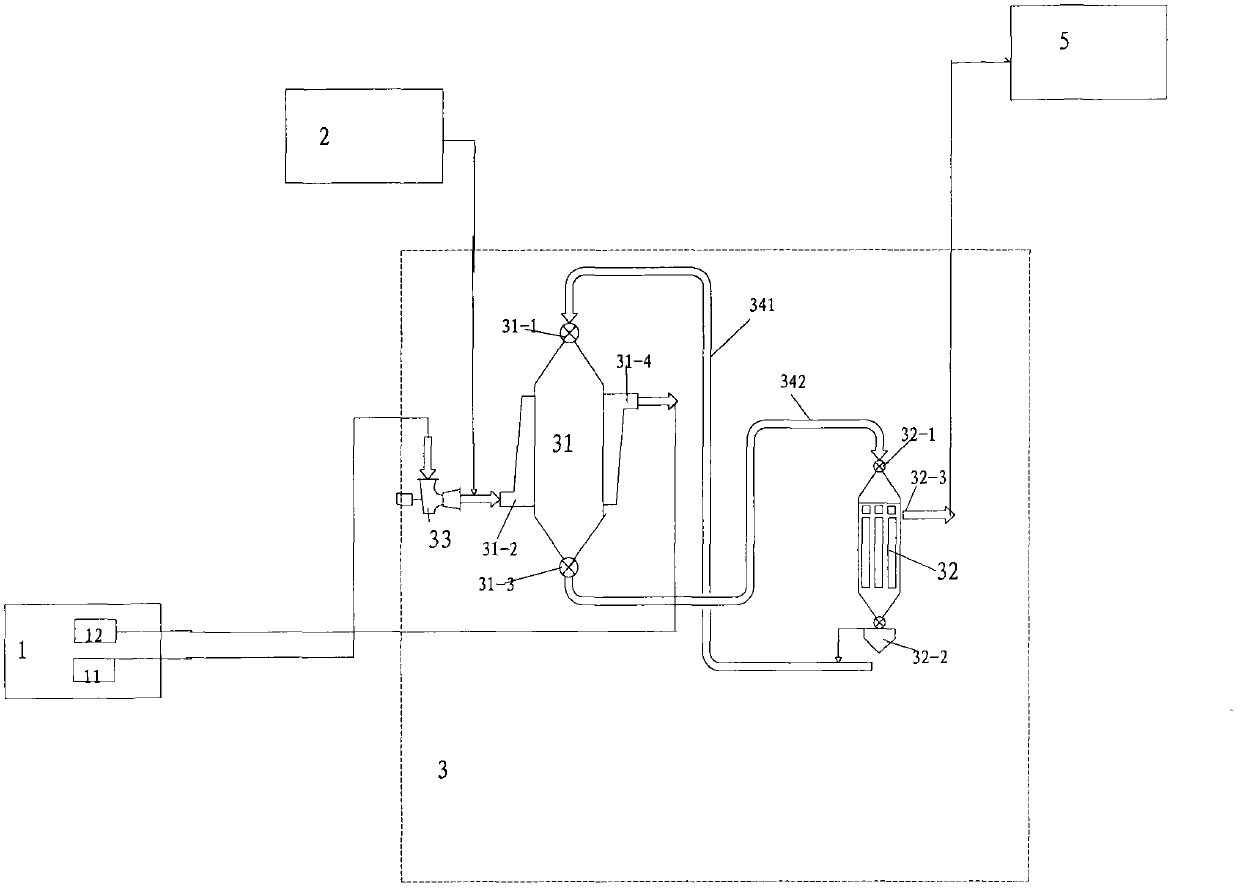

Sintering smoke treatment system and sintering smoke treatment method

A flue gas treatment system and sintering flue gas technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc. Oxygen content is high, achieving the effects of small footprint, low failure rate of equipment operation, and slow operation rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0112] Table 1

[0113]

