Patents

Literature

285results about "Distillation in rotating vessels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

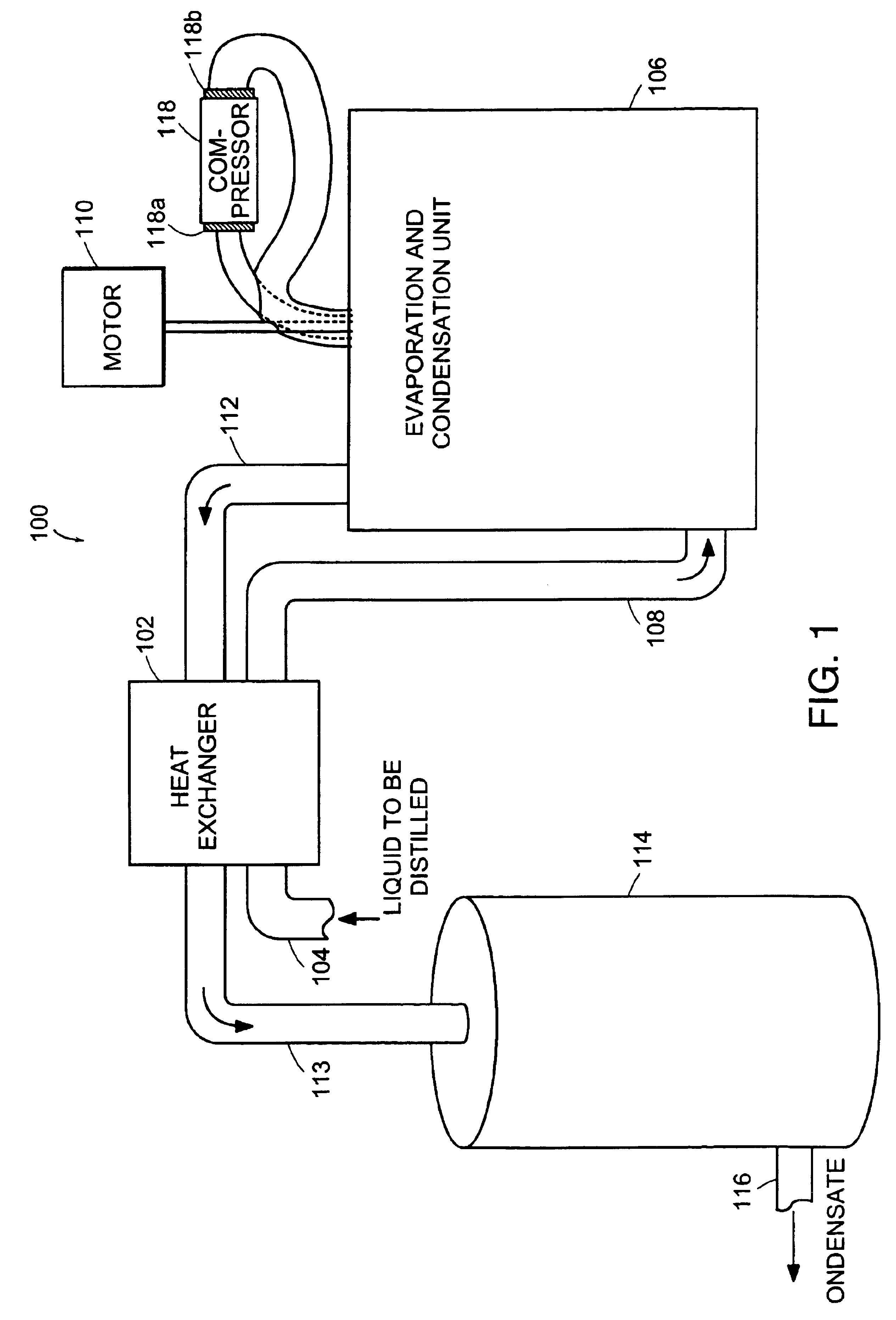

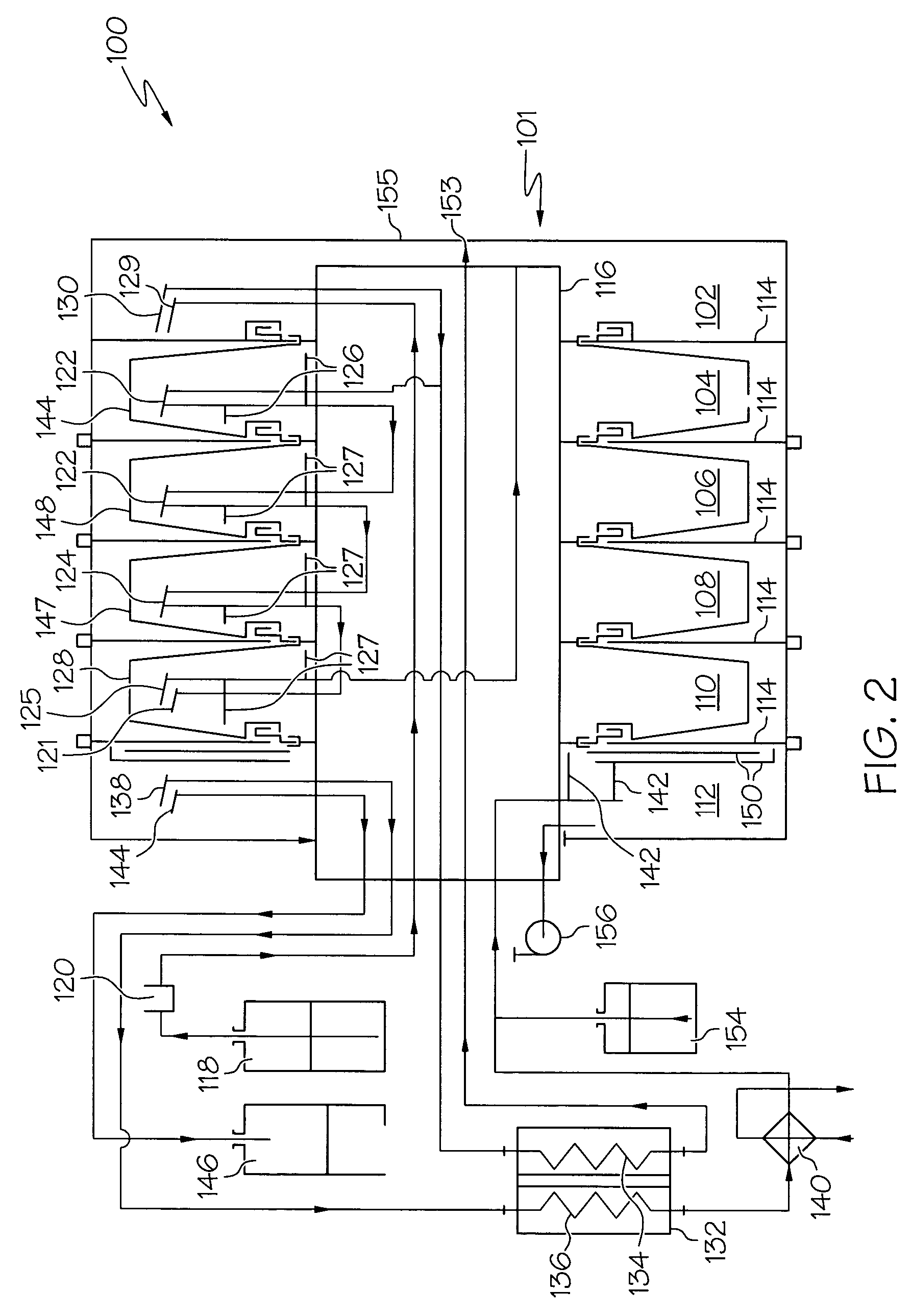

Pressurized vapor cycle liquid distillation

ActiveUS20050016828A1Easy maintenanceMaximize energy efficiencyDistillation regulation/controlUsing liquid separation agentHeat managementDrive shaft

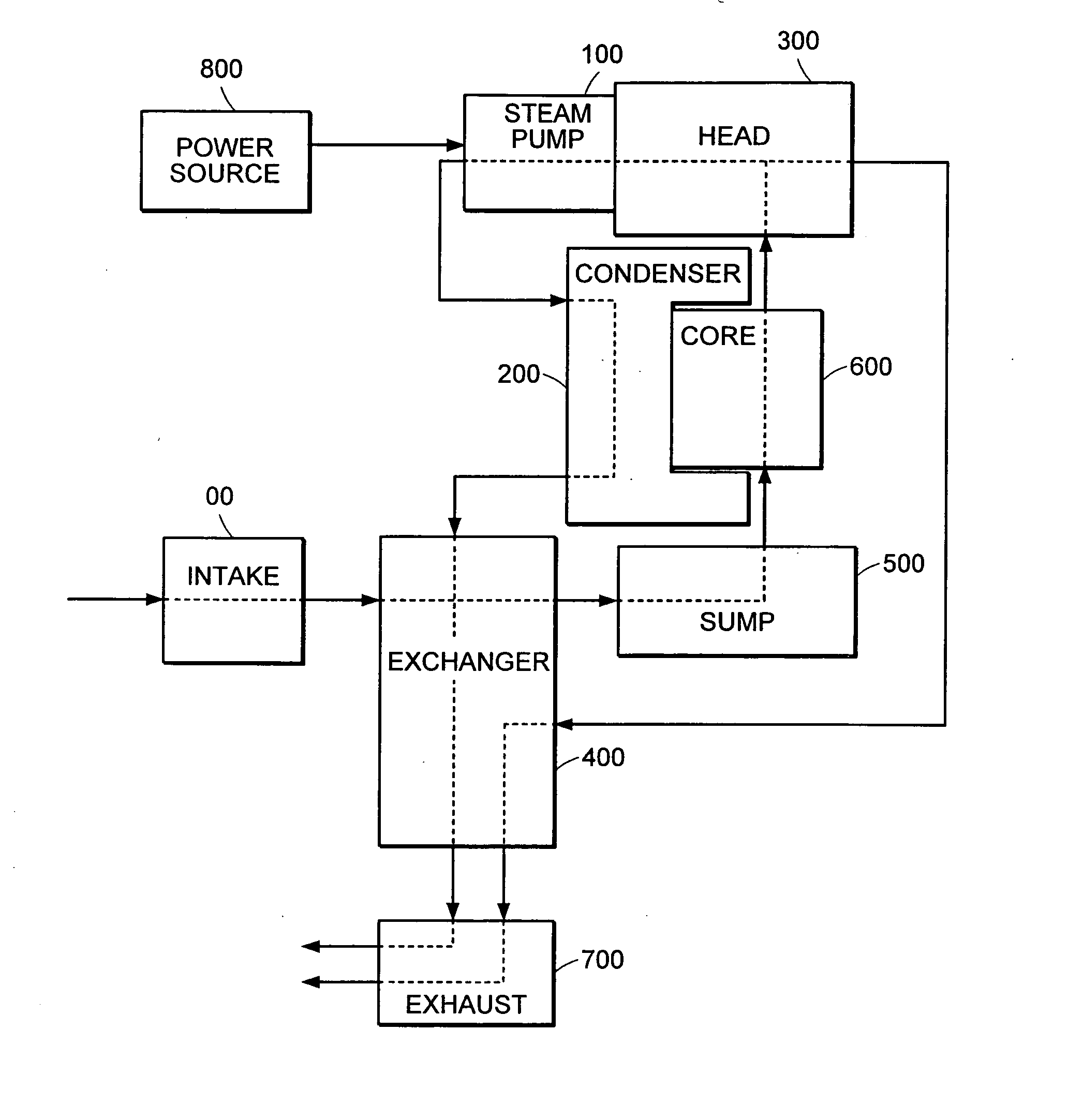

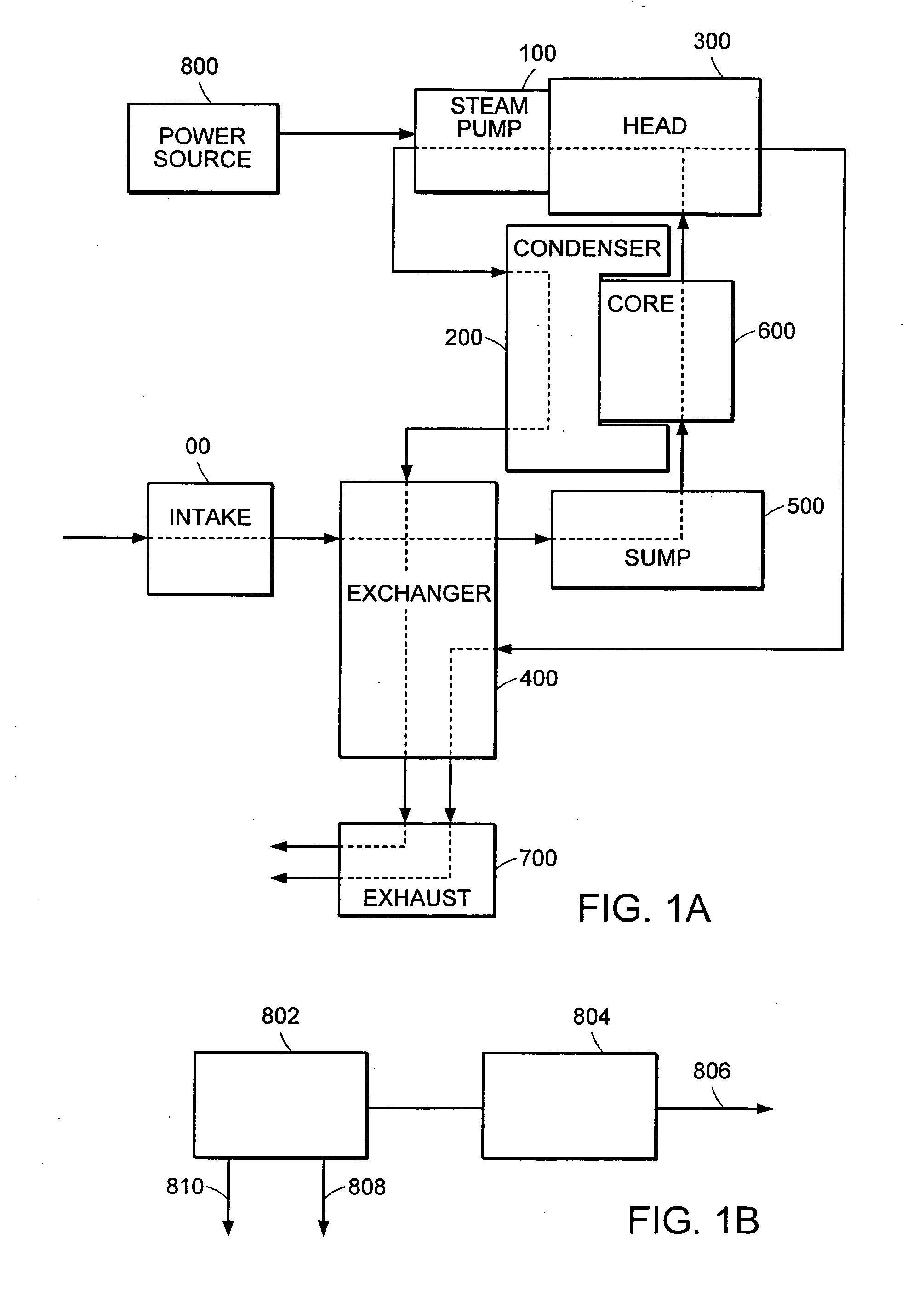

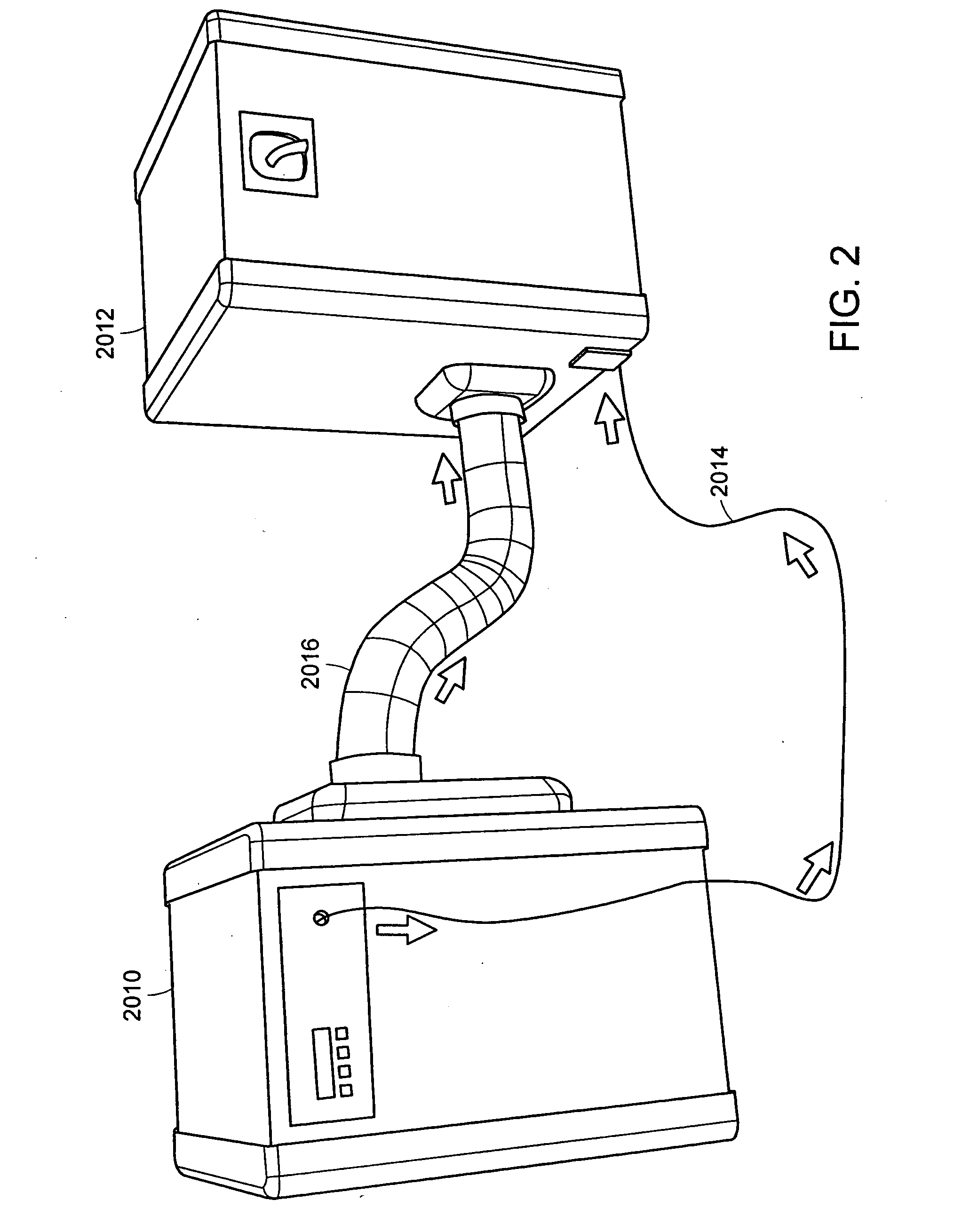

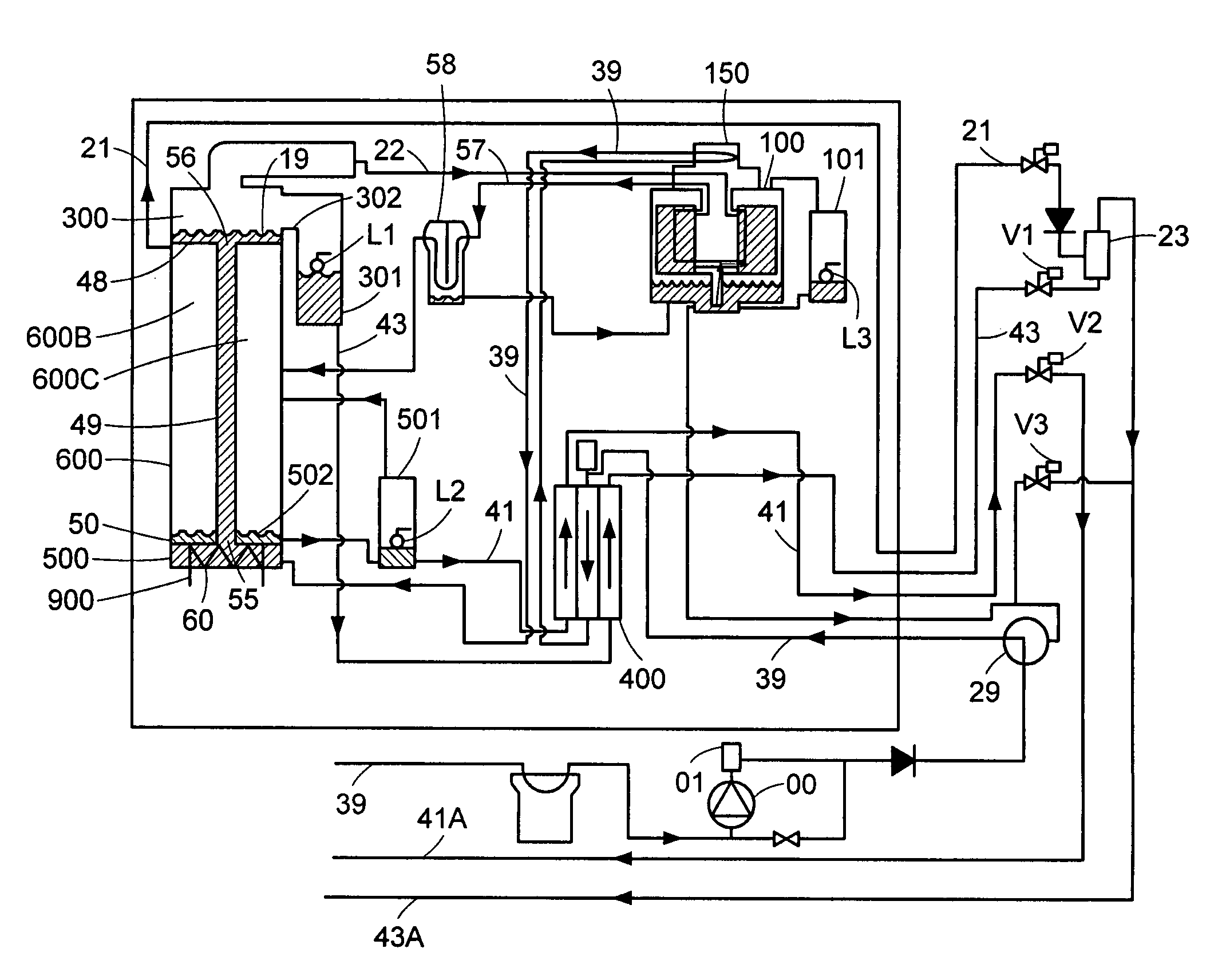

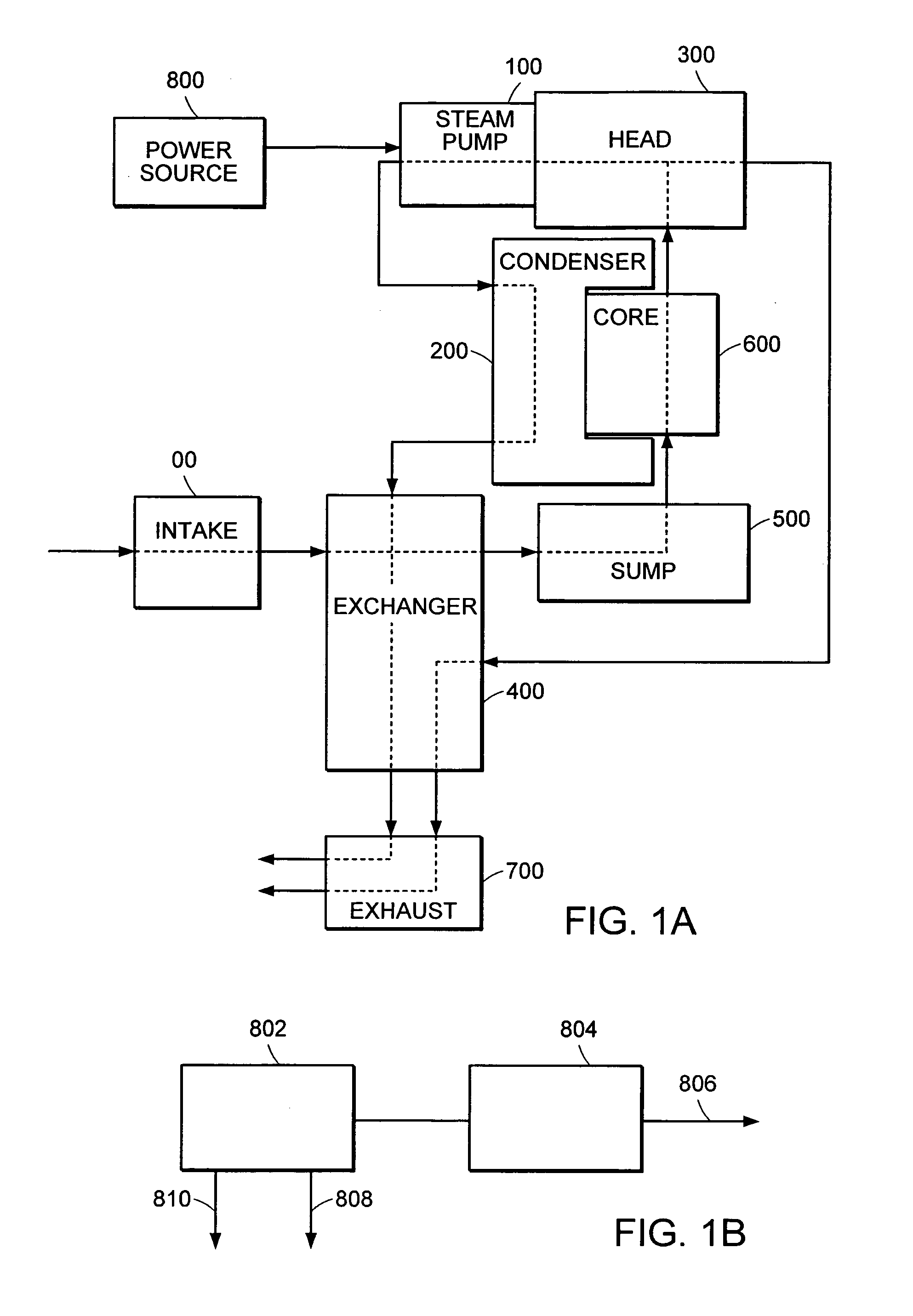

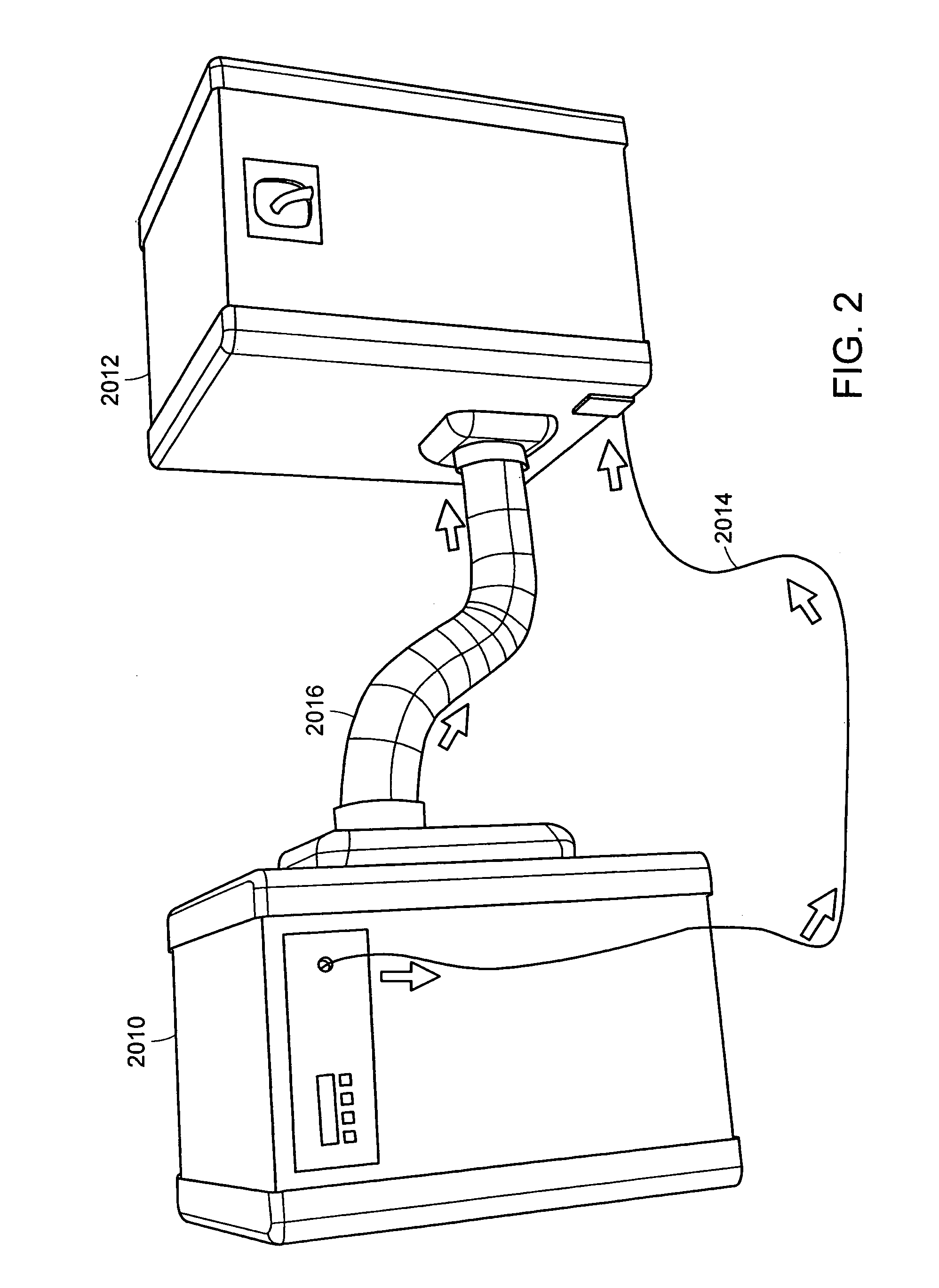

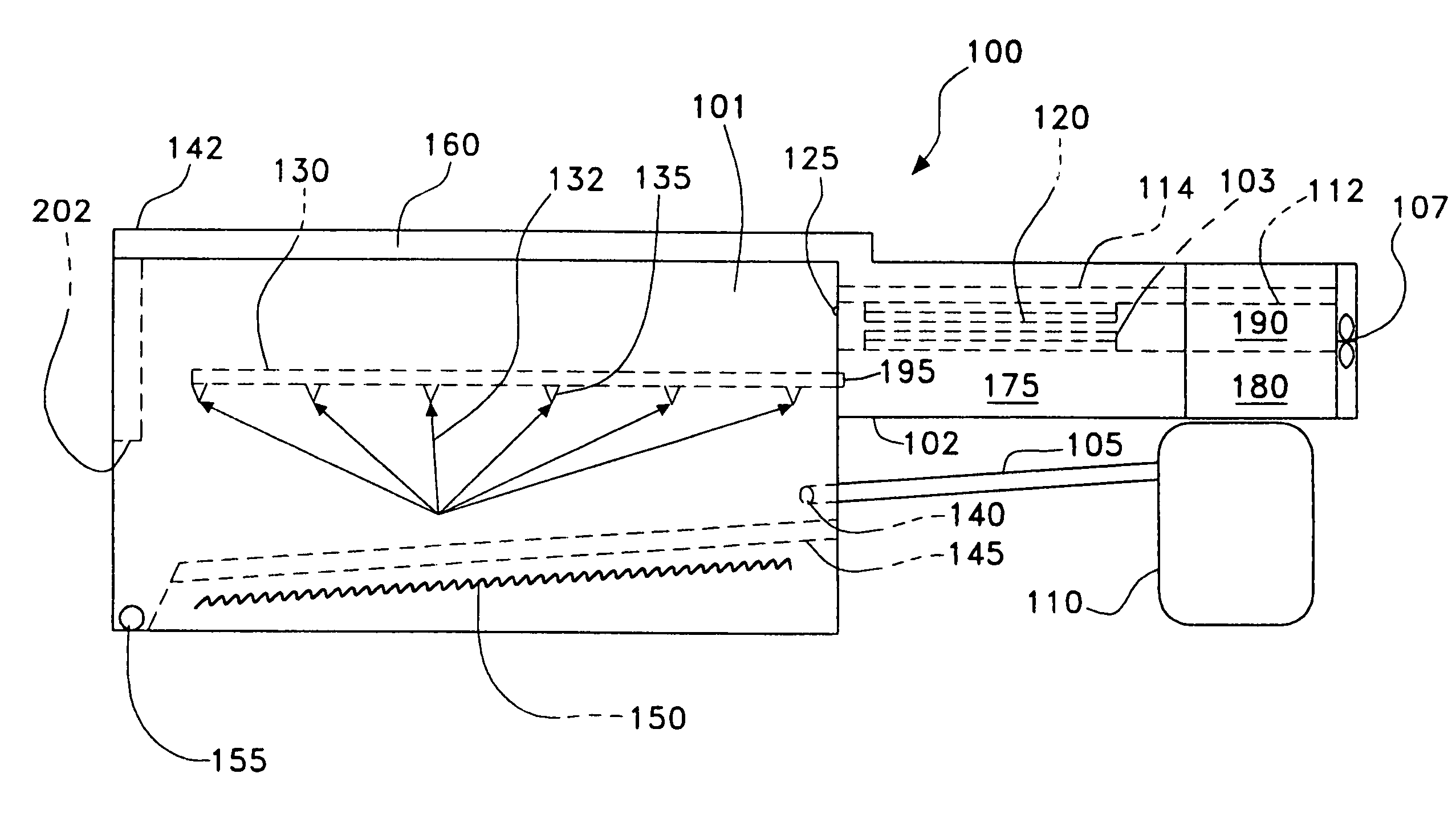

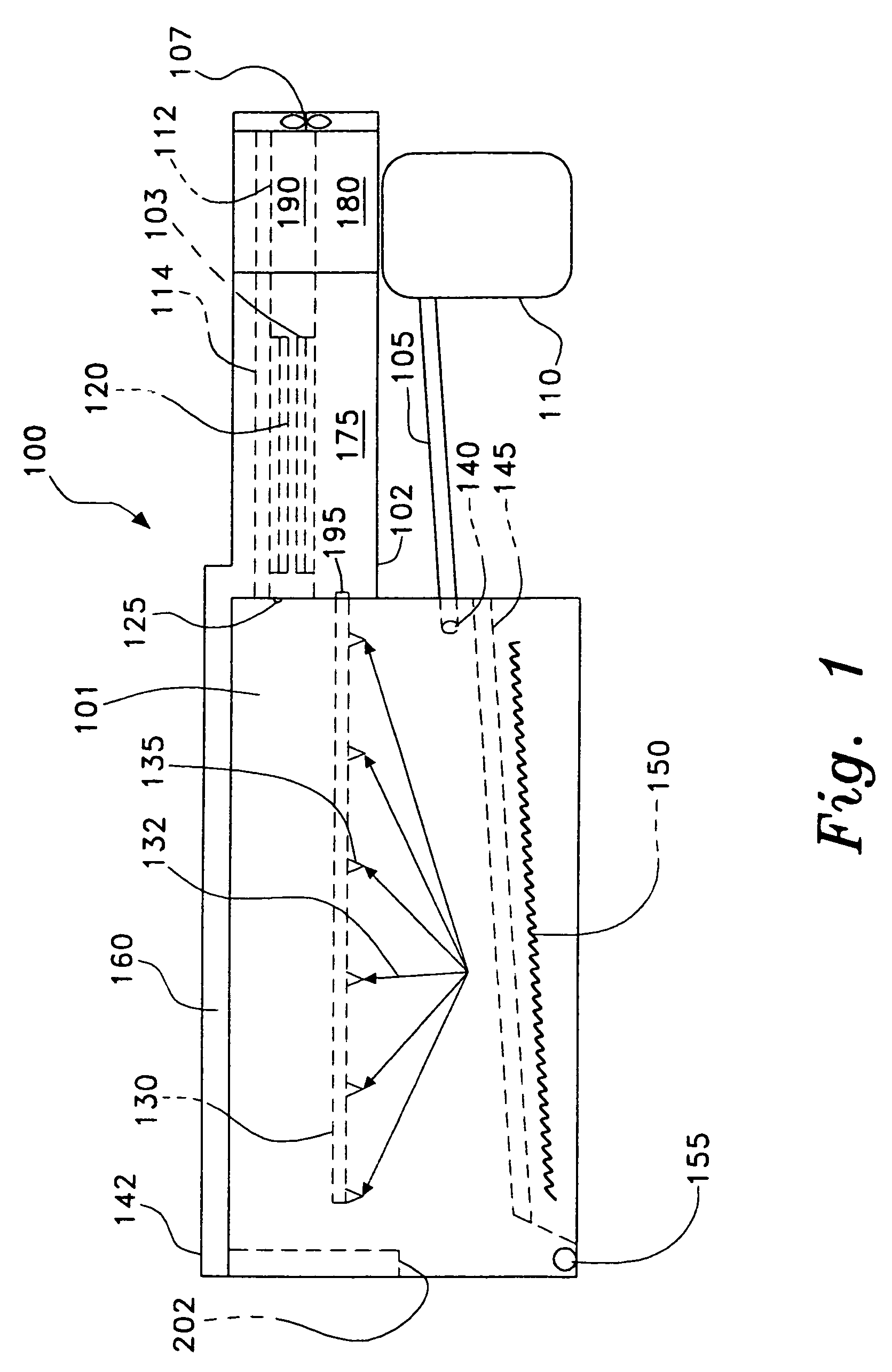

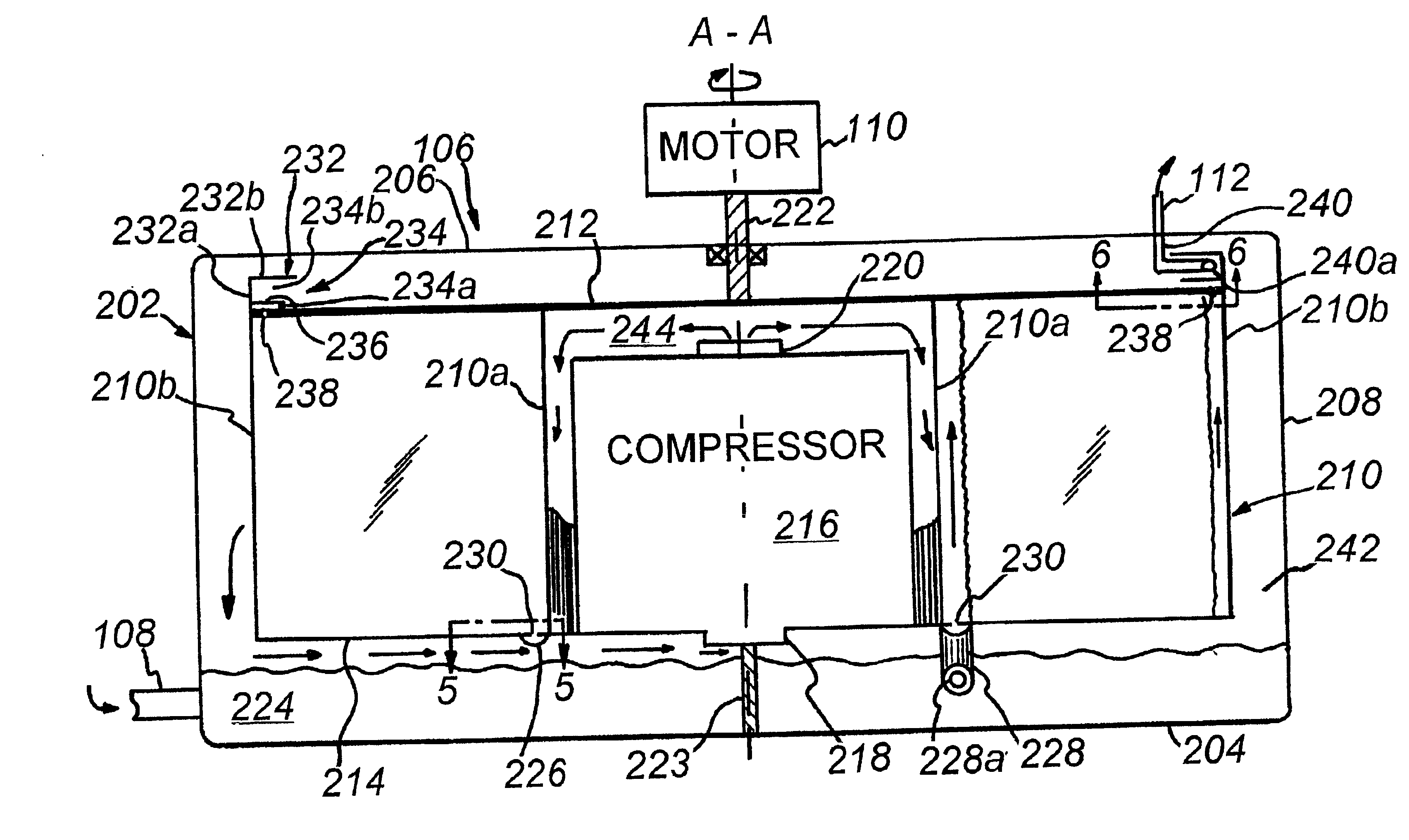

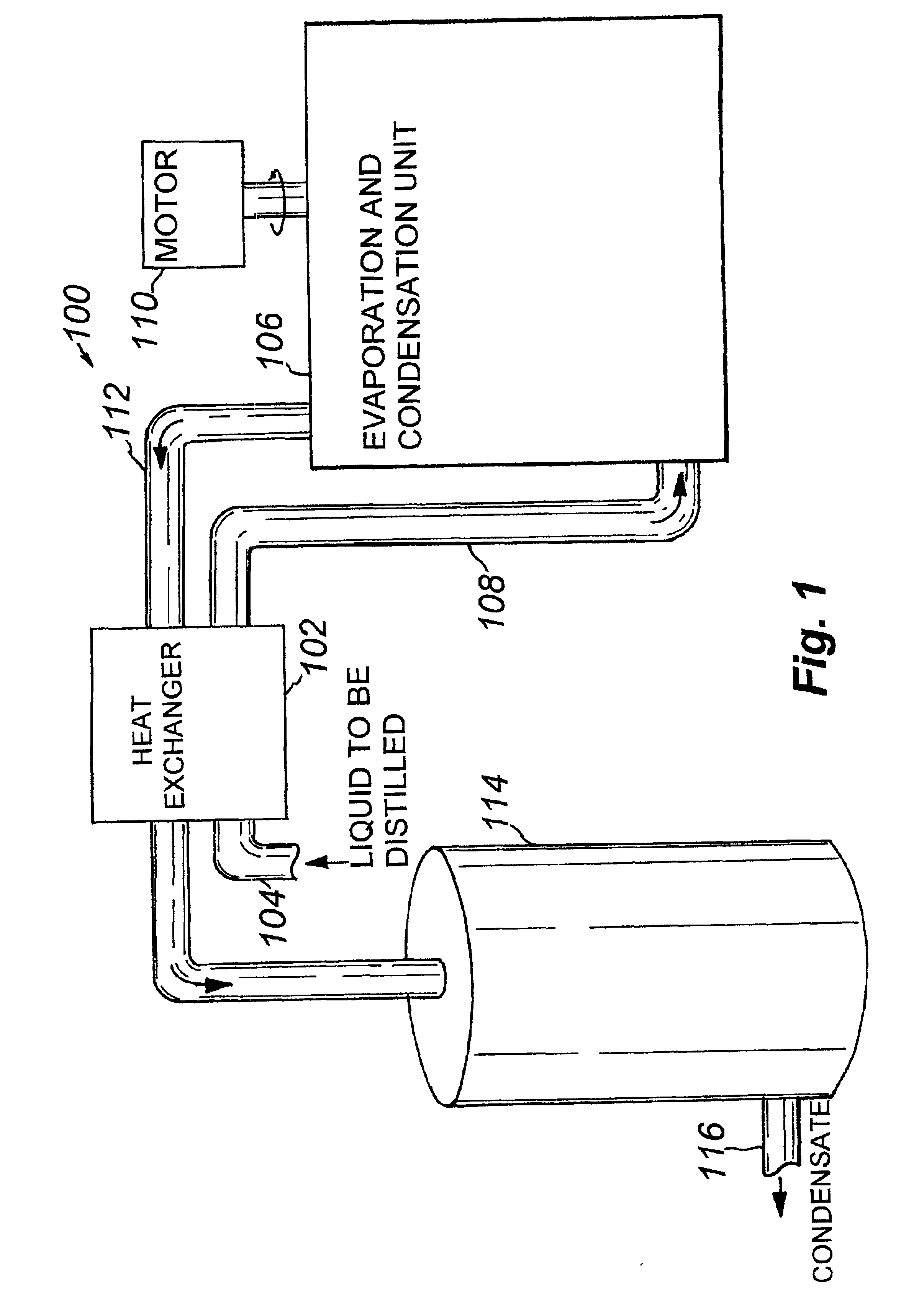

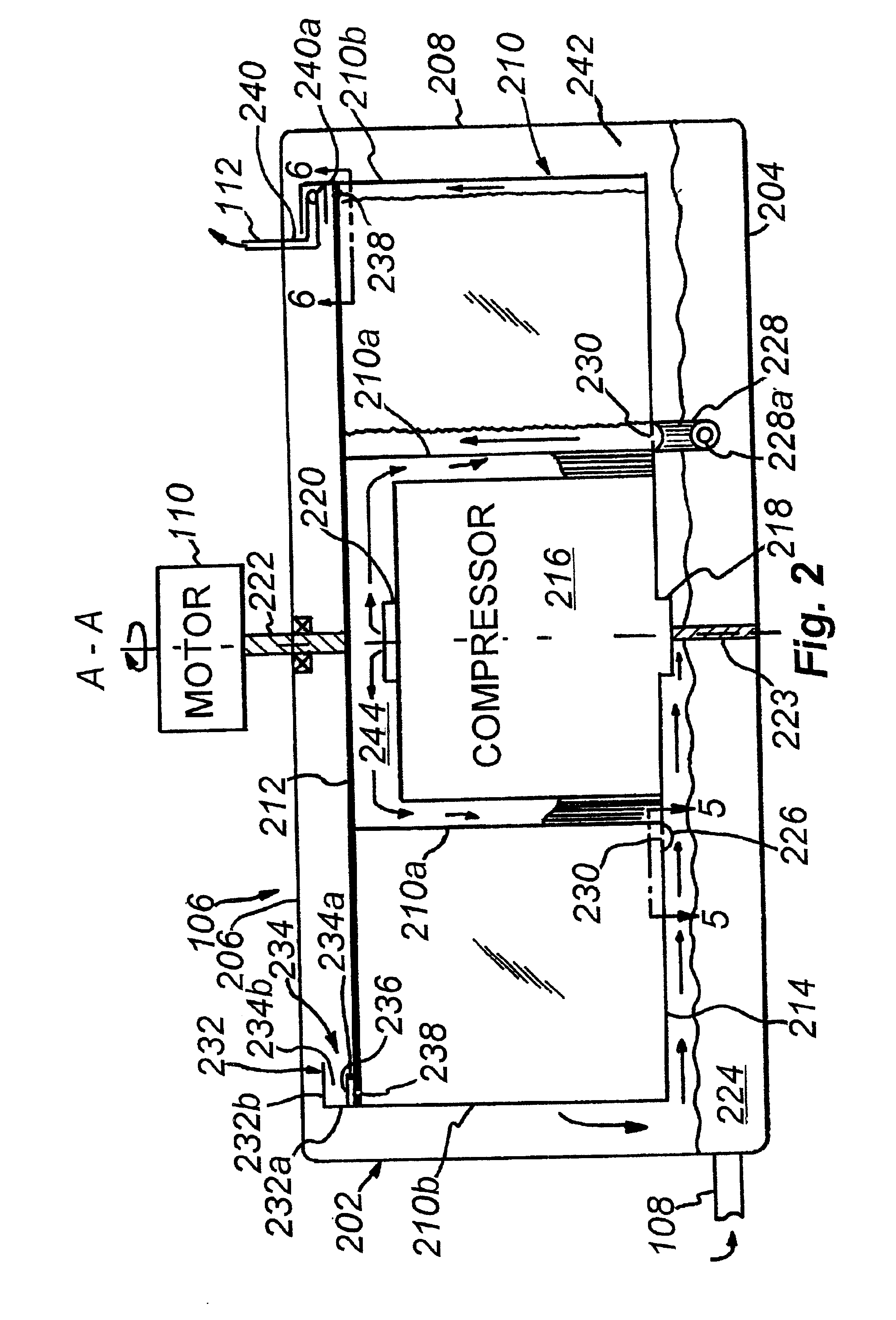

Embodiments of the invention are directed toward a novel pressurized vapor cycle for distilling liquids. In some embodiments of the invention, a liquid purification system is revealed, including the elements of an input for receiving untreated liquid, a vaporizer coupled to the input for transforming the liquid to vapor, a head chamber for collecting the vapor, a vapor pump with an internal drive shaft and an eccentric rotor with a rotatable housing for compressing vapor, and a condenser in communication with the vapor pump for transforming the compressed vapor into a distilled product. Other embodiments of the invention are directed toward heat management, and other process enhancements for making the system especially efficient.

