Patents

Literature

71results about How to "Meet drilling needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

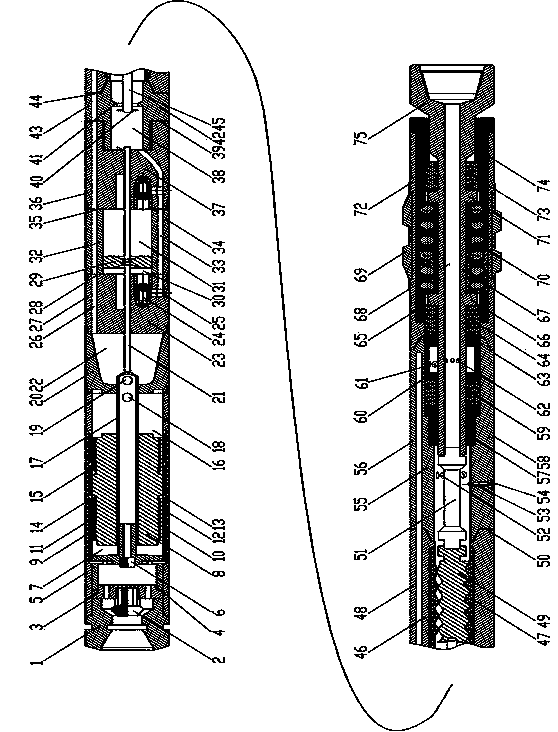

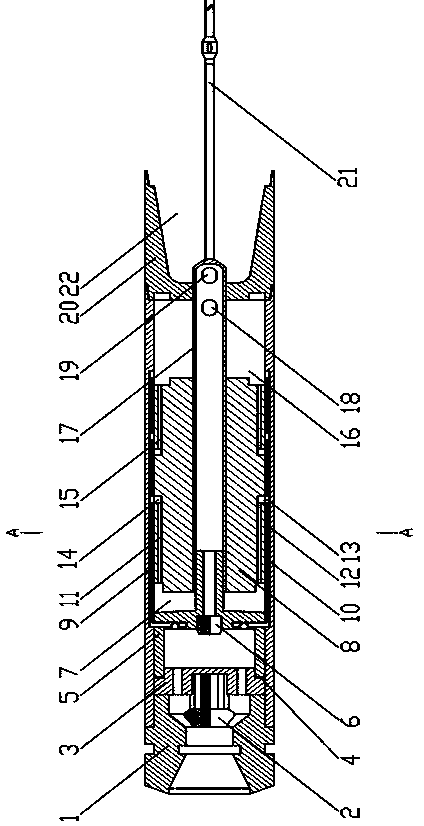

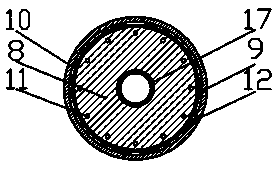

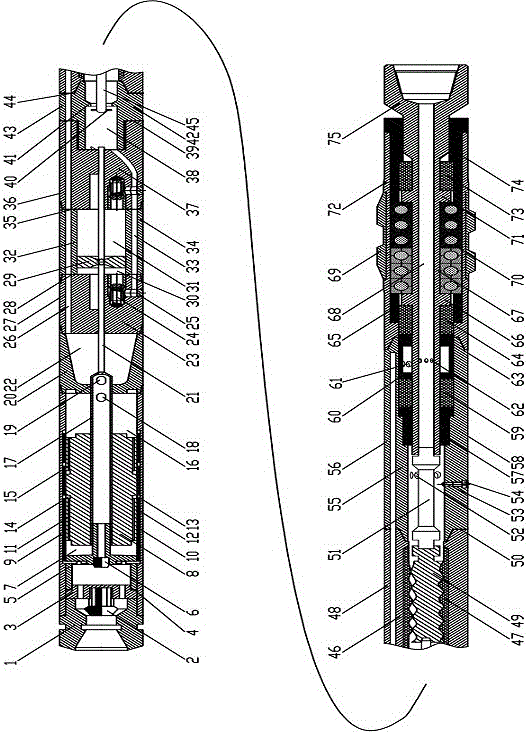

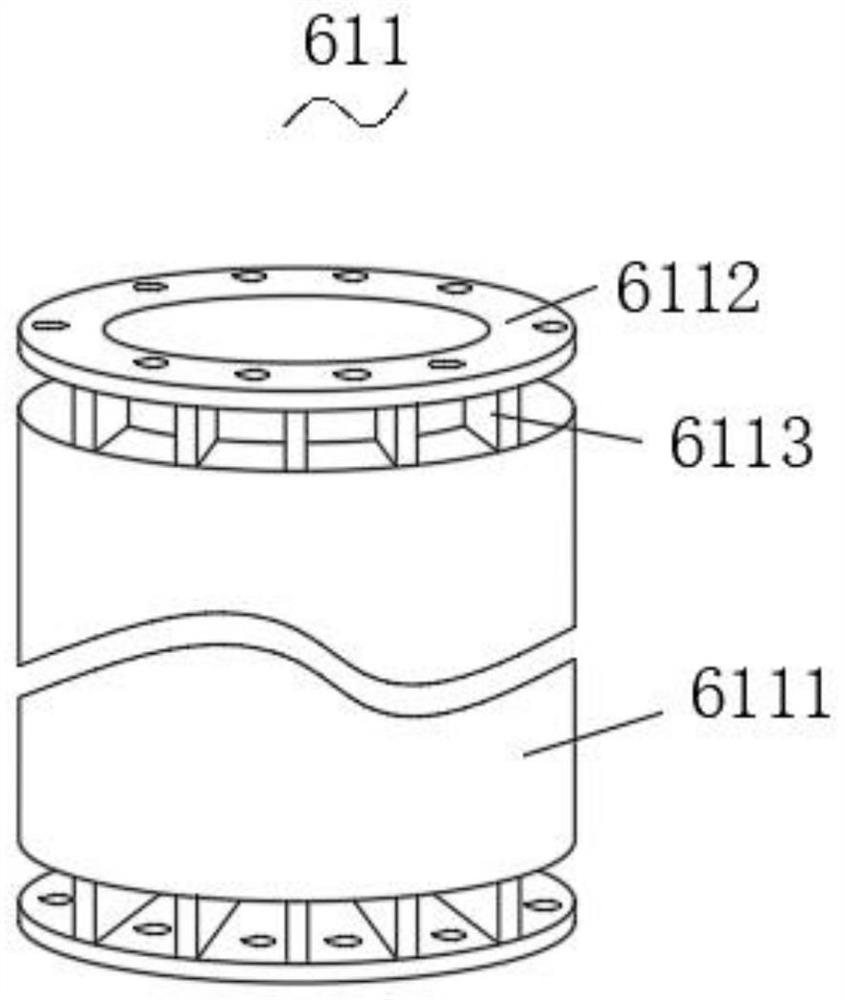

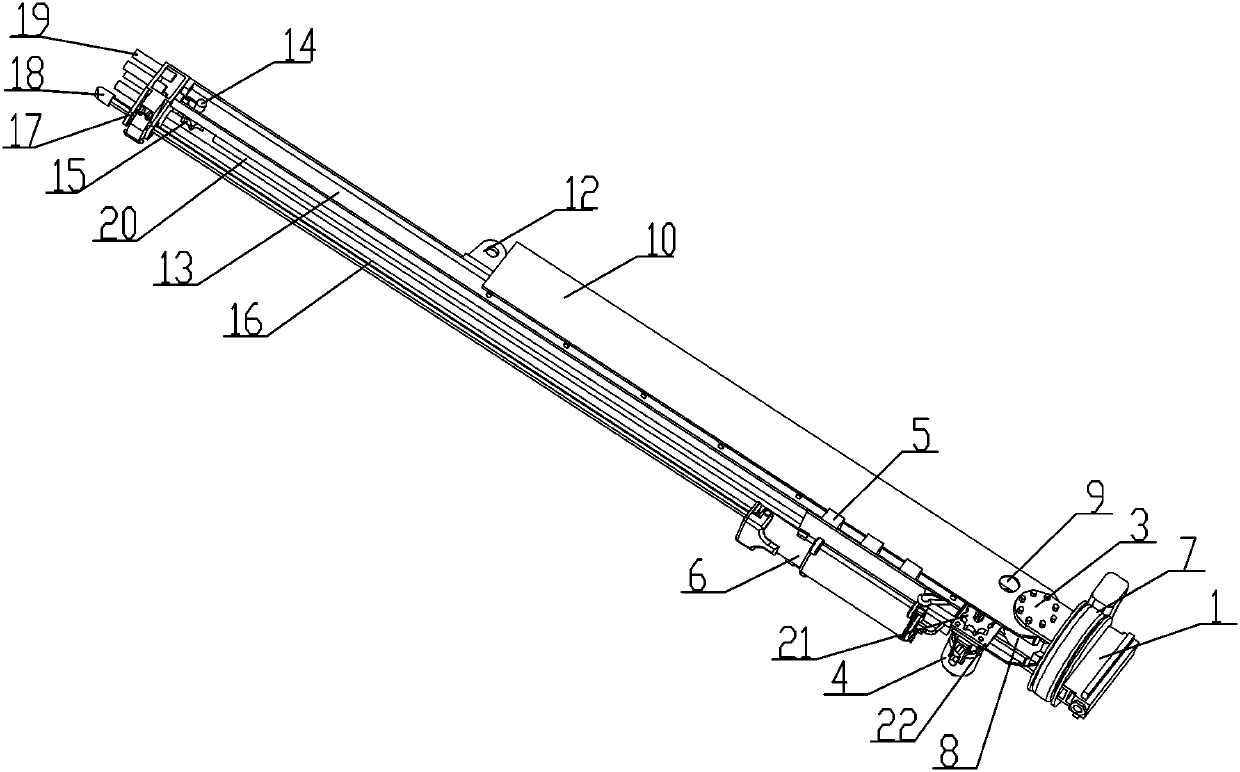

Gas drilling underground motor drilling tool

ActiveCN104213829AAddress lack of motivationMeet drilling needsBorehole drivesHydraulic motorDirectional well

