Patents

Literature

333results about "Fibre cleaning/opening by toothed members" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

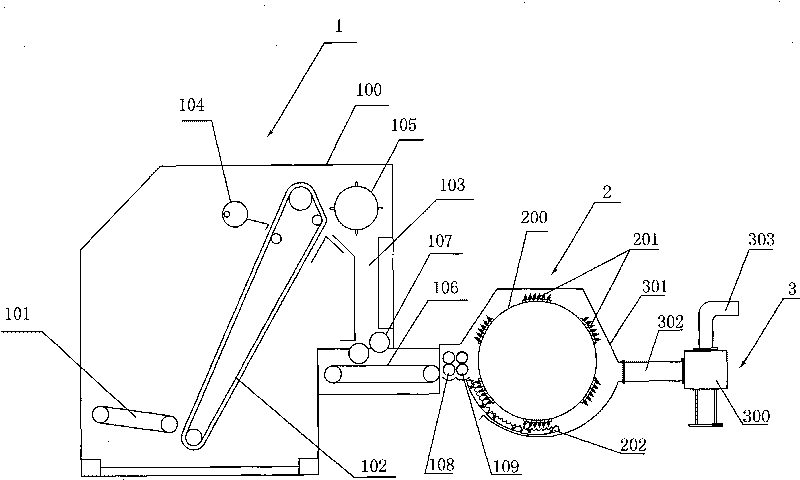

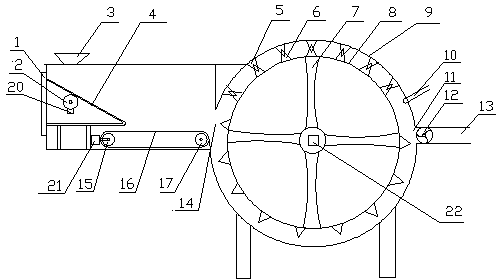

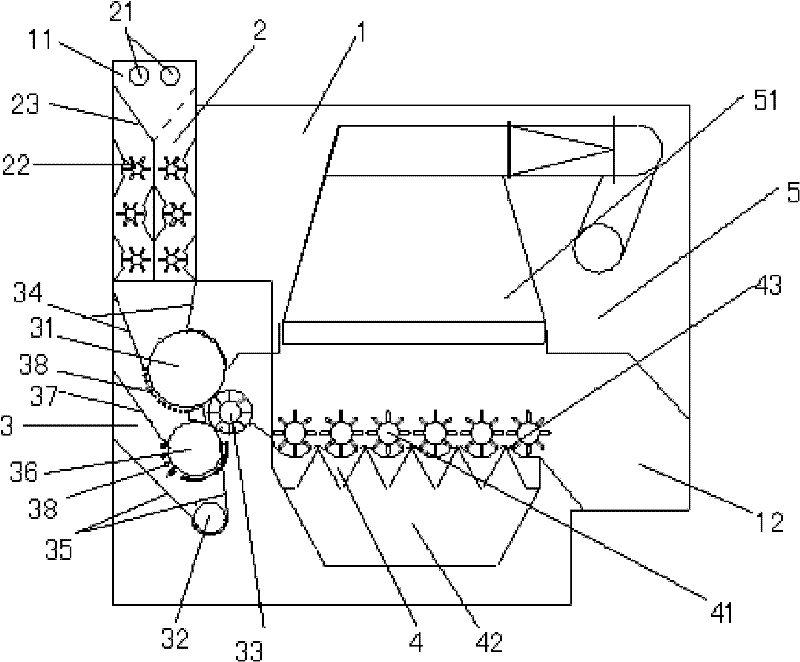

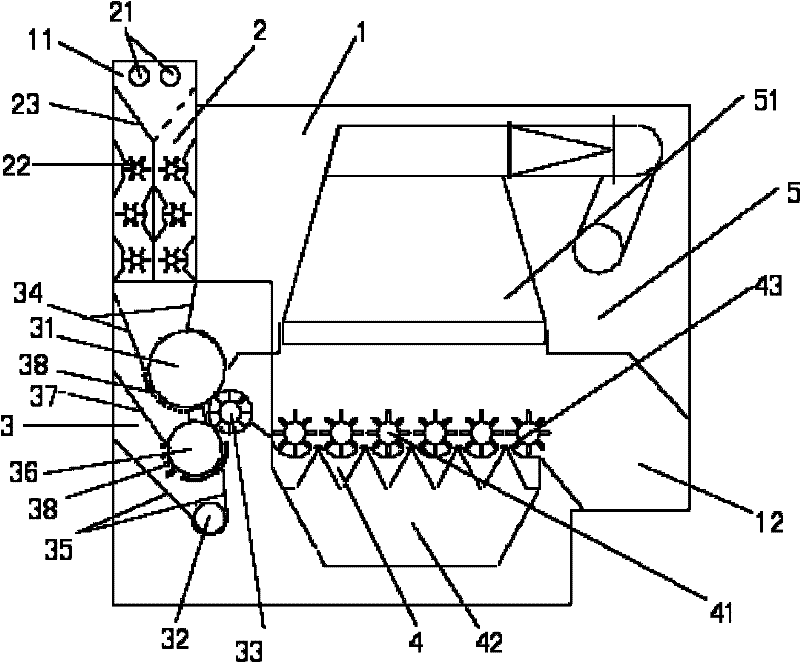

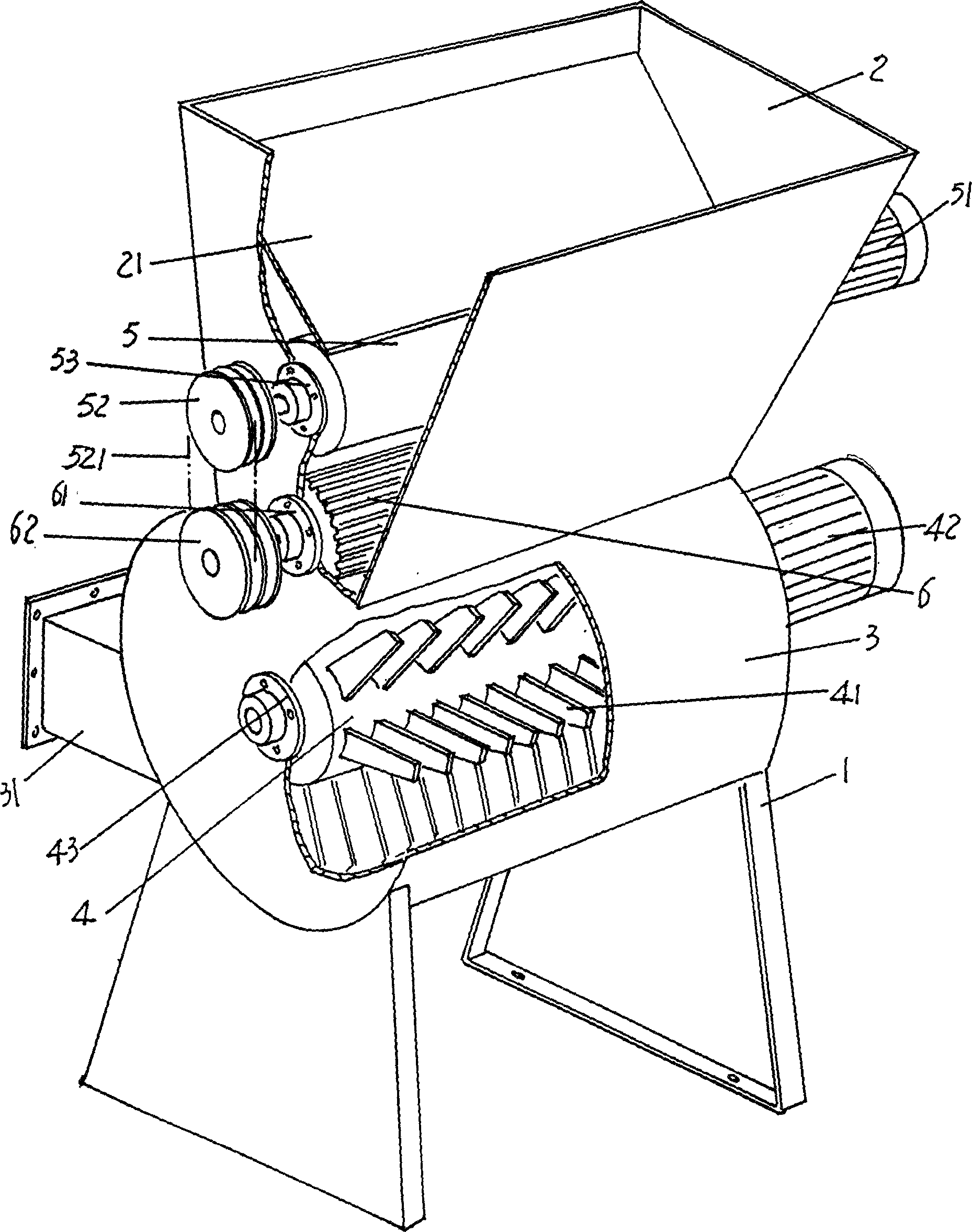

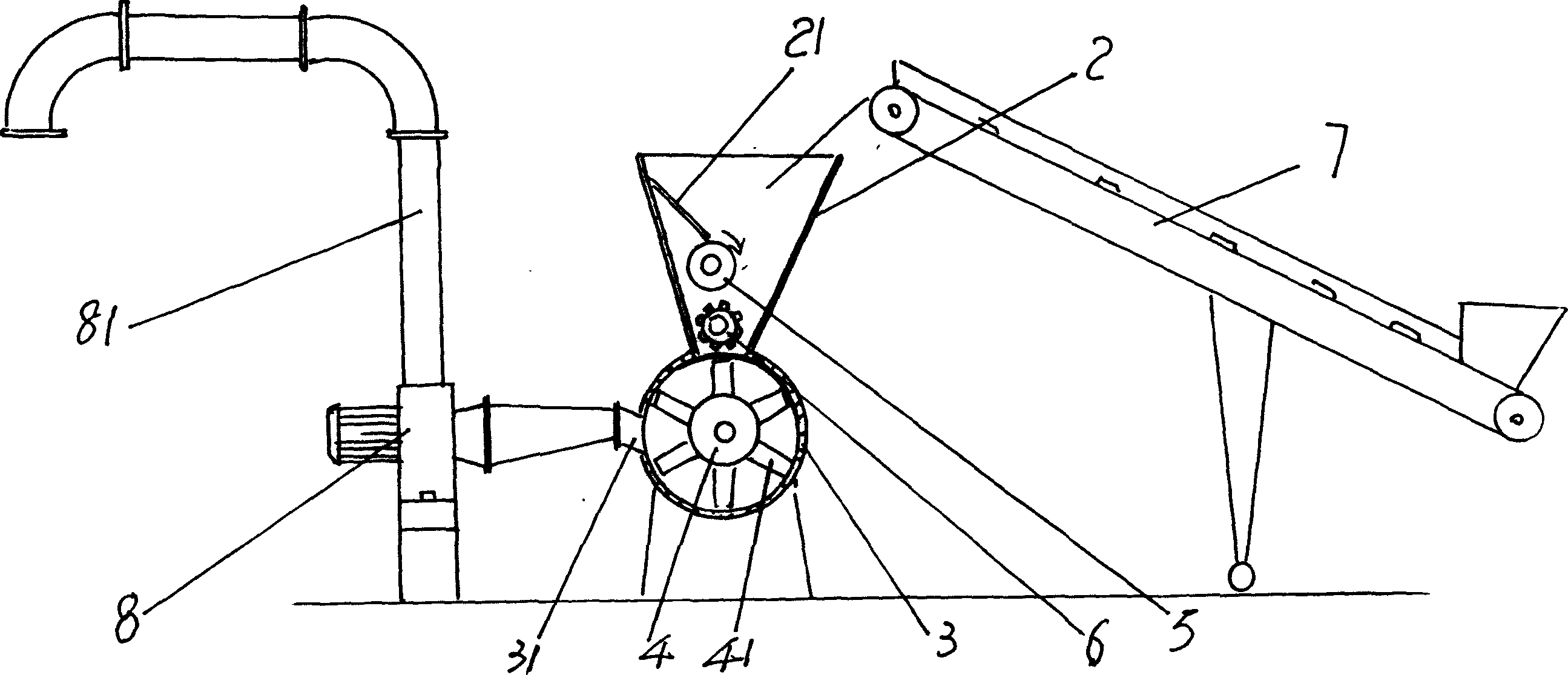

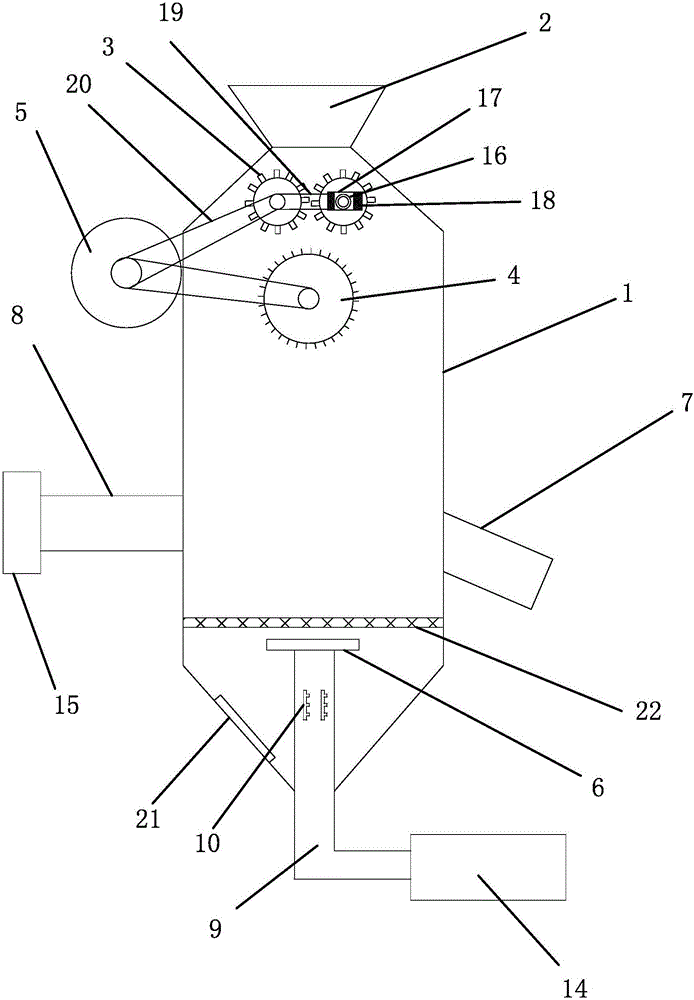

Garnett machine

InactiveCN100368612CLow costIntensiveFibre cleaning/opening by toothed membersCarding machinesMotor driveEngineering

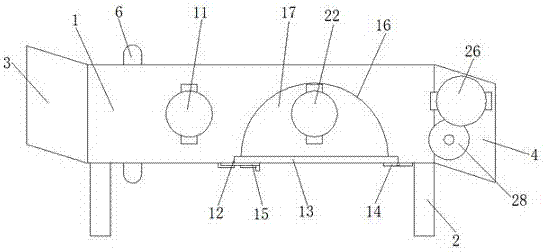

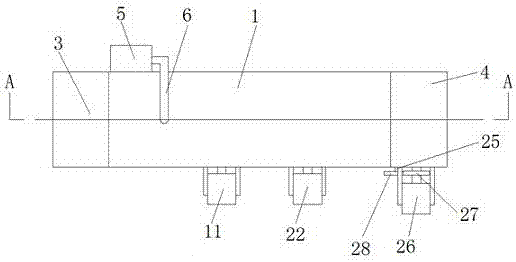

The opening machine comprises a pair of frame wall opposite to each other. One end of the pair of frame wall is higher than the other end. A pre-opening mechanism composed of the first roller, the second roller and coarse opening roller is set at the high end of the frame wall, and the fine opening mechanism composed of the third roller, the fourth roller and fine opening roller is set at the low end of the frame wall. A rolling curtain is set on the frame wall and between the said two opening mechanisms. A cotton collection bucket is set between the pair of frame wall and is communicated with the opening roller. A cotton-discharging mechanism is set the enclosure plate jointed to the end part of the frame wall. It also comprises a first motor driving the first roller and the second roller to rotate, a second motor driving the third roller, the fourth roller and the rolling curtain to move and the third motor driving the coarse opening roller and the fine opening roller to move. Advantages: saved cotton-feeding mechanism and reduced processing and using cost.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

