Patents

Literature

36results about "Mechanical impurity removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

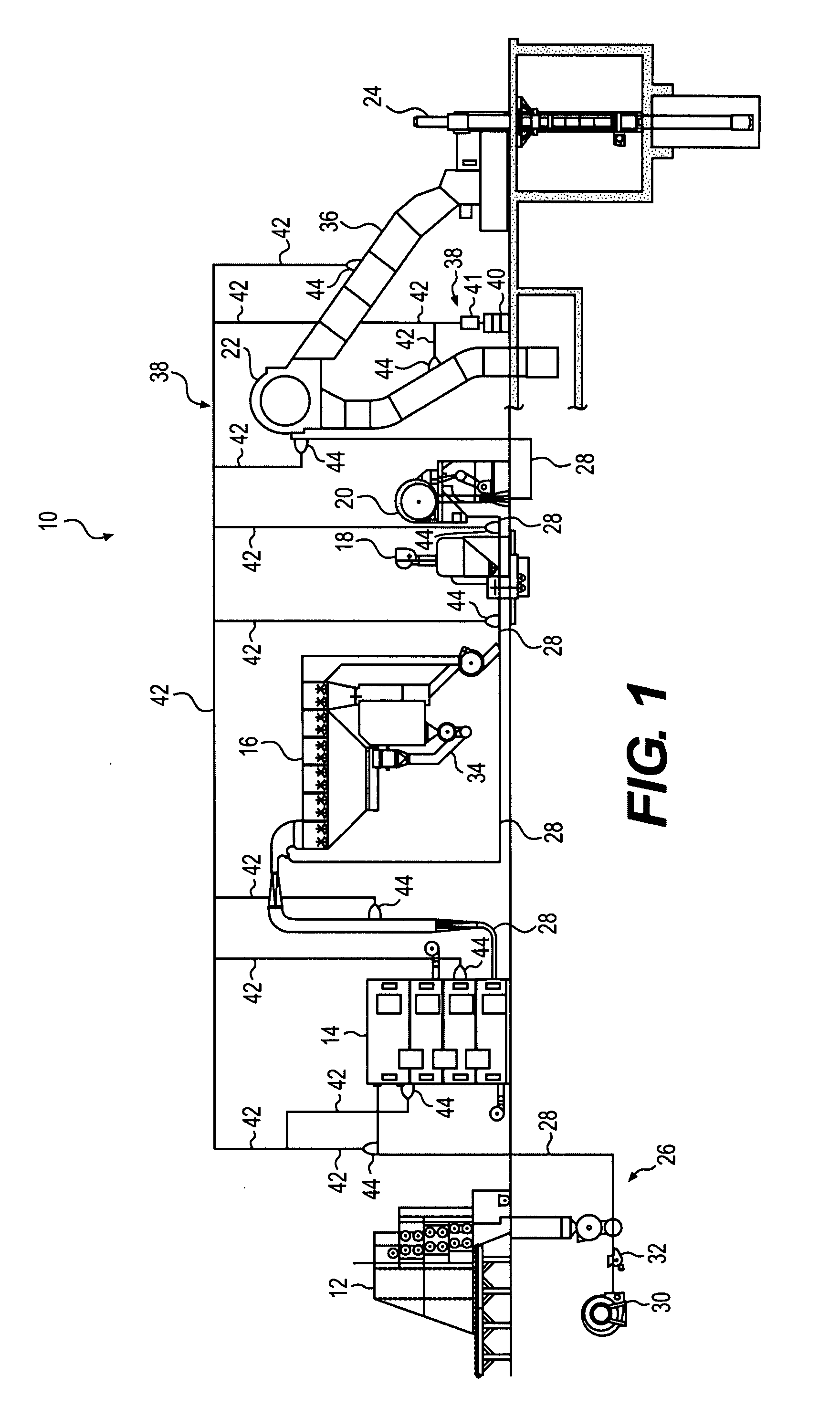

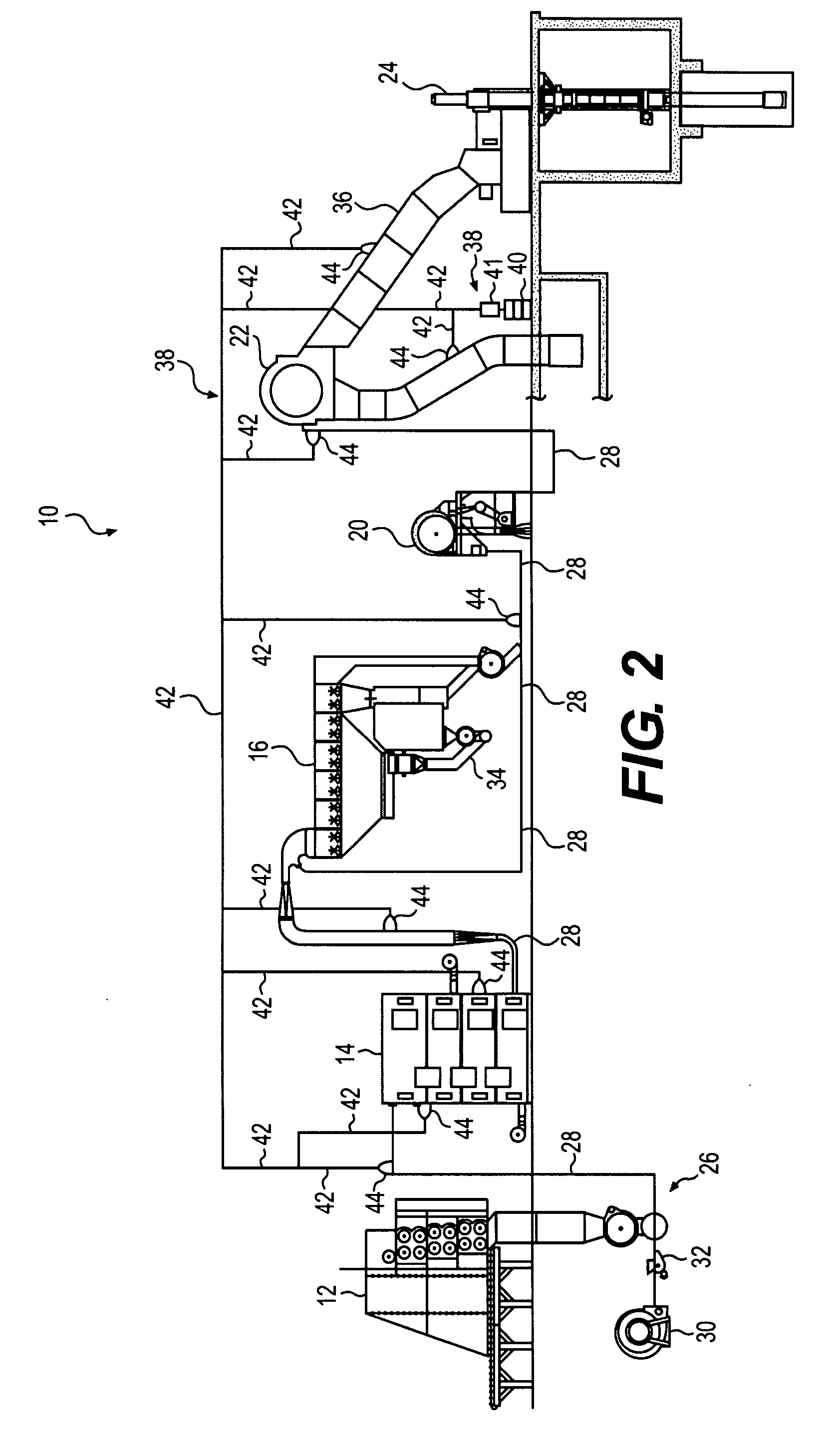

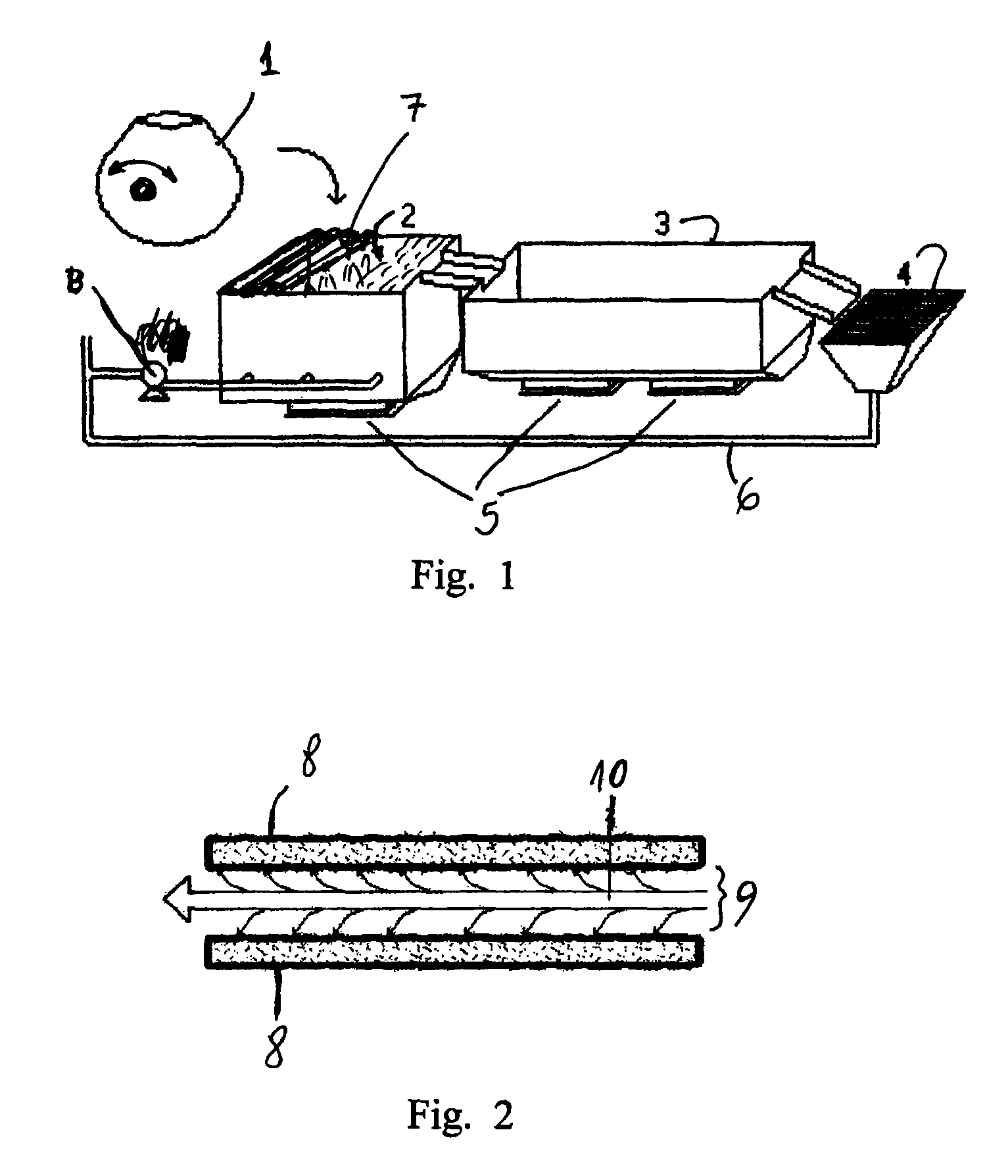

Processing Line of Bast Fiber

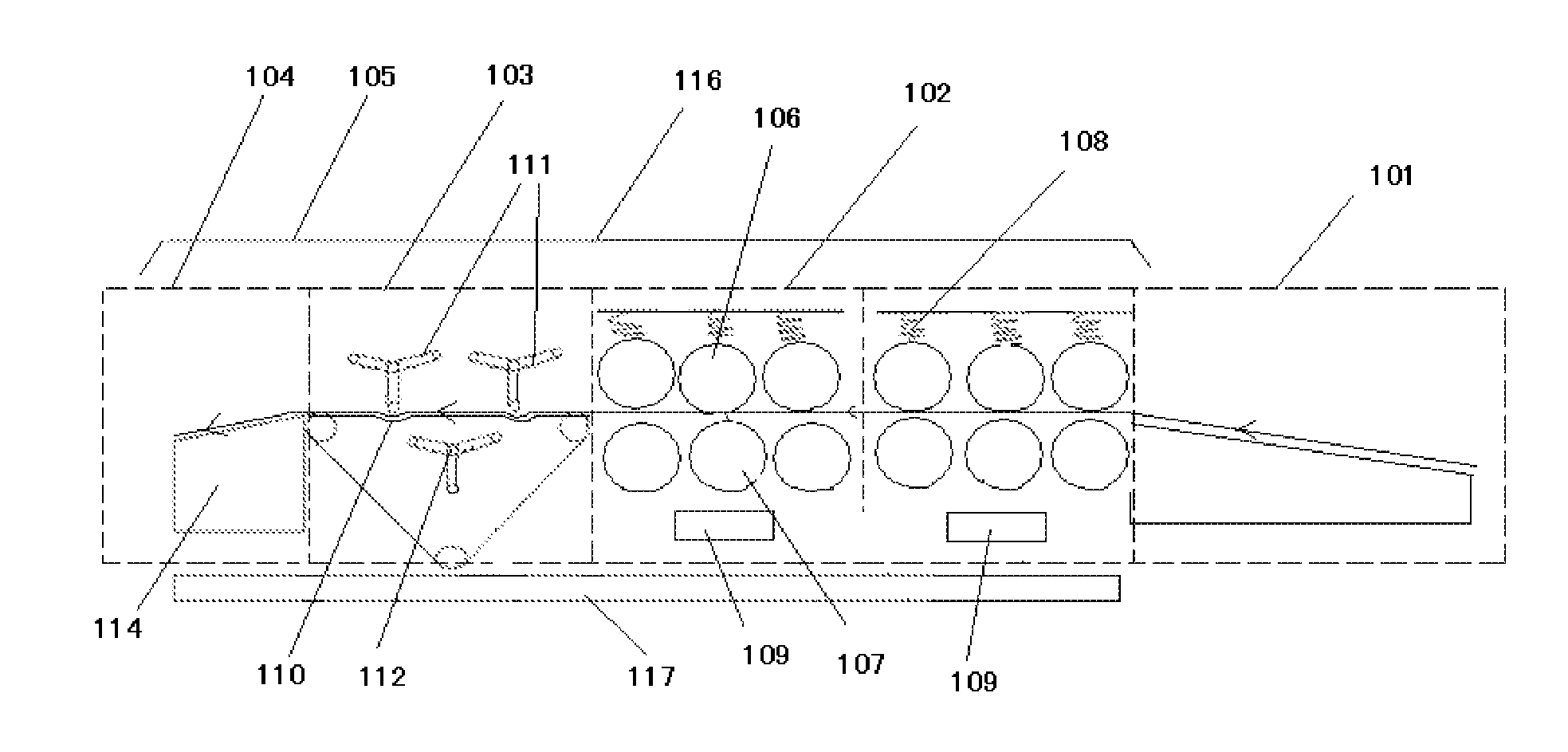

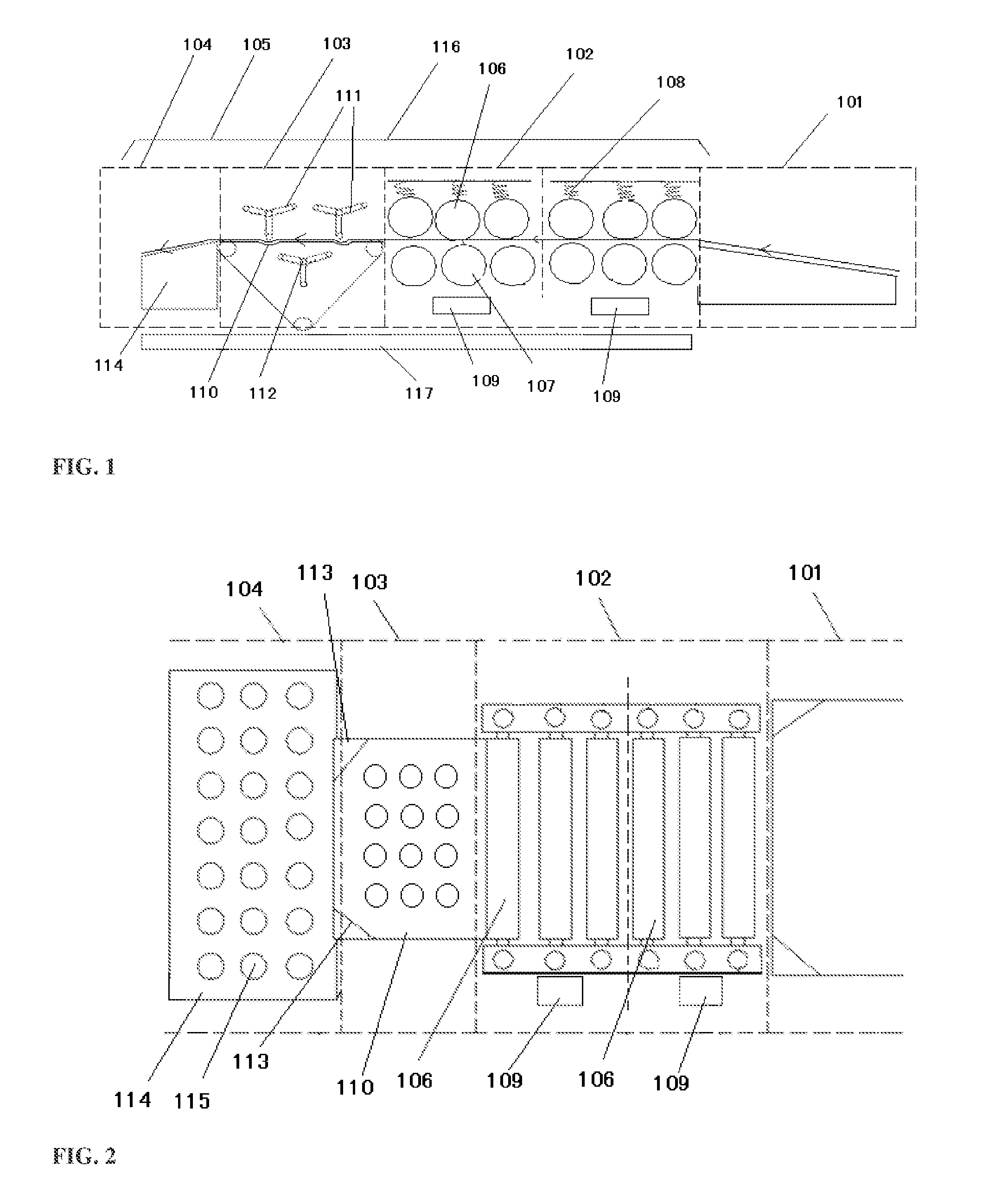

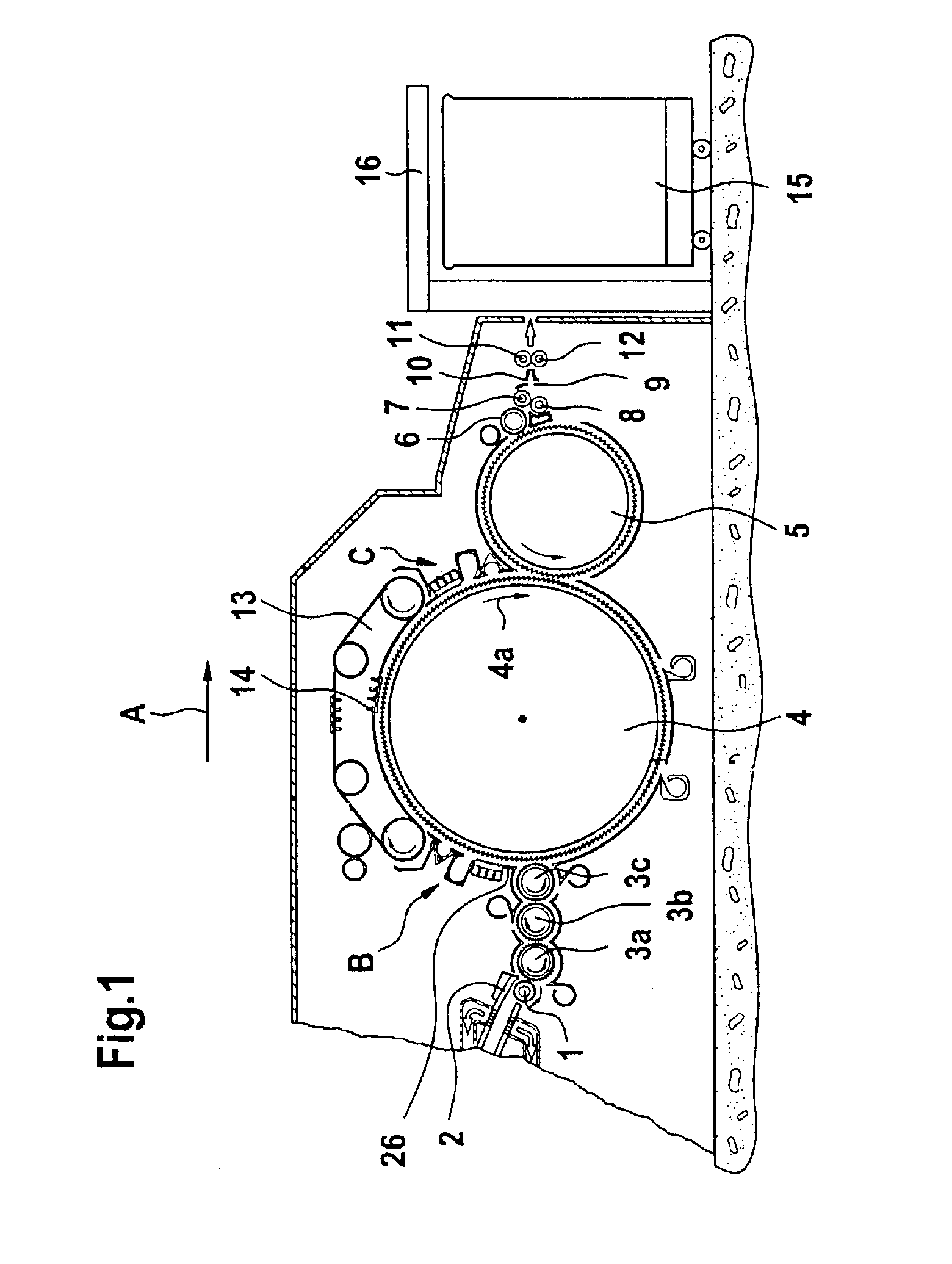

ActiveUS20120324677A1Improve fiber separation indexImprove biochemistry degumming uniformityMechanical impurity removalLubricating devicesCardingEngineering

A processing line of bast fiber is provided. The processing line is comprised of various devices for carding, cutting, degumming, high temperature washing, separating and water washing, softening, drying, batching and applying oil, permeating and reconditioning, stretching-breaking carding, and combing and sorting. The processing line of bast fiber can improve production efficiency, and improve the yield of long hemp fibers. Moreover, the produced fiber has stable quality and is convenient for post-processing.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +2