Owner:DEKA PROD LLP

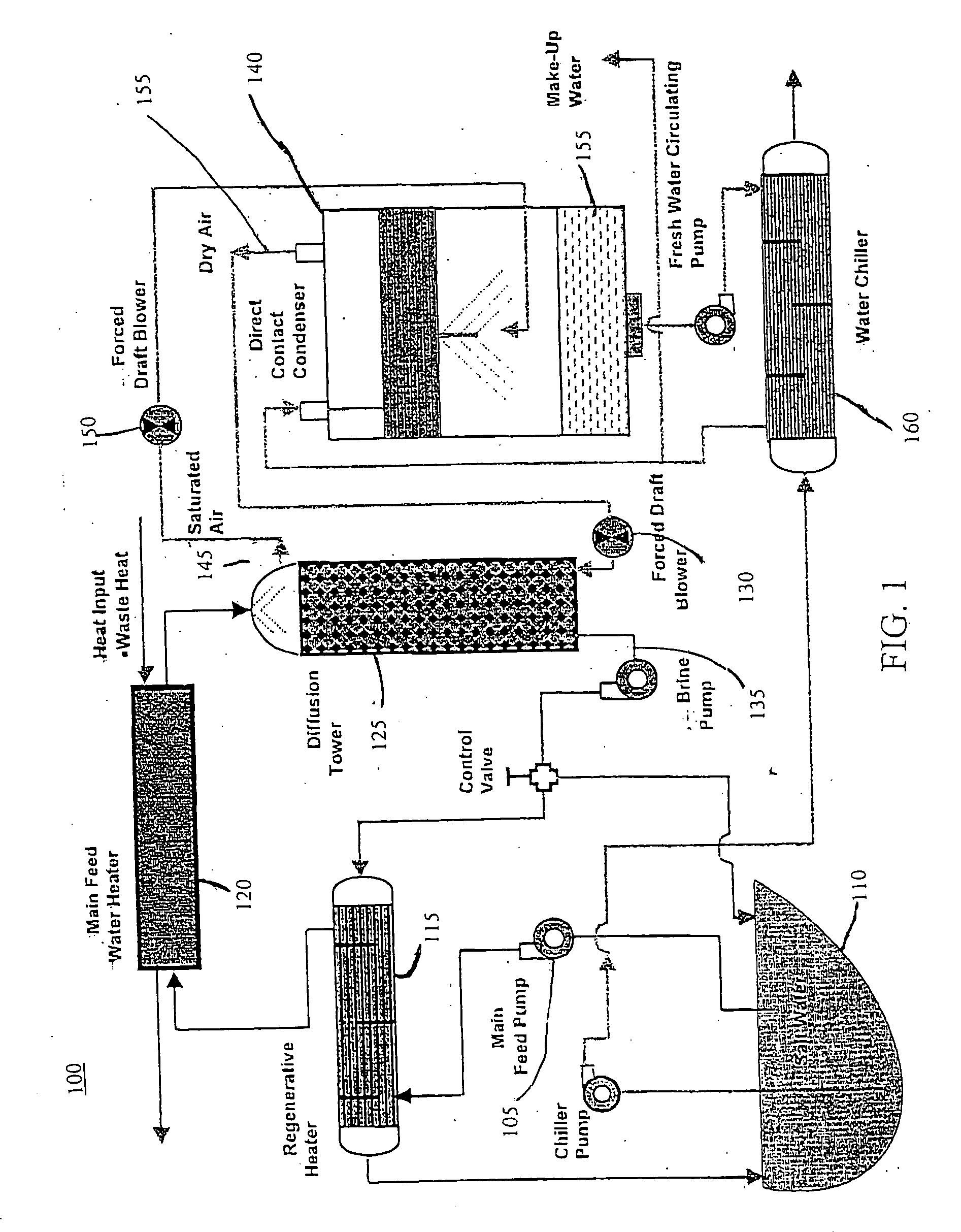

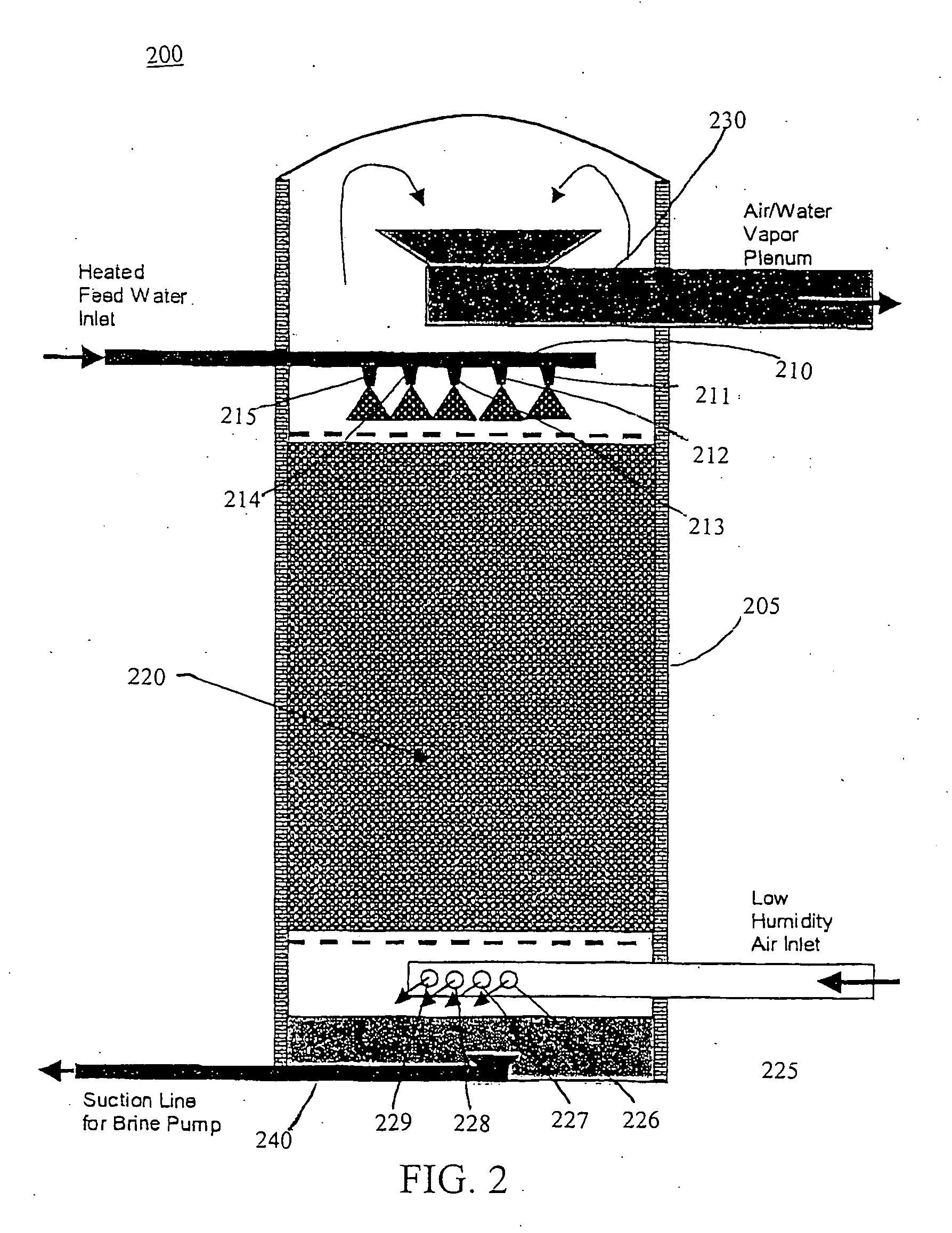

Diffusion driven water purification apparatus and process

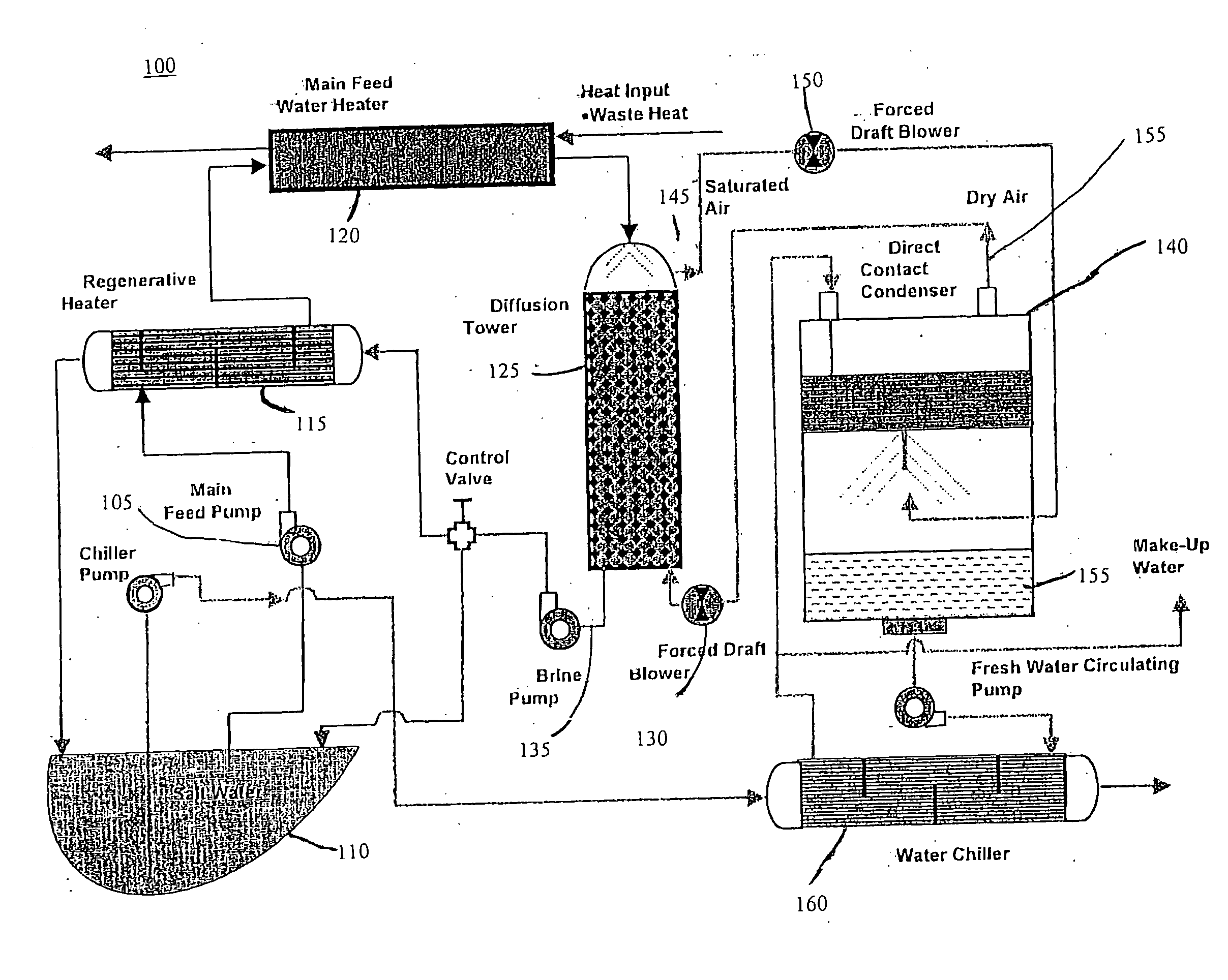

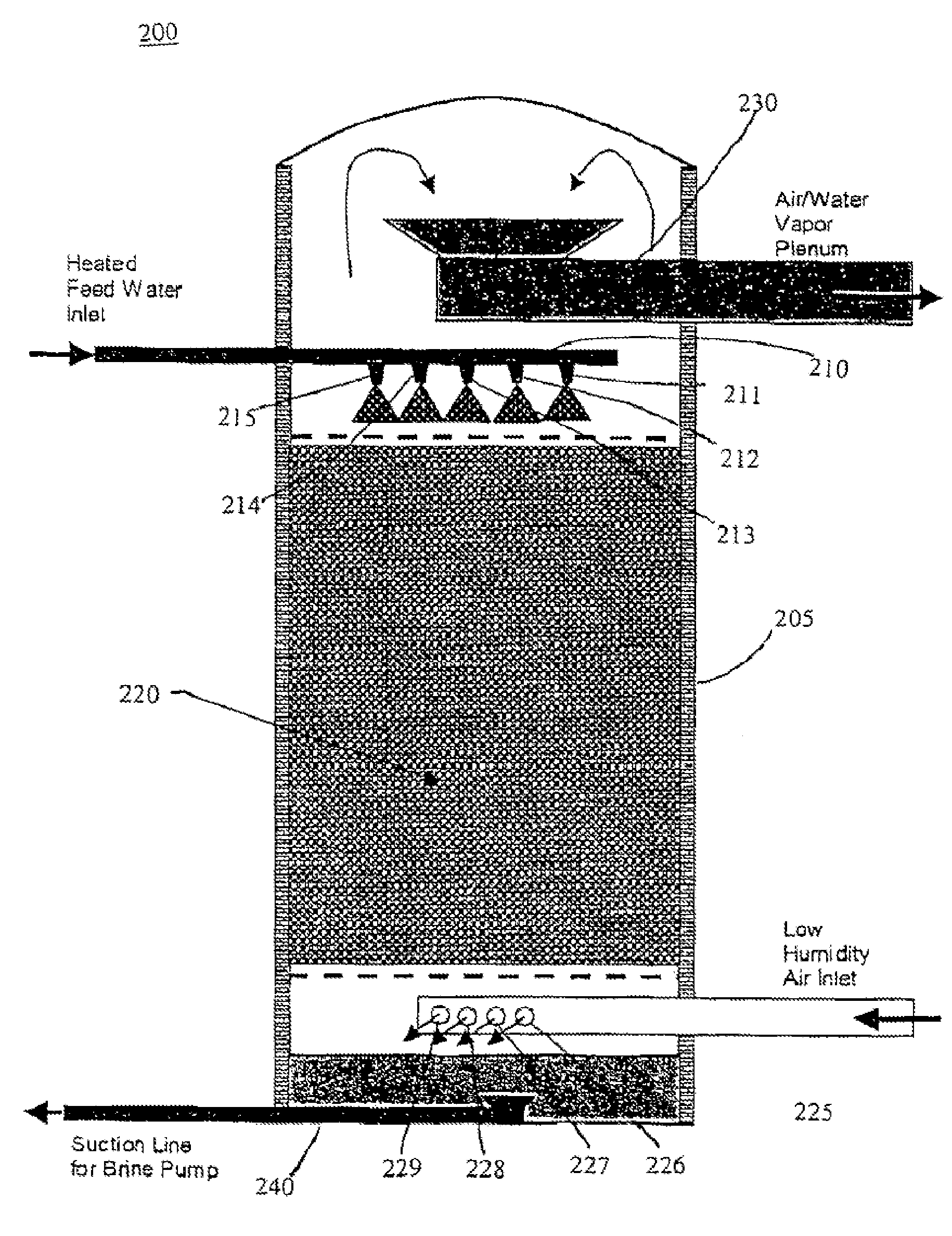

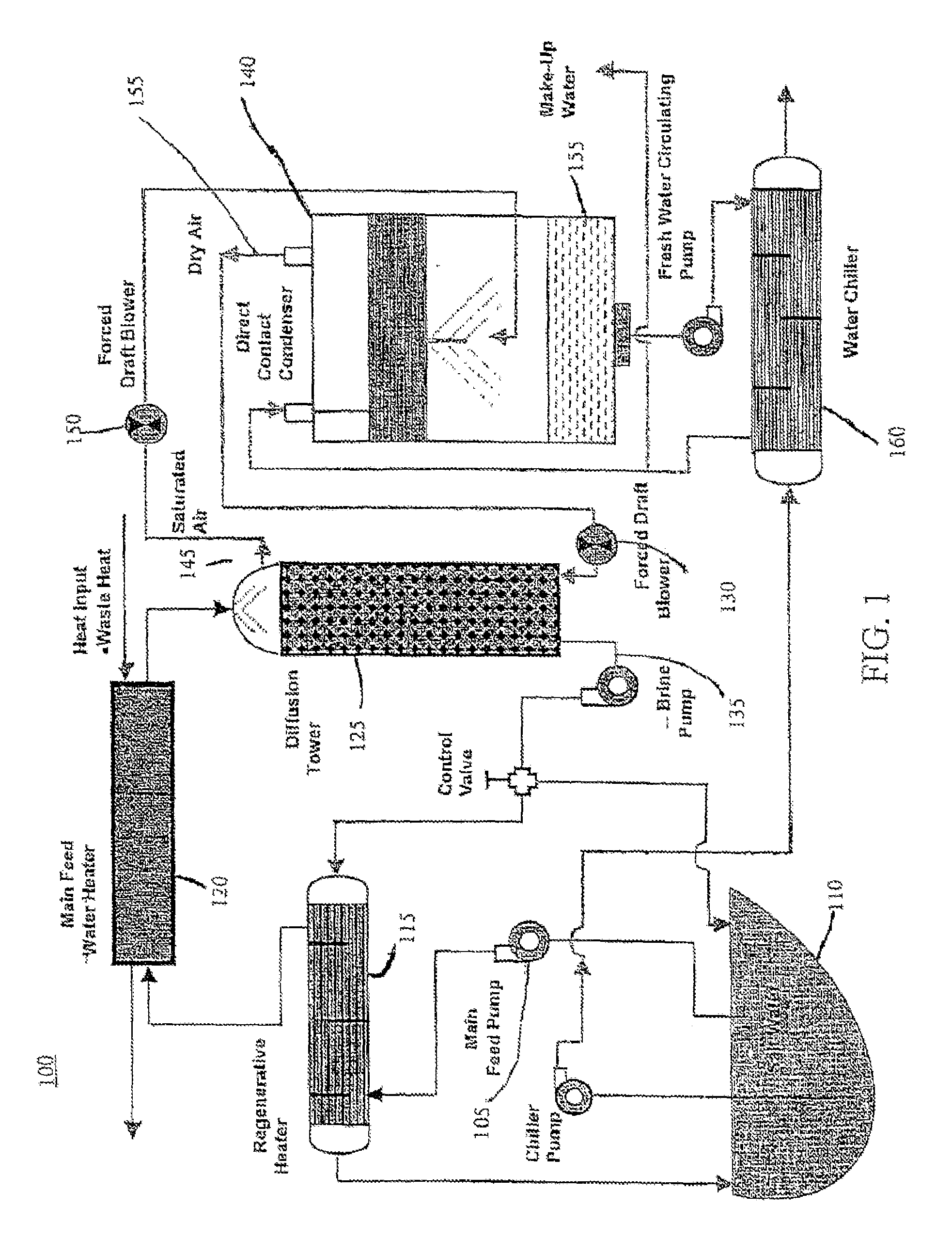

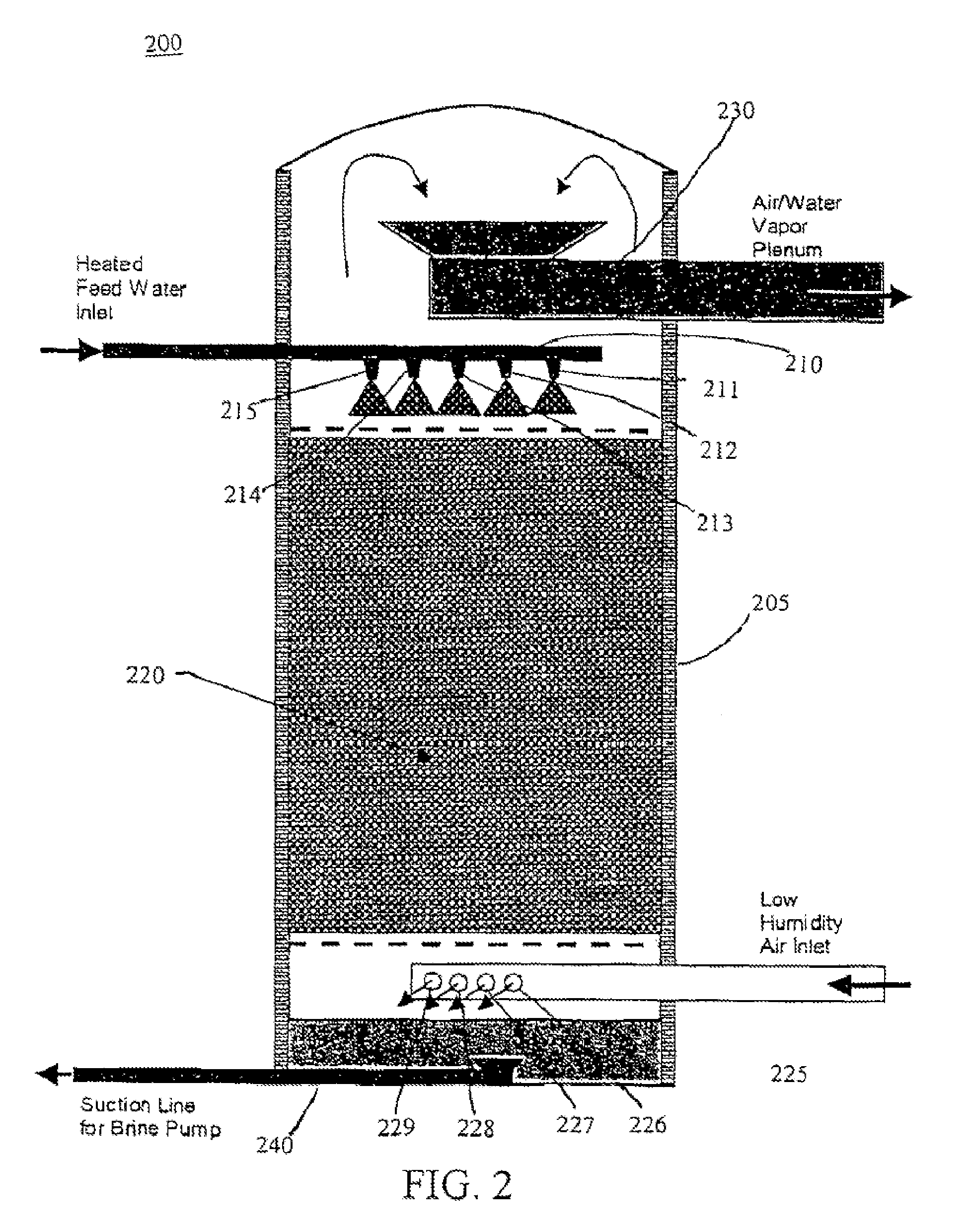

An apparatus for purifying water, such as for desalinization, includes a source of a heated air stream, the heated air stream having a temperature above an ambient temperature. A diffusion tower having high surface area material therein receives a water stream including at least one impurity and creates at least one region having thin films of water therein from the water stream. The heated air stream is directed over the thin films of water to create a humidified air stream that is at least substantially saturated. At least one direct contact condenser is in fluid communication with the humidified air stream for condensing the humidified air stream, thus producing purified water. A power plant can include the apparatus for purifying water, where energy to heat the air stream is provided by low pressure condensing steam.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

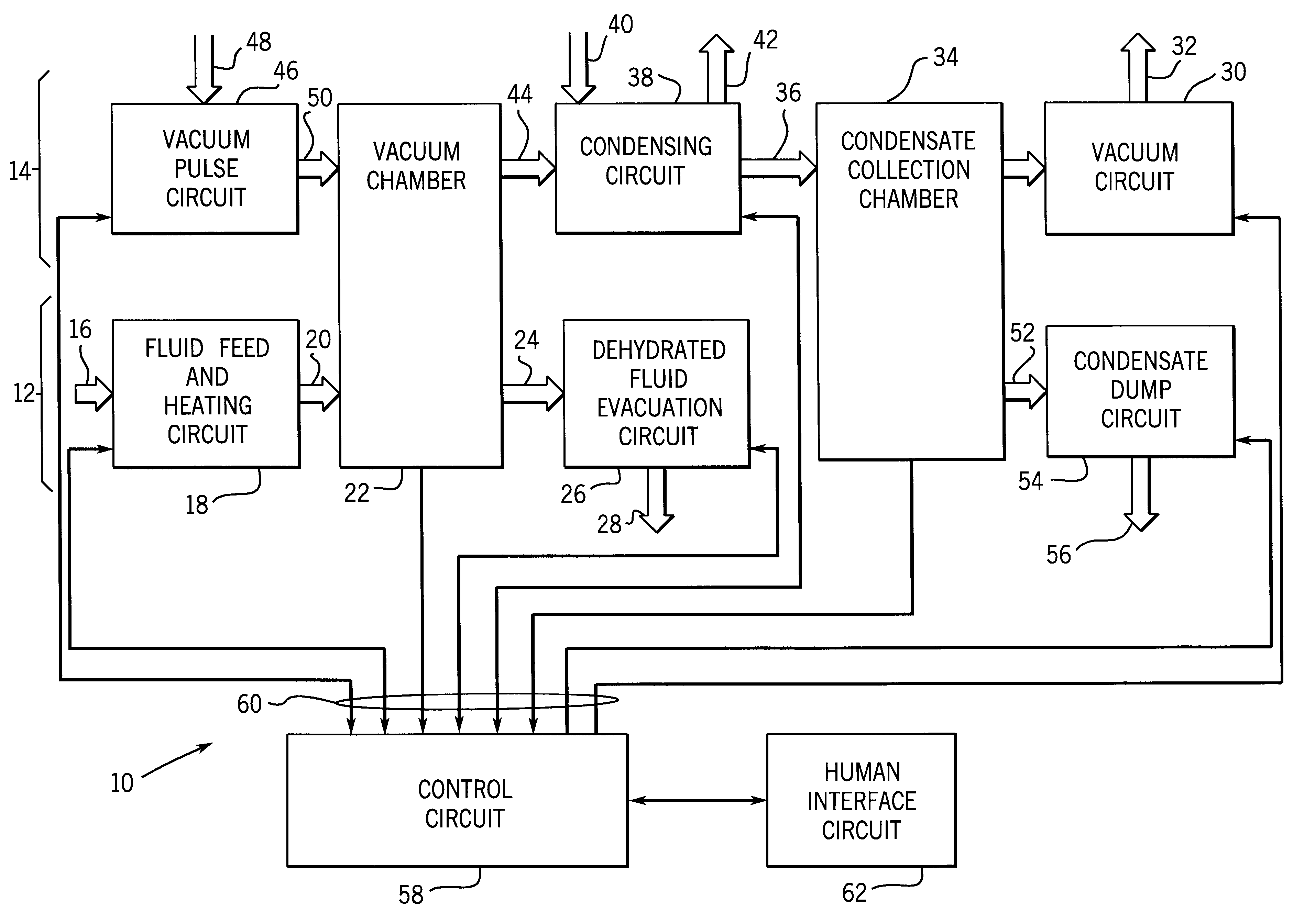

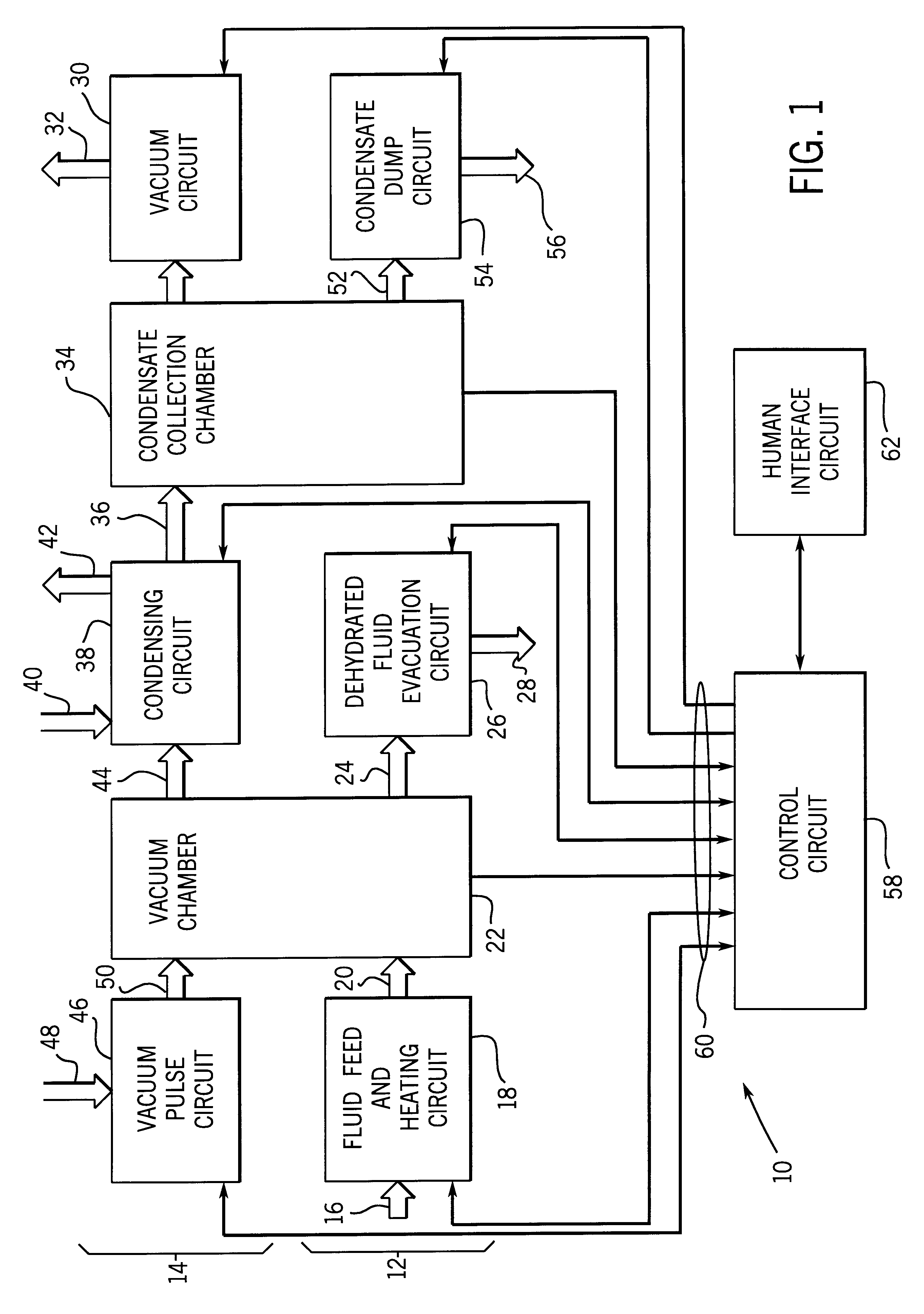

Apparatus for dehydrating oil

InactiveUS6224716B1Distillation regulation/controlEvaporation with vapour compressionVacuum pressureClosed loop

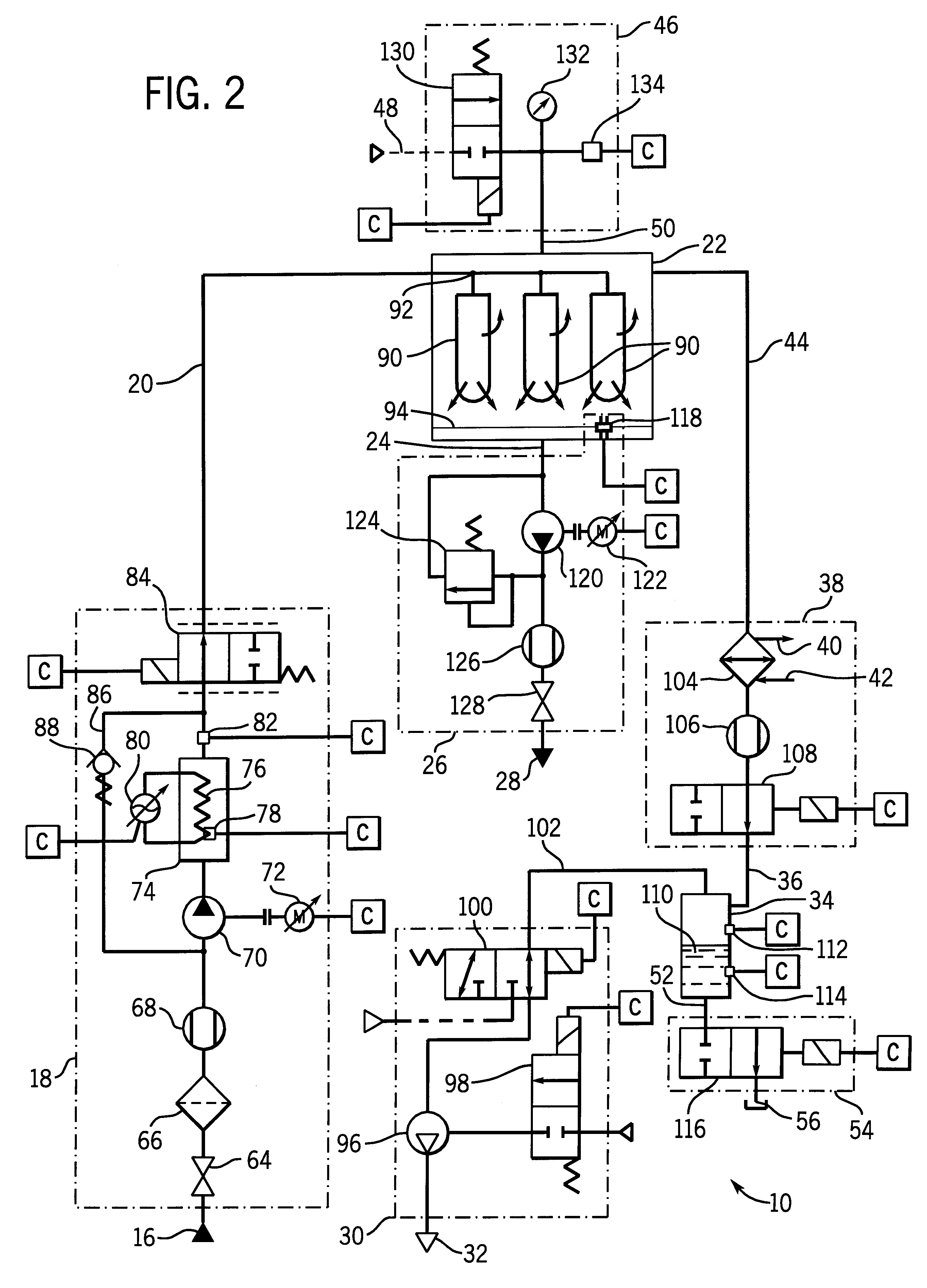

A system for dehydrating lubricating and hydraulic fluids includes a heating circuit and circuitry for creating a vacuum. The heating circuitry introduces a stream of heated fluid into a vacuum chamber in which a partial vacuum is drawn by the vacuum circuit. Aqueous components of the fluid stream are flashed in the vacuum chamber by virtue of the elevated temperature and reduced pressure. Dehydrated fluid is then collected and evacuated from the vacuum chamber. Vapor from the vacuum chamber, including the aqueous components of the fluid stream are collected, condensed and separately evacuated. The heating circuit limits surface temperature of a heating element in a closed-loop manner to avoid degradation of the fluid. The fluid stream is introduced into the vacuum chamber or is recirculated through the heating circuit to maintain a desired level of fluid temperature in a closed-loop manner. The system includes circuits for evacuating dehydrated fluid in a closed-loop manner and for automatically discharging condensate. The technique avoids undesirable foaming of dehydrated fluid within the vacuum chamber. A vacuum pulsing circuit is provided for periodically pulsing vacuum pressure within the vacuum chamber to aid in flashing aqueous components from the heated fluid stream.