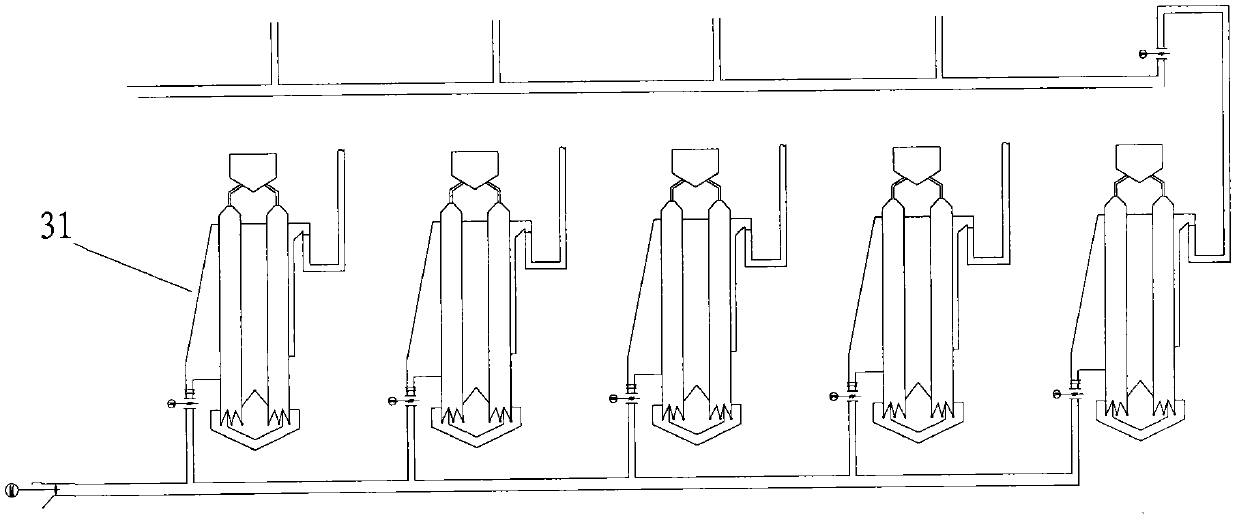

[0114] In this embodiment, six adsorption towers 31 are connected in parallel.

[0115] The sintering flue gas in the sintering machine is led to the air inlet 31-2 of the adsorption tower 31 through the main exhaust fan 11 and the booster fan (adjustable vane axial flow fan) 33, and the outlet pressure of the main exhaust fan 11 is 500Pa. The flow rate of the sintering flue gas at the outlet of the booster fan 33 is 1,865,000m 3 N-wet / h. The above-mentioned sintering flue gas is evenly distributed to six adsorption towers 31 .

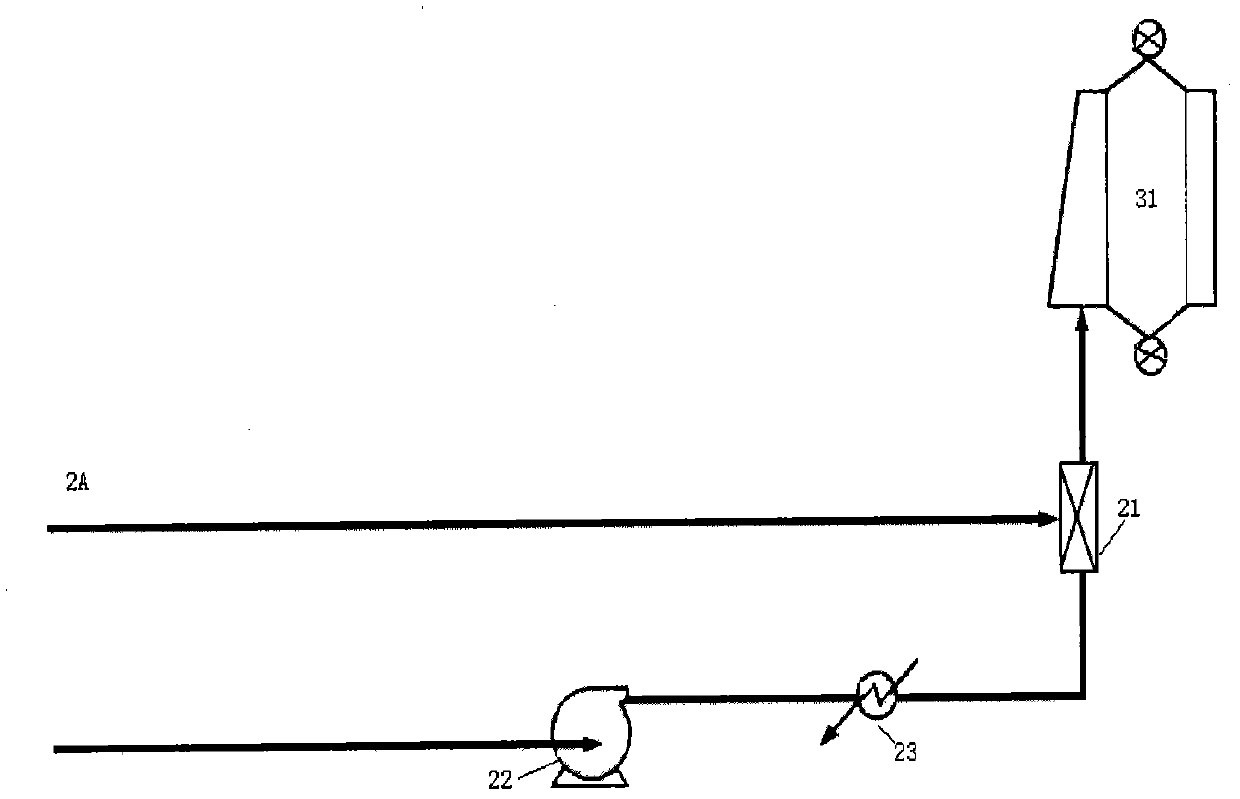

[0116] Gaseous pure ammonia at 150m 3 The flow rate of N / h is sent into the ammonia gas mixer 21, the air is heated to 130°C by the dilution air heater 23, and then the ammonia dilution fan 22 sends the heated air with a flow rate of 6700m 3 N / h is blown into the ammonia gas mixer 21, and ammonia gas is mixed with air in the ammonia gas mixer 21, so that the ammonia gas concentration is reduced to below 5%, and finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com