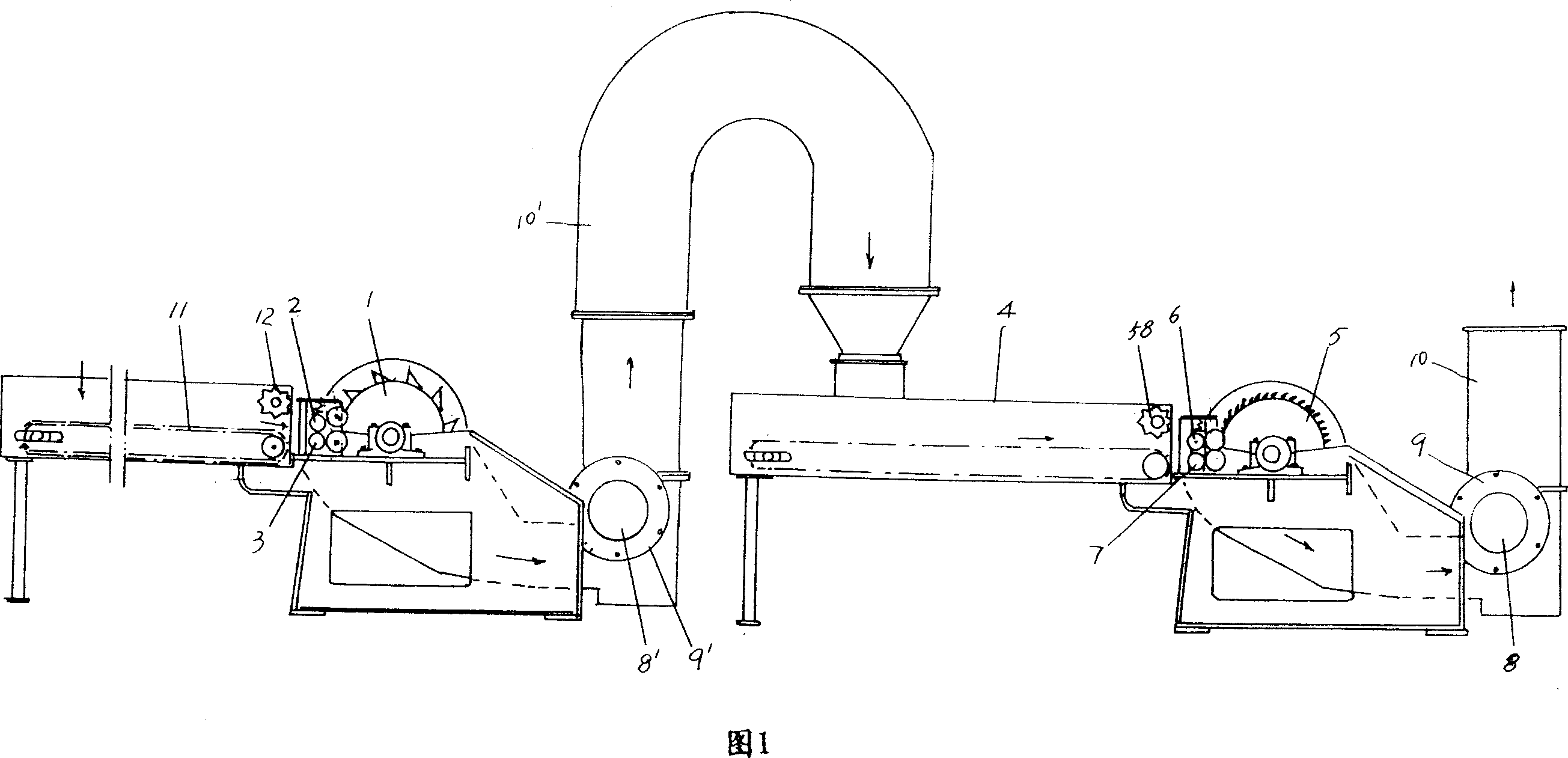

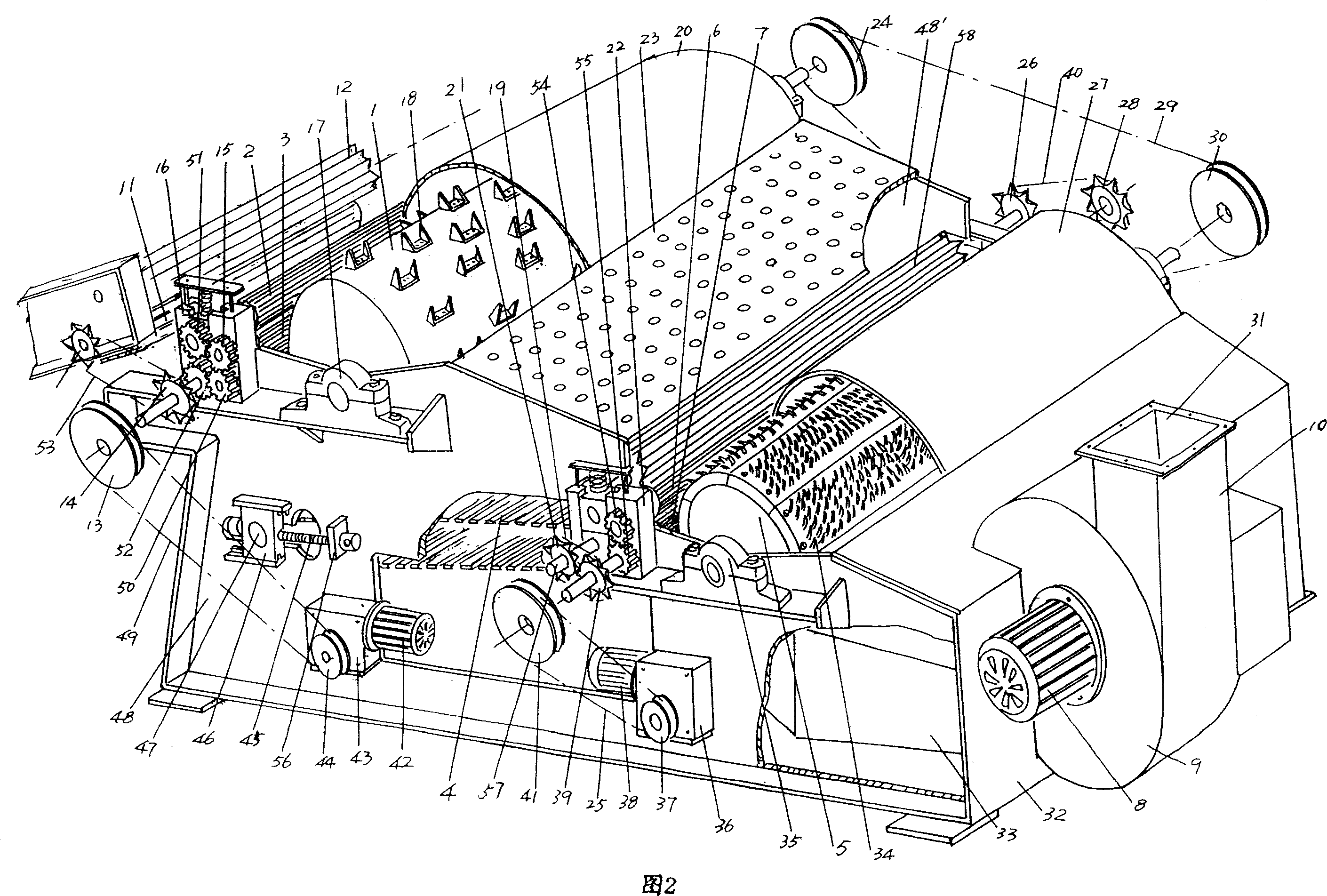

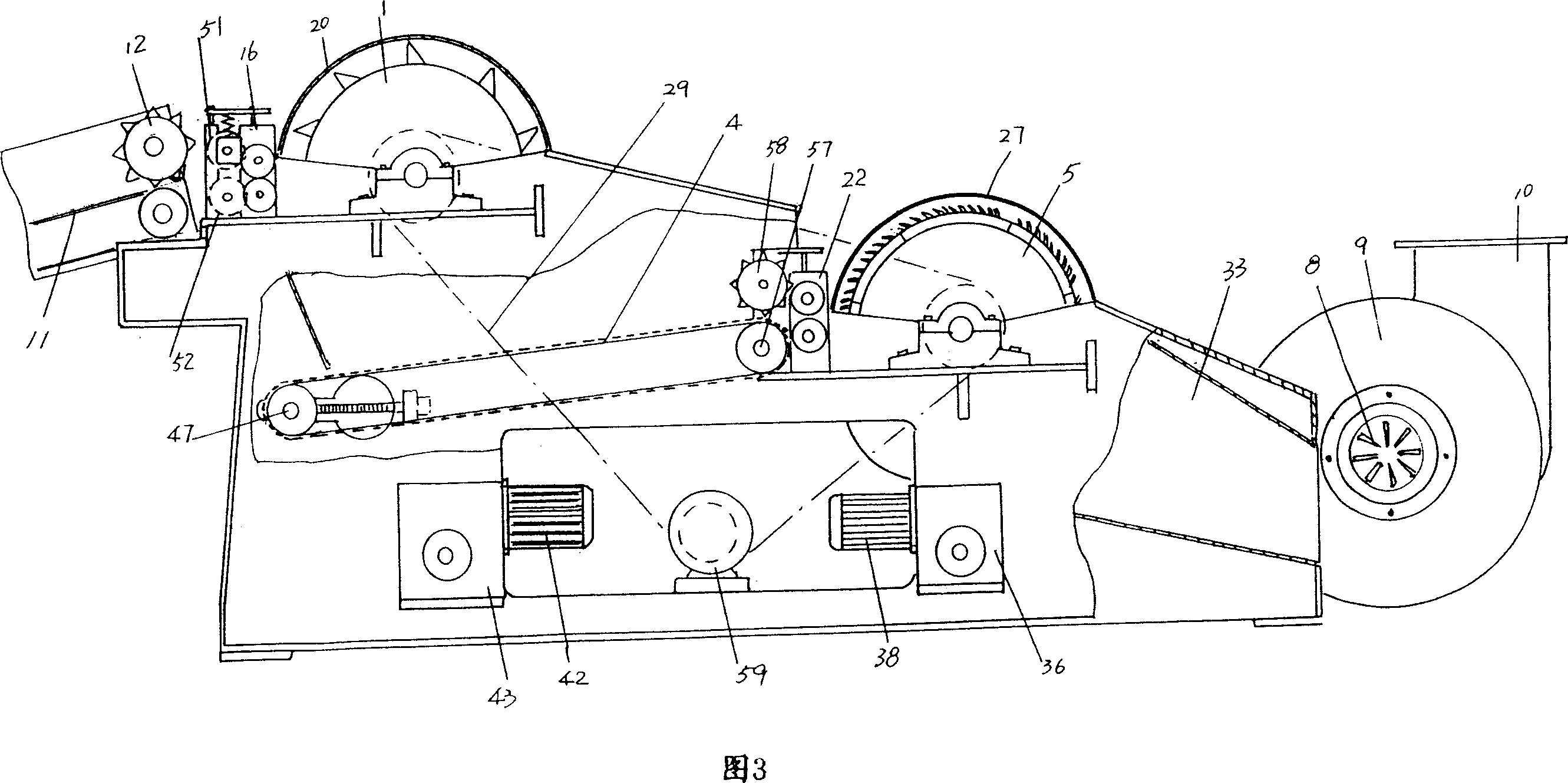

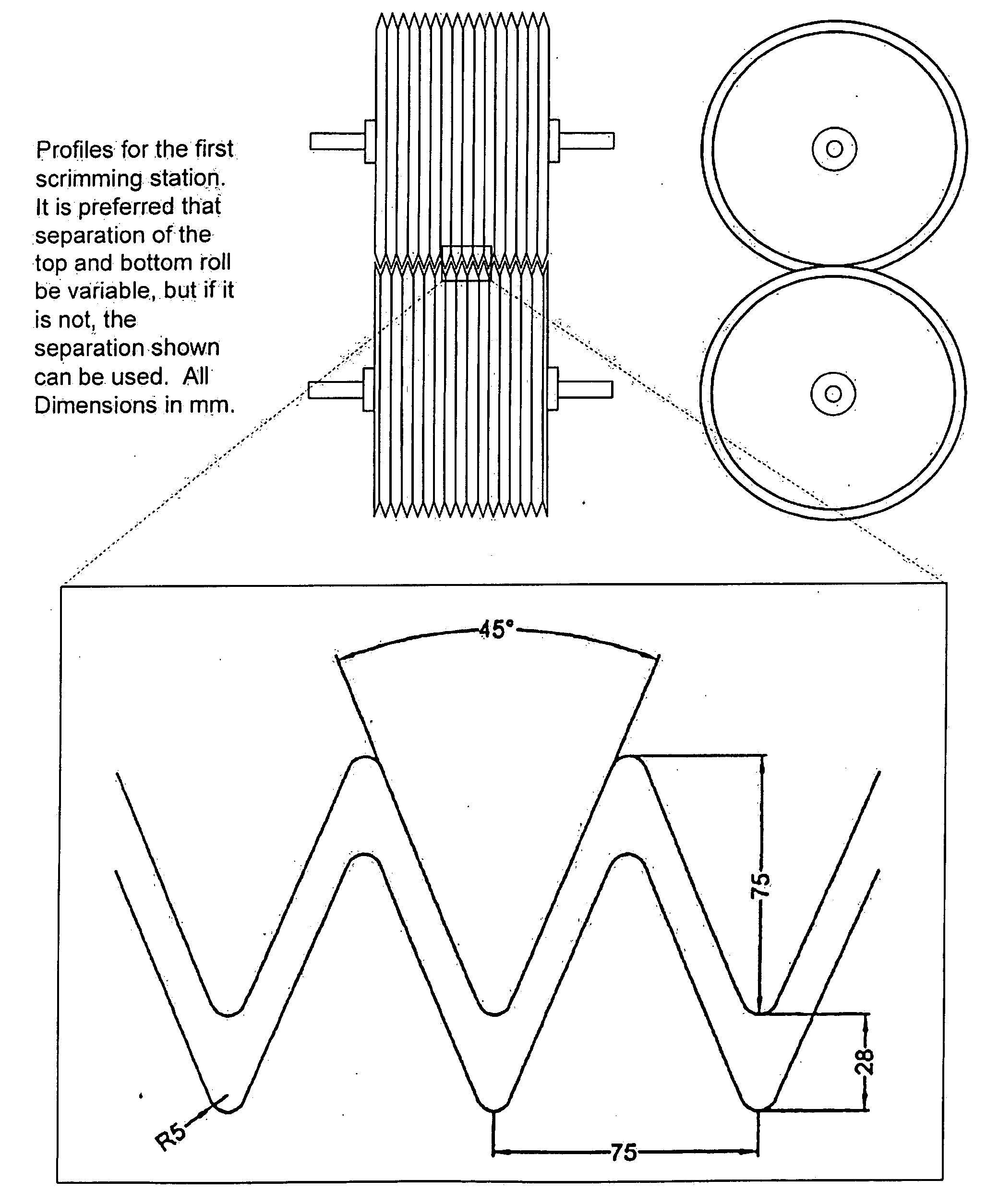

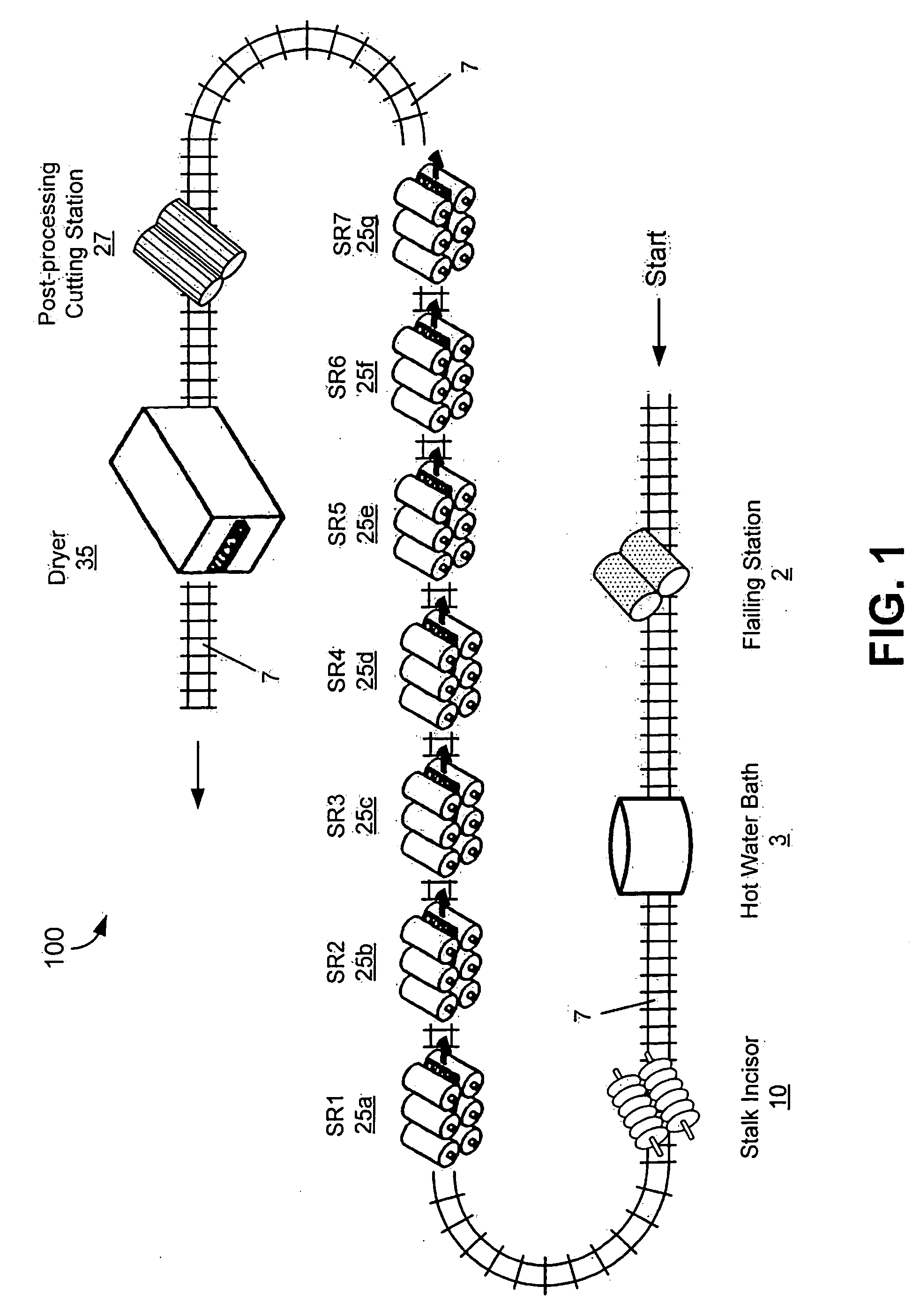

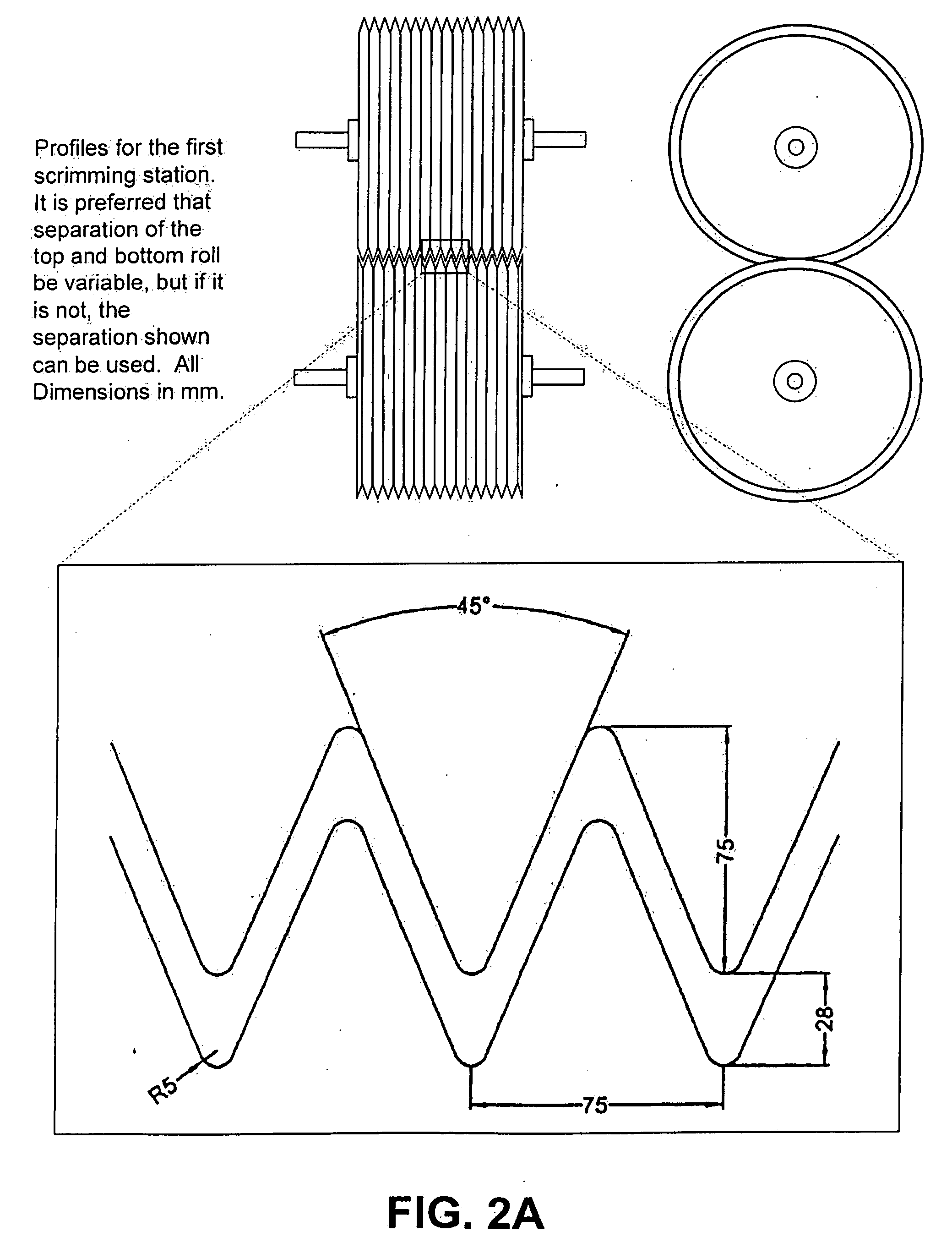

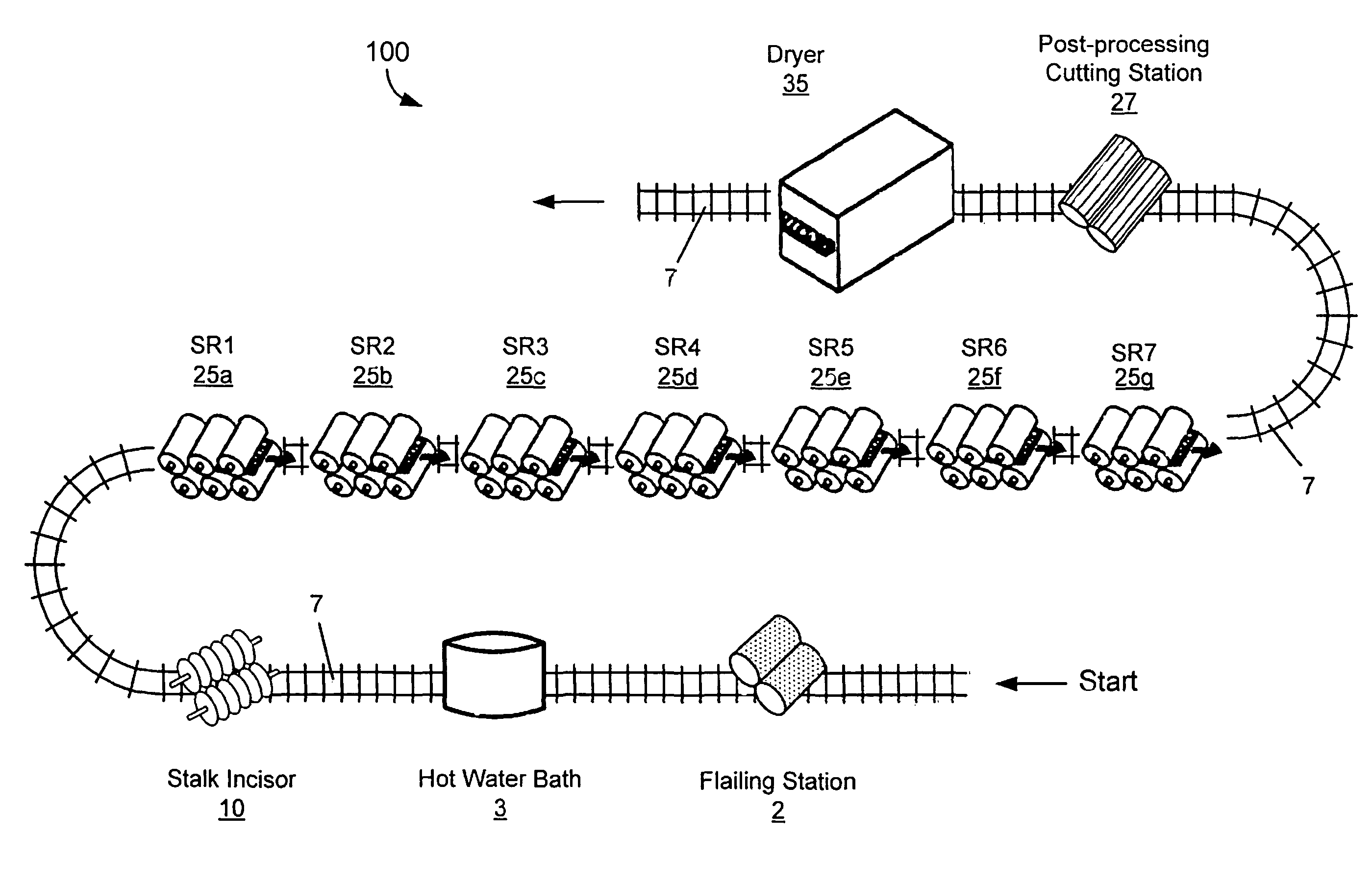

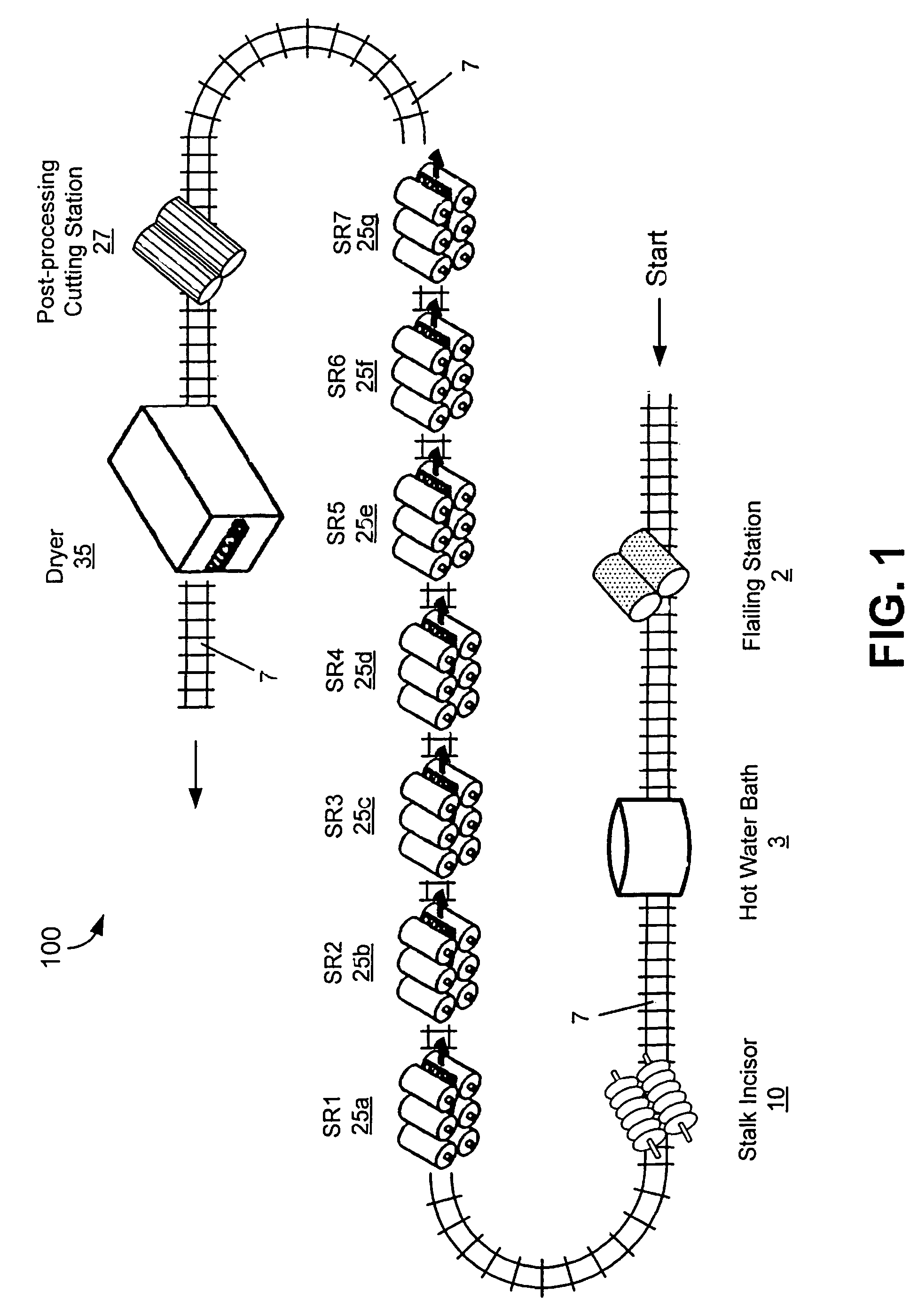

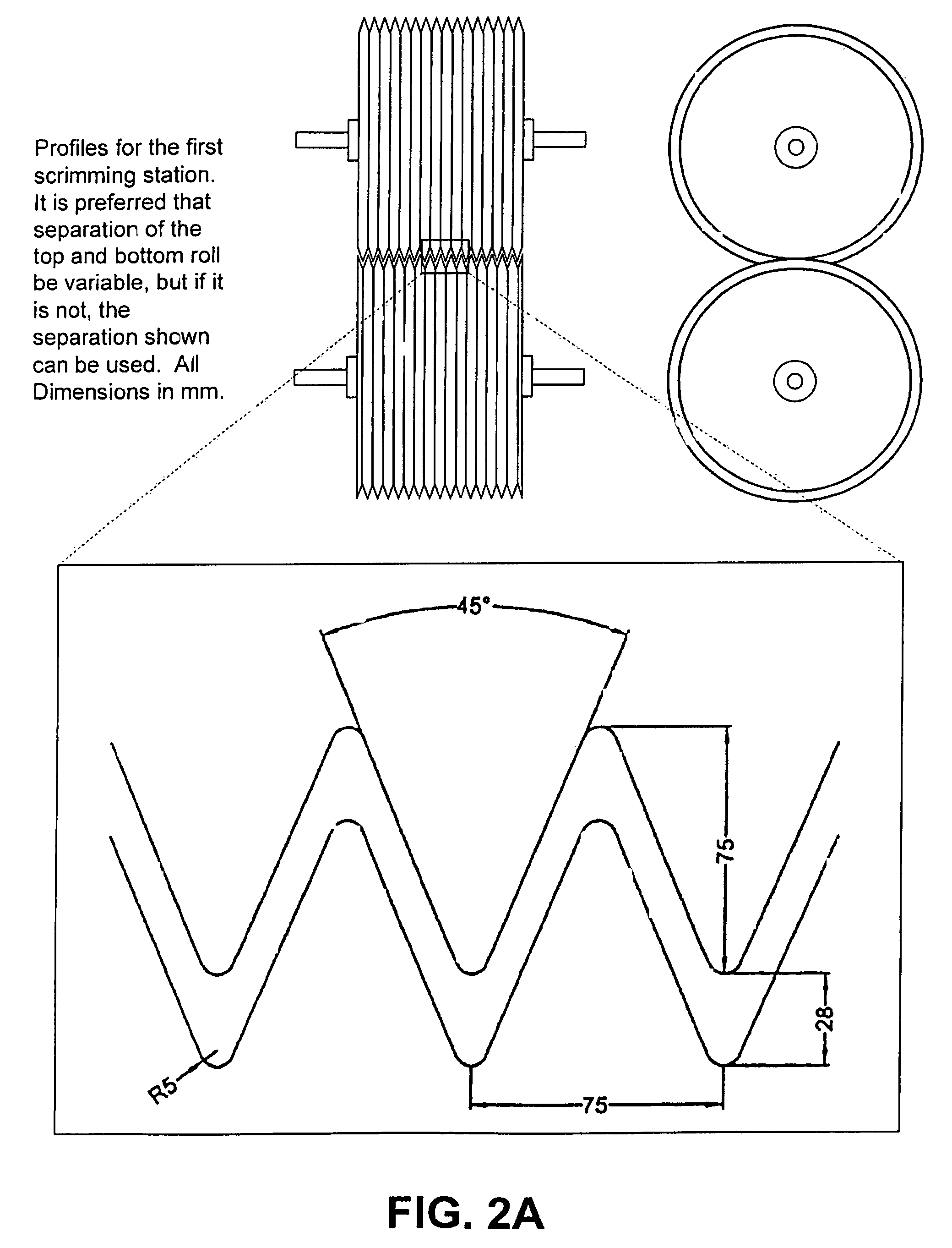

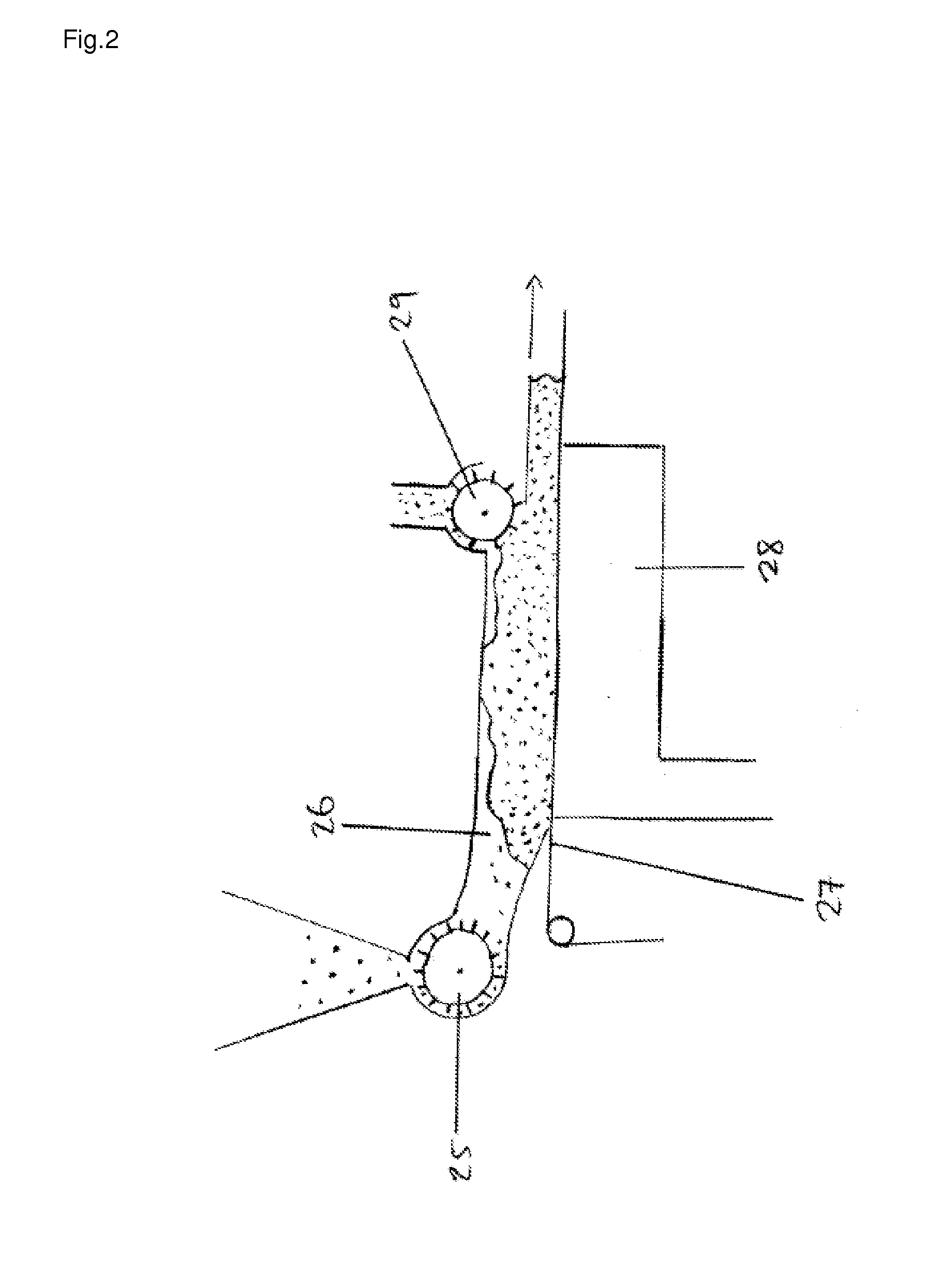

System and method for the separation of bast fibers

InactiveUS20090145563A1Quality improvementEfficient separationFibre cleaning/opening by toothed membersWood working apparatusEngineeringBast fibre

The present invention relates generally to the timber products industry, and particularly to methods and apparatus for the separation of bast fibers. More particularly, the present invention relates to methods and apparatus for use in the separation of inner core from outer bast of bast plants using soaking, cutting, and scrimming methods and apparatuses.

