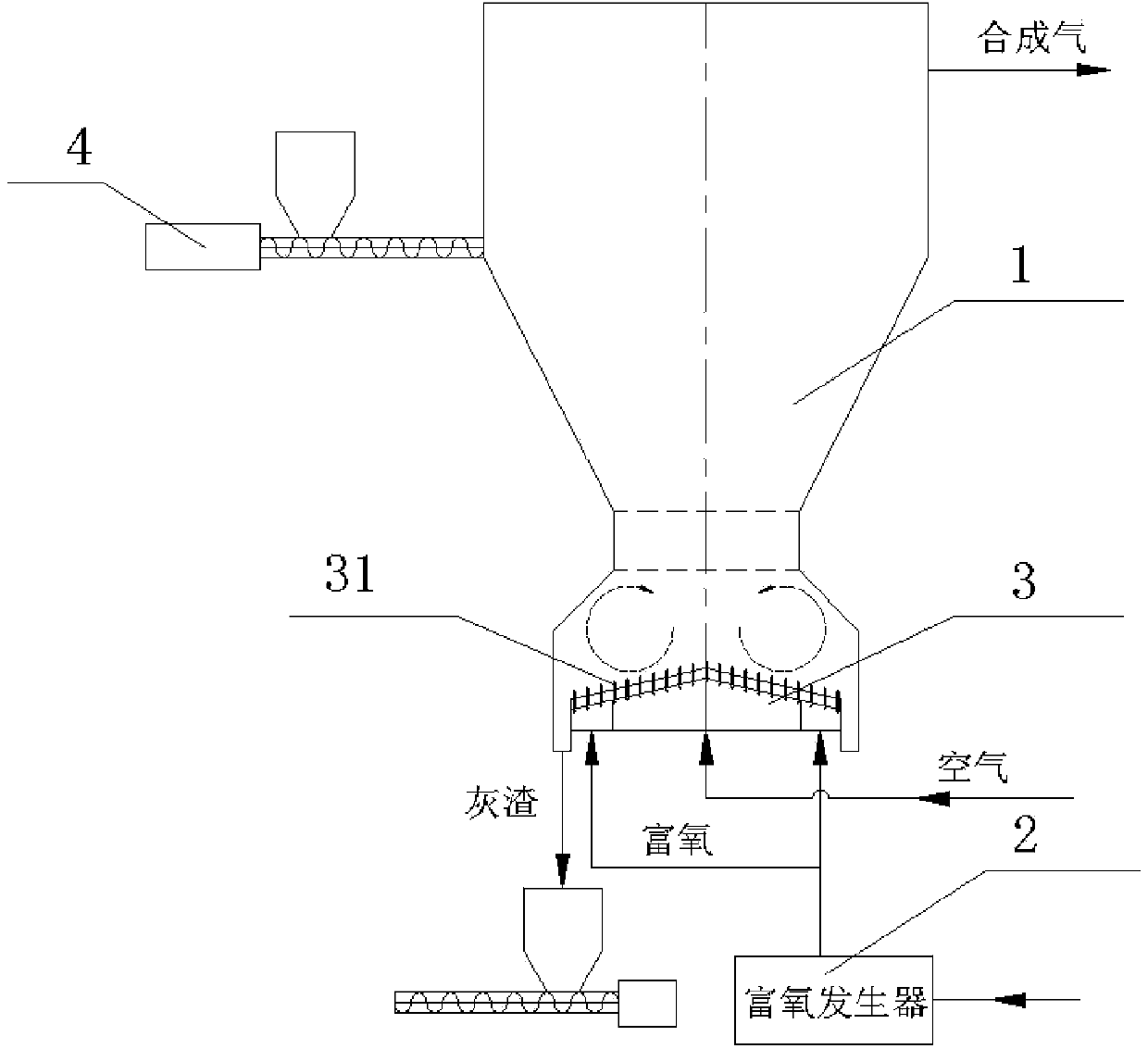

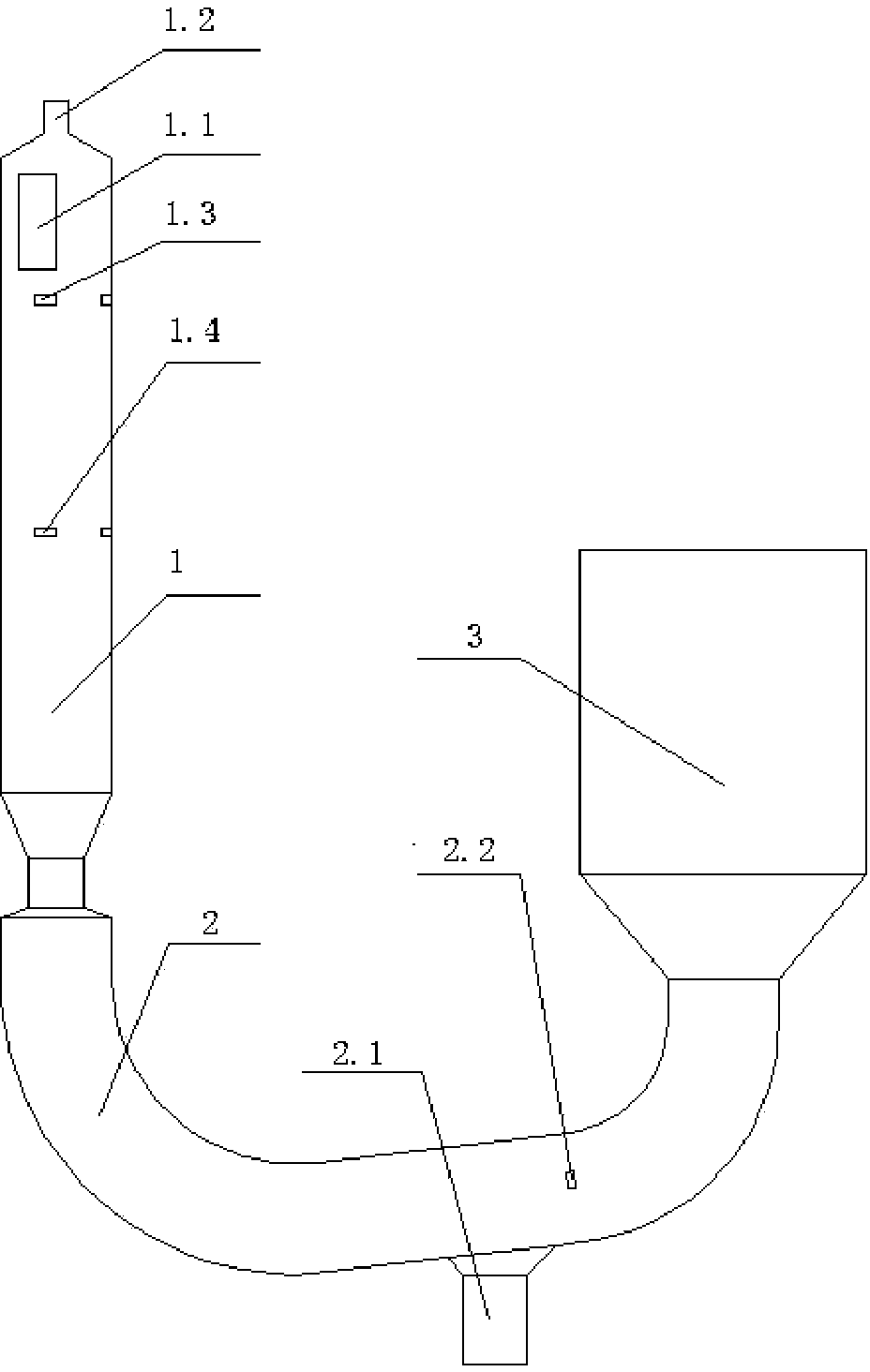

System and method for gasification melting of household refuse and treatment of household refuse leachate

ActiveCN103471105AHigh calorific valueAchieve enrichmentIndirect carbon-dioxide mitigationIncinerator apparatusCrusherTreatment system

The invention provides a system and a method for gasification melting of household refuse and treatment of household refuse leachate. The system comprises a household refuse pretreatment system, a refuse energy recovering system and a refuse leachate concentration and flue gas treatment system, wherein the household refuse pretreatment system comprises a household refuse stock bin, a household refuse crusher, a household refuse sieving machine and a household refuse extrusion dehydrator which are sequentially connected; the refuse energy recovering system comprises a fluidized-bed gasifier, a cyclone melting furnace, a waste heat boiler and an air-supplying and oxygen-enriching system matched with the fluidized-bed gasifier, the cyclone melting furnace and the waste heat boiler; the refuse leachate concentration and flue gas treatment system comprises a leachate concentrating system, a flue gas purifying device and a wastewater treatment device. According to the system, the heat value of the refuge is increased by a pretreatment process; an oxygen-enriching gasifier and a high-temperature cyclone melting furnace technology are used as a recovering system of refuge energy; the refuge leachate is concentrated by using medium-temperature flue gas exhausted by the waste heat boiler; the concentrated leachate is sprayed into the high-temperature cyclone furnace for harmless treatment.

Owner:陕西圣昊朗道科技有限公司

Phosphogypsum water hard road base, road base material and preparation method thereof

The invention discloses a phosphogypsum water hard road base, a road base material and a preparation method thereof, relating to the field of road engineering construction. The preparation method of the road base material comprises the following steps: weighing 85-92 percent of phosphogypsum and 15-8 percent of ordinary portland cement, uniformly mixing and stirring, thereby obtaining a preliminary mixture; weighing 99.7-99.95 percent of preliminary mixture and 0.3-0.05 percent of a phosphogypsum water hard curing agent, uniformly mixing and stirring, thereby obtaining a premix; controlling the moisture content of the premix to be 14-18 percent, thereby obtaining a base material, wherein the phosphogypsum water hard curing agent is prepared by mixing the following components in percentage by mass: 40-60 percent of elastic styrene-acrylic emulsion, 30-20 percent of nanometer alumina sol and 30-20 percent of nanometer silica sol. The road base is prepared from the road base material according to a standard road base construction method. The road base material is produced by utilizing phosphogypsum, the environmental pollution is reduced, and wastes are changed into valuable materials; and moreover, the formed road base is high in crack resistance, difficult to corrode and long in service life.

