Main arm mechanism of rock drill

A technology of rock drill and rotary mechanism, which is applied in drilling equipment, wellbore/well components, earth-moving drilling, etc., can solve the problems of low adjustment accuracy, skew, inability to adjust the length, rotation angle and rotation direction of the main boom, etc. Achieve the effect of ensuring accuracy and purifying the construction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

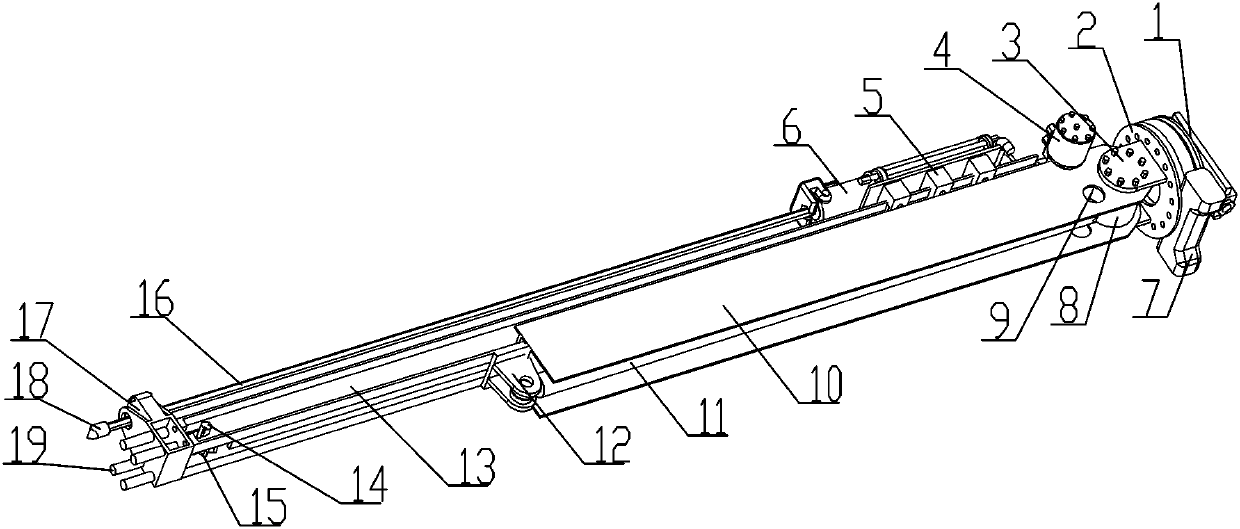

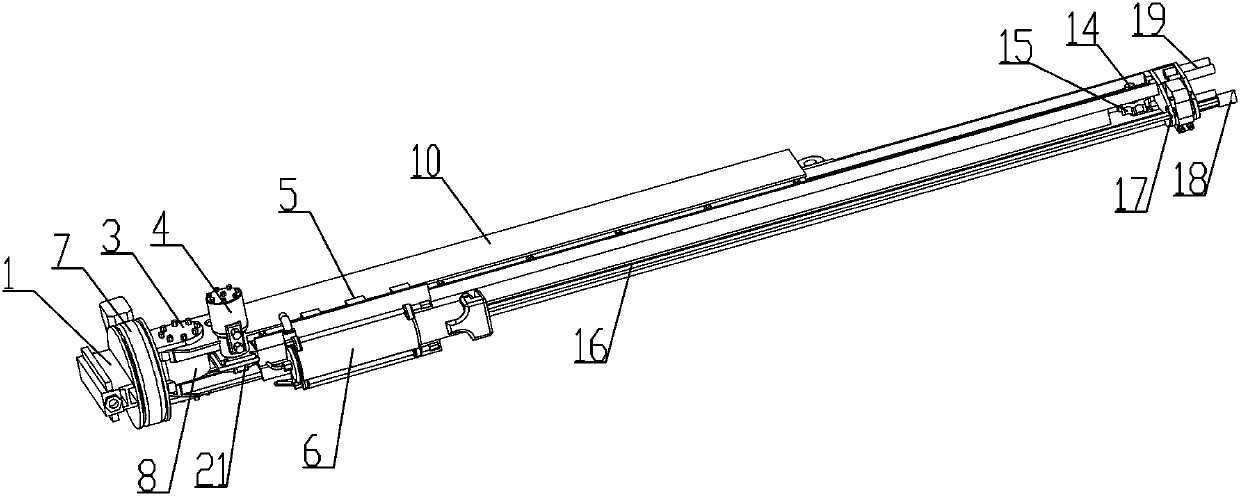

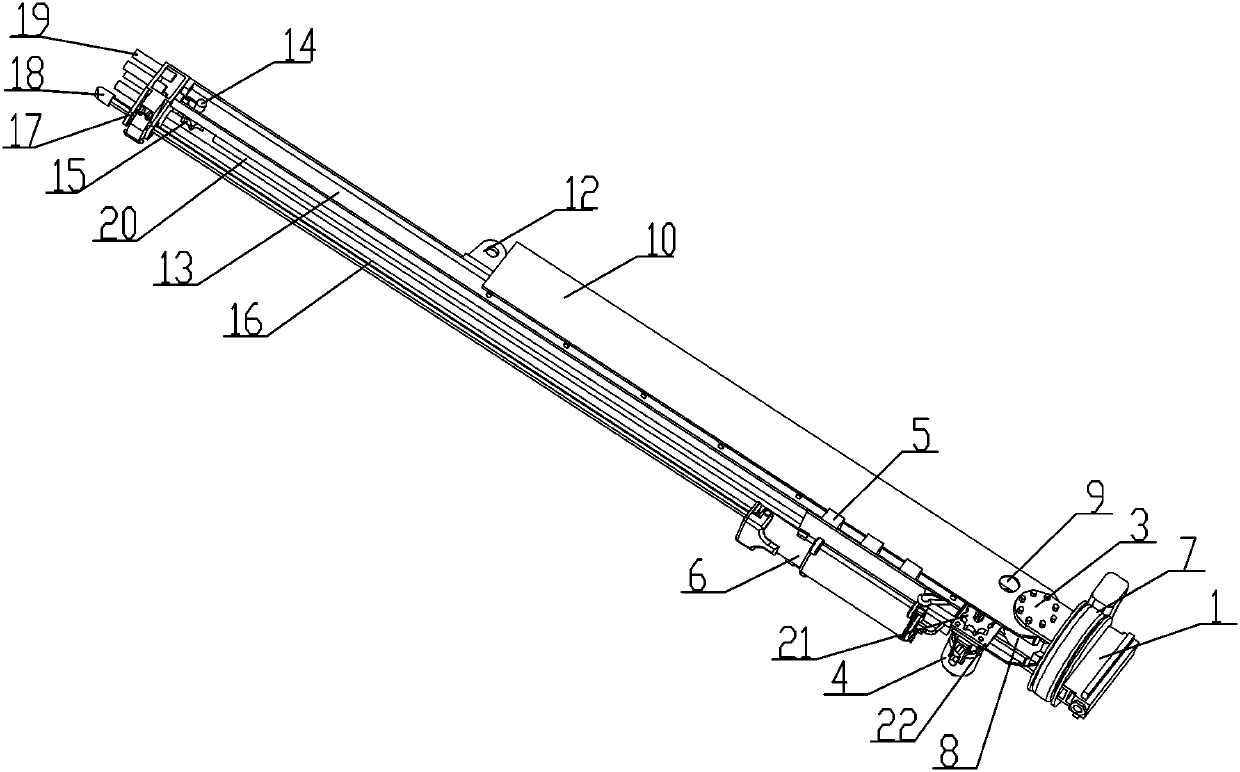

[0026] see Figure 1-4 , a main arm mechanism of a rock drilling machine, which includes a main arm mounting seat 1, a slewing mechanism for driving the slewing action of the main arm is installed on the main arm mounting seat 1; a main arm connecting seat 2 is installed on the main shaft of the slewing mechanism , the end face of the main arm connecting seat 2 is fixed with an ear plate 3, and a main arm 10 is installed between the ear plates 3 through a swing mechanism; A first linear drive mechanism for driving it to slide along the main arm 10 is installed between the telescopic arm 13 and the main arm 10; the rock drill 6 is mounted on the telescopic arm 13 through the sliding fit of the second linear drive mechanism; the The output shaft of the rock drill 6 is connected with a drill rod 16, and a drill bit 18 is installed on the head of the drill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com