Owner:TIMTEK

Cotton slitter with inward wind blowing function

ActiveCN103305969AEasy to dryCompact structureFibre cleaning/opening by air draught arrangementsFibre cleaning/opening by toothed membersNozzle

The invention discloses a cotton slitter with an inward wind blowing function. The cotton slitter comprises a rack box, a feed hopper, a discharging port, a beating roller and a blowpipe, wherein a working cavity is designed inside the rack box; the feed hopper and the discharging port are mounted on opposite surfaces of the rack box respectively and communicated with the working cavity; the bearing roller is mounted in the working cavity, and vertical round rods are distributed on the outer surface of the beating roller; the outer surface of the bearing roller adopts a framework and wire netting structure; the inside of the blowpipe is communicated with an air supply device, and the blowpipe is mounted on the axis of the bearing roller; an air nozzle facing the discharging port is designed on the blowpipe; the lower part of the beating roller is wrapped with a separation net for removing impurities. The cotton slitter has a simple structure, a smaller size, a drying function and a good cotton slitting effect.

Owner:临沂鑫润建铜业有限公司

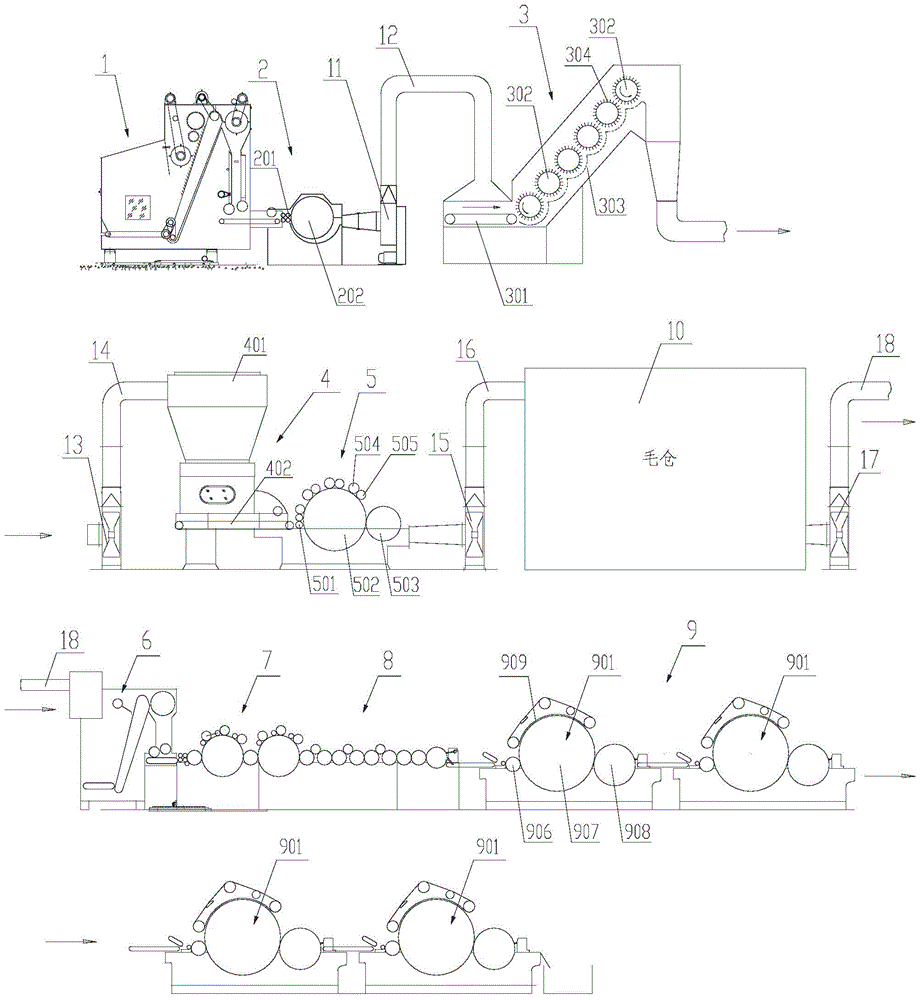

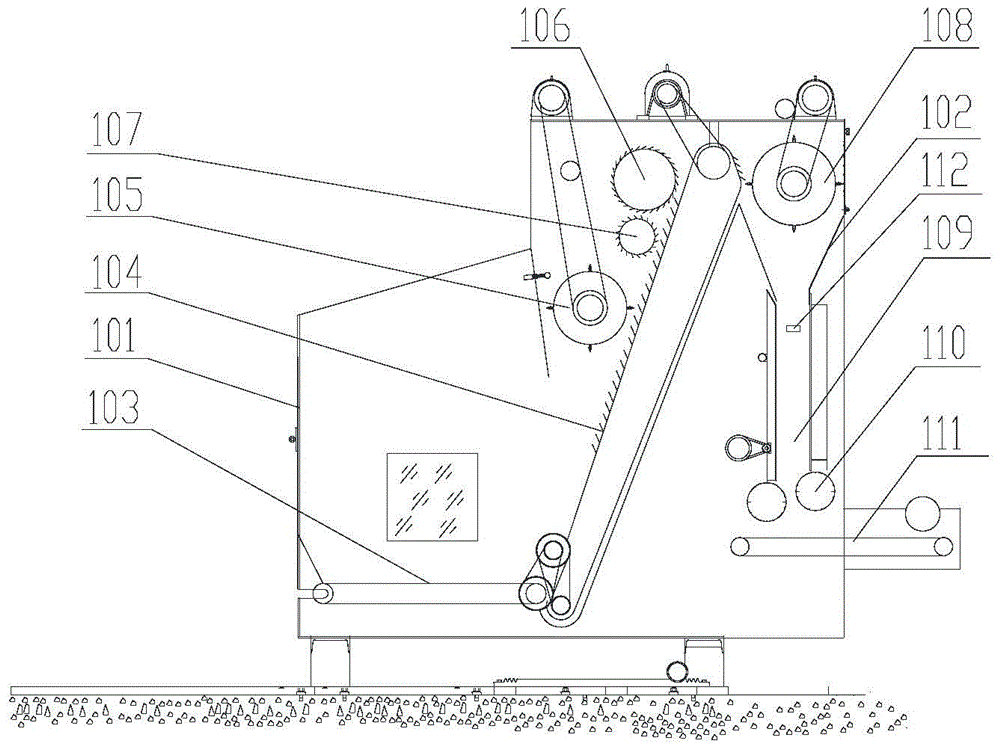

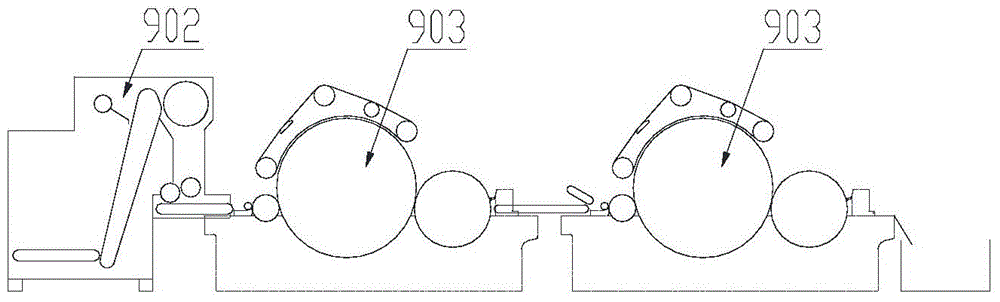

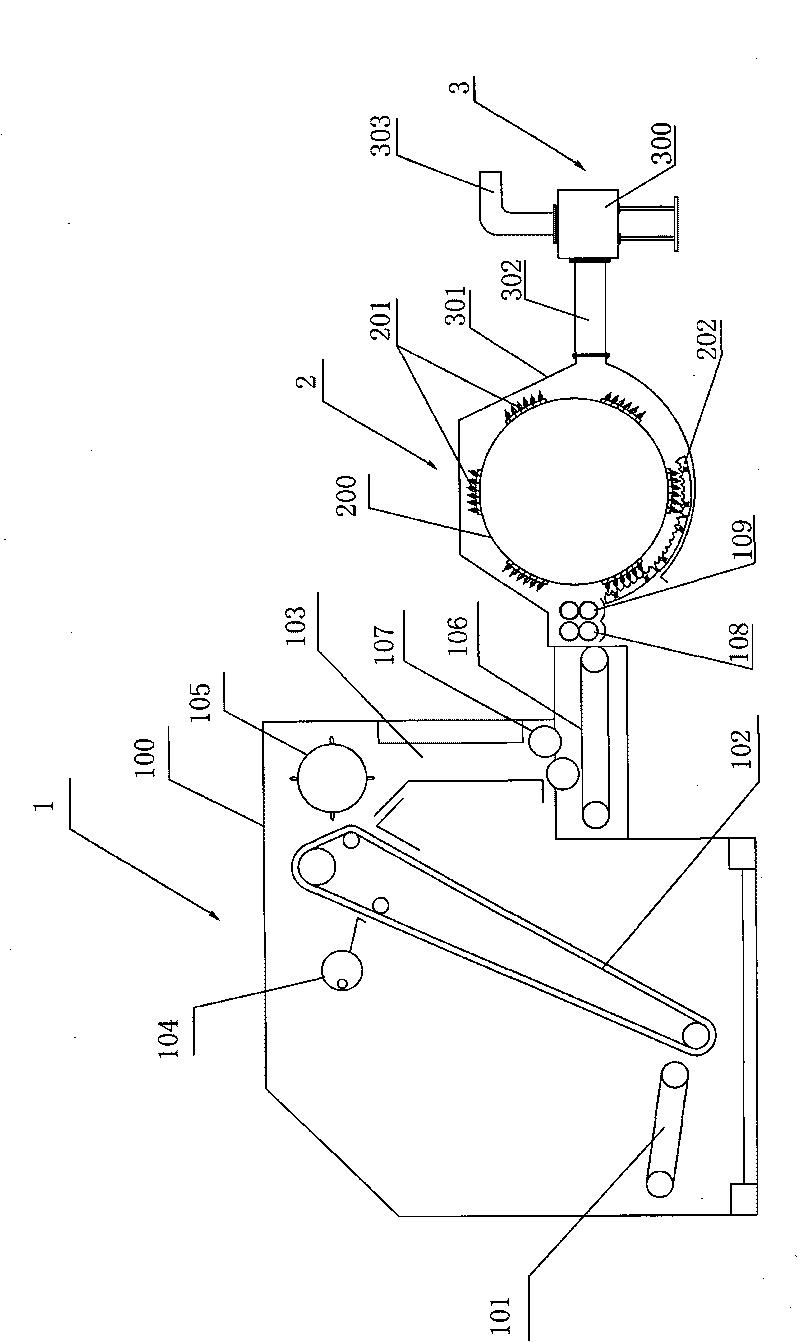

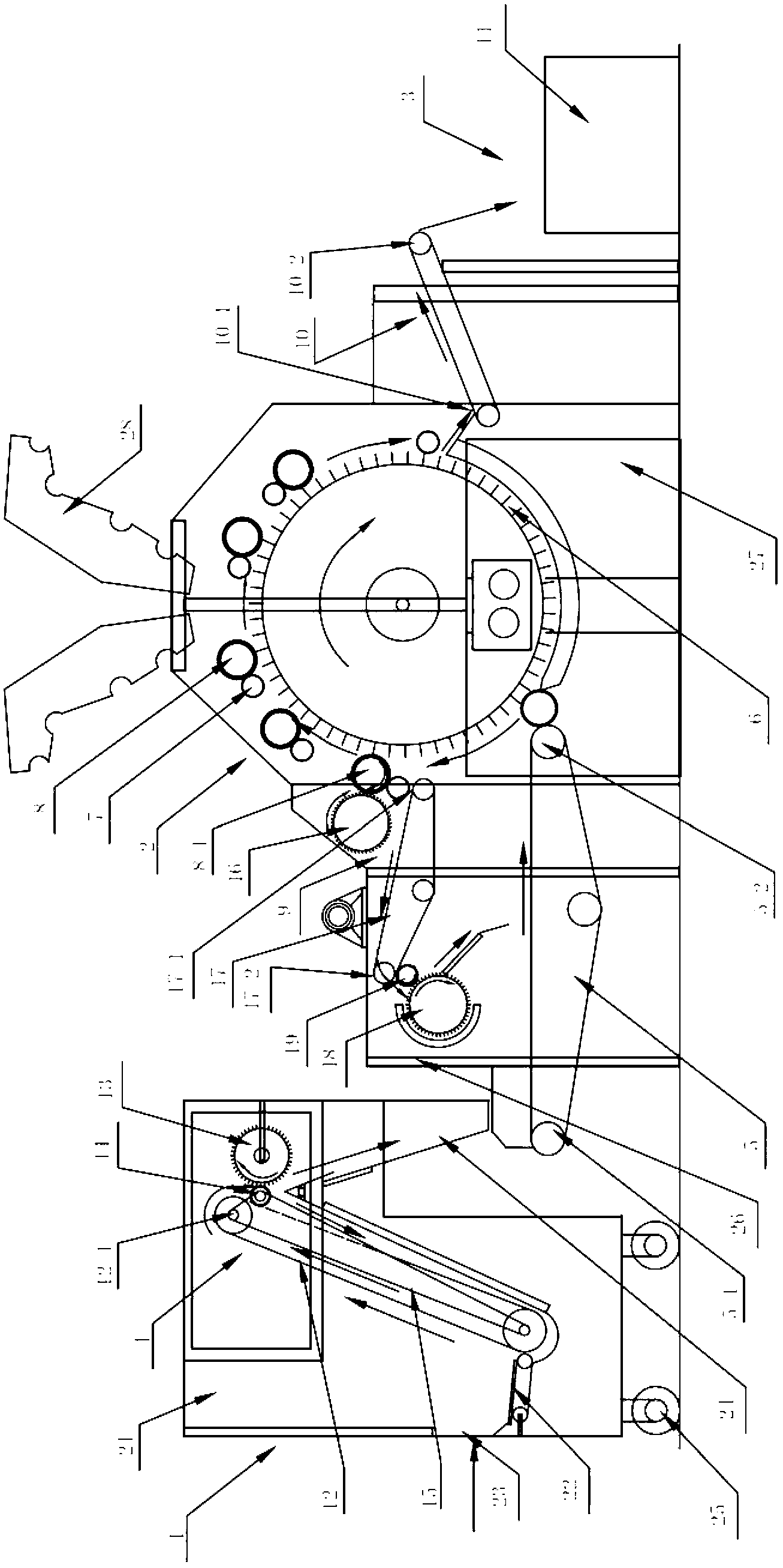

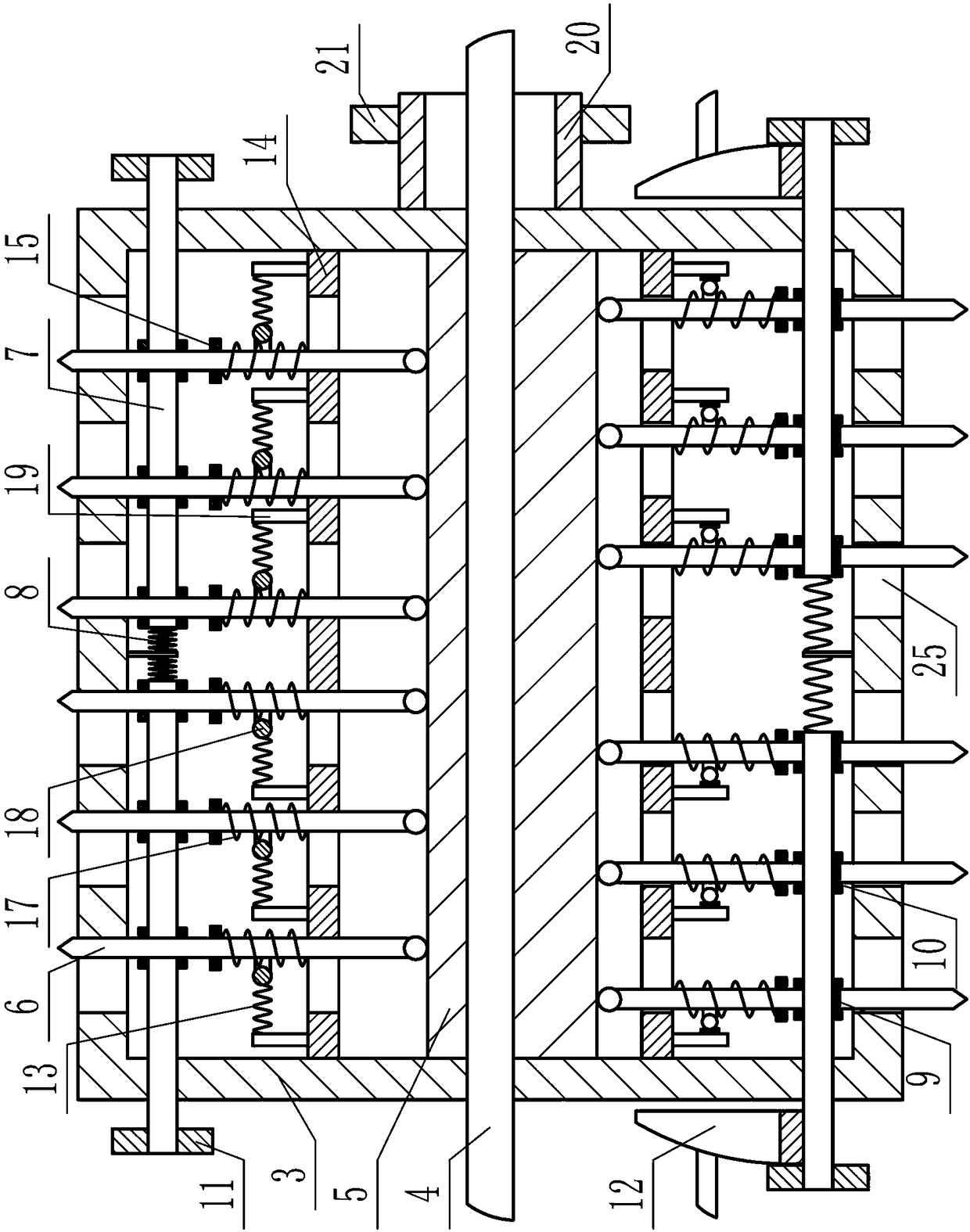

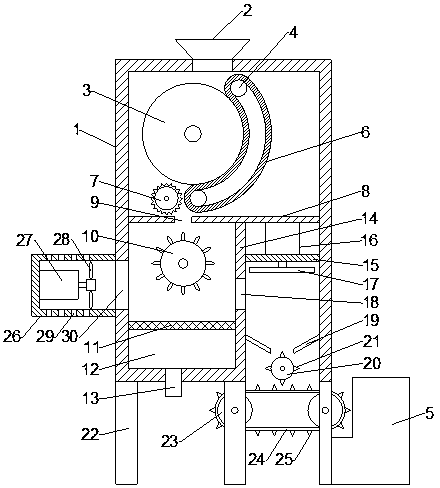

Sheep wool opening and carding complete equipment

ActiveCN105088427AOpen smoothlyInto the uniformFibre cleaning/opening by toothed membersContinuous processingEngineeringSheep wool

The invention belongs to the field of textile machines and particularly discloses sheep wool opening and carding complete equipment. The sheep wool opening and carding complete equipment comprises a first feeding mechanism, a first opening mechanism, a first coarse wood and impurity removal mechanism and a first carding mechanism which are sequentially connected from front to rear. A second feeding mechanism, a second opening mechanism, a third opening mechanism, a wool combination mechanism, a second carding mechanism and a wool bin are sequentially arranged in front of the first feeding mechanism in succession. By means of the design, primary opening, coarse wood and impurity removal and carding processes are conducted on sheep wool before sheep wool enters the first feeding mechanism, it is further guaranteed that sheep wool is evener when entering the first carding mechanism, and follow-up opening, coarse wood and impurity removal and carding effects are improved beneficially.

Owner:青岛东佳纺机(集团)有限公司 +1

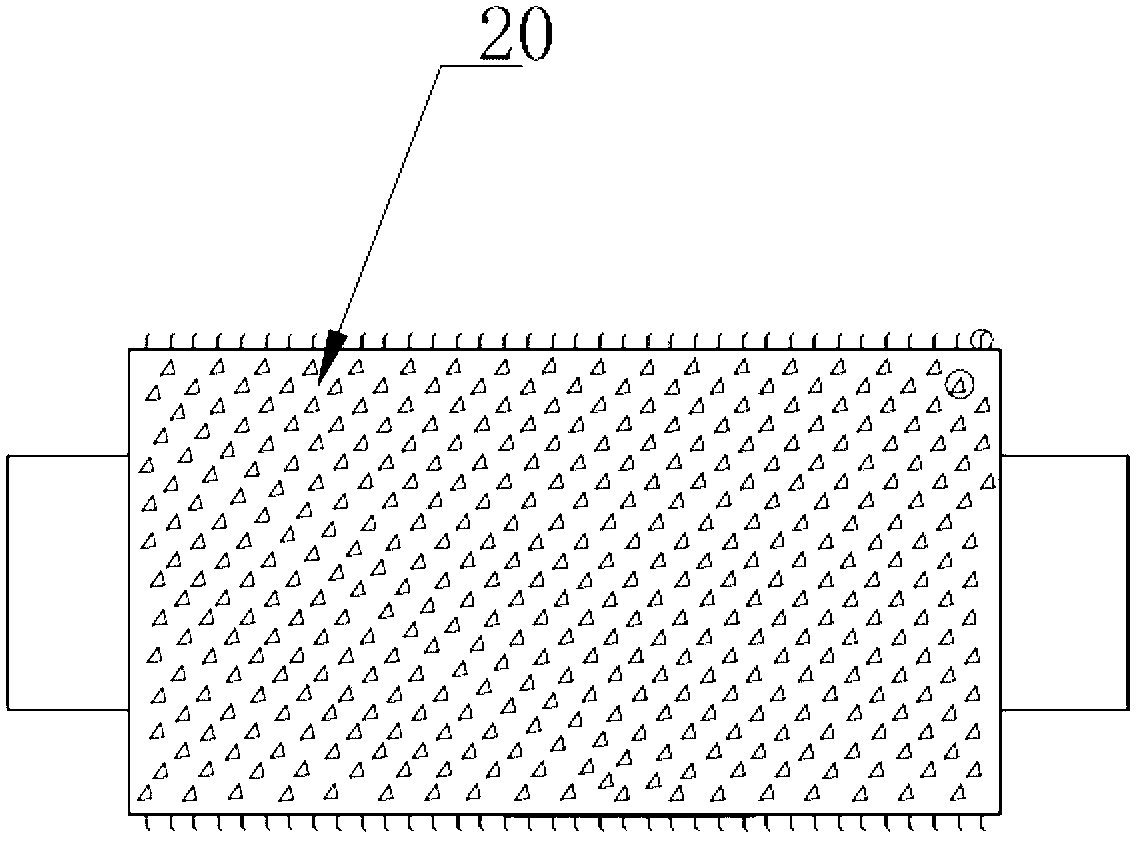

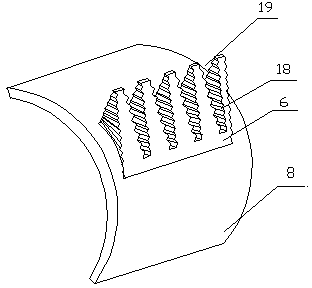

Fine opener with under screen and card clothing

ActiveCN101736446AImprove performanceReasonable useFibre cleaning/opening by toothed membersFibre cleaning/opening machinesFiberEngineering

The invention discloses a fine opener with an under screen and card clothing, which comprises a feeding mechanism, an opening and carding mechanism, and an opened fiber output mechanism. The opening and carding mechanism is provided with a opening roller, a plurality of opening roller fallers are arranged in the circumferential direction of the opening roller, a card wire is arranged on each teasing roller faller, and the under screen is arrange below the opening roller. The fine opener is characterized in that the under screen comprises a supporting light panel, a plurality of under screen faller strips are arranged on the upper supporting surface of the supporting light panel, and each of the under screen faller strips is provided with the card clothing, and an opening and carding region is formed among the opening roller fallers and the under screen faller strips. The invention has a production efficiency increased by more than 20% by verification on condition that the rotating speed of the opening roller and the number of the opening roller fallers are not increased and the opening and carding effect is ensured.

