Patents

Literature

645 results about "Water vapor condensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Condensation is the process by which water vapor in the air is changed into liquid water. Condensation is crucial to the water cycle because it is responsible for the formation of clouds. These clouds may produce precipitation, which is the primary route for water to return to the Earth's surface within the water cycle.

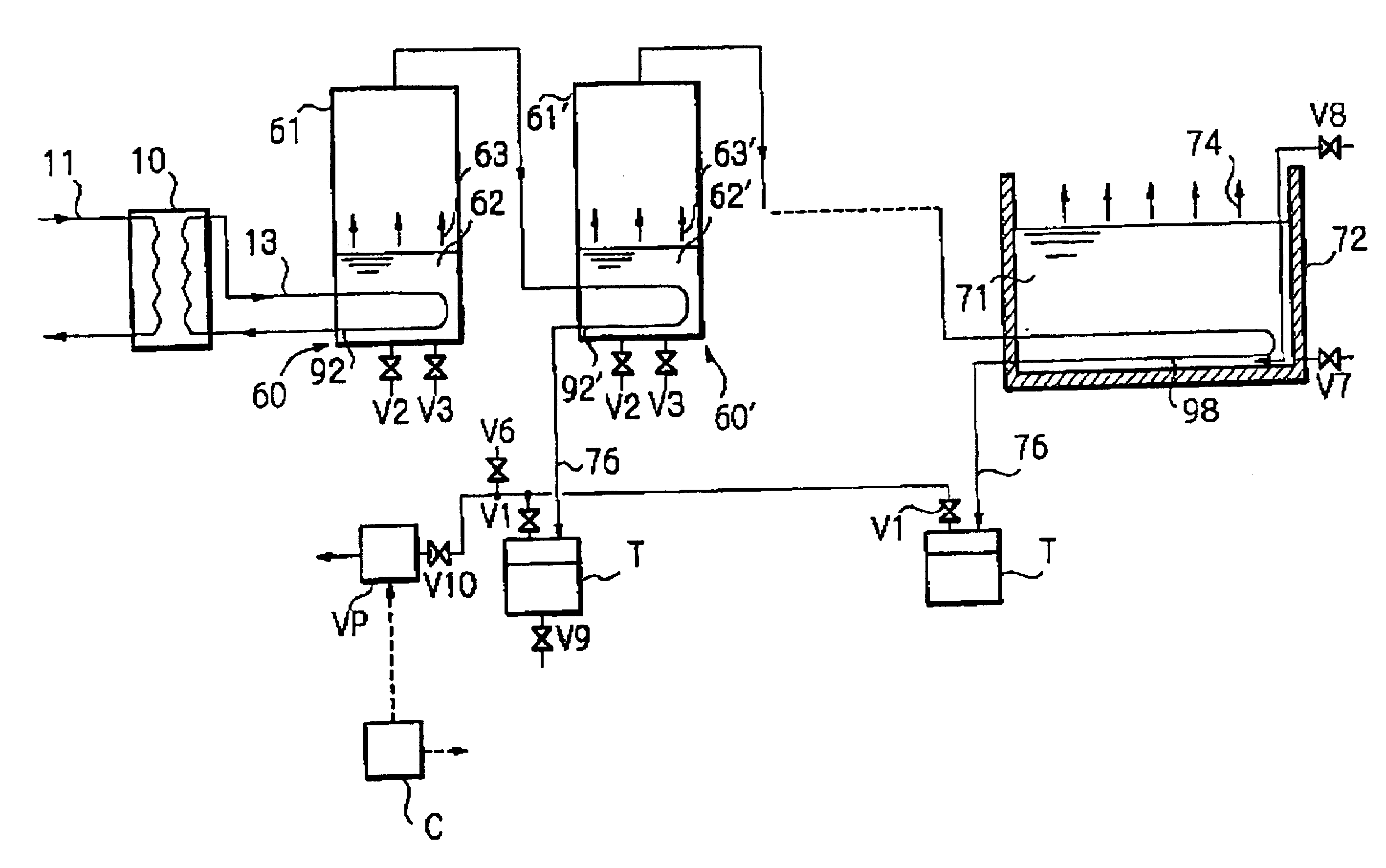

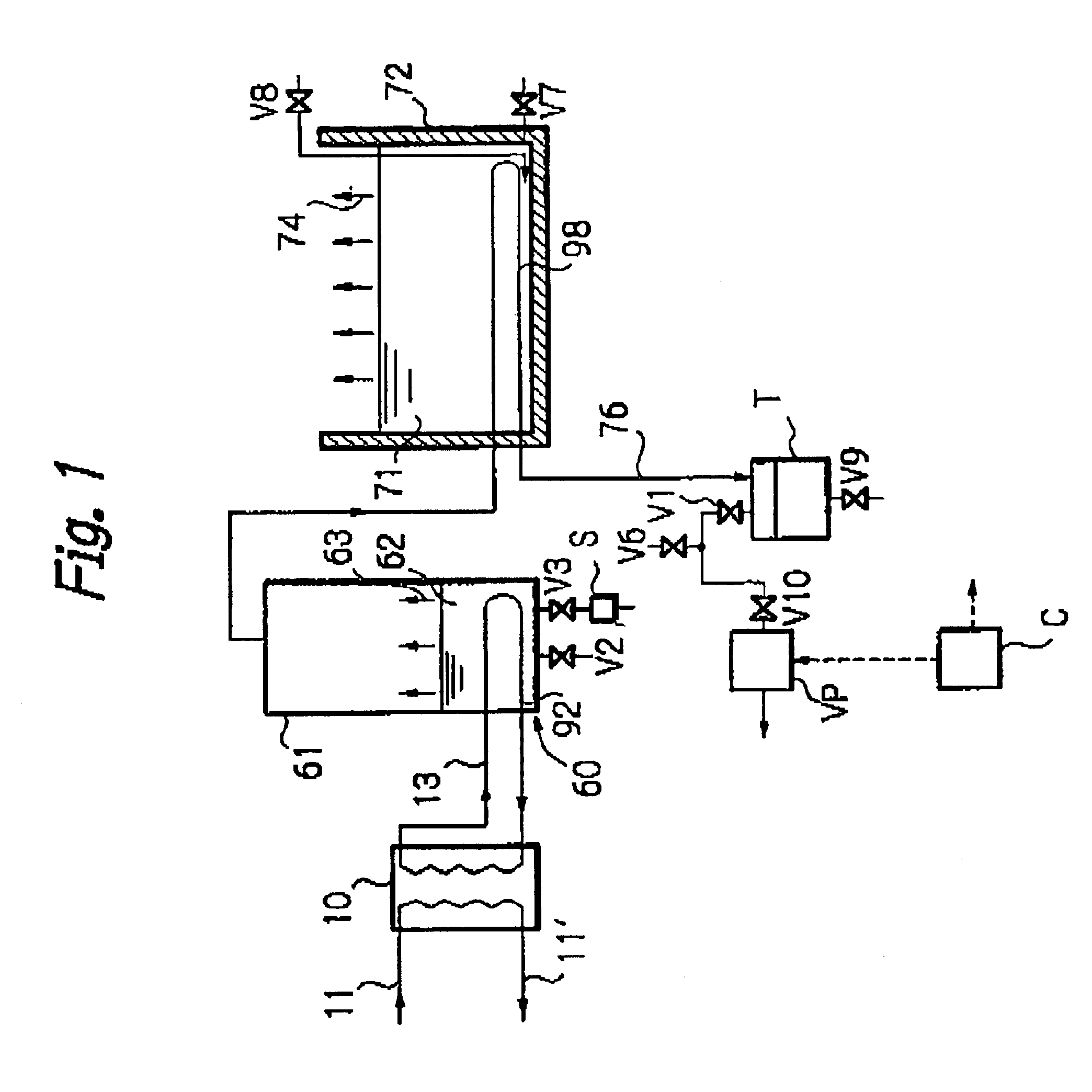

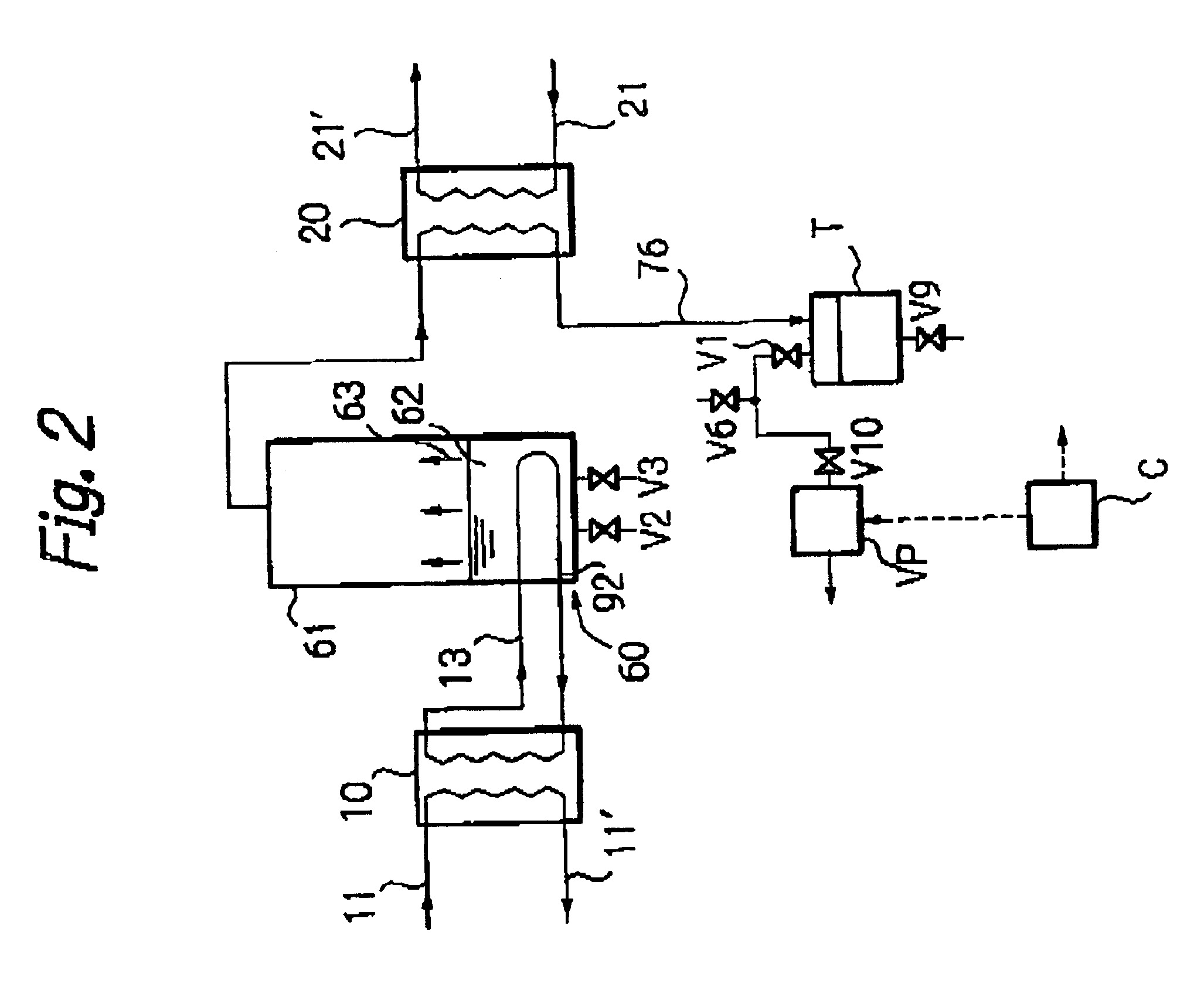

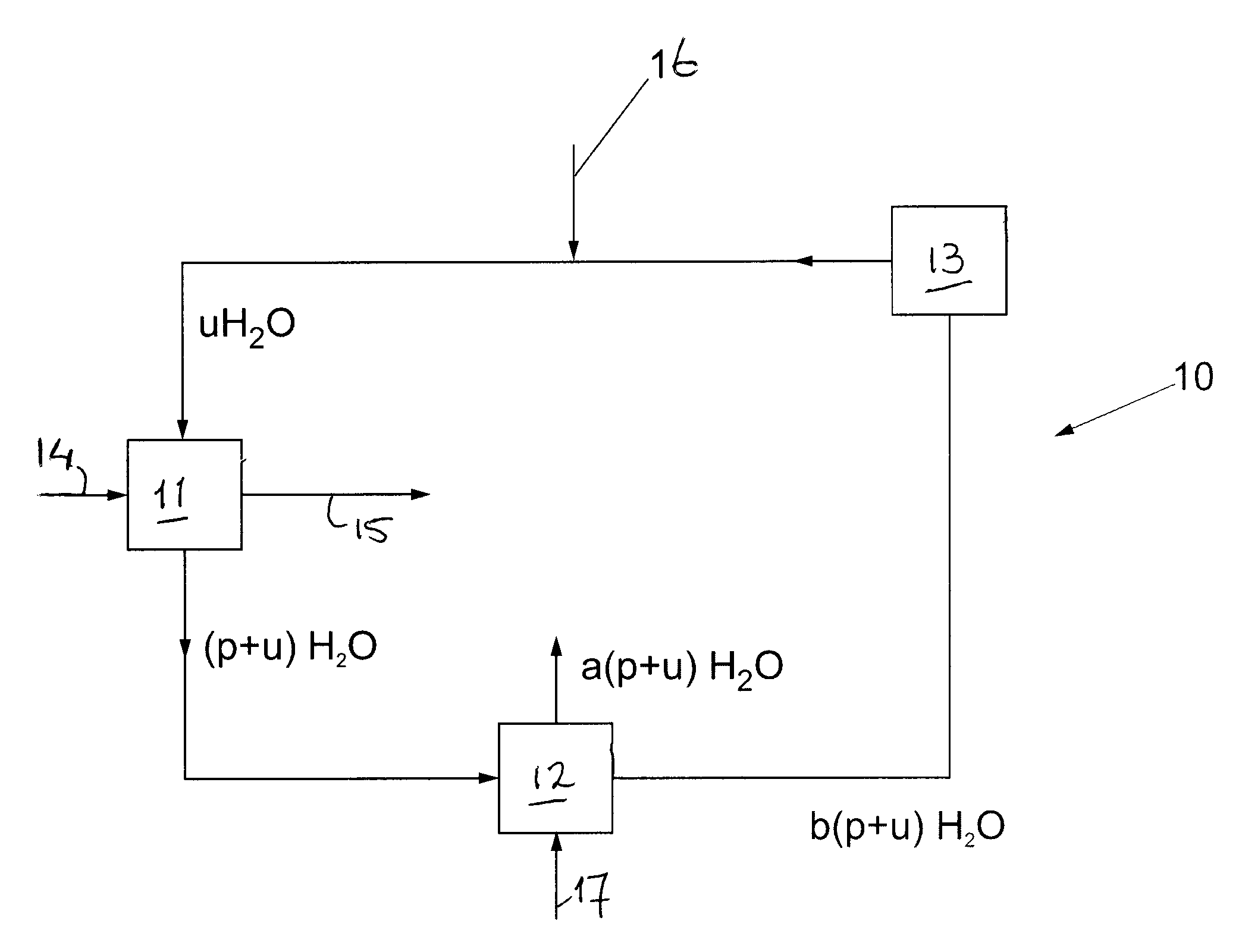

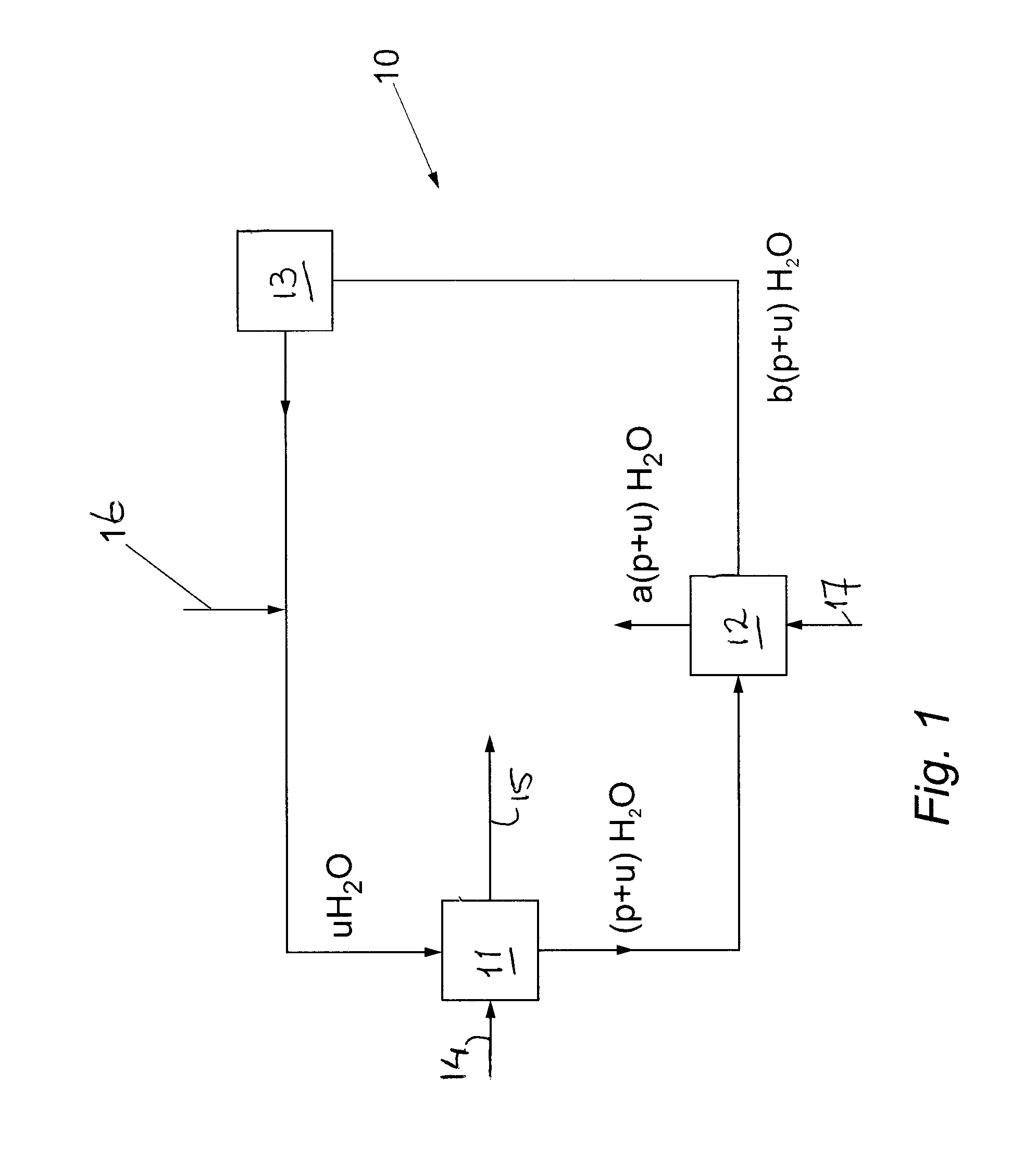

Desalination method and desalination apparatus

InactiveUS6833056B1Number of stage increasingIncrease the number ofAuxillariesGeneral water supply conservationDesalinationDistilled water

A desalination apparatus capable of obtaining fresh water stably at low cost by utilizing low-temperature waste, wherein the desalination apparatus including a heat exchanger 92 cooperating with an evaporation can 60 so as to subject a low-temperature waste heat 11 and raw water 62 in the evaporation can 60 to heat exchange and generate water vapor 63 in the evaporation can 60; a condenser 98 cooperating with a raw water tank 72 so as to receive the water vapor 63 from the evaporation can 60, cool the water vapor 63 by subjecting the water vapor 63 and raw water 71 in the raw water tank 72 to heat exchange and obtain distilled water 76; a distilled water tank for storing the distilled water 76; vacuum means for evacuating the evaporation can 60 and depressurizing the inside thereof so as to promote generation of water vapor 63 in the evaporation can 60; and raw water supply means for supplying raw water to the evaporation can.

