Metal and dust removing device for cotton

A technology for metal dust and cotton, applied in the field of cotton metal dust impurity removal device, can solve the problems of high impurity removal cost, low impurity removal efficiency, affecting cotton quality, etc., and achieves the effect of simple structure and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

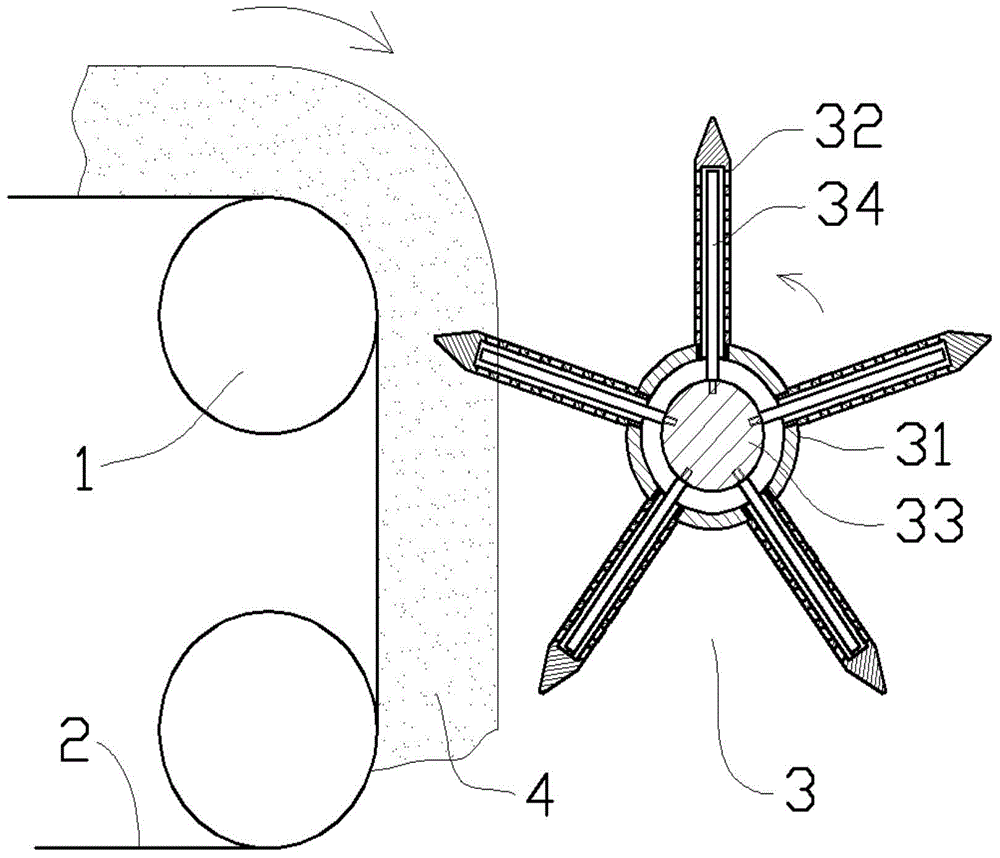

[0009] Such as figure 1 As shown in the embodiment, the cotton metal dust removal device includes a conveyor roller 1 assembled up and down, a conveyor belt 2 is installed between the two conveyor rollers 1, and the vertical side of the conveyor belt 2 is equipped with a conveyor belt parallel to the conveyor roller 1. The licker-in roller 3, the licker-in roller 3 comprises a drum-shaped housing 31, the housing 31 is provided with a circular tube-shaped stabbing tube 32, and the inside of the stabbing tube 32 communicates with the inside of the housing 31, The thorn tube 32 is vertically fixed on the surface of the housing 31, and the housing 31 is equipped with a central shaft 33 on the axis, and the central shaft 33 is fixed with a magnetic bar 34 that goes deep into the inside of the thorn tube 32. Through holes are evenly distributed on the surface of the thorn tube 32 , and an annular cavity is formed between the housing 31 and the central shaft 33 , and the annular cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com