Refined cotton opening machine high in cotton opening efficiency

A technology for refining cotton and a cotton opener, which is applied in the field of refined cotton, can solve the problems that the quality of dispersing cannot meet the process requirements, the gap between the nail teeth and the feeding plate is large, and the rotation accuracy of the dispersing roller is poor, so as to avoid insufficient dispersing and rotating High precision, solve the effect that cannot be relieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with specific examples, but the implementation of the present invention is not limited thereto.

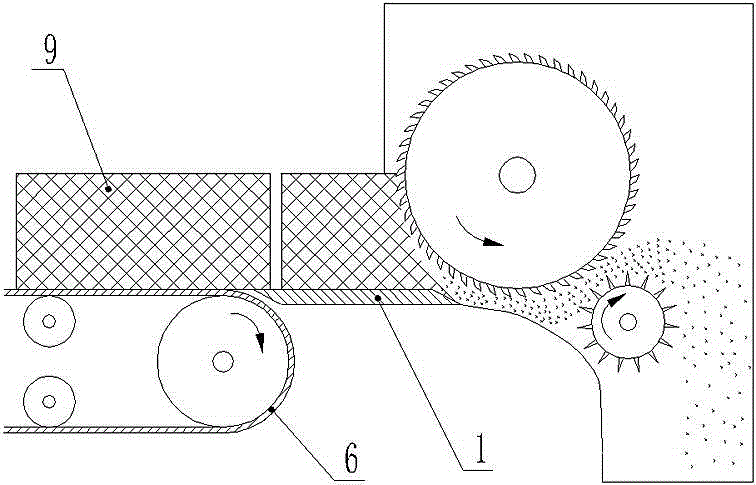

[0025] The cotton opener of the present embodiment takes the cotton bale with a height of 400mm as the loosening object. If the cotton opener of the prior art is adopted, the diameter of a single loosening roller is φ800mm, and the maximum feeding speed is generally only 7kg / min.

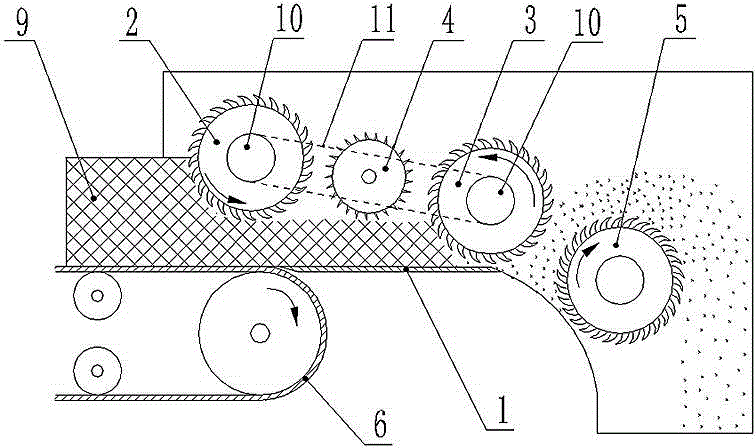

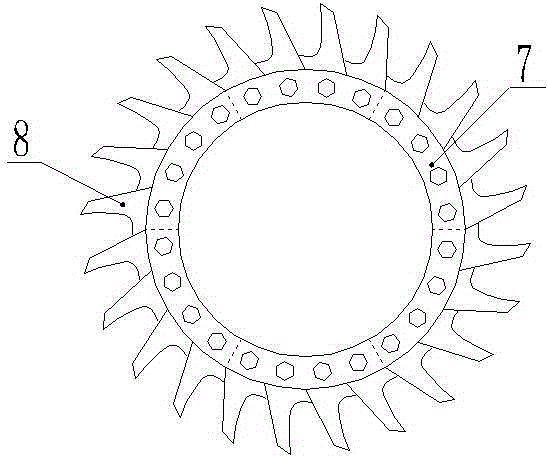

[0026] Such as figure 2 As shown, a high-efficiency refined cotton opener of the present invention includes a belt conveyor 6, a deflagging device, and a feeding plate 1 arranged between the belt conveyor 6 and the deflapping device. The debonding device includes two stages of deflagging rollers for cotton bale 9 debonding, which are respectively the primary deflaking roller 2 and the secondary deflaking roller 3, and the primary deflaking roller 2 and the secondary deflaking roller 3 are fed from the feed end. To th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com