Owner:青岛东佳纺机(集团)有限公司

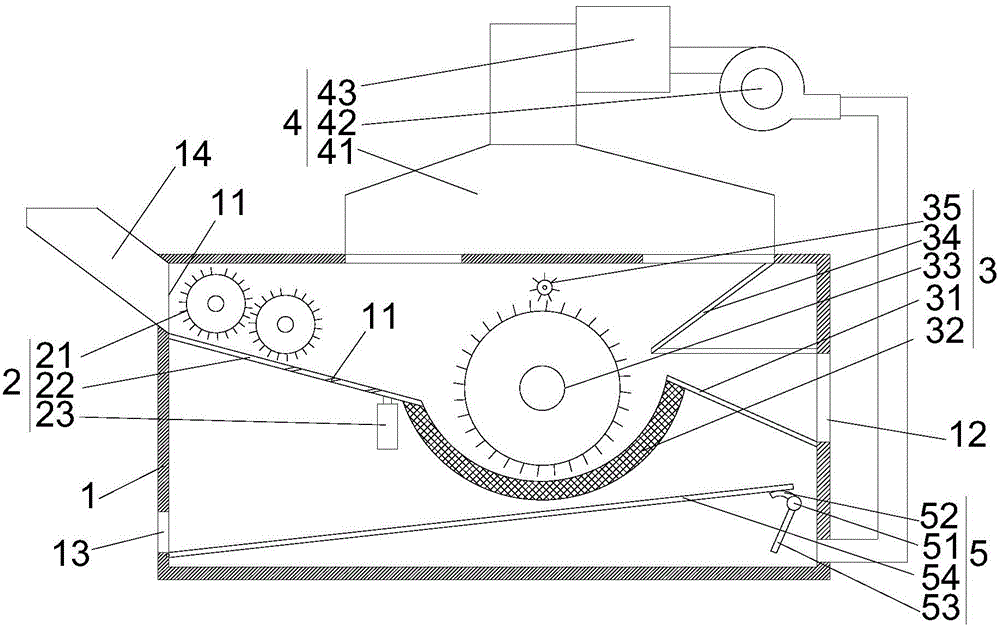

Collagen fiber opener

The invention discloses a collagen fiber opener which comprises a feeding portion, an opening portion and a material receiving portion. A first-time opening mechanism is arranged in the feeding portion and is connected with the feeding end of an opening conveying belt in the opening portion, the discharging end of the opening conveying belt is arranged on the lower portion of one side of a large cylinder which is arranged in the opening portion, a plurality of working rollers which gradually get close to the large cylinder along the rotating direction of the large cylinder and are matched with the large cylinder and fur peeling rollers are arranged on the periphery of the upper portion of the large cylinder, a second-time opening mechanism is arranged above the opening conveying belt, the material receiving end of a material receiving conveying belt in the material receiving portion is arranged on the lower portion of the other side of the large cylinder, and the discharging end of the material receiving conveying belt is arranged at the upper end of a material receiving box. Due to the fact that the first-time opening mechanism and the second-time opening mechanism are arranged in the opener, the opener has the advantages of being compact in structure, ingenious in design, simple in technological process, little in waste of raw materials, little in environment pollution, good in opening effect and the like.

Owner:JIANGYIN JUNHUA TEXTILE TECH

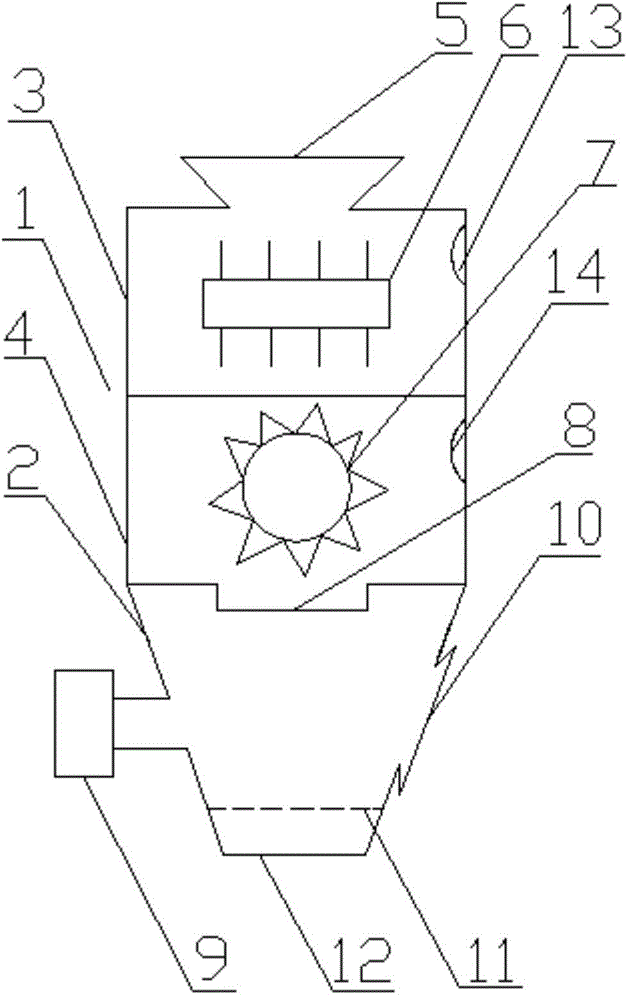

Cotton opener

InactiveCN103590144AIncrease contactEliminate static electricityFibre cleaning/opening by toothed membersFibre cleaning/opening machinesElectric machineryEngineering

The invention discloses a cotton opener and belongs to the technical field of textile machinery. The cotton opener is characterized by comprising a rack. A cotton inlet is formed in the rack, a pre-opening device is arranged on the cotton inlet, a cotton inlet box is arranged behind the pre-opening device, and an atomizing nozzle is arranged above the cotton inlet box. The atomizing nozzle is connected with a static electricity elimination agent through a pipeline with an electromagnetic valve. The underneath of the cotton inlet box is communicated with an opening cavity, an opening cylinder is arranged in the opening cavity, a driving chamber is formed below the rack, a motor is arranged in the driving chamber, a dust collection pipe is arranged on the outer side of the driving chamber, and a dust collection box is arranged above the dust collection pipe. The cotton opener is simple in structure and capable of eliminating the static electricity and improving working efficiency.

Owner:谭国华

Fiber mixing and opening machine

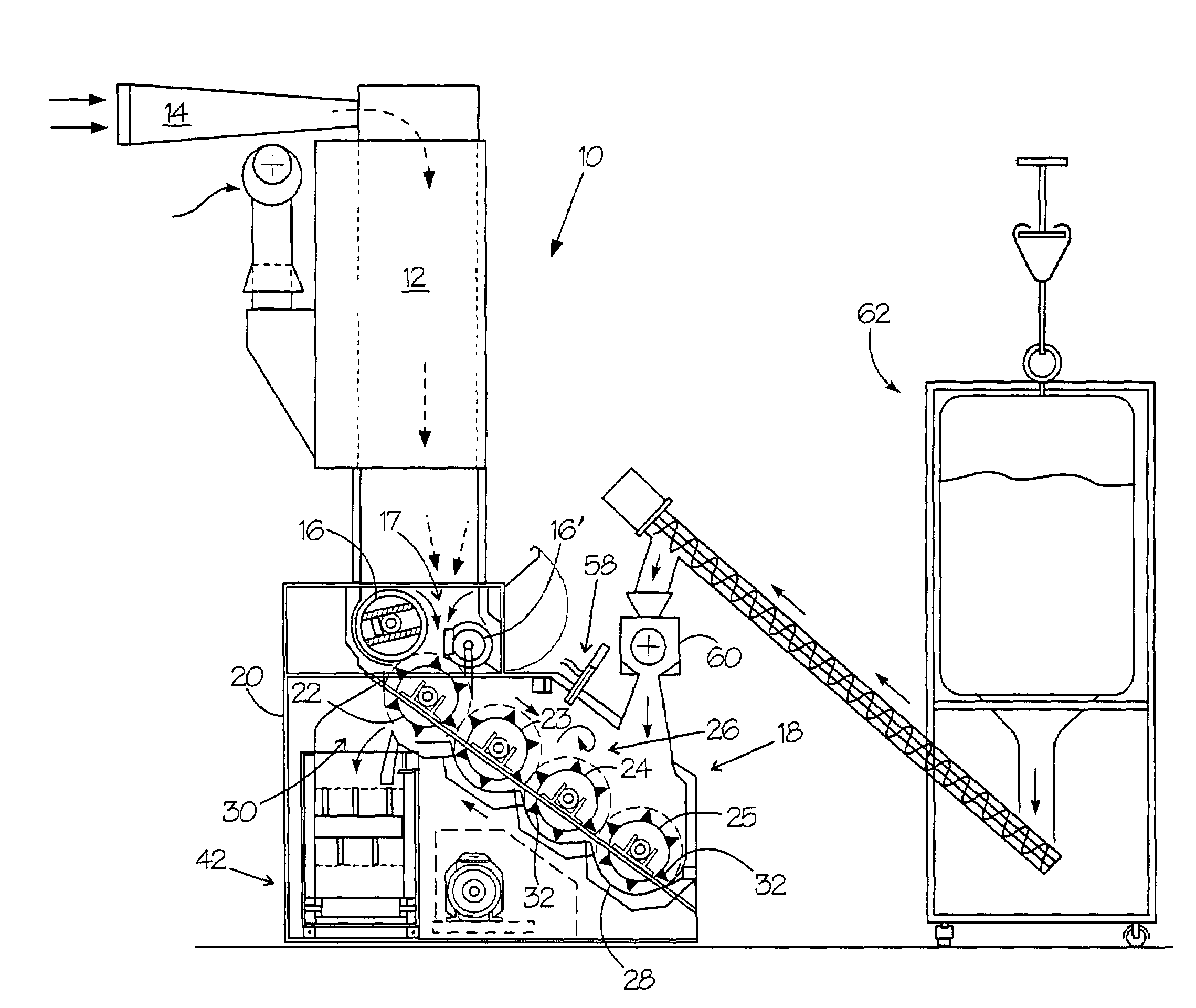

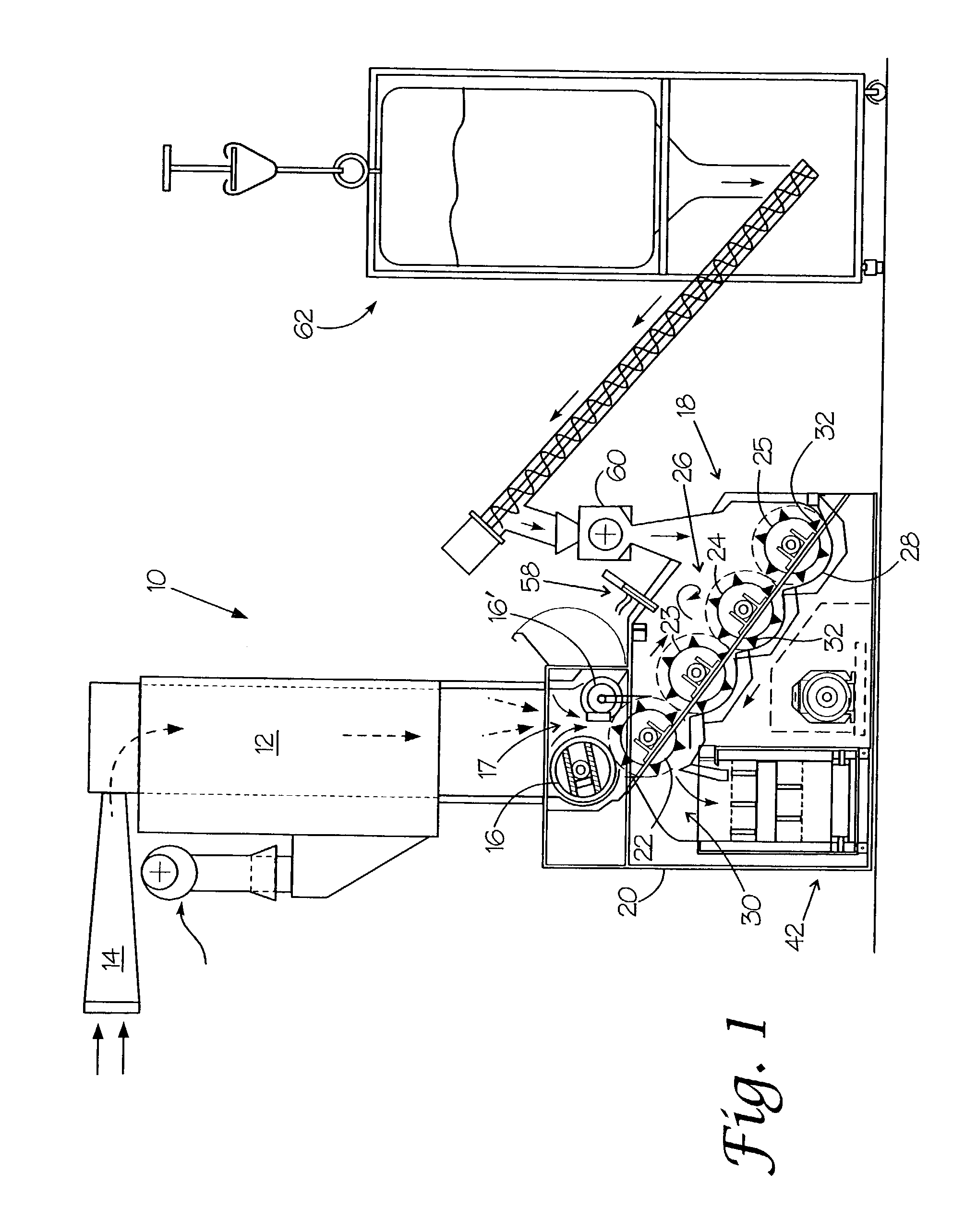

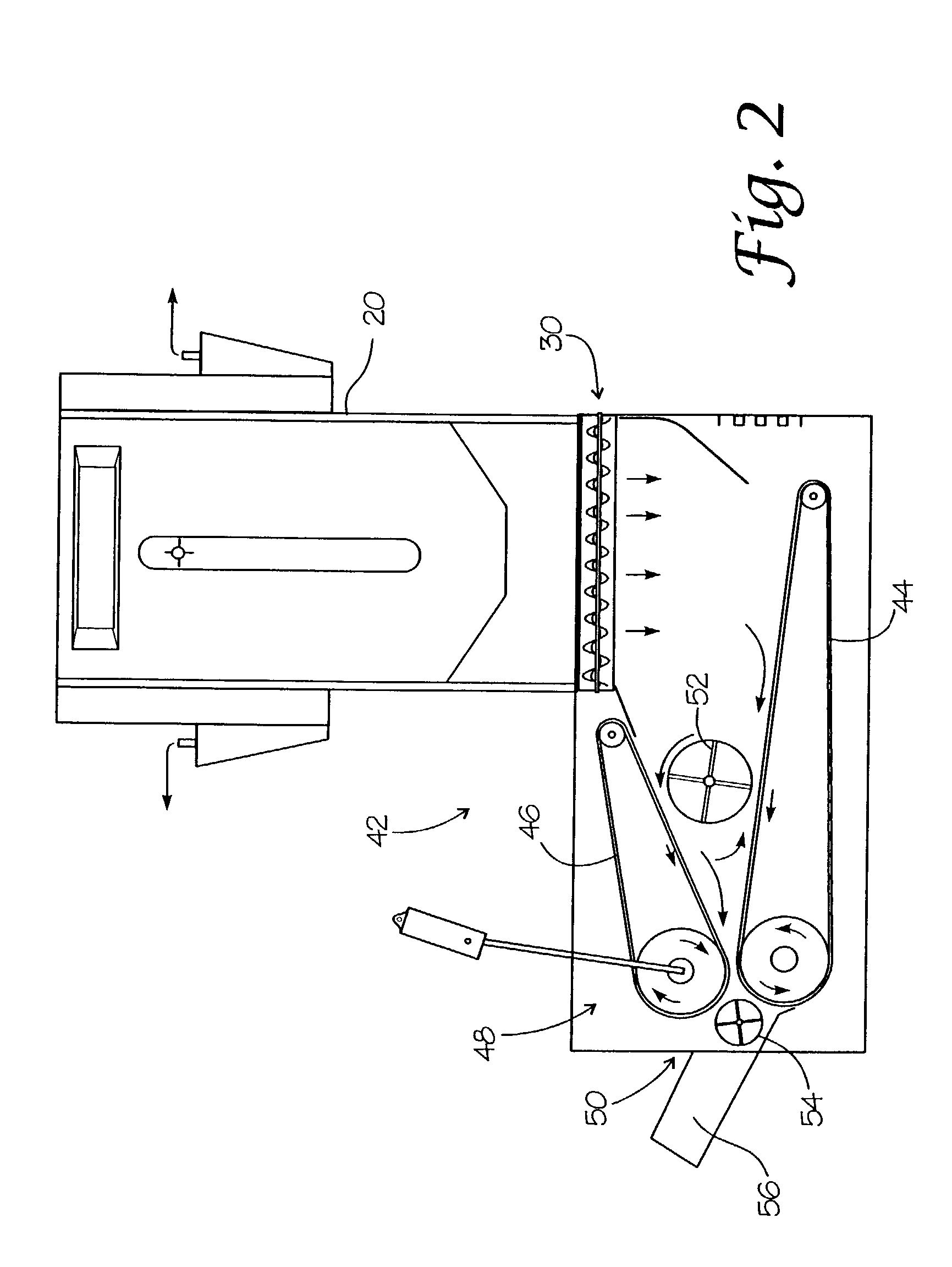

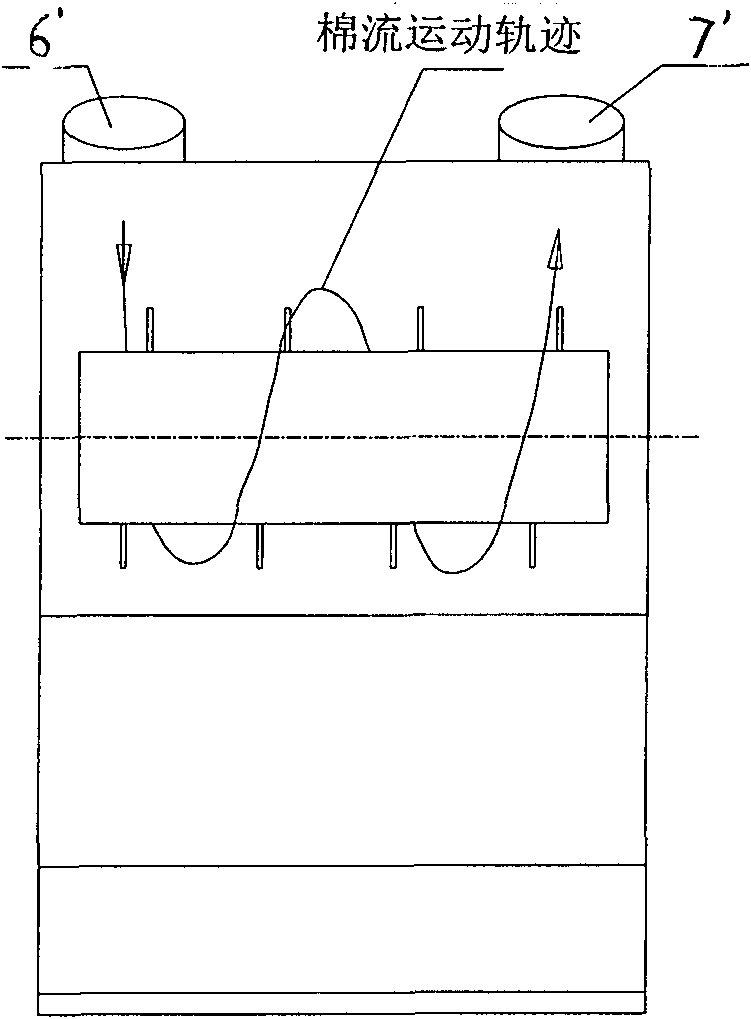

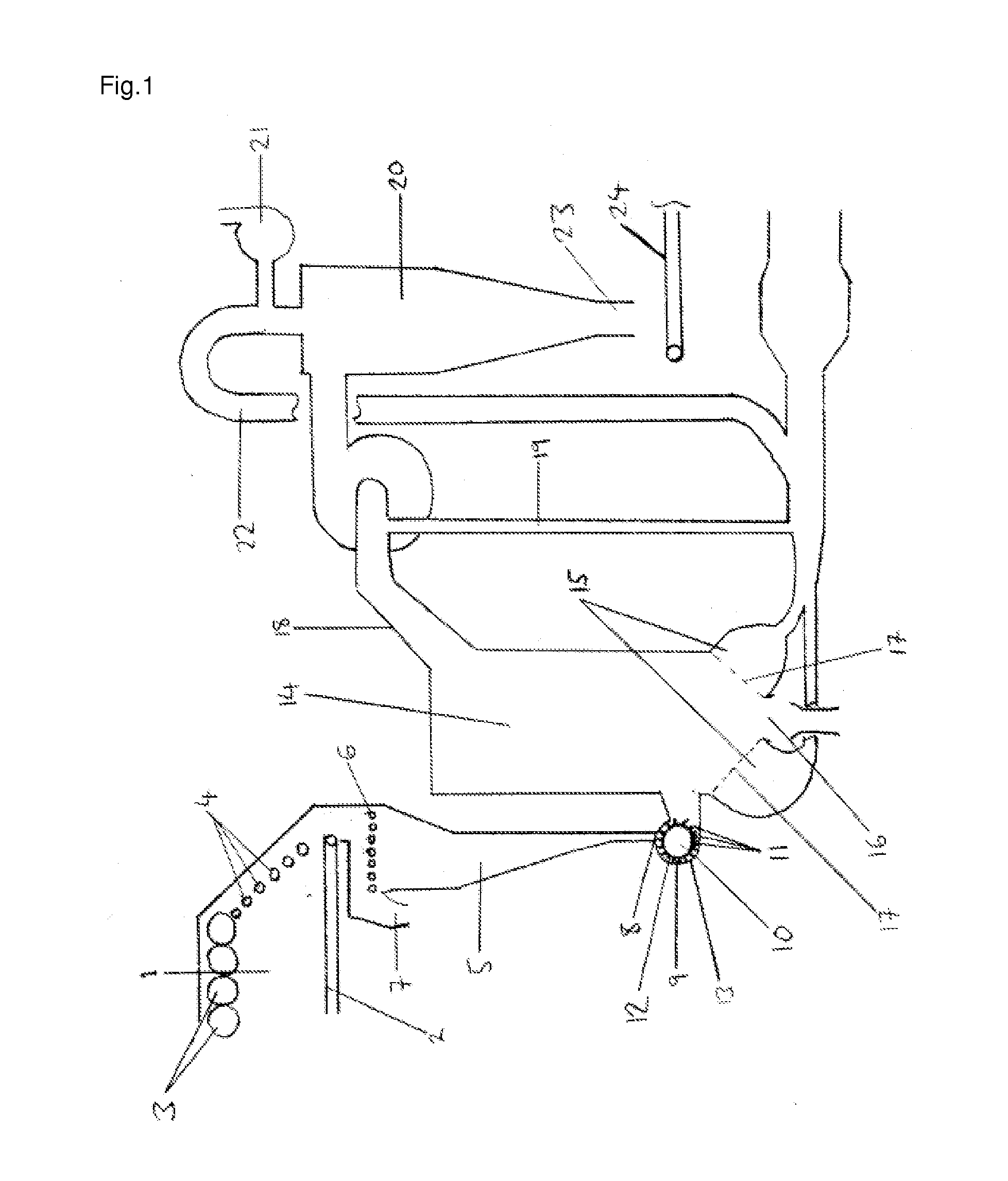

InactiveUS7032273B2Fibre cleaning/opening by beater armsFibre cleaning/opening by toothed membersFiberMechanical engineering

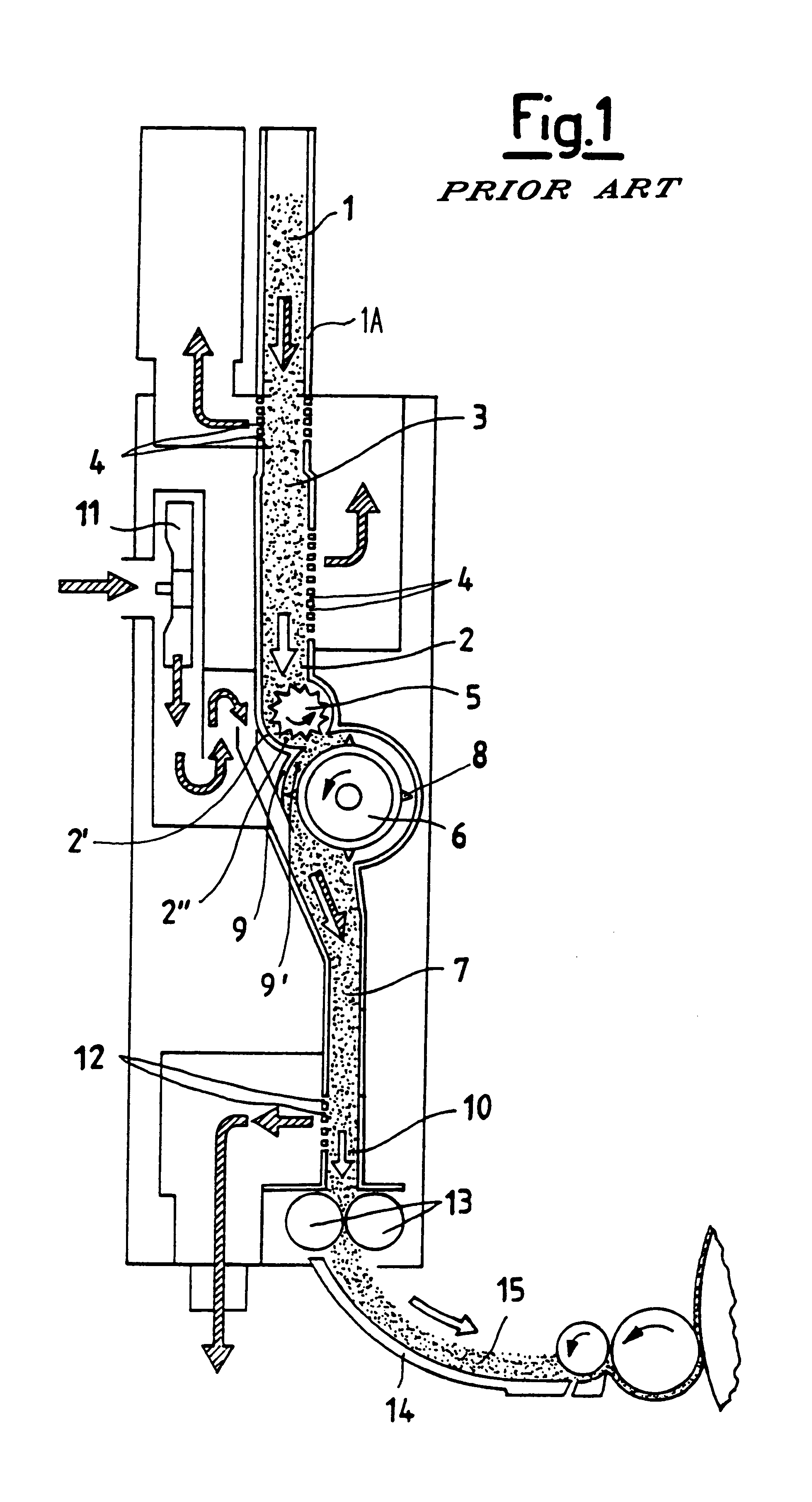

A fiber blending, opening and cleaning arrangement which includes a feed section for delivering a blend of fibers onto a first opening and blending operation, comprising an array of parallel opening and blending rolls rotating in one direction and arranged along an incline and in adjacent positions. The fibers are passed over the rolls in a first direction and under the rolls in a section direction while being also moved along a sinusoid path. Upon existing the array of rolls, the fibers fall into a fine opening and blending operation which fully mixes the fibers.