Owner:EBARA CORP

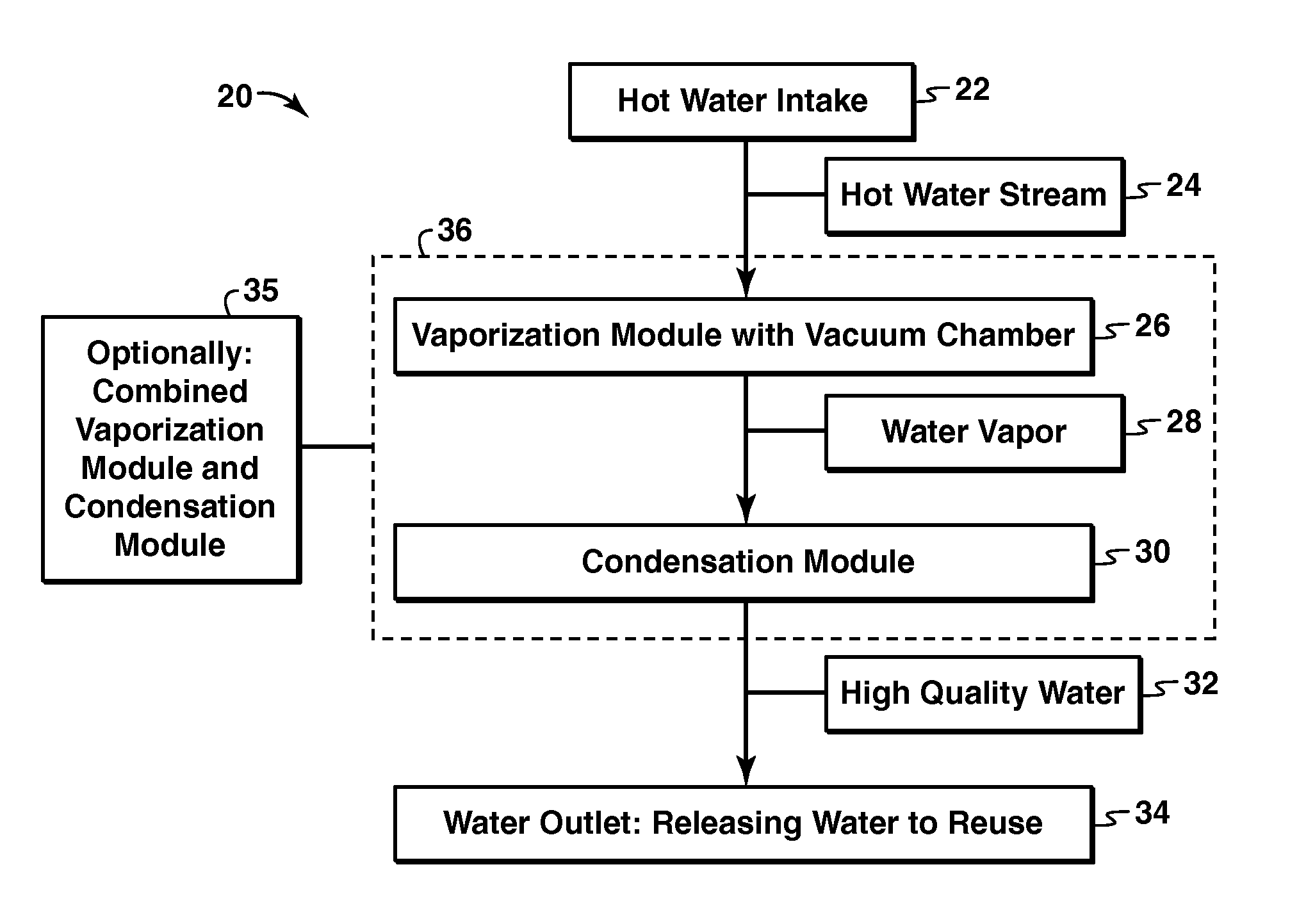

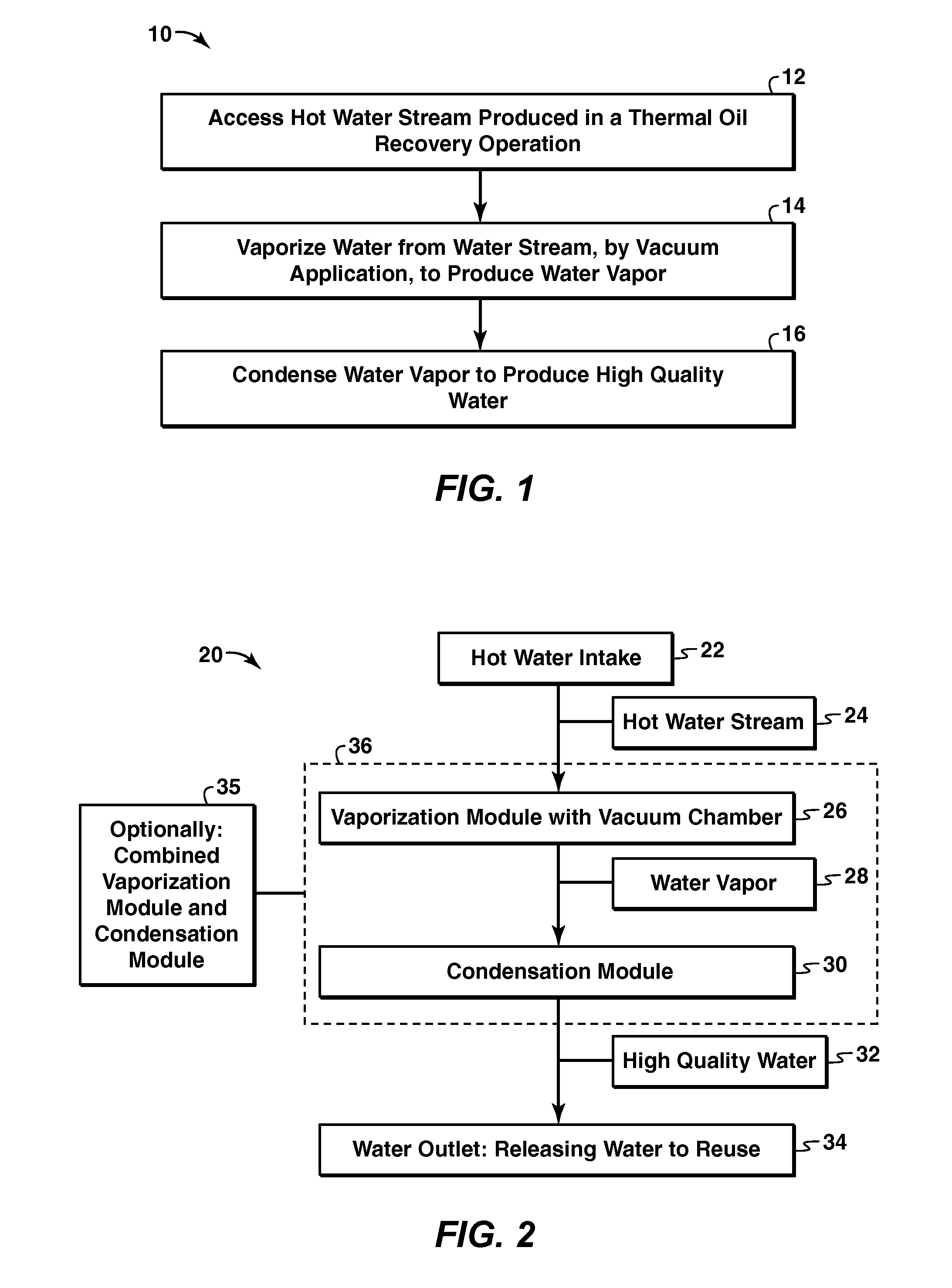

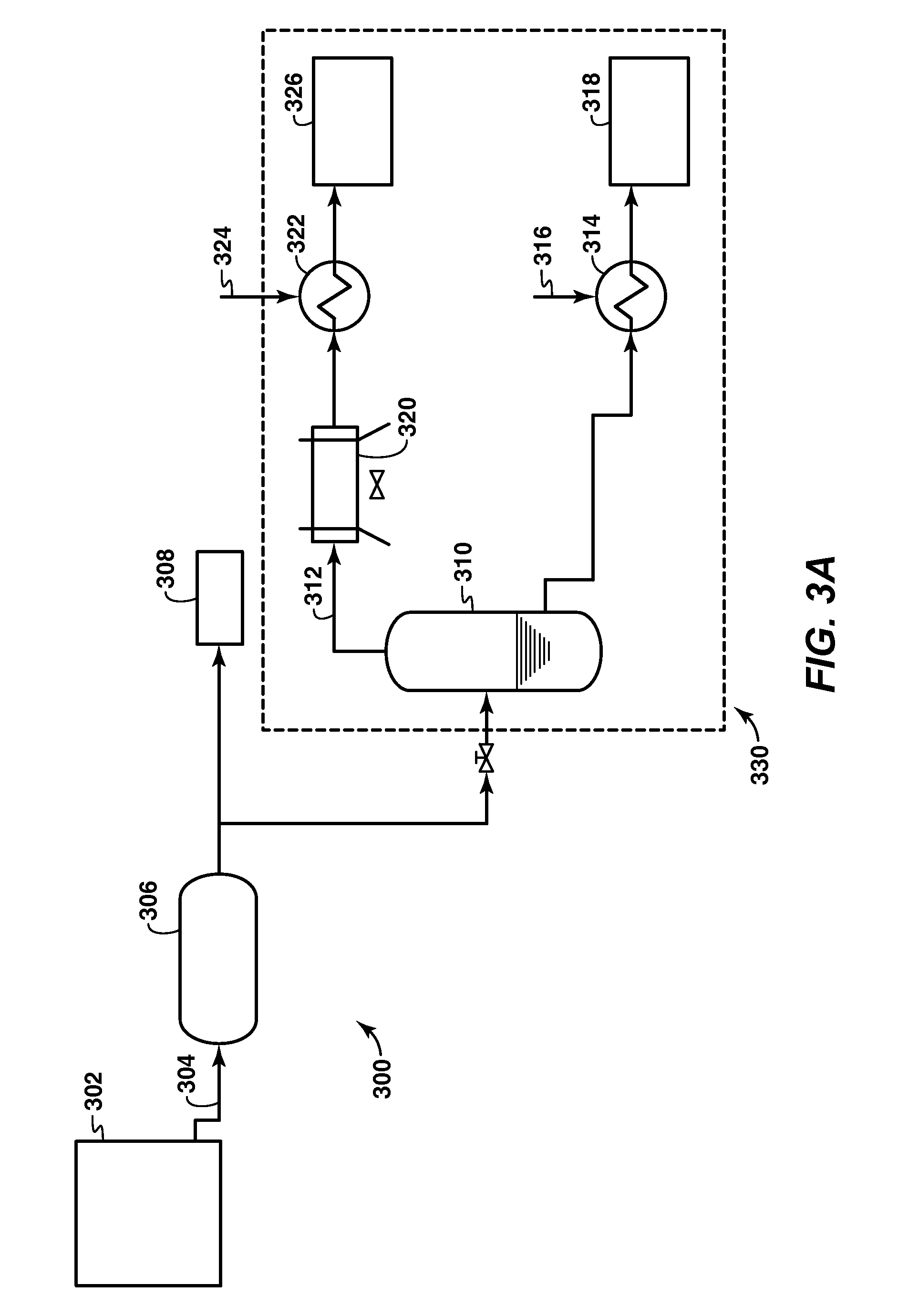

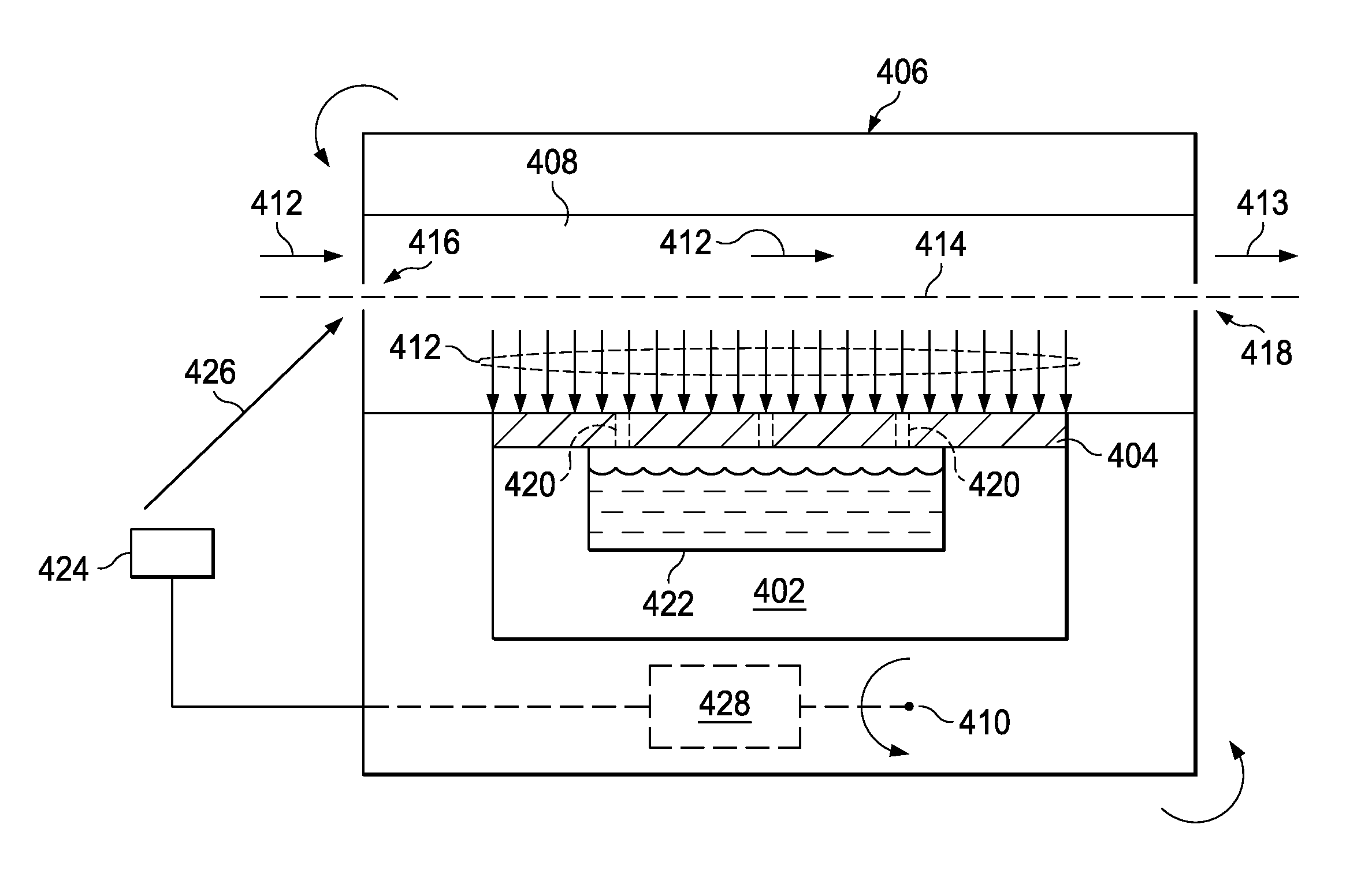

Recovery of high water from produced water arising from a thermal hydrocarbon recovery operation using vaccum technologies

InactiveUS20100282593A1High purityImprove purification effectAuxillariesEvaporation with vapour compressionWater flowVaporization

A method for reducing and re-using waste heat and water resulting from thermal hydrocarbon recovery operations involving accessing a hot water stream produced in a thermal hydrocarbon recovery operation; vaporizing water from the water stream by applying a vacuum, thereby producing water vapor; and condensing the water vapor to produce high quality water. A system is described including a hot water intake interfacing with a hot water stream from a thermal hydrocarbon recovery operation; a vaporization module receiving the hot water stream from the hot water intake, comprising a vacuum chamber in which a vacuum is applied to produce water vapor from the hot water stream; a condensation module in which water vapor produced in the vaporization module is condensed to form high quality water; and a water outlet for releasing the high quality water from the condensation module for re-use within the thermal hydrocarbon recovery operation.

Owner:EXXONMOBIL UPSTREAM RES CO

Process for cooling down a hot flue gas stream

InactiveUS7655071B2Reduce water consumptionConserve waterMethane captureCarbon compoundsFlue gasEvaporation

A process for cooling down a hot flue gas stream comprising water vapour and carbon dioxide, the process including: (a) heat exchange between the hot flue gas stream and a cooling water stream so that the hot flue gas stream is cooled to a cooled down gas stream at a temperature at which at least part of the water vapour therein has condensed and the cooling water stream increases in temperature; (b) combining the condensed water vapour and the cooling water stream to produce a combined water stream; (c) separation of the cooled down gas stream from the combined water stream; (d) cooling the combined water stream by contact with air from the atmosphere and by evaporation of a portion of the combined water stream; (e) using at least part of any non-evaporated and cooled water of the combined water stream as at least part of the cooling water stream for cooling the hot flue gas stream in step (a); and (f) storing any non-evaporated and cooled water of the combined water stream that is not used in step (e) and using the stored water later as at least part of the cooling water stream in step (a).

Owner:SHELL OIL CO

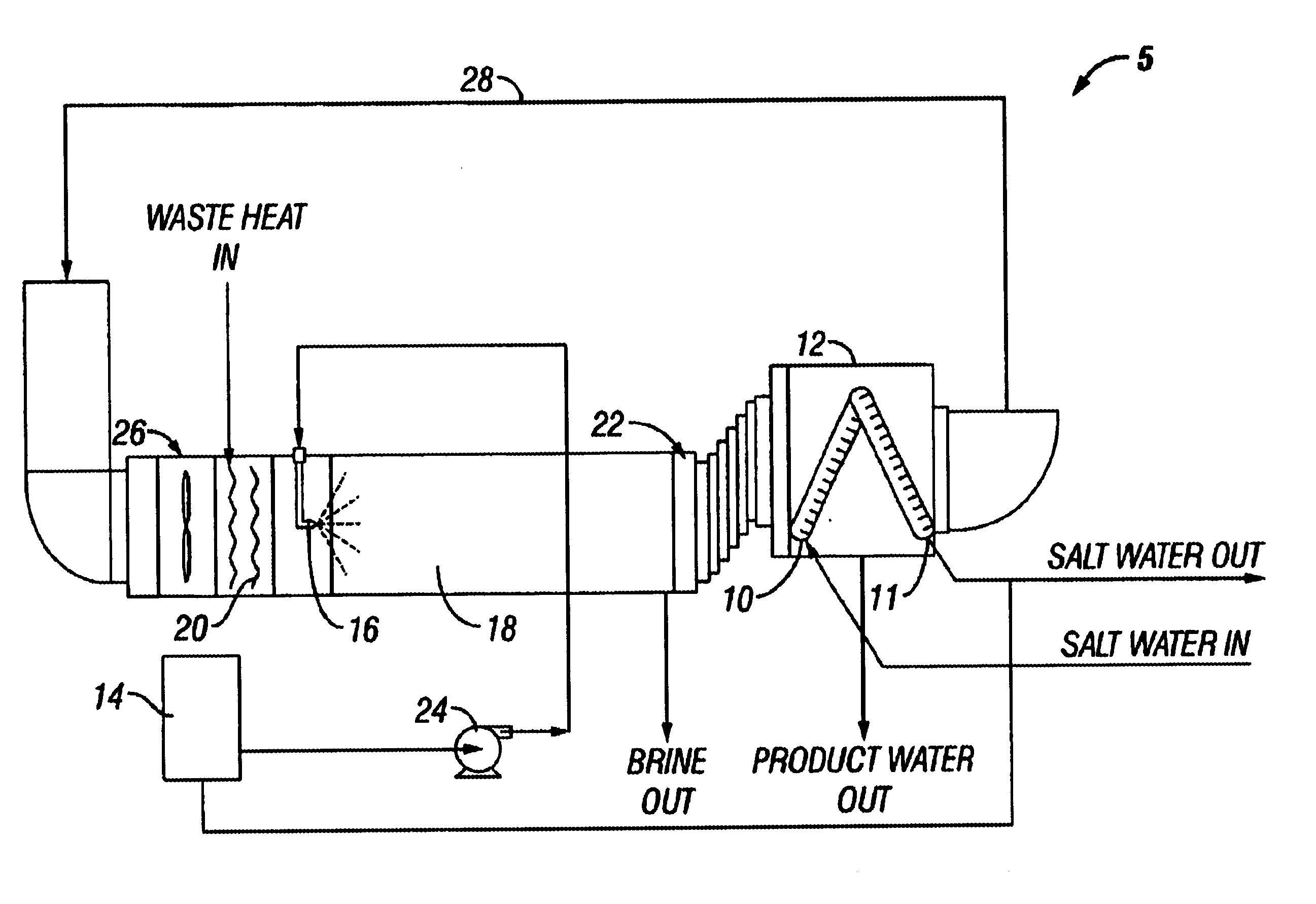

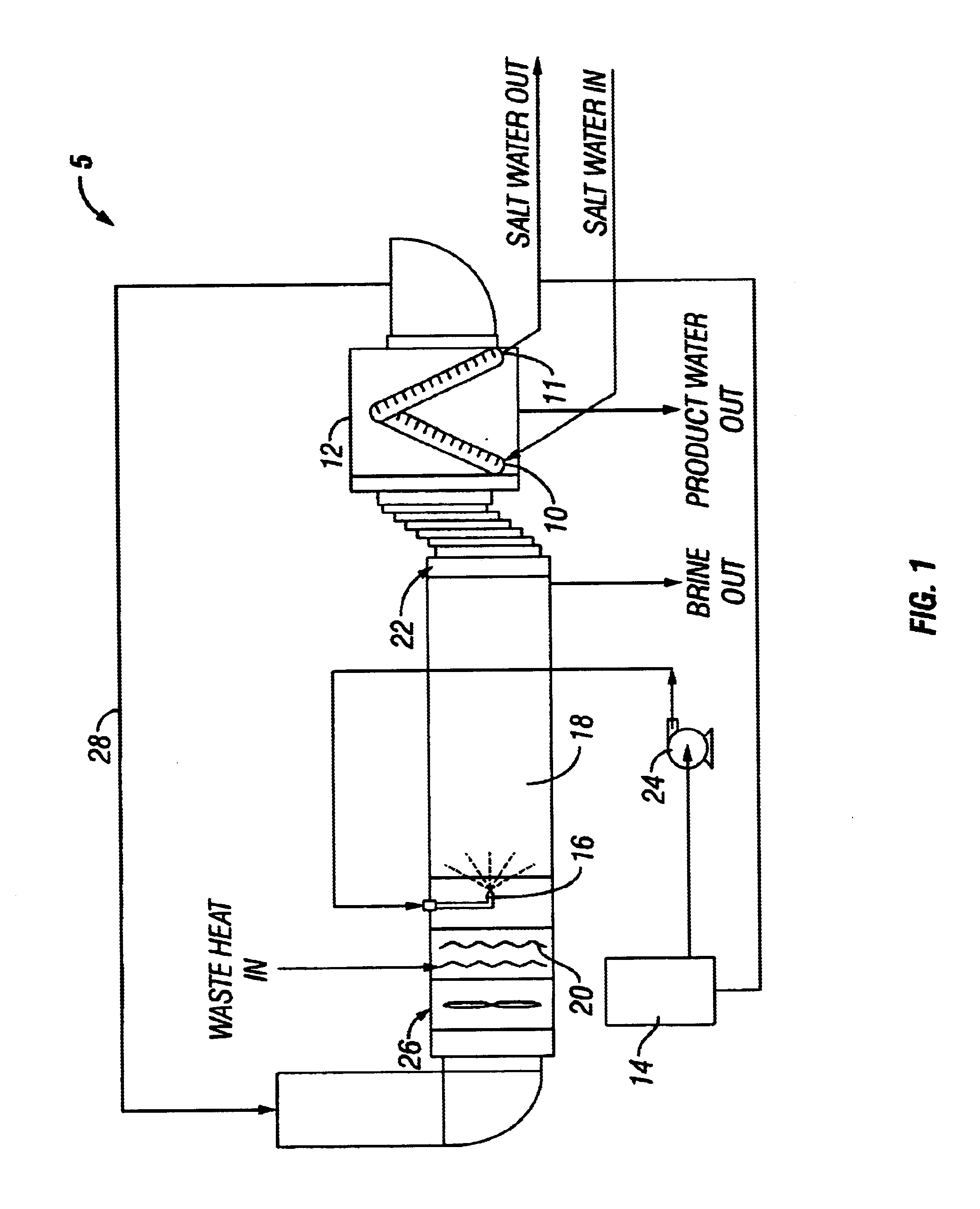

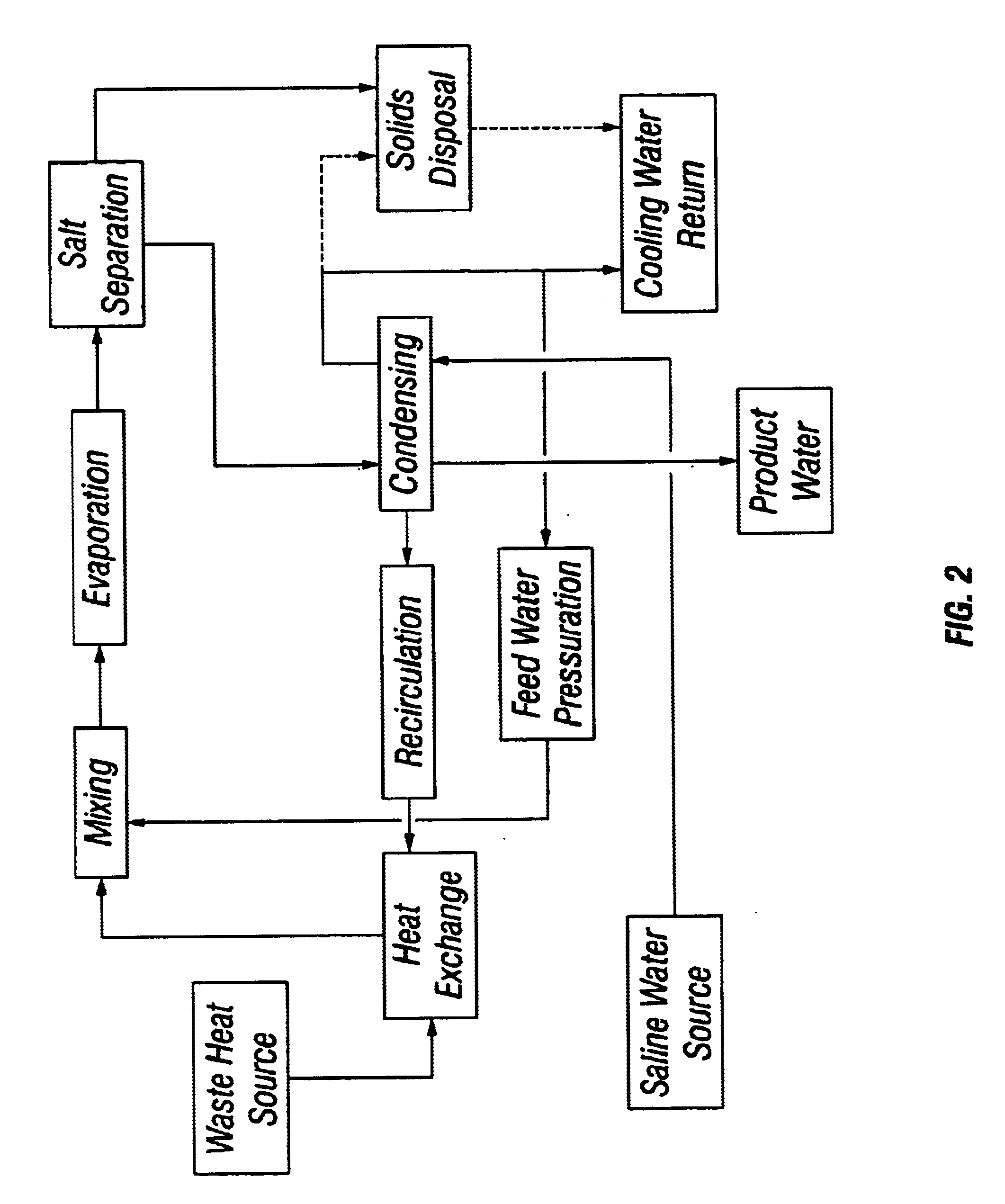

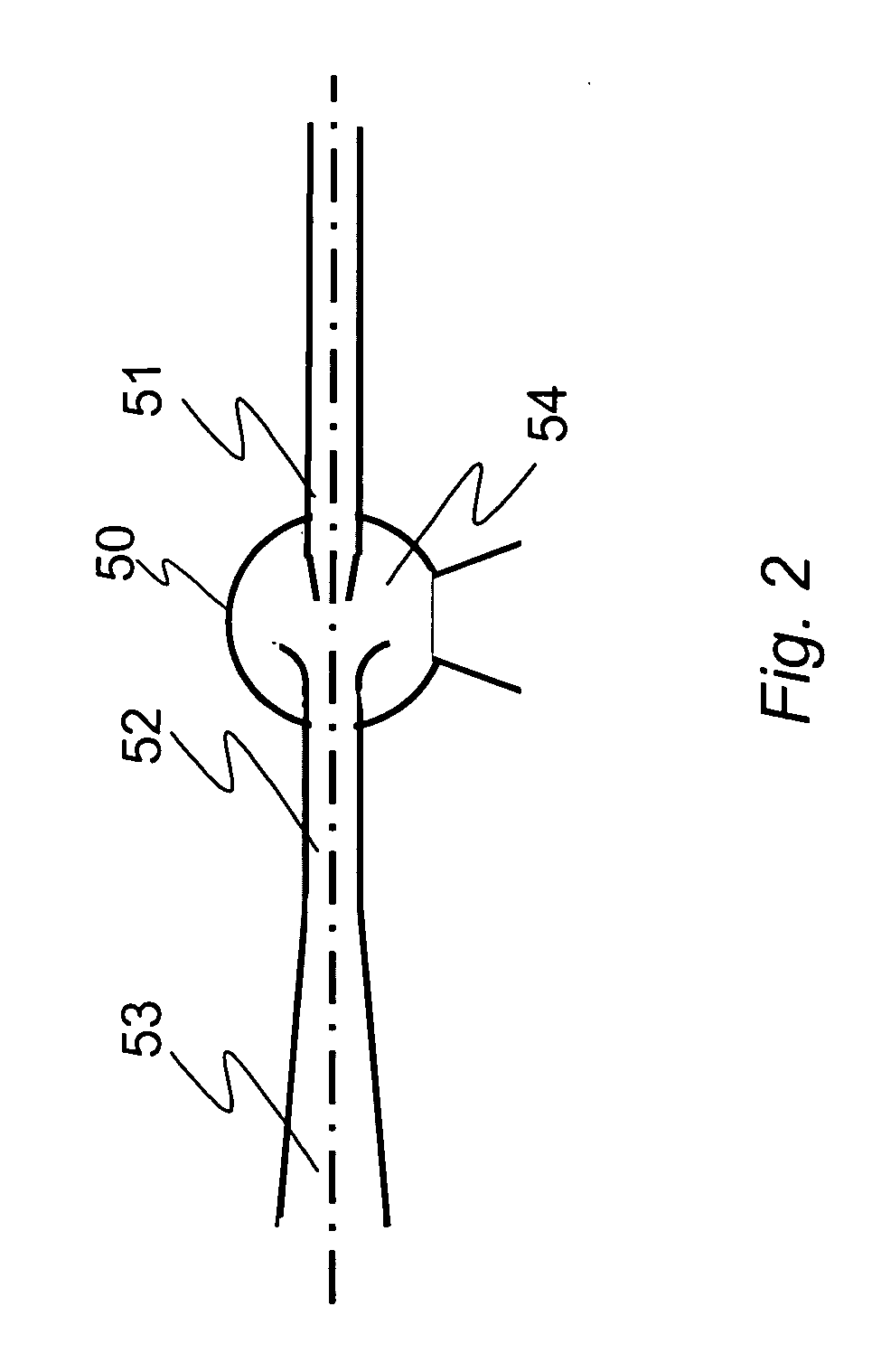

Apparatus and method for thermal desalination based on pressurized formation and evaporation of droplets

A method for removing dissolved solids, particularly salts, from water. An apparatus for performing the inventive method is disclosed. The aqueous solution to be treated, for example sea water, is atomized using special non-pneumatic nozzles, and sprayed into an evaporation chamber through which air, heated by waste heat, is blown. The micro-droplets undergo rapid evaporation in the chamber, resulting in the separation of the salt solids from the vapor phase of the water. The mixture of suspended solids and water vapor is filtered to remove and collect the salts, and the water vapor is condensed to collect the salt-free water.