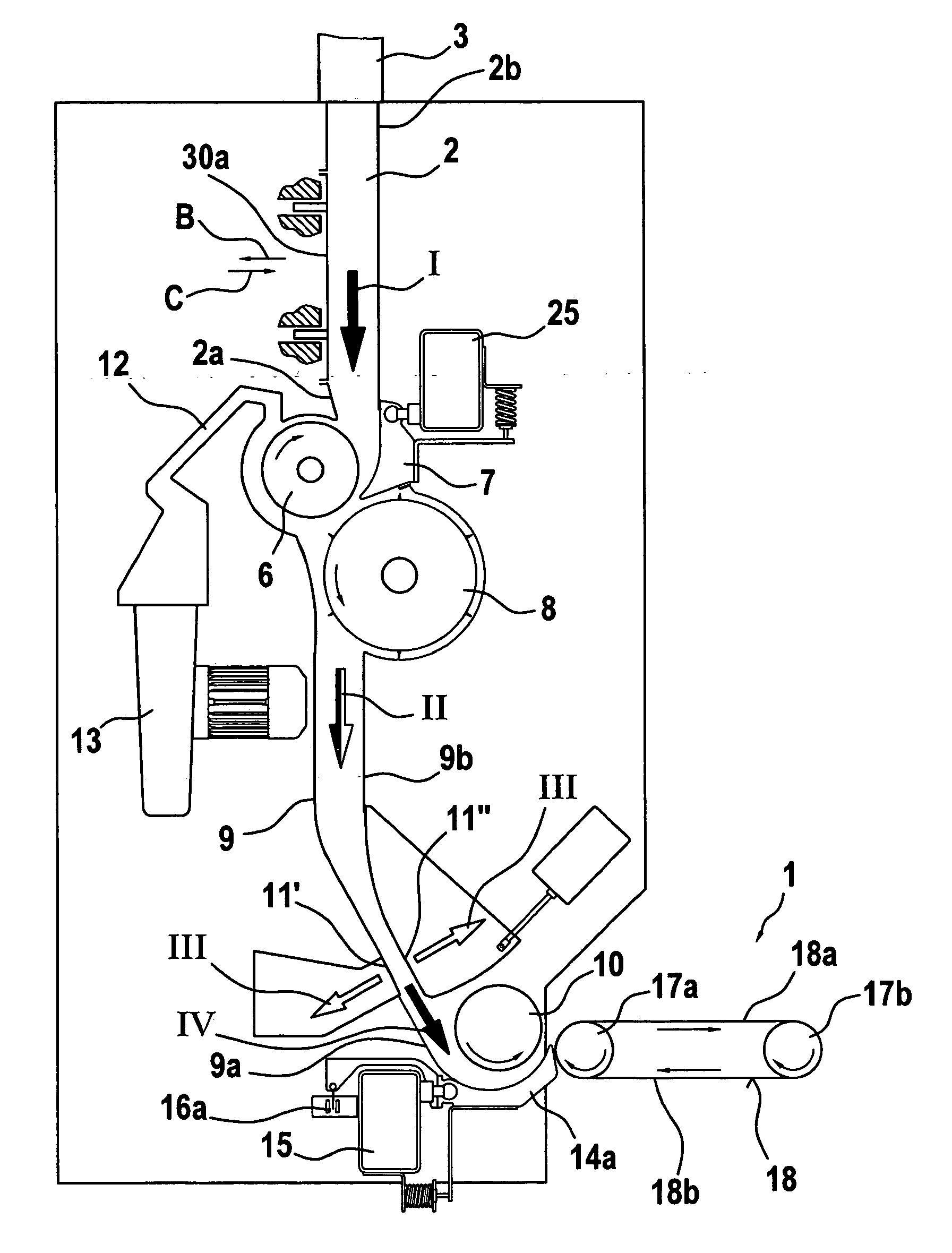

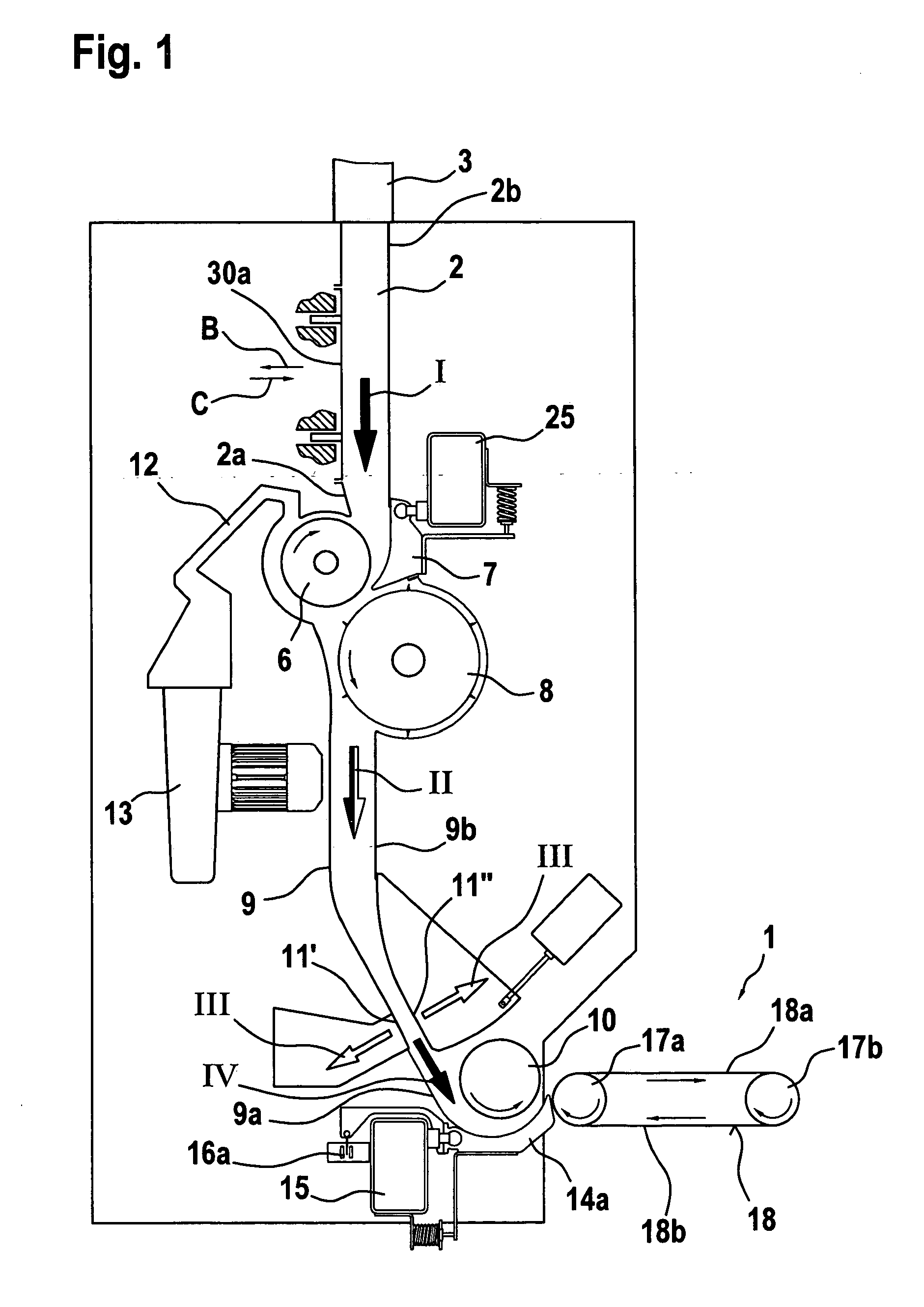

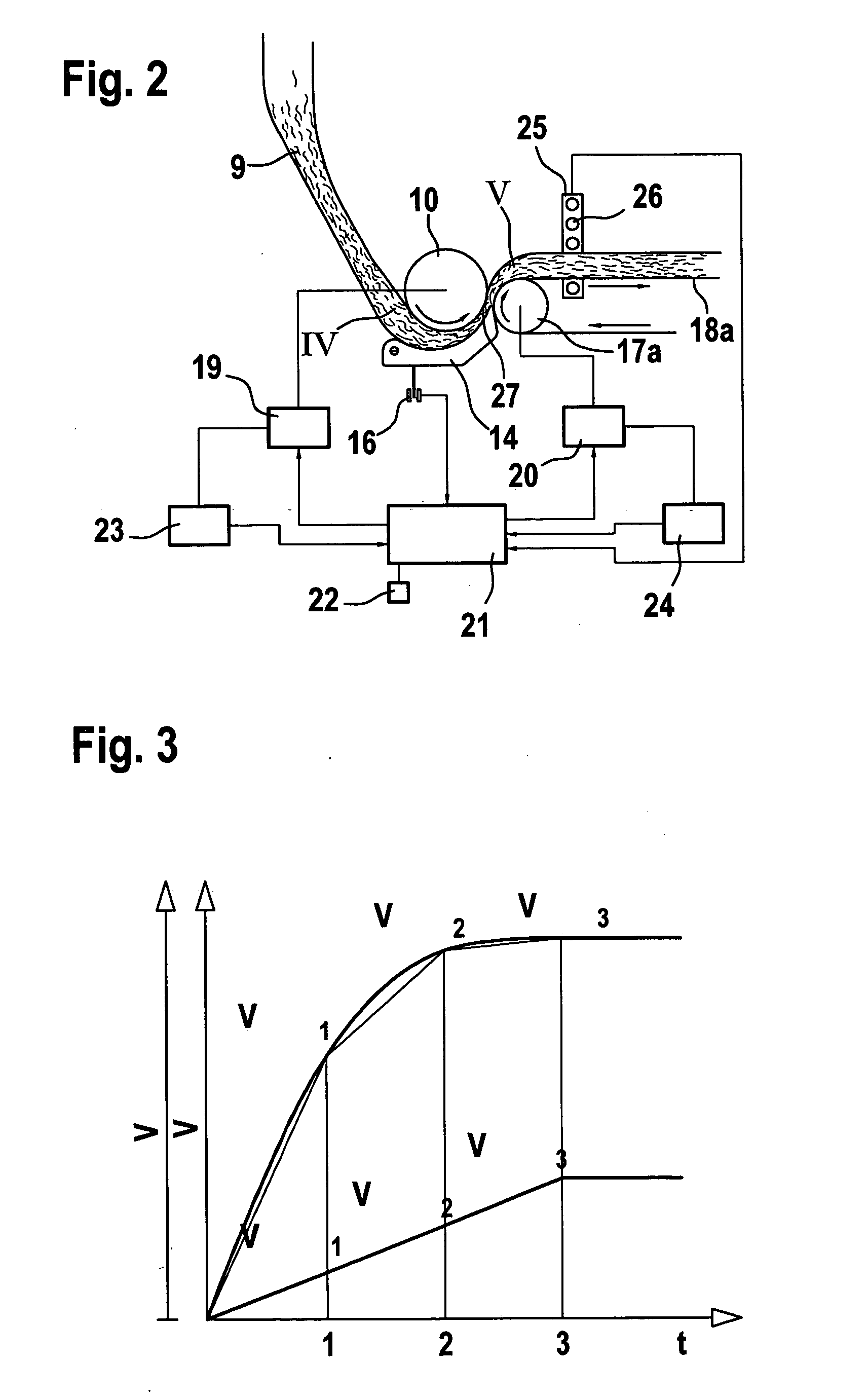

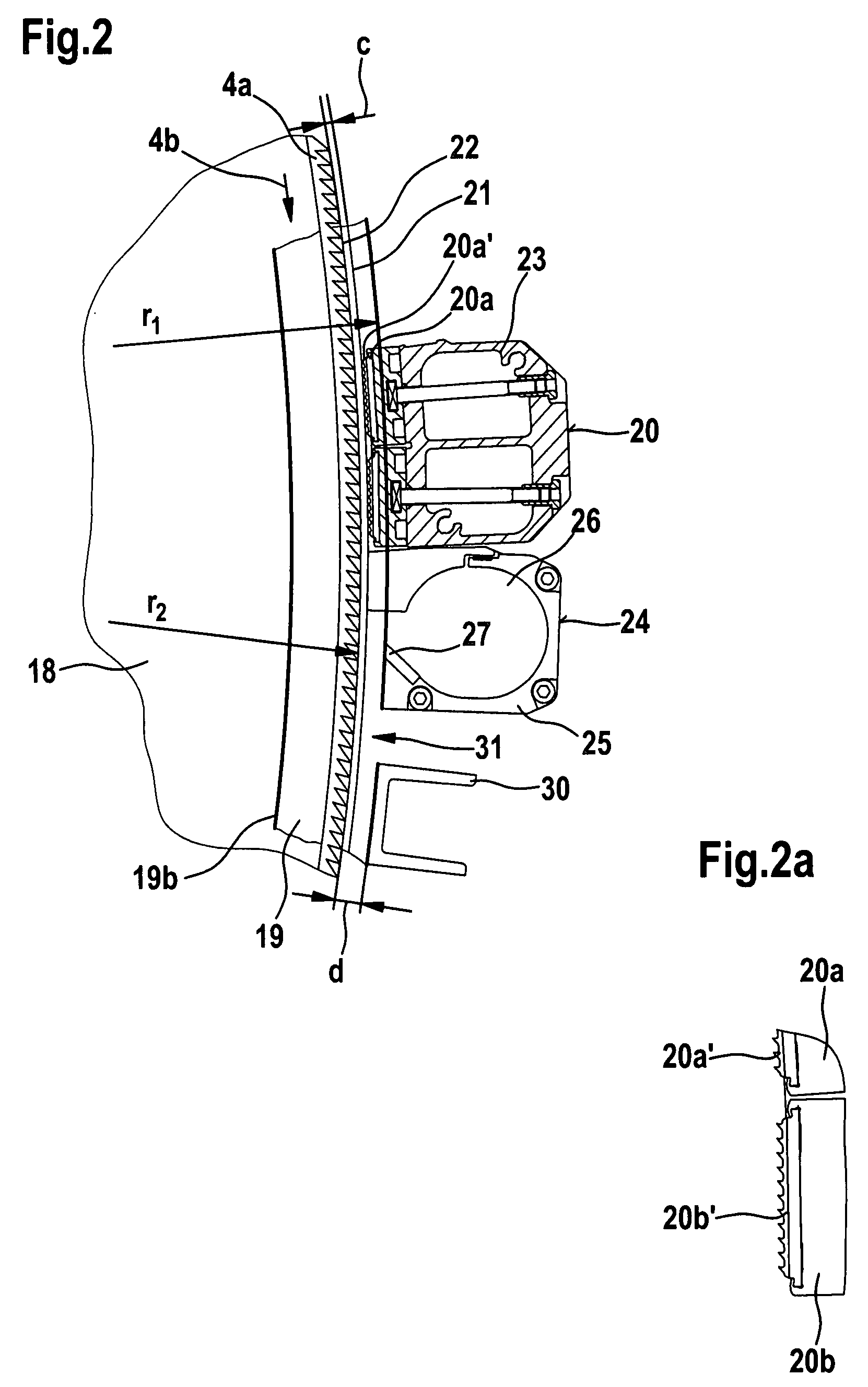

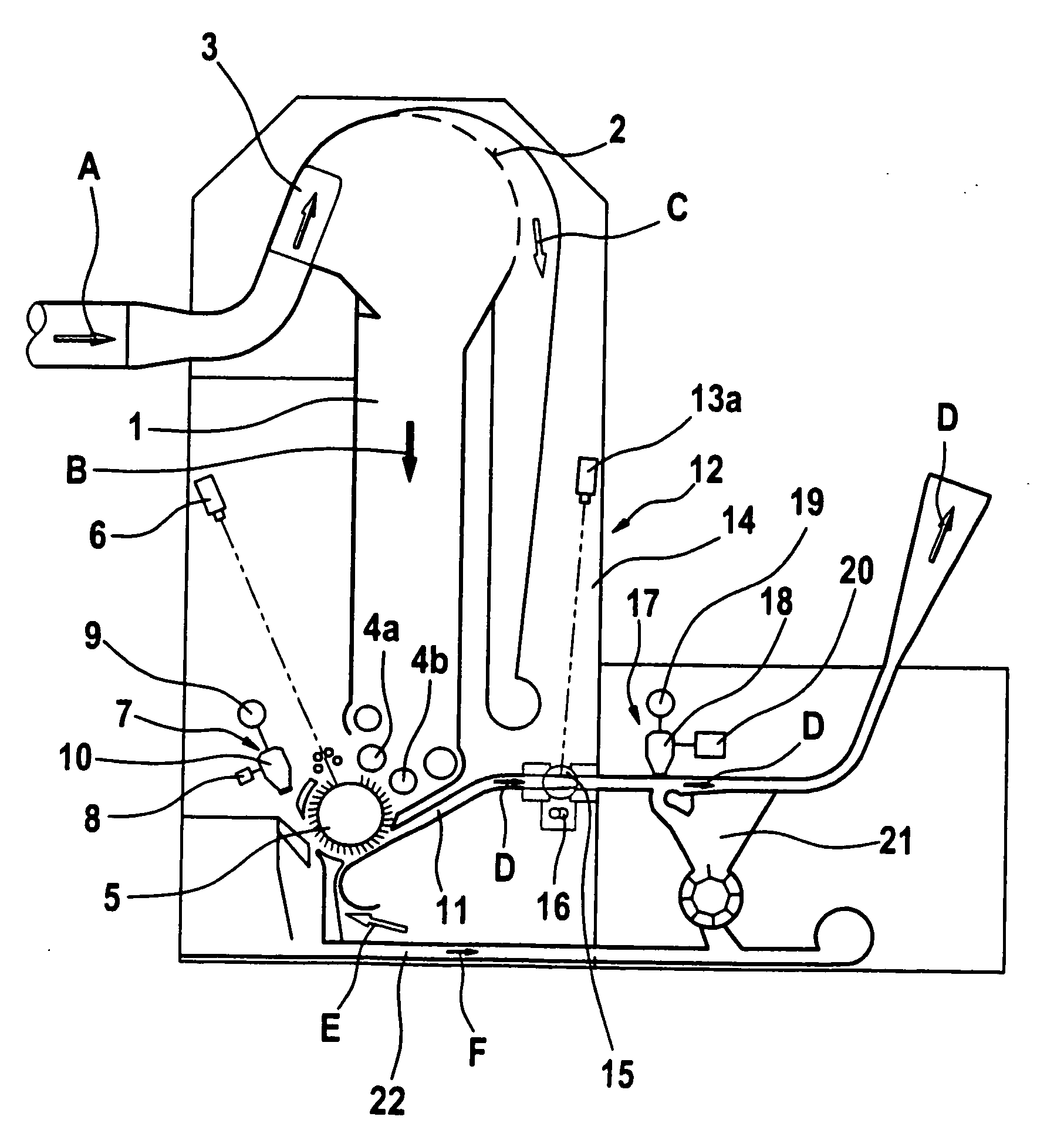

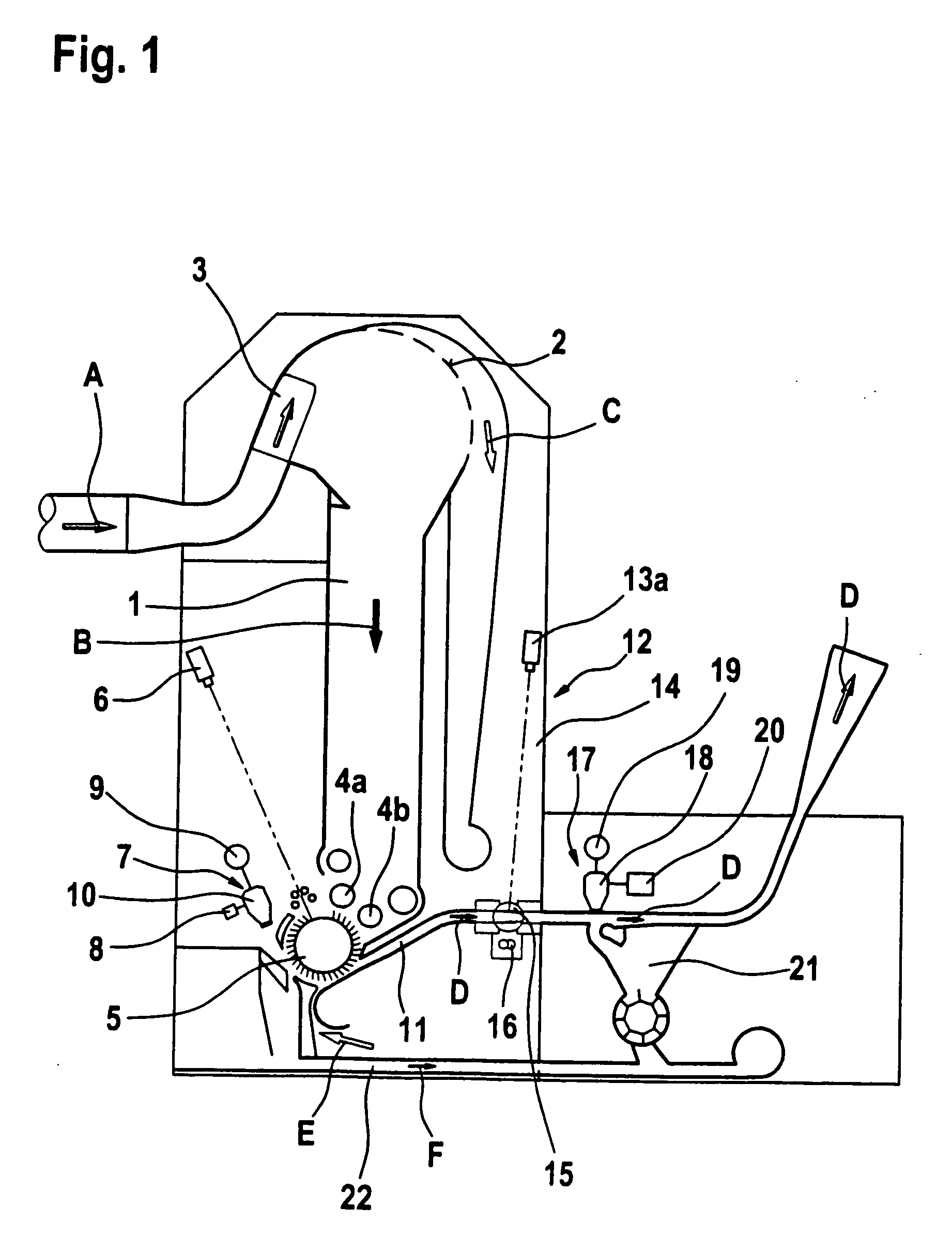

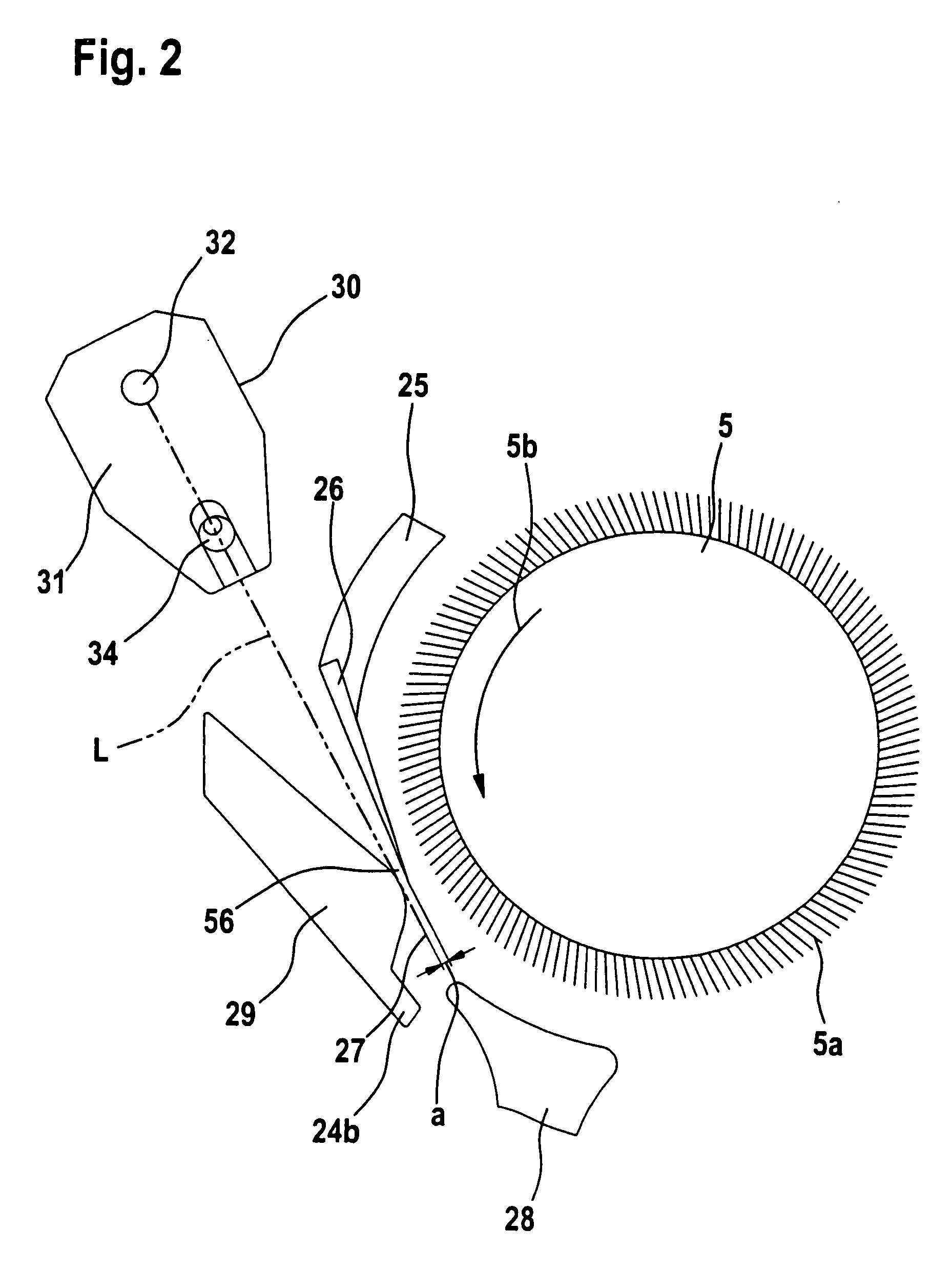

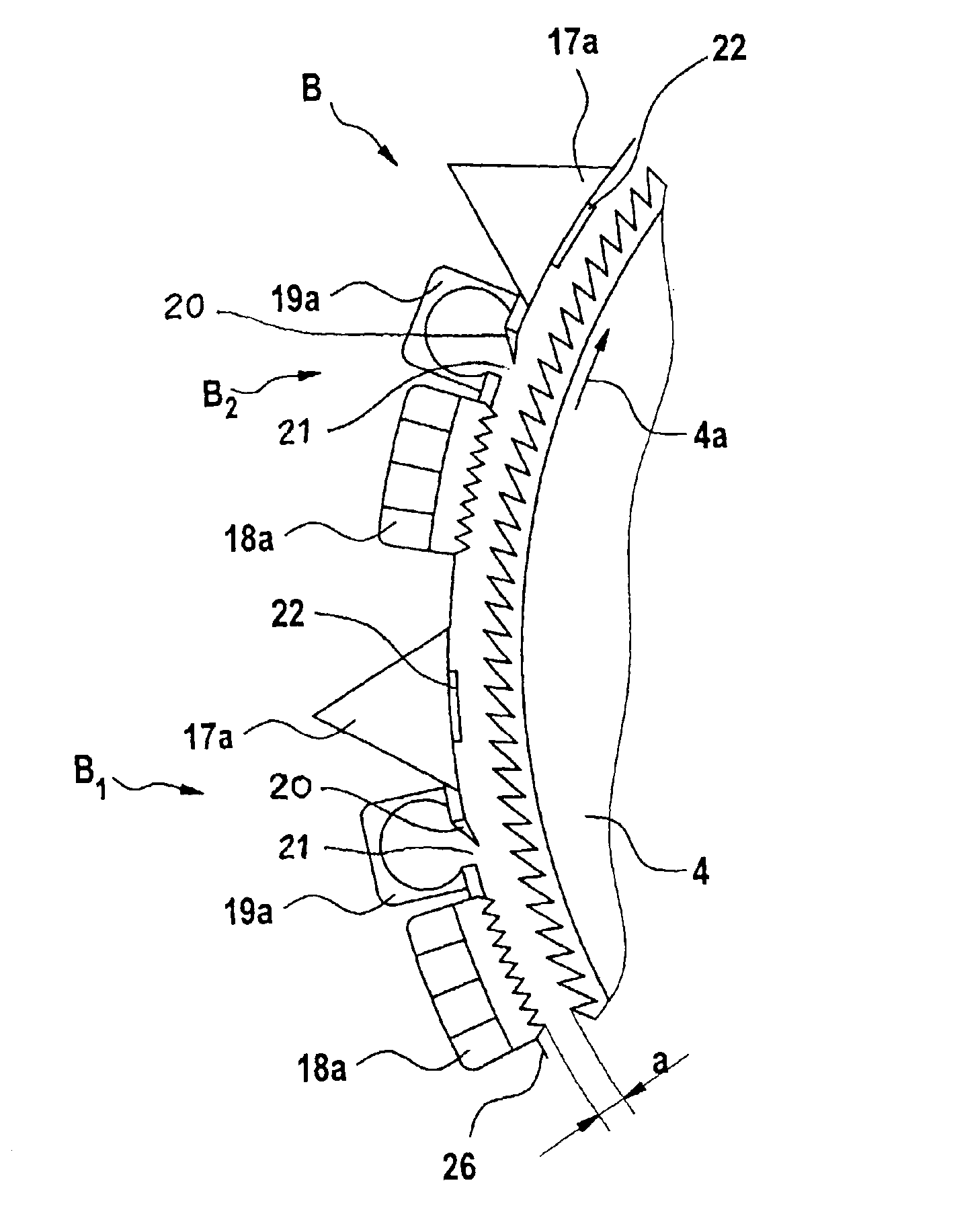

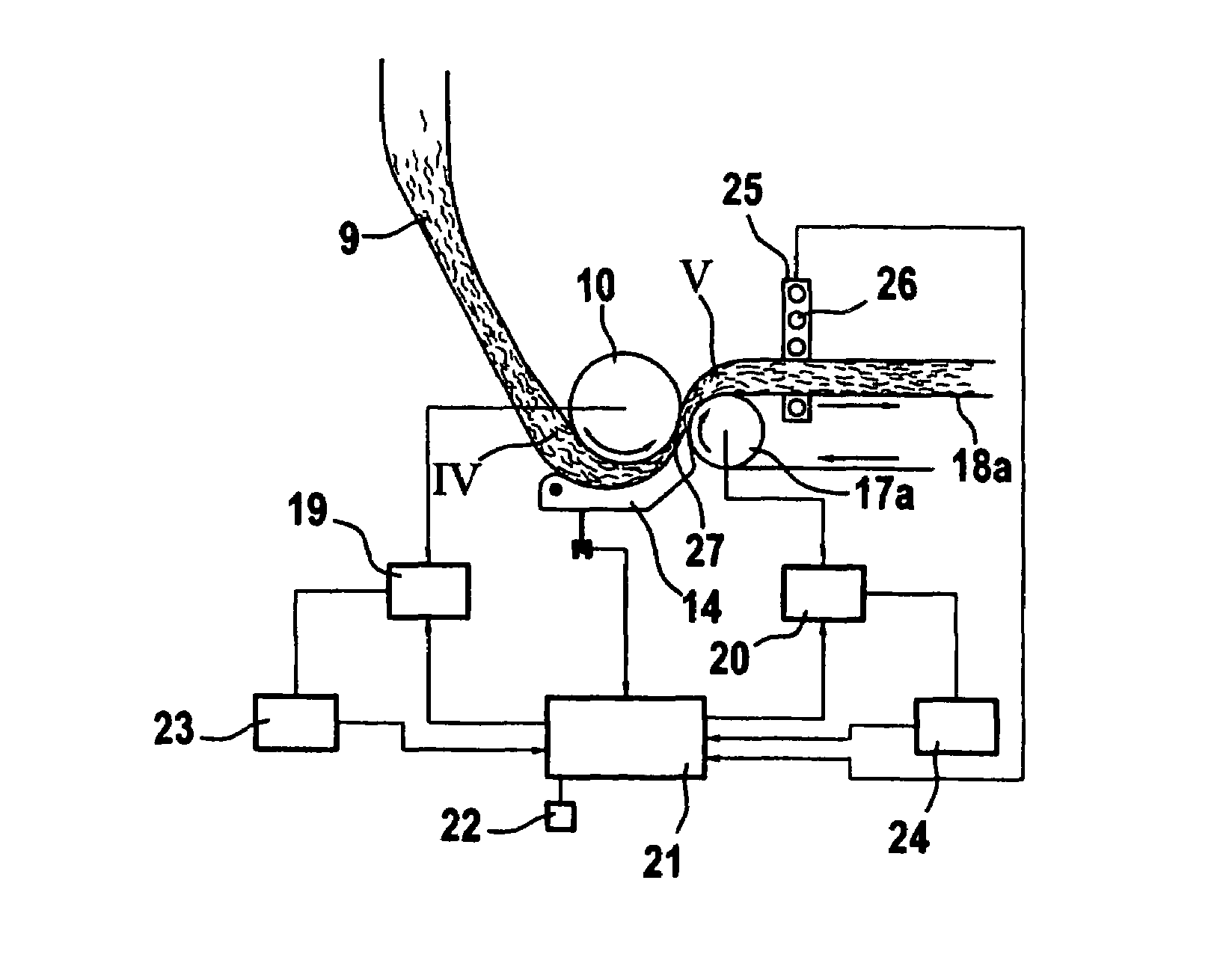

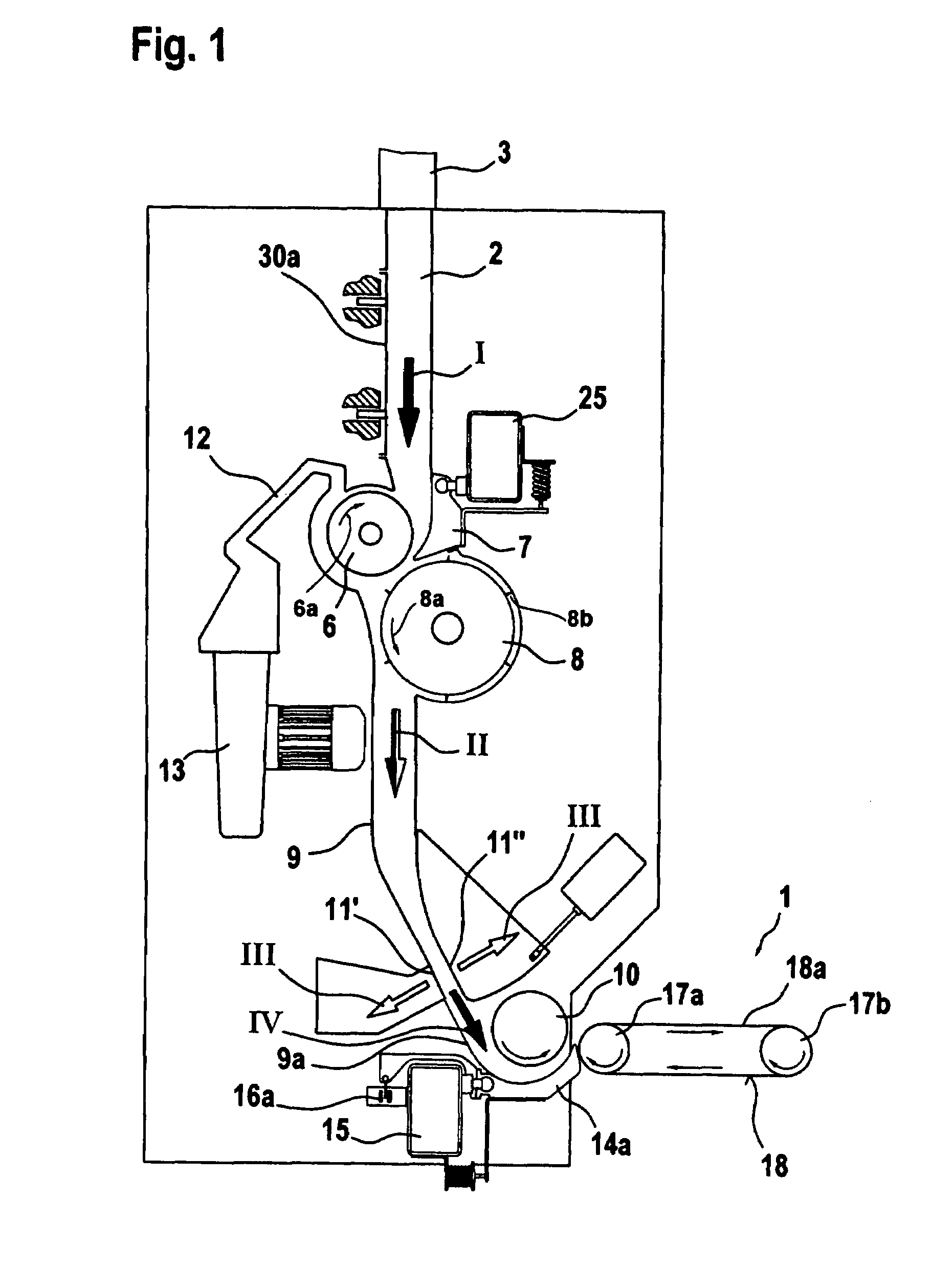

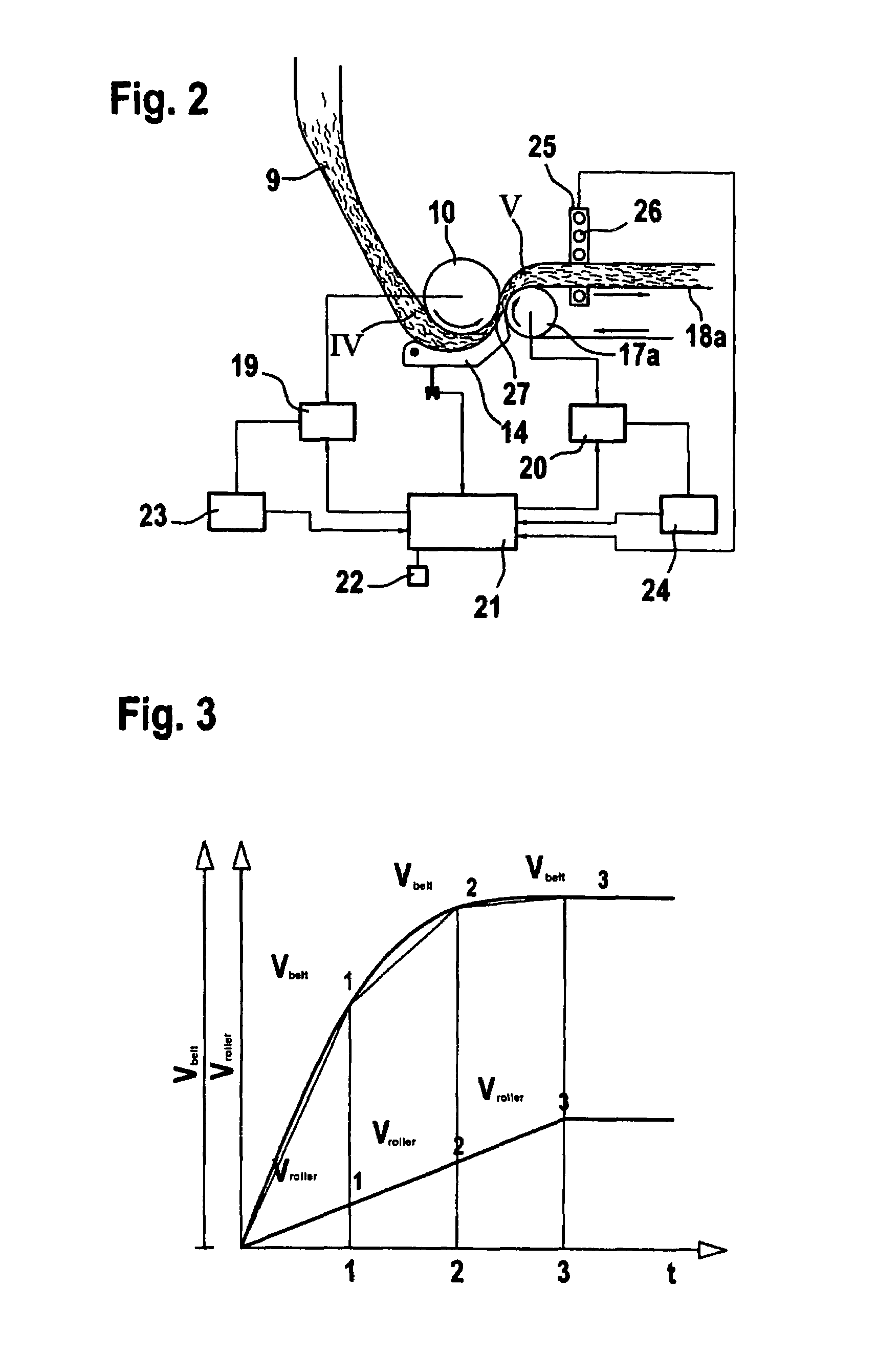

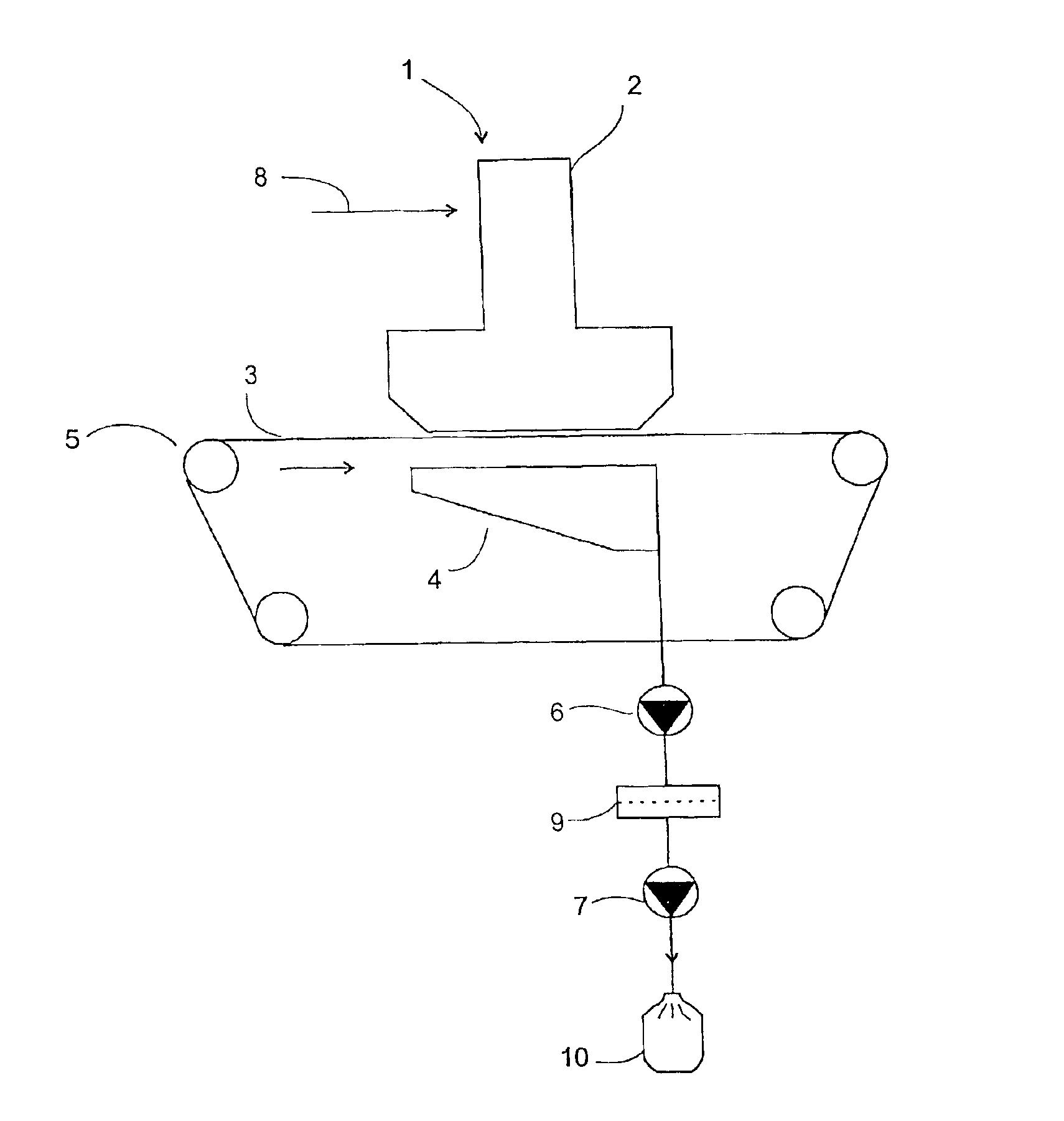

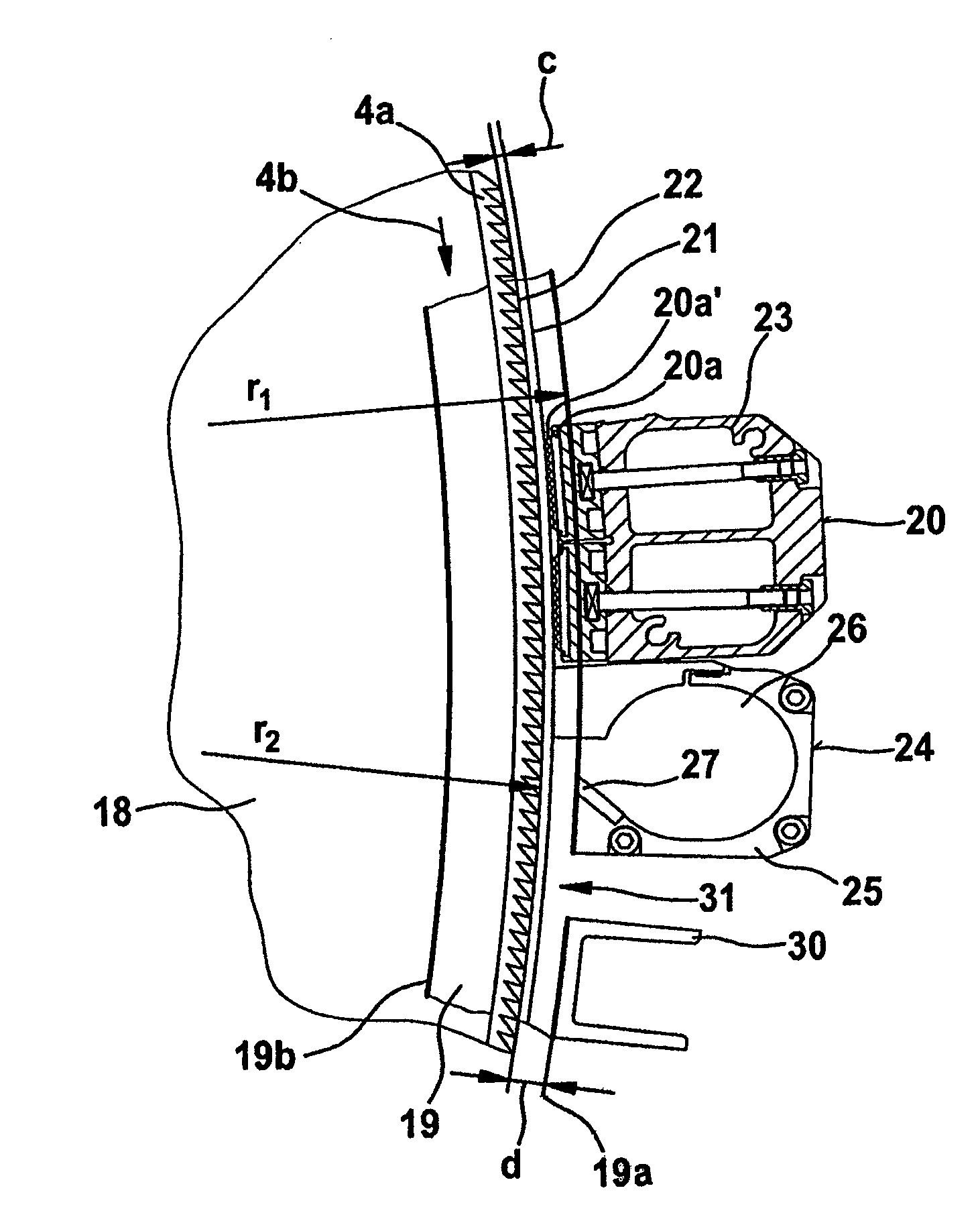

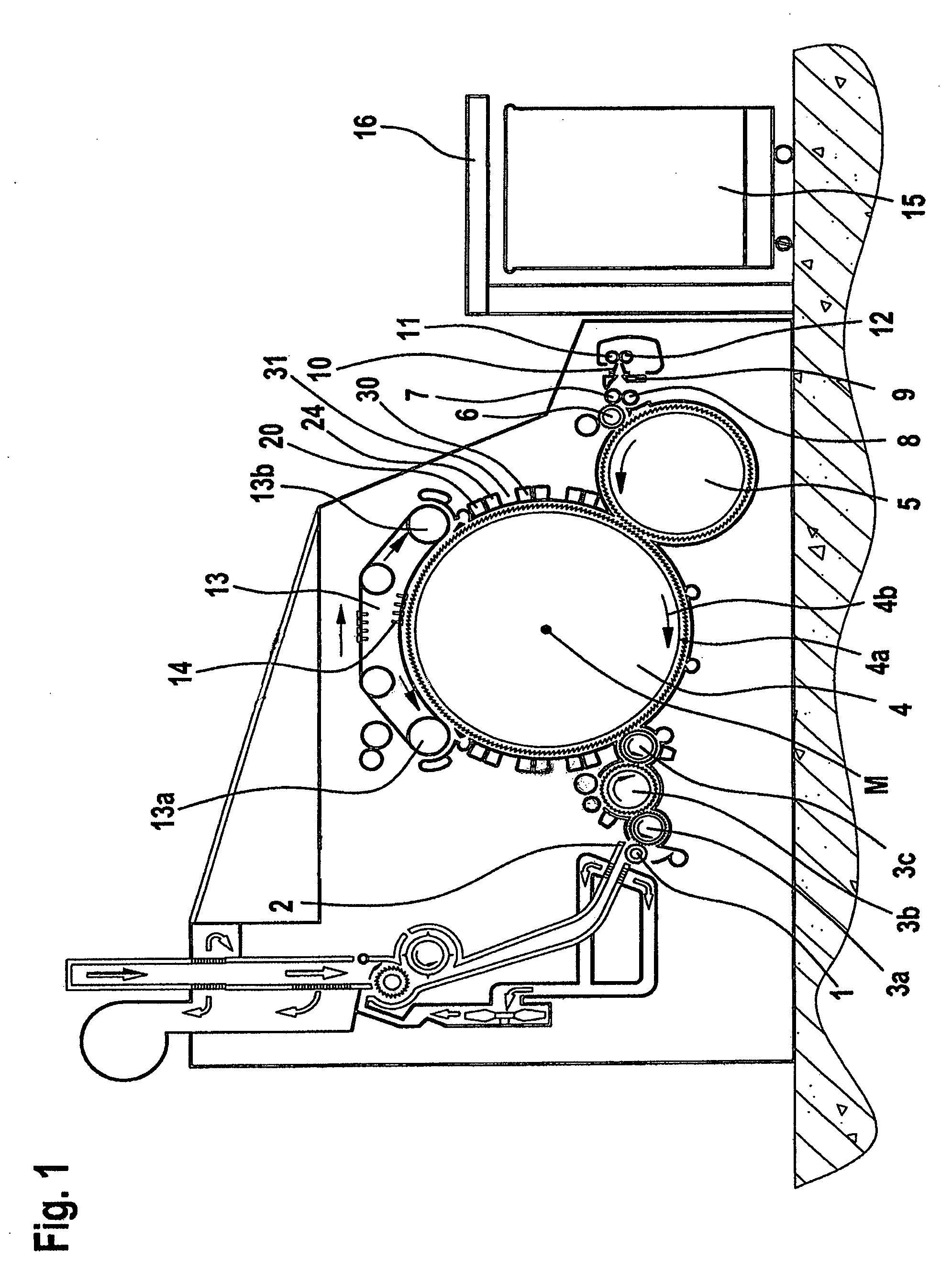

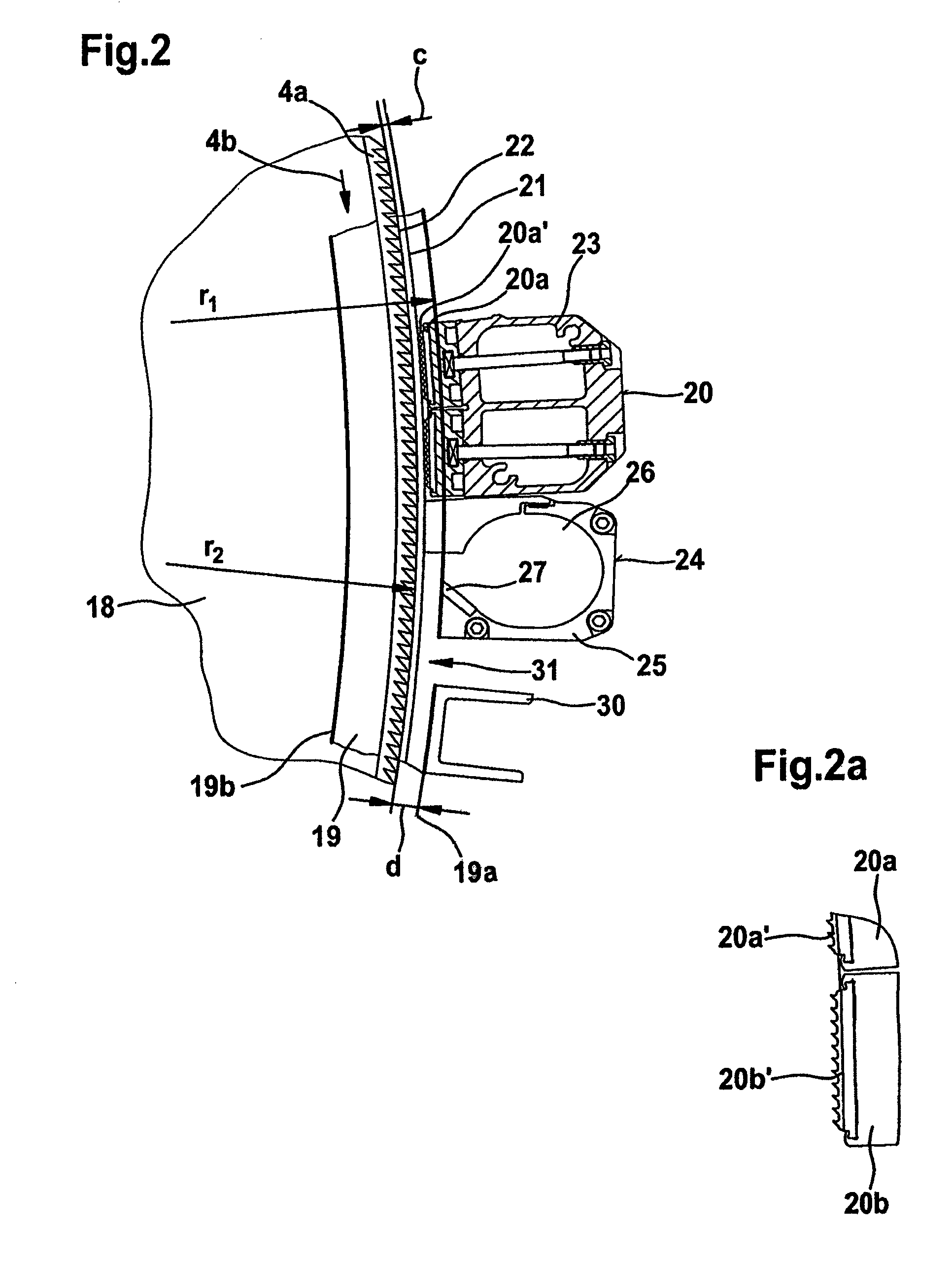

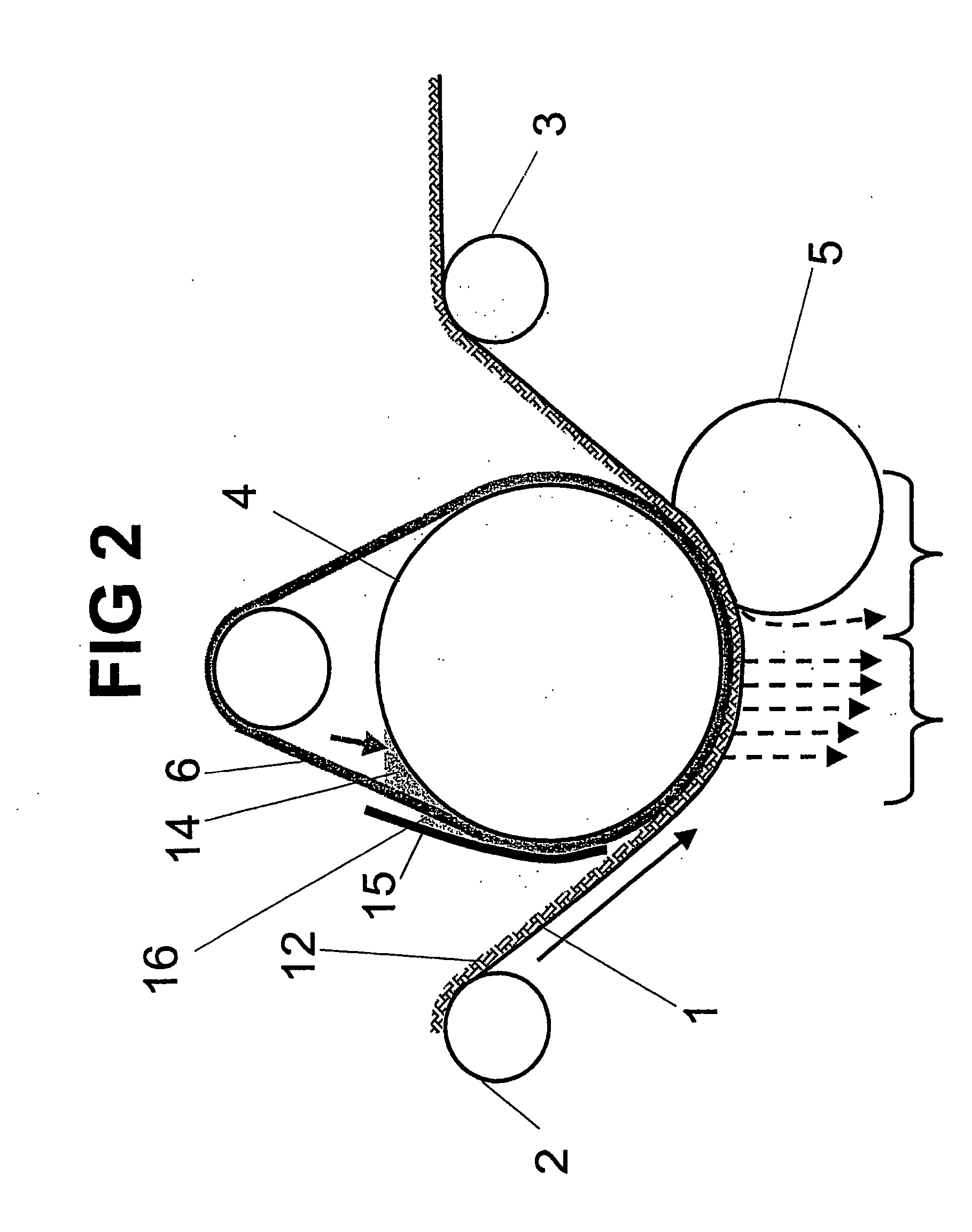

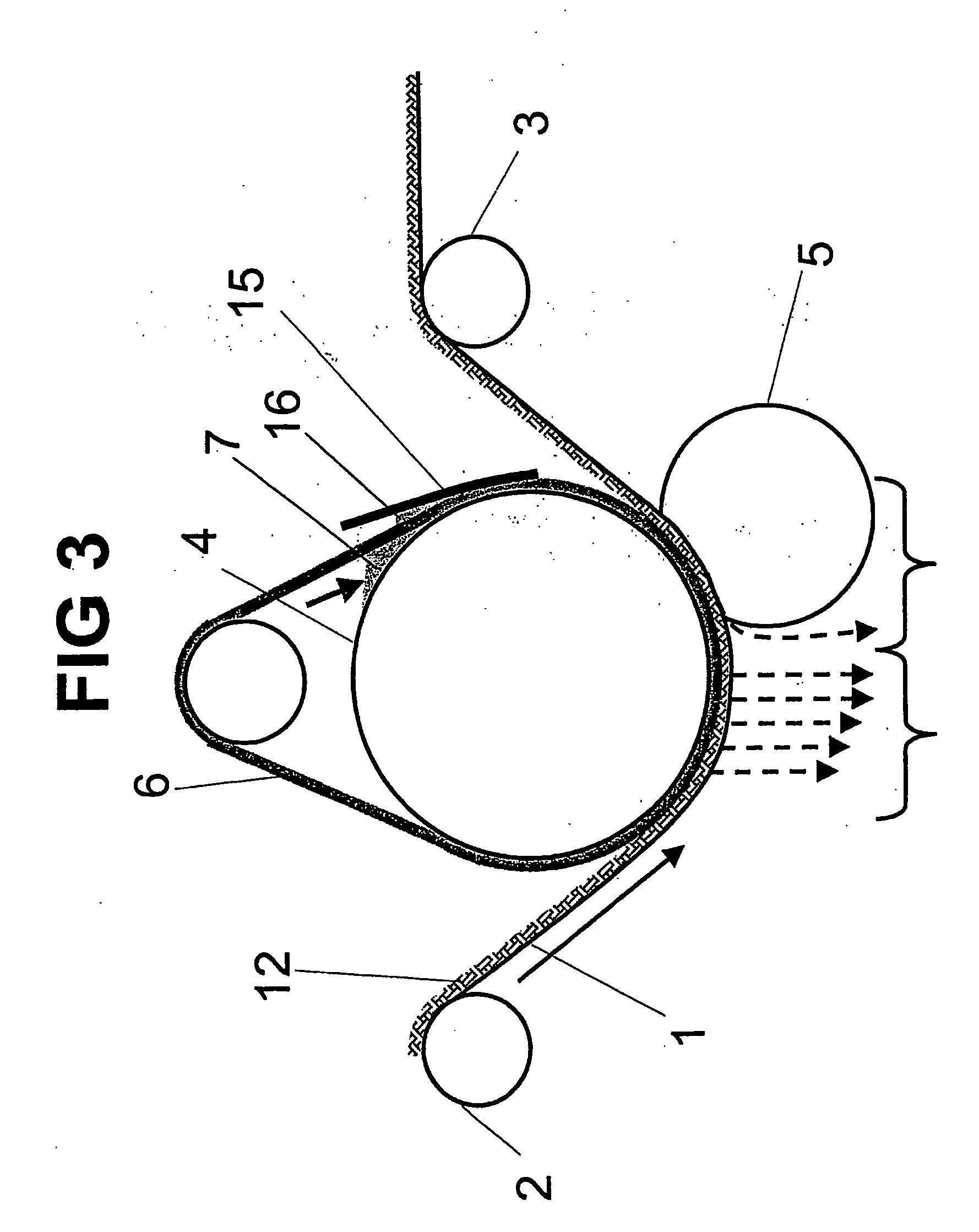

Device on a spinning preparation machine, for example a tuft feeder, having a feed device

A device on a spinning preparation machine, for example a tuft feeder, having a feed device comprising at least one slow-speed feed roller and a counter-element, for example a feed tray, with which fibre material can be supplied to a downstream transport device, has a driven transport element, for example a conveyor belt. In order to provide improved delivery from the