Preparation method and applications of biomass modified TiO2 visible light photocatalyst

A photocatalyst and biomass technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, water pollutants, etc., can solve the problems of restricting industrial applications and low photocatalytic quantum efficiency, and achieve improved quantum efficiency and ratio Large surface area for easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Hydrolyze 10 ml of tetrabutyl titanate in 90 ml of acidic solution with pH=5 to obtain uniform transparent TiO 2 2.3 wt% TiO 2 Sol, adjusted by dialysis to obtain TiO with a pH value of 6 2 Sol.

[0031] (2) After drying 2 grams of soybean orange stalks and crushing them into 200 meshes, add them to TiO 2 sol, stirred at room temperature for 2h, the prepared soybean orange stem-TiO 2 Sol mixture.

[0032] (3) Soybean orange stalk-TiO 2 Soybean orange stalk-TiO was prepared by microwave drying method of sol mixture 2 Gel, the microwave frequency used is 2450 MHz and the power is 500W.

[0033] (4) The obtained soybean orange stalk-TiO 2 The gel was calcined in a calcination furnace at 200°C for 5h to obtain soybean orange stalk-modified TiO 2 Nano visible light photocatalyst.

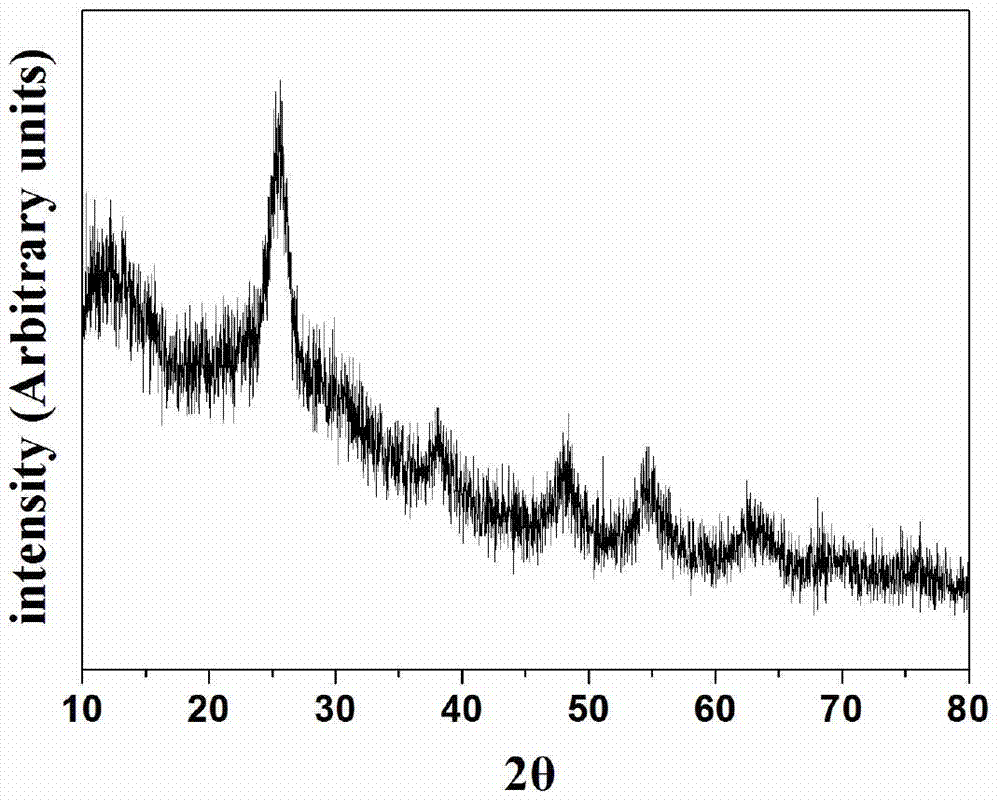

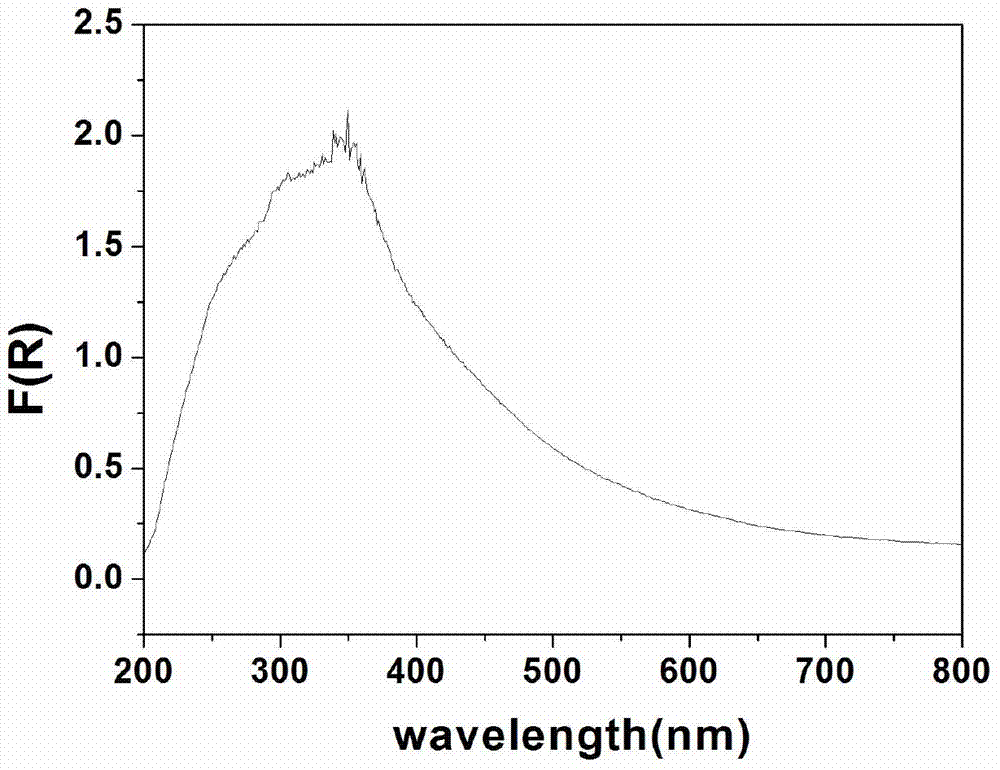

[0034] Soybean straw modified TiO 2 The X-ray diffraction pattern and UV-visible diffuse reflectance pattern of the visible light photocatalyst are shown in Fig. 1 and Fig. 2 .