Owner:OILQUIP

Diffusion driven water purification apparatus and process

Owner:UNIV OF FLORIDA RES FOUNDATION INC

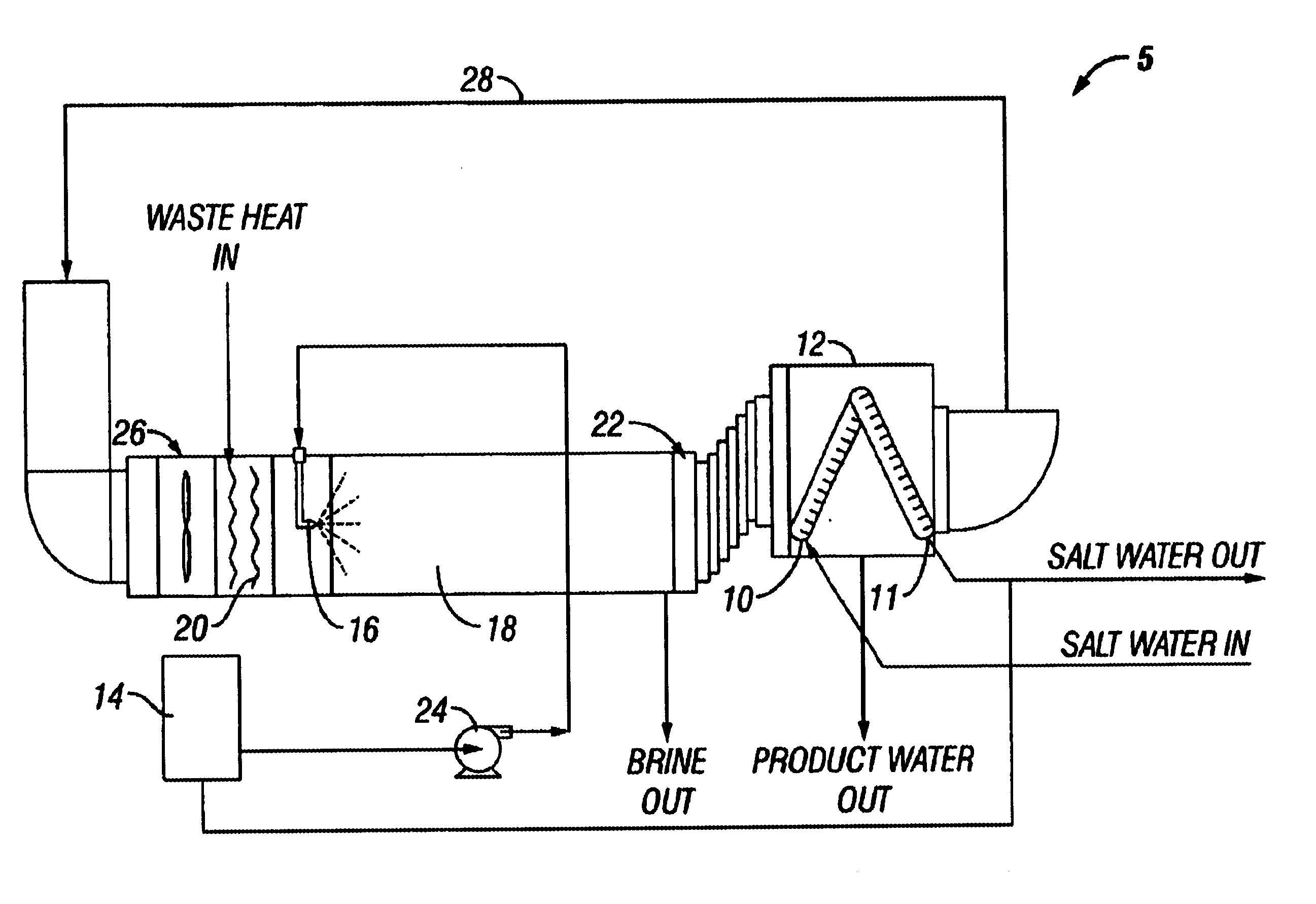

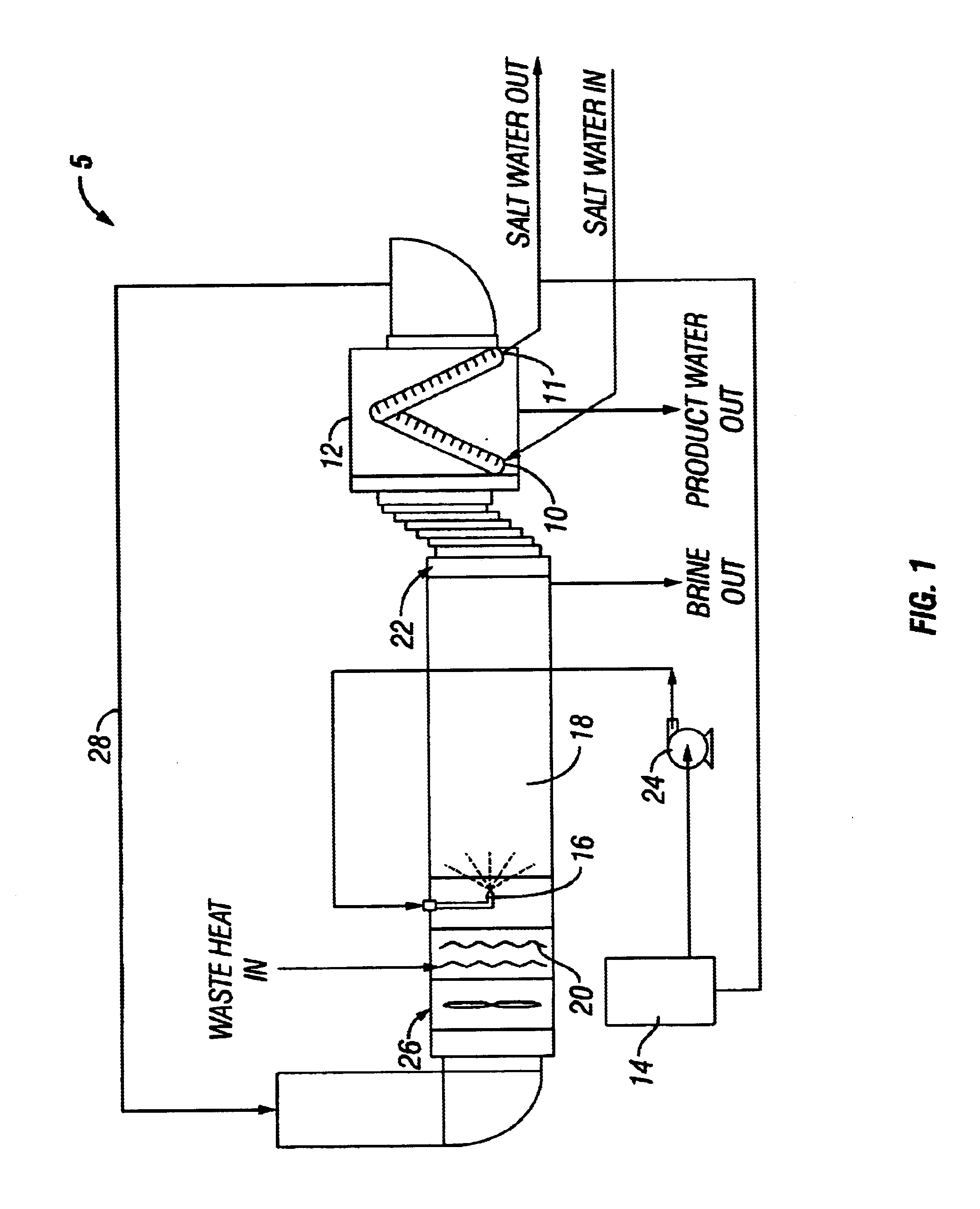

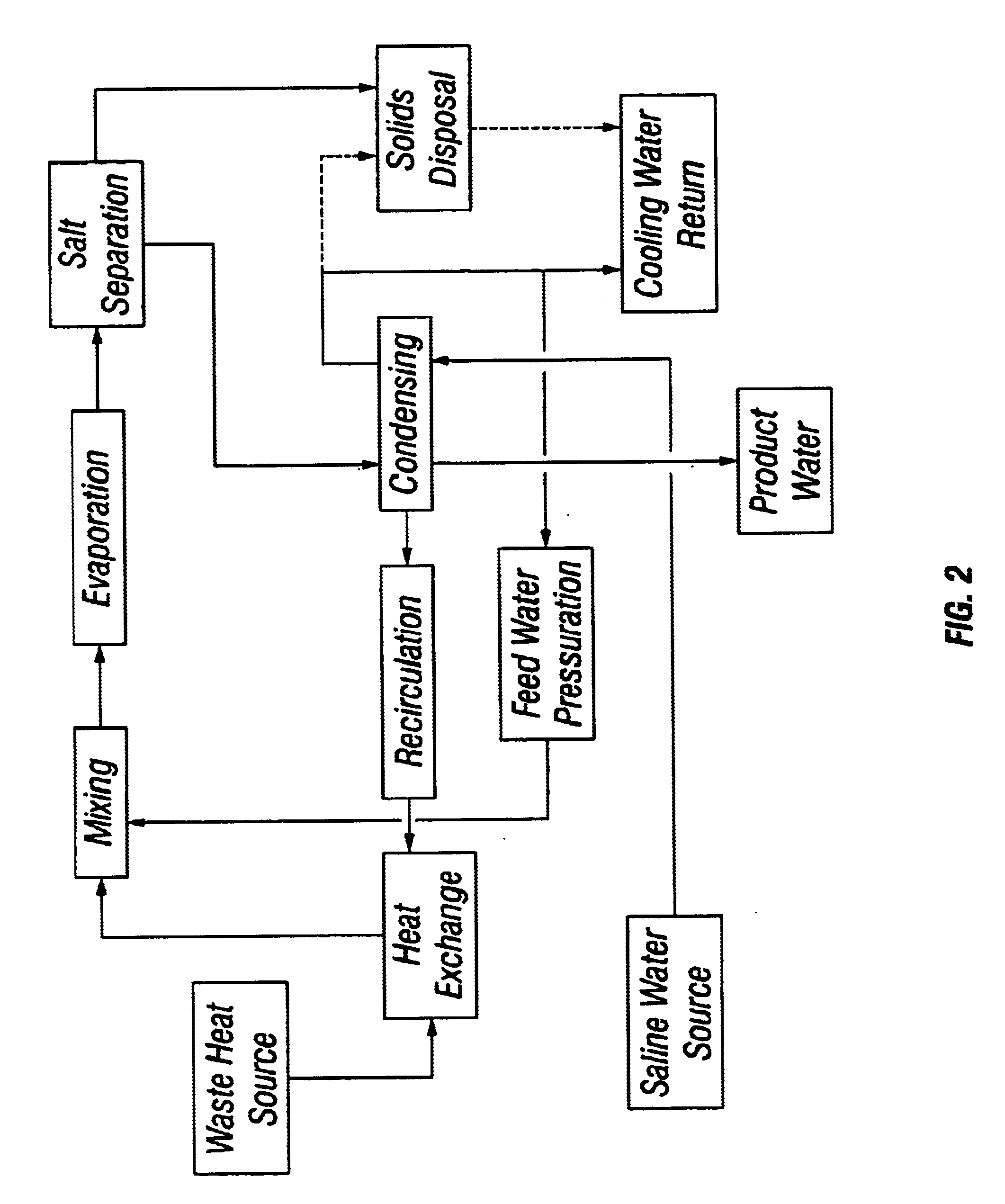

Apparatus and method for thermal desalination based on pressurized formation and evaporation of droplets

A method for removing dissolved solids, particularly salts, from water. An apparatus for performing the inventive method is disclosed. The aqueous solution to be treated, for example sea water, is atomized using special non-pneumatic nozzles, and sprayed into an evaporation chamber through which air, heated by waste heat, is blown. The micro-droplets undergo rapid evaporation in the chamber, resulting in the separation of the salt solids from the vapor phase of the water. The mixture of suspended solids and water vapor is filtered to remove and collect the salts, and the water vapor is condensed to collect the salt-free water.

Owner:AQUASONICS RSE INC

Liquid ring pumps with hermetically sealed motor rotors

ActiveUS7465375B2Easy maintenanceMaximize energy efficiencyGeneral water supply conservationDistillation regulation/controlDrive shaftDistillation

Owner:DEKA PROD LLP

Salt water distillation system

The salt water distillation system includes a sprinkler to form a mist of salt water over a distillation plate. The distillation plate is heated by applying electrical current to a heating coil. The steam is transferred to a condensation chamber and condensed fresh water is collected. During the desalination process, salt impurities are deposited on the hot distillation plate. A sludge remover, i.e., a steam head and movable ram, is provided to clean the distillation plate of the salt impurities. An exhaust fan is provided to cool fresh water condensate and lower air pressure in the system. Heat transferred from the steam during condensation is used to pre-heat the salt water to increase efficiency of the system.

Owner:RIVES MICHAEL L +1

Method and apparatus for purifying water

ActiveUS8097128B1Improve efficiencyImprove throughputLiquid degasificationAuxillariesThermal energyInternal combustion engine

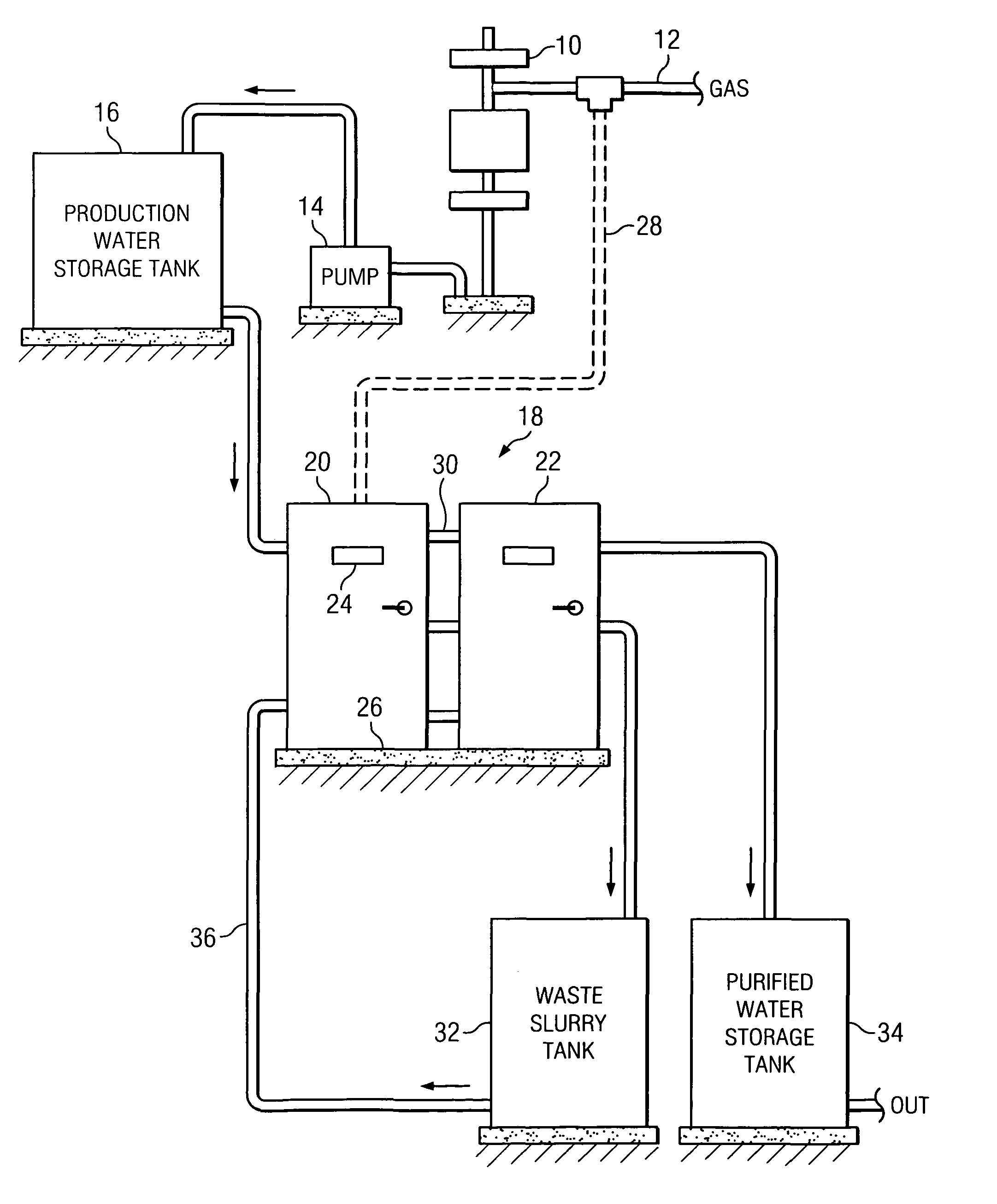

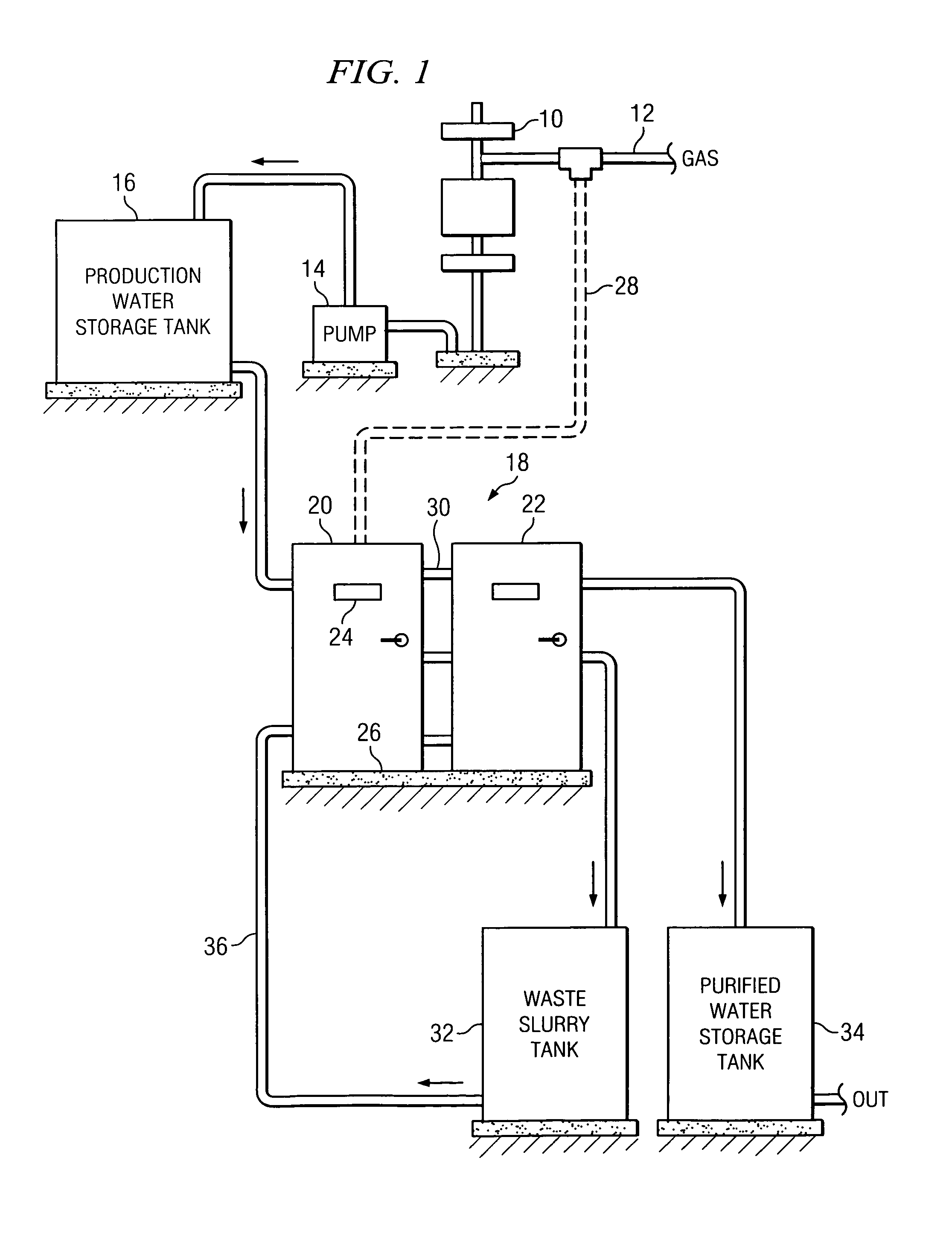

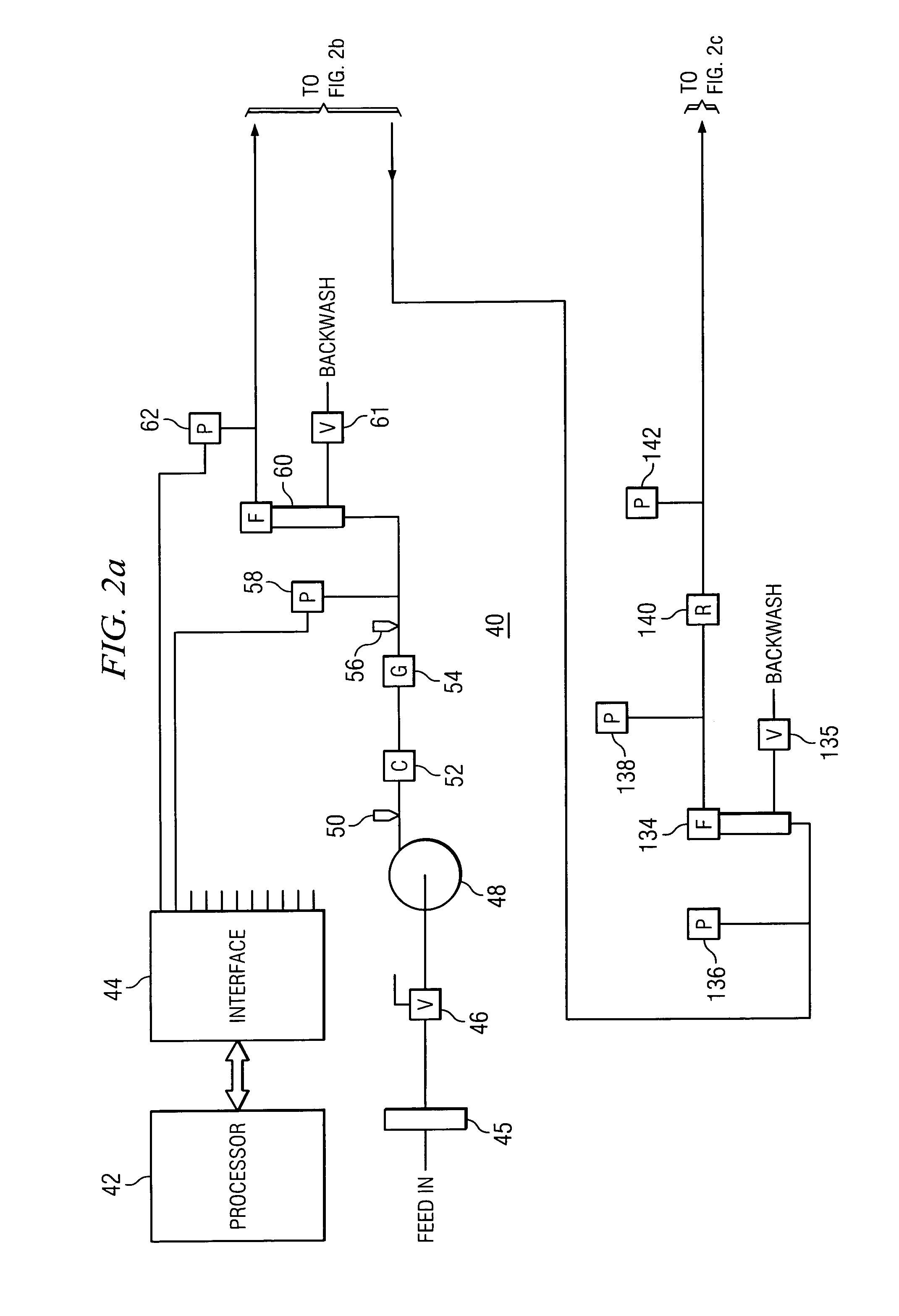

An efficient flash evaporation water purification system located at a hydrocarbon well site. An internal combustion engine uses hydrocarbon fuel from the well and drives a pump to pressurize production water from the well. The engine also generates thermal energy used to preheat the production water. An electrical generator is also driven by the engine to produce electrical power for the water purification system, as well as produce AC power for off-site consumers.

Owner:SHERRY RAYMOND C

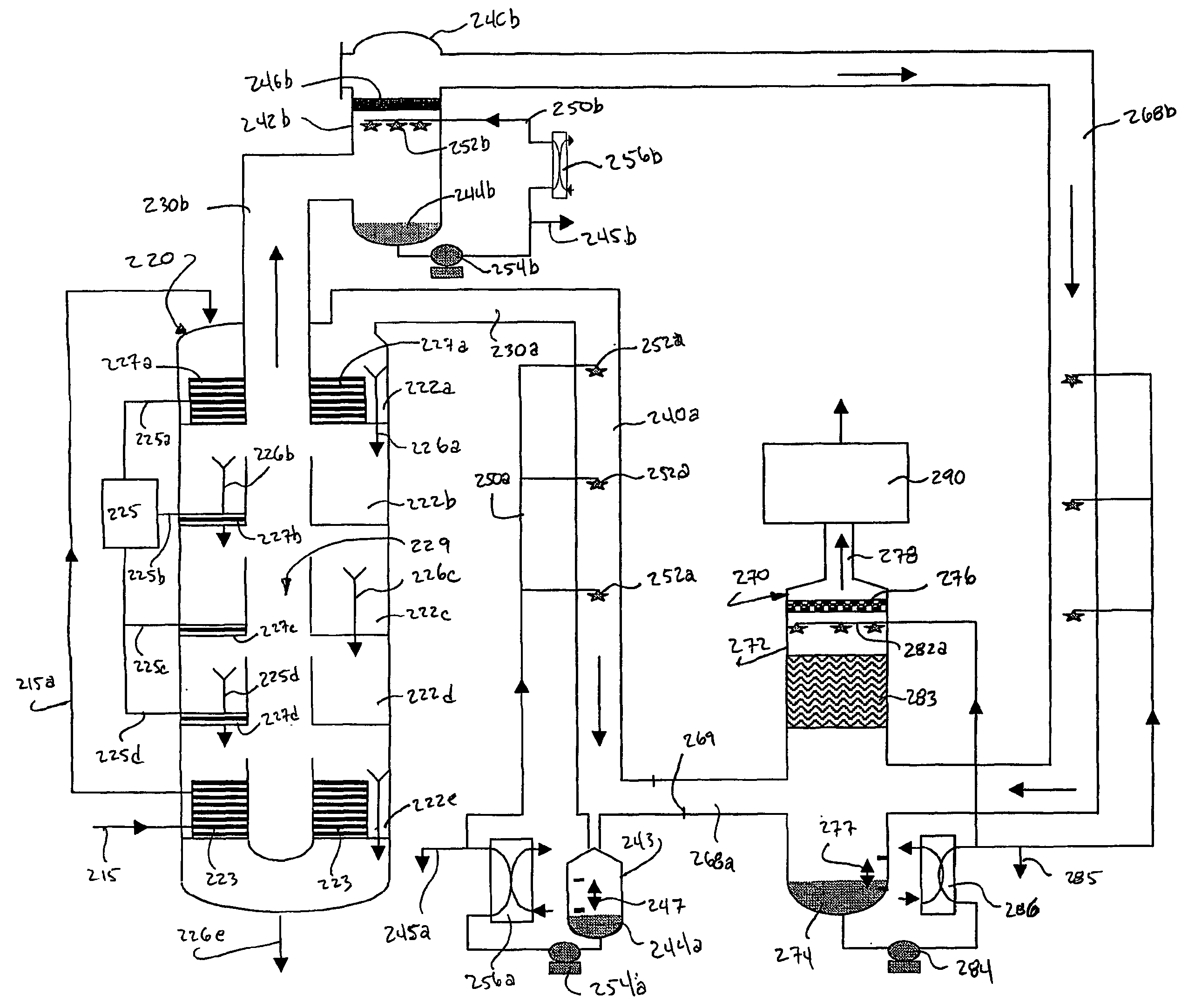

Method and apparatus for simultaneous heat and mass transfer utilizing a carrier-gas

InactiveUS6911121B1Improve concentrationDistillation regulation/controlEnergy based wastewater treatmentDewEvaporation chamber

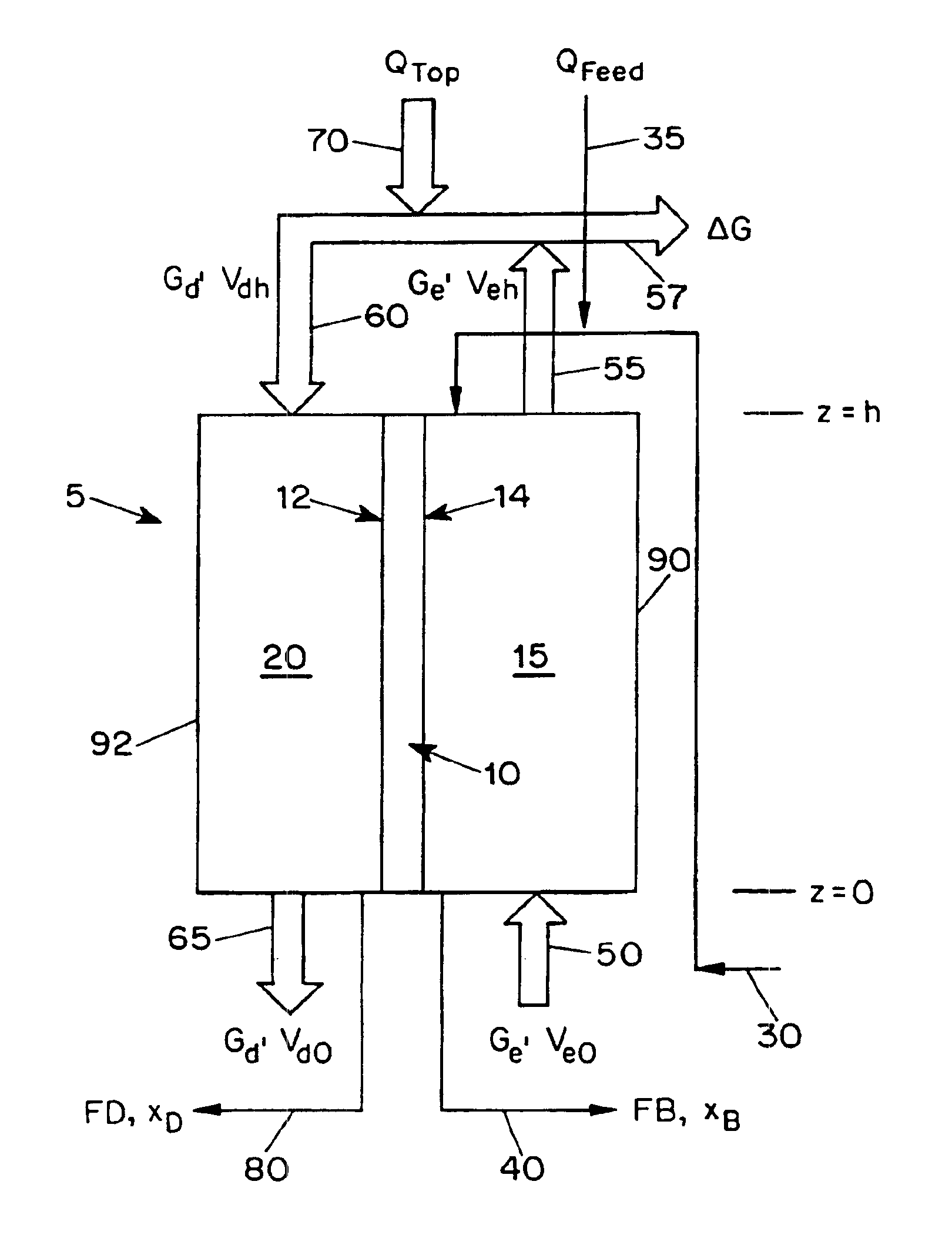

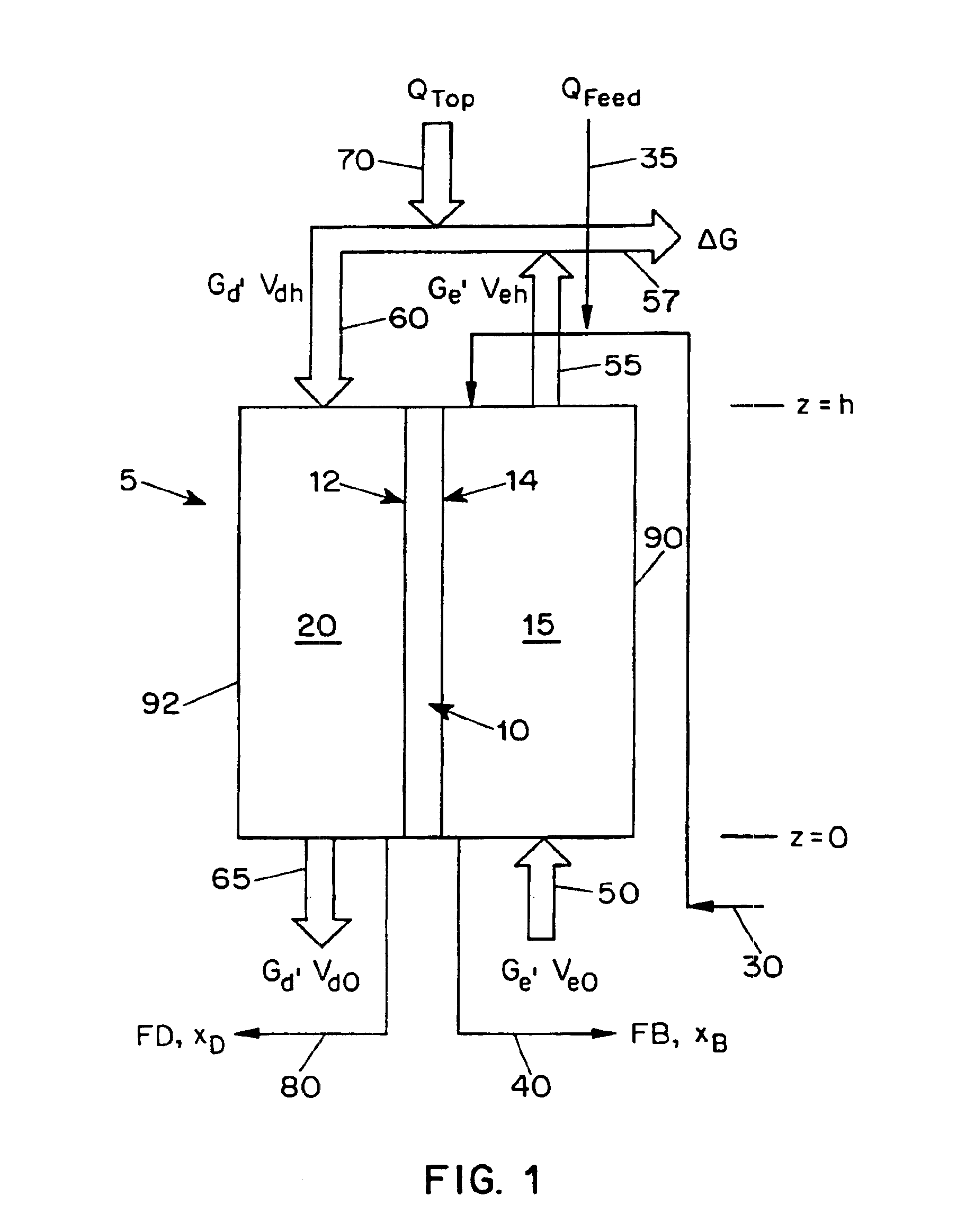

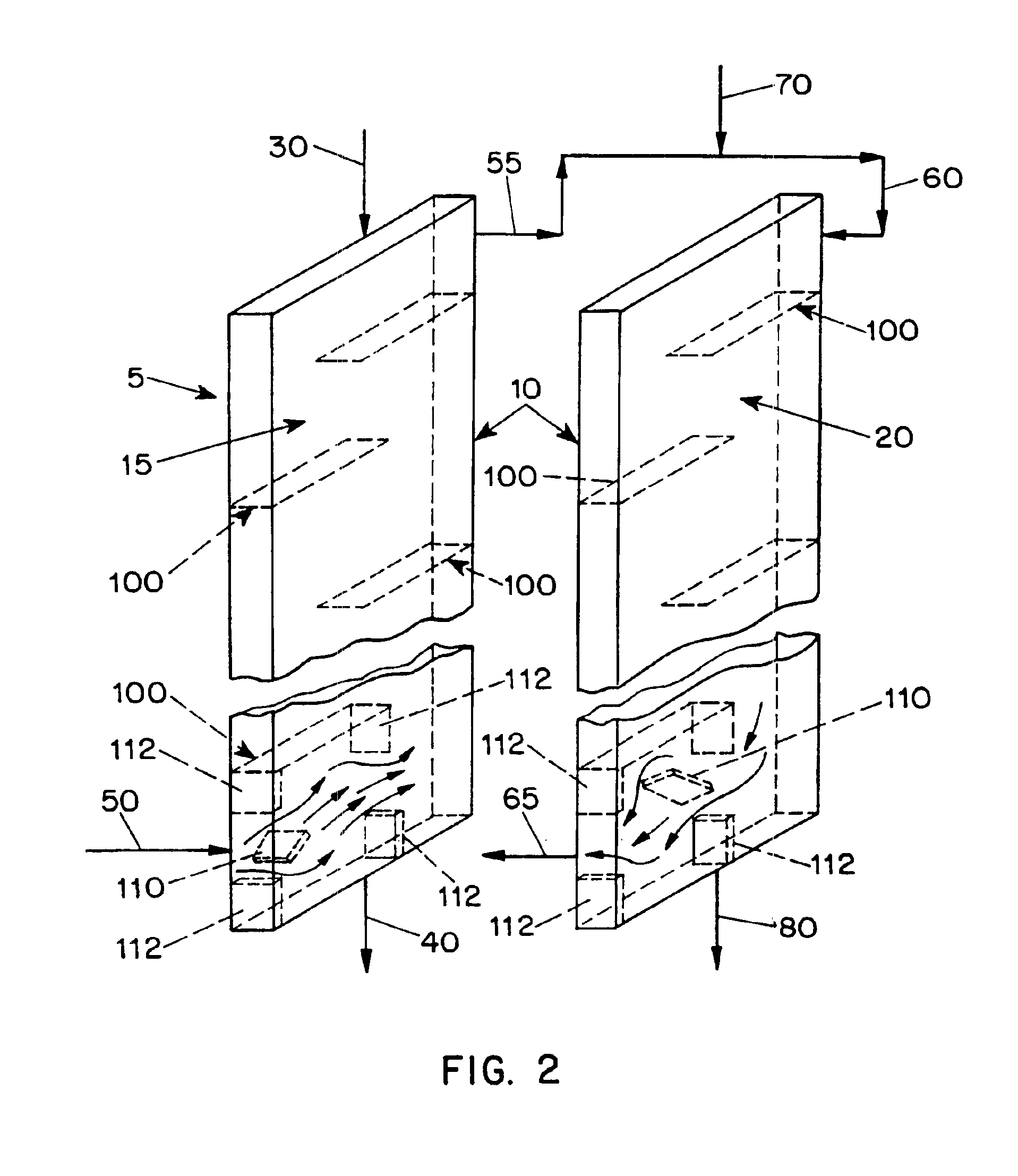

The present application is directed to a continuous contacting apparatus for separating a liquid component from a liquid mixture. The apparatus comprises: (i) an evaporation chamber (15) having first and second ends, an inlet (50) and an outlet (55) for a carrier gas, and an inlet (30) and an outlet (40) for a liquid mixture, wherein the inlet (30) for the liquid mixture and the outlet (55) of the carrier gas are located on the first end of the evaporation chamber (15); (ii) a dew-formation chamber (20) having an inlet (60) and an outlet (65) for a carrier gas and an outlet for the separable liquid component (80), wherein the inlet for the carrier gas (60) of the dew-formation chamber (20) is situated in a countercurrent manner to the inlet for the carrier gas of the evaporation chamber; (iii) a common heat transfer wall (10) providing thermal communication between the evaporation chamber (15) and the dew-formation chamber (20); (iv) a feeding device for providing the liquid mixture onto the evaporation side of the heat transfer wall; (v) an air mover for controlling a flow of a carrier gas through the chambers, wherein the gas flow in the evaporation chamber is countercurrent to the gas flow in the dew-formation chamber; and (vi) a heating apparatus for heating the carrier gas from the outlet of the evaporation chamber, wherein the heated carrier gas is directed to flow into the inlet of the dew-formation chamber. Also described is a process for separating a liquid component from a liquid mixture in a continuous contacting manner comprising employing such an apparatus for such separation.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA +1

