Patents

Literature

3724 results about "Bentonitic clay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bentonite clay is a clay which is an absorbent aluminum phyllosilicate consisting mostly of montmorillonite. The main uses of bentonite clays are for drilling mud, and as a binder, purifier, absorbent and groundwater barrier.

Monolithic honeycomb structure made of porous ceramic and use as a particle filter

InactiveUS6582796B1Prevent the evaporation of the waterEasy curingInternal combustion piston enginesSilencing apparatusSodium BentoniteOxygen

A monolithic honeycomb-type structure useful in particular as a particle filter for exhaust gases from diesel engines has a number of passages that empty into the end faces of said monolith, but are alternately open and sealed. The monolith consists of a porous refractory material that comprises: 70 to 97% by mass of alpha and / or beta crystallographic-type silicon carbide that has at least one particle size and preferably at least two particle sizes, and 3 to 30% by mass of at least one bonding ceramic phase in the form of a micronic powder or particles that are obtained by atomization, comprising at least one simple oxide, for example, B2O3, Al2O3, SiO2, MgO, K2O, Li2O, Na2O, CaO, BaO, TiO, ZrO2 and Fe2O3 and / or at least one mixed oxide, for example, the alkaline aluminosilicates (of Li, Na, or K) or alkaline-earth aluminosilicates (of Mg, Ca, Sr or Ba), clays, bentonite, feldspars or other natural silico-aluminous materials. The production of the monolith comprises a calcination stage under an oxygen-containing atmosphere at a temperature up to 1650° C., but less than 1550° C.

Owner:INST FR DU PETROLE

High SPF transparent or translucent, cytoprotective, biodegradable, UV radiation resistant compositions

ActiveUS20080233060A1Protect the skinEliminating possible endocrine disruption responseCosmetic preparationsToilet preparationsCarrageenanPhospholipid

A composition comprising purified water using ozonation, ionization, or distillation or any combination thereof wherein alcohol may be substituted for, or combined with water at least one emollient including but not limited to chitosan, and aloe vera gel, individually or in any combination; an oil component with spf boosting agents including but not limited to; ethyl macadamiate, non-toxic silicone oil and essential oils, butter milk, waxes impregnated with inorganic sun-block or sunscreen agent and organic / inorganic micronized particles, wood powder and bentonite clay, keratin, either individually or in any combination; at least one inorganic sun-block or sunscreen agent including any metal oxide, glass microsphere, silica and silica compound, and optionally metal oxide pigments with particles that are micronized, submicronized, nanoparticle sized, or otherwise individually or in any combination that can be homogenized in either a water phase, a water-aloe phase, an oil phase or any phase of said composition; at least one emulsifier wherein said emulsifier includes but is not limited to a phospholipid and / or liposome or an aloe vera gel or an ester of coconut oil individually or in any combination, for emulsifying the water, water-aloe, or oil phase in combination with an homogenizer; where any of components are preferably mixed with an homogenizer and where an appropriate thickening agent including but not limited to xanthan gum, carageenan, either individually or in any combination is added as required.

Owner:GRUNE GUERRY L

Metal heavy absorbent and preparation method and use thereof

InactiveCN102389776AEasy to operateImprove efficiencyOther chemical processesWaste water treatment from animal husbandryActive agentKaolin clay

The invention discloses a heavy metal absorbent and a preparation method and use thereof. The heavy metal absorbent is prepared by using an inorganic mineral modified by a surfactant as a carrier and loading organic complexing agent on the carrier, wherein the inorganic mineral is bentonite, kaolin, kieselguhr, zeolite, aluminum oxide or iron oxide; the surfactant is cationic surfactant or nonionic surfactant; and the organic complexing agent is a compound containing a sulfydryl and an amino. The heavy metal absorbent has the advantages of stable performance, environment friendliness, high absorption capacity, high selectivity, convenient post-recovery treatment and the like. The absorption capacities of cadmium, mercury lead and other heavy metals all exceed 100mg / g, and the heavy metal absorbent can achieve good treatment effect in treatment of water and soil environments polluted by heavy metals.

Owner:上海伊克诺环境科技有限公司

Cat litter and making method thereof

InactiveCN102150627AEnhanced adsorption and deodorization abilityImprove deodorization abilityAnimal housingSodium BentoniteSilica gel

The invention discloses cat litter comprising a composition prepared from the following components in percent by weight: 50-80% of inorganic clay, 5-15% of silica gel, 5-20% of organic substrate and 8-20% of mineral matter, wherein the inorganic clay is selected from one or a mixture of attapulgite, bentonite, kaolinite and sepiolite; the organic substrate is selected from one or a mixture of corncob, corn, wheat, clover, peanut hull, walnut shell, pine wood shavings and broadleaved tree wood shavings; and the mineral matter is selected from one or a mixture of perlite, diatomite, pumice and other low-density mineral matters. The cat litter disclosed by the invention has the following advantages of largely strengthened adsorption deodorization capacity due to the addition of the silica gel component, stronger deodorization capacity by utilizing the adsorbability of natural materials, natural fragrance, small weight and strong caking capability, in particular no dust and easiness for treatment; and the cat litter disclosed by the invention is 40% lighter than the traditional bentonite cat litter.

