Preparation method for electrolytic manganese residue porous ceramics

A technology of porous ceramics and electrolytic manganese slag, which is applied in the direction of ceramic products, solid waste removal, and other household appliances to achieve the effect of improving material strength, high compressive strength, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

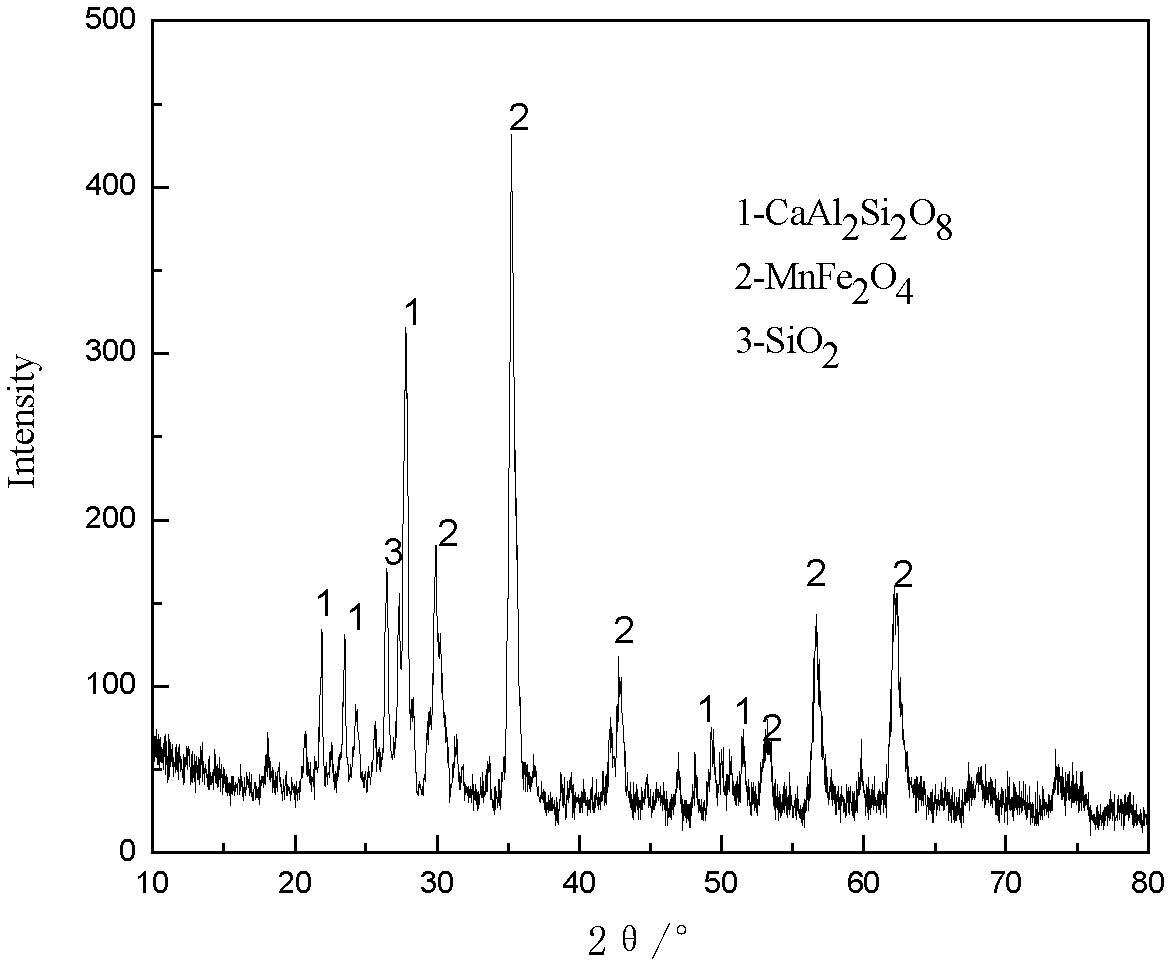

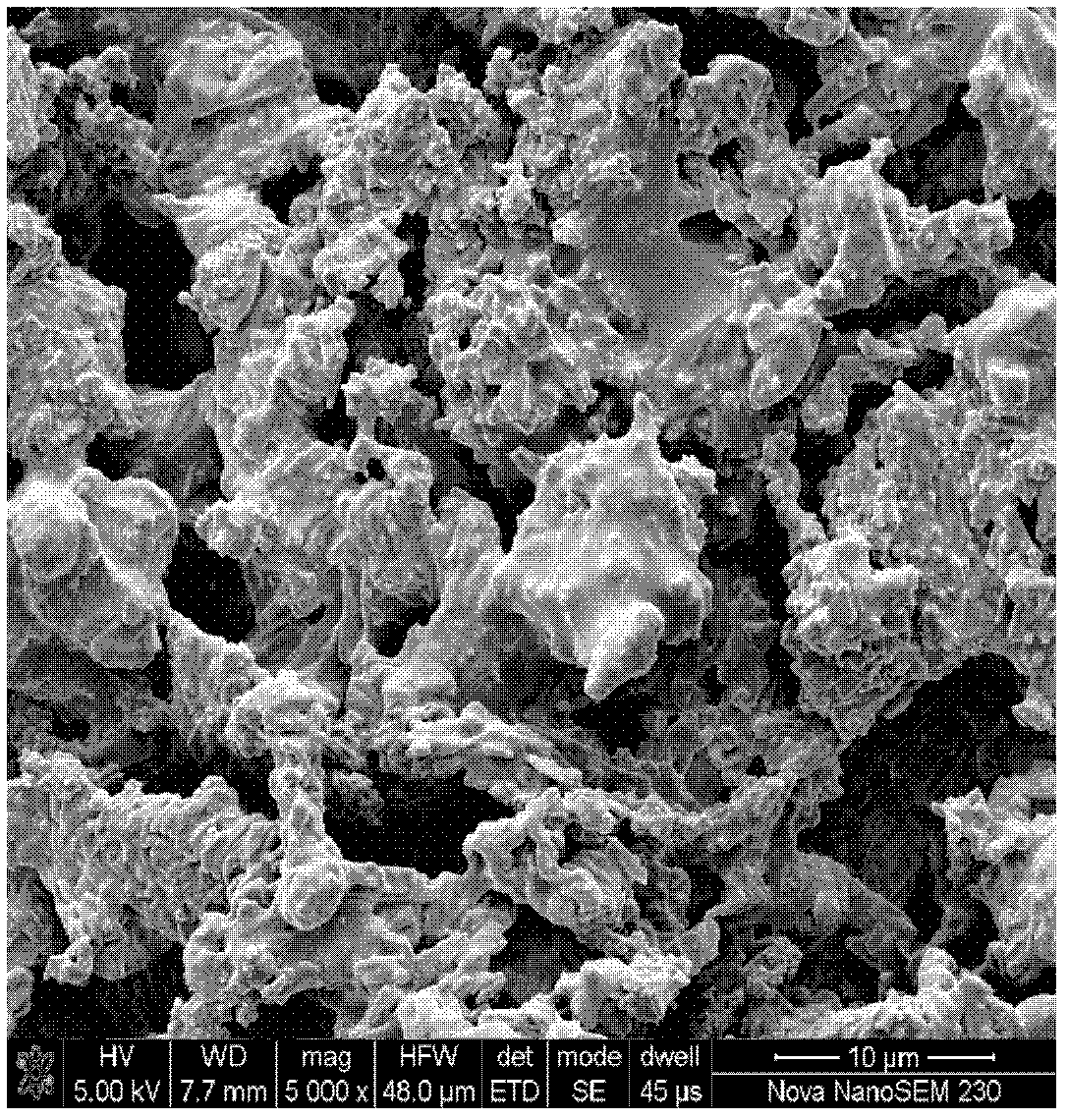

[0031] Embodiment 1 Limestone is porogen

[0032] Take 100 parts of leaching slag of manganese oxide ore and 10 parts of limestone, mix them evenly, put them into a steel mold, press them under a pressure of 8MPa for 3 minutes, take out the green body, let it dry naturally, put it into a high-temperature electric furnace, and change it from room temperature to 3°C The heating rate per minute was increased to 1100° C., heat-preserved and sintered for 1 hour, and taken out after cooling to obtain porous ceramics. The apparent porosity of porous ceramics is 39.58%, the water absorption rate is 23.43%, and the bulk density is 1.95g / cm 3 , the compressive strength is 36.22MPa, the acid resistance is 95.67%, and the alkali resistance is 99.13%.

