Patents

Literature

81results about How to "Meet the requirements of continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

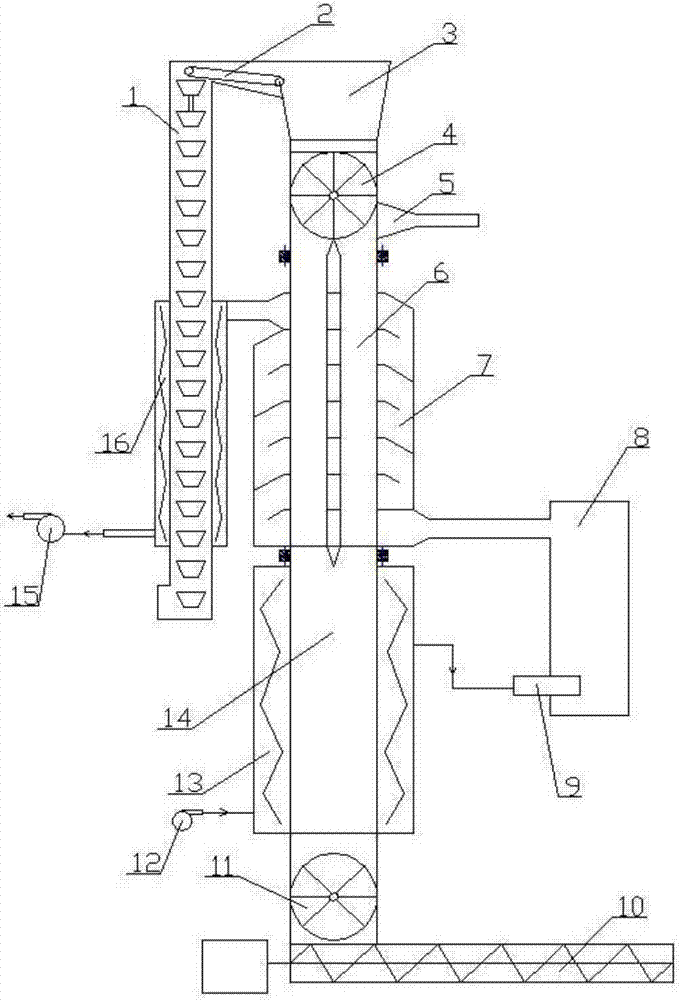

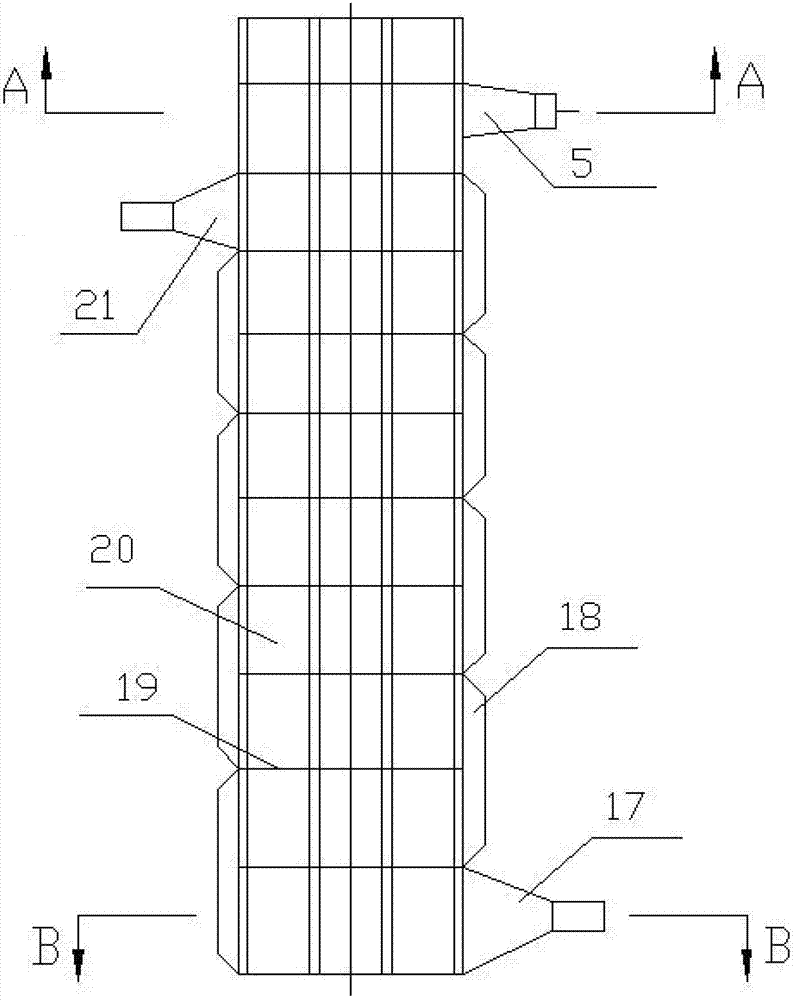

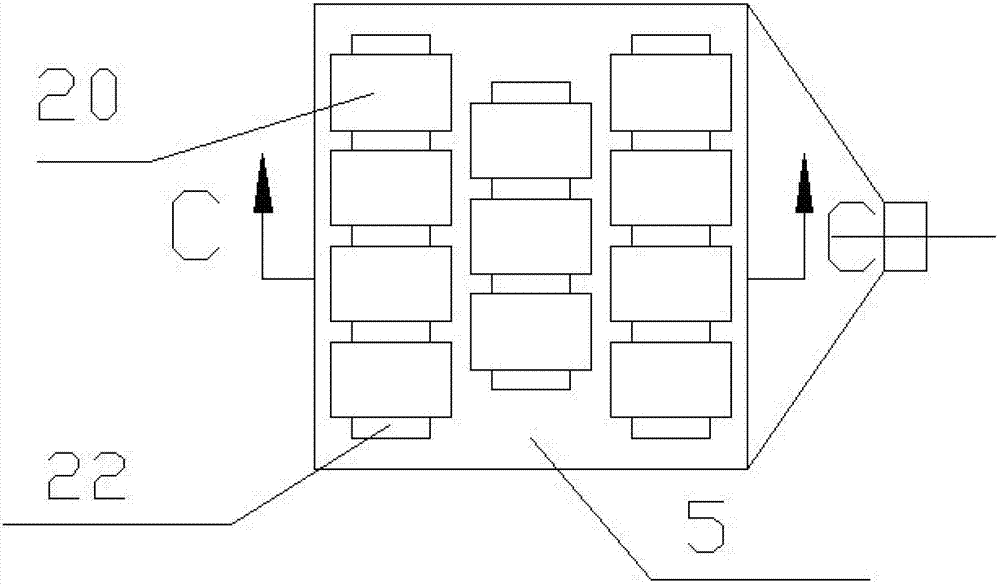

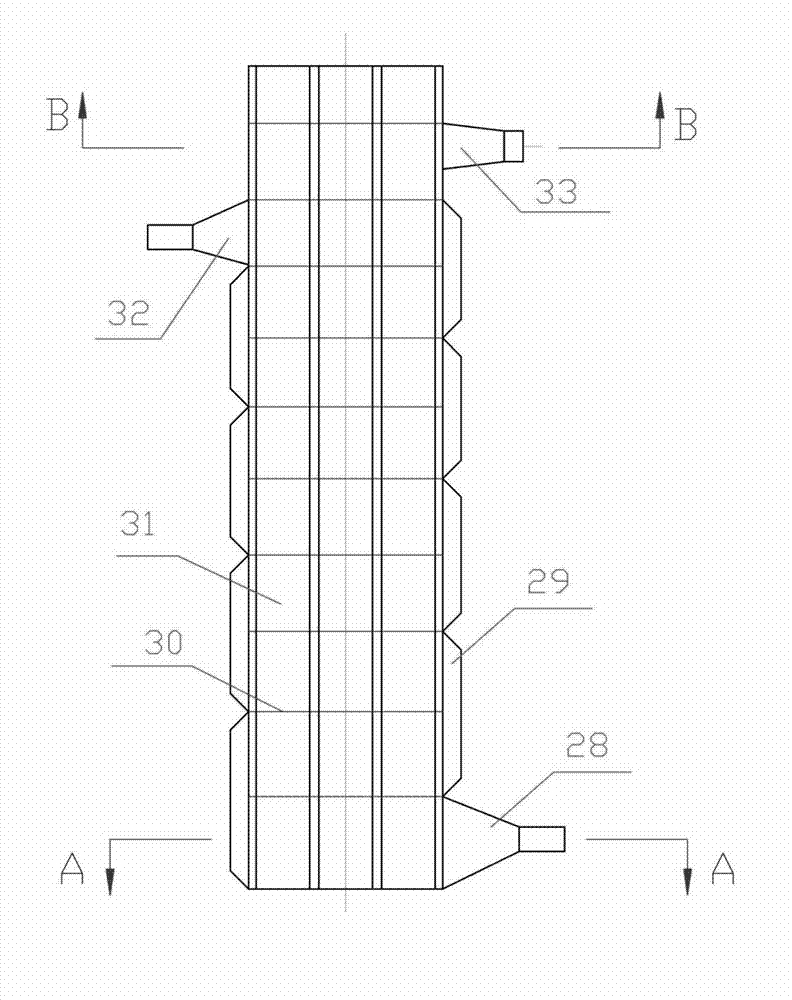

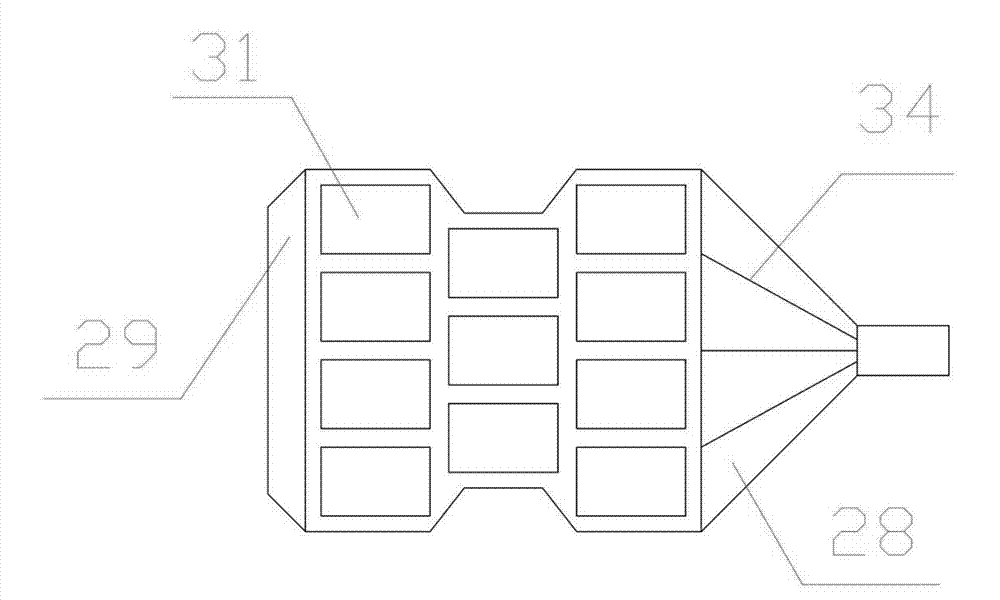

Vertical tube moving bed continuous pyrolysis apparatus for biomass

InactiveCN102816581AFast absorptionShorten production timeBiofuelsEnergy inputVertical tubeMoving bed

The invention discloses a novel vertical tube moving bed continuous pyrolysis apparatus for biomass. The apparatus mainly comprises a combustion heating furnace, a pyrolysis heat supply flue, a vertical tube pyrolysis moving bed, a coke air-cooling pipe, a rotary feed valve, a rotary discharge valve, a discharging packing auger, etc. According to the invention, high temperature flue gas is used to scour rows of pyrolysis vertical tubes in the moving bed to reinforce the effect of heat transfer from an external heat source to pyrolysis equipment, and biomass raw materials successively undergo thermal decomposition in the pyrolysis tubes with a great length-diameter ratio; heat released in cooling of coke is utilized for preheating of heating air, which enables energy to be fully utilized; and through adjustment by the rotary feed valve and the rotary discharge valve and gravity of materials, continuous production in the process of pyrolysis is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

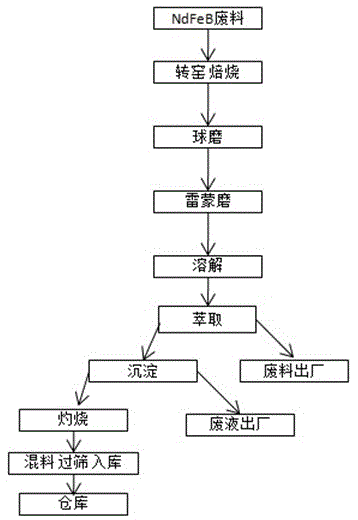

Method for extracting rare earth from oxidized neodymium iron boron waste

InactiveCN102719674AAvoid harmStop pollutionProcess efficiency improvementRare-earth elementElectrolysis

The invention discloses a method for extracting rare earth from oxidized neodymium iron boron waste. The method comprises the following steps of: mixing the neodymium iron boron waste with water and then grinding; oxidizing the ground neodymium iron boron waste; performing primary grinding of the oxidation product; adding acid and leaching; separating solid from liquid; extracting to remove iron; chloridizing rare earth; extracting and separating rare earth; extracting to remove aluminum; precipitating; and firing. By adopting the method disclosed by the invention to recover the rare earth, the rare earth recovery rate is increased by 5-8%; and moreover, the use value of the recovered rare earth is increased, the production cost of further processing is lowered, the problem of muddy objects of the molten salt when in single rare earth electrolysis is effectively solved, the electrolysis efficiency when in the electrolysis of the rare earth metal is improved, the power consumption can be effectively reduced, and the content of the non-rare earth elements in metal such as C, S, O and the like is reduced.

Owner:赣州市永莱宝高新材料有限公司

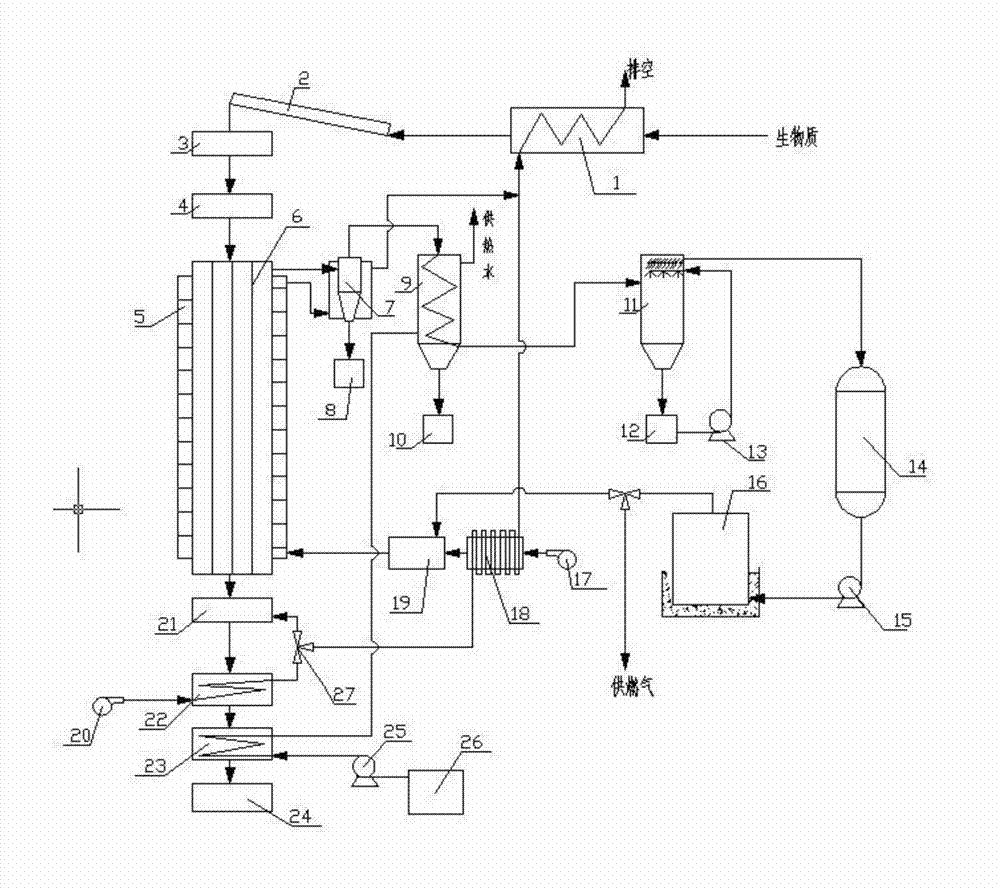

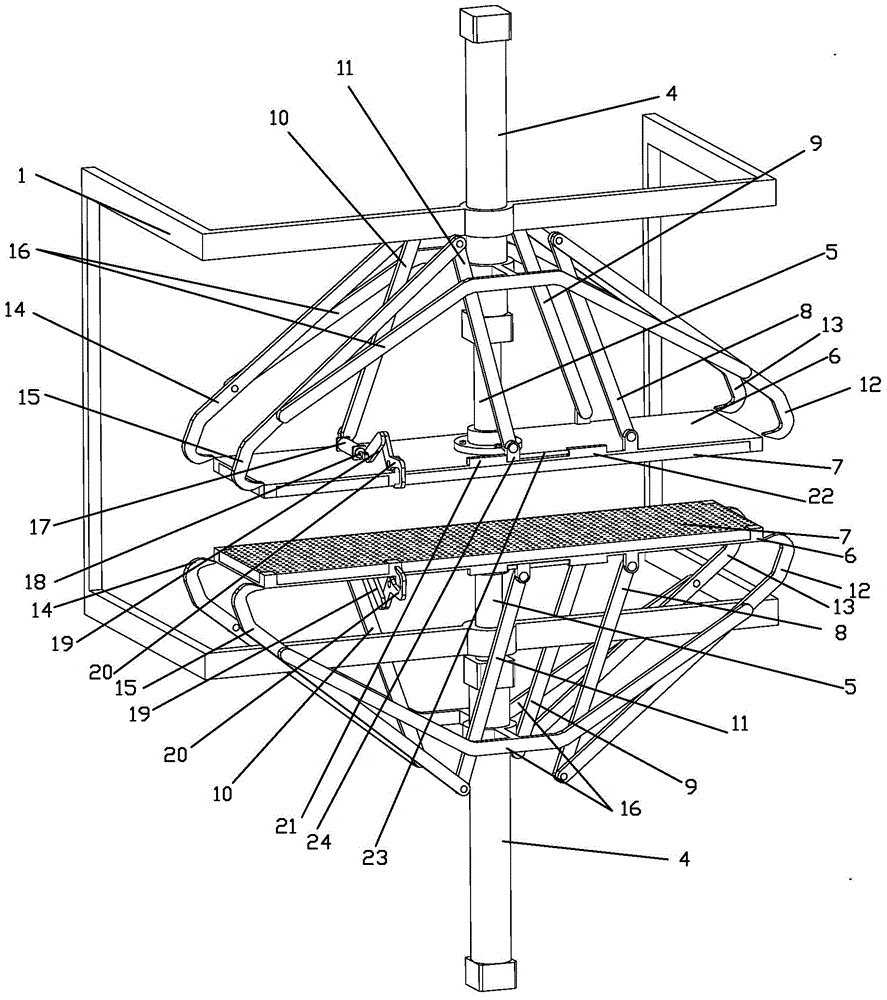

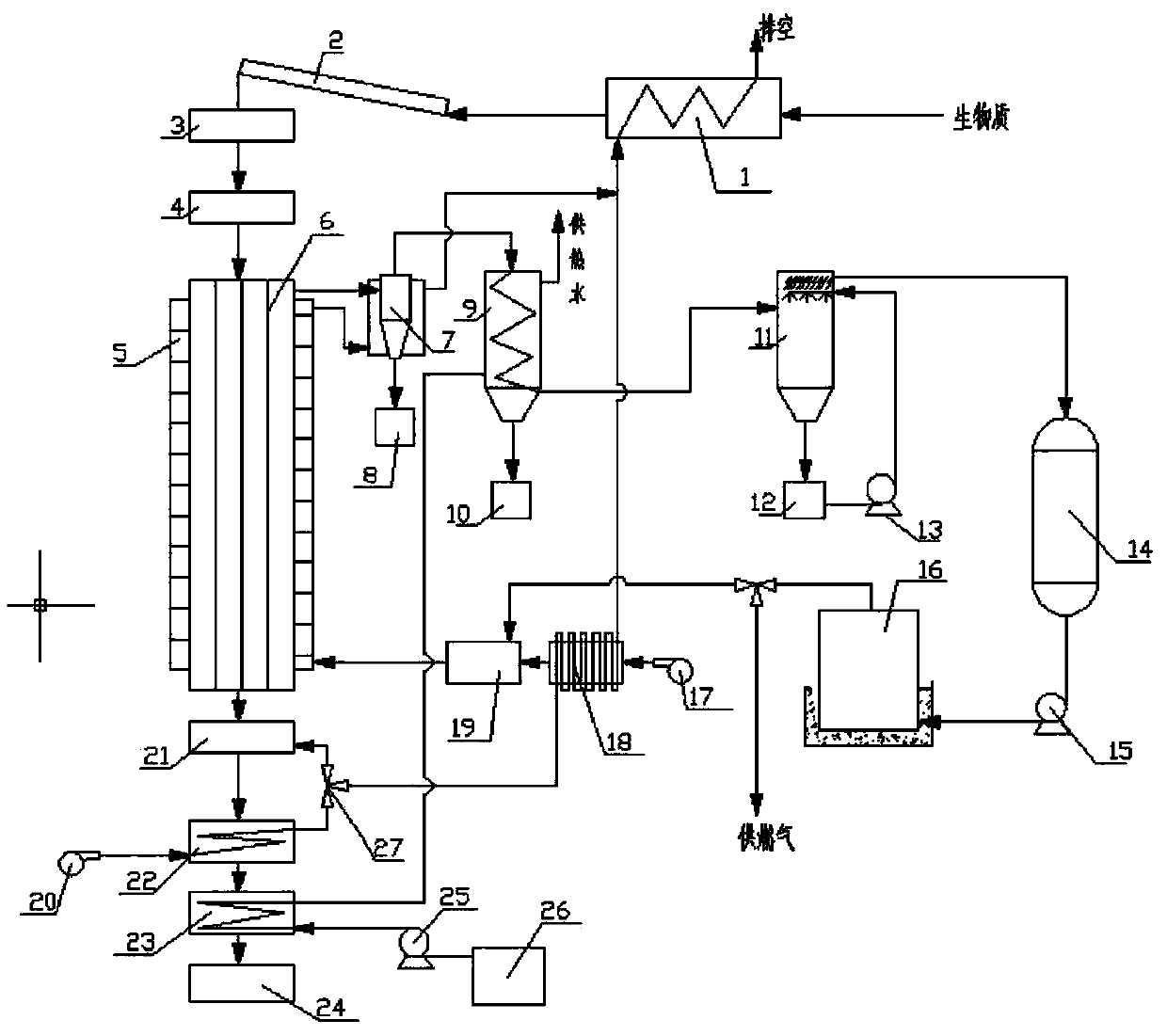

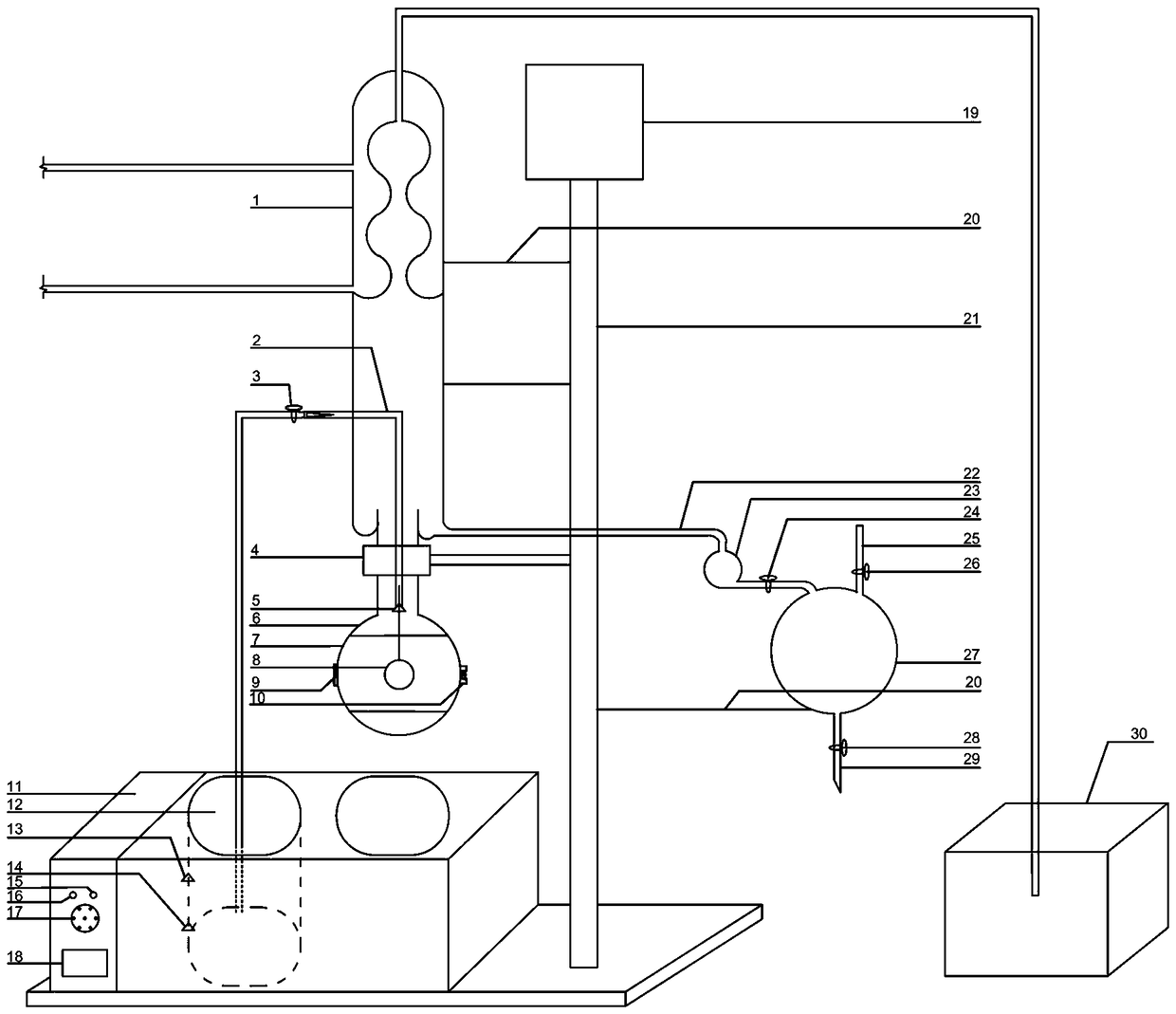

Continuous biomass pyrolytic carbon gas-oil poly-generation system

ActiveCN102776007AShorten the time required for productionImprove reliabilityBiofuelsEnergy inputBiogasBiomass

