Filtering dust collector

A dust collector and filtering technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of reduced working efficiency of dust collectors, easy retention on the surface of the filter screen, and easy dust removal. The effect of enhancing the vibration amplitude and the degree of expansion and contraction, maintaining stability and maintaining work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

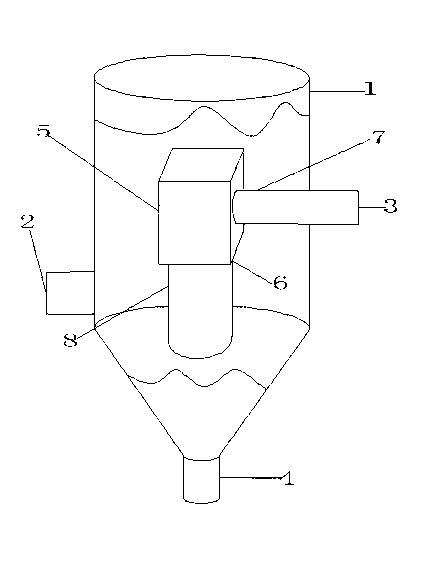

[0032] The structure of filter type dust remover of the present invention is as figure 1 As shown, it includes a housing 1, the upper part of the housing 1 is provided with an air outlet 3, and the lower part of the housing 1 is provided with an air inlet 2, wherein the air outlet 3 and the air inlet 2 can be arranged according to the situation On the side wall on the same side of the housing 1 or on the opposite side wall centered on the axis of the housing 1 , in this embodiment, the air outlet 3 and the air inlet 2 are arranged on the side of the housing 1 On the opposite side wall with the axis as the center; the bottom of the housing 1 is provided with a dust outlet 4, and the dust outlet 4 can be arranged at any position on the bottom of the housing 1 according to the situation. In this embodiment Among them, the dust outlet 4 can be controlled to open and close and is arranged directly below the filter component 8 . A fan 5 and a filter member 8 are fixedly arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com