Blowing foreign fiber machine with function of spreading

A technology for cleaning foreign fibers and functions, which is applied in the direction of cleaning with toothed tools and cleaning with suction devices, which can solve the problems of incomplete cleaning of small foreign fibers, and achieve ingenious structure, novel concept and opening effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

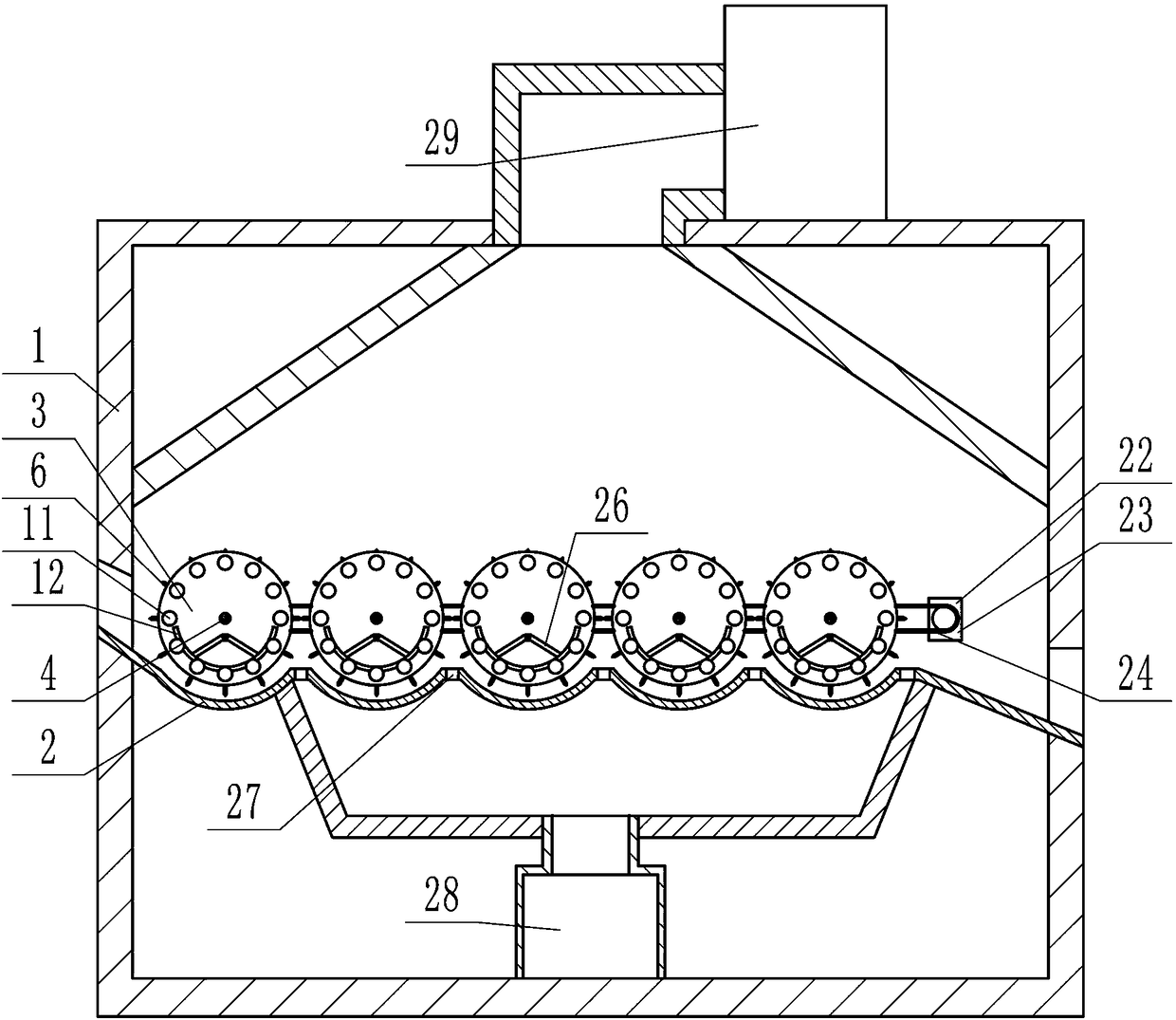

[0016] Depend on Figure 1 to Figure 6 It can be seen that the present invention includes a box body 1, and the box body 1 is provided with a plurality of opening units placed horizontally in the front and rear directions, and the plurality of opening units are arranged at intervals from left to right, and each opening unit is provided with a arc-shaped guide plates 2 arranged at intervals, and multiple guide plates 2 are connected in sequence to form a whole;