Owner:AQUASONICS RSE INC

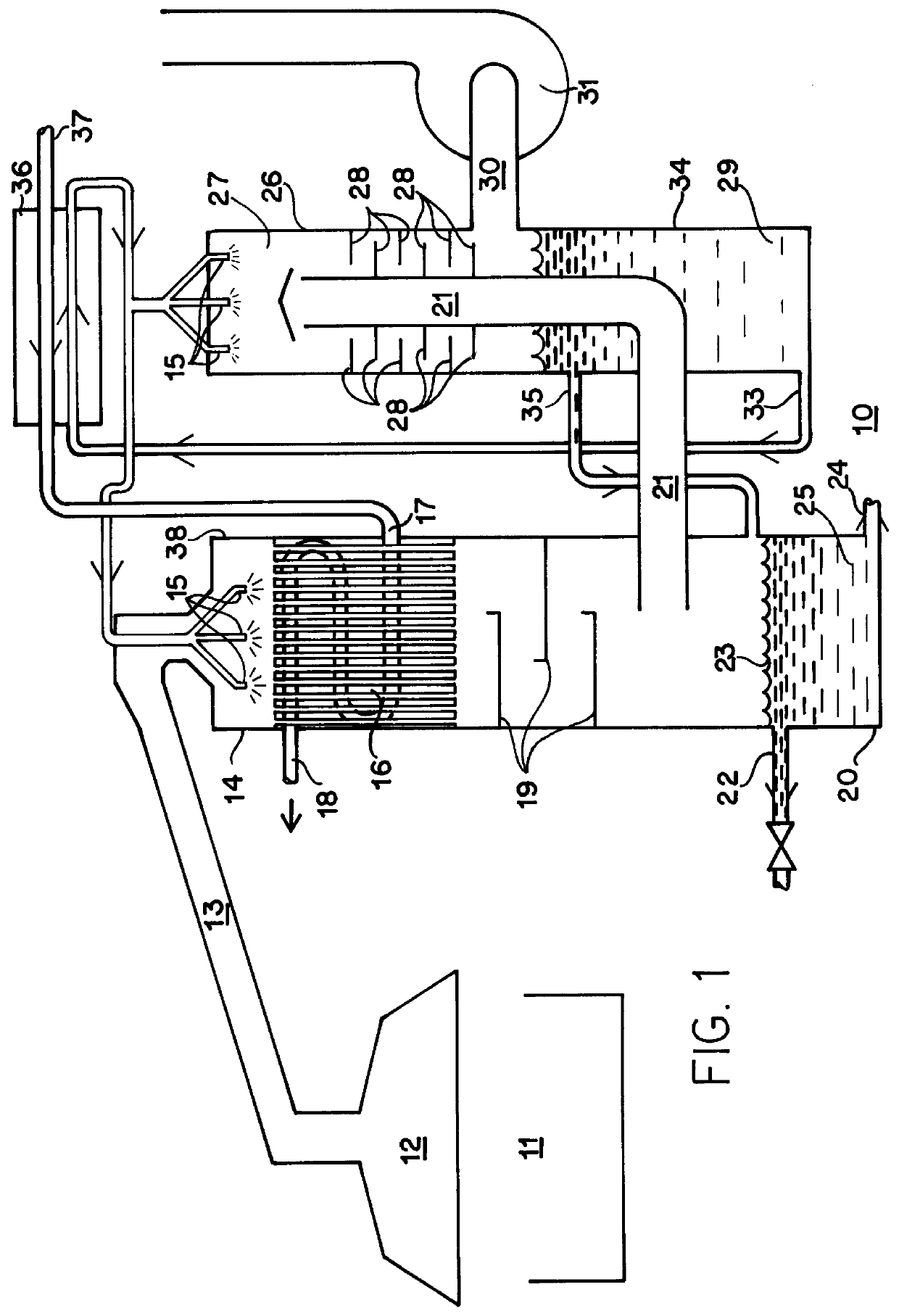

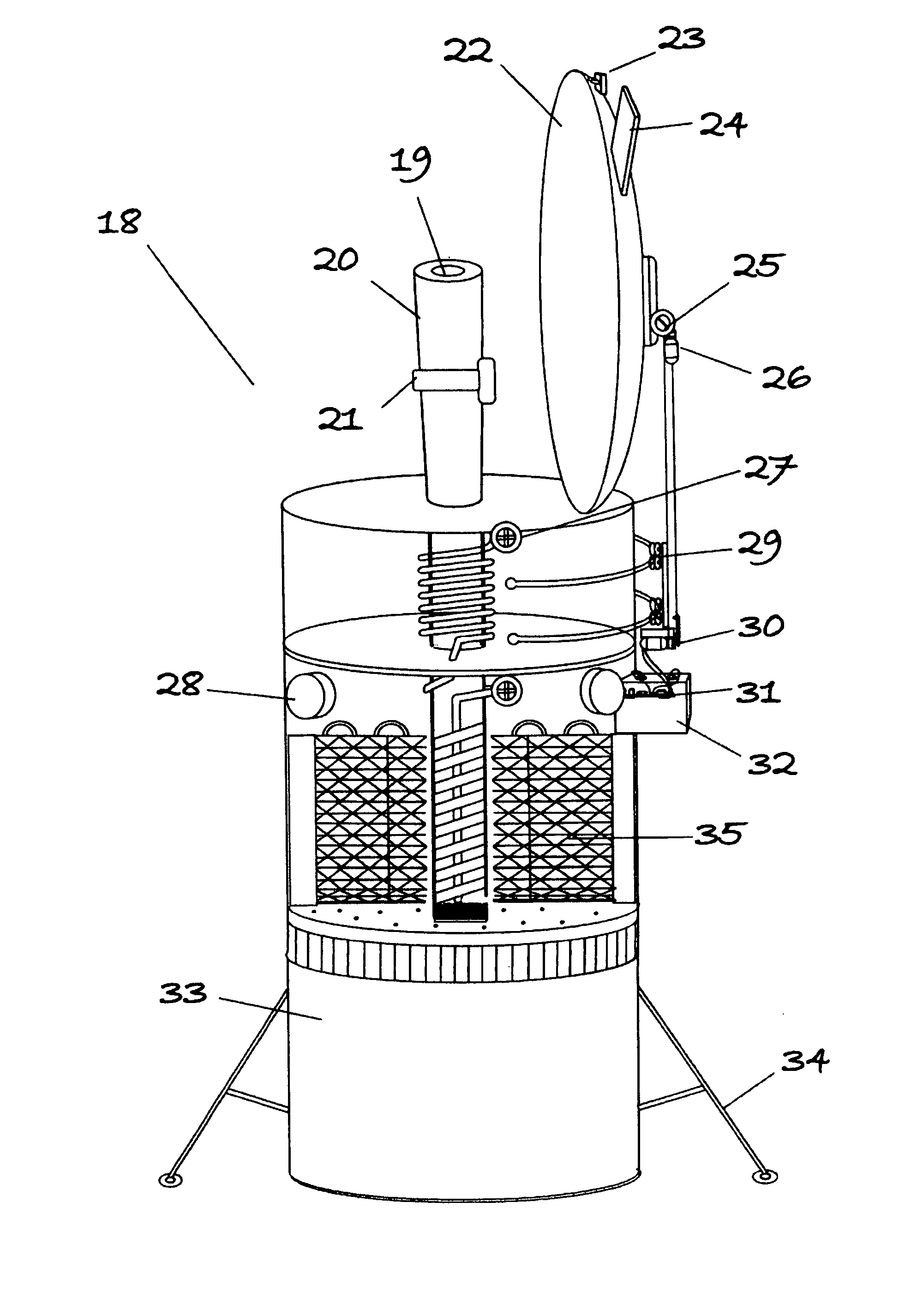

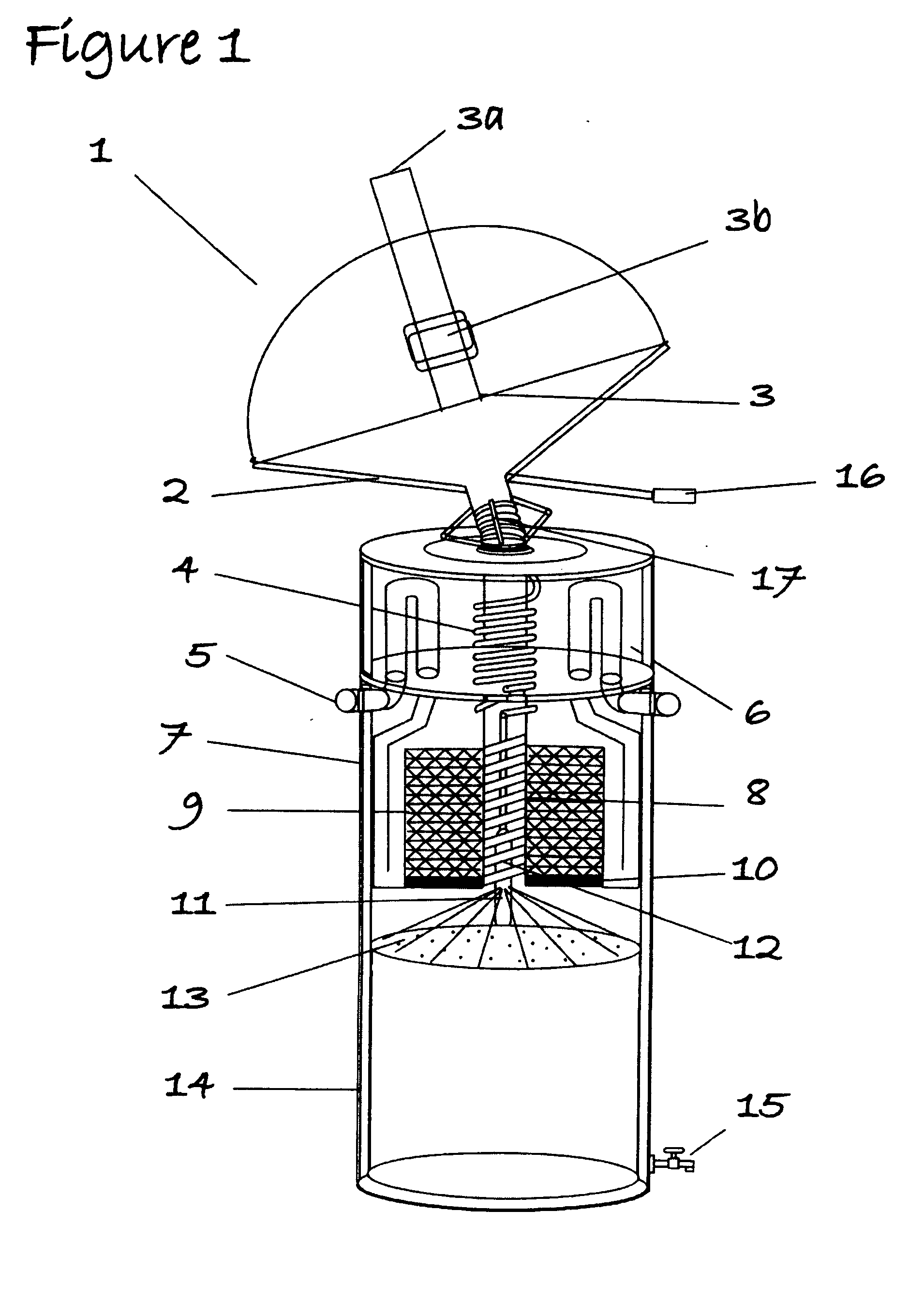

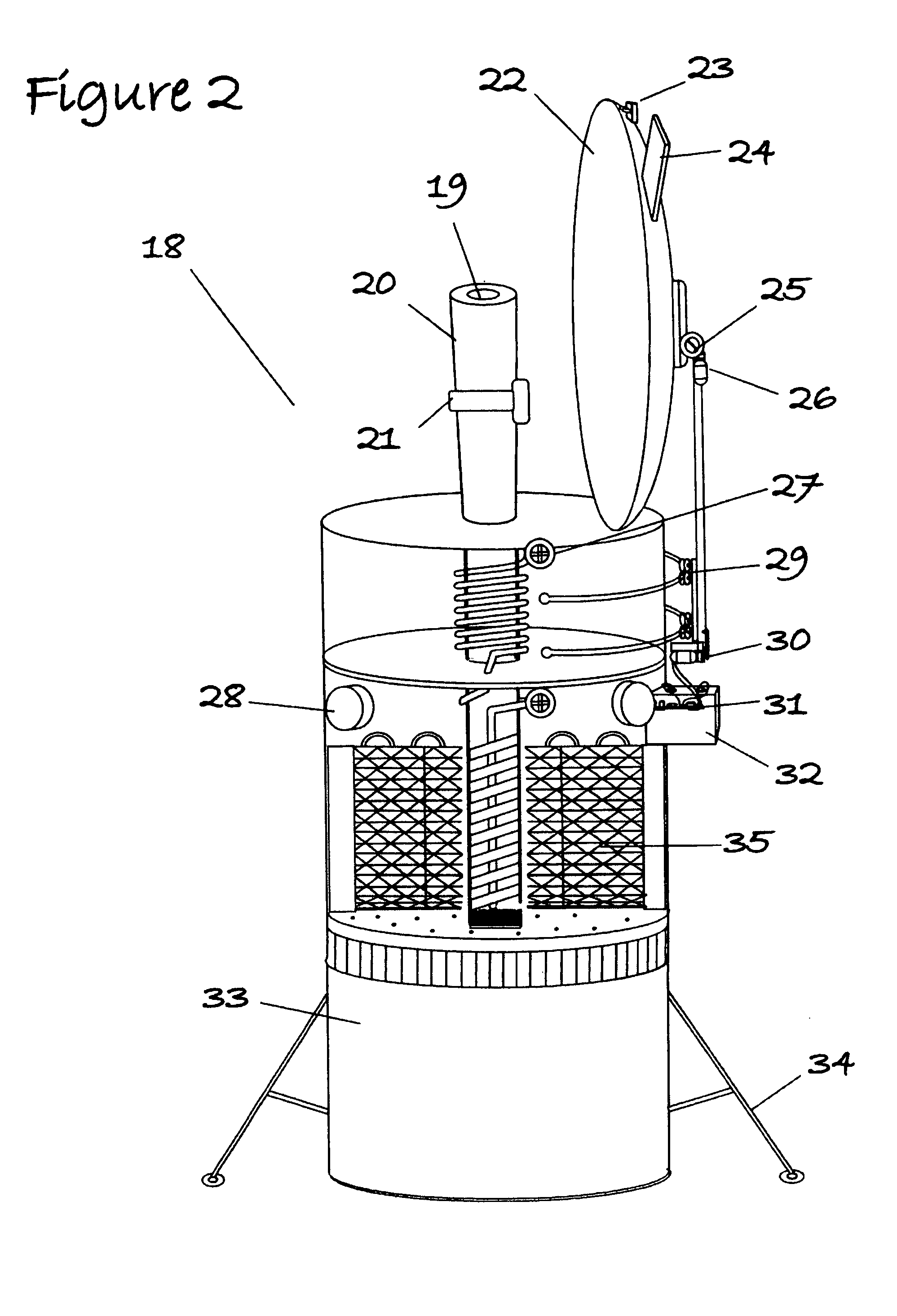

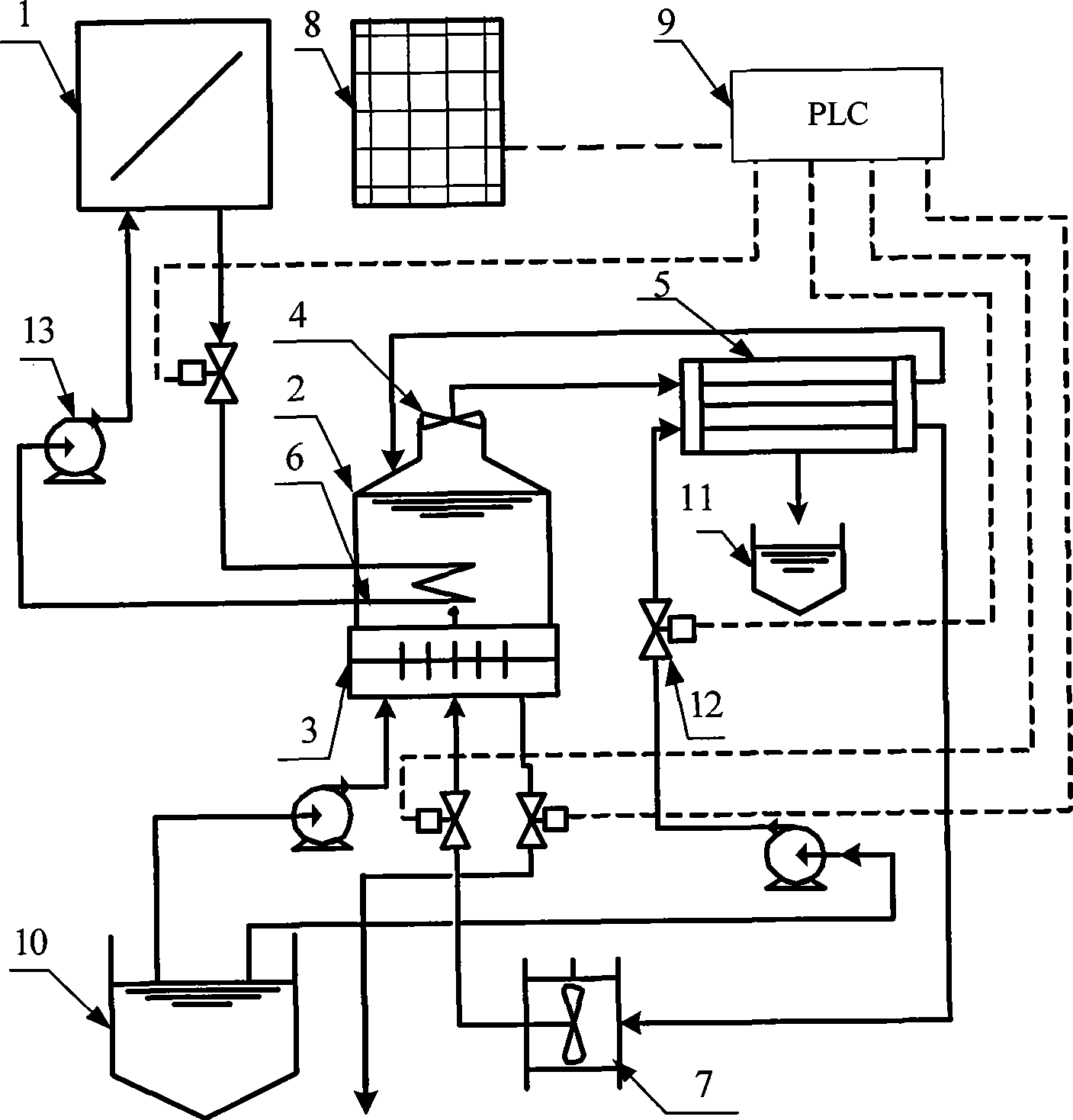

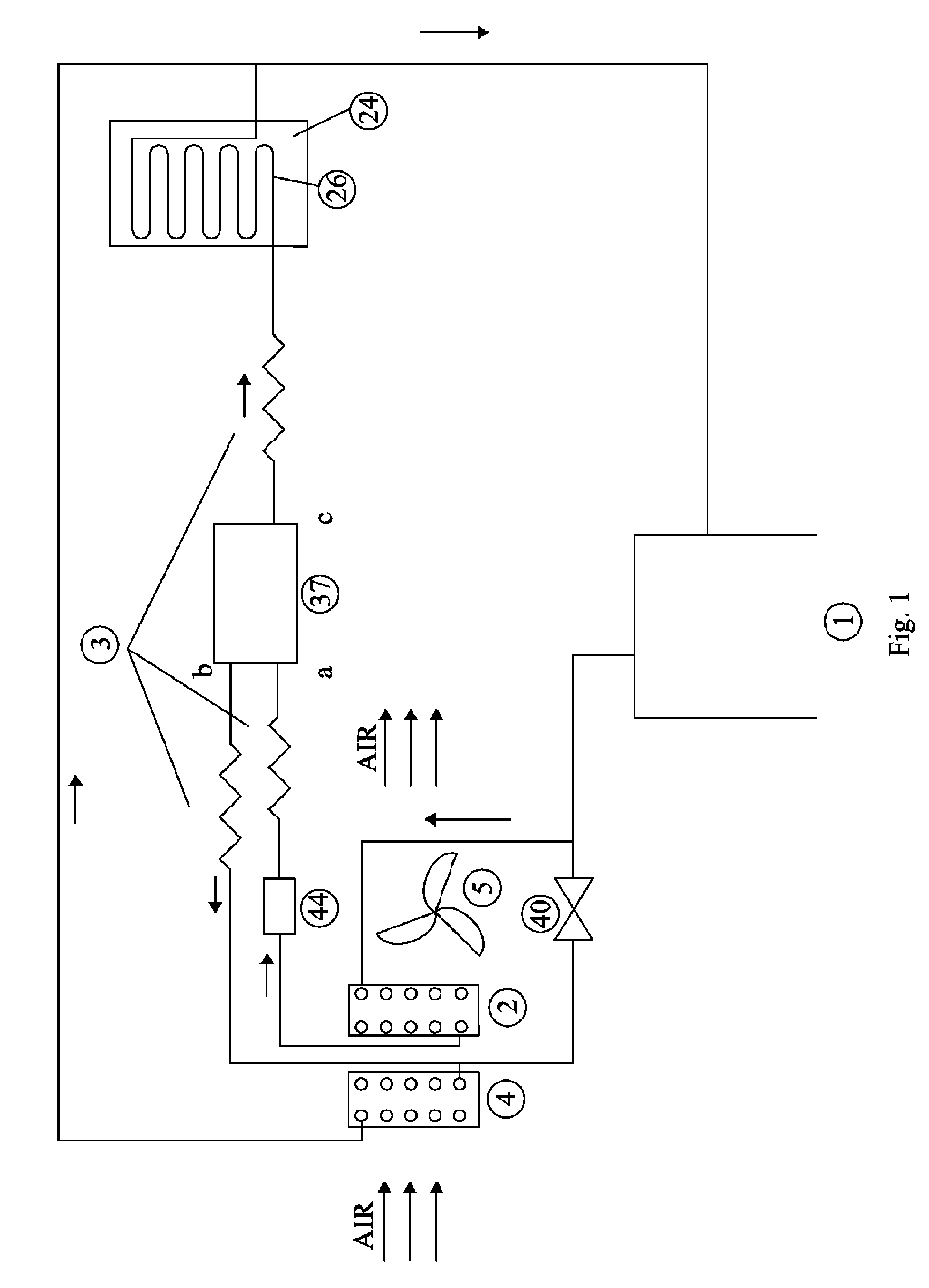

Apparatus and method for extracting heat from contaminated waste steam

InactiveUS6019819ALess energyHotter cooling water temperatureCombination devicesAuxillary pretreatmentAtmospheric airEngineering

Disclosed is a contaminated waste steam heat recovery apparatus 10 and method therefore which includes a primary condensing unit 38, a low pressure water washing unit 26, a liquid to liquid heat exchanger 36 and a vent fan 31. Waste gas is ducted from fryer 11 to a de-super-heating chamber 14 wherein superheated steam is converted to saturated steam by spraying water into the steam using spray nozzles 15. The gas is then introduced into a vertically disposed air to liquid heat exchanger 16 and is drafted downward therethrough. As heat is removed from the waste gas, water vapor in the steam condenses and in the process, collects some of the oil and hydrocarbons present. A plurality of condensate trays 19 are disposed below the bottom end of heat exchanger 16 in a cascading fashion to collect hold the condensate in the airflow path such that it will absorb some of the heat still present in the remaining waste gas. An oil outlet 22 is provided at the top of collection basin 22 for drawing off concentrated oil 23. The waste gas is pulled into a low pressure water washer 26 where it is washed by a second set of spray nozzles 15. Waste gas and water are sucked downward through a set of turbulence inducing baffles 28. The remaining waste gas is sucked out though exhaust tube 30, using vent fan 31, and vented to the atmosphere.

Owner:ALPHA ENGINEERS

Cleaning method and cleaning device of air conditioner

ActiveCN104848507AGuaranteed cleanlinessSatisfy the cleaning effectMechanical apparatusCondensate preventionLiquid waterCleaning methods

The invention provides a cleaning method and cleaning device of an air conditioner. The cleaning method comprises the steps of utilizing a heat exchanger in the air conditioner to condense water vapor in the air conditioner into liquid water, removing dirt adhered to the surface of the heat exchanger, judging whether the air conditioner meets the trigger condition of cleaning procedure execution or not before the cleaning procedure execution, and if the air conditioner meets the trigger condition of cleaning procedure execution, executing the cleaning procedure by adopting processing strategies corresponding to the operation working conditions according to the current operation working conditions. The current operation working conditions of the air conditioner are monitored, corresponding cleaning strategies are respectively taken according to different operation working conditions, and accordingly the cleaning effects of the different operation working conditions are met.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

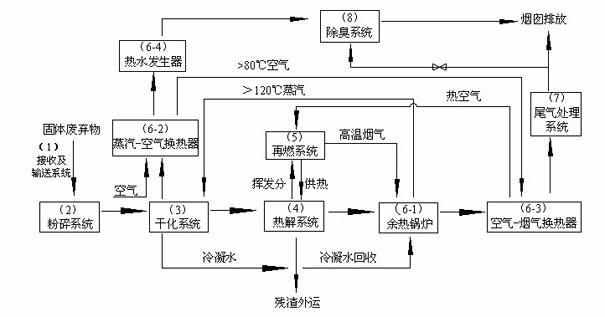

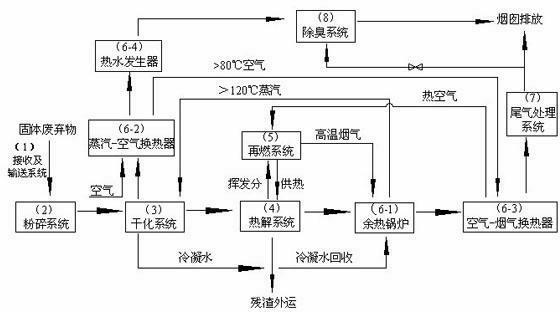

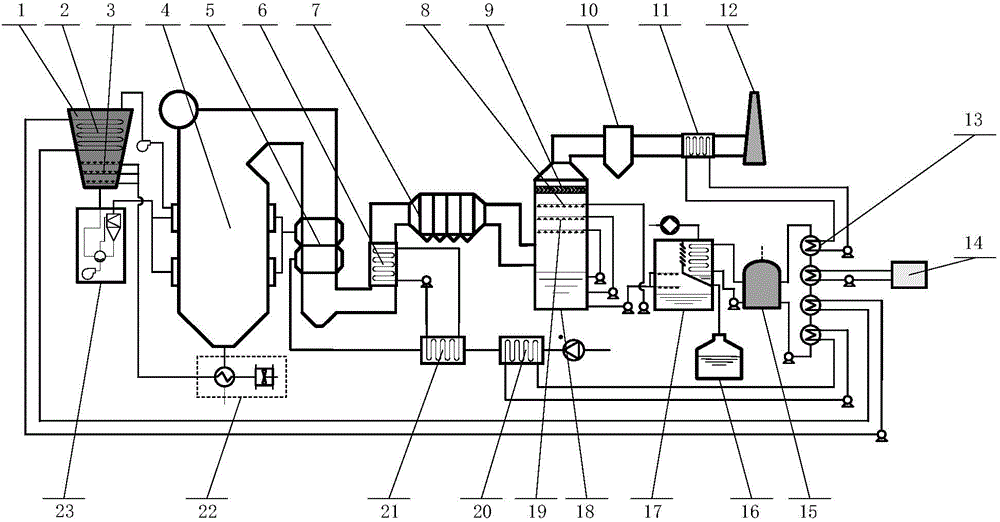

Novel process for pyrolysis of solid wastes

InactiveCN102537973AHas waste heat utilization valueAvoid consumptionSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCombustionRoom temperature

The invention discloses a novel process for pyrolysis of solid wastes. According to the existing pyrolysis technology, the solid wastes with low calorific values and high moisture content are difficult to treat, and effects of being completely harmless, reduced and recycled cannot be achieved. The novel process provided by the invention comprises the following steps of: uniformly crushing the solid wastes by a crushing system and conveying the crushed solid wastes to a drying system to be dried; carrying out the pyrolysis in a pyrolysis system and treating a pyrolyzed product by a re-burning system to provide energy needed by the pyrolysis system; conveying high-temperature smoke into a residual heat boiler to generate saturated vapor with a temperature which is higher than 1000 DEG C; carrying out heat exchange on the vapor by a vapor-air heat exchanger; after raising the temperature of normal-temperature air, conveying the air into the vapor-air heat exchanger to carry out the heat exchange with output smoke of the residual heat boiler; conveying the hot air into the pyrolysis system and carrying out processes of cooling combustion smoke, de-acidifying and removing dust on the smoke of the residual heat boiler through an exhaust gas treatment system; receiving uncondensed gas in condensed odor vapor by the deodorization system, carrying out final treatment on the uncondensed gas and exhausting. According to the invention, the residual heat value of the high-moisture solid wastes is sufficiently utilized and the utilization is not limited by types of the solid wastes, so that the energy source and the operation cost are saved.

Owner:ZHONGCHANG ENVIRONMENT PROTECTION GROUP +1

Atmospheric water collection device

InactiveUS20050103615A1Simple economicalPractical and convenientSolar heating energyAuxillariesAtmospheric airEngineering

The present invention is directed at a solar powered heat exchange system preferably used to drive a water collection device, which condenses water vapour in atmospheric air to water. The device comprises means for drawing the atmospheric air into the device; means for condensing the moisture vapour in the atmospheric air into water; and means for collecting the water.

Owner:FREEDOM WATER CO LTD

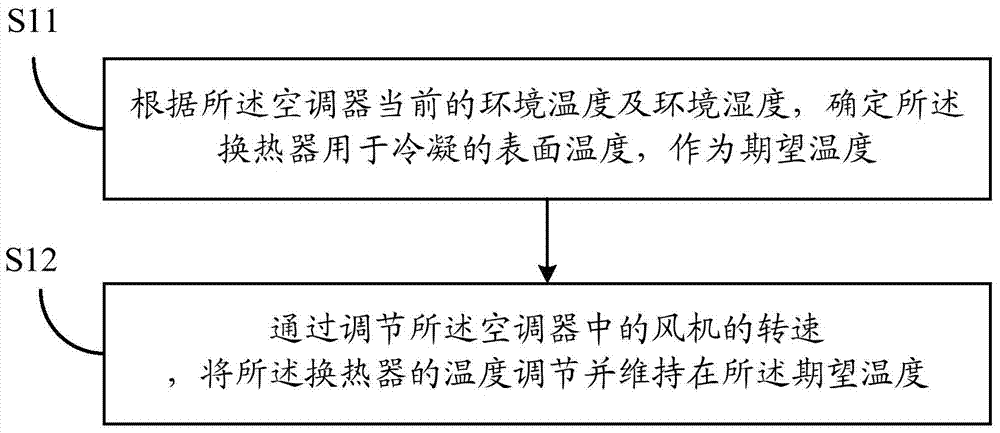

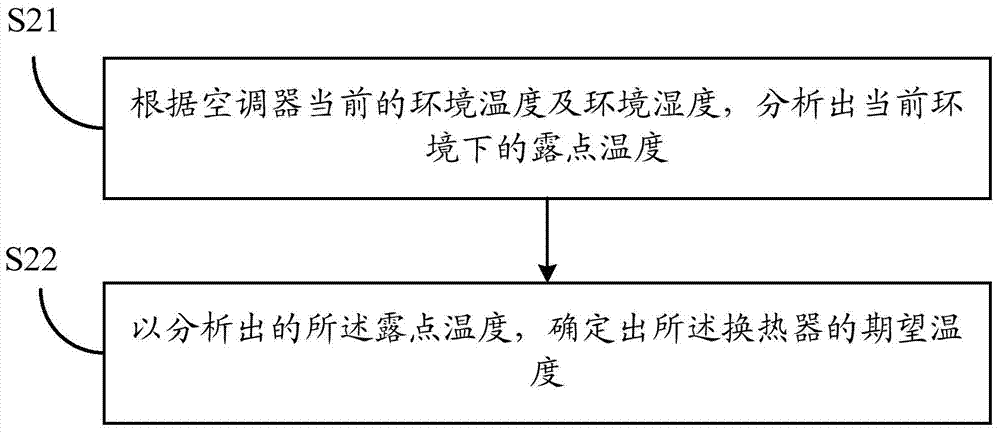

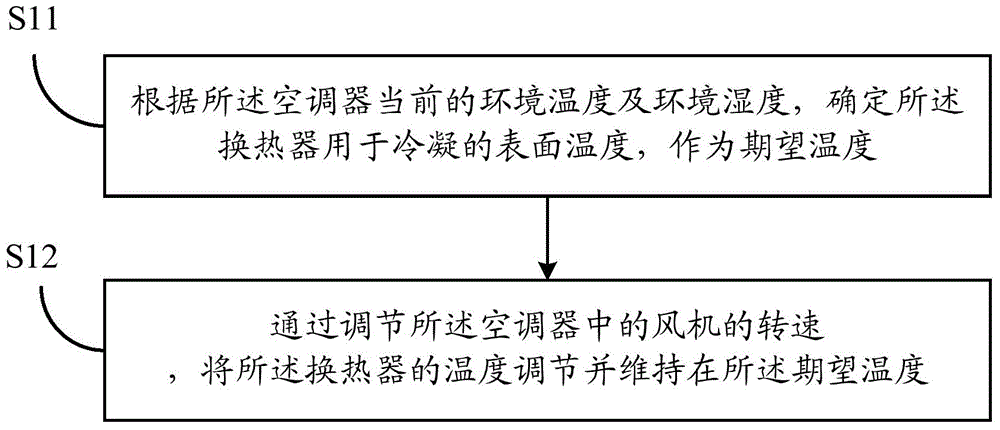

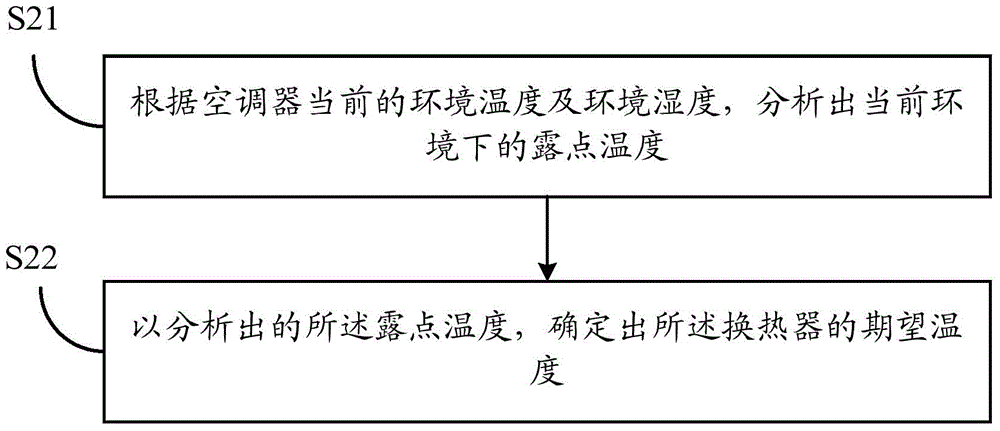

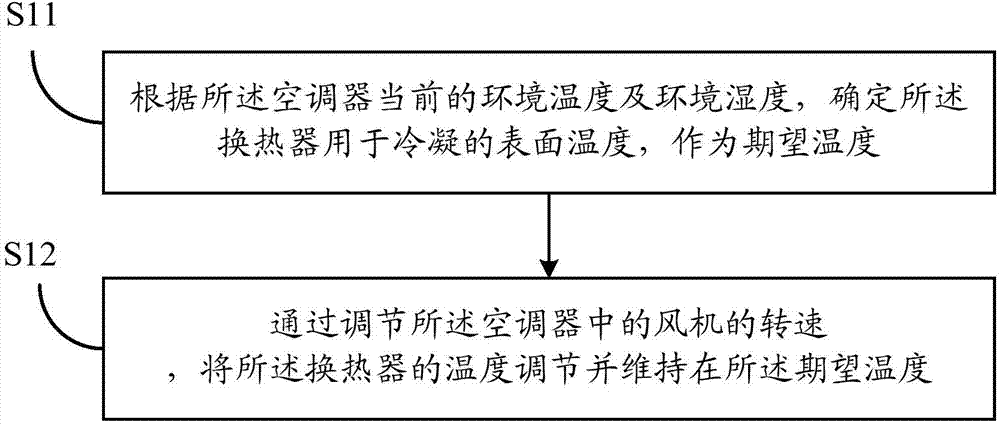

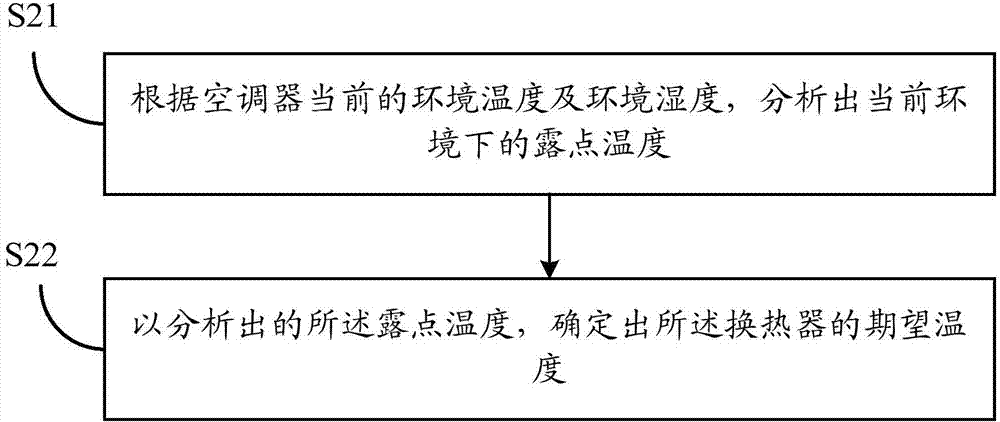

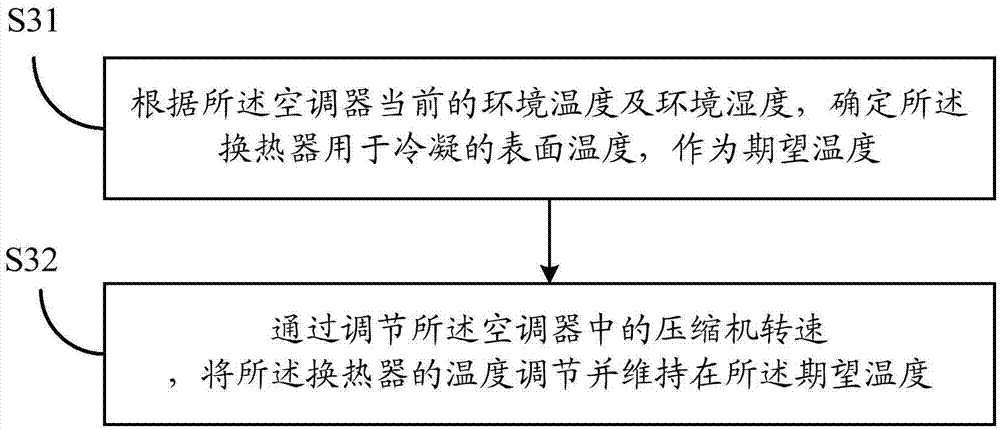

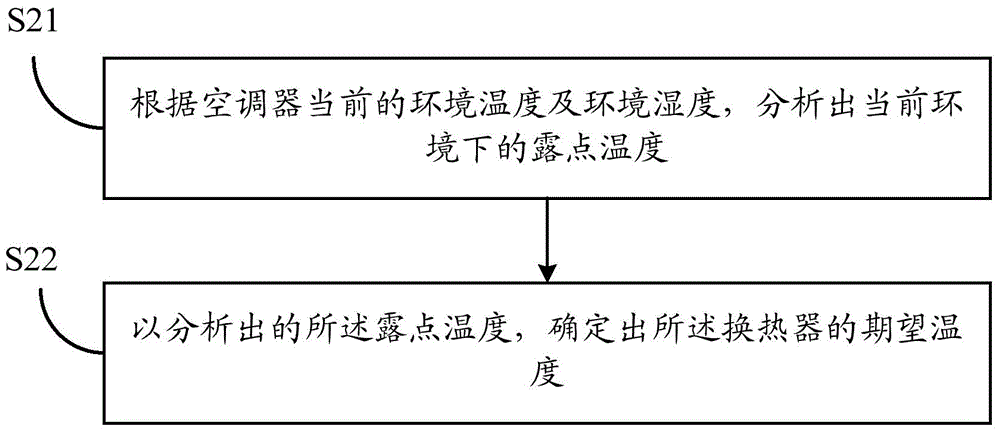

Method and device for controlling heat exchange temperature, collecting condensed water and cleaning air conditioner

