a drilling tool

A technology for drilling tools and blades, which is applied in drilling tool accessories, drilling/drilling equipment, and tools for lathes, etc. It can solve problems such as difficult cost control, unsustainable enterprise site, and edge flanging of holes. Achieve the effect of meeting continuous production, reducing development costs and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

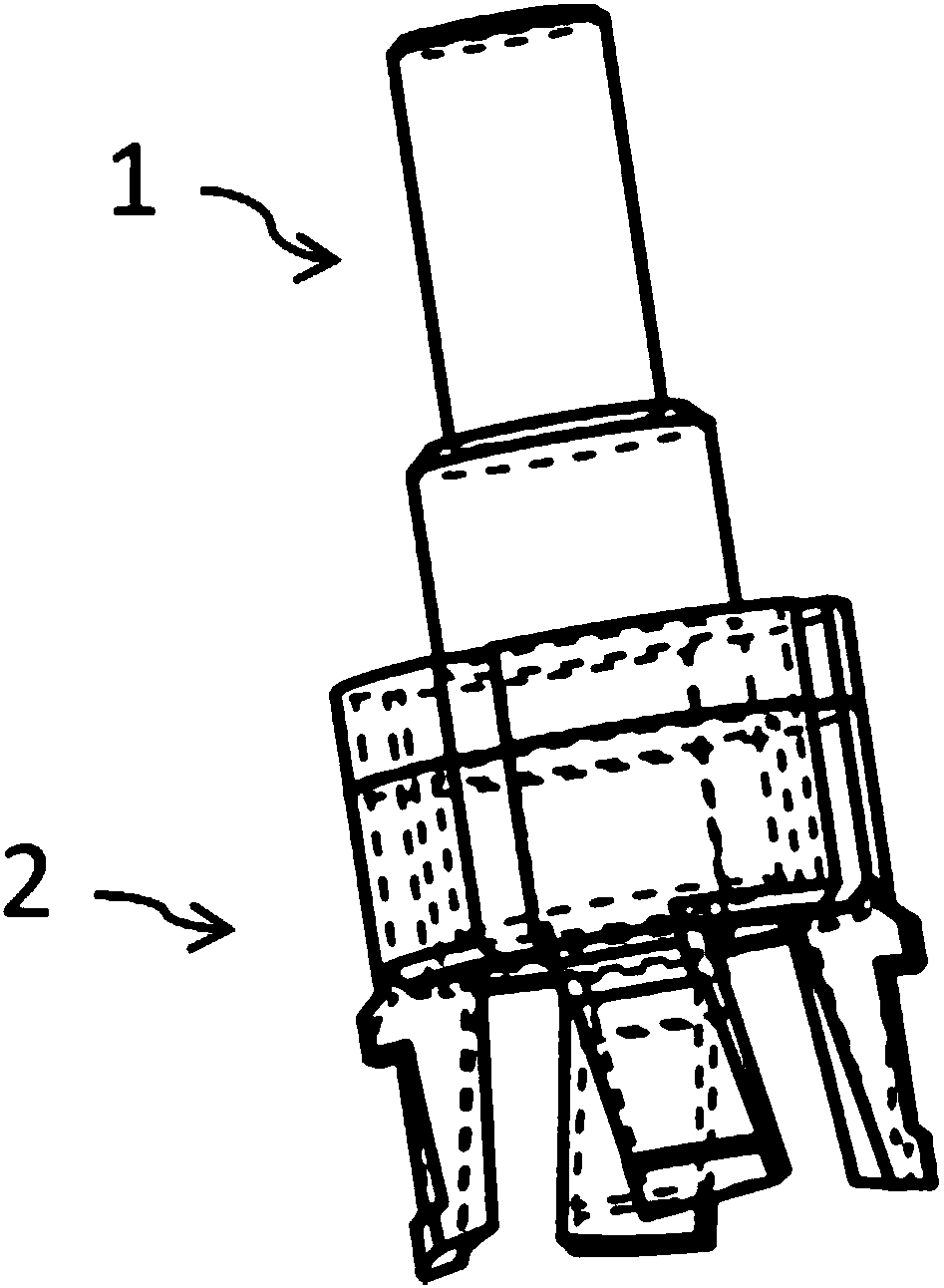

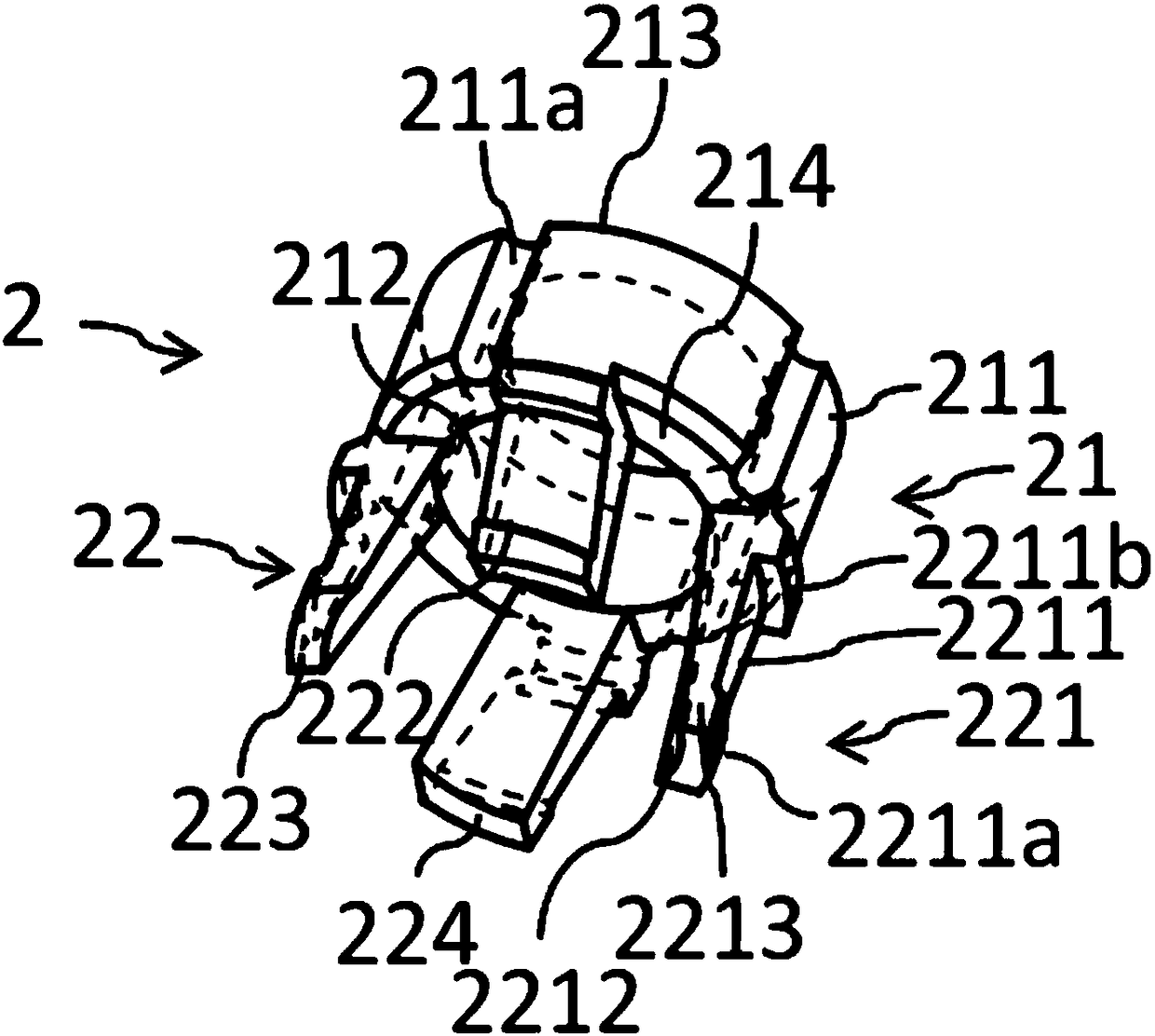

[0021] Such as Figure 1-Figure 3 As shown, the drilling tool according to the present invention includes a handle 1 and a cutter body 2 extending around a central axis, wherein the handle 1 is formed of an alloy material, and