Owner:QINGDAO FRANK FINE CHEM

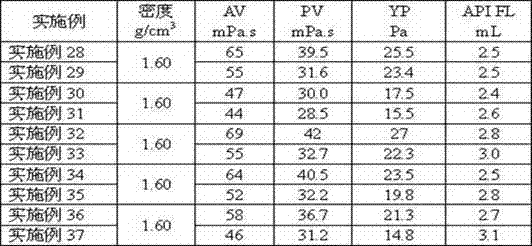

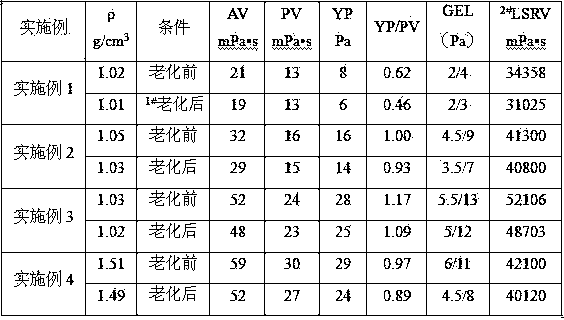

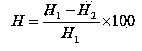

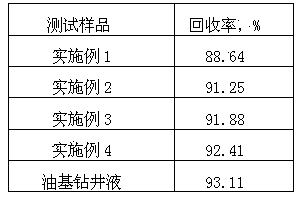

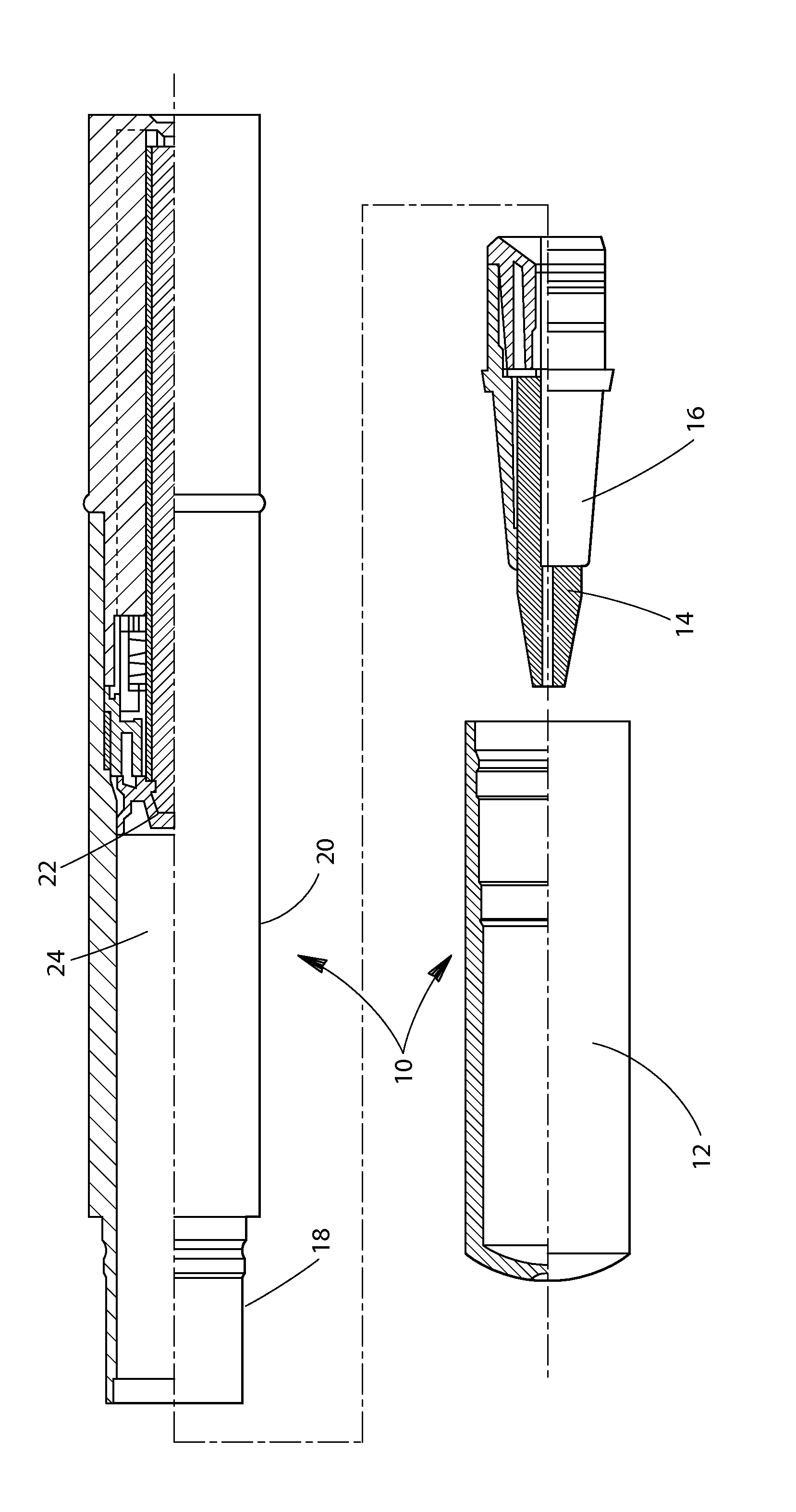

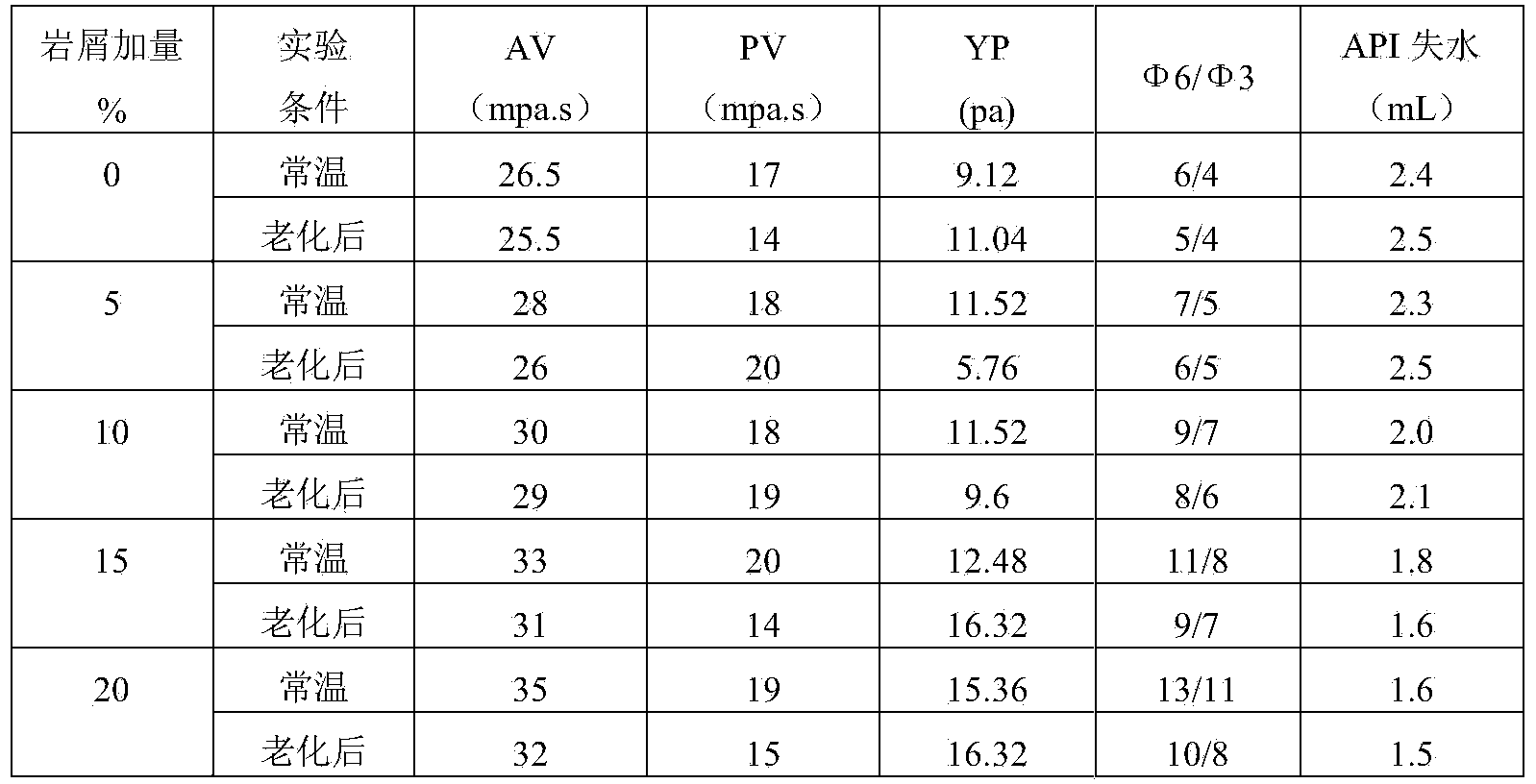

Strong-inhibition anticaving drilling fluid and application thereof

InactiveCN105038737AReduce fluid lossAdjust the flow patternDrilling compositionOrganic chemistryPetroleum engineering

The invention discloses a strong-inhibition anticaving drilling fluid and application thereof. The strong-inhibition anticaving drilling fluid consists of 1000 parts of water, 20 to 60 parts of bentonite for drilling fluid, 5 to 20 parts of sodium carbonate, 5 to 20 parts of alkali, 10 to 20 parts of coating agent, 5 to 20 parts of flow pattern regulator, 5 to 20 parts of shale inhibitor, 10 to 30 parts of borehole stabilizer, 10 to 30 parts of plugging agent, 5 to 30 parts of lubricating agent, 5 to 40 parts of filtrate reducer, 1 to 10 parts of pH regulator, and a proper amount of salts and barite added according to the requirement. The strong-inhibition anticaving drilling fluid has the remarkable characteristics of properties of stabilizing a borehole, protecting an oil layer, improving the drilling speed, and preventing a balled bit and the like from approaching to oil-based drilling fluid.

Owner:北京中科天启油气技术有限公司

Thermal protective coating

ActiveUS7105047B2Extended shelf lifeReduce weightAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

Drilling fluid and preparation method thereof

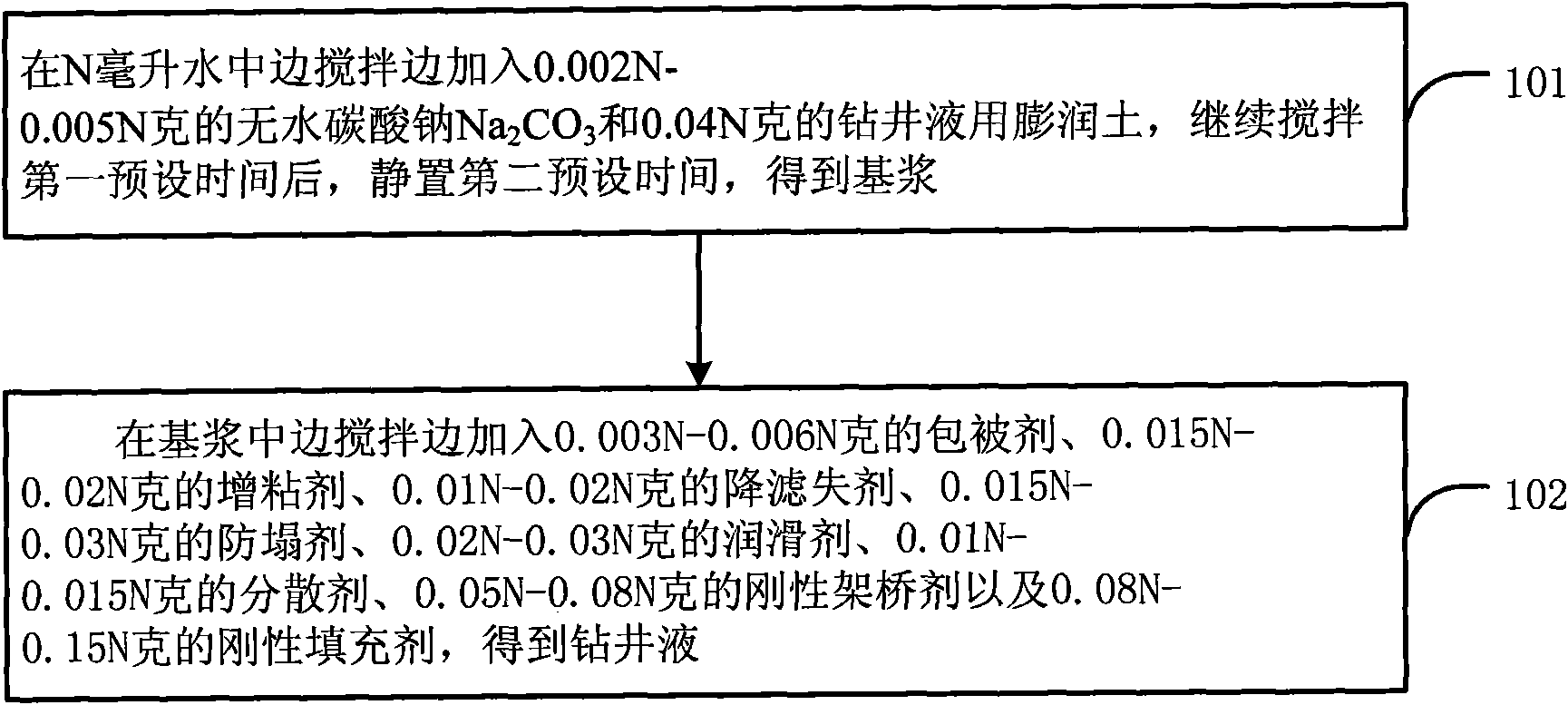

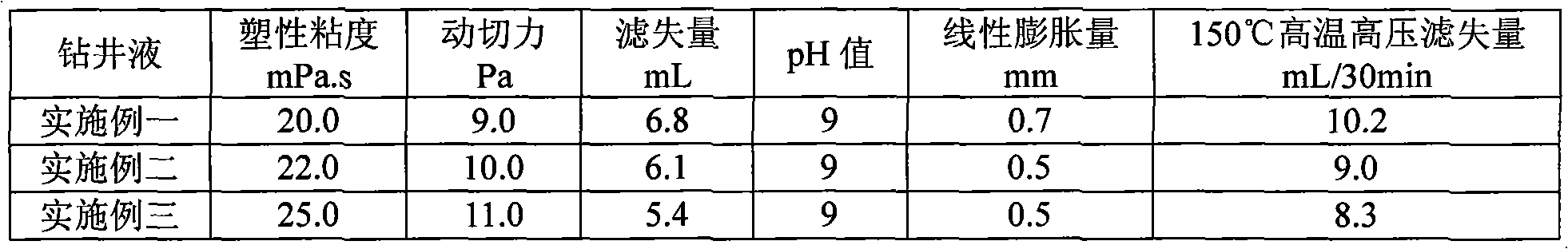

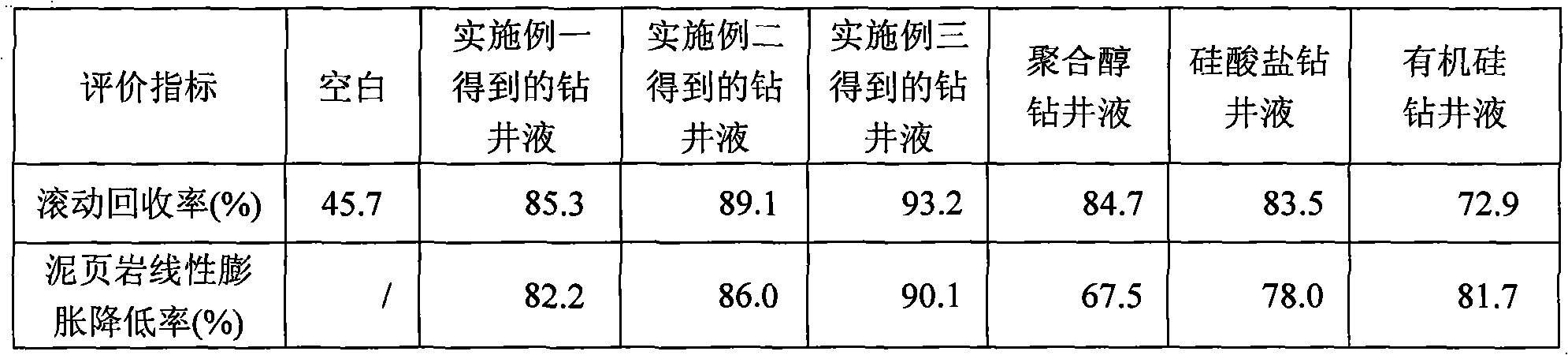

The invention discloses a drilling fluid and a preparation method thereof. The drilling fluid comprises Nml of water, wherein N is a positive number, 0.002N-0.005N gram of anhydrous sodium carbonate Na2CO3, 0.04N gram of bentonite for the drilling fluid, 0.003N-0.006N gram of coating agent, 0.015N-0.02N gram of tackifier, 0.01N-0.02N gram of filtrate reducer, 0.015N-0.03N gram of anti-collapse agent, 0.02N-0.03N gram of lubricant, 0.01N-0.015N gram of dispersing agent, 0.05N-0.08N gram of rigid bridging agent and 0.08N-0.15N gram of rigid filler. The drilling fluid of the invention is applicable to a loss formation and has obvious leakage stoppage effect, a leak-proof function at the same time and obvious inhibiting effect on a formation which is easy to disperse and collapse.