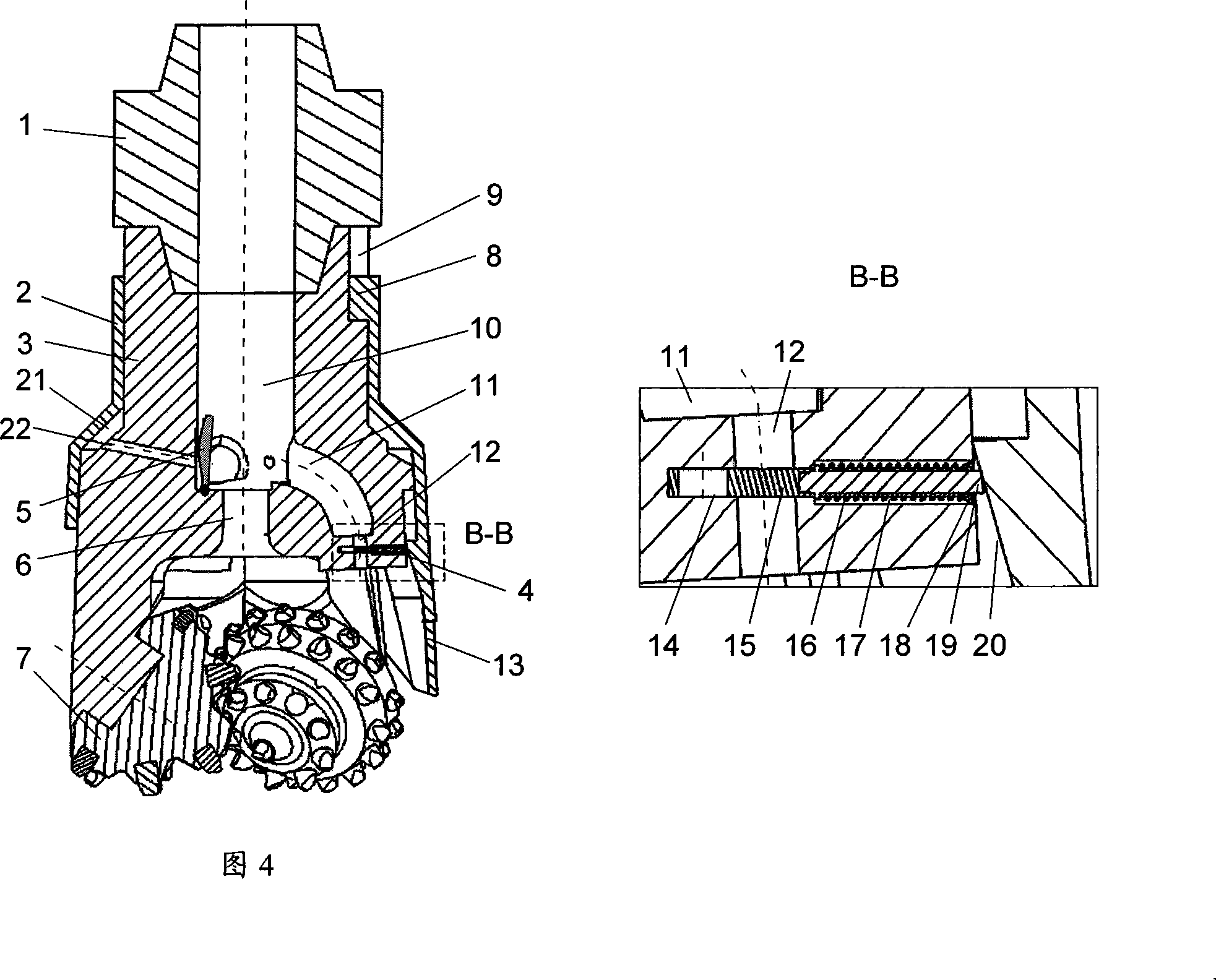

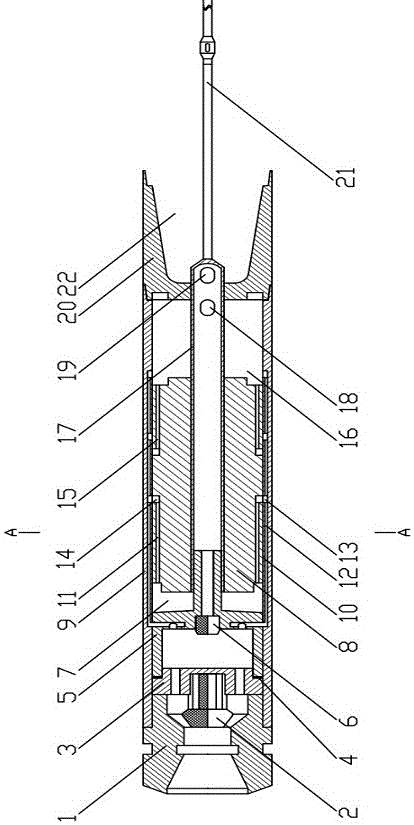

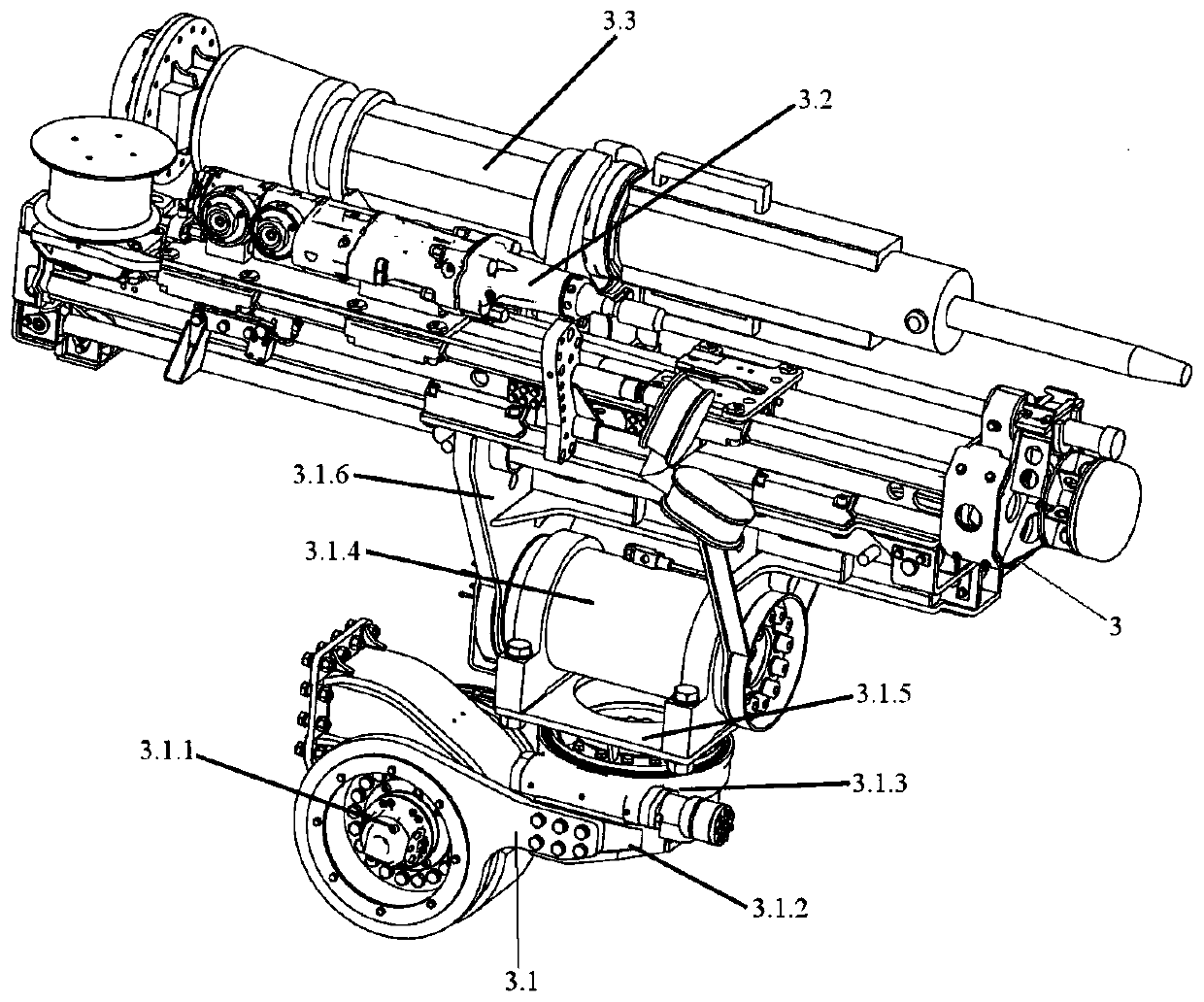

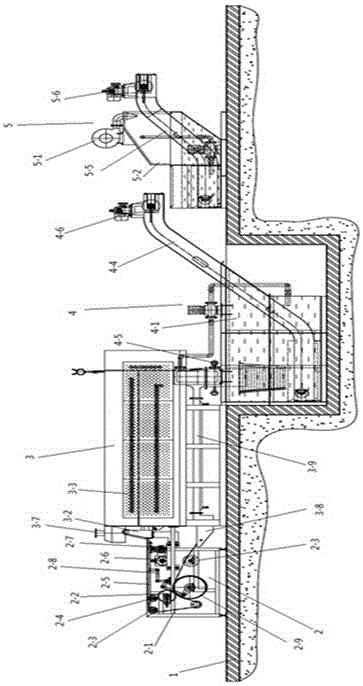

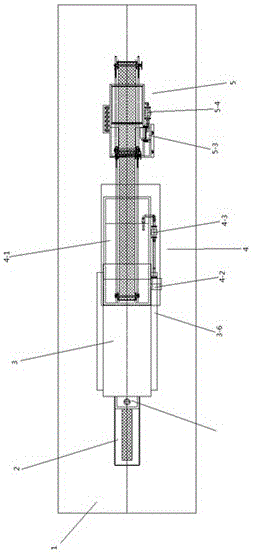

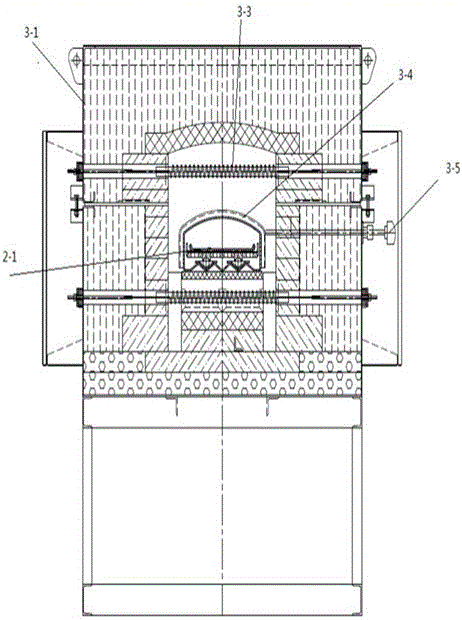

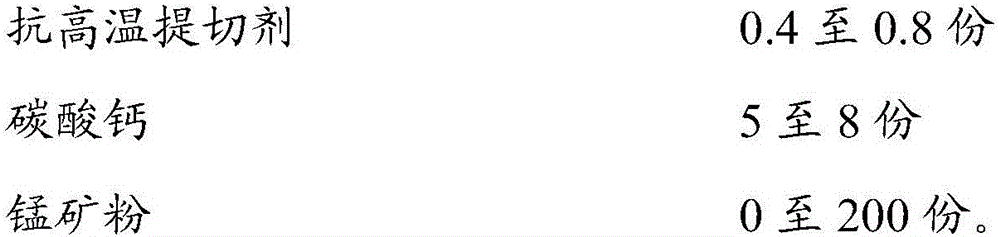

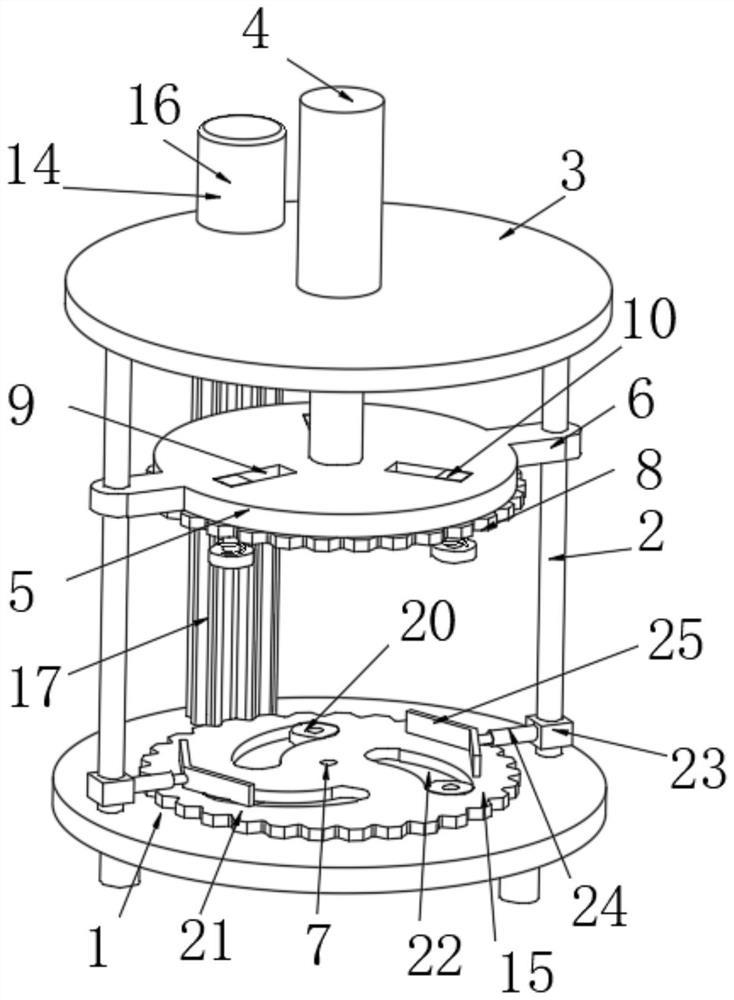

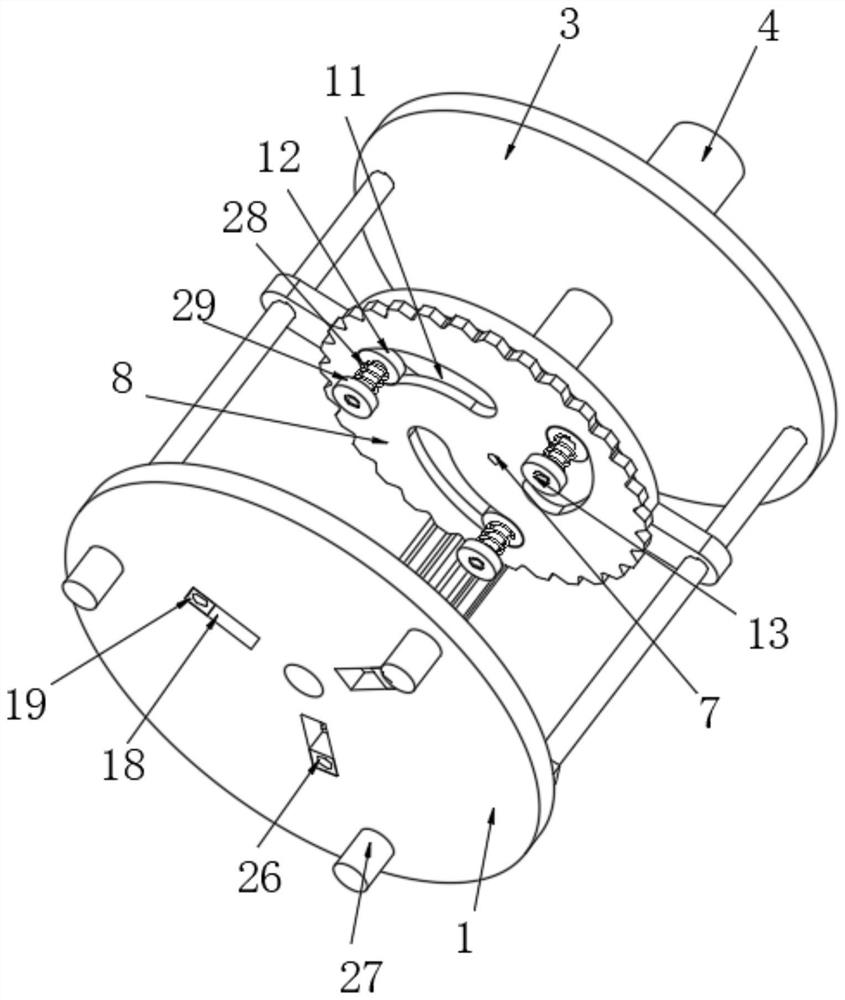

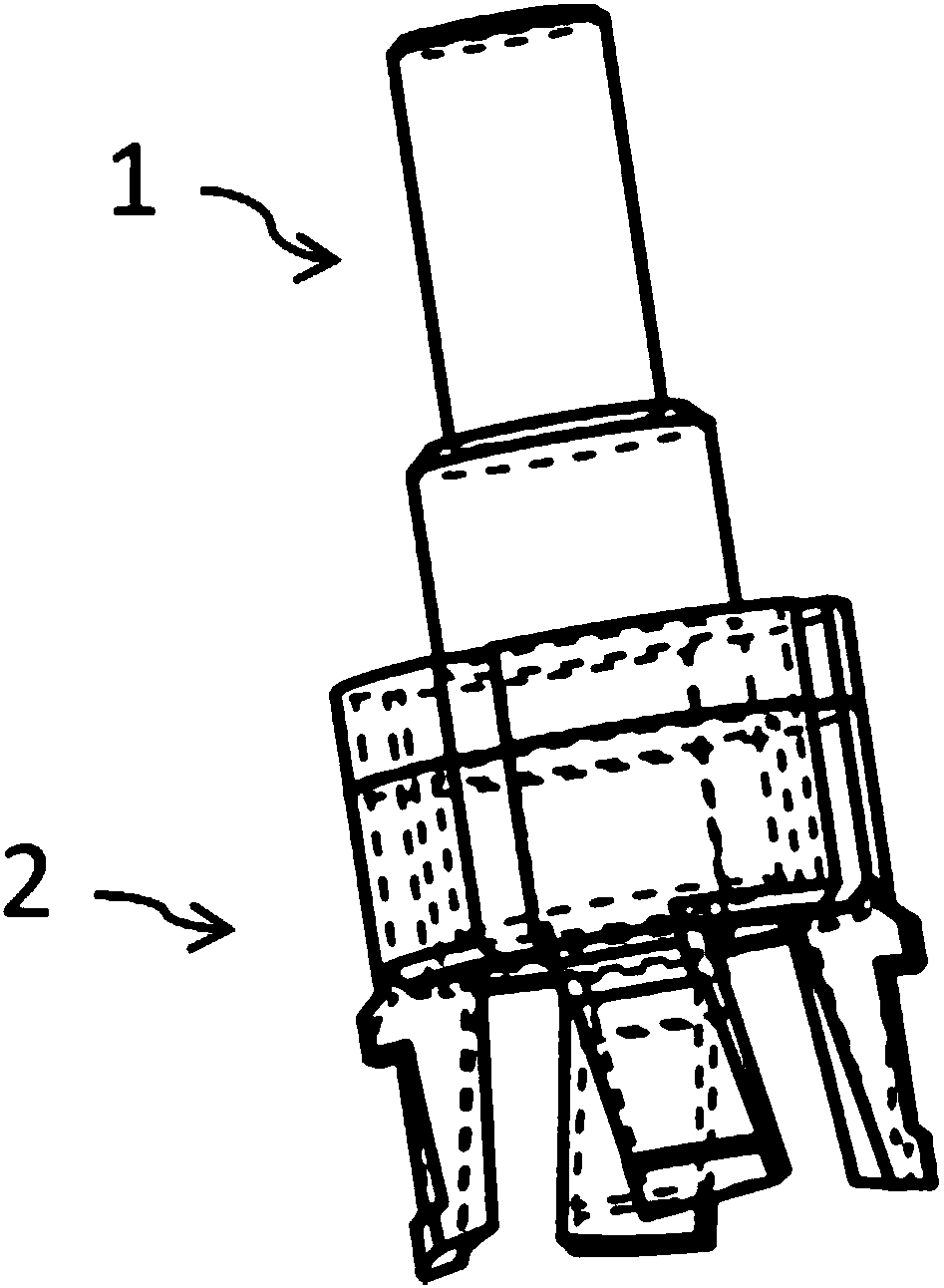

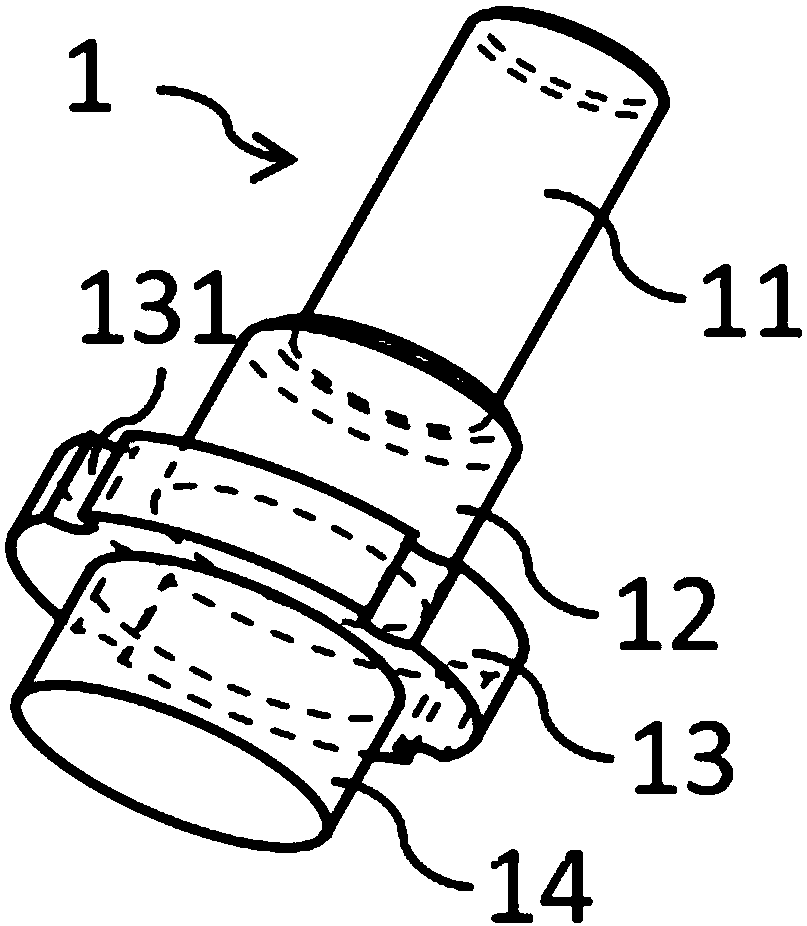

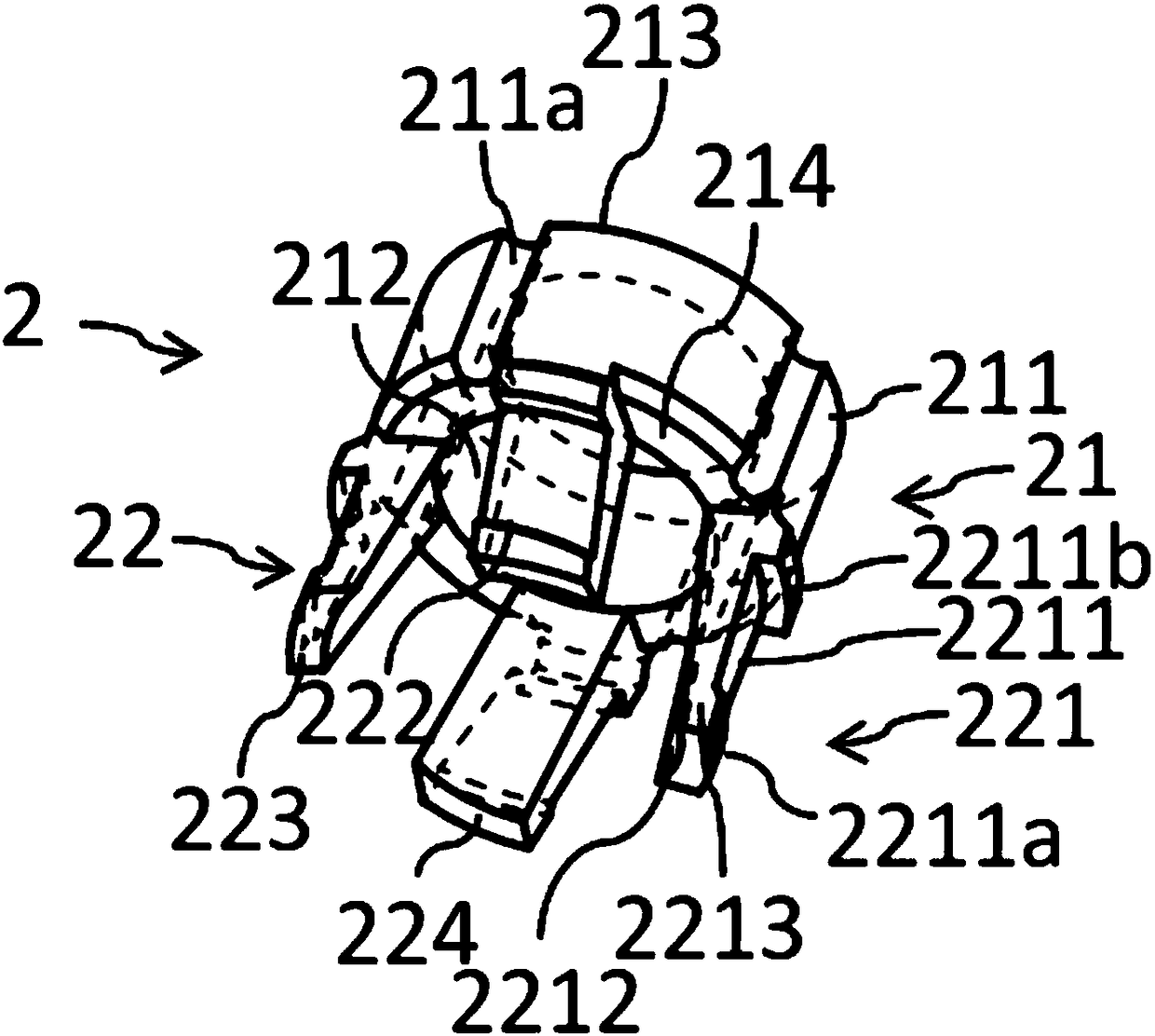

The invention discloses a gas drilling underground motor drilling tool. The gas drilling underground motor drilling tool comprises a double-acting compressed air power short section, a double-acting hydraulic power short section, a closed circulating hydraulic motor and a liquid separation air discharging transmission short section, which are sequentially connected with one another in a threading manner, and a chamber of each part is sealed through a sealing pad after being aligned to one another; a sealing pad d is arranged between the double-acting hydraulic power short section and the closed circulating hydraulic motor. By adopting the gas drilling underground motor drilling tool, the gas energy can be converted to high-pressure hydraulic energy, the rotor is driven to rotate through the closed cycling of hydraulic oil inside a volume-type motor, the power insufficiency caused by the compression when the gas energy is directly used for driving the motor can be overcome, all advantages for adopting the gas as the cycling medium also can be maintained, and the underground power problem of a gas drilling horizontal well, a directional well and a large-displacement well can be effectively solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

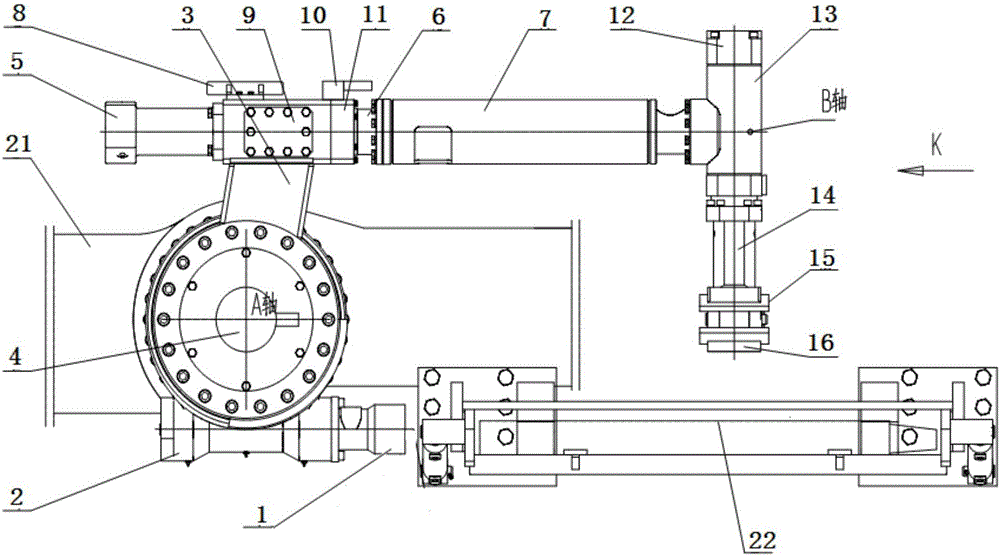

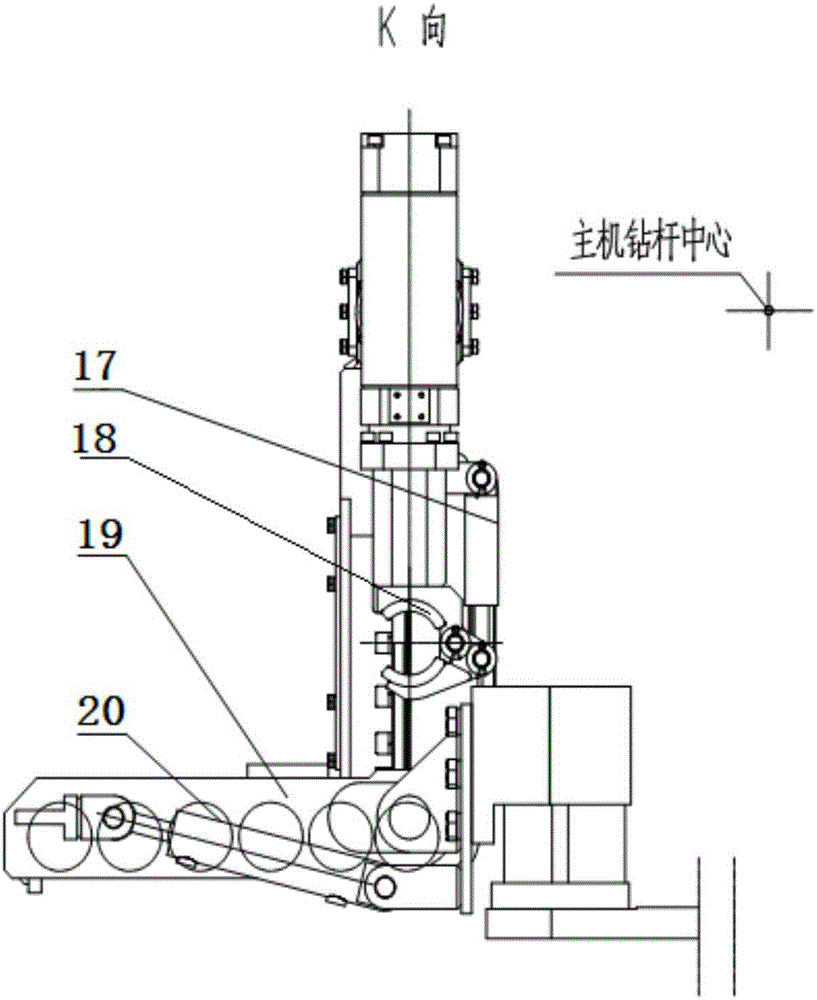

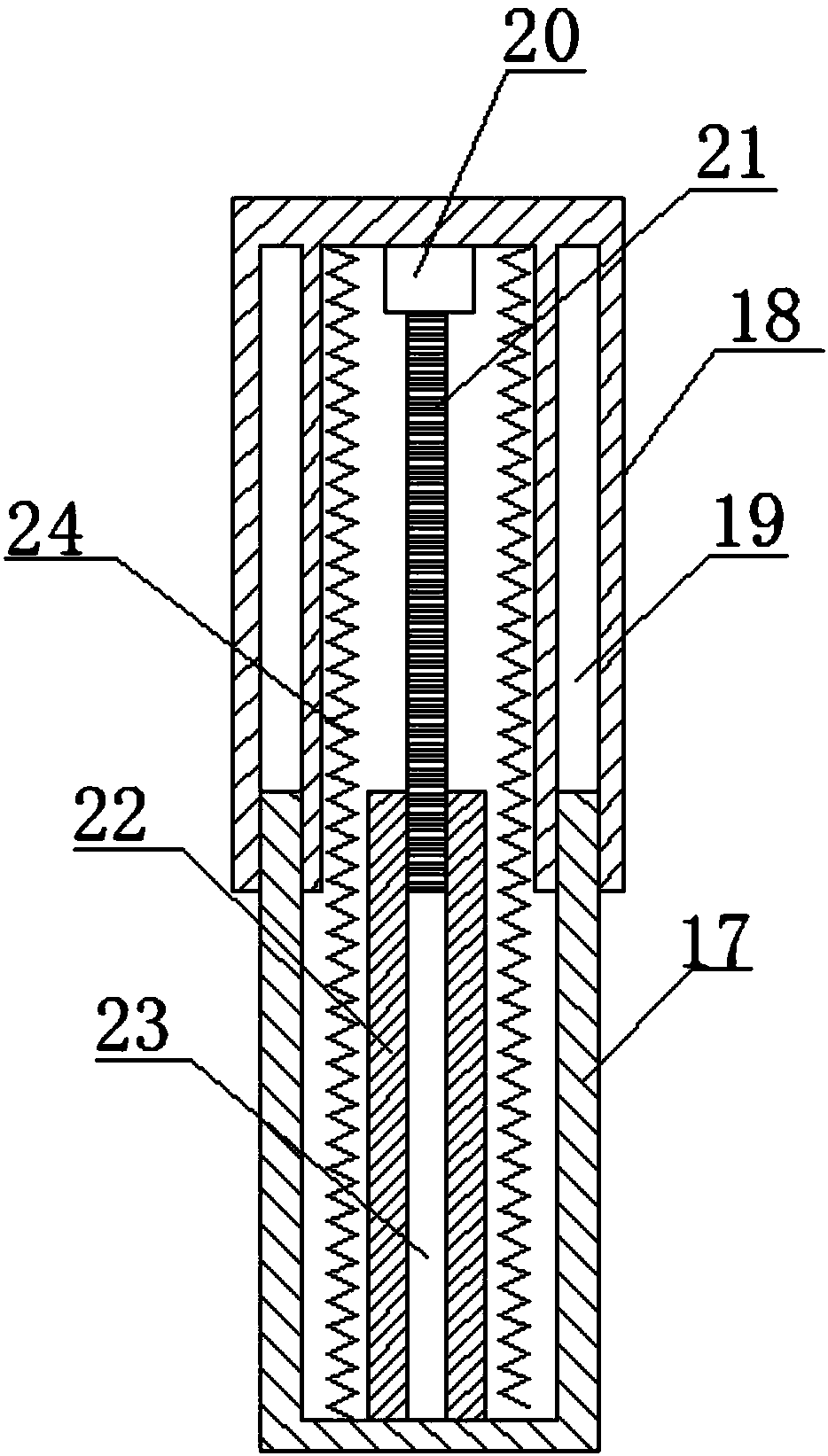

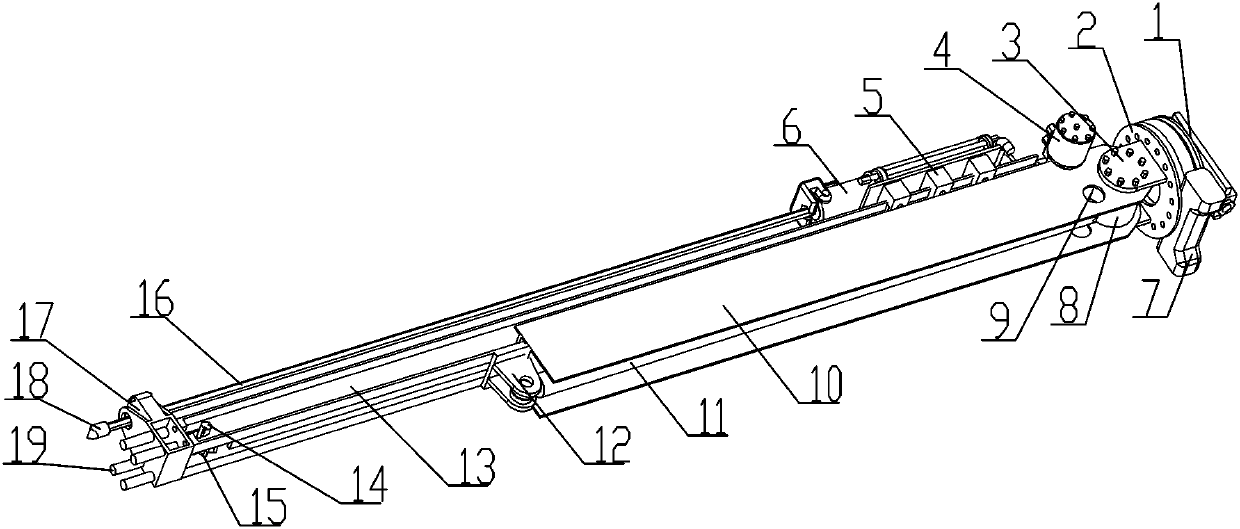

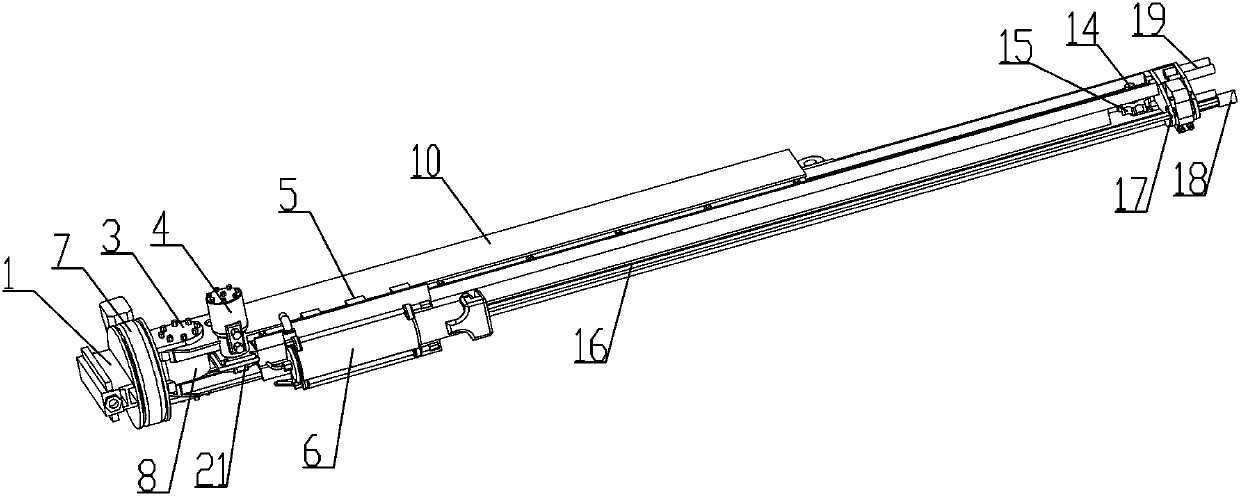

Drill pipe conveying device for coal mine drilling rig

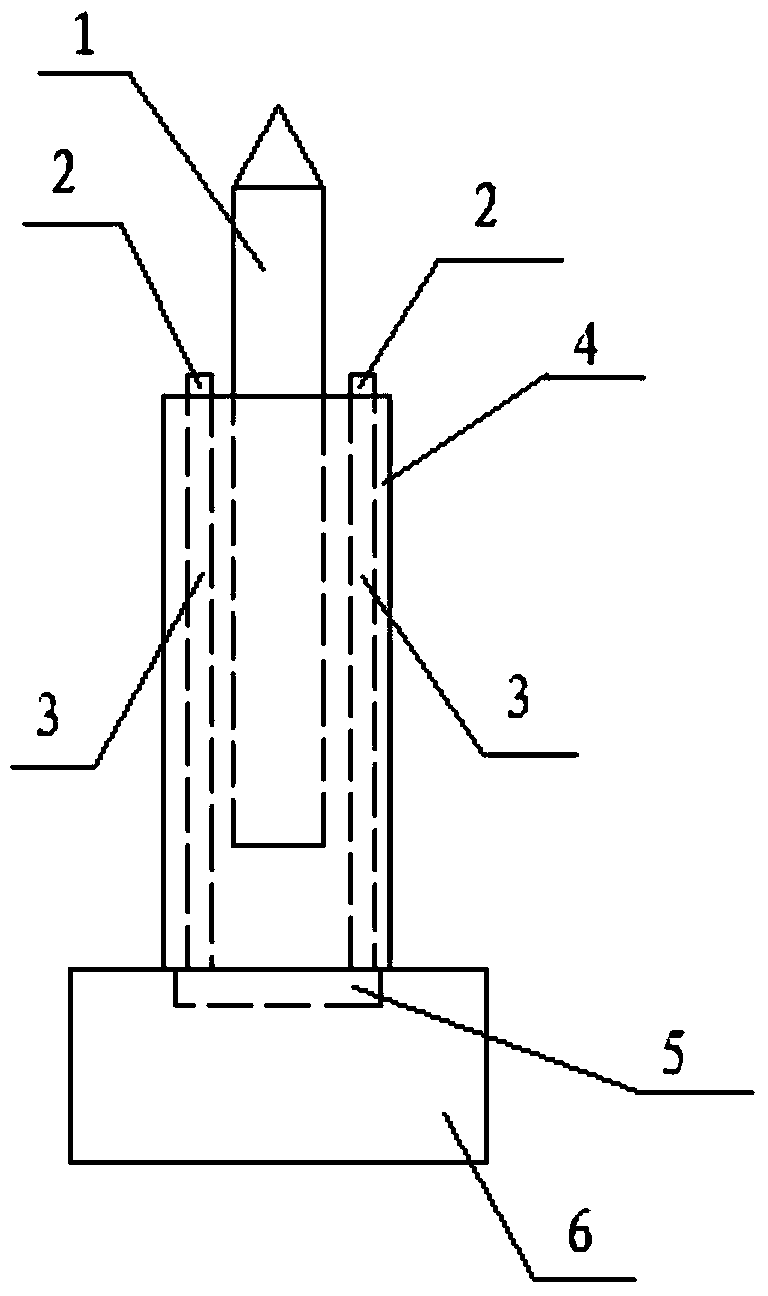

The invention discloses a drill pipe conveying device for a coal mine drilling rig and belongs to the field of machinery design. The drill pipe conveying device comprises an articulated manipulator and a drill pipe box, wherein the articulated manipulator and the drill pipe box are integrated to the same side of the lifting tilting mechanism of the drilling rig; the articulated manipulator comprises a dip angle adjusting joint, a rotation joint, a telescoping joint and a gripper joint, the dip angle adjusting joint is mounted on the lifting tilting mechanism and comprises a dip angle motor, a dip angle reducer and a rotary arm, the rotation joint is mounted on the rotary arm and comprises a rotation motor, a rotation shaft and a rotation arm, the telescoping joint is mounted on the rotation arm and comprises a telescoping device, a telescoping outer cylinder and a telescoping arm, and the gripper joint is mounted on the telescoping arm and comprises an upper fixed jaw, a lower movable jaw and a clamping device. The drill pipe conveying device is large in dip angle adjusting range, accurate in positioning, convenient to mount and maintain, high in anti-pollution capacity, small in size, and the like.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

