Preparation method of polydopamine modified alginic acid microspheres

A technology for modifying seaweed and polydopamine, which is applied in the preparation of microspheres, microcapsule preparations, etc., to achieve the effects of cheap raw materials, easy availability of raw materials, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

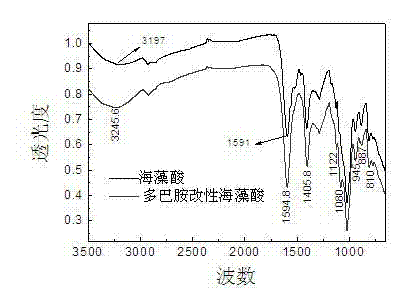

[0020] Dissolve 5.05mmol of alginic acid in 100ml of phosphate buffer solution with pH=5.5, in N 2 Under protection and mechanical stirring, add 5.05mmol of N-hydroxysuccinimide (NHS) and 5.05mmol of 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC), After 30-60 minutes, 15.15 mmol of dopamine was added, and after 12 hours of reaction, it was analyzed three times with ethanol to remove unreacted dopamine and NHS / EDC to obtain Alg-DA, which was lyophilized for use.

[0021] Dissolve 50mg of Alg-DA in 5ml of pH=7.5 Tris-HCl buffer solution to obtain a solution with a concentration of 10mg / ml, and self-polymerize to obtain Alg-PDA after magnetic stirring at room temperature for 24 hours.

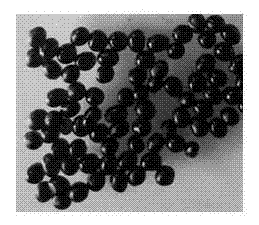

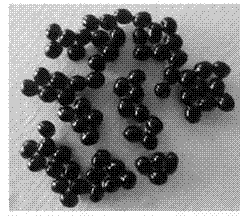

[0022] Use a syringe with an inner diameter of 0.4mm to draw the Alg-PDA solution into 0.2M 25ml CaCl 2 Add dropwise into the solution at a rate of 1 drop / s, filter the microspheres with gauze after aging for 30 minutes, and wash the microspheres with deionized water for 3 tim...

Embodiment 2

[0024] Dissolve 5.05mmol of alginic acid in 100ml of phosphate buffer solution with pH=5.5, in N 2 Under protection and mechanical stirring, add 5.05mmol of N-hydroxysuccinimide (NHS) and 5.05mmol of 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC), After 30-60 minutes, 10.1 mmol of dopamine was added, and after 12 hours of reaction, it was analyzed with ethanol three times to remove unreacted dopamine and NHS / EDC to obtain Alg-DA, which was lyophilized for use.

[0025] Dissolve 50mg of Alg-DA in 5ml of pH=7.5 Tris-HCl buffer solution to obtain a solution with a concentration of 15mg / ml, and self-polymerize to obtain Alg-PDA after magnetic stirring at room temperature for 24 hours.

[0026] Use a syringe with an inner diameter of 0.4mm to draw the Alg-PDA solution into 0.2M 25ml CaCl 2 Add dropwise into the solution at a rate of 1 drop / s, filter the microspheres with gauze after aging for 30 minutes, and wash the microspheres with deionized water for 3 time...

Embodiment 3

[0028] Dissolve 5.05mmol of alginic acid in 100ml of phosphate buffer solution with pH=5.5, in N 2 Under protection and mechanical stirring, add 5.05mmol of N-hydroxysuccinimide (NHS) and 5.05mmol of 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC), After 30-60 minutes, 5.05 mmol of dopamine was added, and after 12 hours of reaction, it was analyzed with ethanol three times to remove unreacted dopamine and NHS / EDC to obtain Alg-DA, which was lyophilized for use.

[0029] Dissolve 50mg of Alg-DA in 5ml of pH=7.5 Tris-HCl buffer solution to obtain a solution with a concentration of 20mg / ml, and self-polymerize to obtain Alg-PDA after magnetic stirring at room temperature for 24 hours.

[0030] Use a syringe with an inner diameter of 0.4mm to draw the Alg-PDA solution into 0.2M 25ml CaCl 2 Add dropwise into the solution at a rate of 1 drop / s, filter the microspheres with gauze after aging for 30 minutes, and wash the microspheres with deionized water for 3 time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com