Sole drilling equipment

A kind of drilling equipment and drill bit technology, which is applied in the field of shoe sole drilling equipment, can solve the problems that it is difficult to meet the needs of various shapes of drilling, and achieve the effects of ensuring mechanical strength and surface cleanliness, strong practicability, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is attached Figure 1-4 The application is described in further detail.

[0039] The embodiment of the present application discloses a shoe sole drilling device.

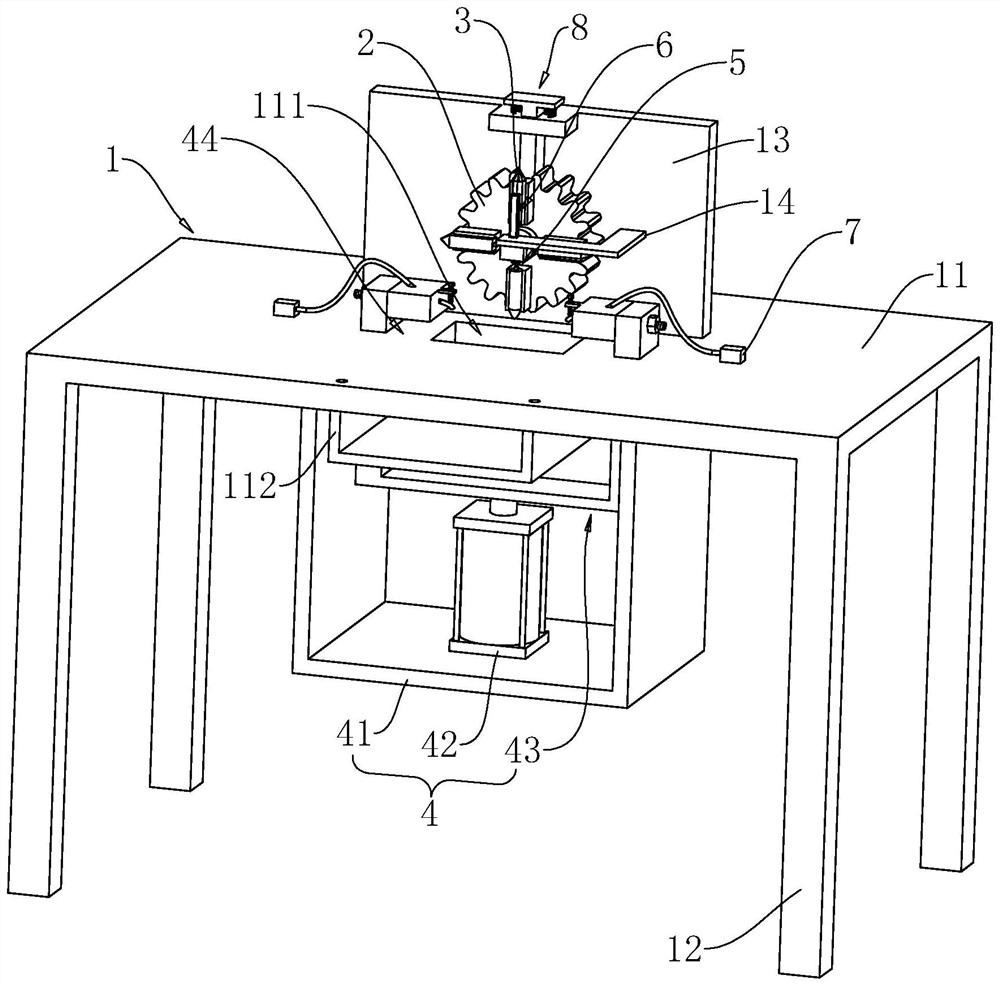

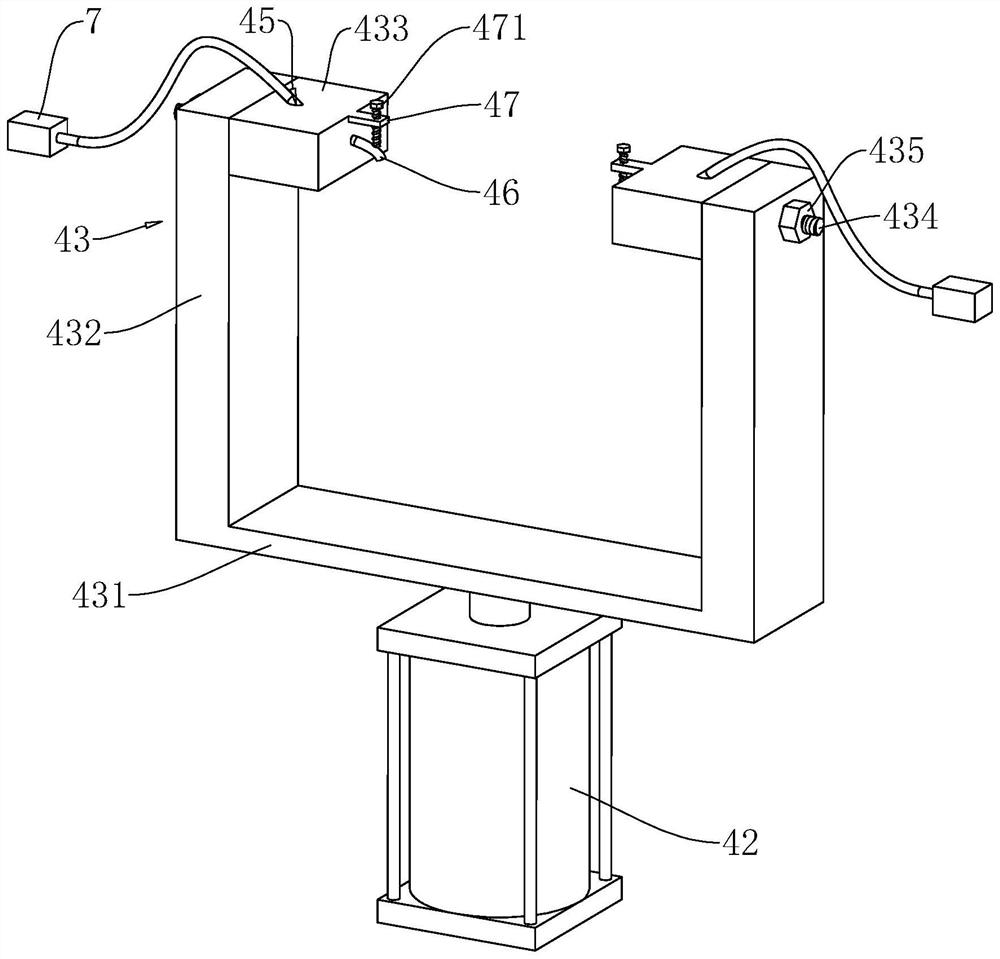

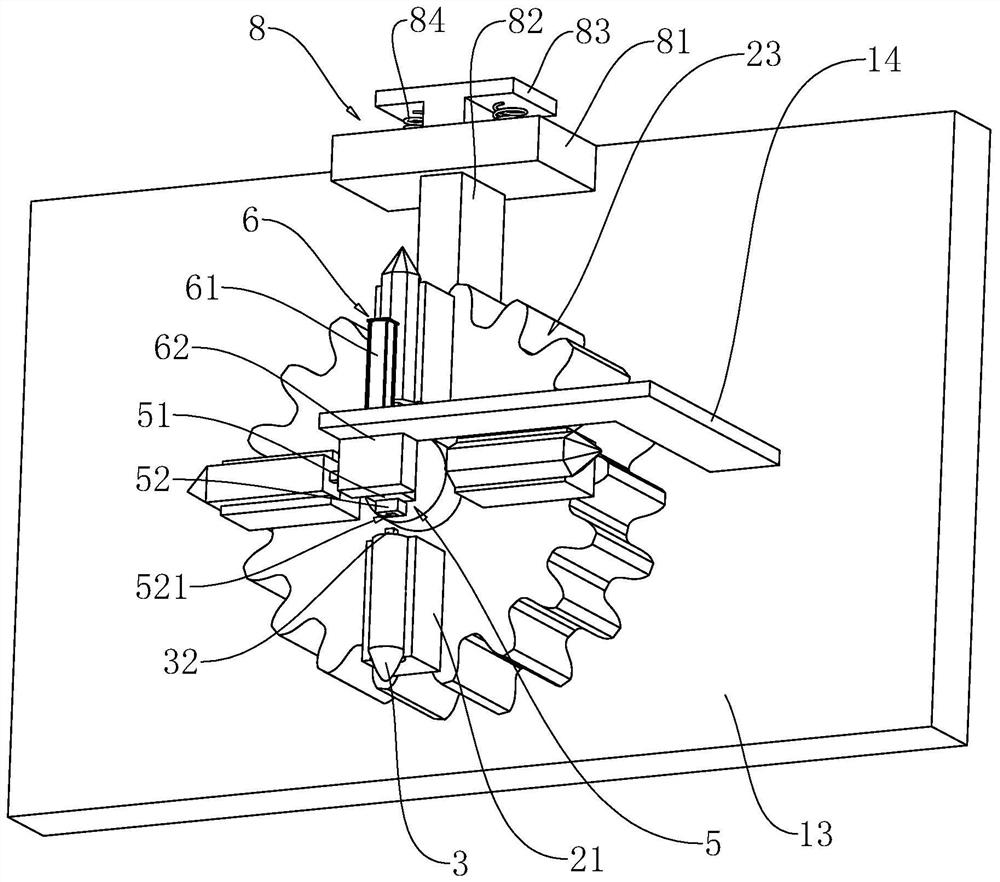

[0040] refer to figure 1 , the sole drilling equipment includes a frame 1, a turntable 2 arranged on the frame 1, a plurality of drill bits 3 detachably connected to the turntable 2, and a positioning assembly 4 for fixing the sole to be processed, and a plurality of drill bits 3 The shapes are different and uniformly distributed along the central axis of the turntable 2 in the circumferential direction. The present embodiment is provided with four drill bits 3, wherein the cross-section of one drill bit 3 is circular, and the cross-sections of the other three drill bits 3 are respectively quadrangular, pentagonal and hexagonal to illustrate its structure. In other embodiments, the drill bit 3 can also be set to other numbers and shapes.

[0041] refer to figure 1 , the frame 1 includes a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com