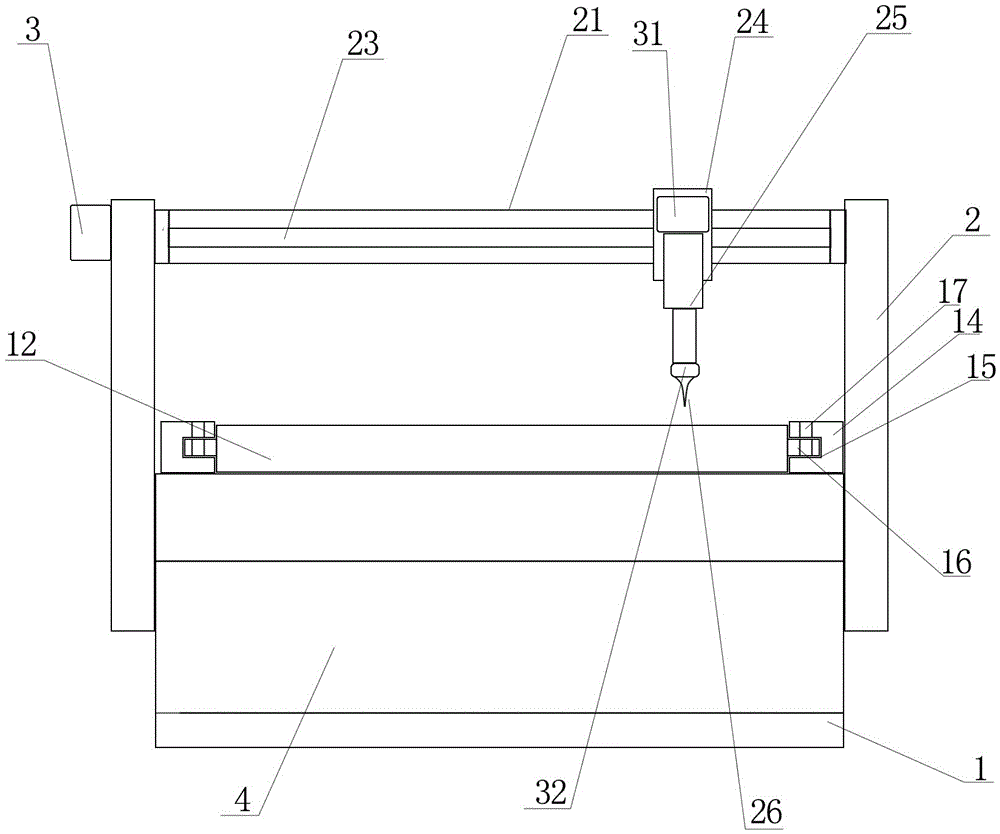

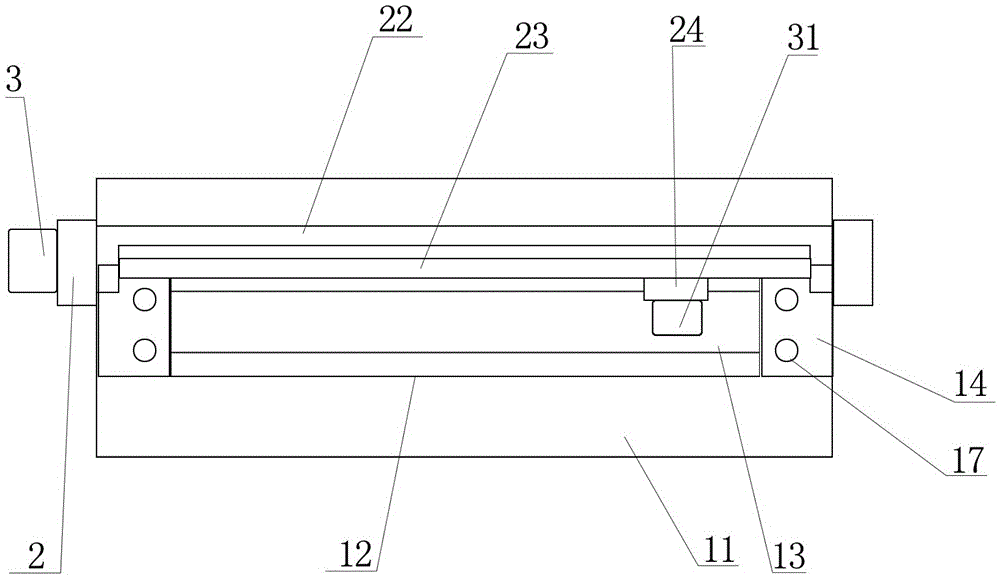

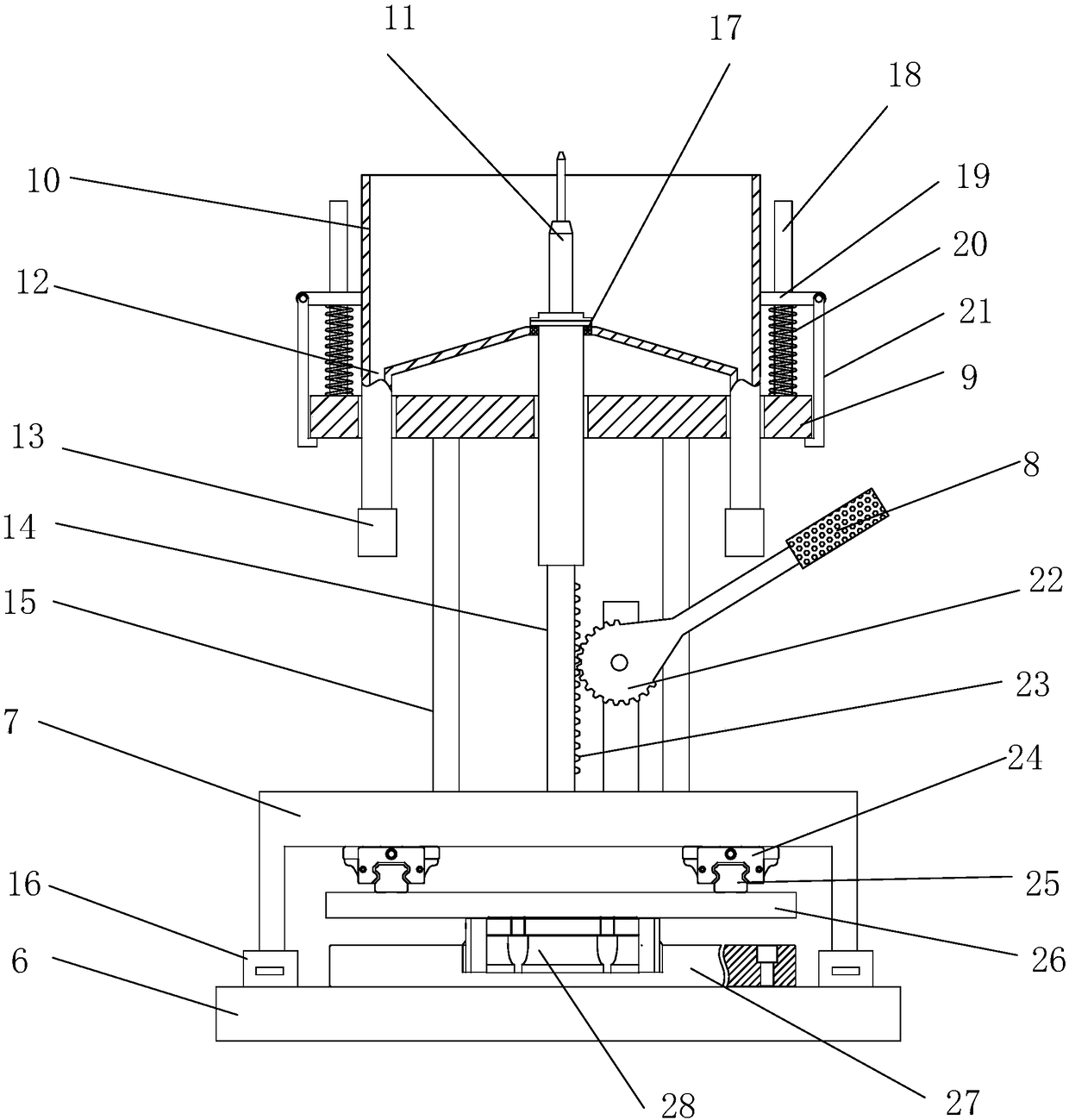

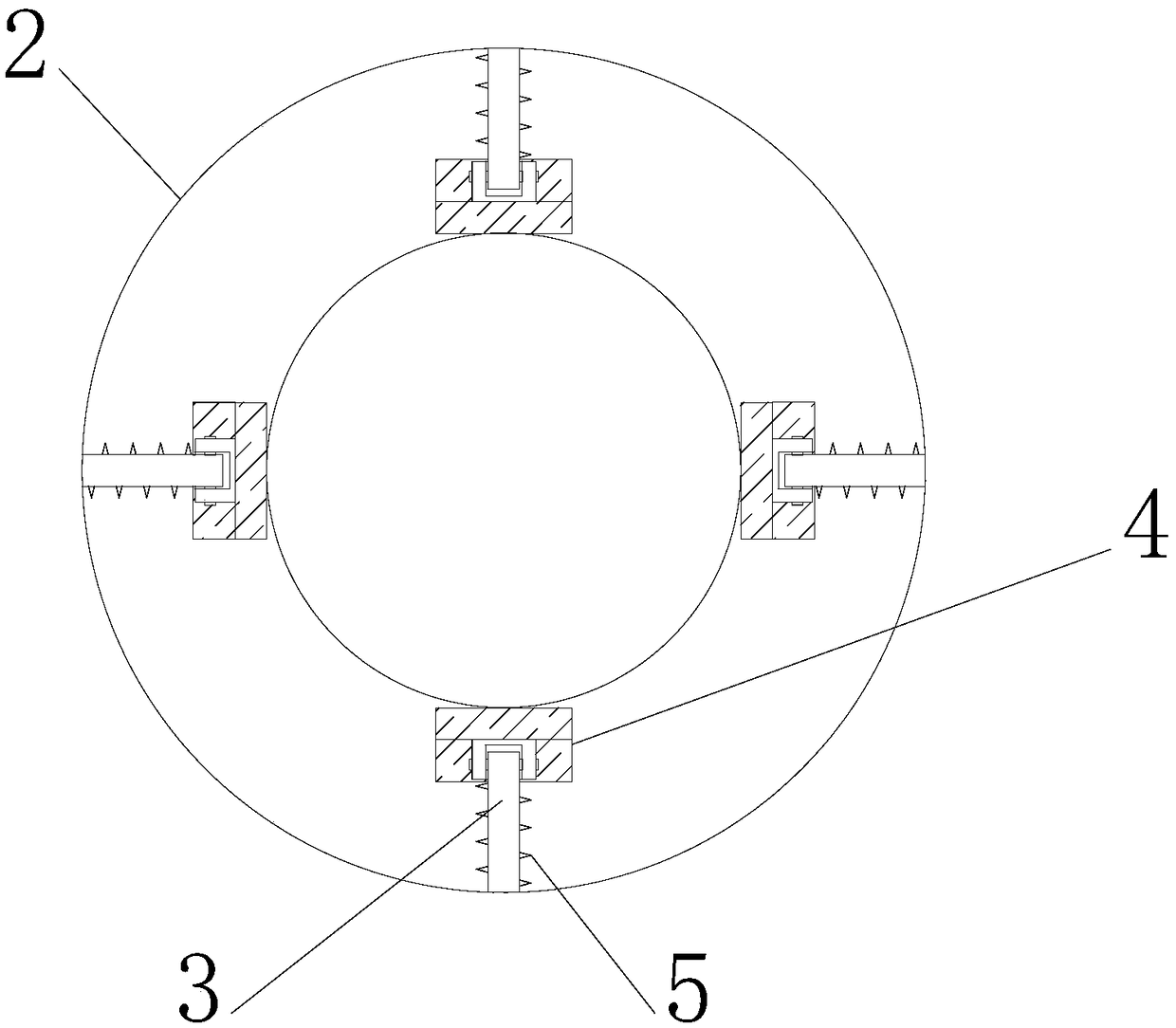

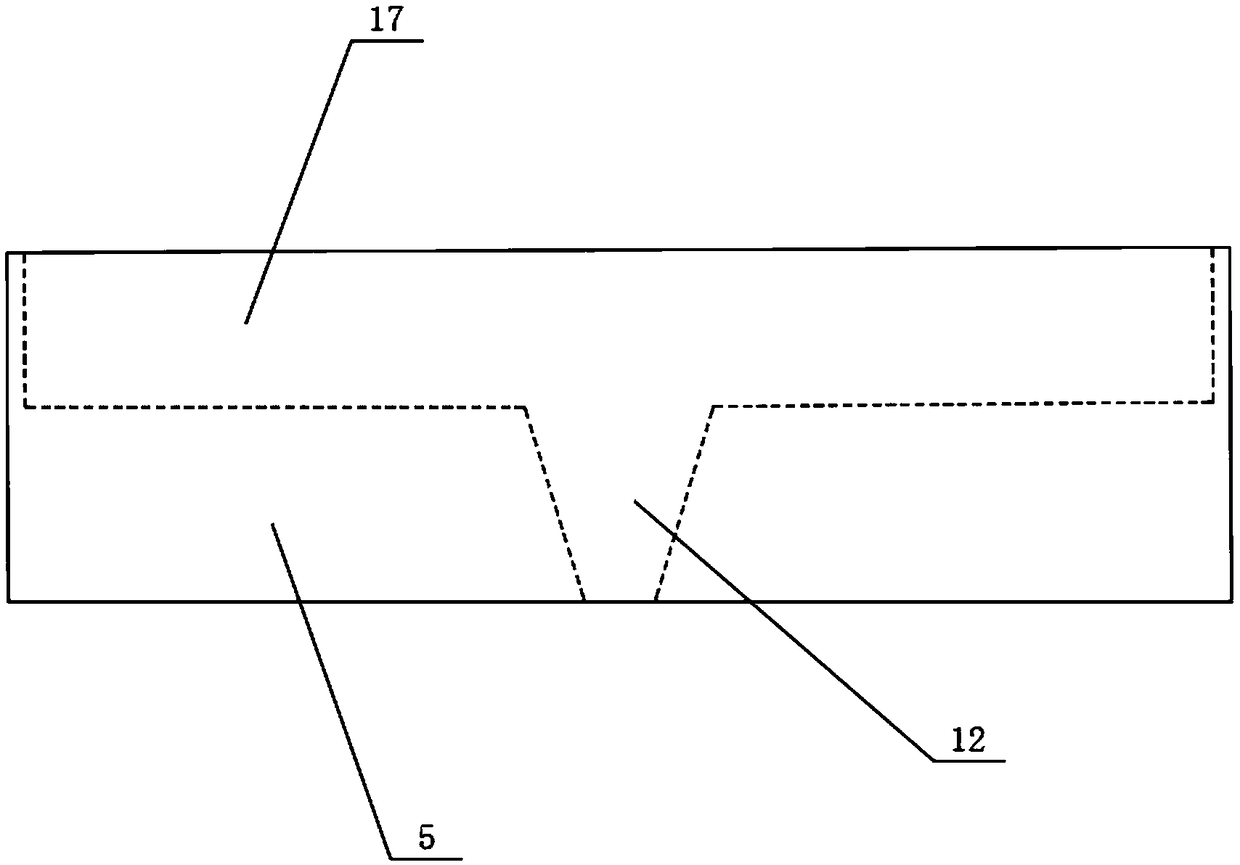

Metal tube drilling machine convenient to dismount

InactiveCN105478838AMeet drilling needsEasy to usePositioning apparatusBoring/drilling componentsEngineeringMetal

The invention discloses a metal tube drilling machine convenient to dismount, which comprises a supporting base. The metal tube drilling machine convenient to dismount is characterized in that the top of the supporting base is a horizontal plane, wherein two sides of the plane are respectively provided with a mounting base; the mounting bases are rectangular; adjacent two side surfaces of the mounting bases are inwards provided with a through slot, respectively; a strip-shaped metal tube fixing base is arranged between the two mounting bases; the two sides of the metal tube fixing base are provided with fixing sheets which are corresponding to the through slots; a plurality of fixing holes are formed in the fixing sheets and the mounting bases; the top of the metal tube fixing base is downwards provided with a rectangular groove used for placing a metal tube; the two sides of the supporting bases are perpendicularly provided with one fixed rod respectively; the two fixed rods are correspondingly arranged; a spiral transverse rod is arranged between the two fixed rods; a fixed plate is arranged on the spiral transverse rod; a telescopic pole is perpendicularly arranged on the fixed plate; and the bottom of the telescopic pole is connected to a rotary drill bit. The metal tube drilling machine convenient to dismount has the advantages of being simple in structure, convenient to use, capable of saving capital, and the like.

Owner:SUZHOU YONGTONG STAINLESS STEEL CO LTD

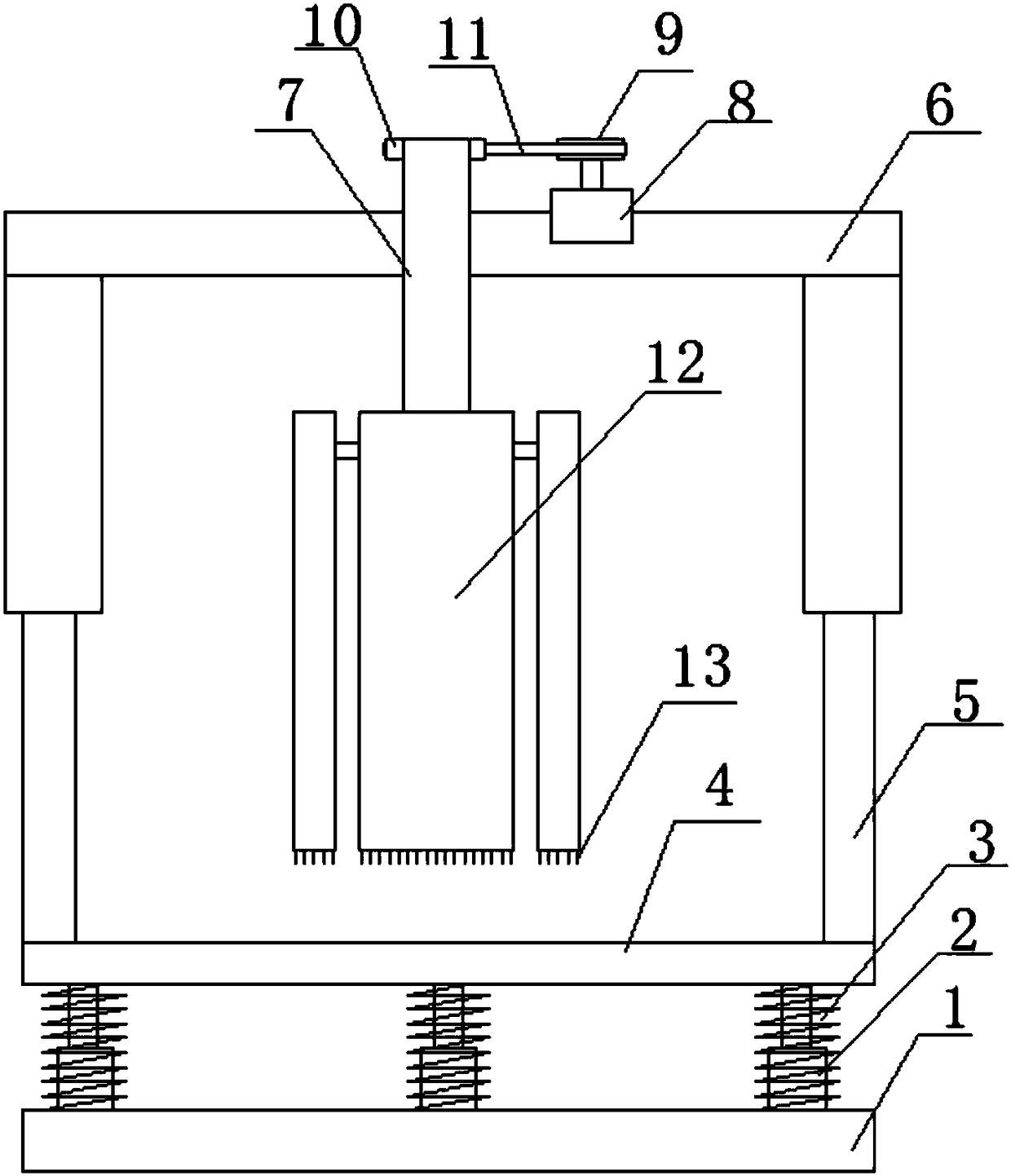

Dust prevention type mining drilling machine

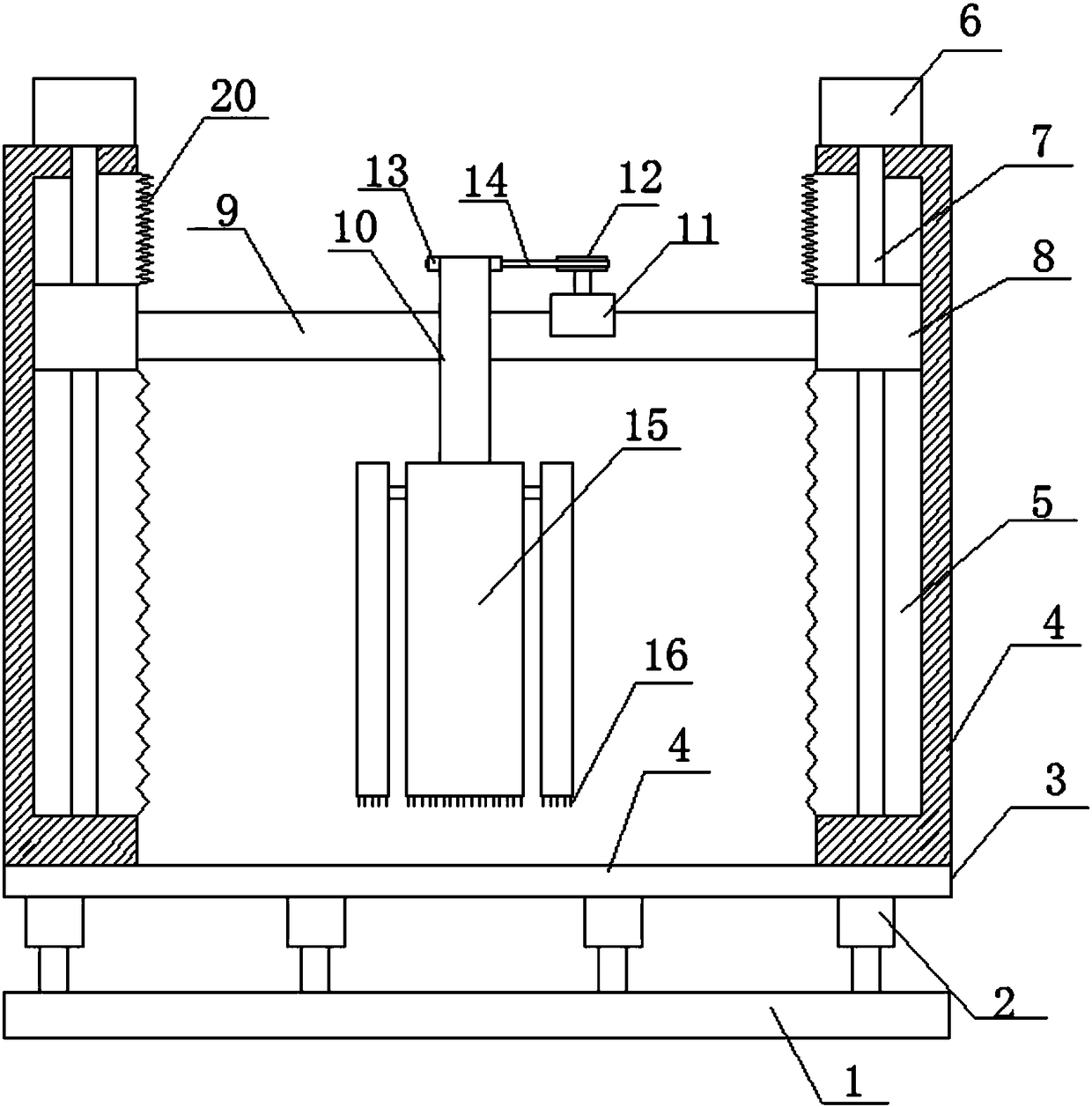

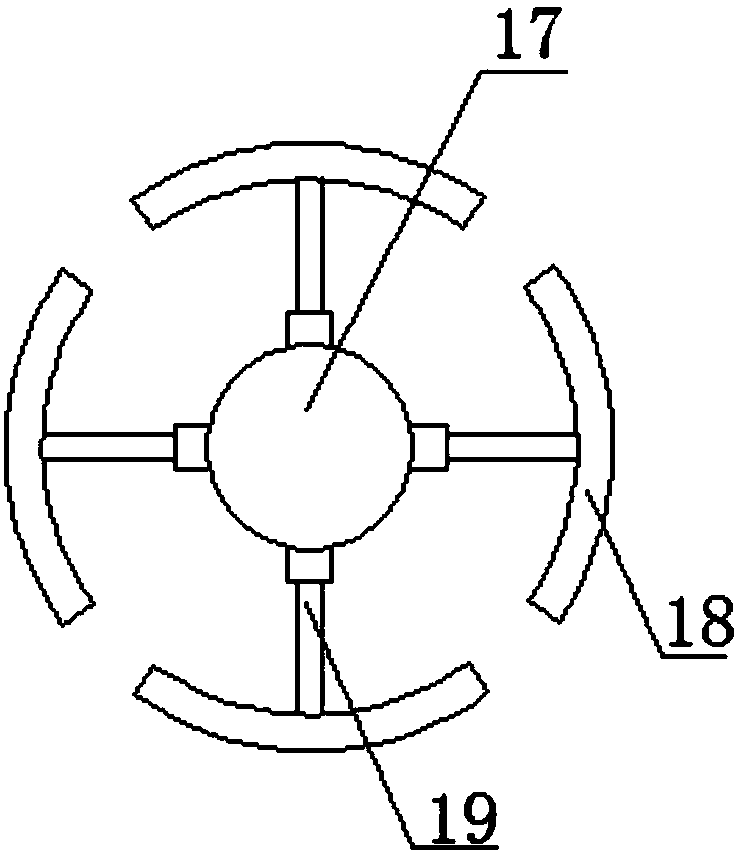

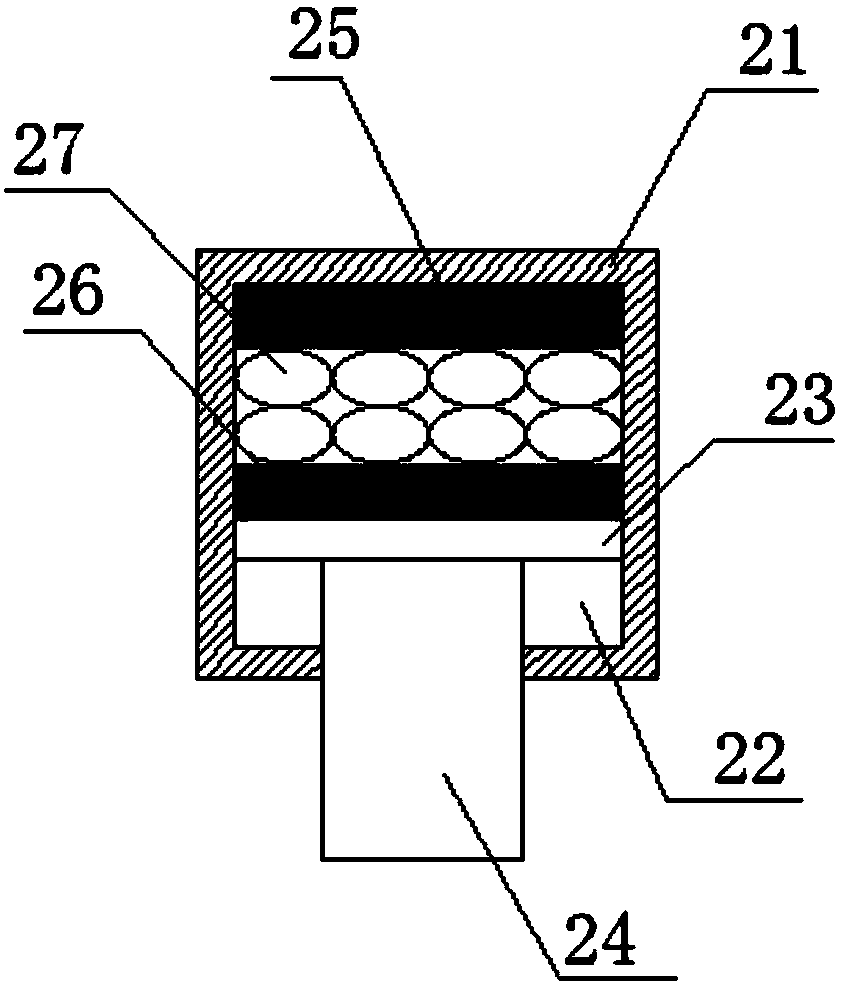

InactiveCN108150109AAvoid pollutionReduce maintenance costsDrill bitsDrilling rodsDrive wheelPrevention types