feed device, or improved takeover by the downstream transport device, and to allow troublefree operation, for the purpose of determining setting values for the optimum speed of the transport element, a function between the measured values of the feed roller speed and the measured values of the transport speed is so determined that the fibre material lies on the moving surface of the transport element.

Owner:TRUETZSCHLER GMBH & CO KG

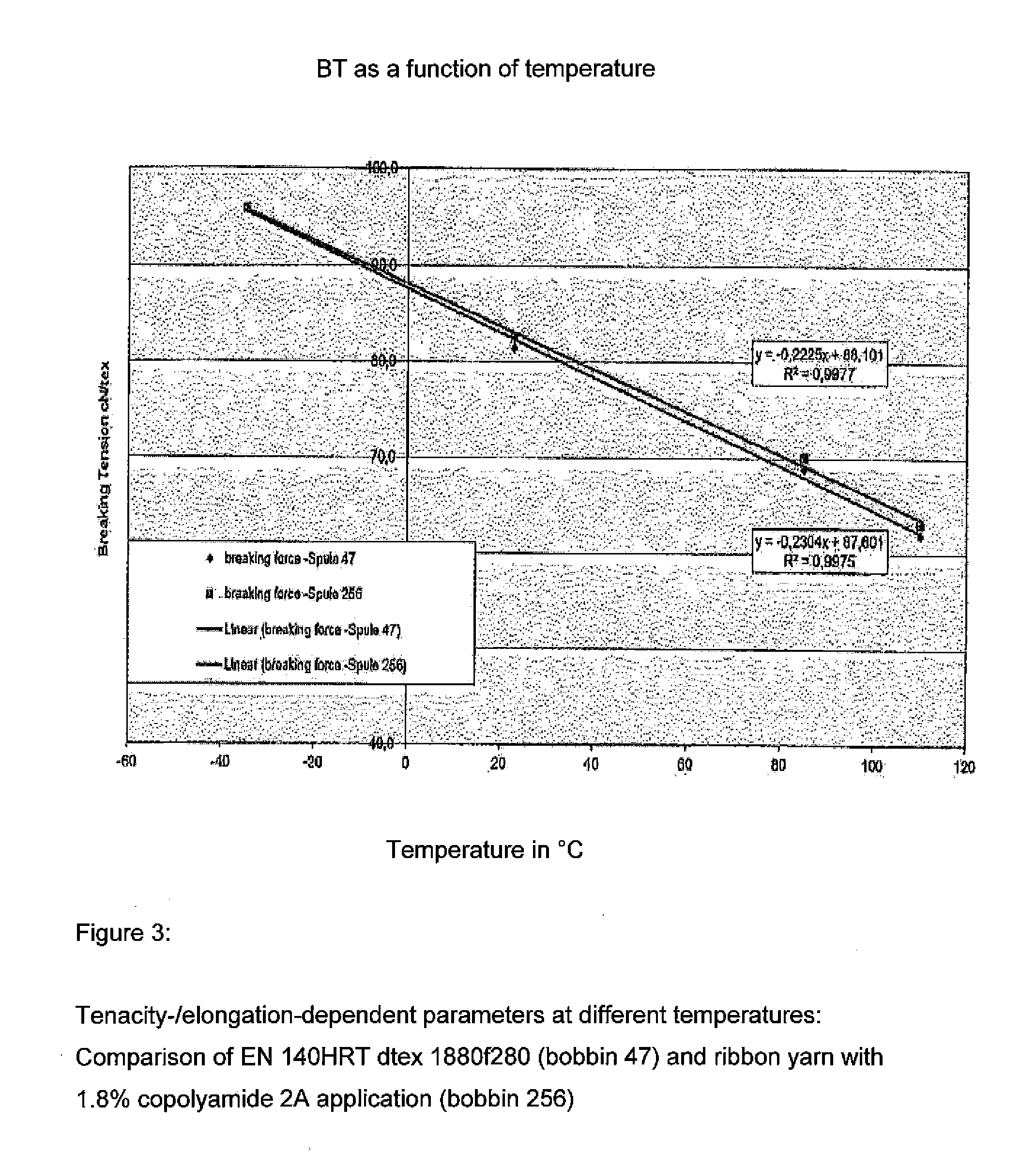

Ribbon yarn

ActiveUS20150167207A1Broaden applicationExcellent combustion resistanceMechanical impurity removalFilament handlingBand shapeEngineering

A method is disclosed for fabricating a ribbon yarn, the method including: spreading the yarn such that not more than five filaments are lying over one another, fixing the yarn by forming a matrix of one or more fixatives, winding the fixed yarn, wherein the fixative or fixatives are selected from a group consisting of copolyamides, copolyesters and silicones and also mixtures or blends thereof. Also described is the ribbon yarn and the application of the ribbon yarns for airbag fabrics, as a tire reinforcement and in textile construction.