The invention discloses a continuous biomass pyrolytic carbon gas-oil poly-generation system. The continuous biomass pyrolytic carbon gas-oil poly-generation system comprises a pyrolysis unit, a condensation unit, a purifying unit, a gas storage unit and a heating unit, wherein the pyrolysis unit is connected with the condensation unit and the heating unit; the gas storage unit is connected with the purifying unit and the heating unit respectively; the condensation unit is connected with a gas storage unit pipeline by the purifying unit; high-temperature smoke gas is generated by the heating unit; the pyrolysis unit performs thermal conversion from biomass into a carbon gas oil product by heat energy generated by high-speed scouring of high-temperature smoke gas and coke is separately stored; bio-oil and gas are separated from carbon gas oil by the condensation unit; impurities in the fuel gas are removed by the purifying unit; and the gas subjected to the impurity removal is stored by the gas storage unit. With the adoption of the continuous biomass pyrolytic carbon gas-oil poly-generation system, targets of continuously producing biogas, a biological coke and bio-oil are realized, so that the product quality is stable, and the application prospect is wide.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Method for processing clearing type pineapple juice

The present invention relates to a method for processing clear type pineapple juice whose clearing rate is upto 99%. Said processing method includes the following steps: selecting pineapple raw material, cleaning, steaming, cutting, pressure filtering, enzymolysis treatment, inactivating enzyme, filtering, centrifugal separation, ultrafiltering, reverse osmosis, high-temperature flash-sterilization, thermal filling and sealing so as to obtain the invented clear type pineapple juice.

Owner:GUANGZHOU NANLIAN IND

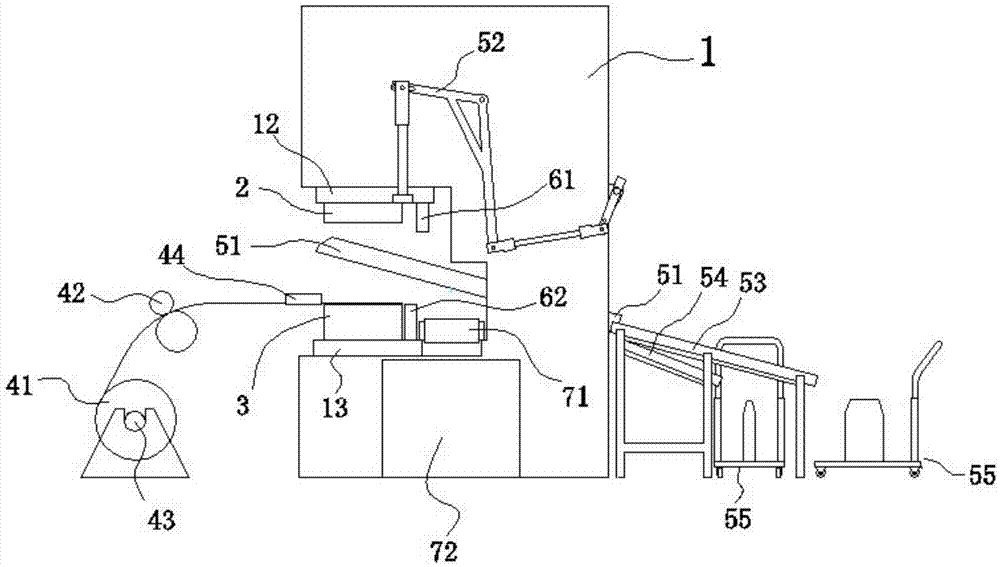

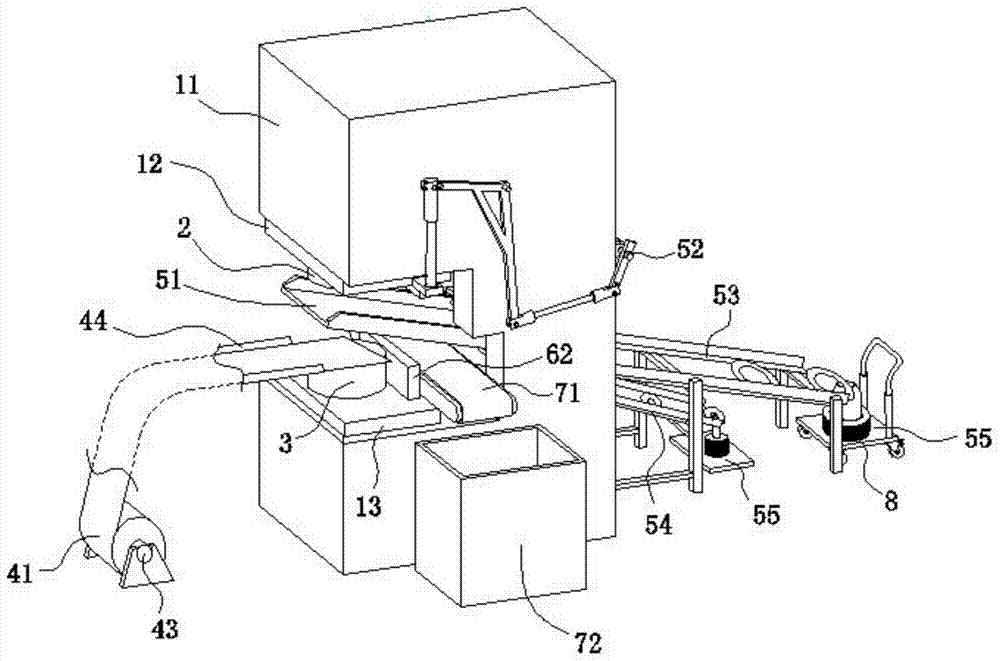

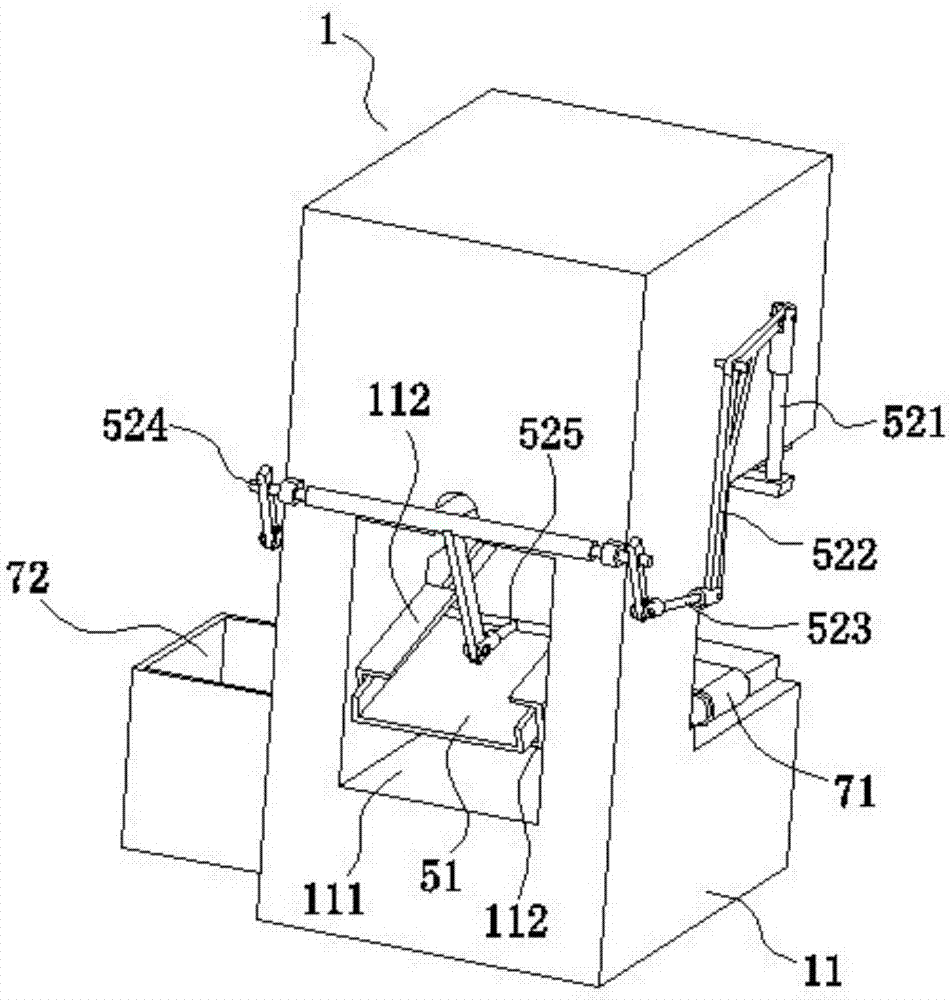

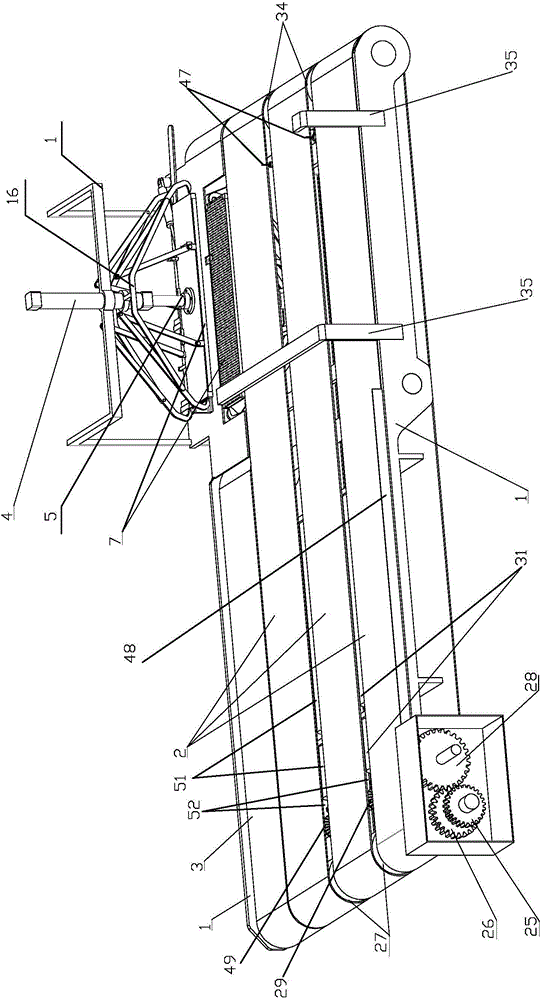

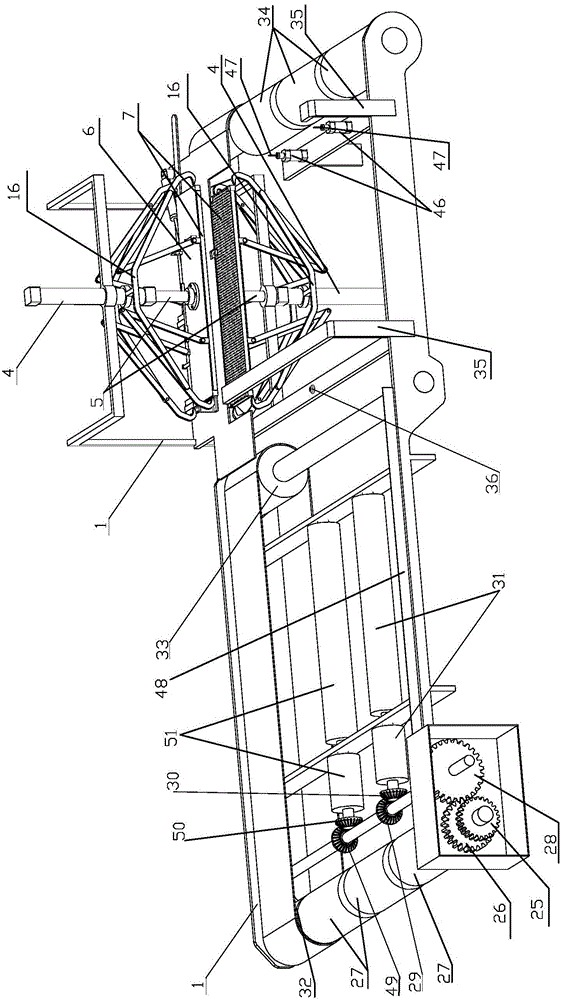

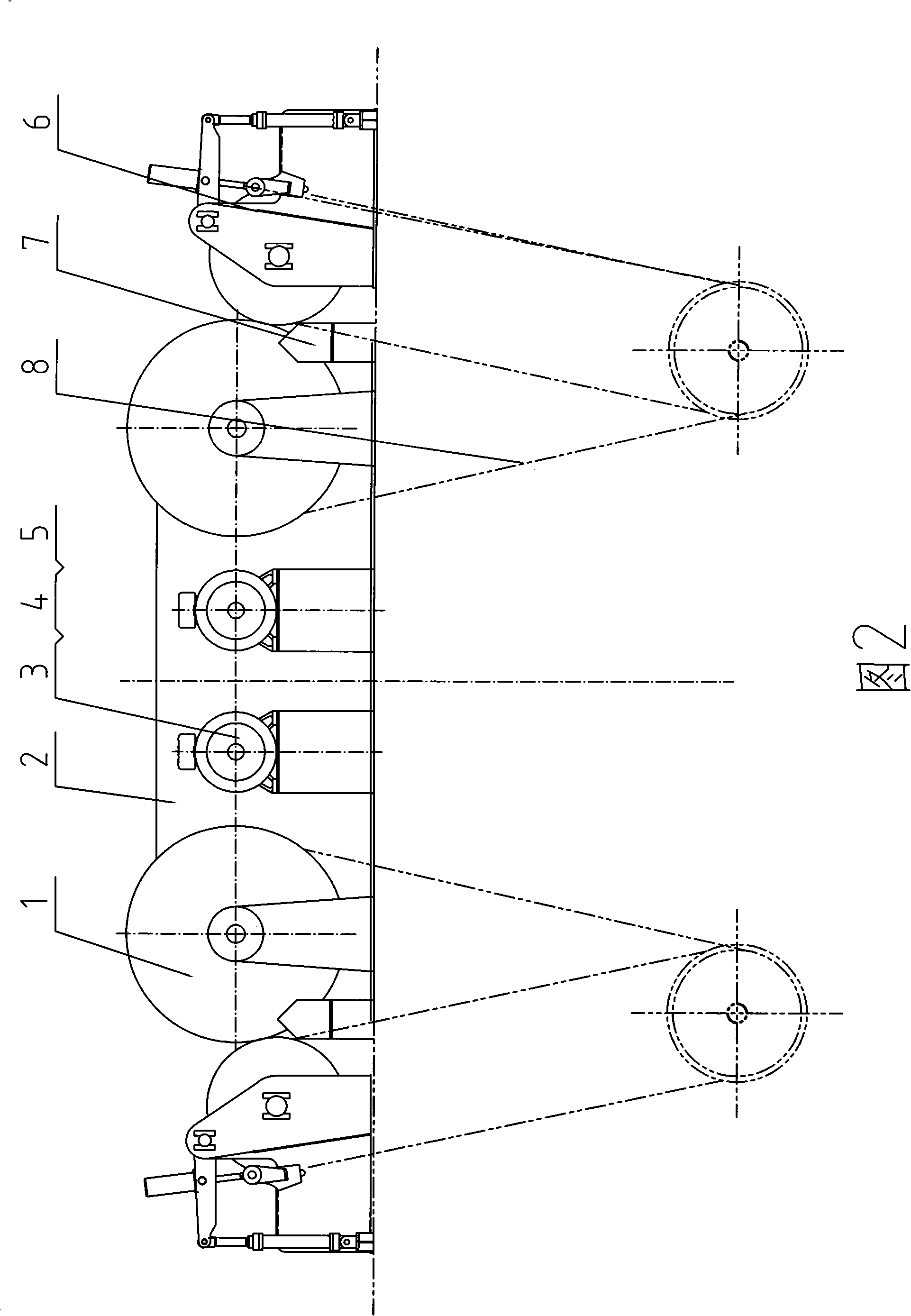

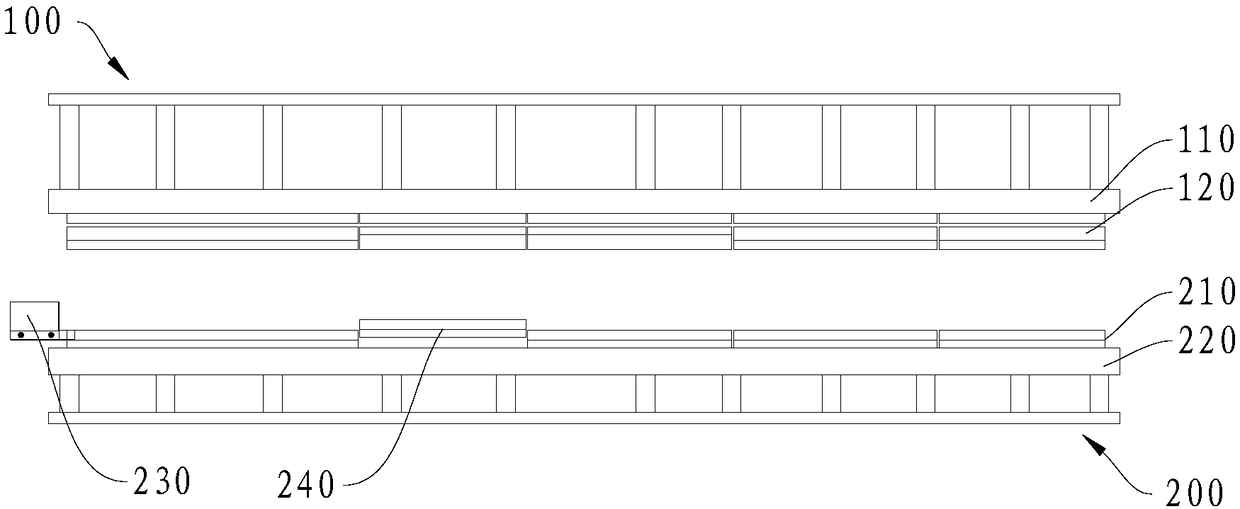

Automatic production device for stator piece and rotor piece

ActiveCN106890882AAutomate operationsLabor savingMetal-working feeding devicesManufacturing stator/rotor bodiesStatorContinuous production

The invention discloses an automatic production device for a stator piece and a rotor piece. The automatic production device comprises a punch, a control system, an upper mould, a lower mould, an air suction device, a feeding device, a finished product receiving device, waste material cutters and a waste material receiving device. The punch is provided with a punch frame, an upper mould seat and a lower mould seat. The upper mould and the lower mould are mounted on the upper mould seat and the lower mould seat correspondingly. The air suction device is connected with the upper mould. The feeding device is arranged in front of the punch and provided with a material coil and a coil conveying mechanism. The punch frame is provided with a material collecting cavity. Sliding rails are arranged in the material collecting cavity. The finished product receiving device is provided with a material channel and a movable arm. The material channel is slidably connected with the sliding rails. One end of the movable arm is connected with the material channel, and the other end of the movable arm is connected with the upper mould seat. The waste material cutters comprise the upper cutter and the lower cutter. The waste material receiving device is provided with a conveying belt. The control system is electrically connected with the air suction device, the coil conveying mechanism, a driving unit and the waste receiving device. Manpower is reduced, the cost is lowered, efficiency is improved, and the requirement for continuous mass production is met.