Owner:黄菁华 +2

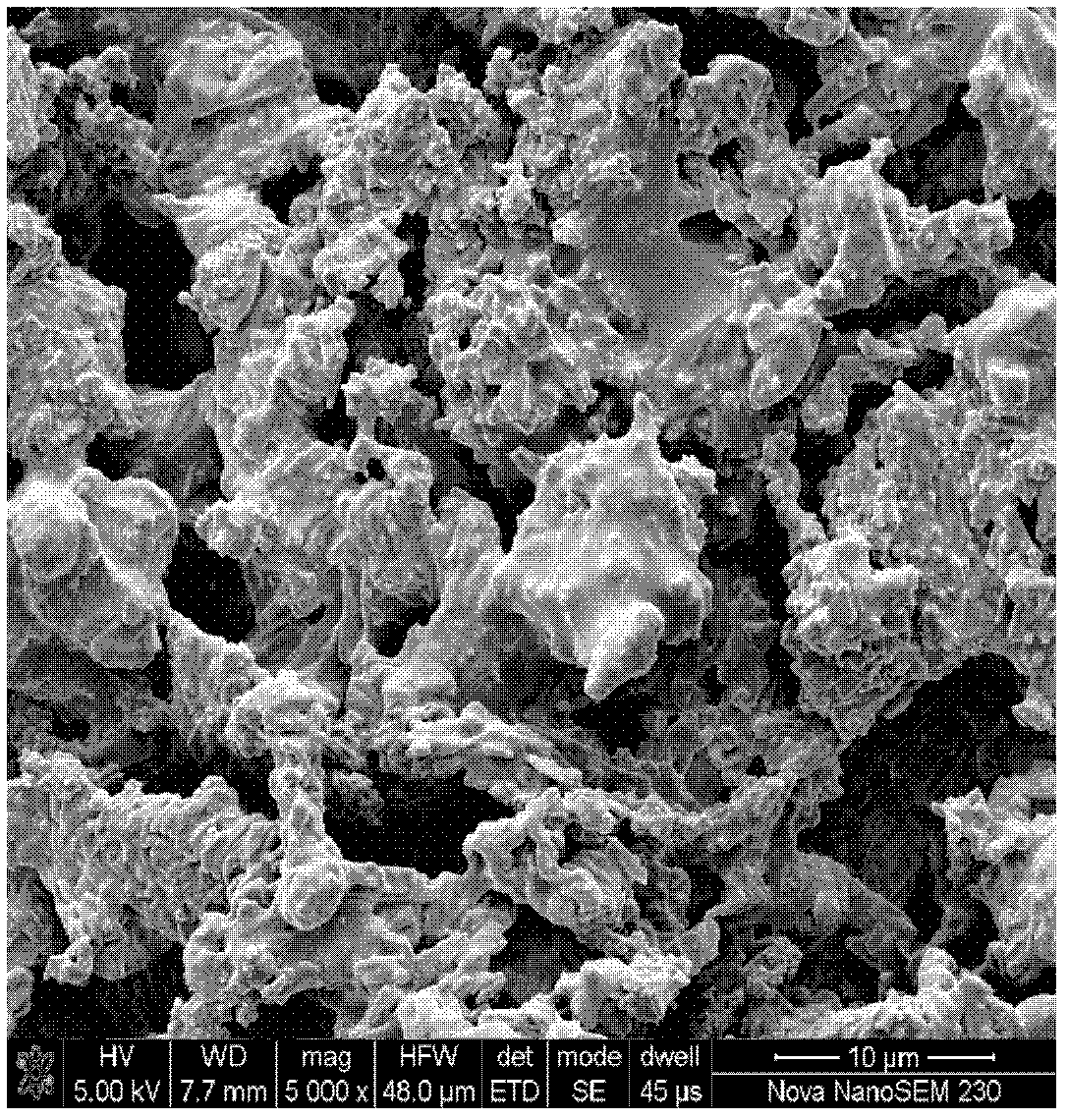

Preparation method for electrolytic manganese residue porous ceramics

ActiveCN102584316ARaw materials are cheap and easy to getSimple processSolid waste disposalCeramicwareTemperature controlElectrolysis

The invention relates to a preparation method for electrolytic manganese residue porous ceramics. The manganese residue is taken as aggregate; the additives, such as pore-forming agent, binding agent and fluxing agent, are added; and a porous ceramic material is prepared according to a mould pressing forming and solid-phase sintering method. The preparation method specifically comprises the following steps of: mixing the manganese residue, the pore-forming agent, the binding agent and the fluxing agent; adding water, and then mixing uniformly; pressing and forming by using a steel mould, thereby obtaining a green ware; and after drying, placing the green ware into a high-temperature electric furnace for sintering under the condition of temperature controlled by programs, thereby obtainingthe porous ceramics. According to the method provided by the invention, a plenty of manganese residues are efficiently utilized; the environmental pollution is reduced; the wastes are turned into valuable things; the method has the advantages of simple preparation process, low cost, and the like; and the prepared electrolytic manganese residue porous ceramics are high in strength and porosity andcan serve as excellent adsorbing materials and filtering materials.

