Seed-cotton foreign fiber cleaning machine

A technology for cleaning machines and foreign fibers, applied in the field of cleaning machines, can solve the problems of large running resistance of fans, poor output adaptability, shutdown, etc., and achieve the effects of simple equipment structure, improved cleaning efficiency and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

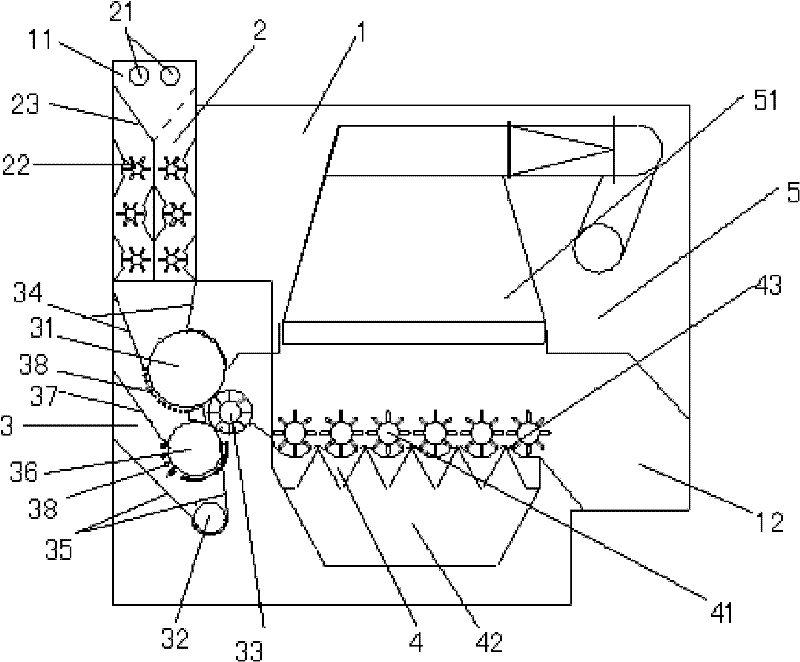

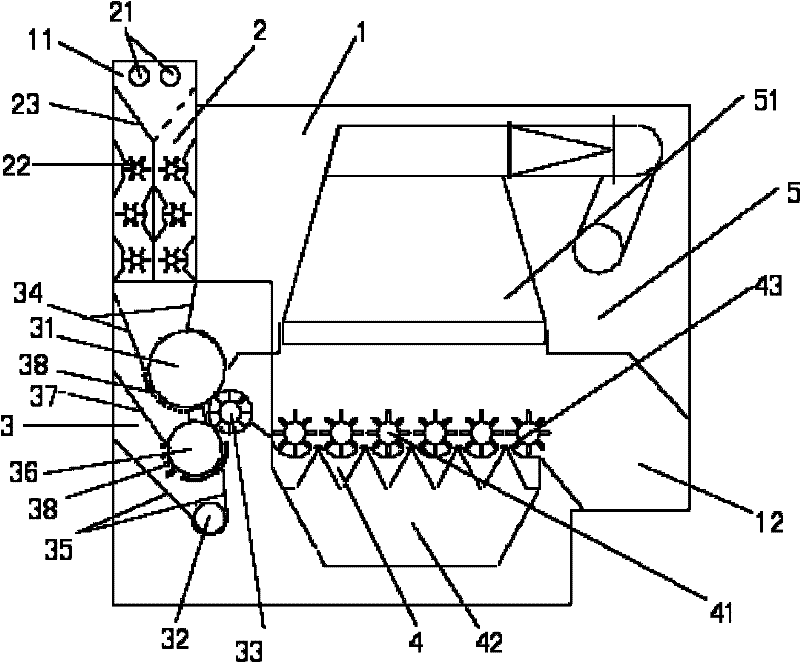

[0011] Such as figure 1 As shown, the present invention includes a box body 1, and in the box body 1, a winding cleaning device 2, a pull-up cleaning device 3, a boiling opening device 4 and a wind cleaning device 5 are arranged.

[0012] The winding cleaning device 2 of the present invention comprises two flower feeding rollers 21 arranged at the entrance 11 of the box body 1, and two groups of winding rollers 22 arranged in two channels are arranged below the two flower feeding rollers 21, and the two groups of winding rollers 22 An adjustment plate 23 is arranged at the passage boundary of the channel, and the adjustment adjustment plate 23 can close the channel of one group of winding rollers 22, so that the channel of the other group of winding rollers 22 is in an open state.

[0013] The net cleaning device 3 of hook pulling of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com