Owner:苏州市华能发电机有限公司

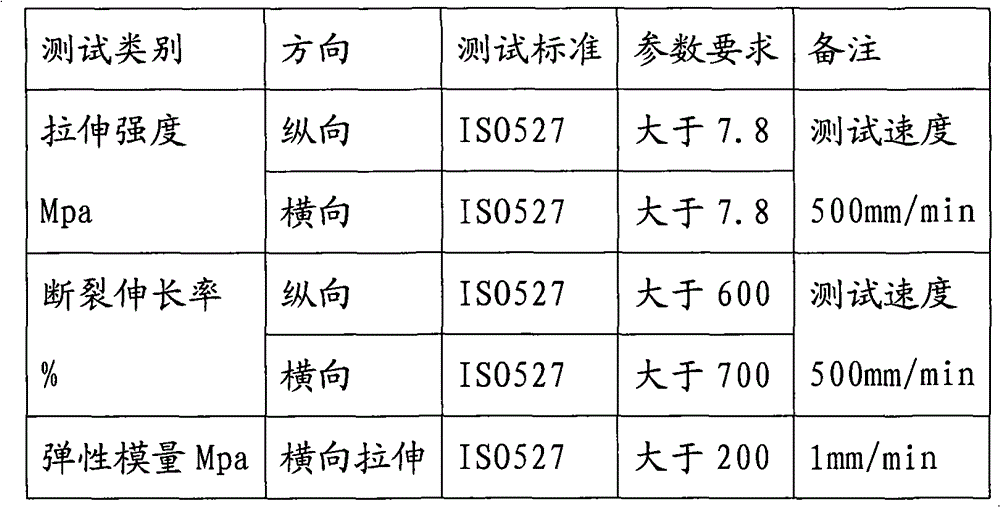

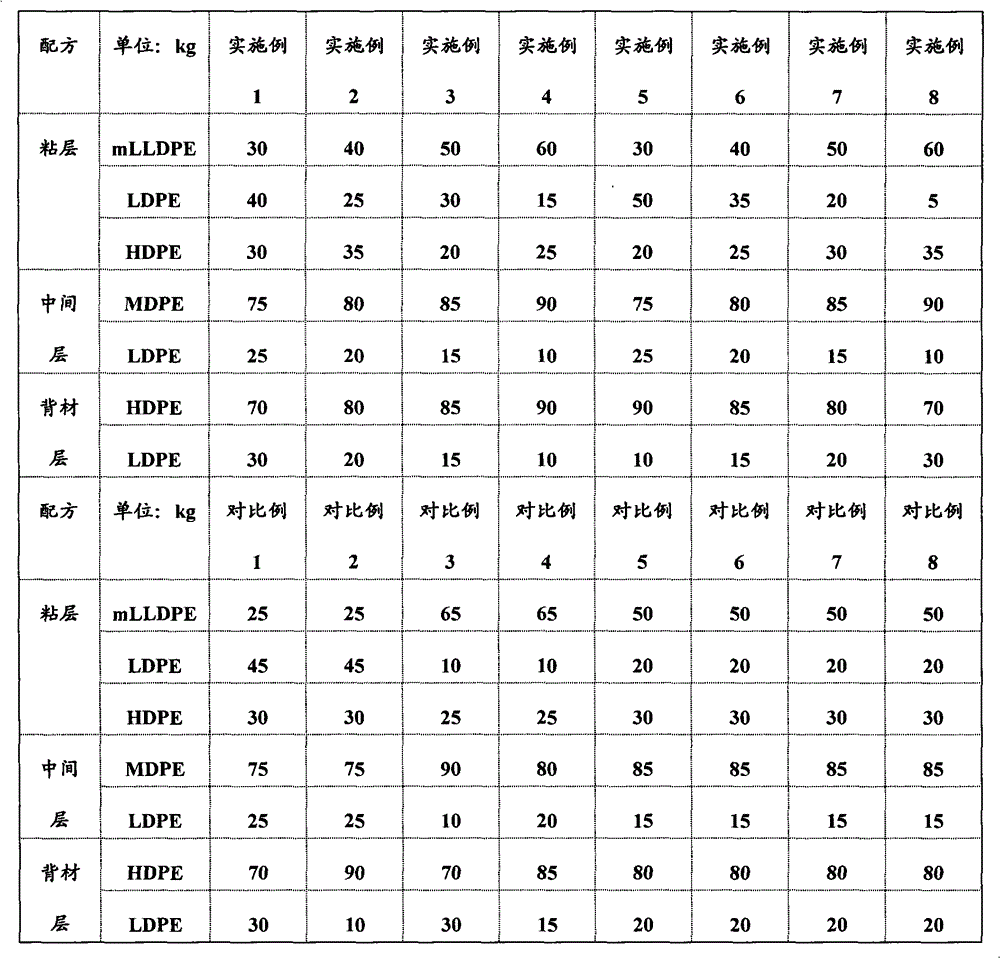

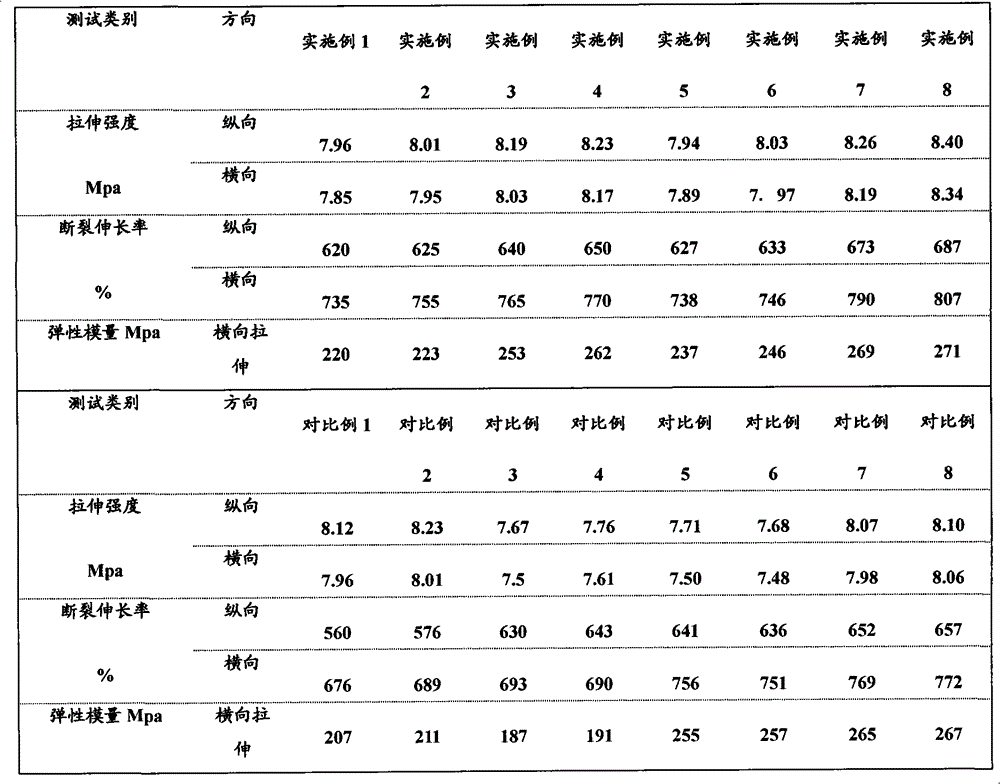

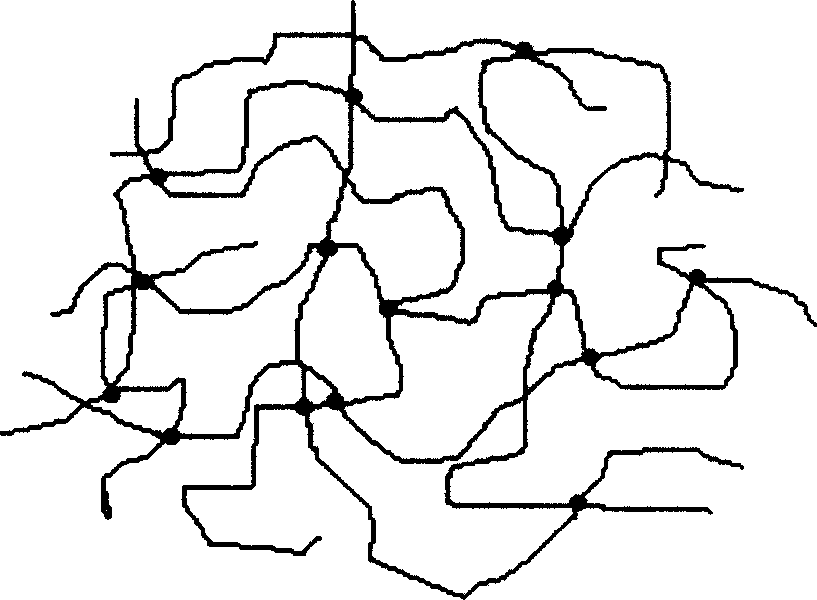

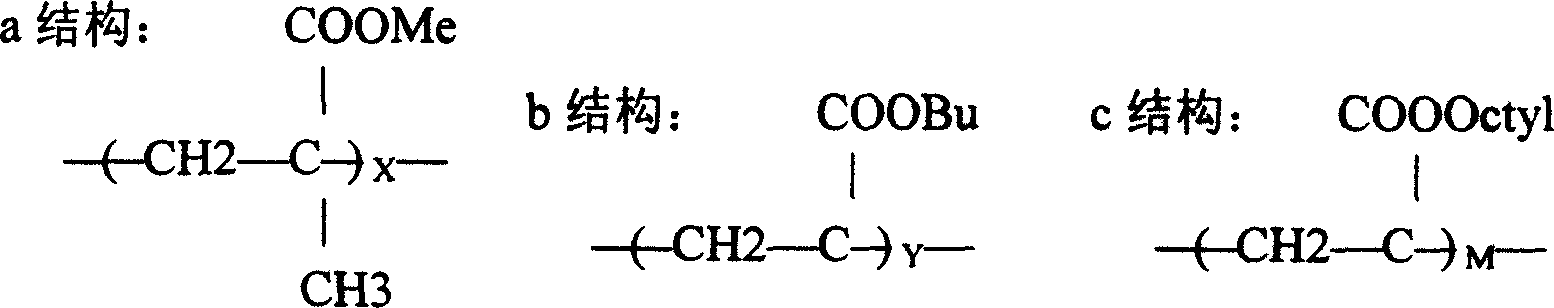

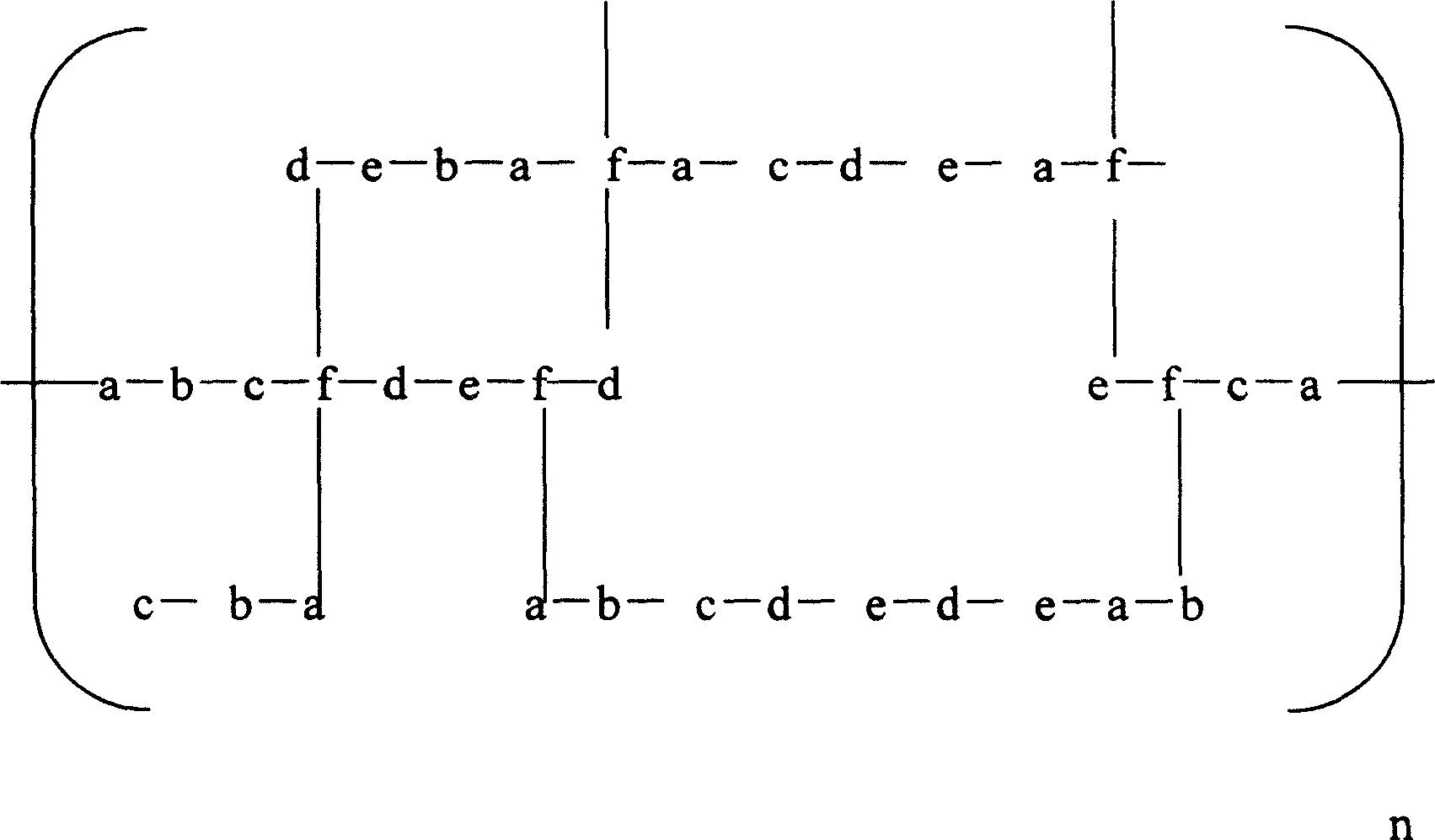

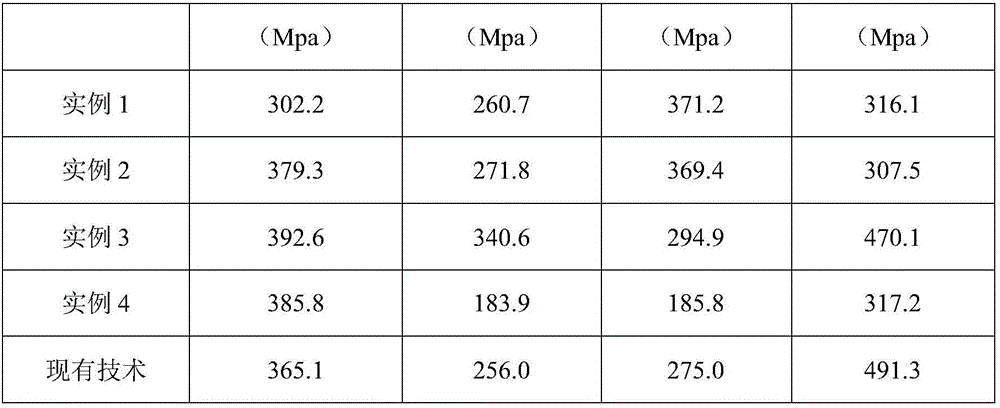

High-stiffness high-strength heat-sealing embossed film and preparation method thereof

ActiveCN102719200AGood processing performanceMaintain extrusion stabilityFlexible coversWrappersElastic modulusHigh stiffness

Owner:佛山新长盛塑料薄膜有限公司

Baking-free no-methanal coating dyeing nano adhesive water-based latex

This invention includes a kind of face baking-free formaldehyde coating dying nanometer adhesive water latex, the adhesive borns from the following steps. The pre-crosslinking monomer, soft monomer, hydrophilic monomer, anion and the non-ion types emulsify complex emulsifying agent and initiator. It is to get together the precrosslinking monomer, soft monomer, hard monomer, water hydrophile monomer , and get close to water get the hybrid body and initiator aqueous solution to join to emulsify to respond, moderate in the distilled waters, filter to make. This latex not only make in simple method, but also print to dye to process the application in the textile product, needing below 100 deg.C to dry but did not need to be baked, the hand feeling is soft, the degree of the wet or dry friction meets the request.

Owner:DONGHUA UNIV

Cement bag opening and folding device of cement bag folding machine

ActiveCN104553068ASimple structureOvercome the weak point of weak pneumatic adsorptionBox making operationsPaper-makingEngineeringMechanical engineering

The invention discloses a cement bag opening and folding device of a cement bag folding machine. The cement bag folding machine comprises a frame. The cement bag opening and folding device is mounted on the frame. The cement bag opening and folding device comprises an upper opening unit, a lower opening unit and a folding unit. The cement bag opening and folding device of the cement bag folding machine is simple in structure, light, quick and capable of overcoming the deficiency of infirm pneumatic suction due to air leakage of unsealed cement bags and meeting the requirements of continuous automatic production.

Owner:ZHEJIANG SCI-TECH UNIV

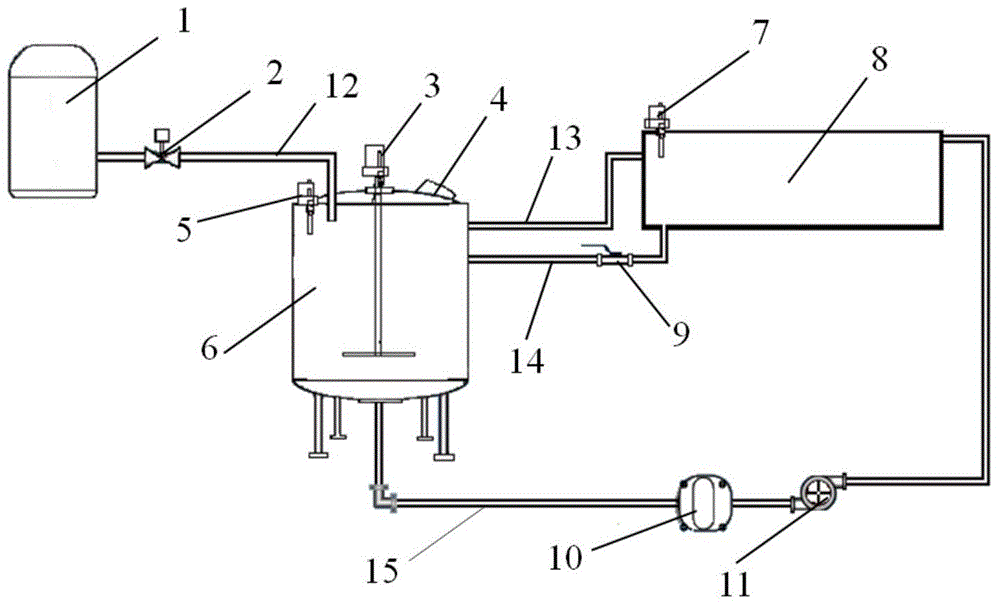

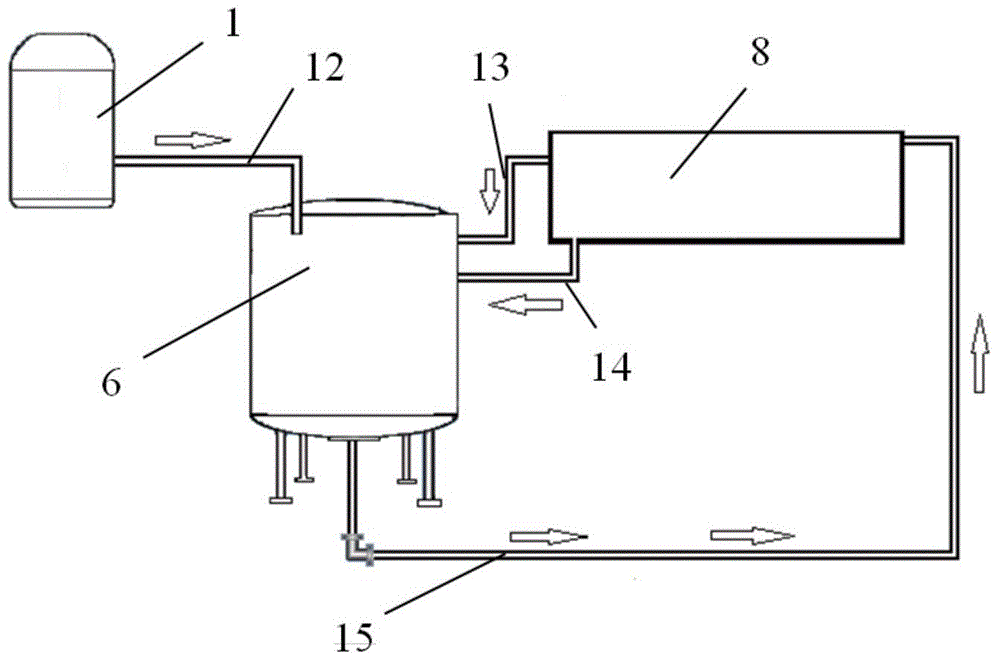

Glue liquid circulation system used for honeycomb glue coating process

InactiveCN104907230ALess cleaning workEnsure safetyLiquid surface applicatorsPaper/cardboard articlesDiaphragm pumpAutomatic control

The present invention relates to a glue liquid circulation system used for a honeycomb glue coating process, the glue fluid circulation system is characterized by including a glue coating tank, a stirring bucket, a solvent bucket, a viscosity sensor, a pneumatic stirring paddle, a pneumatic diaphragm pump, liquid level sensors and a viscosity sensor. The stirring bucket is provided with the pneumatic stirring paddle, a raw glue injection port and the liquid level sensor, a solvent valve is mounted on a pipeline between the stirring bucket and a solvent bucket, the glue coating tank is provided with the liquid level sensor, a glue supplementing pipeline, a circulation pipeline and a residue glue collection pipeline are in connection with the glue coating tank and the stirring bucket, the glue supplementing pipeline is provided with the viscosity sensor and the pneumatic diaphragm pump, and the residue glue collection pipeline is provided with a ball valve. The glue liquid circulation system can implement automatic control of glue liquid viscosity and homogeneity in the honeycomb glue coating process, is high in efficiency, easy to operate, and low in device cost, and can meet the glue strip stability in the glue coating production process.