Owner:PHP FIBERS GMBH

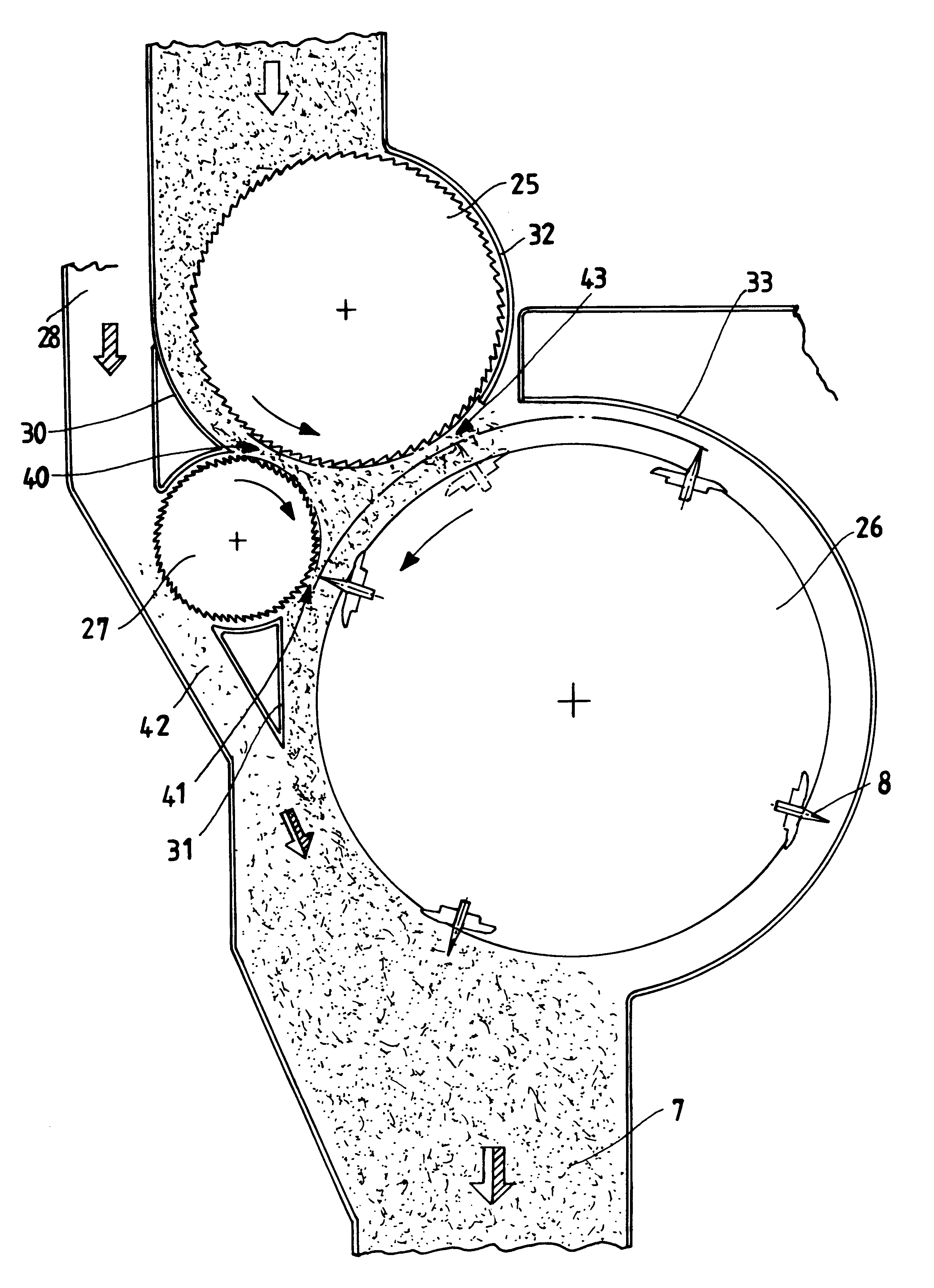

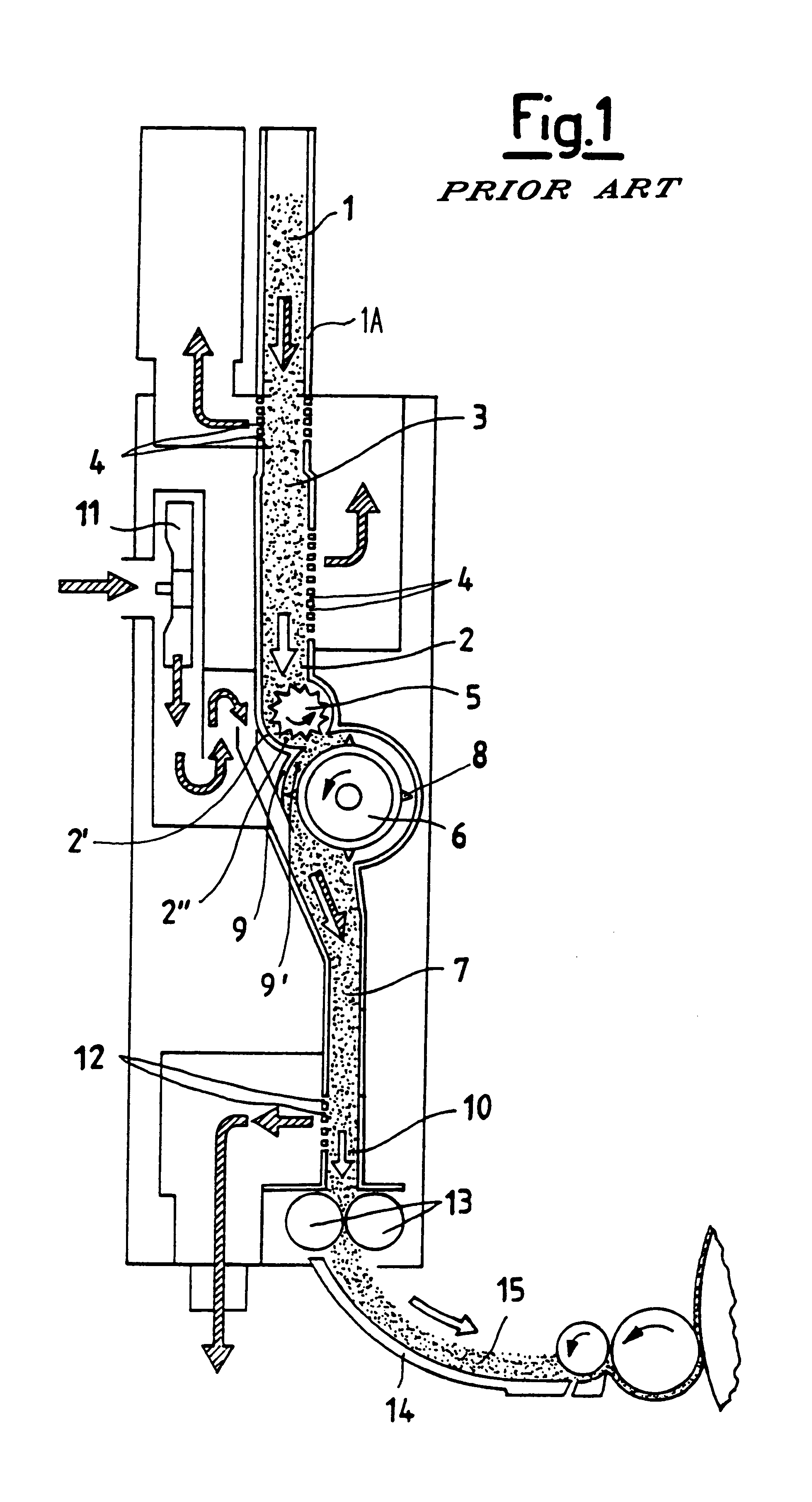

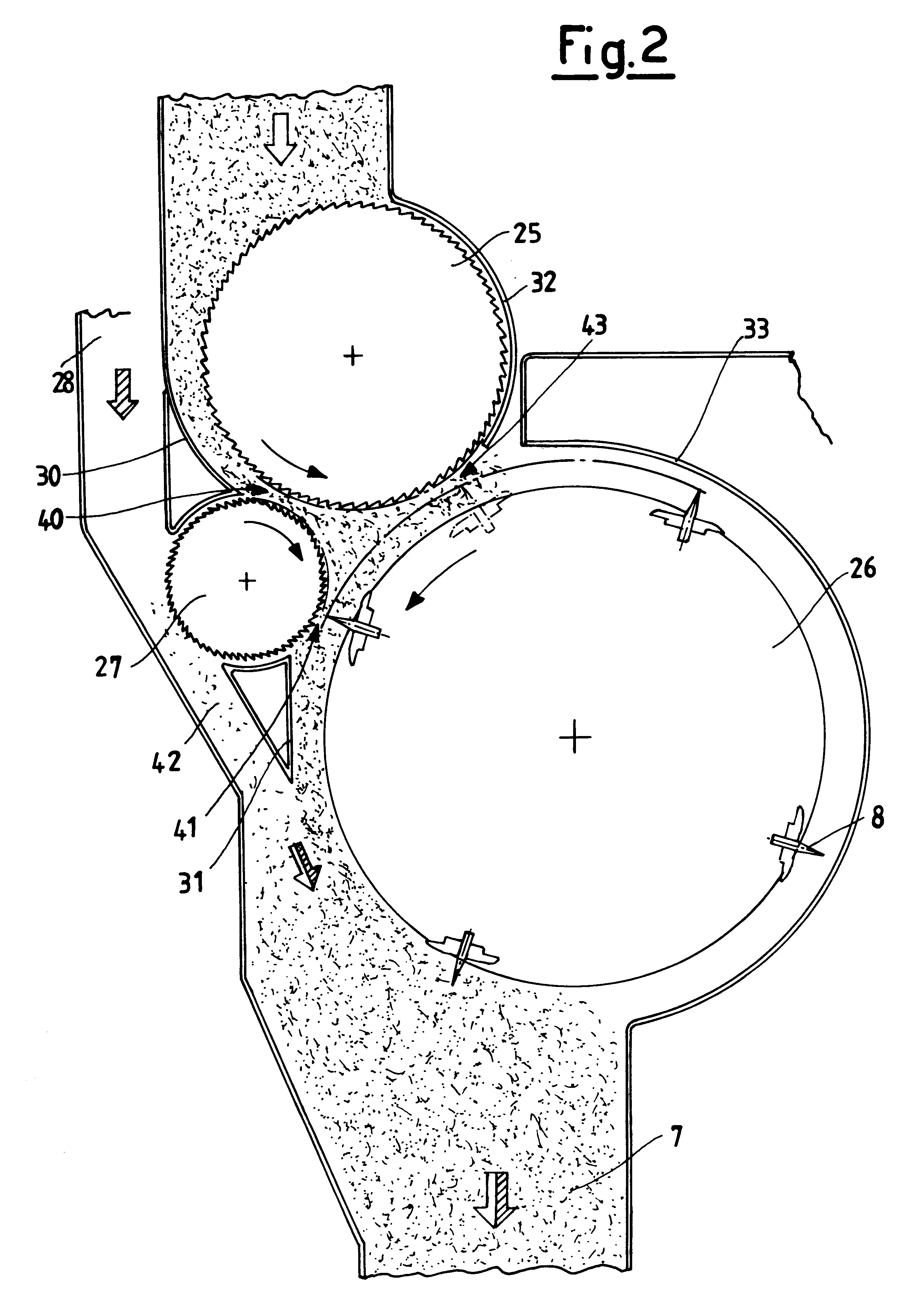

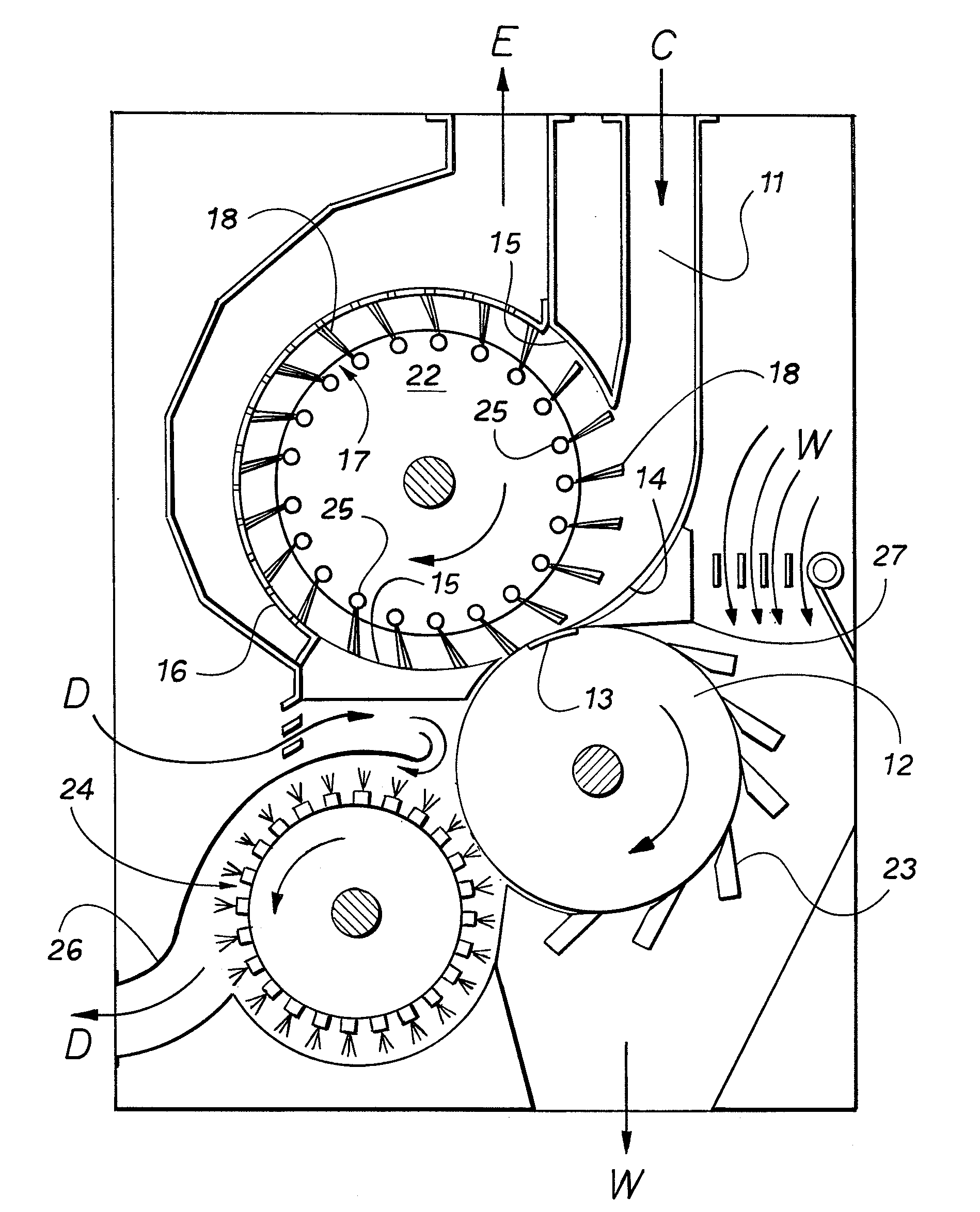

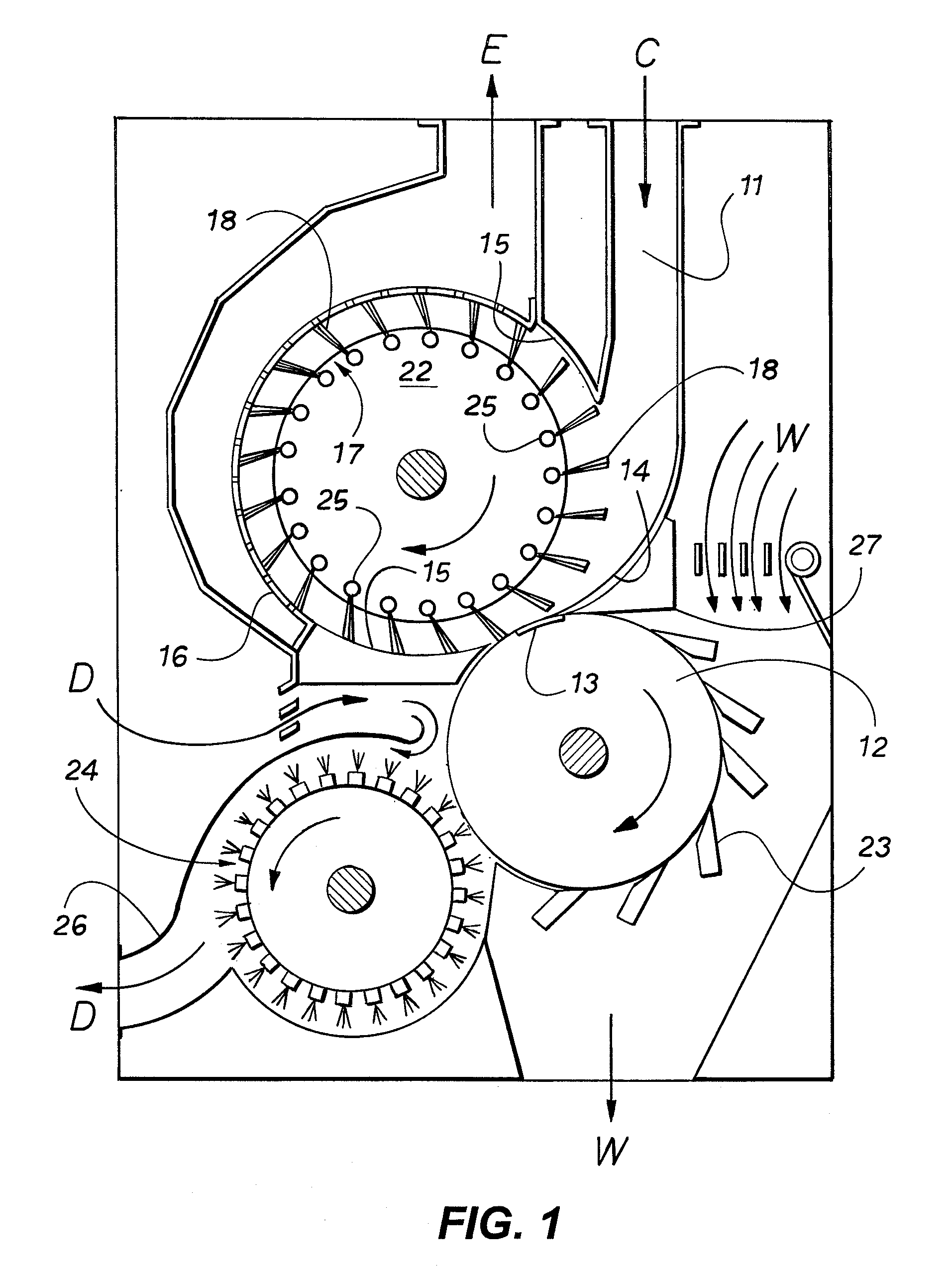

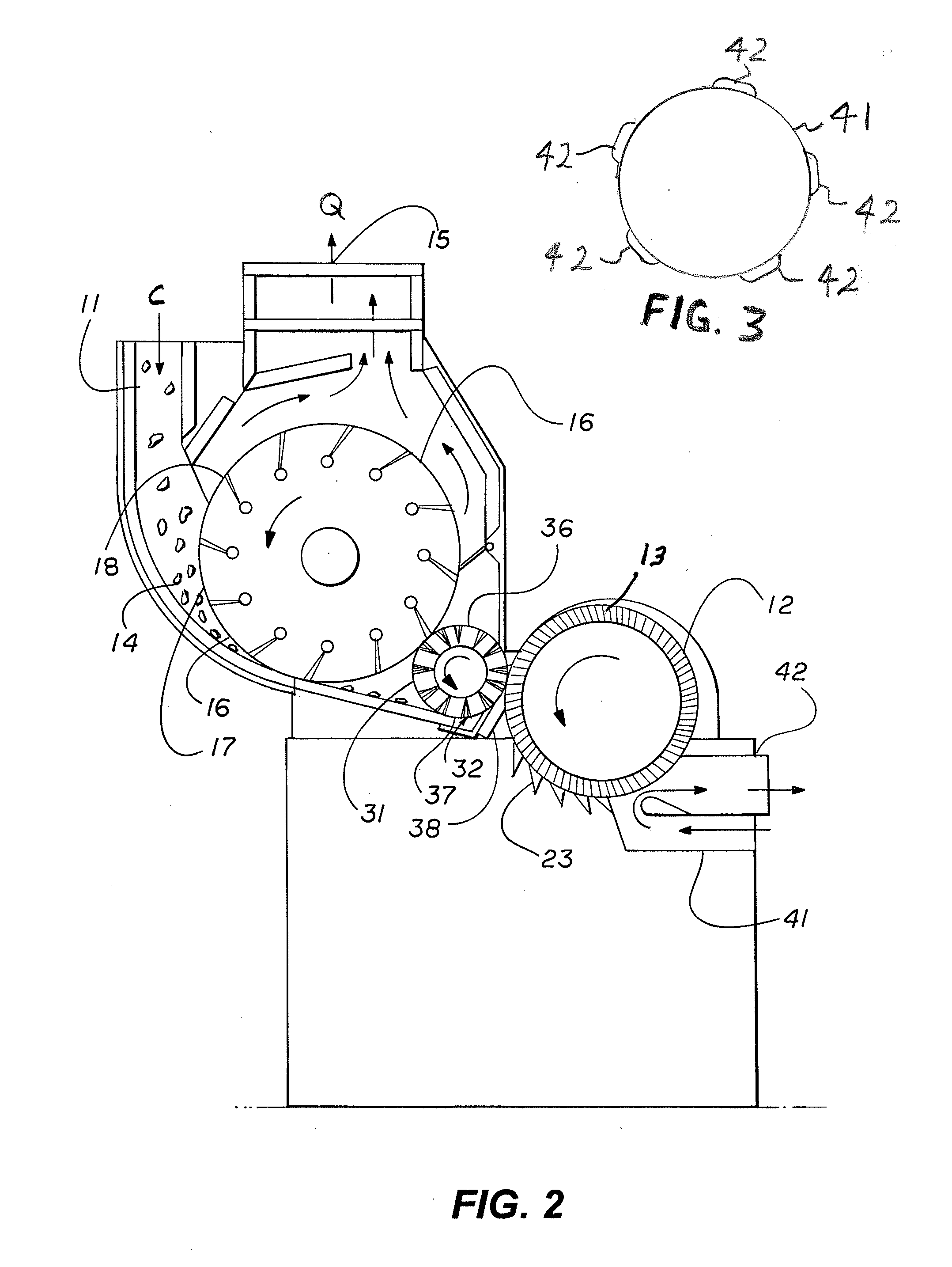

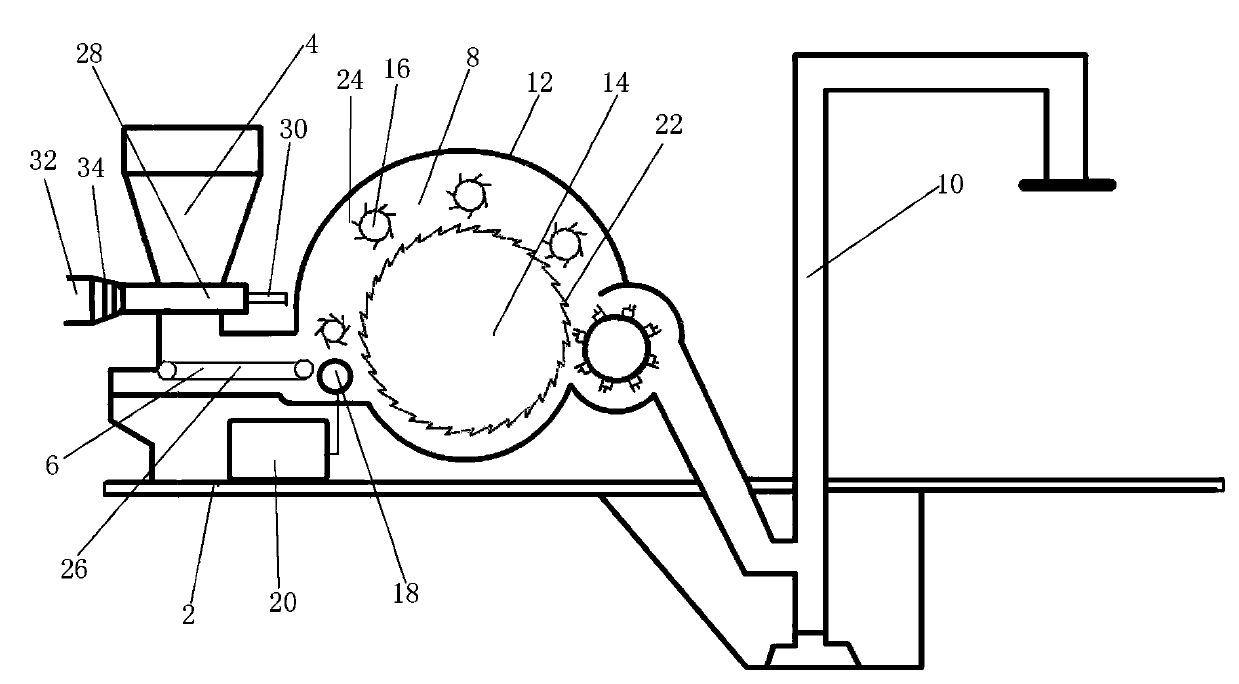

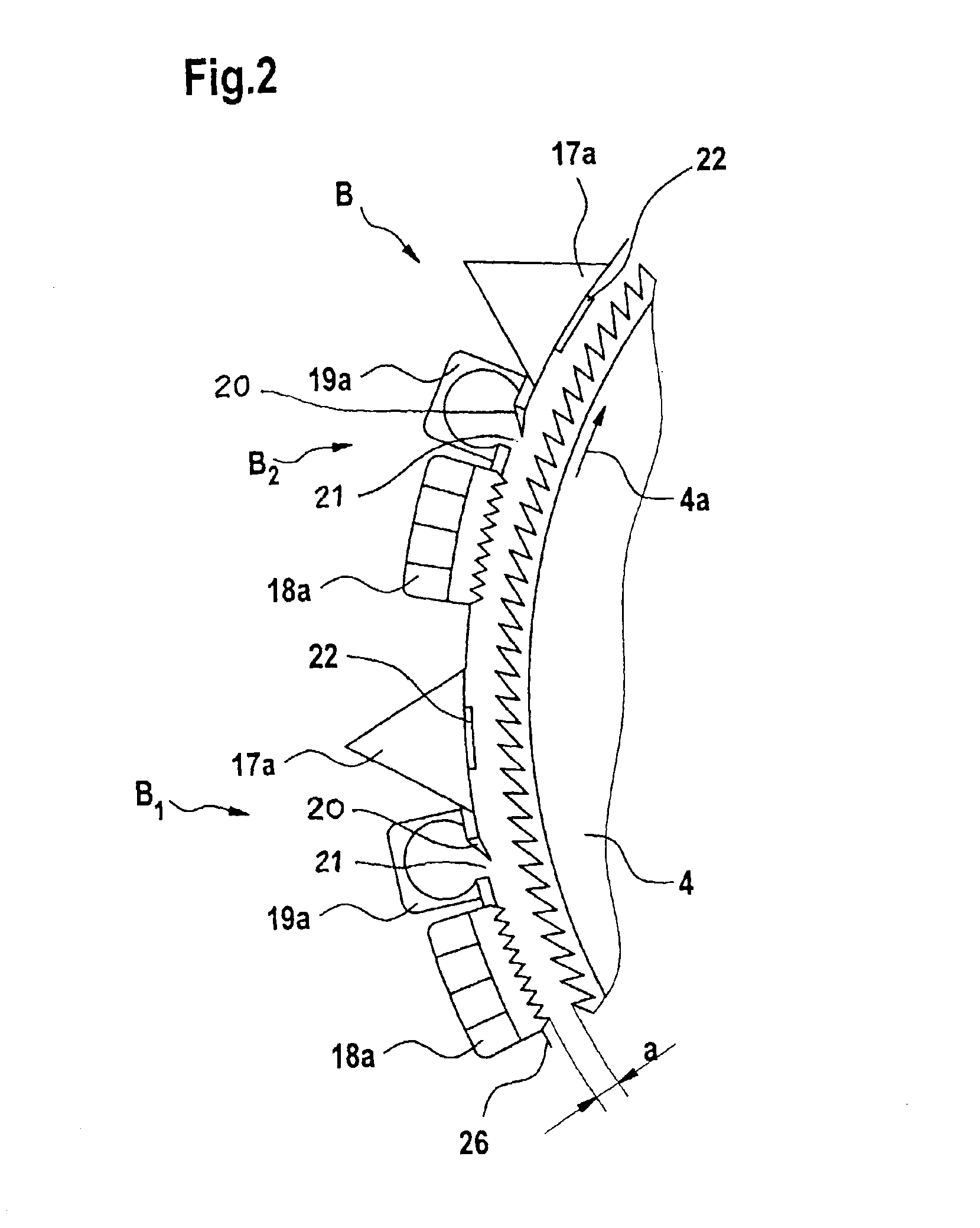

Device for preparation and opening of flock fibers to be supplied to a carder

InactiveUS6195841B1Mechanical impurity removalFibre cleaning/opening by toothed membersFiberEngineering

Silo for supply of flock fibers to a carder, which silo is subdivided into superimposed chambers, between which there is interposed a set of rollers which regulate the descending flow, and carry out breaking and separation of the fibrous material, in which a supply roller, an auxiliary supply roller and a breaker roller are disposed in a triangle, in which the surface of the auxiliary roller opposite that which is tangent to the supply roller is exposed to the flow of air which descends downwards, together with the fibers worked by the breaker roller.

Owner:MARZOLI

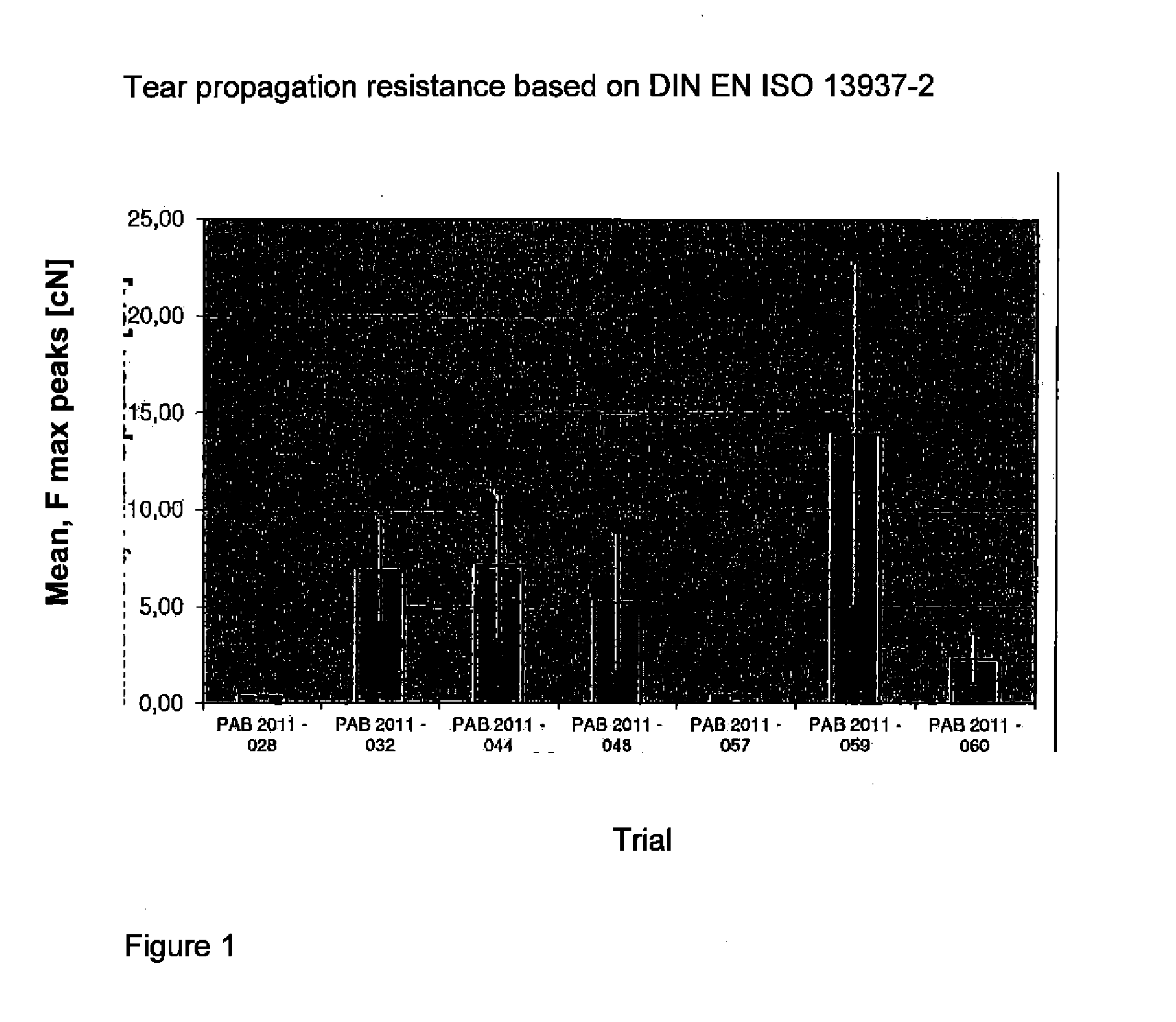

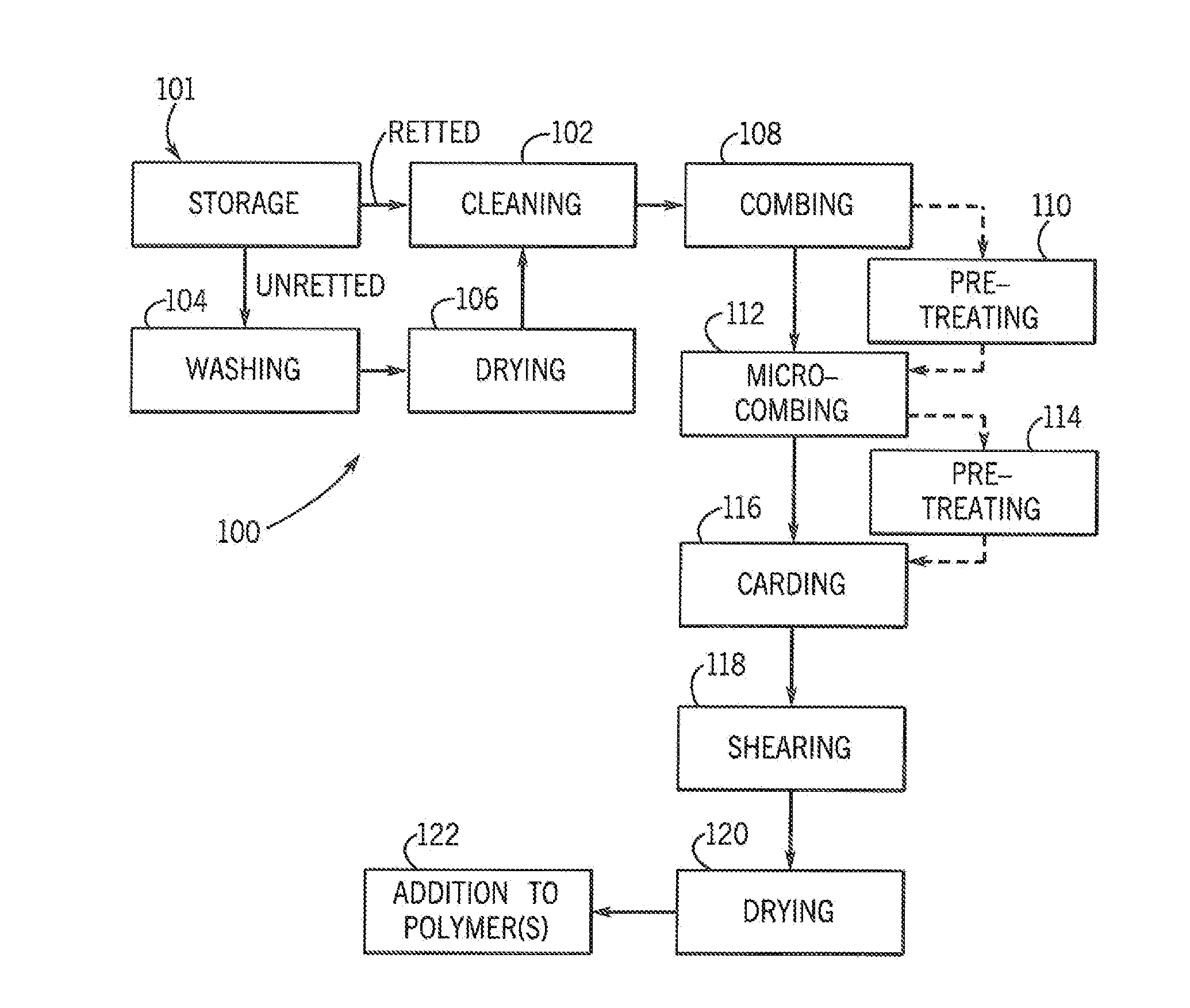

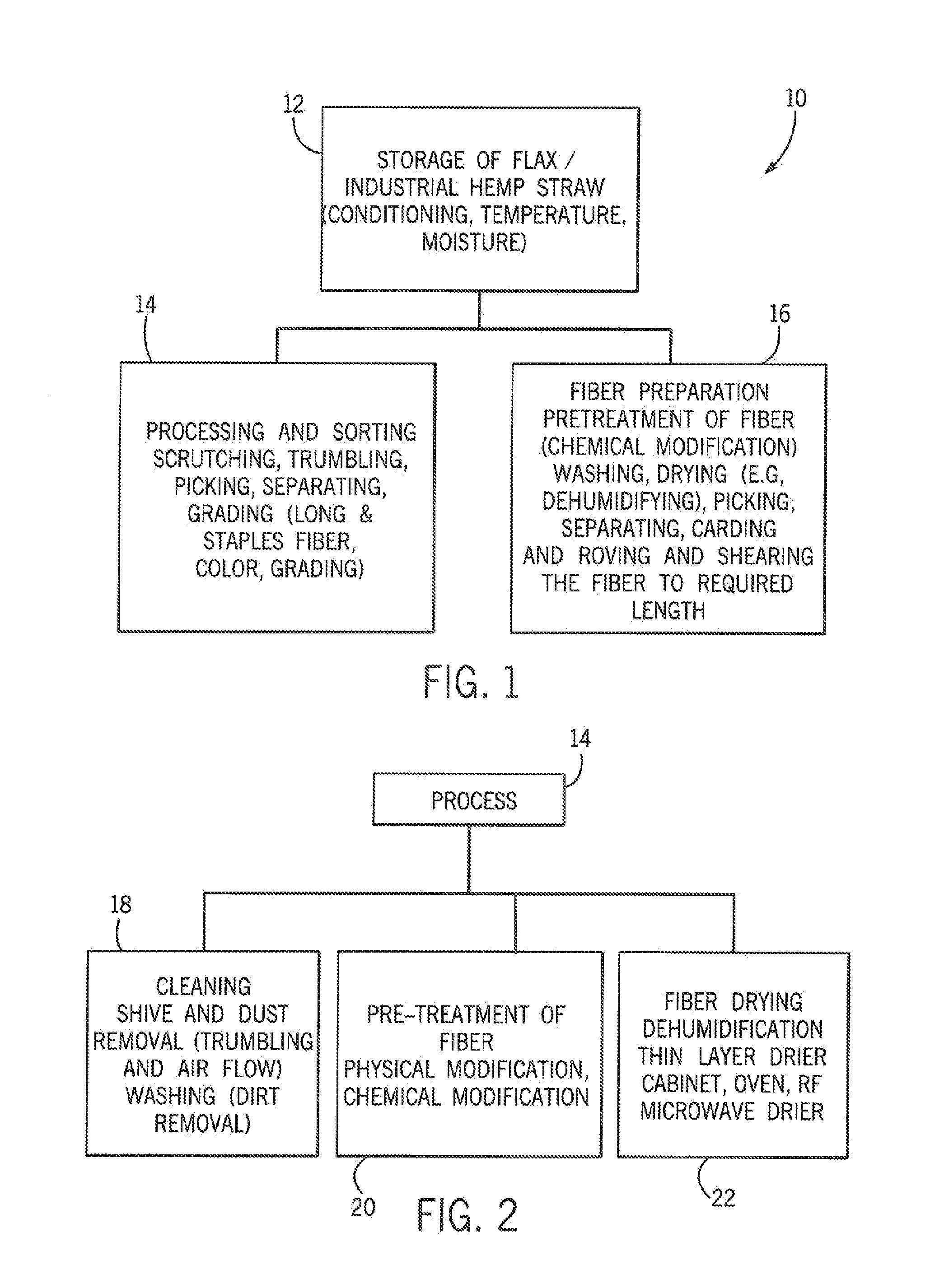

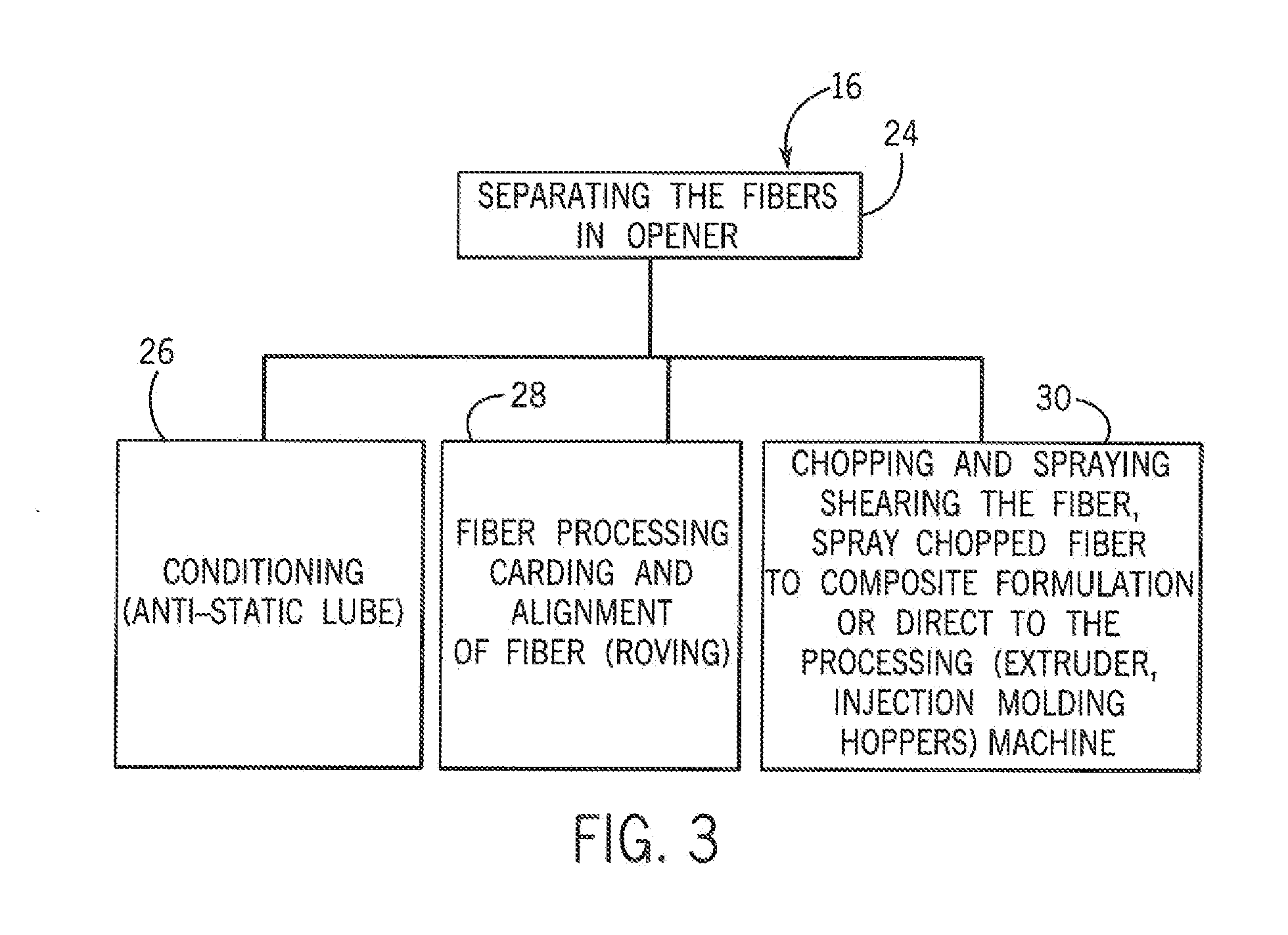

Method To Process Oilseed Flax Fiber For Use In Biocomposite Materials

ActiveUS20150166745A1Retention strengthOptimizationMechanical impurity removalFibre cleaning/opening by air draught arrangementsFlax fiberSISAL

A method and system for the production of fibers for use in biocomposites is provided that includes the ability to use both retted and unretted straw, that keeps the molecular structure of the fibers intact by subjecting the fibers to minimal stress, that maximizes the fiber's aspect ratio, that maximizes the strength of the fibers, and that minimizes time and energy inputs, along with maintaining the fibers in good condition for bonding to the polymer(s) used with the fibers to form the biocomposite material. This consequently increases the functionality of the biocomposites produced (i.e. reinforcement, sound absorption, light weight, heat capacity, etc.), increasing their marketability. Additionally, as the disclosed method does not damage the fibers, oilseed flax straw, as well as all types of fibrous materials (i.e. fiber flax, banana, jute, industrial hemp, sisal, coir) etc., can be processed in bio composite materials.