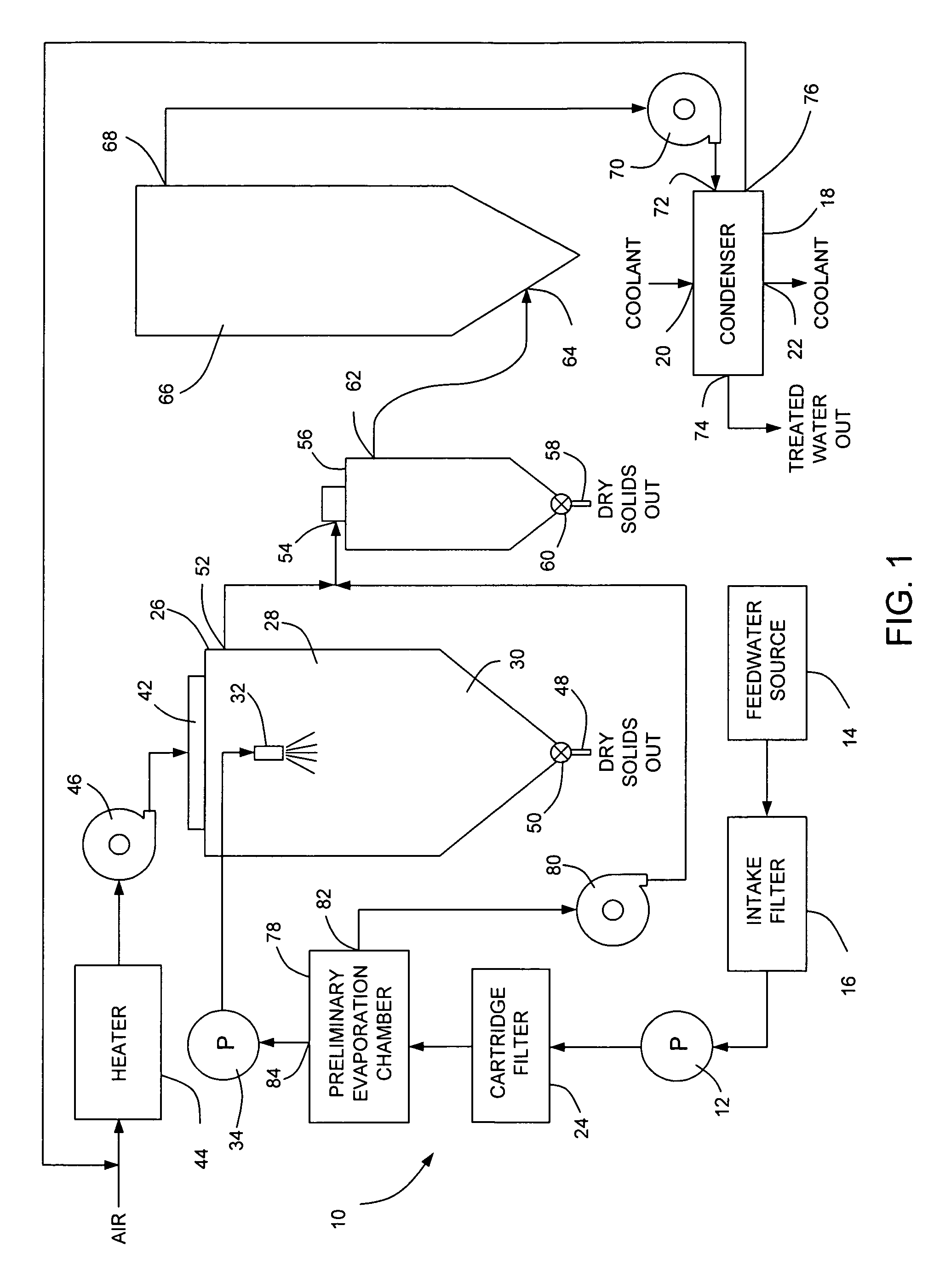

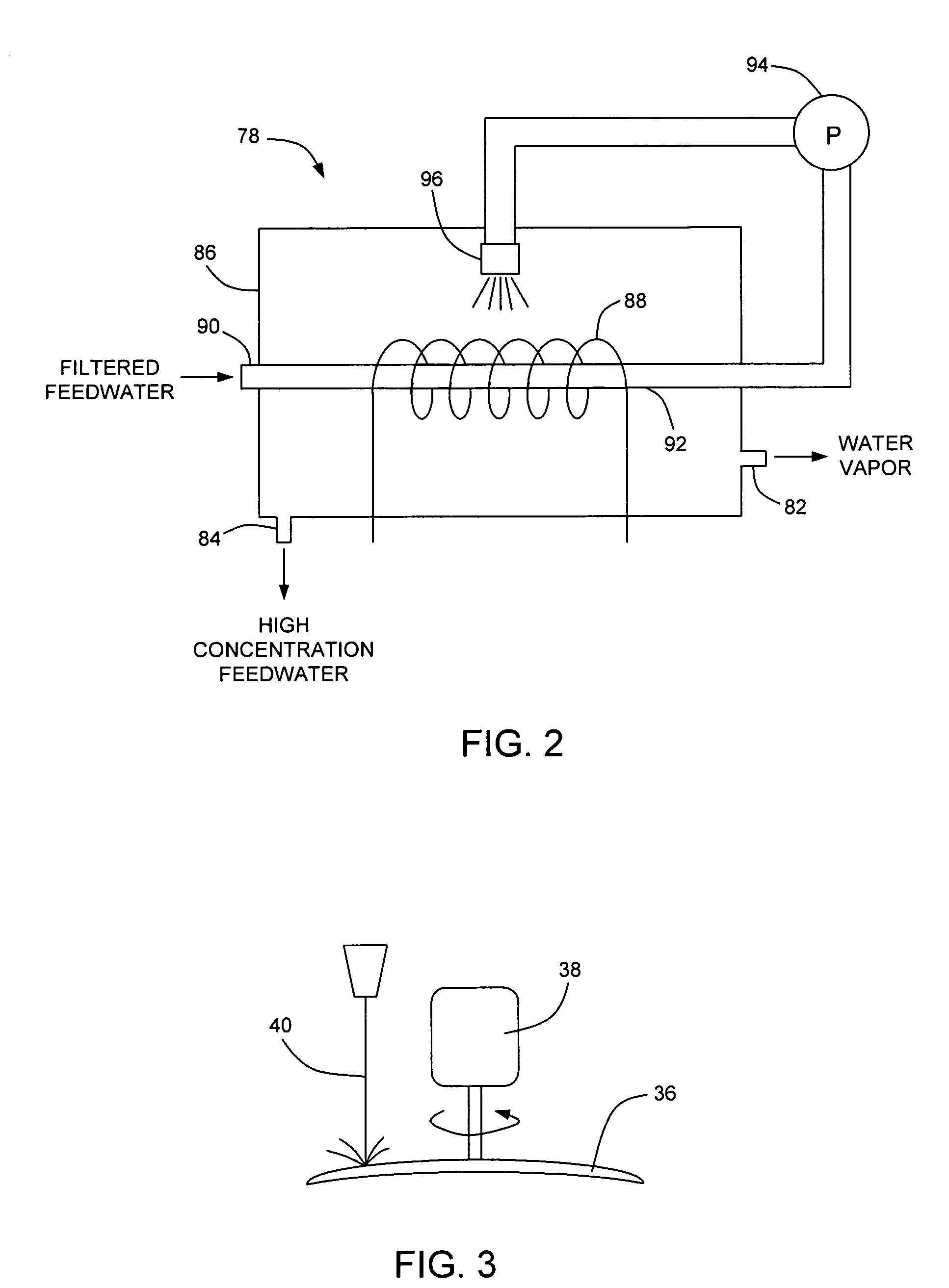

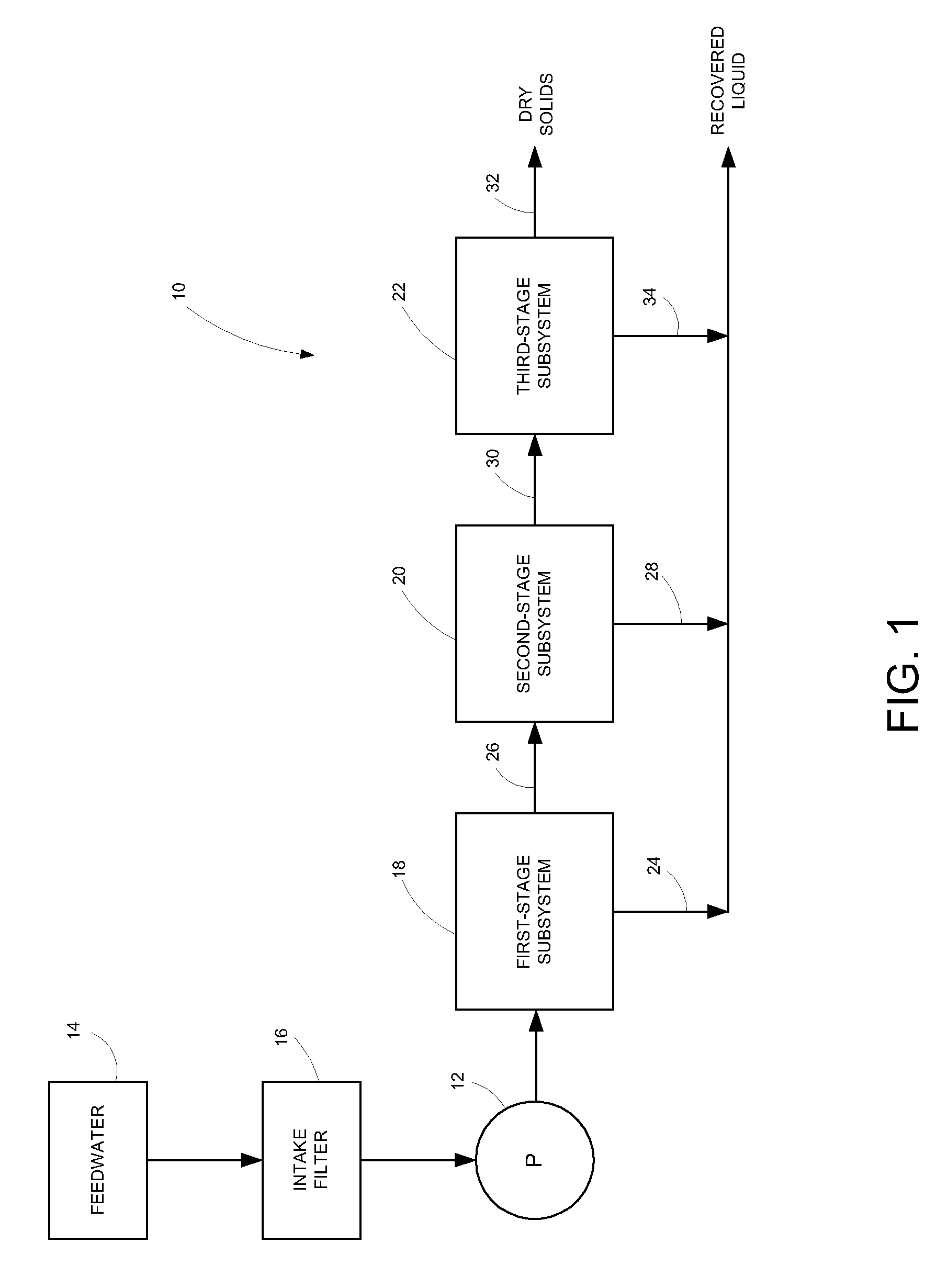

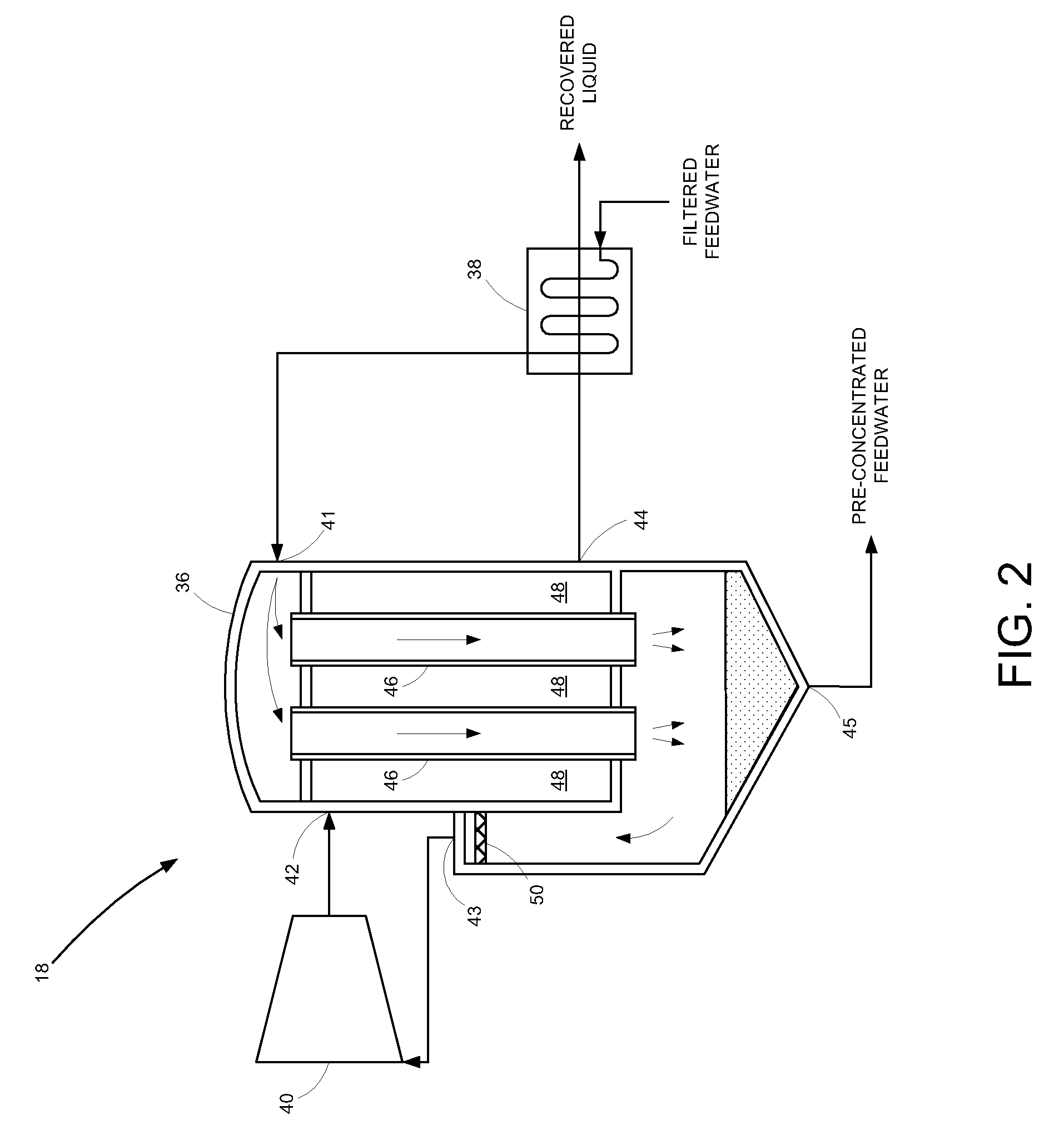

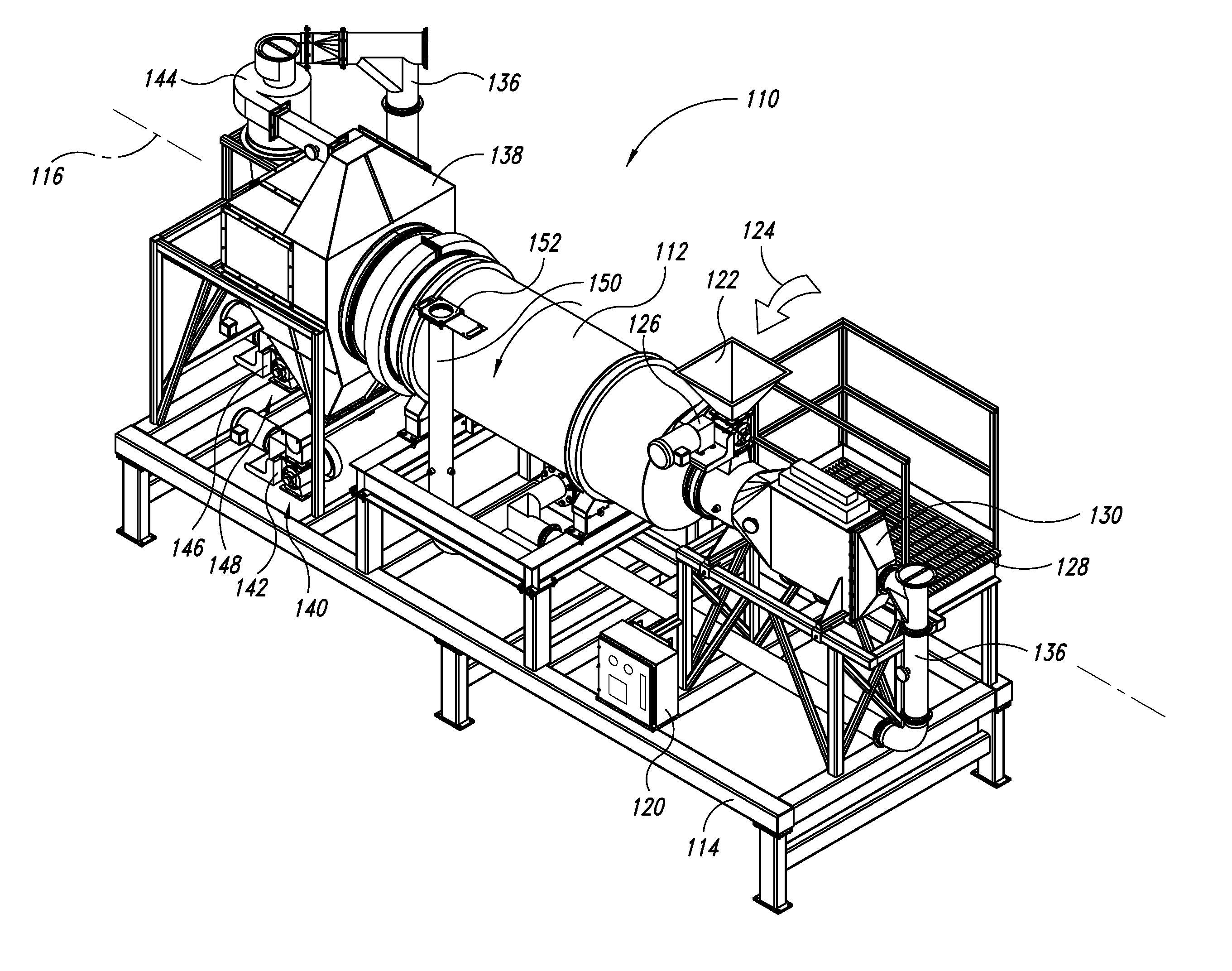

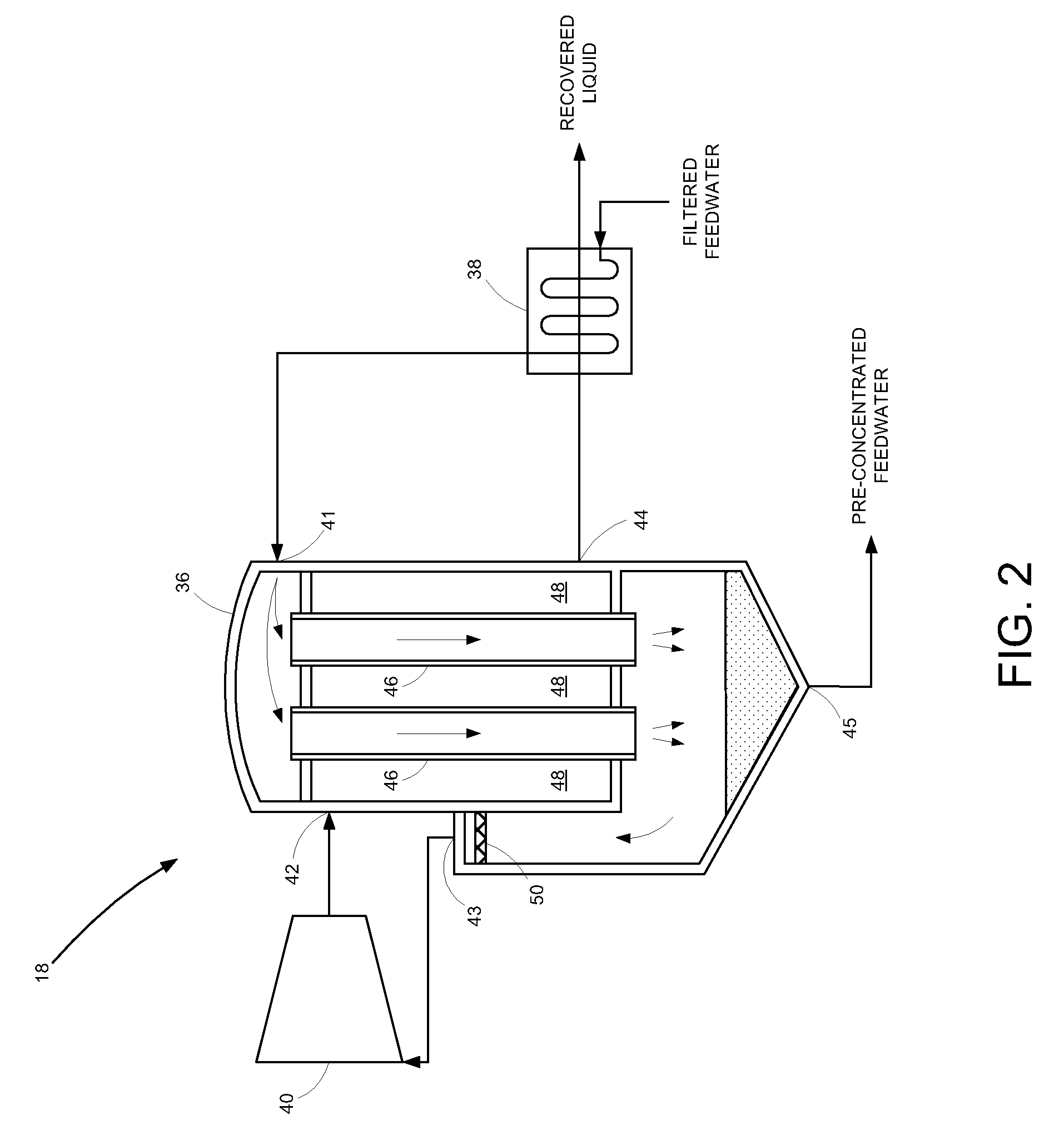

Method and system for separating solids from liquids

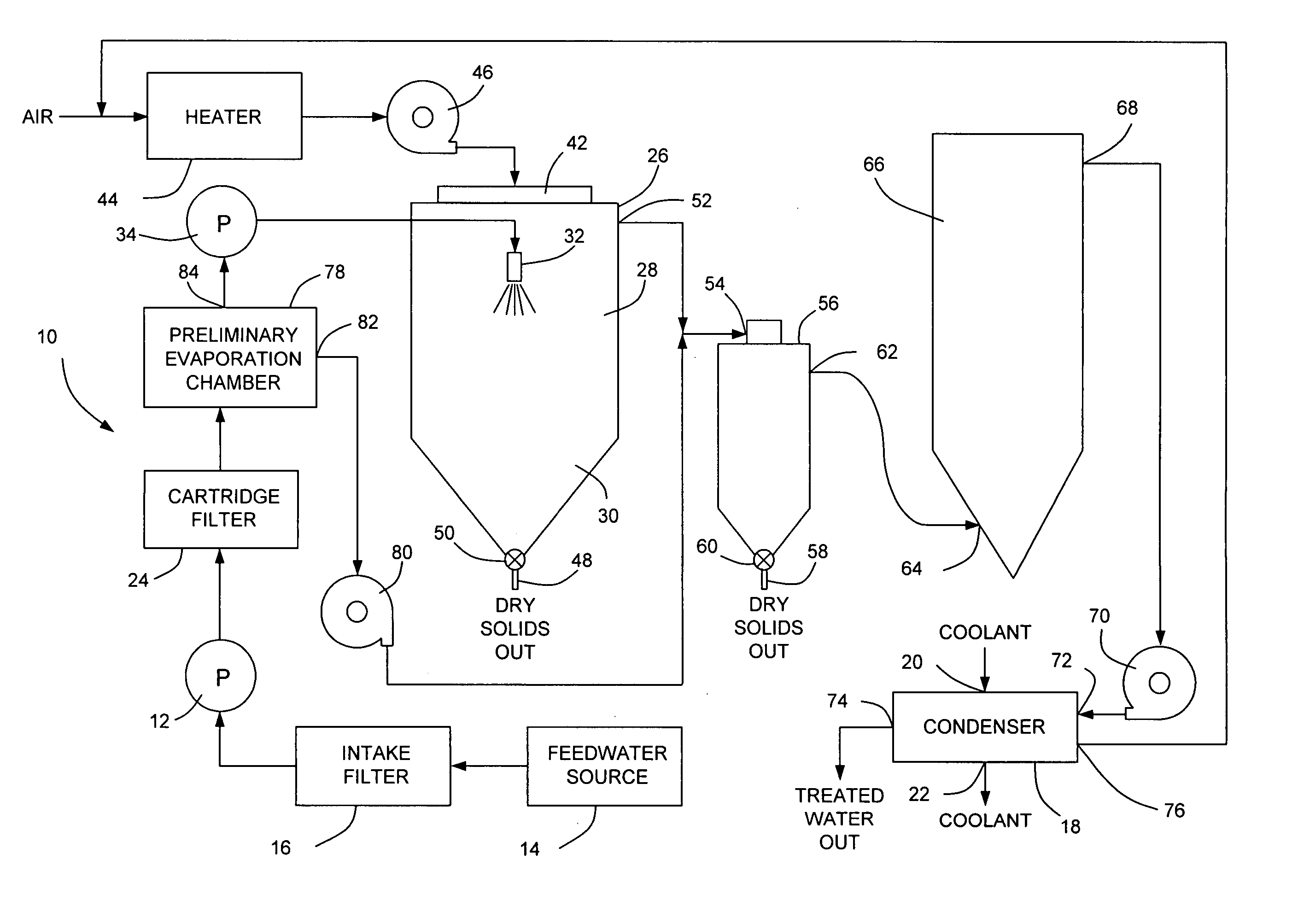

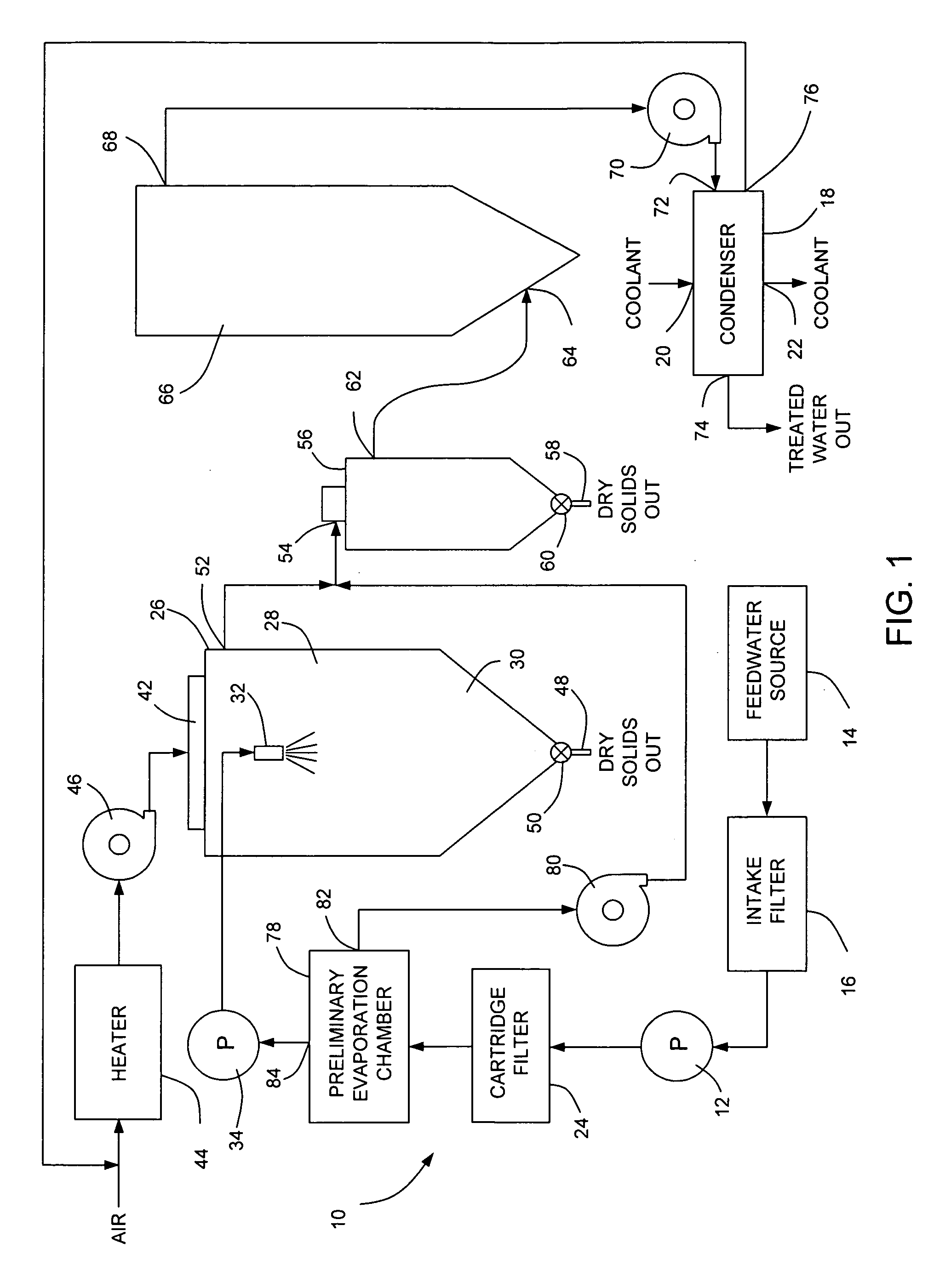

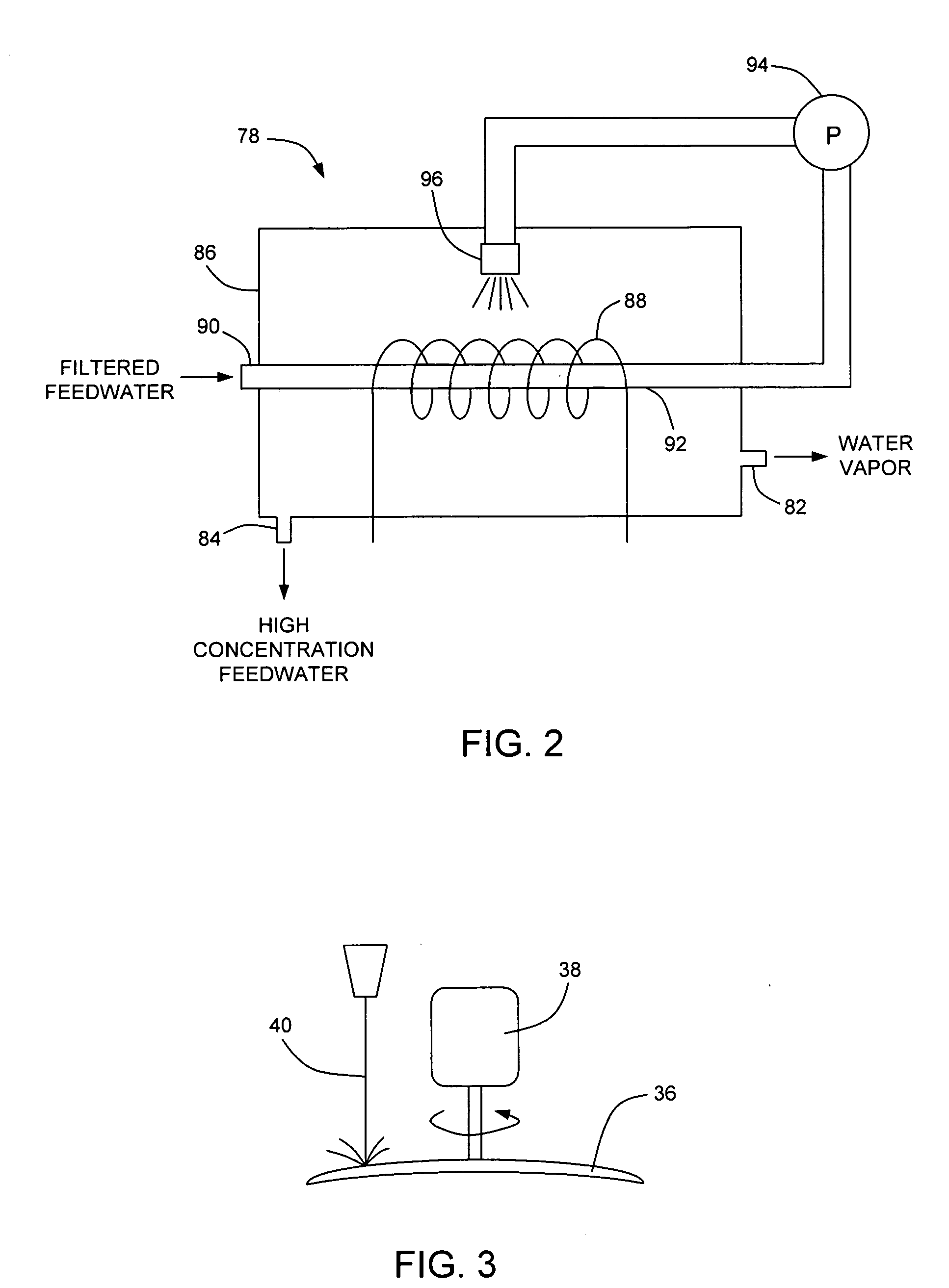

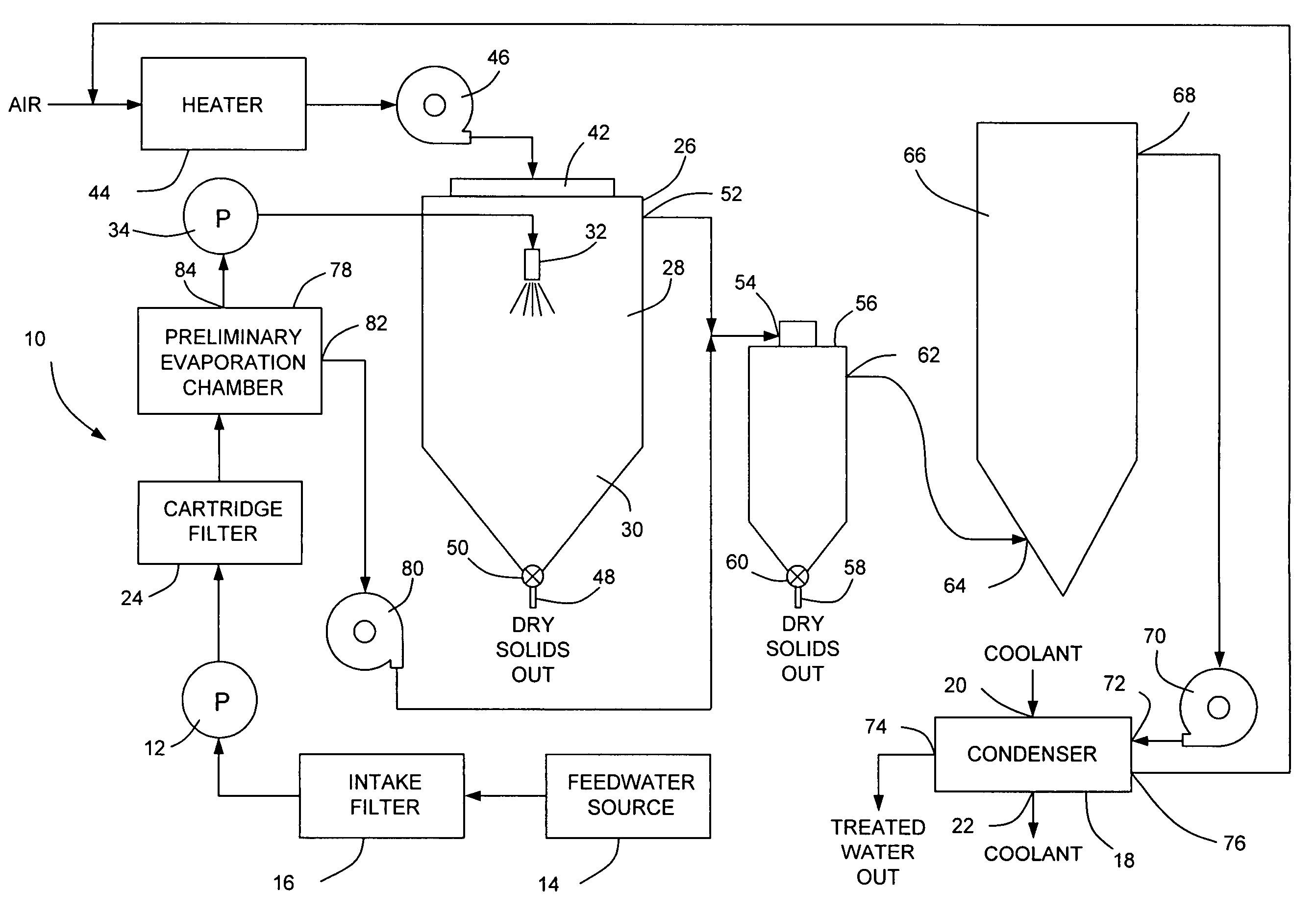

A method and system for treating feedwater includes evaporating a portion of the feedwater in a first evaporation chamber so as to separate water vapor from the remaining feedwater. Droplets of the remaining feedwater are dispersed into a stream of hot air produced in a second evaporation chamber. The droplets evaporate and solids in the feedwater precipitate. The precipitated solids are collected in the lower section of the second evaporation chamber. Water vapor discharged from both evaporation chambers can be treated in a cyclone separator to remove residual solids therefrom. The cleansed water vapor output from the cyclone separator can be condensed to recover clean water. Dry solids can be discharged from the second evaporation chamber and the cyclone separator for recovery.

Owner:WATERVAP

Method and apparatus for phase change enhancement

ActiveUS20050183832A1Distillation regulation/controlVacuum distillation separationEngineeringPhase change

A method of operating an evaporator is described. In evaporator feed water, a Taylor bubble is developed which has an outer surface including a thin film in contact with an inner surface of an outer wall of an evaporator tube. The Taylor bubble is heated as it rises within the evaporator tube so that liquid in the thin film transitions into vapor within the bubble.

Owner:DEKA PROD LLP

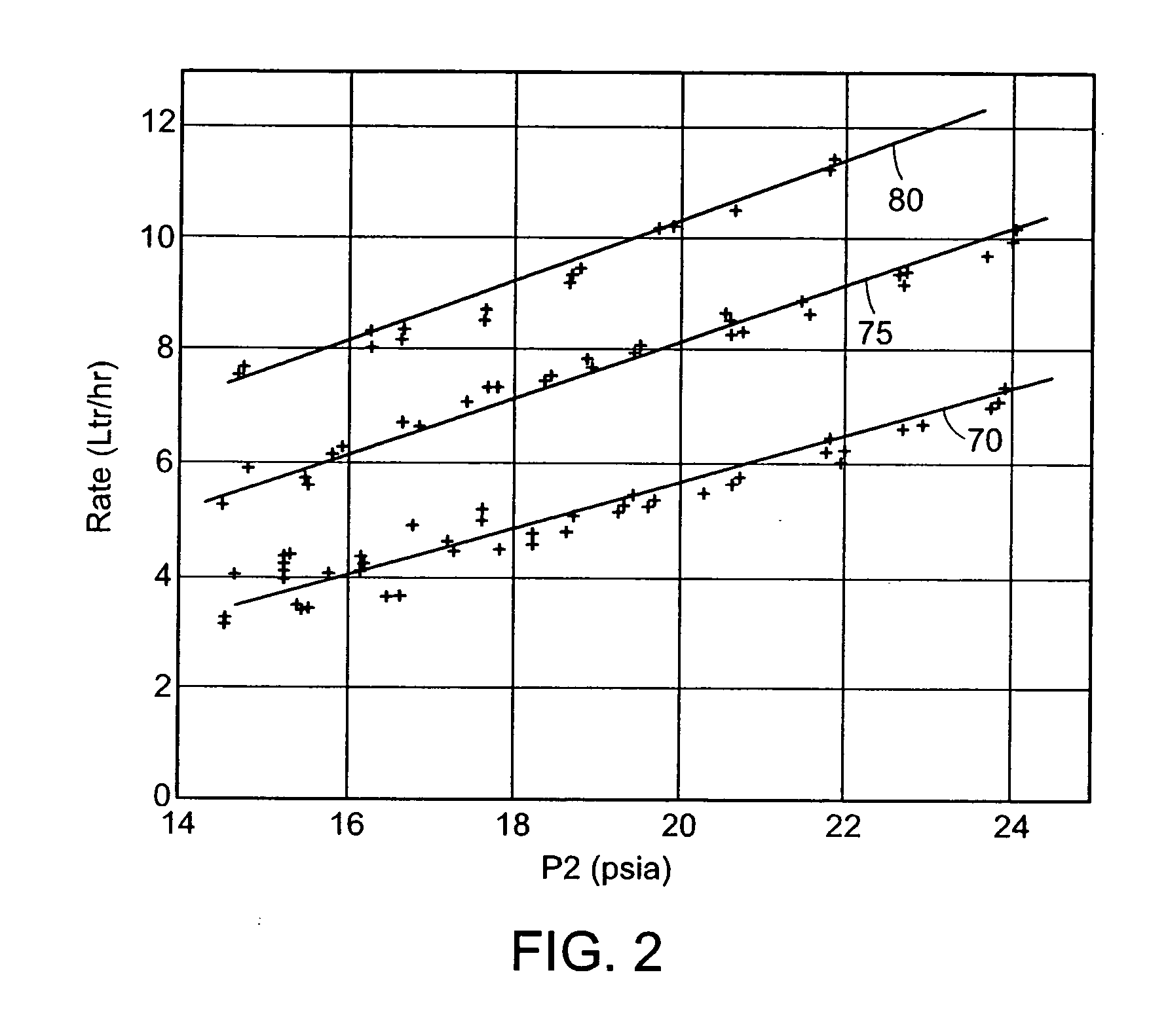

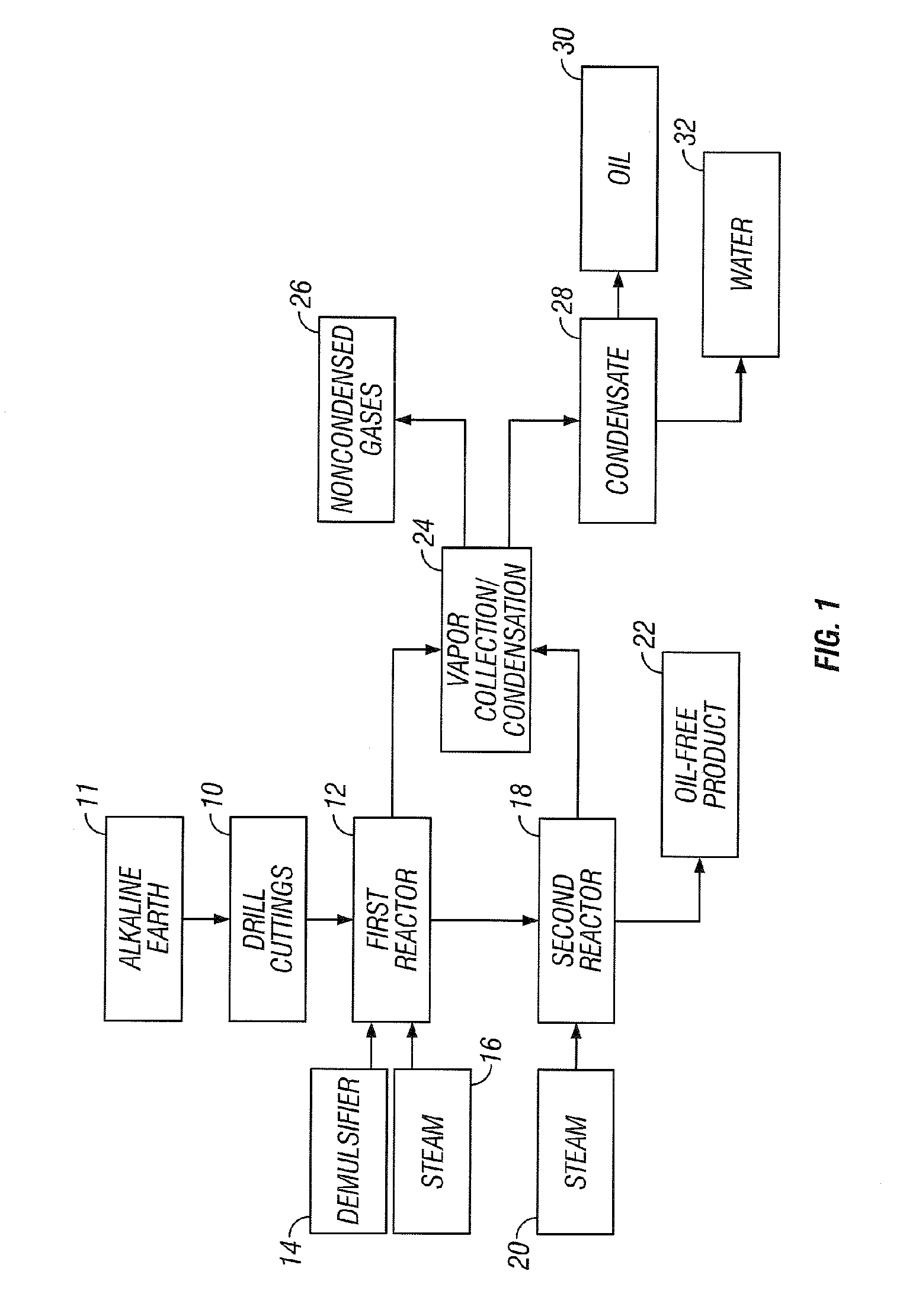

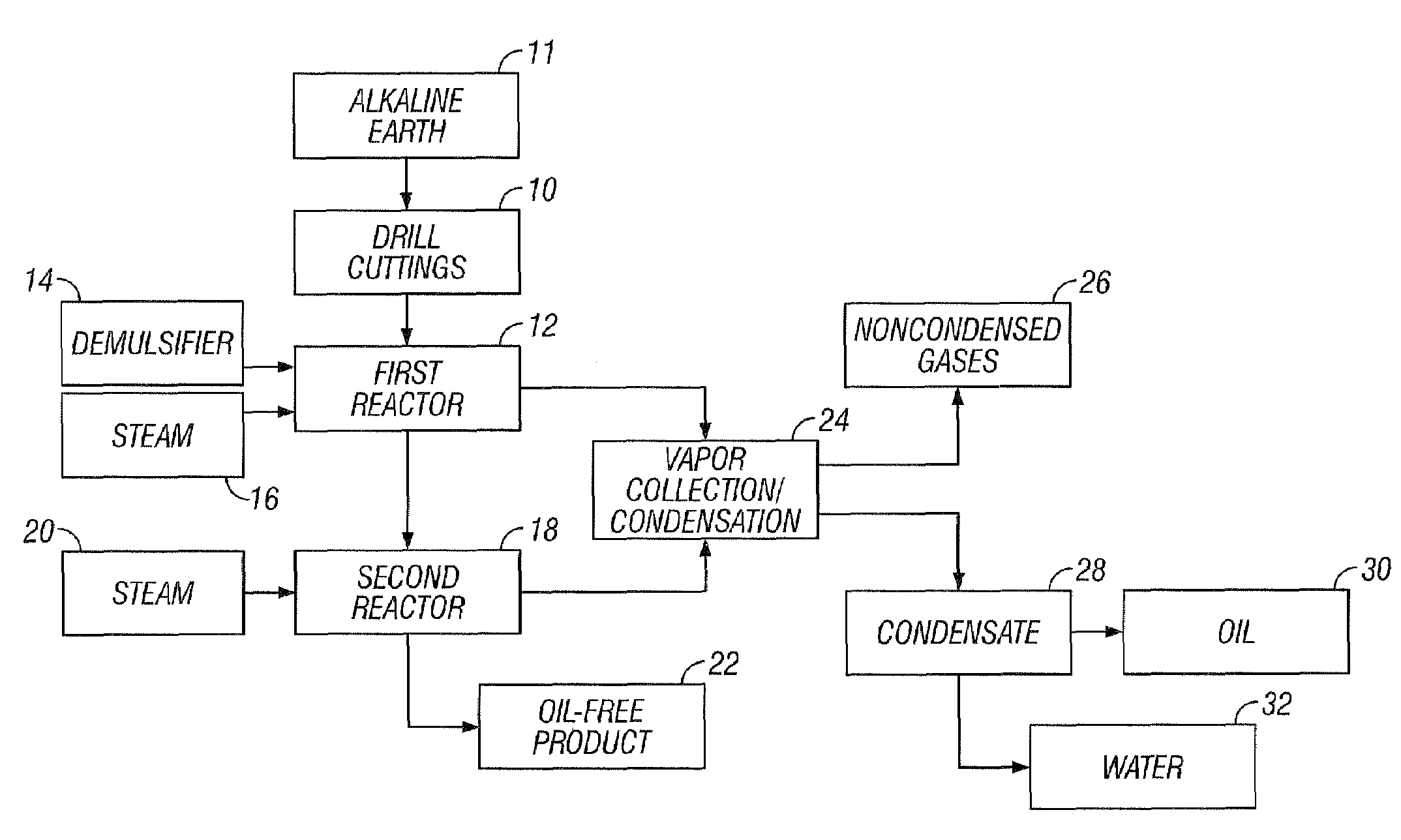

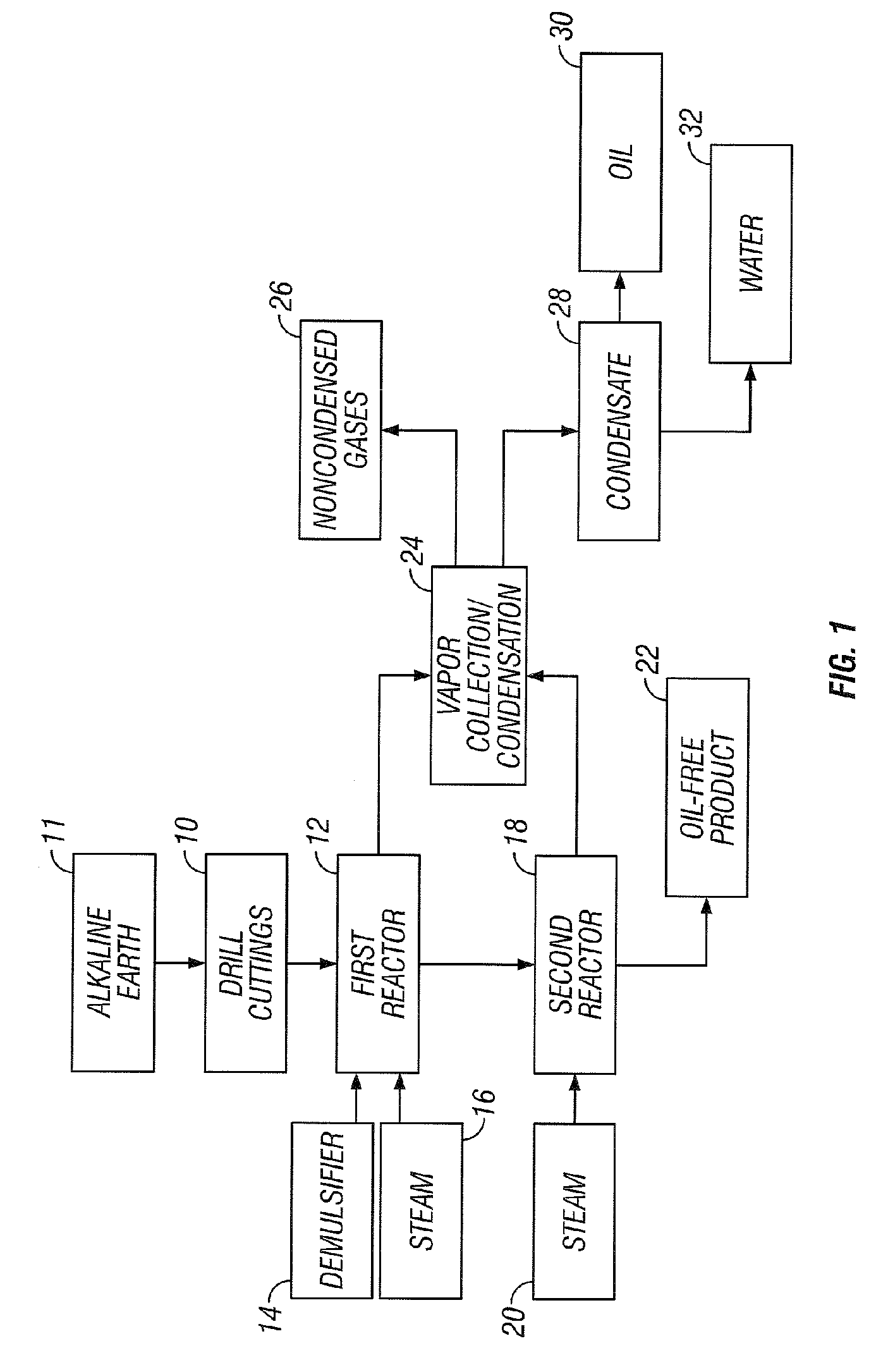

Oil contaminated substrate treatment method and apparatus

InactiveUS20050145418A1Rapid contaminant removalIncrease shearDewatering/demulsification with chemical meansSolid waste disposalEmulsionCollection system

A method and apparatus for treating for disposal oil contaminated substrates, such as drill cuttings from drilling with an oil-based mud, by steam distillation. If necessary, the contaminated substrate 10 can be pretreated with an emulsion breaker 14. The contaminated substrate 10 can be treated with steam 16 in a first mixing still 12. The substrate can be optionally treated with a second steam source 20 in a second mixing still 18. The steam provides heat to vaporize the oil, moisture to treat the substrate and water to the reaction mixture. Recoverable constituents in the vapor can be condensed in a vapor collection system 24. The treated substrate 22 is essentially free of oil and can have a controlled water content. The process exhibits low energy consumption, rapid treatment, compact equipment and a high degree of process control.

