Method for removing metal ions from aqueous solution by use of hydrotalcite

A technology of metal ions and heavy metal ions, applied in the field of water treatment, can solve the problems of weak mechanical strength of adsorbents, low removal efficiency, poor chemical stability, etc., to improve the surrounding environment, high economic and social benefits, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

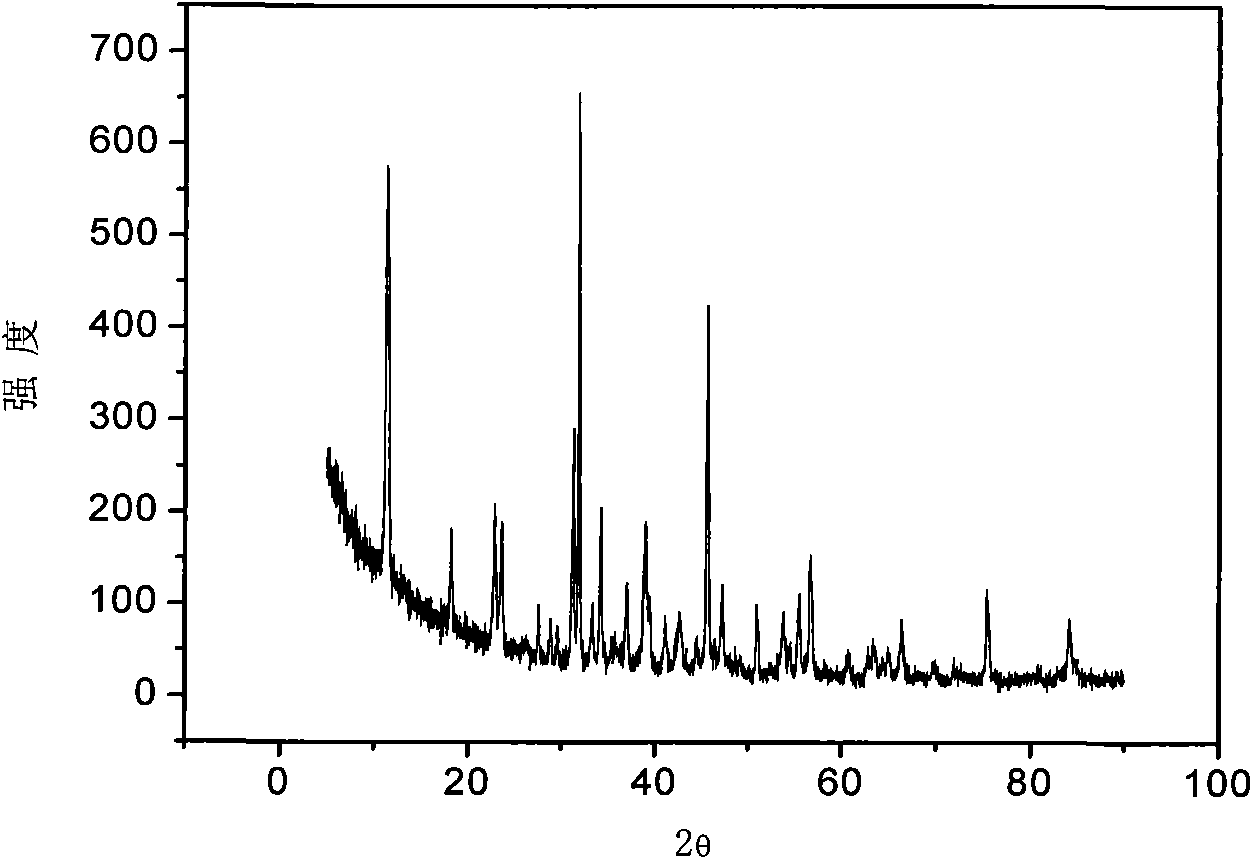

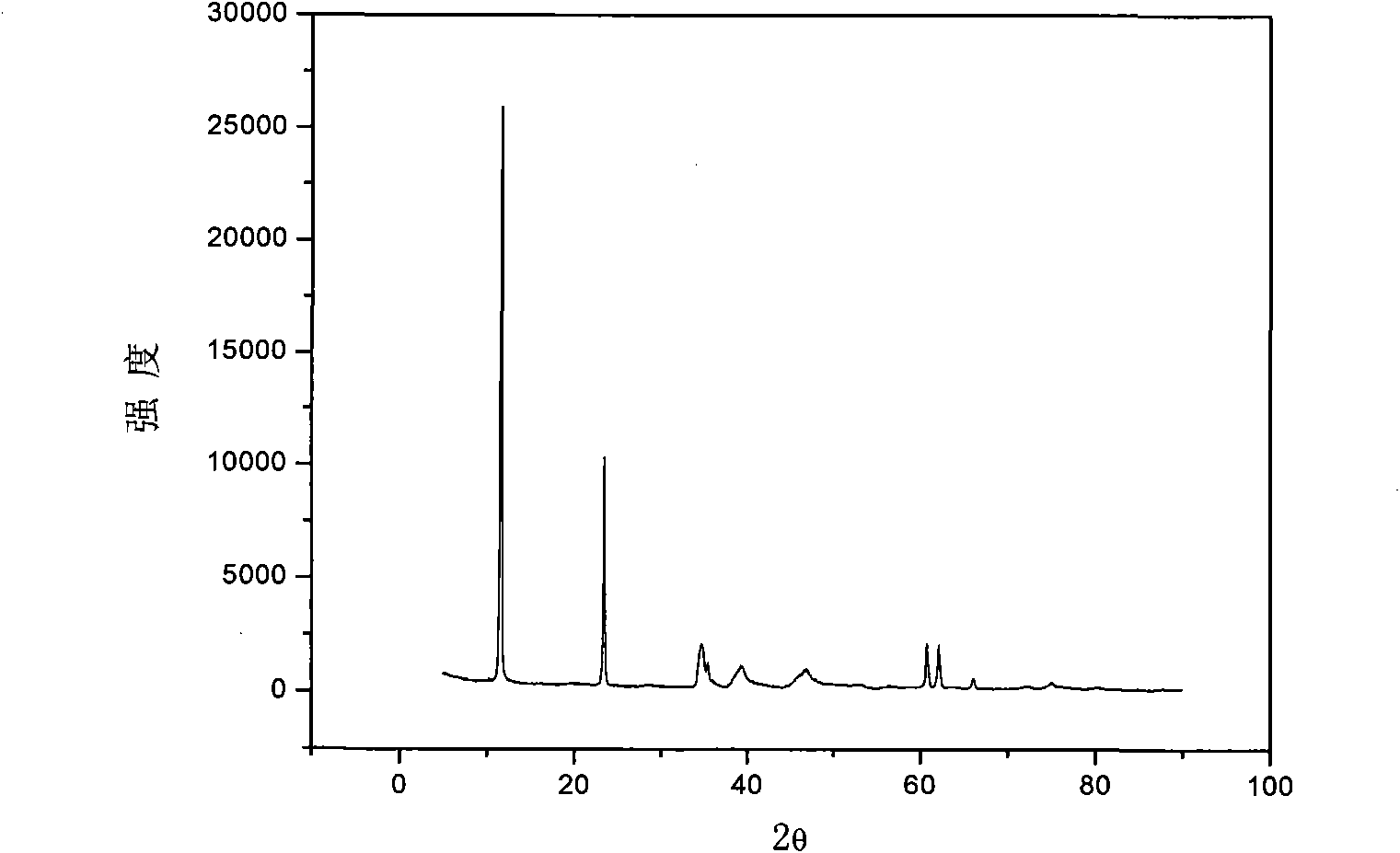

Image

Examples

Embodiment 1

[0035] (1) the by-product calcium chloride in the soda ash industry is dissolved in water, is made into the solution A that concentration is 0.5mol / L;

[0036] (2) Add sodium hydroxide and aluminum hydroxide to water, heat to dissolve sodium hydroxide and aluminum hydroxide to obtain sodium aluminate solution B; wherein, Na in the sodium aluminate solution 2 O and Al 2 o 3 The molar ratio of is 1.5;

[0037] (3) 300ml of solution B prepared in step (2) is added in the reaction tank with jacket, and in the jacket of the reaction tank with jacket, pass into a circulating oil bath, and the temperature of solution B is adjusted to 30 ℃, under the stirring speed of 200rpm, add 300ml of solution A prepared in step (1) into the reaction tank, and control the ratio of calcium