Owner:AVIC COMPOSITES

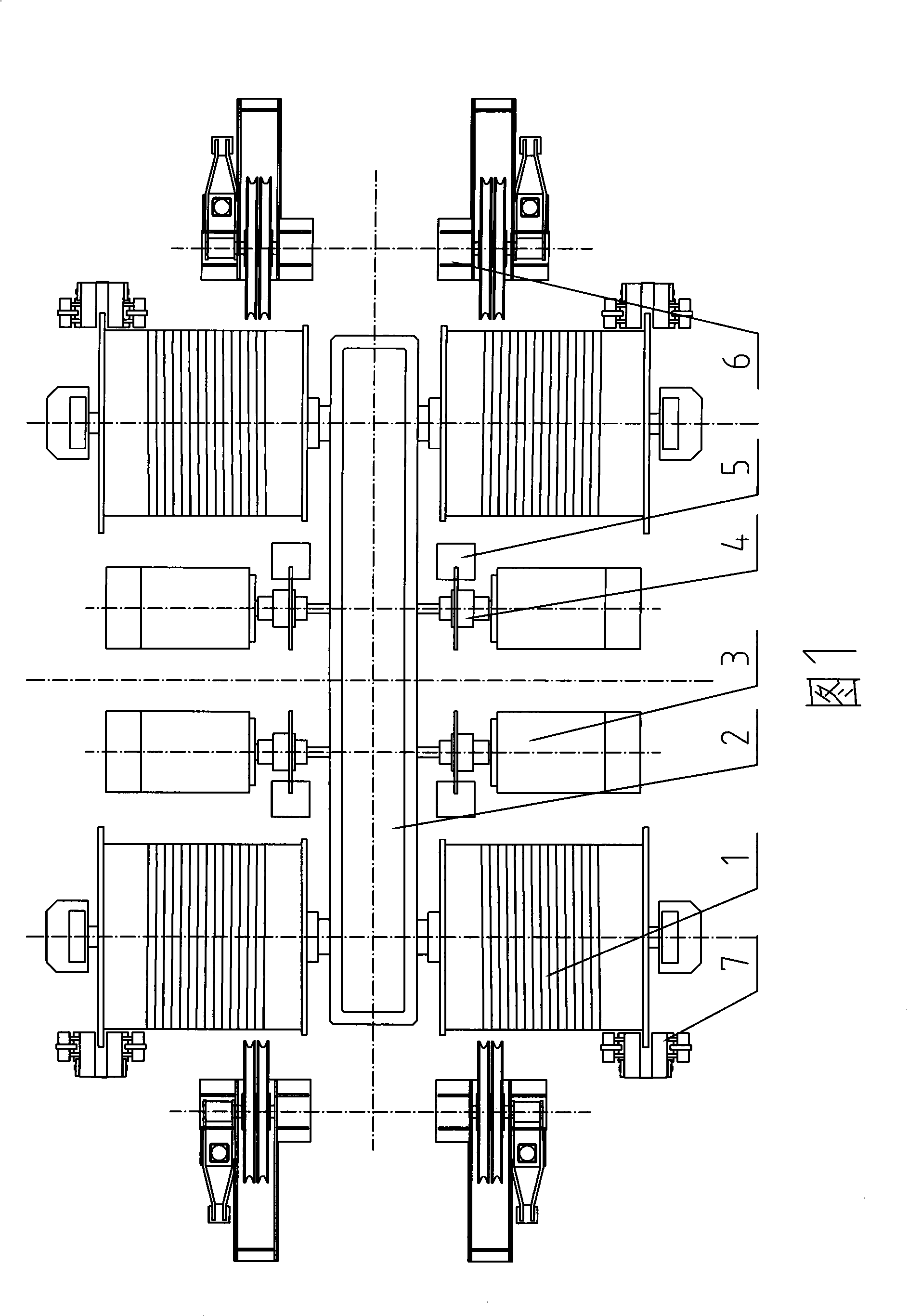

Hoisting mechanism of crane for coke pot

InactiveCN101343024AImprove reliabilityImprove securityCoke quenchingWinding mechanismsCouplingDistributed structure

The invention provides a lifting mechanism of a coke tank carrying crane, which relates to the lifting transportation and coking machinery; the lifting mechanism is composed of a winding drum group, a planetary reducer, a motor, couplings, brakes, a crown block group and a safety brake; the planetary reducer mounted on the pulley frame is provided with four input shaft ends and four output shaft ends which are symmetrically distributed. The four input shafts are arranged on the middle part of the planetary reducer and connected with the motor respectively through the couplings; the brakes are respectively mounted on the couplings; the four output shafts are arranged on both sides of the end part of the planetary reducer and connected with the single linkage winding drum group respectively; the safety brake directly acts on the winding drum edge of the single linkage winding drum group; the crown block group is mounted on the opposite side of the single linkage winding drum group. The lifting mechanism of the coke tank carrying crane has the advantages of novel structure, safety, reliability, great bearing capacity, symmetrically-distributed structure, even stress and being the lifting mechanism device of the novel coke tank carrying crane with economical and practical properties.

Owner:DALIAN HUARUI CO LTD

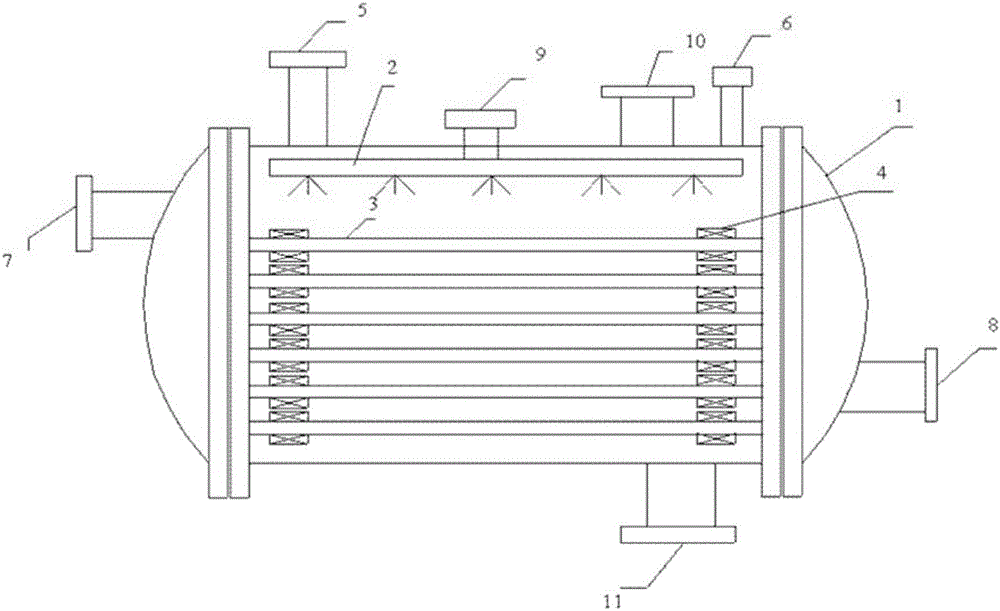

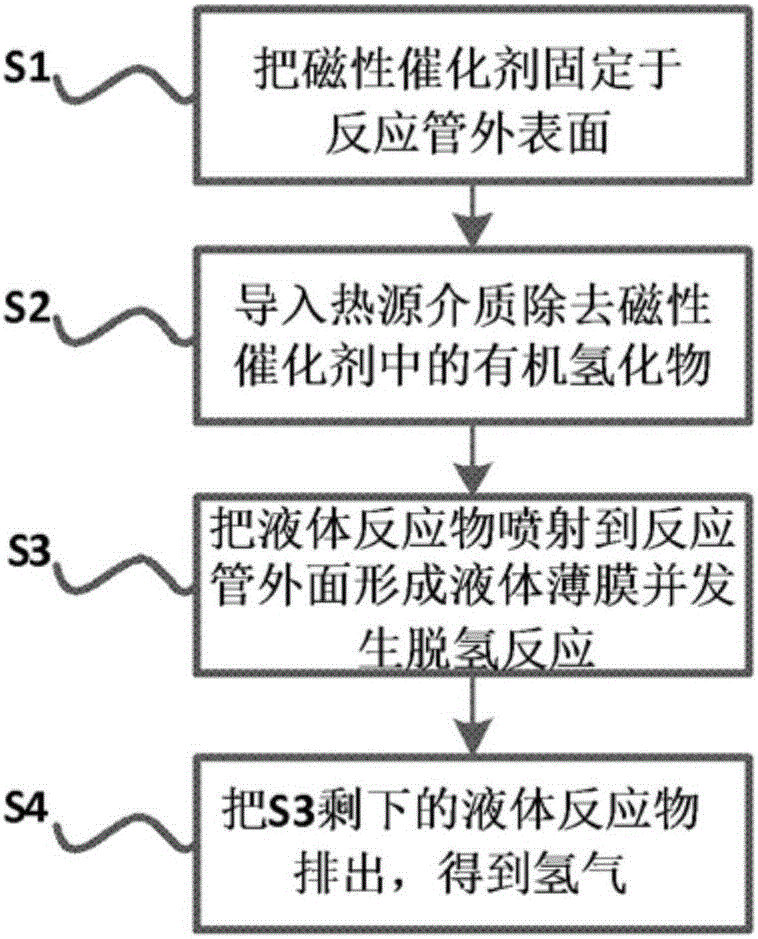

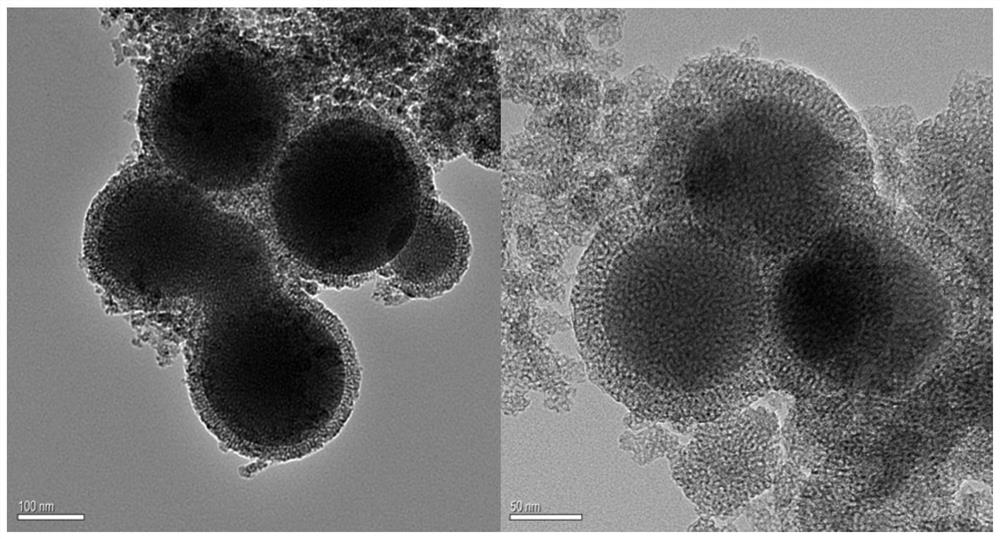

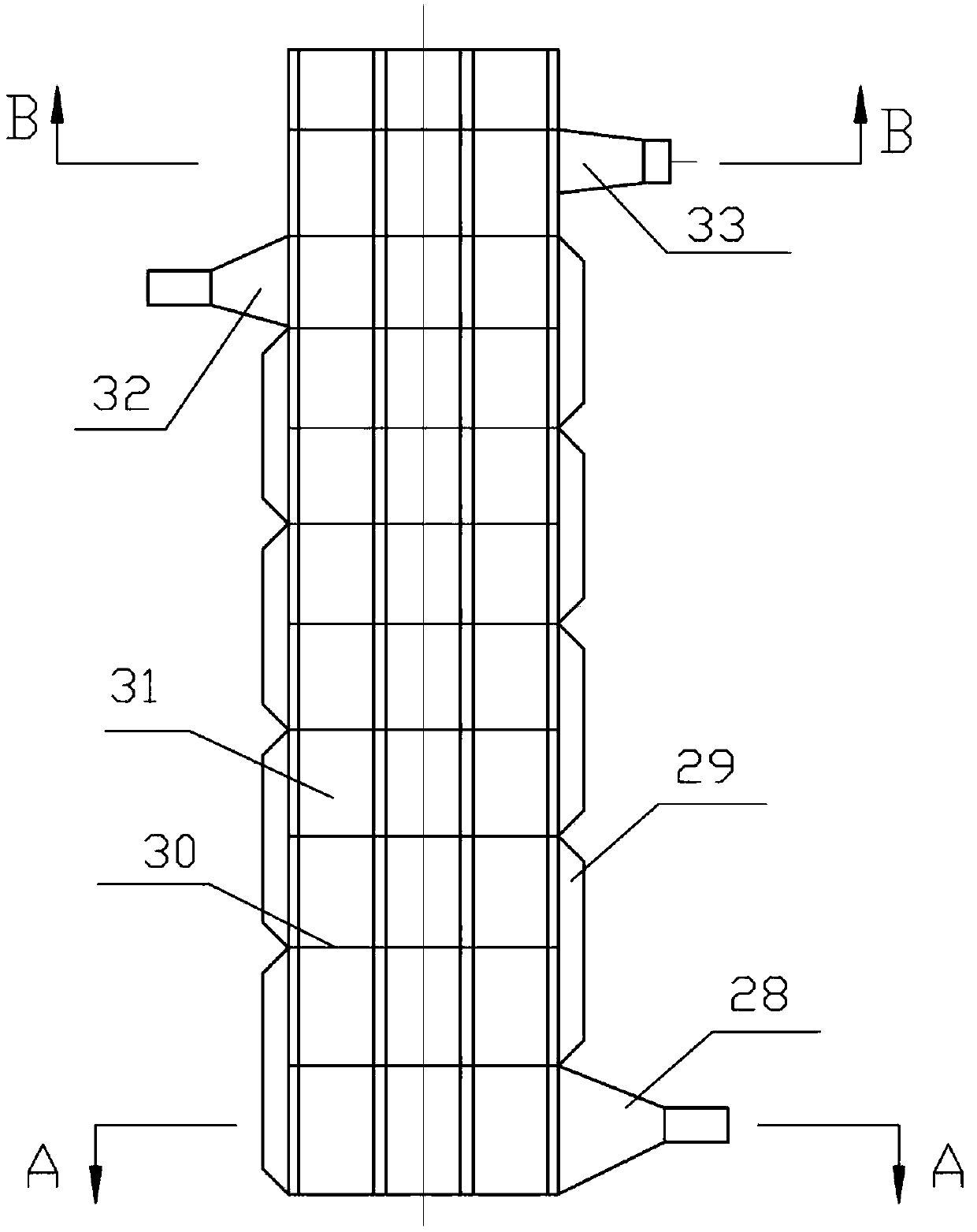

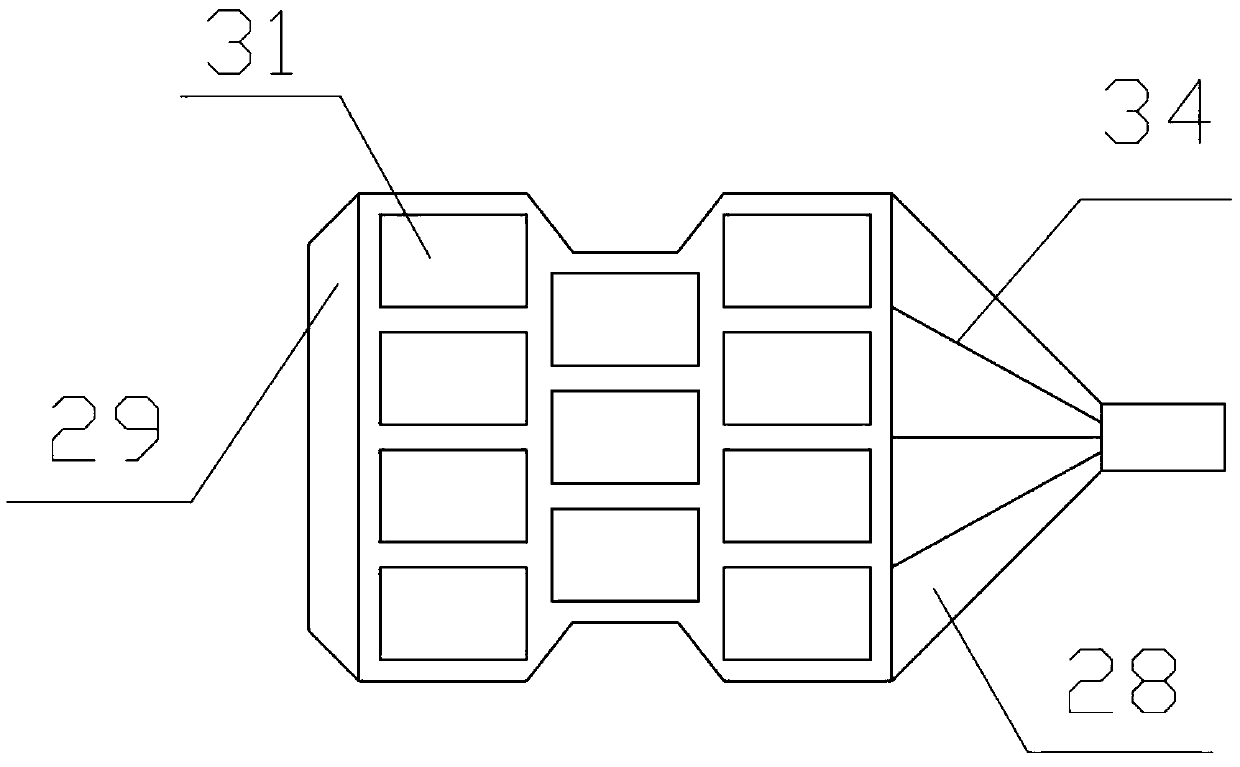

Device for dehydrogenating liquid organic hydride

ActiveCN106698339AImprove overall heat transfer coefficientImprove utilization efficiencyHydrogenHydrogen/synthetic gas productionReaction tubeContinuous production

The invention discloses a device for dehydrogenating liquid organic hydride. The device is composed of a shell, a liquid distributor, reaction tubes, electromagnetic coils, and a fluid inlet / outlet adapter tube; the reaction tubes are evenly arranged in the device, a thermal medium flowing in each tube provides heat for reaction; the electromagnetic coil is an electrified coil wound on two ends of each reaction tube according to a certain direction, each reaction tube can be magnetized after the electronic coil is electrified; a catalyst is adsorbed to the outer side of the tube, and an organic hydride thin liquid film is formed to generate the dehydrogenation reaction. Compared with the prior art, the device disclosed by the invention has the following advantages that the filling and replacing of the catalyst are extremely simple and convenient by performing power on / power off operation on the electromagnetic coils, and the continuous production requirement can be satisfied.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

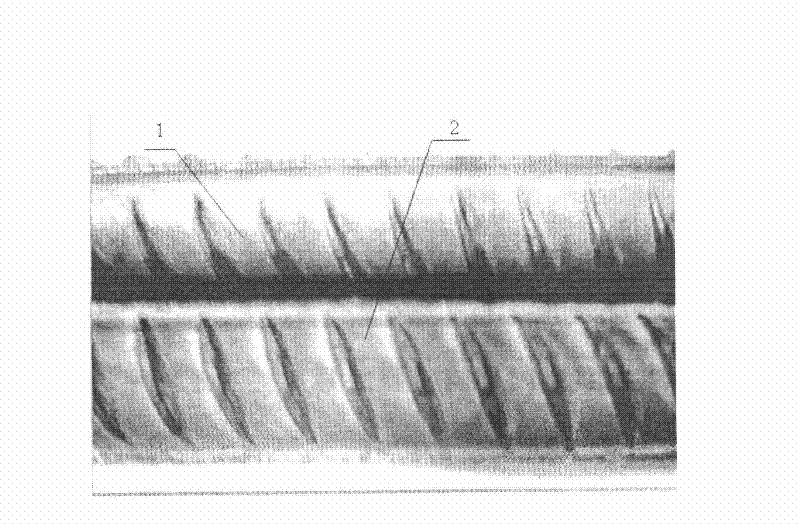

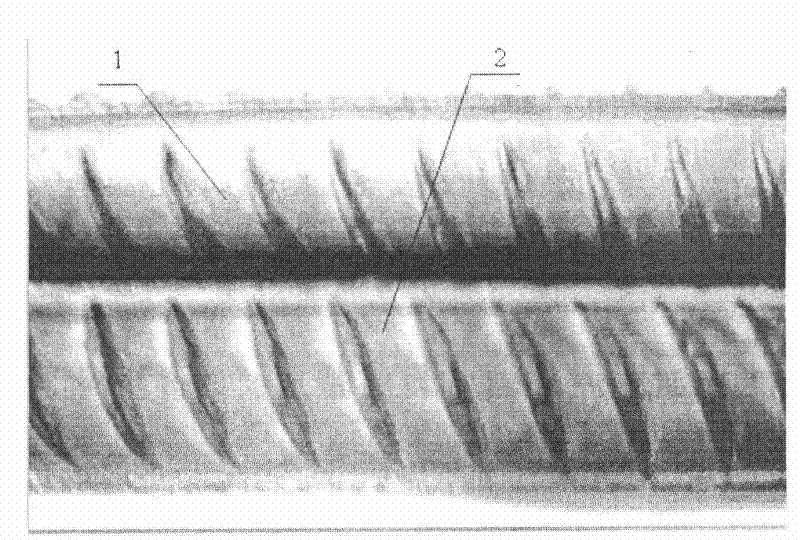

On-line rust-proof method for twisted steel

InactiveCN102392210AHigh surface glossMeet the requirements of continuous productionSolid state diffusion coatingWater vaporOxygen

The invention discloses an on-line rust-proof method for twisted steel. The method comprises the following step: ejecting steam or mixture of steam and oxygen to the twisted steel subjected to waste heat processing so as to generate a protective layer on the surface of the twisted steel. According to the on-line rust-proof method for twisted steel, the twisted steel with good surface gloss can be obtained. In addition, the method can satisfy the continuous production requirement of the twisted steel, and the production cost can not be obviously increased.

Owner:LAIWU IRON & STEEL GRP

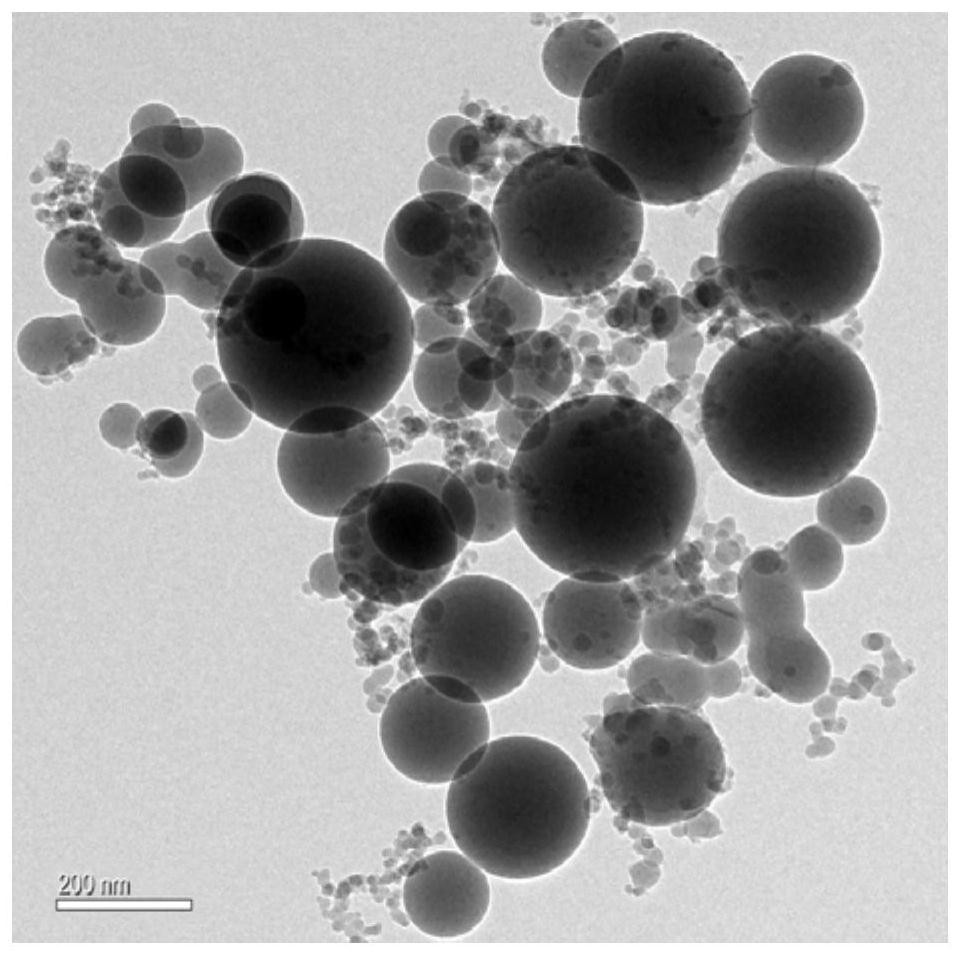

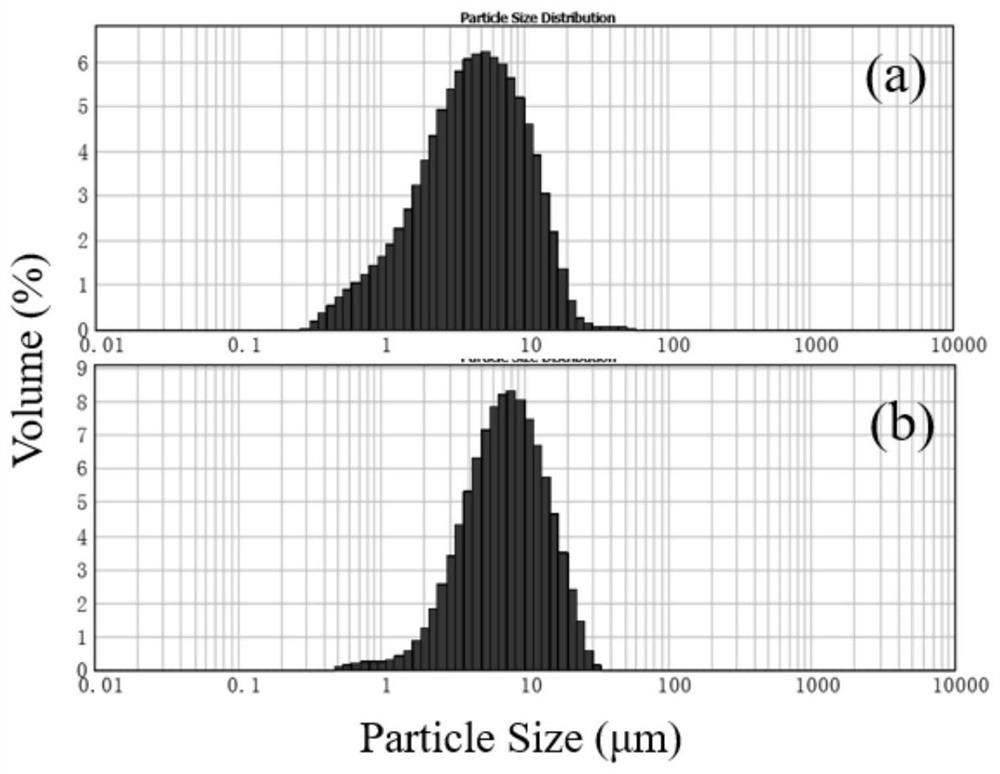

Microwave composite dielectric substrate for high-frequency and high-speed environment and preparation method of dielectric substrate

ActiveCN112940416ALow dielectric constantSmall coefficient of thermal expansionSynthetic resin layered productsLaminationThermal dilatationSilicic acid

The invention relates to a microwave composite dielectric substrate for a high-frequency and high-speed environment and a preparation method of the microwave composite dielectric substrate, and belongs to the field of microwave dielectrics. Silicon dioxide ceramic powder with a porous structure is constructed by using the nano solid silicon dioxide ceramic powder and tetraethyl orthosilicate through a hydrothermal method, compared with mesoporous silicon dioxide generated by directly using tetraethyl orthosilicate as a single silicon source, the yield is higher, the reaction conditions are relatively simple, and batch production is hopeful; porous silicon dioxide ceramic nanospheres are modified by a coupling agent and then are mixed with polytetrafluoroethylene, and the modified silicon dioxide ceramic nanospheres are uniformly mixed with a polymer matrix through calendaring molding and a vacuum hot pressing method, so that the plate is compact and has high dielectric properties and mechanical strength; and the prepared microwave composite dielectric substrate is low in dielectric constant and low in thermal expansion coefficient.