ActiveCN104833067AAchieve cleanlinessAchieve adjustmentMechanical apparatusSpace heating and ventilation safety systemsLiquid stateEngineering

The invention relates to a method and a device for controlling heat exchange temperature, collecting condensed water and cleaning an air conditioner. A heat exchanger in the air conditioner is utilized for condensing water vapor in the air conditioner into liquid-state water; dirt attached to the surface of the heat exchanger is cleared away; the surface temperature, used for condensation, of the heat exchanger is determined according to the current environment temperature and the current environment humidity, and is used as the expected temperature; the temperature of the heat exchanger is regulated and is maintained at the expected temperature through regulating the rotating speed of a compressor and the rotating speed of a fan in the air conditioner. Through analyzing the influence of the environment temperature and the environment humidity on the dew point, the optimum temperature of the heat exchanger in the current environment is determined, and sufficient condensed water is obtained for clearing dust and dirt on the surface of the heat exchanger. When the practical temperature of the heat exchanger is not consistent with the optimum temperature, the rise or the reduction of the surface temperature of the heat exchanger is realized through regulating the rotating speed of the compressor and the rotating speed of the fan, the surface temperature of the heat exchanger is maintained at the determined optimum temperature, and the water vapor in the air conditioner is condensed into liquid-state water.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

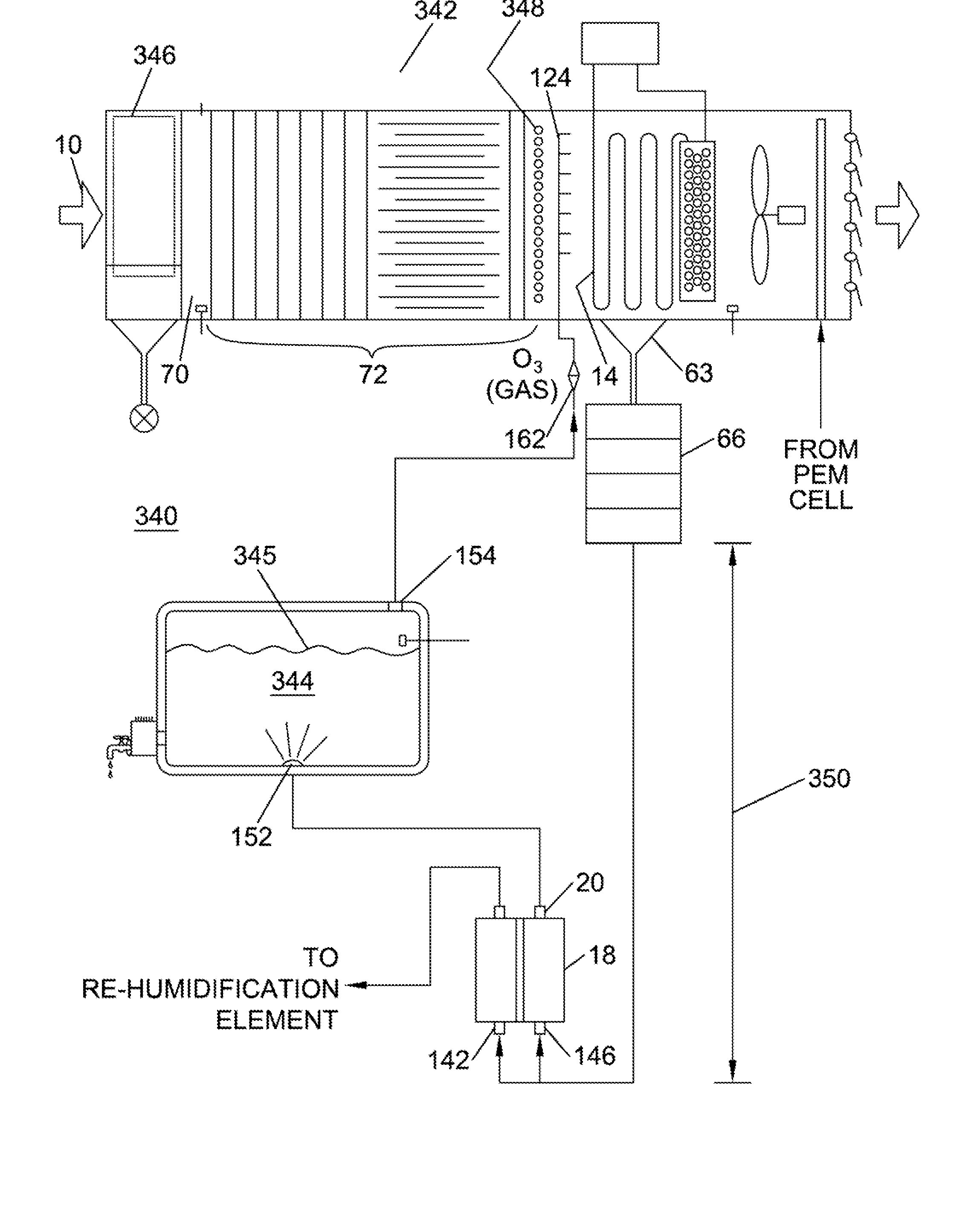

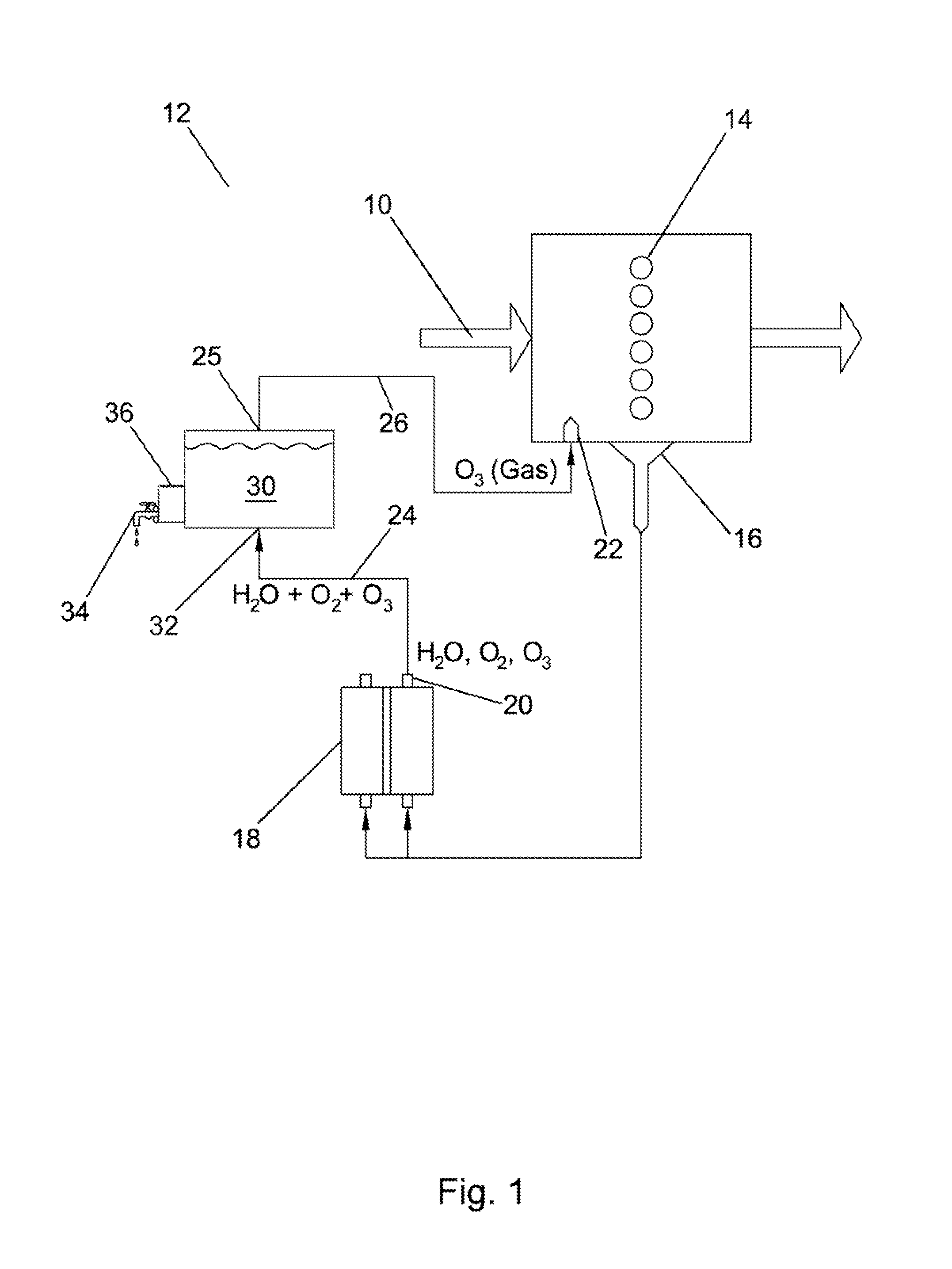

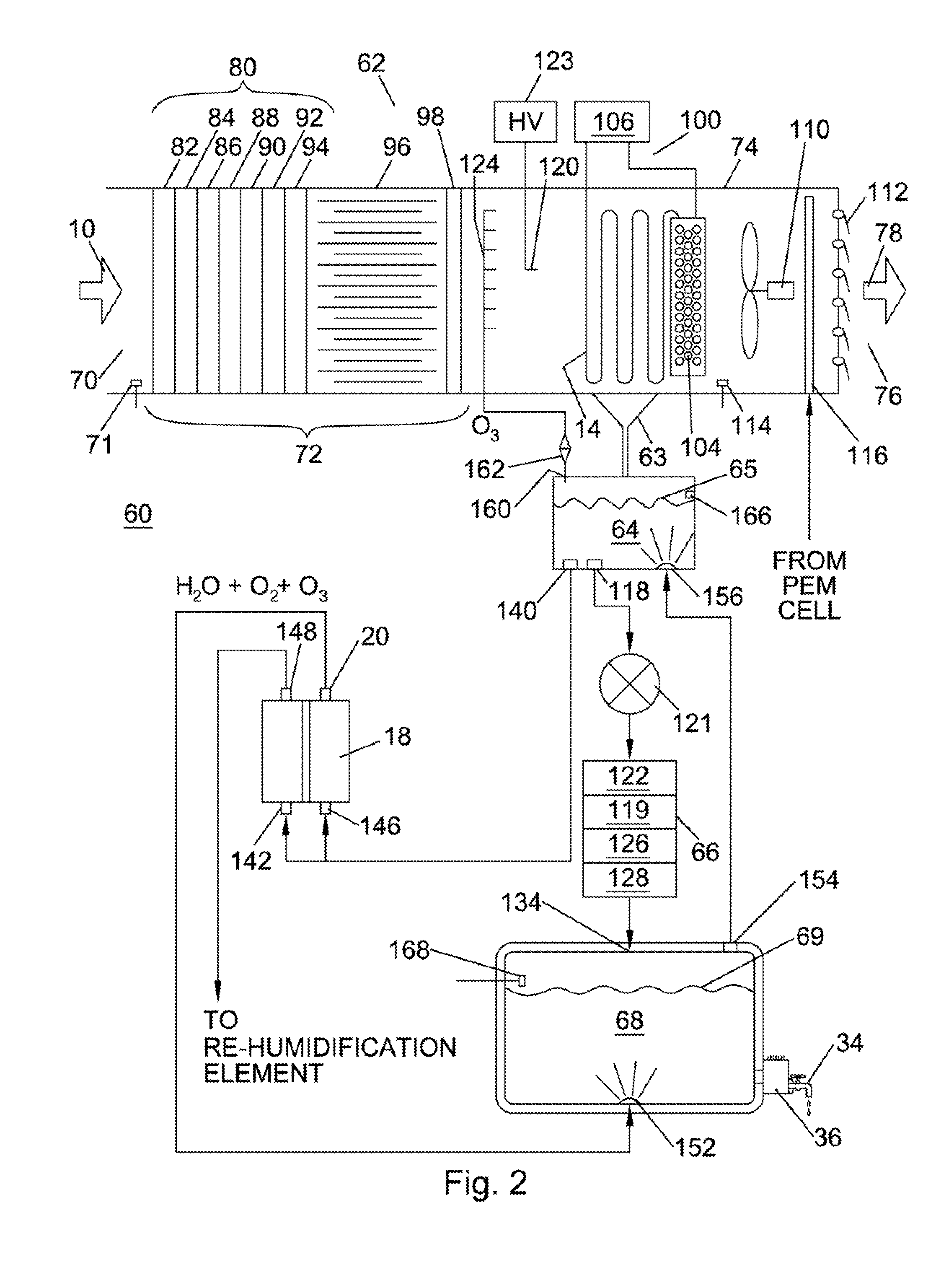

Apparatus and Method For Generating Water From an Air Stream

InactiveUS20070295021A1Fuel cell combinationsLighting and heating apparatusOzone generatorEnvironmental engineering

An apparatus and method for generating water from an air stream is disclosed. The apparatus has an inlet for receiving an air stream, a condensing element located in the air stream, a collector for gathering water vapor condensate that is formed on the condensing element when the condensing element temperature drops below the dew point temperature of the ambient air stream, and an ozone generator that precisely generates ozone required to disinfect the water vapor condensate. In some embodiments of the invention, the ozone is also added to the air stream for disinfecting the air stream and associated elements of the apparatus.

Owner:CONVERGITECH

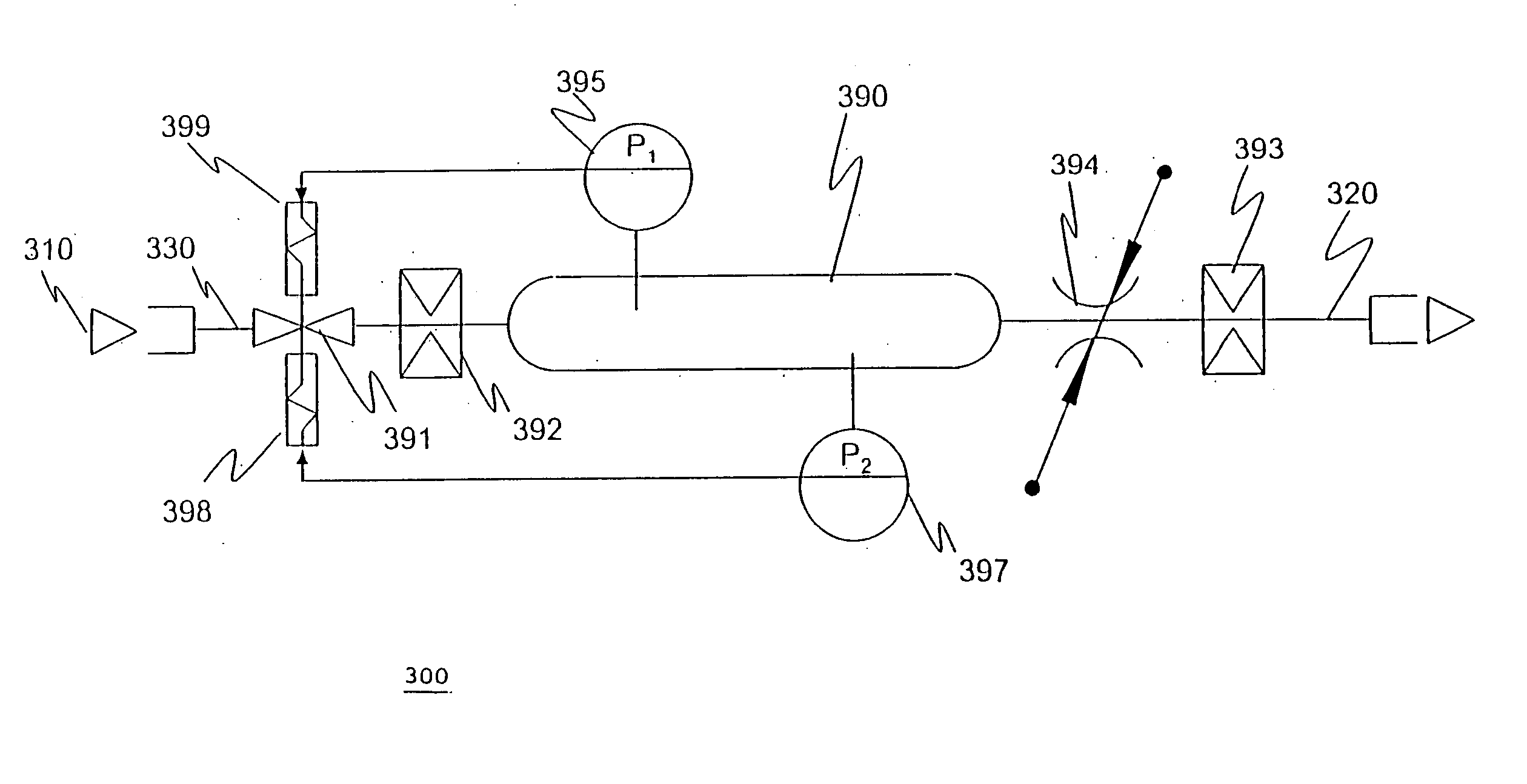

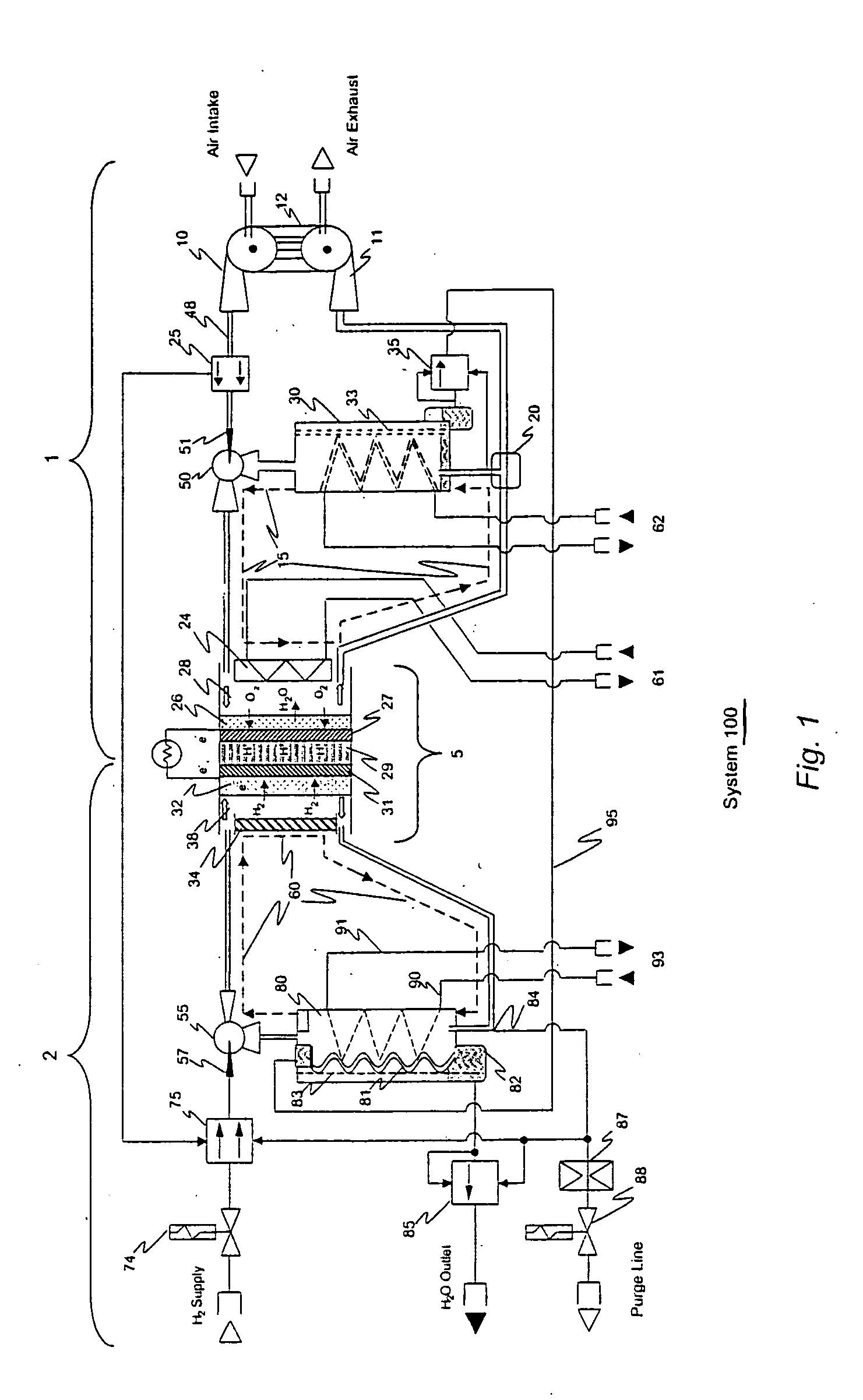

Fuel cell with integrated feedback control

InactiveUS20050100777A1Volume adjustableEasy loadingCell electrodesFuel cell auxillariesElectrochemical responsePartial oxidation

A recirculating reagent fuel-cell includes an ion-exchange membrane interposed between an anode and cathode anode to form a membrane / electrode assembly (MEA), the MEA interposed between a fuel gas diffusion layer and an oxidant gas diffusion layer. An oxidant and fuel flow network are provided having an input portion for supplying reagent and an output portion for removing reagent after electrochemical reaction. At least one of the oxidant flow network and fuel flow network includes a recirculation loop, the recirculation loop feeding back a portion of the fuel or oxidant after electrochemical reaction to their respective input portion. The fuel flow network can include a water vapor condenser to extract water from the cathodes in proportion to the external load on the fuel cell stack and the fuel flow network can include an evaporator, where water is fed to the evaporator in the fuel loop from the condenser in the oxidant feed loop.