Owner:CNH IND CANADA

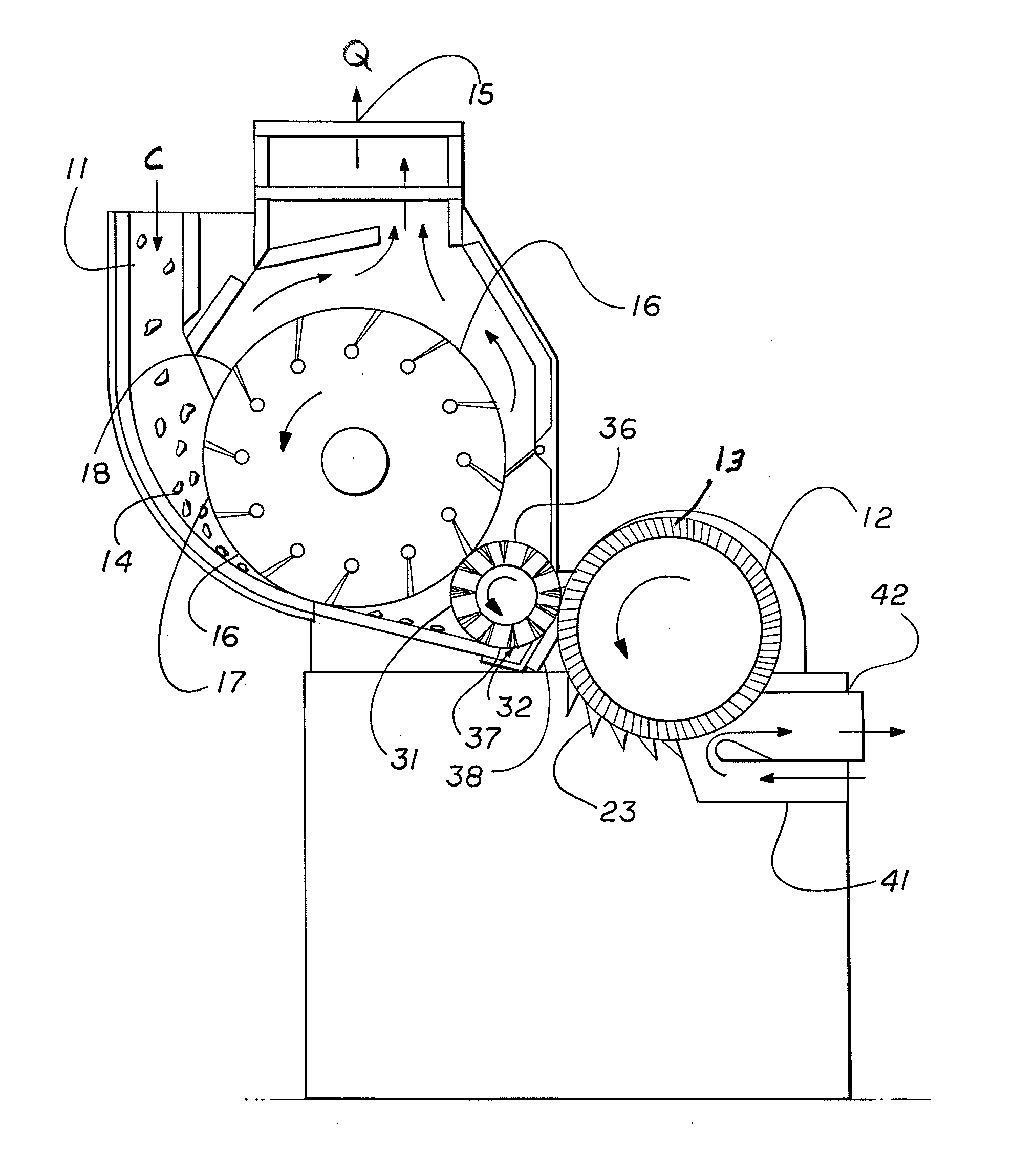

Method and Apparatus for Separating Foreign Matter From Fibrous Material

ActiveUS20090172918A1Simple methodEliminate needMechanical impurity removalLubricating devicesForeign matterFiber

An apparatus for cleaning foreign matter from separated tufts of fiber uses a revolving open reel type structure mounted within a porous housing to separate a conveying air stream from tufts of fiber conveyed thereby and deliver the tufts to a toothed cleaning cylinder which passes beneath a plurality of cleaning bars. The open reel utilizes brush like outer surfaces to sweep tufts of fiber from the housing back into the air stream adjacent the cleaning cylinder.

Owner:LUMMUS INDS

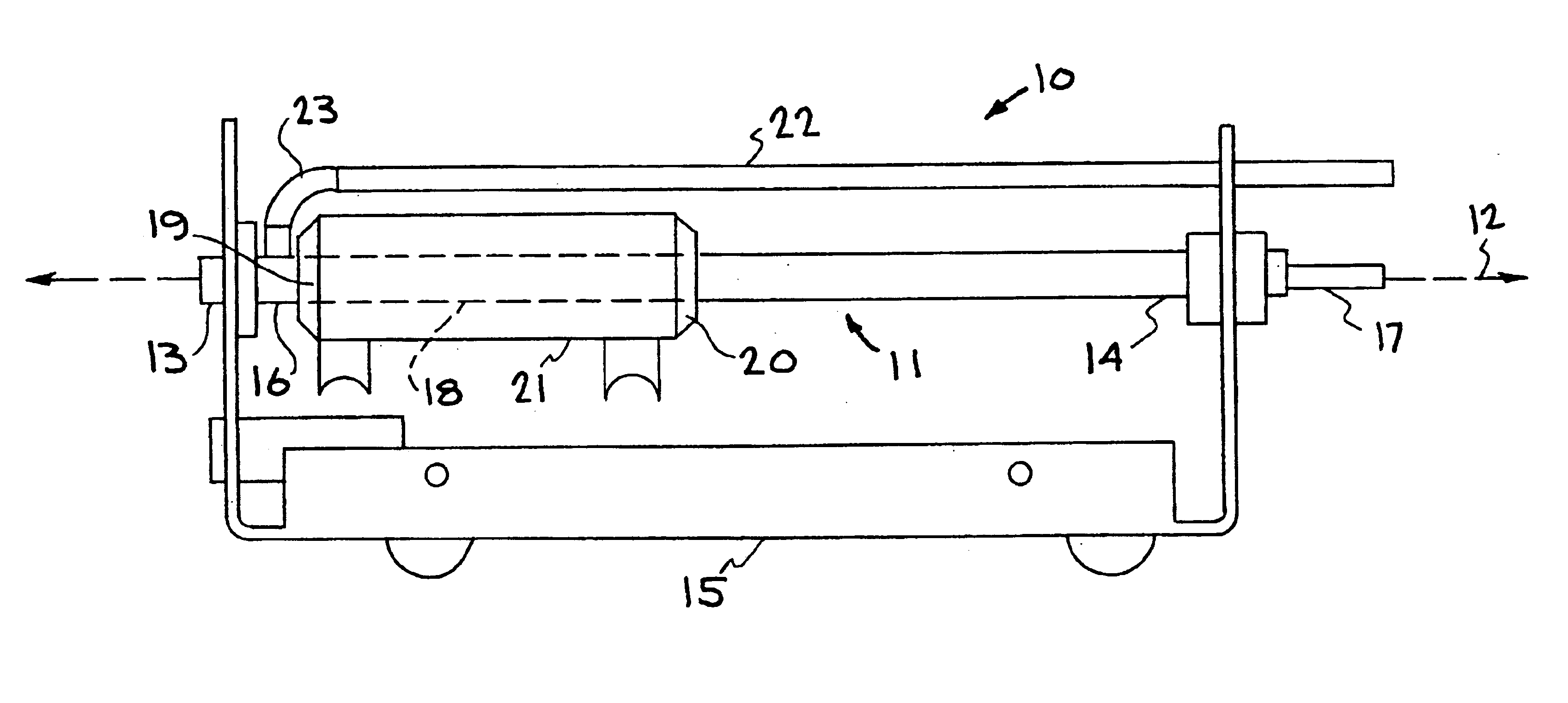

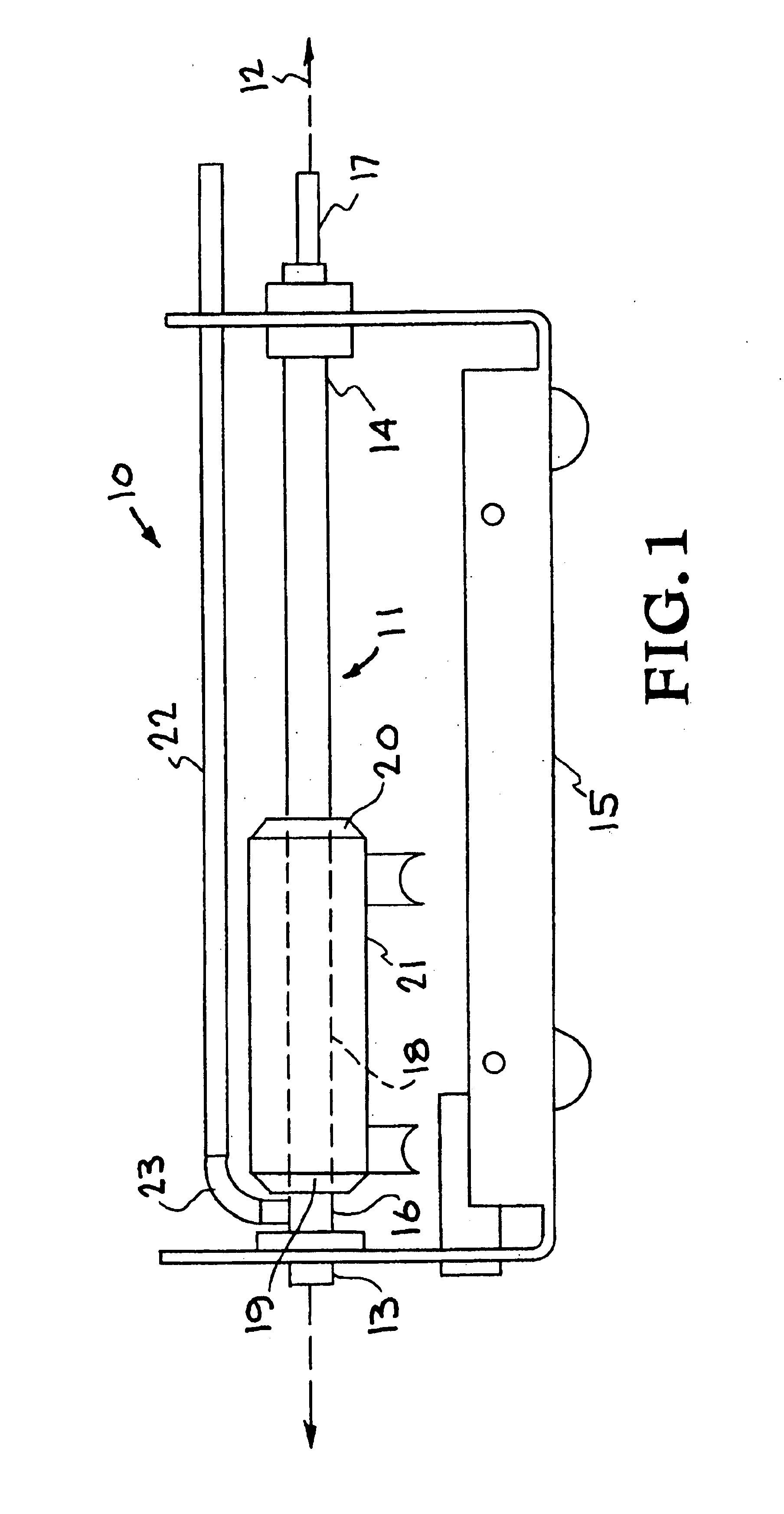

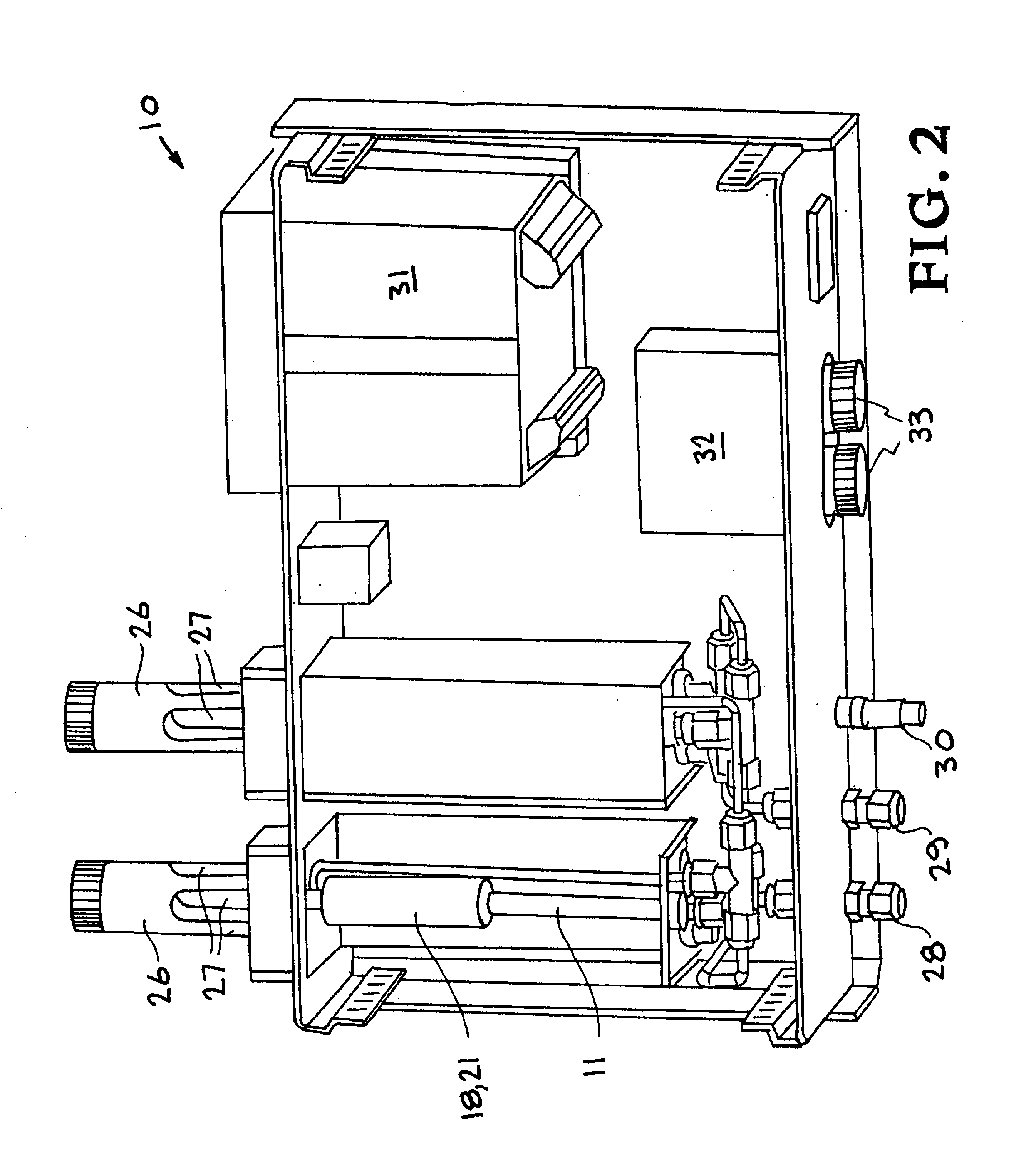

Solid phase microextraction fiber cleaning and conditioning apparatus and method

ActiveUS7047661B2Enhanced agitationIncrease desorptionMechanical impurity removalDrying solid materials with heatFiberSolid-phase microextraction

A SPME-fiber cleaning and conditioning apparatus and method having an elongated heating chamber with first and second opposite ends. The first end is capable of insertably receiving a SPME fiber portion of a SPME device, and the second end is a fluid outlet. A heater is provided for heating the chamber and heat-treating an inserted SPME fiber. Contaminants and other particles are agitated, desorbed and purged from the inserted SPME fiber by flowing a fluid through the chamber from the first end to the second end, away from the SPME device. Additionally, turbulence may be produced in the flow at a location adjacent the first end, to enhance agitation, desorption, and purging. A holder may also be provided extending from the first end for supporting the SPME device in a substantially horizontal orientation when the SPME fiber is positioned in the chamber.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Method for reeling silk at low temperature by utilizing strongly alkaline electrolyzed water

InactiveCN102605436ALow costIncrease productionMechanical impurity removalSilk reelingWater bathsWastewater

The invention discloses a method for reeling silk at low temperature by utilizing strongly alkaline electrolyzed water, falling into silk making technical field. The method includes subjecting common tap water to electrolytic treatment via water electrolyzer or electrolytic cell, to obtain strongly alkaline electrolyzed water with pH of 11.0-12.0; performing constant-temperature oscillation swelling soaking treatment on silkworm cocoon in strongly alkaline electrolyzed water at 60-80 DEG C directly for 5-10 min; and taking strongly alkaline electrolyzed water as reeling hot water bath, transferring the swollen silkworm cocoon to the reeling hot water bath at 40-70 DEG C, and immediately reeling silk, to obtain raw silk product. The inventive method performs reeling at low temperature, to improve product quality and save energy. The invention can realize industrial production of strongly alkaline electrolyzed water at low cost and high yield, high-efficiency low-cost recovery of sericin, and cyclic utilization of reeling waste water after simple purification treatment, to thereby avoid environmental pollution caused by a large amount of waste liquid.

Owner:SUZHOU UNIV

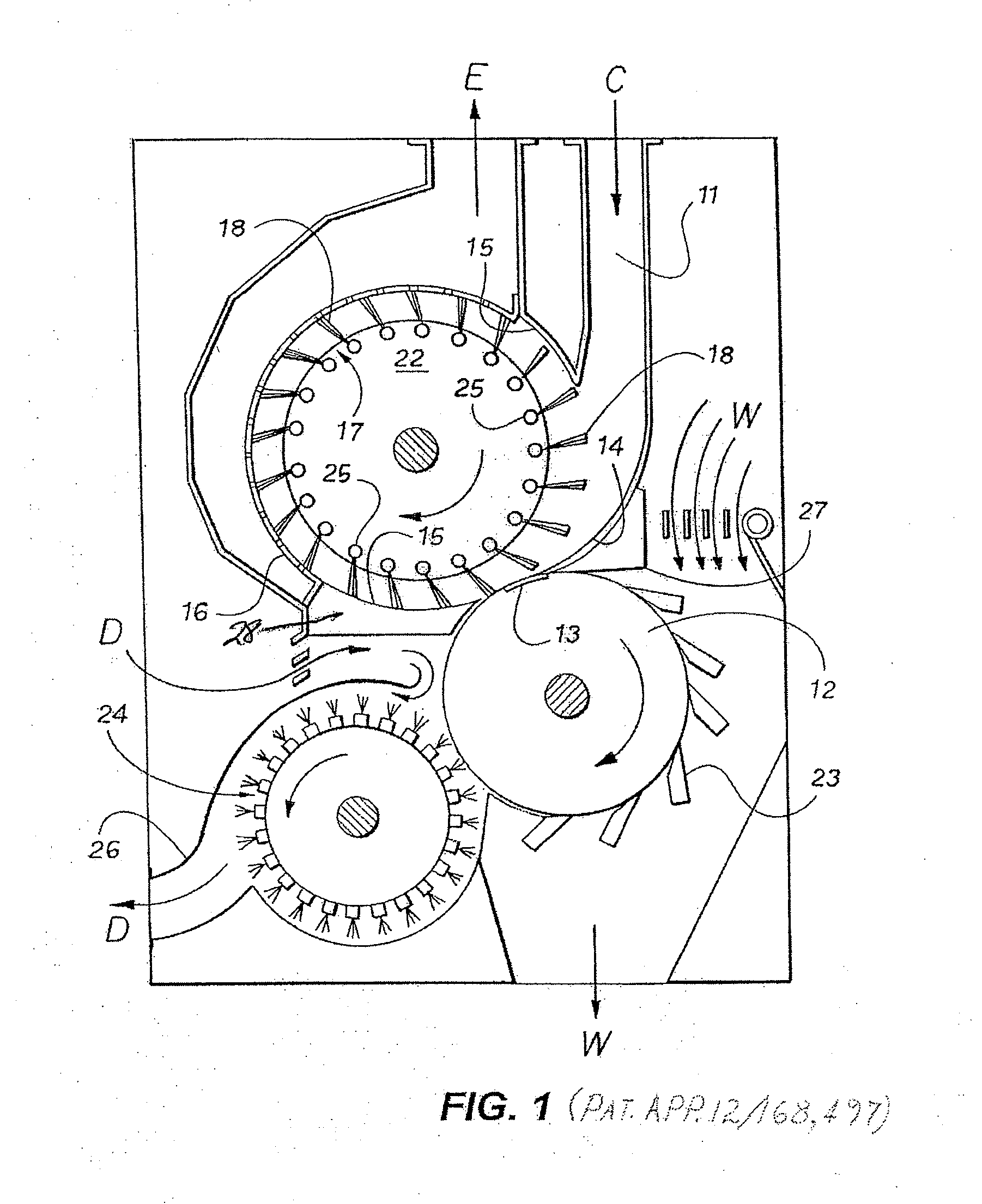

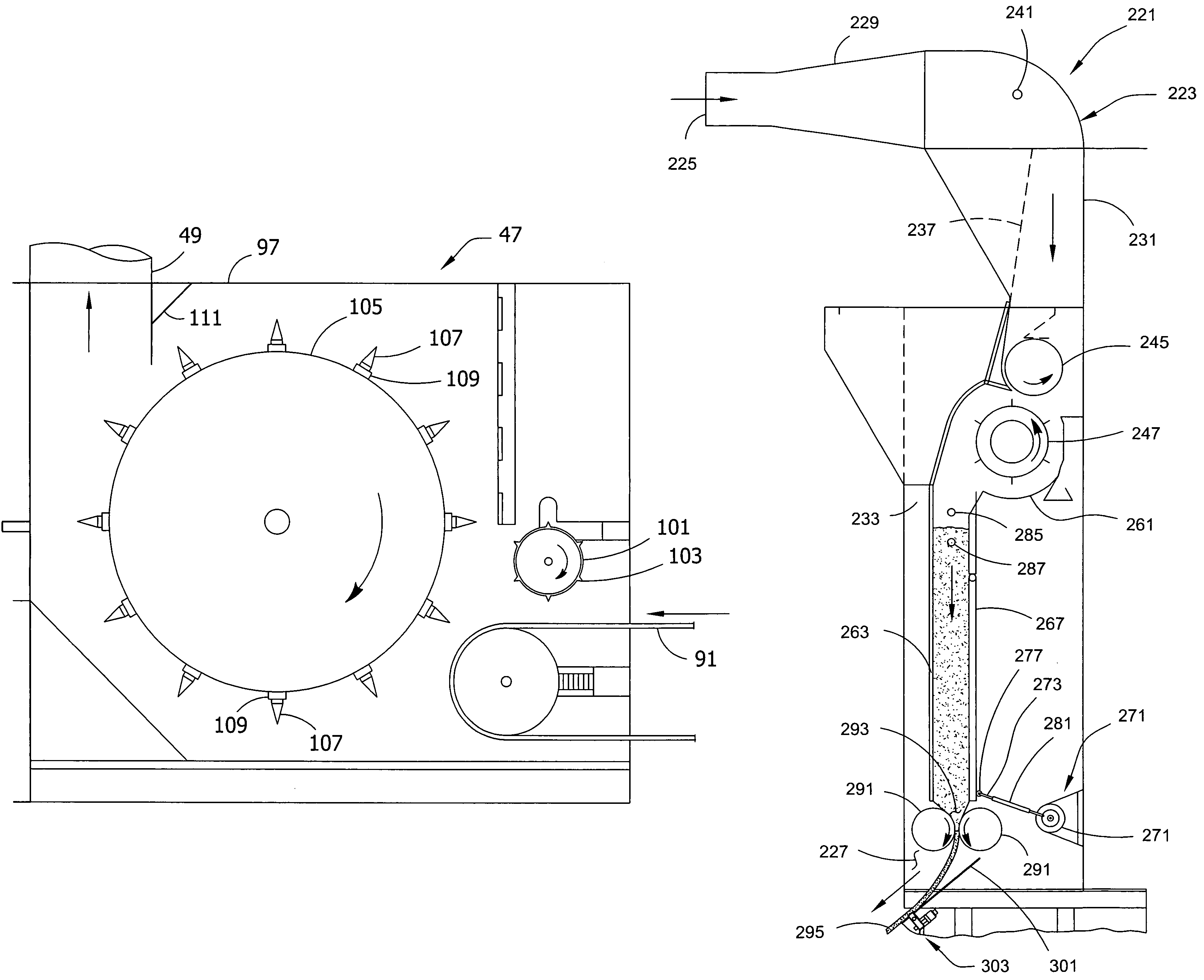

Method and Apparatus for Separating Foreign Matter from Fibrous Material

ActiveUS20100306966A1High speed separation and cleaningSimple methodMechanical impurity removalVegetable fibre separation from seedsForeign matterFiber

An apparatus for cleaning foreign matter from separated tufts of fiber uses a transfer cylinder intermediate a revolving open reel type structure mounted within a porous housing to separate a conveying air stream from tufts of fiber conveyed thereby and a toothed cleaning cylinder to separate air flow through said revolving reel from said cleaning cylinder such that air is not drawn through said cleaning cylinder into said porous housing.