Owner:WUHAN UNIV OF TECH

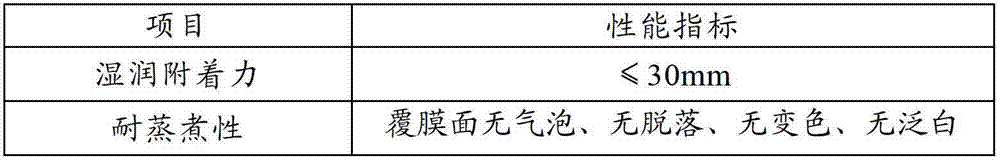

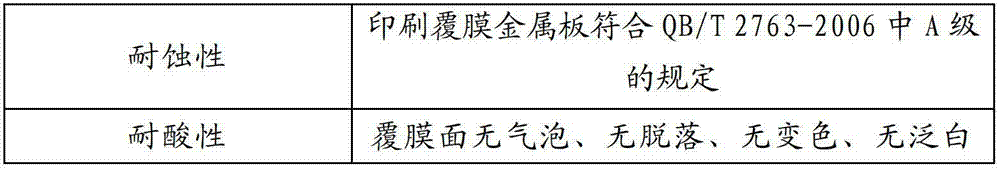

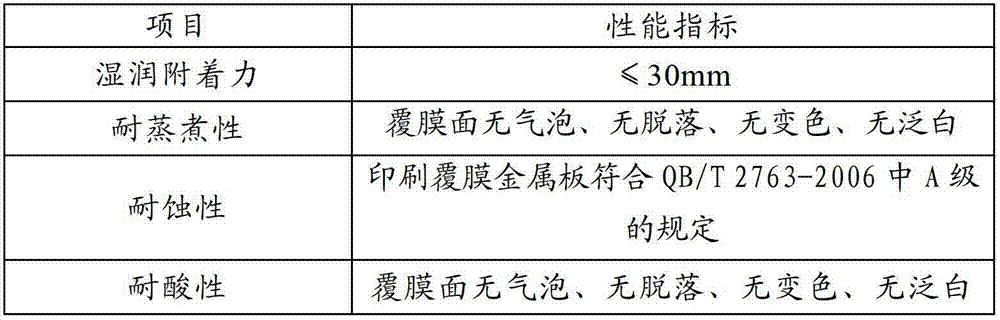

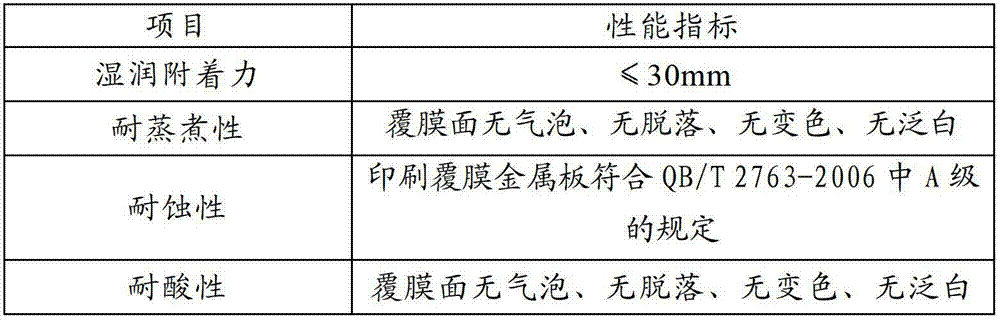

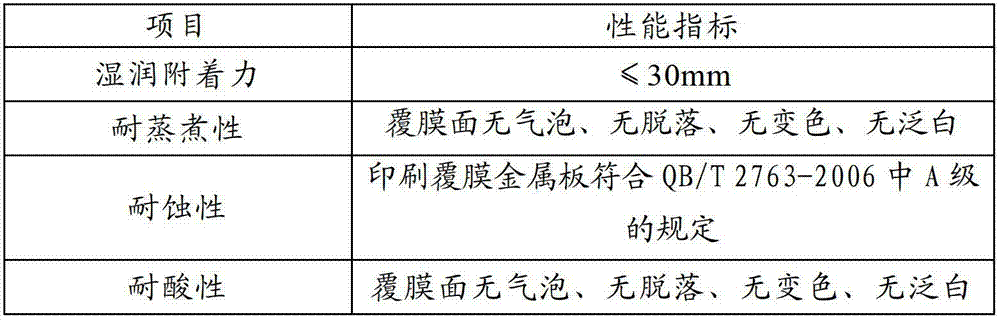

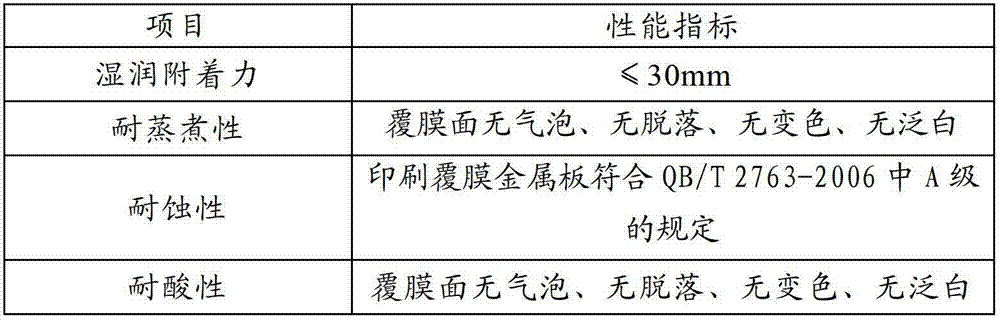

Printing film-laminated metal plate and production method thereof

ActiveCN102825863AImprove safety qualitySimple processing technologyLaminationLamination apparatusPolyesterMetal substrate

The invention provides a printing film-laminated metal plate and a production method thereof. The printing film-laminated metal plate comprises a metal substrate, a printing composite film and an inner film, wherein the metal substrate is positioned between the printing composite film and the inner film so as to form no-adhesive attachment; the printing composite film is formed by dry composition between an intaglio-printing film and a polyester film modified by isophthalic acid; one side of the intaglio-printing film with printing patterns is attached with the acid-modified polyester film, and one side of the intaglio-printing film attached with the metal substrate is the acid-modified polyester film; and the inner film is made of no-printing-pattern film or intaglio-printing film, and one side of the intaglio-printing film with the printing patterns is attached with the metal substrate. The invention also provides the production method of the printing film-laminated metal plate. The printing film-laminated metal plate provided by the invention has the advantages that the printed patterns are sealed between the film and the metal substrate, so that the safety of the printing film-laminated metal plate is obviously improved and the processing process is simplified.

Owner:ORG TECH CO LTD

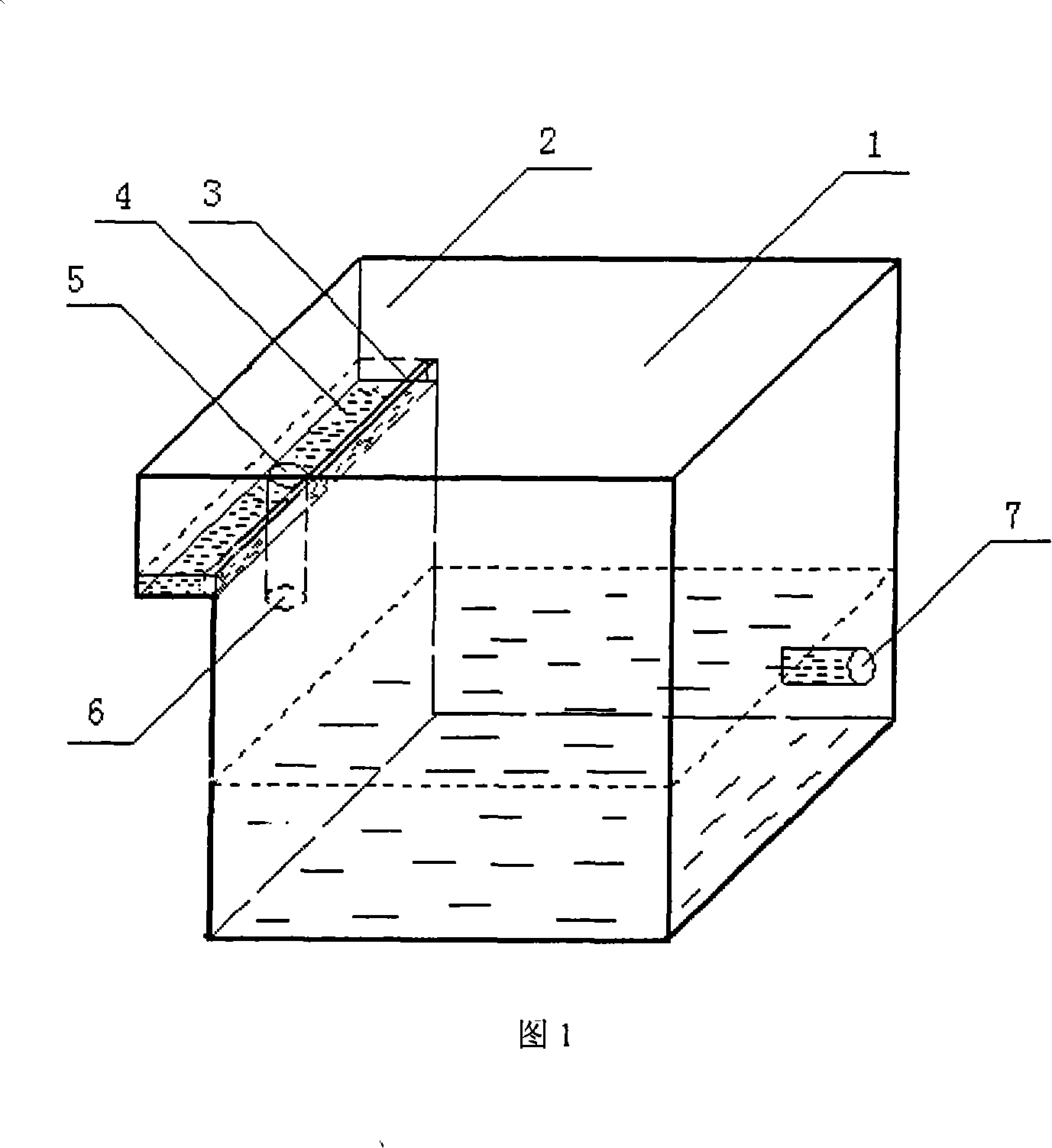

Photographic emulsion supplying device

InactiveCN101131541AEliminate a bubblePrevent secondary bubblesPhotomechanical coating apparatusCold cathode manufactureEngineeringBottle

This invention discloses a sort defoamer feedway which prevents the production of the air bubble in the supplied course of the sensitive liquid and advances the quality of the gelatinize availably, it aims at this problem that the supplied gelatinize of the tapered bottle has the entrapped air bubble in the production of the printing gelatinize of the exiting color kinescope manufacturing. It consists of the inlet and the outlet of the sensitive liquid, the outlet of the sensitive liquid in this invention is fitted in the leaning underside of a side of a rectangle box, the upside of another side of this rectangle box has a prominent flat roof, and it has a clapboard that it makes the clapboard to be beleaguered a flooding launder, this bottom of the flooding launder connects with the inlet of the sensitive gelatinize. This invention has the defoamer function, and ensures the stabilization of the sensitive liquid level and the constant of the latex flux. It satisfies not only the request of the continuous production, but also ensures the quality of the printing gelatinizes.

Owner:CAIHONG GRP ELECTRONICS CO LTD

Method for preparing corundum microporous aerator pipe

InactiveCN101885604AIncreased aeration densityReduce energy consumptionTreatment using aerobic processesSustainable biological treatmentCross-linkAdhesive

The invention belongs to the field of environmental protection and discloses a method for preparing a corundum microporous aerator pipe. The corundum microporous aerator pipe is prepared by mixing, curing, extruding, airing and solidifying and sintering corundum powder, kaolin, a pore-forming agent, an adhesive, a cross-linking agent and water which are used as raw materials sequentially, wherein the cross-linking agent is N-hydroxymethyl acrylamide and the using amount of the cross-linking agent is 10 to 20 percent of the mass of the adhesive. The corundum microporous aerator pipe prepared by the method has the advantages of high aeration density and oxygenation efficiency, high strength, long service life and length of more than 1 meter.

Owner:JIANGSU YIYANG WATER IND

Printing coated metal plate and production method thereof

ActiveCN102825862AImprove barrier propertiesAvoid moving outLaminationLamination apparatusAdhesiveEngineering

The invention provides a printing coated metal plate and a production method thereof. The printing coated metal plate comprises a metal substrate, an outer film and an inner film, wherein the metal substrate is positioned between the outer film and the inner film and are stuck to the outer film and the inner film without any adhesive; at least one of the outer film and the inner film is an intaglio printing film; and a printing pattern is formed on the side, stuck to the metal substrate, of the intaglio printing film. The invention also provides a production method of the printing coated metal plate. The printing coated metal plate is produced by the process that coating is performed after printing, and the printing pattern is sealed between the thin film and the metal substrate, so that the safety quality of the printing coated metal plate is obviously improved and the machining process is simplified.

Owner:ORG TECH CO LTD

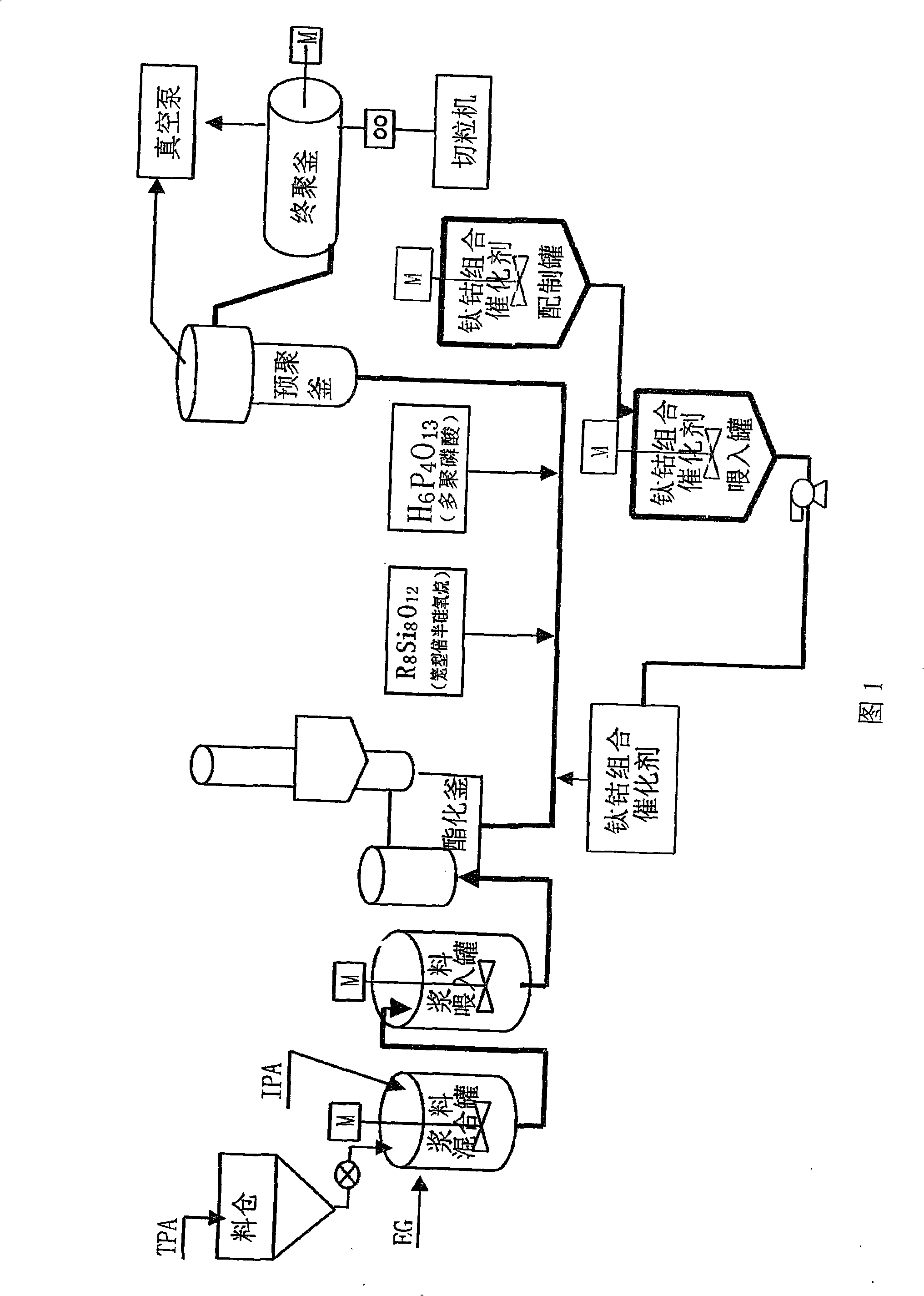

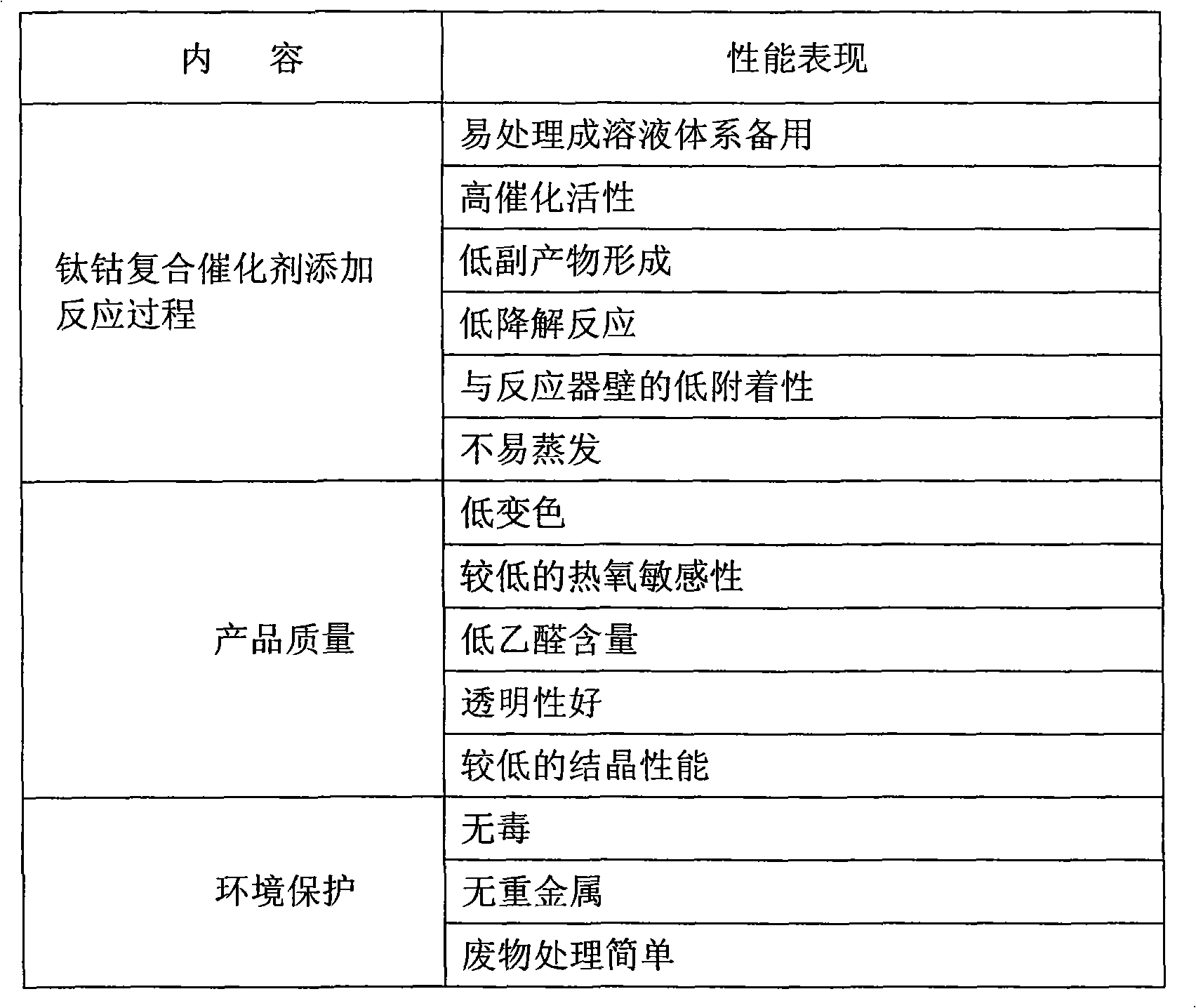

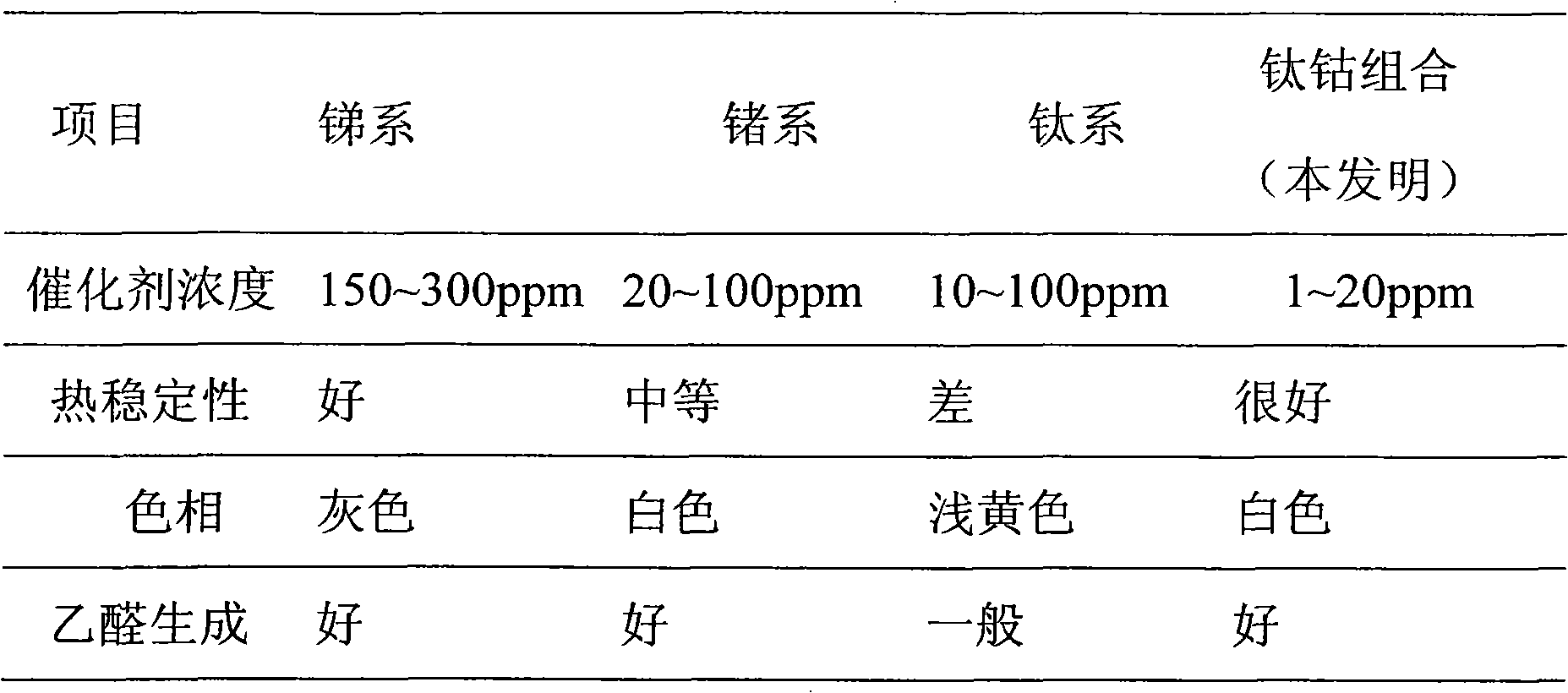

Process for producing stibium-free environment-friendly polyethylene terephthalate for bottle