Owner:ULTIMATE COMBUSTION

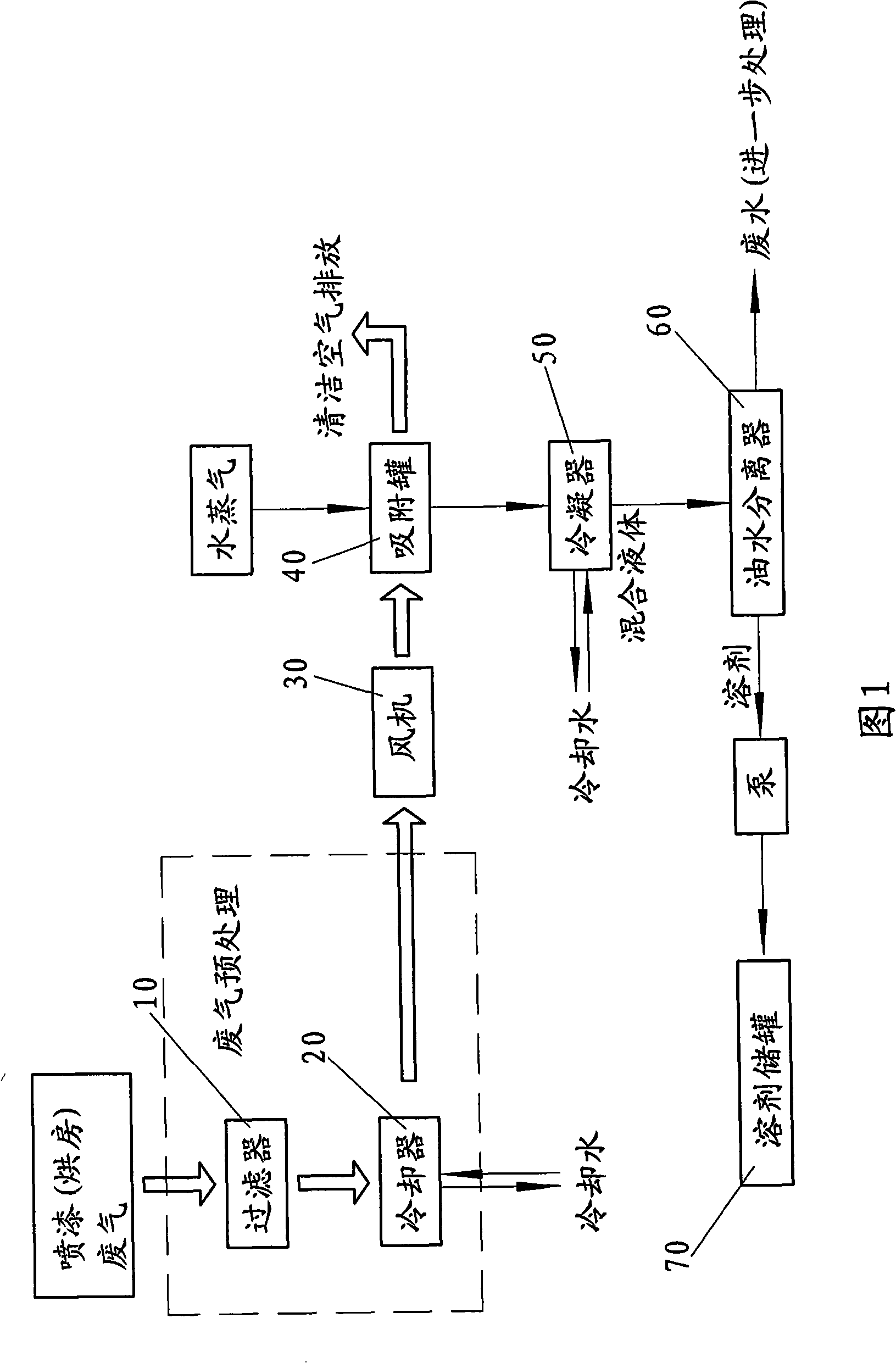

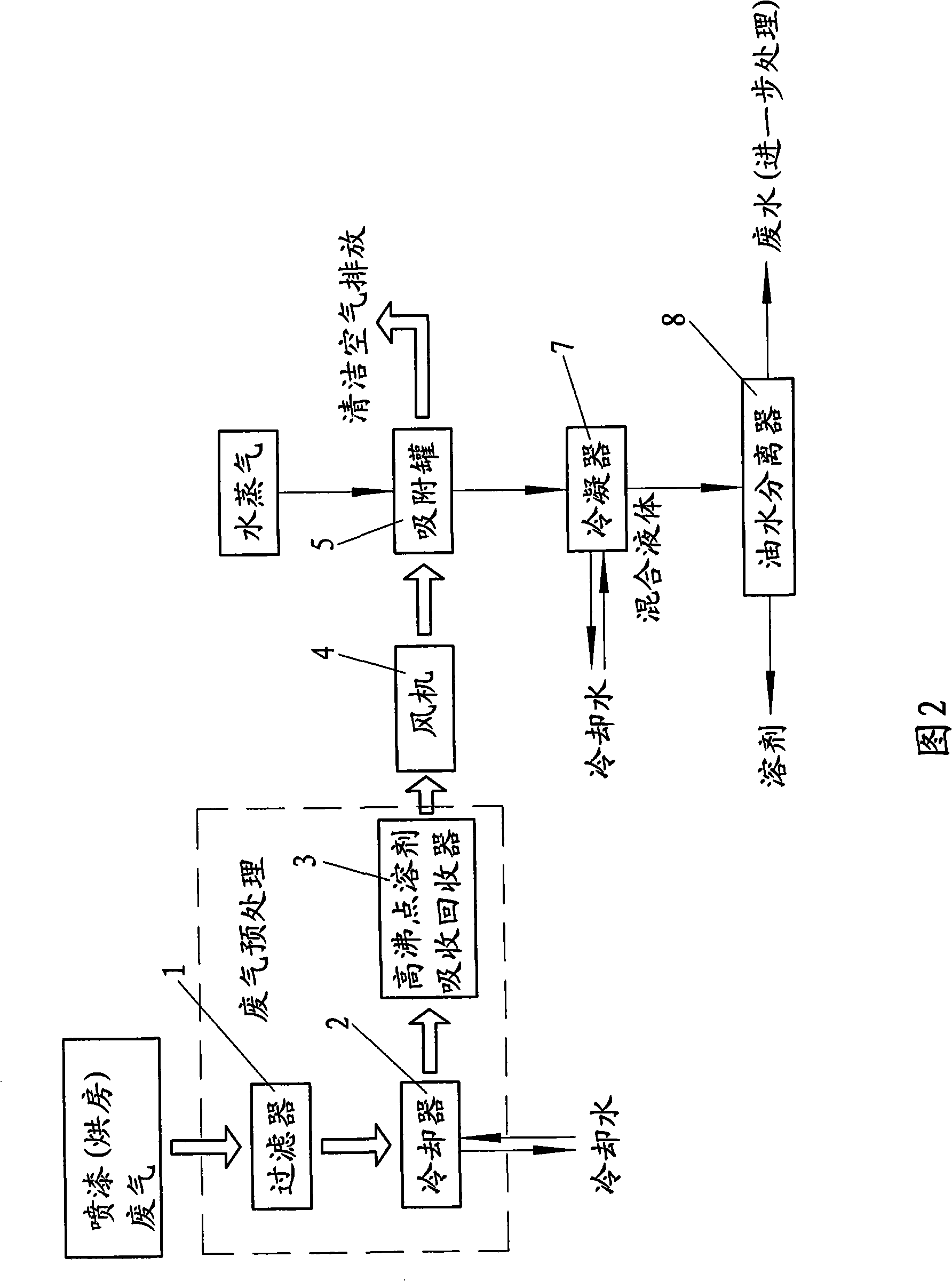

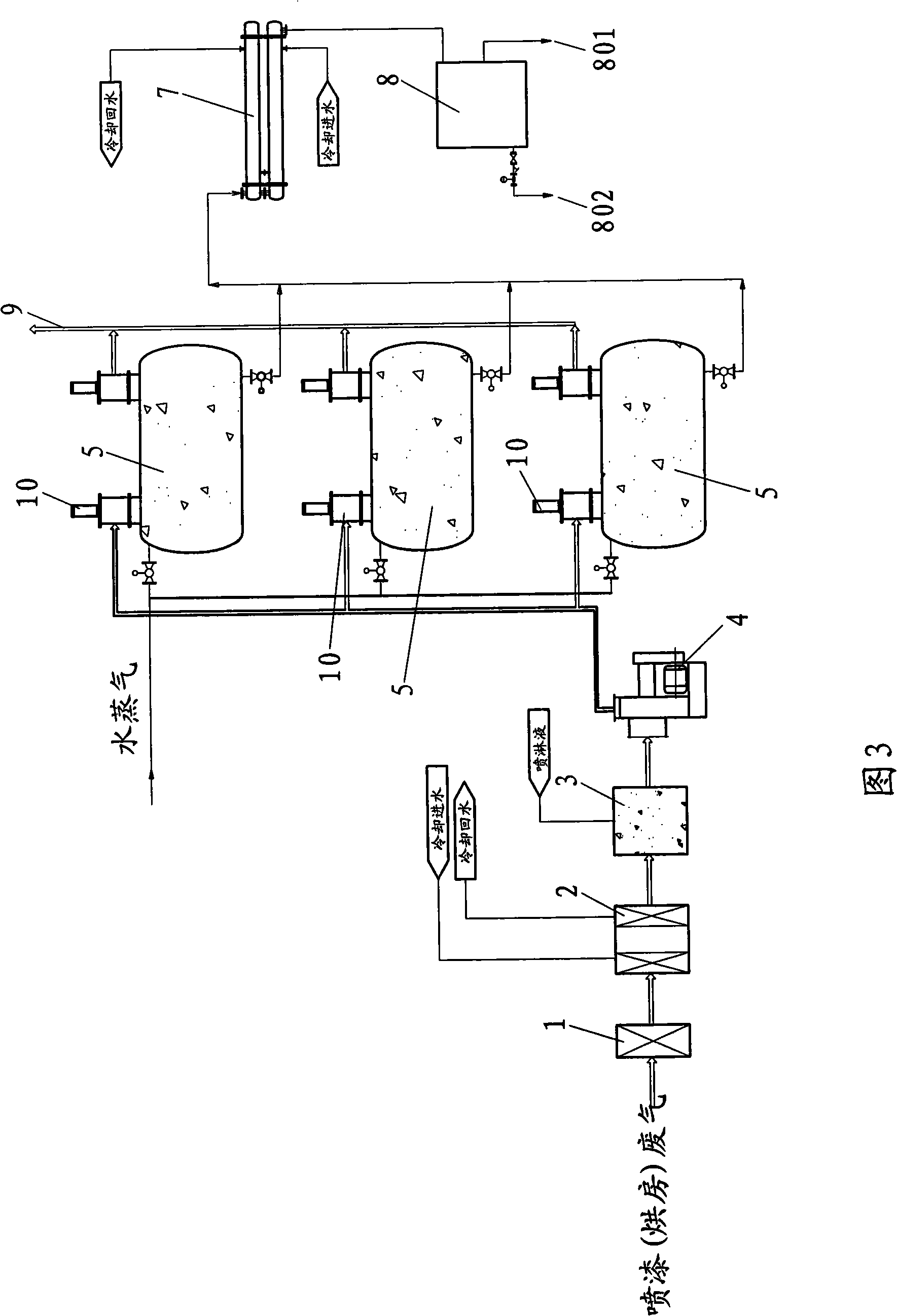

Method for cleaning, recovering and treating painted lacquer exhaust organic gas and device

ActiveCN101274150AGuaranteed uptimeDisplay and monitor working status in real timeDispersed particle separationVapor condensationFiltrationLacquer

The invention discloses a spraying paint organic exhaust gas purification recovery disposal method and a device. The method has the steps as follows: (1) the dust and paint mist of the spraying paint organic exhaust gas are removed by filtration, and high boiling point organic solvent component with the boiling point more than 110 DEG C is condensed; (2) a high boiling point solvent absorption recoverer is used for recovering the high boiling point organic solvent; (3) residual organic exhaust gas is sent into an adsorption tank, the organic solvent component in the exhaust gas is adsorbed, and the exhaust gas is exhausted after being adsorbed by the adsorption tank; (4) by adopting a vapour desorption method, the organic solvent adsorbed by the adsorption tank is desorbed; (5) the desorbed solvent steam and vapour are condensed as liquid; (6) the condensed mixed liquid is separated by the oil and water separator, the separated organic solvent can be used again, and the separated wastewater can be disposed separately. Therefore, precious resources can be recovered, secondary pollution can be reduced, the recovered solvent can be used again, and the consumption of energy source can be reduced.

Owner:蔡志煌

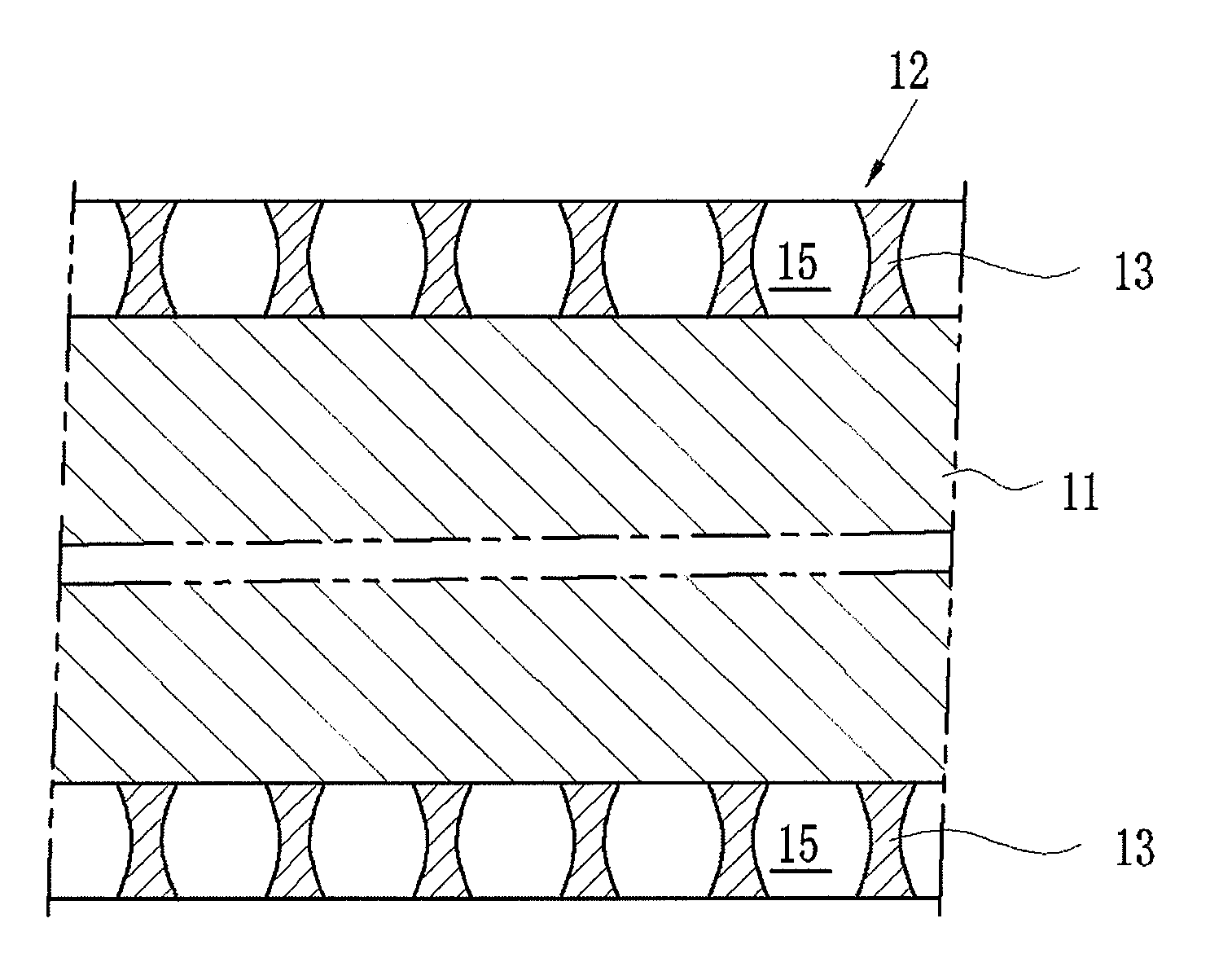

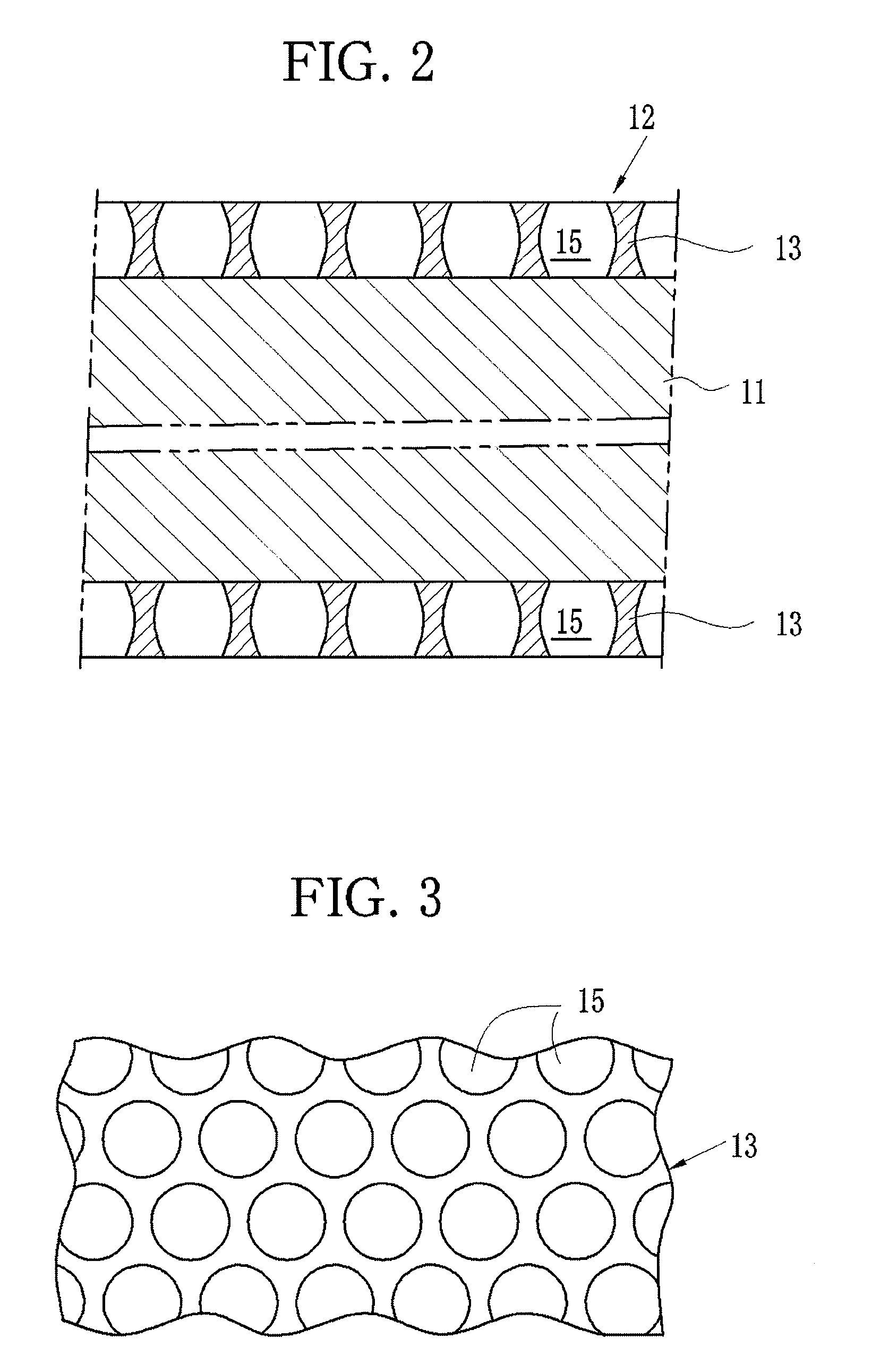

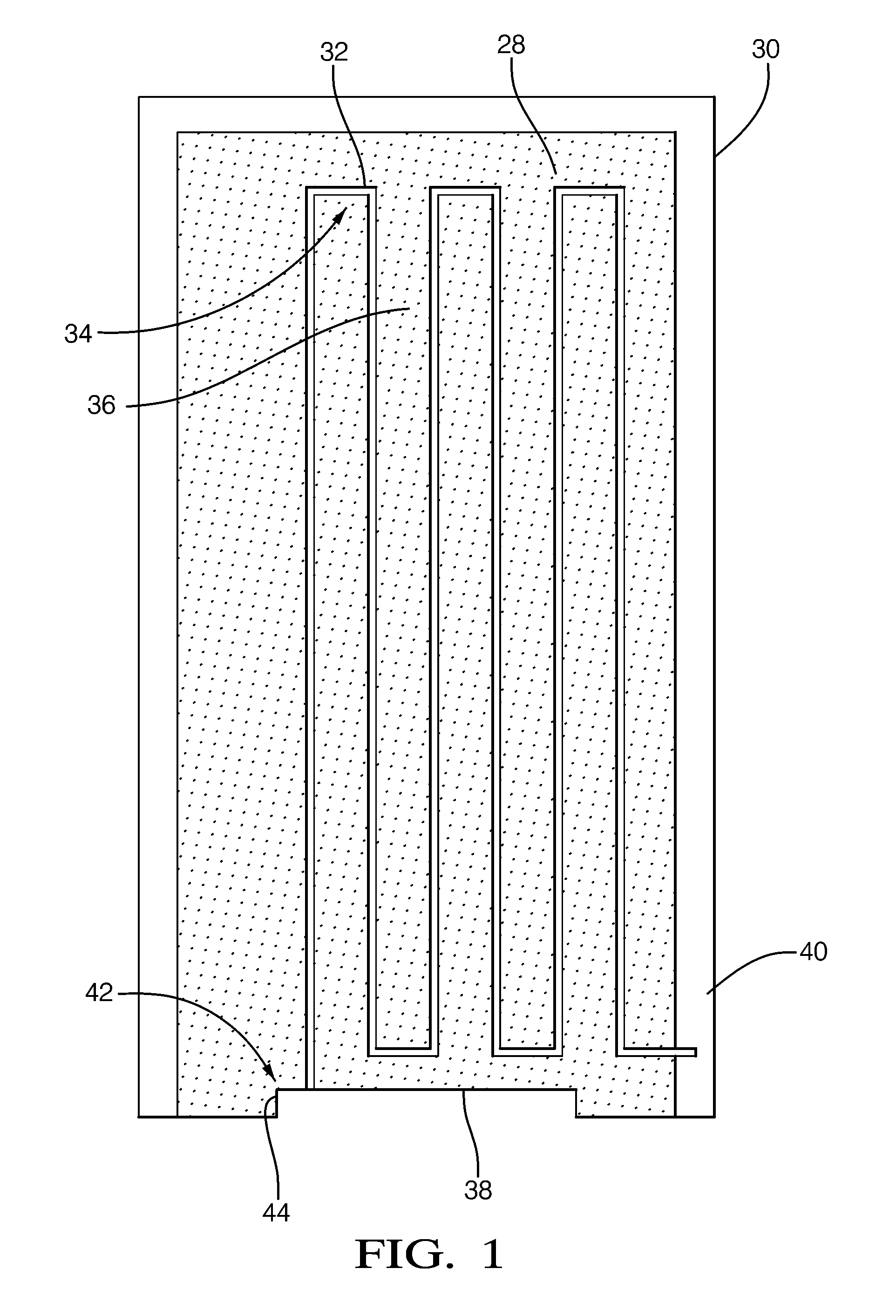

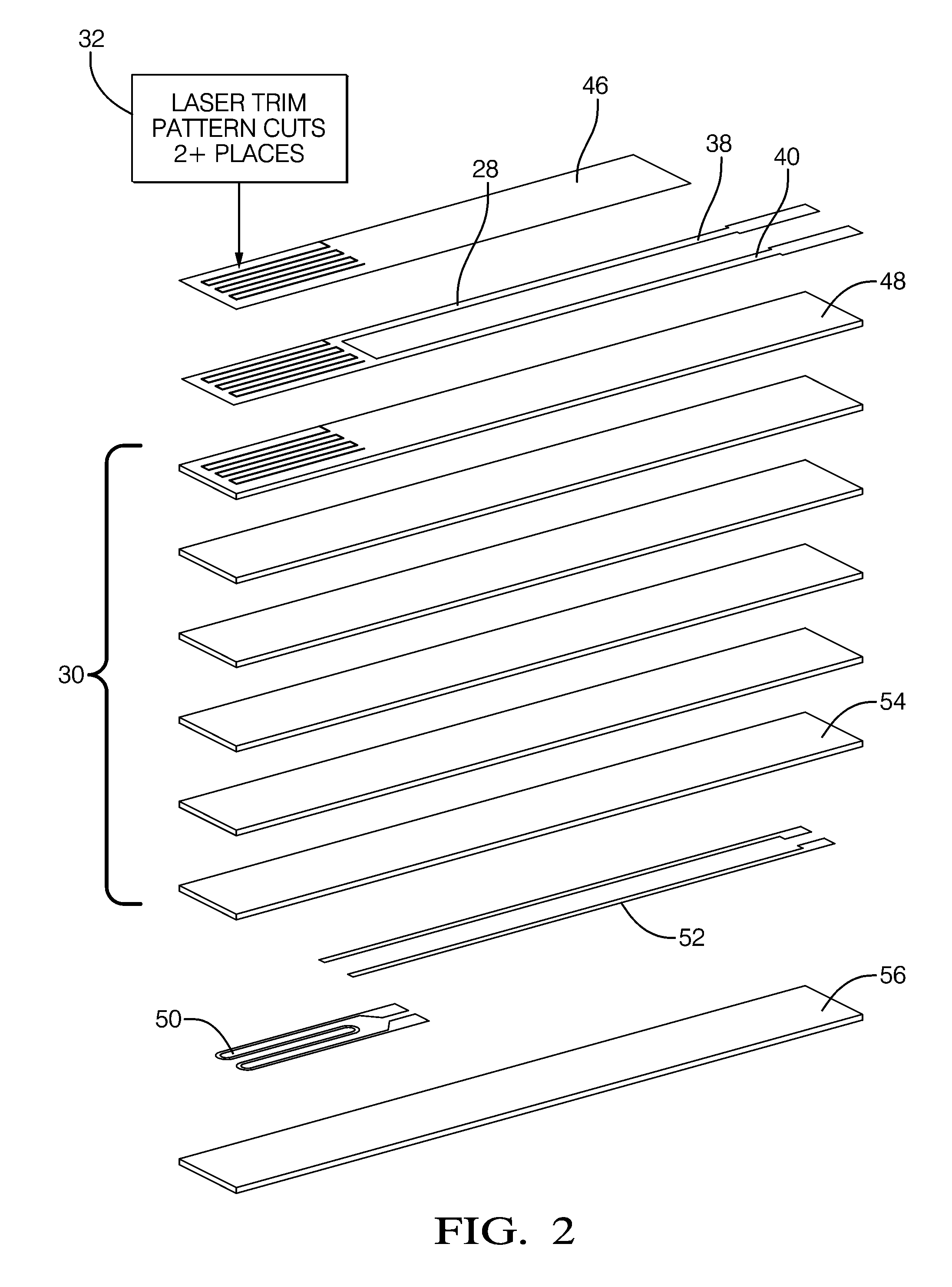

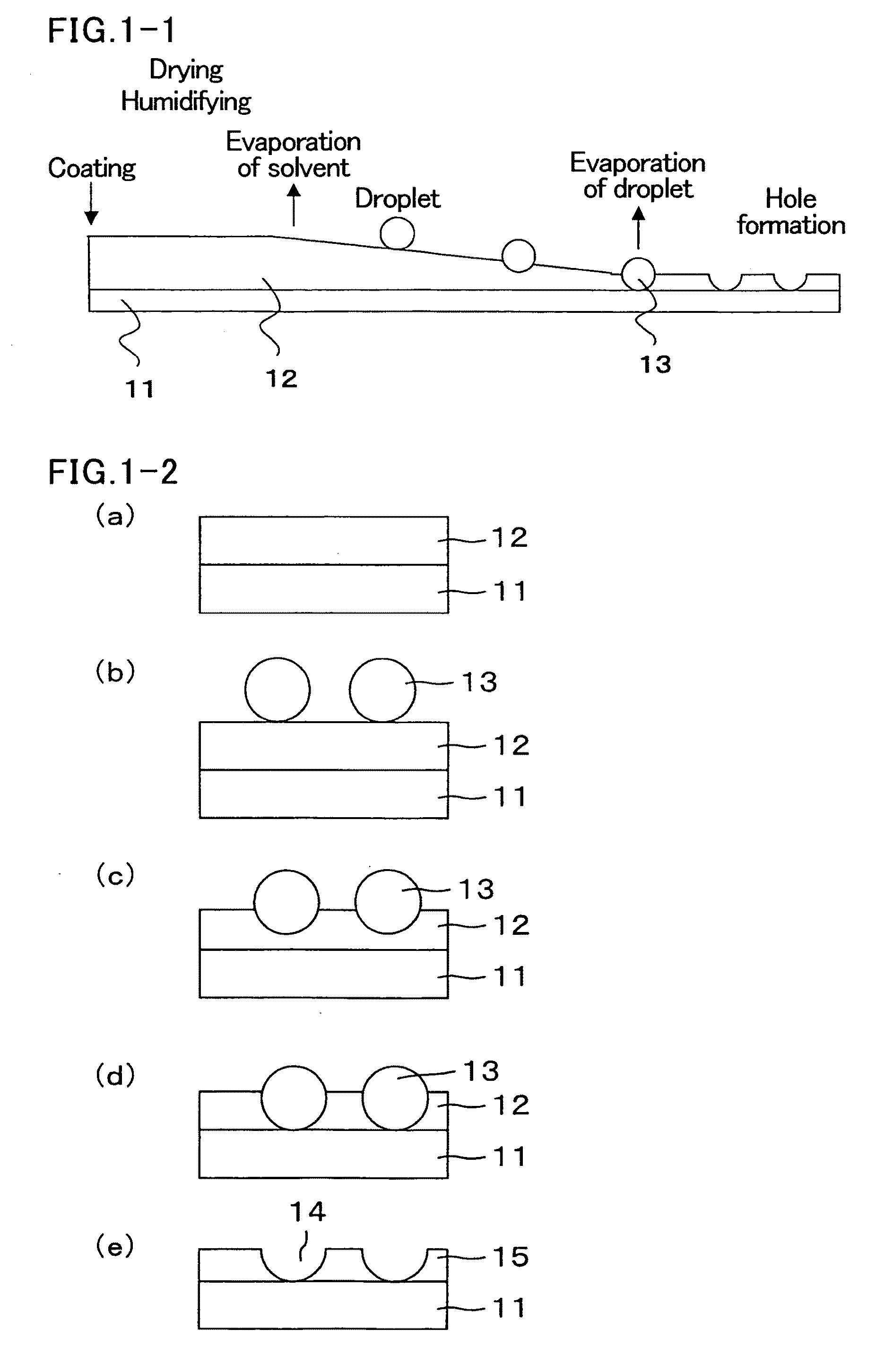

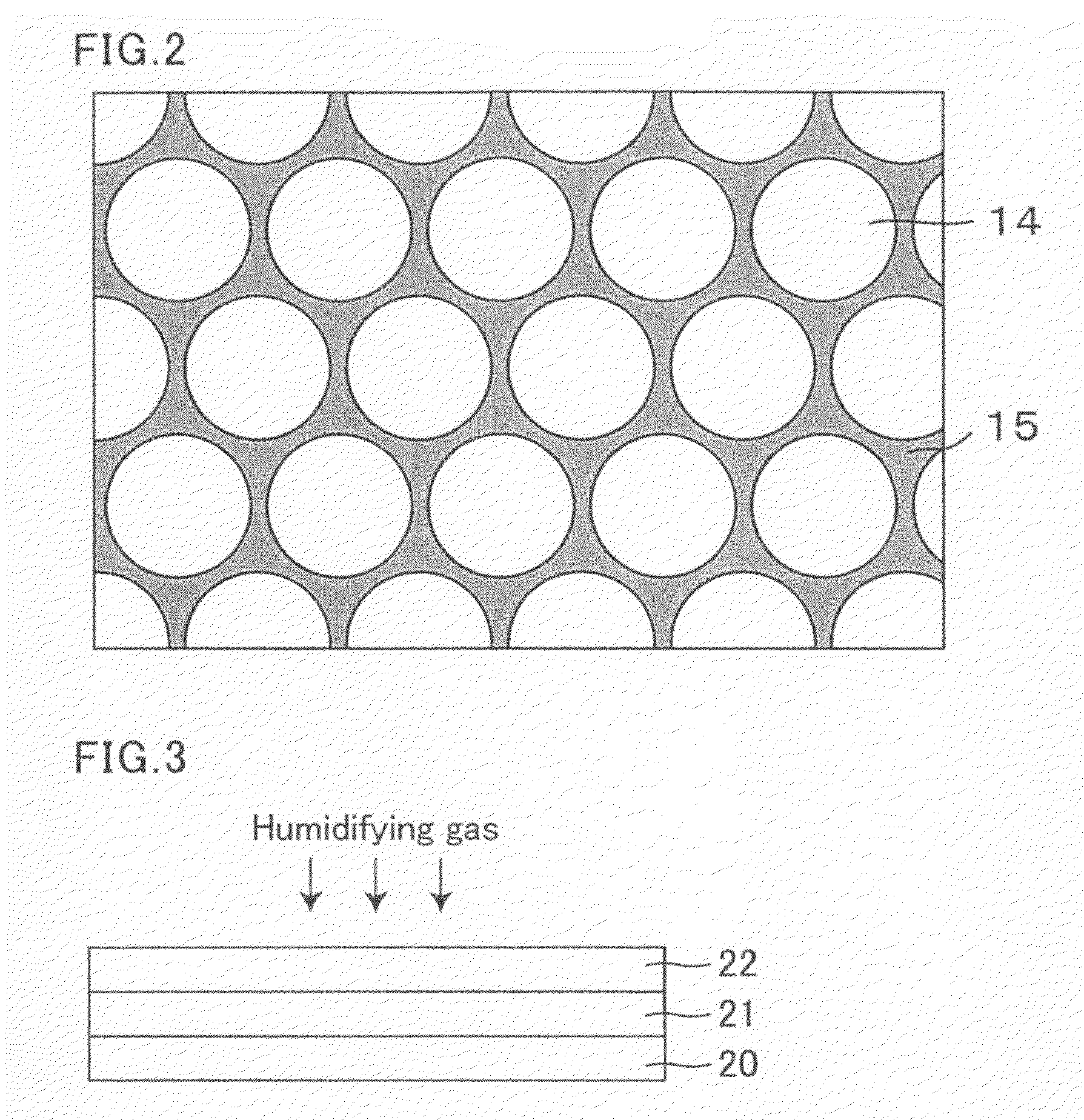

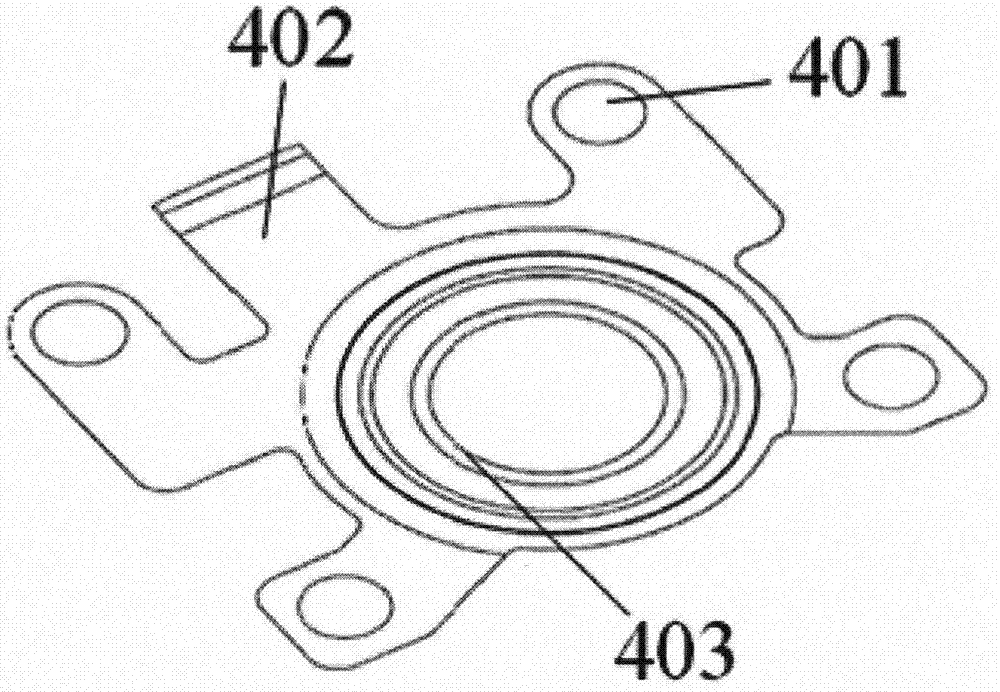

Stent with porous membrane and manufacturing method thereof

InactiveUS20100070026A1Restrict collapseControl deformationStentsMembranesPorous membranePolymer solution

A dipping bath contains a polymer solution. Stent body members are dipped into the polymer solution. The polymer solution forms membrane on the surface of the stent body member. Humid atmosphere is created around the stent body members with the membrane to condense water vapor into water droplets on the surface of the membrane. After growing the water droplets to water drops, a solvent is evaporated, and the water drops penetrate into the membrane. Then, the water drops are evaporated with leaving pores in the membrane. The water drops function as templates.