Owner:RACIONAL ENERGY & ENVIRONMENT

Multiple application purification and recycling device

InactiveUS20070170049A1Easy constructionFlexible operationDistillation regulation/controlEvaporation with vapour compressionDistillationMultiple applications

A multiple application recycling and purification device has a coaxial core that is horizontally oriented, non-rotating, cylindrical distillation chamber. The enhanced, completely coaxial configuration continuously cleans the entire distillation chamber and spreads a thin film of liquid to enhance distillation and positively aid in the removal of remaining contaminants. Through a timed and positioned valve, the device removes and purges lower-temperature contaminants. Timed valves and sensors control all phases of the distillation to provide a coaxially integrated, stand-alone, adaptable, scalable and maintenance free distillation unit that self-monitors, self-cleans and economically functions to produce the pure distilled liquid, e.g., water. This device can be modified to purify any numerous array of liquids and can be scaled to produce any amount of purified liquids for either household, commercial, or industrial applications.

Owner:MANSUR CORP

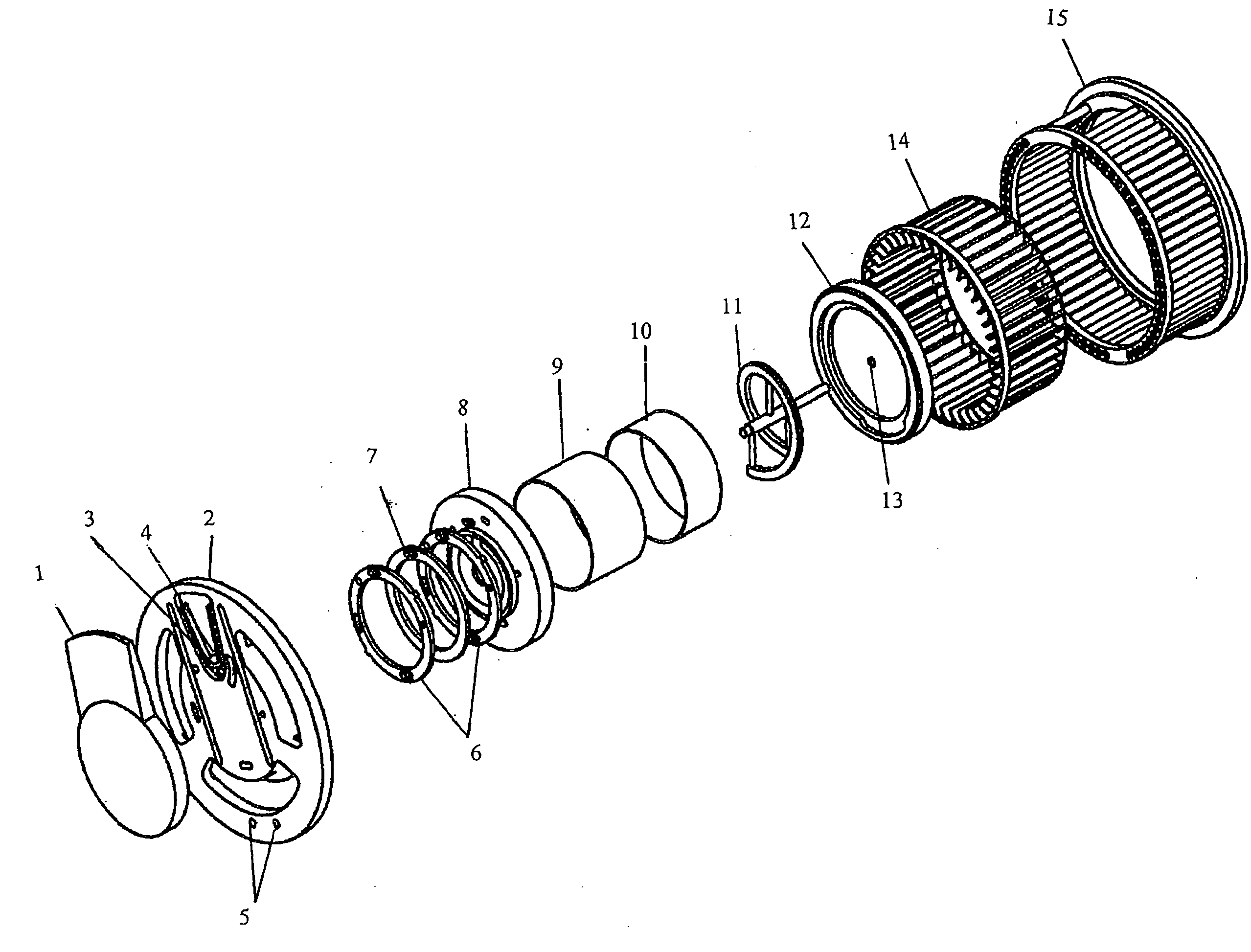

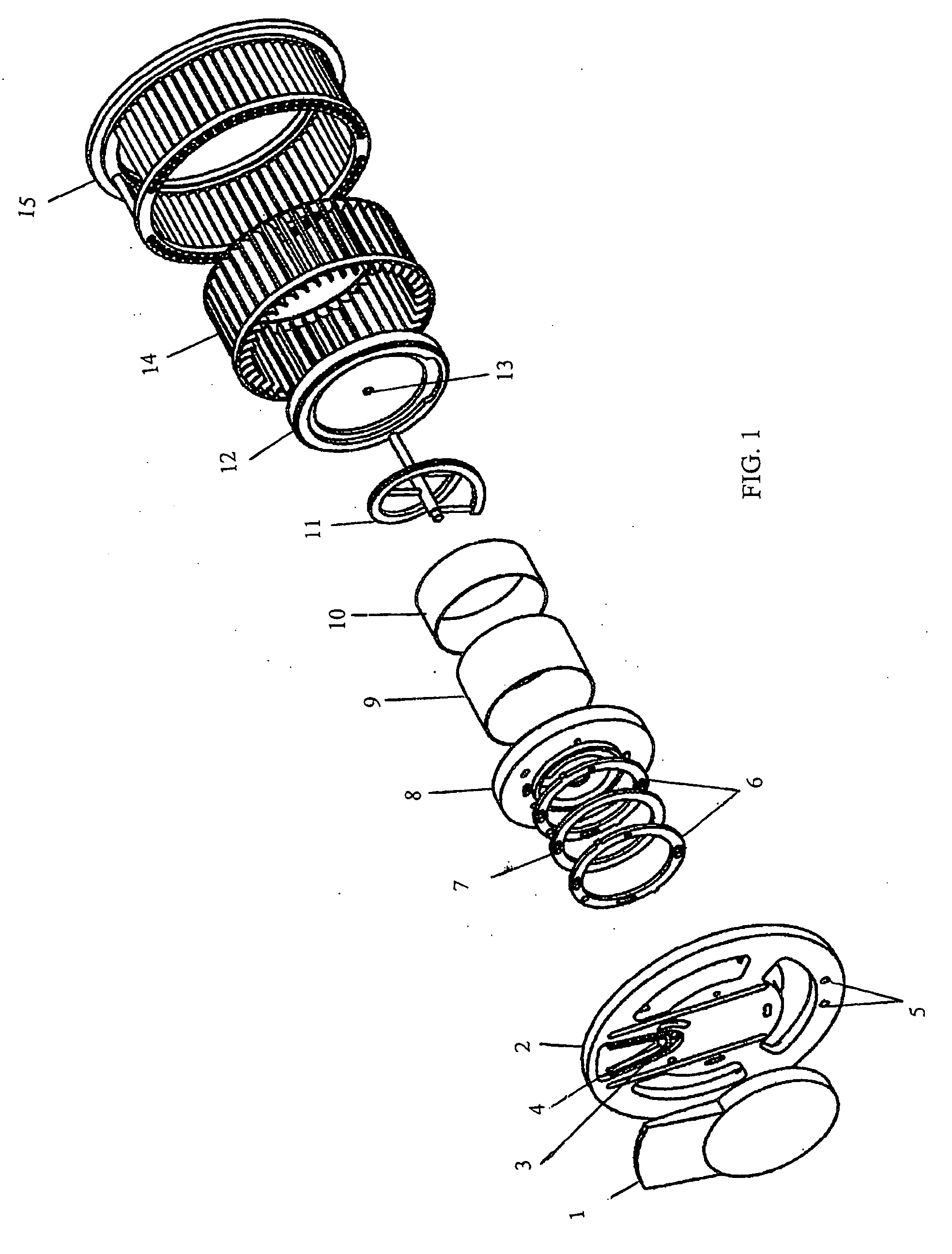

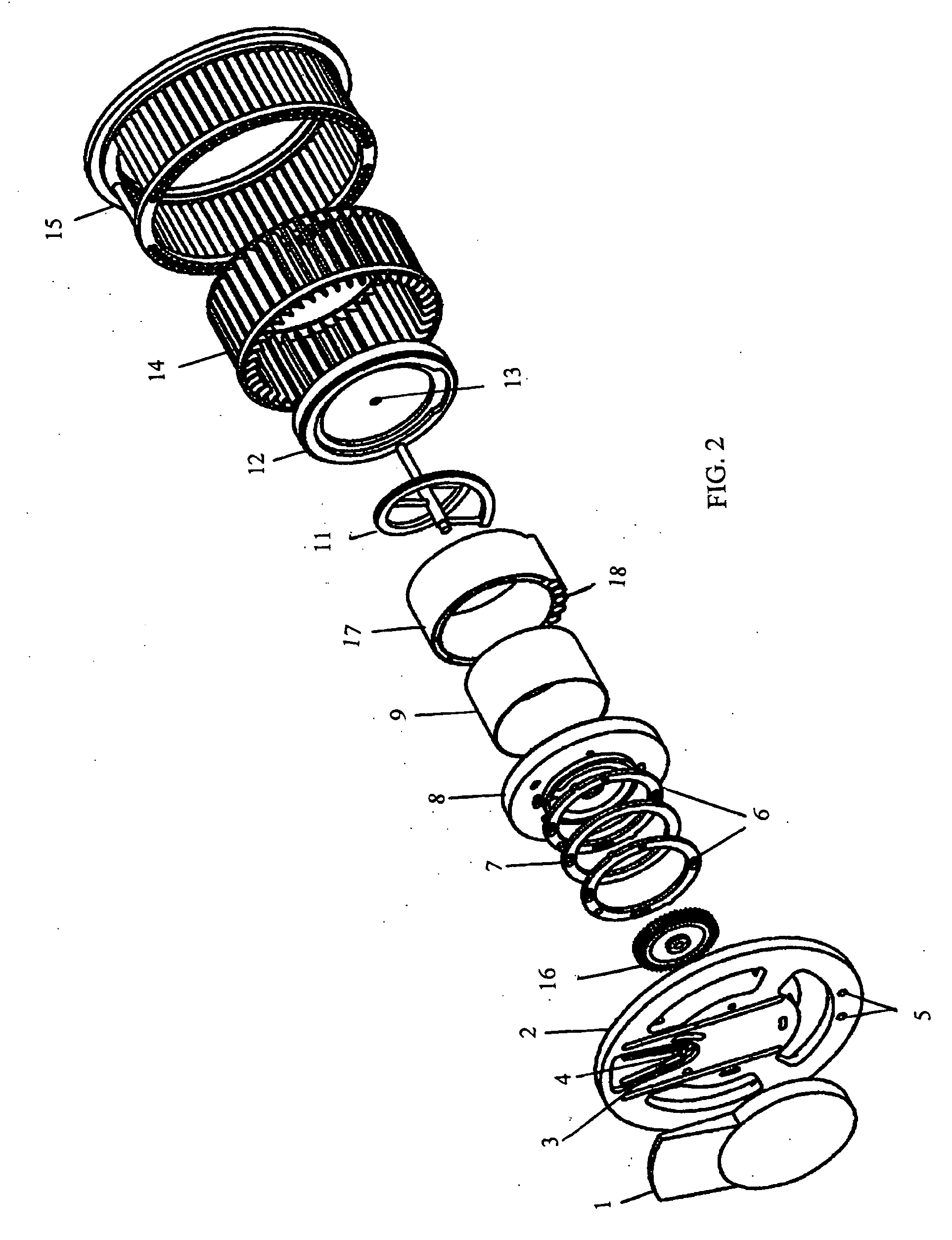

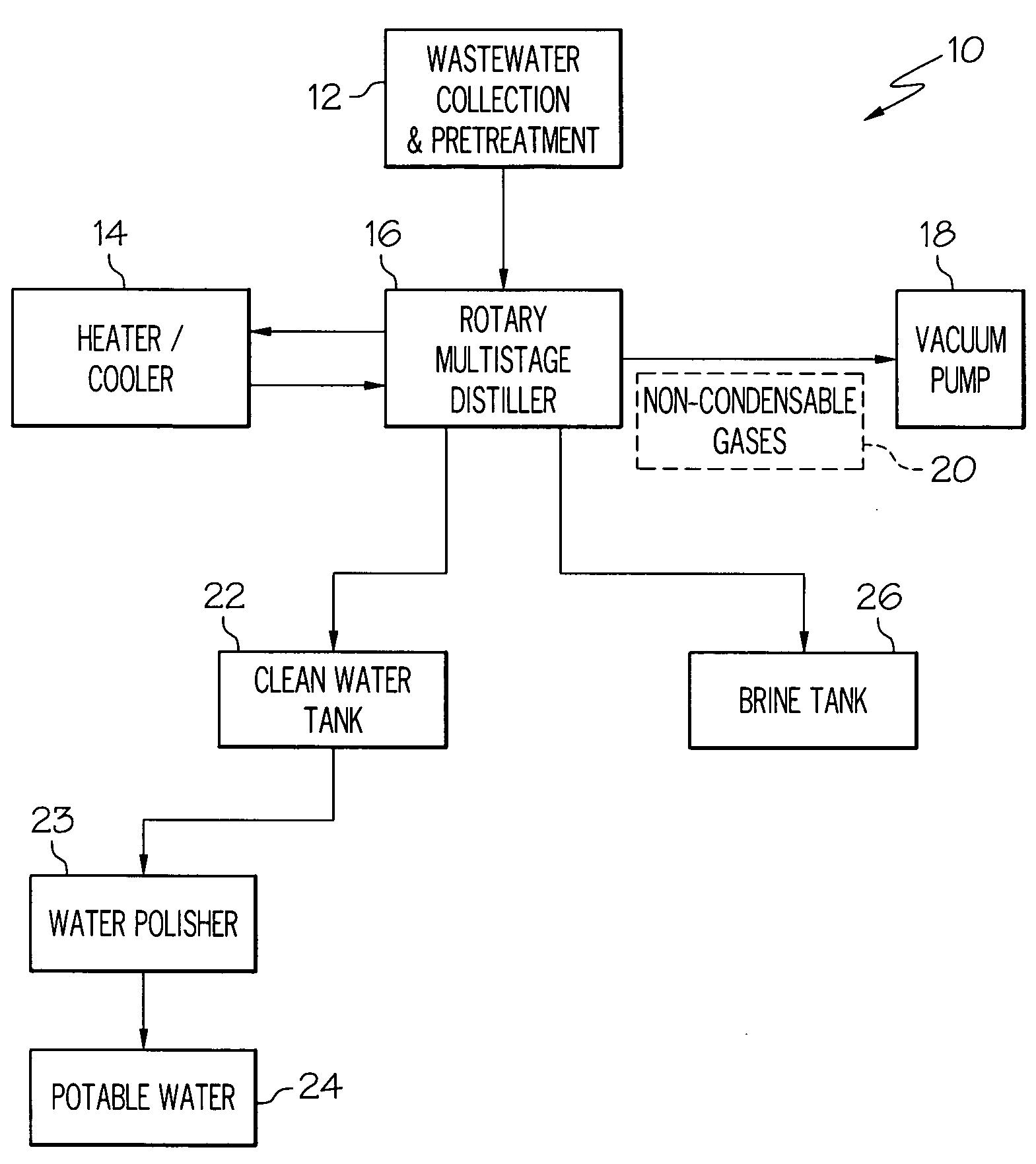

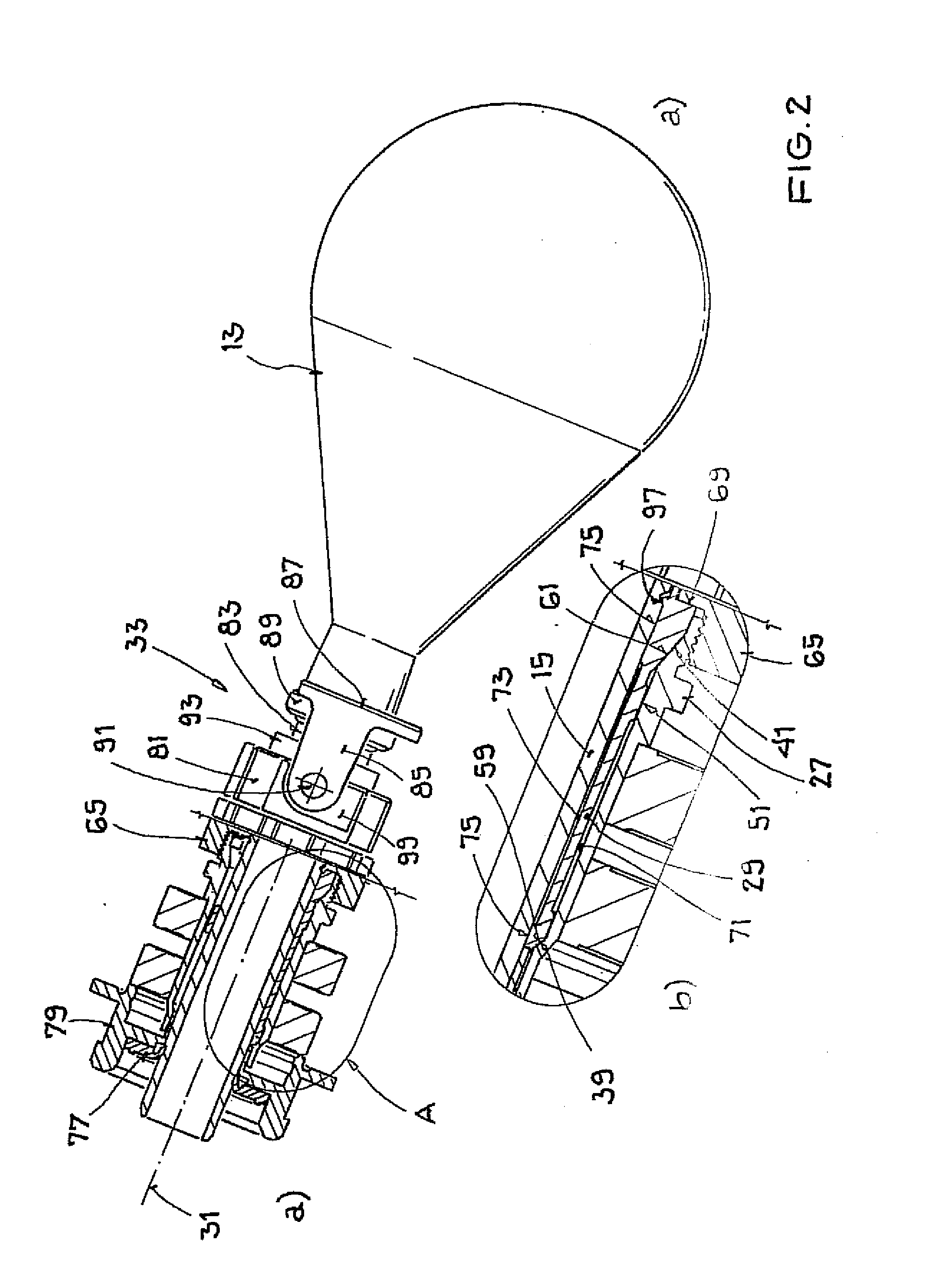

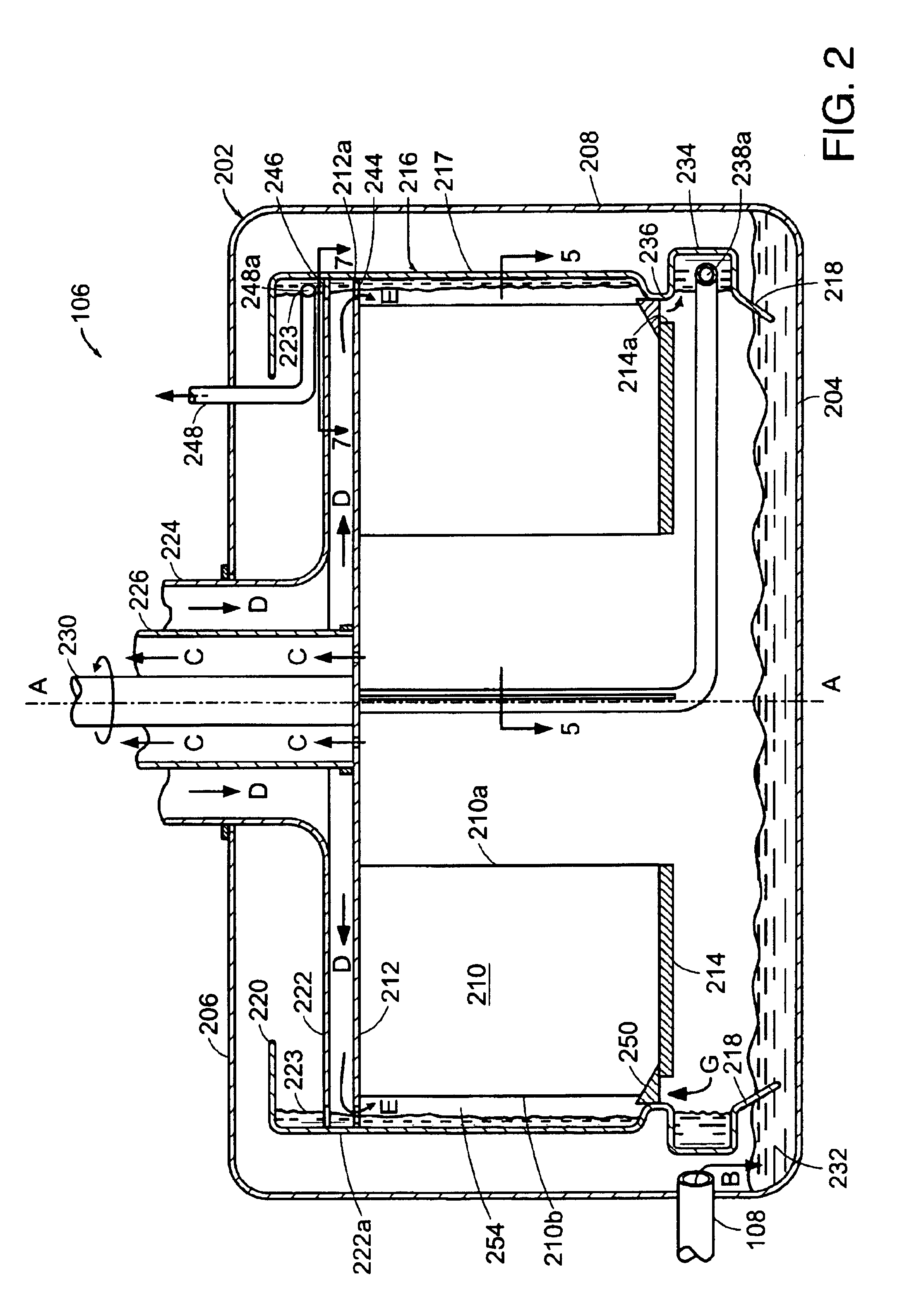

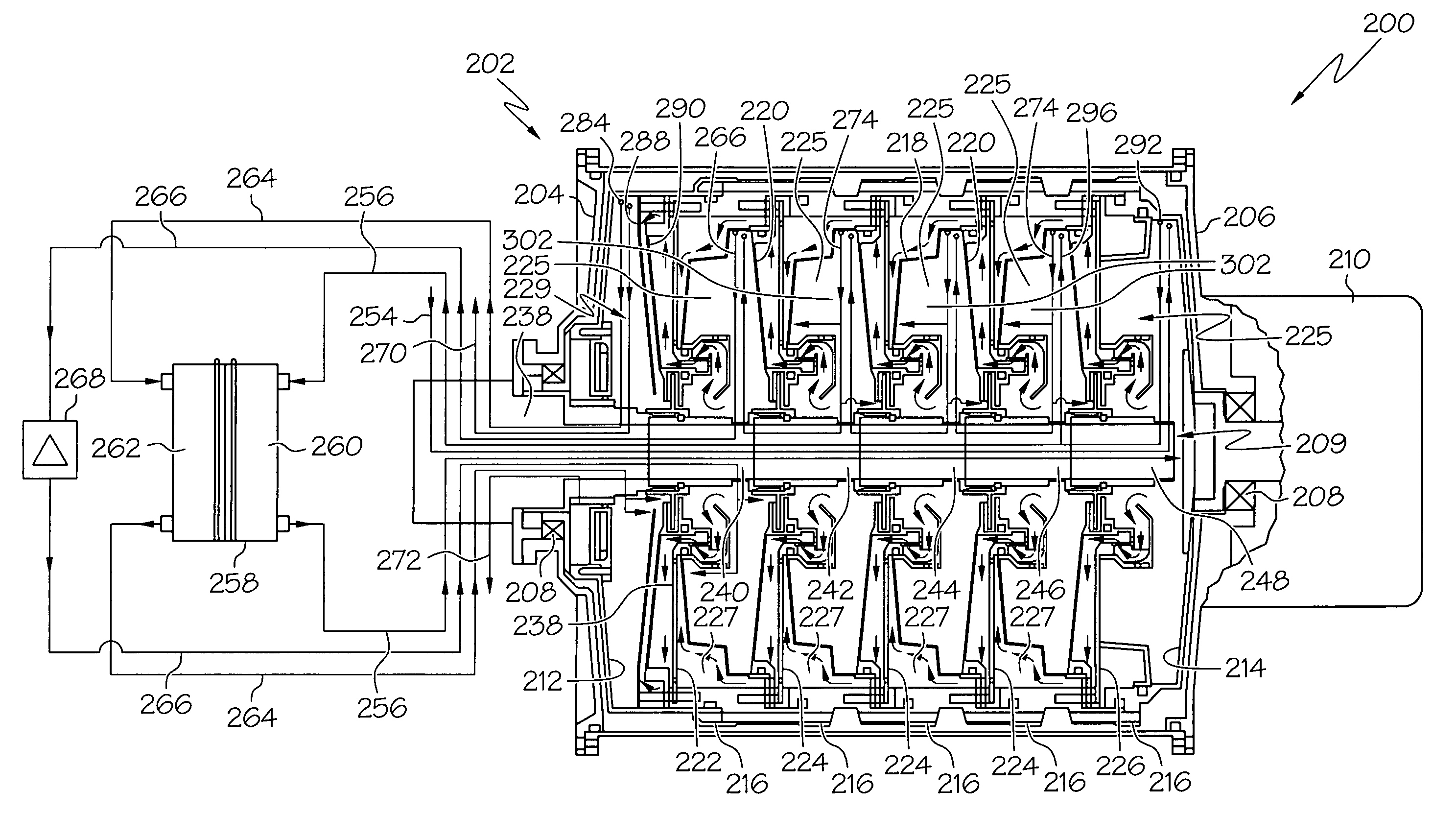

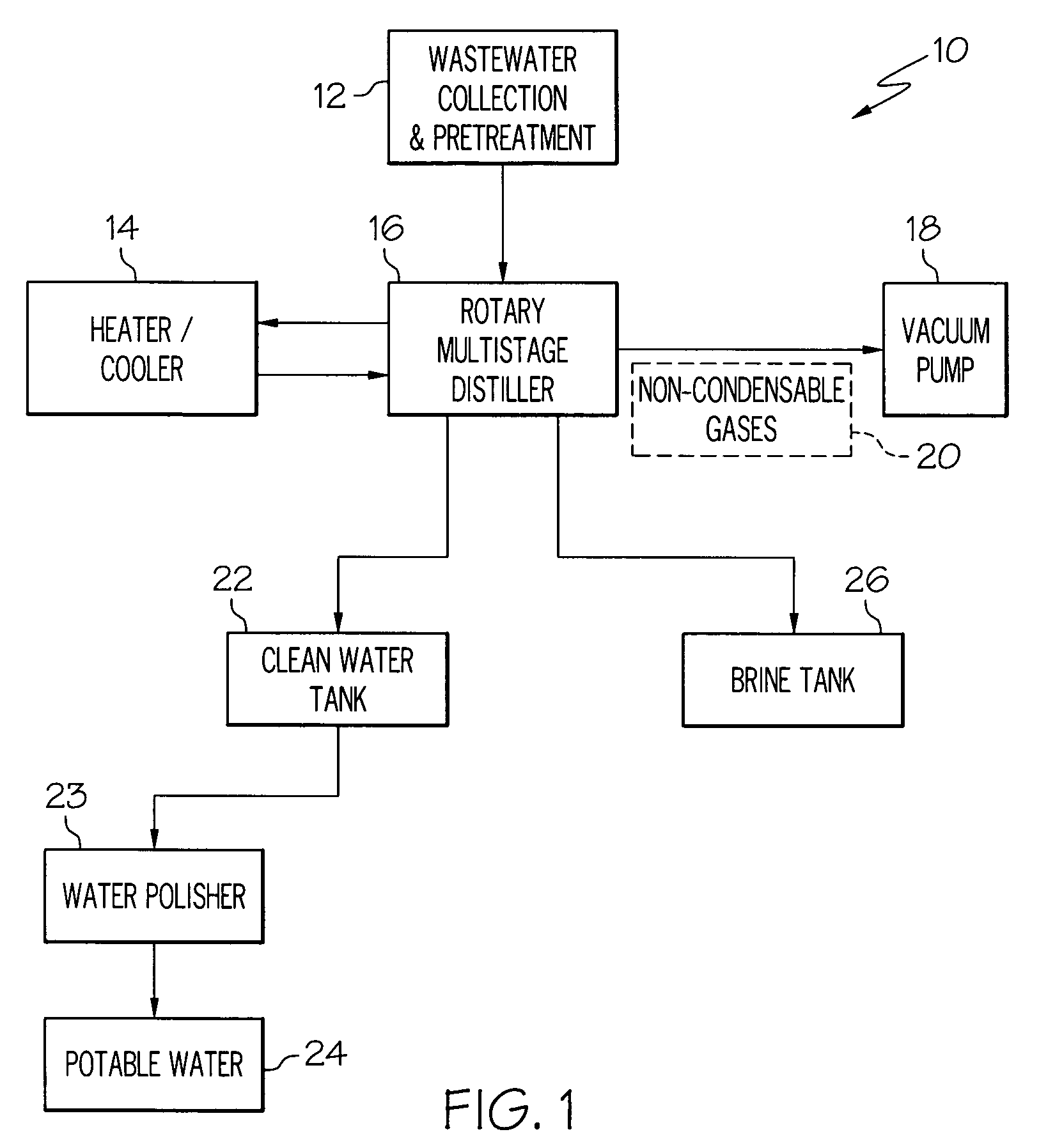

Apparatus and methods for water regeneration from waste

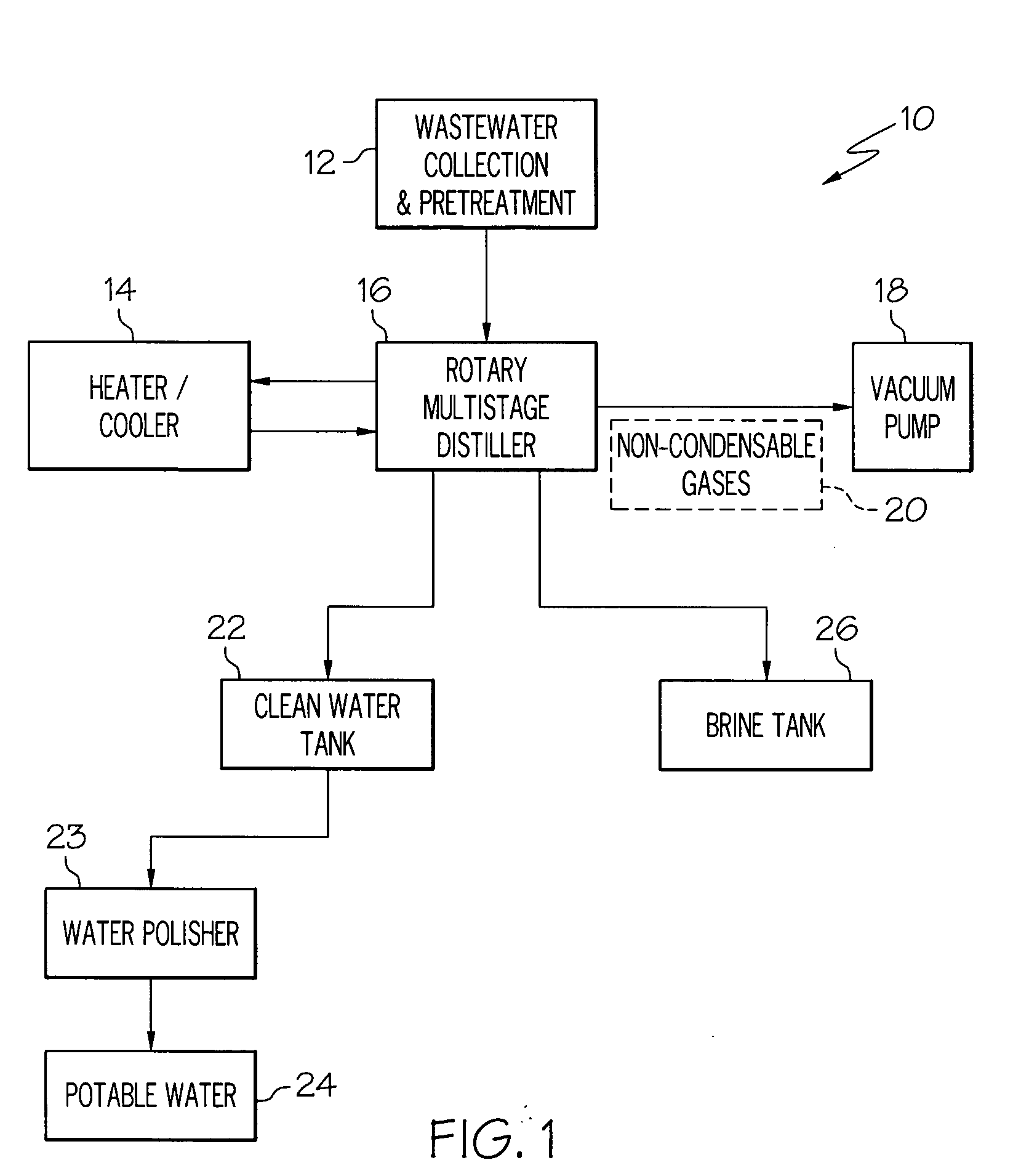

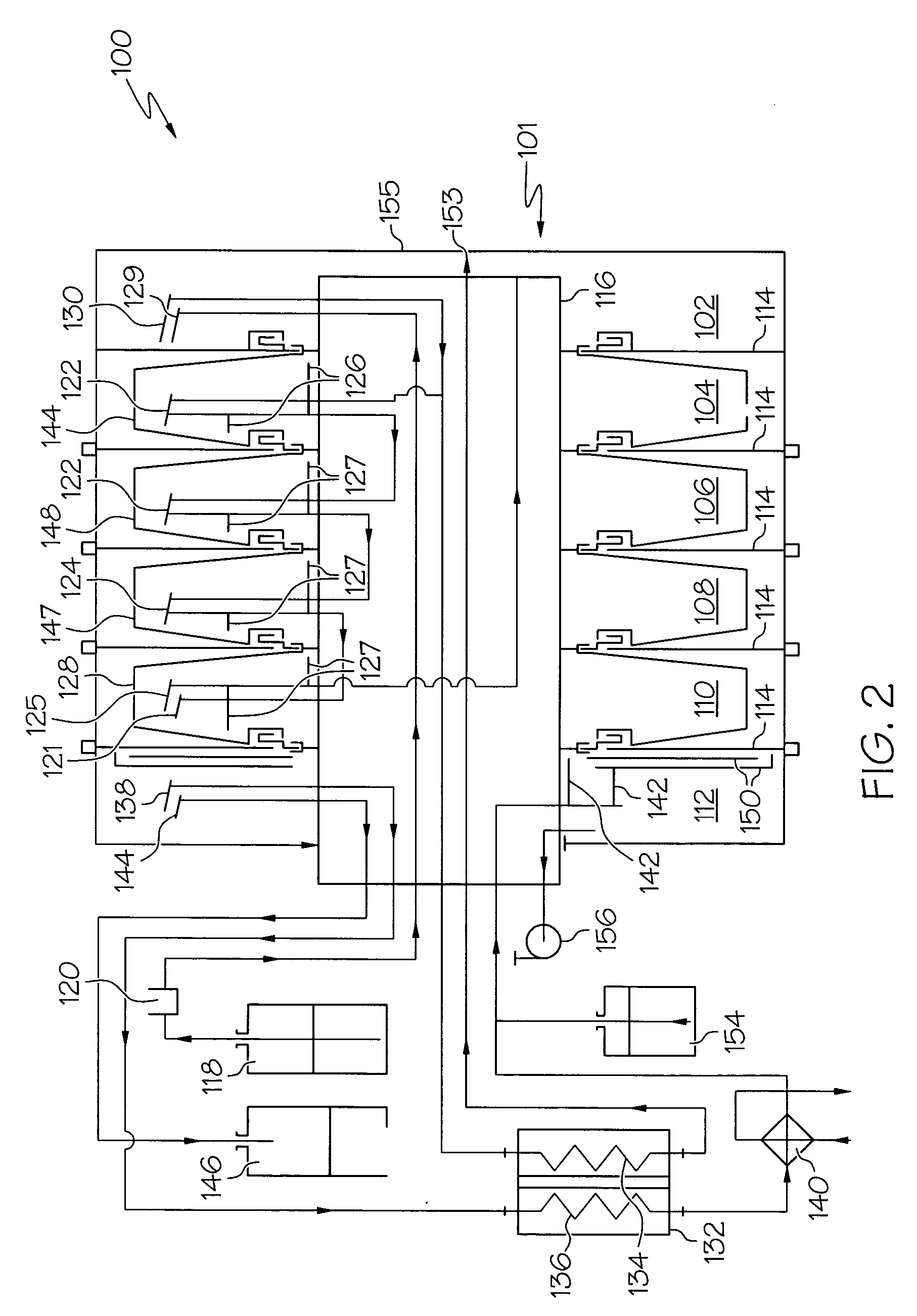

ActiveUS20070102276A1Distillation regulation/controlDistillation in boilers/stillsDistillationWash water