Owner:LUMMUS INDS

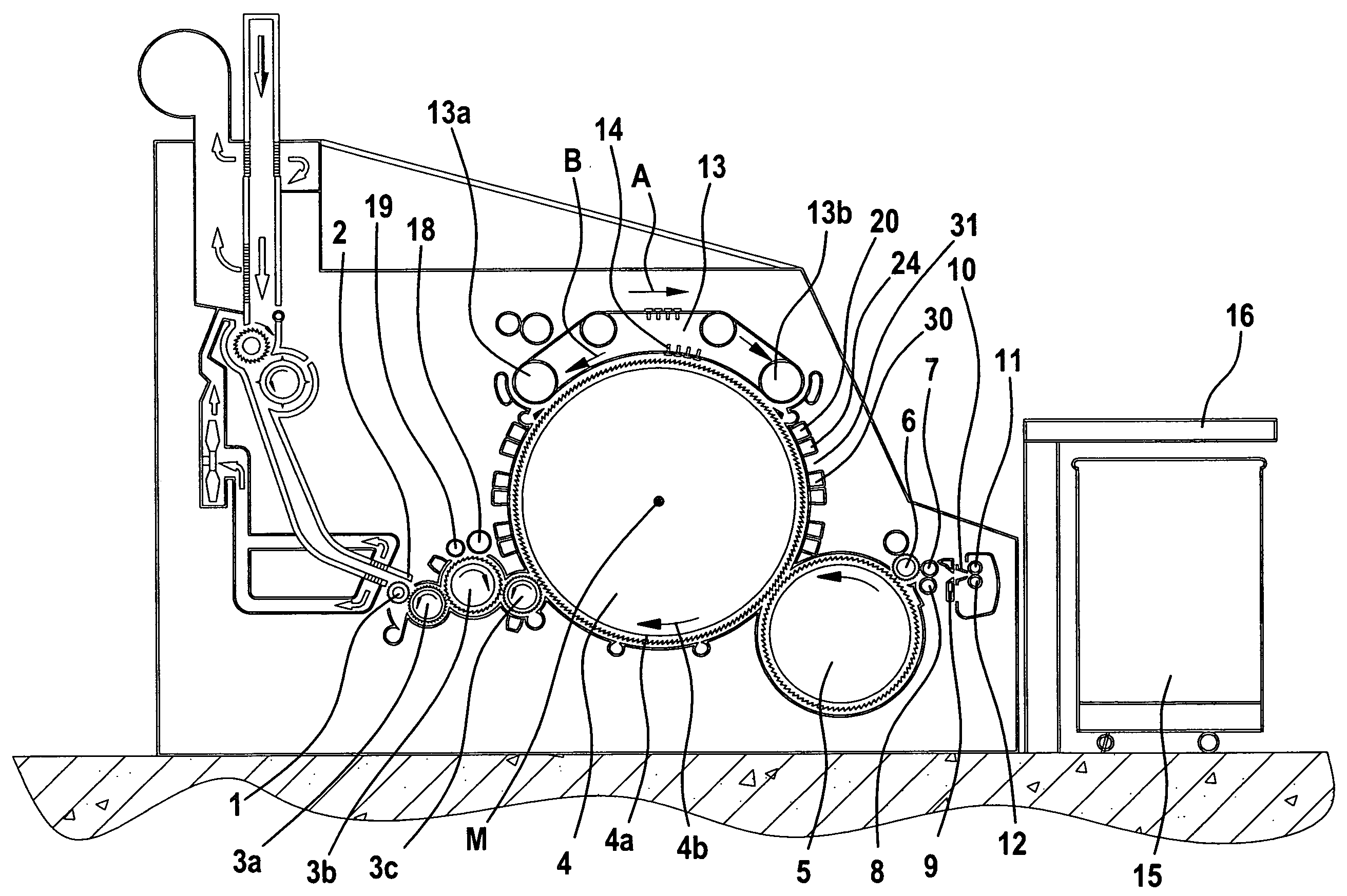

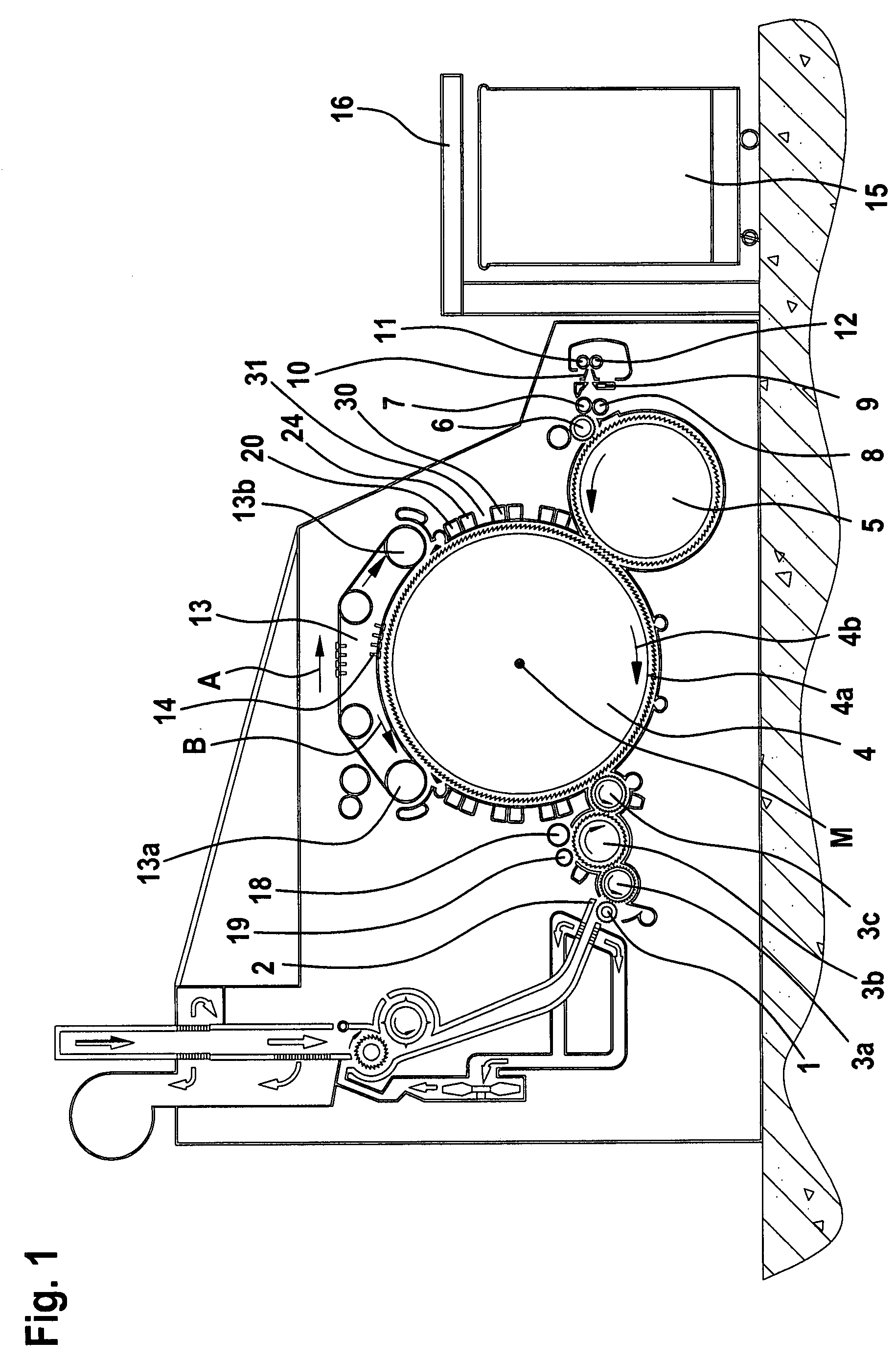

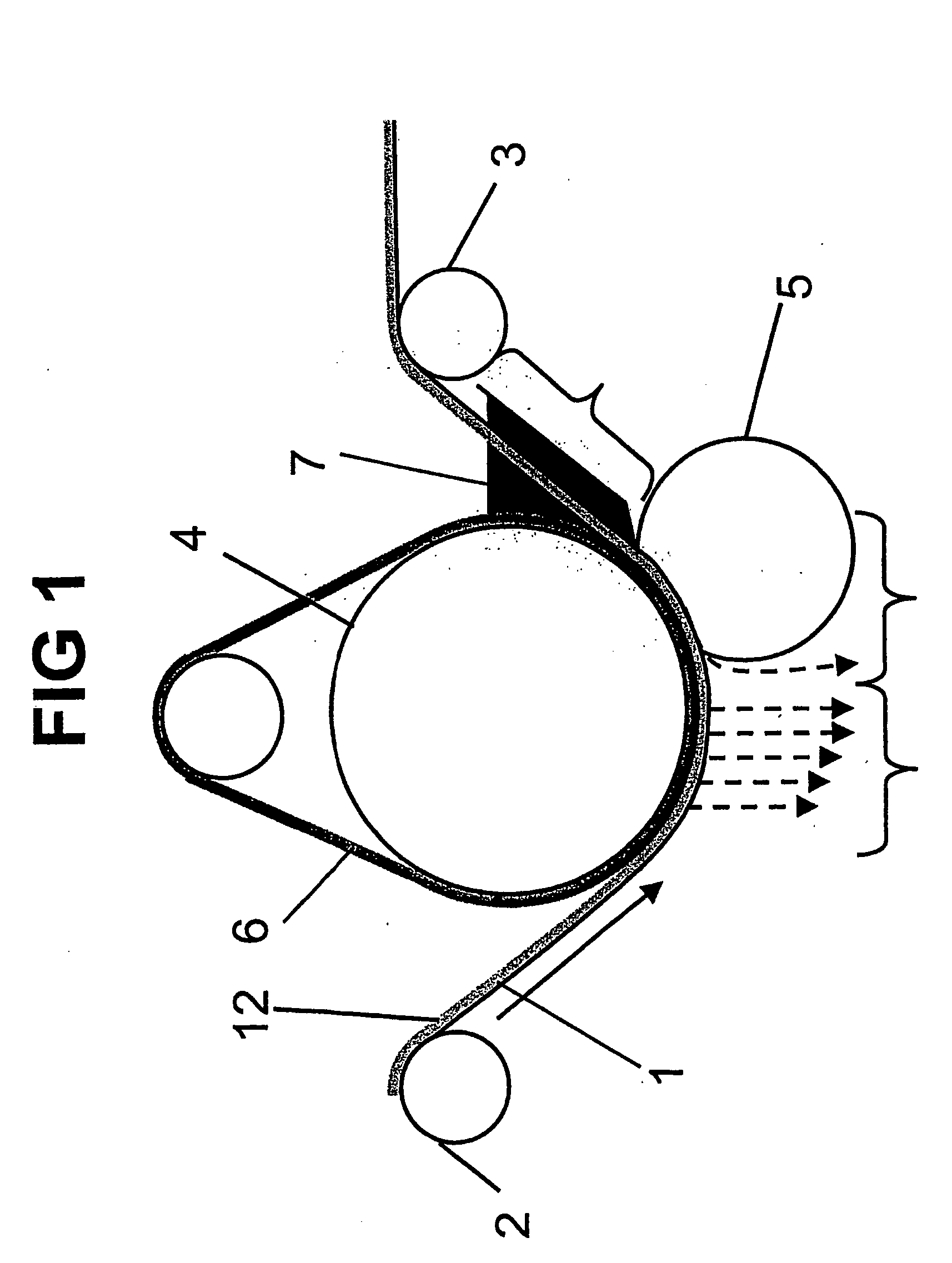

Apparatus on a flat card or roller card for textile fibres, such as cotton, synthetic fibres or the like, for removing short fibres

InactiveUS20070180670A1Easy dischargeEasy to separateMechanical impurity removalFibre cleaning/openingTextile fiberEngineering

An apparatus on a carding machine has a covering comprising work and cover elements lying opposite the clothing of a high-speed cylinder. There is, in succession, an air exhaust opening for the exit of air and an opening for entry of air, past which openings a flow of fibres and air is passed. To allow improved detachment and elimination of short fibres in a simple manner, the spacing of the covering upstream of the exhaust opening is smaller than the spacing of the covering between air exhaust opening and air inlet opening and an airflow flows against the direction of rotation of the cylinder along the surface of the cylinder and flows with short fibres through the air exhaust opening.

Owner:TRUETZSCHLER GMBH & CO KG

Method for separating feather fibers from poultry feather raw material

InactiveCN104651983AAchieve fine separationEasy separationMechanical impurity removalFibre separationFiberMaterials science

The invention provides a method for separating feather fibers from a poultry feather raw material. The method comprises four steps, namely washing, stripping, carrying out multistage separation and drying, wherein in the step of multistage separation, the feather fibers are subjected to multistage separation by using slit type screens of different screen slit widths, the fine separation of the feather fibers is realized, more choices are provided for the further full utilization of the feather fibers, and thus, the application is more convenient. In addition, the method provided by the invention only comprises four steps, each step is simple and feasible and does not need complicated and expensive equipment, embodied in that only the step (3) of the four steps adopts the slit type screens as a multistage separation device for the feather fibers, and the slit type screens are common devices for papermaking and are simple in structure, so that the separating operation is simple, convenient and feasible.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

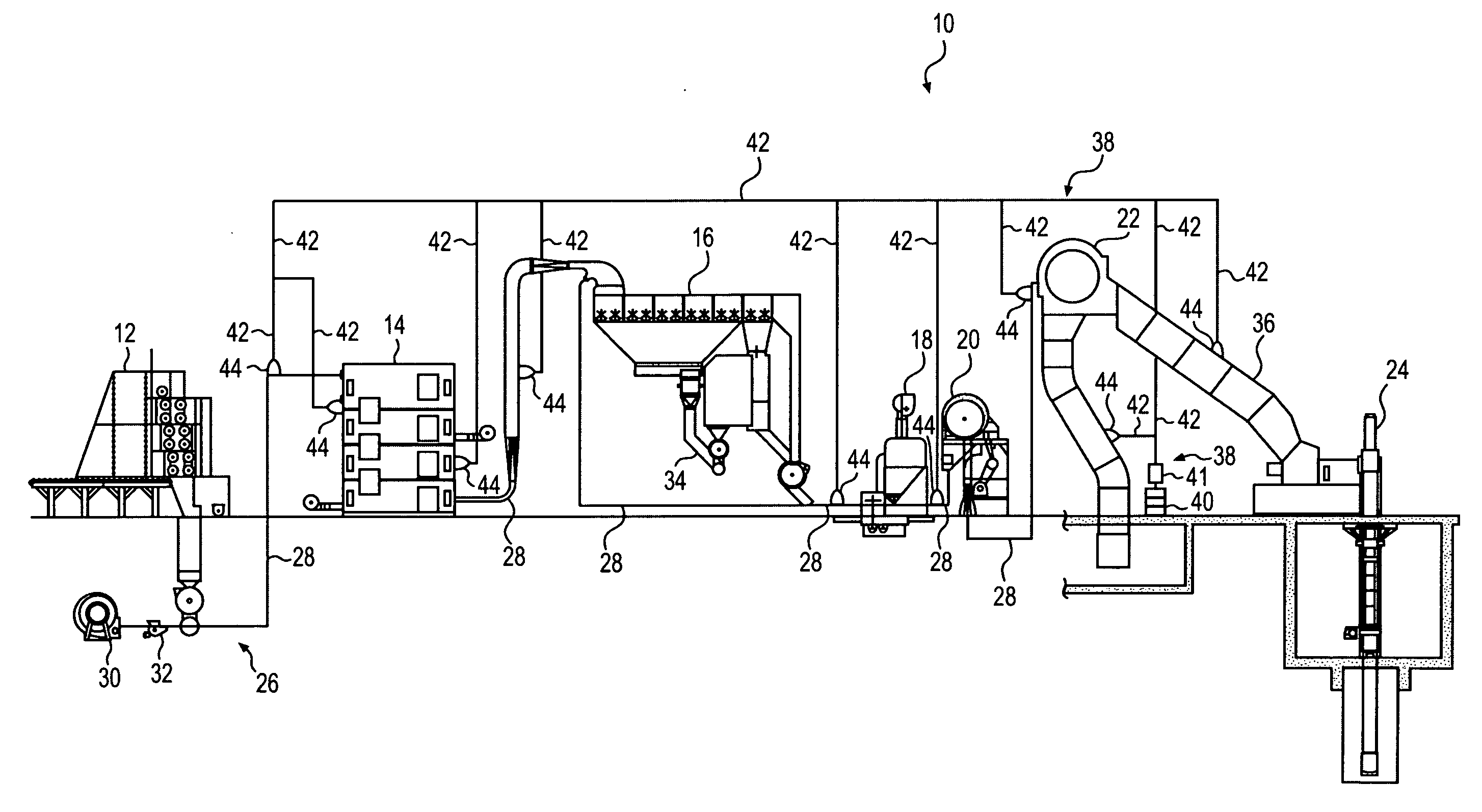

System and method for processing fiber

InactiveUS20070192997A1Mechanical impurity removalSafety devices for fibre treatmentFiberEngineering

A system for processing fibers includes a dryer configured to remove moisture from at least a portion of the fibers, and a cleaner configured to remove at least one of dirt, sticks, and seeds from the portion of the fibers. The system further includes a conduit for transferring the portion of the fibers between the dryer and the cleaner, and a treatment system configured to apply chemical to the portion of the fibers. The system for processing fibers is configured to alter at least one of a color characteristic, moisture content, and a texture characteristic of the portion of the fibers via application of chemical to the portion of the fibers.

Owner:WINN WILLIAM E

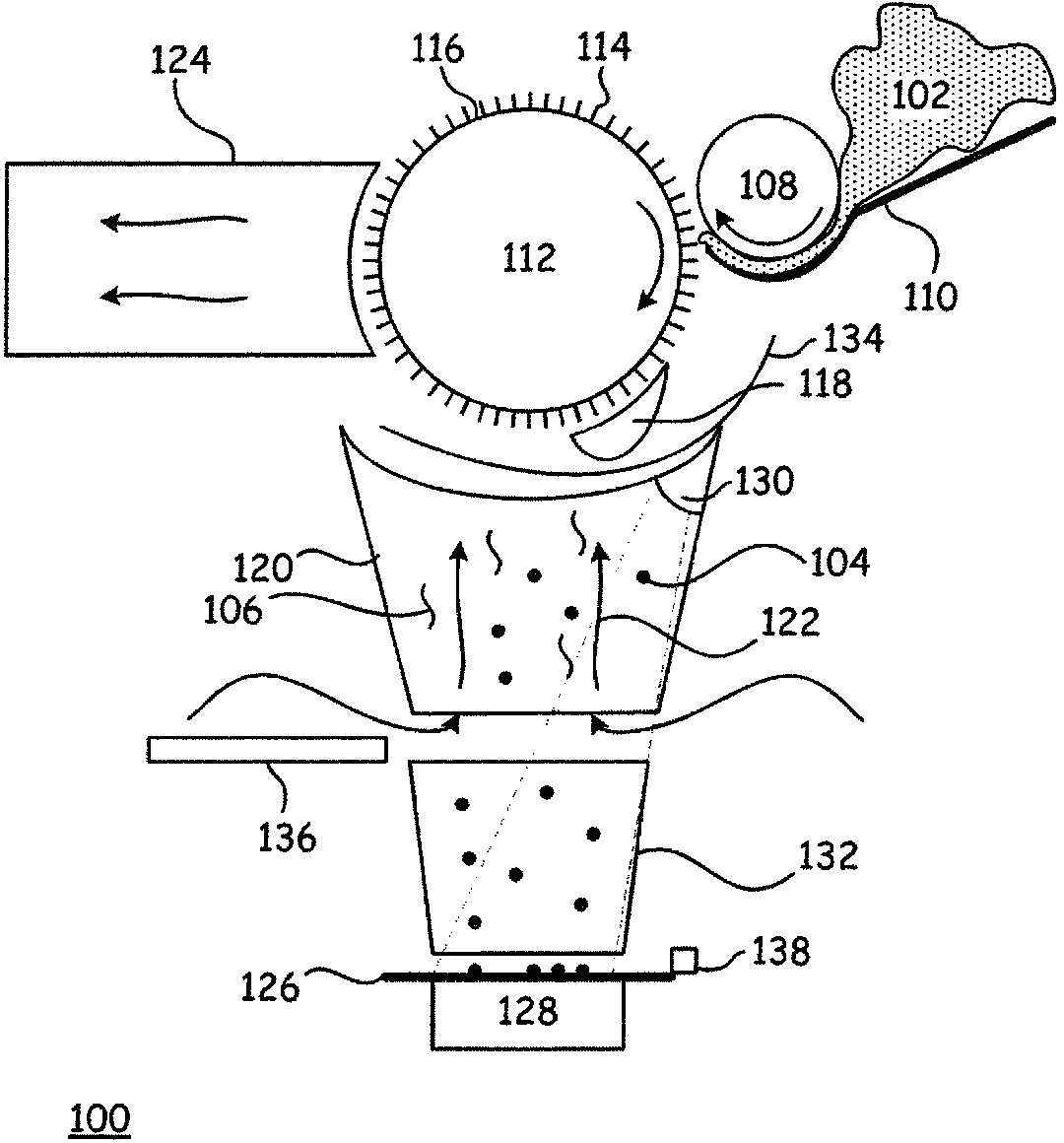

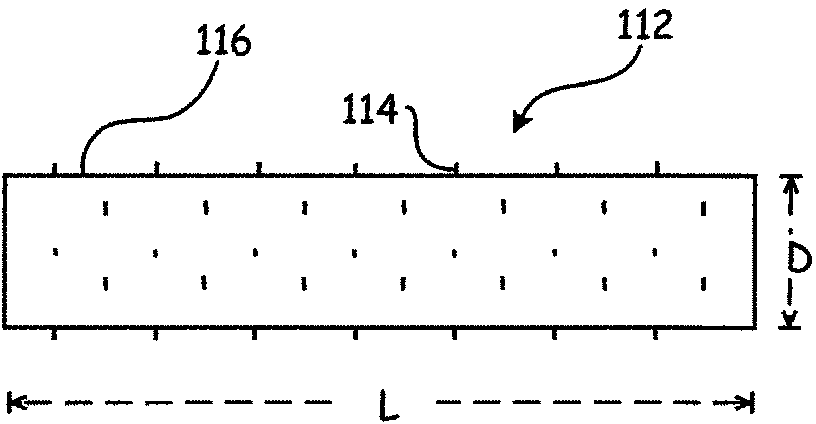

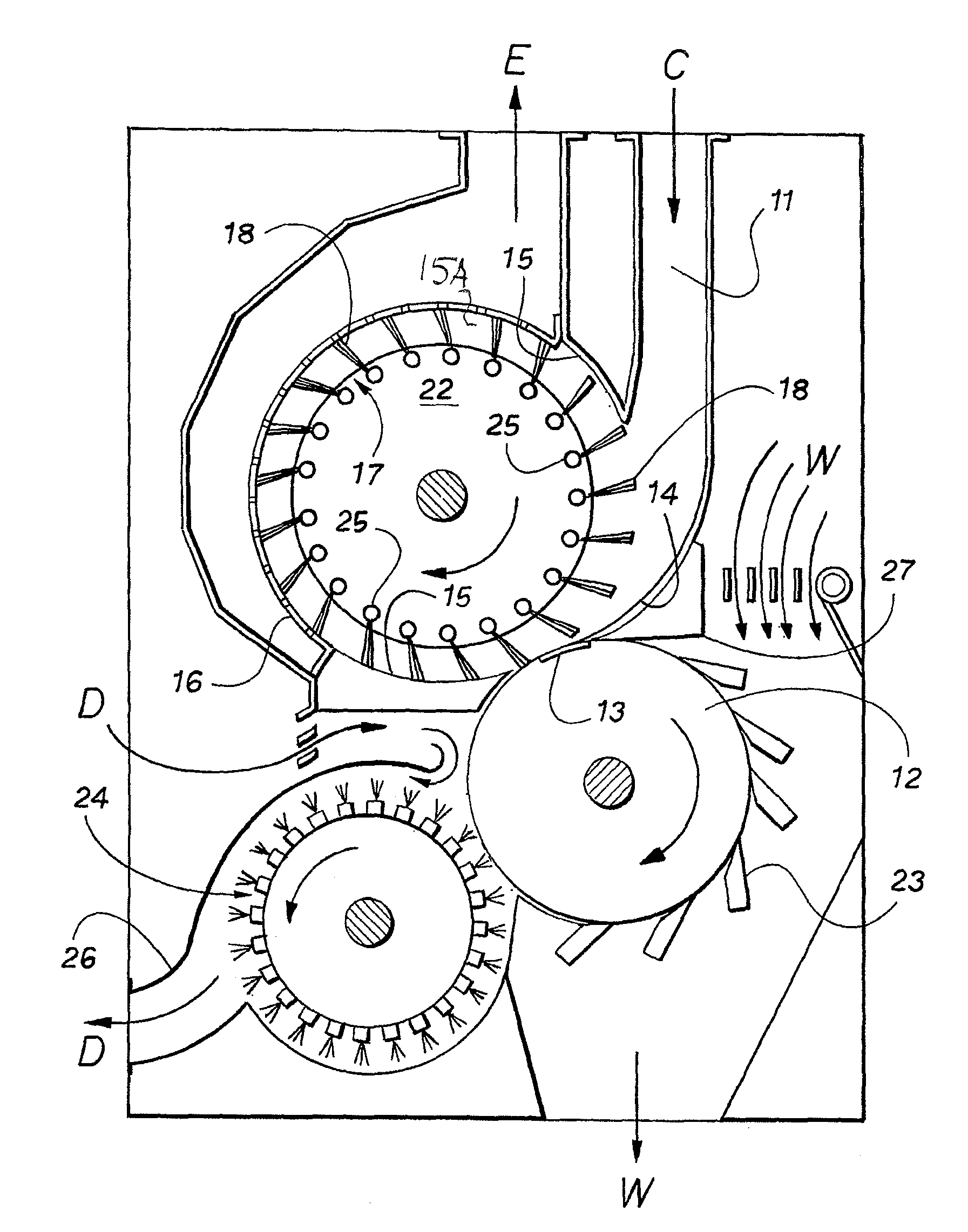

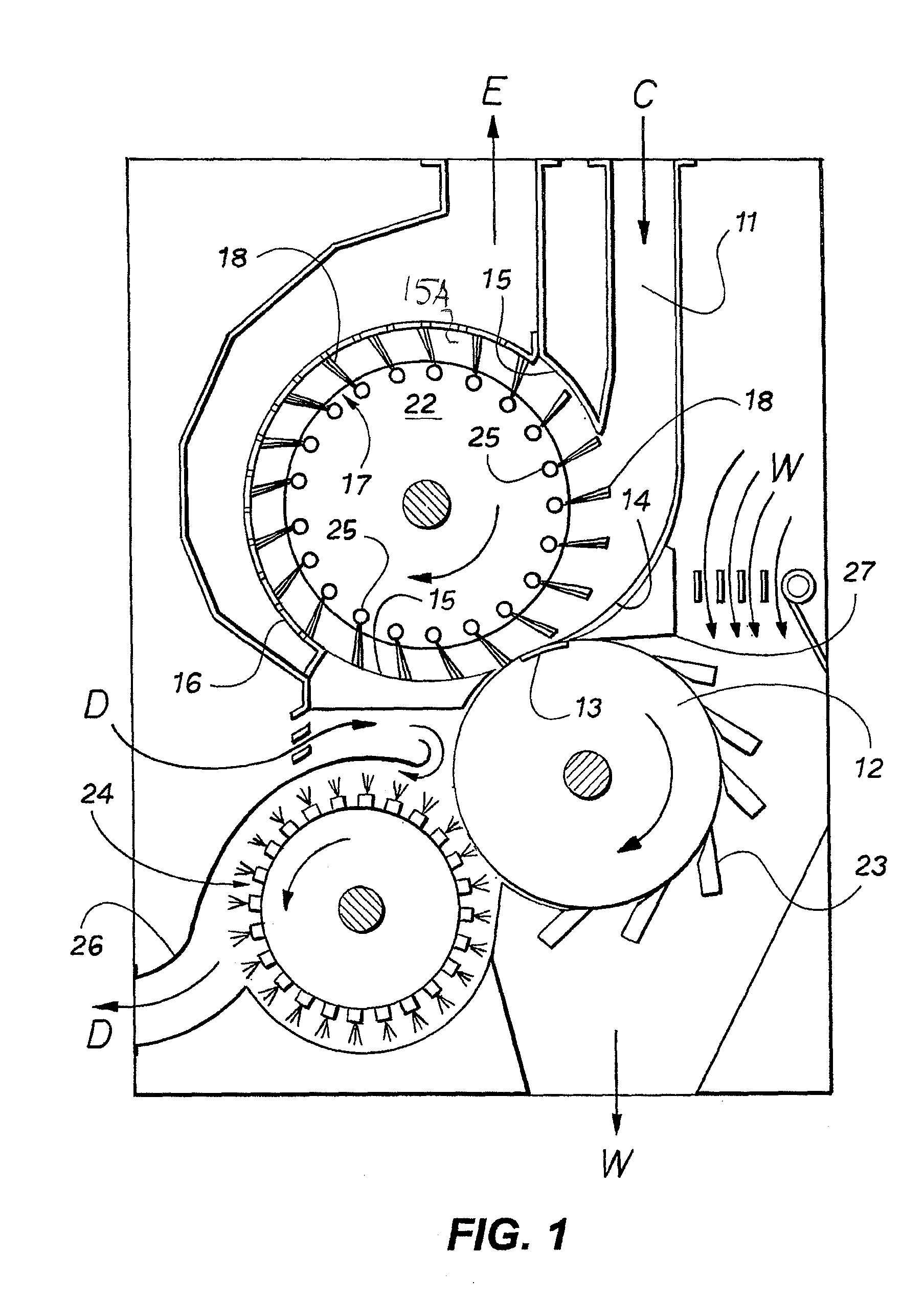

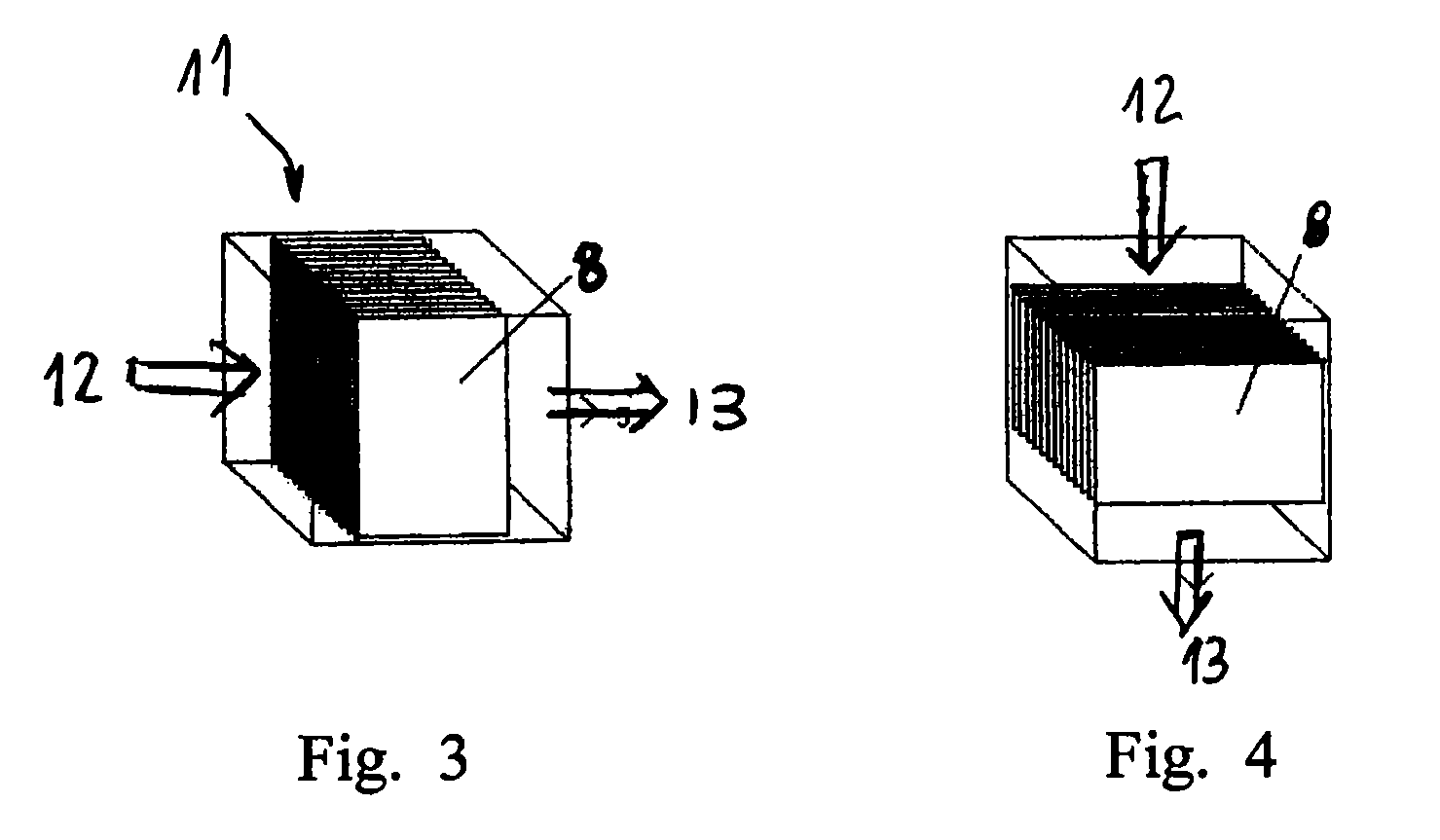

Trash separator

ActiveCN103510188AEasy to weighEasy to collectMechanical impurity removalFibre cleaning/opening by air draught arrangementsFiberCounter flow

A separation apparatus (100) for processing a fiber sample (102) that includes both fibers (106) and trash (104) is provided. The separation apparatus comprises a separation cylinder (112) and a collection surface (126) for receiving the trash (104) from the separation cylinder (112). The counter-flow air (122) moves in a separation region between the separation cylinder (112) and the collection surface (126), in a direction that is substantially perpendicular to and towards the underside surface of the separation cylinder (112). The counter-flow air (122) has at each position within the separation region an air-flow velocity sufficient for the counter-flow air (122) to blow the fibers (106) that are not originally retained by the protrusions (114) up toward the separation cylinder (112), and yet insufficient to prevent gravity from pulling the trash (104) downward through the counter-flow air (122).

Owner:USTER TECHNOLOGIES

Method and apparatus for separating foreign matter from fibrous material

ActiveUS7779514B2Simple methodEliminate needMechanical impurity removalVegetable fibre separation from seedsForeign matterFiber

An apparatus for cleaning foreign matter from separated tufts of fiber uses a revolving open reel type structure mounted within a porous housing to separate a conveying air stream from tufts of fiber conveyed thereby and deliver the tufts to a toothed cleaning cylinder which passes beneath a plurality of cleaning bars. The open reel utilizes brush like outer surfaces to sweep tufts of fiber from the housing back into the air stream adjacent the cleaning cylinder.

Owner:LUMMUS INDS

Apparatus in spinning preparation for separating foreign objects at a high-speed roll for opening or doffing fibre material

InactiveUS20080178431A1Reduce the ratioAct quicklyMechanical impurity removalFibre cleaning/opening by air draught arrangementsFiberEngineering

In an apparatus in spinning preparation for separating foreign objects at a roll for opening or doffing fibre material, at least one device for separating the foreign objects is associated with a face of the roll. That device comprises an arrangement for producing a current of blast air flowing onto the face for detaching the foreign objects and carrying them away. The arrangement comprises a plurality of blast nozzles arranged across the width of the roll. To permit separation and allow rapid changes of the action of the blast air current, a bar for mounting the blast nozzles is present and the outlet of the blast nozzles is locally displaceable in relation to the face of the roll.