Owner:PINTO AKIVA

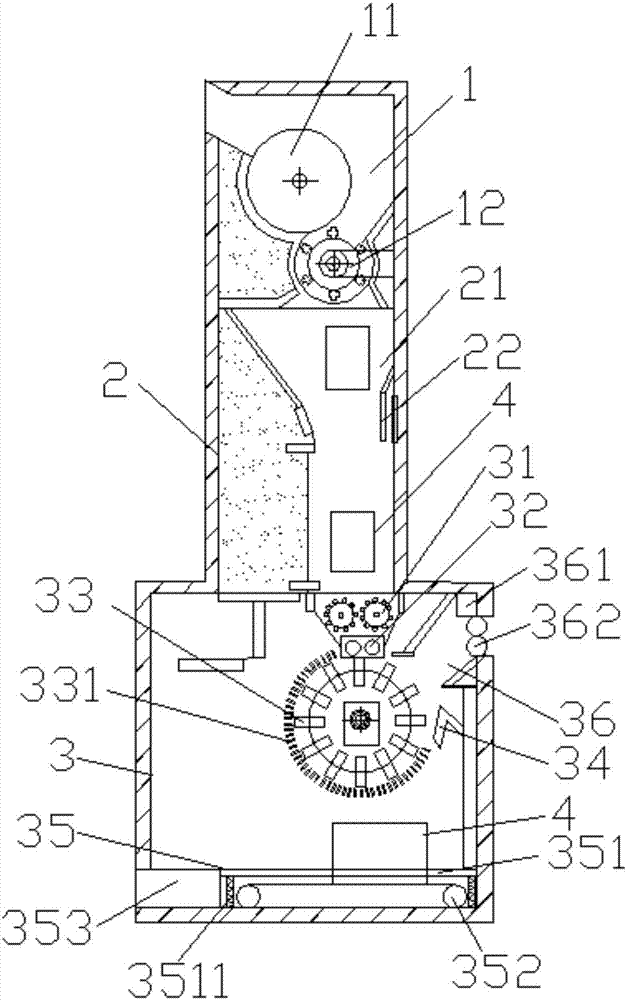

Procedure and system for opening and proportioning synthetic material

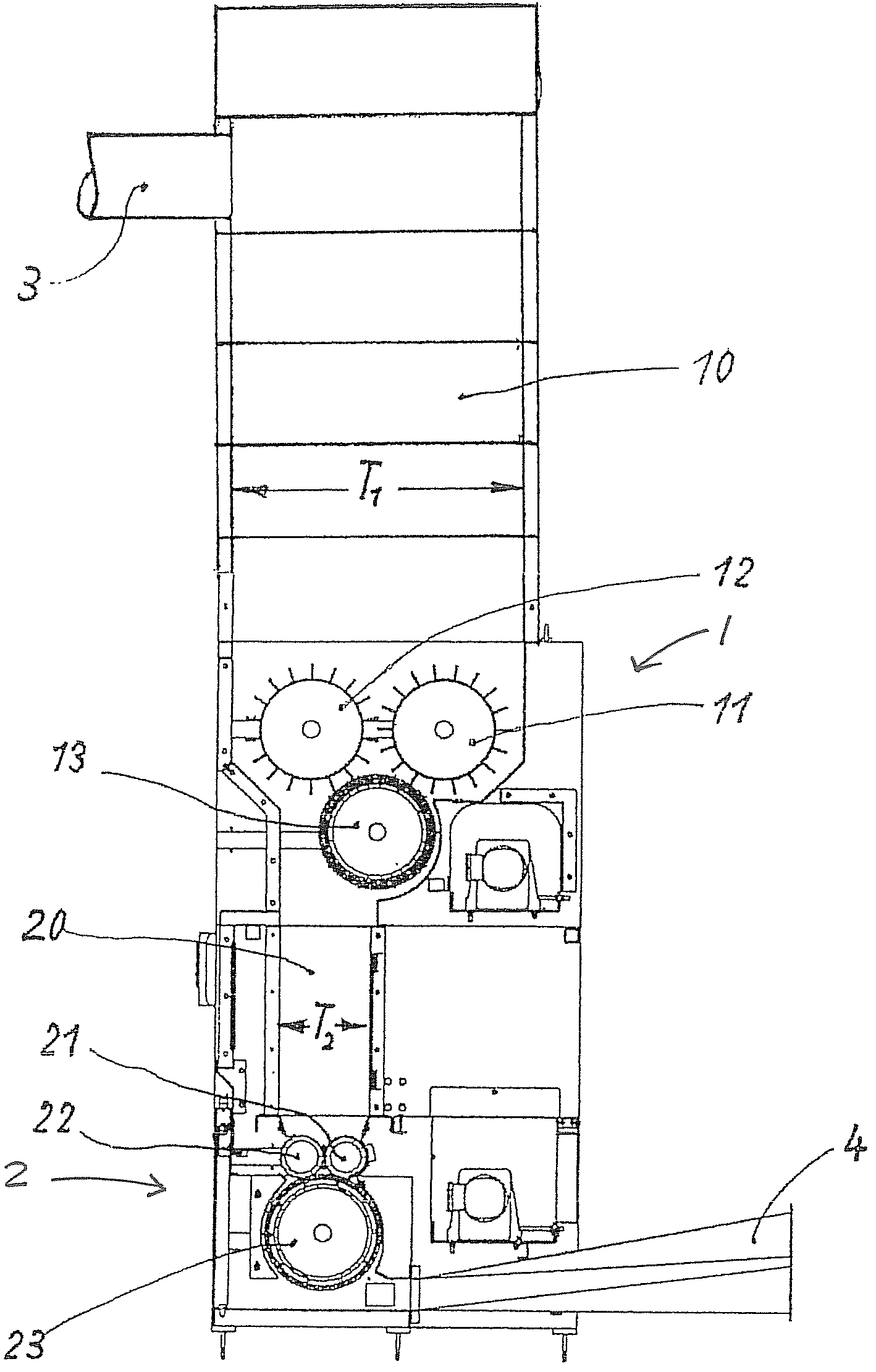

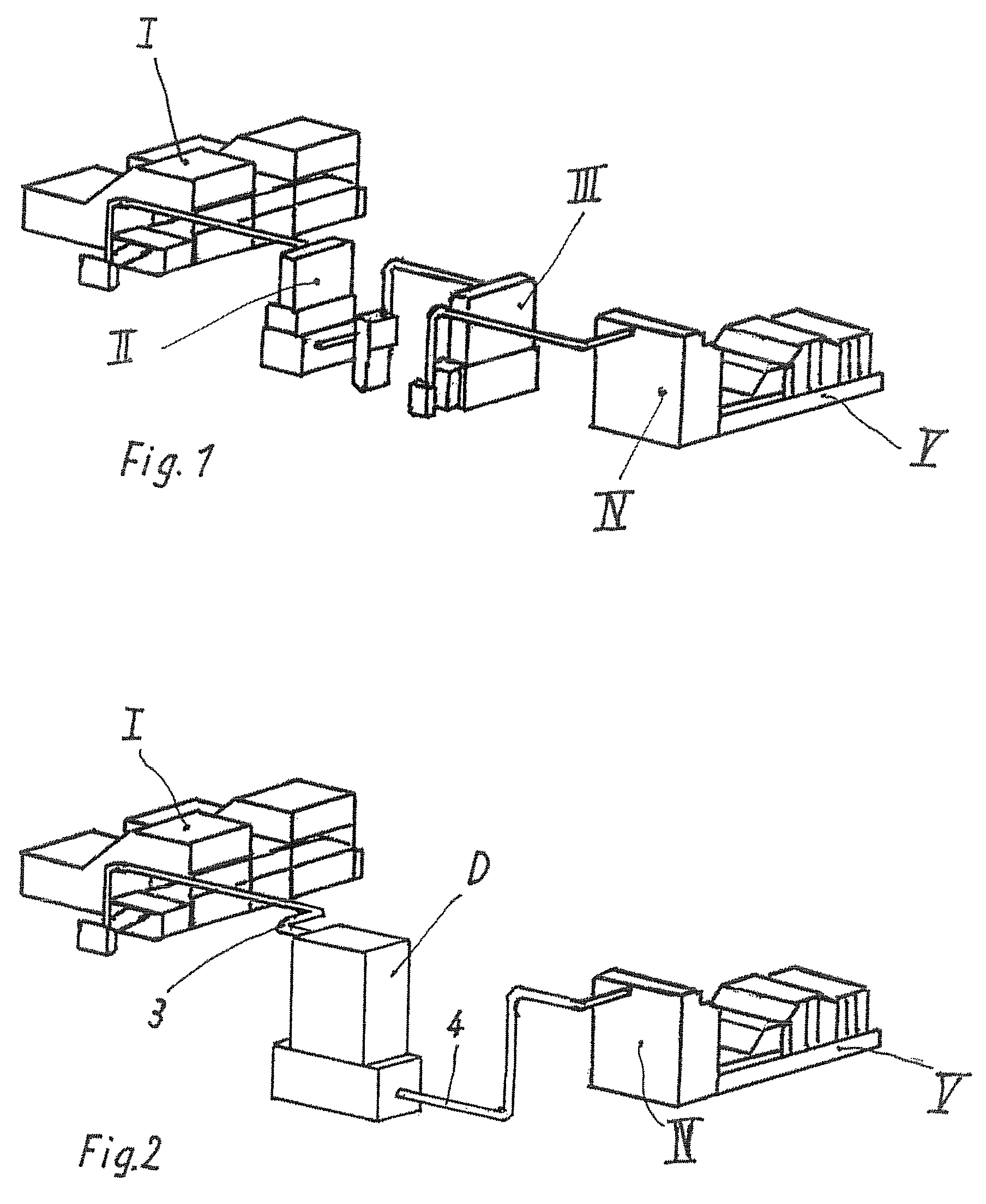

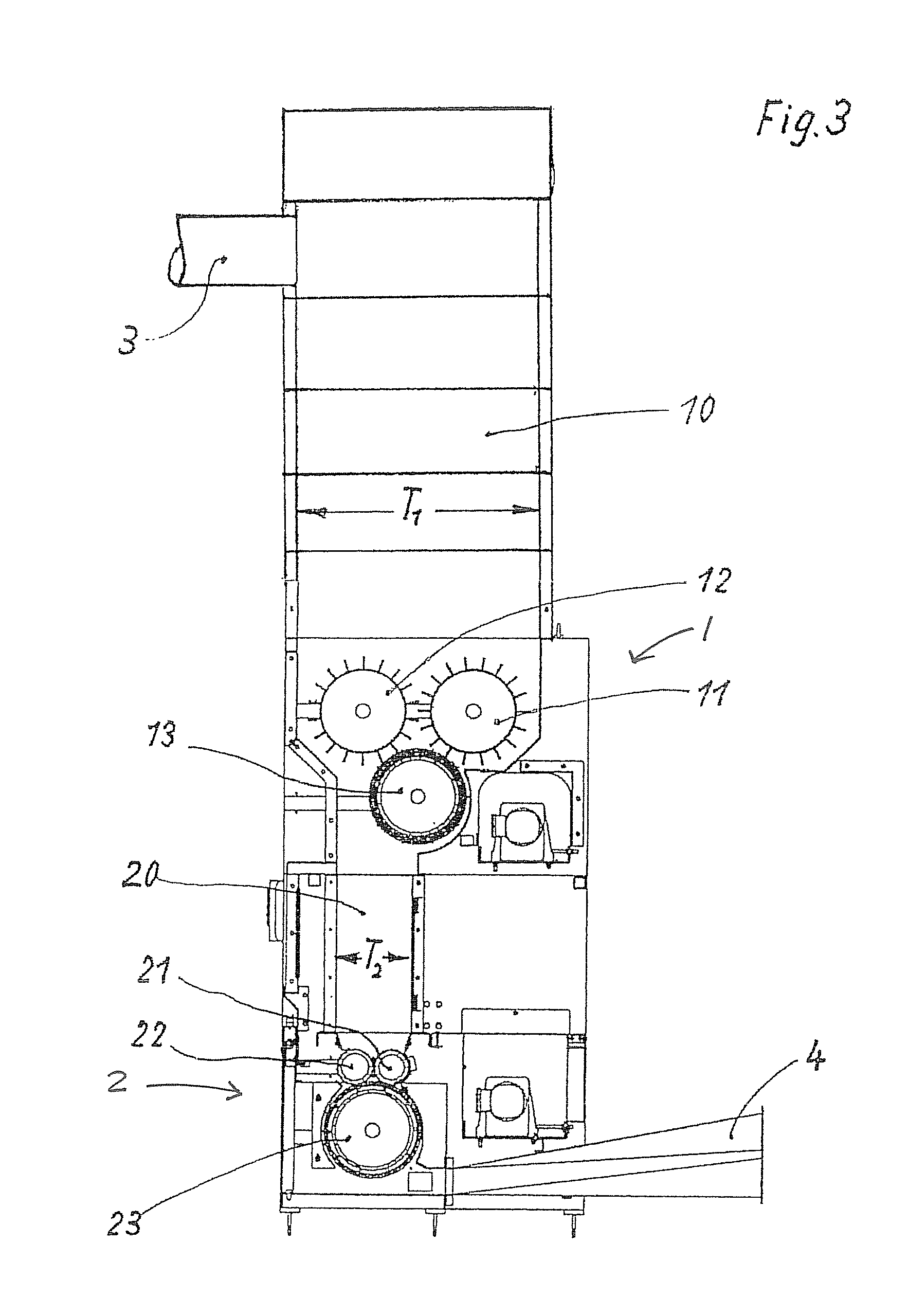

ActiveUS7752715B2Avoid Level FluctuationsDensity of fiber uniformFibre cleaning and opening machine combinationsFibre cleaning/opening by toothed membersFiberSynthetic materials

A method and a device for opening and dosing fiber feeds the fiber material via a feeding shaft of an opening device. The fiber material is processed in a first opening step of a dosing opener and is fed without an interconnecting pneumatic means to the feeding shaft of a second opening step. A large-volume feeding shaft has been placed before the first opening device from which the fiber material is delivered to a feeding shaft with a considerably smaller volume that delivers the fiber material to a second opening device. Both opening devices and their associated feeding shafts are placed on top of one other.

Owner:TEMAFA MASCHFAB

Opener for cotton spinning

InactiveCN107988661AFast fluffyImprove opening efficiencyFibre cleaning/opening by toothed membersAgricultural engineeringElectric machinery

The invention discloses an opener for cotton spinning. The opener for cotton spinning relates to the technical field of textile machinery, and comprises a tank body, wherein two support legs are fixedly connected to the left end and the right end of a lower surface of the tank body; a discharge end of a feeding pipe is fixedly communicated to the left end of the tank body; a feeding end of a discharge pipe is fixedly communicated to the right end of the tank body; a hot air fan is fixedly arranged on the back surface of the tank body; an air outlet end of the hot air fan is fixedly communicated with air inlet ends of two air outlet pipes through a three-way pipe. According to the opener for cotton spinning, the hot air fan is fixedly arranged on the back surface of the tank body; a pattingrod I and a patting rod II are fixedly connected to an outer side surface of a first connecting ring; a first motor is utilized for driving a rotary shaft I to rotate so as to drive the patting rod Iand the patting rod II to pat cotton, and hot air blown into the tank body through the hot air fan is matched, so that the cotton can quickly become fluffy, the opening efficiency of the cotton is favorably improved, and the problem mentioned in a background technology is solved.

Owner:胡和萍

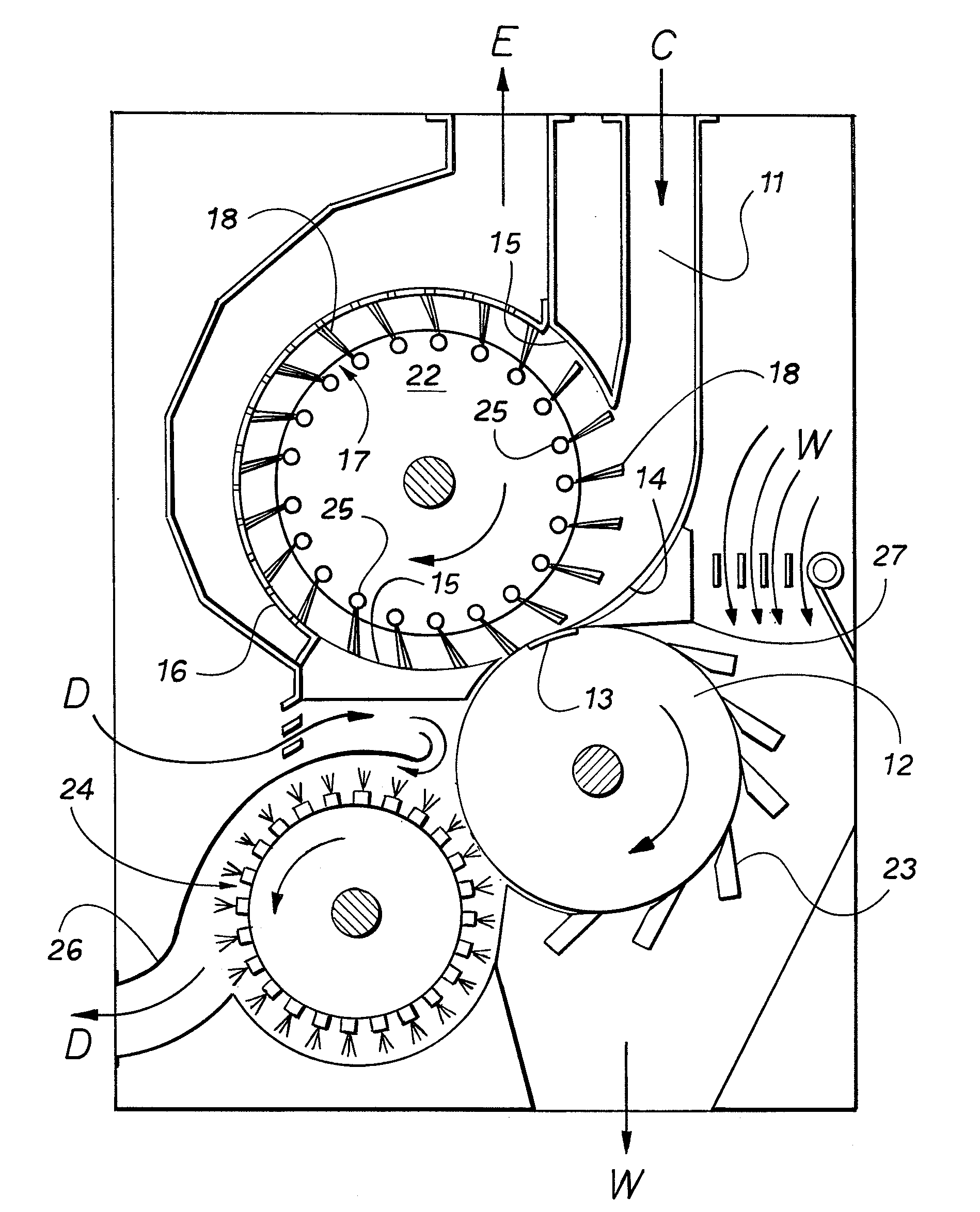

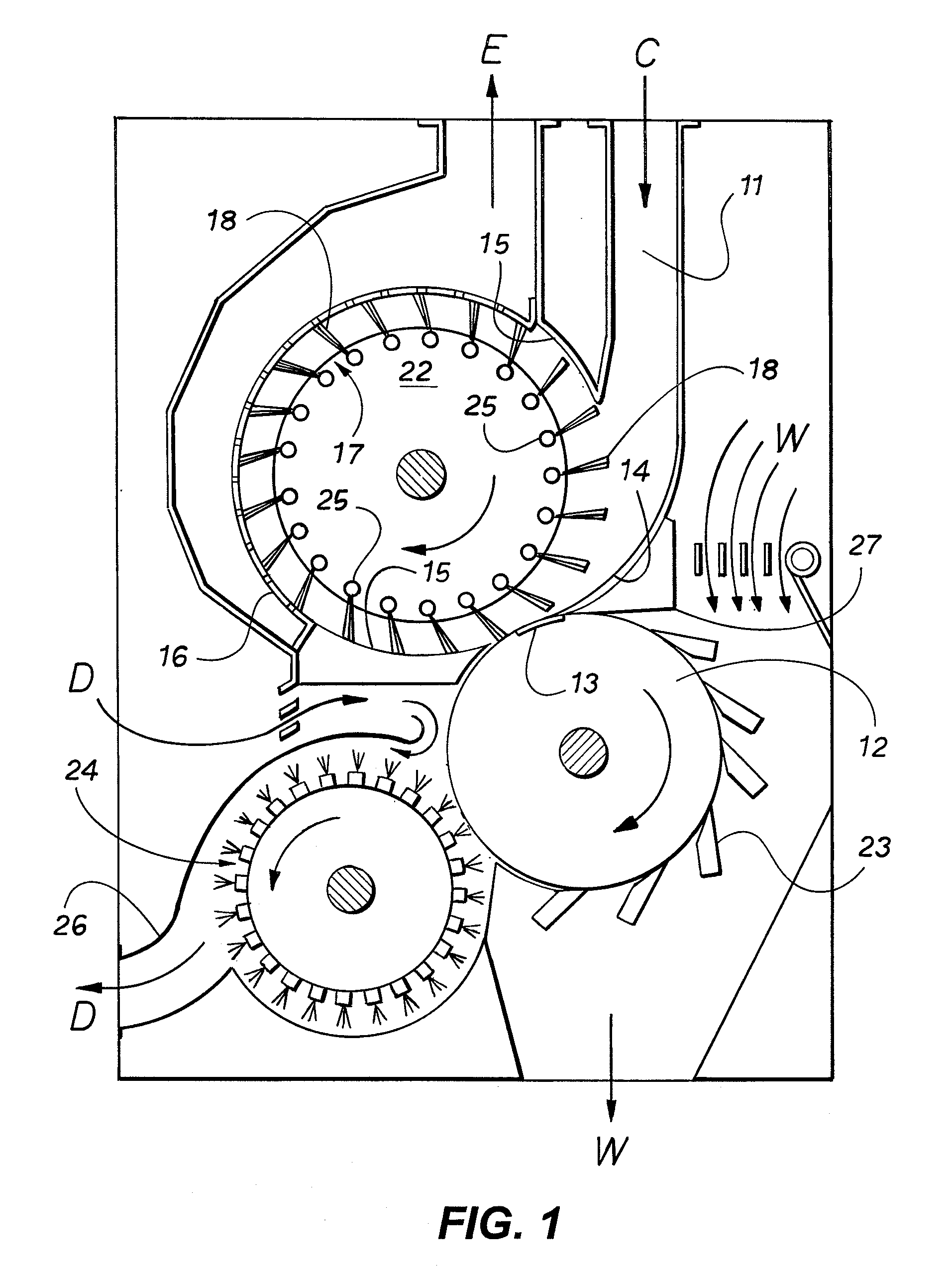

Device for preparation and opening of flock fibers to be supplied to a carder

InactiveUS6195841B1Mechanical impurity removalFibre cleaning/opening by toothed membersFiberEngineering