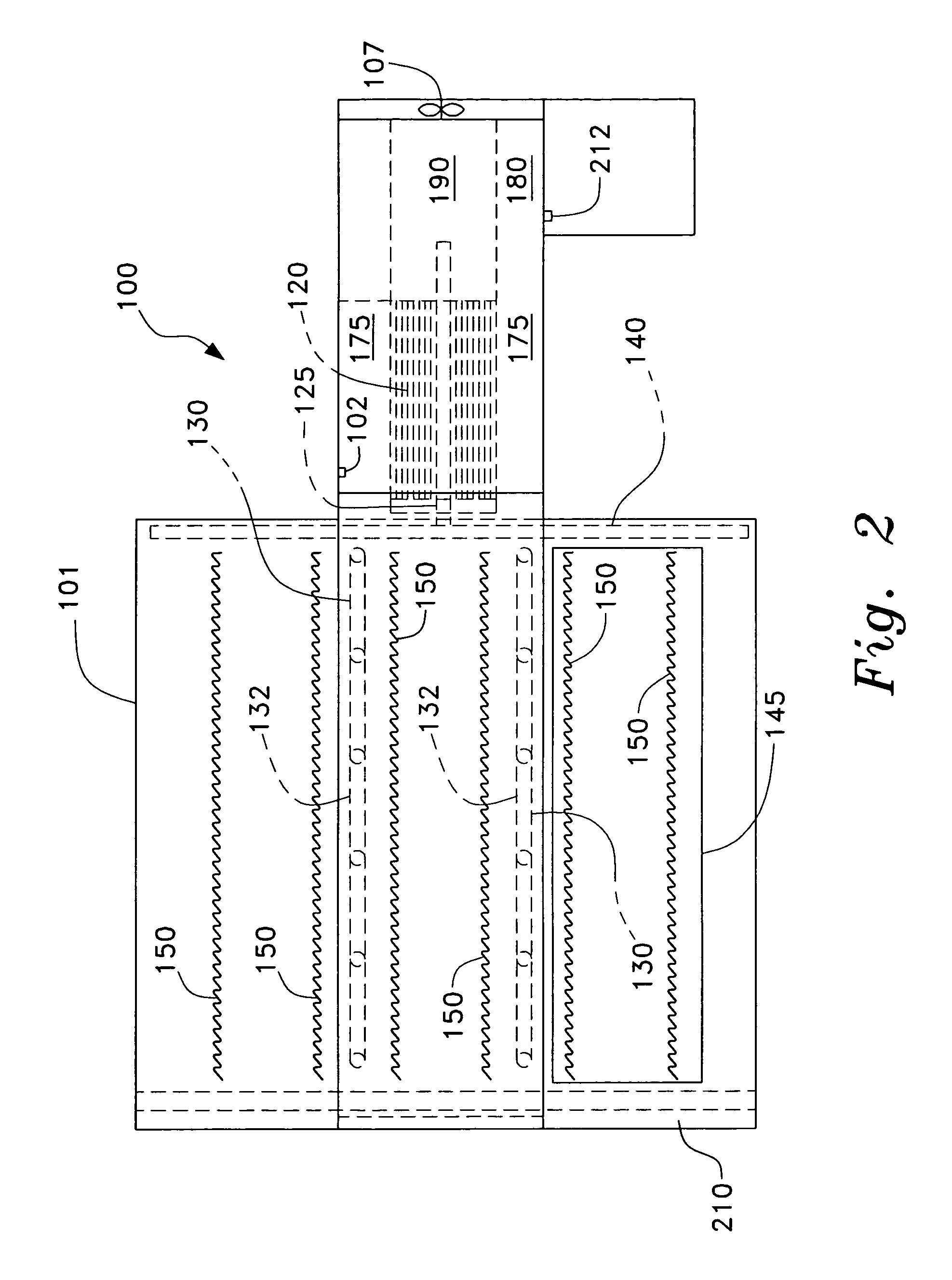

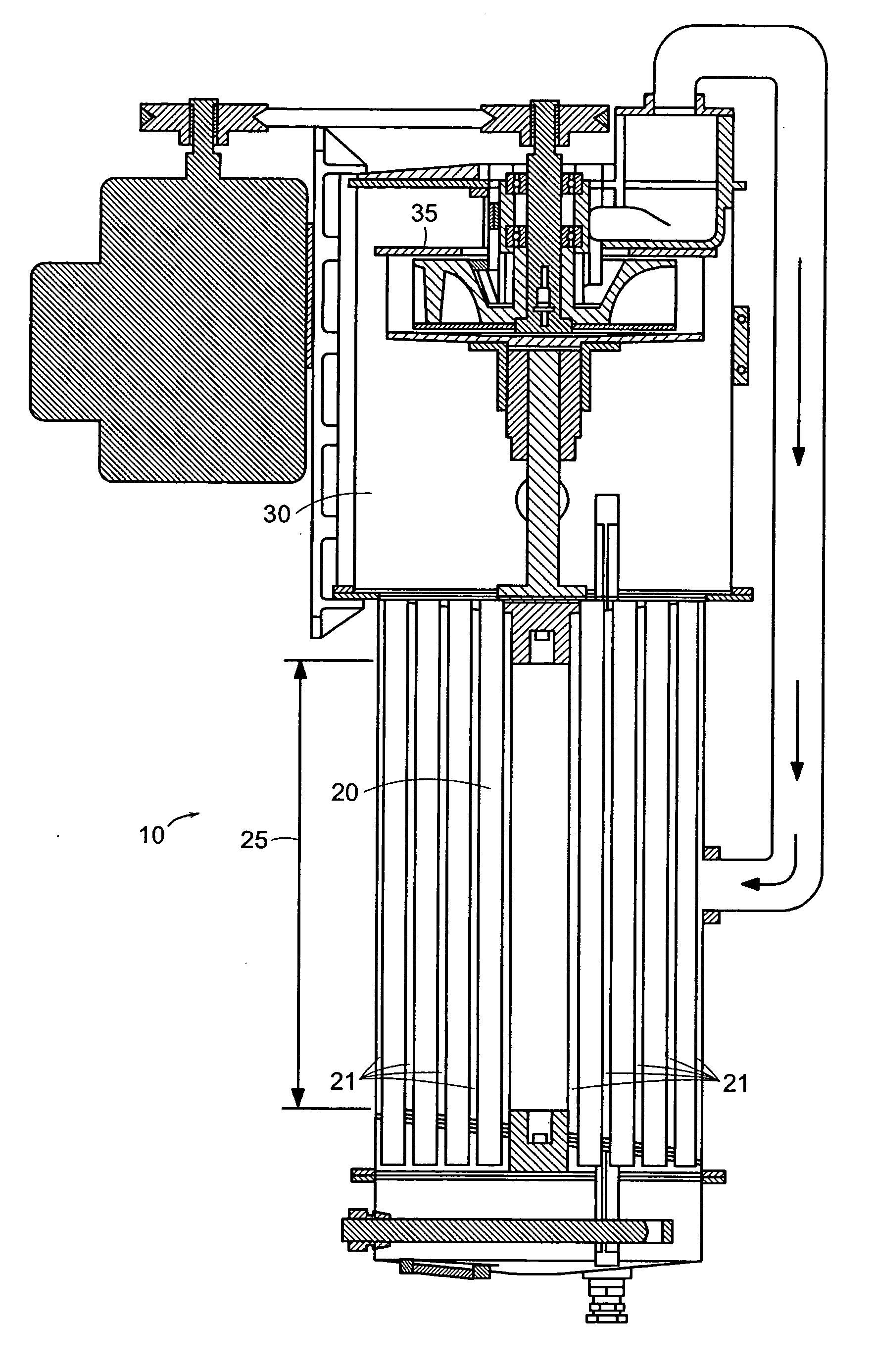

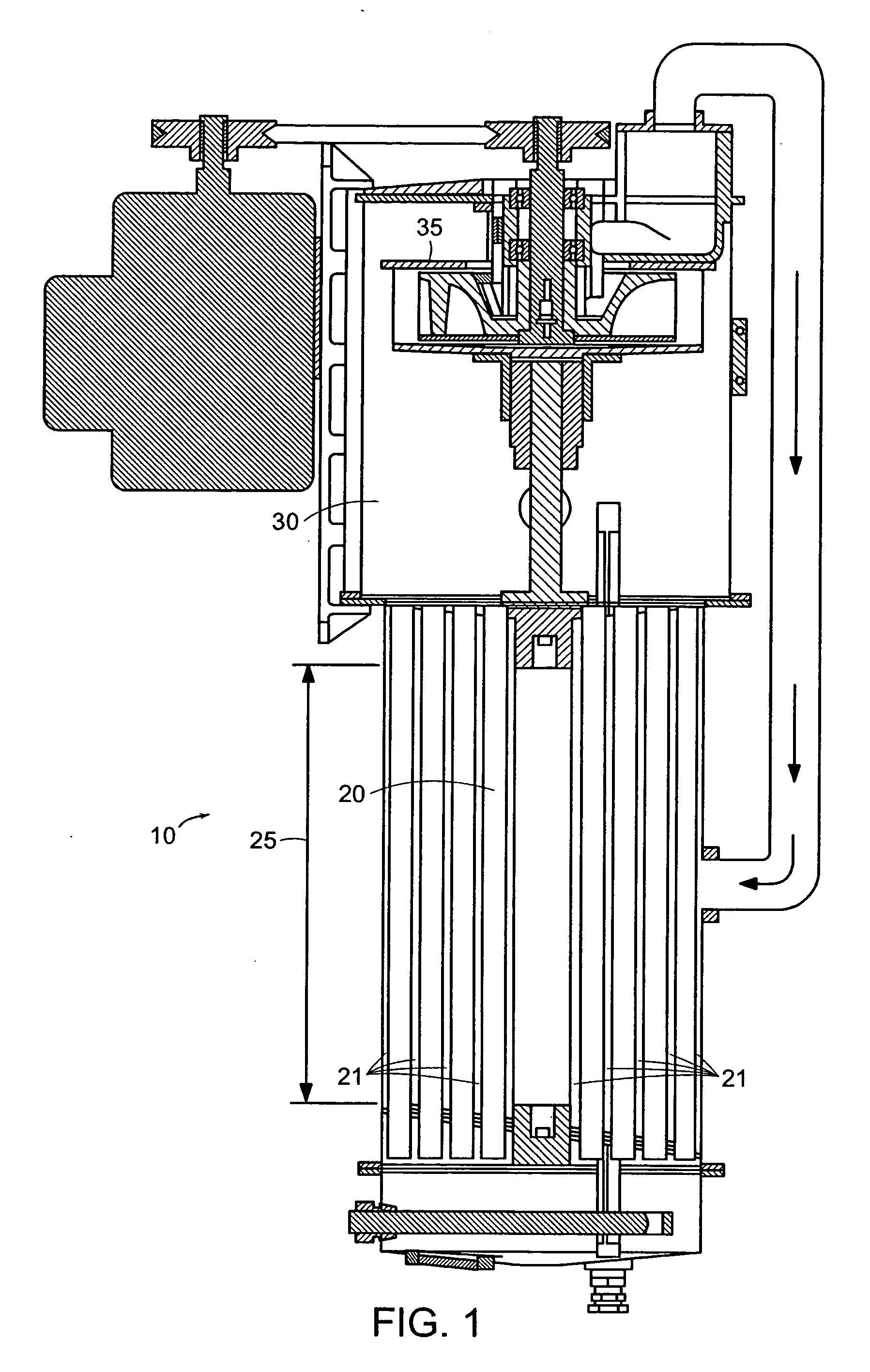

A rotary multi-stage distiller for recovery of water from wastewater is provided. The rotary multi-stage distiller of the present invention can recover water from a wide variety of aqueous wastewaters such as, but not limited to, urine, condensate from air conditioning systems, wash water containing foaming soaps, seawater or polluted water. The multi-stage distiller can operate under vacuum conditions permitting the distillation to occur at low temperatures. The multi-stage distiller uses centrifugal forces for fluid pumping and for vapor / liquid separation. The multi-stage distiller comprises hydraulic seals for each stage which eliminate contamination of clean, recovered water by condensed waste water during the regeneration process. The multi-stage distiller also comprises a stationary shaft of stacked segments where each segment is associated with an individual stage of the multi-stage distiller. The number of stages therefore, of the multi-stage distiller of the present invention can be readily adjusted as needed by either adding a segment with a stage to the stationary shaft or removing a segment of the shaft with a stage to decrease the number of stages.

Owner:HONEYWELL INT INC

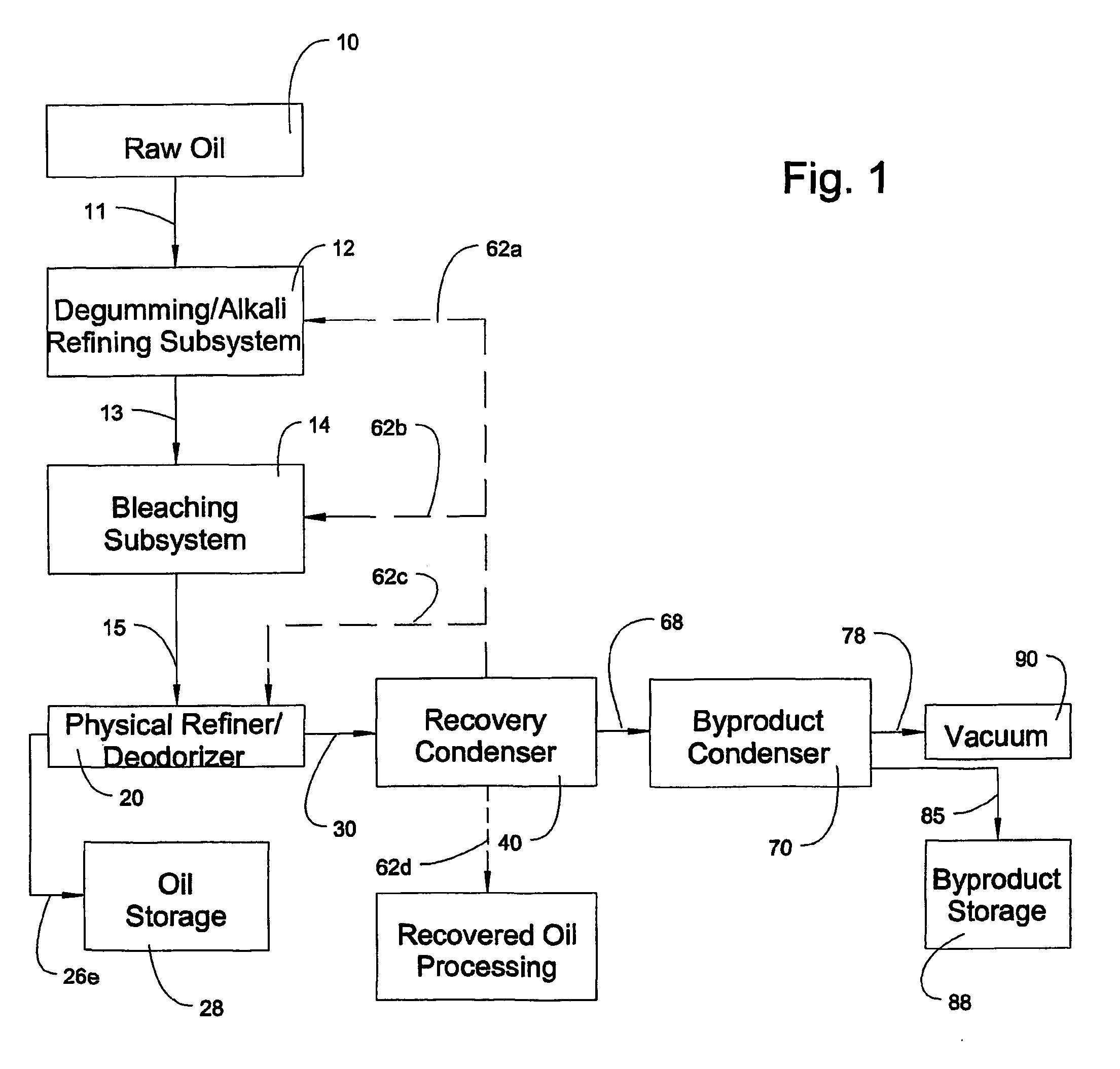

Method and apparatus for processing vegetable oils

InactiveUS7597783B2Fatty oils/acids recovery from wasteOrganic compound preparationVegetable oilVolatiles

Methods for processing oils and apparatus for carrying out such methods are disclosed herein. One embodiment provides a method for processing a partially processed oil, wherein the oil includes glycerides and a volatilizable impurity fraction. The partially processed oil may be processed by driving off a first volatiles stream having a portion of the glycerides and at least a portion of the volatilizable impurity fraction, leaving a deodorized oil. The first volatiles stream may be introduced into a first condensing chamber and a glyceride-rich, impurity-poor fraction may be condensed from the first volatiles stream, leaving a glyceride-poor, impurity-rich second volatiles stream. The second volatiles stream may be passed into a second condensing chamber and a glyceride-poor, impurity-rich second condensate may be condensed from the second volatiles stream.

Owner:CARGILL INC

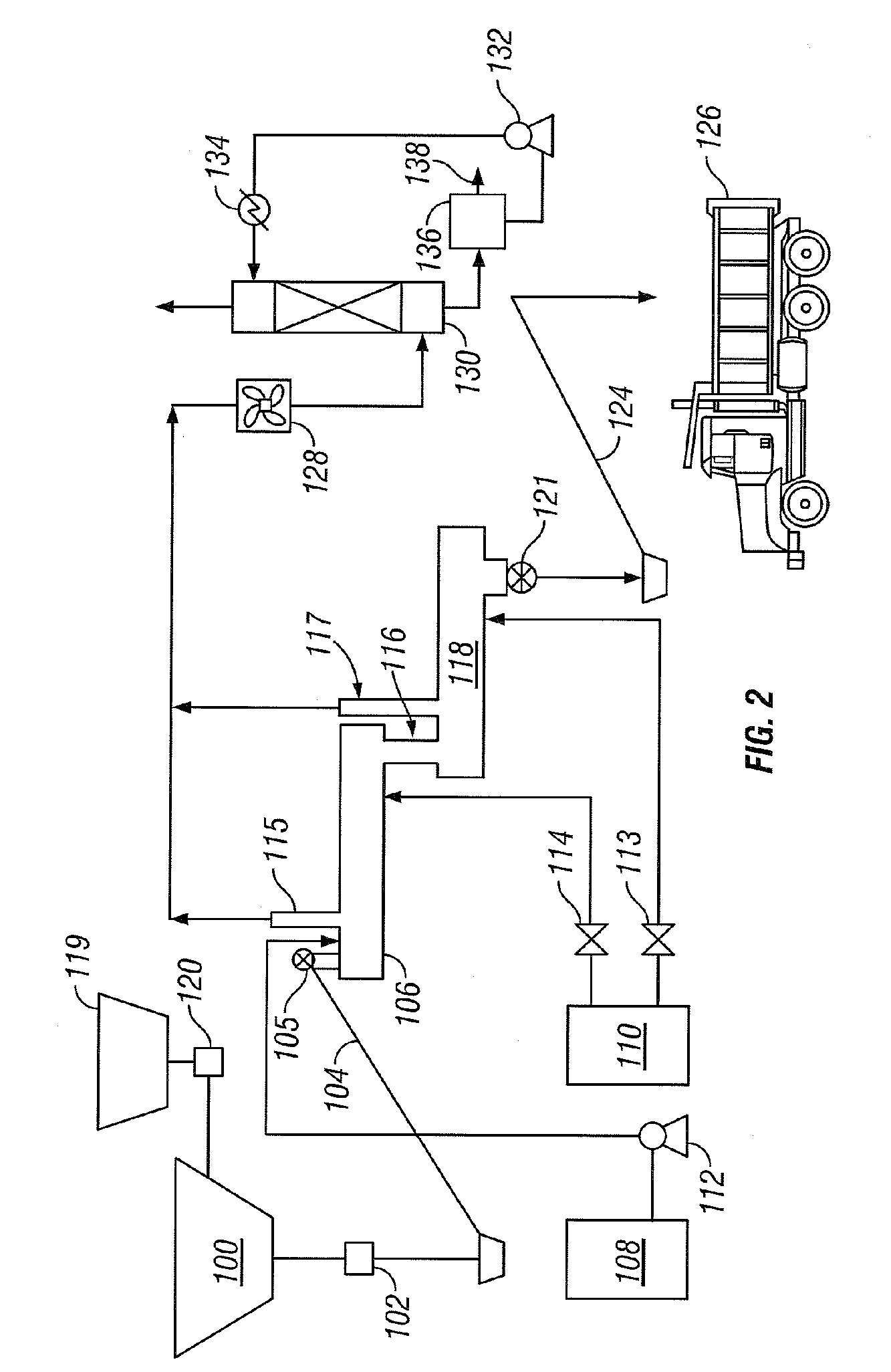

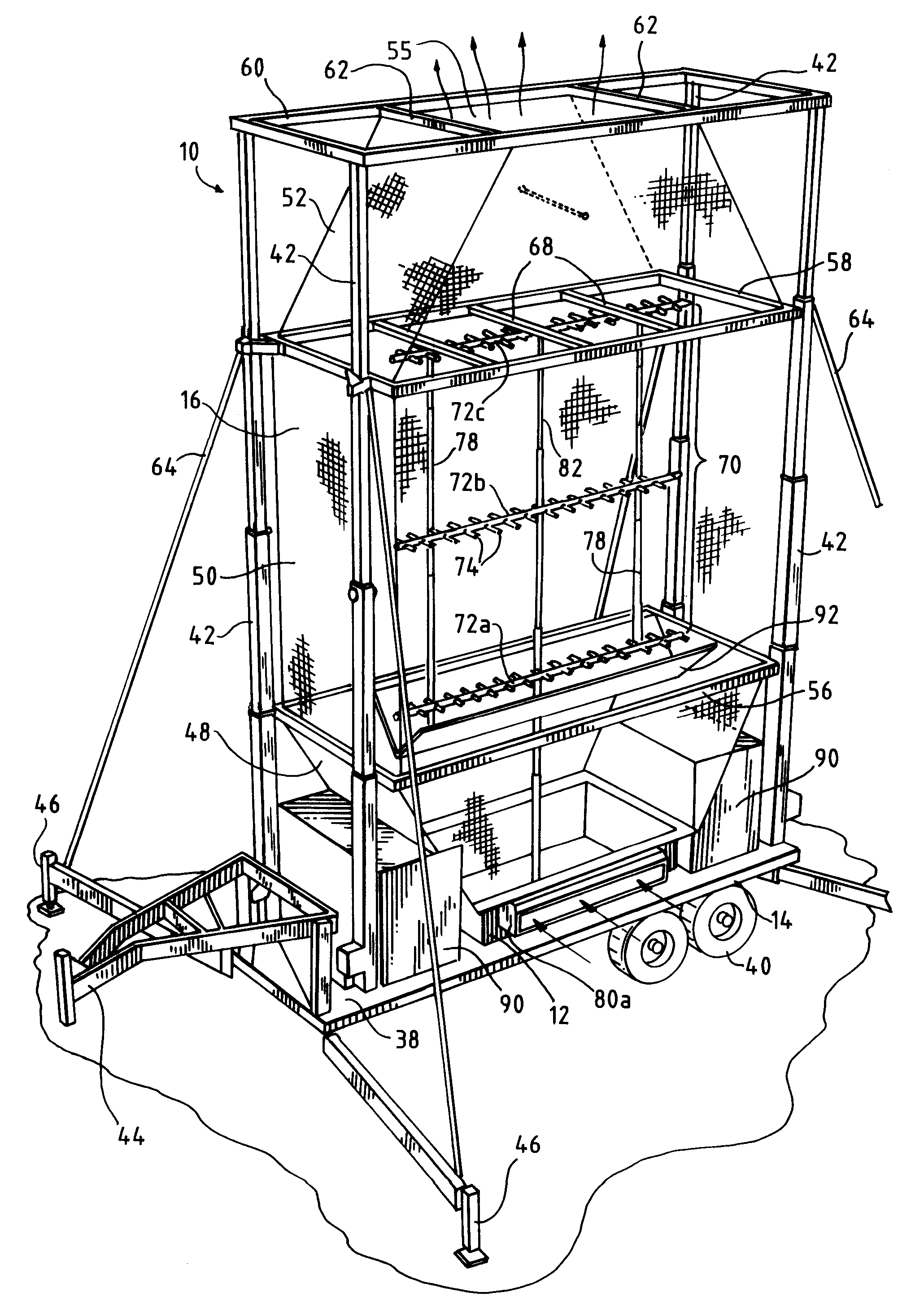

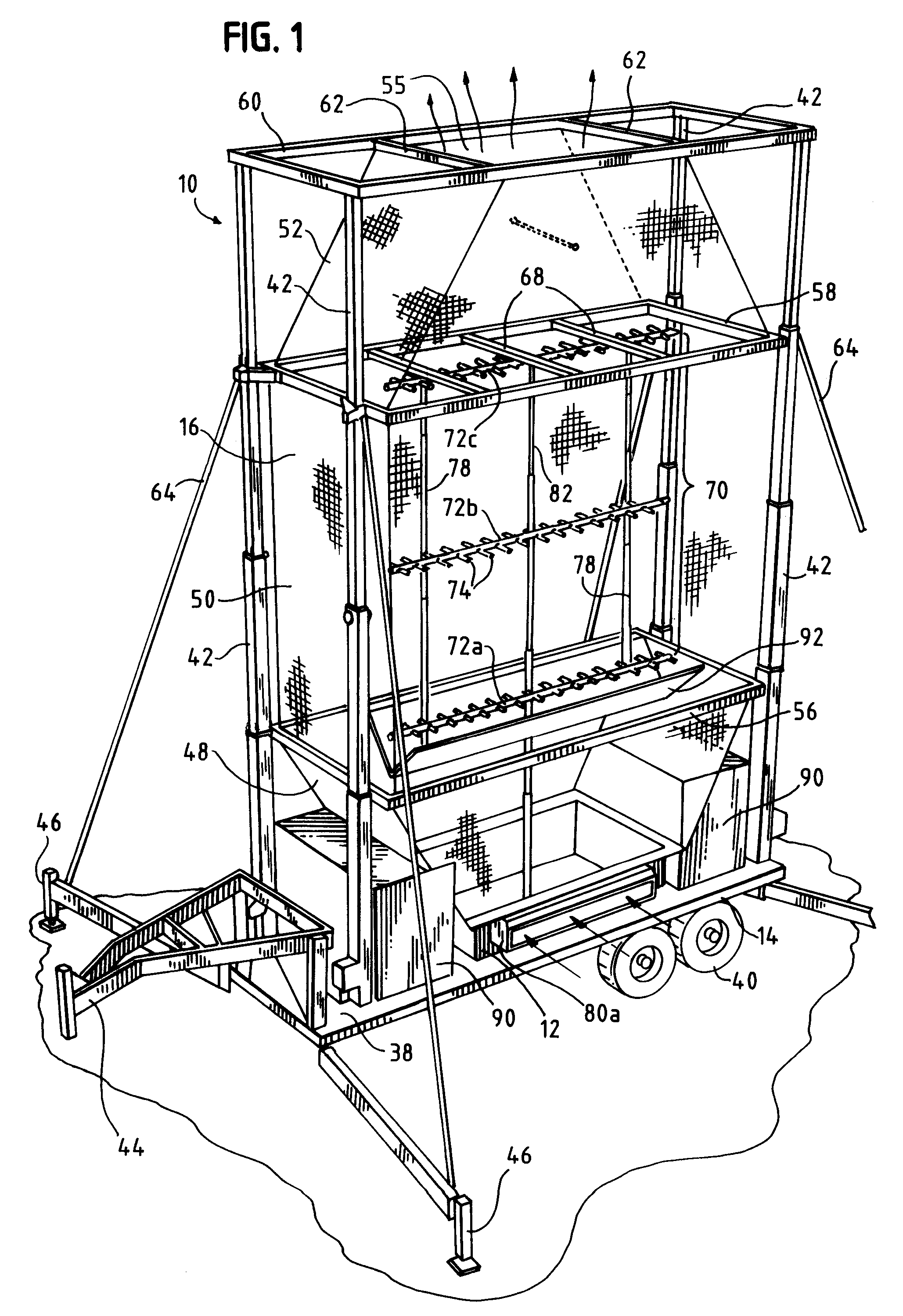

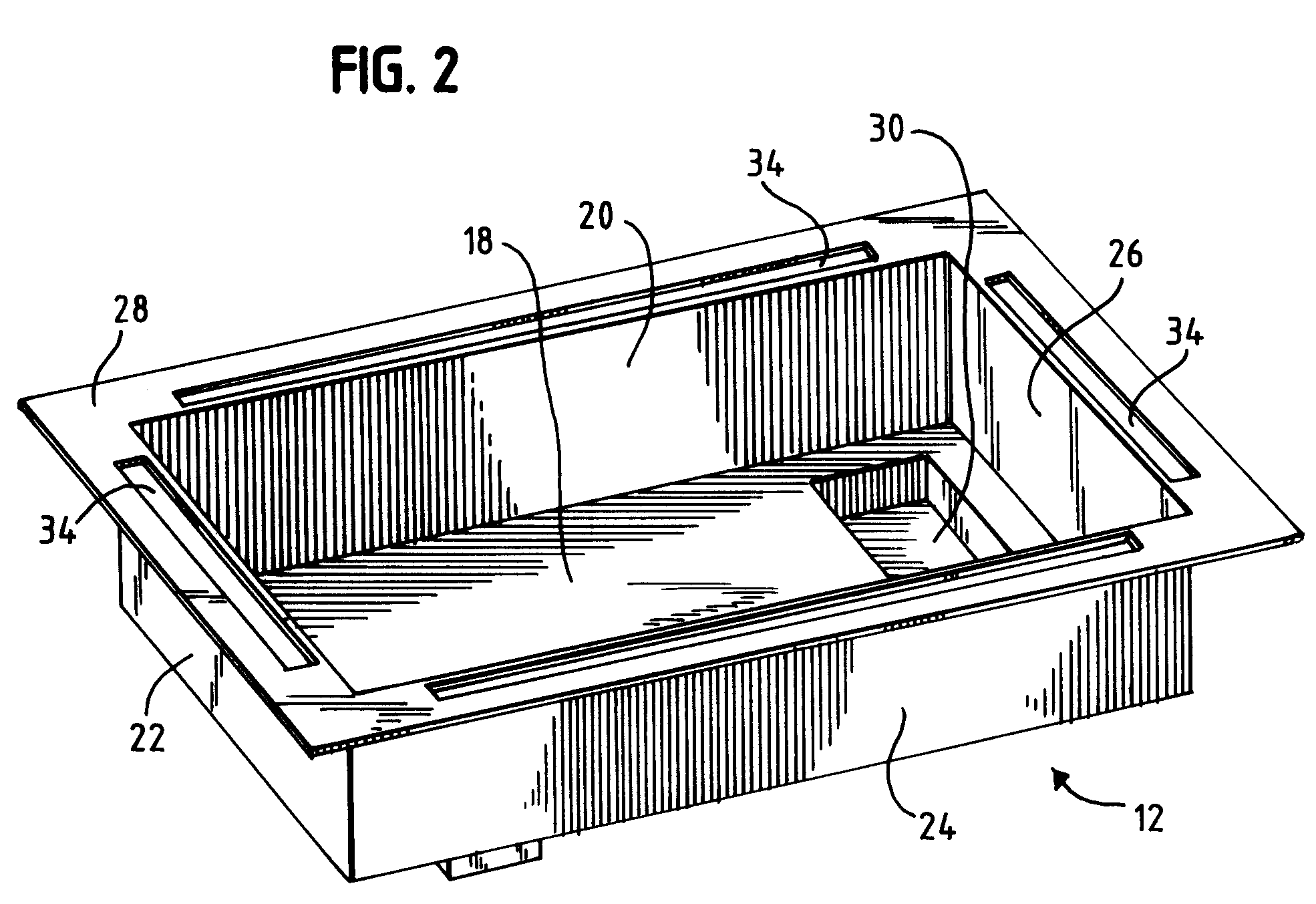

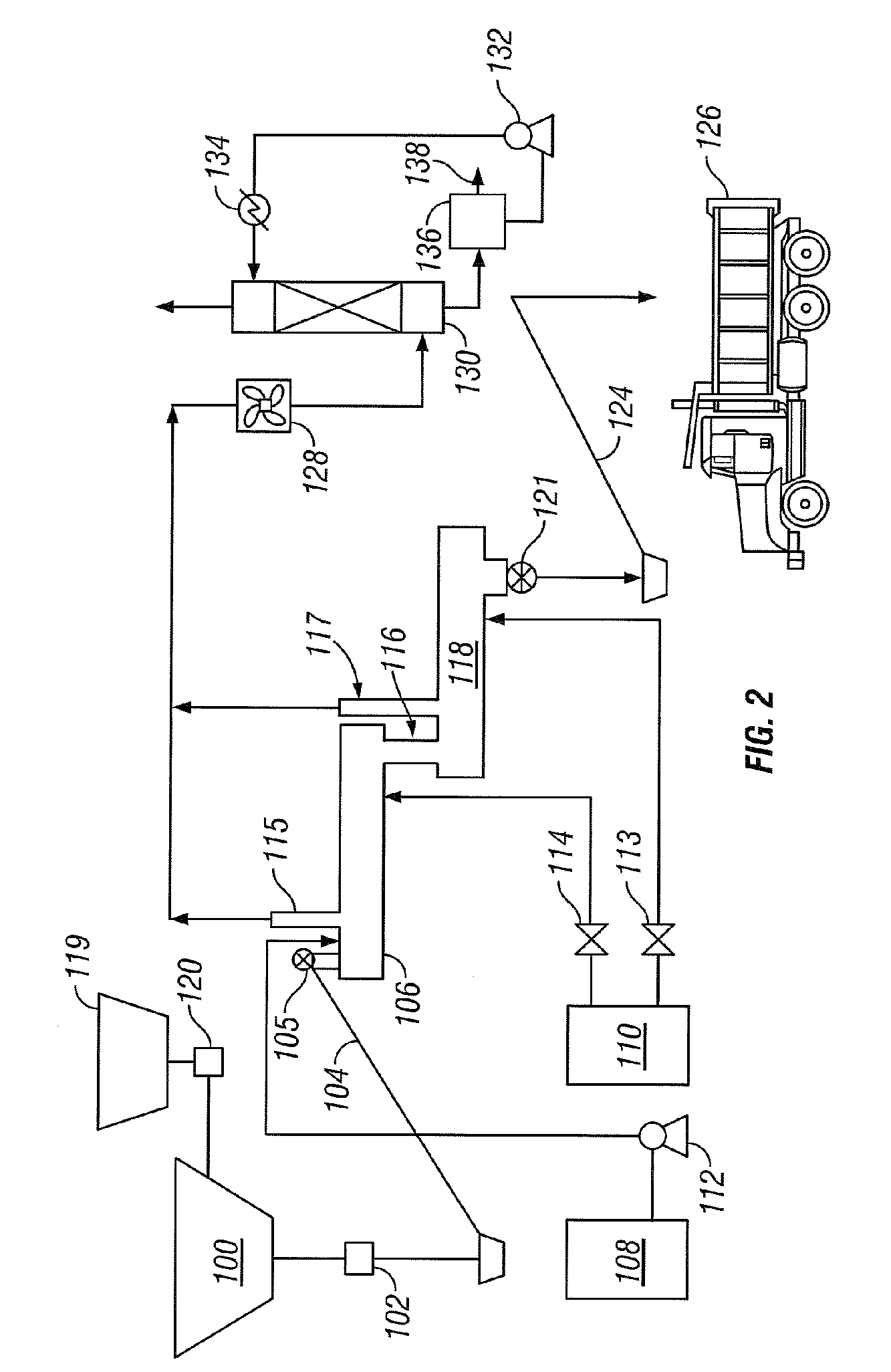

Portable evaporation chamber

InactiveUS7722739B2Speed up evaporationImprove stabilityMechanical conveying coke ovensEvaporator accessoriesZero temperatureWastewater

A self-contained evaporation system for use in disposing of excess water from oil and gas drilling operations is provided. The system includes a water holding tank in which the wastewater is preheated, an evaporation chamber mounted over the holding tank and having an open top, a nozzle system located within the chamber for producing a fine liquid mist, and fans disposed within the chamber for producing an air flow that carries the mist out the open top of the chamber. The system can be set up and taken down by one person in an hour or less, can be used with pond or tank operations, and is capable of operating in high winds and sub-zero temperatures. The system can be carried and mounted on a trailer for easy transport to and from various drilling sites.

Owner:EVAPORITE SYST

Method and device for separating electric field-separation membrane coupling

InactiveCN101716465AReduced activityReduce riskSemi-permeable membranesDispersed particle separationSeparation factorScreening effect

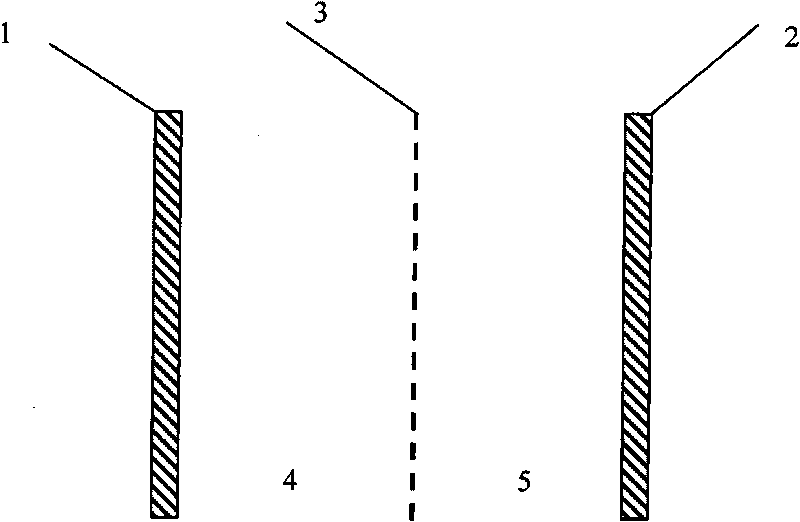

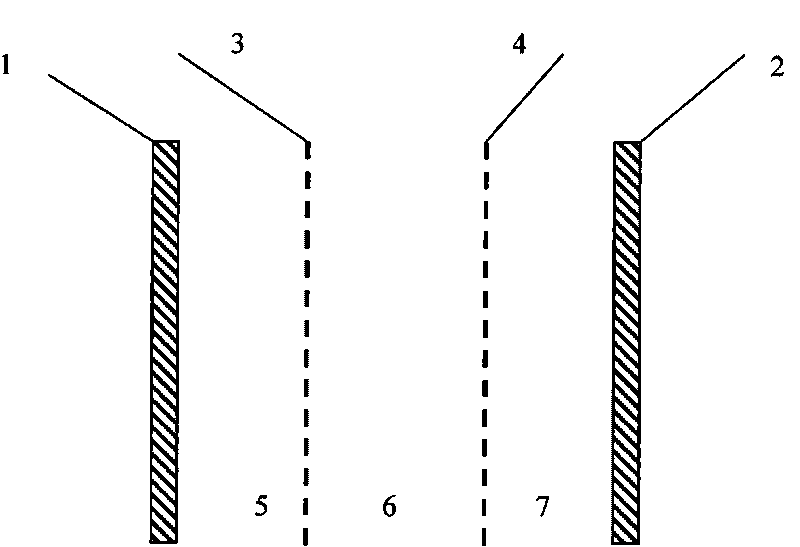

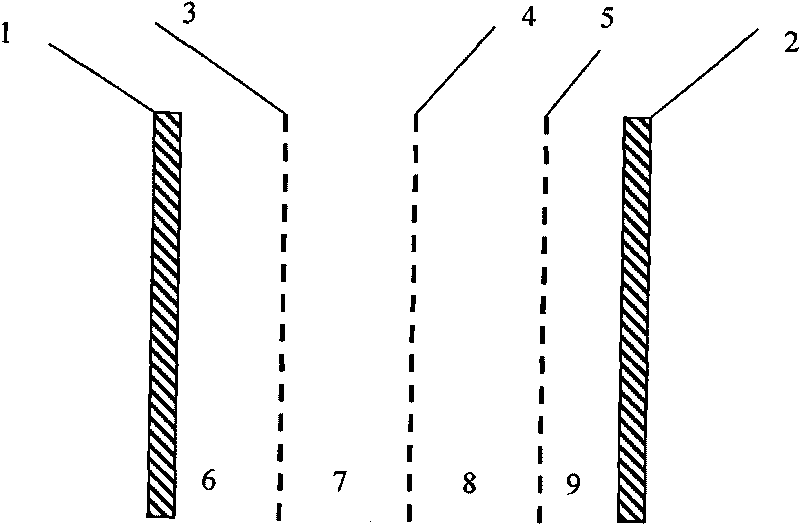

The invention discloses a method and a device for separating electric field-separation membrane coupling, which are characterized in that: separation membranes with different natures are parallelly arranged, and the outmost sides are provided with electrodes so as to form a plurality of layers of runners formed between the separation membranes and between the separation membranes and the electrodes; and fluid to be separated flows through the runners in a staggered way, and a DC electric field is applied in the direction vertical to the runners, so that electriferous molecules or microparticles generate deviation or dialytic electrophoretic behavior under the condition of the electric field, and an aperture screening effect of the separation membranes is combined so as to realize the process of quick and high-efficiency separation. The process can be performed only under the driving of the electric field, and also can be performed under the driving of the electric field and pressure. Compared with the conventional membrane process and electrophoresis process, the method and the device can greatly improve concentration and separation efficiency, improve separation factors, realize the separation which cannot be realized by the conventional membrane process, obviously reduce membrane fouling and improve the service life of the membranes.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

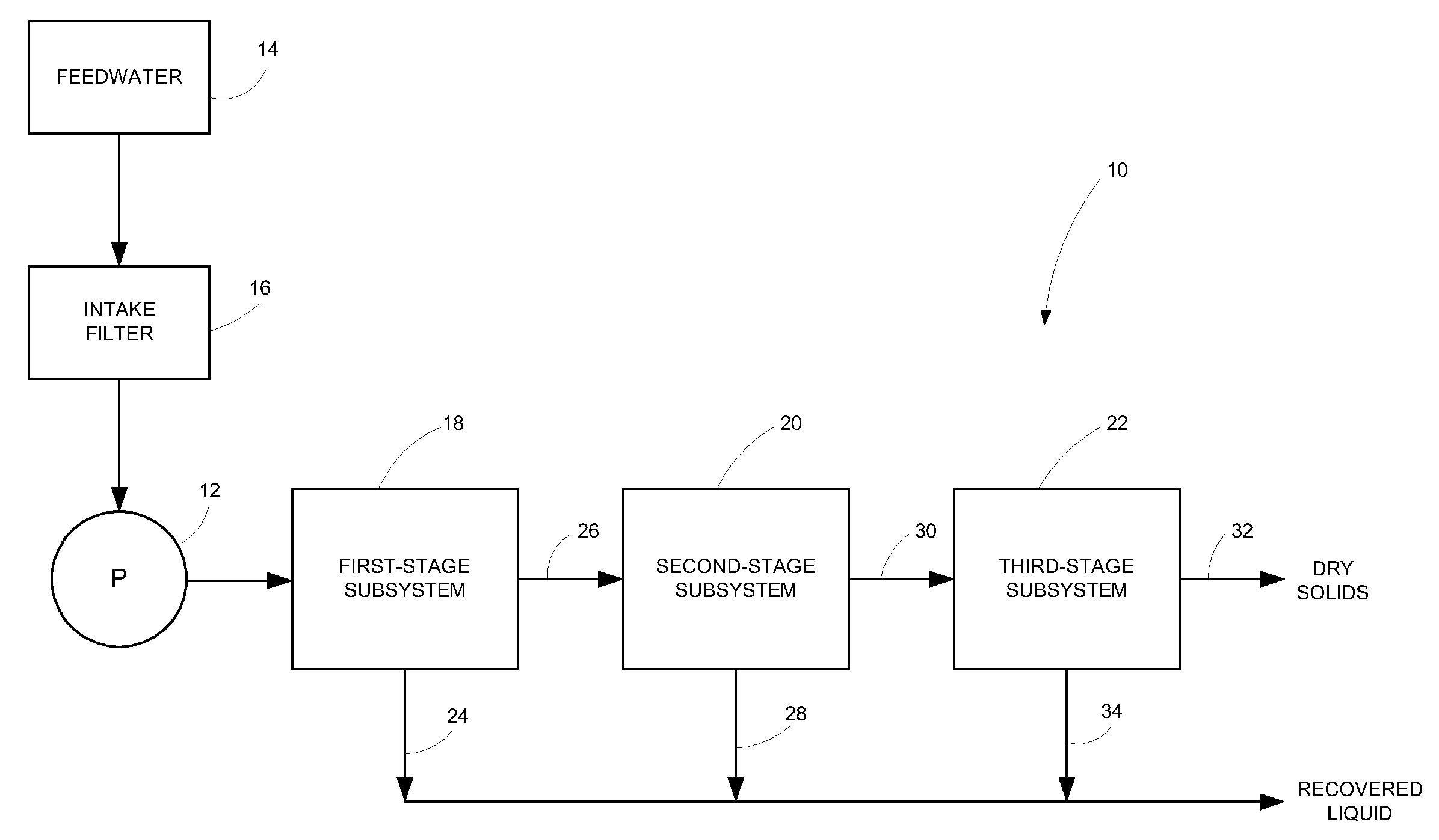

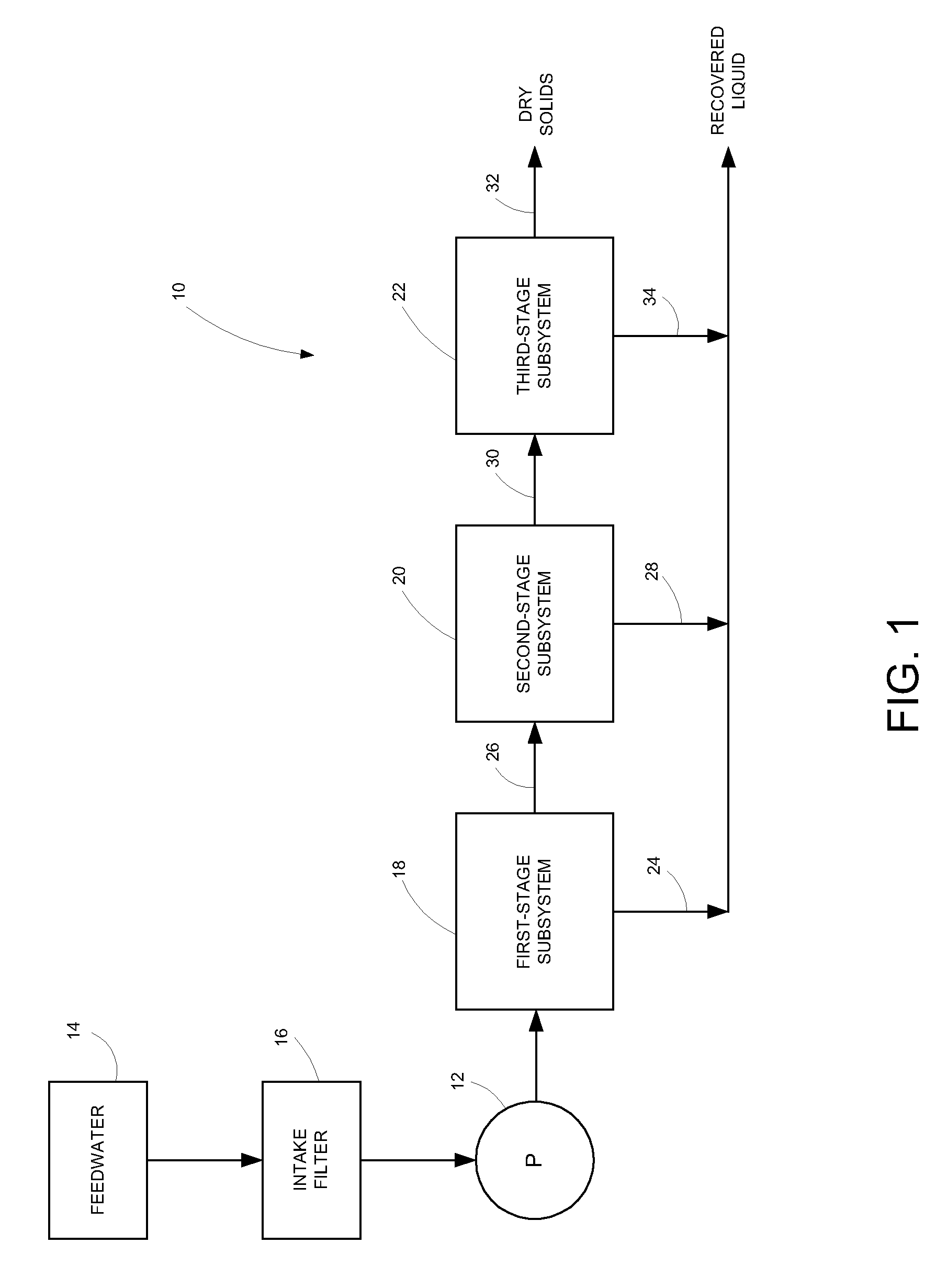

Method and system for separating solids from liquids

A method and system for treating feedwater includes evaporating a portion of the feedwater in a first evaporation chamber so as to separate water vapor from the remaining feedwater. Droplets of the remaining feedwater are dispersed into a stream of hot air produced in a second evaporation chamber. The droplets evaporate and solids in the feedwater precipitate. The precipitated solids are collected in the lower section of the second evaporation chamber. Water vapor discharged from both evaporation chambers can be treated in a cyclone separator to remove residual solids therefrom. The cleansed water vapor output from the cyclone separator can be condensed to recover clean water. Dry solids can be discharged from the second evaporation chamber and the cyclone separator for recovery.

