Sludge treatment method based on wet oxidation

A wet oxidation and sludge treatment technology, which is applied in sludge treatment, oxidation treatment sludge, water/sludge/sewage treatment, etc., can solve the problems of high energy consumption, secondary pollution, and poor fertilizer efficiency in dry treatment process , to achieve effective reuse, reduce energy consumption, and increase mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

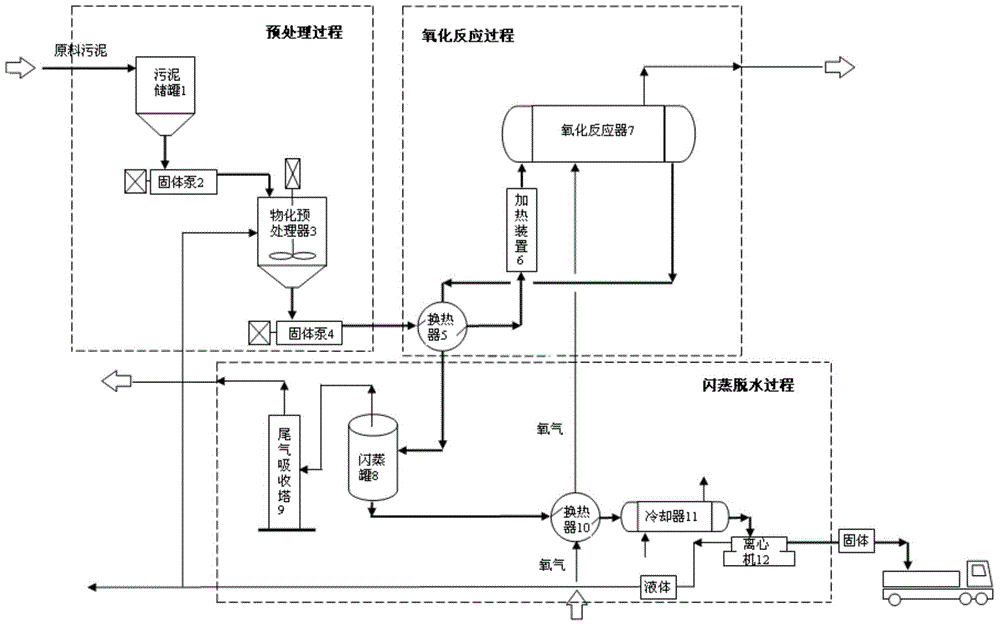

[0027] Such as figure 1 Shown, adopt the inventive method to treat sludge, comprise the following steps:

[0028] 1) Preprocessing process:

[0029]The raw sludge is sent to the sludge storage tank 1 through the conveyor, and the raw sludge in the sludge storage tank 1 flows out from the outlet at the bottom of the tank, and is transported to the physical and chemical preprocessor 3 by the solid pump 2, and at the same time to the physical and chemical pretreatment The hot liquid is passed into the device 3, and the ratio of the mass of the hot liquid and the raw sludge mass is 0.5:1, so that the hot liquid and the sludge material are fully mixed, the sludge material is preheated and its flow is increased To prevent the sludge material from scabbing and scaling, after the preparation of the sludge material in the physical and chemical preprocessor 3 is completed, the sludge material is output through the solid pump 4.

[0030] The temperature of the liquid in the above-menti...

Embodiment 2

[0041] Such as figure 1 Shown, adopt the inventive method to treat sludge, comprise the following steps:

[0042] 1) Preprocessing process:

[0043] The raw sludge is sent to the sludge storage tank 1 through the conveyor, and the raw sludge in the sludge storage tank 1 flows out from the outlet at the bottom of the tank, and is transported to the physical and chemical preprocessor 3 by the solid pump 2, and at the same time to the physical and chemical pretreatment The hot liquid is introduced into the device 3, and the ratio of the mass of the hot liquid and the mass of the raw sludge is 1:1, so that the hot liquid is fully mixed with the sludge material, preheats the sludge material and increases its flow To prevent the sludge material from scabbing and scaling, after the preparation of the sludge material in the physical and chemical preprocessor 3 is completed, the sludge material is output through the solid pump 4.

[0044] The temperature of the above-mentioned liquid...

Embodiment 3

[0055] Such as figure 1 Shown, adopt the inventive method to treat sludge, comprise the following steps:

[0056] 1) Preprocessing process:

[0057] The raw sludge is sent to the sludge storage tank 1 through the conveyor, and the raw sludge in the sludge storage tank 1 flows out from the outlet at the bottom of the tank, and is transported to the physical and chemical preprocessor 3 by the solid pump 2, and at the same time to the physical and chemical pretreatment The hot liquid is passed into the device 3, and the ratio of the mass of the heated liquid to the mass of the raw sludge is 0.8:1, so that the hot liquid and the sludge material are fully mixed, the sludge material is preheated and its flow is increased To prevent the sludge material from scabbing and scaling; after the preparation of the sludge material in the physical and chemical preprocessor 3, the sludge material is output through the solid pump 4.

[0058] The temperature of the above-mentioned hot liquid p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com