The invention relates to a preparation method of polyethylene therephthalate used in an antimony-free environmentally-friendly bottle. The technical process of the technology is that: fine terephthalic acid and ethylene glycol are stirred in a slurry mixing can, are pumped into a slurry feeding can, and then enter an esterification kettle through a slurry injection nozzle to generate oligomer. Additives on siphonium line of the esterified oligomer are injected into a prepolymerization kettle through a pump and materials, after reaching the top of the prepolymerization kettle, and flow to a final polymerization kettle. The method is characterized in that the additives on a pipeline from the oligomer and into the prepolymerization kettle comprise a catalyst, a stabilizer and a dispersant, wherein, the catalyst is titanium-cobalt composite catalyst, the stabilizer is polyphosphoric acid and the dispersant is cage-type silsesquioxane; a pipe reactor is arranged on the pipeline from the oligomer and into the prepolymerization kettle, the additives are dissolved respectively in ethylene glycol to prepare a mixture liquid, the mixture liquid, after being fed into the can, is injected into the pipeline from the oligomer and into the prepolymerization kettle by using the nozzle, and enters the prepolymerization kettle after being mixed evenly in the pipe reactor. The preparation method is excellent in decentrality and low in b value.

Owner:JIANGSU XINGYE PLASTIC

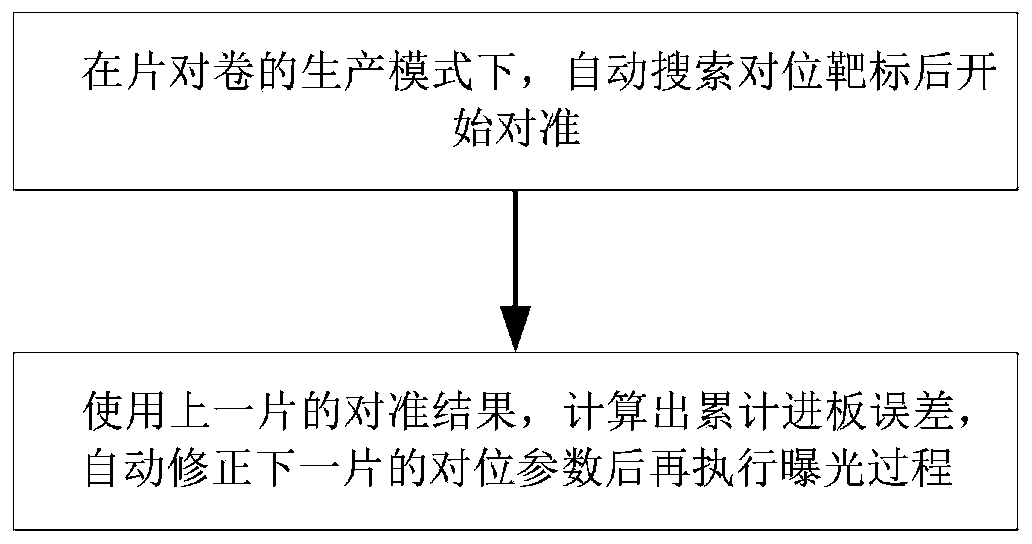

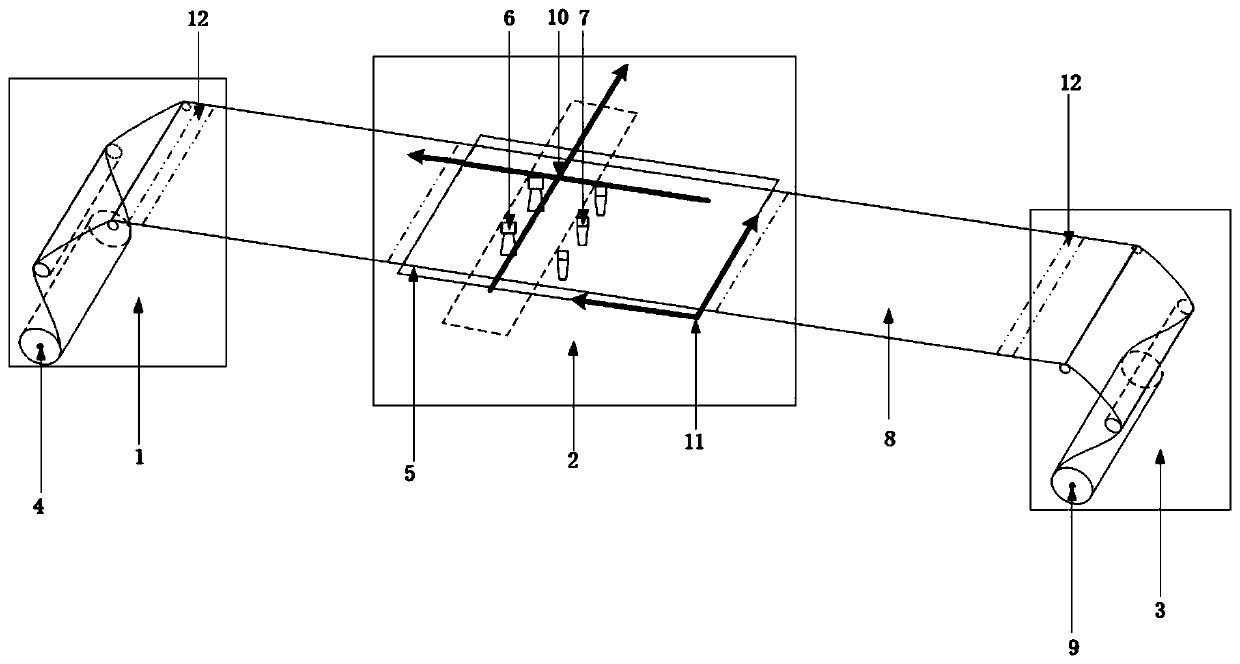

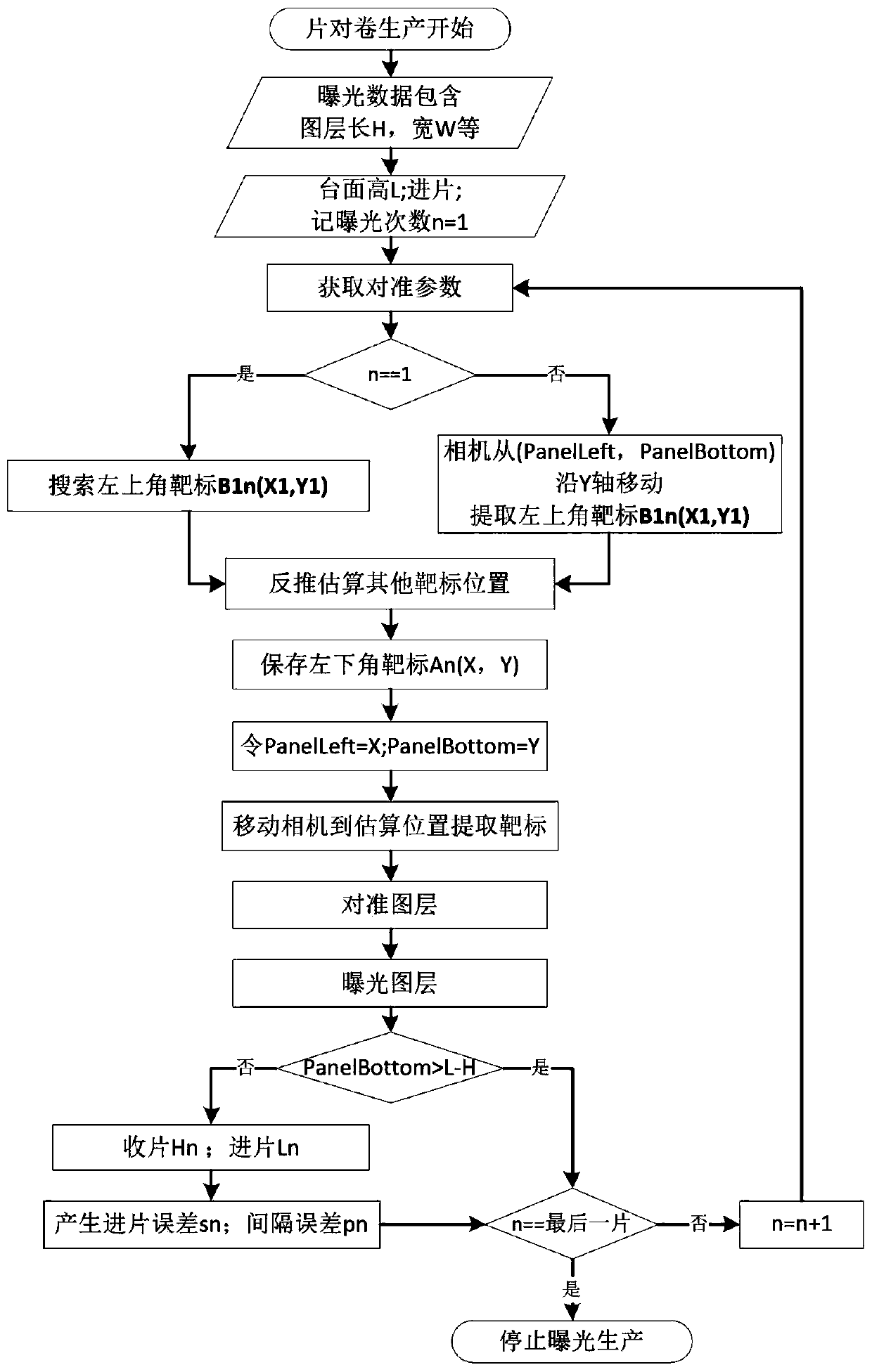

Alignment method of maskless laser direct writing lithography device during sheet-to-roll producing

ActiveCN110632826ATroubleshoot spacing errorsMeet the requirements of continuous productionPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistEngineering

The invention provides an alignment method of a maskless laser direct writing lithography device during sheet-to-roll producing. Single-sheet exposure is changed into roll-to-roll continuous exposure.The technical problems of the length error of the retracting plate and the spacing error of sheets of a winding and unwinding mechanism are overcome. A roll-to-roll maskless laser direct writing lithography device comprises the steps that in a sheet-to-roll production mode, the device automatically searches for an alignment target and starts alignment; the alignment result of the previous sheet is used to calculate the cumulative plate feeding error; and the device automatically corrects the alignment parameters of the next sheet and then performs an exposure process. According to the invention, the alignment problem of the roll-to-roll maskless laser direct writing lithography device during sheet-to-roll producing is overcome; aiming at the sheet-feed error and the sheet spacing error generated during sheet-to-roll producing, the coordinates of the target point recorded by sheet alignment are used as the positioning marks for an alignment camera, which corrects the sheet-feed error and the sheet spacing error, and saves the target searching time of the camera.

Owner:HEFEI CHIP FOUND MICROELECTRONICS EQUIP CO LTD

Method for recovering rare earth elements from waste neodymium iron boron leftover material

InactiveCN102154557AAvoid harmStop pollutionProcess efficiency improvementRare-earth elementSpontaneous combustion

The invention discloses a method for recovering rare earth elements from a waste neodymium iron boron leftover material, comprising the following steps: cutting the waste neodymium iron boron leftover material into small pieces; then, introducing the small pieces into the first cylinder ring part of an internal-heating spontaneous-combustion rotary kiln with multiple cylinder rings through a continuous feeding mode; and controlling the internal temperature, the induced air amount, the material dwell time and the like of the first cylinder ring and the rest cylinder ring positions so as to fully oxidize and roast the waste neodymium iron boron material; and leaching the preprocessed material with hydrochloric acid, comprehensively decontaminating, carrying out extraction separation, precipitating and roasting to obtain rare earth oxide. According to the method, harm and pollution on on-site operation personnel and peripheral environment by raised dust and micro powder in the original preprocessing link can be avoided, inert gas consumption is avoided, coal and electricity power consumption can be drastically reduced, labor intensity is greatly lowered, an operation period is greatly shortened, and the requirement of continuous production can be satisfied.