Owner:CHINA UNITED COALBED METHANE NAT ENGRES CENT +1

Green powdered paint and its prepn

The present invention discloses one kind of green powdered paint and its preparation process. The green powdered paint consists of re-dispersible polymer latex powder 5-20 wt%, white cement 20-40 wt%, calcium carbonate 20-45 wt%, titanium white powder 5-25 wt%, diatomite 2-8 wt%, bentonite 1-2 wt%, cellulose ether 0.2-0.5 wt%, defoaming agent 0.2-0.5 wt% and coloring pigment 0-4 wt%. It is prepared through mixing all the components in a stirrer, and packing. It is used after mixing with water in construction site. It has the combined decoration functions of both putty and emulsion paint and may be used widely for decorating inner and outer wall.

Owner:SOUTH CHINA UNIV OF TECH

Multimodal polymeric foam containing an absorbent clay

Prepare a multimodal polymeric foam from a foamable composition containing a polymer, an absorbent clay, and a blowing agent composition containing water and carbon dioxide and that contains less than 0.2 parts by weight of bentonite based on 100 parts by weight of polymer.

Owner:DOW GLOBAL TECH LLC

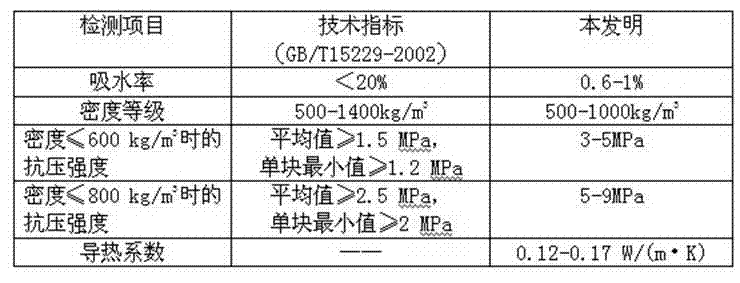

Method for preparing foam ceramic self-insulation wall material by utilizing solid wastes

InactiveCN103396150AReduce manufacturing costRealize comprehensive utilizationSolid waste disposalCeramicwareChromium sesquioxideInsulation layer

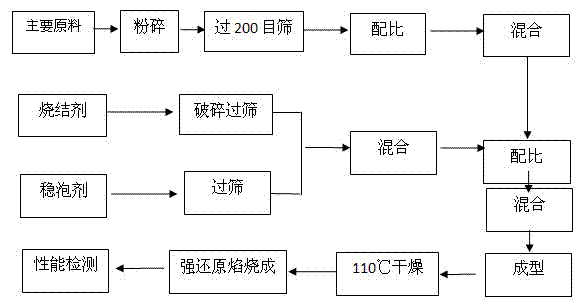

The invention relates to a method for preparing a foam ceramic self-insulation wall material by utilizing solid wastes. The wall material comprises a main material and an admixture. The main material is prepared from the following components in proportion: 25% to 35% of chromium slags, 19% to 27% of coal gangue, 20% to 26% of waste ceramic polishing residues, 17% to 25% of albite and 1% to 6% of bentonite. The method comprises the following steps of: adding 16 to 20g of the admixture into every 200g of the main material; evenly mixing and screening the mixture; putting the mixture into a die; molding the mixture in a pressing manner and drying; sintering the mixture under a strong reducing atmosphere at the temperature of 1120-1180 DEG C, thereby obtaining the foam ceramic self-insulation wall material. The carbon in the coal gangue can serve as a foaming agent or a reducing agent, so that hexavalent chromium is reduced into chromium sesquioxide at the high temperature and under the strong reducing atmosphere. Thus, the toxicity of the chromium slags is eliminated. The prepared foam ceramic self-insulation wall material is low in pyroconductivity, small in density and low in water absorption rate; the usage temperature can reach 900 DEG C. In addition, the foam ceramic self-insulation wall material is complete in fire resistance, high in strength and long in service life, and can be used for replacing the existing wall materials and flammable insulation materials. The wall material integrates protection and thermal insulation functions; an exterior wall insulating layer is not required. Thus, the construction cost is lowered.