Owner:TRUETZSCHLER GMBH & CO KG

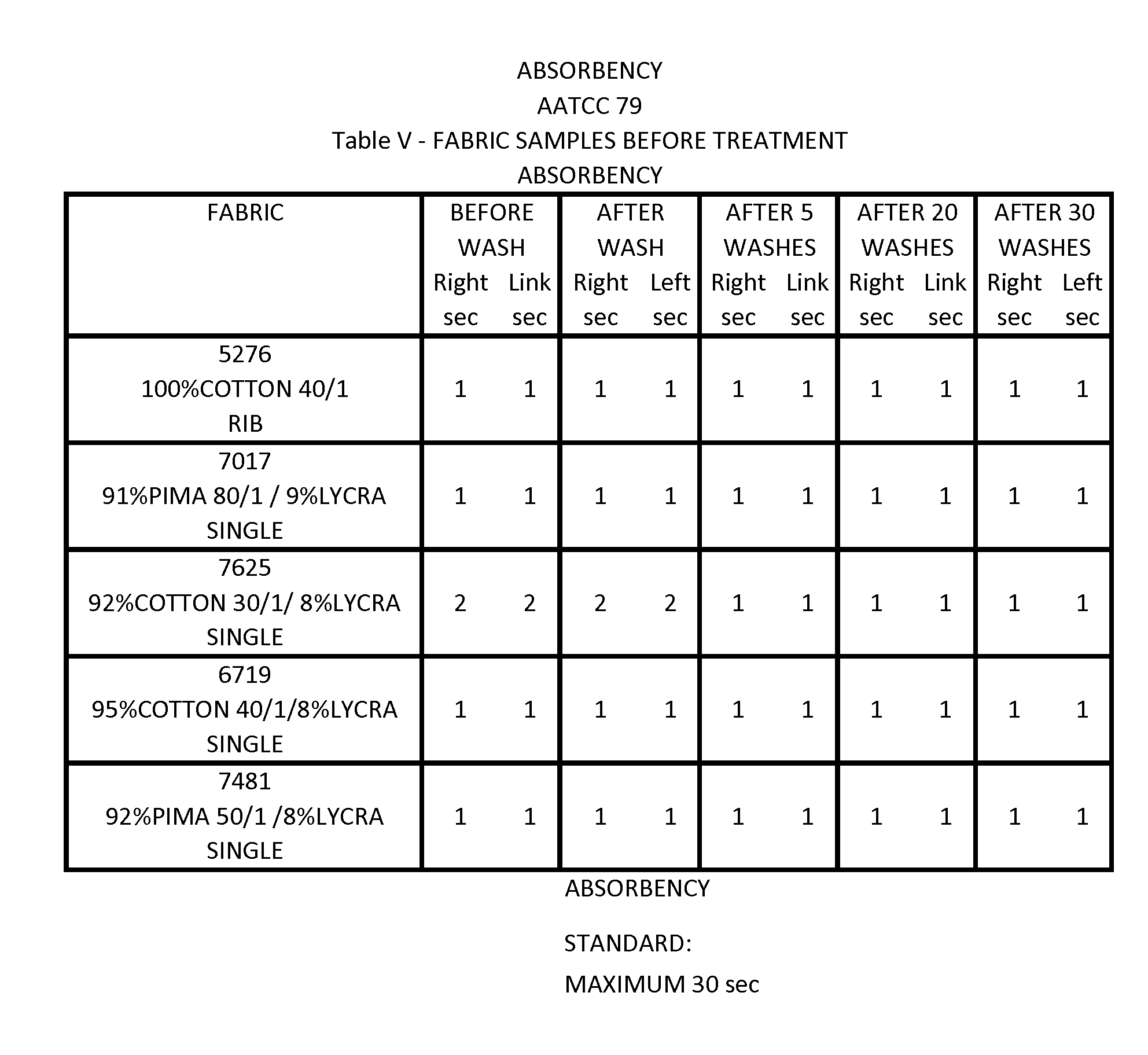

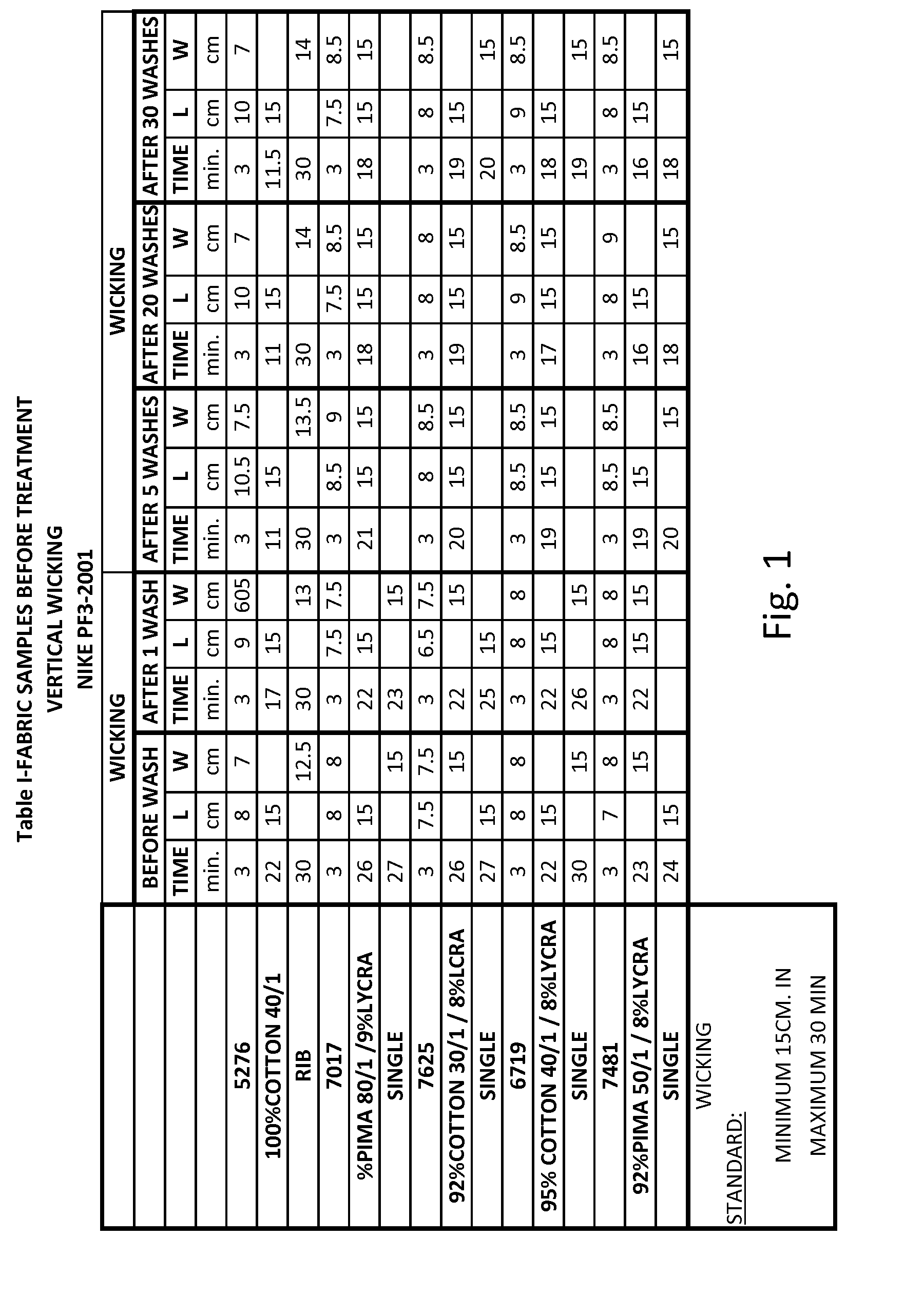

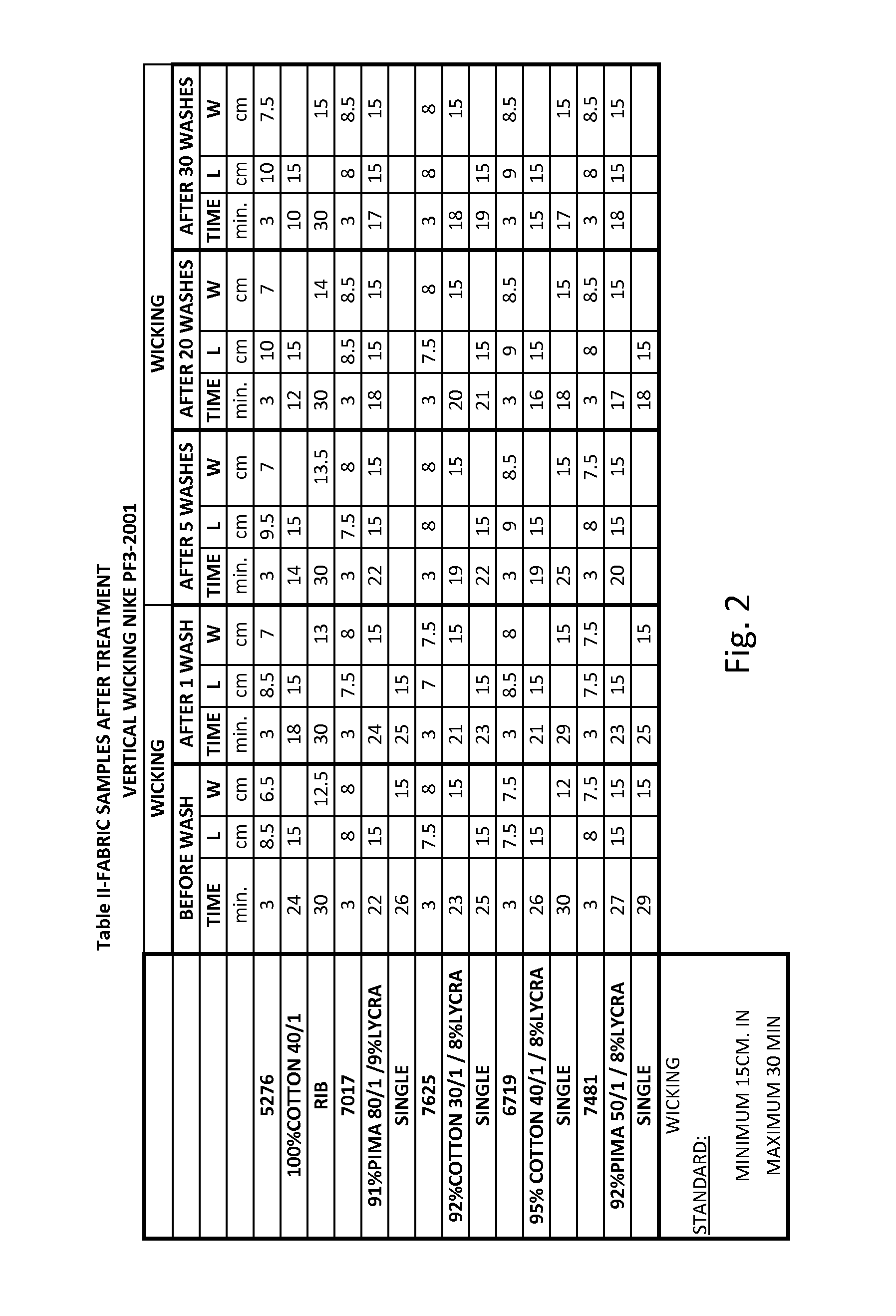

Moisture-management in hydrophilic fibers

ActiveUS20080128044A1Improved moisture-management performanceImprove performanceMechanical impurity removalLubricating devicesHydrophilizationPolymer science

Provided is a fabric having improved moisture-management performance and being resilient to repeated washing, as well as a process for manufacturing the fabric. The process, employing consecutive steps of hydrophilization and hydrophobization, includes defatting cotton or cellulose fibers and their coating with silicone nanoparticles.

Owner:DELTA GALIL INDUSTRIES

Hydrocarbon sequestering product, a method to obtain the product, a method to sequester hydrocarbons and a hydrocarbon sequestration facility

InactiveUS20080300441A1Low productionReduced operating requirementsMechanical impurity removalContaminated soil reclamationHydrocarbonChemistry

A hydrocarbon sequestering product, a method to obtain the product, and a method and a facility to sequester hydrocarbons, wherein the product comprises an oleophilic filamentous material that gets in contact with a medium contaminated by one or more hydrocarbons with the purpose of sequestrating the hydrocarbon(s) present in the medium to free it from said hydrocarbons.

Owner:R CIANCAGLINI Y ASOCIADOS

Novel blending willow

InactiveCN103628144AEliminate static electricityImprove dust removal effectMechanical impurity removalSpinningDust control

The invention provides a novel blending willow which comprises a machine frame, a wool storage box, a wool feeding component, an opening component and a wool outlet pipe, wherein the wool storage box, the wool feeding component, the opening component and the wool outlet pipe are located on the machine frame and sequentially arranged in the direction of a blending process, and the interiors of the wool storage box, the wool feeding component, the opening component and the wool outlet pipe are communicated. The opening component comprises a box body, an opening roller and a plurality of working rollers, wherein the opening roller is arranged inside the box body in a penetrated mode, and the working rollers are located inside the box body and arranged in the circumferential direction of the upper half circumference of the opening roller. The novel blending willow is characterized in that a static electricity induction rod is arranged at the position of a wool inlet of the box body, and a power supplier electrically connected with the static electricity induction rod is arranged on the machine frame. The novel blending willow solves the problem that in the prior art, static electricity generated by tearing and friction between wool fibers inside the blending willow can not be eliminated, has the advantages of being simple in structure and good in static electricity eliminating effect and dust removal effect, and can be popularized and applied to any machine in the technical field of wool spinning machines.

Owner:SUZHOU JUNYI TEXTILE

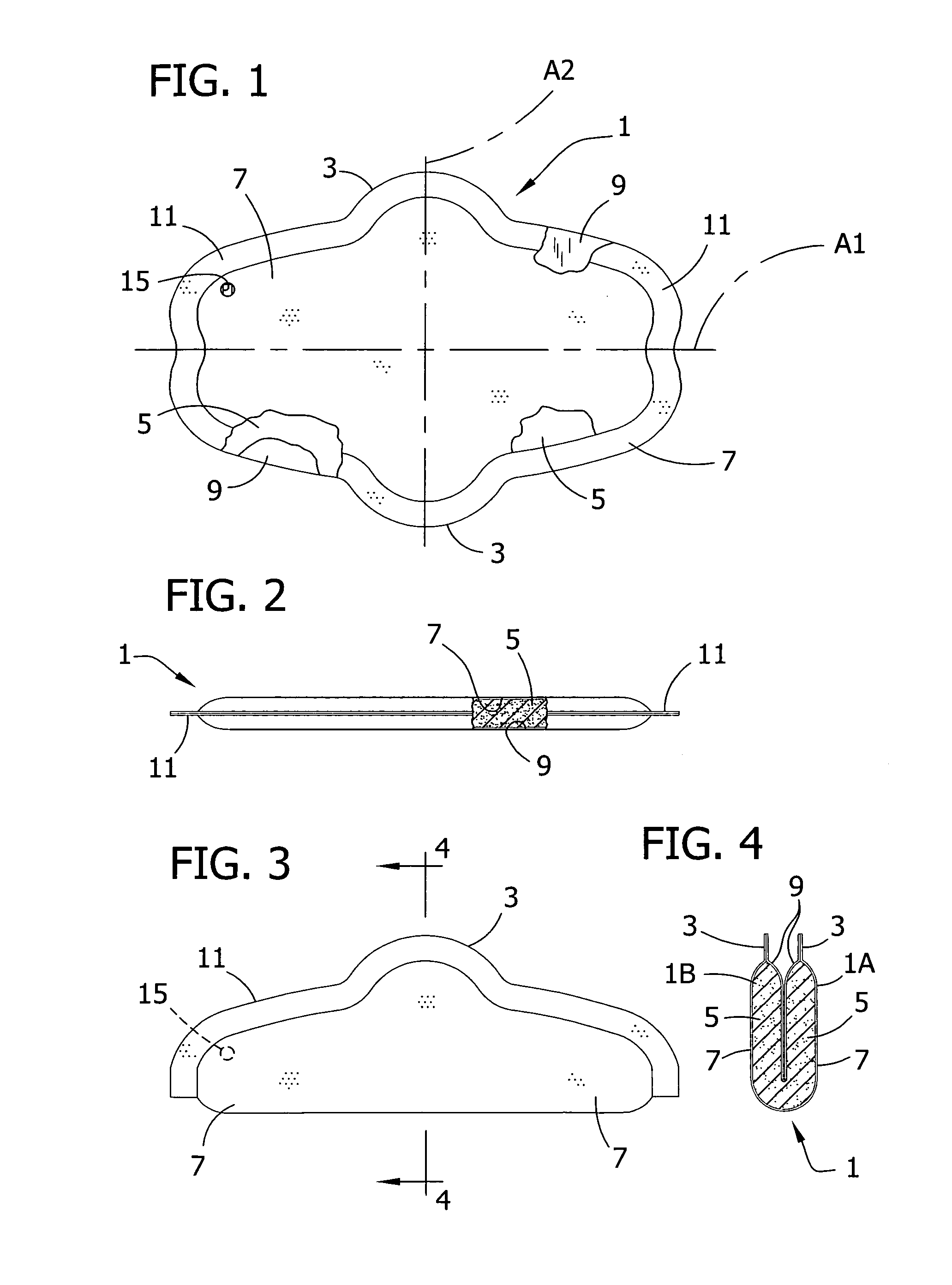

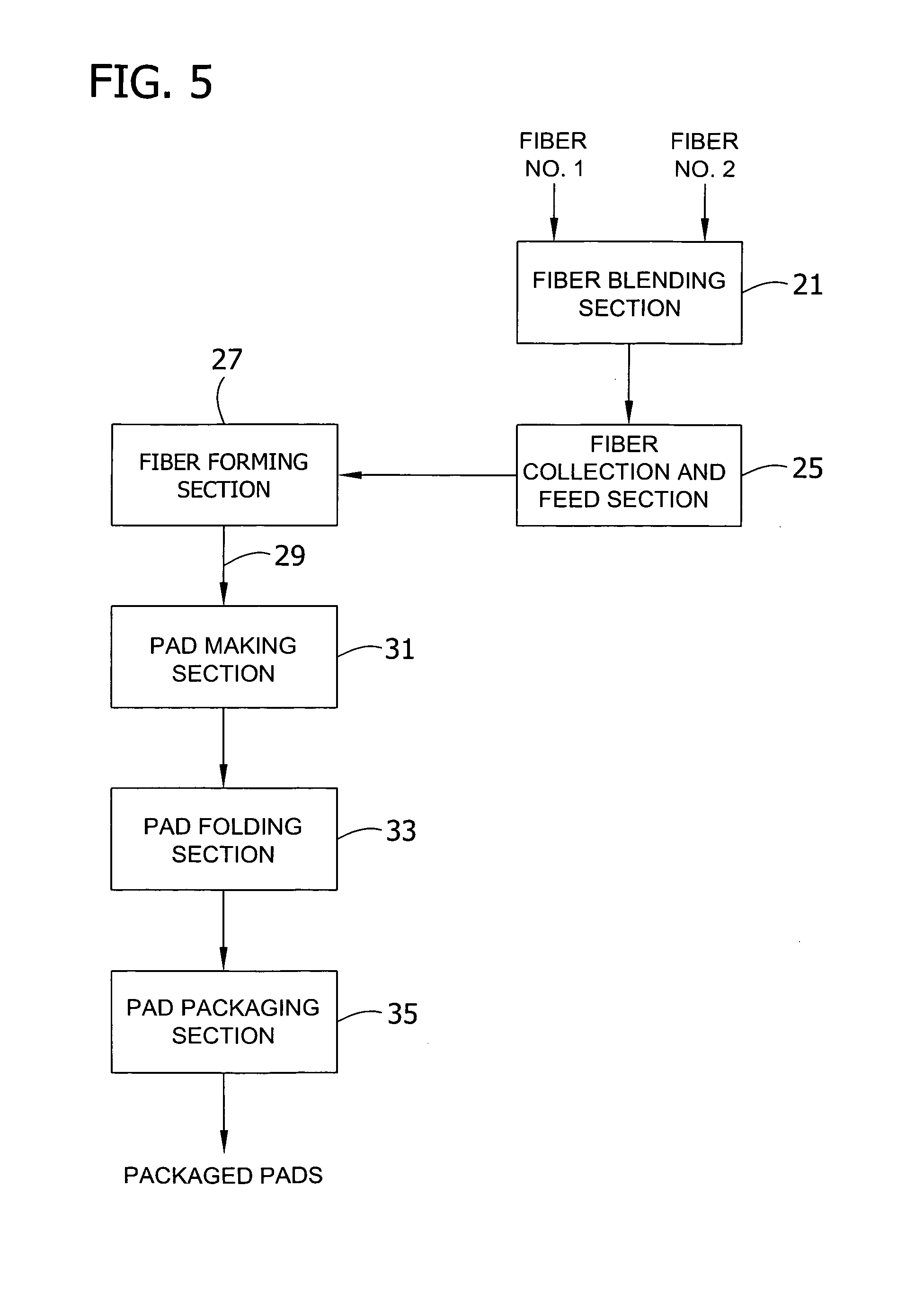

Fiber blending apparatus and method

InactiveUS7082645B2Efficient and economic productionTight manufacturing toleranceMechanical impurity removalContinuous processingDelivery systemHybrid fibre

The invention is directed to method and apparatus for blending fibers. In one aspect, the apparatus comprises blending apparatus for blending fibers of different materials, at least one of which is absorbent, and for conveying the blended fibers to a fiber collection station. A first weighing apparatus weighs out a first quantity of first fibers at a first weigh station. A second weighing apparatus weighs out a quantity of second fibers at a second weigh station. The first and second quantities of fibers are conveyed to a blend opener having a beater roll rotatable in the blend opener. The beater roll opens and mixes the fibers. The fibers are entrained in an air stream by a pneumatic conveyor system and conveyed to a fine opener. The fine opener has a rotatable clothing roll to further open and mix the fibers. The pneumatic conveyor system is operable to separate fiber fines from longer fibers and to deliver the longer fibers to said fine opener. The blended fibers can be used for making pads, such as feminine protection pads.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Carbon fiber surface oil changing method

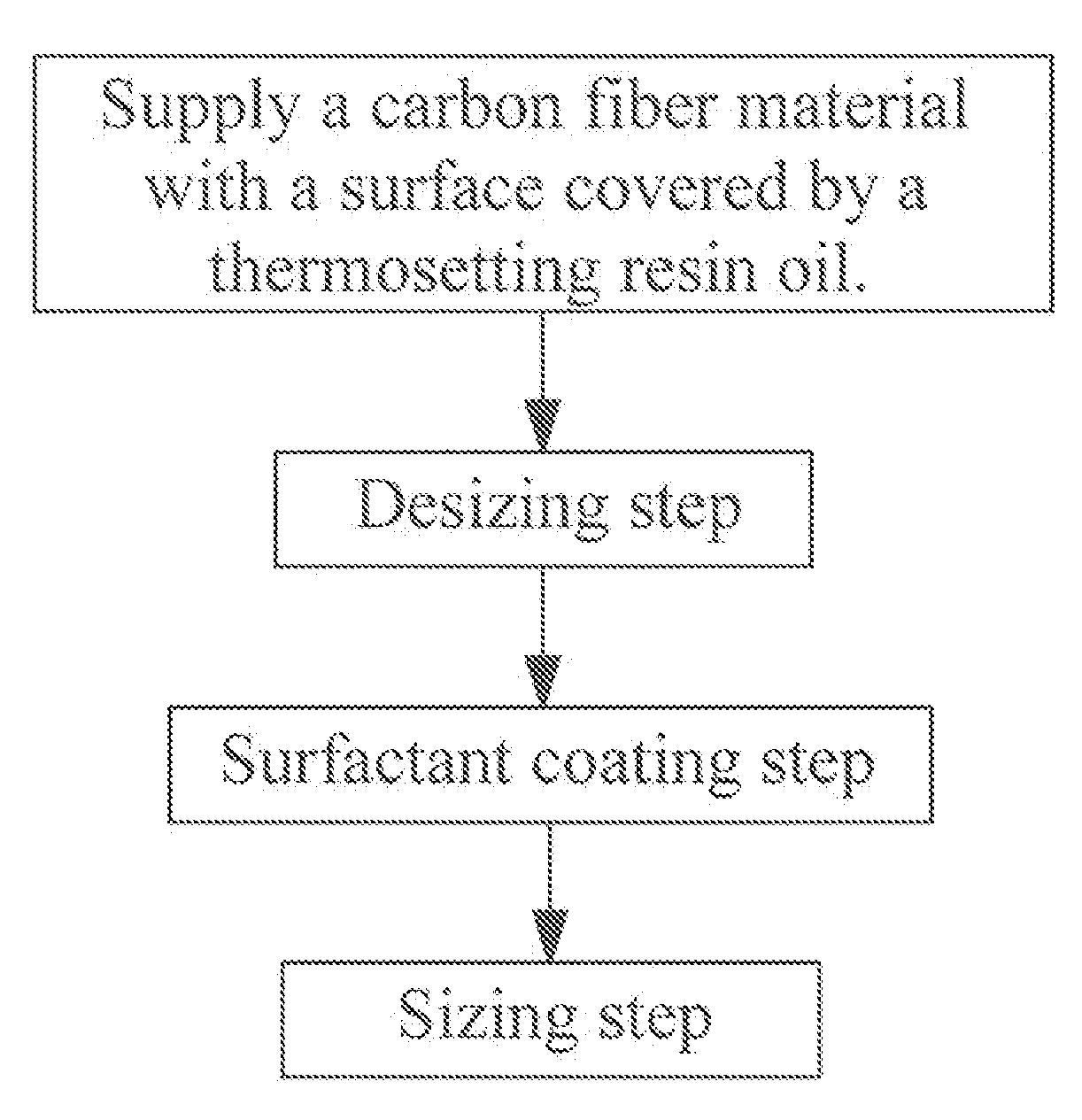

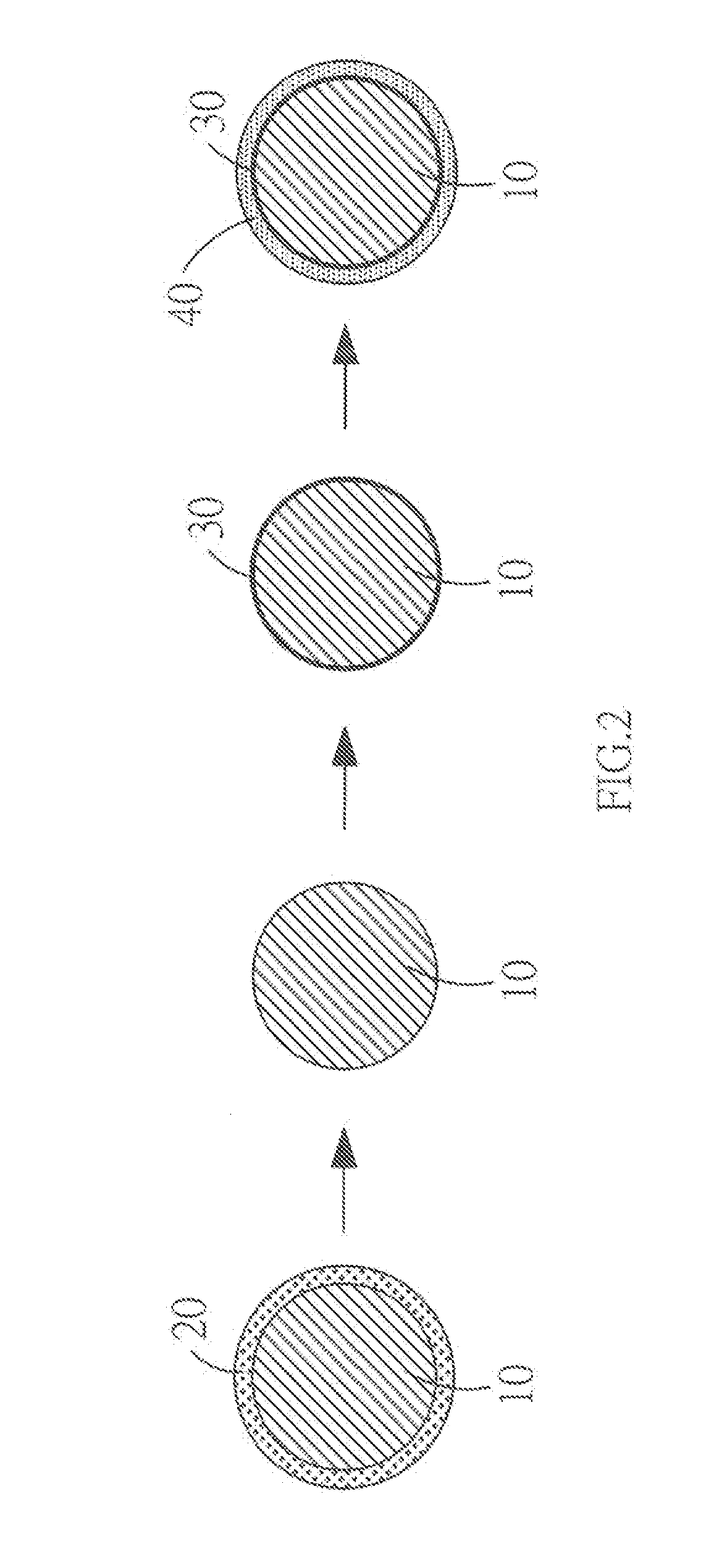

ActiveUS20150044373A1Overcomes drawbackMechanical impurity removalFibre cleaning/openingFiberCarbon fibers

A changing method includes the steps of supplying a carbon fiber material with a surface covered by a thermosetting resin oil, performing a desizing step to remove the thermosetting resin oil from the surface of the carbon fiber material, performing a surfactant coating step to coat a surfactant onto the surface of the carbon fiber material, and performing a sizing step to cover a surface of the surfactant by a thermosetting resin oil, so as to obtain a carbon fiber material with a thermosetting resin oil coated onto the surface of the carbon fiber material.

Owner:UHT UNITECH

Multi-element separation modules for a fiber processing machine

InactiveUS6880206B2High assembling precisionEasy to separateMechanical impurity removalSafety devices for fibre treatmentCardingComputer module

A device is provided for separating out foreign particles and / or neps in a pre-carding zone and / or a post-carding zone of a carding machine having a carding cylinder. The device has at least two modules arranged opposite the carding cylinder in the pre-carding zone and / or the post-carding zone. Each module has a plurality of operating elements, the elements being arranged beside one another as seen in a circumferential direction of the cylinder. The operating elements are fixed carding elements, suctioning devices, and / or separating knives.

Owner:TRUETZSCHLER GMBH & CO KG

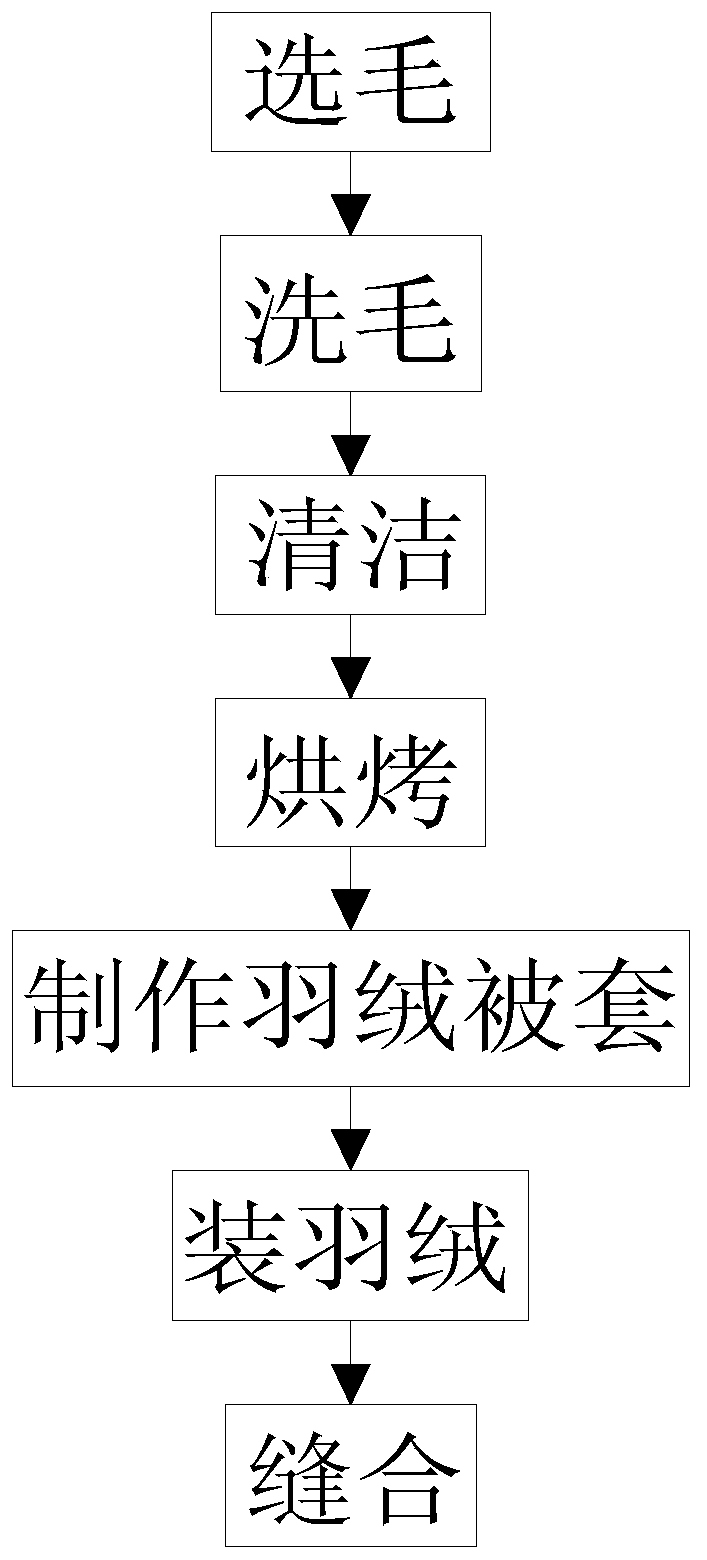

Manufacturing process of novel down quilt

InactiveCN110693269AGood warmth retentionImprove user experienceMechanical impurity removalBlanketProcess engineeringLaundry

The invention discloses a manufacturing process of a novel down quilt. The method comprises the following steps: selecting down, washing down, cleaning, baking, manufacturing a down quilt cover, filling with down and sewing; down of goose and duck bodies is used as fillers; the manufactured novel down quilt is fluffy, soft and good in warm-keeping effect, the cloth bag is thrown into purified water dissolved with laundry detergent to be stirred and soaked for 2 hours through the down washing step, the purposes of degreasing, sterilizing and disinfecting feathers and killing mites, feather liceand worm eggs of the mites are achieved, meanwhile, the unpleasant smell of the feathers is removed, and the use experience of the novel down quilt is improved.

Owner:安徽省皖西羽绒厂

Hydrocarbon sequestering product

InactiveUS8567613B2Low productionReduced operating requirementsMechanical impurity removalContaminated soil reclamationHydrocarbonEnvironmental chemistry

A hydrocarbon sequestering product, a method to obtain the product, and a method and a facility to sequester hydrocarbons, wherein the product comprises an oleophilic filamentous material that gets in contact with a medium contaminated by one or more hydrocarbons with the purpose of sequestrating the hydrocarbon(s) present in the medium to free it from said hydrocarbons.