Owner:LIANYUNGANG ZHAOYU NEW MATERIAL IND

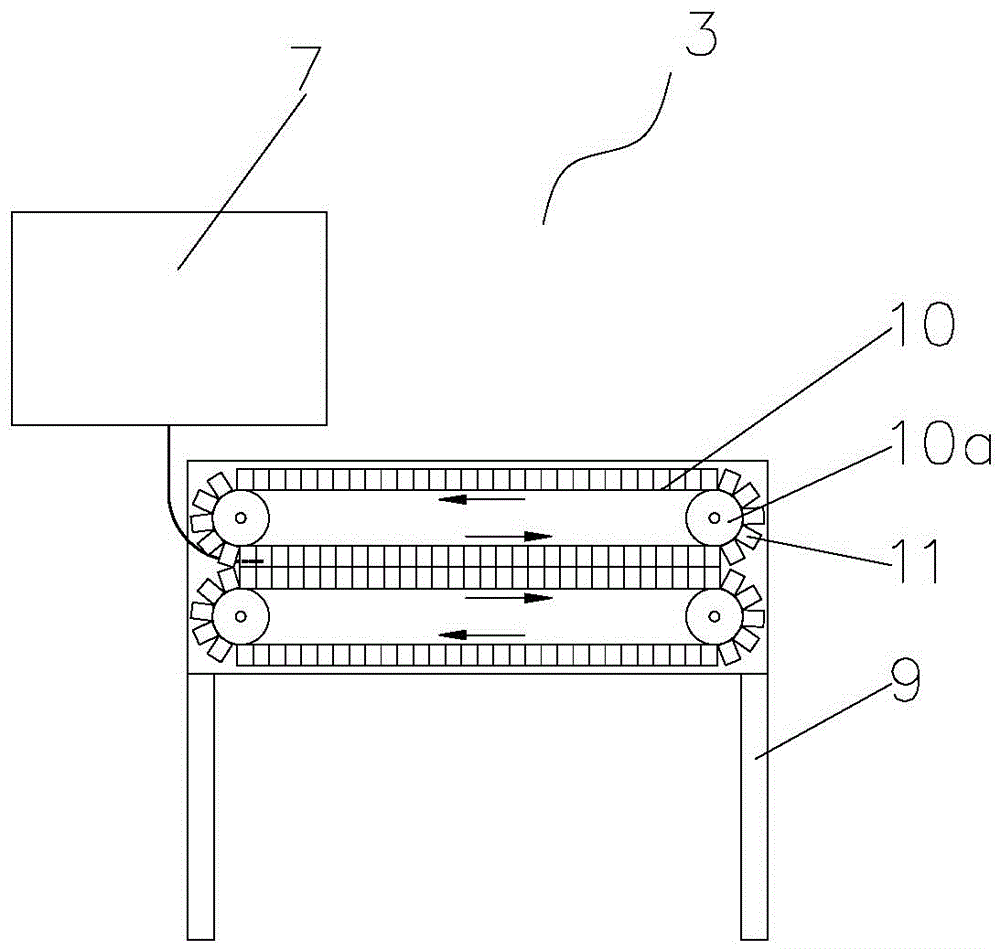

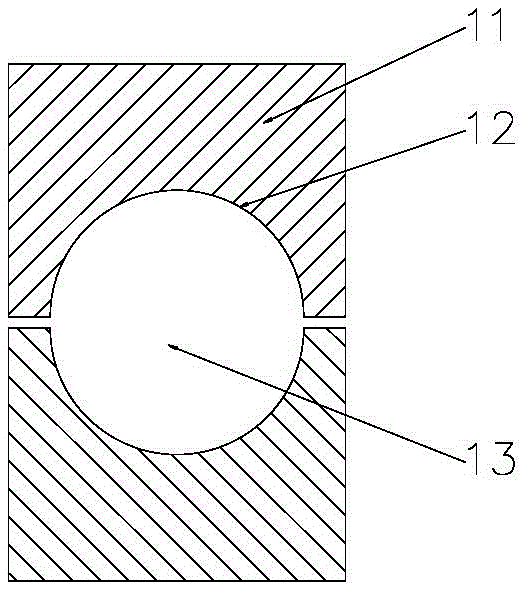

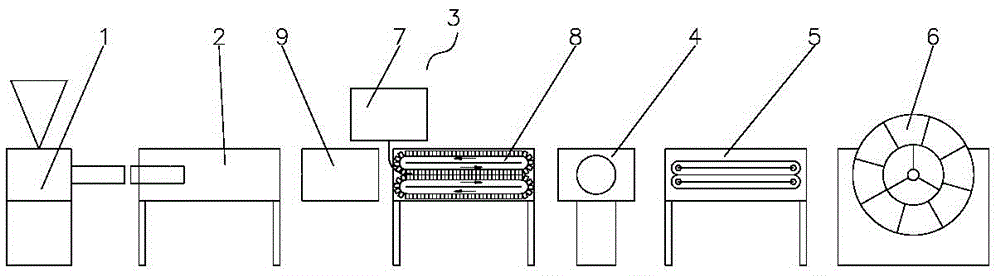

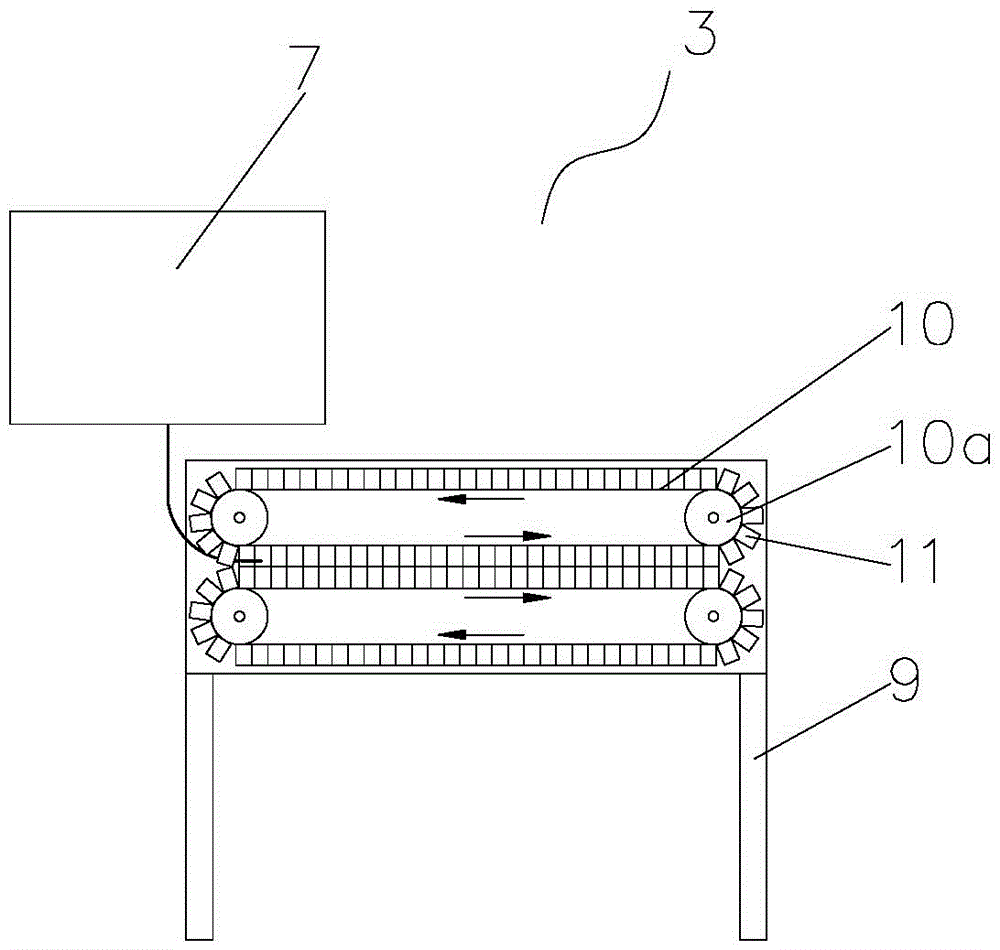

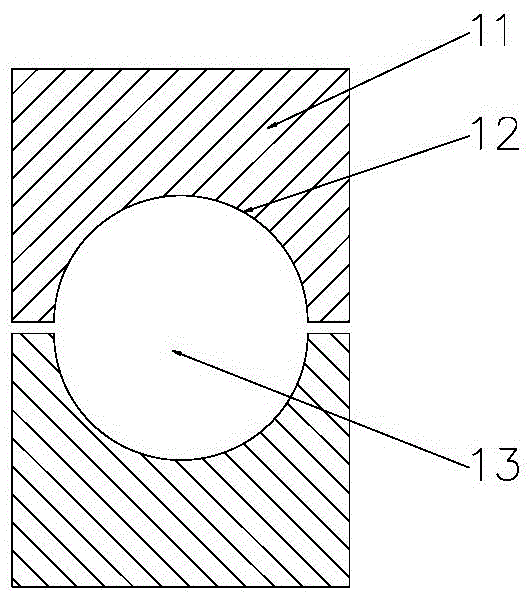

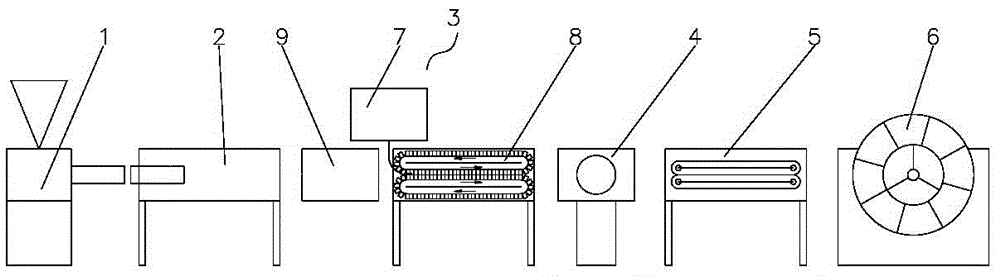

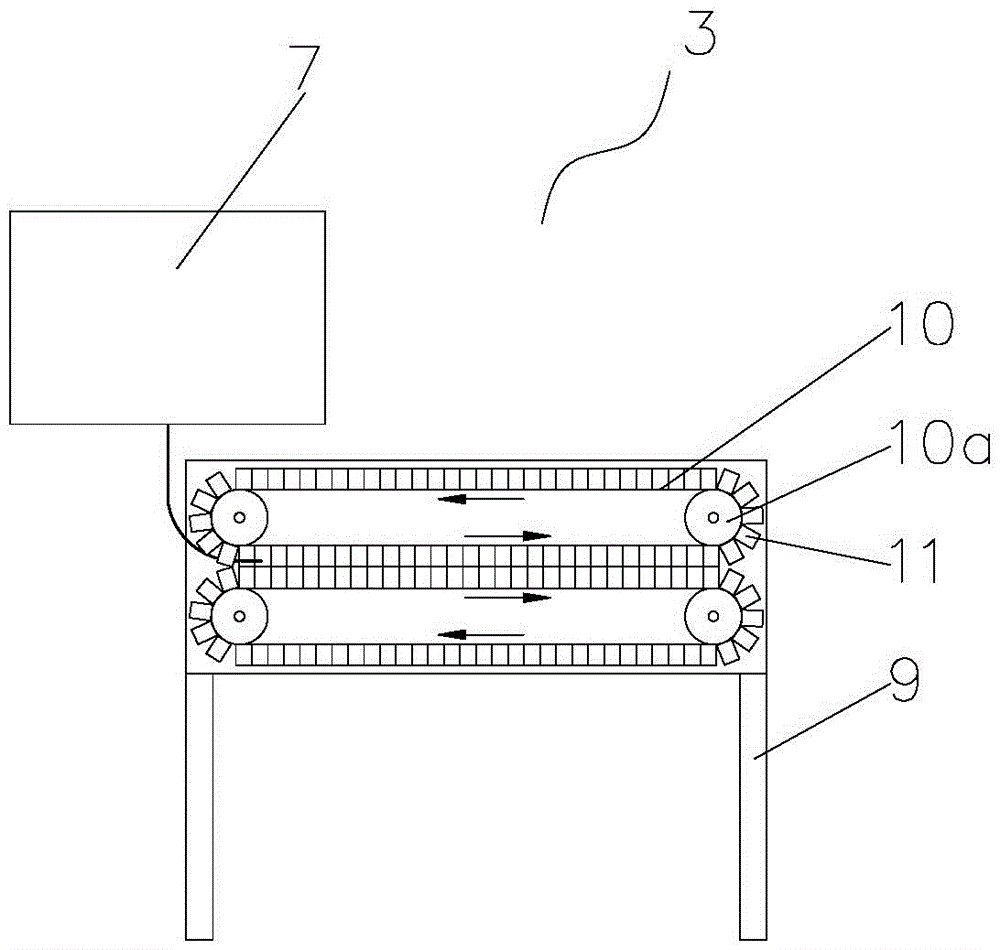

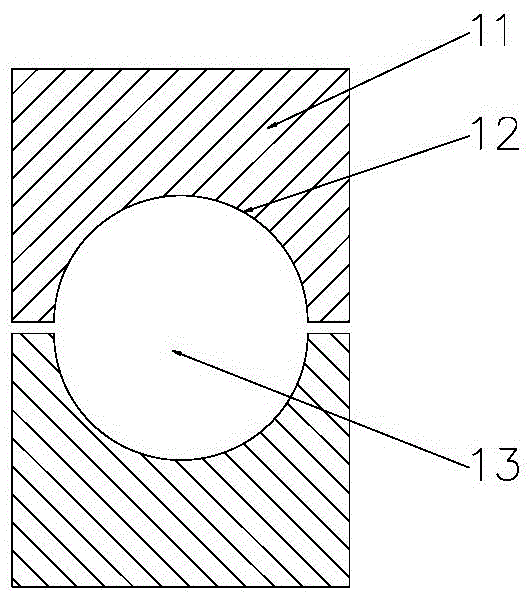

Continuous production equipment and production method for thermal insulation layer of plastic thermal insulation pipeline

InactiveCN105904642AMeet the requirements of continuous productionTubular articlesThermal insulationConveyor belt

The invention discloses continuous production equipment for a thermal insulation layer of a plastic thermal insulation pipeline. The continuous production equipment comprises a foaming machine and a thermal insulation layer molding device, wherein the thermal insulation layer molding device comprises a rack; two conveyer belt mechanisms are arranged on the rack; each conveyor belt mechanism comprises belt pulleys and a conveyer belt mounted on the belt pulleys in a sleeving manner; two adjacent belt pulleys are working belt pulleys of which a central connection line is parallel to the feed direction of a working inner pipe; thermal insulation layer molding mold units are mounted on the conveying belt; semicircular grooves are formed in the end faces of one ends, back to the conveying belts, of the thermal insulation layer molding mold units; the thermal insulation layer molding mold units which are respectively arranged on the two conveyer belts and are located between the two corresponding working belt pulleys are matched with each other and are spliced through the semicircular grooves to form a round-tube-shaped thermal insulation layer molding channel for allowing the working inner pipe to pass through; the geometric dimension of the thermal insulation layer molding channel is larger than that of the inner working pipe; and a foaming material output port of the foaming machine is in the thermal insulation layer molding channel. The invention further discloses a continuous production method for the thermal insulation layer of the plastic thermal insulation pipeline.

Owner:GOODY SCI & TECH CO LTD

Production technology for producing prefabricated plastic thermal insulation pipeline through one-step method

InactiveCN105904749ARealize continuous productionOvercome the defect that it can only be produced piece by pieceTubular articlesThermal insulationMechanical engineering

The invention discloses a production technology for producing a prefabricated plastic thermal insulation pipeline through a one-step method. The production technology comprises the steps of 1) extrusion molding of a working inner pipe: continuously molding the working inner pipe of the plastic thermal insulation pipeline through utilizing an extrusion device; 2) shaping and cooling of the working inner pipe: shaping and cooling the working inner tube through utilizing a shaping and cooling device; 3) continuous wrapping of thermal insulation layer on the working inner tube: continuously wrapping the working inner tube with the thermal insulation layer through utilizing a continuous foaming molding device; and 4) continuous gluing of an outer protective layer on the thermal insulation layer: continuously gluing an outer protective layer on the thermal insulation layer through utilizing an outer coating device. According to the production technology for producing the prefabricated plastic thermal insulation pipeline through the one-step method, the defect that an existing thermal insulation pipeline can only be produced section by section is overcome, and the continuous production of the plastic thermal insulation pipeline can be achieved.

Owner:GOODY SCI & TECH CO LTD

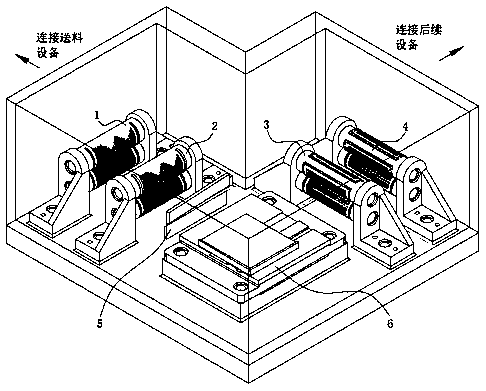

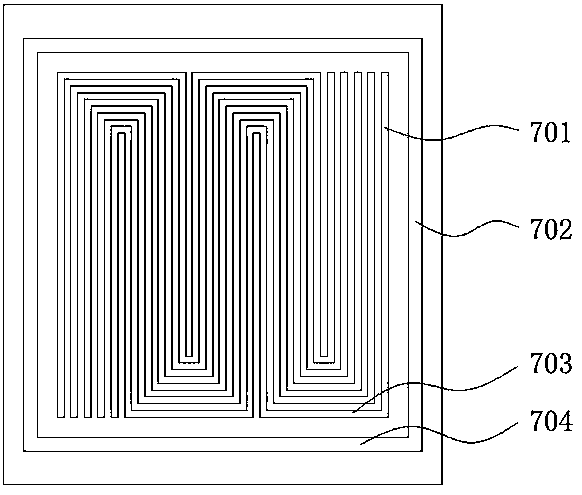

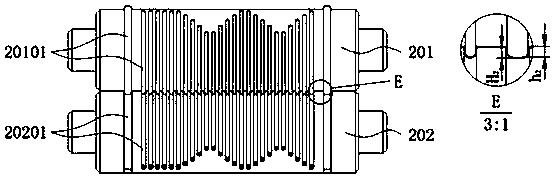

Longitudinal roller rolling forming equipment and method for metal polar plate flowing channels of fuel cell

The invention discloses longitudinal roller rolling forming equipment and a longitudinal roller rolling forming method for metal polar plate flowing channels of a fuel cell. The forming equipment comprises a linear flowing channel longitudinal roller rolling forming device, a polar plate shearing device, a polar plate transferring device, a U-shaped flowing channel longitudinal roller rolling forming device and a rack, wherein the linear flowing channel longitudinal roller rolling forming device comprises a linear flowing channel longitudinal roller rolling pre-forming device and a linear flowing channel longitudinal roller rolling secondary forming device, and the U-shaped flowing channel longitudinal roller rolling forming device comprises a U-shaped flowing channel longitudinal roller pre-forming device and a U-shaped flowing channel longitudinal roller rolling secondary forming device. According to the method, the linear flowing channel longitudinal roller rolling forming device isadopted to complete forming of the linear flowing channels and sealing grooves which are parallel to the linear flowing channels, and the U-shaped flowing channel longitudinal roller rolling formingdevice is adopted to complete forming of the U-shaped flowing channels and sealing grooves which are parallel to the U-shaped flowing channels. According to the equipment and the method, pre-forming and secondary forming are adopted so that the depth of the flowing channels can be increased, cracking is avoided, moreover, resilience is reduced, and continuous production requirements can be met.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

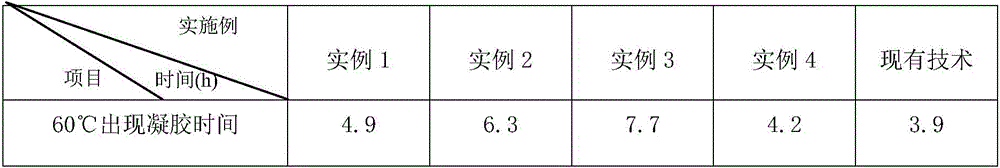

Glass fiber reinforced plastics antenna housing profile and preparation method thereof

The invention relates to a glass fiber reinforced plastics antenna housing profile. The profile is prepared from the following chemical elements of 65% by mass of glass fiber and 35% by mass of a resin compound, wherein the resin compound is prepared from, 100 parts of resin, 15 parts of filler, 3 parts of color paste, 1 part of a release agent, 0.2 part of an antioxidant and 3 parts of a curing system, the curing system comprises an accelerator and initiators, the initiators comprise BPO, AW and TBPB, and the component ratio of the accelerator to BPO to AW to TBPB is 0.5:(0.4-0.1):(0.1-0.4):(0.4-0.1). According to the glass fiber reinforced plastics profile, after the multiple initiators are added into the resin compound for combination, the gelation time of the resin compound is prolonged, the gelation time is prolonged to 7-8 h from 3-4 h in the prior art, and the phenomenon that resin is subjected to a cross-linking and curing reaction in advance in a feed trough is avoided.

Owner:NANJING HUAGE ELECTRONICS & AUTOMOBILE PLASTIC IND

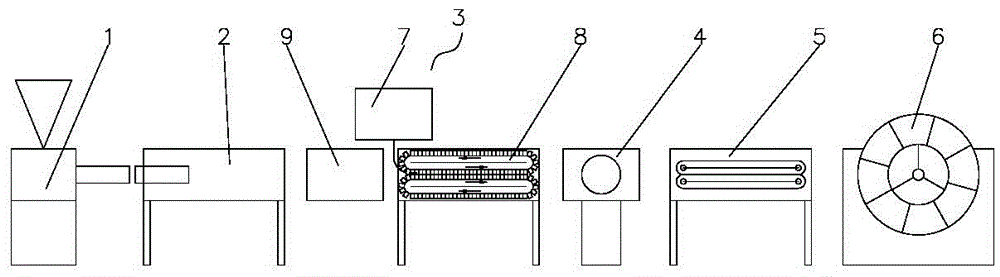

Production line for producing prefabricated plastic insulation pipeline through one-step method

InactiveCN106079472ARealize continuous productionOvercome the defect that it can only be produced piece by pieceCoatingsTubular articlesProduction lineInsulation layer

The invention discloses a production line for producing a prefabricated plastic insulation pipeline through a one-step method. The production line comprises an extrusion device used for extrusion forming of a work inner pipe, a shaping and cooling device used for shaping and cooling the work inner pipe, a continuous foam forming device used for wrapping the work inner pipe with an insulation layer in a continuous foaming mode, an outer covering device used for continuously attaching an outer protective layer to the insulation layer, and a pulling device used for pulling the plastic insulation pipeline, wherein the extrusion device, the shaping and cooling device, the continuous foam forming device, the outer covering device and the pulling device are arranged in sequence. The extrusion device comprises a plastic extruder and a forming mold installed on the plastic extruder and used for forming the work inner pipe. The shaping and cooling device comprises a negative-pressure shaping box and a cooling device, and the negative-pressure shaping box and the cooling device are integrally arranged. A shaping mold used for shaping the work inner pipe is arranged in the negative-pressure shaping box. The continuous foam forming device comprises a foaming machine and an insulation layer forming device used for continuously wrapping the work inner pipe with the insulation layer. By the adoption of the production line for producing the prefabricated plastic insulation pipeline through the one-step method, continuous production of the plastic insulation pipeline can be achieved.

Owner:GOODY SCI & TECH CO LTD

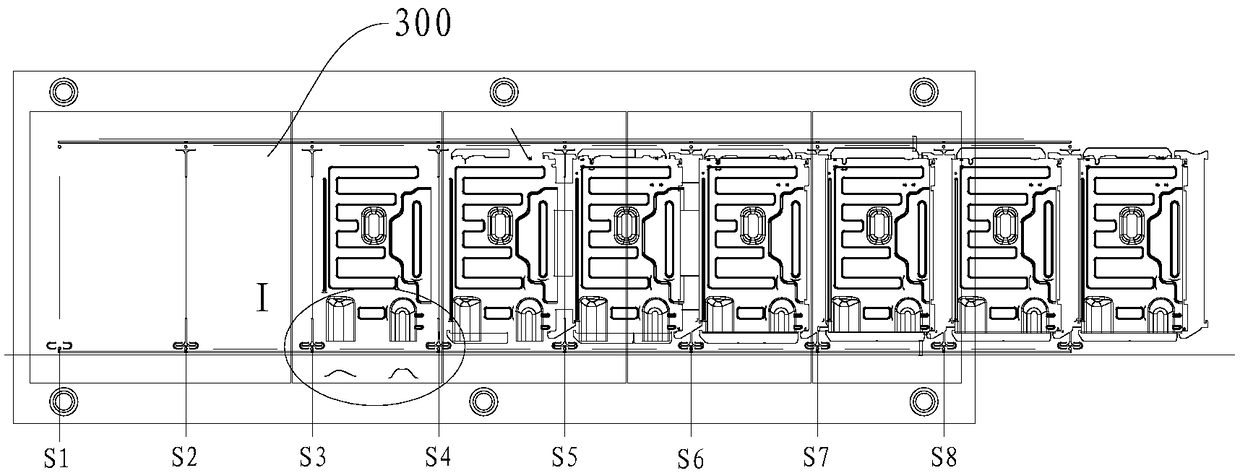

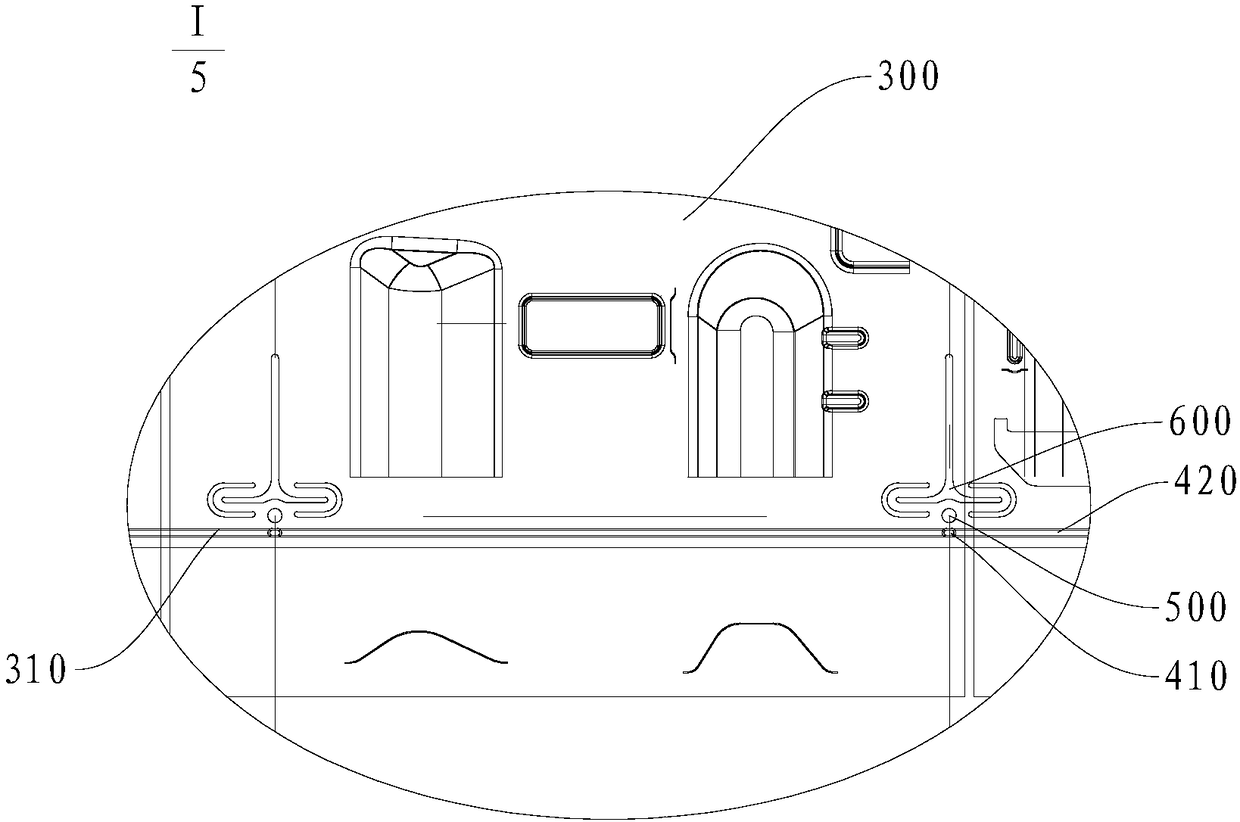

Continuous die

ActiveCN108296357ASmooth feedingPrecise feedingShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention discloses a continuous die, relates to the technical field of dies, and aims at providing a continuous die capable of preventing unable alignment due to material strip softening, correctin feeding alignment, smooth in feeding and simple in structure. The continuous die comprises an upper die, a lower die and a material strip alignment structure, a material strip is arranged on the lower die, and strengthening ribs are arranged on the two sides of the material strip. The material strip alignment structure comprises alignment grooves and alignment pins, and the alignment grooves are formed in the strengthening ribs. The alignment pins are fixedly arranged on all stations of the lower die and are matched with the alignment grooves, and the movement of the material strip is guided.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

Continuous biomass pyrolytic carbon gas-oil poly-generation system

ActiveCN102776007BFast absorptionShorten production timeBiofuelsEnergy inputPyrolytic carbonProcess engineering

The invention discloses a continuous biomass pyrolytic carbon gas-oil poly-generation system. The continuous biomass pyrolytic carbon gas-oil poly-generation system comprises a pyrolysis unit, a condensation unit, a purifying unit, a gas storage unit and a heating unit, wherein the pyrolysis unit is connected with the condensation unit and the heating unit; the gas storage unit is connected with the purifying unit and the heating unit respectively; the condensation unit is connected with a gas storage unit pipeline by the purifying unit; high-temperature smoke gas is generated by the heating unit; the pyrolysis unit performs thermal conversion from biomass into a carbon gas oil product by heat energy generated by high-speed scouring of high-temperature smoke gas and coke is separately stored; bio-oil and gas are separated from carbon gas oil by the condensation unit; impurities in the fuel gas are removed by the purifying unit; and the gas subjected to the impurity removal is stored by the gas storage unit. With the adoption of the continuous biomass pyrolytic carbon gas-oil poly-generation system, targets of continuously producing biogas, a biological coke and bio-oil are realized, so that the product quality is stable, and the application prospect is wide.