Owner:CENT SOUTH UNIV

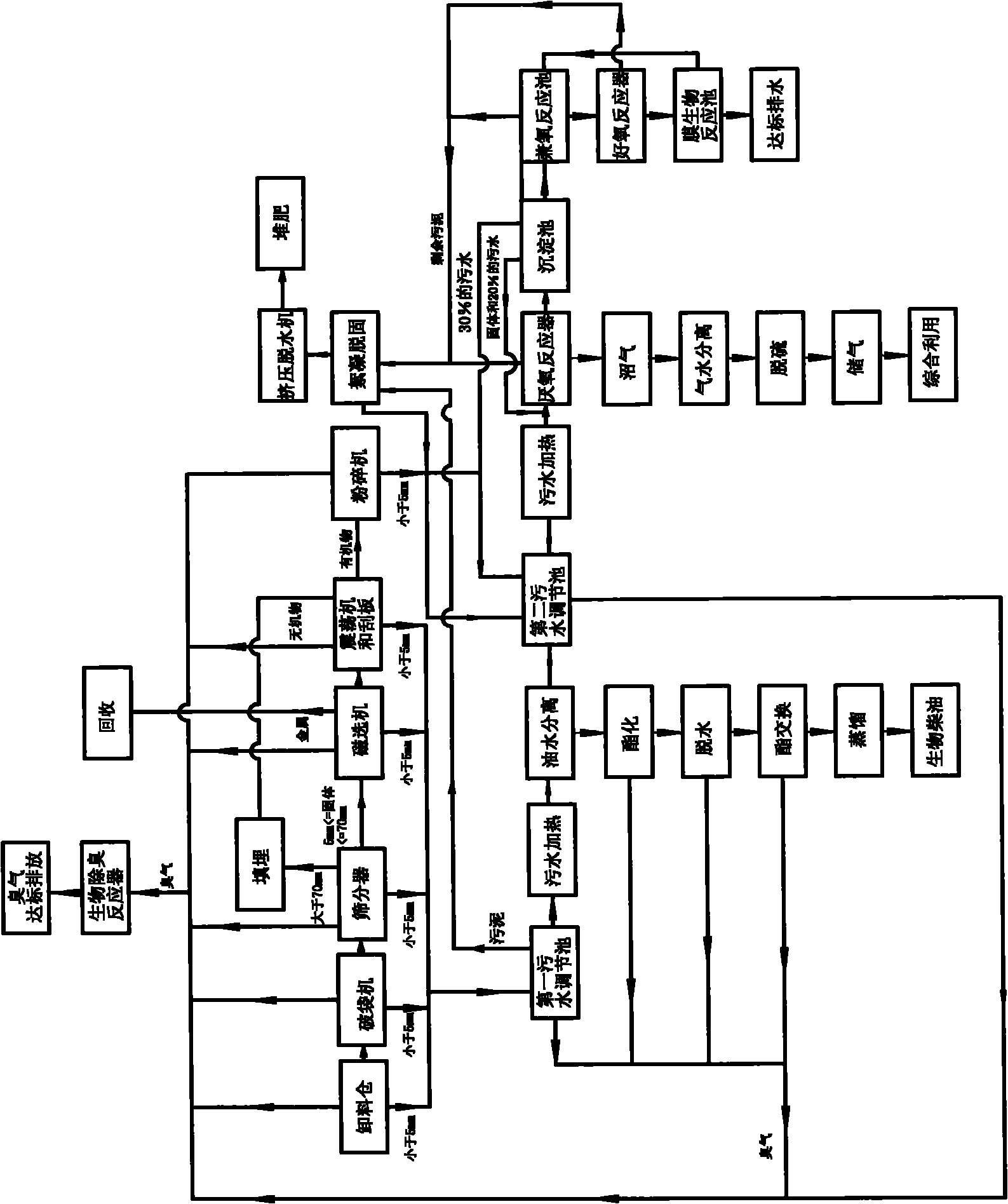

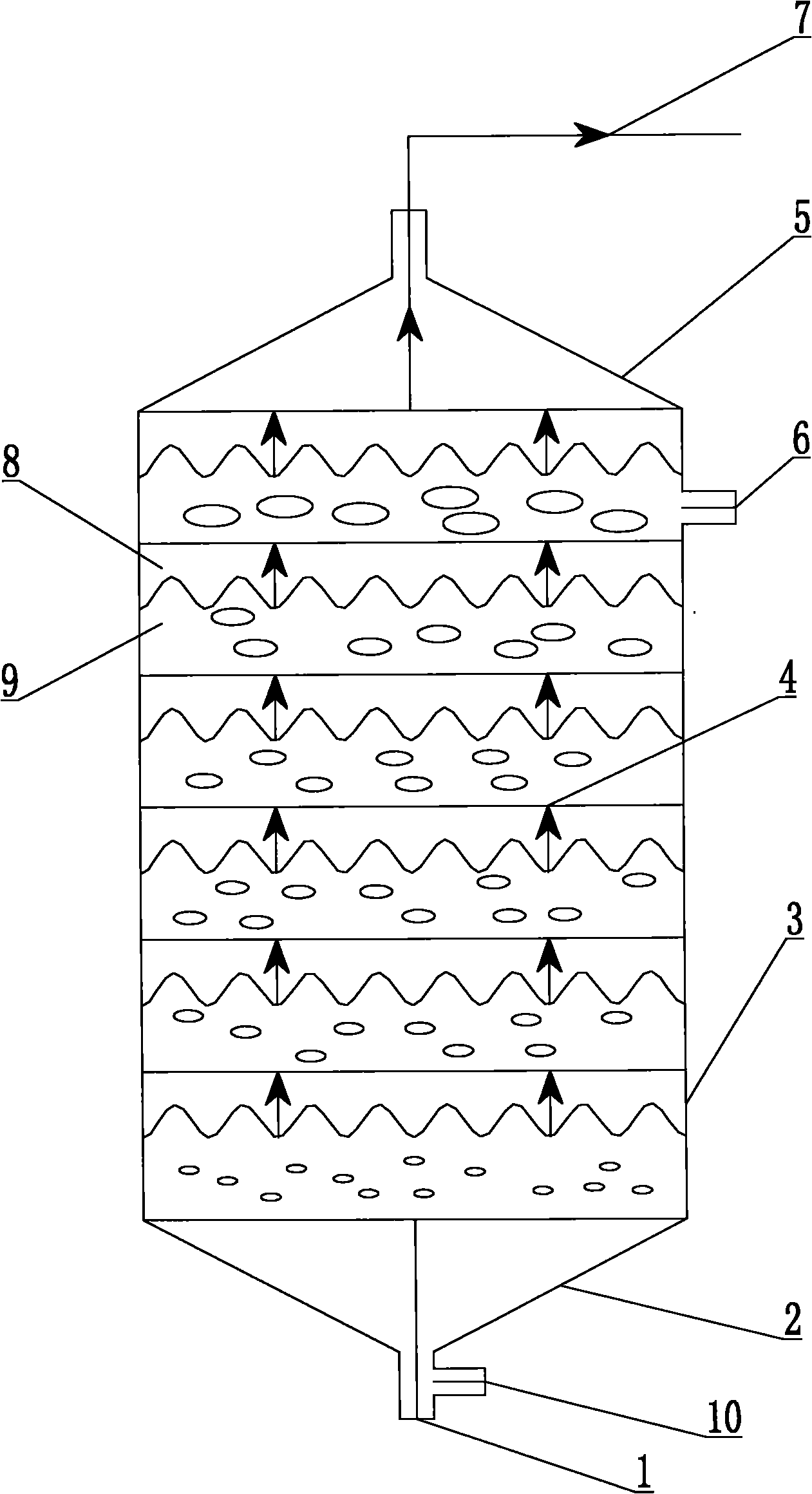

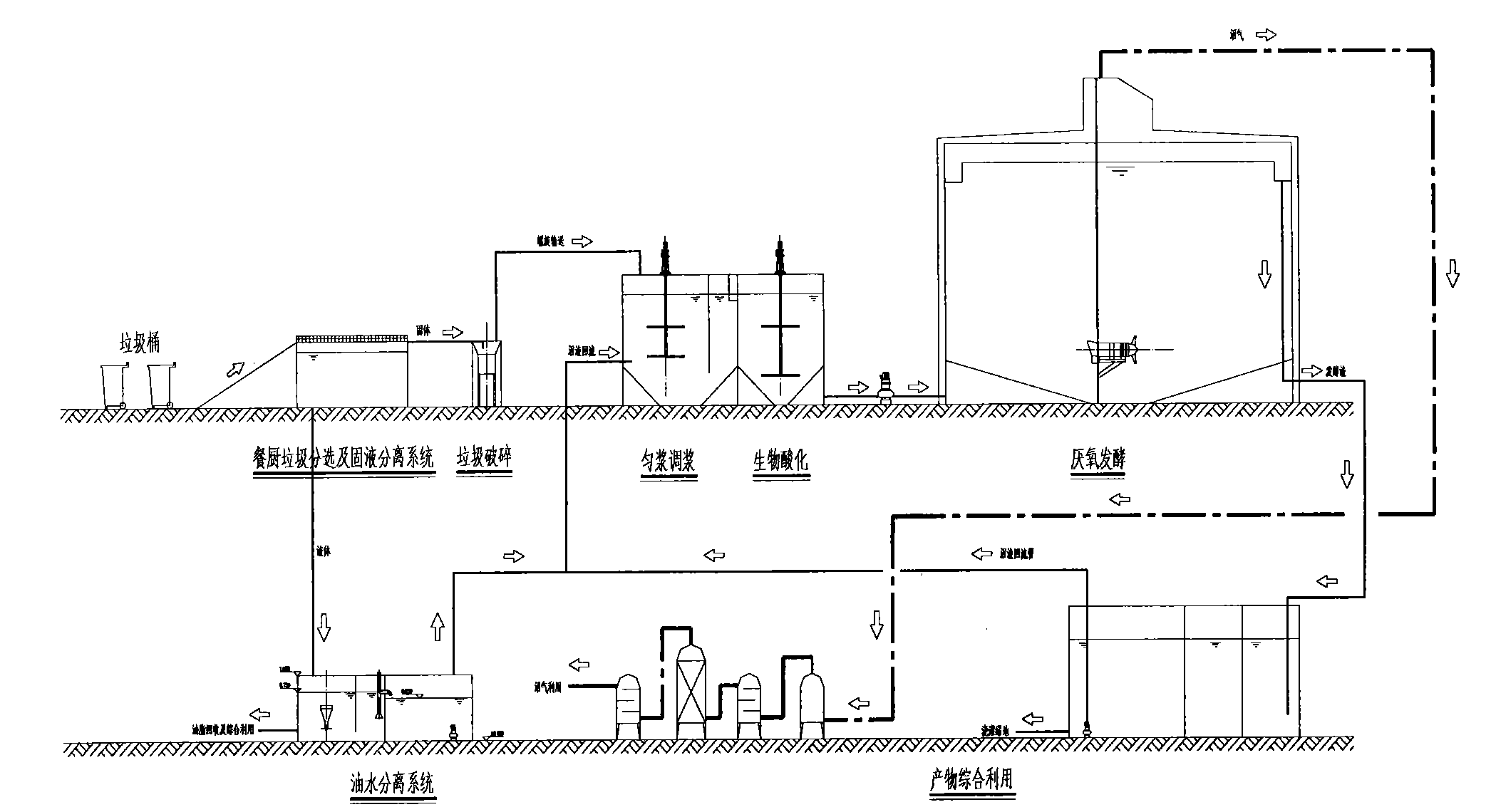

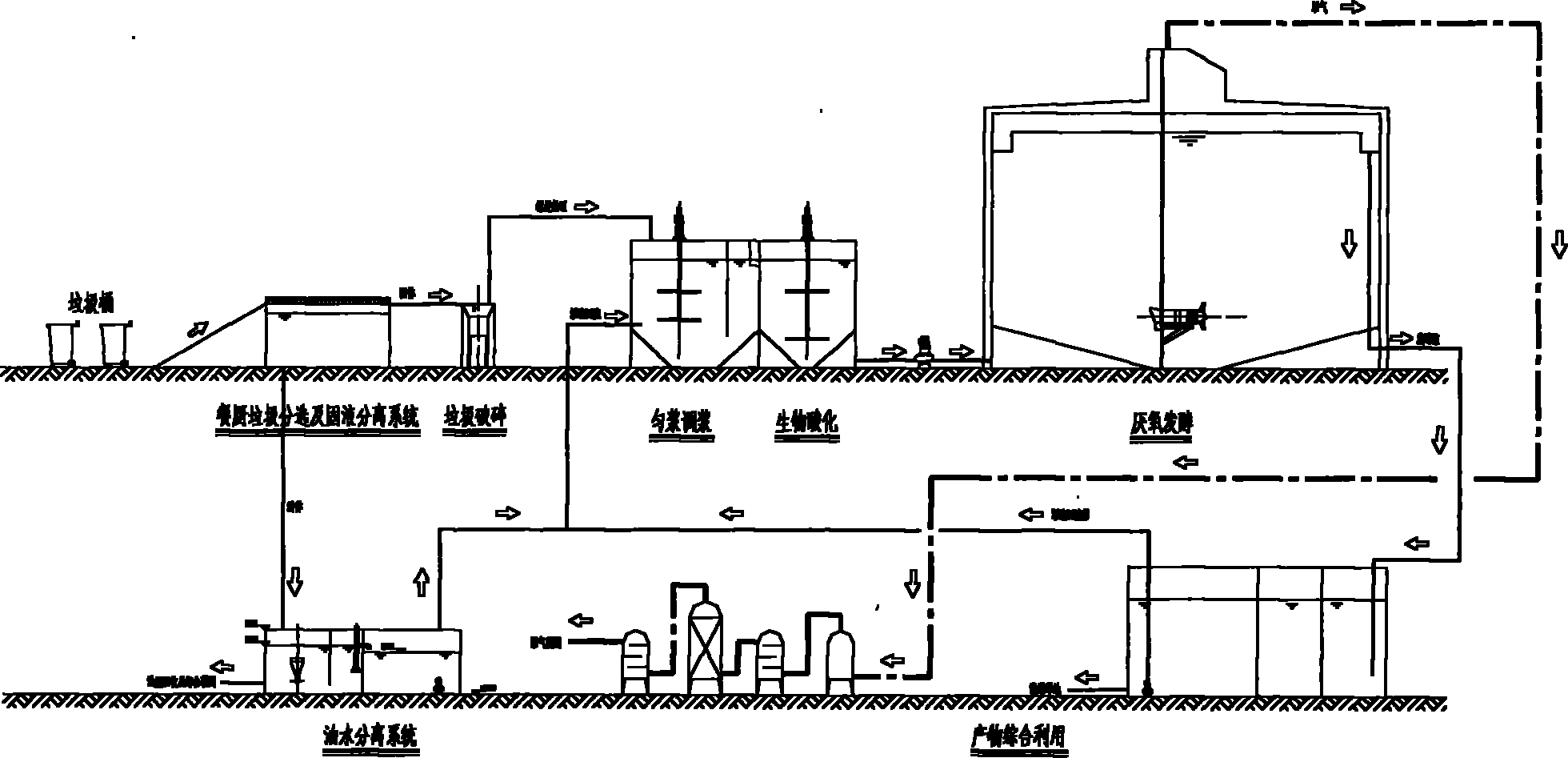

Method for realizing innocent treatment and comprehensive utilization of kitchen waste

ActiveCN102601101ARealize harmless treatmentLower energy costsFatty oils/acids recovery from wasteBio-organic fraction processingOil and greaseEnvironmental engineering

The invention relates to a method for realizing innocent treatment and comprehensive utilization of kitchen waste, comprising the steps of 1, sorting kitchen waste; 2, separating solid and liquid; 3, separating oil and water; 4, crushing waste; 5, performing homogenate and size mixing; 6, biologically acidifying; 7, performing anaerobic fermenting; and 8, comprehensively utilizing product. The process method is simple; the investment operation cost is low; the oil in the waste can be extracted; the biogas is produced by anaerobic fermentation of the kitchen waste, and the organic fertilizer can be produced, therefore, the innocent treatment of the kitchen waste can be realized, the waste can be converted into energy, and the virtuous circle of resource substance can be realized.

Owner:北京中源创能工程技术有限公司

Method for innocent treatment of arsenic sulfide residues

InactiveCN105963902ARealize harmless treatmentReduce arsenic leaching concentrationChemical protectionRoom temperatureArsenic sulfide

The invention discloses a method for harmless treatment of arsenic sulfide slag, which comprises the following steps: adding water to arsenic sulfide slag at room temperature, mixing to obtain mixture I, adding sodium sulfide to react to obtain mixture II, and then Add oxidant to carry out oxidation reaction to obtain mixture III, then add iron salt or aluminum salt for reaction to obtain mixture IV, and then add cement. The invention has the advantages of being able to effectively reduce the arsenic leaching concentration of the arsenic sulfide slag, the treated arsenic sulfide slag meets the requirements for hazardous waste landfill, simple process flow, small volume increase, strong operability, short stirring time, and low consumption.

