Chromic slag wet method detoxifcation and resource comprehensive utilization new technique

A new process, the technology of chromium slag, applied in the field of comprehensive resource reuse, can solve the problems of secondary pollution, poor economic benefits, and less chromium slag consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

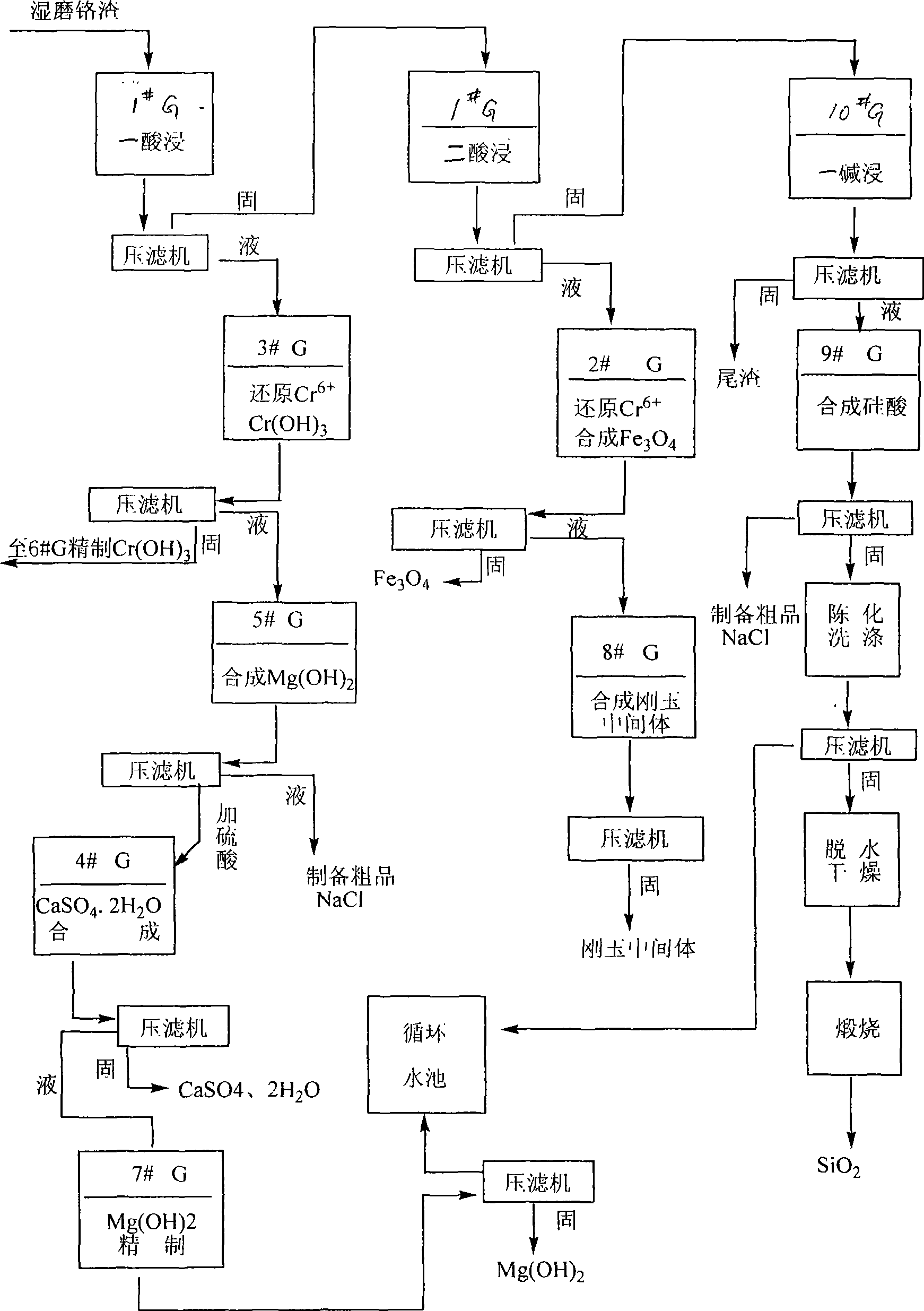

Image

Examples

Embodiment 1

[0020] Ball mill the chromium slag to 80-200 mesh and put 200 kg of chromium slag into the stirring tank; then dilute 400 kg of hydrochloric acid with 800 kg of pure water and slowly add it into the stirring tank for "one acid leaching", that is, the first acid leaching. The pH value of the solution in the tank is controlled at 5 to 6. After stirring, the plate and frame filter press is used for solid-liquid separation. The filtrate is introduced into the reduction synthesis mixing tank, and sodium sulfite solution is added to reduce the hexavalent chromium to trivalent chromium. Slowly add a certain amount of caustic soda Aqueous solution, keep the pH value at 6 and press filter after stirring to obtain chromium hydroxide (crude product). After the filtrate is introduced into the synthesis tank, add 1:4 milk of lime to adjust the pH value to 11, stir and then enter the filter press. The filtrate is introduced into the crystallization evaporator to produce sodium chloride (cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com