Trash separator

A separation device and impurity technology, applied in the direction of solid separation, cleaning with suction device, grading, etc., can solve the problems of large space, difficult to determine the total impurity content and occupation of the original fiber sample, and achieve the effect of easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

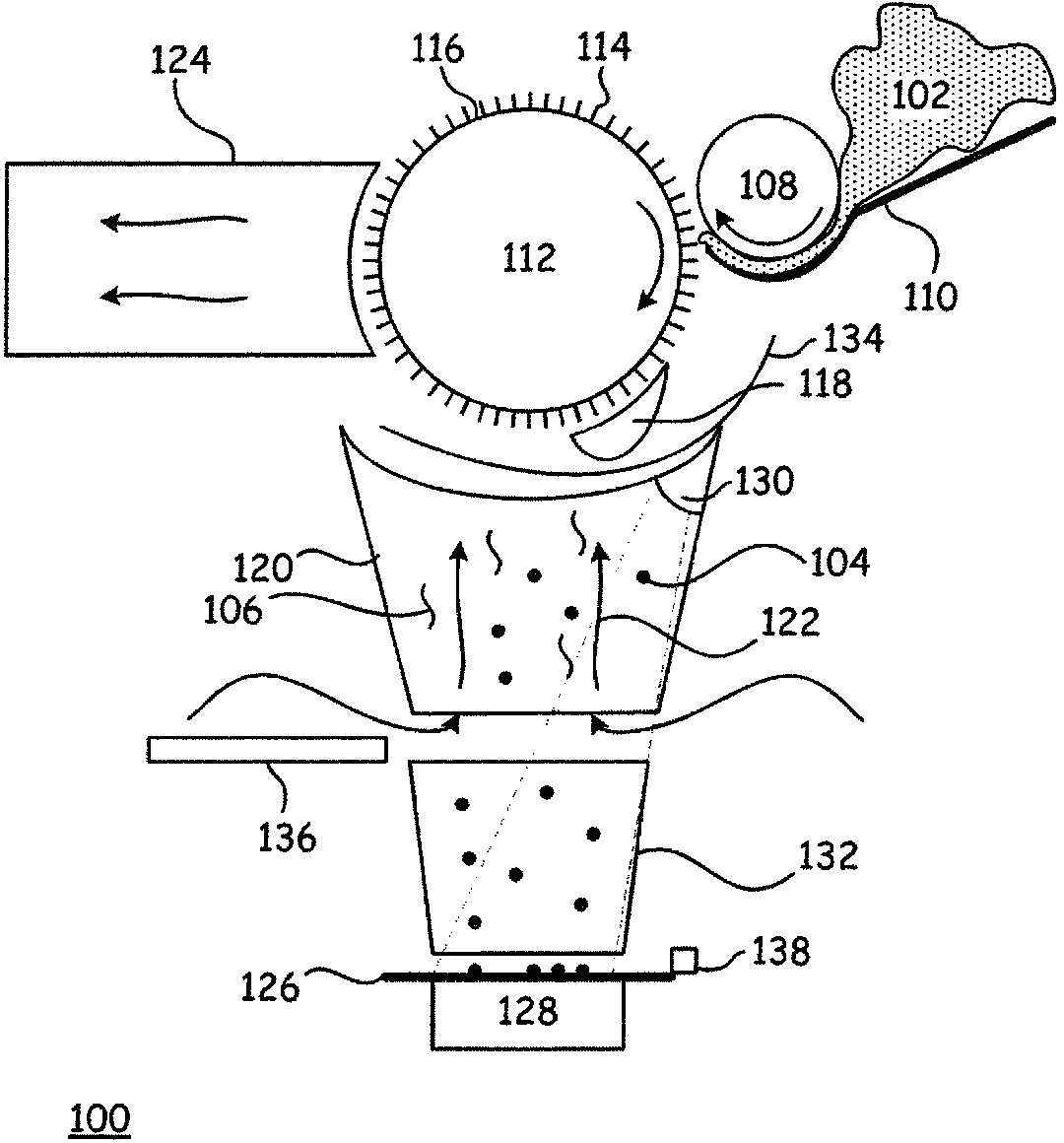

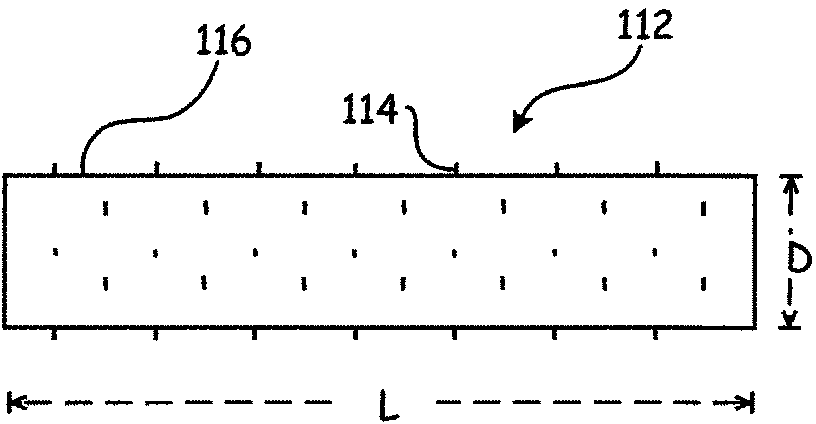

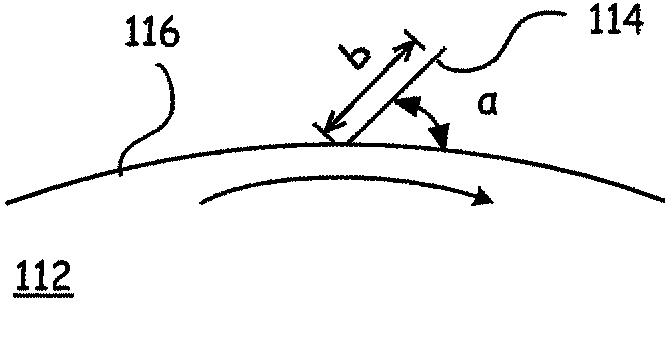

[0037] Referring now to the figures, various embodiments of a trash separation device 100 operable to separate trash particles 104 from fibers 106 in a fiber sample 102 are described. Fiber sample 102 can take a variety of forms. In one embodiment, fiber sample 102 is cotton, but in other embodiments, fiber sample 102 is formed from other natural or man-made fibers, or combinations thereof. Fiber sample 102 includes both individual fibers 106 and foreign particles 104 .

[0038] exist figure 1 In the illustrated embodiment, the fiber sample 102 is supplied to the foreign material separation device 100 by supplying it between a supply roller 108 and a supply surface or plate 110 . supply roller 108 along (e.g. figure 1 shown) in the first direction from approximately one revolution per minute (0.017s -1 ) to about four revolutions per minute (0.067s -1 ) rotates at a speed such that the fiber sample 102 is drawn between the supply roller 108 and the supply surface 110. In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com