Owner:HENAN COAL CHEM IND GROUP INST +1

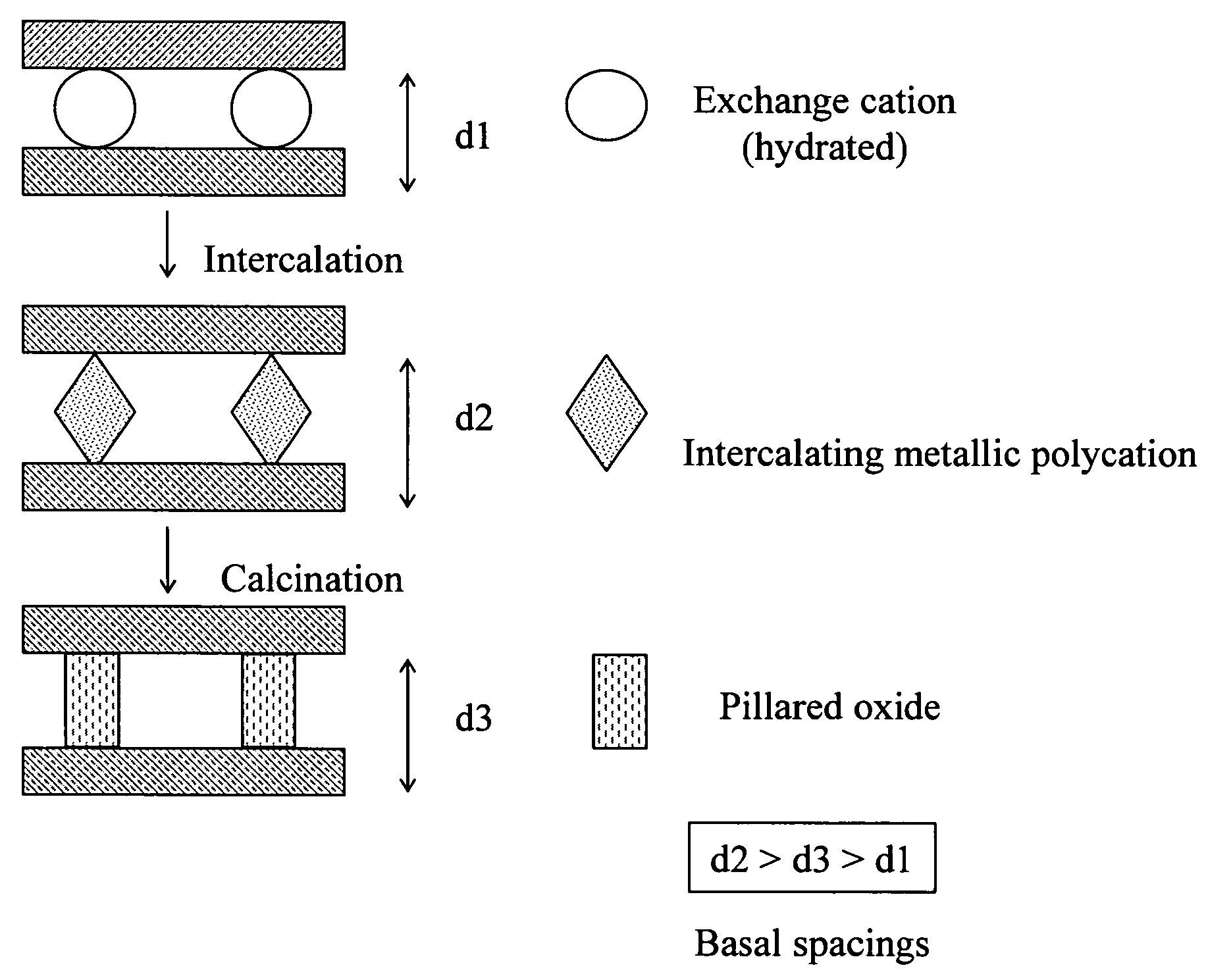

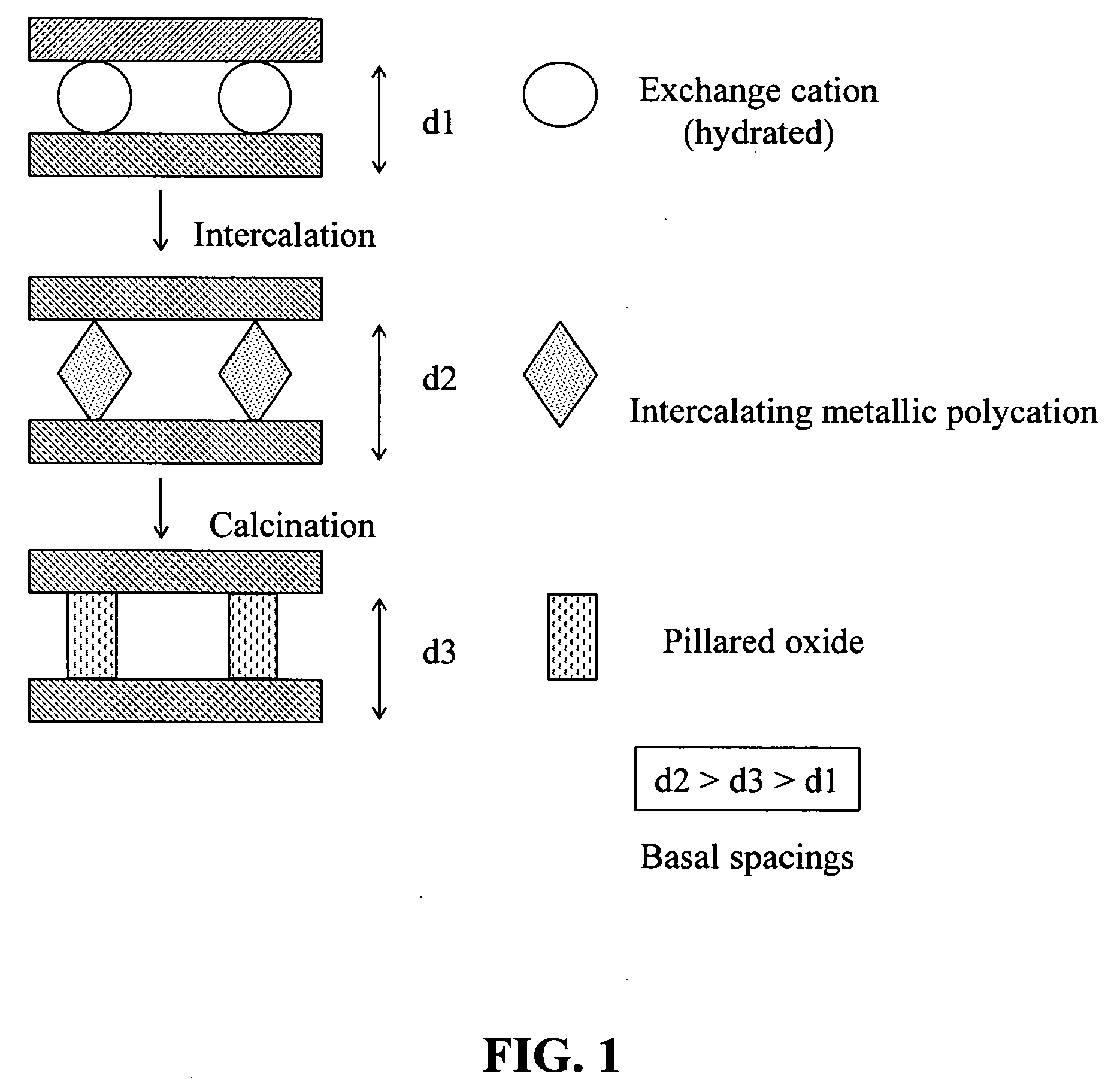

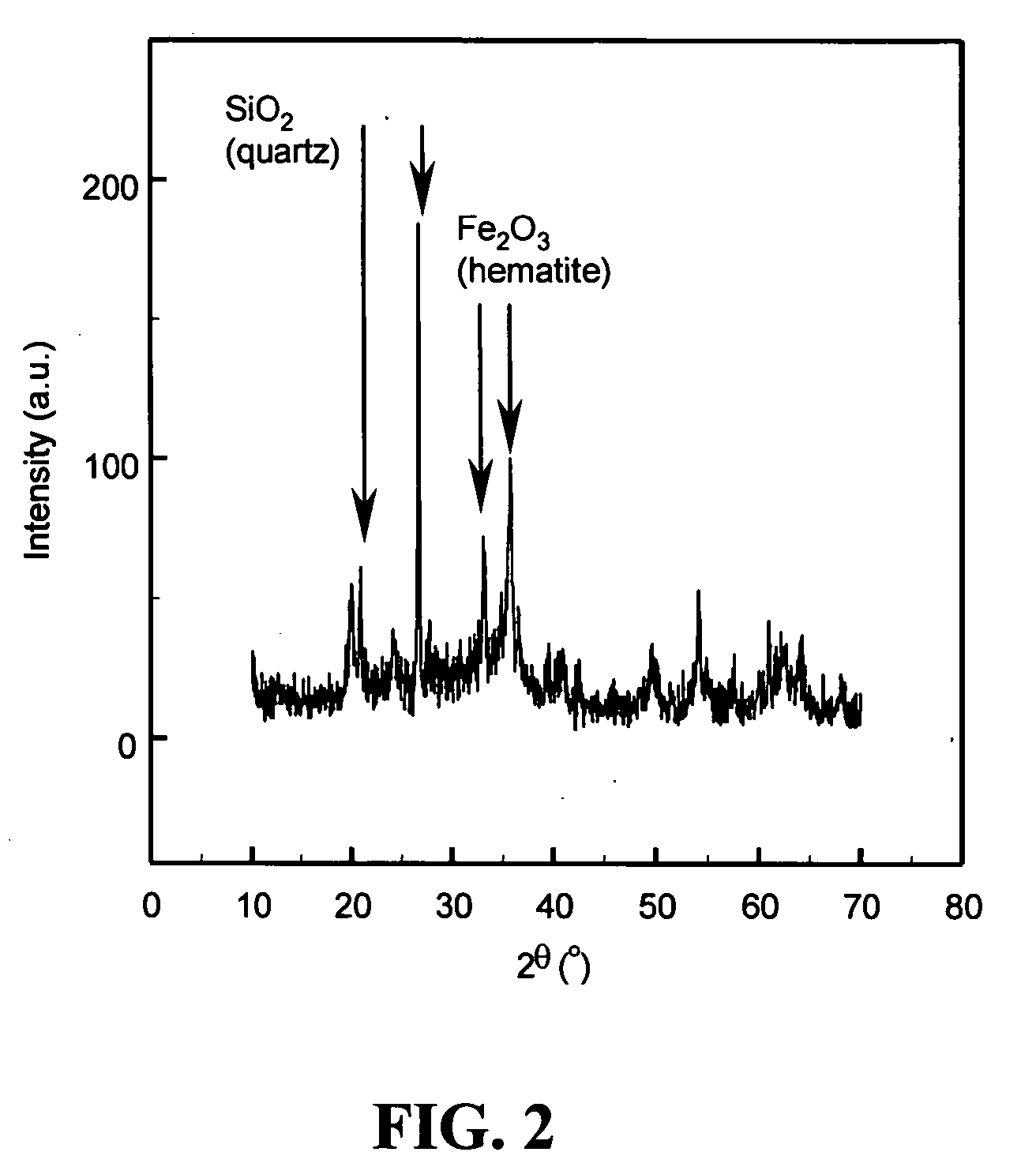

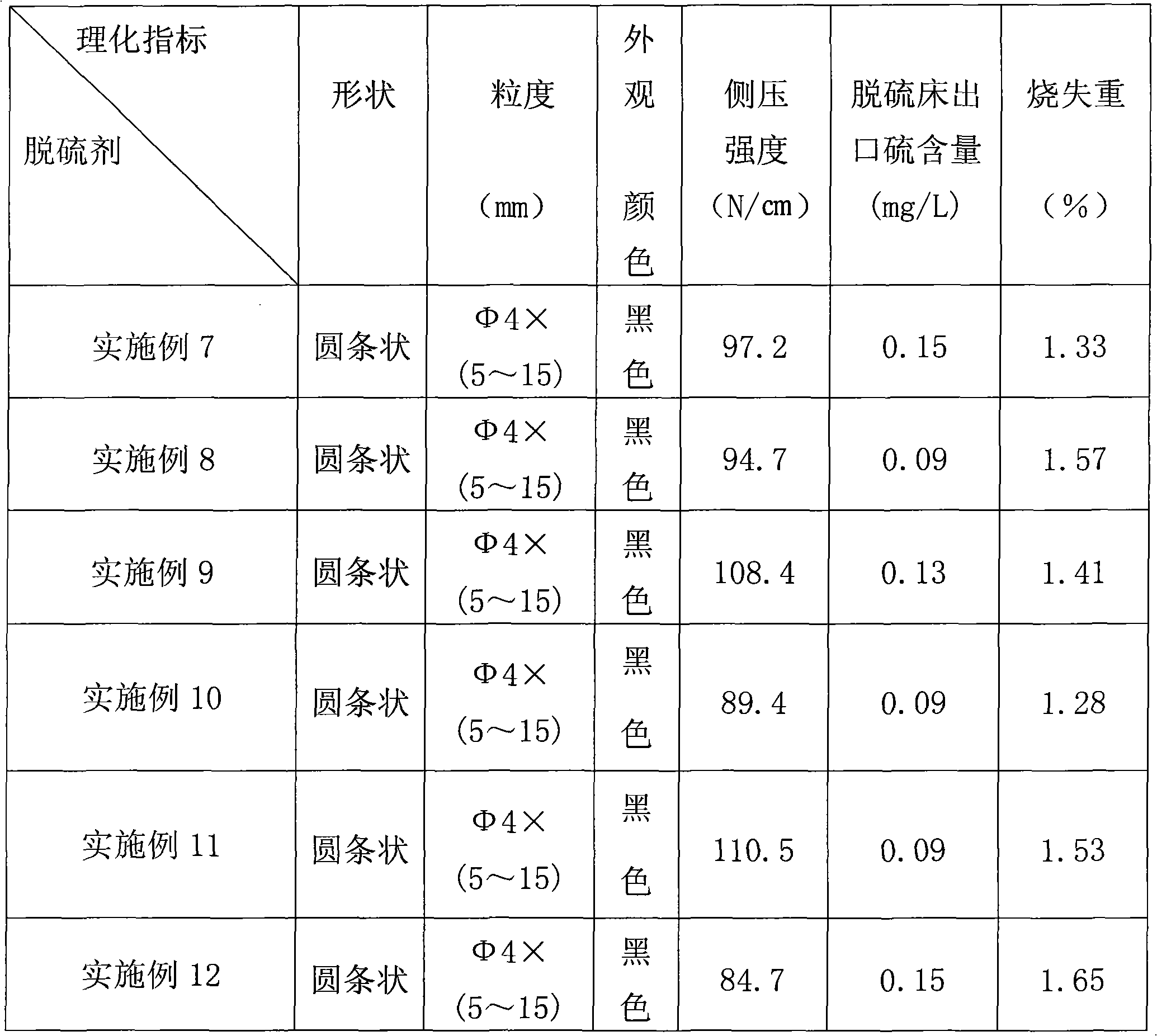

Synthesis of bentonite clay-based iron nanocomposite and its use as a heterogeneous photo fenton catalyst

InactiveUS20060076299A1Material nanotechnologyWater/sewage treatment by irradiationSodium BentoniteAdvanced oxidation process

The present invention provides a method of synthesizing bentonite clay-based Fe nanocomposite, that may be used as a heterogeneous photo Fenton catalyst in advanced oxidation processes (AOP's) for wastewater treatment.

Owner:THE HONG KONG UNIV OF SCI & TECH

Polyamine drilling fluid

ActiveCN102391842AImprove rheologyImprove high temperature resistanceDrilling compositionWell drillingPetrochemical

The invention belongs to the field of petrochemical drilling technology, and relates to polyamines drilling fluid used in the petroleum drilling process. The polyamines drilling fluid mainly contains 0.1-5% of shale inhibitor, 0.1-5% of fluid loss additive, 0.1-5% of coating agent, 0.1-5% of lubricating agent, 0-5% of thickening agent, 0-5% of plugging agent, 1-10% of slurry compounding soil, and pH regulator and weighting agent which are blended and added according to the need; and the polyamines drilling fluid also contains the balance of water used for preparing the drilling fluid. The polyamines drilling fluid has stronger capability of inhibiting hydrous expansion and hydrous disintegration of bentonite, has good rheological property and high-temperature resistance, and is applicable to oil reservoir and oil gas drilling engineering with high water sensitivity and higher clay content.

Owner:CHINA PETROCHEMICAL CORP +1

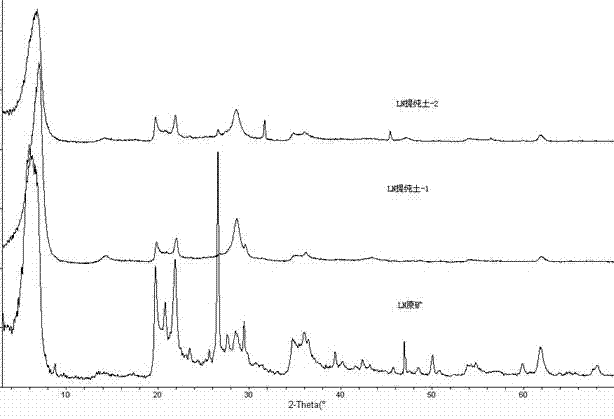

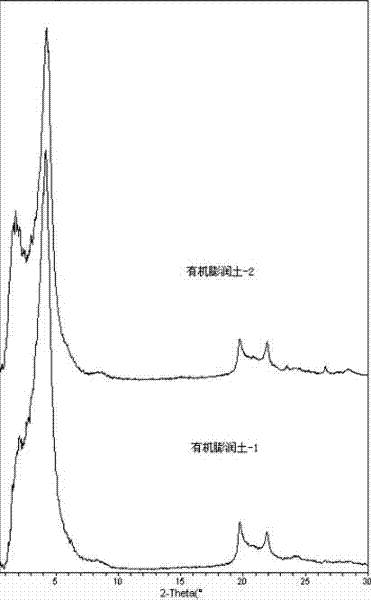

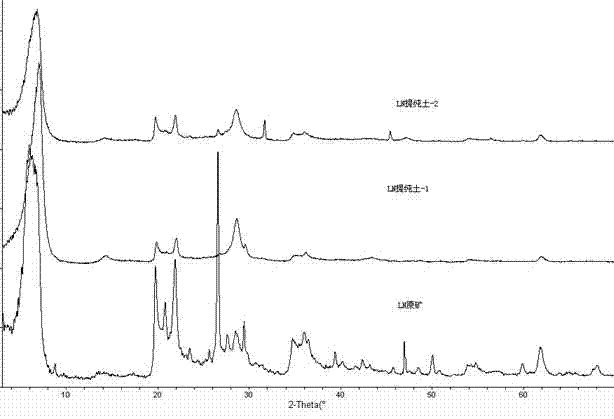

Method for preparing high-viscosity organic bentonite by virtue of calcium-based bentonite