The invention discloses a dust prevention type mining drilling machine. The dust prevention type mining drilling machine comprises a lower support and an upper support, a plurality of damping devicesare arranged between the lower support and the upper support, supporting columns are left-right symmetrically arranged on the upper side of the upper support, a lifting cavity is formed in the inner side of each supporting column, a first motor is arranged at the upper end of each supporting column, a threaded rod is arranged at the output end of each first motor, a lifting seat is arranged on each threaded rod, a lifting plate is arranged between the two lifting seats, a rotary shaft is arranged in the middle of the lifting plate, a second motor is arranged on the upper side of the lifting plate, a driving wheel is arranged at the output end of the second motor, a driven wheel is arranged at the upper end of the rotary shaft, a drilling cylinder is arranged at the lower end of the rotaryshaft, the drilling cylinder comprises an excavation cylinder, the upper end of the excavation cylinder is fixedly connected with the lower end of the rotary shaft, a plurality of telescopic devices are arranged on the upper portion of the outer side of the excavation cylinder, and excavation sheets are arranged at the outer ends of the telescopic devices. The dust prevention type mining drillingmachine is simple in structure and convenient to use, can adjust the diameter of drilling, and is wide in application range and long in service life.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

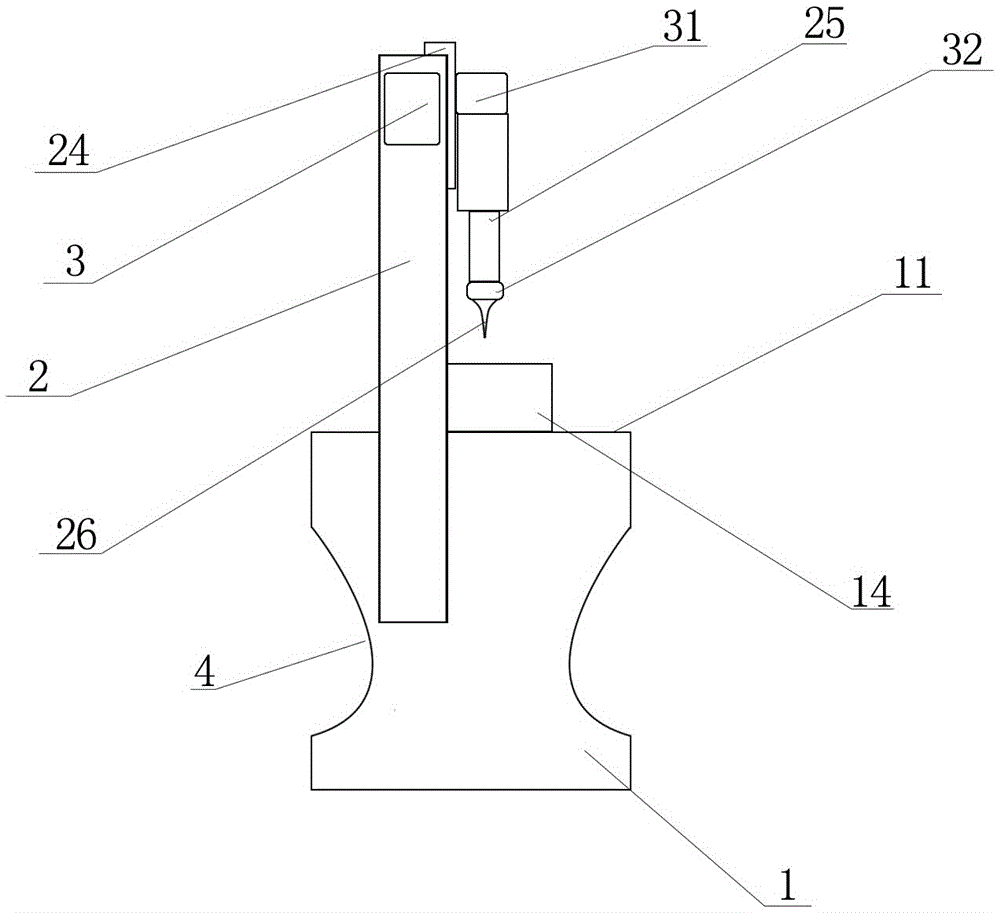

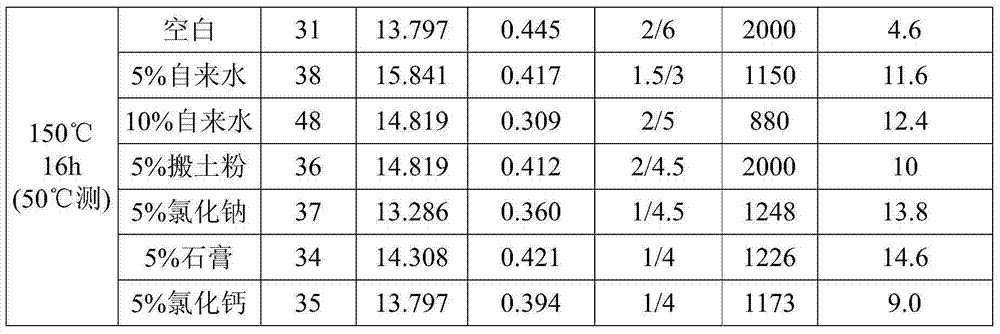

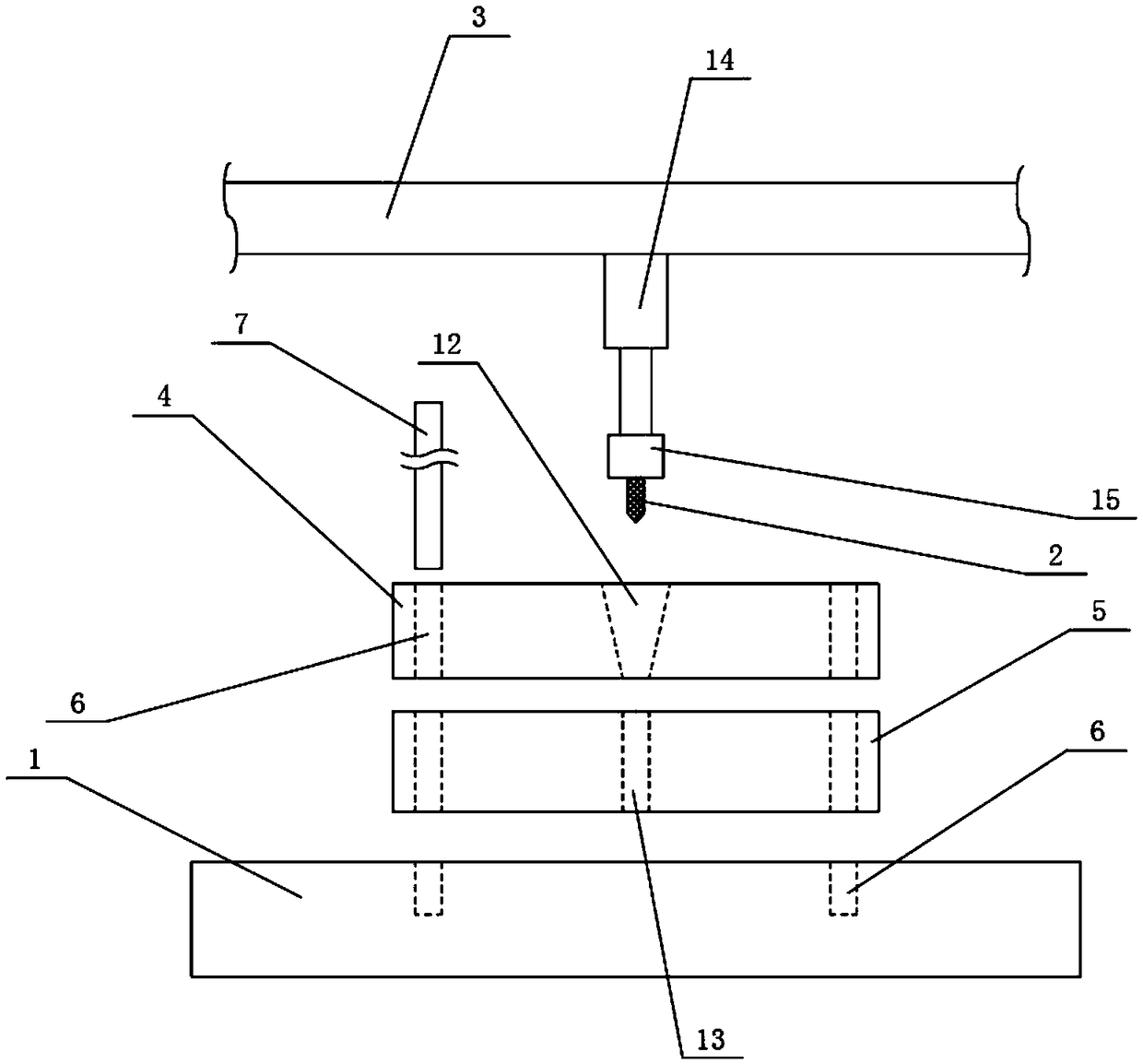

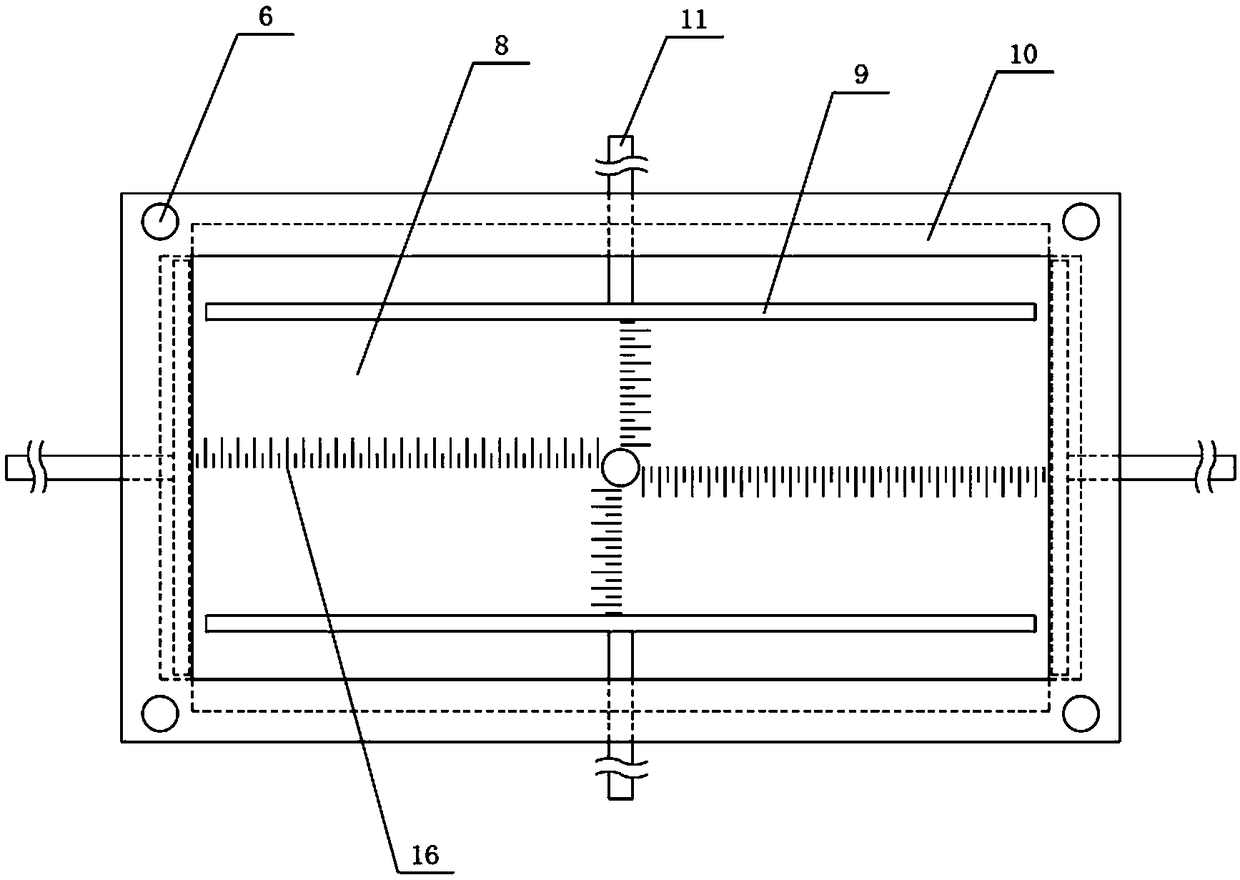

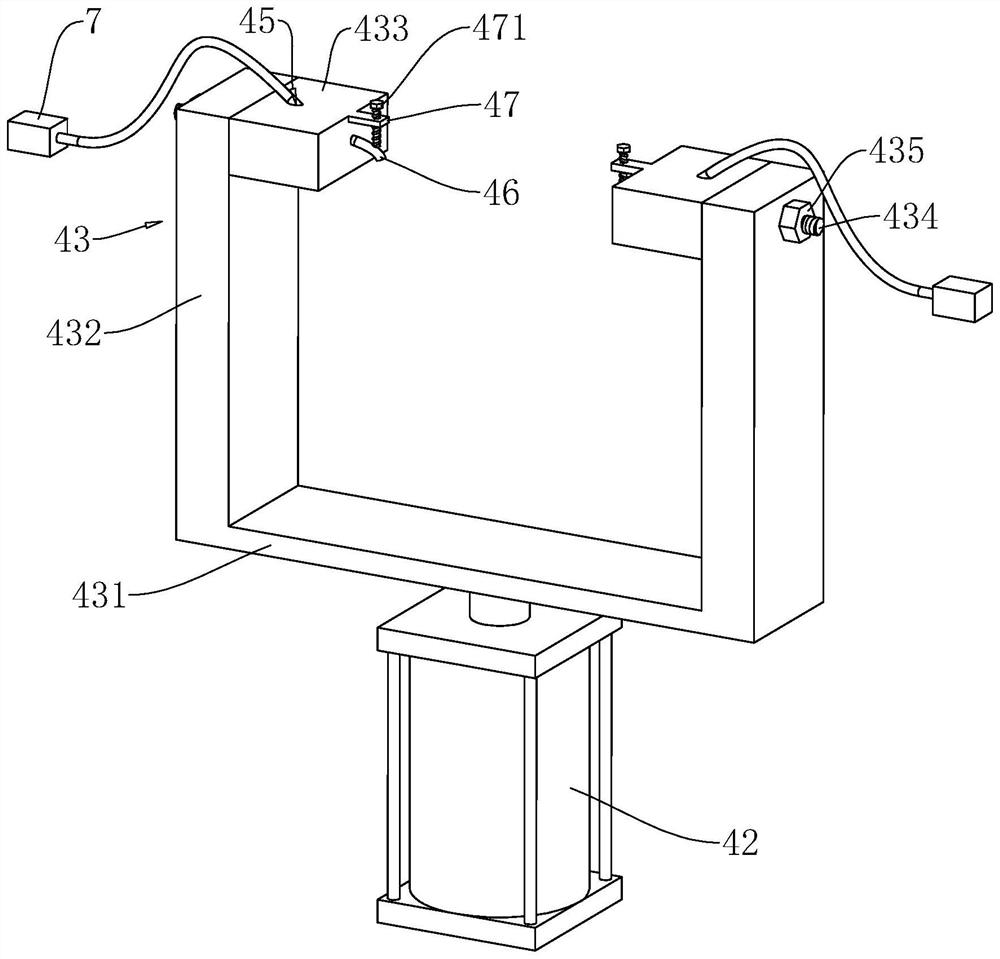

Building top plate vertical drilling device for building construction

ActiveCN108356326AMeet drilling needsAvoid spillingWork benchesPortable drilling machinesDual axisDrill

The invention provides a building top plate vertical drilling device for building construction. The device comprises a construction platform, a height adjusting mechanism is arranged on the construction platform, the height adjusting mechanism is provided with a dual-axis displacement adjusting mechanism used for adjusting the position of an electric drill, and the dual-axis displacement adjustingmechanism comprises a main supporting plate, wherein the position of the main supporting plate can be adjusted in the front-back direction and the left-right direction, and the main supporting platecan be locked. An upper supporting plate is arranged above the main supporting plate, the upper supporting plate and the main supporting plate are connected through a plurality of connection columns,a lifting main shaft is arranged in the upper supporting plate, the electric drill is fixed to the top of the lifting main shaft, and a dust removal box with an opening in the top capable of ascendingand descending is arranged above the upper supporting plate. By means of the device, the electric drill can be rapidly positioned and operated, it is ensured that the electric drill carries out vertical drilling operation at the accurate position, and meanwhile dust will not be scattered during drilling.

Owner:日照市国丰远大住宅工业有限公司

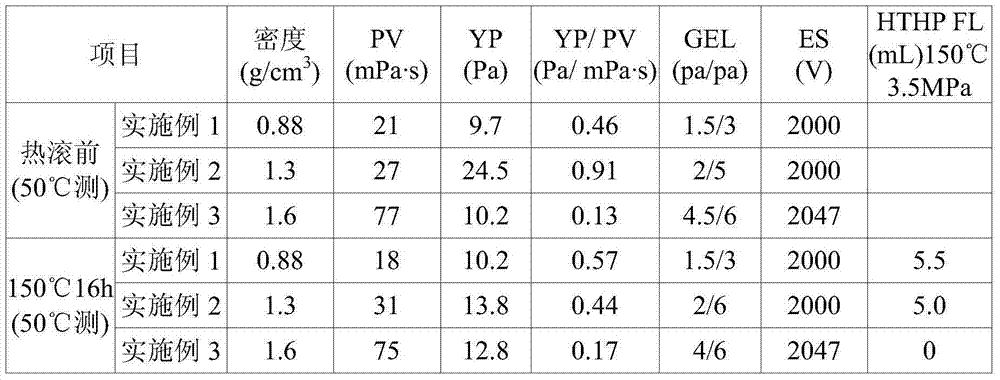

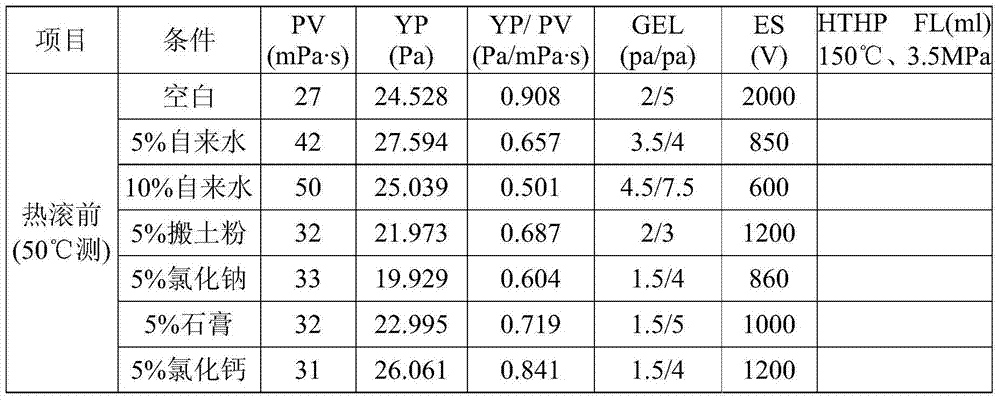

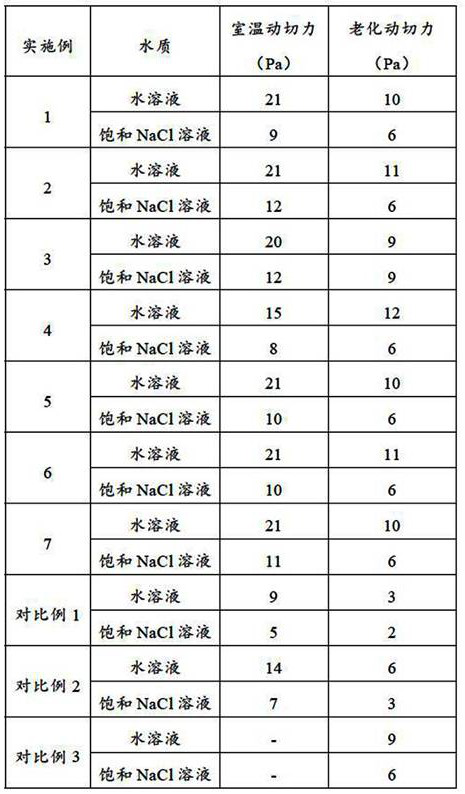

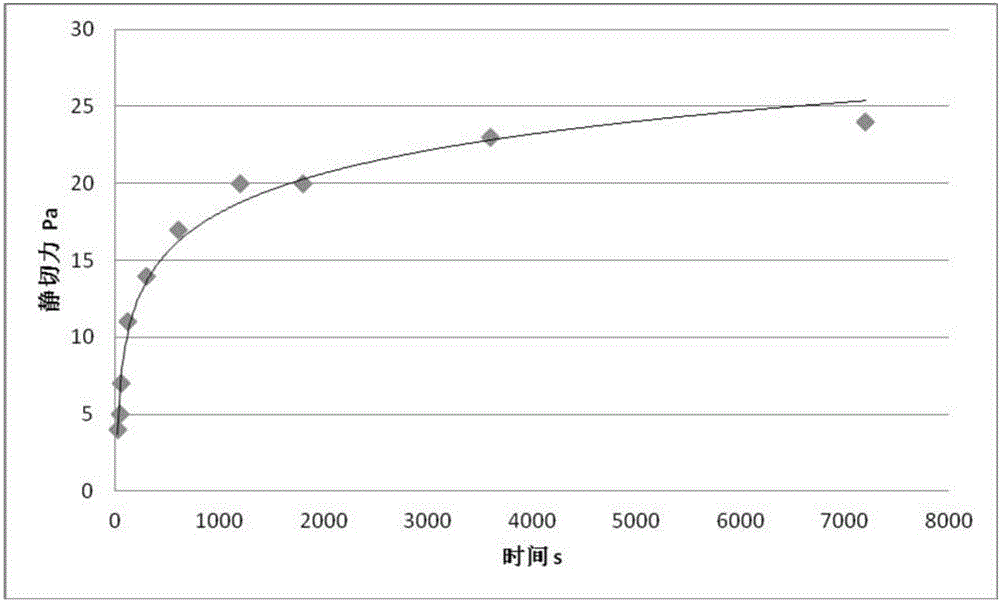

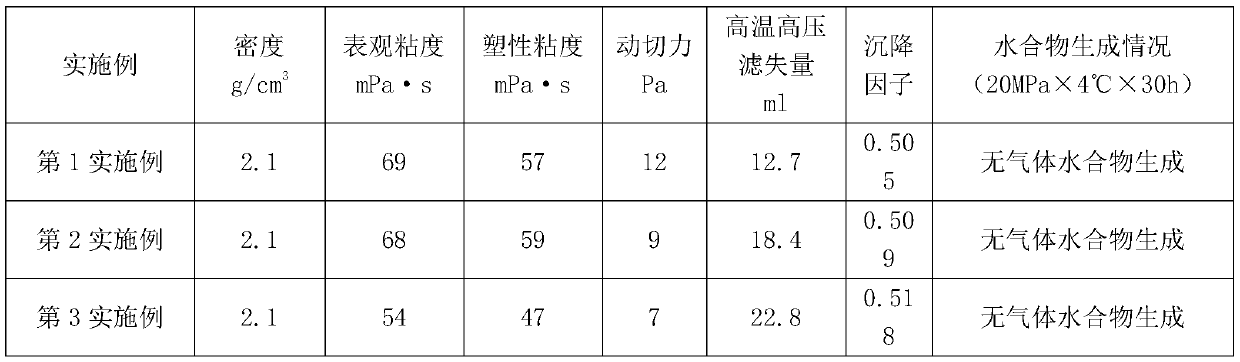

Plant oil-based drilling fluid and preparation method thereof

The invention provides a plant oil-based drilling fluid and a preparation method thereof. The plant oil-based drilling fluid comprises plant oil, a saline solution and a treating agent, wherein the volume ratio of the plant oil to the saline solution is (80:20) to (95:5); the treating agent comprises an emulsifier, a wetting agent, organic soil and a filtrate reducer. Based on 100mL of plant oil and saline solution, the content of the emulsifier is 2.5-3.5g, content of the wetting agent is 0.5-0.8g, the content of the organic soil is 0.5-2g and content of the filtrate reducer is 3-5g; the density of the drilling fluid is 0.88-1.6g / cm<3>. As the selected base oil is plant oil in the natural biologic chain, the plant oil-based drilling fluid provided by the invention can be biodegraded and further has the advantages of good emulsion stability, low high-temperature and high-pressure filter loss and good water-resisting, soil-resisting, salt calcium-resisting and gypsum pollution-resisting capacities.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

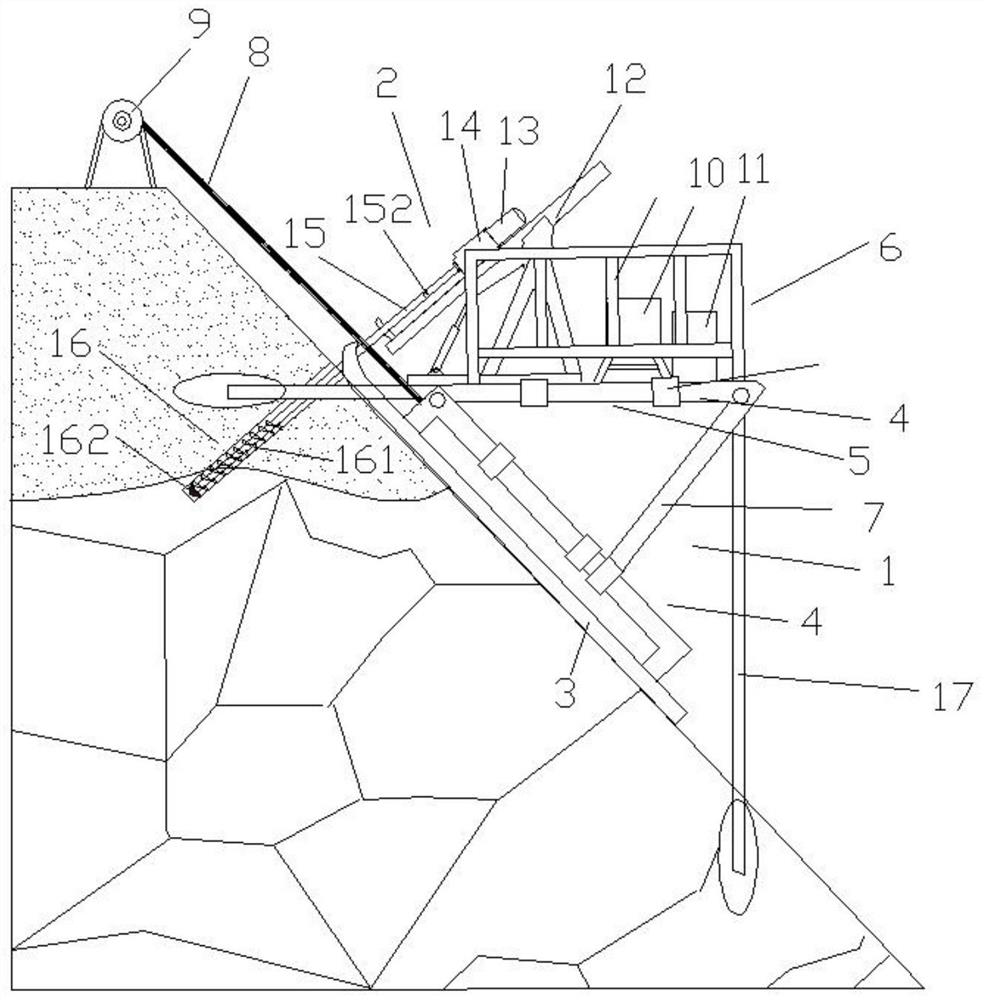

Construction method of drilling device for complex high and steep side slope

The invention discloses a construction method of a drilling device for a complex high and steep side slope. The drilling device comprises a drilling machine support, a drilling machine base and a drilling machine; the drilling machine support comprises a sliding plate, a chassis is arranged on the sliding plate, the front end of the chassis is hinged to the front end of a platform, a supporting component is hinged to the platform and connected with a chassis fastener, and the width of the chassis and the width of the platform are adjustable; and the drilling machine comprises a power distribution system, an air compression system, a gear, a rock drilling component, a soil drilling component, a drill rod and a drill bit. The construction method comprises the following steps of 1, pulling the drilling machine support to a specified position; 2, unfolding and locking the support; 3, adjusting the angle between the chassis and the platform; 4, mounting the drilling machine; and 5, startingdrilling. The device solves the problem that it is difficult to drill in the complex high and steep side slope, can adapt to various rock-soil body stratums, can cope with complex slope surface conditions such as concavo-convex surfaces and flourishing forests, is flexible in action and safe and reliable in performance, and can fully cope with existing complex high and steep side slope reinforcement engineering.

