Rotary evaporator

A technology of rotary evaporator and evaporating flask, which is applied in the direction of evaporation, distillation in a rotating container, distillation separation, etc. It can solve the problems of increasing production costs, falling off of evaporating flasks, and reduced yield, so as to meet the requirements of continuous production and discharging. Easy to operate and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

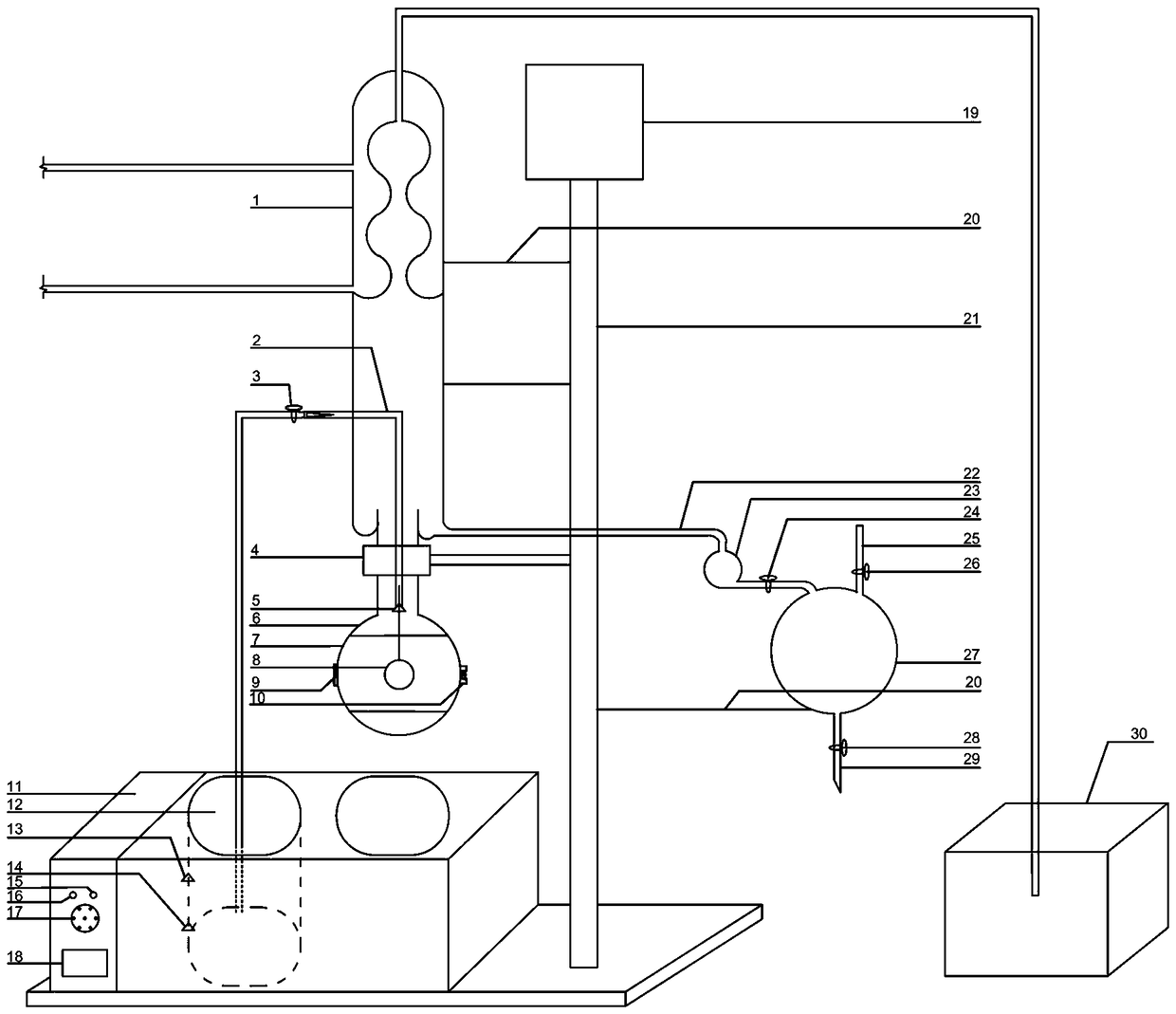

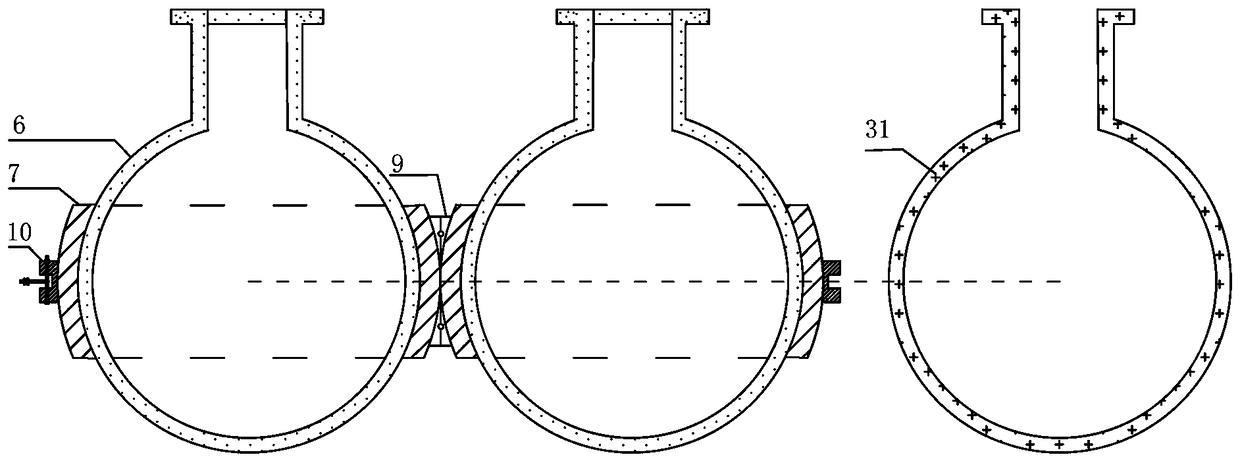

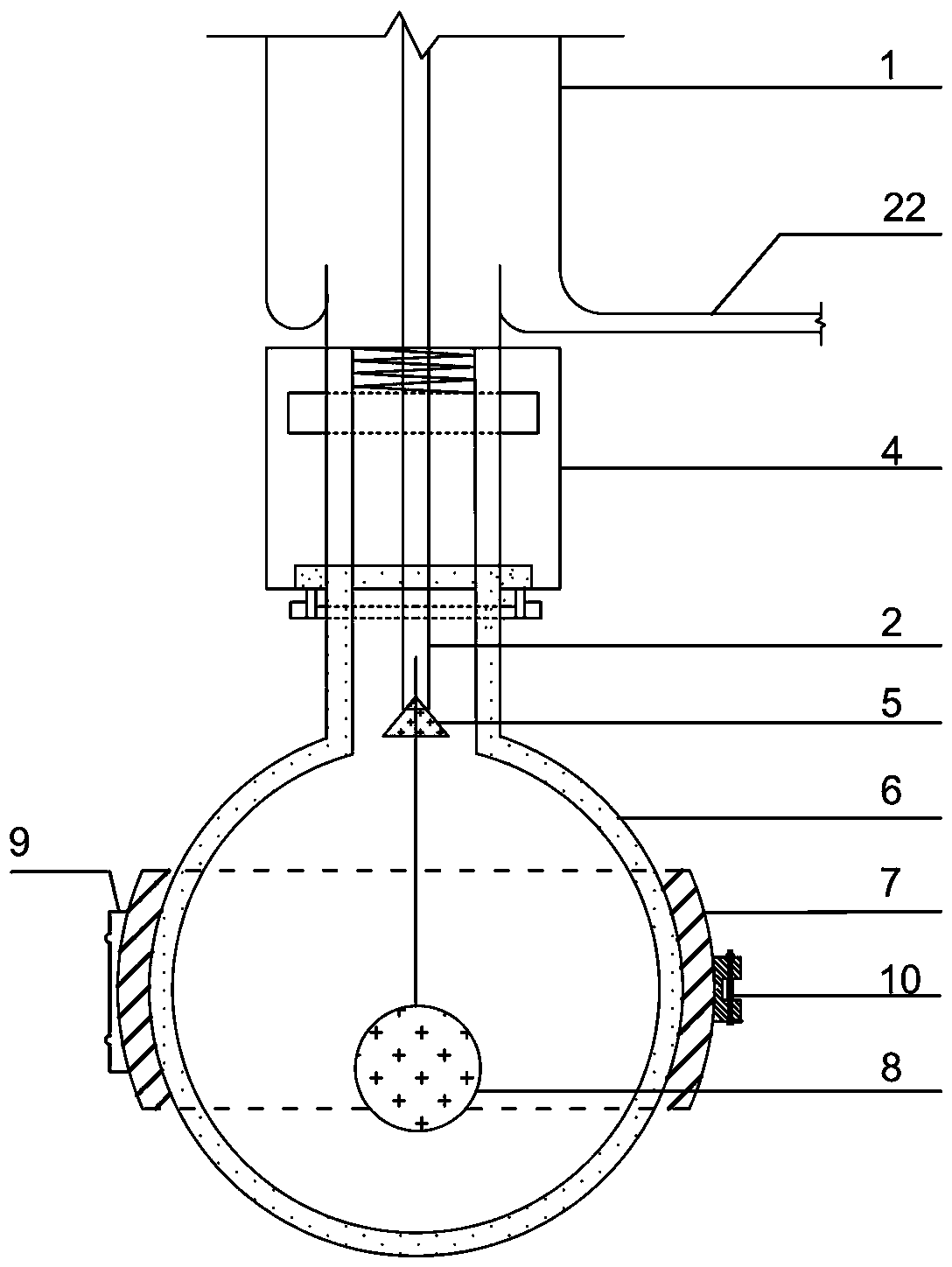

[0025] Example: refer to Figure 1-3 , a rotary evaporator, comprising a condenser tube 1, a feed tube 2, a feed valve 3, a rotary evaporator host 4, a conduit plug 5, an evaporating flask 6, a sealing jacket 7, a float 8, a jacket shaft 9, and a jacket Bolt 10, water bath 11, liquid storage bottle 12, maximum liquid level sensor 13, minimum liquid level sensor 14, maximum liquid level indicator light 15, minimum liquid level indicator light 16, alarm 17, temperature control panel 18, control Device 19, fixing clip 20, bracket 21, liquid outlet pipe 22, buffer chamber 23, liquid outlet valve 24, vent pipe 25, vent valve 26, recovery bottle 27, discharge valve 28, discharge pipe 29, vacuum pump 30, seal Circle 31.

[0026] How to use: Before use, adjust the height of the conduit plug 5 on the upper part of the float 8, put it into the evaporating bottle 6, seal the evaporating bottle 6 through the sealing ring 31 and the sealing jacket 7, start the vacuum pump 30, and connect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com