ActiveCN102259881AEffectively fixedPrevent replicationSilicon compoundsPhysical chemistryOrganic chemistry

Owner:ZHEJIANG FENGHONG NEW MATERIAL

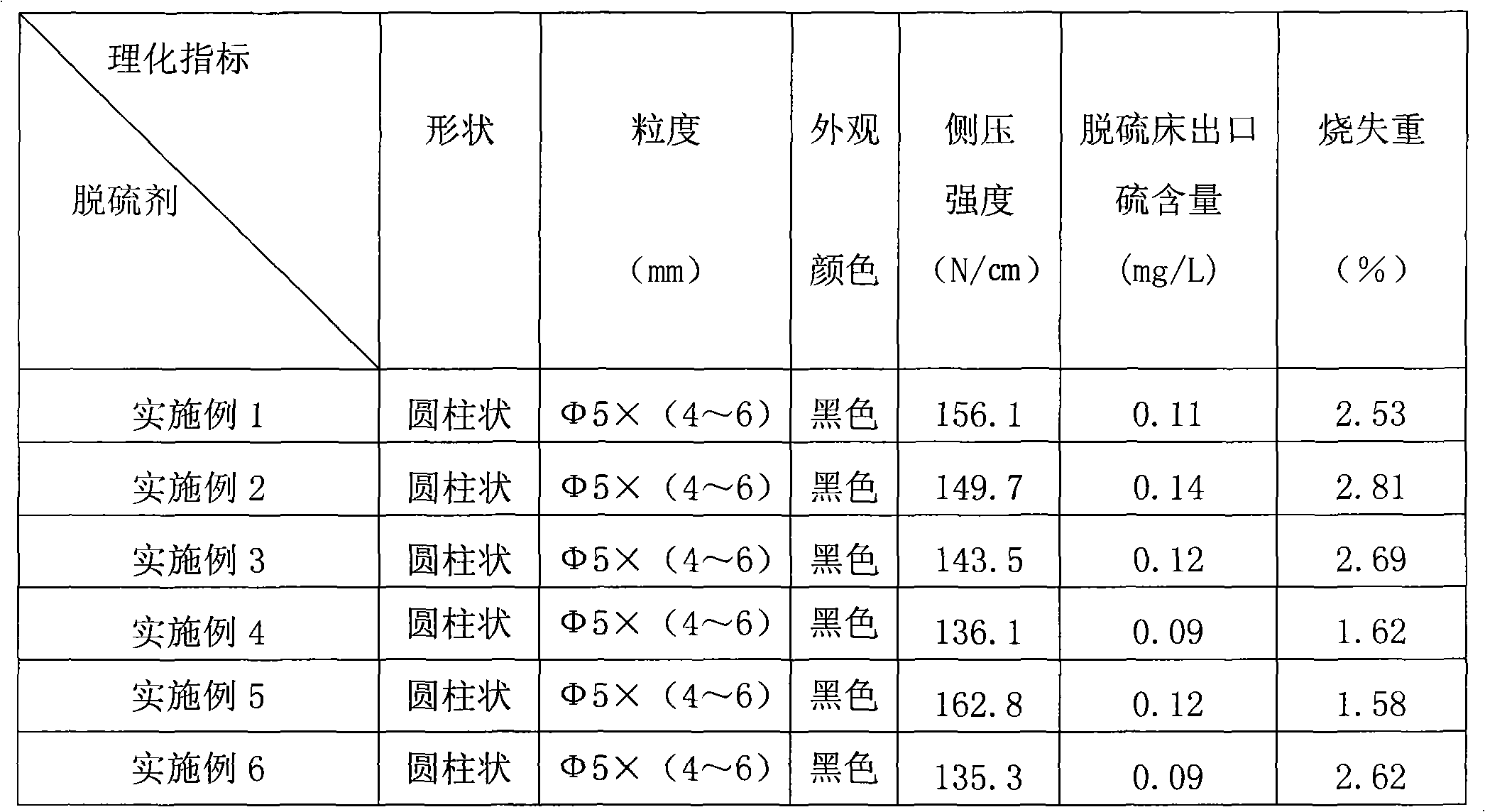

Desulfurizing agent for reforming stock oil and preparation method thereof

InactiveCN101643664AExpand the range of raw materialsLow raw material costRefining with metal oxidesAluminiumSulfide

The invention relates to a desulfurizing agent for reforming stock oil and a preparation method thereof, in particular to the desulfurizing agent used for desorbing sulfides in the reforming stock oilsuch as H2S and the like. The desulfurizing agent is characterized by consisting of 10%-40% of ZnO, 15%-22% of NiO, 10%-17% of Al2O3, 5%-22% of SiO2 and the balance inevitable impurities. The desulfurizing agent takes zinc and nickel as active components and bentonite (or diatomite, or white clay, or zeolite, or high-alumina cement and or common cement) as a carrier, and active components thereofare directly present in the form of oxides of zinc and nickel or oxides transformed by corresponding carbonate (basic carbonate) and nitrate. In the invention, the desulfurizing agent has enlarged raw material range, thus effectively reducing raw material cost, simplifying production process of the desulfurizing agent, lowering production cost, improving strength to more than twice, and prolonging service life of the desulfurizing agent.

Owner:JINDUICHENG MOLYBDENUM CO LTD

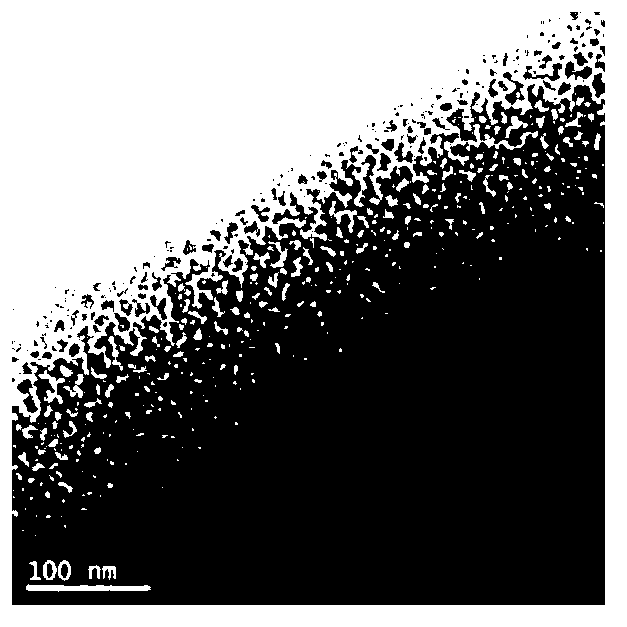

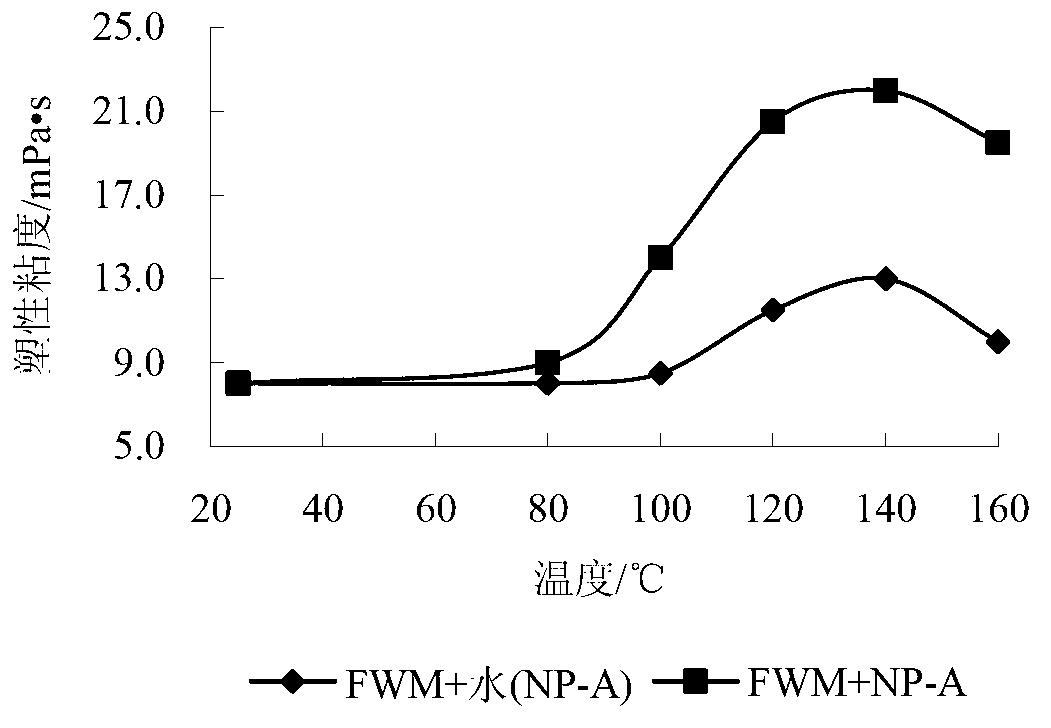

Method of utilizing nanometer silicon dioxide to improve properties of water-based drilling fluid at different temperatures

ActiveCN103013469AImprove the blocking effectImprove stabilityDrilling compositionWater basedFiltration

The invention provides a method of utilizing nanometer silicon dioxide to improve properties of water-based drilling fluid at different temperatures. The method comprises a step of adding a nanometer silicon dioxide dispersing agent into base mud, wherein the mass of the nanometer silicon dioxide particle in the nanometer silicon dioxide dispersing agent is 5-10% of total mass of the base mud and the nanometer silicon dioxide dispersing agent. Due to the nano-scale particle size, the nanometer silicon dioxide material can be filled into small holes and cracks of the shale stratum to improve the plugging effect of the water-based drilling fluid, slow down the trend of permeation of the drilling fluid to the stratum and expansion and chipping of the stratum after water absorption, and improve the stability of the borehole wall. The nanometer silicon dioxide can strengthen the stability of fresh-water base mud and bentonite base mud by increasing the negative charge level of the system. The nanometer silicon dioxide also can enable the base mud to form thinner and compact mud cakes and facilitate the de-filtration effect to be obvious.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Baking-free gravel attapulgite building garbage ceramsite

InactiveCN102503281AUniform particle sizeImprove yieldSolid waste managementExpanded clay aggregateWaste material

The invention discloses baking-free gravel attapulgite building garbage ceramsite. The key point of the technical scheme is that the baking-free gravel attapulgite building garbage ceramsite consists of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, building garbage powder, red bentonite powder, kieselguhr tailing powder and cement. The baking-free gravel attapulgite building garbage ceramsite is produced by the following steps of mixing the ingredients, granulating, maintaining, sieving and packaging.. The baking-free gravel attapulgite building garbage ceramsite is an irregularly-shaped granule and has a rough and hard surface light weight, high strength, high durability and a good heat-preserving and sound-insulating effect; and a large amount of fine pores are formed in the granule. The baking-free gravel attapulgite building garbage ceramsite is produced by utilizing the building garbage and tailings comprehensively, so that the utilization rate of resources is improved, waste materials are changed into wealth, and environment is protected. Besides, the baking-free gravel attapulgite building garbage ceramsite is suitable for producing concrete heat-preserving building blocks and heat-preserving and sound-insulating materials.