the cutter body 2 is formed of a cemented carbide material. Or formed into one by welding, such as figure 1 shown. In particular, the present invention uses hard materials to form the cutter body 2, which solves the problems of stress wear and material corrosion of the cutter edge, and ensures the cutting stability of the drilling cutter during the drilling process.

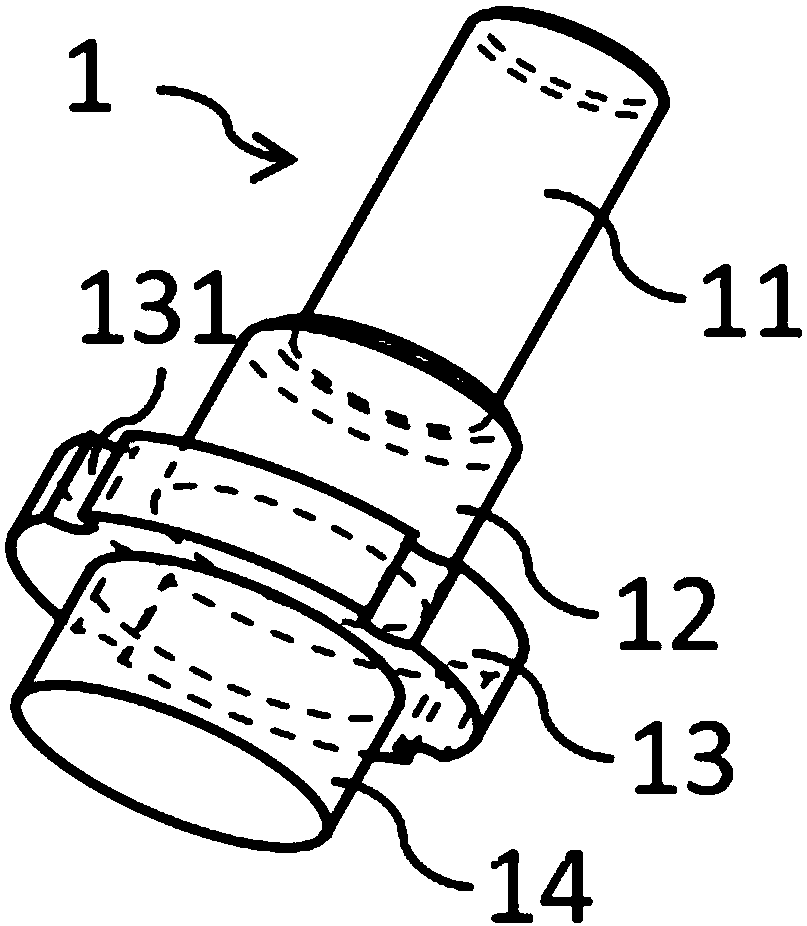

[0022] Such as figure 2 As shown, the tool holder 1 includes a first cylindrical section 11, a second cylindrical section 12, a third cylindrical section 13 and a fourth cylindrical section 14 arranged coaxially in sequence, wherein the diameter of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com