Owner:云南大地丰源环保有限公司

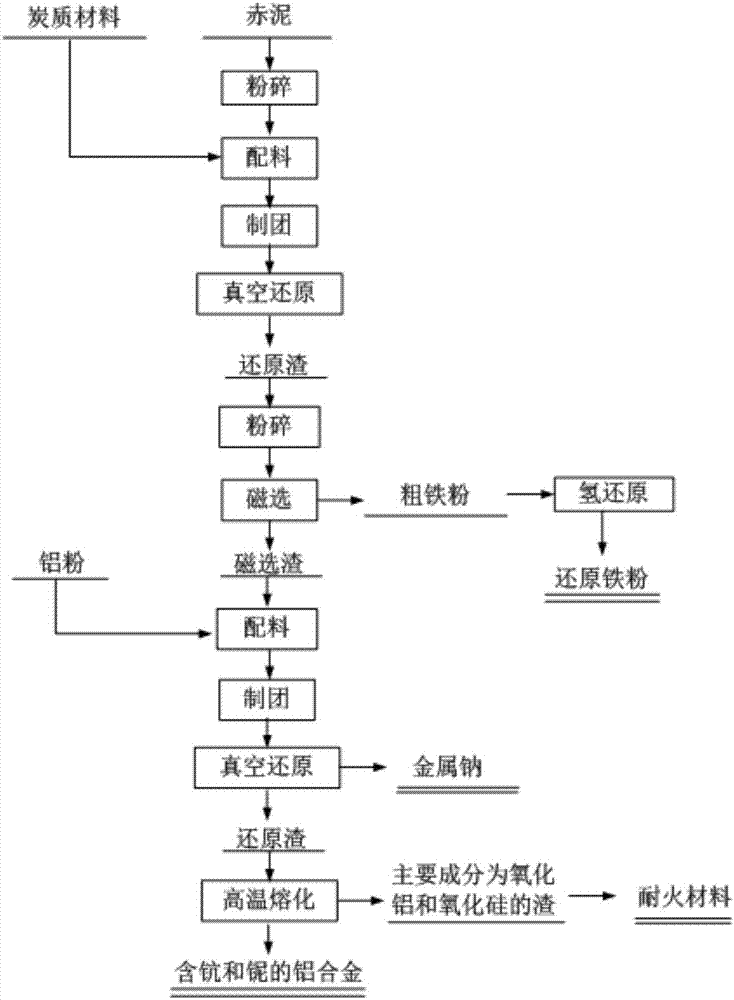

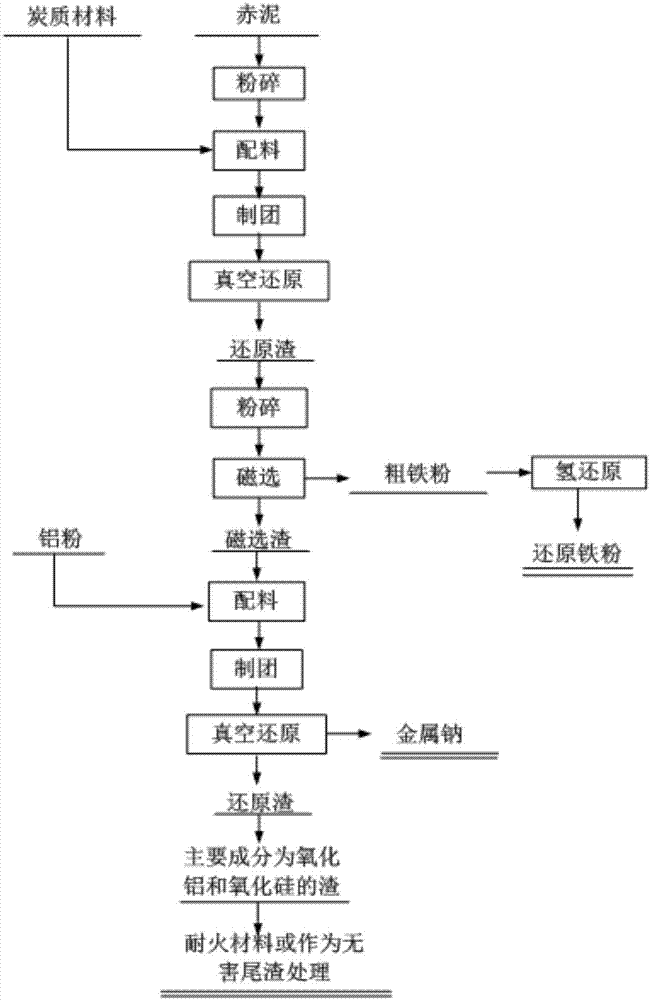

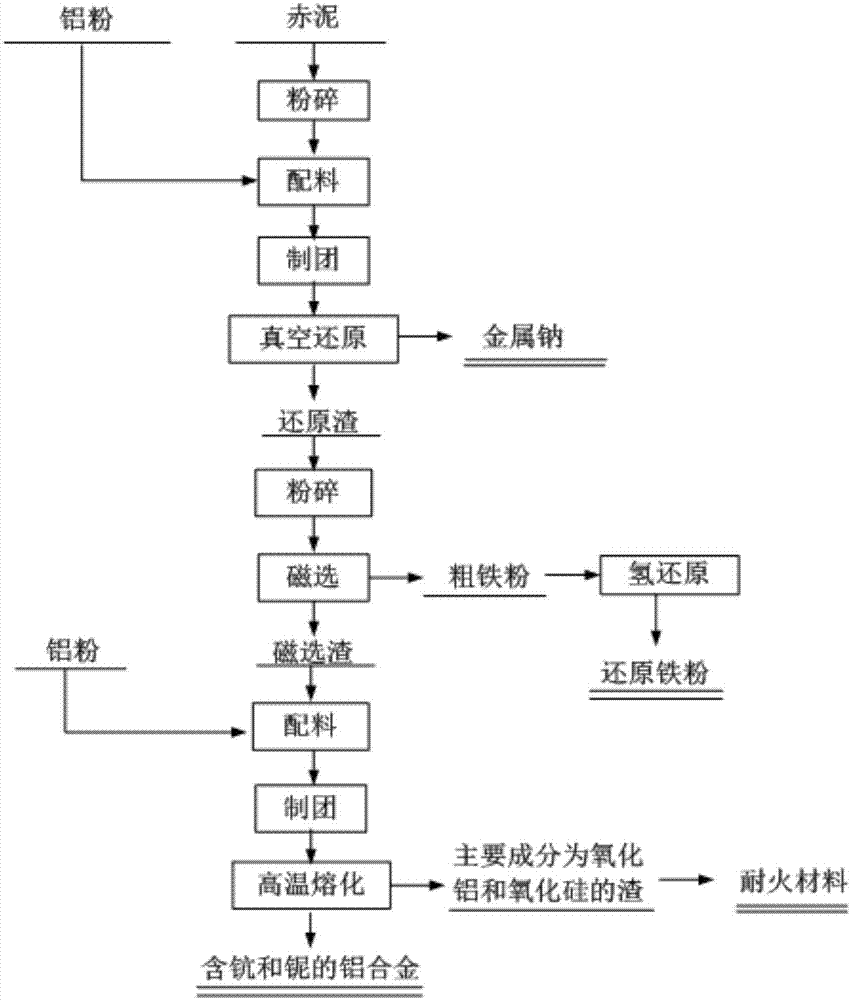

Comprehensive utilization method for aluminum oxide red mud

ActiveCN107083485AAchieve removalAchieve recyclingRetort furnacesProcess efficiency improvementNiobiumSlag

The invention belongs to the technical field of metallurgy and environmental protection, and particularly relates to a comprehensive utilization method for aluminum oxide red mud. The comprehensive utilization method for the aluminum oxide red mud aims at solving the problem that the aluminum oxide red mud is difficult to treat and recycle effectively, the red mud is treated by adopting a vacuum thermal reduction method, carbon or aluminum serves as a reducing agent, iron oxide in the red mud is reduced into metal iron under a vacuum condition, then iron in reducing slag is separated out through magnetic separation to be used for producing reduced iron powder, combined-state sodium oxide is reduced into metallic sodium and is distilled out, and therefore, the purposes of dealkalization and alkali recovery from the red mud can be achieved; and meanwhile, other valuable substances (such as scandium, niobium, cesium) in the red mud are reduced to metallic states and form an alloy with aluminum so as to be separated from the slag with the main components being silicon oxide and aluminum oxide, and therefore the effects of harmless treatment of the aluminum oxide red mud and comprehensive recovery and utilization of the valuable elements can be achieved, and no waste gas, waste water, waste slag or other secondary pollution is generated in the treatment process.

Owner:NORTHEASTERN UNIV

Method for preparing liquid biofertilizer through organic waste liquid

The invention discloses a method for preparing liquid biofertilizer through organic waste liquid. The method comprises the following steps: A, primary fermentation; B, high-order oxidation treatment: performing high-order full oxidation treatment on the primary fermentation liquid obtained in the step A through the high-voltage pulse liquid discharge and plasma discharge technologies to prepare a high-activity treating liquid; C, secondary fermentation: supplementing a sufficient silicon source and inorganic nutrients in the high-activity treating liquid obtained in the step B, inoculating a compound microbial agent into the treating liquid to perform secondary fermentation cultivation to prepare a biological bacterium liquid; D, nutrition complexing and mixing: adding a plant growth nutrient and an accelerating agent into the biological bacterium liquid obtained in the step C to prepare the efficient liquid microbe fertilizer. According to the method, complete innocent treatment of the organic waste liquid is realized, and meanwhile, the fertility utilization rate of the organic waste liquid is greatly increased.