Owner:FUJIFILM CORP

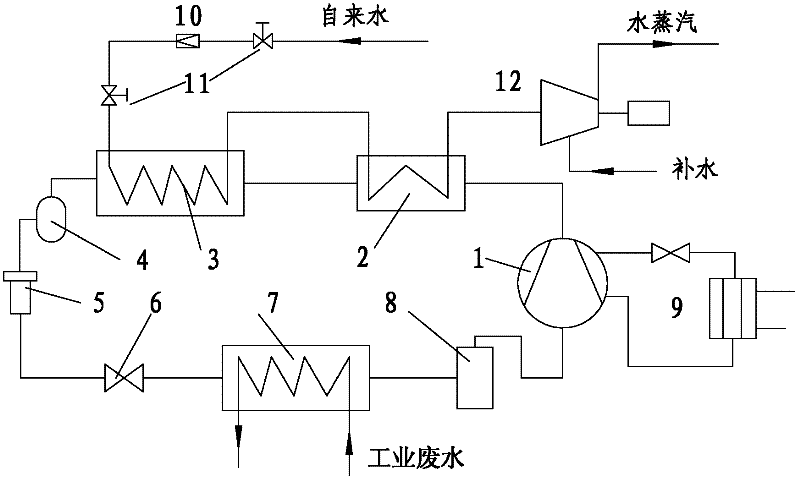

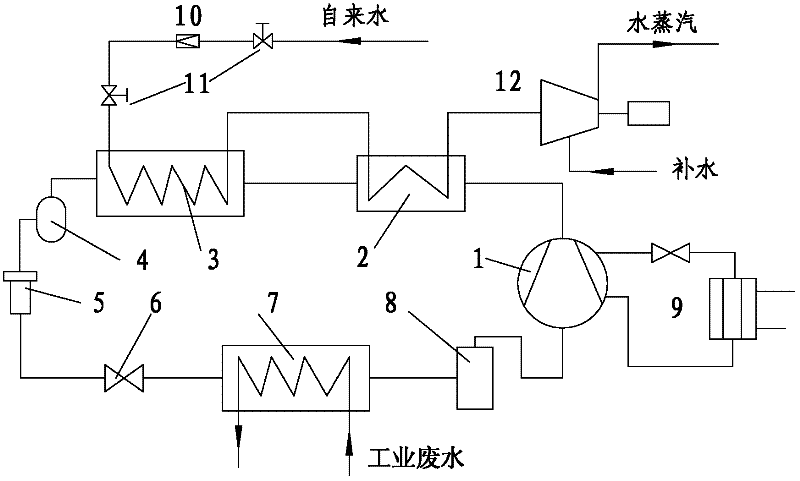

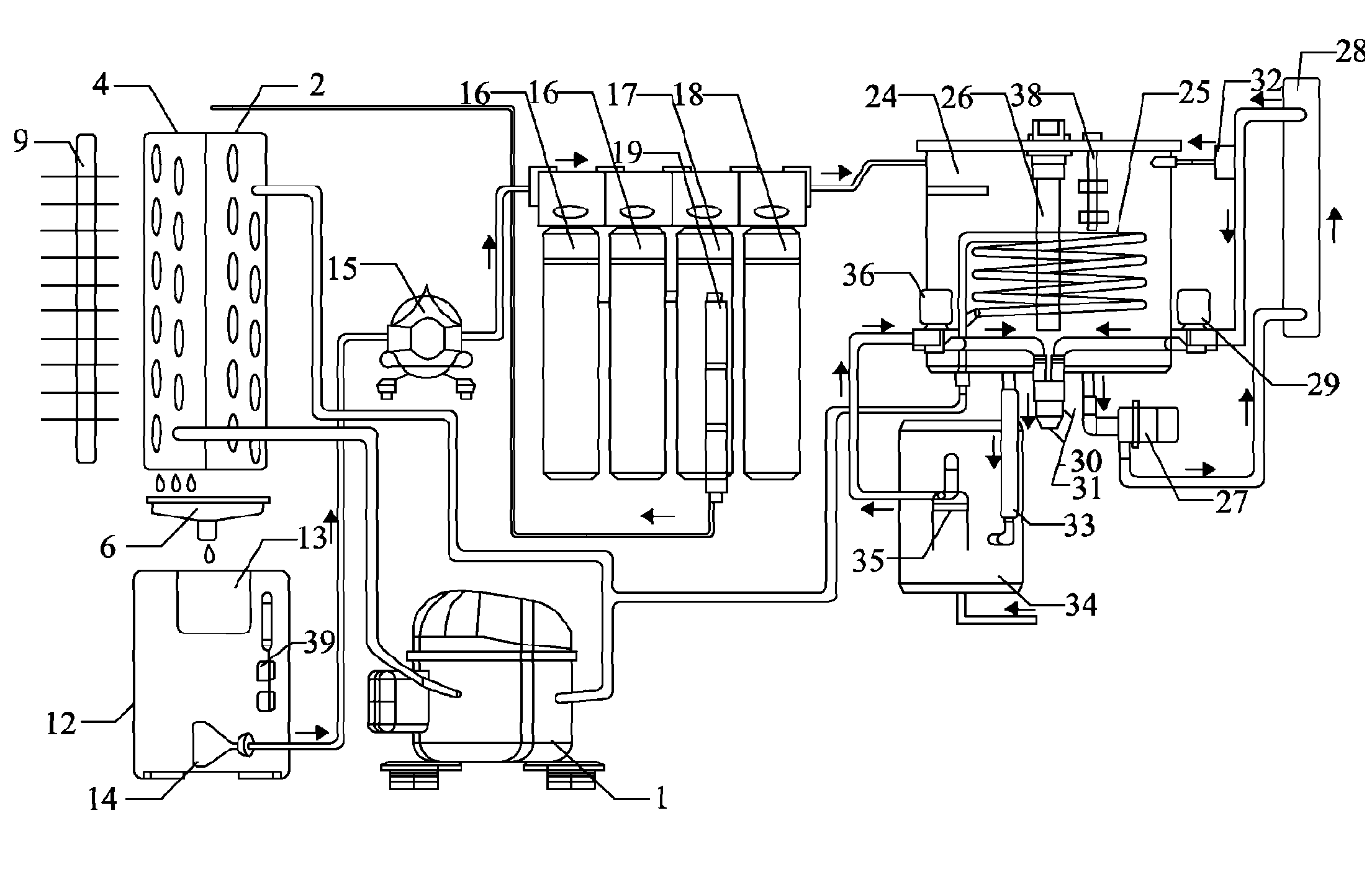

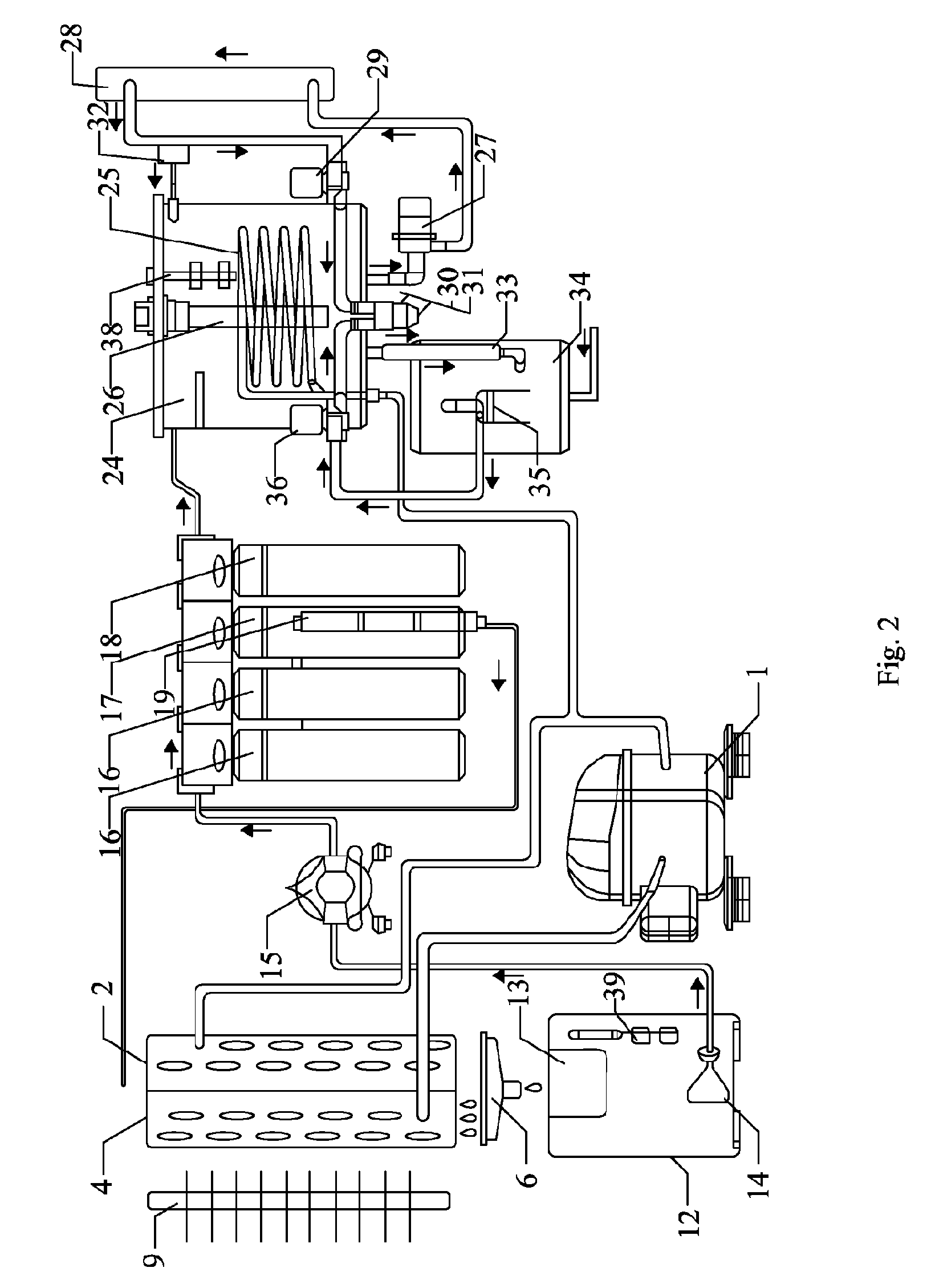

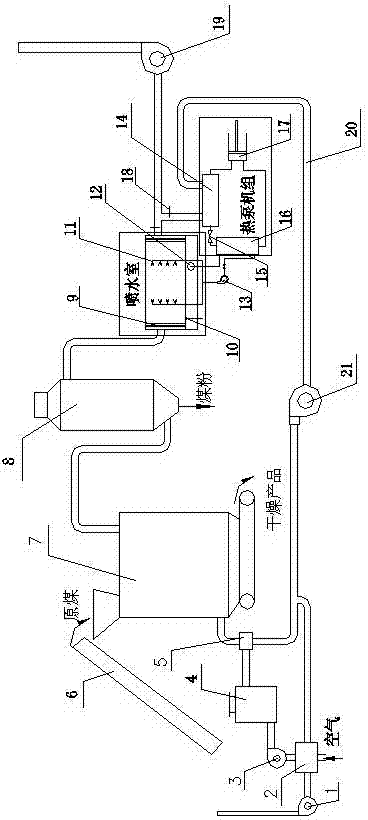

High-temperature vapor heat pump system for generating vapor by utilizing low-grade waste heat

InactiveCN102226604AMeet the needs of industrial productionEfficient recyclingHeat pumpsEnergy industryLower gradeLow graded

The invention discloses a high-temperature vapor heat pump system for generating vapor by utilizing low-grade waste heat, which comprises a heat pump circulating device and a water vapor generation circulating device, wherein the heat pump system recycles the industrial waste heat (20-40 DEG C) and exhausts the heat in a condenser; water on the other side absorbs the heat to be evaporated into the 80 DEG C water vapor; the heat is absorbed by a heat regenerator and becomes overheated vapor under the negative pressure; the overheated vapor is supplied to industrial production through the pressurization of a water vapor compressor, thereby recycling the industrial waste heat and solving the problem that a common heat pump cannot generate vapor below 100 DEG C, which is an innovative system form. The invention has the innovation points that the heat pump system with excellent energy saving performance is combined with the water vapor generation circulation; and the water vapor is generated under the negative pressure, and the waste heat is fully utilized and recycled and the problems which cannot be overcome by the common heat pump are solved.

Owner:XI AN JIAOTONG UNIV

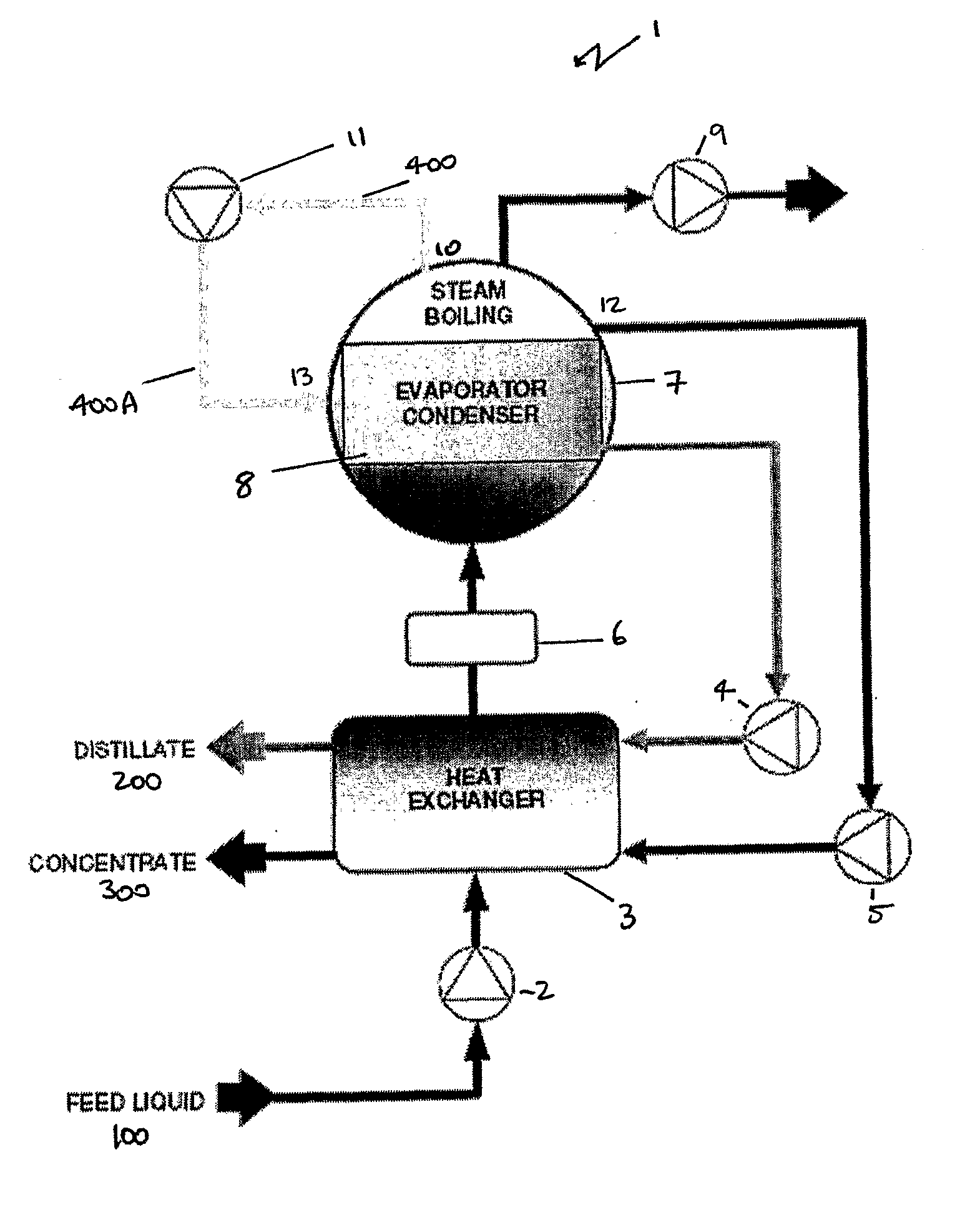

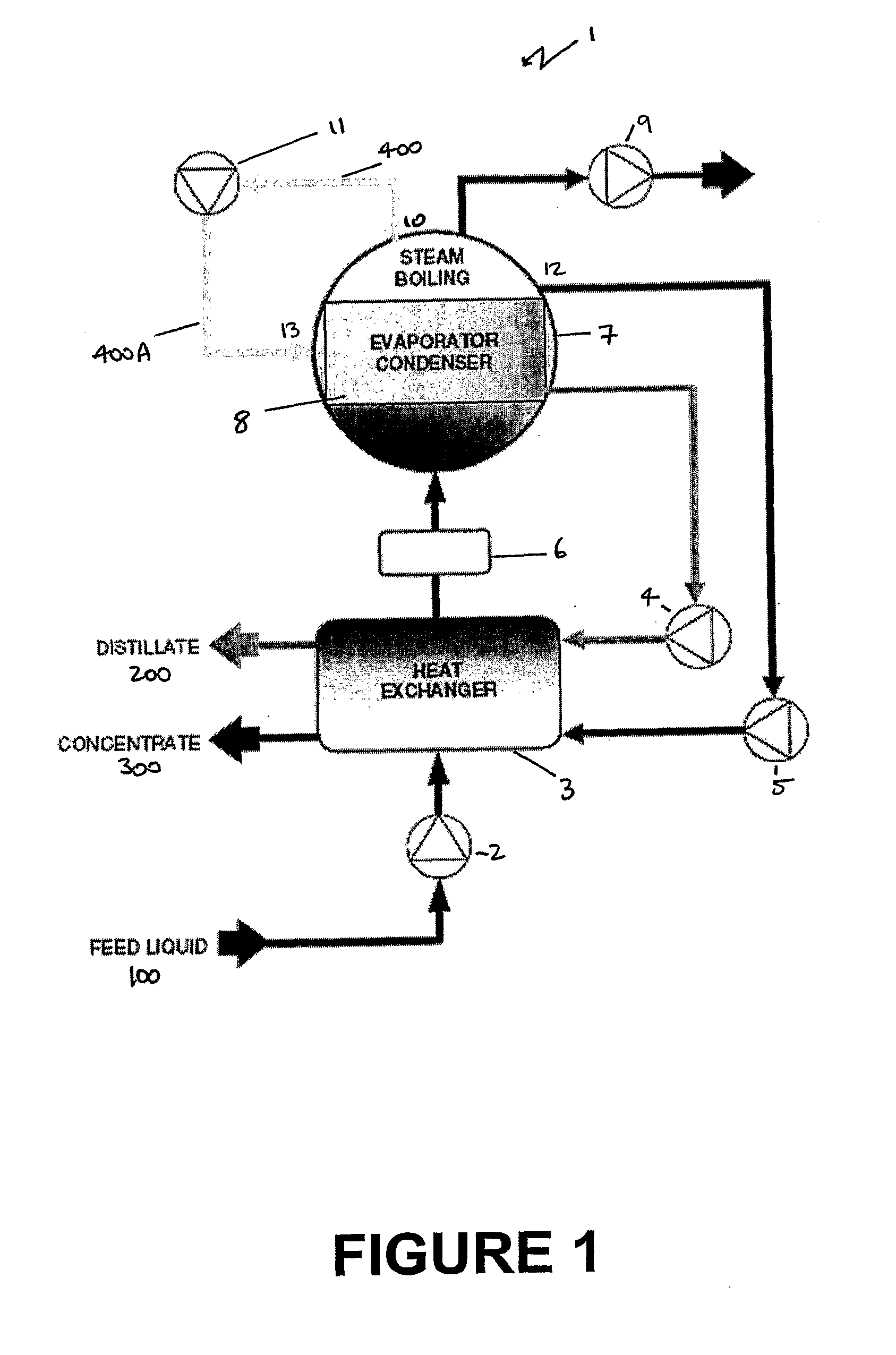

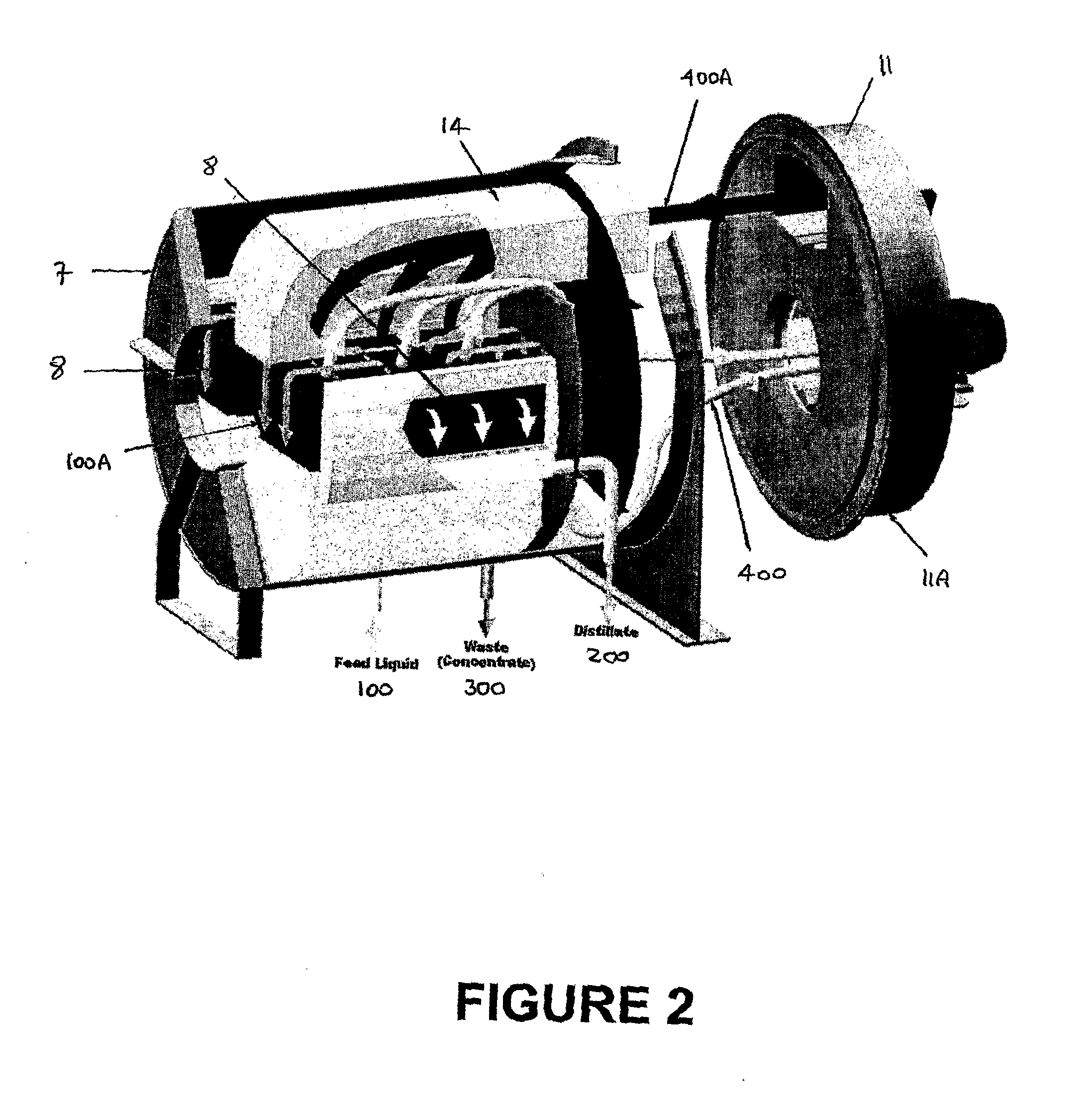

Distillation apparatus

InactiveUS20100200388A1Evaporation with vapour compressionSeawater treatmentPlate heat exchangerDistillation

A modular distillation apparatus including at least one heat exchanger that preheats contaminated liquids; a heater that heats the contaminated liquid from the heat exchanger; an evaporator condenser adapted to boil the contaminated liquid coming out of the heater to produce water vapor and contaminant concentrate, and condense the water vapor into distilled water; a vacuum chamber capable of operating at below atmospheric pressure, the vacuum chamber housing the evaporator condenser and including at least one partition to separate the distilled water from the contaminant concentrate; a vapor compressor operably associated with the vacuum chamber to receive water vapor from the evaporator condenser in the vacuum chamber and pump the water vapor at pressure back through the evaporator condenser, wherein the heat exchanger recovers sensible heat from outgoing condensed distilled water and contaminant concentrate recycled from the vacuum chamber.

Owner:EQUUS ENVIRONMENTAL

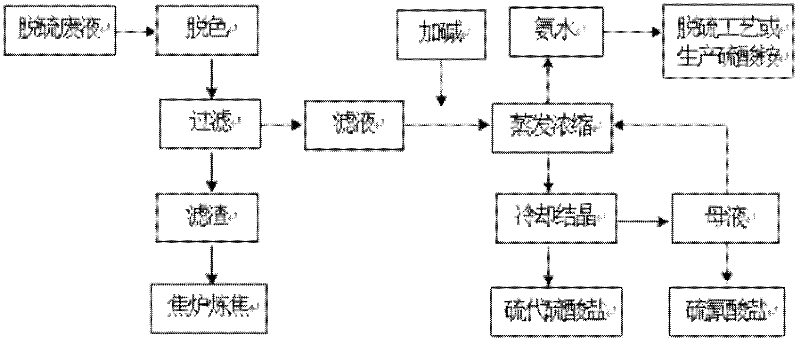

Method for treating desulfurization waste liquid of wet oxidation method

ActiveCN102295379AReduce manufacturing costNot easily decomposed by heatThiosulfates/dithionites/polythionitesThiocyanic acidSodium thiocyanateEvaporation

A method for treating desulfurization waste liquid of a wet oxidation method. The method comprises the following steps: firstly adding a decolorant into desulfurization waste liquid for decolorizing treatment, filtering after decolorization, adding alkali into the filtrate, controlling the PH to be 8-9, performing evaporation concentration under a condition with a negative pressure, condensing the evaporated ammonia gas and water vapor to obtain concentrated ammonia liquor which can be returned to the system for recycle or be used to produce ammonium sulfate, performing fractional crystallization of the concentrated desulfurization liquid to respectively obtain high-purity sodium thiocyanate and sodium hyposulfite. The invention has a simple process, and stable operations, and effectively solves the problem of difficult HPF desulfurization waste liquid treatment in coking enterprises; the method not only reduces the discharge of the waste liquid, but also recovers a lot of chemical products with economic value, and the method has quite significant economic benefits and environmental benefits.

Owner:SHOUGANG CORPORATION

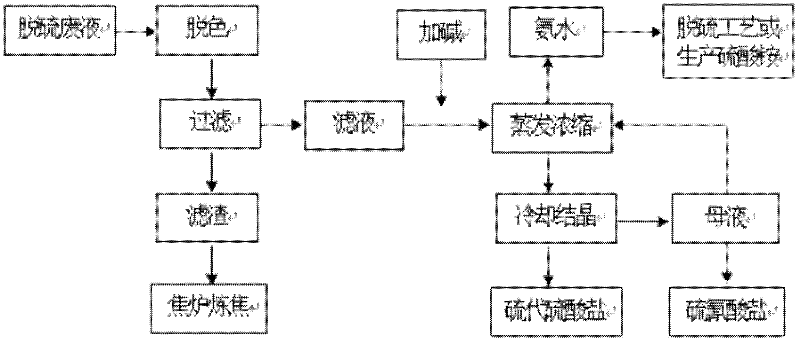

Method and apparatus for seawater desalination by comprehensive utilization of solar energy

InactiveCN101481154ASimple structureImprove reliabilityGeneral water supply conservationSeawater treatmentAir pumpEngineering

The invention discloses a method and a device for seawater desalination by comprehensively using solar energy. The device comprises a solar energy heat collector, a bubble evaporator, an air distributor, an induced fan, a condensing heat regenerator, a heat exchanging pipe, an air pump, a solar panel, a main controller, a salt water tank, a desalted water, four electromagnetic valves and three centrifugal pumps, wherein the solar energy heat collector absorbs the solar energy heating closed circulating water which enters the heat exchanging pipe to exchange heat with the seawater inside the bubble evaporator; wet gas is introduced into the bottom of the bubble evaporator by the air pump, the gas passes through high temperature seawater in the form of small bubbles from top to bottom through the air distributor, the temperature of air is increased, and the relative humidity is increased; the induced fan discharges high humidity air and forms negative pressure at the upper part of the liquid surface so that the partial pressure of the liquid phase is reduced; the high humidity air is discharged and enters the condensing heat regenerator to exchange heat with the low-temperature seawater, the water vapor forms desalted water after condensed, the air enters the bubble evaporator through the air pump, and the cold seawater absorbs the heat of the high humidity air and enters the bubble evaporator. The device has simple structure, saves energy and protects the environment.