Owner:R CIANCAGLINI Y ASOCIADOS

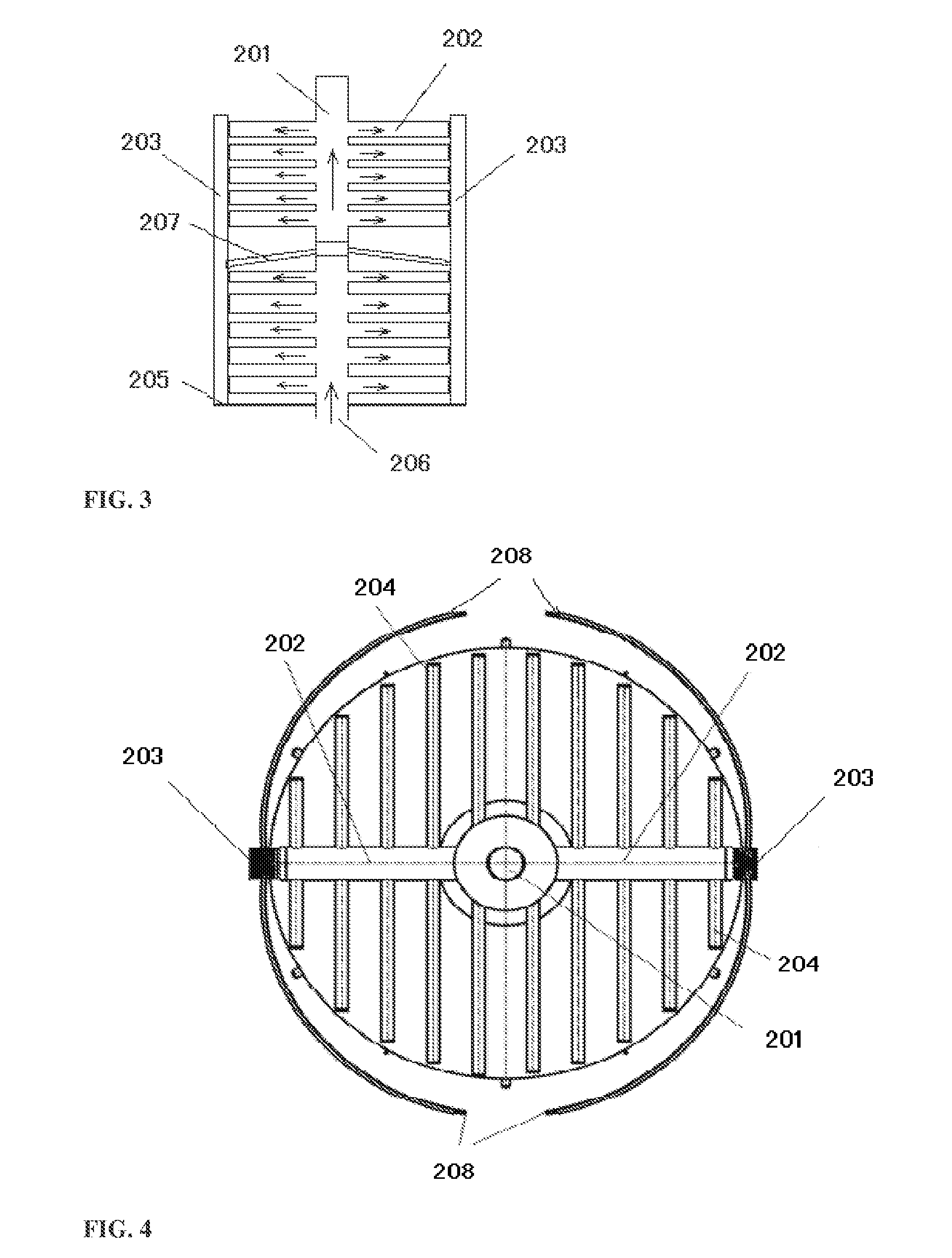

Impurities separation device

ActiveCN103510188BEasy to separateSmall space requirementMechanical impurity removalFibre cleaning/opening by air draught arrangementsFiberEngineering

A separation device (100) for processing a fiber sample (102) comprising both fibers (106) and impurities (104), comprising a separation cylinder (112) and a collection surface (126) for receiving Impurities (104) fall from forest (112). The reverse air flow (122) in the separation zone between the separation cylinder (112) and the collection surface (126) along a direction substantially perpendicular to the separation cylinder (112) and towards the underside of the separation cylinder (112) direction movement. Reverse air flow (122) has enough to make reverse air flow (122) not be blown to separation cylinder (112) by the fiber (106) originally held by pin (114) at every position place in the separation area, and insufficient Air flow velocity to prevent gravity from pulling impurities (104) down into reverse air flow (122).

Owner:USTER TECHNOLOGIES

Device on a spinning preparation machine, for example a tuft feeder, having a feed device

Owner:TRUETZSCHLER GMBH & CO KG

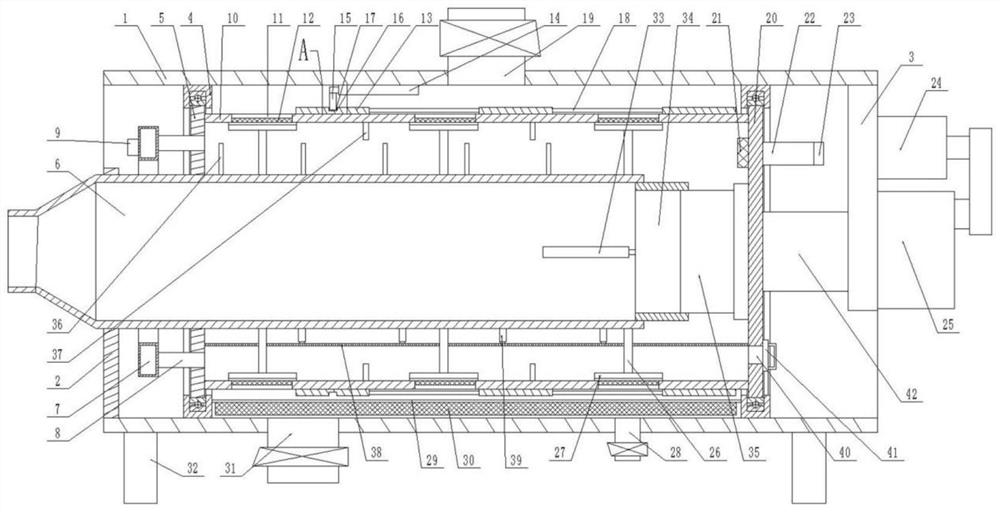

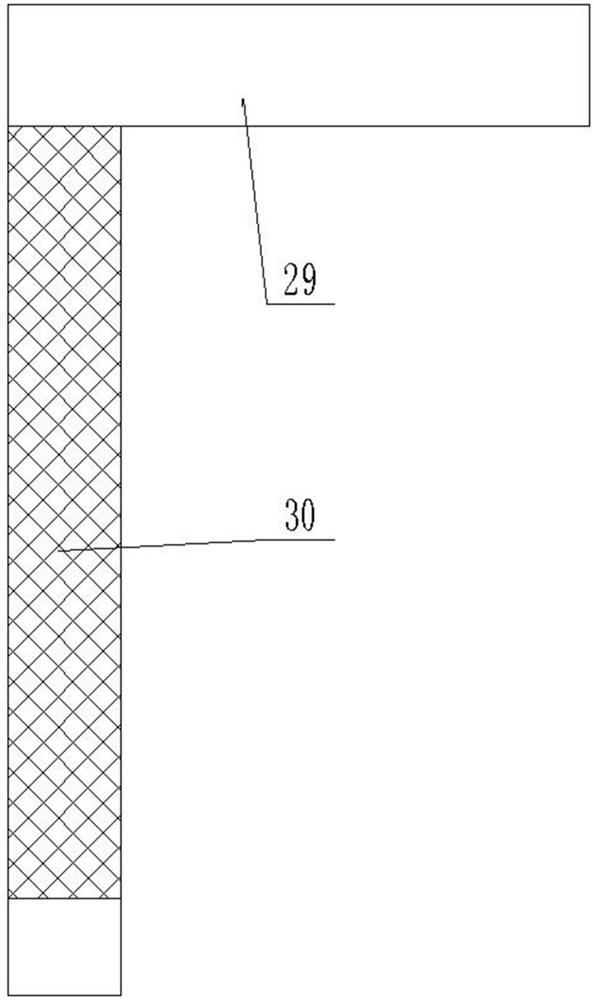

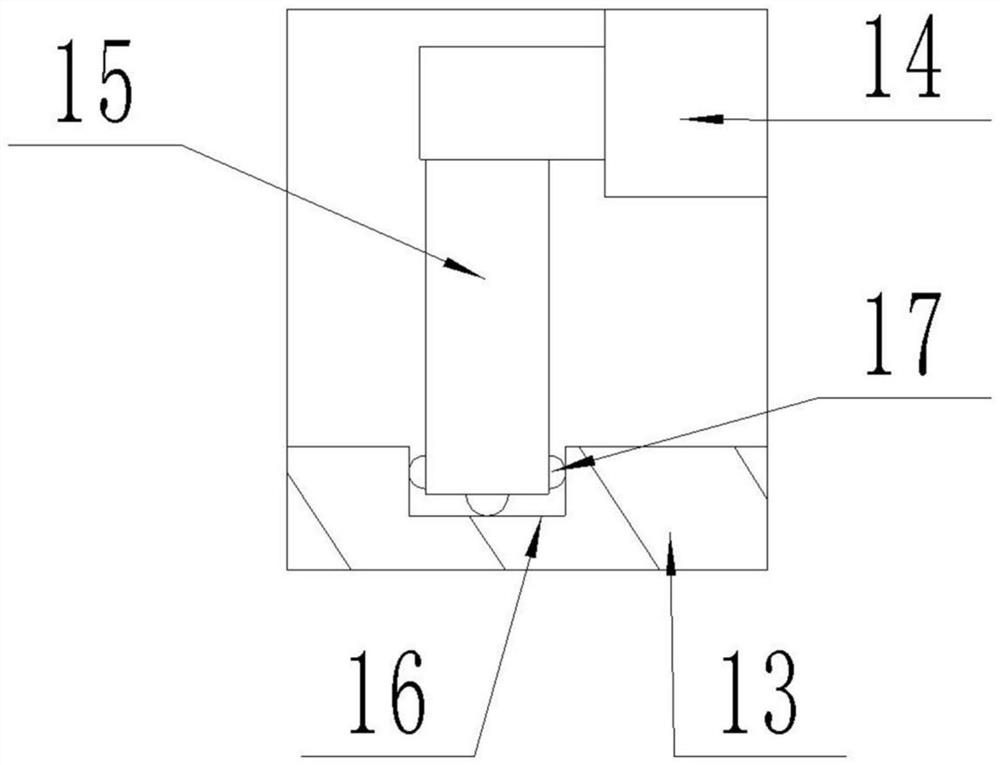

Energy-saving fine down feather production device

ActiveCN113981549AShort processing cycleIncrease productivityMechanical impurity removalDrying gas arrangementsStructural engineeringMechanical engineering

The invention relates to the technical field of down feather production, in particular to an energy-saving fine down feather production device. The device comprises an outer sleeve, a core pipe is located in the inner sleeve, a plurality of sliding sleeves are evenly distributed on the outer side of the inner sleeve in the axial direction, slotted holes are formed in the upper end and the lower end of the inner sleeve on the left sides of the sliding sleeves, arc-shaped filter screens are fixed in the slotted holes, a filter plate is arranged in the inner sleeve below the core pipe, and a blow-off pipe and a filling pipe which are communicated with the outer sleeve are fixed to the lower end of the outer sleeve. An air outlet pipe communicated with the outer sleeve is fixed to the upper end of the outer sleeve, a left supporting plate is fixed in the lower side of the left end of the outer sleeve and fixedly connected with the core pipe, and a right supporting plate is fixed to the upper side of the right end of the core pipe. According to the device, the down feather treatment period can be shortened, the down feather production efficiency can be improved, energy consumption can be reduced, the device is compact in structure and small in occupied space, down feathers can be effectively soaked, the cleaning time is shortened, the down feathers can be sorted, and the quality of the produced down feathers can be improved.

Owner:HENAN PENGDA DOWN PROD

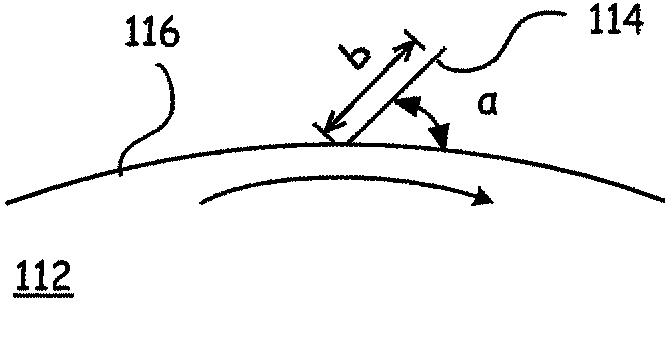

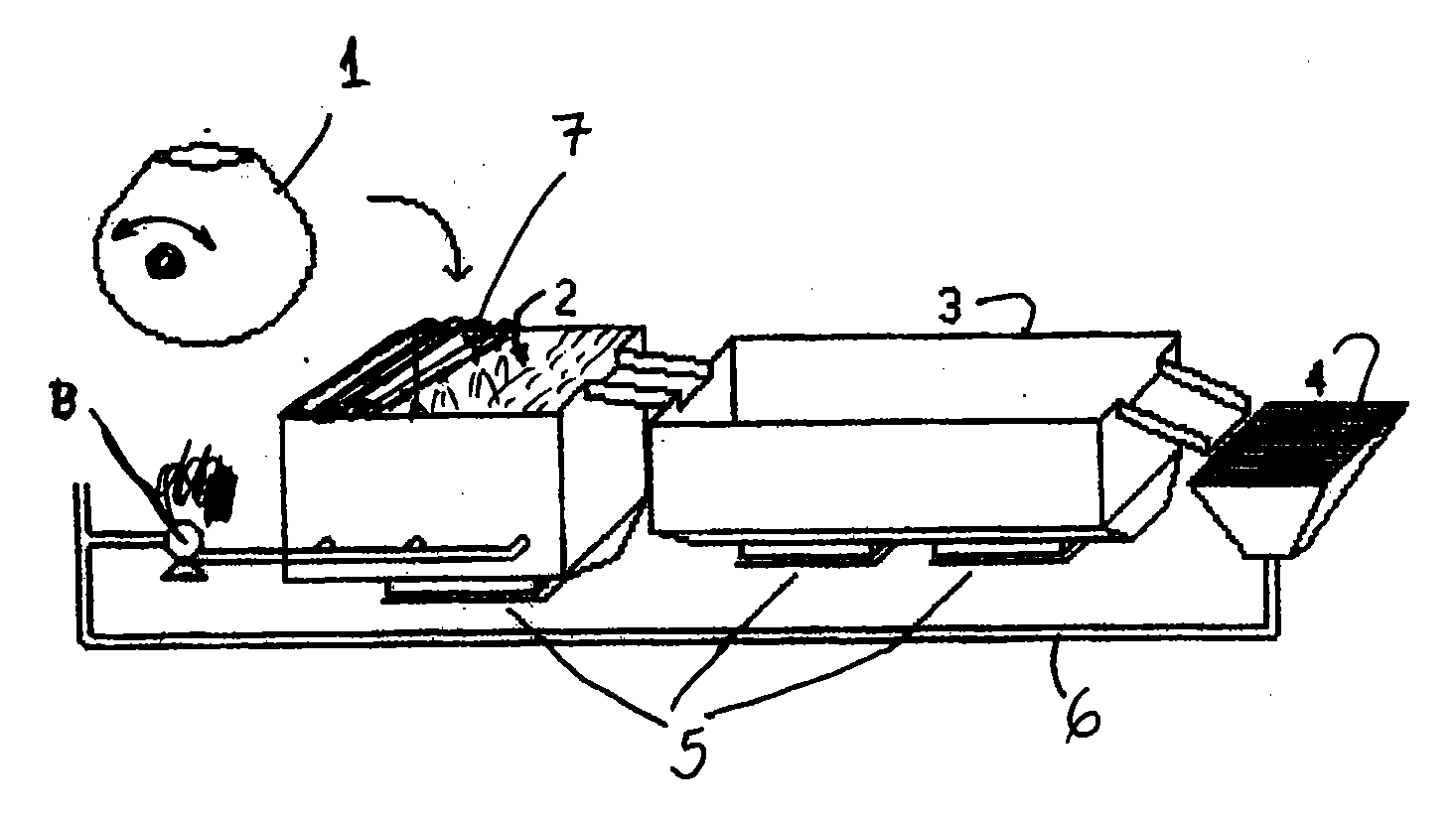

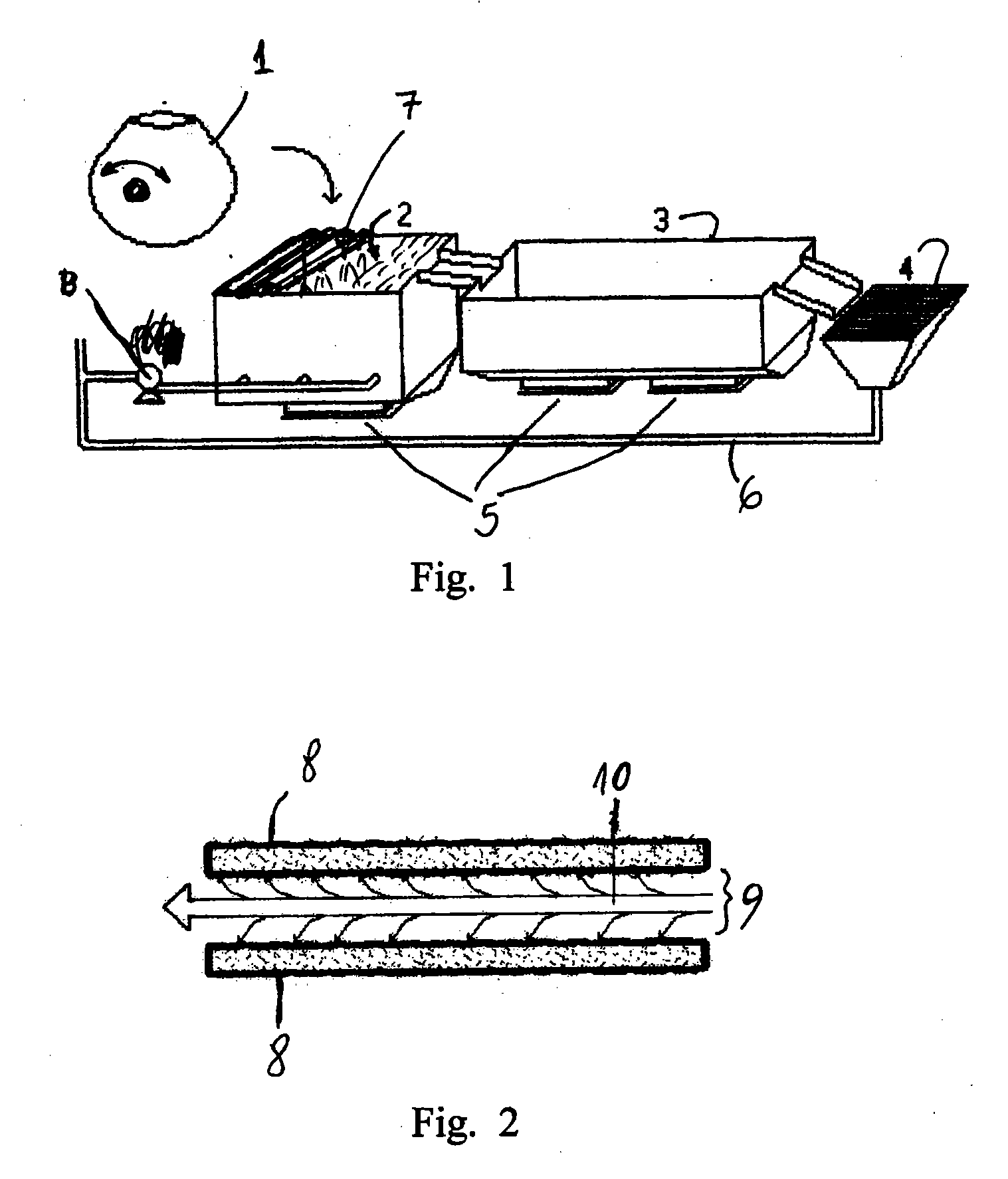

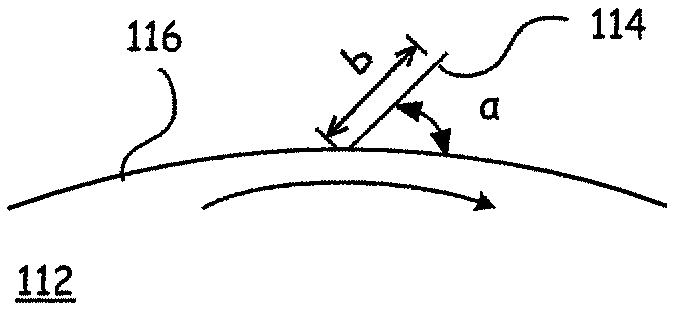

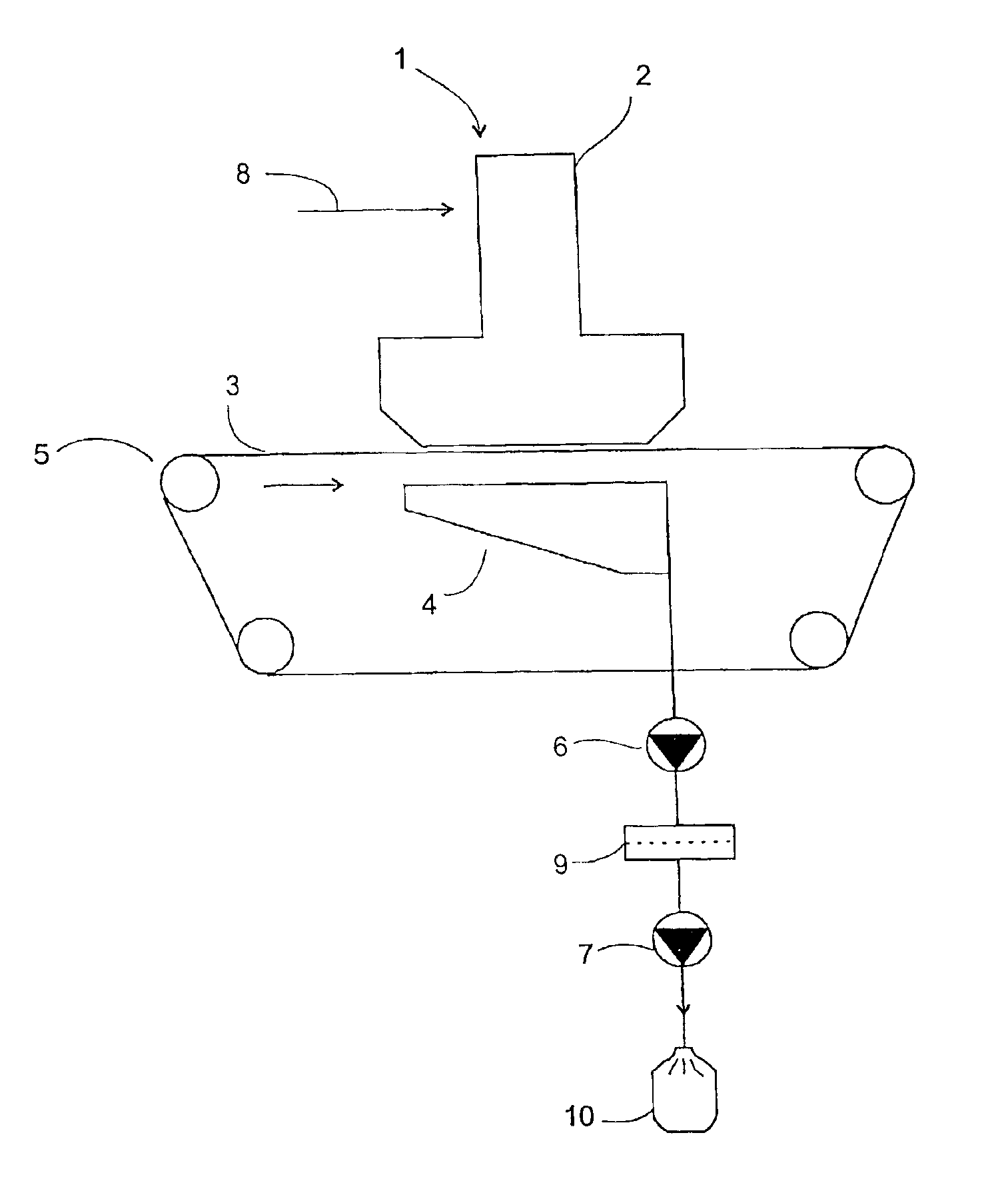

Plant for removing fines from fiber fluff

InactiveUS6883209B2Efficient separationQuality improvementMechanical impurity removalFibre cleaning/openingWater useFiber

A plant for removing fines from fiber fluff. The plant includes a forming wire, a forming head which is placed above the forming wire and arranged for air-laying fiber fluff into a layer upon the forming wire, at least one channel for carrying, in a flow of air, fibers from a supply of fibers into the forming head, a suction box placed beneath the forming wire, at least one vacuum fan connected to the suction box for generating an air flow from the forming head, through the fluff, the forming wire, and the suction box to the at least one vacuum fan. The mesh count of the forming wire mainly allow only the fines contained in the fluff to pass through the forming wire. The troublesome and costly filtering of the water used in a hydroentangling process is advantageously eliminated when using fluff, which is freed from fines by means of the plant according to the invention. Air-laid webs produced of the fine-free fibers also have a high quality.

Owner:OERLIKON TEXTILE GMBH & CO KG

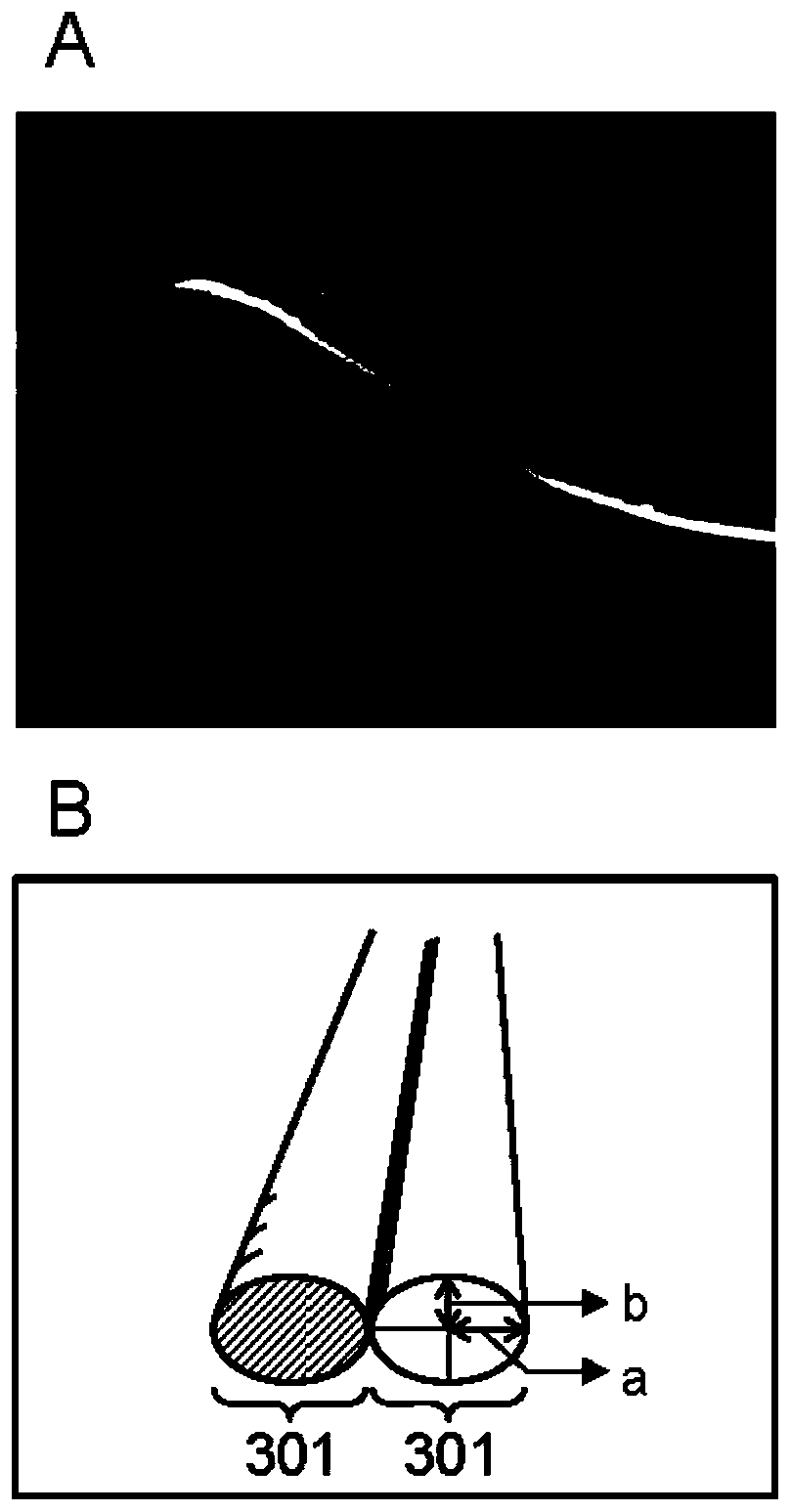

Method for producing long bagworm silk threads and production device therefor

ActiveCN110753765AEx situ implementation of production methodsMechanical impurity removalSilk reelingPolymer scienceSpinning

The present invention addresses the problem of developing a method for producing bagworm silk threads that are long and are of a purity that does not include impurities such as pieces of leaves or twigs, and to develop a device for implementing this production method. The present invention provides a method for producing long bagworm silk threads, the method including: a spinning step in which thenest-holding leg parts of a bagworm are locked to a linear path which can lock the leg parts and has a width smaller than the left-right maximum leg opening width of the bagworm to be used, and spinning is continuously performed along the linear path; and a collecting step in which the long silk threads are collected from the linear path after the spinning step.

Owner:NAT AGRI & FOOD RES ORG

Apparatus on a flat card or roller card for textile fibres, such as cotton, synthetic fibres or the like, for removing short fibres

InactiveUS7730591B2Easy to separateSpeed up the flowMechanical impurity removalFibre cleaning/openingTextile fiberEngineering

An apparatus on a carding machine has a covering comprising work and cover elements lying opposite the clothing of a high-speed cylinder. There is, in succession, an air exhaust opening for the exit of air and an opening for entry of air, past which openings a flow of fibers and air is passed. To allow improved detachment and elimination of short fibers in a simple manner, the spacing of the covering upstream of the exhaust opening is smaller than the spacing of the covering between air exhaust opening and air inlet opening and an airflow flows against the direction of rotation of the cylinder along the surface of the cylinder and flows with short fibers through the air exhaust opening.

Owner:TRUETZSCHLER GMBH & CO KG

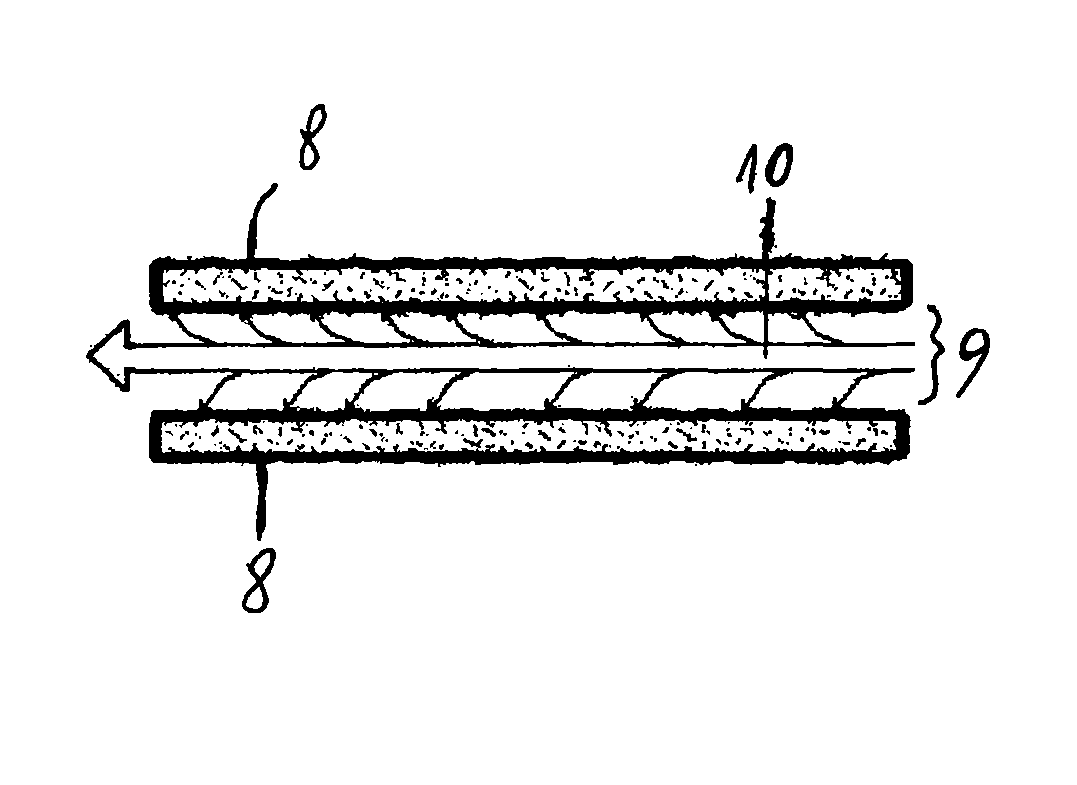

Process and arrangement for replacing intra-fiber liquid in fibers with a replacement liquid

InactiveUS20060124259A1Mechanical impurity removalSemi-permeable membranesFiberBiomedical engineering

A process and apparatus for replacing intra-fiber liquid in fibers by a replacement liquid, includes compressing the fiber cake to express a substantial quantity of intra-fiber liquid to the space between the fibers; forcibly supplying replacement liquid to the fiber cake during the compression thereby replacing the intra-fiber liquid from the space between the fibers and letting the fibers expand while supplying additional replacement liquid. The invention gets rid of or significantly reduces the content of contaminating material in not only the areas between the fibers in a fiber cake but also in the fiber wall pores and the lumen and replaces this liquid by a replacement liquid.

Owner:STF 1 SKOGSINDNS TEKNISKA FORSKNINGSINST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com