Owner:高洁

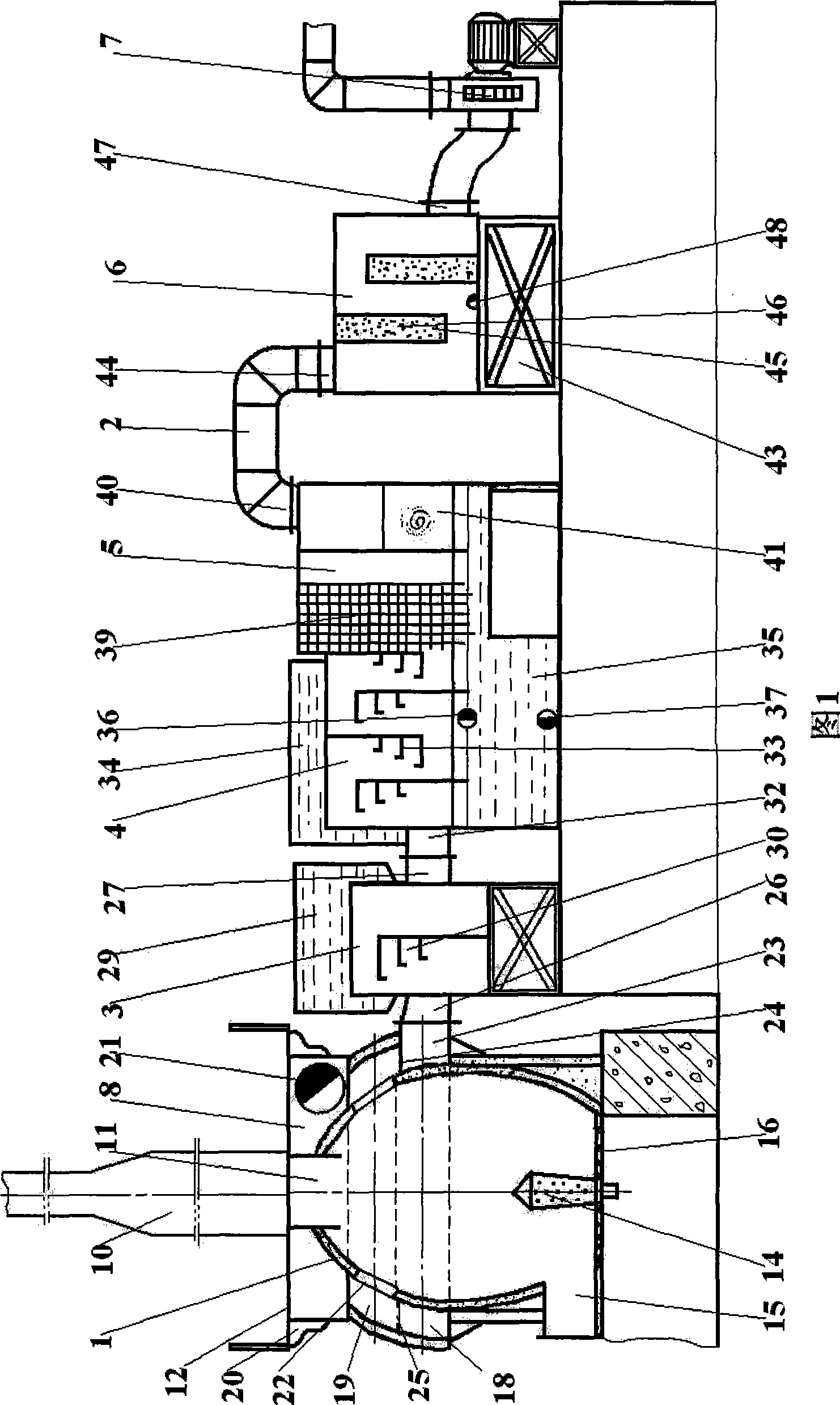

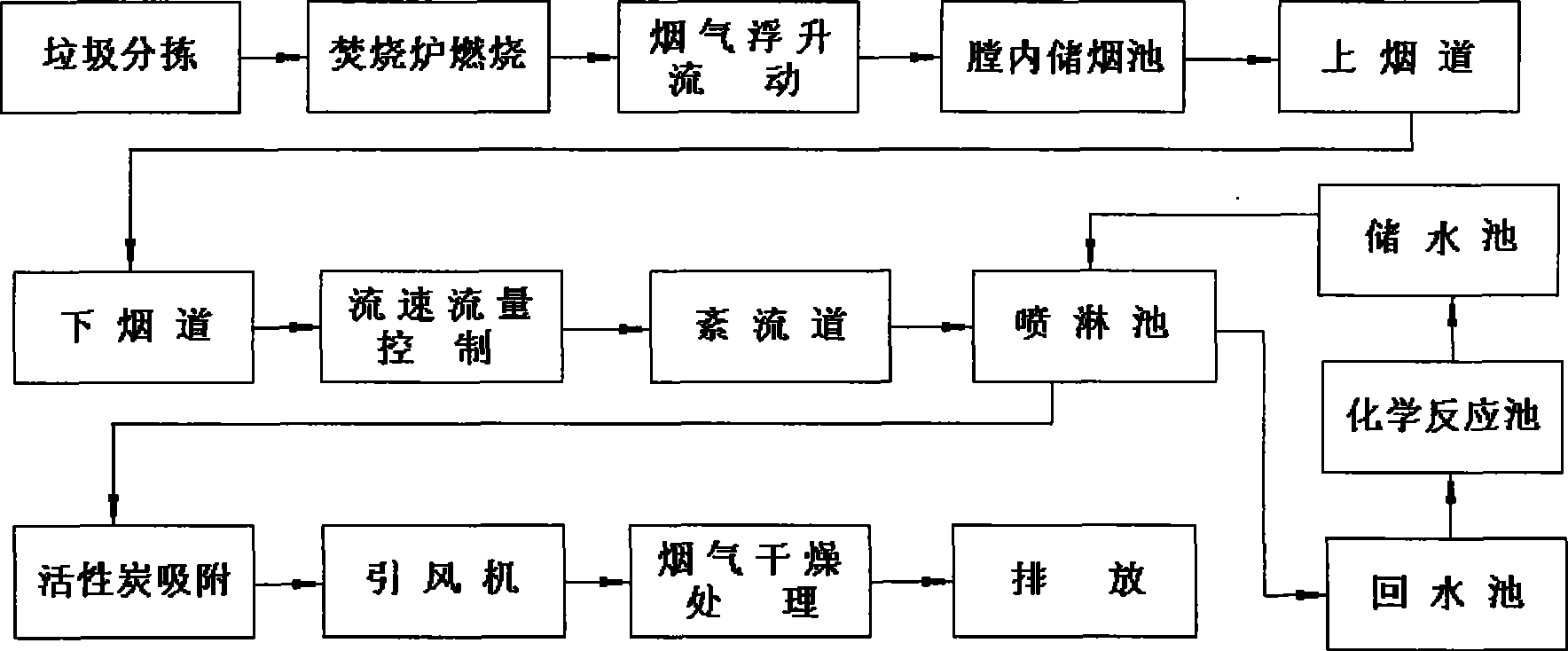

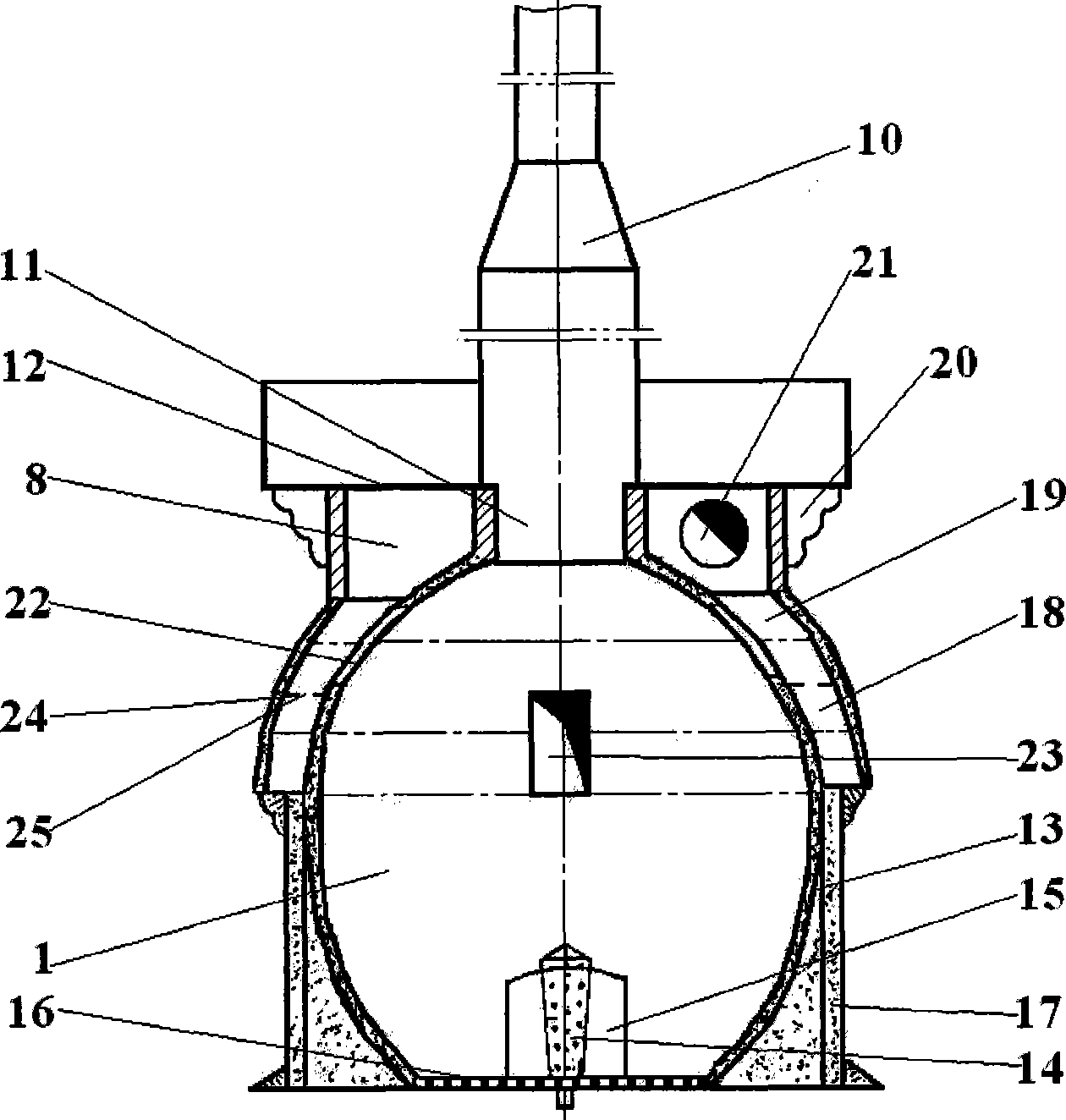

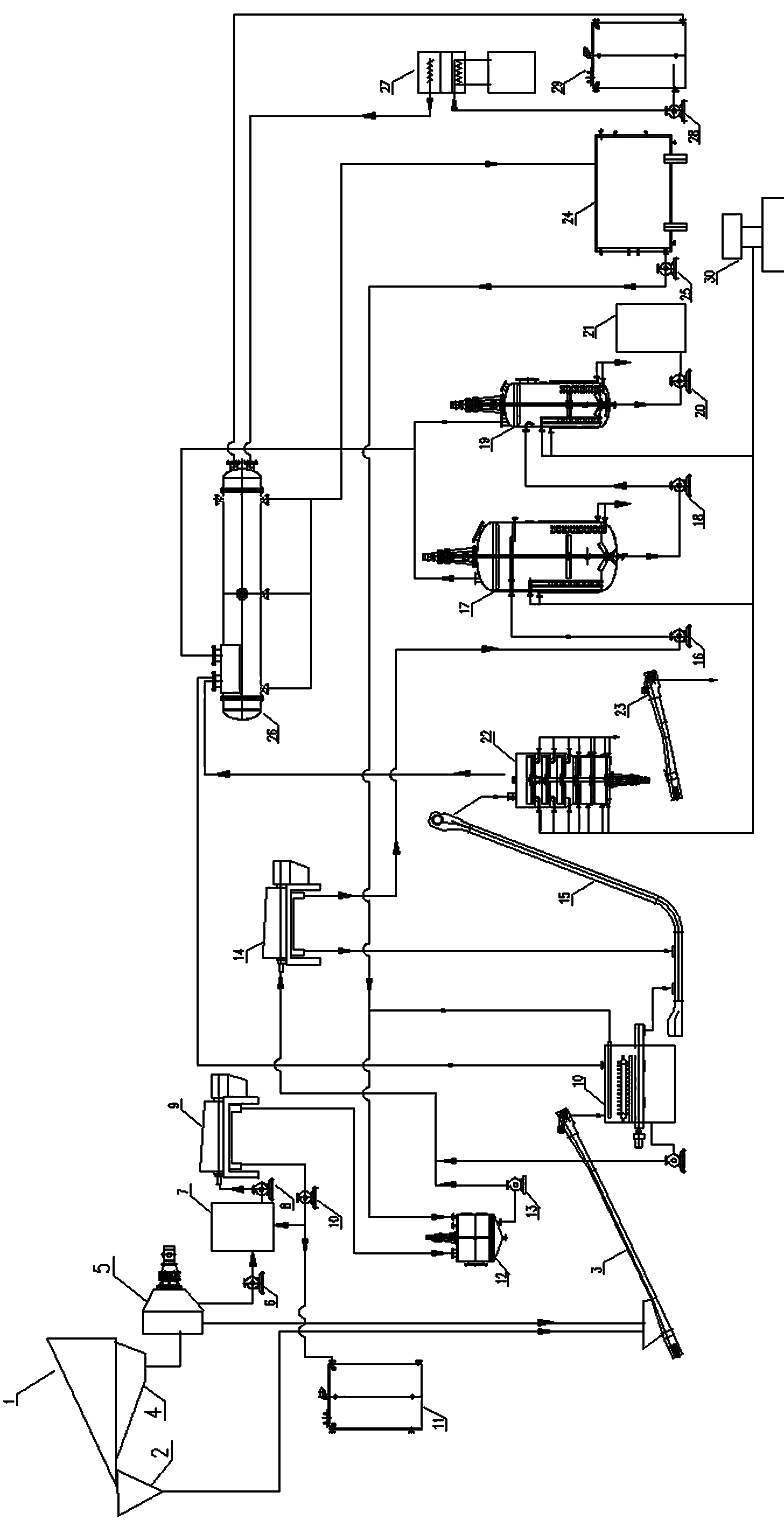

Refuse incineration processing equipment and method

InactiveCN101368732ABurn fullyImprove combustion efficiencyUsing liquid separation agentIncinerator apparatusFlue gasTreatment field

The invention discloses a garbage incineration treatment device which belongs to the garbage harmless treatment field; the technical proposal includes that: according to the flow sequence of the flue gas generated in an incinerator body (1), a flow and flow velocity control component (3), a turbulent flow flue gas channel (4), a high pressure spraying dust removal pool (5), an active carbon absorption chamber (6), an induced draft fan (7) and a flue gas drying chamber (8) are arranged in the flue gas treatment facility; wherein, the flue gas drying chamber (8) is arranged on the upper part of the incinerator body (1) around the outer wall of the furnace body; the outlet of the flue gas drying chamber is connected with a chimney (10). Besides, the invention also discloses the corresponding treatment method adopted by the treatment device. The technical proposal is adopted to improve the efficiency of the garbage incineration; the insulation property of the furnace body is higher and the garbage incineration becomes more sufficient; the dust removal and drying effects of the flue gas are better; the finally exhausted flue gas is enabled to be purer, so as to realize the harmless treatment of the flue gas.