Owner:许庆华

Process for the preparation of doped pentasil-type zeolite using doped seeds

The present invention relates to a process for the preparation of doped pentasil-type zeolite, which process comprises the steps of:a) preparing an aqueous precursor mixture from a silicon source, an aluminium source, and doped non-zeolitic seeds; andb) thermally treating the precursor mixture to form a doped pentasil-type zeolite.The term “non-zeolitic seeds” includes seeds made from materials selected from the group consisting of (i) X-ray amorphous materials, (ii) milled crystalline materials, such as milled zeolites, that have a relative crystallinity of not more than 75%, and (iii) crystalline materials other than zeolites, such as clays (e,g, bentonite and kaolin) and (low) crystalline aluminas.

Owner:ALBEMARLE NETHERLANDS BV

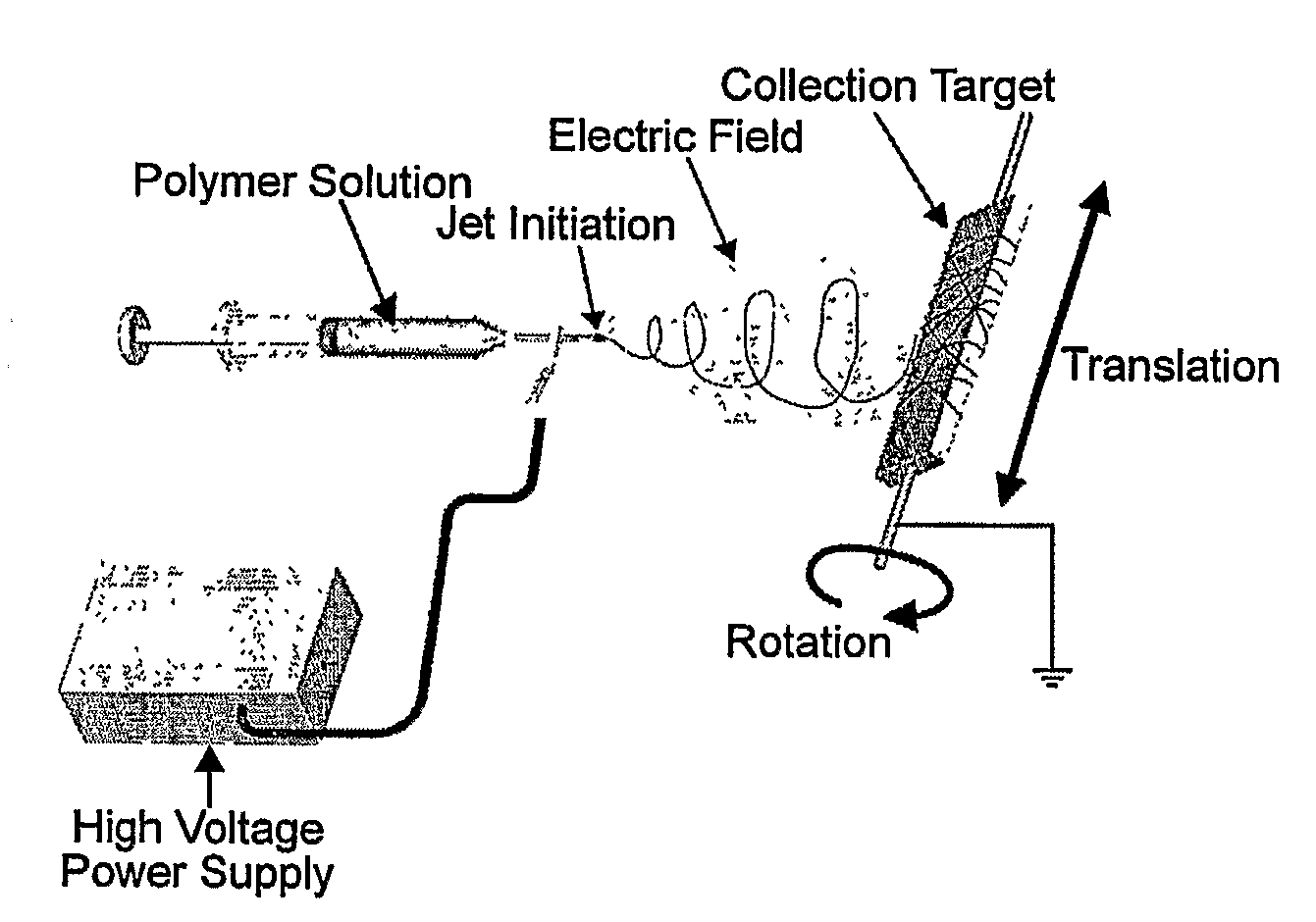

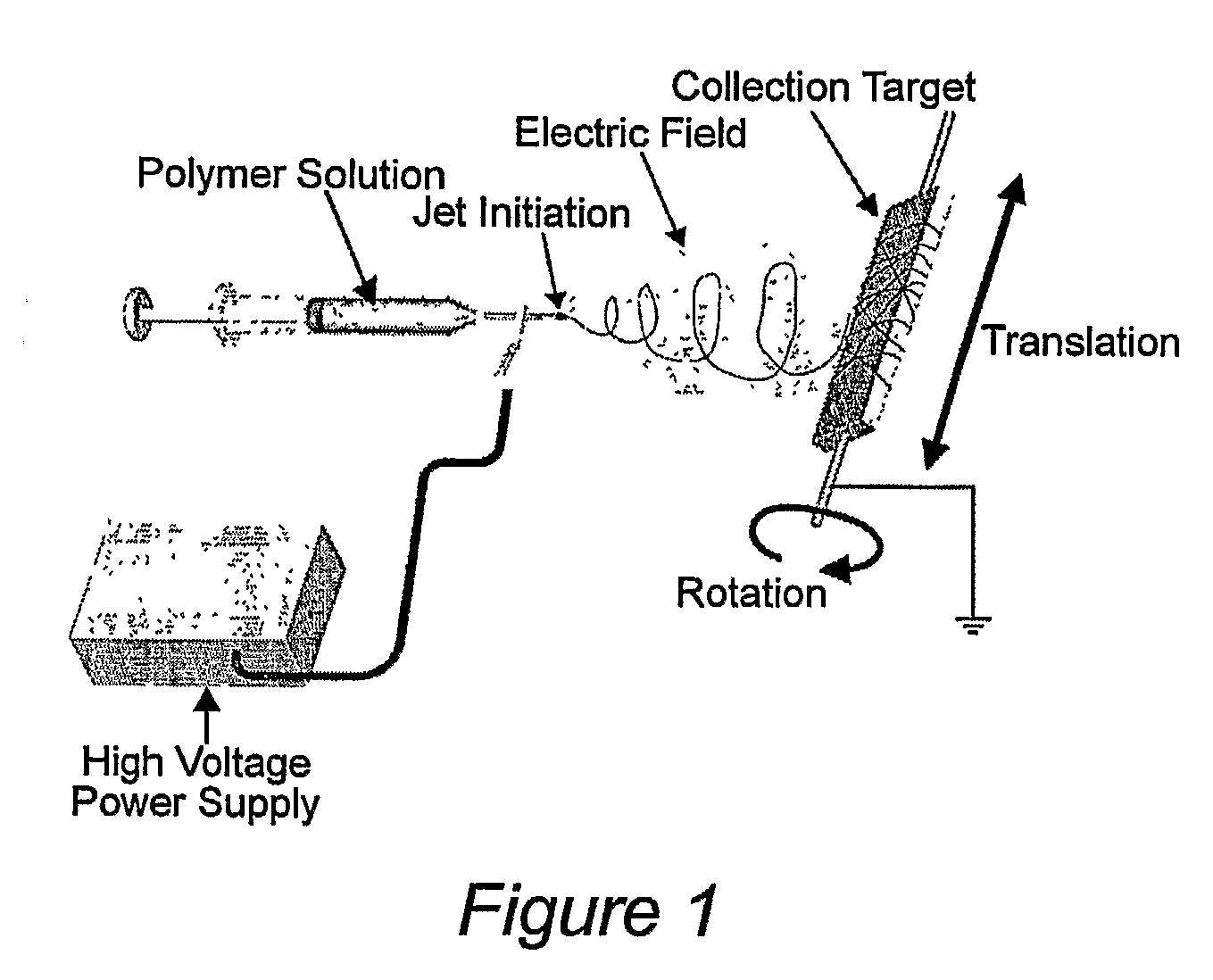

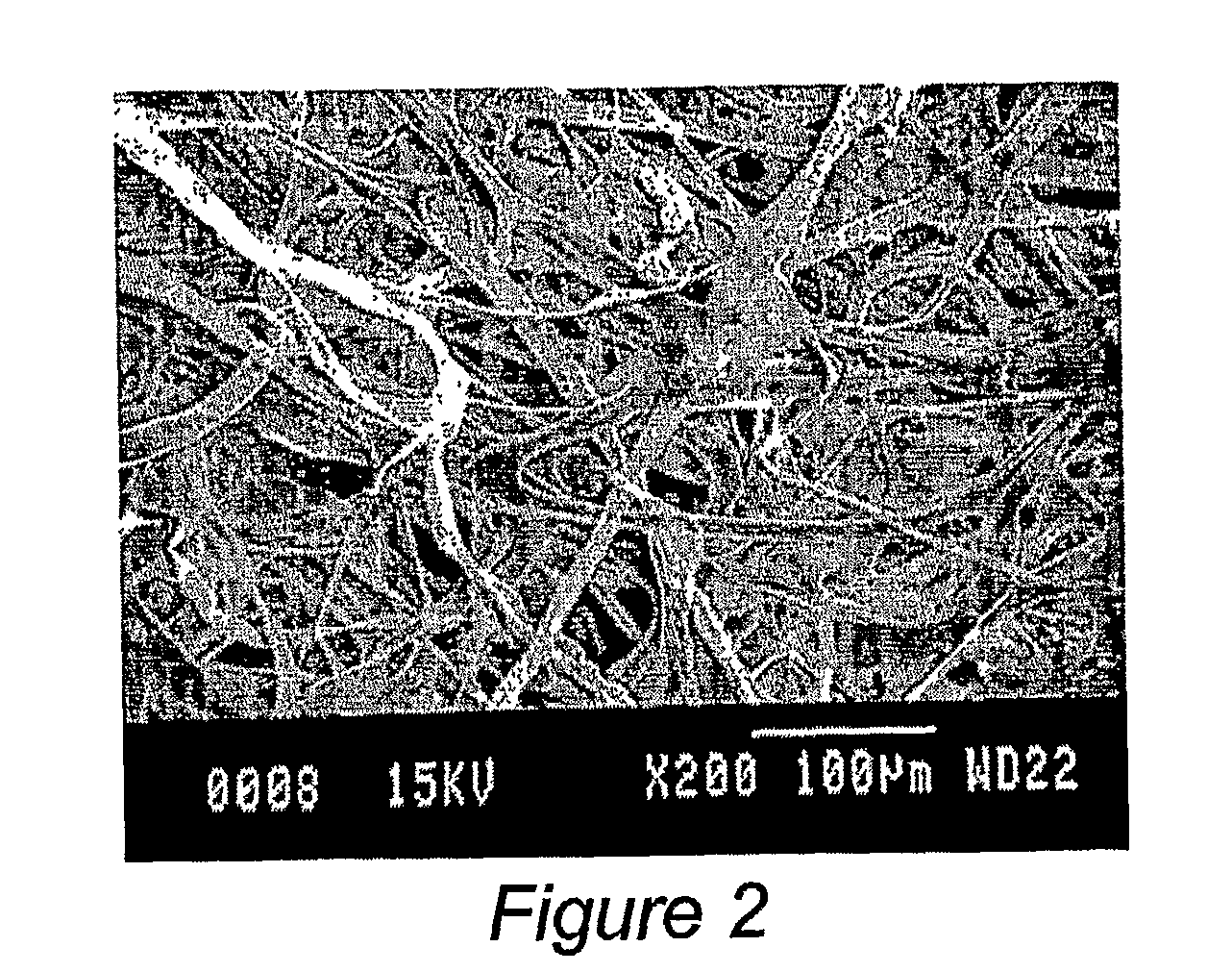

Mineral technologies (MT) for acute hemostasis and for the treatment of acute wounds and chronic ulcers