Owner:HUAZHONG UNIV OF SCI & TECH +1

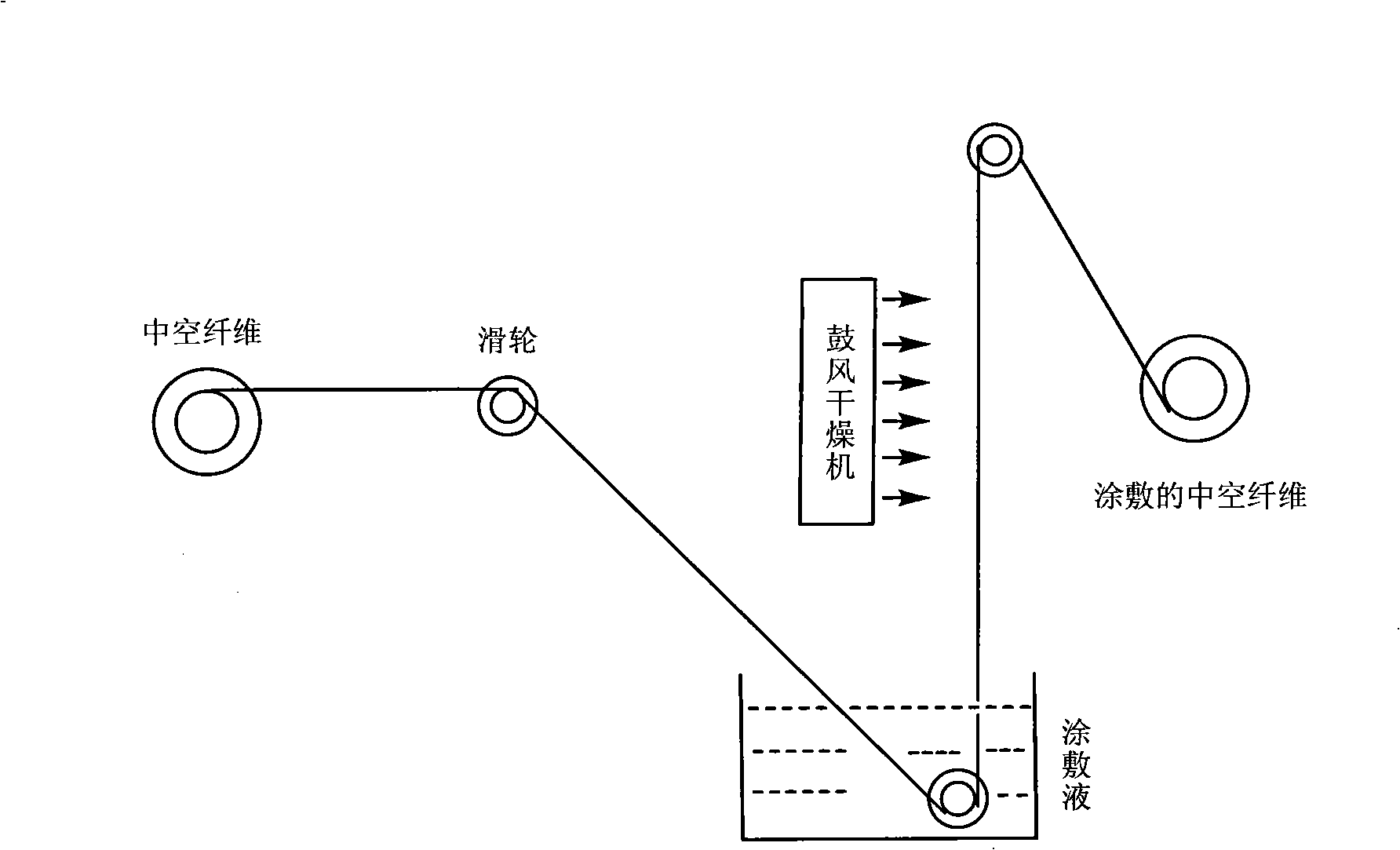

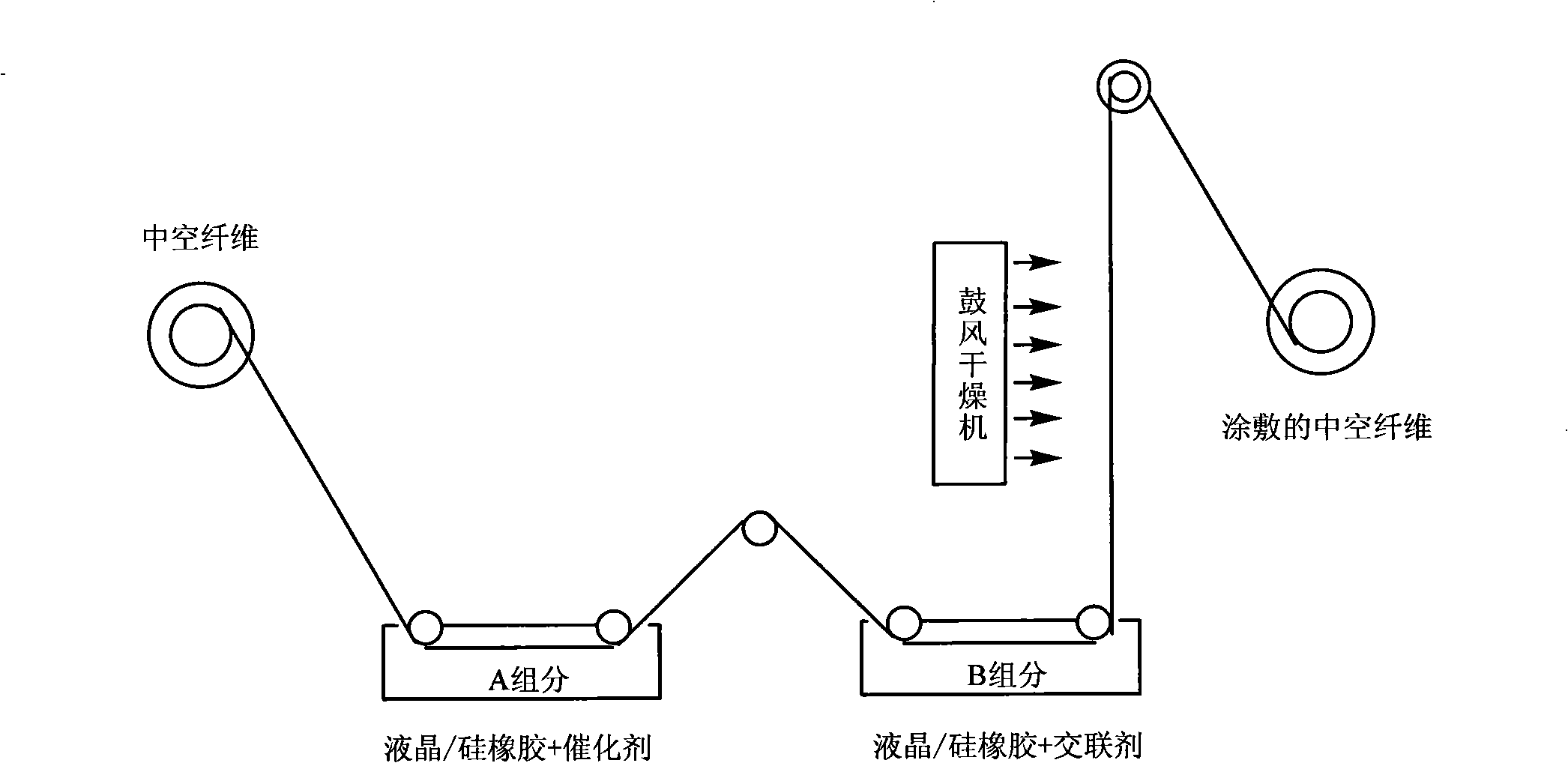

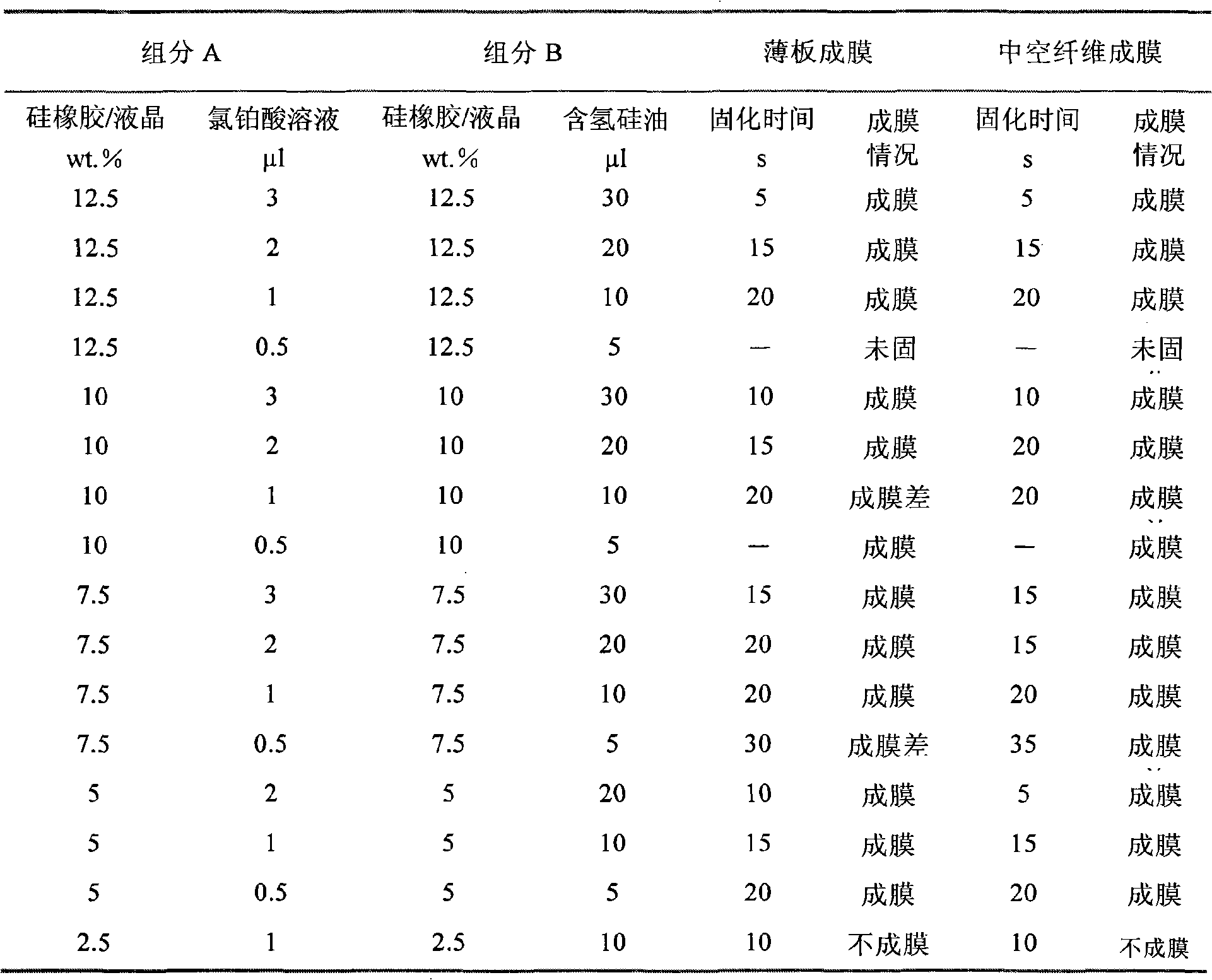

Manufacturing method for coating silicon rubber/liquid crystal cross linking membrane on bi-component hollow fiber

The invention discloses a manufacturing method for coating a silicon rubber / liquid crystal cross linking membrane on bi-component hollow fiber. The method includes the following steps of: (1) dissolving silicon rubber / gadoleic acid cholesterol ester liquid crystal and adding catalyst to make component A; (2) dissolving silicon rubber / gadoleic acid cholesterol ester liquid crystal and adding cross linker to make component B; and (3) dipping the hollow fiber first in the component A and then in the component B and obtaining a hollow fiber composite membrane coated with the silicon rubber / liquid crystal cross linking membrane on surface through heating, cross linking and solidification. The two components can react at room temperature to be solidified. To shorten the solidification time, heating process is adopted, and the thickness of a coated membrane is controlled simultaneously when the completeness and uniformity of the coated membrane are improved, thus being in line with the technical requirements of industrial continuous production. Aiming at the defects that the usage period of coating liquid in a single component is short, the hollow fiber coated membrane clings mutually easily and the continuous operation is difficult to realize in technology and the like, the invention develops the bi-component method coating technology of hollow fiber and provides a preparation method of continuous operation for the surface coating of the hollow fiber membrane.

Owner:JINAN UNIVERSITY

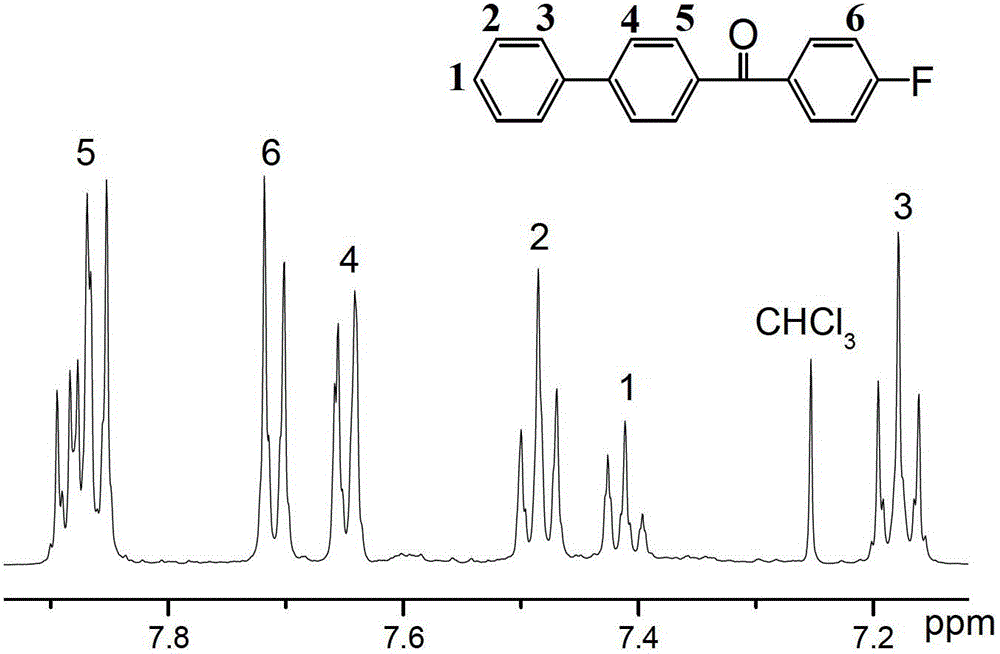

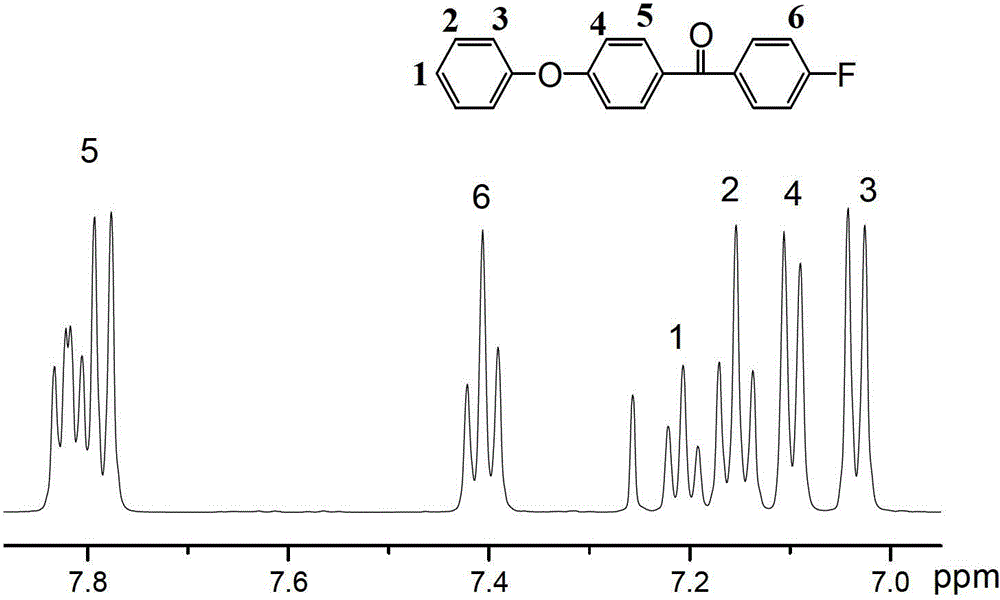

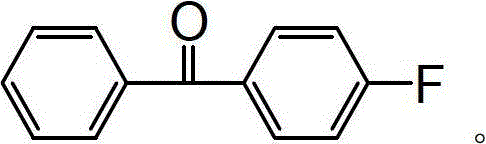

Method for preparing benzene end-capping polyaryletherketone polyme

ActiveCN102702459BMeet the requirements of continuous productionOrganic compound preparationCarbonyl compound preparation by condensationChemical reactionPhenyl Ethers

The invention relates to a method for preparing benzene end-capping polyaryletherketone polymers, which belongs to the technical field of high polymer materials. The preparation method comprises the steps as follows: using 4-(p fluorophenyl acyl) biphenyl or 4-(p fluorophenyl acyl) phenyl ether as an end-capping agent, using 4,4'-difluorobenzophenone and a bisphenol monomer as reactants, and using a nucleophilic route to prepare the benzene end-capping polyaryletherketone polymers with glass transition temperature of 147 DEG C and initial thermo-gravimetric temperature above 540 DEG C. Two detailed chemical equations describing the preparation process are attached. With two end-capping monomers having boiling points above 320 DEG C and suitable process conditions, the method for preparing the benzene end-capping polyaryletherketone polymers solves the technical problem caused by the fact that the p fluorophenyl acyl has low boiling point and volatilizes in an end-capping reaction in the prior art, and synthetizes polyaryletherketone with a benzene oxygen end group and polyaryletherketone with a biphenyl end group, so as to meet the requirement of continuous industrial production.

Owner:山东君昊高性能聚合物有限公司

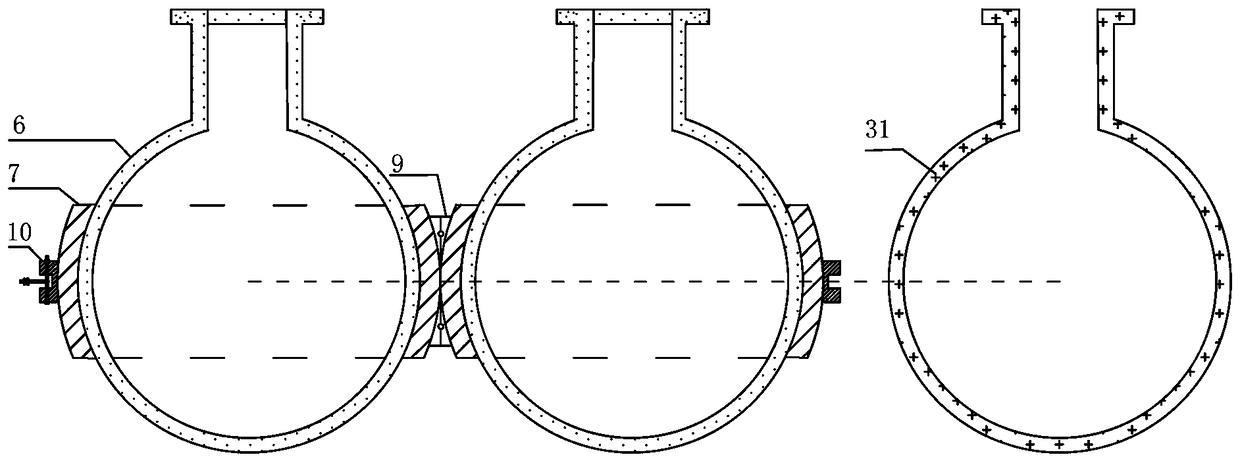

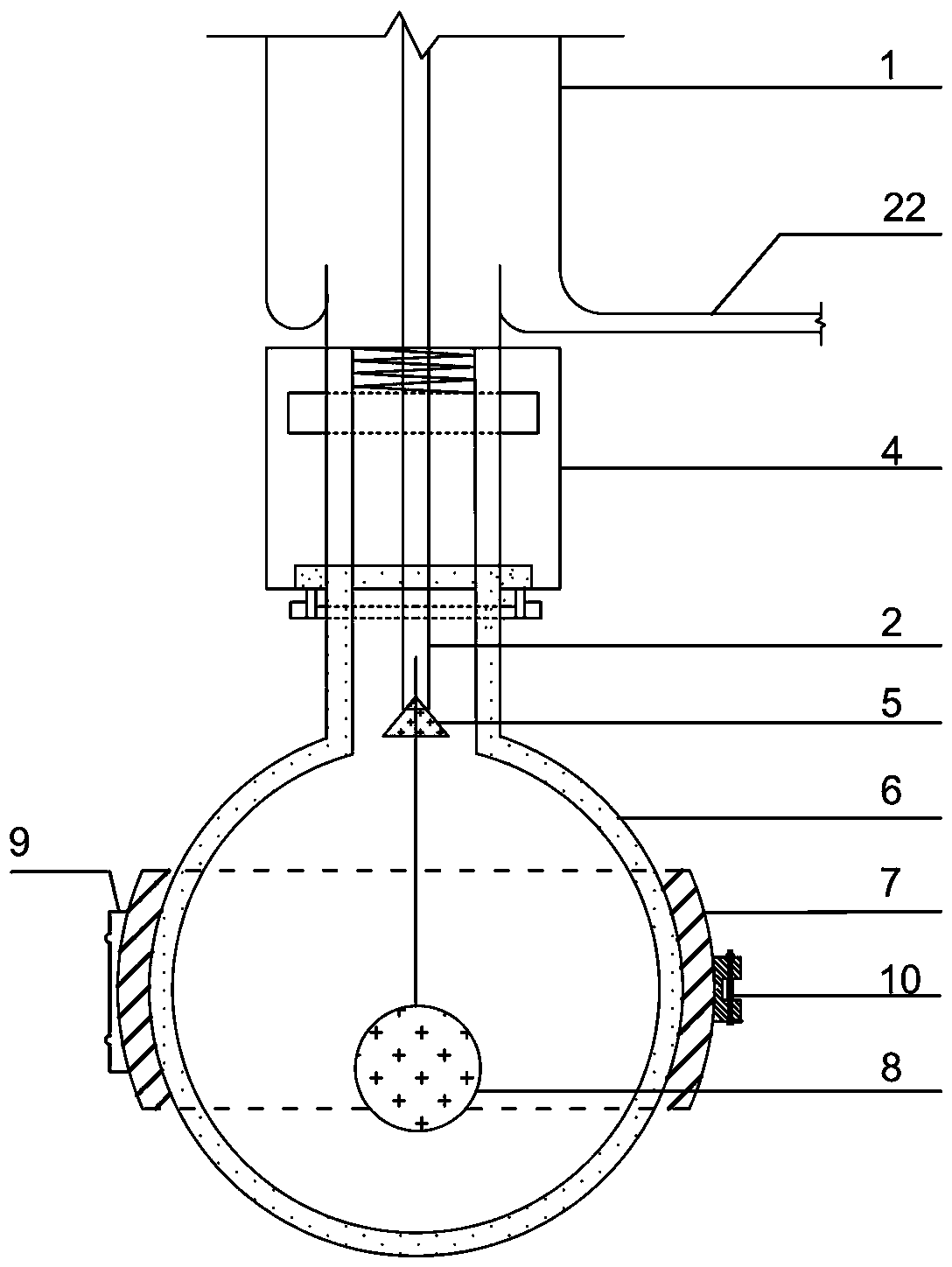

Rotary evaporator

PendingCN108815872AAvoid damageExtend your lifeEvaporationDistillation in rotating vesselsWater bathsRotary evaporator

The invention relates to the field of evaporation drying equipment, and particularly relates to a rotary evaporator. The technical scheme adopted in the invention is as the follows that the rotary evaporator comprises a vacuum pump, a condensation pipe, a feeding pipe, a feeding valve, a rotary evaporation main machine, a floating ball liquid level meter, a liquid storage bottle, an evaporation bottle, a recovery bottle, a water bath, a controller and a support frame. The rotary evaporator is characterized in that the top of the support frame is provided with the controller; adjustable fixingclamps are arranged on the support frame; one fixing clamp at one side of the support frame is used to fix the condensation pipe and the rotary evaporation main machine; one fixing clamp at the otherside of the support frame is used to fix the recovery bottle; the upper end of the rotary evaporation main machine is connected with the condensation pipe; the lower end of the rotary evaporation mainmachine is connected with the evaporation bottle; a floater capable of adjusting the height of a duct plug is arranged in the evaporation bottle; the liquid storage bottle and the evaporation bottleare arranged in the same water bath; and the evaporation bottle consists of two hemispheres which are symmetric with each other from left to right, is sealed by a sealing ring, and is fixed by a fixing clamp sleeve. The rotary evaporator provided by the invention has the advantages that the evaporation bottle is vertically installed, so that the loss of the rotary evaporation main machine is reduced; automatic feeding can be realized; the distillate is easy to discharge; and continuous production can be carried out.

Owner:余立汜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com