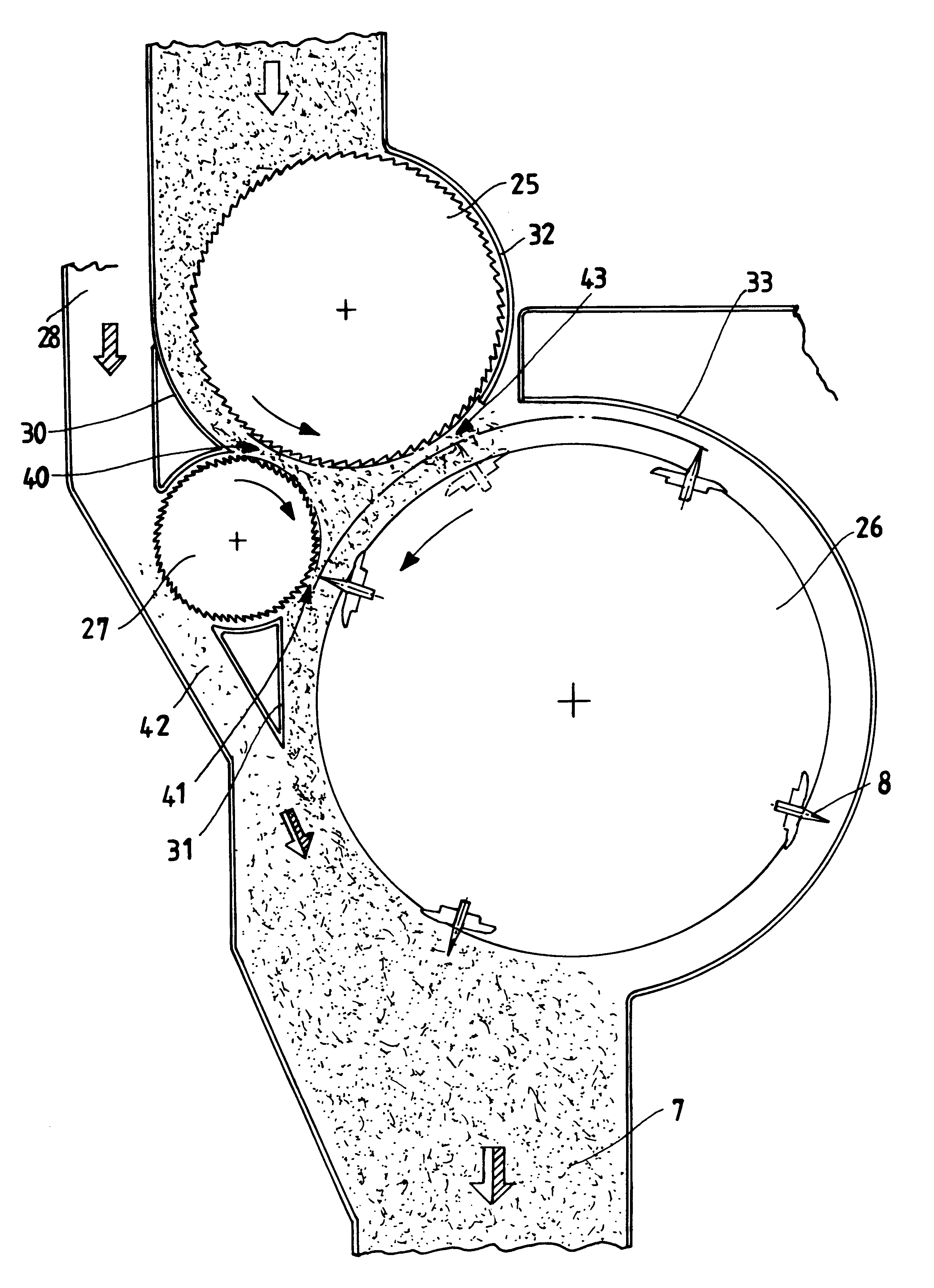

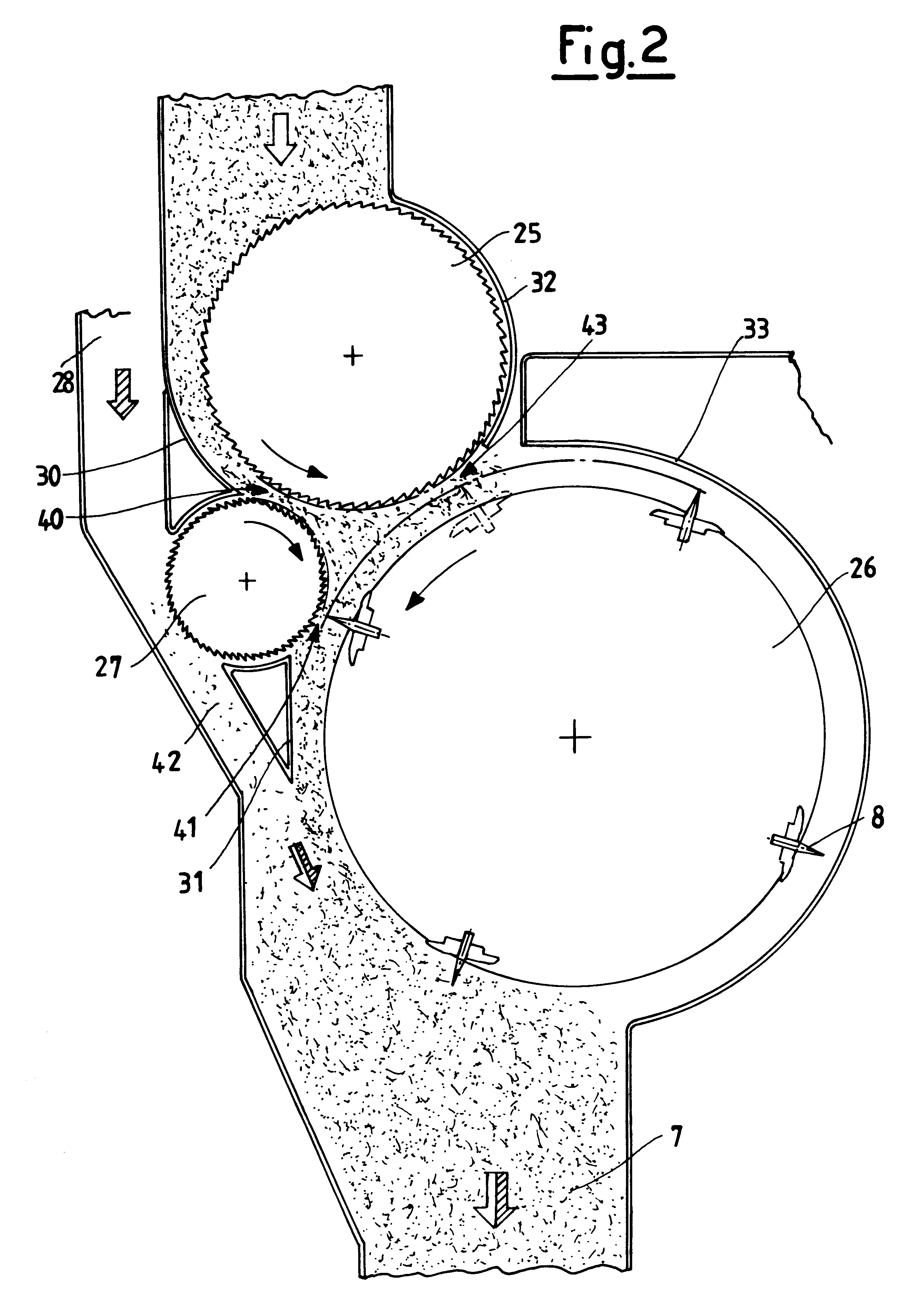

Silo for supply of flock fibers to a carder, which silo is subdivided into superimposed chambers, between which there is interposed a set of rollers which regulate the descending flow, and carry out breaking and separation of the fibrous material, in which a supply roller, an auxiliary supply roller and a breaker roller are disposed in a triangle, in which the surface of the auxiliary roller opposite that which is tangent to the supply roller is exposed to the flow of air which descends downwards, together with the fibers worked by the breaker roller.

Owner:MARZOLI

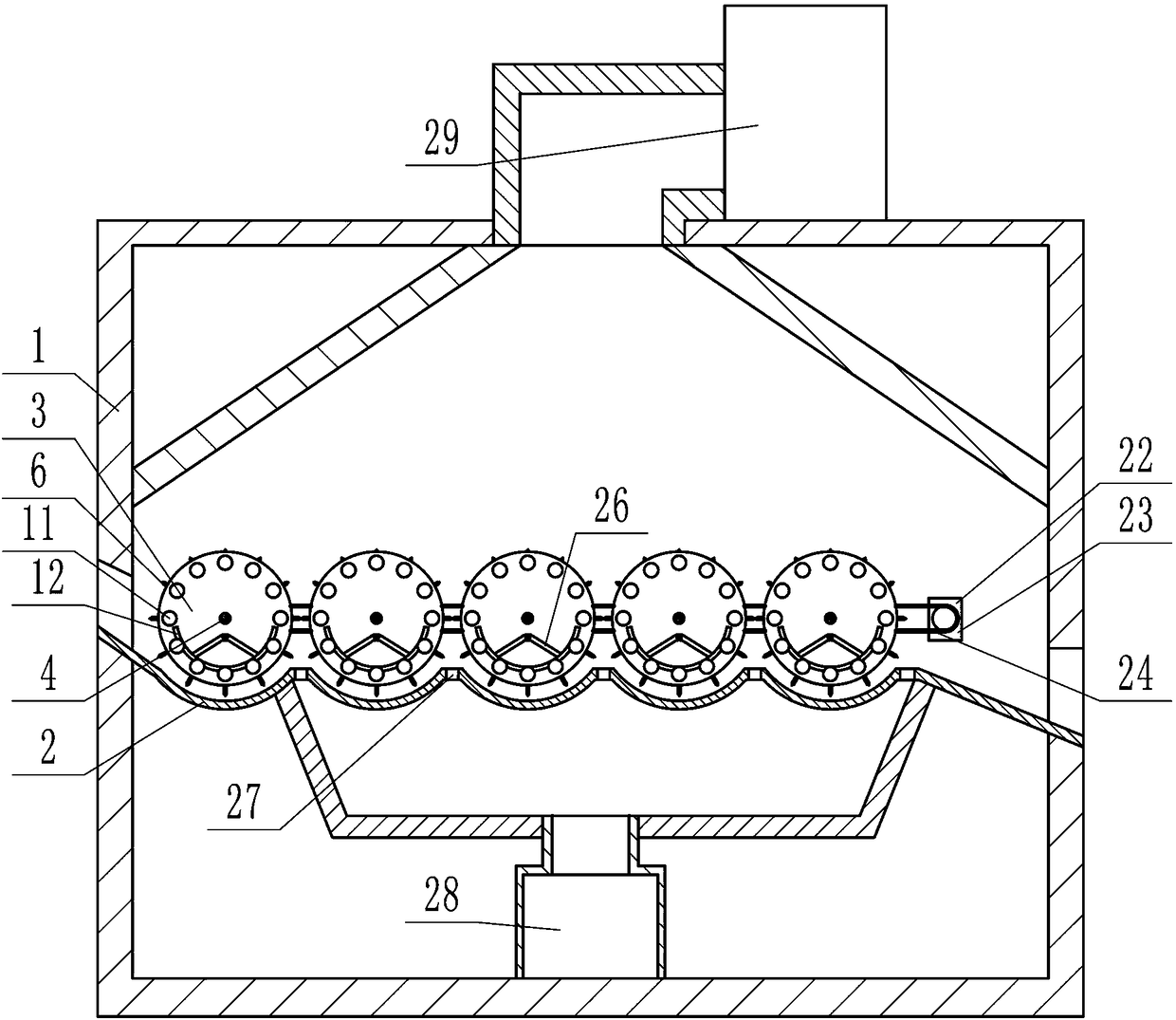

Blowing foreign fiber machine with function of spreading

ActiveCN108547014ANovel ideaIngenious structureFibre cleaning/opening by air draught arrangementsFibre cleaning/opening by toothed membersFiberEdge surface

The invention relates to a blowing foreign fiber machine with a function of spreading, and effectively solves the problem that the small foreign fiber cleaning of an existing foreign fiber cleaning machine is not complete. According to the technical scheme, the blowing foreign fiber machine comprises a box body, wherein the box body is internally provided with a plurality of rotatable first cylinders, the first cylinders are horizontally arranged along forward and backward directions, the first cylinders are internally fixedly provided with cams, a plurality of sets of stirring rods are circumferentially uniformly distributed on the first cylinders, the rotation of the first cylinders makes the stirring rods move along the radial directions of the first cylinders under the squeezing actionof the outer edge surface of the cams, same sides of each set of stirring rods are provided with two pull rods, each stirring rod is provided with a blocking rod, each pull rod is provided with a clamping groove, the outer side of each pull rod is provided with a blocking plate, front and back end faces of each first cylinder are respectively provided with an arc-shaped protruding block, the rotation of the first cylinders drives the blocking plates to contact with the protruding blocks, it is achieved that the pull rods drive the stirring rods to move toward the outer side under the squeezing action of the arc-shaped protruding locks, and the stirring rods are provided with compression springs capable of making the positions of the center faces on the front and back directions of the first cylinders reset. The blowing foreign fiber machine with the function of spreading has the advantages that the conception is novel, the structure is ingenious, and the practicability is high.

Owner:桐乡市常新农机专业合作社

Vertical cotton opener

InactiveCN103290528ACompact structureEasy to connect and arrangeFibre cleaning/opening by toothed membersEngineeringVertical channel

The invention discloses a vertical cotton opener which comprises a feeding opening, a discharging opening, a cotton storage box and a beating device. The feeding opening and the discharging opening face upwards in parallel, the discharging opening is vertically communicated with the beating device through a vertical channel at the lower portion the discharging opening, a blowing device which supplies air upwards is installed below the vertical channel, the feeding opening and the cotton storage box are separated from the discharging opening and the vertical channel through a vertical separation board, and the beating device is located below the vertical separation board. The vertical cotton opener is compact in structure and integrally in a cube shape; due to the fact that the feeding opening and the discharging opening face upwards in parallel, connection and arrangement in a production line are convenient; due to the fact that the feeding part and the discharging part are separated, interference in air flow does not exist.

Owner:SUZHOU QISHANG TEXTILE

Novel cotton slitting machine

InactiveCN103993391ANo leakageSimple structureFibre cleaning/opening by toothed membersFibre cleaning/opening machinesEngineeringRotating drum

The invention discloses a novel cotton slitting machine. The novel cotton slitting machine comprises a feeding area and a cotton slitting area. A feeding opening is formed in the upper left side of the feeding area, a filer screen is arranged below the feeding opening, and a vibrating shaft is arranged below the filter screen. A feeding device is arranged on the lower right portion of the filter screen, and a raw material inlet is formed in the right side of the feeding device. A rotating drum is arranged in the middle of the cotton slitting area, cotton slitting cloths are arranged on the surface of the rotating drum at intervals, and the cotton slitting cloths are trapezoidal. Sawtooth notches are formed in the upper surface and the two inclined planes of each trapezoid, and toothlike pull troughs are formed in the two sides of each notch and the two sides of each cotton slitting block. Cotton slitting rakes which are the same as the cotton slitting area in shape are arranged on the upper portion of the inner side of a circular housing of the cotton slitting area, and the cotton slitting rakes and the cotton slitting blocks are crossed and staggered. A suction fan is arranged at a discharging opening, so that cotton is sucked into a pipeline to be conveyed to the next working procedure, and an air nozzle is arranged above the discharging opening. The novel cotton slitting machine is simple in structure, convenient to operate, capable of filtering the dust in the cotton, high in yield, high in efficiency, even in cotton slitting, free of dust and flock leakage, and small in noise for the reason that drum-type rotating sawteeth are used for cotton slitting in a crossed mode.

Owner:JIANGSU SHUANGYING TEXTILE TECH

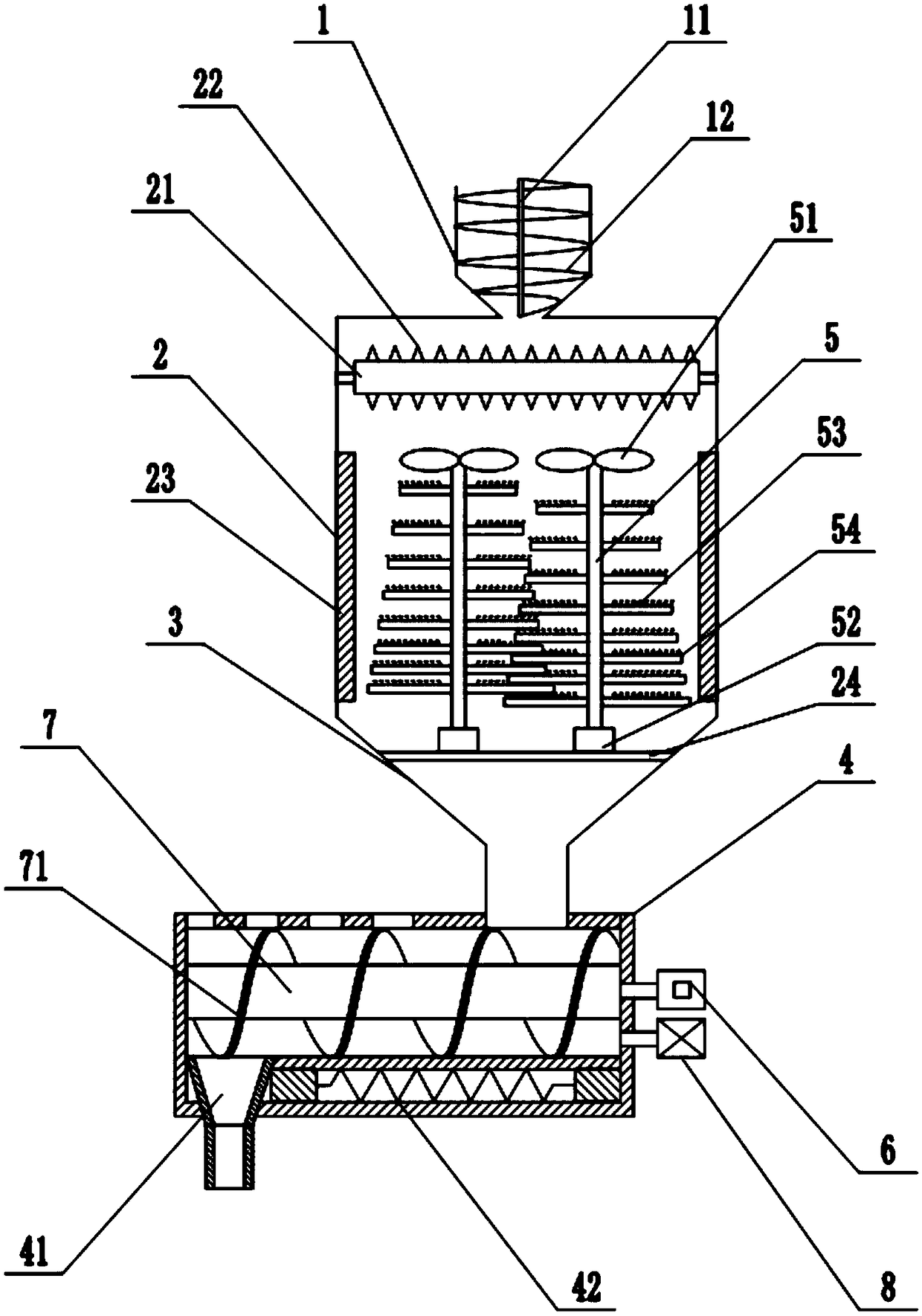

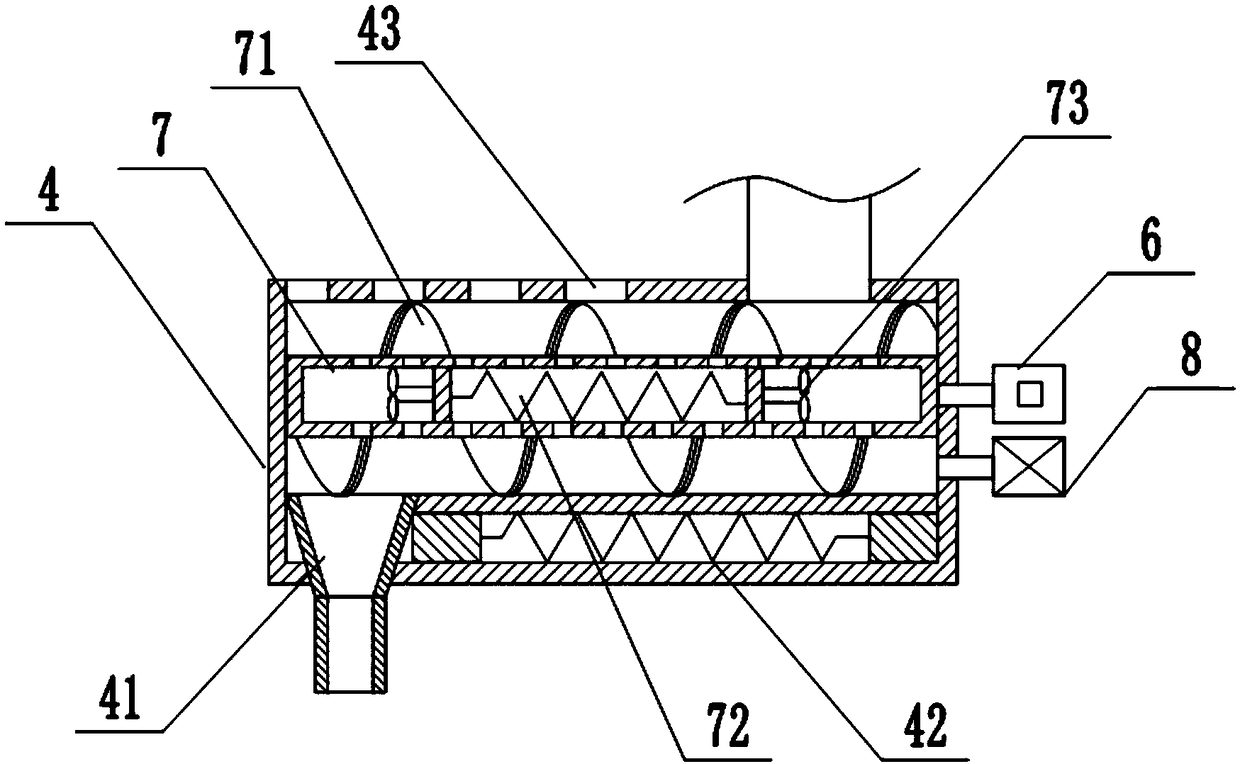

Cotton fluffing equipment

InactiveCN108950745AFast fallSpeed up the flowFibre cleaning/opening by toothed membersFibre cleaning/opening machinesEngineering

The invention relates to the technical field of spinning equipment, and discloses cotton fluffing equipment. The cotton fluffing equipment comprises a feeding hopper, a fluffing box, a conical guidinghopper and a discharging device; a rotary roller and rotary rods are arranged in the fluffing box, barbs are densely arranged on the rotary roller, fixing plates are arranged on the rotary rods, andbent hooks are densely arranged on the fixing plates; the discharging device comprises a box body, a rotary cylinder is rotatably connected into the box body, a second motor is connected to the rotarycylinder, a spiral pushing belt is arranged on the outer wall of the rotary cylinder, and a heating layer is arranged at the bottom of the box body. When the cotton fluffing equipment is in use, therotary roller in the fluffing box rotates to preliminarily tear cotton, and under the effect of the bent hooks on the fixing plates, the cotton is torn again, so that the cotton is torn into pieces, and gets soft and fluffy. The cotton fluffing equipment is novel in structure, and solves the problem existing in the prior art that when a fluffing cotton filler conducts cotton fluffing, fine floccules in the cotton easily drift away.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

Method and Apparatus for Separating Foreign Matter From Fibrous Material

ActiveUS20090172918A1Simple methodEliminate needMechanical impurity removalLubricating devicesForeign matterFiber

An apparatus for cleaning foreign matter from separated tufts of fiber uses a revolving open reel type structure mounted within a porous housing to separate a conveying air stream from tufts of fiber conveyed thereby and deliver the tufts to a toothed cleaning cylinder which passes beneath a plurality of cleaning bars. The open reel utilizes brush like outer surfaces to sweep tufts of fiber from the housing back into the air stream adjacent the cleaning cylinder.

Owner:LUMMUS INDS

Seed-cotton foreign fiber cleaning machine

ActiveCN102191589AEasy to cleanImprove cleaning efficiencyFibre cleaning/opening by air draught arrangementsFibre cleaning and opening machine combinationsFiberEngineering

The invention relates to a combined-type seed-cotton foreign fiber cleaning machine which is characterized by comprising a tank body which is internally provided with a winding and cleaning device, a hook-pull purification cleaning device, a boiling and opening device and a wind power cleaning device, wherein the winding and cleaning device comprises two pattern feeding rollers; two groups of winding rollers are arranged under the two pattern feeding rollers; a regulating plate is arranged at a passageway dividing place of the two groups of winding rollers; the hook-pull purification cleaning device comprises at least one rack roller, one auger and one doffing roller, wherein the auger is arranged under the rack roller; the doffing roller is arranged slantwise under the rack roller; the boiling and opening device comprises a row of opening rollers; an air bellows which is connected with a fan is arranged under the opening rollers; a plurality of seam-type blast nozzles are arranged on the tops of the air bellows; each seam-type blast nozzle is arranged between any two adjacent opening rollers; and the wind power cleaning device comprises a gettering cover which is connected with the fan. The seed-cotton foreign fiber cleaning machine has a good seed-cotton cleaning effect and high cleaning efficiency and can be widely applied to cotton processing factories for cleaning various foreign fibers in seed cotton.

