Method for preparing benzene end-capping polyaryletherketone polyme

A polyaryletherketone and polymer technology, which is applied in the field of polyaryletherketone synthesis, can solve the problems of being unsuitable for industrial production, unable to carry out continuous production, and inaccurate final capping dose, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

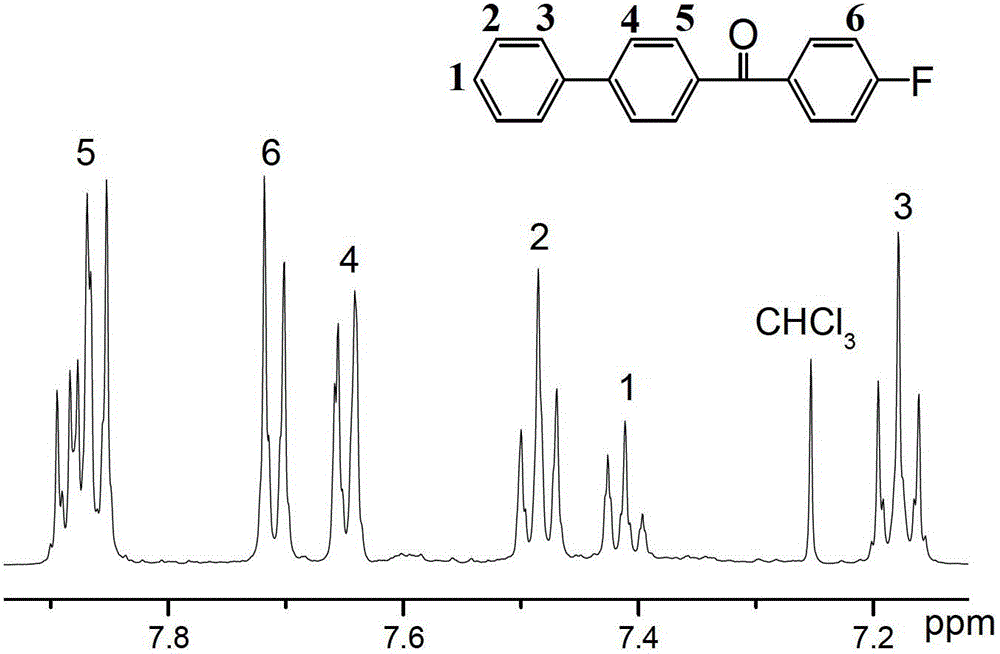

[0033] Add 154.21g of biphenyl and 450ml of dichloromethane into the three-necked flask, stir until the former is completely dissolved in the latter, then cool the system down to about 0°C, slowly add 133.50g of aluminum trichloride, and stir until no bubbles come out. After fully mixing 158.56g of p-fluorobenzoyl chloride and 50ml of dichloromethane, slowly add it dropwise to the above reaction system, stir slowly for 0.5 hours, then raise the temperature to about 20°C and stir for about 5 hours, then pour the reactant into ice hydrochloric acid aqueous solution , fully shaken, poured out the water, washed 4 times with hydrochloric acid aqueous solution, evaporated dichloromethane to dryness to obtain a solid, and recrystallized from a mixed solution of dichloromethane and ethanol (volume ratio 1:1) to obtain 4- Fluorobenzoyl diphenyl ether 192.04g. Its NMR spectrum is as figure 1 shown.

Embodiment 2

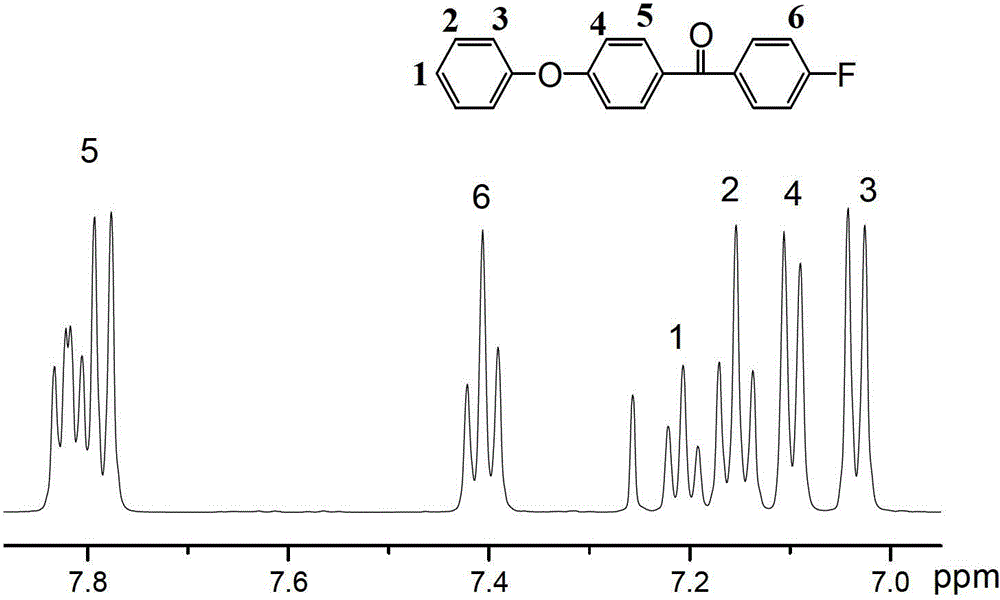

[0035]Add 170.21g of diphenyl ether and 450ml of dichloromethane into the three-necked flask, stir until the former is completely dissolved in the latter, then cool the system down to about 0°C, slowly add 133.50g of aluminum trichloride, and stir until no bubbles come out. After fully mixing 158.56g of p-fluorobenzoyl chloride and 50ml of dichloromethane, slowly add it dropwise to the above reaction system, stir slowly for 0.5 hours, then raise the temperature to about 20°C and stir for about 5 hours, then pour the reactant into ice hydrochloric acid aqueous solution , fully shaken, poured out the water, washed 4 times with aqueous hydrochloric acid, evaporated dichloromethane to dryness to obtain a solid, and recrystallized from ethanol to obtain 263 g of 4-fluorobenzoyl diphenyl ether as a white solid. Its NMR spectrum is as figure 2 shown.

Embodiment 3

[0037] Add 40.4g of 4,4'-difluorodiphenyl ketone and 146g of diphenyl sulfone (30% solid content) into a three-neck flask equipped with mechanical stirring and a thermometer, under nitrogen protection, heat to 160°C, and then add anhydrous Potassium carbonate 1.41g and anhydrous sodium carbonate 21.17g, then heated to 165°C, add hydroquinone 30.43g, continue to heat to 200°C and control the temperature for 1 hour, gradually raise the temperature to 250°C for 15 minutes, and then control the temperature at 280°C 1 hour, finally heated to 320°C for 3 hours, added 1.42 g of 4-(p-fluorobenzoyl)biphenyl and reacted for 1 hour, poured the product into water, crushed with a pulverizer, filtered, and directly boiled the solid with ethanol or acetone Boil and filter by the same method, repeat 5-6 times, then boil with distilled water, filter, repeat 5-6 times, dry in an oven to obtain refined polymer. The yield is 97%, the glass transition temperature is 147°C, and the melting point is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com