Water-based drilling fluid applicable to horizontal shale and preparation method thereof

A water-based drilling fluid and mud shale technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as difficulty in low cost, backward supporting technologies, and water-based drilling fluids that cannot meet the needs of drilling. , to reduce friction, improve inhibition performance, and enhance the ability to carry cuttings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

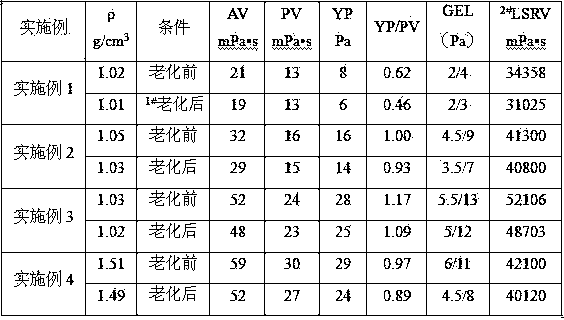

Embodiment 1

[0030] Prepare water-based drilling fluid suitable for horizontal shale formations without adding weight: add 400g fresh water to a high mixing cup, turn on the mixer, and add 8g sodium bentonite, 0.16g sodium carbonate, 0.8g XC-60 while stirring at 10000r / min ( Shengda Cellulose Factory, Dongying City, Shandong Province), 2g organic amine (produced by Shengli Oilfield Shengli Chemical Co., Ltd.), 12g sulfomethyl phenolic resin (SMP-I), 2g small molecule coating agent, 8g modified asphalt (Beijing Hongqin Petroleum Additive Co., Ltd. produces HQ-1), 4g aluminum-based polymer, 12g calcium carbonate, 12g vegetable oil lubricant, 2g sorbitan monooleate.

Embodiment 2

[0032] Prepare water-based drilling fluid suitable for horizontal shale formations without adding weight: add 400g of fresh water to a high mixing cup, turn on the mixer, add 12g of sodium bentonite, 0.16g of sodium carbonate, 1.2g of XC-60 ( Products produced by Shengda Cellulose Factory in Dongying City, Shandong Province), 2g organic amines (products produced by Shengli Oilfield Shengli Chemical Co., Ltd.), 8g sulfomethyl phenolic resin (SMP-I), 8g hyperbranched phenolic resin (SPC ), 6g small molecule coating agent, 12g sulfonated pitch (produced by Shengli Oilfield Shengli Chemical Co., Ltd.), 4g aluminum-based polymer, 12g calcium carbonate, 18g vegetable oil lubricant, 2g sorbitan monooleate.

Embodiment 3

[0034] Prepare water-based drilling fluid suitable for horizontal shale formations without adding weight: add 400g of fresh water to a high mixing cup, turn on the mixer, add 24g of sodium bentonite, 1.2g of sodium carbonate, 4g of XC-60 (Shandong Dongying Shengda Cellulose Factory), 8g organic amine (produced by Shengli Oilfield Shengli Chemical Co., Ltd.), 32g hyperbranched phenolic resin (SPC), 8g small molecule coating agent, 20g sulfonated pitch, 8g aluminum-based polymer material, 24g calcium carbonate, 24 glass pellets, 4g sorbitan monooleate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Expansion height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com