Owner:DALIAN UNIV OF TECH

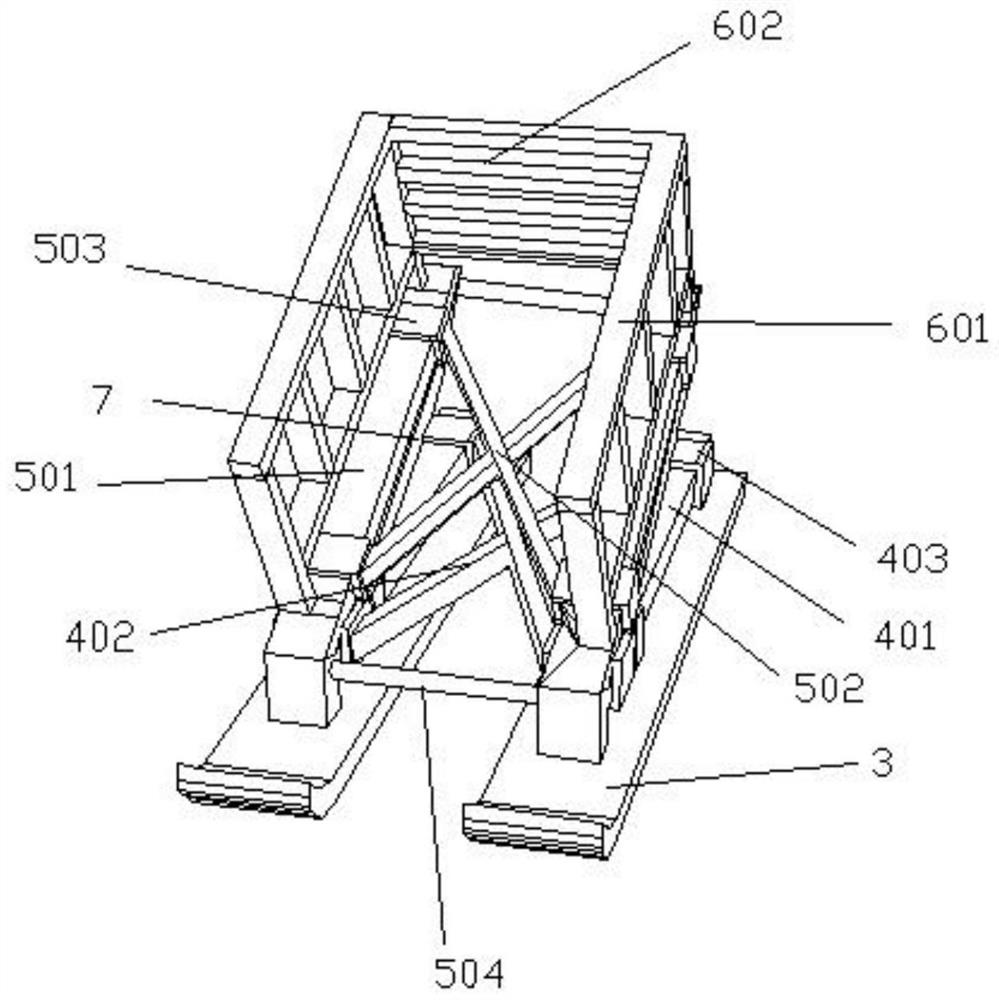

Positive cycle and reverse circulation dual-purpose three teeth roller bit

The invention relates to a positive cycle and reverse cycle double-duty three cone bit which is adopted when in positive cycle drilling or reverse cycle drilling and is mainly composed of a crossover sub, a reverse cycle flow inducing hood, a drill bit body, a reverse cycle flow passage valve, a nozzle flow passage valve, a reverse cycle flow passage, a sealing cavity which controls the reverse cycle flow inducing hood to go upwards and downwards and the like, when in the reverse cycle drilling, the reverse cycle flow inducing hood goes downwards, simultaneously, the reverse cycle flow passage valve opens, the nozzle valve closes, and a flow inducing baffle plate directly induces annular fluid into the well bottom to strengthen the carrying cutting capacity of the fluid. When in the positive cycle drilling, reverse cycle flow inducing hood goes upwards, simultaneously, the reverse cycle flow passage valve closes, and the nozzle valve opens, which realizes the positive cycle drilling. In the process of drilling, Automatic switches between the positive cycle drilling and the negative cycle drilling are realized through the negative cycle flow passage valve, the nozzle flow passage valve and a sealing cavity passage according to the liquid flowing direction.

Owner:SOUTHWEST PETROLEUM UNIV

Adjustable drilling machine for mining

InactiveCN108086919AAvoid pollutionReduce maintenance costsDrill bitsConstructionsEngineeringThreaded rod

The invention discloses an adjustable drilling machine for mining. The drilling machine comprises a lower bracket and an upper bracket. Horizontally symmetrical lifting devices are arranged on the upper side of the upper bracket. Each lifting device includes a supporting cylinder and a telescopic cylinder. Sliding chambers are formed in the walls of the supporting cylinders, the upper ends of thetelescopic cylinders are arranged in the sliding chambers, first motors are arranged at the upper ends of the interiors of the supporting cylinders, and threaded rods are arranged at the output ends of the first motors. Supporting columns are arranged in the telescopic cylinders, thread chambers are formed in the supporting columns, and the threaded rods are in threaded connection with the threaded chambers. Dust-proof covers are arranged on the outer sides of the supporting columns and the threaded rods, a lifting plate is arranged on the lifting devices, a rotating shaft is arranged in the middle of the lifting plate, and a drilling cylinder is arranged at the lower end of the rotating shaft. The drilling cylinder includes a digging cylinder, the upper end of the digging cylinder is fixedly connected with the lower end of the rotating shaft, a plurality of telescopic devices are disposed on the upper portion of the outer side of the digging cylinder, and digging pieces are arranged at the outer ends of the telescopic devices. The drilling machine is simple in structure and convenient to use and has a wide application range and long service life. The drilling diameter can be adjusted.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

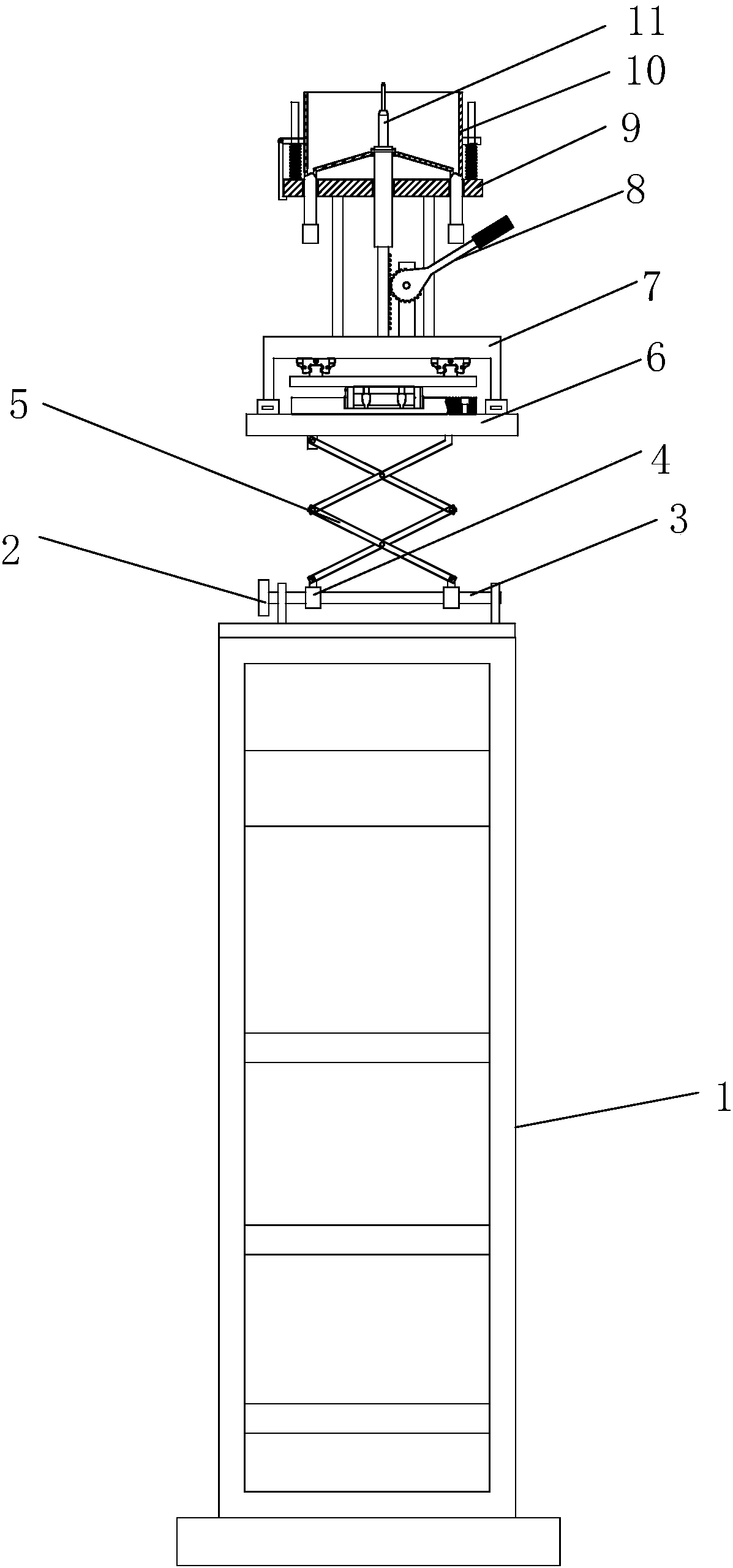

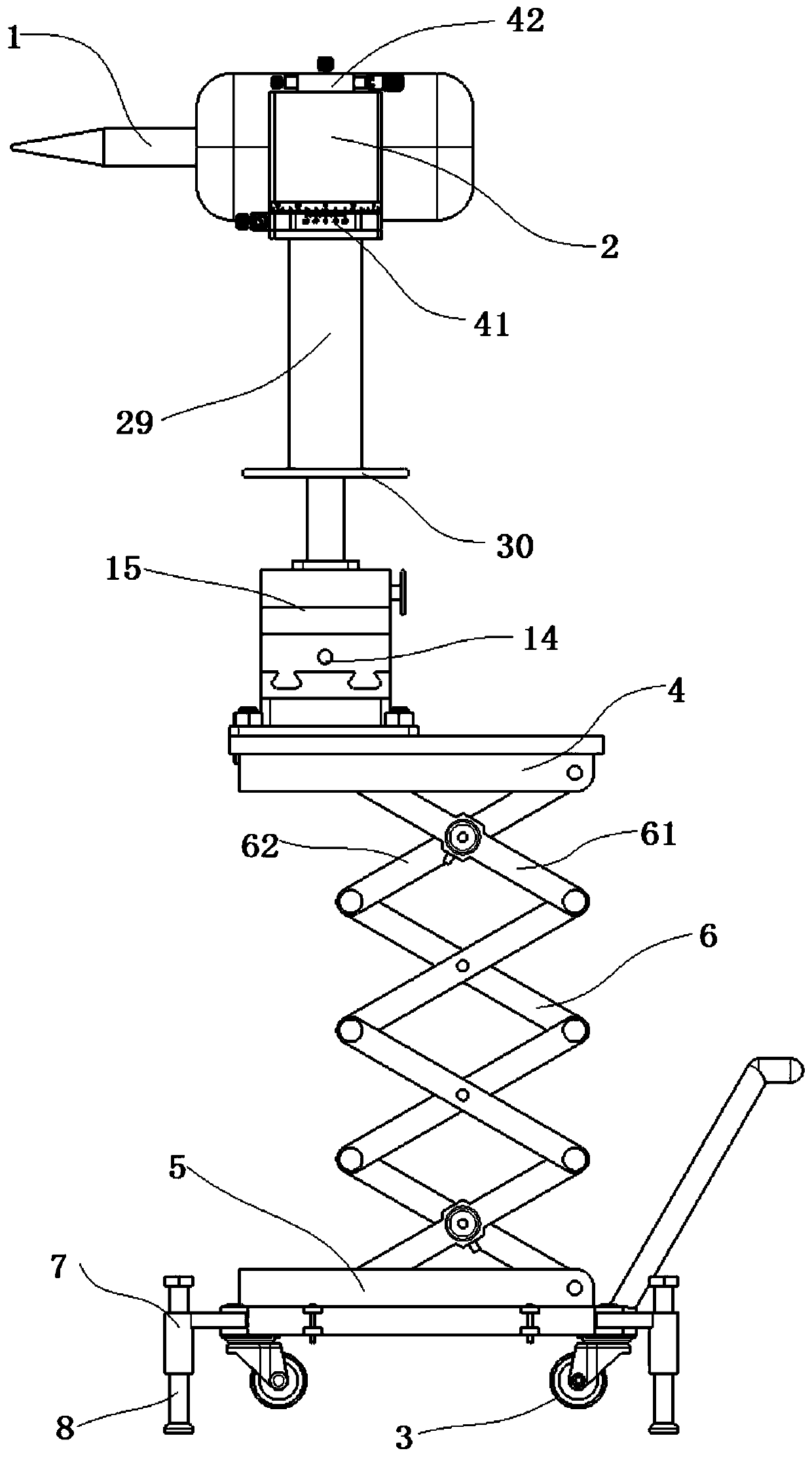

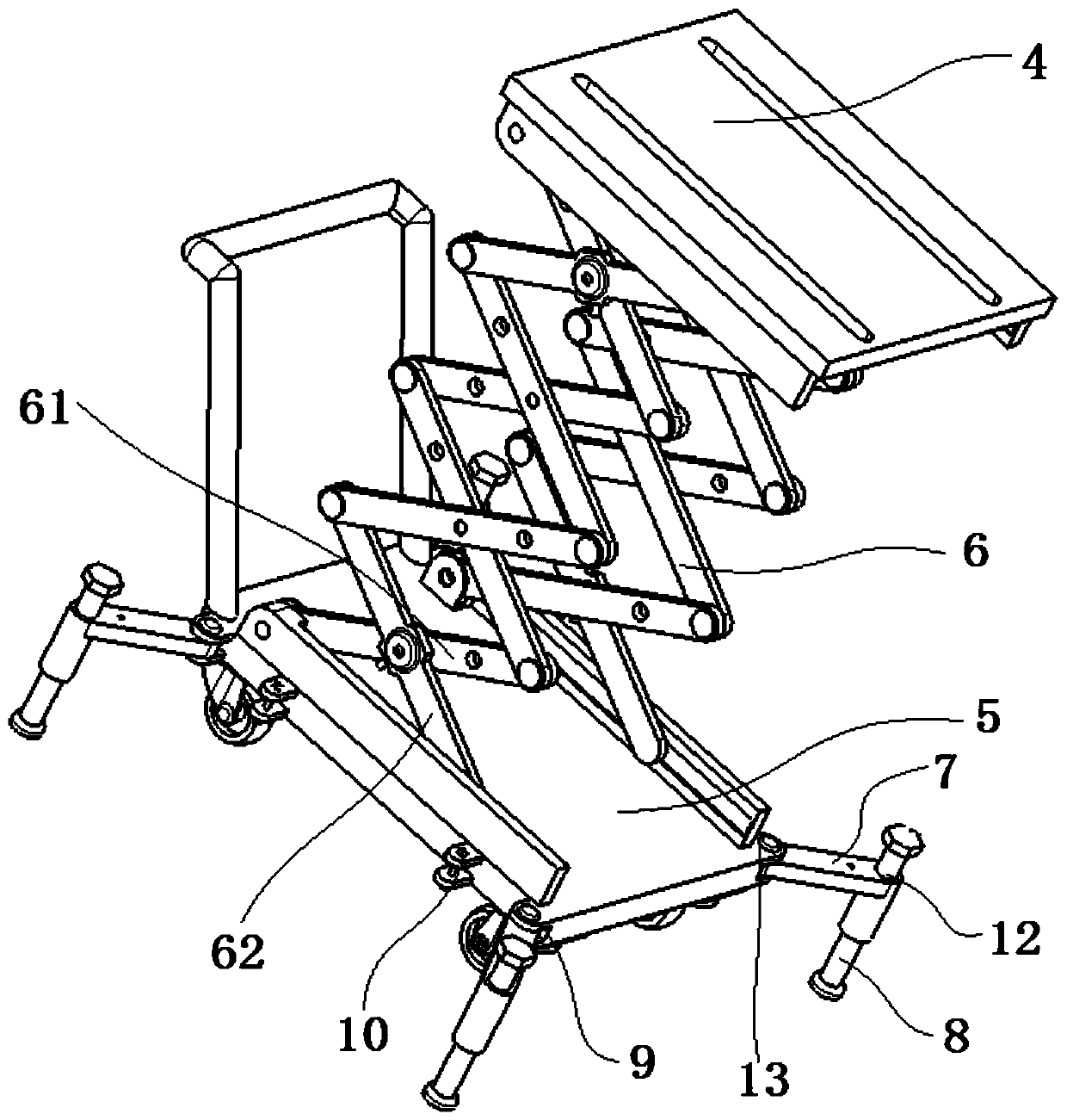

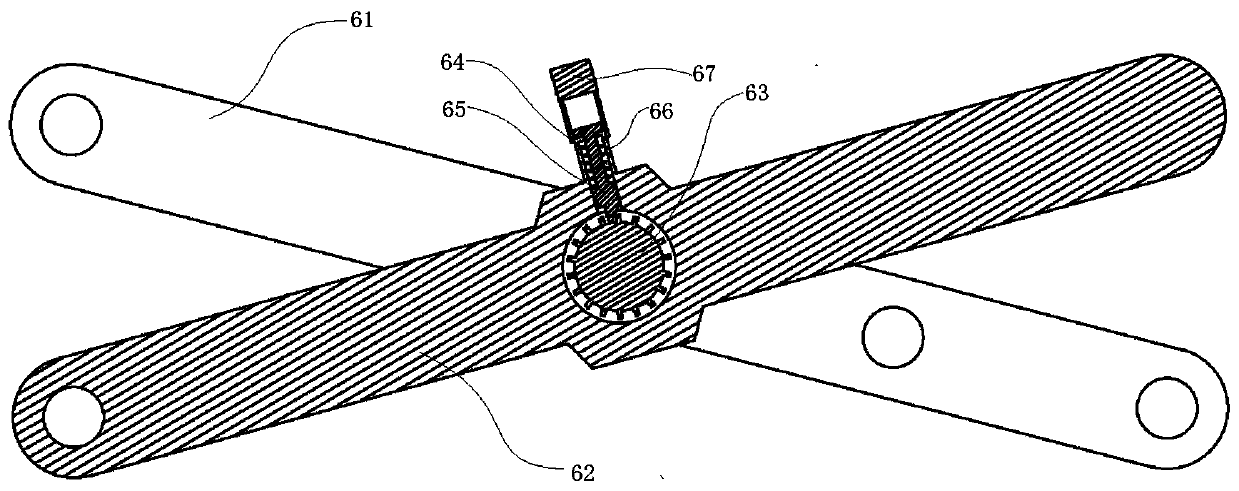

Wall drilling device for building construction and drilling method

PendingCN111216252APrevent rolloverAdjust levelWorking accessoriesStone-like material working toolsRotary stageArchitectural engineering

The invention discloses a wall drilling device for building construction and a drilling method. The wall drilling device comprises a lifting platform vehicle and an electric drill body. A position adjusting table is arranged at the top of the lifting platform vehicle. A height adjusting device is arranged on the top of the position adjusting table. A rotating table is arranged on the top of the height adjusting device. A mounting block is arranged on the top of the rotating table. An overturning device is arranged on the side wall of the mounting block. The electric drill body is fixedly connected with the overturning device. The position adjusting table is used for adjusting the position of the electric drill body in the horizontal plane. The height adjusting device is used for adjustingthe height of the electric drill body. The rotating table is used for controlling the electric drill body to rotate in the plane. The overturning device is used for controlling the pitching angle of the electric drill body. According to the wall drilling device for building construction and the drilling method, by arranging the lifting platform vehicle, the position of the electric drill body in the height direction is adjusted, and drilling requirements of different drilling heights are met; and by means of the position adjusting table, the position of a drill bit body can be conveniently adjusted, and the drilling precision is ensured.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

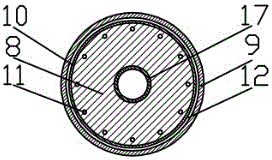

Downhole power drilling tools for gas drilling

ActiveCN104213829BAddress lack of motivationMeet drilling needsBorehole drivesHorizontal wellsClosed loop

The invention discloses a downhole power drilling tool for gas drilling, which comprises a double-acting compressed air power sub-joint, a double-acting hydraulic power sub-joint, a closed circulation type liquid drive motor and a liquid-isolated and exhaust-driven sub-joint. Double-acting pneumatic power sub-joints, double-acting hydraulic power sub-joints, closed cycle liquid-driven motors, and liquid-isolation and exhaust transmission sub-joints are sequentially connected by threads, and the chambers of each part are aligned and sealed by gaskets; the gasket d is set at Between the double-acting hydraulic power nipple and the closed circulation hydraulic drive motor. The invention can convert gas energy into high-pressure liquid energy, and drive the rotor to rotate through the closed circulation of hydraulic oil in the volumetric motor, which overcomes the lack of power caused by the compressibility when the gas directly drives the motor, and also retains the gas as a cycle All the advantages of the medium effectively solve the downhole power problem of gas drilling horizontal wells, directional wells and extended reach wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

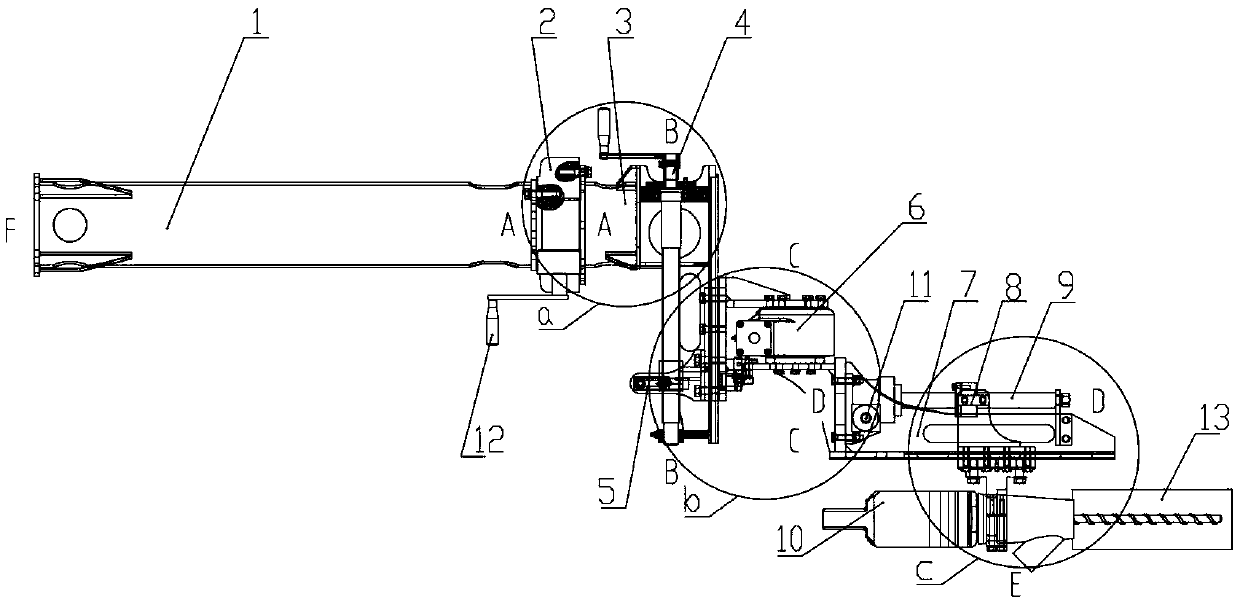

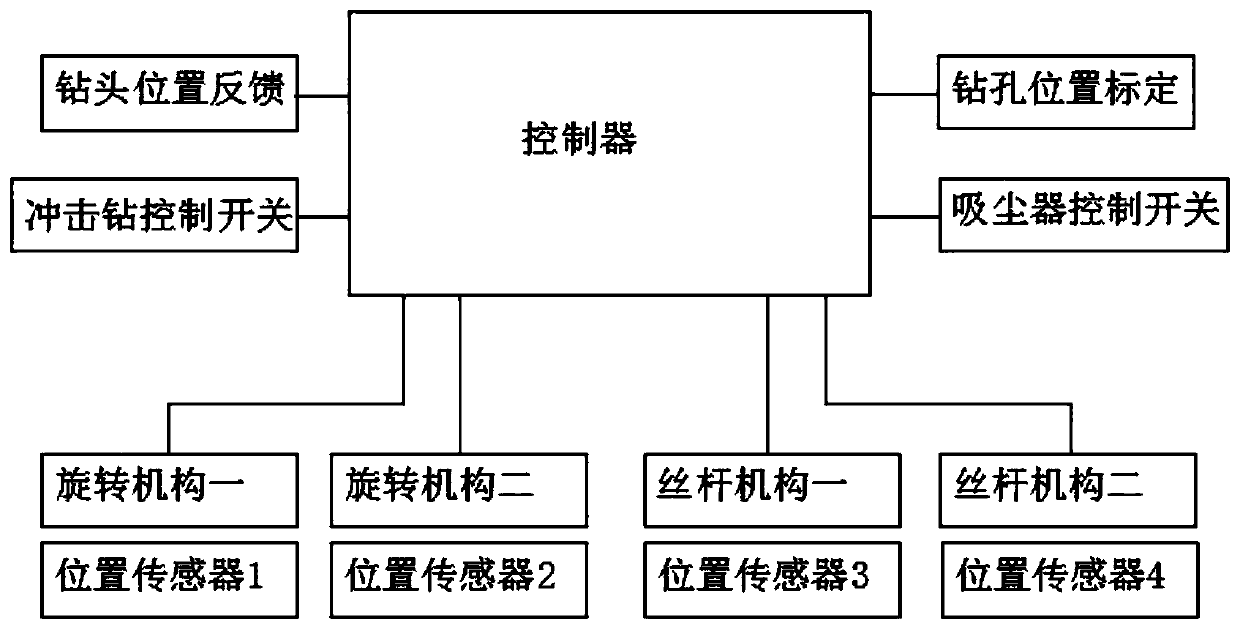

Mobile and mountable drilling device

PendingCN109605579AMeet drilling needsEasy replacementWorking accessoriesStone-like material working toolsWorking environmentEngineering

The invention discloses a mobile and mountable drilling device. The device comprises a base, a first rotating mechanism and a first mounting bracket. The first rotating mechanism is movably arranged at the right end of the base and rotationally connected with the base. The first mounting bracket is connected with the base through the first rotating mechanism. A percussion drill is clamped to a fixing position of the device, accordingly, the functions of up-down moving, horizontal rotating, vertical deflecting, horizontal moving and the like of a drill bit are achieved, drilling requirements ofdifferent angles and positions can be met, meanwhile, a telescopic dust collector is arranged in the position of the drill bit of the percussion drill, the collector is connected with a dust collector, dust produced during drilling can be actively collected and taken away forcibly through the dust collector in real time and then stored in a dust storage box, the problem of dust raising in a working environment is solved, and the device can be mounted on any operating platform according to requirements and is convenient to mount and high in mobility, so that problems raised in the background art are solved.