Owner:WATERVAP

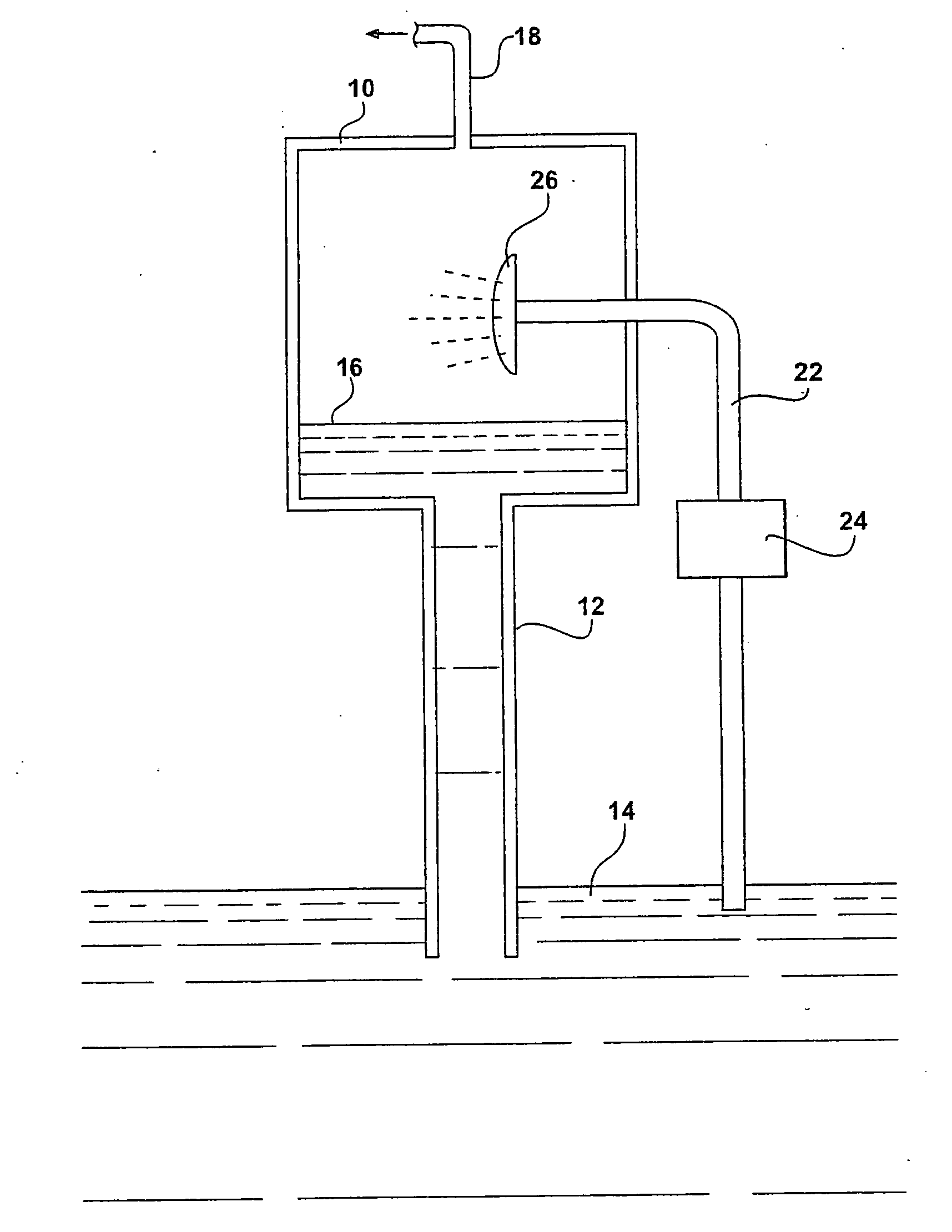

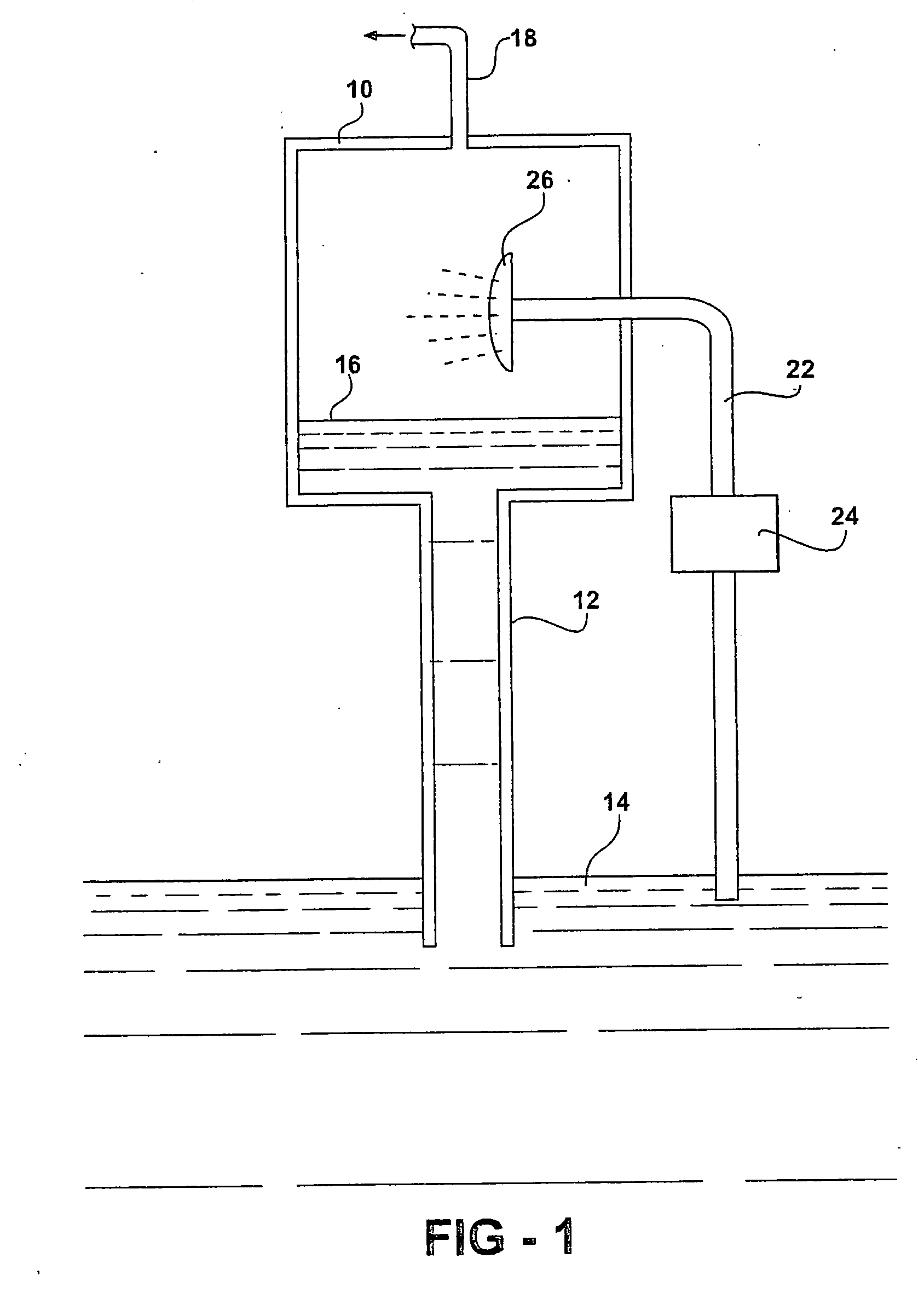

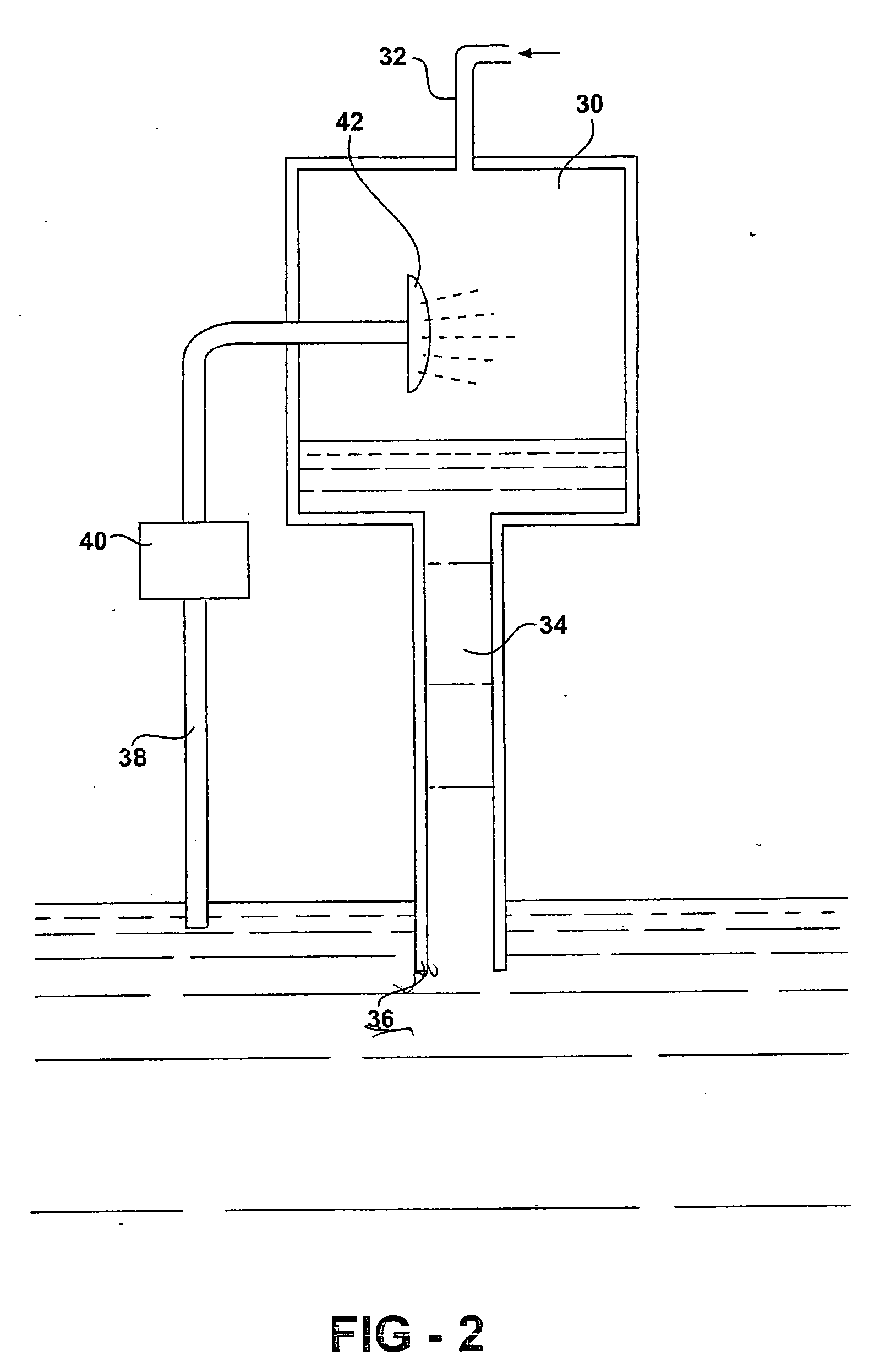

Low energy vacuum distillation method and apparatus

InactiveUS20060157335A1Lower initial costMaintenance freeLiquid degasificationGeneral water supply conservationDegasserWater source

A subatmospheric pressure desalinating still employs a closed top, open bottom pipe filled with source water to be distilled, such as seawater, having a height greater than the height of a column of seawater that can be supported by the pressure at the bottom of the tank so that a subatmospheric pressure volume is formed at the top. Water from the source is also pumped into the subatmospheric volume and passed through an evaporator which enlarges its surface volume. A small percentage of the water is vaporized and the balance is cooled to provide the heat of vaporization and falls into the top of the seawater column, creating a downward flow. The vapor is drawn from the vacuum and condensed, preferably in a second subatmospheric volume above a column of fresh water. A degasser for the water to be distilled prevents the accumulation of gases dissolved in the seawater or the like in the subatmospheric volume.

Owner:LEVINE MICHAEL R +4

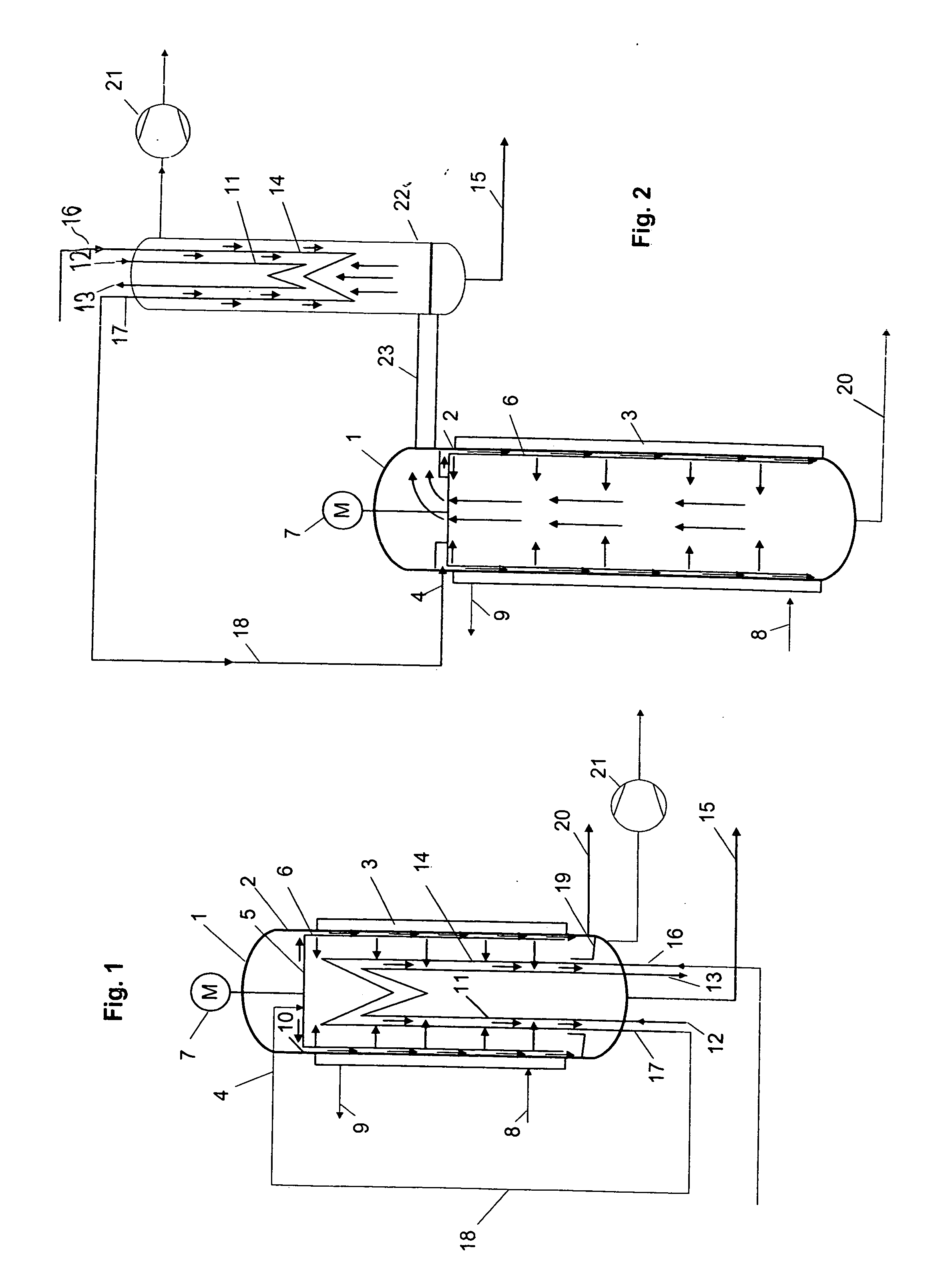

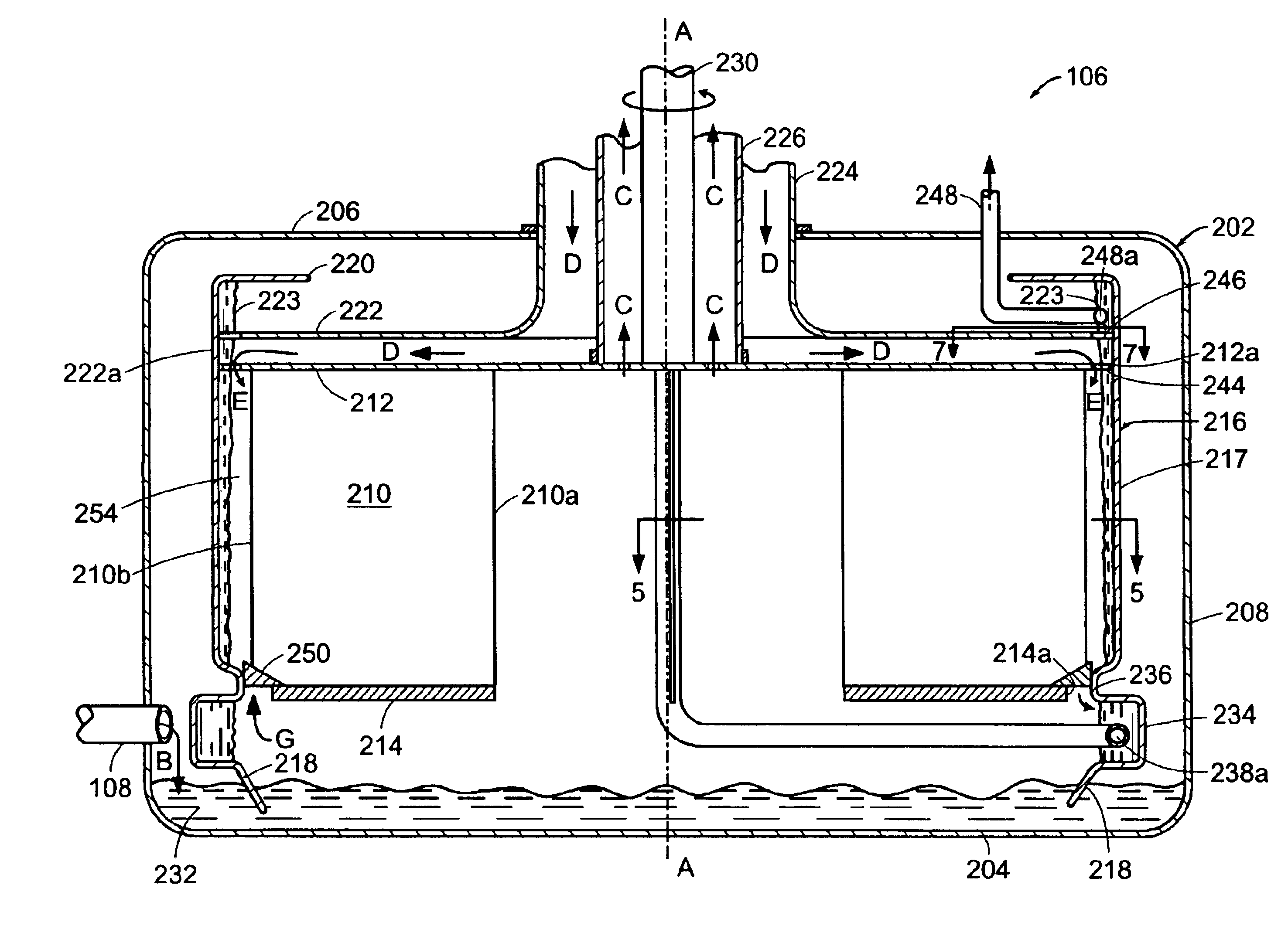

Rotating fluid evaporator and condenser

An evaporator and condenser unit for use in distilling a liquid, such as water, includes a rotary heat exchanger plate having a plurality of accordion-style folds, and having its two ends joined together so as to give the folded plate a generally circular form. The adjacent panels of the folded plate define spaces between their oppositely facing surfaces, and these spaces are alternatingly configured as evaporating and condensing chambers. The evaporating chambers have their inner edges sealed by corresponding folds, while the condensing chambers have their outer edges sealed by corresponding folds. The folded plate is disposed between first and second end plates, and is mounted for rotation about its axis in a housing having a sump containing the liquid to be distilled. Liquid is supplied to the evaporating chambers and compressed vapor is supplied to the condensing chambers. Condensate is removed from the condensing chambers.

Owner:ZANAQUA TECH

Method and system for treating feedwater

Owner:AHT SOLUTIONS +1

Thin-film evaporator

ActiveUS20060231378A1Energy efficiencyEvaporators/condensersVapor condensationChemical reactionLine tubing

A thin-film evaporator comprising a vertical drum (1), a supply line (4) that is arranged in the upper region of the drum (1) and is used to supply a medium to be evaporated, a heating jacket (3) arranged on the periphery of the drum and forming vapours, a discharge line (20) for discharging the residue left in the lower end of the drum, and a condenser (11) supplied with a coolant, for increasing the separating capacity and optionally for performing chemical reactions, is characterized in that an inner device (24) influencing the action of the thin-film evaporator is provided in the path of the vapours from the heating jacket (3) to the condenser (11).

Owner:VTU HLDG GMBH

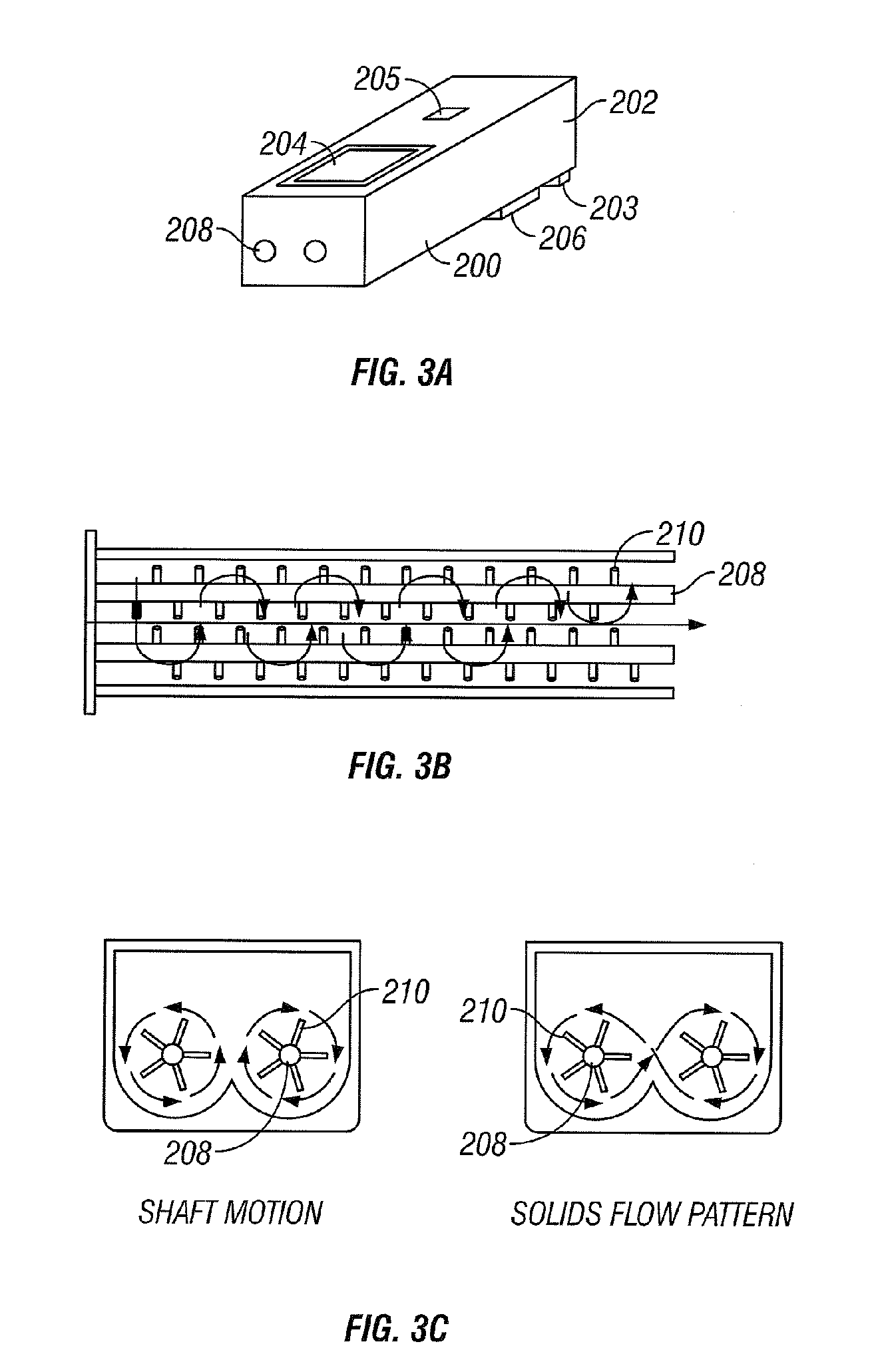

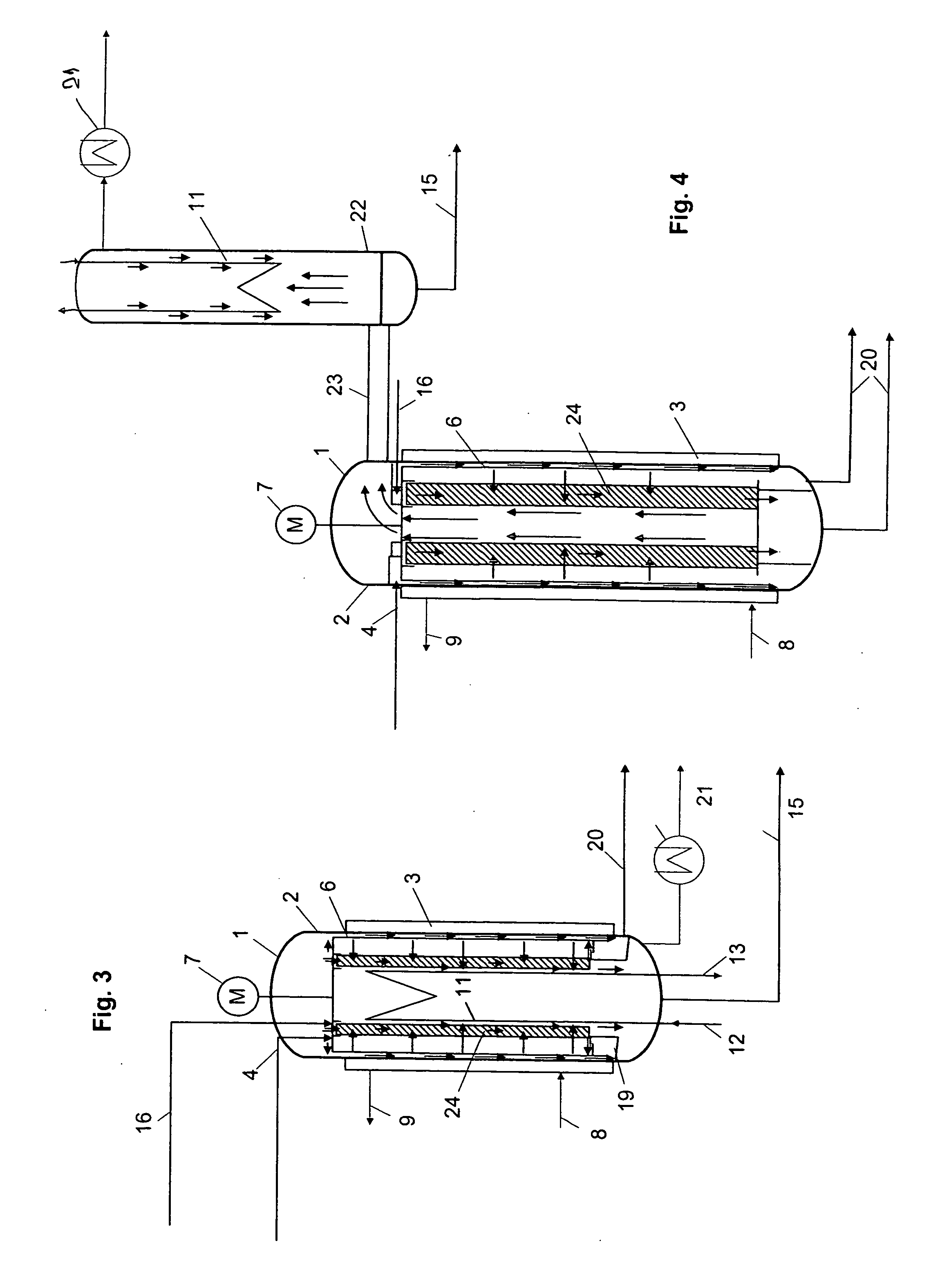

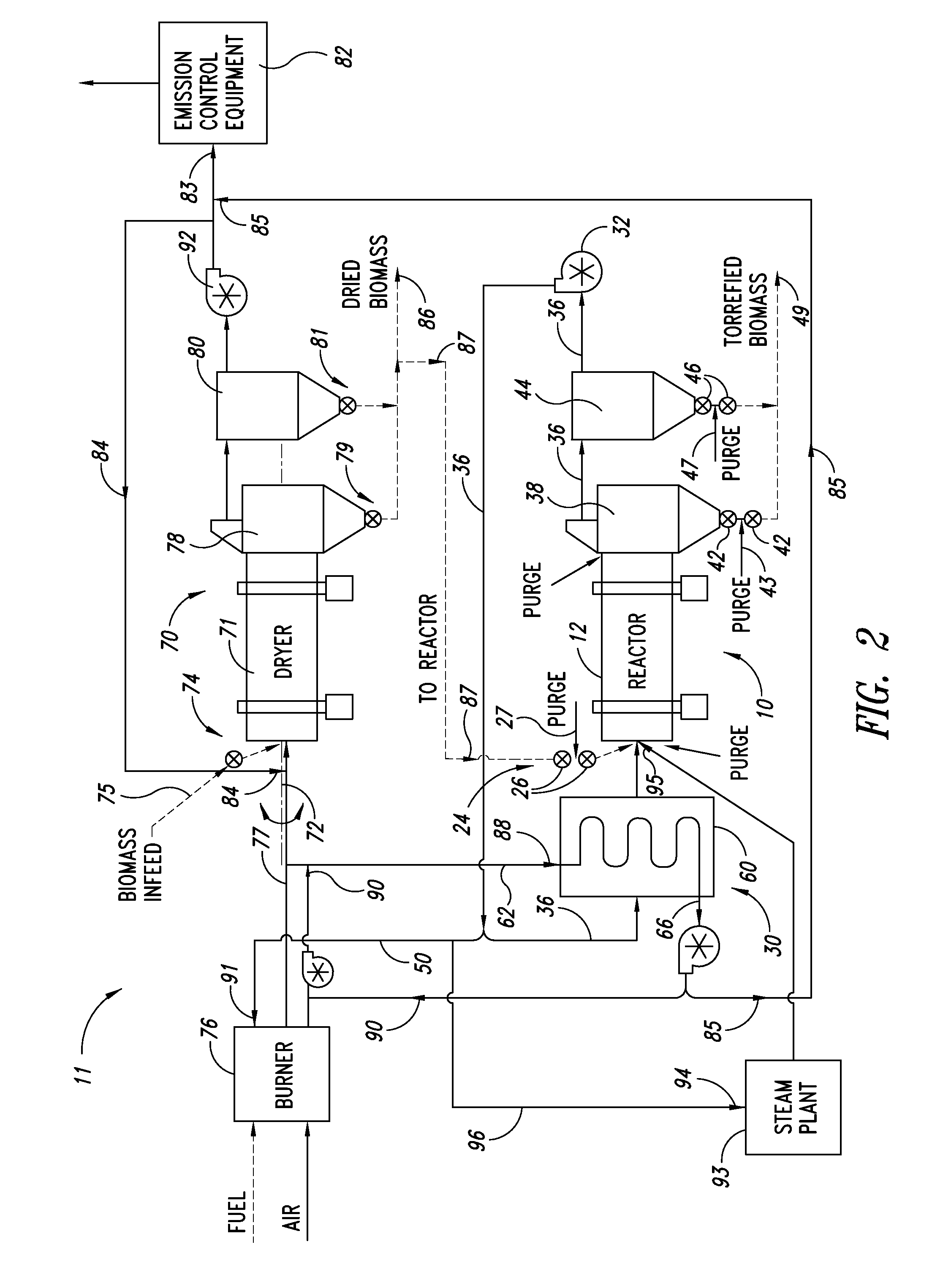

Biomass torrefaction system and method

ActiveUS8246788B2Improve scalabilityEasy to controlCombustible gas coke oven heatingDrying solid materials with heatProcess engineeringTorrefaction

A biomass torrefaction system is provided which enables a continuous torrefaction process that involves the introduction of biomass particles into a rotating reactor drum having a low oxygen environment. The particles are conveyed through the drum by a heated gas stream and simultaneously torrefied thereby. Gas exiting the drum is recirculated back to a heat source for reheating the gas prior to reentering the drum. A method of biomass torrefaction is also provided.

Owner:TEAL SALES

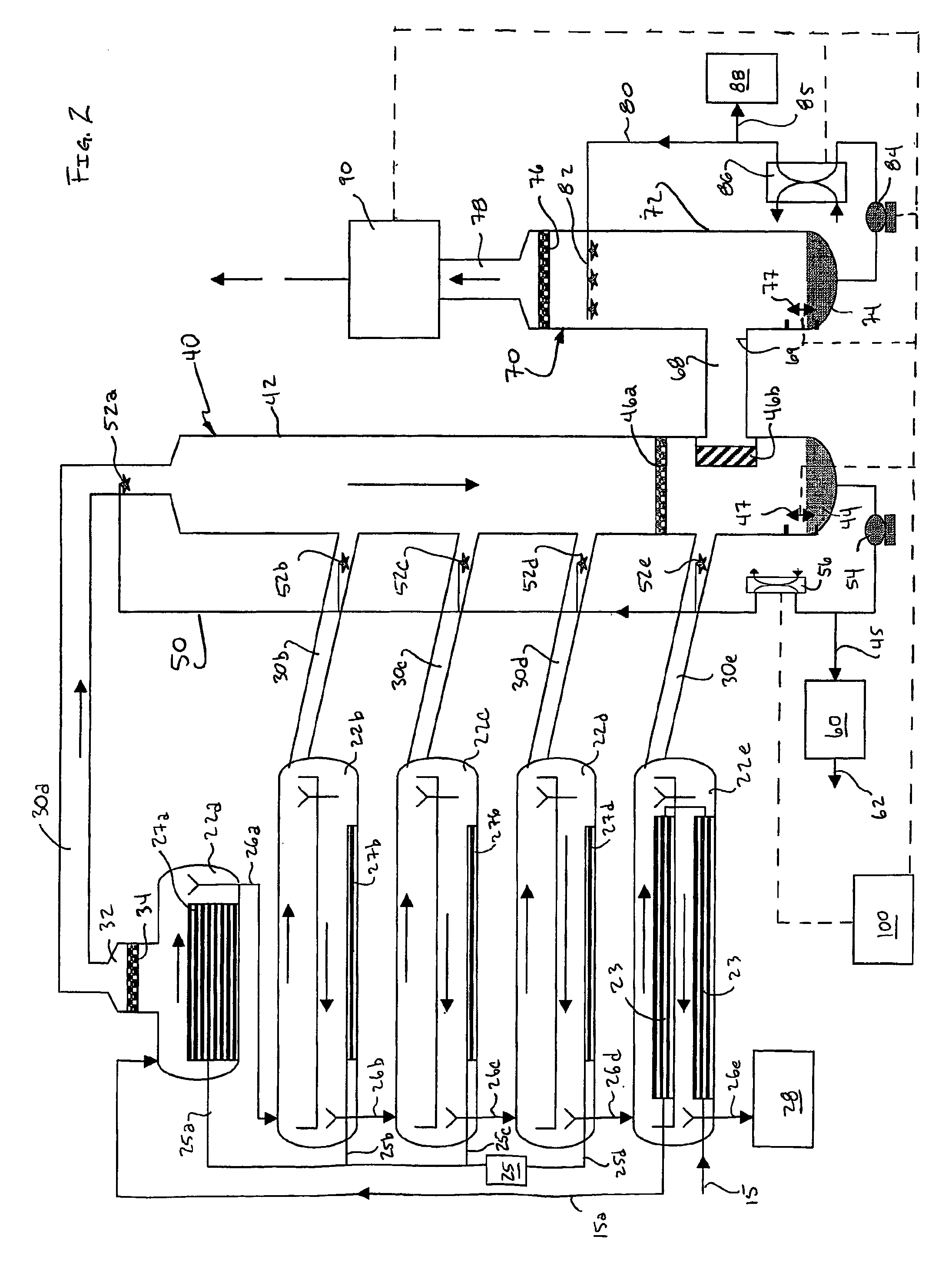

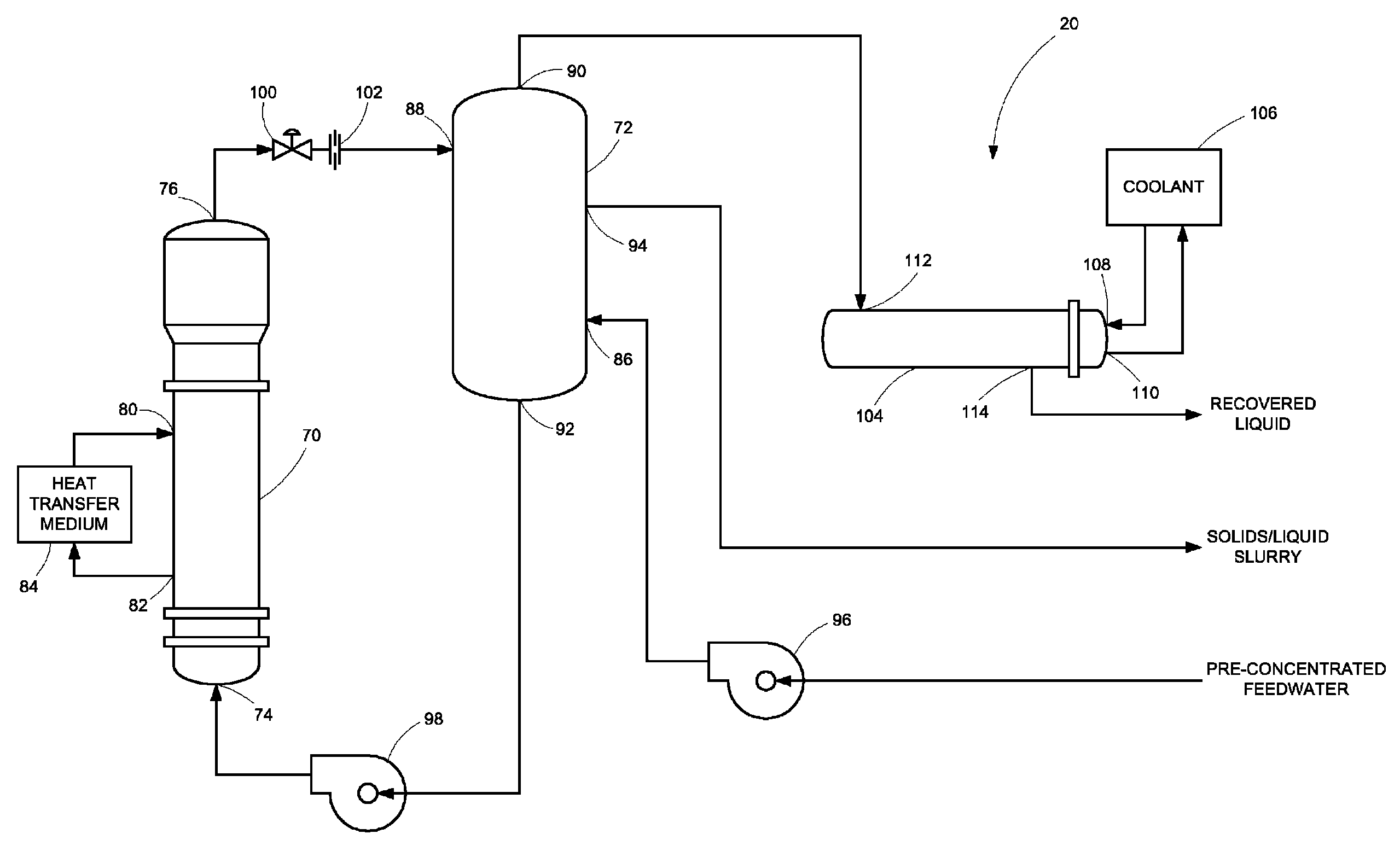

Method and system for treating feedwater

A system for treating feedwater includes a fluidized bed heat exchanger unit connected to receive feedwater and a flash concentrator column connected to receive feedwater discharged from the fluidized bed heat exchanger unit. A spray dryer is provided to receive a solids / liquid slurry discharged from the flash concentrator column. Feedwater can be treated by converting dissolved solids in the feedwater to suspended solids, vaporizing a portion of the feedwater to produce a solids / liquid slurry, and separating solids from the solids / liquid slurry.