Owner:北京智棉科技有限公司

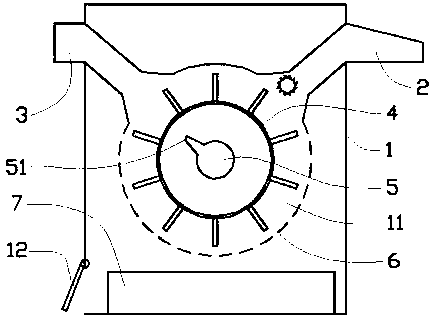

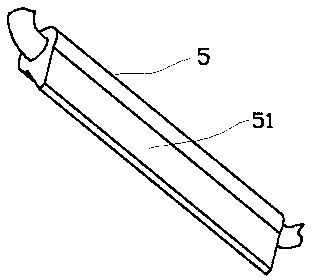

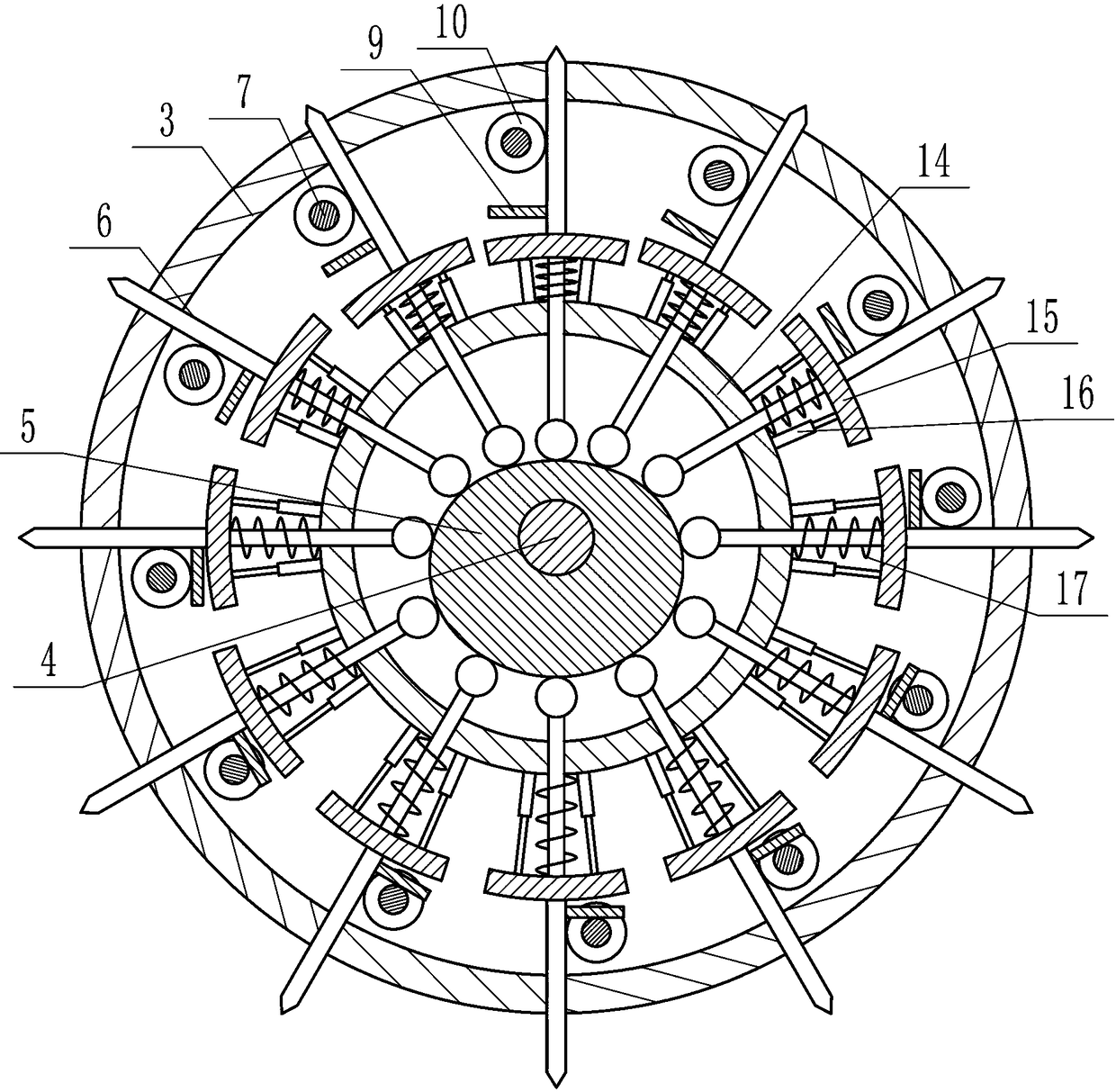

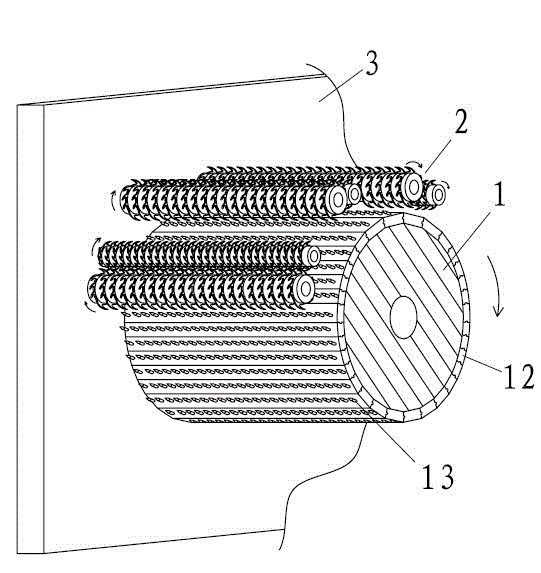

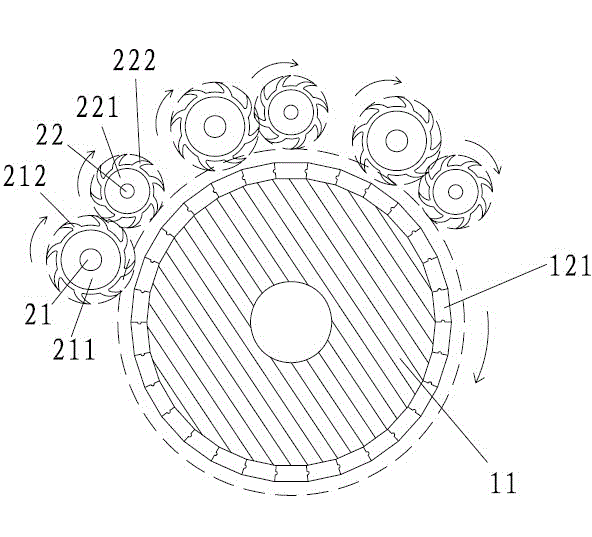

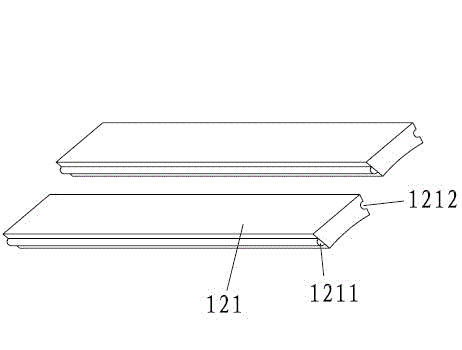

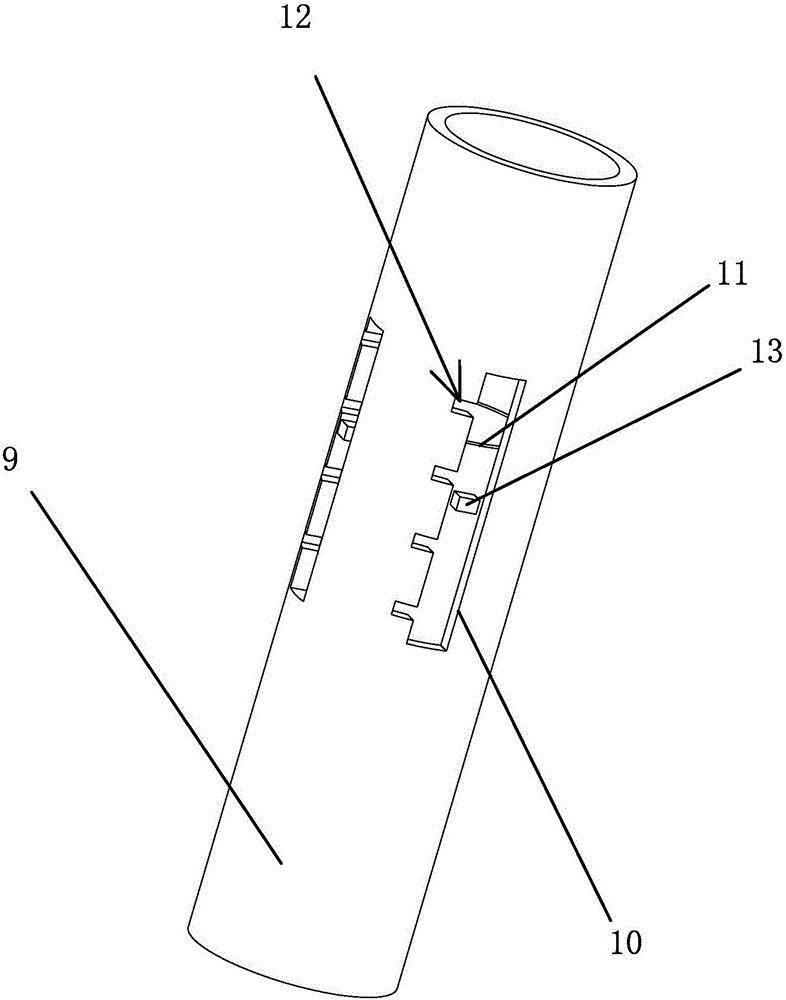

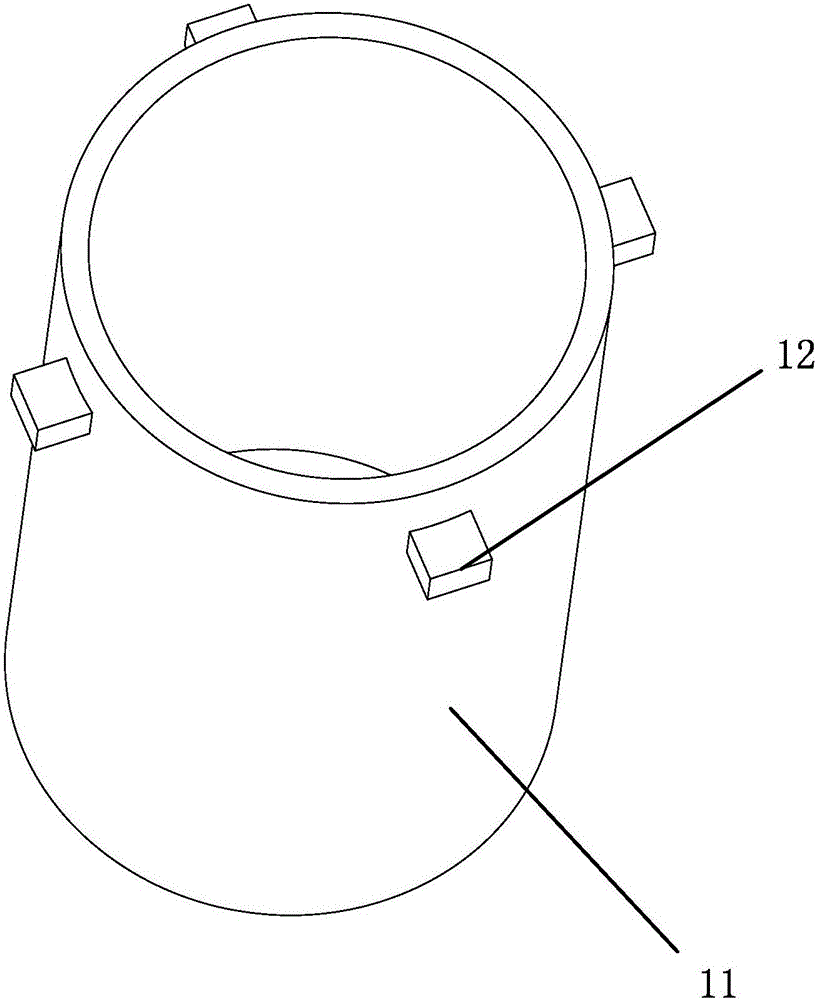

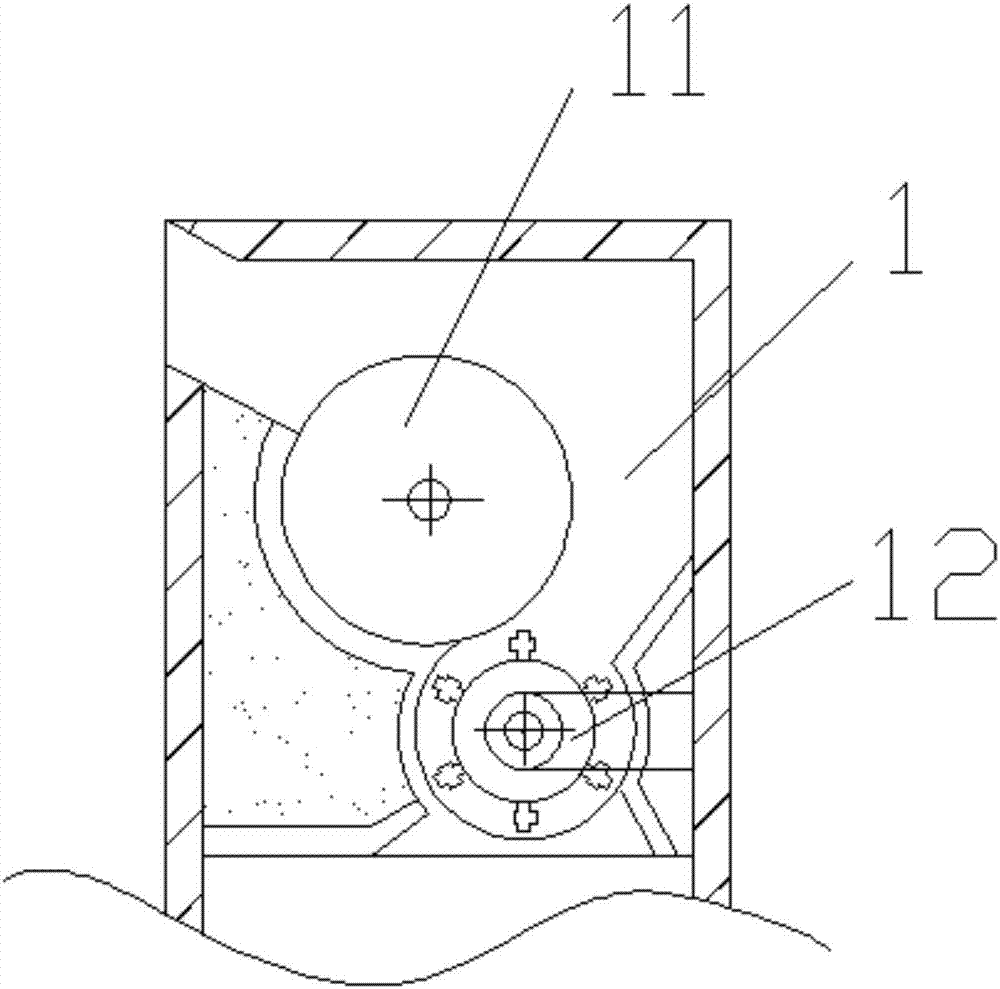

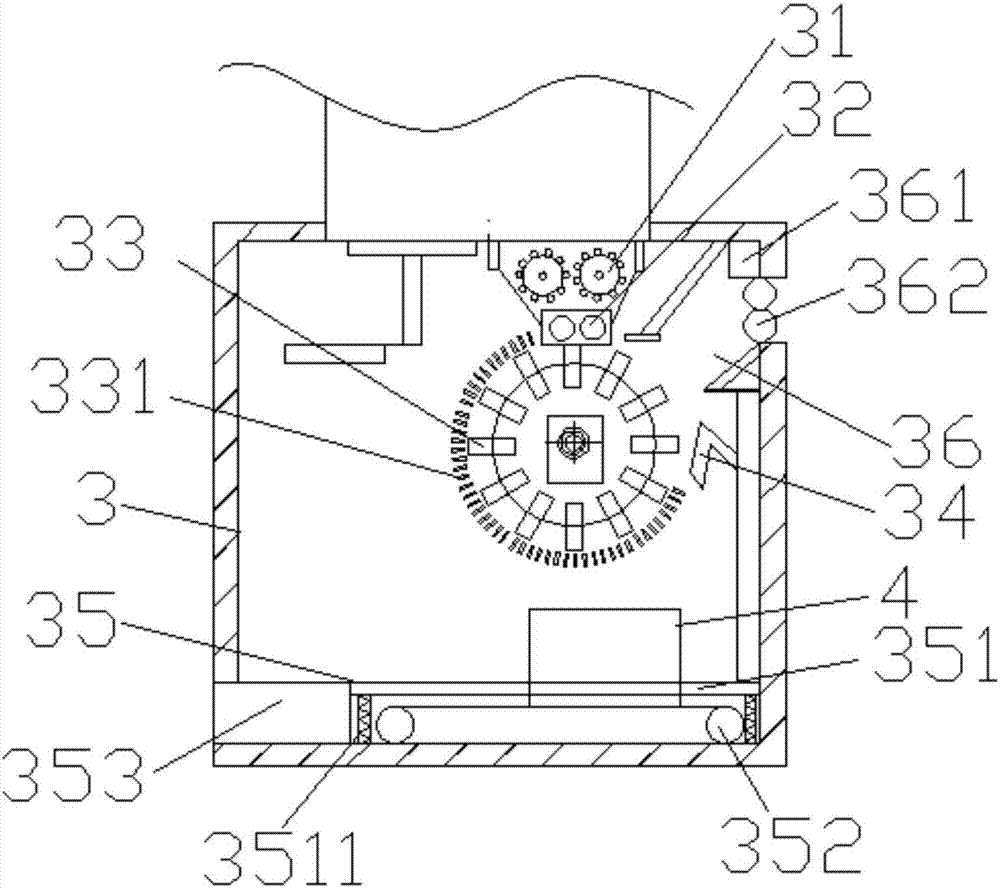

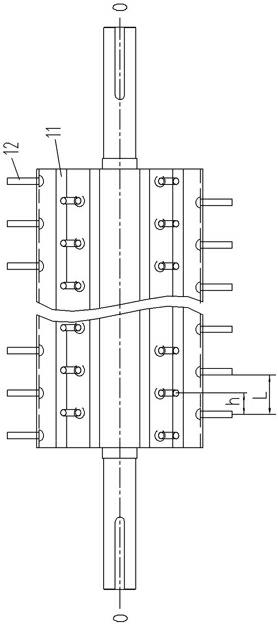

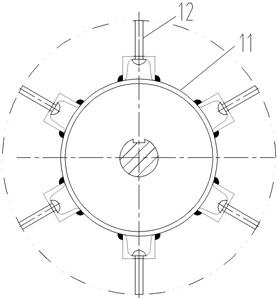

Opening mechanism and opener comprising same

InactiveCN102747458AEasy maintenanceNot easy to damageFibre cleaning/opening by toothed membersFibre cleaning/opening machinesEngineeringMechanical engineering

The invention relates to an opening mechanism and an opener comprising the same, relates to cashmere production equipment and particularly relates to an opening and carding unit for raw cashmere. According to the technical scheme, the opening mechanism comprises a cylinder and at least one opening roller set. The cylinder comprises a drum, a mounting layer and a needle loop. The mounting layer fixed to the outer wall of the drum is composed of a plurality of plates. The cylinder has the advantages of convenience to maintenance, labor saving, and low potential safety hazard.

Owner:湖州珍贝羊绒制品有限公司

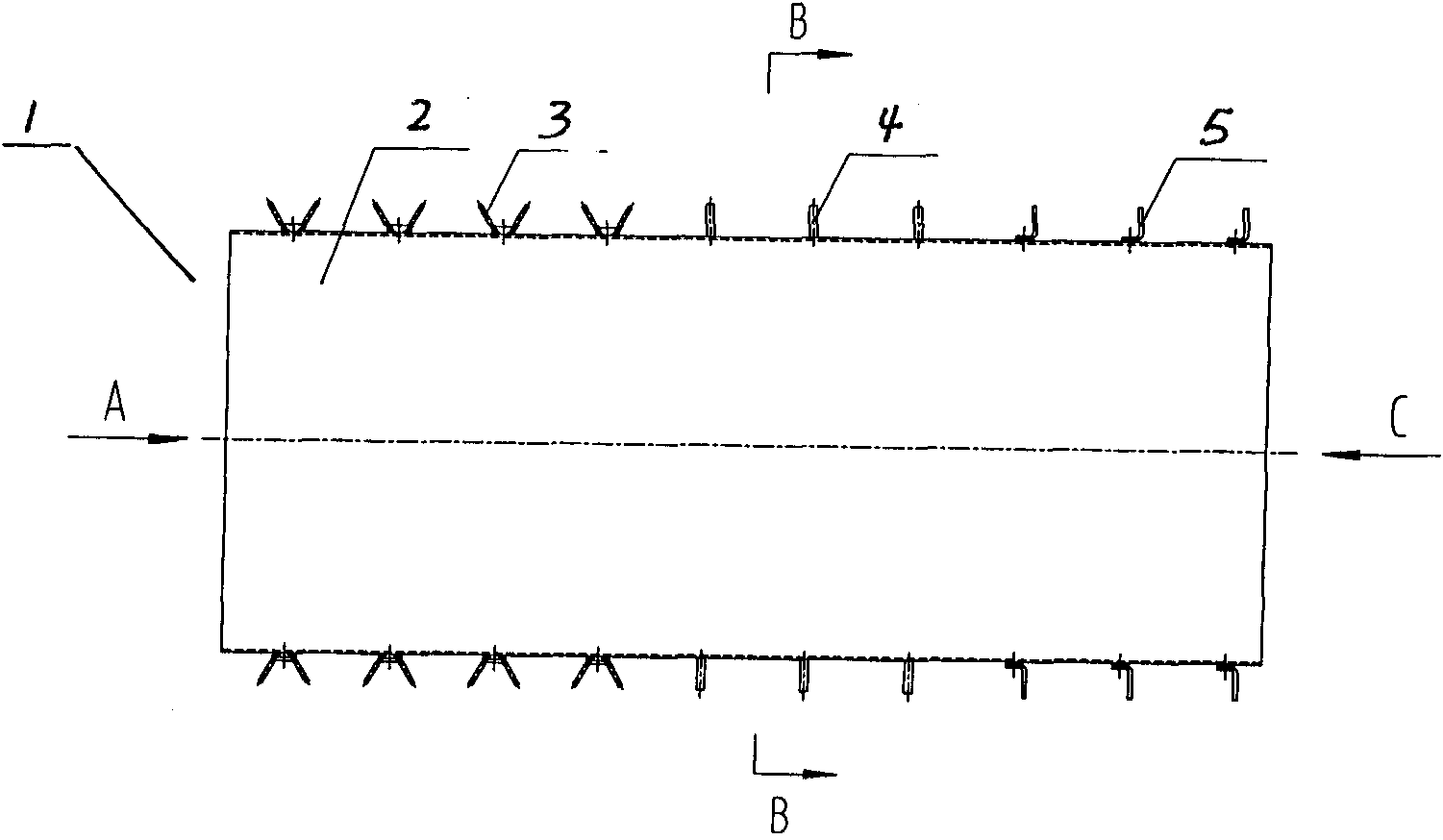

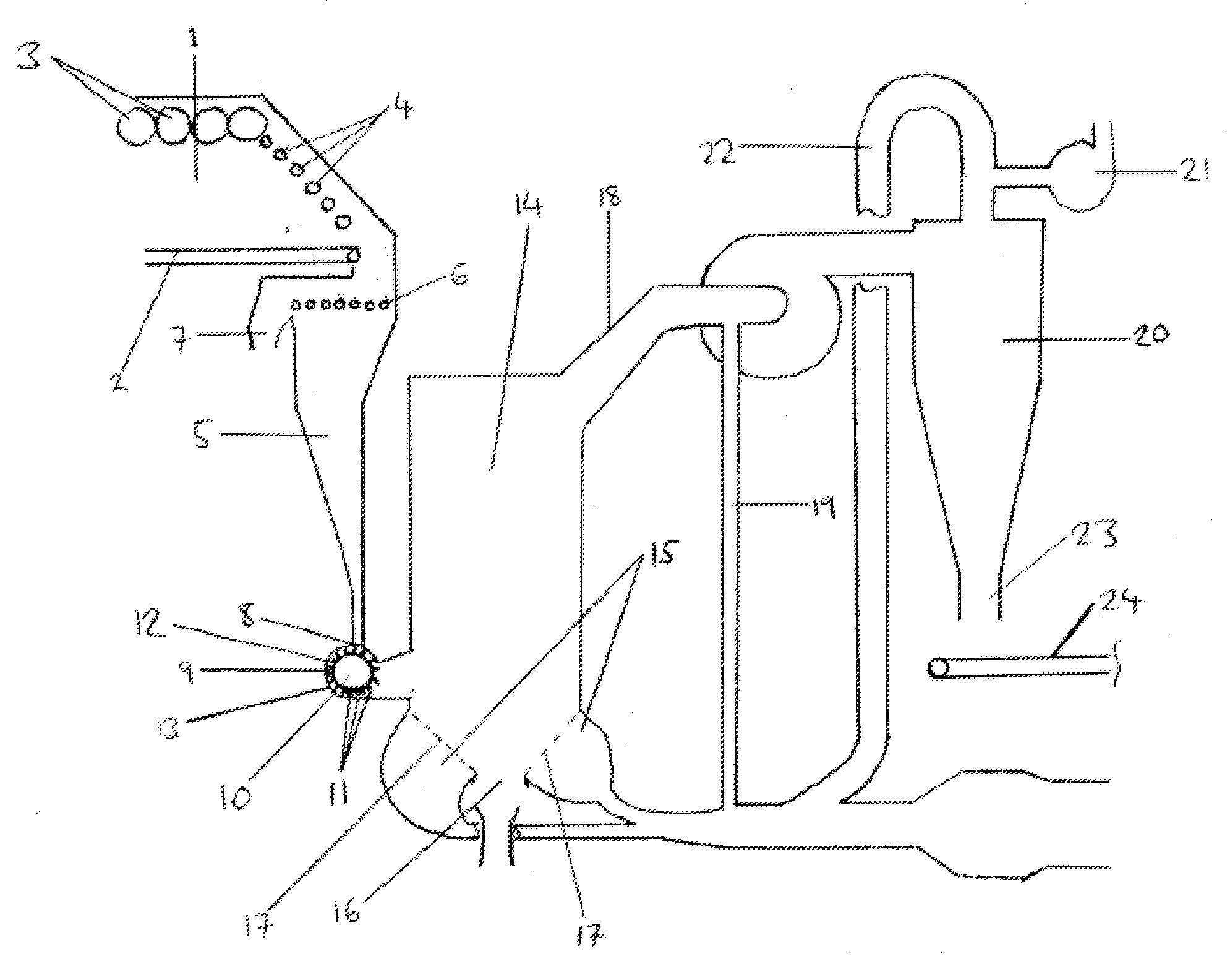

Opening and cleaning method for axial flow opener for opening picking or blowing carding process and special composite beater device thereof

ActiveCN101812745AMeet free strikeSatisfy the weak first and then the strongFibre cleaning/opening by toothed membersFibre cleaning/opening machinesState of artFiber

The invention provides an opening and cleaning method for an axial flow opener for opening picking or blowing carding process, and a special composite beater device. The method comprises the step that a cotton block to be opened makes spiral movement along beaters under common action of the beaters and air flow after the cotton block to be opened is fed into a beater chamber. The method is characterized in that the cotton block is subjected to opening and cleaning in different beating modes in turns when the cotton block makes spiral movement from a cotton inlet to a cotton outlet. The special composite beater device comprises beater cylinders, and is characterized in that the beater cylinders are provided with a blade region, a bar-shaped brad region and a V-shaped brad region in sequence from the inlet end to the outlet end. A reducing mode that the beater outer diameter is reduced from the inlet to the outlet in turns is adopted, so distances between beaters and grid bars are increased from the inlet to the outlet in turns to adapt to the condition that the cotton block is gradually opened and expanded in the forwarding process. The method has reasonable opening mode, high cleaning efficiency and fiber destruction prevention, and achieves the effect of developing strong points and avoiding weak points compared with the prior art.

Owner:CHTC HEAVY IND +1

Cotton cleaning machine

InactiveCN105019061AEfficient removalThe opening process is sufficientFibre cleaning/opening by air draught arrangementsFibre cleaning/opening by toothed membersFiberPulp and paper industry

The invention provides a cotton cleaning machine, comprising a cotton loosening device and an impurity removing device, wherein the cotton loosening device comprises a first cotton loosening chamber and a second cotton loosening chamber, a feed port is formed in the top of the first cotton loosening chamber, a needle licker-in is arranged inside the first cotton loosening chamber, the second cotton loosening chamber is arranged at the bottom of the first cotton loosening chamber, a breaking roller is arranged inside the second cotton loosening chamber, an outlet is formed in the bottom of the second cotton loosening chamber and communicated with the impurity removing device, the left side of the impurity removing device is connected with a draught fan, a discharge port is formed in the right side of the impurity removing device, and a filter screen and a sundry box are sequentially arranged at the bottom of the impurity removing device from top to bottom. The cotton cleaning machine has the advantages that after being primarily loosened through the needle licker-in in the first cotton loosening chamber, cotton bales enter the second cotton loosening chamber to be secondarily loosened through the breaking roller, and therefore the cotton loosening process is more sufficient; moreover, impurities are removed through air flow, impurities mixed in cotton fibers are effectively removed, and therefore cotton bundles suitable for spinning are obtained.