Owner:陕西奥力信工程机械有限公司

Tackifier for drilling fluid and preparation method thereof

The invention provides a tackifier for drilling fluid and a preparation method of the tackifier, and relates to the field of oilfield drilling and high-molecular polymerization, the method comprises the following steps: performing quaternization reaction on unsaturated amino acid ester and halogenated alkane to obtain a long-chain hydrophobic monomer; a long-chain hydrophobic monomer, acrylamide, acrylic acid, a sulfonic monomer, a surfactant, deionized water, a pH regulator and an initiator are subjected to a polymerization reaction, and the tackifier for the drilling fluid is obtained. The tackifier for the drilling fluid prepared by the invention is excellent in dissolving property, good in temperature resistance and salt resistance, and strong in rock carrying capacity, tackifying capacity, flow regulating capacity and hydration dispersing capacity for inhibiting clay and drilling cuttings, and the temperature resistance and high-temperature stability of the solid-free drilling fluid can be improved.

Owner:SHANDONG NUOER BIOLOGICAL TECH

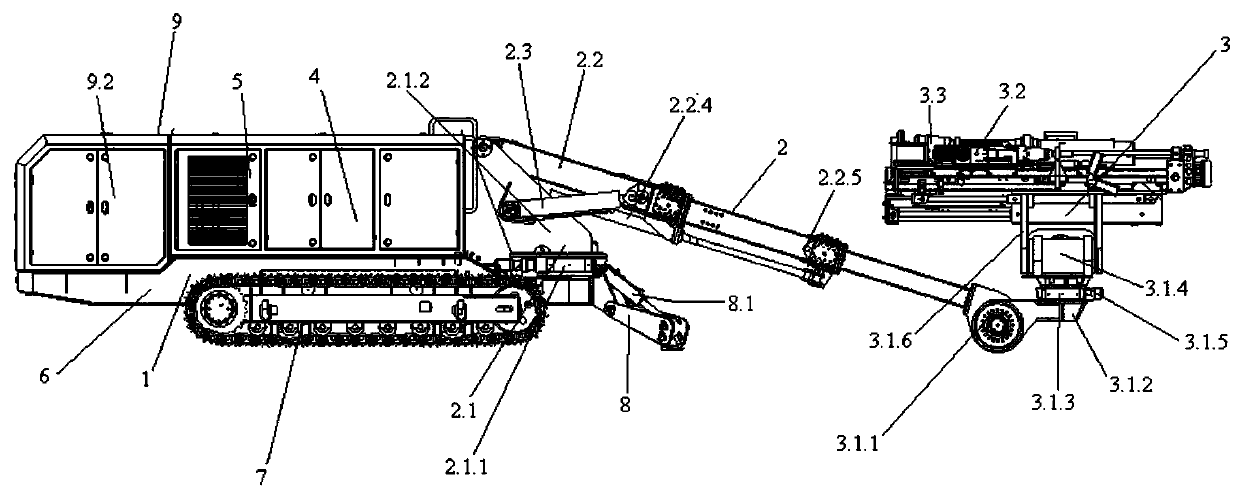

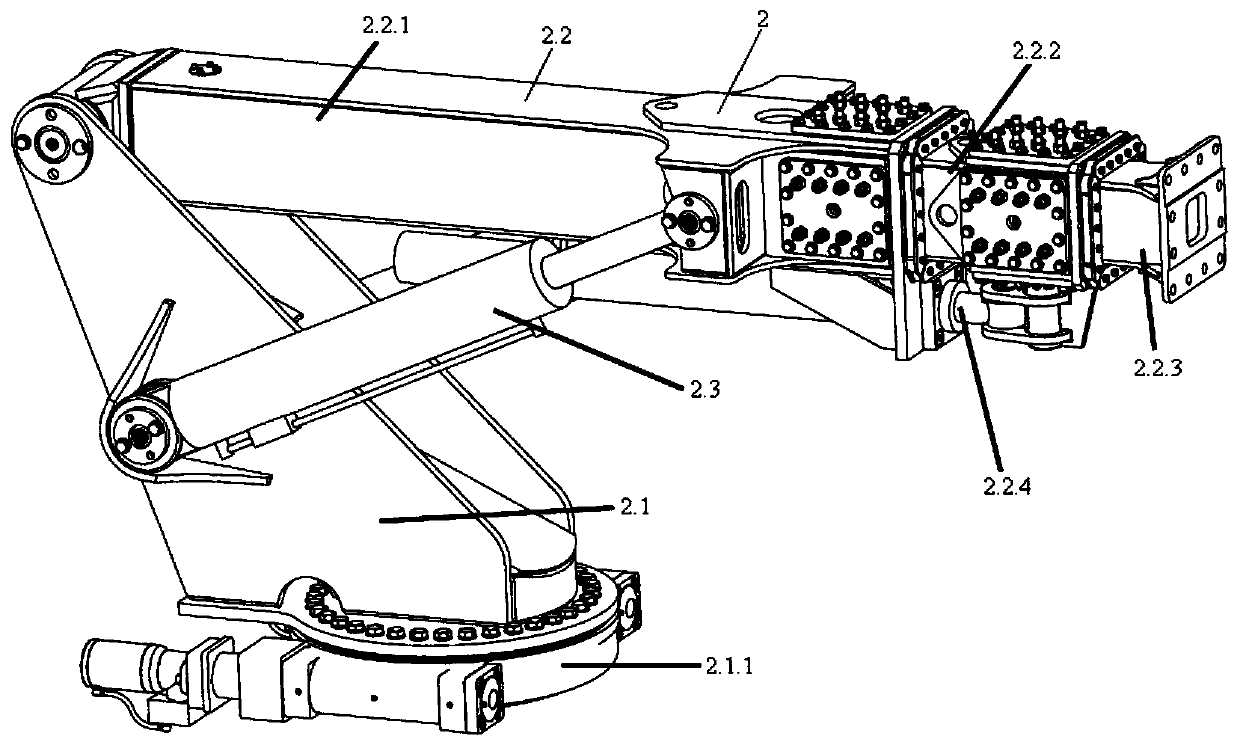

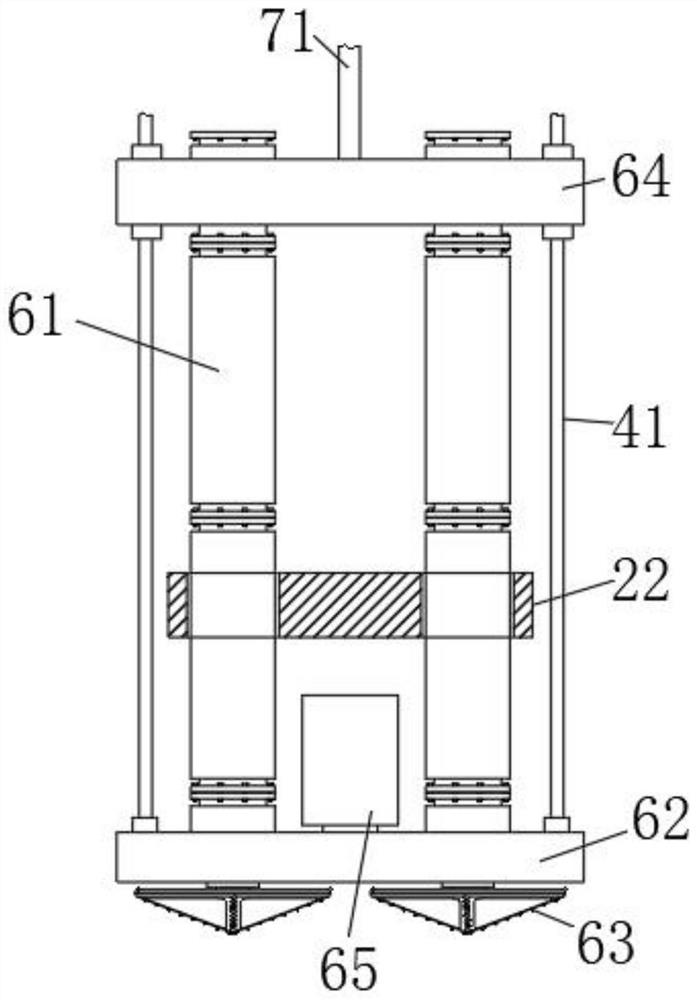

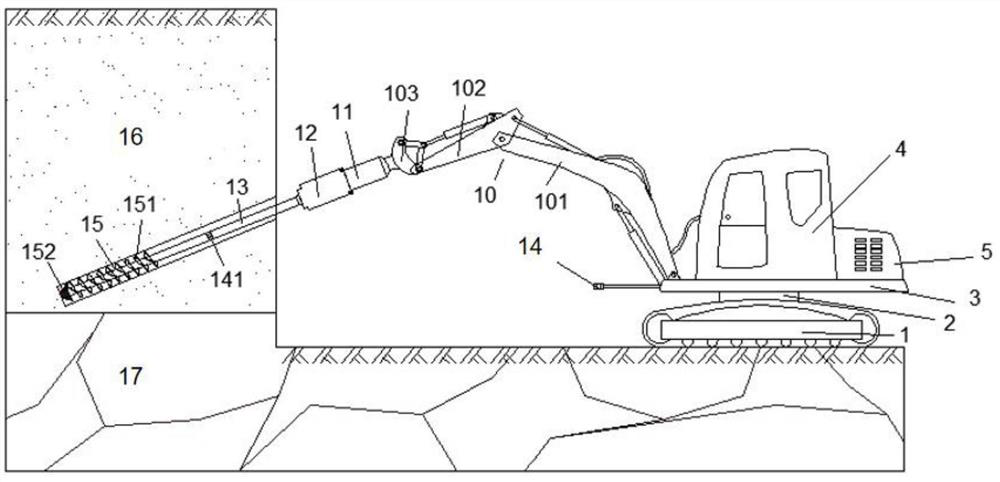

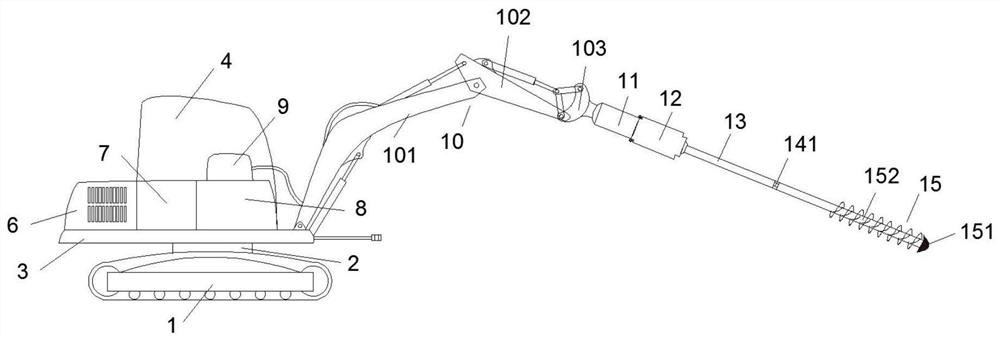

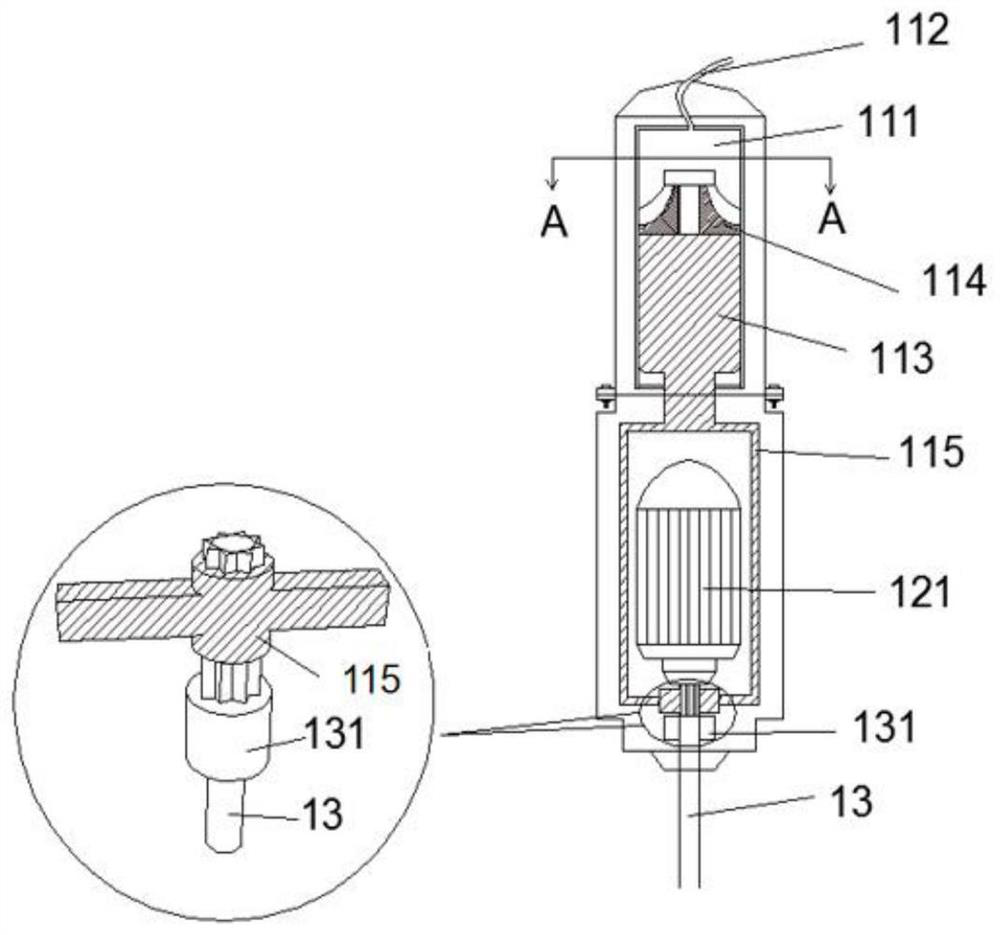

Drilling-splitting trolley

InactiveCN111594212AImprove construction safetyImprove the construction environmentTunnelsMachine partsVehicle frame

The invention provides a drilling-splitting trolley which comprises a chassis, a crane arm mechanism, a drilling-splitting mechanism, a hydraulic system and an electric control system, wherein a trolley frame is arranged on the chassis; a crawler is arranged at the bottom of the trolley frame; a supporting leg is arranged at the front part of the trolley frame; the crane arm mechanism comprises arotating platform, an telescopic arm and a pitch oil cylinder; the telescopic arm is connected with the rotating platform; the pitch oil cylinder is arranged between the rotating platform and the telescopic arm; through the extension and retraction of the pitch oil cylinder, the telescopic arm can be driven to move up and down; the rotating platform is used for driving the telescopic arm to swingleft and right; the drilling-splitting mechanism comprises a rotating component, a rock drilling machine part and a splitting machine part; the rock drilling machine part and the splitting machine part are integrated as well as connected with the telescopic arm through the rotating component; the hydraulic system is used for providing power for the drilling-splitting mechanism; and the electric control system is used for controlling the running of the drilling-splitting mechanism. According to the drilling-splitting trolley, the integrated design of the rock drilling machine part and the splitting machine part is adopted, so that the combination of actions can be reduced during the constriction operation of the drilling-splitting trolley, the operation can be simplified, and the drilling-splitting construction efficiency can be improved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

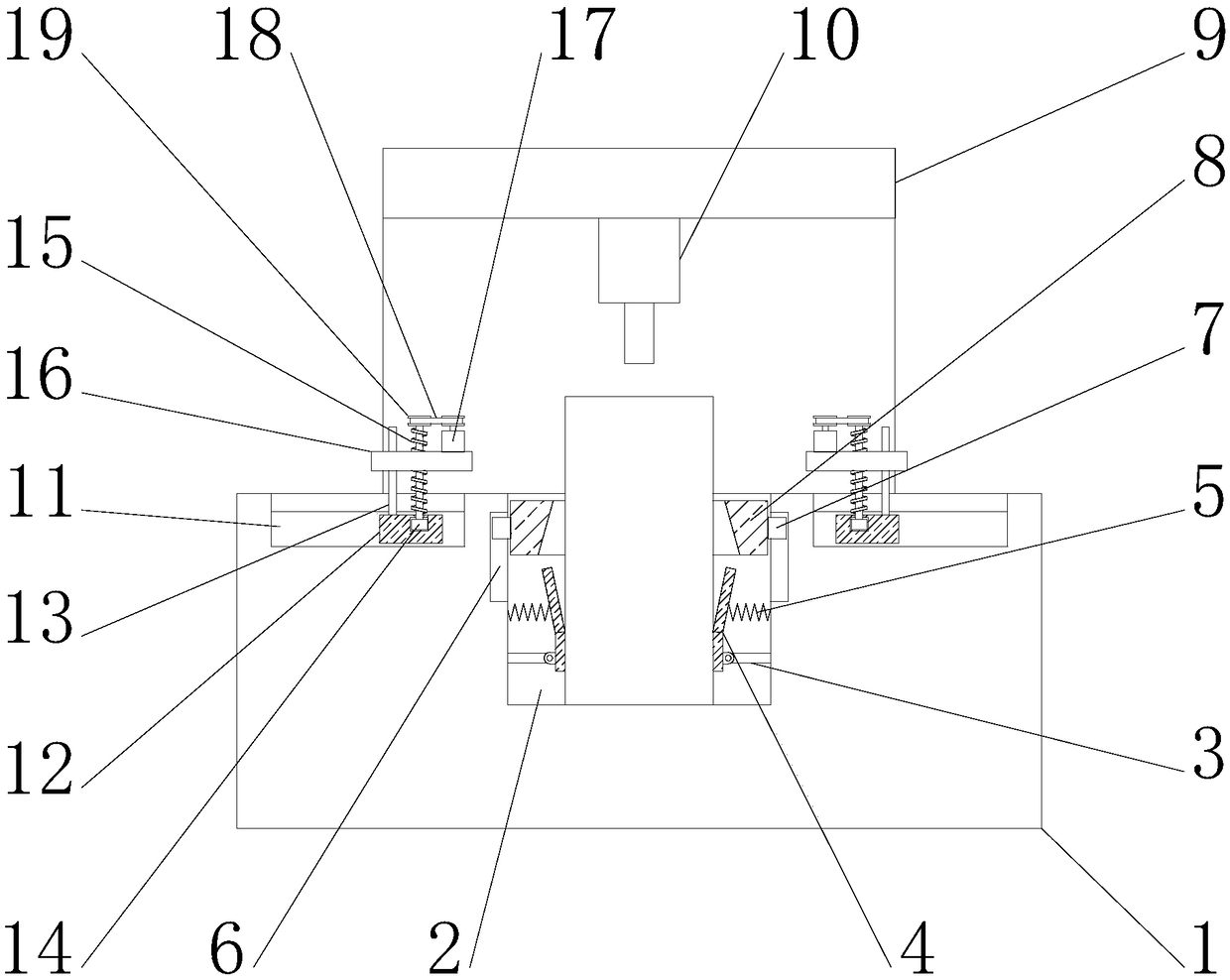

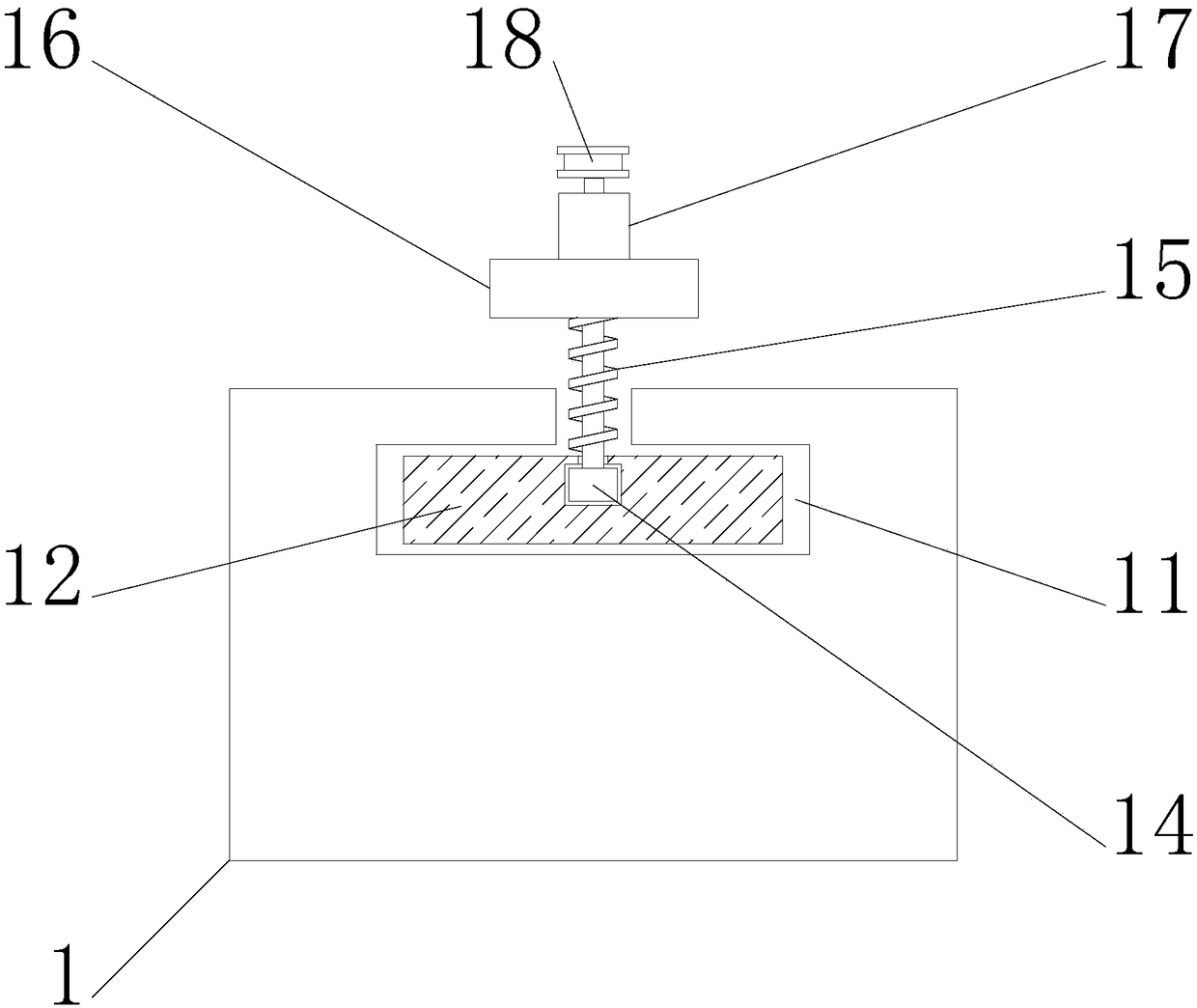

Machine tool machining device facilitating workpiece fixing

InactiveCN108637742AEasy clampingSimple structurePositioning apparatusMetal-working holdersEngineeringWorkload

The invention discloses a machine tool machining device facilitating workpiece fixing. The machine tool machining device comprises a base, a containing groove, fixing rods, fixing plates, springs, grooves, fixing blocks, limiting plates, a supporting frame, a drill bit, sliding grooves, sliding blocks, limiting rods, rotation shafts, lead screws, pressing plates, motors, belt wheels and rotation wheels. The machine tool machining device facilitating workpiece fixing is simple in structure and convenient to operate; through the design of the containing groove and the pressing plates, the drilling requirement for columnar workpieces and platy workpieces can be met, the workpieces different in shape can be better clamped, the applicability of equipment is improved, and the workload of operators is reduced. Through the arrangement of the fixing plates of the machine tool machining device facilitating workpiece fixing, the workpiece can be better placed at the center position of the containing groove, and lowering of the technology effect due to workpiece deflection is avoided; and through movement of the limiting plates, workpiece fixing is facilitated, the workpiece fixing difficultyis lowered, and the work efficiency is improved.

Owner:GAOYOU LIBO MACHINE TOOL ACCESSORIES FACTORY

Automatic heat treatment system for stainless steel shank of micro-drill

ActiveCN106119505AMeet drilling needsImprove welding strengthFurnace typesHeat treatment process controlCarbideAlloy

Aiming at solving the problems that a solid carbide drill for drilling of a printed circuit board is high in cost, and the drilling quality of a drill formed by welding of a stainless steel shank and tungsten carbide cannot be up to the standard of a solid tungsten carbide drill due to the welding strength, the invention provides an automatic heat treatment system for a stainless steel shank of a micro-drill. The automatic heat treatment system can perform heating, quenching and cleaning treatment on the stainless steel shank, and the treated stainless steel shank is welded with tungsten carbide, so that the welding strength is remarkably improved, and the drilling requirement of the printed circuit board is satisfied.

Owner:JIANGMEN JIANTAO HI TECH

Clay-free high temperature resistance reservoir drilling fluid and preparation method thereof

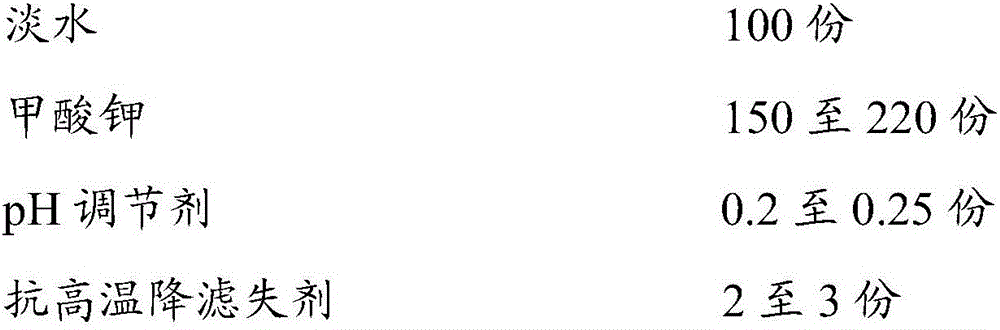

ActiveCN106433581AIncreased co-inhibitionExcellent shear thinning propertiesDrilling compositionCalcium carbonateCarrying capacity

The invention relates to clay-free high temperature resistance reservoir drilling fluid and a preparation method of the fluid. The reservoir drilling fluid comprises 100 parts by weight of fresh water, 150-220 parts by weight of potassium formate, 0.2-0.25 parts by weight of pH (potential of hydrogen) regulator, 2-3 parts by weight of high temperature resistance fluid loss agent, 0.4-0.8 parts by weight of high temperature resistance shear strength improving agent, 5-8 parts by weight of calcium carbonate, and 0-200 parts by weight of manganese ore powder. The method comprises the steps of dissolving the parts by weight of potassium formate in the fresh water, and adding the parts by weight of pH regulator, high temperature resistance fluid loss agent, high temperature resistance shear strength improving agent, calcium carbonate and manganese ore powder for agitation. The reservoir drilling fluid can meet higher density requirements, has good stability, can keep stable when used at high temperature (such as 150-160 DEG C), has good reservoir protection performance, sedimentation stability and highly-deviated well cutting carrying capacity and can meet drilling requirements of a horizontal well.