Embodiment 2

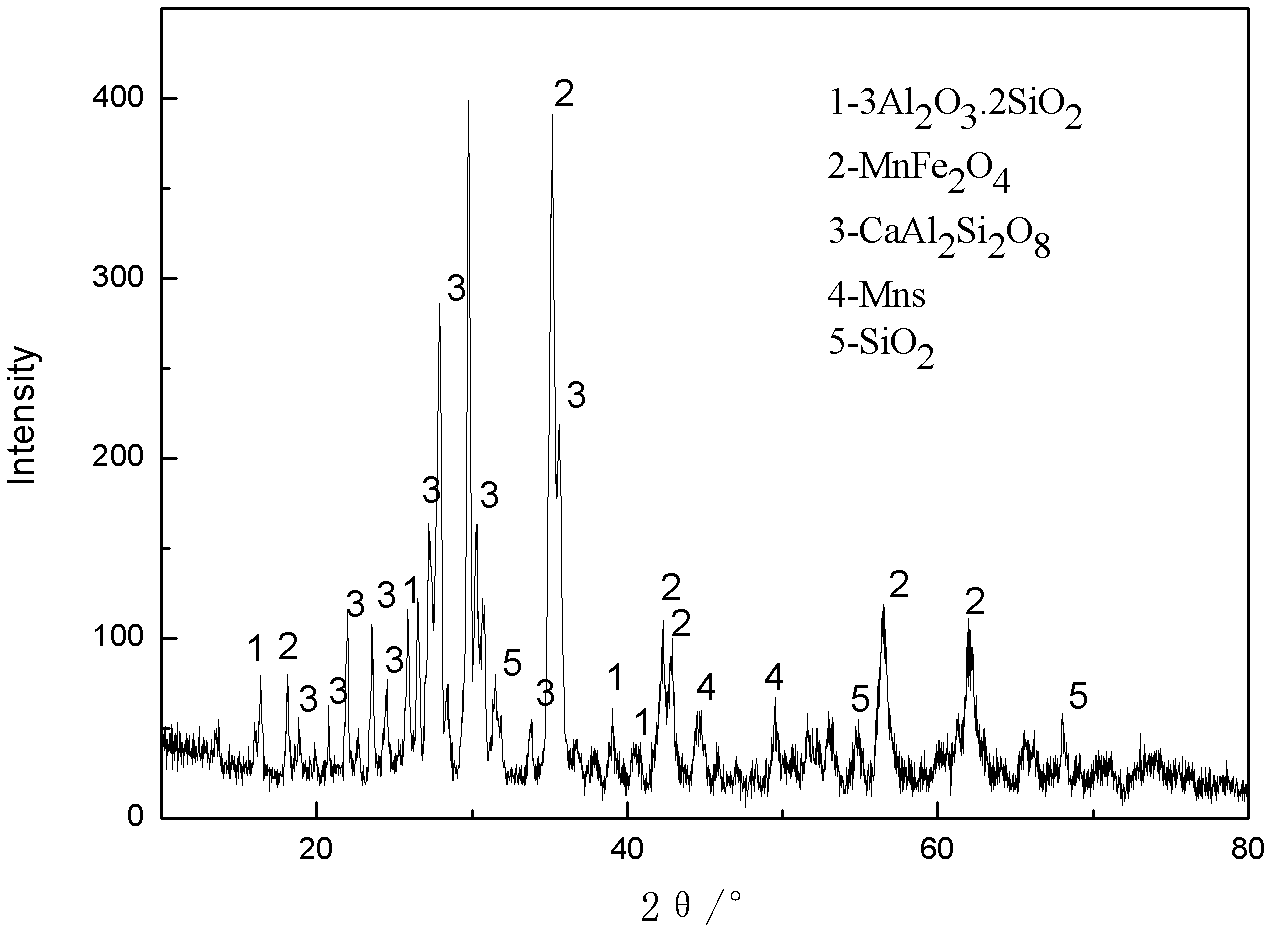

[0033] Embodiment 2 Coal powder is porogen

[0034] Take 100 parts of manganese carbonate ore leaching slag, 25 parts of coal powder, mix them evenly, put them into a steel mold, press them under a pressure of 4MPa for 2 minutes, take out the green body, dry it naturally, put it into a high-temperature electric furnace, and heat it from room temperature to 3 The heating rate was raised to 1070°C at a rate of °C / min, held for 1 hour for sintering, and taken out after cooling to obtain porous ceramics. The apparent porosity of porous ceramics is 69.27%, the water absorption rate is 65.58%, and the bulk density is 1.05g / cm 3 , the compressive strength is 6.83MPa, the acid resistance is 90.02%, and the alkali resistance is 98.98%.

Embodiment 3

[0035] Embodiment 3 carbon powder is porogen

[0036] Take 100 parts of leaching slag of manganese oxide ore, 25 parts of carbon powder, mix them evenly, put them into a steel mold, press them under a pressure of 2MPa for 3 minutes, take out the green body, put it in an electric furnace and keep the temperature at 105°C to dry for 5 hours. Put it into a high-temperature electric furnace, raise the temperature from room temperature to 1070° C. at a rate of 3° C. / min, keep it for sintering for 1 hour, take it out after cooling, and obtain porous ceramics. The apparent porosity of the ceramic is 66.85%, the water absorption rate is 66.71%, and the bulk density is 1.04g / cm 3 , the compressive strength is 2.61MPa, the acid resistance is 92.42%, and the alkali resistance is 97.25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com