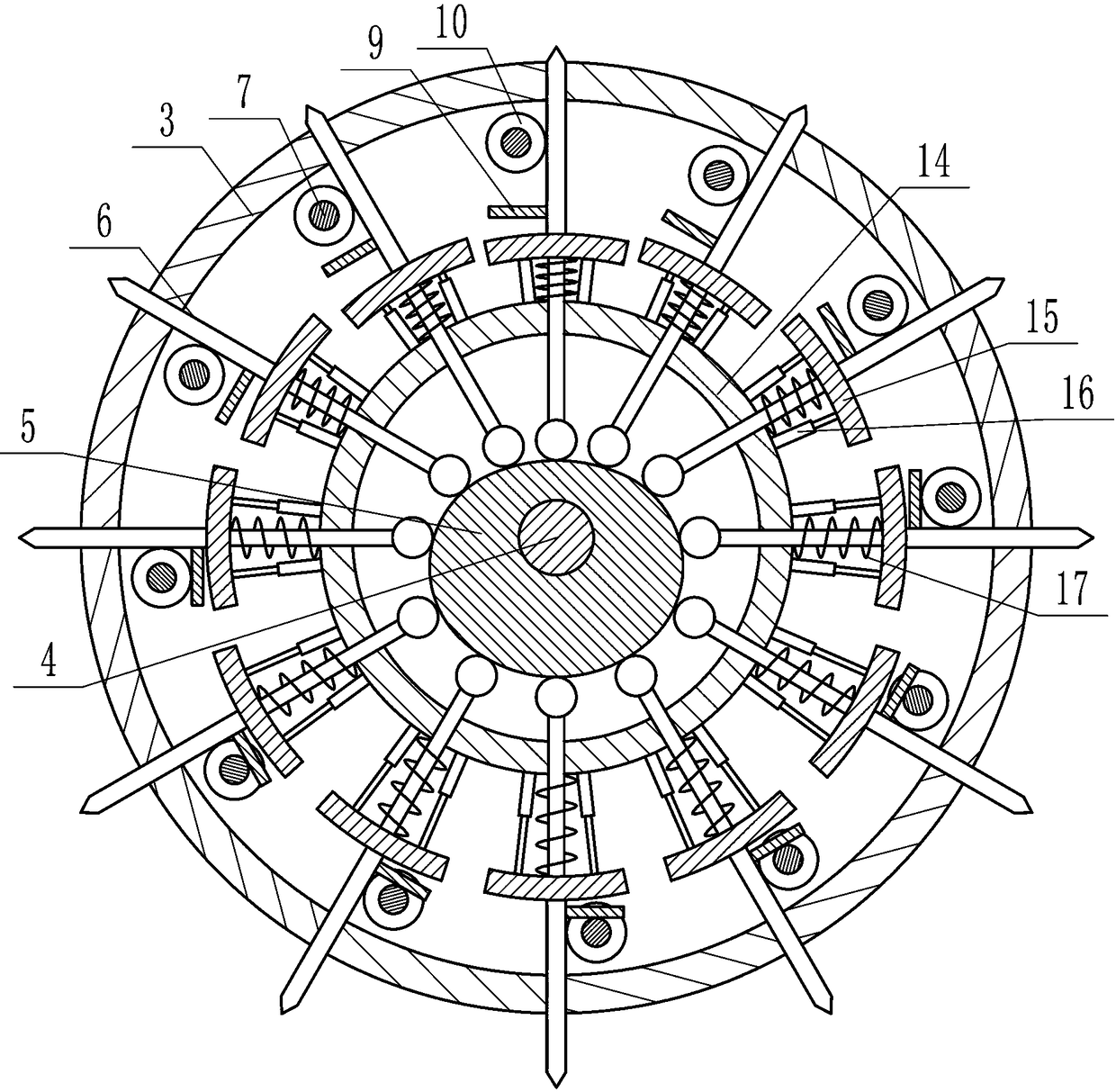

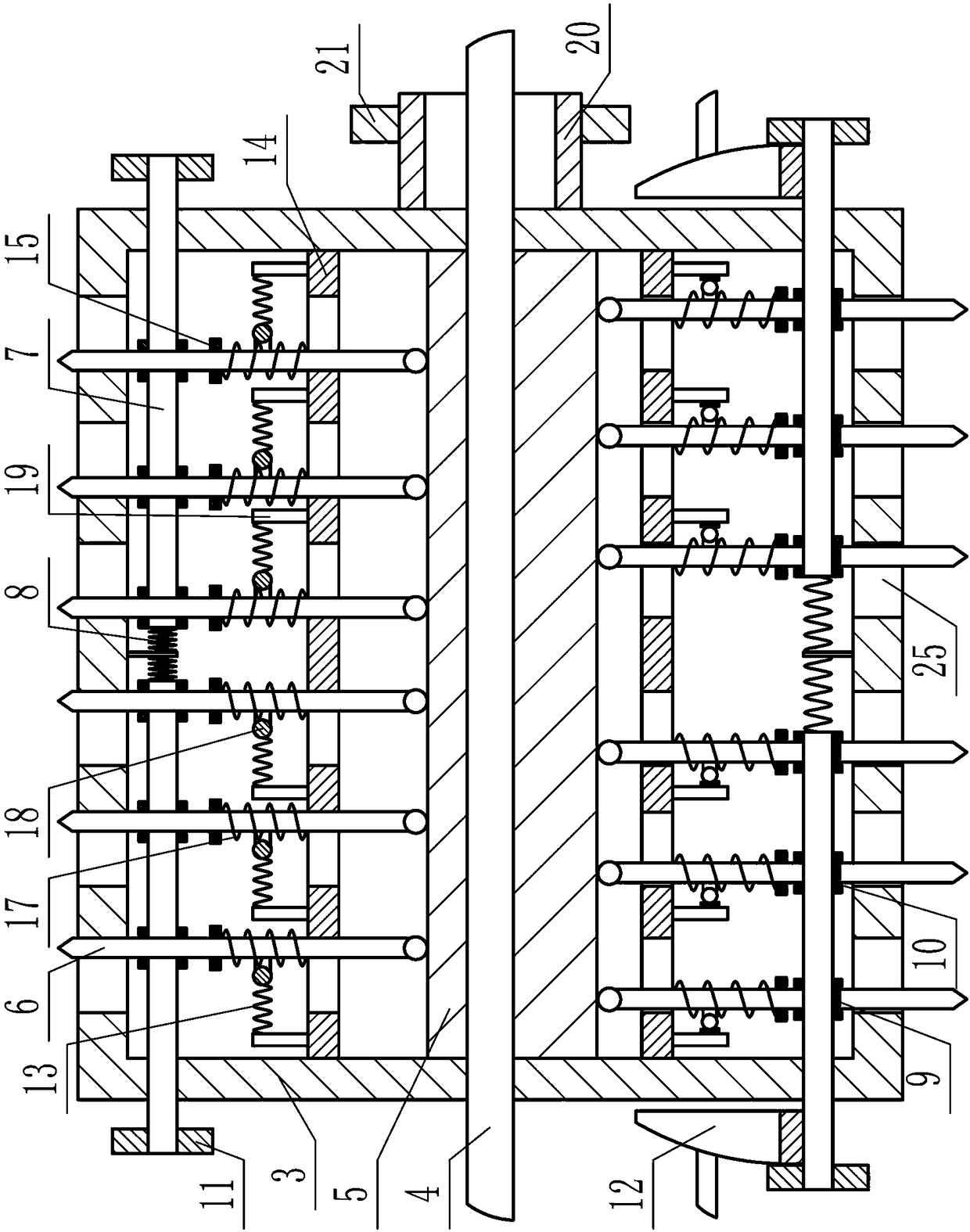

[0017] The opening unit includes a rotatable first cylinder 3 placed horizontally in the front and rear directions, and a fixed shaft 4 coaxially installed and non-rotatable is arranged inside the first cylinder 3, and the two ends of the fixed shaft 4 protrude The first cylinder 3, the part where the fixed shaft 4 is placed in the first cylinder 3 is fixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com