ActiveUS20090155342A1Effective treatmentEffective controlBiocideElectric discharge heatingAcute woundClay minerals

Compositions comprising clay minerals and methods for their use in promoting hemostasis are provided. The compositions comprise clay minerals such as bentonite, and facilitate blood clotting when applied to a hemorrhaging wound. Electrospun or electrosprayed materials (e.g. bandages, micron beads, etc.) which include clay minerals, and methods for the treatment of acute hemorrhage, are also provided.

Owner:VIRGINIA COMMONWEALTH UNIV

Clay molding sand for cast steel and preparation method thereof

The invention discloses clay molding sand for cast steel and a preparation method thereof. The clay molding sand is prepared from the following raw materials in parts by weight: 60-80 parts of quartz sand, 20-30 parts of forsterite sand, 8-12 parts of bentonite, 5-8 parts of composite powder, 4-6 parts of talcum powder, 2-3 parts of nanometer aluminum oxide, 3-5 parts of pine sawdust, 2-4 parts of alpha-starch, 1-2 parts of dextrin, 3-6 parts of calcium phosphate, 1.5-2.5 parts of sulfite lye and 4-8 parts of water. The molding sand is high-temperature resistant, high in strength and high in impact resistance, can be used for overcoming the defects on hot spot parts and avoiding sand adhesion, and a phenomenon that the sand mold is broken due to impact force of liquid steel casting is avoided. Moreover, the clay molding sand is low in air release amount, good in air permeability effect and high in liquidity, the defects of air holes, cold shut and shrinkage porosity in the casting can be effectively overcome, and the yield of the casting is improved.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Water-based drilling fluid applicable to horizontal shale and preparation method thereof

InactiveCN103937470AEnhanced inhibitory effectIncrease speedDrilling compositionComponents of crude oilTackifier

Owner:CHINA PETROCHEMICAL CORP +1

SPF compositions

InactiveUS20080219938A1Improve protectionEnhance immune responseCosmetic preparationsToilet preparationsSodium BentoniteOil phase

A composition comprising; water purified using ozonation, ionization, or distillation or any combination thereof wherein alcohol may be substituted for, or combined with water; at least one emollient including but not limited to chitosan, and aloe vera gel, individually or in any combination; an oil component with spf boosting agents including but not limited to; silicone oil and essential oils, butter milk, waxes impregnated with inorganic sun-block or sunscreen agent and organic / inorganic micronized particles, wood powder and bentonite clay, keratin, either individually or in any combination; at least one inorganic sun-block or sunscreen agent including any metal oxide, glass microsphere, silica and silica compound, and optionally metal oxide pigments with particles that are micronized, submicronized, nanoparticle sized, or otherwise individually or in any combination that can be homogenized in either a water phase, a water-aloe phase, or an oil phase or any phase of the composition; at least one emulsifier such that the emulsifier includes but is not limited to a phospholipid and / or liposome or an aloe vera gel or an ester of coconut oil individually or in any combination, for emulsification of the water, water-aloe, and / or the oil phases. Any of components are preferably mixed using an homogenizer and an appropriate thickening agent including but not limited to xanthan gum, and / or carageenan, either individually or in any combination that is added as required.

Owner:GRUNE GUERRY L

Modified phosphogypsum and its preparation

The present invention discloses a modified phosphogypsum and its preparation process. Its main weight composition is formed from 10-30% of additive (one, two or three kinds of aluminium sulfate slag, alum stone, plant ash, bentonite, slag, dickite, waste liquor and waste residue of paper mill and soda plant, white mud and sepiolite) and 70-90% of phosphogypsum. The phosphogypsum and additive are mixed together, and stacked at a certain temp. so as to obtain the modified phosphogypsum. If said modified phosphogypsum is closed-heated at 30-100 deg.C for 8-48 hr., and formed, dried and can be made into the cement retarded, and if the modified phosphogypsum closed-heated for 8-24 hr, is calcined at 600-900 deg.C, and can be made into cement reinforcing agent.

Owner:孙国庆 +1

Mixed casting molding sand and preparation method thereof

The invention discloses a mixed casting molding sand and a preparation method thereof. The preparation method mainly comprises: performing dry mixing of component raw materials including quartz sand, attapulgite, wax, asbestos, a furan resin, a phenolic resin, bentonite and potassium dichromate by certain weight parts; and adding water, mixing, placing sand, molding, casting, cooling and separating to obtain finished product. The preparation method of the invention is simple, the formula is reasonable, the cost is low, the production efficiency is high, the surface of an aluminum sand piece is made smooth by strictly controlling the particle size of quartz sand, and the breathability is high.

Owner:邹平县永通金属材料有限公司

Methods for smoothing wrinkles and skin texture imperfections

InactiveUS20130189332A1Excellent initialExcellent lasting contractionCosmetic preparationsBiocideWrinkle skinKaolinite

A method for smoothing skin comprising applying a composition that has from about 0.5 to about 4% sodium silicate as measured by silica content (SiO2) and from about 0.1% to about 4.0% of a polyvalent silicate. The composition is provided in a carrier, for example, from about 10 to 98% water, and can be in the form of a water gel or oil-in-water emulsion. A second composition is applied before or after the first composition wherein the second composition is selected from the group consisting of an oil-in-water emulsion, water-in-oil emulsion, thickened water gel, thickened oil phase, encapsulated oil phase, solid oil phase, and mixtures thereof. The polyvalent silicate can be a silicate clay selected from the group consisting of bentonite, laponite, smectite, and kaolinite.

Owner:THE PROCTER & GAMBLE COMPANY

Cement-based penetrable crystallized waterproof paint, preparation method and construction method thereof

The invention relates to a cement-based penetrable crystallized waterproof paint, a preparation method and a construction method thereof. The cement-based penetrable crystallized waterproof paint is prepared from the following raw materials in percentage by weight: 65 to 70 percent of cement, 3 to 10 percent of modified bentonite, 2 to 5 percent of modified sodium silicate, 1 to 5 percent of diffusant, 0.5 to 1 percent of penetrant, 2 to 10 percent of wollastonite and 15 to 25 percent of quartz sand. The waterproof paint can recover minute cracks on concrete interfaces and inhibit the water seepage and damp of base interfaces effectively. In addition, the waterproof paint is high in capacity of freezing resistance, high-temperature resistance, chloridion resistance and acid and alkali resistance, and has a long waterproof effect. According to the cement-based penetrable crystallized waterproof paint, leveling layers on the concrete interfaces are saved, and protective layers are savedafter the concrete interfaces are coated, so the waterproof construction is simple. The cement-based penetrable crystallized waterproof paint is suitable for constructional engineering such as underground engineering, subway tunnels, civil air-defense construction, water ponds, oil sumps, sewage tanks, barns, bathrooms, roof squares, parking platforms, high-grade roadways and the like, and is used for processing defects of cracks, honeycomb pitted surfaces and the like of the concrete interfaces.

Owner:姜哲 +1

Inorganic composite material for absorbent refining multiple metal ion industrial sewage and application method thereof

ActiveCN102658082AGood adsorption propertiesImprove purification effectOther chemical processesWater/sewage treatment by sorptionCelluloseIndustrial waste water

The invention provides an inorganic composite material for absorbent refining multiple metal ion industrial sewage. The inorganic composite material is prepared by mixing, by percentage by weight, 5-15% of intercalation expandable graphite, 10-25% of hydroxyapatite, 5-15% of zeolite, 5-10% of rectorite, 5-10% of chalk, 5-25% of bentonite and 15-40% of kieselguhr, adding 5wt% of clear water of total mass of mixture and 5wt% of sodium carboxymethylcellulose, evenly mixing to prepare spheroidal particle with the grain size of 1-3mm, and roasting for 2h at the temperature of 200-800 DEG C after drying. The inorganic composite material is apt to obtain technique materials and simple in handling process, and is used for absorbent refining of the multiple metal ion industrial sewage.