Owner:SHE COUNTY LVYUAN ENVIRONMENTAL PROTECTION EQUIP CO LTD

Device for recycling mud and diesel oil base from waste oil-base mud

The invention discloses a device for recycling mud and a diesel oil base from waste oil-base mud and belongs to the technical field of processing of pollutants generated in the process of oil and gas drilling. By the adoption of the device for recycling the mud and the diesel oil base from the waste oil-base mud, the oil-base mud is recycled from oil-containing refuse, such as the waste oil-base mud and drilling cuttings containing oil, generated in the oil-base mud drilling process through the centrifugal filtration-centrifugal sedimentation coupling technology, and the diesel oil base is recycled from a separated low-oil-content solid phase through a leaching-evaporation separating device. The recycled oil-base mud can be reused in drilling engineering. The recycled diesel oil base can be used for re-preparation of the oil base mud. According to the device for recycling the mud and the diesel oil base from the waste oil-base mud, resource recycling and harmless treatment of the oil-containing refuse generated in the oil-base mud drilling process are achieved, cost is low, no secondary pollution is caused, resources can be recycled, operation is easy, the oil-base mud and the diesel oil base are recycled from the oil-containing refuge as much as possible, and the recycled oil-based mud can be reused.

Owner:四川博盛永业工程技术有限公司

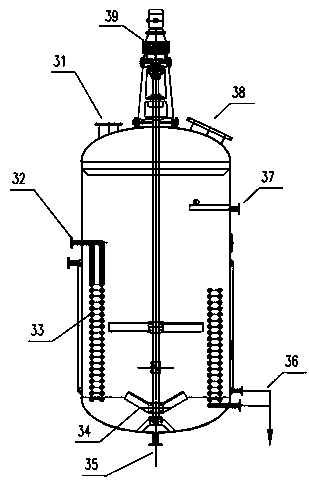

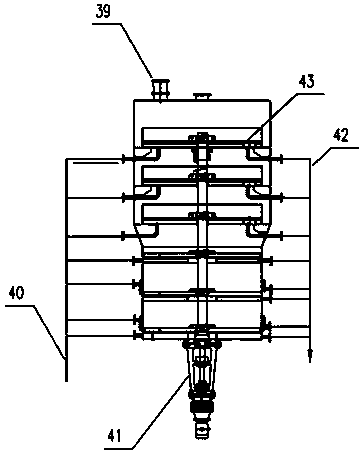

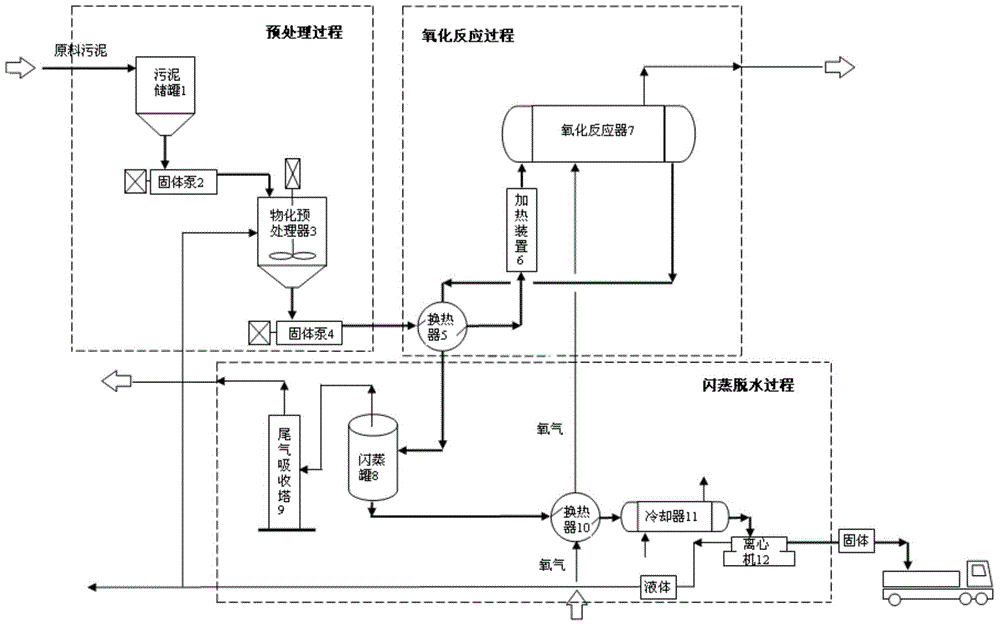

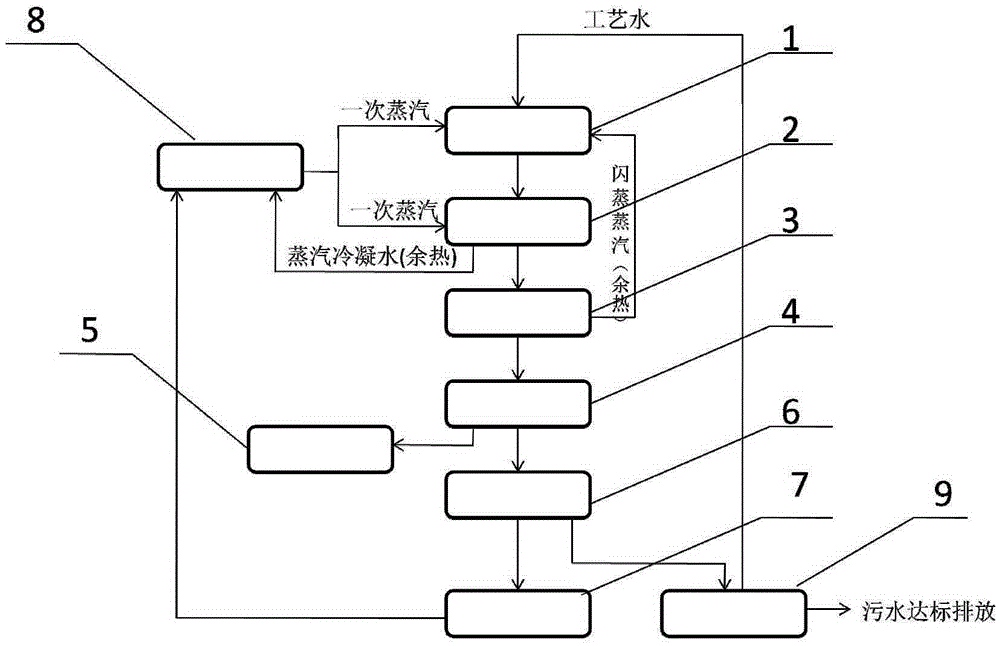

Sludge treatment method based on wet oxidation

ActiveCN104355514AReduce processing costsRealize harmless treatmentSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationWater vaporProduct gas

The invention relates to a sludge treatment method based on wet oxidation. The sludge treatment method comprises the following steps: fully mixing a sludge material and hot liquid in a physical-chemical pre-treater during a pretreatment process; after the preparation of the sludge material is completed, conveying the sludge material into an oxidation reaction process; during the oxidation reaction process, carrying out wet oxidation reaction between the sludge material and oxygen of which the temperature is 60 DEG C-80 DEG C in an oxidation reactor, wherein gas and high-temperature material are generated after the wet oxidation reaction is completed, and the gas mainly contains carbon dioxide and water vapor and is directly discharged into the air; enabling the high-temperature material to enter into a flash dehydration process, wherein the high-temperature material firstly enters a flash tank for flashing to produce gas and material, the produced gas is purified and then discharged into the air; enabling the generated material to pass through a heat exchanger, then carrying out solid-liquid separation to obtain separated solids and liquid which can be used for the second time. By the sludge treatment method, the sludge can be efficiently and reasonably treated so that the treated sludge can be recycled. The sludge treatment method can be widely applied to sludge treatment.

Owner:北京绿创生态科技有限公司

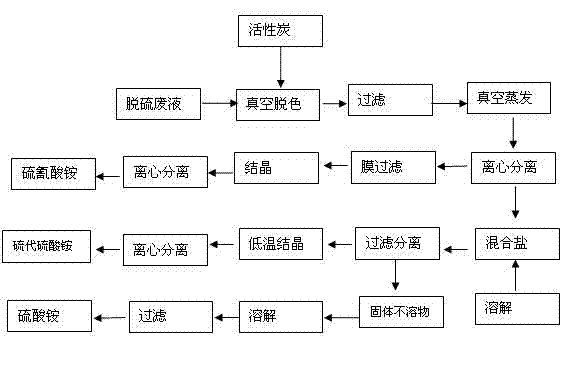

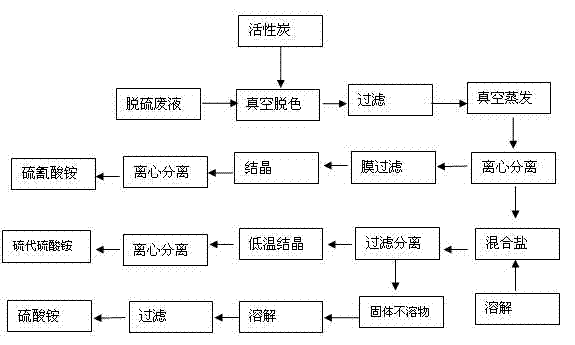

A comprehensive recovery process of desulfurization waste liquid auxiliary salt in coking plant

InactiveCN102259894ASimple processClear processThiosulfates/dithionites/polythionitesThiocyanic acidAmmonium sulfateChemistry

The invention belongs to the field of environmental protection, and particularly discloses a comprehensive recovery process for desulfurization waste liquid secondary salt in a coking plant. The comprehensive recovery process is characterized in that: the desulfurization waste liquid is decolorized, evaporated, and separated to obtain a solid mixture of ammonium thiosulfate and ammonium sulfate and a separation liquid, and the separation liquid is filtered, crystallized, washed, and dried to obtain ammonium thiocyanate finished product. The invention has a simple process and a clear process, and can simultaneously recycle three secondary salts of ammonium thiocyanate, ammonium thiosulfate and ammonium sulfate in the desulfurization waste liquid with less energy consumption. The whole process is a physical process, and no other chemicals are introduced to avoid It prevents secondary pollution and realizes the harmless treatment of wastewater.

Owner:SHANDONG MEIKE POWER

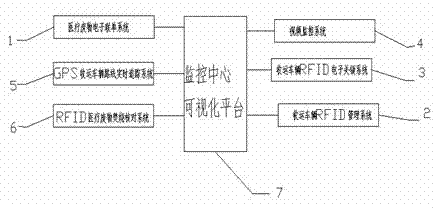

Medical waste processing system based on radio frequency identification device (RFID) technology

InactiveCN103093327AGrasp the disposal situationRealize harmless treatmentLogisticsElectronic waste recyclingVideo monitoringThe Internet

The invention relates to a medical waste processing system based on the radio frequency identification device (RFID) technology. The medical waste processing system based on the RFID technology comprises a medical waste electronic receipt system, a collection and transportation vehicle RFID management system, a collection and transportation vehicle RFID electronic locking system, a video monitoring system, a global position system (GPS) vehicle collection and transportation route real-time tracking system, an RFID medical waste burning check system and a monitoring center visualization platform. The medical waste processing system based on the RFID technology is characterized in that medical waste processing vehicles with RFID chips are automatically distinguished by utilization of the technologies such as an RFID and a wireless fidelity (WIFI) of the internet of Things, a plurality of distinguishing devices are used for monitoring medical waste processing procedures and positioning a medical waste processing route, and whole-process electronic monitoring of medical waste processing is achieved.