Owner:CHINA NAT OFFSHORE OIL CORP +1

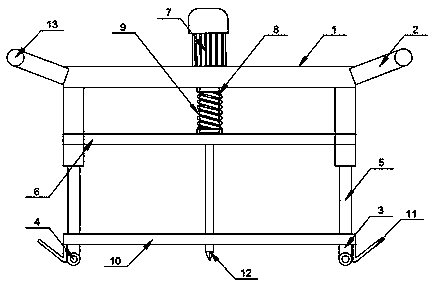

Spiral dust collection drilling machine

InactiveCN103551628AReduce dust pollutionBeneficial to human healthWorking accessoriesPortable drilling machinesHuman healthEngineering

The invention relates to a spiral dust collection drilling machine. The spiral dust collection drilling machine comprises a power mechanism, a rotary mechanism, a drill bit, a dust collection mechanism and a dust collection pipeline, wherein the rotary mechanism is movably connected with the power mechanism; the drill bit is arranged on the rotary mechanism; the dust collection mechanism is fixedly arranged at the top end of the rotary mechanism and is fixedly connected with the dust collection pipeline; the dust collection pipeline is positioned inside the rotary mechanism. The spiral dust collection drilling machine has the beneficial effects of meeting drilling requirements for different depths, reducing dust pollution and facilitating human health.

Owner:GUILIN FUGANG NEW MATERIAL

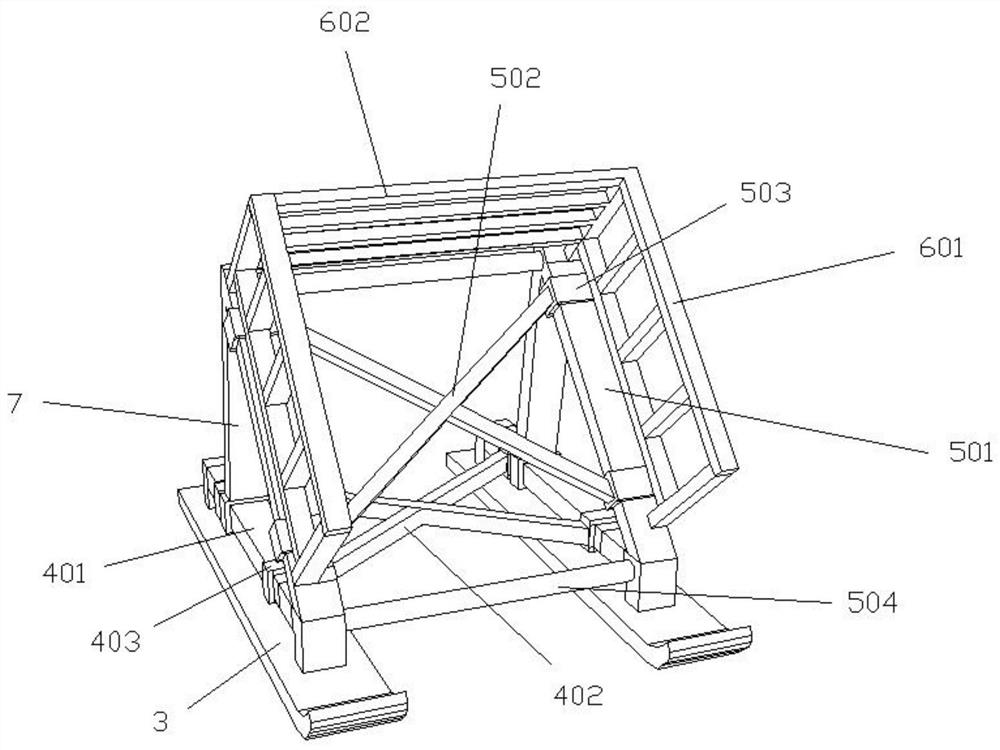

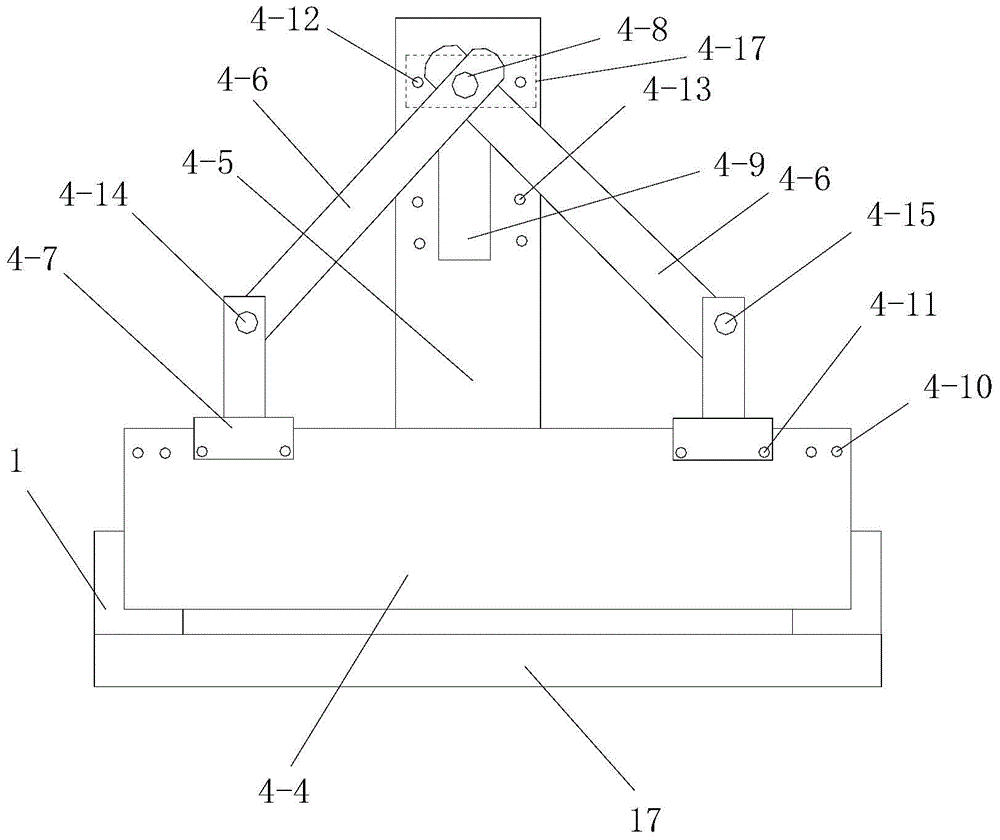

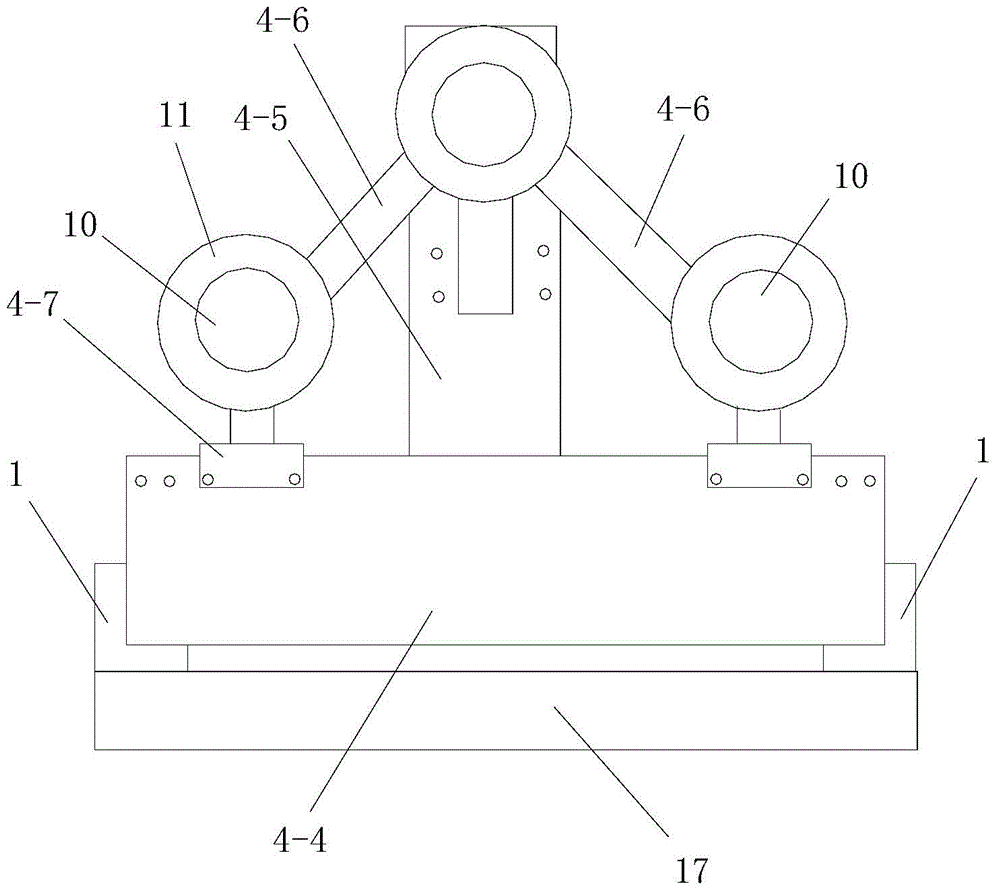

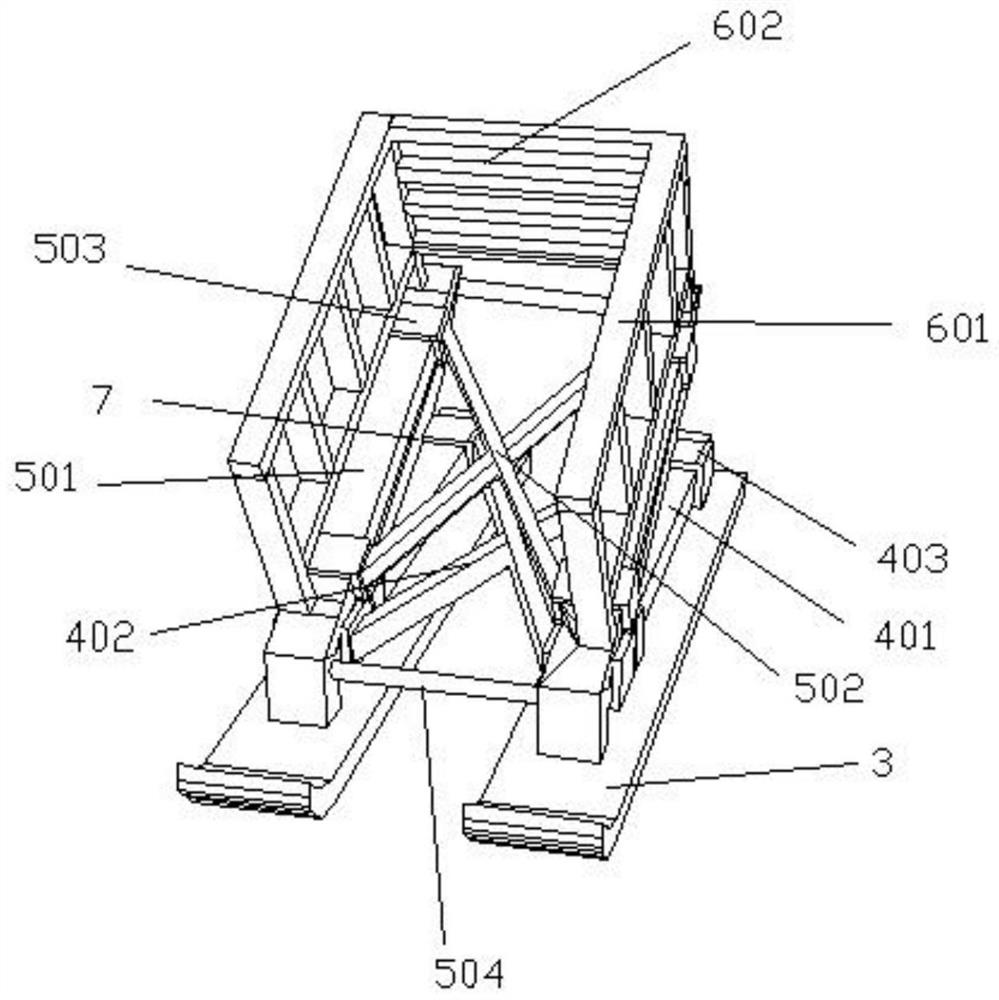

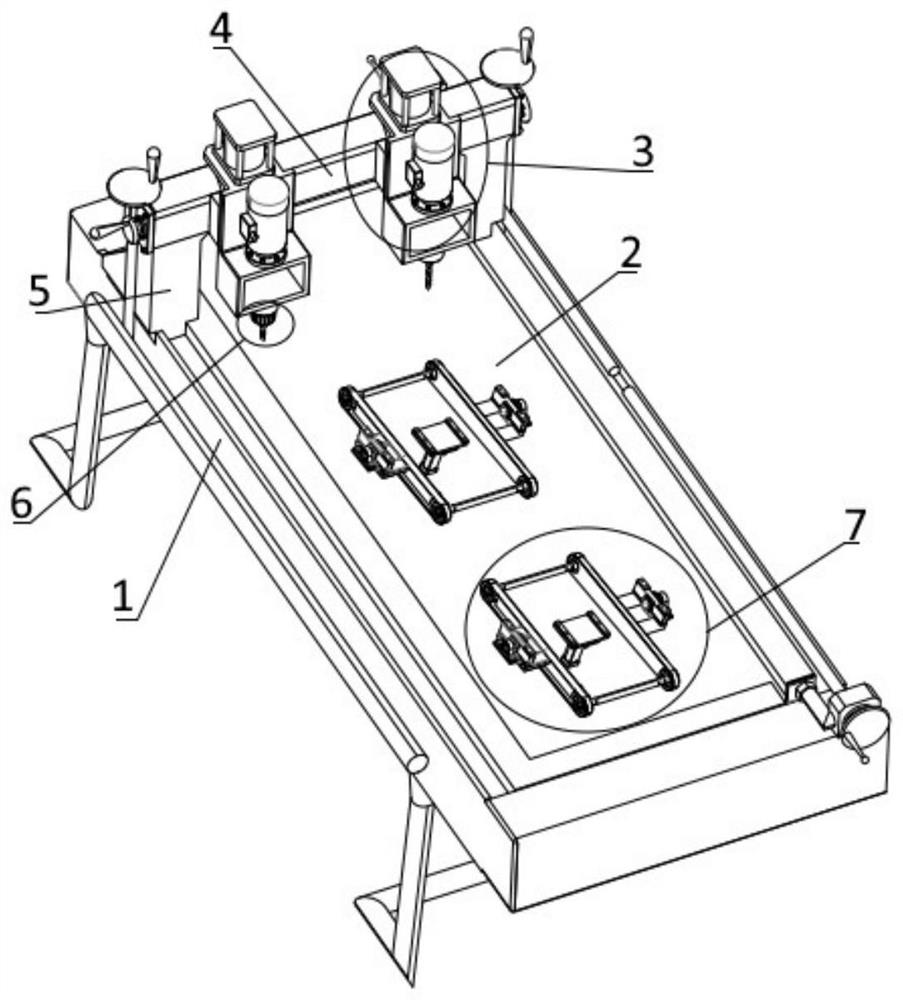

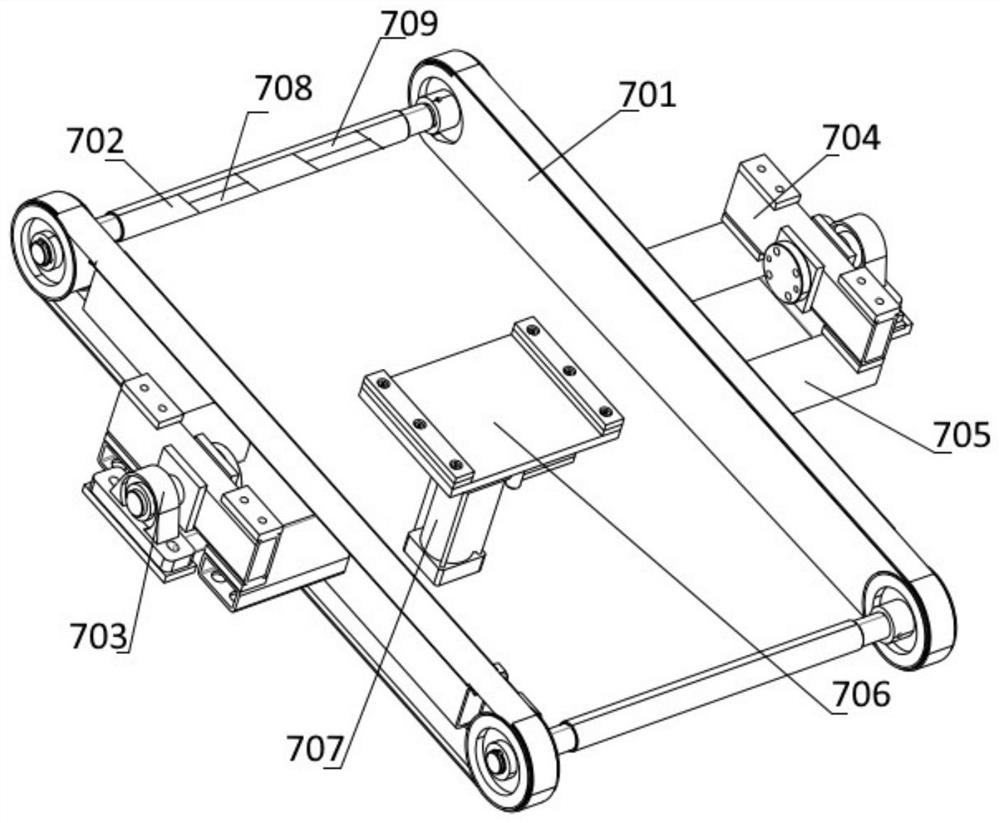

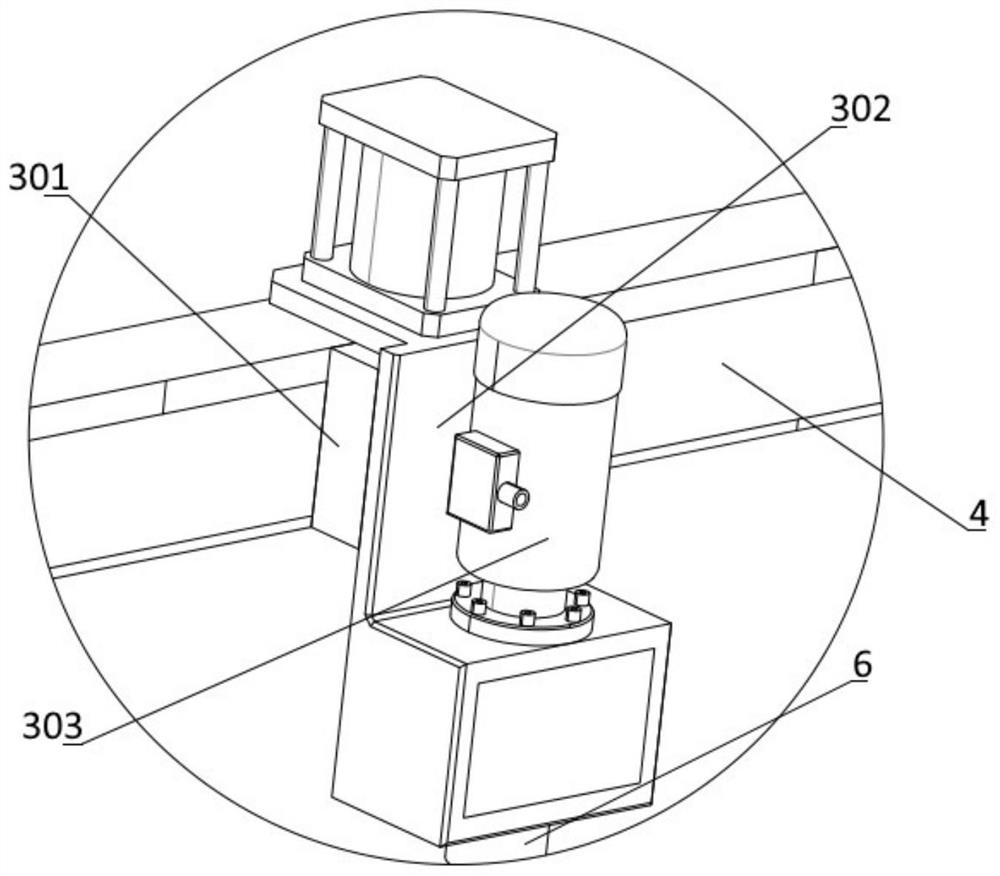

Three-hole-site synchronous drilling-type advanced geological drilling device

InactiveCN105672881ASimple structureReasonable designDerricks/mastsDirectional drillingHydraulic cylinderWorkbench

The invention discloses a three-hole-site synchronous drilling-type advanced geological drilling device. The three-hole-site synchronous drilling-type advanced geological drilling device comprises a horizontal workbench, two horizontal steel rails, a back-side push rack, a back limiting rack snapped onto the two horizontal steel rails, a horizontal sliding rack sliding along the two horizontal steel rails, a hydraulic cylinder pushing the horizontal sliding rack to slide and a front-end support table located at the front ends of the two horizontal steel rails. The horizontal sliding rack comprises a rectangular support, a vertical installation board installed above the middle of the rectangular support, two oblique connecting rods installed above the rectangular support on the left and right sides and two horizontal sliding seats moving along the upper part of the rectangular support from the left to the right. An adjustable triangular support is formed by the two oblique connecting rods and the two horizontal sliding seats. Three horizontal drilling rigs are respectively installed at three vertexes of the rectangular support of the adjustable triangular support. The three-hole-site synchronous drilling-type advanced geological drilling device has following beneficial effects: the three-hole-site synchronous drilling-type advanced geological drilling device is simple in structure, reasonable in design, easy and convenient in application and fine in application effect; and the three horizontal drilling rigs are driven to move back and forth during a drilling process so that three-hole-site synchronous drilling is achieved.

Owner:XIAN YUEFU ELECTRICAL TECH

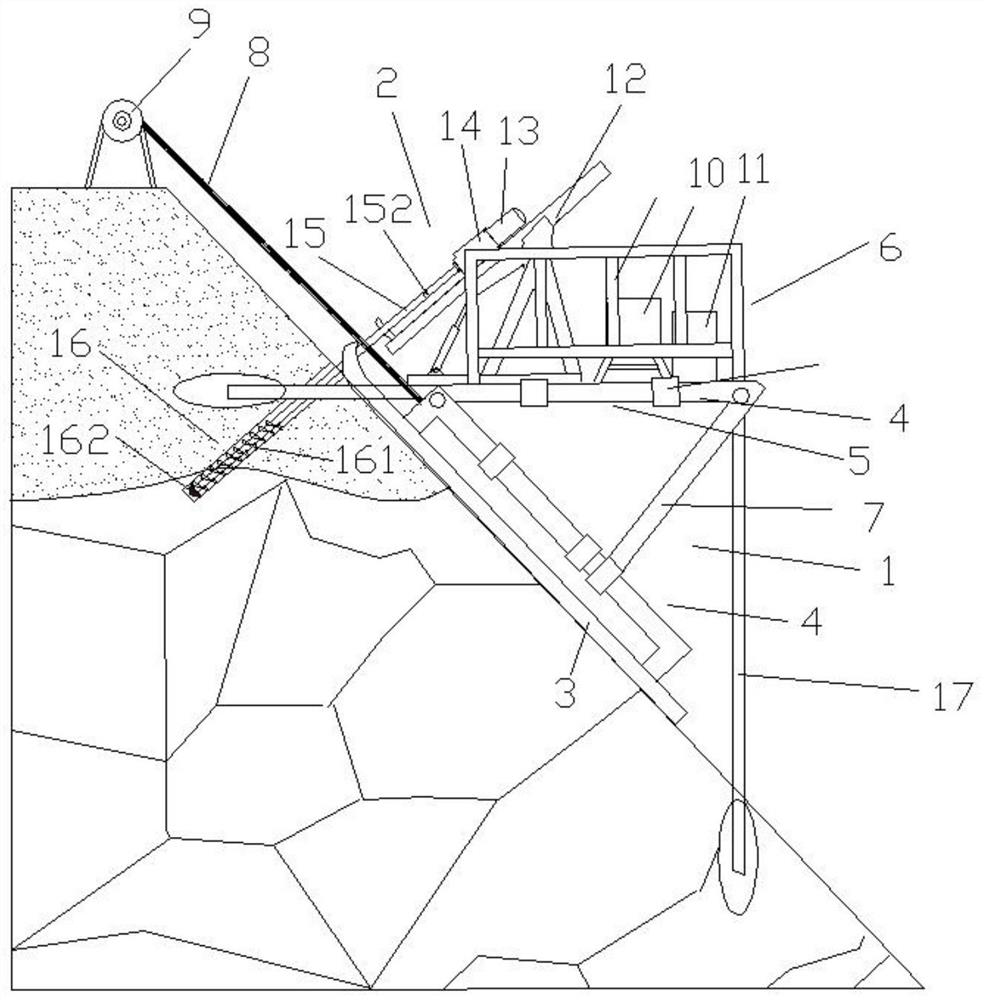

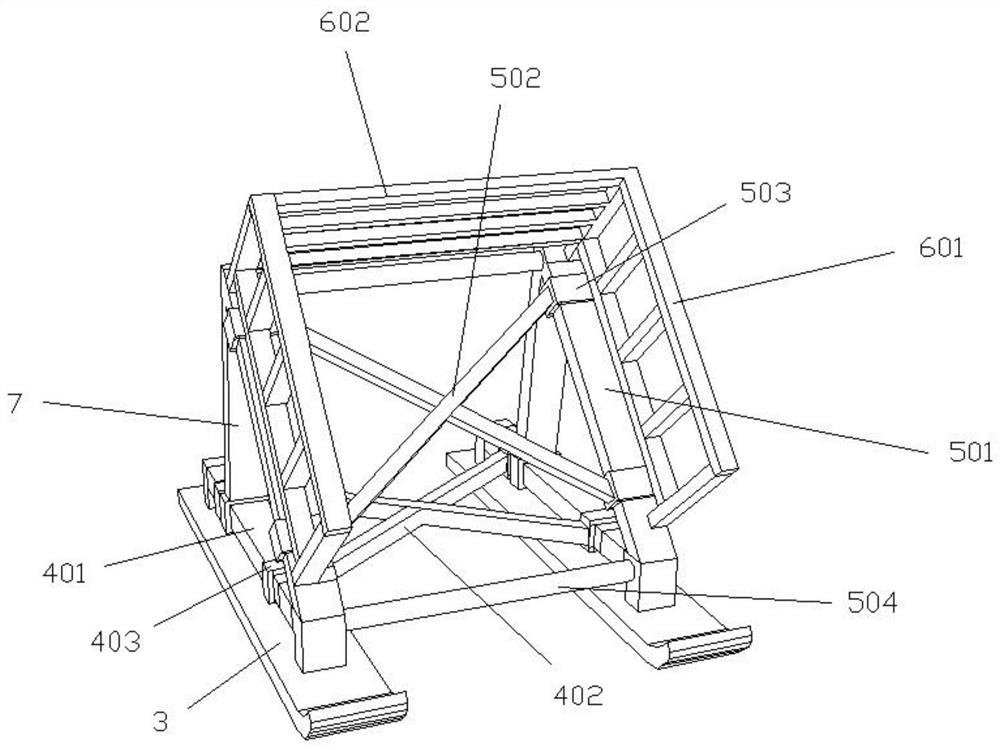

Construction method of a drilling device for complex high and steep slopes

The invention discloses a construction method of a drilling device for complex high and steep slopes. The drilling device comprises a drilling machine support, a drilling machine base and a drilling machine. The drilling machine bracket includes a slide plate, on which there is a chassis, the front end of the chassis is hingedly connected with the front end of the platform, the supporting member is hingedly connected with the platform, and connected with the chassis fastener, and the width of the chassis and the platform can be adjusted; the drilling machine includes a power distribution system , air pressure system, gears, rock drilling components, soil drilling components, drill pipes and drill bits; construction methods include: 1) Pull the drilling machine bracket to the designated position; 2) Expand the bracket and lock it; 3) Adjust the chassis and platform Angle; 4) Install the drilling machine; 5) Start drilling. The invention solves the problem of difficult drilling of complex high and steep slopes, can be adapted to various rock and soil strata, and can deal with complex slope conditions such as unevenness and lush forests. It is flexible in action, safe and reliable in performance, and can fully cope with existing Reinforcement works for complex high and steep slopes.