Owner:AHT SOLUTIONS +1

Oil contaminated substrate treatment method and apparatus

InactiveUS7690445B2Dewatering/demulsification with chemical meansTransportation and packagingCollection systemEngineering

A method and apparatus for treating for disposal oil contaminated substrates, such as drill cuttings from drilling with an oil-based mud, by steam distillation. If necessary, the contaminated substrate 10 can be pretreated with an emulsion breaker 14. The contaminated substrate 10 can be treated with steam 16 in a first mixing still 12. The substrate can be optionally treated with a second steam source 20 in a second mixing still 18. The steam provides heat to vaporize the oil, moisture to treat the substrate and water to the reaction mixture. Recoverable constituents in the vapor can be condensed in a vapor collection system 24. The treated substrate 22 is essentially free of oil and can have a controlled water content. The process exhibits low energy consumption, rapid treatment, compact equipment and a high degree of process control.

Owner:RACIONAL ENERGY & ENVIRONMENT

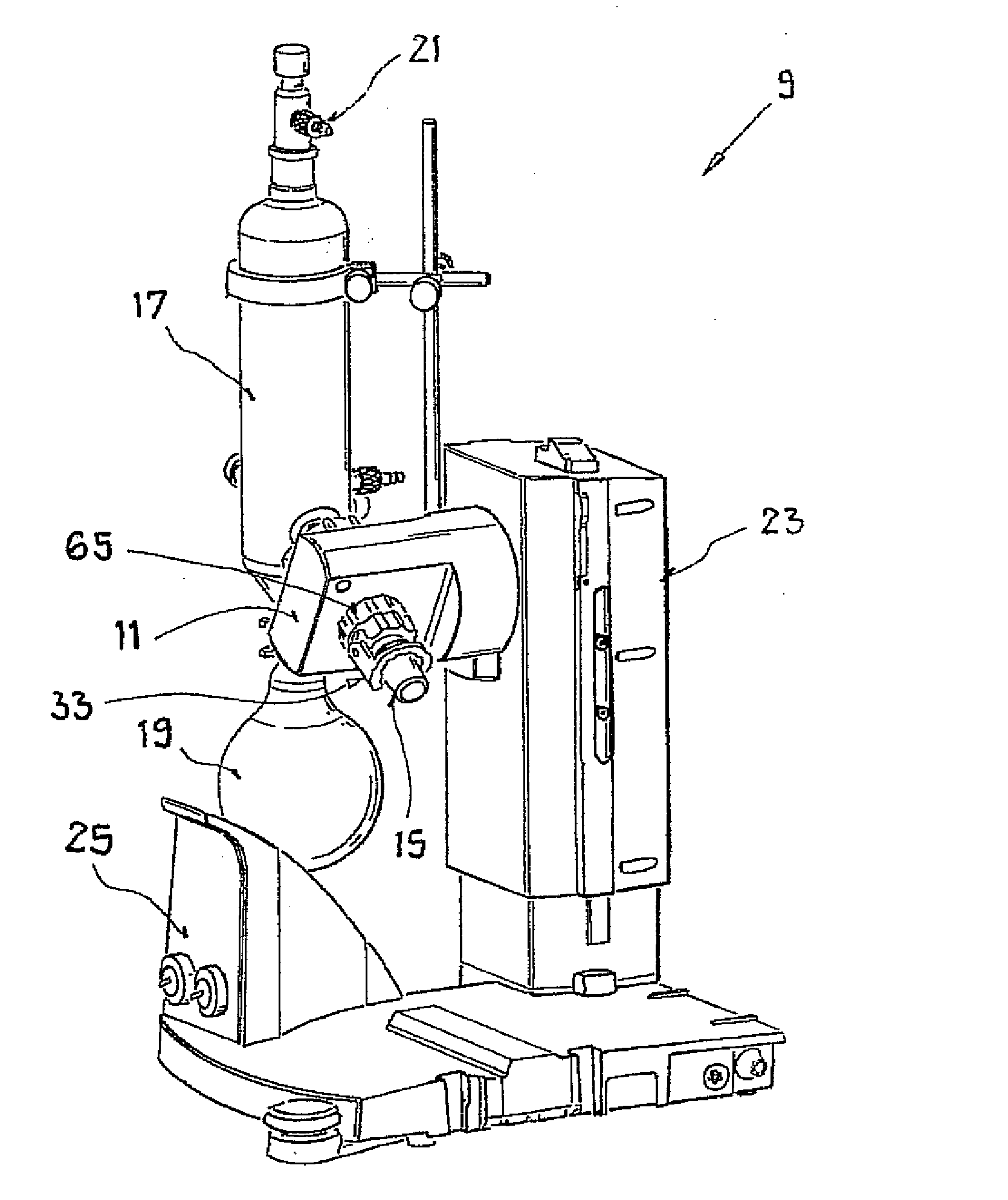

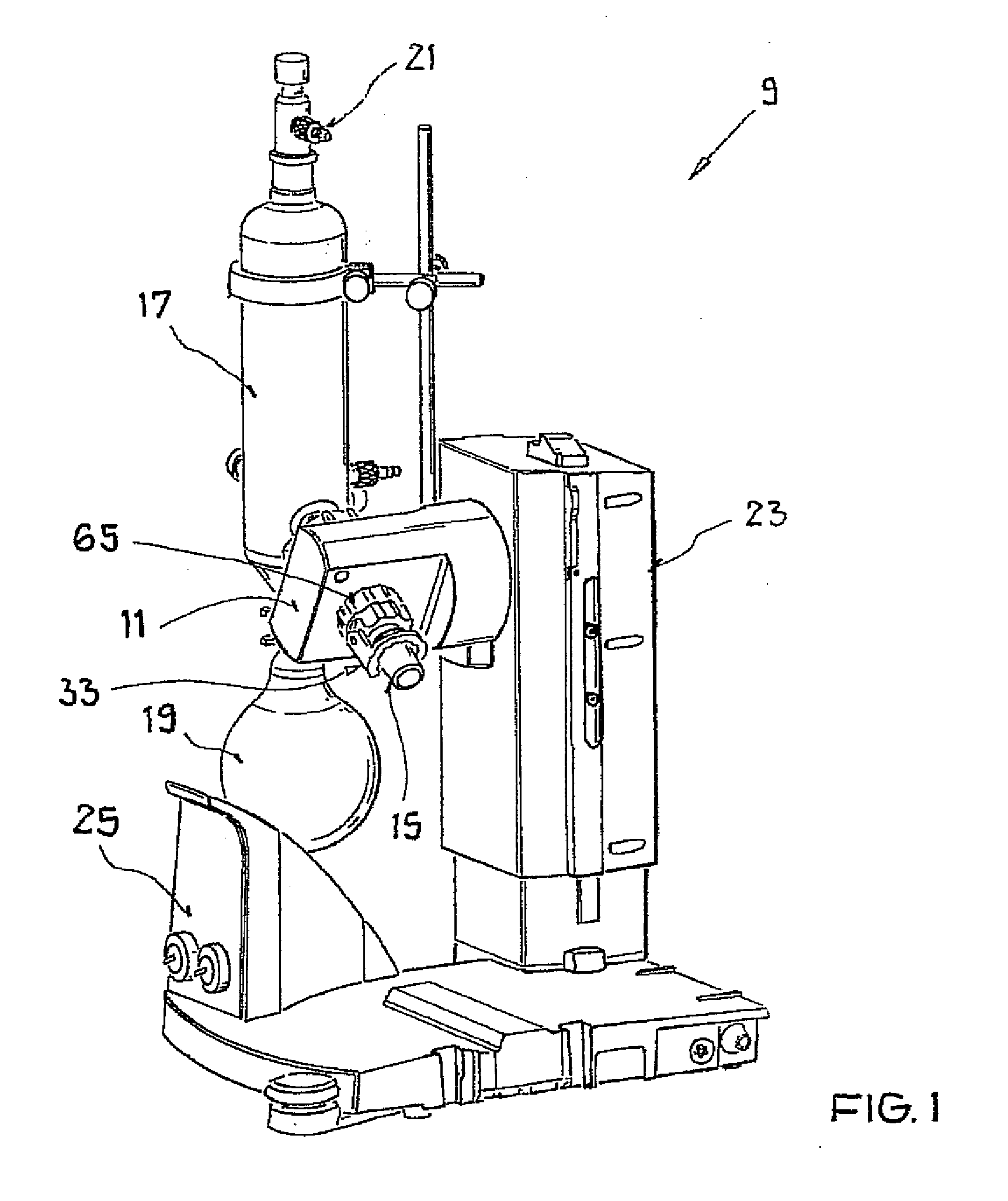

Rotary evaporator

ActiveUS20100193345A1Extended service lifeImprove accuracyPipe-jointsDistillationRotary evaporatorMechanical engineering

The invention relates to a rotary evaporator comprising a rotary drive having a hub and a clamping insert with a sleeve-like basic shape, in particular a clamping sleeve, for the clamping of a steam leadthrough formed as a hollow glass shaft in the hub of the rotary drive, wherein the clamping insert has a longitudinal axis and a first and a second axial end, wherein the clamping insert has two clamping sections which are arranged spaced apart from one another in the longitudinal direction and which each have an outer cross-section tapering toward the first end and of which the clamping arrangement arranged closer to the second end has a larger maximum outer cross-section.

Owner:HANS HEIDOLPH

Rotating heat exchanger

An evaporator and condenser unit for use in distilling a liquid, such as water, includes a rotary heat exchanger plate having a plurality of folds or pleats. Adjacent panels of the folded plate define spaces between their oppositely facing surfaces, and these spaces are alternatingly configured as evaporating and condensing chambers. The evaporating chambers, moreover, are defined between adjacent panels that are joined at an outer diameter fold, while the condensing chambers are defined between adjacent panels that are joined at an inner diameter fold. The evaporating chambers are thus closed at their outer diameter ends and open at their inner diameter ends, while the condensing chambers are closed at their inner diameter ends and open at their outer diameter ends.

Owner:ZANAQUA TECH

Apparatus and methods for water regeneration from waste

Owner:HONEYWELL INT INC

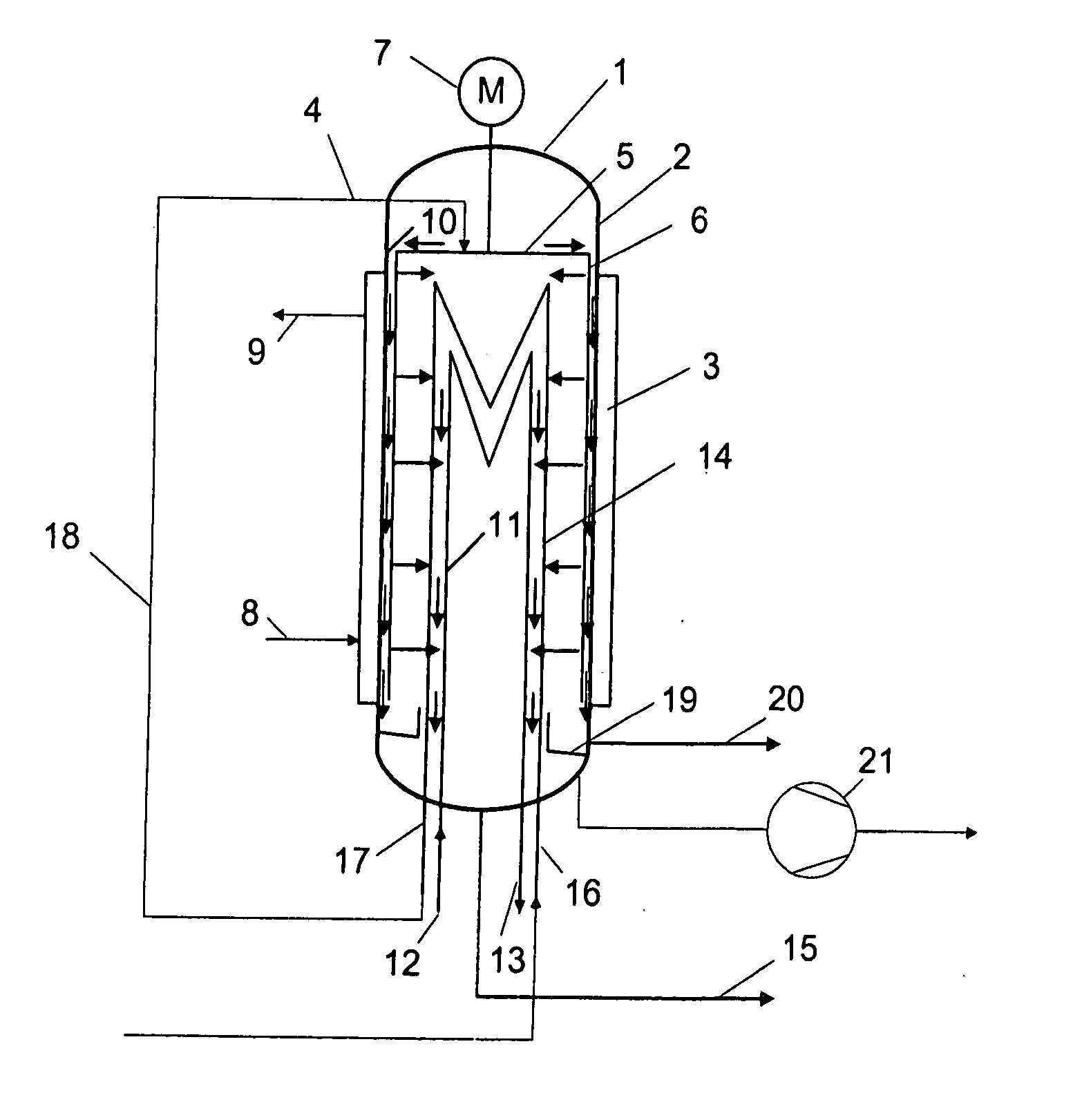

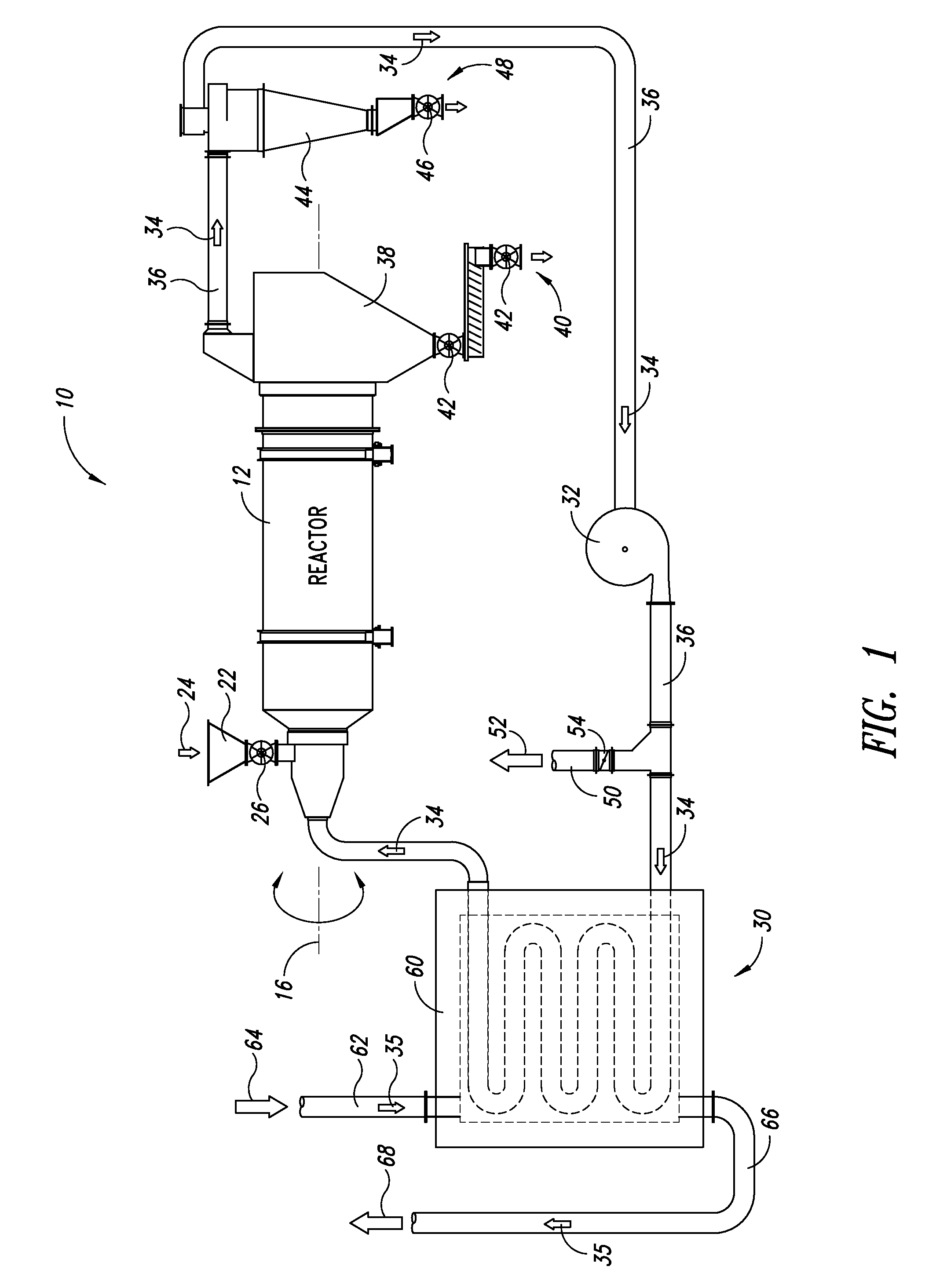

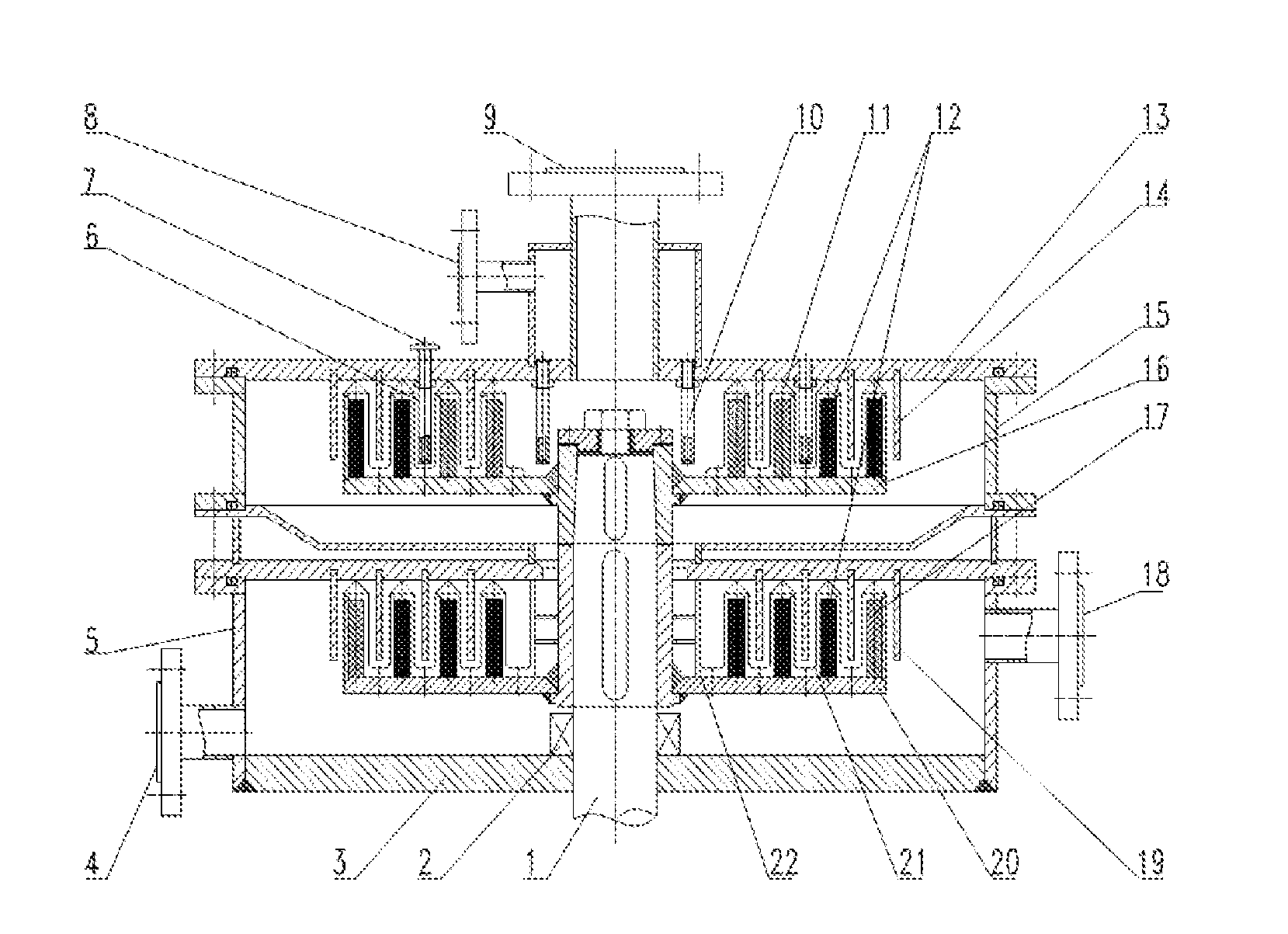

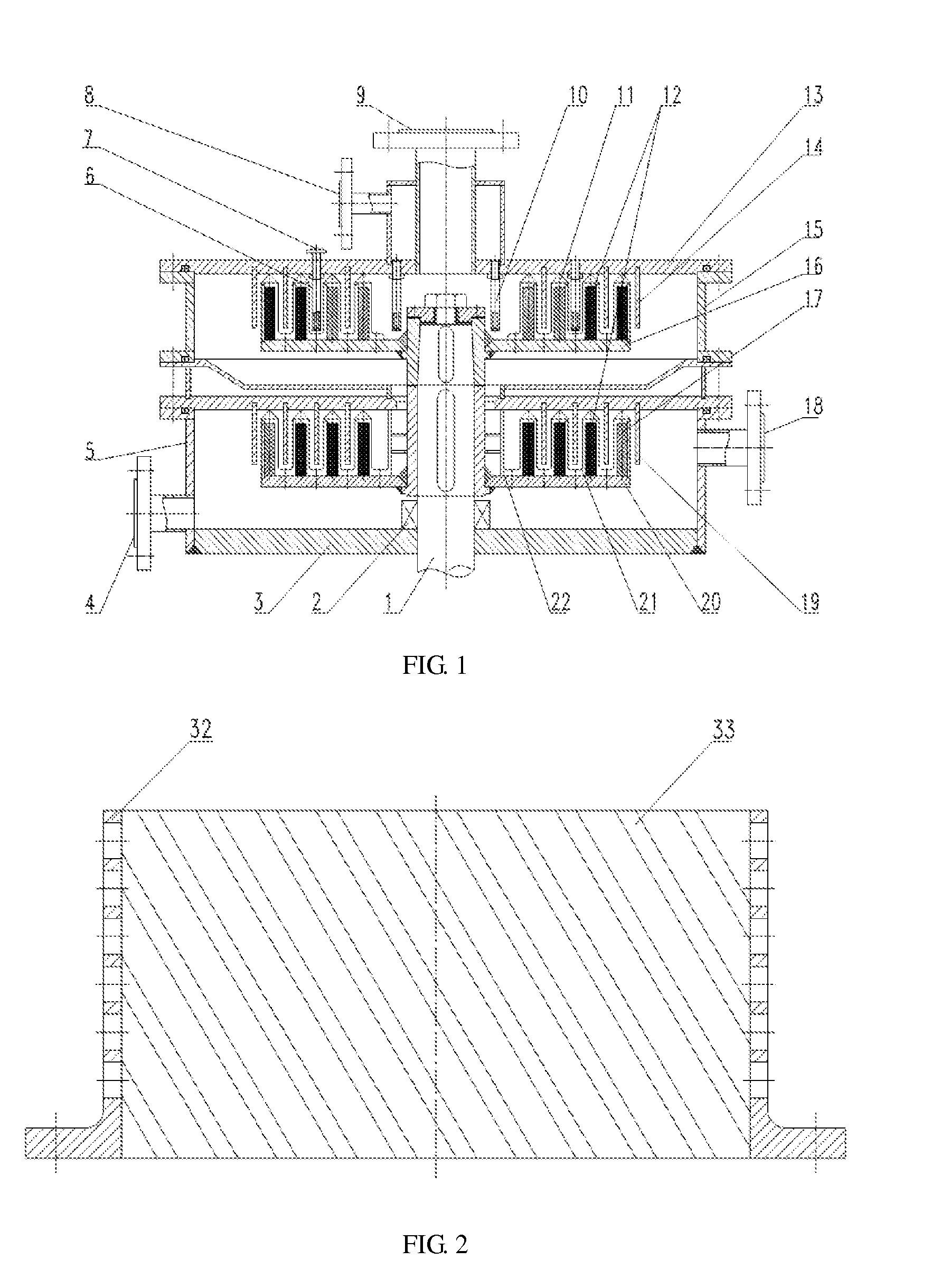

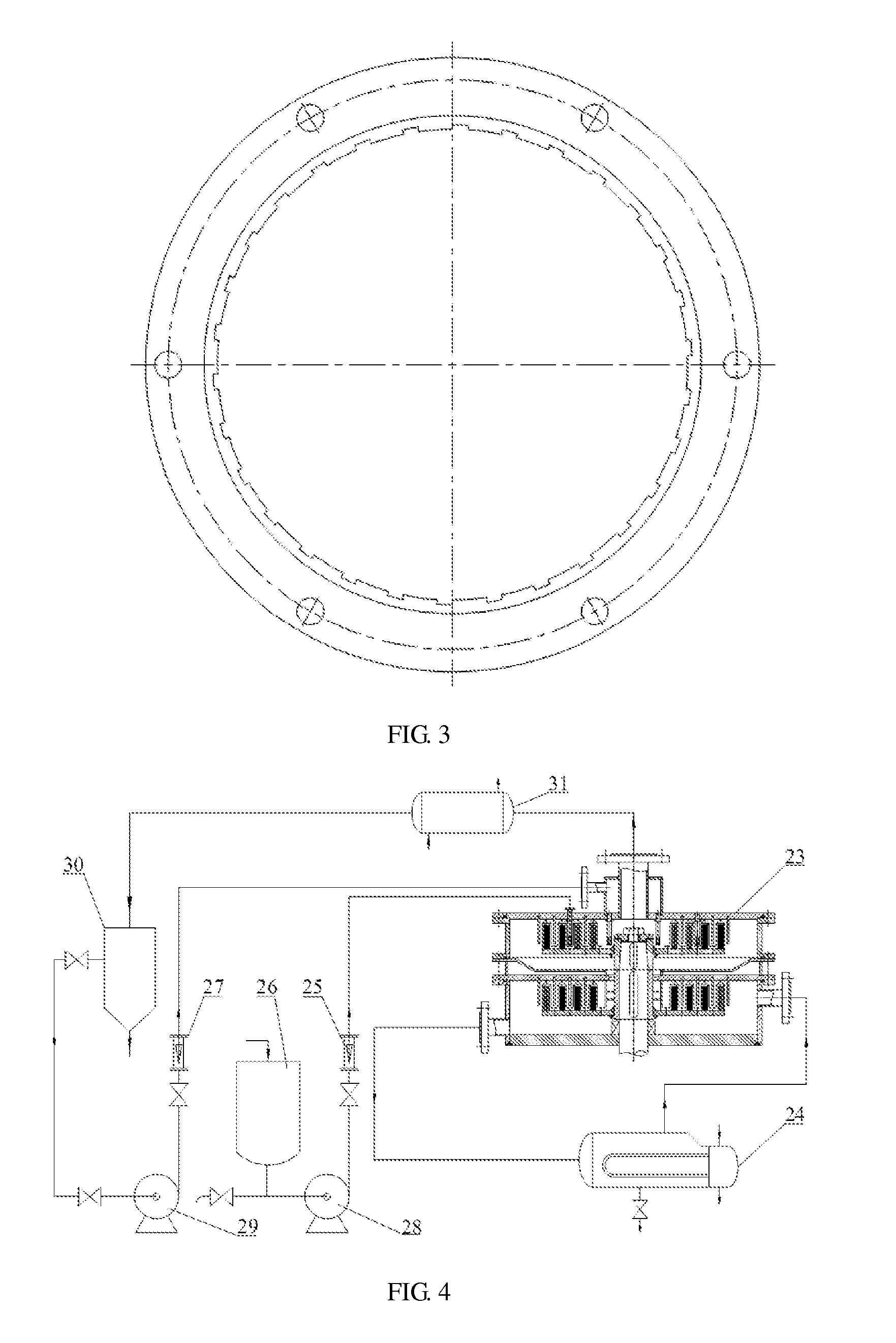

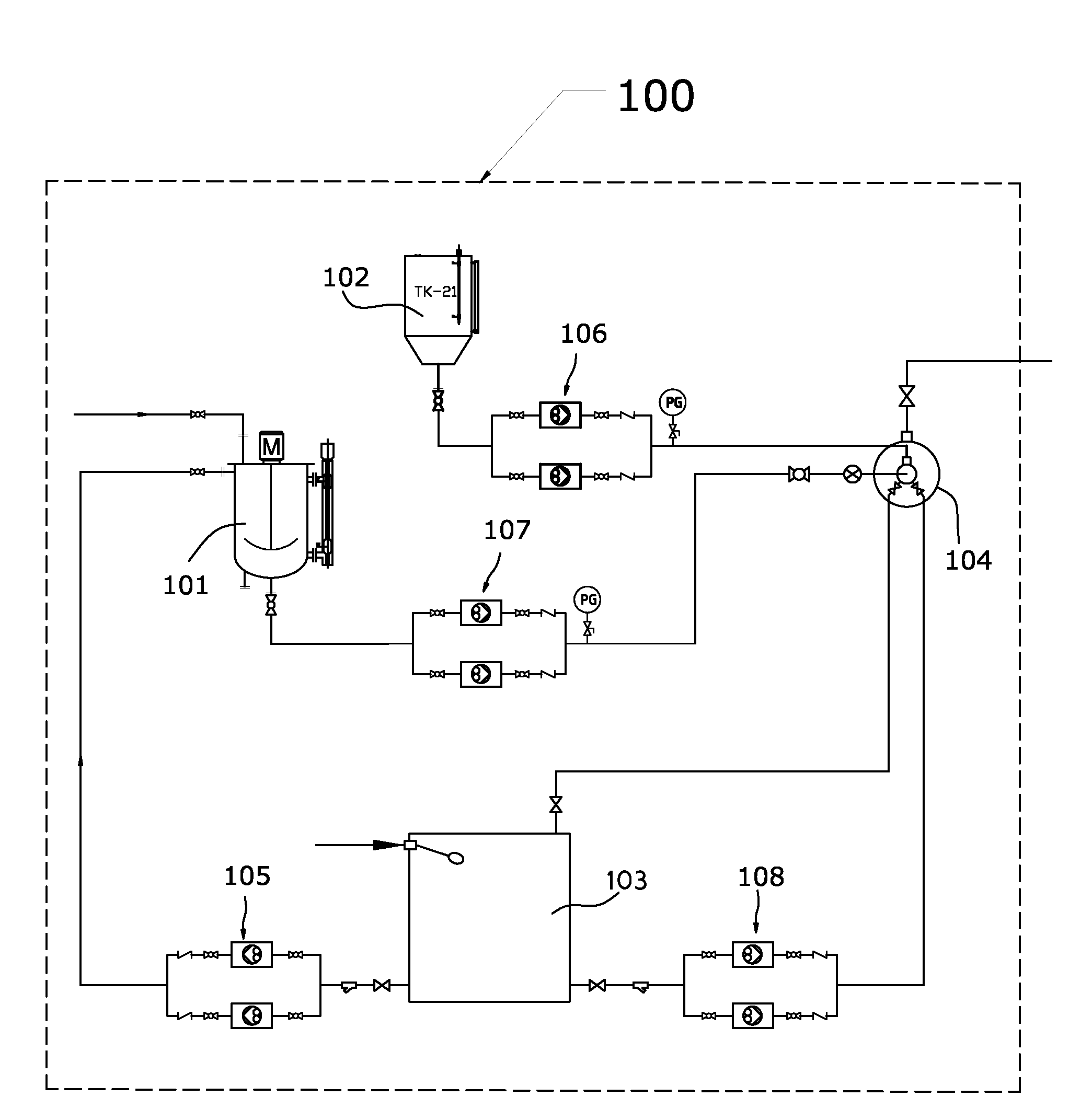

Reactive distillation apparatus for a multistage counter-current rotating bed and its application

ActiveUS20110214979A1Improve mass-transfer efficiencyImprove efficiency separationLiquid-gas reaction processesDistillation in rotating vesselsWire gauzeGas phase

The present invention discloses a reactive distillation apparatus for multistage counter-current rotating bed and its application, the apparatus comprises a closed shell, in the center of which a revolving shaft linking each shell section is set, the said shaft is provided with two or more rotors in series connection, a feeding inlet, a reflux inlet and an outlet of the gas phase are mounted on the top end face of the shell while a waste liquid outlet and an inlet of the gas phase are set on the bottom end face of the shell, the said shell consists of an upper section of the shell and a lower section of the shell along the axial direction, the said rotor consists of a rotating disc firmly connecting with the revolving shaft and a static disc mounted to the shell, a group of concentric dynamic filler rings but with different diameters are installed at intervals along the radial direction, wherein the wall of the dynamic filler rings is holed, and the ring clearance between the dynamic filler rings is configured with static rings fastened on the static disc; the filler filled in the said dynamic filler ring includes a catalytic filler and a wire gauze filler with the catalyst filler filled in the dynamic filler ring of the outer circle of the upper rotor and the inner circle of the lower rotor and the wire gauze filler filled in the rest of the dynamic filler rings, to make the whole rotor structure equivalent to the distillation section, reactive distillation section and stripping section; a feeding inlet is arranged on the top cover of the shell corresponding to the spray nozzle of raw material liquid; a rotating liquid distributor is arranged on the inner side of the innermost dynamic filler ring of the said lower rotor. The catalyst of the present invention not only plays the role of catalytic reaction, but also increases the interphase mass transfer area; the present invention improves the mass transfer efficiency and the separation efficiency of the reactive distillation process.

Owner:BEIJING UNIV OF CHEM TECH

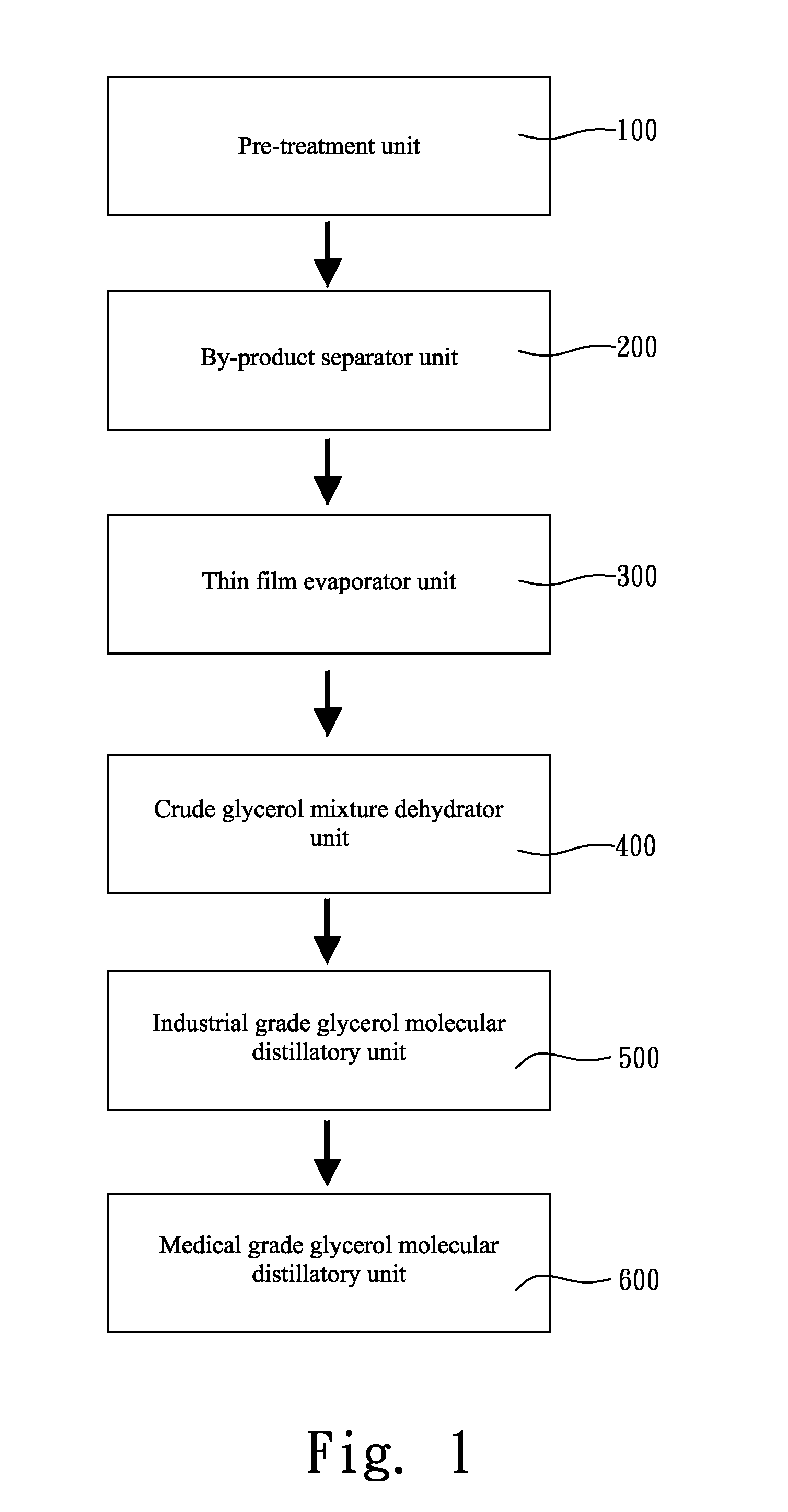

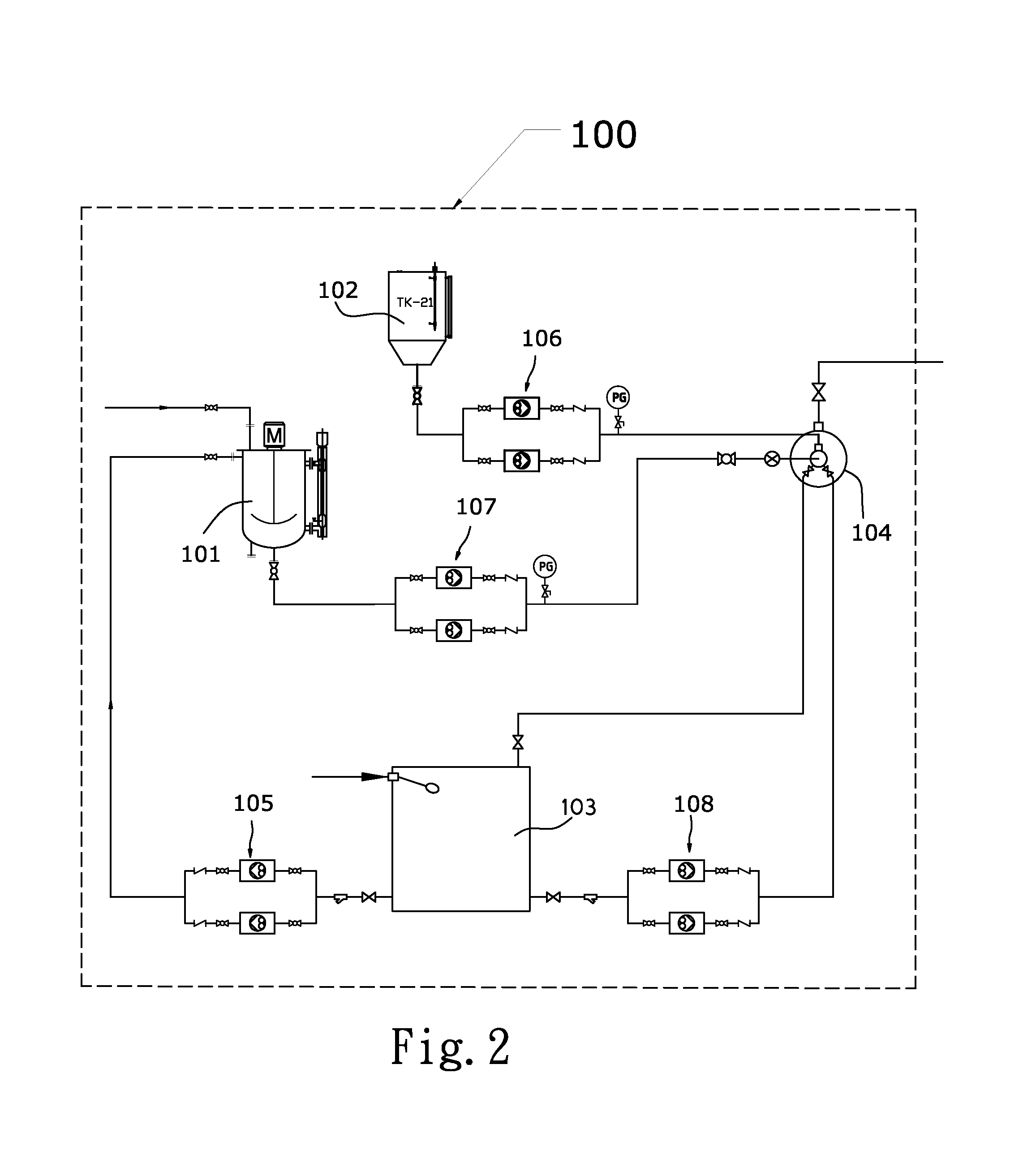

Glycerol (Medical Grade) Preparation Method using a By-Product of a Bio-Diesel Process

A glycerol preparation method for preparation of medical grade glycerol from a by-product of a bio-diesel process by means of thin film evaporation and molecular distillation include a first stage phosphoric acid chemical reaction process and a posterior by-product centrifugal separation process to have the phosphoric acid chemical reaction by-product be separated into free fatty acid, potassium phosphoric acid, and a crude glycerol and methanol mixture. The crude glycerol and methanol mixture is further processed through a first step of thin film evaporation process where methanol is reclaimed, a second step of thin film evaporation process where the mixture is dehydrated, a third step of molecular distillation process where an industrial grade glycerol of purity over 95% is extracted, and a fourth step of molecular distillation process where a medical grade glycerol of purity in exceed of 99.75% that meets USP / BP standards is extracted.

Owner:CHANG WEI MING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com