Owner:QINGDAO ZHONGKE SOFTWARE

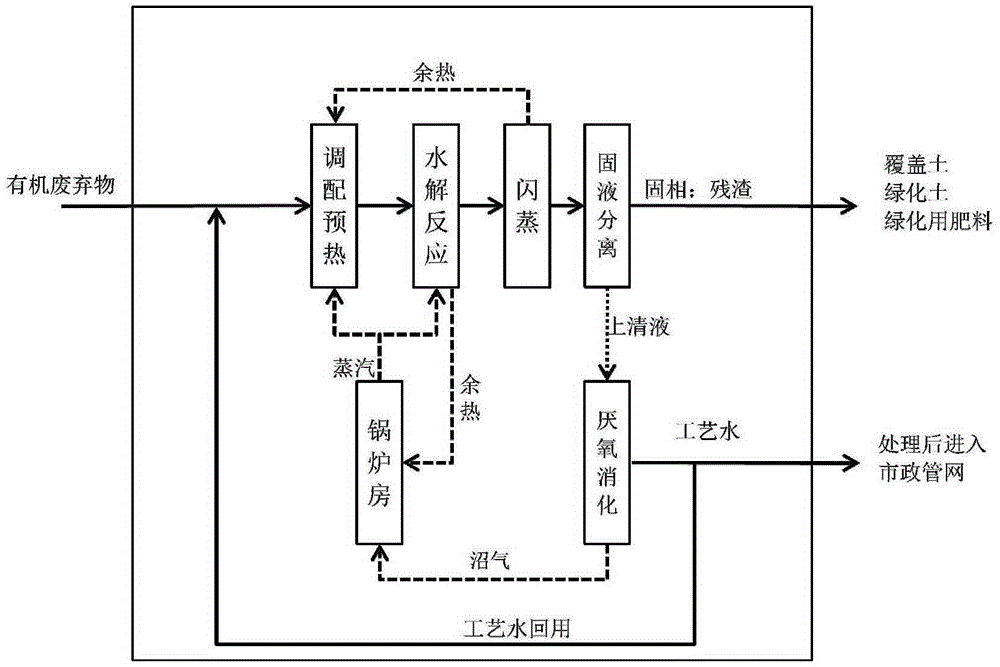

Energy regeneration method for solid organic waste alkaline thermal hydrolysis supernate

InactiveCN105396862ALow viscosityImprove liquiditySolid waste disposalWaste based fuelTemperature controlEnergy regeneration

The invention relates to an energy regeneration method for solid organic waste alkaline thermal hydrolysis supernate. Solid organic waste mainly comprises kitchen waste and sludge. The energy regeneration method for the solid organic waste alkaline thermal hydrolysis supernate comprises the following steps that (1) after the organic waste, water and alkali hydrolysis agents are proportioned and mixed in a proportioning and preheating tank, heating is conducted, so that the temperature of the materials in the tank is increased to 30-99 DEG C; (2) the materials in the proportioning and preheating tank are sent into a reaction kettle through a pump for the temperature rise reaction, and finally the temperature of the materials is controlled between 100 DEG C and 140 DEG C, and the reaction continues to be conducted for 90-120 minutes; (3) the materials after the hydrolysis reaction are conveyed into a flash evaporation tank for pressure relief and cooling, so that the temperature of the materials is decreased to 50-100 DEG C; (4) clarified liquid and solid are obtained after solid-liquid separation; and (5) the liquid obtained after solid-liquid separation is delivered into an anaerobic digestion system for anaerobic digestion treatment, and thus marsh gas is generated. By the adoption of the energy regeneration method for the solid organic waste alkaline thermal hydrolysis supernate, toxin removal, stabilization, minimization and energy regeneration of the organic waste can be achieved at a time.

Owner:天津市裕川环境科技有限公司

Biological orgamic fertilizer and prepn thereof

ActiveCN1834066AImprove stress resistanceImprove disease resistanceBio-organic fraction processingBacteriaMicroorganismBiotechnology

This invention relates to a method to prepare a kind of bioorganic fertilizer and its application. The preparation method includes following steps: a) proliferation and cultivation of microorganism species; b) cultivation of microorganism species against stalk antibody; c) adsorption onto a carrier and drying into organic decomposers; d) preprocessing of organic waste; e) inoculation complex fermentation and f) continuous high-temperature fermentation and nontoxification. This invention has the advantages of advanced technique, low production cost, stable product quality and long fertility persistence and can be widely applied in the production of corns, vegetables, fruits and all kinds of economic crops. Besides, it is a green method makes considerable economic, social and environmental benefits.

Owner:上海联业农业科技有限公司

Processing method for cephalosporin dreg

ActiveCN103146761AEasy to handleDeal with economical and thoroughWaste based fuelSludge processingActivated sludgeResource utilization

The invention discloses a processing method for cephalosporin dreg. The processing method comprises the following process steps of: (A) thermal alkaline hydrolysis and separation treatment: uniformly mixing cephalosporin dreg, water and alkali, carrying out constant-temperature alkaline hydrolysis reaction, and carrying out solid-liquid separation at a certain temperature after the constant-temperature alkaline hydrolysis reaction, so as to obtain sediments to be standby; and (B) anaerobic digestion treatment: inoculating anaerobic activated sludge into an anaerobic fermentation tank, mixing the sediments obtained in the step (A) with excess sludge produced by utilizing wastewater biological treatment, injecting the mixture into the fermentation tank, carrying out constant-temperature stirring, and carrying out biogas residue discharging and feeding during fermentation. According to the processing method for the cephalosporin dreg, drug residues in the cephalosporin dreg can be completely removed, the problem that the anaerobic fermentation of single cephalosporin dreg cannot be effectively sustained is solved, and the reduction and innocent treatment to the cephalosporin dreg are realized; and biogas residues produced during the processing process can be used for preparing raw materials of organic fertilizers, the produced sewage gas can be used as clean fuels, and safe and effective disposition and resource utilization to the cephalosporin dreg are realized.