Owner:DALIAN UNIV OF TECH

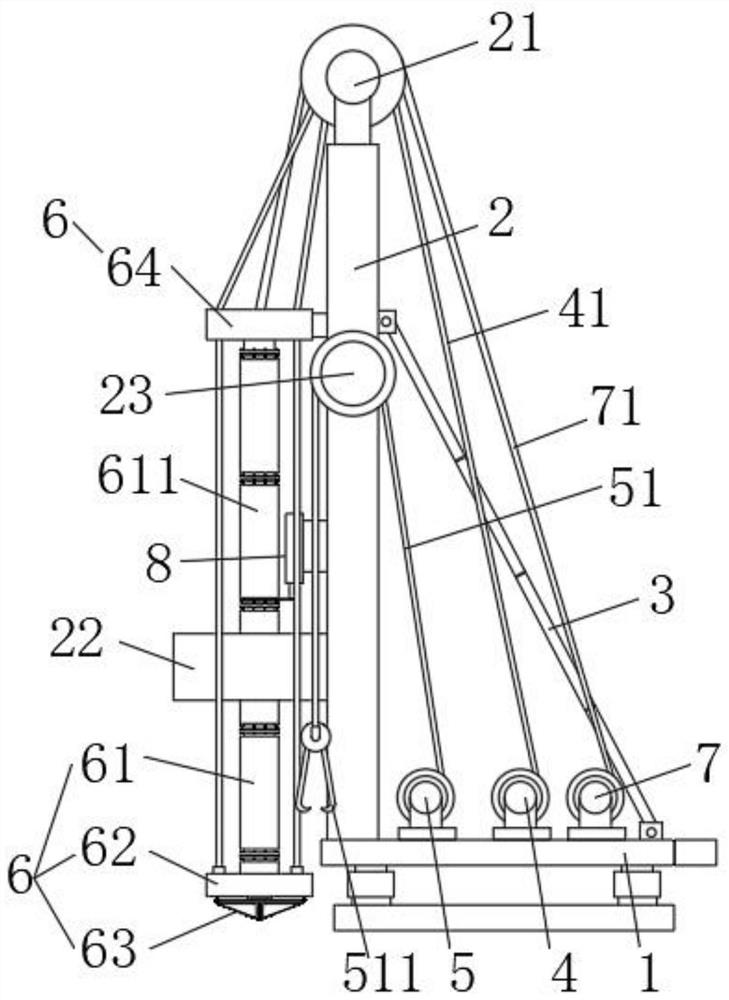

Novel grooving machine facilitating deep hole operation

InactiveCN112196474AIncreased drilling depthReduce construction costsDrilling rodsDerricks/mastsElectric machineryDrill bit

The invention provides a novel grooving machine facilitating deep hole operation. The novel grooving machine comprises a machine base, wherein a stand column is vertically arranged on the side edge ofthe surface of the machine base; the stand column and the machine base are connected through an inclined rod; a guide base is vertically arranged at the bottom end of the outer wall of the stand column; a drilling mechanism penetrates through the interior of the guide base in a sliding mode; the drilling mechanism comprises a submersible guide rod assembly, a knife rest, a drill bit, a fixing plate and a submersible motor; the drill bit is of a hollow structure; a water outlet is formed in the outer wall of the drill bit; a pressurizing mechanism is installed on the outer wall of the stand column; and a first traction mechanism, a second traction mechanism and a submersible guide rod lifting mechanism are arranged on the surface of the machine base. According to the novel grooving machine, a steel wire rope is adopted for traction, so that the overall height of the equipment is reduced; the drilling mechanism can be separately and additionally provided with a drill rod, so that the drilling depth can be prolonged, and meanwhile, the equipment is provided with the lifting mechanism, so that the construction cost is reduced; and the upper end and the lower end of the drilling mechanism can be restrained and positioned, so that the perpendicularity is guaranteed.

Owner:南京集优智库信息技术有限公司

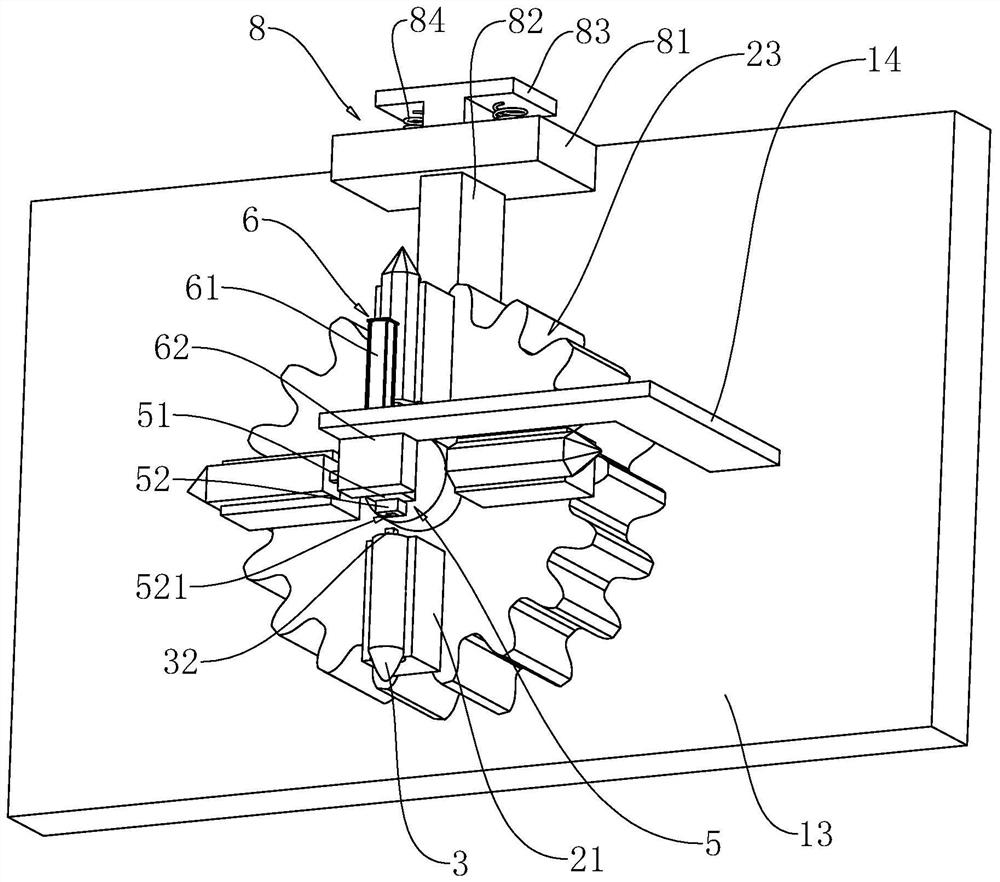

Construction method of spiral impact drilling device suitable for rock and soil

ActiveCN112502610APrecise control of drilling angleAccurate control of drilling inclinationDrill bitsDrilling rodsAir compressionGear wheel

The invention discloses a construction method of a spiral impact drilling device suitable for rock and soil. The drilling device comprises a drilling machine system and a drilling machine support, wherein the drilling machine support comprises a walking chassis mechanism, a rotating mechanism is arranged on the chassis mechanism, a working platform is arranged on the rotating mechanism, a drivingand operating room is arranged on the working platform, a movable arm is arranged at the front end of the working platform, and the front end of the movable arm is connected with the drilling system;and the drilling system comprises a power distribution system, an air compression system, a rock drilling component, a soil drilling component, a gear, a drill rod and a drill bit. The construction method comprises the steps of enabling the drilling machine support to travel to a designated position; installing a drilling system; adjusting the initial height and the drilling angle of the drill bit; and starting drilling. According to the construction method, the problem that drilling equipment cannot be suitable for different soil layers can be solved, and the method can adapt to different stratum conditions since the drilling angle can be accurately controlled and high maneuverability is achieved; moreover, the method is environmentally-friendly and can save energy and reduce noise; and in addition, the drill bit is firm and reliable, and therefore the method is suitable for slope and foundation pit supporting engineering.

Owner:DALIAN UNIV OF TECH

Deepwater high-density drilling fluid capable of resisting high temperature of 220 DEG C

The invention discloses a deepwater high-density drilling fluid capable of resisting a high temperature of 220 DEG C, wherein the drilling fluid comprises: 100 parts of seawater, 0.1-0.2 part of sodaash, 0.2-0.3 part of caustic soda, 1.2-1.5 parts of bentonite, 0.2-0.3 part of a flow type regulator, 2.0-3.0 parts of a tackifying and shear strength improving agent, 5.0-8.0 parts of a high-temperature-resistant filtrate reducer, 2.0-4.0 parts of a high-temperature anti-collapse agent, 15.0-20.0 parts of a hydrate inhibitor and 420-650 parts of a weighting agent. According to the invention, thedeepwater high-density drilling fluid has good sedimentation stability, good rheological property, good water loss wall-building property and other properties under high-temperature conditions, and meets the exploration and development of deepwater high-temperature and high-pressure wells.

Owner:CHINA NAT OFFSHORE OIL CORP +1

A stamping device for the production and processing of mechanical parts

The invention discloses a stamping device for the production and processing of mechanical parts, which comprises a base and a stamping tool. The top of the base is symmetrically fixed with a column, the top of the column is fixed with a top plate, and the center of the top of the top plate is fixed with a hydraulic cylinder. The end of the output shaft of the hydraulic cylinder is fixed with a mounting plate, the side wall of the mounting plate is symmetrically fixed with ear plates, and the ear plates are slidably connected to the column, and the bottom of the mounting plate is connected to the first drive gear through a rotating shaft , the interior of the mounting plate is equiangularly provided with a first chute, the interior of the first chute is slidably connected with a first slider, the interior of the first drive gear is equiangularly provided with a first arc-shaped groove, the The bottom of the first slider is fixed with a first connecting column, and the first connecting column is slidably connected in the first arc-shaped groove. The bottom of the first connecting column is fixed with a stamping tool. This stamping device is used for the production and processing of mechanical parts. The drilling efficiency is improved, and the drilling requirements of different hole spacings can be met.

Owner:LAIZHOU KASIKAITE IND & TRADE CO LTD

Main arm mechanism of rock drill

InactiveCN110284841AGuaranteed accuracyEasy to adjustConstructionsDerricks/mastsStructural engineeringDrill bit

The invention provides a main arm mechanism of a rock drill. The main arm mechanism comprises a main arm mounting seat, wherein a rotary mechanism for driving the rotary action of a main arm is mounted on the main arm mounting seat; a main arm connecting seat is mounted on a main shaft of the rotary mechanism, lug plates are fixed on the end face of the main arm connecting seat; the main arm is mounted between the lug plates through a swing mechanism; a telescopic arm for mounting the rock drill is slidably mounted on the main arm in a matched mode, and a first linear driving mechanism for driving the telescopic arm to slide along the main arm is mounted between the telescopic arm and the main arm; the rock drill is slidably mounted on the telescopic arm through a second linear driving mechanism in a matched mode; and an output shaft of the rock drill is connected with a drill pipe, and a drill bit is mounted on the head of the drill pipe. The main arm mechanism can adjust the length of the rock drill conveniently, the rotation angle of the rock drill is further adjusted conveniently, and the drilling accuracy is high, thus the drilling efficiency of shot holes is greatly improved.

Owner:CHINA THREE GORGES UNIV

Automatic drilling robot for circuit board and drilling method thereof

InactiveCN114012831AImprove drilling efficiencyImprove efficiencyPrinted circuit manufactureMetal working apparatusProcess engineeringDrill hole

According to an automatic drilling robot for a circuit board and a drilling method thereof. An industrial robot replaces manpower to complete drilling work on the circuit board, the manpower only needs to place the circuit board to be drilled on a transmission assembly in sequence, and the drilling efficiency of the circuit board can be effectively improved. The automatic drilling robot is provided with the turnover mechanism, the circuit board can be turned over, therefore, drilling operation can be performed on the two surfaces of the circuit board, and the drilling requirements of different circuit boards are met. And meanwhile, the drilling arm is an adjustable drilling arm, a plurality of switchable drilling heads are arranged, the size of the drilling arm can be adjusted according to different drilling requirements, the drilling heads do not need to be replaced and adjusted manually, and the efficiency of drilling operation on the circuit board is further effectively improved.

Owner:南京西通信息科技有限公司

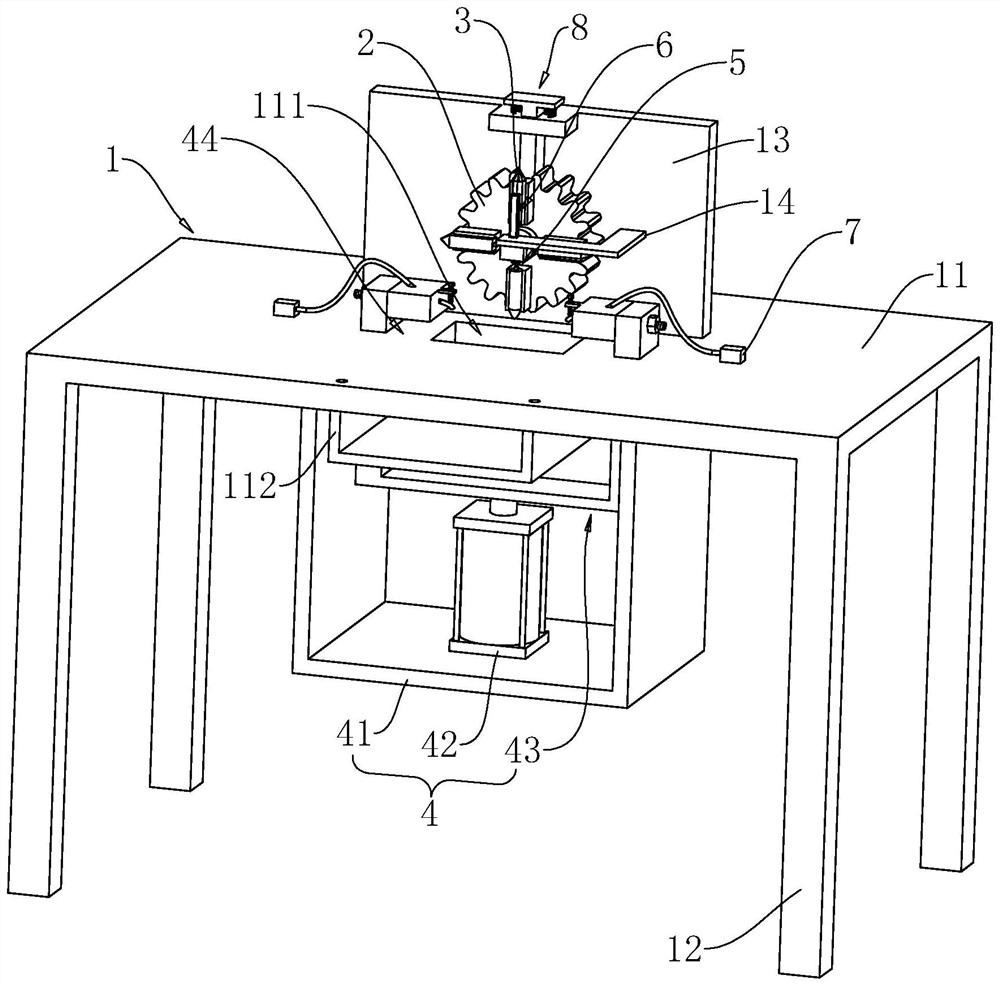

Punching device for sheet-like metal parts

InactiveCN109014279AReduce deformationReduce manufacturing costMaintainance and safety accessoriesBoring/drilling machinesPunch pressEngineering

The invention discloses a punching device for sheet-like metal parts. The punching device comprises a fixing mechanism for fixing the parts to be processed, a workbench for supporting the fixing mechanism, a punching tool for performing drilling on the parts to be processed, a drive mechanism for driving the punching tool, and a cross beam arranged above the workbench and used for installation ofthe drive mechanism. By fixing the parts to be processed through the fixing mechanism and using the punching tool to replace a punch press to drill the parts to be processed, the purposes of reducingthe production cost, reducing deformation of workpieces and ensuring the punching quality are achieved.

Owner:盐城市崇光包装有限公司

Sole drilling equipment

The invention relates to the technical field of shoe material processing equipment, and discloses sole drilling equipment which comprises a rack, a rotating disc rotationally arranged on the rack, a plurality of drill bits detachably connected to the rotating disc and a positioning assembly used for fixing a to-be-processed sole, and the multiple drill bits are different in shape and distributed in the circumferential direction along the central axis of the rotating disc; a support is arranged on the machine frame, a rotating assembly and a lifting assembly used for driving the rotating assembly to vertically move are connected to the support, the rotating assembly comprises a rotating motor and a rotating block arranged on an output shaft of the rotating motor, and a non-circular inserting groove is formed in the bottom face of the rotating block. Inserting blocks with the same shape as the inserting grooves are fixed to the sides, close to the central axis of the rotary disc, of the drill bits, and the inserting blocks on the drill bits can sequentially move to the positions under the inserting grooves along with the rotary disc and are embedded into the inserting grooves. The drilling device has the effect that the drilling requirements of various shapes can be met.

Owner:夏书妍

Drilling device used for road engineering

InactiveCN109594929AReduce vibrationWork lessDrilling rodsDerricks/mastsRoad engineeringVibratory sensation

The invention discloses a drilling device used for road engineering. The drilling device comprises a rack, wherein push rods are arranged at two ends of the top of the rack respectively; a second supporting plate is arranged at the bottom of the rack; a telescopic rod is arranged between the rack and the second supporting plate; pulley columns are arranged at two ends of the bottom of the second supporting plate respectively; a pulley is arranged at the bottom of each pulley column; a first supporting plate is arranged at the bottom of the rack; two ends of the first supporting plate are fixedly connected with the telescopic rod; a motor is arranged at the top of the rack; the output shaft end of the motor is connected with a drill sleeve; a damping spring is arranged outside the drill sleeve in a sleeving mode; and the top of the damping spring is connected with the bottom of the rack. The drilling device is provided with the damping spring made of a silicomanganese spring steel material, the vibratory sensation of a drilling machine can be alleviated effectively, moreover, a spongy layer is arranged outside each push rod in the sleeving mode, influences of the equipment on constructors can be further reduced, and the operation of the constructors is facilitated preferably.

Owner:新沂海悦建设有限公司

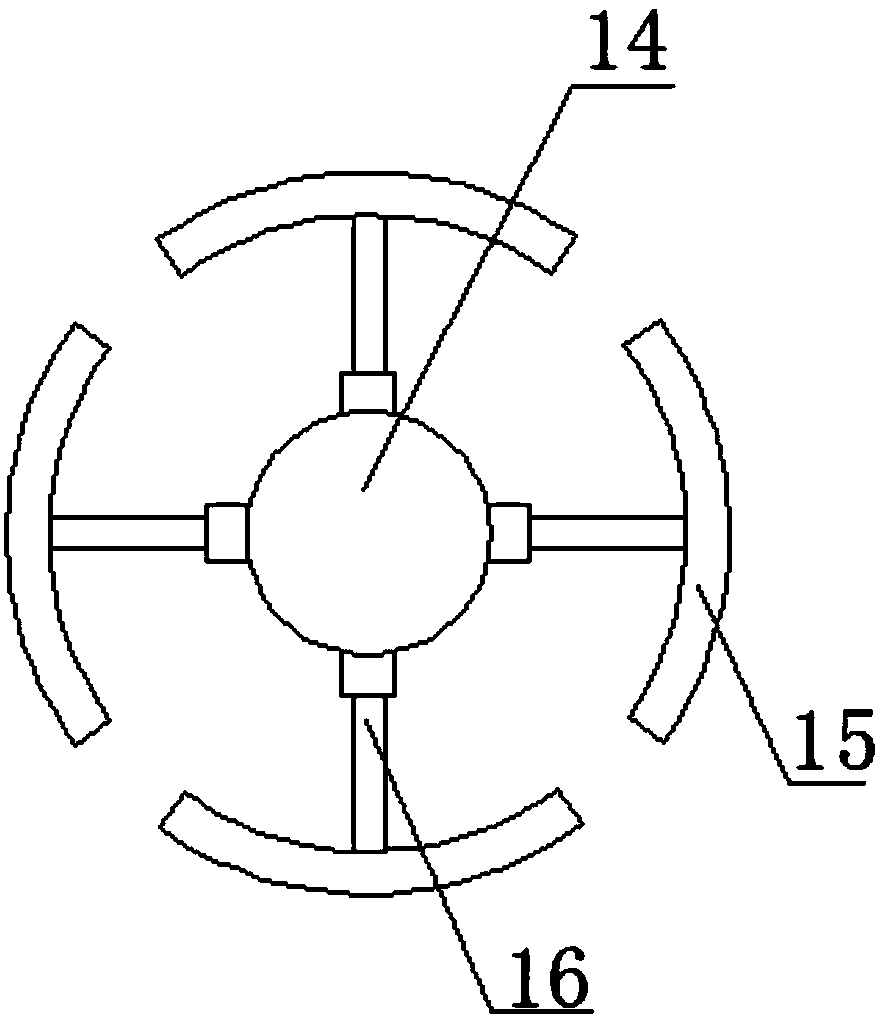

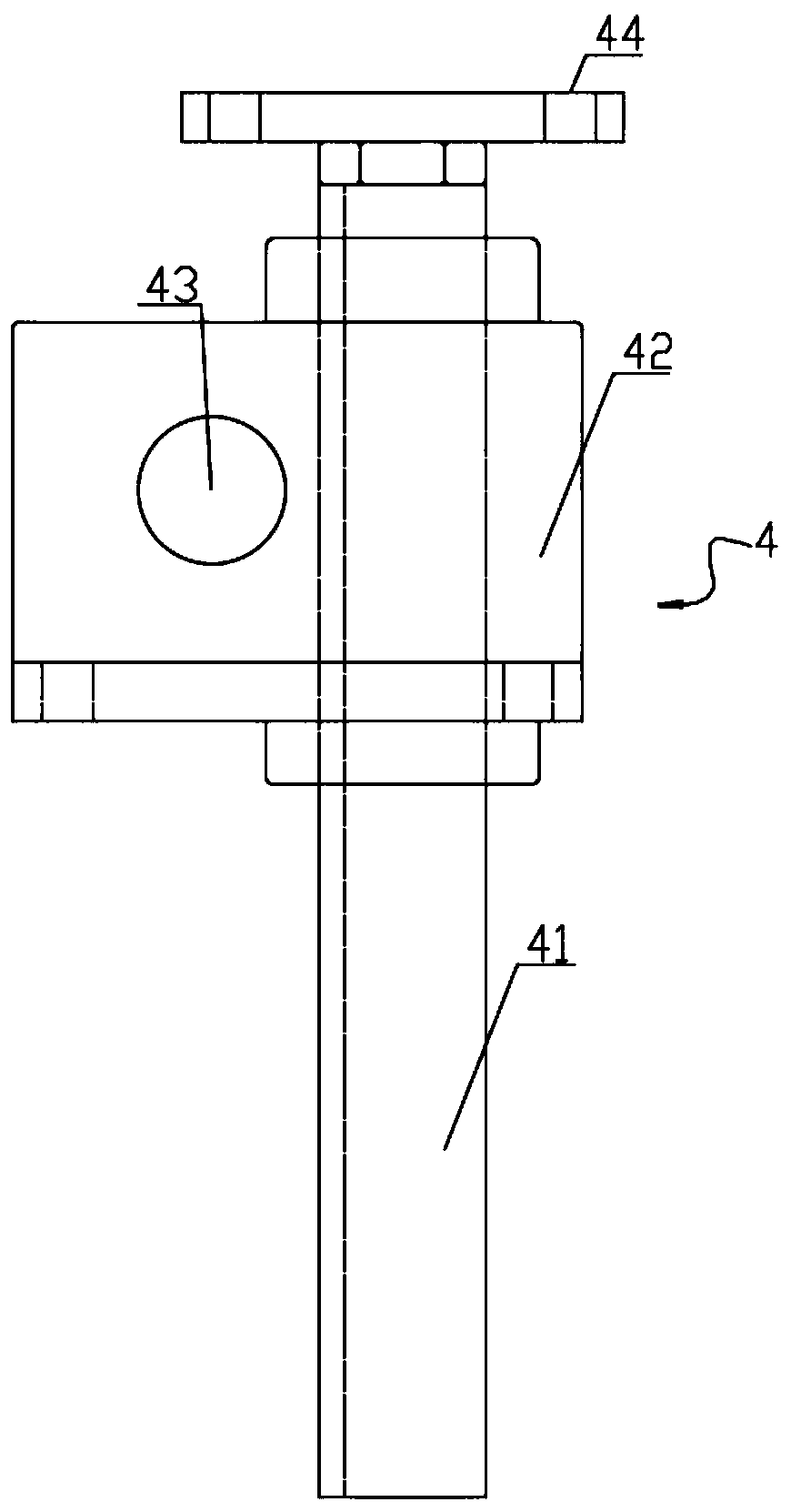

a drilling tool

ActiveCN106625870BSave spaceSeparation in timeTransportation and packagingCutting insertsEngineeringCircular segment

The invention relates to a drilling tool, comprising a shank and a tool body which are connected to each other and extend around a central axis. The tool body includes a ring segment and a blade structure, the ring segment and the tool handle are connected and fixed, and the blade structure includes a Four evenly spaced circumferentially spaced cutting edges extend from the ring segment, the four cutting edges are arranged left-handed around the central axis, respectively extending from the circular ring segment away from the central axis and away from the shank, each cutting edge comprising a circumferential The outer surface of the blade and the inner surface of the blade are extended, the end of each blade away from the annular segment is provided with a leading edge extending radially outward from the outer surface of the blade, and the other end adjacent to the annular segment is provided with a front edge from the outer surface of the blade. The outer surface of the blade extends radially outward of the rear edge, and a hollow groove is formed between the front edge and the rear edge. The drilling tool of the invention is matched with the robot to form flexible drilling equipment, so as to meet the drilling requirements of different products, which can not only effectively save the factory site of the enterprise, but also reduce the development cost of the equipment.

Owner:YANFENG PLASTIC OMNIUM AUTOMOTIVE EXTERIOR SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com