Anti-aging graphene nanometer environment-friendly modified plastic color master batch and preparation technology thereof

A graphene and anti-aging technology, which is applied in the field of nanomaterials, can solve the problems of expansion flame retardant PPHRR decline, etc., and achieve the effect of improving toughness, improving thermal aging cracking resistance, and simple and scientific preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

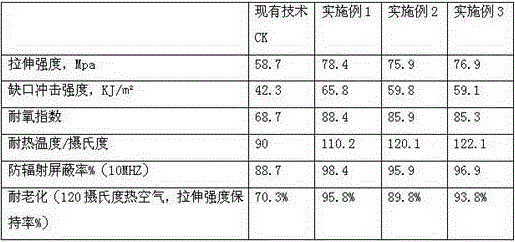

Examples

Embodiment 1

[0020] A kind of anti-aging graphene nano-environmentally friendly modified plastic color masterbatch and its preparation process

[0021] An anti-aging graphene nano-environmentally friendly modified plastic color masterbatch, which includes the composition raw materials: it includes 55 parts by weight of pigment, 15 parts by weight of butylene phthalate, tetrafluoroethylene-hexafluoro 10 parts by weight of propylene copolymer, 10 parts by weight of acrylonitrile-styrene-acrylate copolymer, 60 parts by weight of polycarbonate, 10 parts by weight of nano barium carbonate, 20 parts by weight of aramid short fiber, 2 parts by weight of silicon carbide lamella , 15 parts by weight of polylactic chitosan, 10 parts by weight of nano-graphene, 80 parts by weight of ethylene-vinyl acetate copolymer, 40 parts by weight of high-density polyethylene, 6 parts of pitch-based carbon fiber powder, non-halogenated organic phosphinate 5 parts, 8 parts of hexamethylenetetramine, 2 parts of tri...

Embodiment 2

[0032] A kind of anti-aging graphene nano-environmentally friendly modified plastic color masterbatch and its preparation process

[0033] An anti-aging graphene nano-environmentally friendly modified plastic color masterbatch, which includes the composition raw materials: it includes: 75 parts by weight of pigment, 25 parts by weight of butylene phthalate, tetrafluoroethylene-hexafluoro 15 parts by weight of propylene copolymer, 20 parts by weight of acrylonitrile-styrene-acrylate copolymer, 80 parts by weight of polycarbonate, 15 parts by weight of nano barium carbonate, 25 parts by weight of aramid short fiber, 10 parts by weight of silicon carbide lamella , 20 parts by weight of polylactic chitosan, 15 parts by weight of nano-graphene, 90 parts by weight of ethylene-vinyl acetate copolymer, 50 parts by weight of high-density polyethylene, 8 parts of pitch-based carbon fiber powder, non-halogenated organic phosphinate 7 parts, 10 parts of hexamethylenetetramine, 4 parts of ...

Embodiment 3

[0044] An anti-aging graphene nano-environmentally friendly modified plastic color masterbatch, which includes: 20 parts by weight of butylene phthalate, 12 parts by weight of tetrafluoroethylene-hexafluoropropylene copolymer, acrylonitrile-styrene - 15 parts by weight of acrylate copolymer, 70 parts by weight of polycarbonate, 12 parts by weight of nano-barium carbonate, 22 parts by weight of aramid short fiber, 5 parts by weight of silicon carbide platelet, 18 parts by weight of polylactic chitosan, nano-graphite 12 parts by weight of alkene, 85 parts by weight of ethylene-vinyl acetate copolymer, 45 parts by weight of high-density polyethylene, 60 parts by weight of pigment, 0.4 part by weight of conductive mica powder, 0.3 part by weight of nano-conductive graphite powder, trimer of polyisocyanate 0.9 parts by weight, 33 parts by weight of pitch-based carbon fiber powder, 6 parts by weight of non-halogenated organic phosphinate, 9 parts by weight of hexamethylenetetramine, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com