Owner:ZHEJIANG UNIV

Method and System for Diagnostics of a Particulate Matter Sensor

ActiveUS20110107815A1Vehicle testingElectrical controlElectrical resistance and conductanceParticulates

A diagnostic method and system is described for diagnosing an operating condition of a conductive particulate matter sensor. The sensor has a substrate and two electrodes on the substrate adapted to collect particulate matter between the electrodes, thereby establishing an electrically conductive path through collected particulate matter between the electrodes that can be detected by measuring electrical resistance between the electrodes, Relect. The diagnosis is performed by detecting whether water vapor condensate may be present between the electrodes and if it is, then measuring resistance between the electrodes while subjecting the sensor to conditions sufficient to evaporate any water vapor condensate and diagnosing a validation that the sensor is in proper operating condition if resistance increases in a manner consistent with evaporation of condensate.

Owner:DELPHI TECH IP LTD

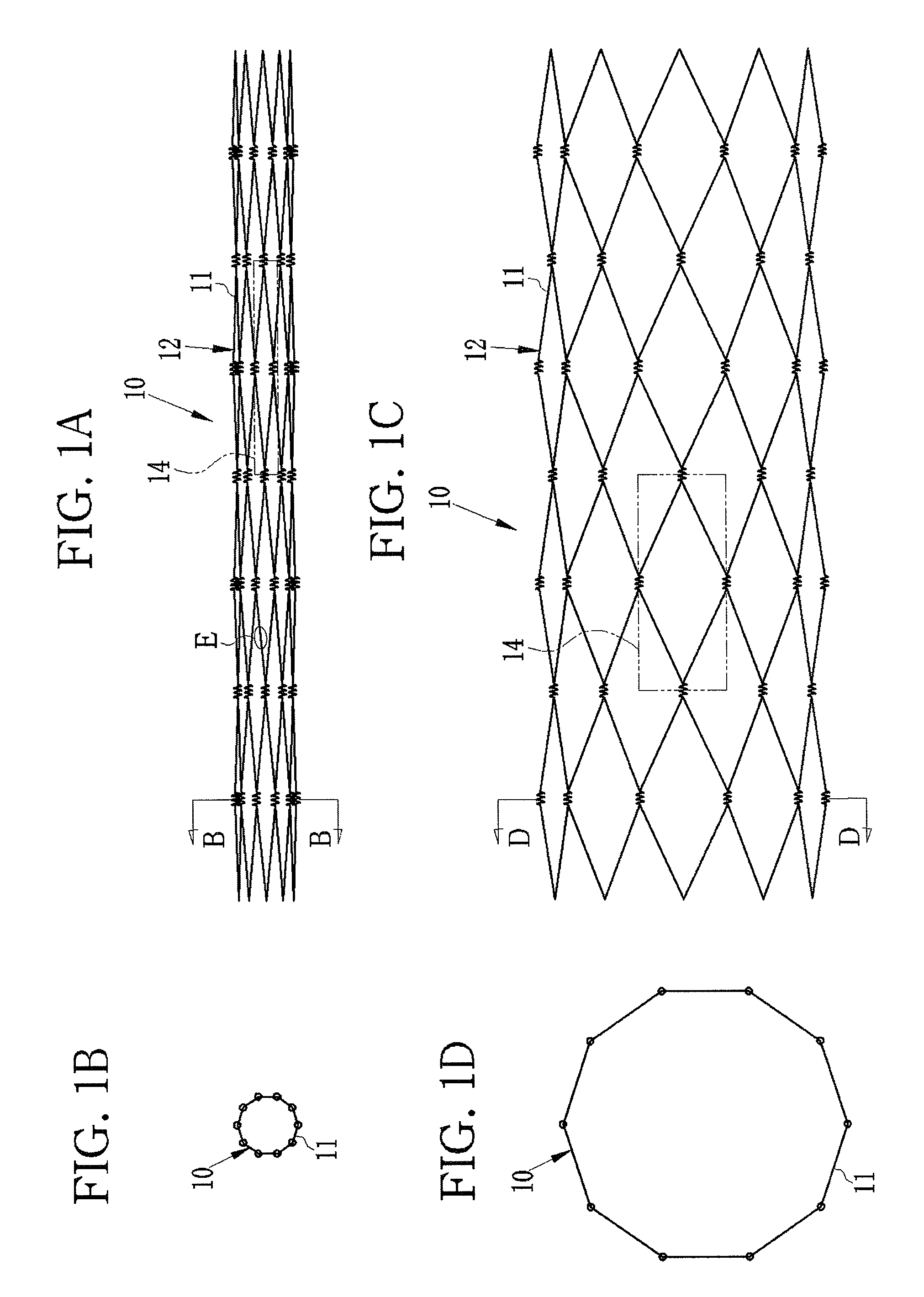

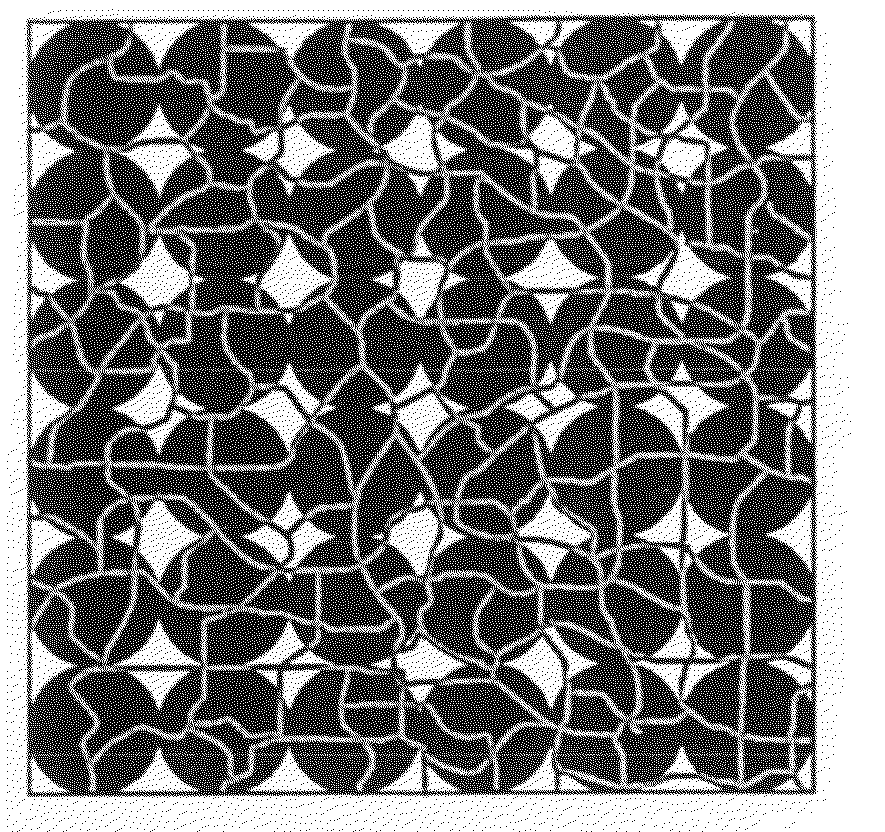

Process for producing conductive film and conductive film

InactiveUS20110124252A1Uniform surfaceHigh light transmittanceConductive layers on insulating-supportsWarp knittingPolymer scienceOrganic solvent

The present invention has an object to provide a process for producing a conductive film, which enables low-cost, easy production of conductive mesh films that have a fine mesh structure and can prevent moiré patterns when used in displays and the like, and a conductive film. The production process includes applying an organic solvent dispersion containing conductive fine particles to a substrate; and evaporating the organic solvent while condensing water vapor in air into water droplets on the surface of the applied organic solvent dispersion. The conductive film has a mesh shape and the mesh shape is formed by mesh lines made of a conductive material and holes. The average area of the holes is not more than 400 μm2, and the mesh lines each have a width of not more than 5 μm.

Owner:NIPPON SHOKUBAI CO LTD

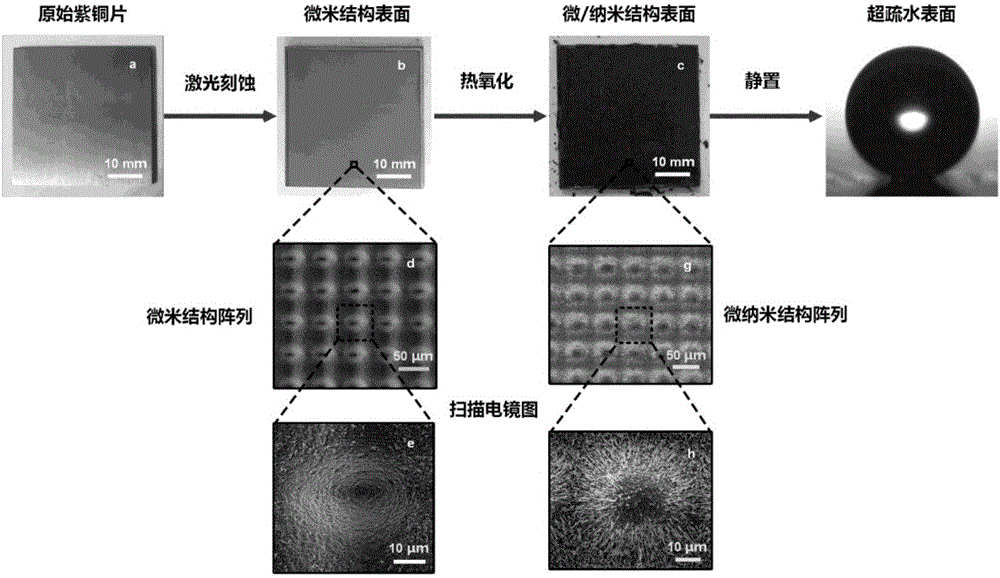

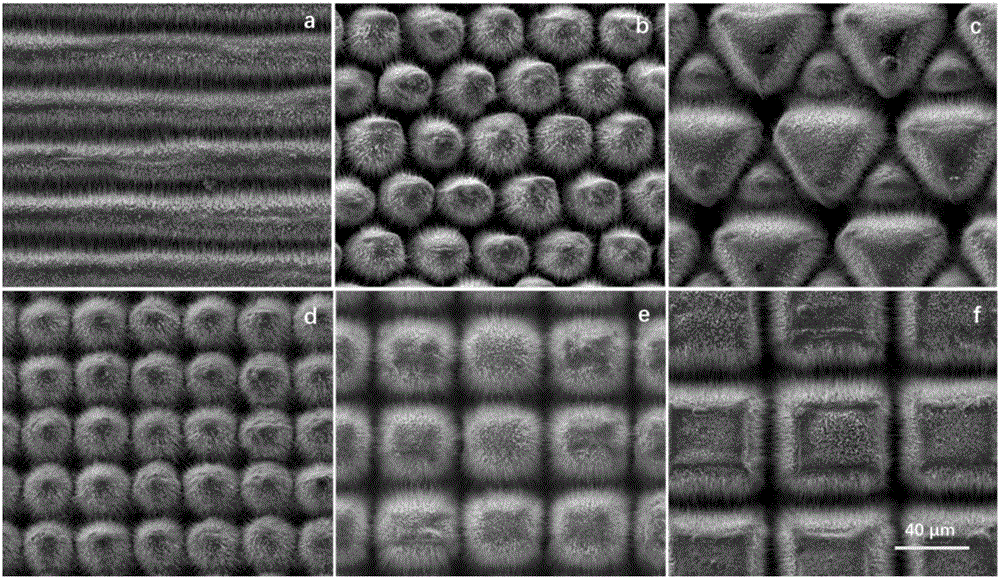

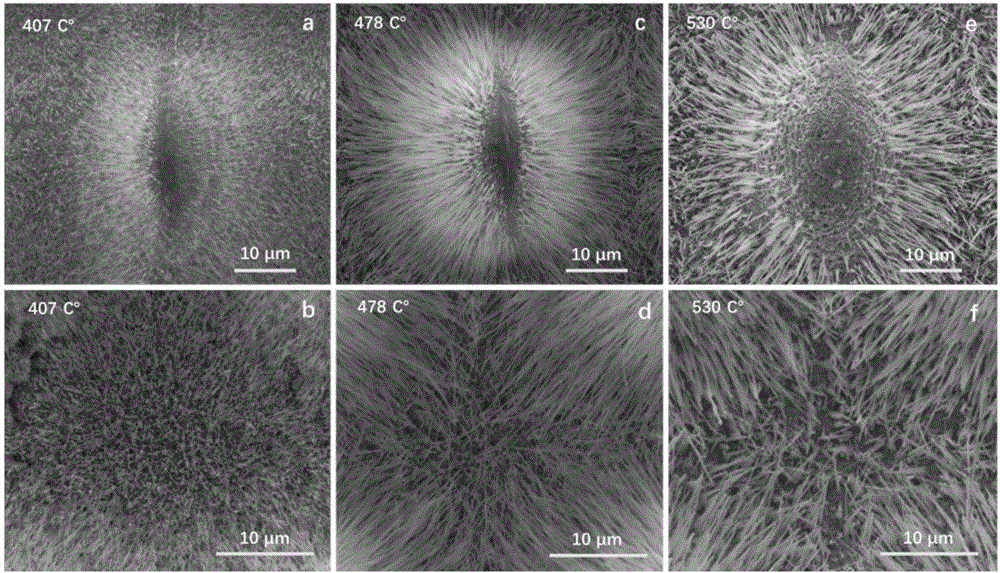

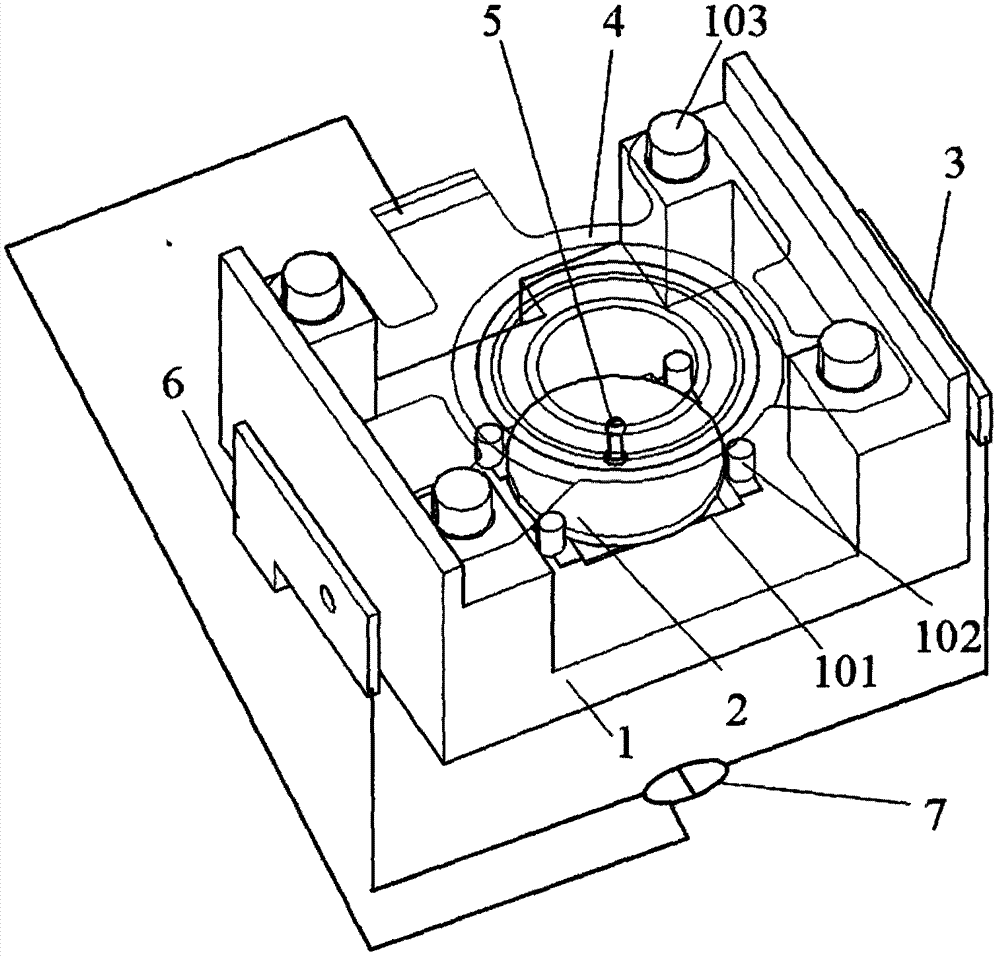

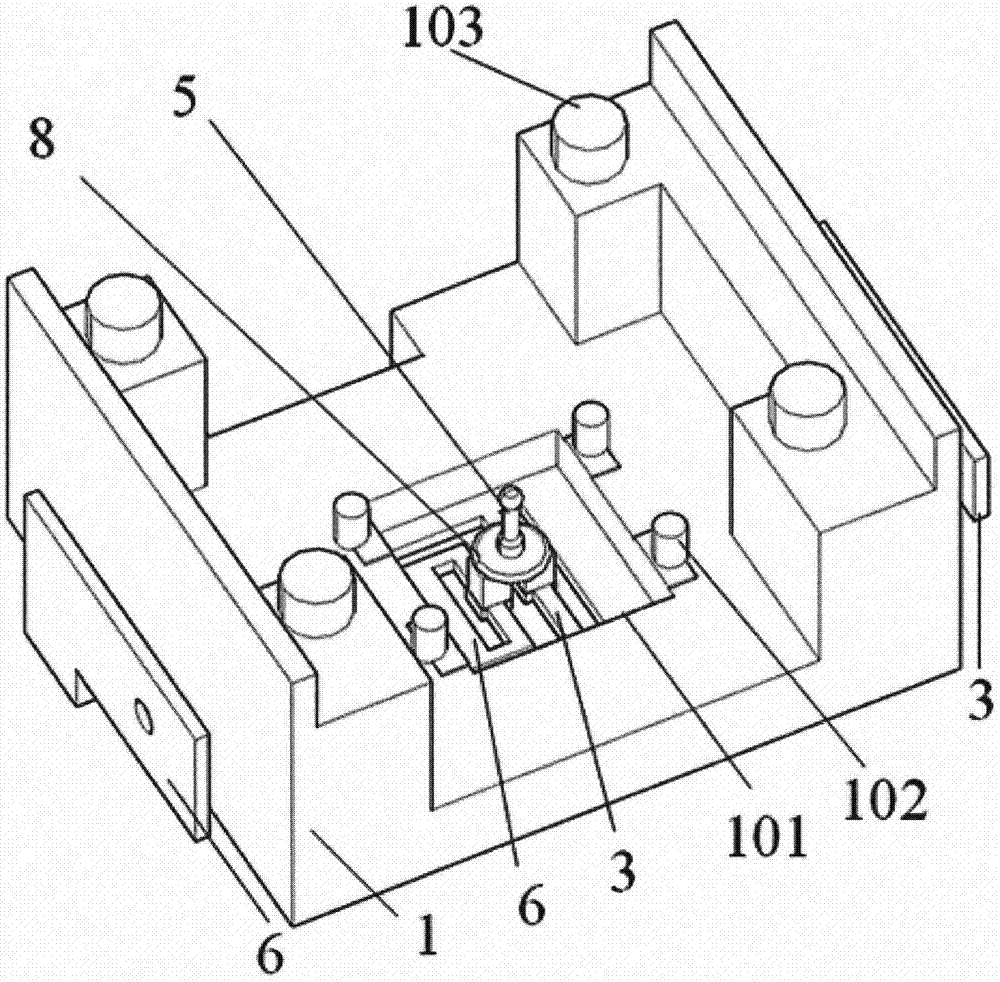

Micro-nanostructure controlled copper-based superhydrophobic surface and preparation method and application thereof

InactiveCN107522161AReduce pollutionEasy to mass manufactureSemi-permeable membranesVolume/mass flow by thermal effectsMicro structureNanowire

The invention discloses a micro-nanostructure controlled copper-based superhydrophobic surface and a preparation method and application thereof. The copper-based superhydrophobic surface comprises micro structure arrays and nanowires, wherein center spacing of the micro structure arrays is 10 to 500[mu]m, the height of each micro structure array is 5 to 500[mu]m; the nanowires have the diameter of 40 to 200nm, the length of 2 to 50[mu]m and average spacing of 0.1 to 3[mu]m; and the nanowires grow in parallel to the direction of a local normal of the copper-based superhydrophobic surface and has the ingredient being copper oxide. The copper-based superhydrophobic surface can implement liquid droplet bouncing heat exchange of water vapor condensation and can also promote classical droplet condensation so as to reinforce heat exchange. Moreover, the micro-nanostructure controlled copper-based superhydrophobic surface can also be used for the fields of self-cleaning, corrosion resistance, ice prevention, frosting resistance and the like.

Owner:TSINGHUA UNIV

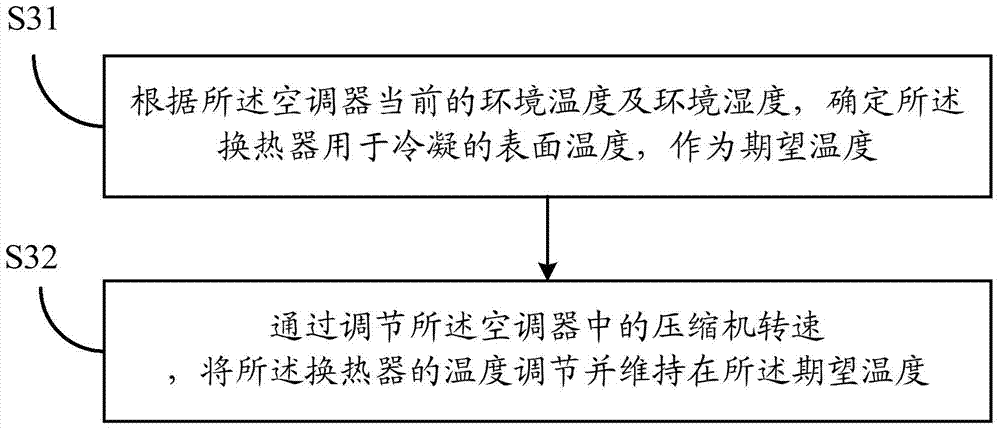

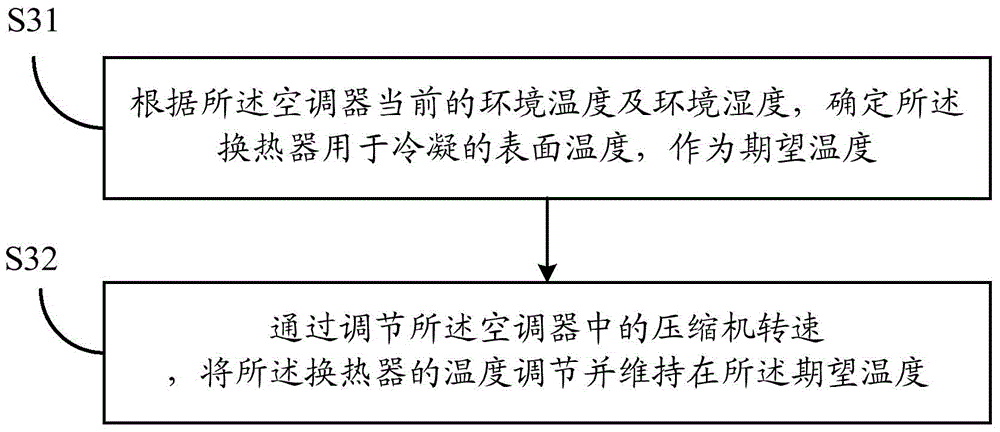

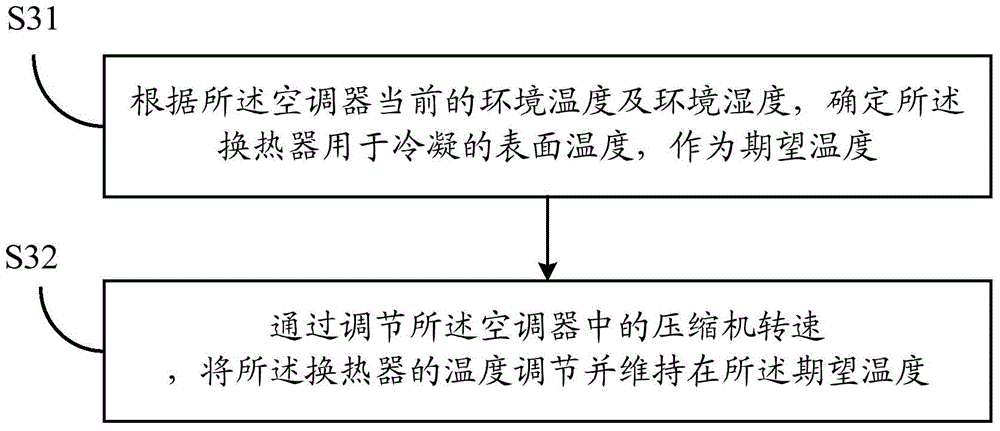

Method and device for collecting condensed water to clean air conditioner based on rotation speed regulation of compressor

ActiveCN104848481ATemperature rise or fallAchieve cleanlinessMechanical apparatusSpace heating and ventilation safety systemsLiquid waterEngineering

A method and a device for collecting a condensed water to clean an air conditioner based on rotation speed regulation of a compressor are disclosed. A heat exchanger in the air conditioner is used for condensing water vapor inside the air conditioner into a liquid water, and thereby cleaning the dirt adhered on the surface of the heat exchanger. The step of condensing the water vapor into the liquid water comprises: determining a surface temperature for condensation of the heat exchanger as an expected temperature, on the basis of a current environment temperature and a current environment humidity of the air conditioner; regulating and maintaining the temperature of the heat exchanger at the expected temperature by regulating the rotation speed of the compressor in the air conditioner. An optimal temperature of the heat exchanger in the current environment is determined by analyzing the influence of the environment temperature and the environment humidity to the dew point, thereby acquiring enough condensed water for cleaning the dirt on the surface of the heat exchanger. When the actual temperature of the heat exchanger is unequal to the expected temperature, the rotation speed of the compressor is regulated to rise up or lower down the temperature of the heat exchanger, accordingly maintaining the temperature of the heat exchanger at the determined optimal temperature, and thereby achieving the automatic cleaning and self-adaptive regulation of the heat exchanger, and ensuring the cleaning effect of the heat exchanger.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