Owner:陕西合兴硅砂有限公司

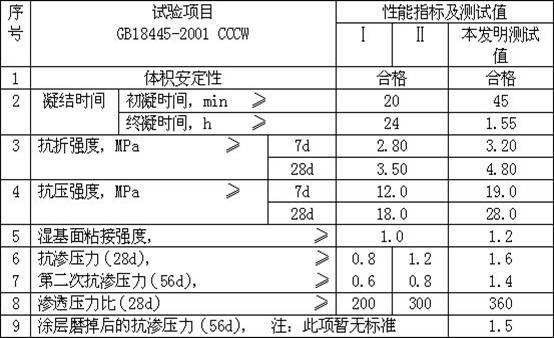

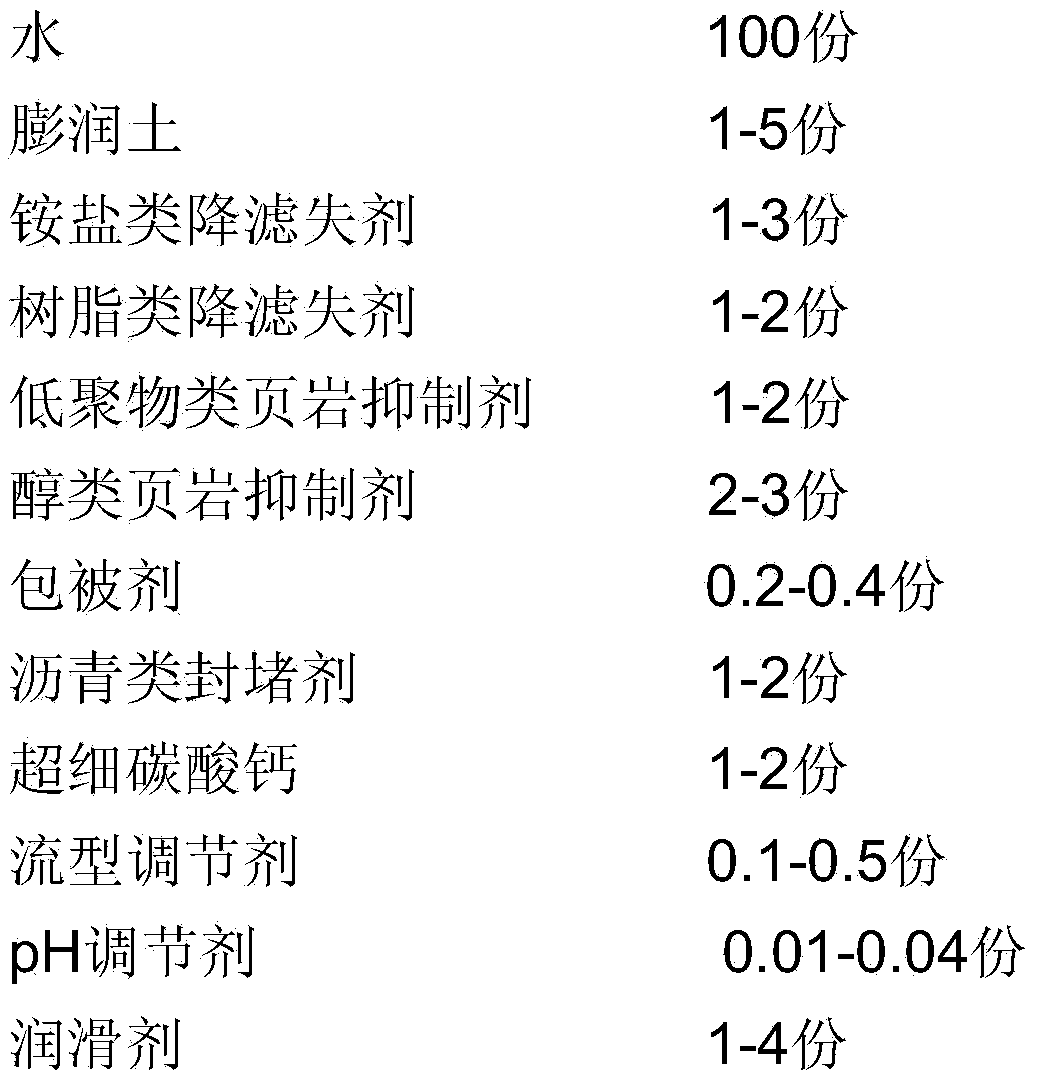

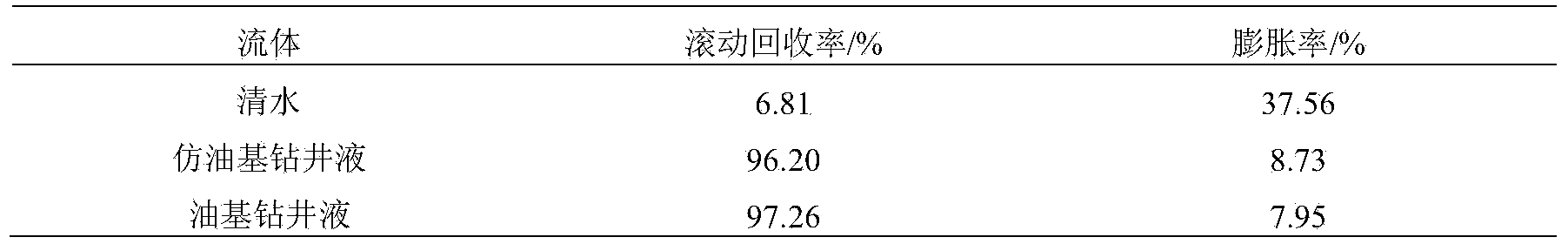

Oil-base imitating drilling fluid with characteristics of strong inhibition, strong blocking and high lubricity

InactiveCN104388065AEnhanced inhibitory effectStrong blockingDrilling compositionWater basedUltra fine

The present invention relates to an oil-base imitating drilling fluid with characteristics of strong inhibition, strong blocking and high lubricity. In the prior art, the existing amine compound-containing water-base drilling fluid provides the weak blocking capability for the mud shale micro-crack, and the lubricity can not completely meet the construction requirement. With the oil-base imitating drilling fluid of the present invention, the problems in the prior art are mainly solved. The oil-base imitating drilling fluid comprises, by weight, 100 parts of water, 1-5 parts of bentonite, 1-3 parts of an ammonium salt filtrate reducer, 1-2 parts of a resin filtrate reducer, 1-2 parts of an oligomer shale inhibitor, 2-3 parts of an alcohol shale inhibitor, 0.2-0.4 part of a coating agent, 1-2 parts of an asphalt blocking agent, 1-2 parts of ultra-fine calcium carbonate, 0.1-0.5 part of a flow type adjusting agent, 0.01-0.04 part of a pH value adjusting agent, and 1-4 parts of a lubricant. According to the present invention, the oil-base imitating drilling fluid of the present invention is the water-base drilling fluid having the performance equivalent to the oil-base drilling fluid, the safe, rapid and efficient drilling construction in the mud shale stratum and the unconventional dense oil reservoir is ensured, and the new technical support is provided for the effective development of the oil and gas reservoir.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Fluorite slag-containing aerated concrete block

The invention discloses a fluorite slag-containing aerated concrete block. The fluorite slag-containing aerated concrete block is prepared from the following raw materials by the conventional process for preparing the aerated concreted block: 25 to 30 weight parts of coal ash, 5 to 10 weight parts of cement, 10 to 15 weight parts of quick lime, 5 to 10 weight parts of modified nano powder, 5 to 10 weight parts of volcanic rock powder, 3 to 5 weight parts of gypsum, 0.05 to 0.1 weight part of aluminum powder, 0.02 to 0.08 weight part of peregal, 0.03 to 0.08 weight part of oxyparaffin soap, 0.3 to 0.5 weight part of soda ash, 0.5 to 0.8 weight part of bentonite, 0.3 to 0.5 weight part of zinc stearate, 0.01 to 0.03 weight part of aluminum hydroxide, 0.05 to 0.1 weight part of sodium hexametaphosphate and an appropriate amount of water. Nano mineral powder is added, so that the volume weight of the brick, and the energy consumption are reduced; the aerated brick is high in thermal insulation performance and sound insulation performance; compared with the conventional aerated concrete block, the fluorite slag-containing aerated concrete block has the advantages that the thermal insulation performance and the sound insulation performance are improved obviously; the raw materials are mixed according to an optimized formula; and the intensity and the freezing resistance of the brick are improved obviously.

Owner:沛县铸本混凝土有限公司

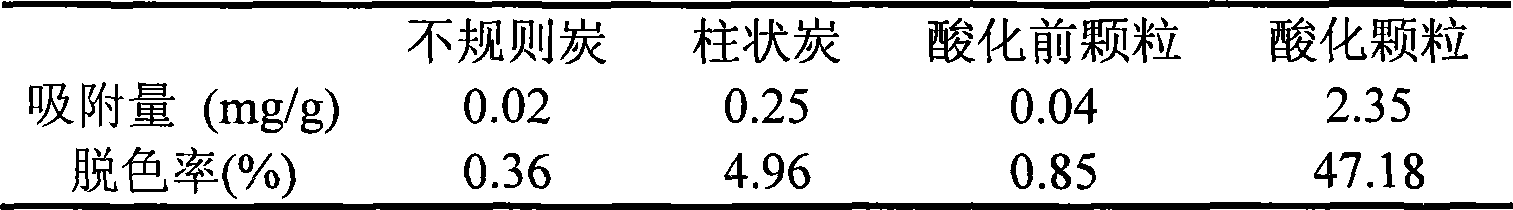

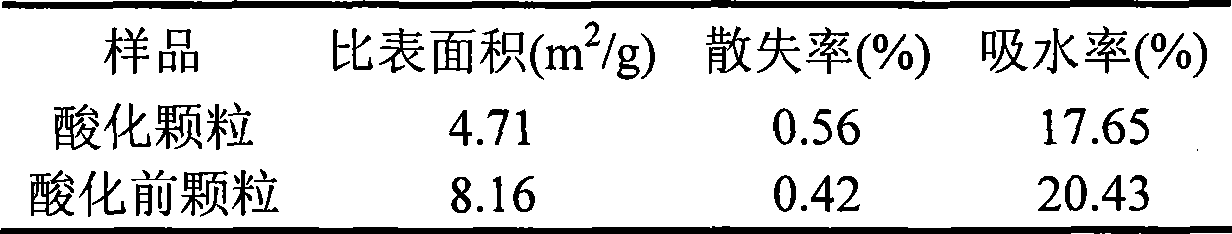

Preparation method of acidification sludge bentonite granules

InactiveCN101362073AReasonable designSimple processOther chemical processesGranulation by material expressionSodium BentoniteSludge

The invention relates to a preparation method of acidified sludge bentonite particles, pertaining to the technical field of environmental protection. Sludge and nano-bentonite powder are mixed together according to a certain ration, porous sludge bentonite particles are prepared by roasting under high temperature and the activity of the porous sludge bentonite particles is further modified by sulphuric acid to prepare the acidified sludge bentonite particles. The acidified sludge bentonite particles is yellow solid particles, with organic substance content reaching 165.788mg / g, specified surface area being 4.71m<2> / g, lost ratio being 0.56 percent and water absorptivity being 17.65 percent. The preparation method has the advantages of simple technology, economic efficiency, low cost, and the like, and the prepared acidified sludge bentonite particles have stable quality, uniform appearance and good absorptivity, thereby not only realizing the utilization of sludge as resource and the reduction of the pollution caused by the sludge, but also having wide application value in the aspect of decoloring processing of waste water produced in printing and dyeing, and realizing the purpose of treating waste by utilizing waste.

Owner:SHANDONG UNIV

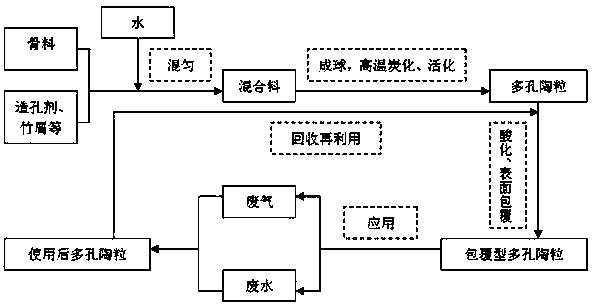

Bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron as well as preparation method and application of bamboo-charcoal-shaped porous ceramsite

ActiveCN104291797AImprove physical strengthGood processing effectCeramicwareExpanded clay aggregateHoneycomb

The invention provides bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron as well as a preparation method and application of the bamboo-charcoal-shaped porous ceramsite. The preparation method of the bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron comprises the following steps: taking alpha-Al2O3 powder as ceramsite primary aggregate, clay and bentonite as auxiliary aggregates and surface-activated bamboo bits as bamboo charcoal preparation materials to combine with a pore forming agent to prepare pores without adding a sintering aid or a binder; adopting graded sintering at 400-600 DEG C to obtain bamboo-charcoal-shaped porous ceramsite by once molding; then, preparing the product bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron by virtue of a reducing coating process of the coating material, wherein the product bamboo-charcoal-shaped porous ceramsite is a deep dark small ball with a grain size of 2-10 mm, internally a porous honeycomb spherical structure with a surface pore size of 15-25 mu m, has water absorption of 20-35% and a specific surface area of 40-60m<2> / g. The preparation method disclosed by the invention is environmentally friendly simple and energy-saving in preparation process, various in treated pollutants, and suitable for treating non-biodegradable wastewater such as flue gas wastewater, heavy metal wastewater, phenol-containing wastewater, emulsified oil wastewater, note printing and printing and dyeing wastewater, and raw material are easily available.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com