Embodiment 2

[0036] (1) 11 milliliters of tetraisopropyl titanate were hydrolyzed in 89 milliliters of pH=3 acidic solution to obtain uniform transparent TiO 2 3.0 wt% TiO 2 sol, TiO with pH 6 was obtained by dialysis 2 Sol.

[0037] (2) After crushing 5 grams of dry cow dung into 100 meshes, add it to TiO 2 Sol, stirred at room temperature for 3h, the dry cow dung-TiO 2 Sol mixture.

[0038] (3) Dry cow dung-TiO 2 The sol mixture was heated and dried under stirring to obtain dry cow dung-TiO 2 Gel, the heating temperature is 120°C.

[0039] (4) the obtained dry cow dung-TiO 2 The gel was calcined in a calcination furnace at 300 °C for 3 h to obtain cow dung modified TiO 2 Visible light photocatalyst.

Embodiment 3

[0041] (1) Hydrolyze 17.5 ml of tetrabutyl titanate in 82.5 ml of alkaline solution with pH=8.5 to obtain uniform transparent TiO 2 4.0 wt% TiO 2 Sol, adjusted by dialysis to obtain TiO with a pH value of 7 2 Sol.

[0042] (2) After drying and grinding 7 grams of sawdust into 150 mesh, add TiO 2 Sol, stirred at room temperature for 1h, sawdust-TiO 2 Sol mixture.

[0043] (3) Sawdust-TiO 2 Sawdust-TiO was prepared from sol mixture by microwave drying method 2 For sol-gel, the microwave frequency used is 2450 MHz and the power is 600 W.

[0044] (4) Calcining the obtained gel at 300°C for 3h to obtain sawdust modified TiO 2 Visible light photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com