Owner:TIANJIN JINGLONG TEXTILE RUBBER

Novel scutcher

ActiveCN105970361ASufficiency of increase or decreaseQuality improvementFibre cleaning/opening by toothed membersFibre cleaning/opening machinesEngineering

The invention provides a novel scutcher. The novel scutcher comprises a scutching box, an initial scutching mechanism, a fine scutching mechanism and a dust removal mechanism. A feed port, a discharge port and an impurity output opening are formed in one side of the scutching box. The initial scutching mechanism comprises at least two small hitting rollers and a cotton guide plate. Prods are arranged on the small hitting rollers. The cotton guide plate is obliquely installed in the scutching box. Multiple impurity guide holes are obliquely formed in the cotton guide plate. The fine scutching mechanism comprises a cotton output plate, a dust removal knife, a large hitting roller and a cotton return plate. A prod is arranged on the large hitting roller. The dust removal mechanism comprises a dust removal cover, a dust removal box and a draught fan. The dust removal cover is communicated with the upper end of the scutching box. The communicating positions of the dust removal cover and the scutching box are located on the two sides of the large hitting roller, the dust removal cover is in pipeline communication with the dust removal box, the dust removal box is in pipeline communication with an air inlet of the draught fan, an outlet of the draught fan is communicated with the scutching box, and the communicating position of the air outlet of the draught fan and the scutching box and the discharge port are located in the same side of the scutching box, and the communicating position is located below the discharge port. Cotton bales can be efficiently subjected to disassembly, impurity removal and dust removal.

Owner:WANGJIANG RUNHUA TEXTILE

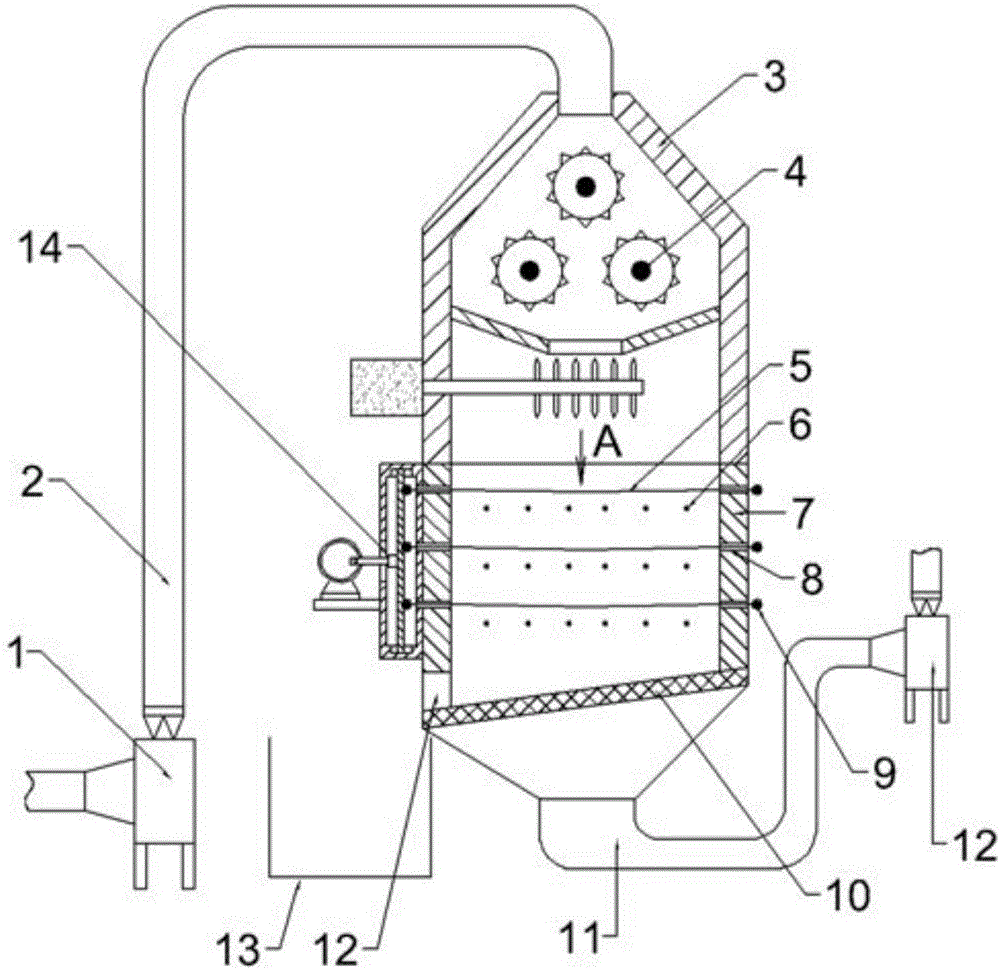

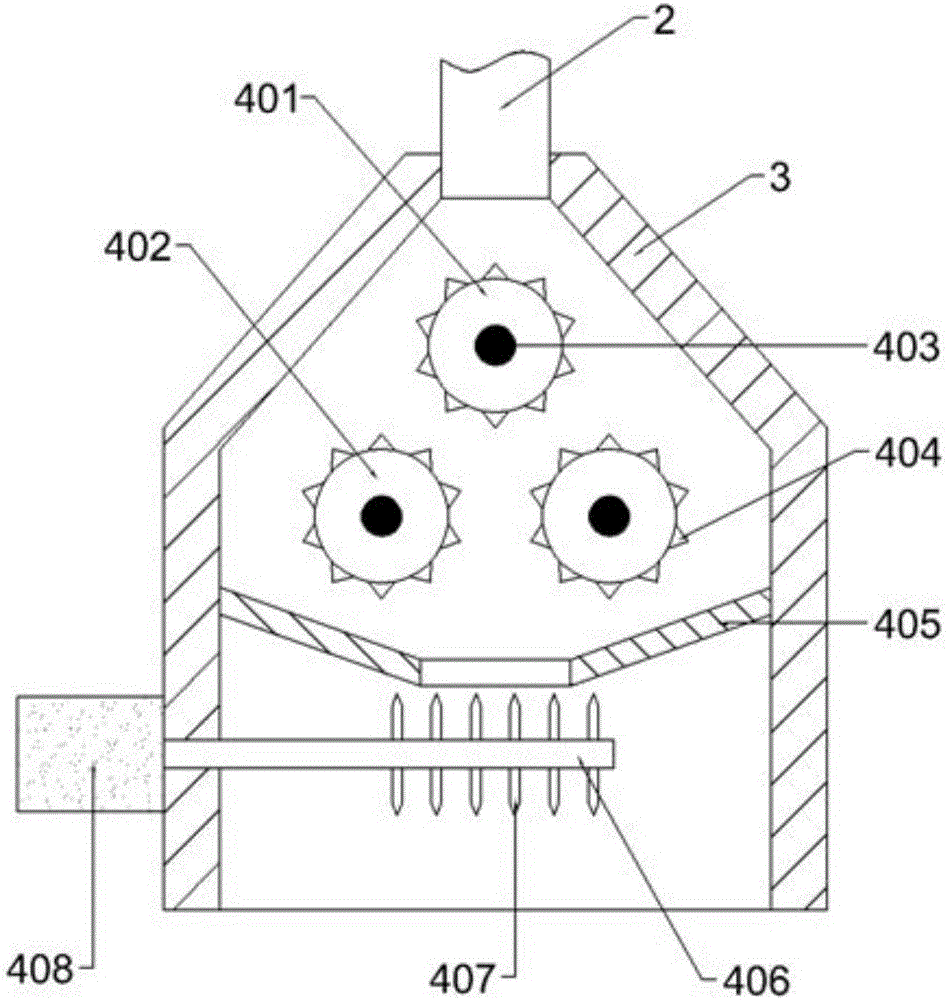

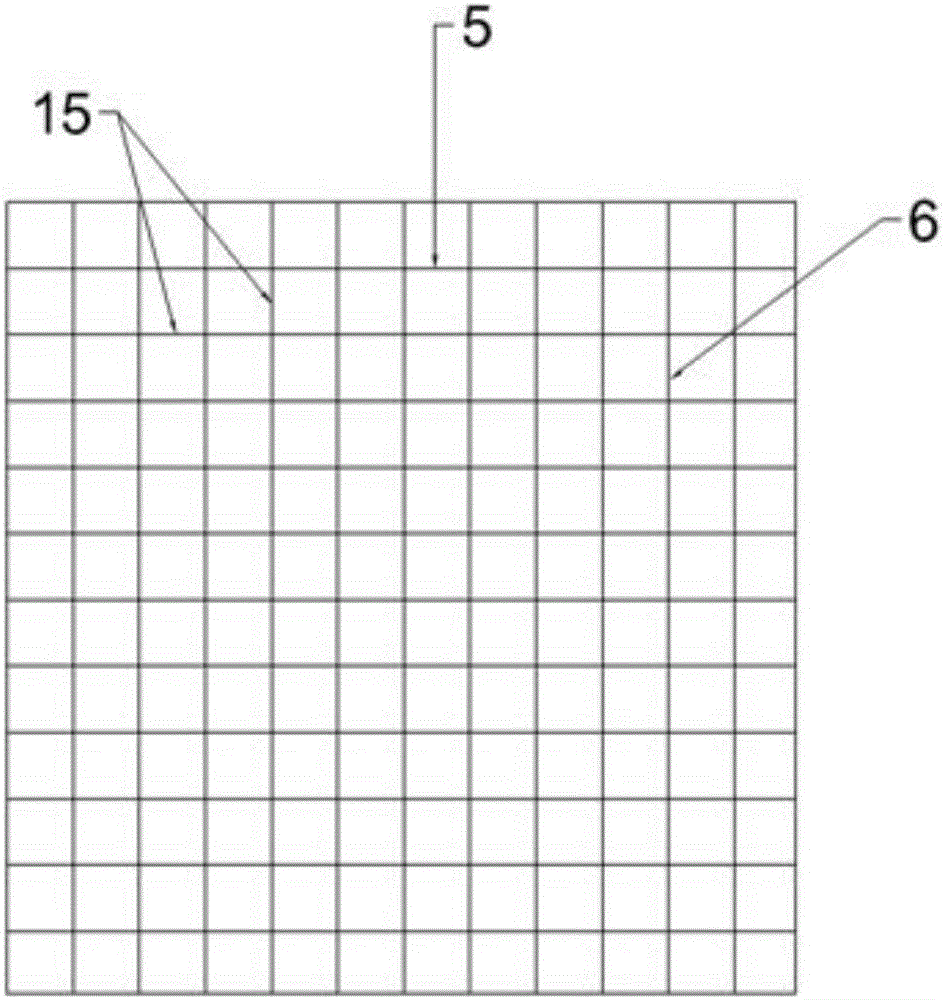

Fiber opening equipment

InactiveCN106835370AReduce damageImprove the opening effectFibre cleaning/opening by toothed membersFibre cleaning/opening machinesFiberEngineering

The invention relates to a fiber opening device, comprising a cotton conveying fan, a conveying pipeline and a pre-opening box, the cotton conveying fan is connected to the top of the pre-opening box through a conveying pipeline, and the pre-opening box is an upper small The lower large round table and cylinder are composed of a pre-opening device in the pre-opening box; the lower end of the pre-opening box is fixedly connected with the opening box, and several layers of left and right vibrating opening layers are arranged in the opening box. A front and rear vibration opening layer is arranged below the left and right vibration opening layer. The beneficial effect of the present invention is that a pre-opening device is provided to pre-open the fiber raw materials, which improves the opening effect of the fiber raw materials; the vibration device is used to realize the oscillating wave on the silk thread, and quickly bounces the fiber raw materials, so that the fibers are fully Opening reduces the degree of damage to fibers. The invention has the advantages of reasonable structural design, convenient use, good opening effect, etc., and has certain popularization and application value.

Owner:安徽谢佑圣电子科技有限公司

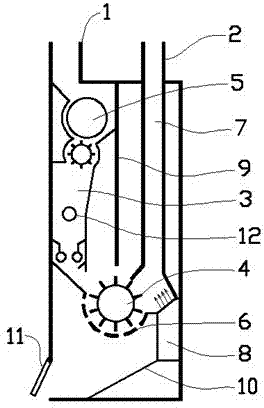

Jute fiber loosening machine

InactiveCN1904160AImprove picking efficiencyLabor savingFibre cleaning/opening by toothed membersMechanical fibre separationTextile fiberWorking environment

A hemp fiber loosing machine. It includes: rack, loose bowl body, loose roller, hopper, yummy treats roller. Merits: drips yard lumber by the hopper introduction hemp textile fiber to drip to yummy treats roller, by digs up on loose roller, the rabble blade dig up pine effectively, draws out after the discharge hole, the entire process cannot create textile fiber rips pounds smashing destruction; The yummy treats roller, ferment roller, loose roller assuming the whole disposes from the top downward, making use of the advantage of digging up in the loose roller rabble blade efficiency, it does not carry on loose hemp artificially, saves labor and improves work environment. It can also reduce time for drying, and conserves energy above 25%.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

System and method for the separation of bast fibers

InactiveUS8075735B2Efficient separationSoftening of outer bastFibre cleaning/opening by toothed membersWood working apparatusFiberScreening method

The present invention relates generally to the timber products industry, and particularly to methods and apparatus for the separation of bast fibers. More particularly, the present invention relates to methods and apparatus for use in the separation of inner core from outer bast of bast plants using soaking, cutting, and scrimming methods and apparatuses.

Owner:TIMTEK

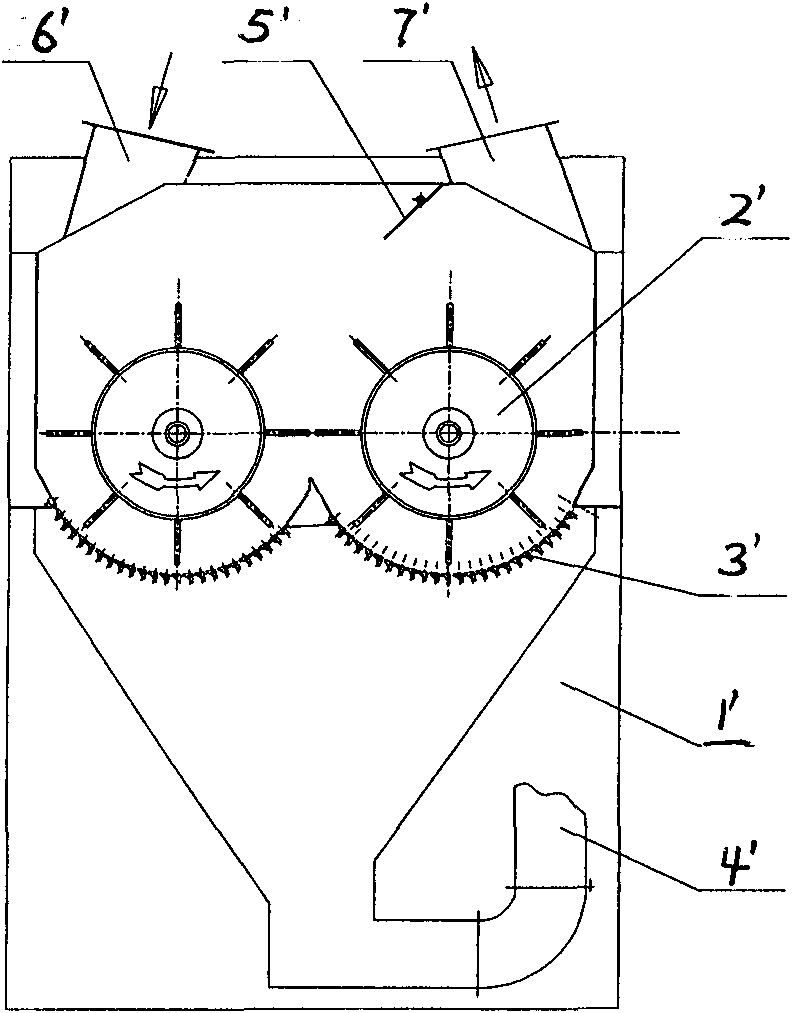

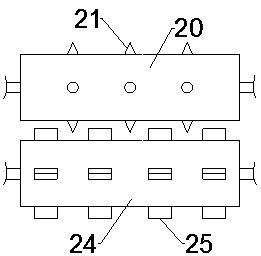

Opening and picking machine

ActiveCN105155043ASimple structureEasy to implementFibre cleaning/opening by toothed membersFibre cleaning/opening machinesYarnAir volume

The invention provides an opening and picking machine and belongs to the technical field of weaving equipment. The opening and picking machine comprises a housing having a cavity. A feeding port communicated with the cavity is formed in the upper end of the housing; two horizontally arranged breaking rollers are rotationally connected in the cavity; a needling roller is arranged under the breaking rollers; a motor driving the breaking rollers and the needling rollers to rotate at the same time is fixed on the outer wall of the housing; the lower end of the housing is in a trapezoidal shape; a first air inlet is formed in the bottom of the housing; a discharging port and a second air inlet are formed in the side wall of the housing; the discharging port faces the second air inlet; the air inlet part is provided with an air inlet pipe connected with the cavity, and a first air draught fan; one end of the air inlet pipe extends into the housing; an outlet end of the air inlet pipeline in the cavity is sealed and a lateral air exhaust port is arranged on the side part of the outlet end; an adjusting structure adjusting air volume is arranged on the lateral air exhaust port; and the second air inlet is provided with a second air draught fan. Product quality can be controlled and suitability of products to the market can be enhanced; and cotton yarn waste in the opening and picking machine can be reduced.

Owner:东营慈母坊家纺有限责任公司

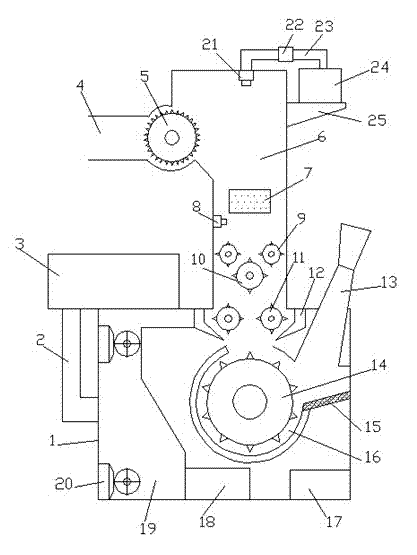

Comb needle cotton slitting machine

PendingCN107164846AWon't hurtAvoid cloggingFibre cleaning and opening machine combinationsFibre cleaning/opening by toothed membersFiberEngineering

The invention discloses a comb needle cotton slitting machine which comprises a cotton condenser, a transfer cotton box and a cotton outlet box; a dust cage and a cotton stripping beater are arranged in the cotton condenser; the transfer cotton box is provided with a cotton conveying channel; the cotton outlet box comprises a woolen roller, a cotton feeding roller, a comb needle beater, a flow guide plate, a dust removal device and a cotton outlet channel; the cotton feeding roller is arranged under the wooden roller; the comb needle beater is arranged under the cotton feeding roller, and dust grids are arranged outside three fourths of circumference of the comb needle beater; the cotton outlet channel is formed above the flow guide plate; the dust removal device comprises a vibrating sieve, a conveying belt and a dust collector and is arranged under the comb needle beater; the vibrating sieve is arranged above the conveying belt; the dust collector is arranged at one end of the conveying belt. The comb needle cotton slitting machine disclosed by the embodiment of the invention has the benefits that with the adoption of the comb needle beater, fibers cannot be damaged; small particle of dust passing through the vibrating sieve can be conveyed to the vicinity of the dust collector through the conveying belt; the dust collector can suck dust to ensure inside cleanness of the comb needle cotton slitting machine, and the cleanness of the fibers is ensured.

Owner:NINGXIA RUYI SCIENCE & TECHNOLOGY FASHION INDUSTRY CO LTD

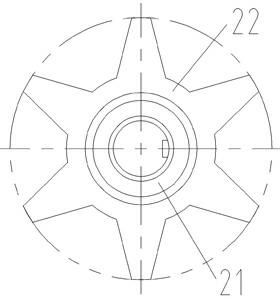

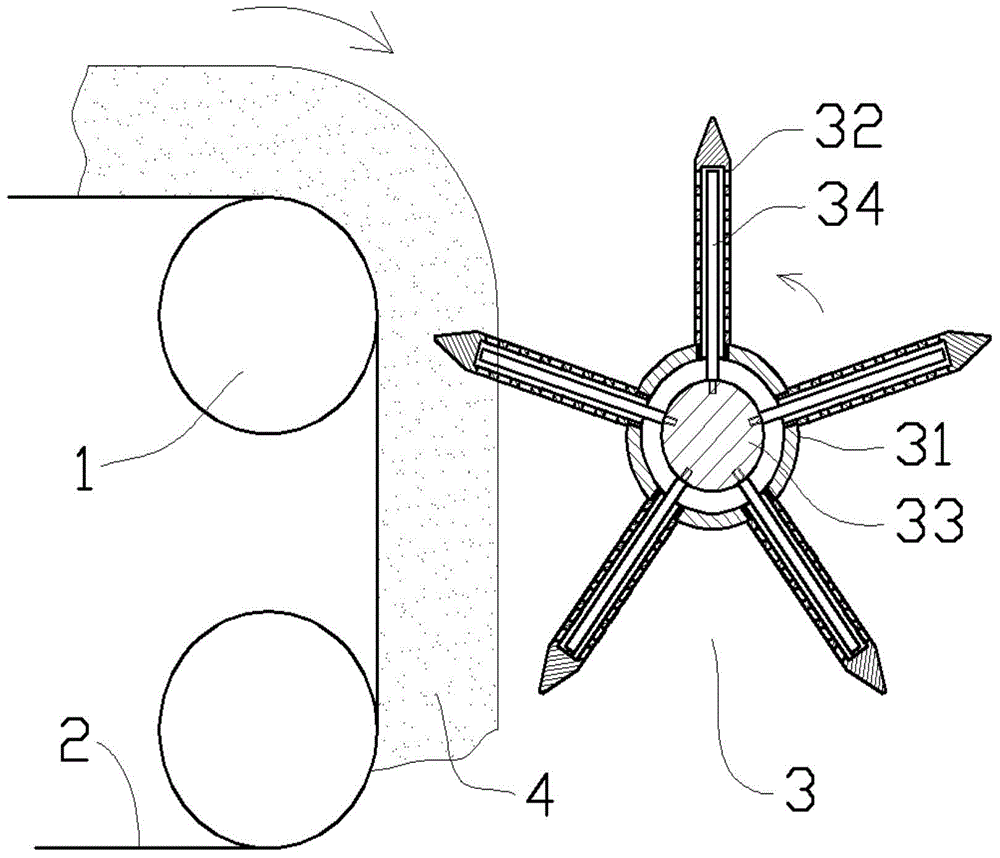

Plucker roller for cotton feeder

ActiveCN102560749AAvoid crossingExtended service lifeFibre cleaning/opening by toothed membersShortest distanceAxial distance

The invention discloses a plucker roller for a cotton feeder capable of easily penetrating through heavy and special impurities, comprising an expansion cylinder, along with the axis O-O direction of the expansion cylinder, a plurality of J corner star-like discs with J tips are sequentially arranged with one another, wherein J is more than or equal to 6 and is less than or equal to 8, the expansion cylinder sequentially penetrates through the centers of the discs, the discs are fixed on the expansion cylinder, an inclined angle between the discs and the axis O-O is alpha, wherein alpha is more than or equal to 60 degrees and is less than or equal to 80 degrees, one point on the axis O-O is taken as a datum point, the leaning directions of the discs at one side of the datum point are just opposite to that of the discs at another side of the datum point, the distance occupied by each disc on the axis O-O is Y, and Y is more than h and is less than Jh / 2, the axial shortest distance Z between the two adjoining discs at the same side of the datum point is less than or equal to h, the axial distance L between the two adjoining discs at the same side of the datum point is equal to Y+Z and is more than 2h, and the beating gas h is less than or equal to 60mm.

Owner:SHANDONG SWAN COTTON INDAL MACHINERY STOCK

Impurity-removal automatic feeding device for carding machine

PendingCN109183205AEfficient removal of impuritiesSimple structureFibre cleaning/opening by air draught arrangementsFibre cleaning and opening machine combinationsDrive wheelEngineering

The invention discloses an impurity-removal automatic feeding device for a carding machine. The device includes an outer box, an inner box, supporting legs, a motor, a stirring shaft, a feeding port,a discharging port, a sliding baffle plate, a spring, a heating wire, an air distribution plate, an induced draft fan and a drying box, wherein the bottom of the outer box is provided with multiple supporting legs, the inner box is located inside the outer box, bottom plates of the inner and outer boxes are overlapped, the motor is arranged on the left side of the outer box, a rotating shaft of the motor penetrates through the outer box and is connected with a driving wheel, the stirring shaft is arranged inside the inner box, a left end of the stirring shaft penetrates through the inner box,the stirring shaft is connected with a driven wheel, the driven wheel and a driving wheel are engaged with each other, the inner box is further provided with the feeding port penetrating through the top of the outer box, the discharging port is arranged below the inner box, the sliding baffle plate is arranged at the discharging port, the spring is arranged between a right end of the sliding baffle plate and the outer box, the air distribution plate is further disposed above the inner box inside the outer box, the air distribution plate is provided with the heating wire, and an air inlet pipeis arranged at a top plate of the outer box above the heating wire.

Owner:湖州萌星服饰有限公司

Method for manufacturing a mineral fiber-containing element and element produced by that method

ActiveUS20120190262A1Consistent and even appearanceEqually distributedFibre cleaning/opening by toothed membersFibre cleaning/opening machinesFiberMaterials science

Owner:ROCKWOOL AS

Metal and dust removing device for cotton

InactiveCN104099690AImprove removal efficiencySimple structureFibre cleaning/opening by air draught arrangementsFibre cleaning/opening by toothed membersEngineeringImpurity

The invention provides a metal and dust removing device for cotton. The metal and dust removing device comprises conveying rollers assembled in an vertical direction, a conveying belt is assembled between the two conveying rollers, a licker-in is assembled on the lateral side in the vertical direction of the conveying belt and comprises a shell, round-pipe-shaped licker-in pipes are uniformly distributed on the shell, the inside of each licker-in pipe is communicated with that of the shell, and the licker-in pipes are vertically fixed on the surface of the shell; a central shaft is assembled on the axis of the shell, magnetic rods entering inside the licker-in pipes are fixed on the central shaft, through holes are uniformly distributed on the surface of each licker-in pipe, an annular cavity is formed between the shell and the central shaft and connected with an air incoming end of a fan through a pipeline, and the shell and the central shaft are driven to synchronously rotate by a transmission device. The metal and dust removing device can remove metal and dust in the process of belt conveying and is simple in structure and high in overall impurity removing efficiency.

Owner:WUJIANG TEXTILE SCI & TECH CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com