Owner:河北华药环境保护研究所有限公司

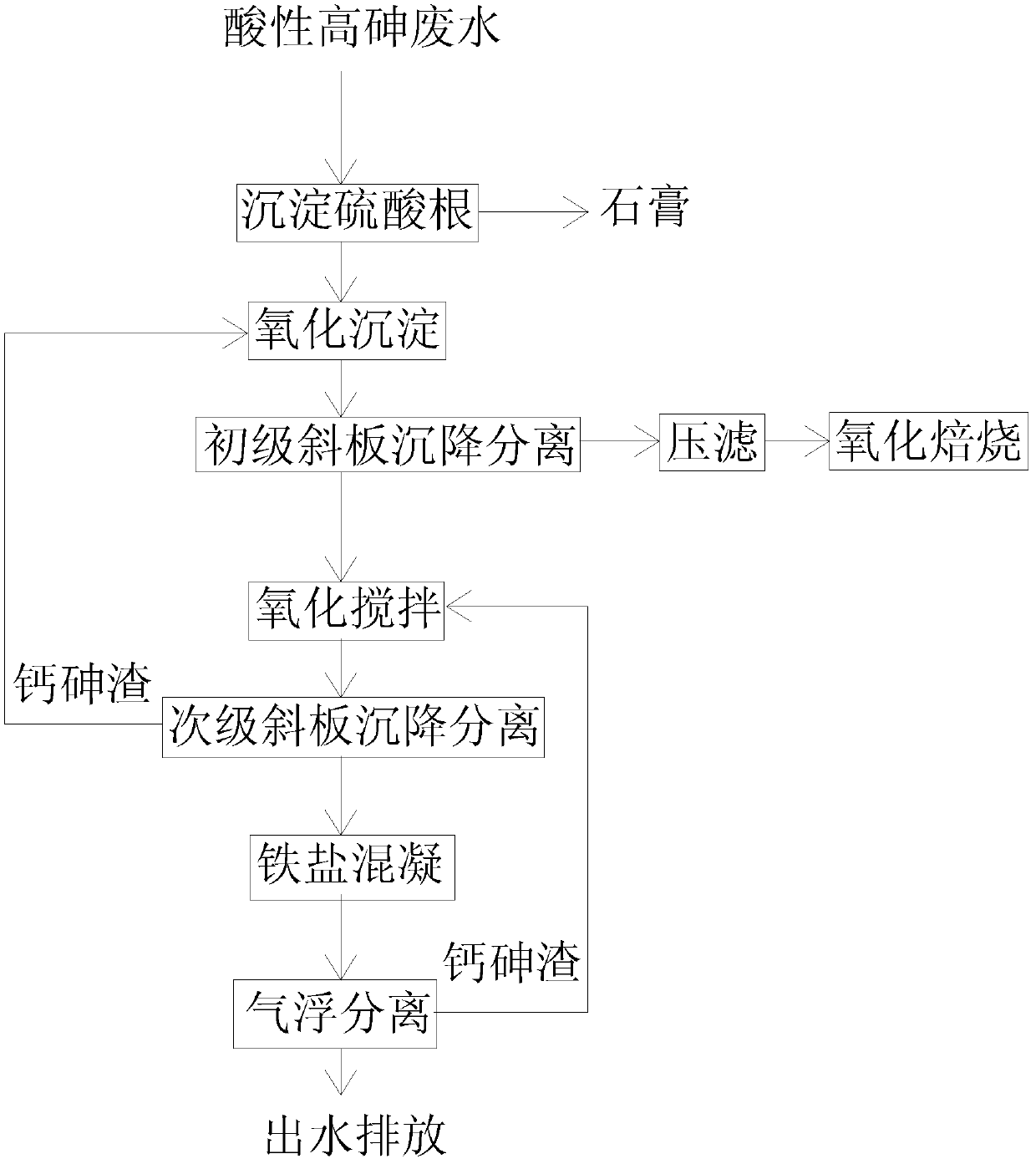

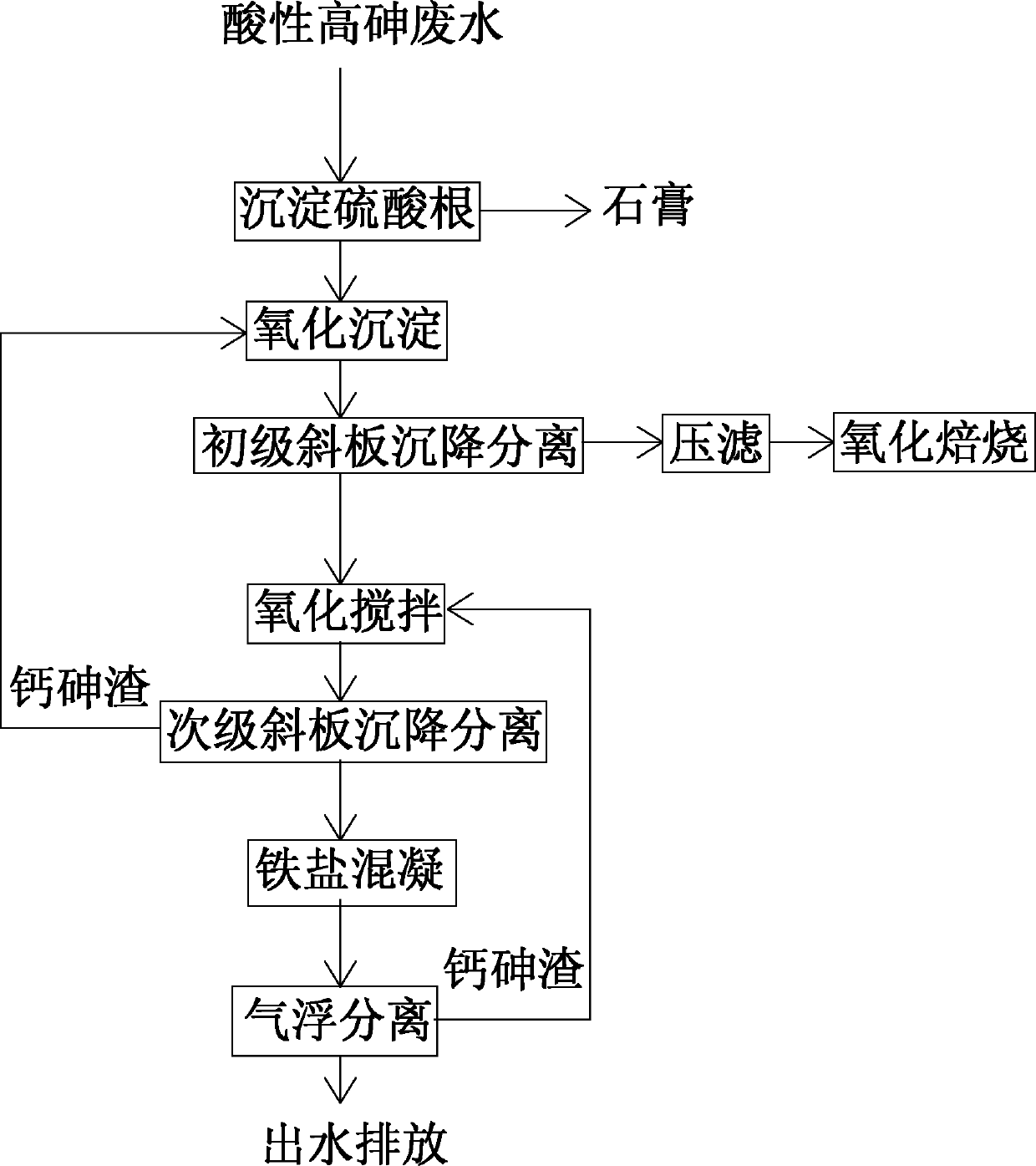

Coupling process method for high-concentration arsenic acidic wastewater

InactiveCN102603099AHigh removal rateReduce dosageWater contaminantsWaste water treatment from metallurgical processHigh concentrationIron salts

The invention discloses a coupling process method for high-concentration arsenic acidic wastewater. The coupling process method comprises the steps of (1) precipitating sulfate radical; (2) performing oxidation precipitation; (3) performing settling separation by a primary sloping panel; (4) performing oxidation and stirring; (5) performing settling separation by a secondary sloping panel; (6) coagulating an iron salt; and (7) performing air floating separation. The coupling process method has the advantages that yielding water is stable and easy to reach the standard, the agent dosage is small, the operation cost is low, the slag discharging amount is small, and arsenic slag can be cured effectively.

Owner:SHENZHEN MINGDENG TECH

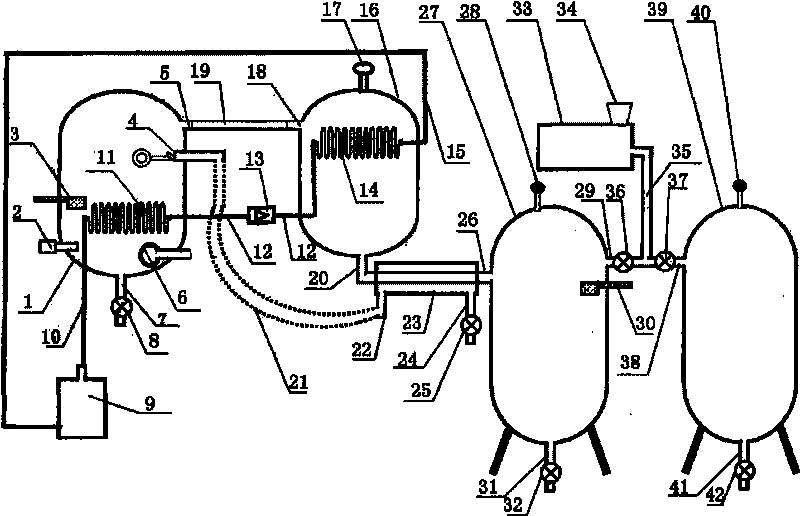

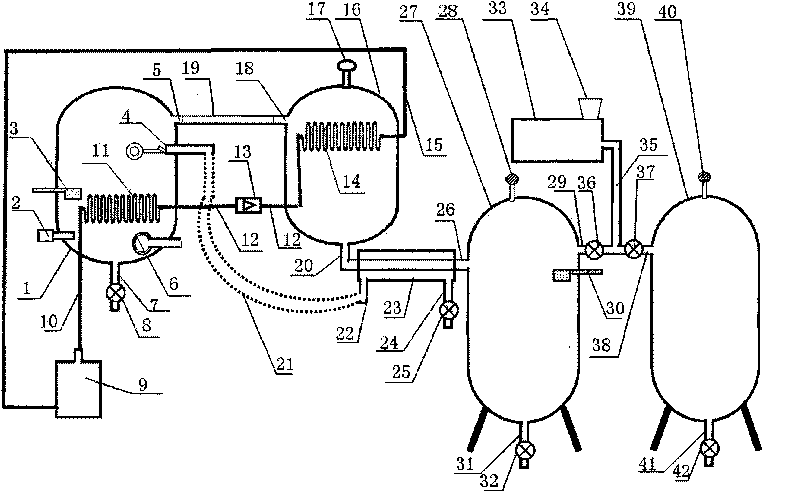

Vacuum heat pump type distilling apparatus

InactiveCN101721824AImprove economic efficiencyIncrease profitVacuum distillation separationWater/sewage treatment by heatingEvaporatorEngineering

Owner:凌建军

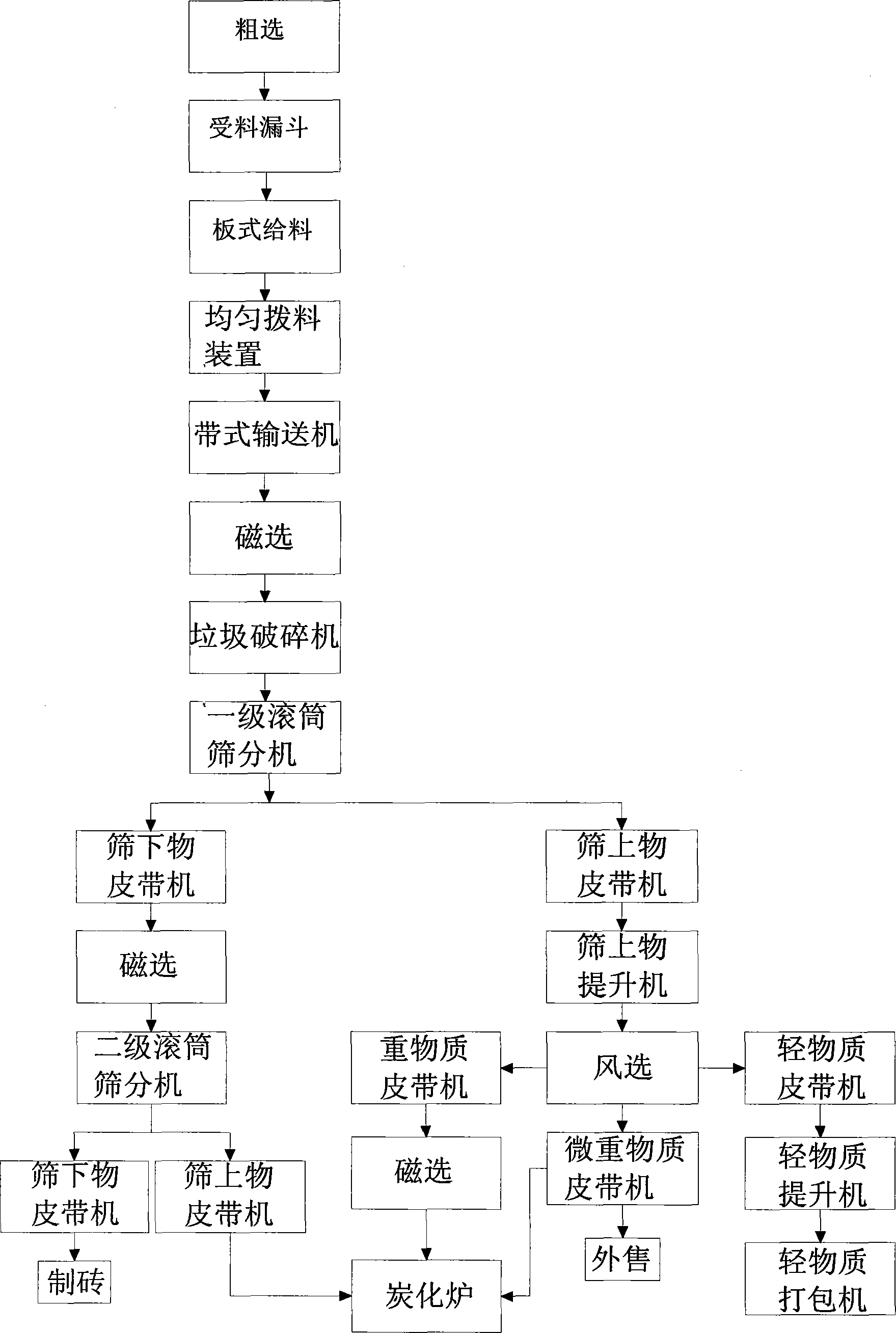

Integrated household garbage treatment method

ActiveCN103909085AImprove efficiencyRealize the effect of turning waste into treasureConstruction waste recoverySolid waste disposalMagnetic separatorCarbonization

The invention relates to an integrated household garbage treatment method. According to the integrated household garbage treatment method, household garbage is subjected to rapid innocent treatment by virtue of procedures of rough selection, loading, magnetic separation, crushing screening, winnowing, secondary magnetic separation and anaerobic carbonization; a first-stage drum sieving machine, a second-stage drum sieving machine, a strong-magnetism iron separator and an anaerobic carbonization furnace are utilized for carrying out mechanization treatment on the household garbage, and the household garbage is sequentially subjected to crushing screening and magnetic separation, so that the utilization efficiency of the strong-magnetism iron separator is greatly increased, and the innocent treatment of the household garbage is realized by virtue of the anaerobic carbonization furnace; meanwhile, the household garbage can be made into coal and building materials and can be converted into heat energy by virtue of the method, so that an effect of recycling of the garbage is realized.

Owner:DEZHOU QUNFENG MACHINERY MFG

Flower planting nutrient soil and production method thereof

InactiveCN102863265ARealize harmless treatmentHarm reductionBio-organic fraction processingOrganic fertiliser preparationFlowering seasonDecomposition

The invention relates to a flower planting nutrient soil and a production method thereof. The method comprises the steps of 1) mixing municipal domestic sludge, food waste residues and yeast liquid waste according to the proportion of (75-85):(15-25):(0.5-1.5), and stirring uniformly; 2), adding a certain amount of active microorganisms into raw materials in the step 1), and conducting continuous fermentation for 15-18 days; 3), placing the raw materials after fermentation into a decomposition bin until the temperature is lowered to the room temperature, and obtaining the flower planting nutrient soil; and detecting N, P and K of the decomposed nutrient soil and the content of organic matters and adjusting the nutrient soil by adding a large amount of elements such as N, P and K. According to the production method of the flower planting nutrient soil, the sources of the raw materials are rich, the production period is short, the cost is low, and the produced flower planting nutrient soil is nutritious and capable of improving the survival of plantlets, prolonging the flower season and improving the quality of the flower.

Owner:GUANGDONG SHENGYIN FLOWER & HORTICULTURE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com