Method for preparing foam ceramic self-insulation wall material by utilizing solid wastes

A technology for solid waste and wall materials, which is applied in the preparation of foam ceramic self-insulation wall materials and the field of preparation thereof, can solve the problems of complex harmless treatment process of chrome slag, low cost, difficulty in mass utilization and the like, and achieves thermal insulation. Outstanding thermal insulation effect, high porosity, and the effect of ensuring durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

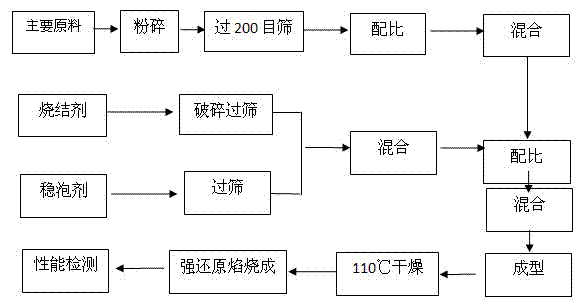

Method used

Image

Examples

Embodiment 1

[0025] A foam ceramic self-insulating wall material, the wall material is composed of main materials and additives, the main materials are chromium slag, coal gangue, ceramic polishing waste slag, albite feldspar, and bentonite. The main ingredients are all passed through a 200 mesh sieve, and weighed according to the ratio of 31%: 20%: 20%: 25%: 4% by weight, and 19g of admixture is added to every 200g of main ingredients, mixed evenly, and then mixed under a pressure of 5MPa Press down to form and dry at 110°C. The admixture is a sintering agent and a foam stabilizer, expressed in weight ratio, and the two are composed in a ratio of 7:1.

[0026] Described sintering agent is frit, and the chemical composition of frit is: SiO 2 40%, Al 2 o 3 4%, Fe 2 o 3 1%, CaO 15%, MgO 1%, K 2 O and Na 2 Total O 5%, PbO 12%, ZnO 8%, B 2 o 3 11%, Li 2 O 3%; The foam stabilizer is tricalcium phosphate.

[0027] Firing according to the following temperature system: from room tem...

Embodiment 2

[0030] It is basically the same as Example 1, and the difference is that the major ingredients are chromium slag, coal gangue, ceramic polishing waste, albite, and bentonite according to the proportioning composition of 30%: 19%: 23%: 22%: 6%. Add 20g of admixture per 200g of main material.

[0031] Described sintering agent is frit, and the chemical composition of frit is: SiO 2 41%, Al 2 o 3 5%, Fe 2 o 3 2%, CaO 9%, MgO 2%, K 2 O and Na 2 Total O 6%, PbO 14%, ZnO 9%, B 2 o 3 10%, Li 2 O 2%.

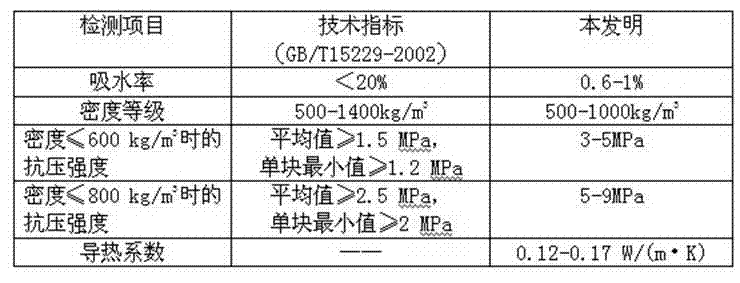

[0032] Technical indicators of this product: water absorption rate 0.7%, density 850 kg / m 3 , compressive strength 8.2 MPa, thermal conductivity 0.15 W / (mK).

Embodiment 3

[0034]Basically the same as Example 1, the difference is that the major ingredients are chromium slag, coal gangue, ceramic polishing waste, albite, bentonite, and the proportioning composition of 25%:24%:25%:21%:5% , every 200g of the main material is added with 18g of admixture to obtain the mixture, which is fired at 1150°C, and the volume fraction of CO in the flame gas is 5%.

[0035] Described sintering agent is frit, and the chemical composition of frit is: SiO 2 42%, Al 2 o 3 6%, Fe 2 o 3 1.5%, CaO 7.5%, MgO 3%, K 2 O and Na 2 Total O 7%, PbO 12%, ZnO 10%, B 2 o 3 10%, Li 2 O 1%.

[0036] Technical indicators of the product: water absorption 0.82%, density 670 kg / m 3 , compressive strength 6.8 MPa, thermal conductivity 0.13W / (mK).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com