chloride and sodium aluminate in the mixed solution of calcium chloride and sodium aluminate in the reaction tank. The molar ratio was 8, the reaction temperature was controlled at 30°C, and the feeding rate o...

Embodiment 2

[0043] Get some underground drinking water (the content of detected As is 2.3ppm) 500mL in the reactor tank with jacket, get the dry calcium aluminum hydrotalcite 0.5g that embodiment 1 step (4) obtains and join in the reactor, in After stirring (200 rpm) at 25°C for 20 minutes, no As was found in the aqueous solution.

Embodiment 3

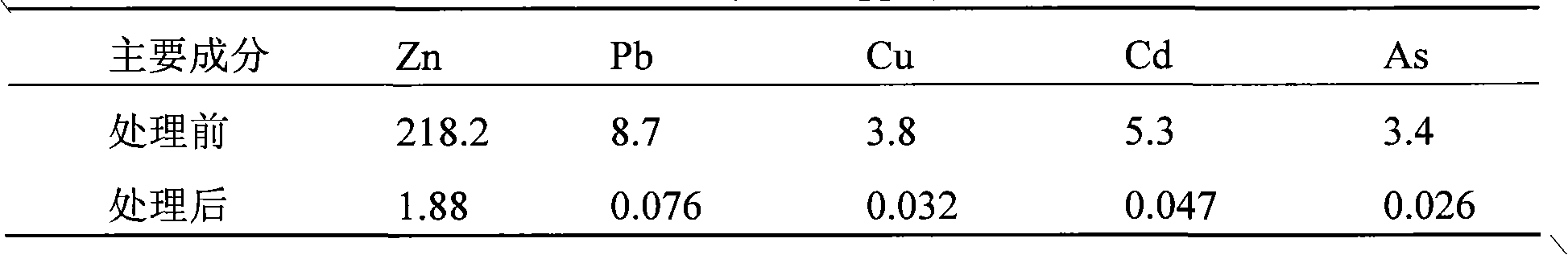

[0045] Get 500mL of tailings water from a uranium mine in Jiangxi (see Table 2 for composition) in a jacketed reaction tank, first use alkaline solution to adjust the waste water to weak alkalinity, then get the dry calcium that is obtained in Example 1 step (4) Add 2.5g of aluminum hydrotalcite into the reactor, and stir (200rpm) at 45°C for 20 minutes; it is found that the removal rate of Cr, Cd, Mo, Fe, and Mn in the wastewater is above 99%, and the radioactive elements Ra, Th , The removal rate of U is above 90% (Table 2).

[0046] Table 2 Treatment of tailings water from a uranium mine in Jiangxi with calcium aluminum hydrotalcite (unit: ppm)

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com