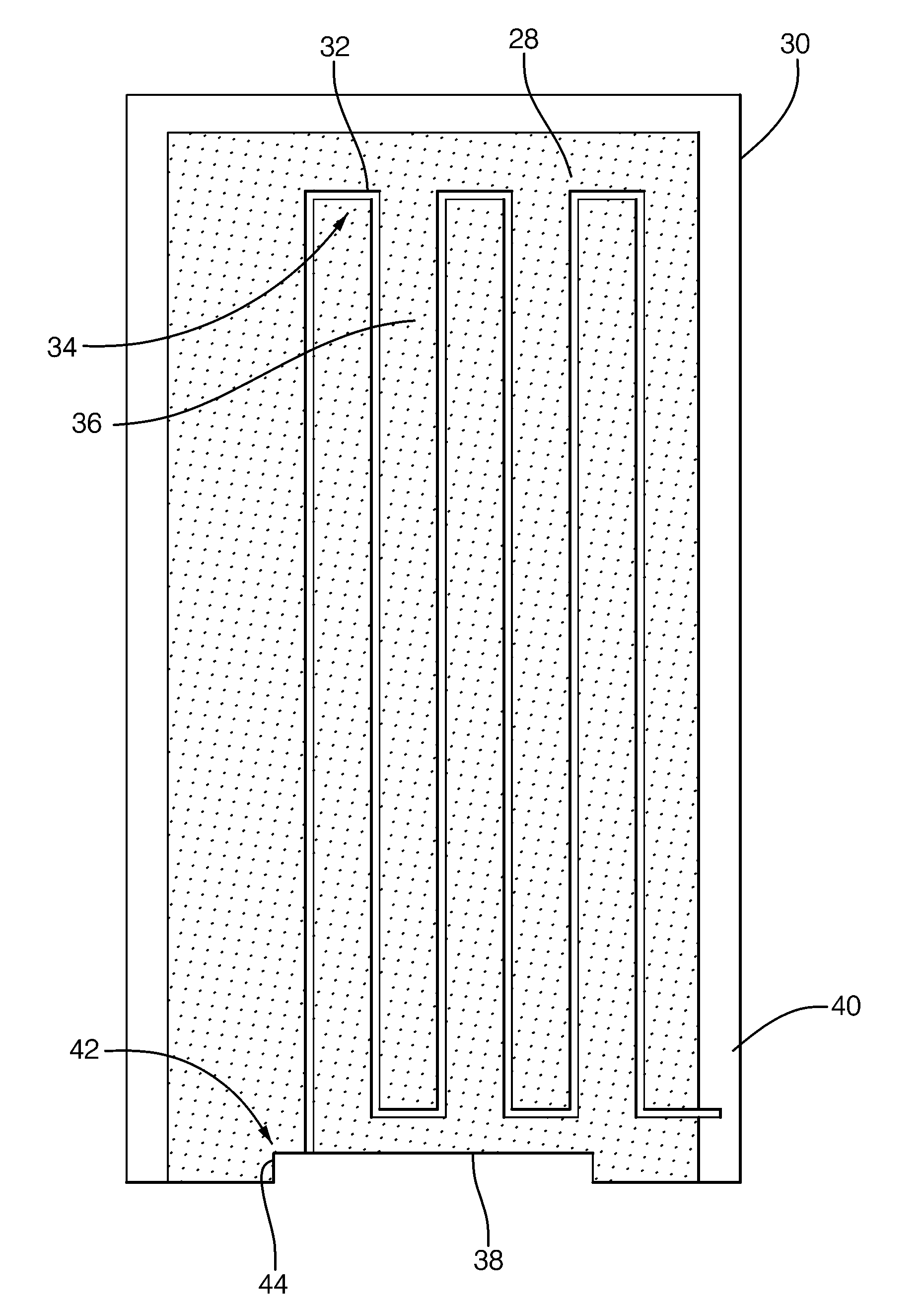

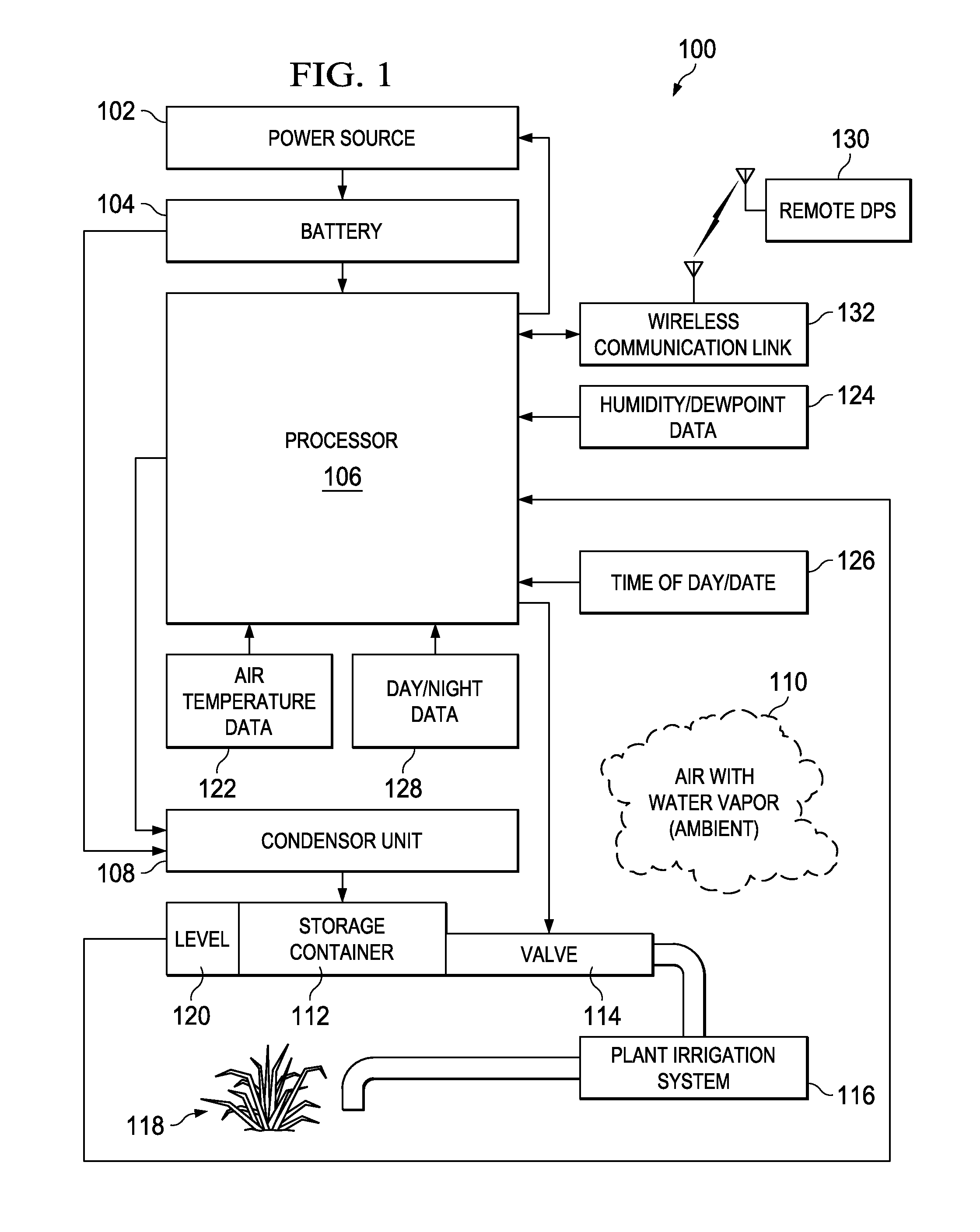

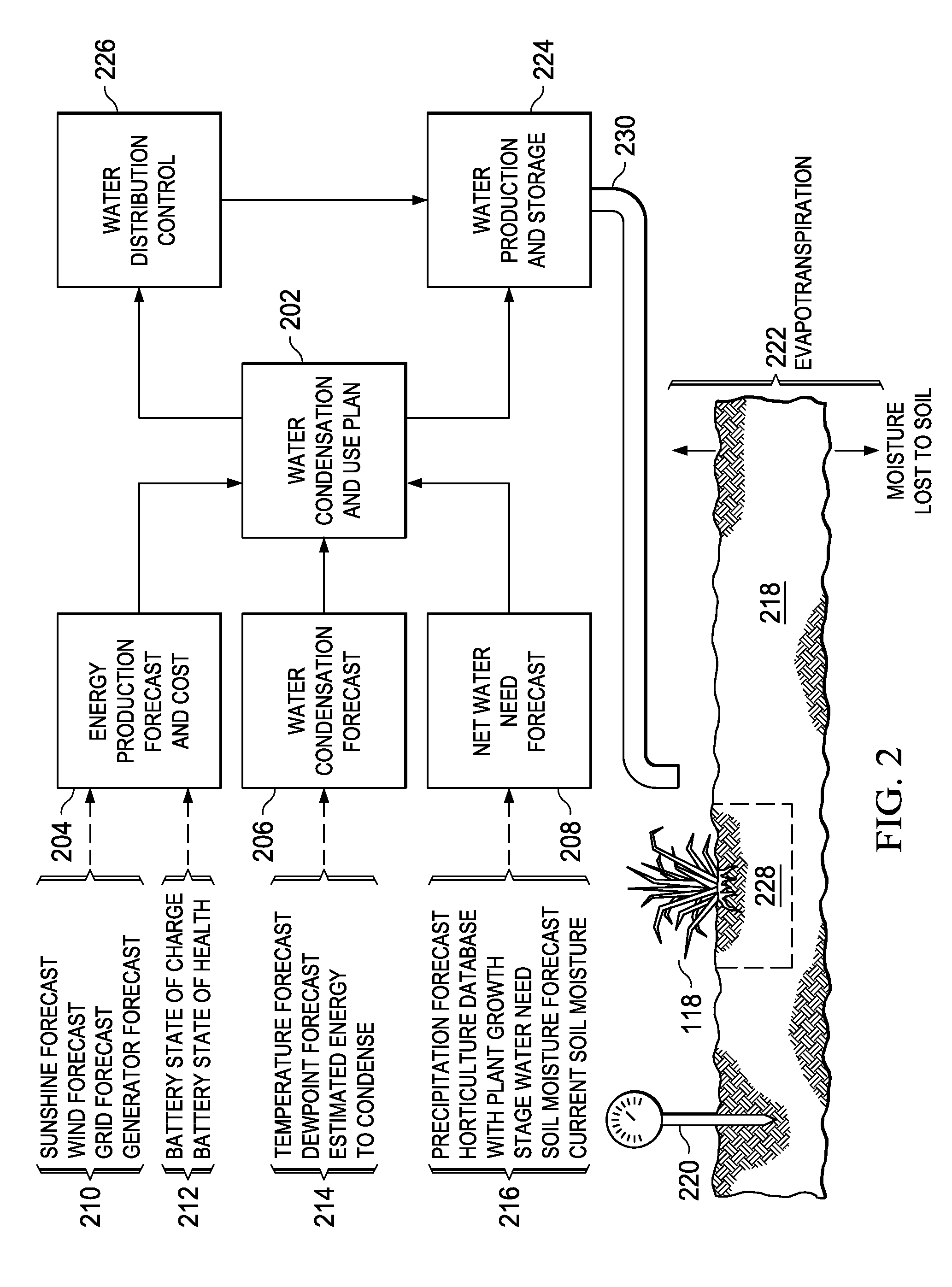

System and method for irrigation using atmospheric water

ActiveUS8321061B2Improve efficiencyIncrease valueSelf-acting watering devicesCompression machines with non-reversible cycleEngineeringWater vapor condensation

An embodiment of the invention delivers water to plants of a specified type which reside in a quantity of soil. A condensing unit is operated at optimum intervals to condense water vapor in the air into water in liquid form. The condensed water is stored in a reservoir connected to an irrigation system, which can deliver water from the reservoir to each of the plants. A database is established that contains horticultural information, wherein the horticultural information comprises a set of values representing the water needed by plants of the specified type at different stages of growth. Estimates of soil moisture content are generated during a specified time period. Optimum watering intervals are computed during the specified time period, at least in part, as a function of the set of values contained in the horticultural database, and also as a function of the estimates of moisture content. The irrigation system is operated to deliver water to each plant during respective optimum watering intervals.

Owner:DEERE & CO

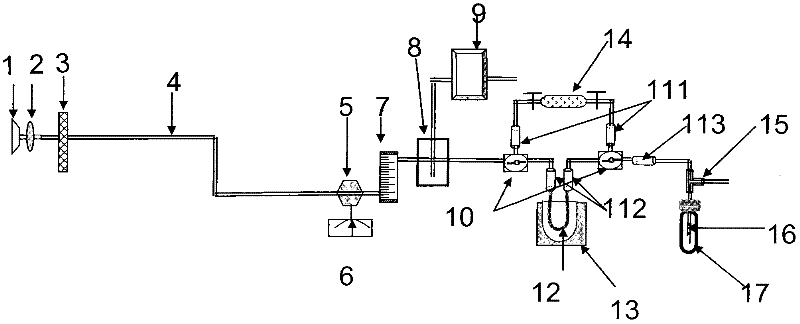

Device and method for synchronously collecting atmosphere CO2 and water vapor samples

InactiveCN102589936AKeep coldNo fractionation effectWithdrawing sample devicesAtmospheric airIsotopic composition

The invention provides a device and method for independently or synchronously collecting atmosphere CO2 and water vapor samples, which are mainly used for synchronously collecting air CO2 and water vapor samples in the open and are especially applicable to analyzing the concentrations of CO2 and water vapor in the air and the isotopic compositions of 13C in CO2 and 2H(D) / 180 in the water vapor. Meanwhile, the device and the method are also applicable to independently collecting CO2 or water vapor sample. The device and the method are widely applied to researches in the aspects of ecology, atmosphere and environment and are convenient for field installation and removal. The device comprises an atmosphere filtering system, a gas extraction system, an atmosphere CO2 and H2O concentration analysis and measurement module, a water vapor condensation and storage system, a CO2 gas sampling and storage system and a gas drying system.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

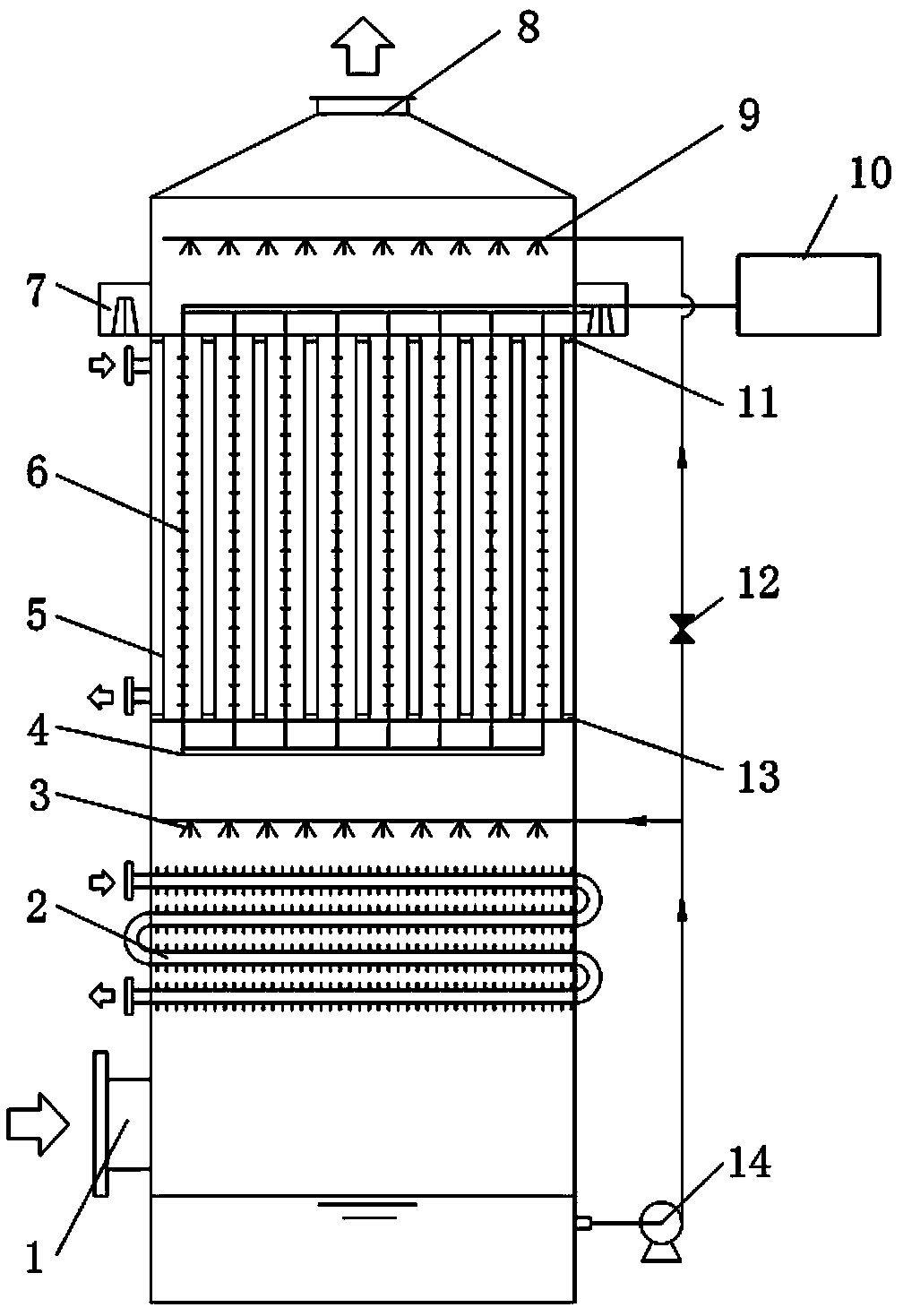

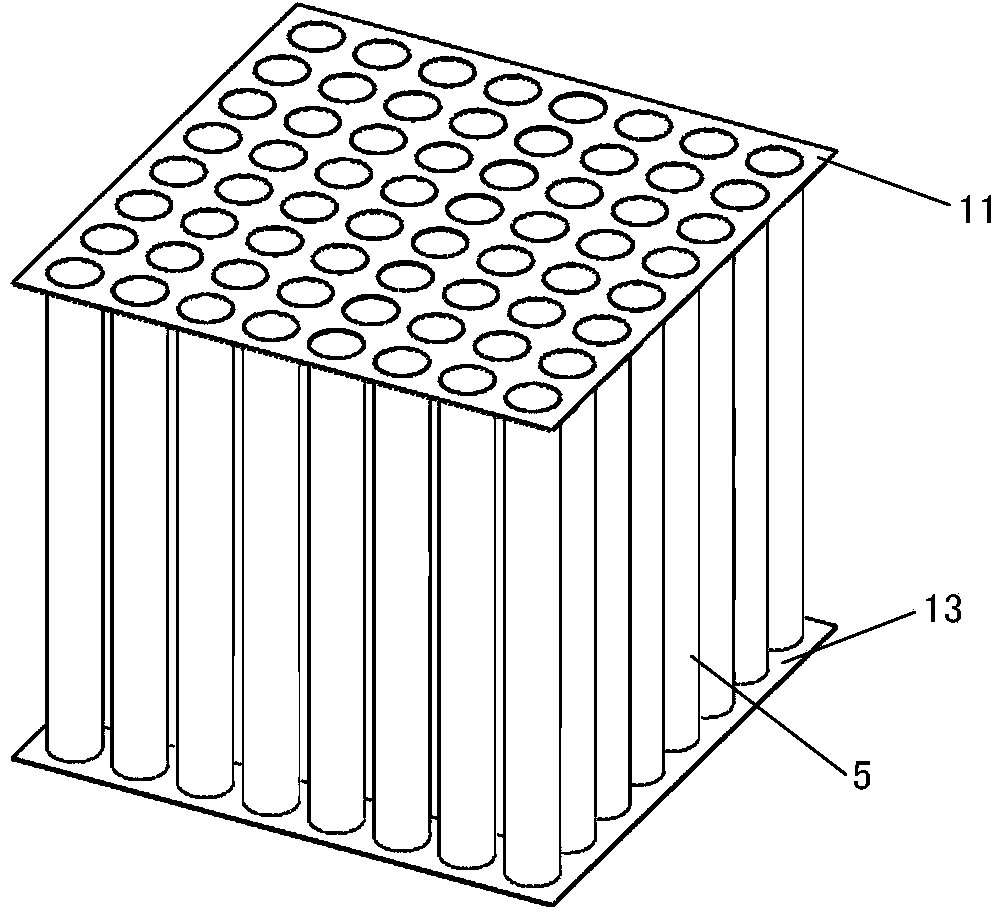

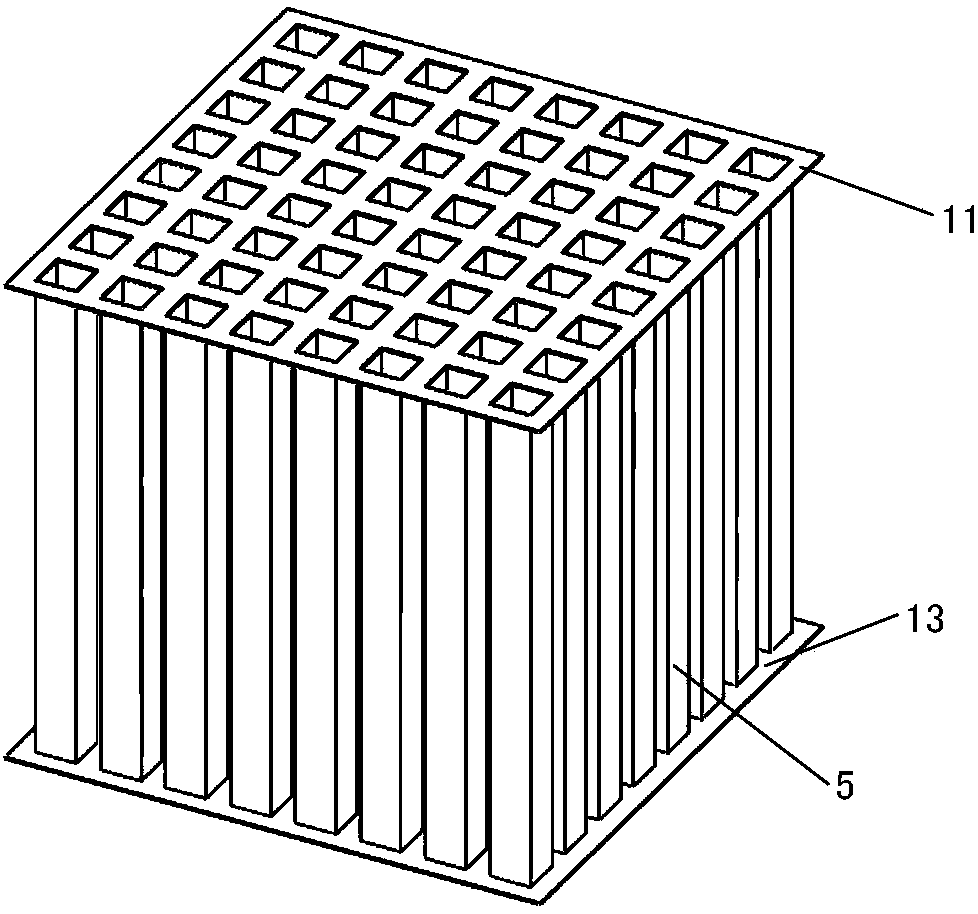

Efficient wet type electric dedusting and purifying device and method for smoke obtained after wet desulphurization

InactiveCN104226479AEnhanced deep purification performanceLarge particle sizeExternal electric electrostatic seperatorParticulatesHigh pressure

The invention discloses an efficient wet type electric dedusting and purifying device and method for smoke obtained after wet desulphurization. The device comprises a gas inlet, a heat exchange pipe, multiple humidifying nozzles, a cathode fixing frame, multiple dust collecting pipes, multiple washing nozzles and a gas outlet, which are arranged in a shell in sequence from bottom to top, wherein the upper ends and the lower ends of the dust collecting pipes are connected with an upper tube sheet and a lower tube sheet in a sealing manner, respectively, so as to form a dust collecting pipe bundle; multiple discharge electrode wires are arranged in the dust collecting pipes respectively and are fixed by the cathode fixing frame; the cathode fixing frame is connected with a high-voltage power source outside the shell; when the smoke obtained after wet desulphurization is purified, the smoke is introduced into the device from the gas inlet, is cooled through the heat exchange pipe and is humidified and cooled through spraying of the humidifying nozzles, so as to reach a saturated or oversaturated water vapor state; when the smoke passes through the dust collecting pipes, water vapor condensation phase change occurs; particulates are collected to the inner surfaces of the dust collecting pipes under the action of an electric field force. The efficient wet type electric dedusting and purifying device integrates water vapor condensation phase change and wet type electric dedusting, so that the deep purification effect of the smoke obtained after wet desulphurization can be realized.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Apparatus and methods for creating sparkling water from the atmosphere

What is disclosed is a system designed to extract water moisture from the atmosphere, highly purify and condition the extracted water, and provide optional carbonation of the extracted water for human consumption. In one embodiment, the device collects water-vapor condensation from filtered intake air, then subjects the condensate to a series of purification filters and to a sterilization process in order to produce drinking water, while also providing a means to combine the purified water with CO2 gas to facilitate dispensing carbonated water and / or carbonated drinks.

Owner:ECOLOBLUE

Nanometer water ion generation method without addition of water and device

The invention discloses a nanometer water ion generation method without addition of water and a device. The method comprises following steps of firstly, condensing vapor in air; and then, breaking the condensation water to form nanometer water ions. The condensation step of the vapor in the air is that surface temperature of a discharge electrode is reduced to be lower than the air dew point temperature, so at this moment, vapor contained in the air is condensed on the surface of the discharge electrode. The step for forming nanometer water ions of the condensation water is that high voltage is imposed on the discharge electrode to break the condensation water on the surface of the discharge electrode into nanometer water ions. The discharge electrode is in the shape of a needle, and the head is in the shape of a circular ball or an elliptic ball. The nanometer water ion generation device made based on the above method comprises a fixed housing. The discharge electrode is arranged in the fixed housing. The lower end of the discharge electrode is connected with a refrigeration device. A high voltage electrode is arranged on the upper side of the discharge electrode.

Owner:HANGZHOU DAZHAN ELECTROMECHANICAL TECH CO LTD

Coal-fired power plant flue gas heat regenerative system and energy-saving water-saving ultra-clean discharging method

ActiveCN104930539AImprove solubilityImprove desulfurization efficiencyIndirect carbon-dioxide mitigationLump/pulverulent fuel preparationSlurryWater vapor condensation

The invention discloses a coal-fired power plant flue gas heat regenerative system and an energy-saving water-saving ultra-clean discharging method. The temperature of the flue gas is reduced to about 90-110 DEG.C through a low-temperature coal economizer, and the recycled flue gas heat heats primary and secondary wind entering a boiler through a steam air heaters, so that the first stage of heat regenerative cycles is achieved. The temperature of the flue gas at the outlet of a desulfurization tower is reduced to 30-40 DEG.C through a vacuum flash evaporation and solidification device and a low-temperature heat pump heat exchange device, and a part of water vapor of the flue gas is condensed and collected, so that water is saved. The low-temperature heat pump heat exchange device absorbs the latent heat released in flue gas sensible heat and condensation processes, and dry as-fired coal and air are heated, so that the second stage of heat regenerative cycles is achieved. A boiler slag discharge system recycles the waste heat of heat slag, and the as-fired coal is heated, so that the third stage of heat regenerative cycles is achieved. When the waste heat is not used up, the remained waste heat can be utilized, so that energy is saved. Low-temperature desulphurization slurry led out from the vacuum flash evaporation and solidification device is injected into the desulfurization tower, so that the desulphurization efficiency is improved, and an ultra-clean discharging objective is achieved.

Owner:SHANDONG UNIV +2

Process method for preparing polyoxymethylene dimethyl ethers

ActiveCN105566077AAvoid cloggingAchieve dehydrationOrganic compound preparationCarbonyl compound separation/purificationCyclic processLiquid water

The invention discloses a process method for preparing polyoxymethylene dimethyl ethers. The method includes the steps that formaldehyde gas is cooled to 100 DEG C and below, so that vapor is removed; dehydrated gas formaldehyde is directly absorbed by a mixture of polyoxymethylene dimethyl ethers DMM1-2 and polyoxymethylene dimethyl ethers DMM6-10 of different degrees of polymerization, then a reaction is conducted, polyoxymethylene dimethyl ethers DMM 3-5 are prepared, and DMM1-2 and DMM 6-10 with the DMM 3-5 separated continuously serve as raw materials and are recycled. According to the method, formaldehyde gas generated by methanol oxidation is cooled to 100 DEG C and below, vapor is condensed into liquid water, the purpose of dehydration is achieved, and due to the fact that water in the formaldehyde is removed before being absorbed by reactant, and the situations that a polycondensation reaction occurs and device is blocked by paraformaldehyde generated by formaldehyde polycondensation are avoided; the mixture of the DMM1-2 and DMM6-10 also participates in a polymerization reaction and a depropagation reaction in the cyclic process and is finally converted to the polyoxymethylene dimethyl ethers DMM3-5 of the target degree of polymerization. The method is simple in process and easy to operate, the speed for generating the DMM3-5 is high, the conversion rate of the DMM3-5 is high, and energy consumption and equipment investment are lowered.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

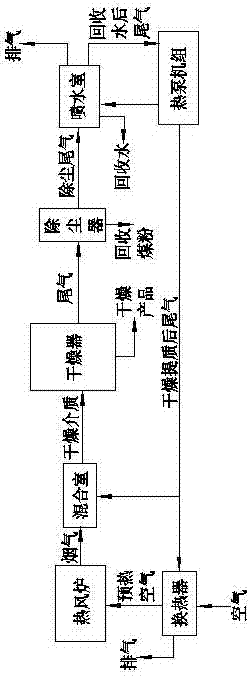

Lignite drying water recycling and drying tail gas recycling system

InactiveCN103575068AImprove recycling efficiencyPromote circulationDrying solid materials with heatDispersed particle filtrationWater useVolatiles

The invention relates to a lignite drying water recycling and drying tail gas recycling system which comprises a hot blast heater, a drier, a dry type deduster, a heat pump machine set, a mixing chamber and a water spraying chamber, wherein the mixing chamber is used for mixing fume of the hot blast heater and a recycled tail gas heated by the heat pump machine set into low-temperature hot fume to be used as a drying medium of the drier; the dried tail gas and the cold water sprayed out from a nozzle of the water spraying chamber are sufficiently mixed and subjected to heat-humidity exchange in the water spraying chamber; part of steam in the dried tail gas is condensed into water to be recycled; at the same time, visible heat and latent heat of vaporization are released; the cold water used in the water spraying chamber is supplied by the heat pump machine set; the water recycled in the water spraying chamber flows out through an overflowing tube and is collected. The fume discharged from the water spraying chamber is heated by an air cooling condenser of the heat pump machine set, is subsequently fed into the mixing chamber, is mixed with the fume generated from the hot blast furnace, and is subsequently used as the drying medium of the drier. The system is at a low temperature and is dry, and the oxygen content of the drying medium is low, so that volatiles in coal are prevented from being lost, and precious water resource is recycled.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

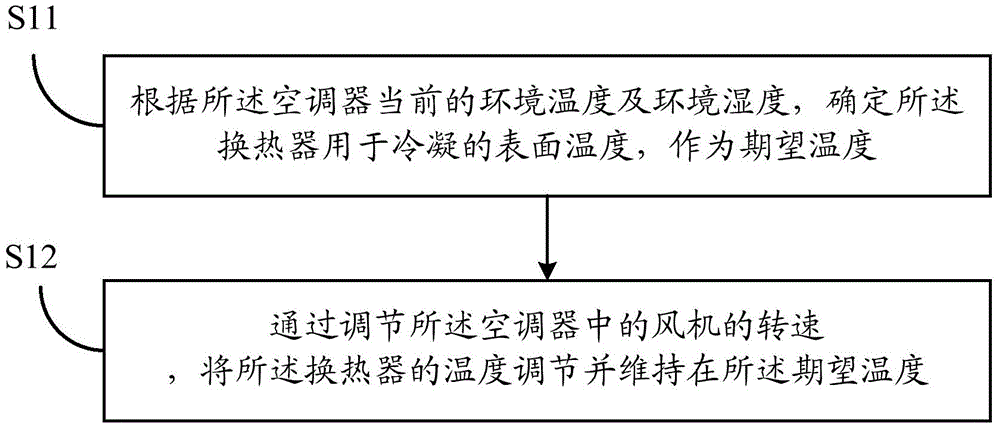

Method and device for collecting condensed water to clean air conditioner on basis of wind speed regulation

ActiveCN104833052ATemperature rise or fallAchieve cleanlinessMechanical apparatusCondensate preventionLiquid stateEngineering

The invention provides a method and a device for collecting condensed water to clean an air conditioner on the basis of wind speed regulation. A heat exchanger in the air conditioner is used for condensing water vapor in the air conditioner into liquid state water; dirt attached on the surface of the heat exchanger is removed; the surface temperature, used for condensing, of the heat exchanger is determined according to the current environment temperature and the environment humidity of the air conditioner and is used as the expected temperature; through regulating the rotating speed of a fan in the air conditioner, the temperature of the heat exchanger is regulated and is maintained at the expected temperature. The optimum temperature of the heat exchanger in the current environment is determined through analyzing the influence of the environment temperature and environment humidity on a dew point, so that the sufficient quantity of condensing water can be obtained to clear the dust and dirt on the surface of the heat exchanger. When the actual temperature of the heat exchanger is different from the optimum temperature, the regulation on the rotating speed of the fan is utilized for realizing the temperature rise or reduction of the heat exchanger; the temperature of the heat exchanger is maintained at the determined optimum temperature; the automatic cleaning and the self-adaptation cleaning of the heat exchanger are realized; in addition, the cleaning effect of the heat exchanger is ensured.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com