Patents

Literature

223 results about "Boiler slag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boiler slag is a coarse, granular, incombustible by-product of coal combustion and is thus classified as a coal combustion byproduct. It is angular, dense, and very hard. Boiler slag is only produced in a wet-bottom boiler, as this boiler has a special design that keeps bottom ash in a molten state until it is removed.

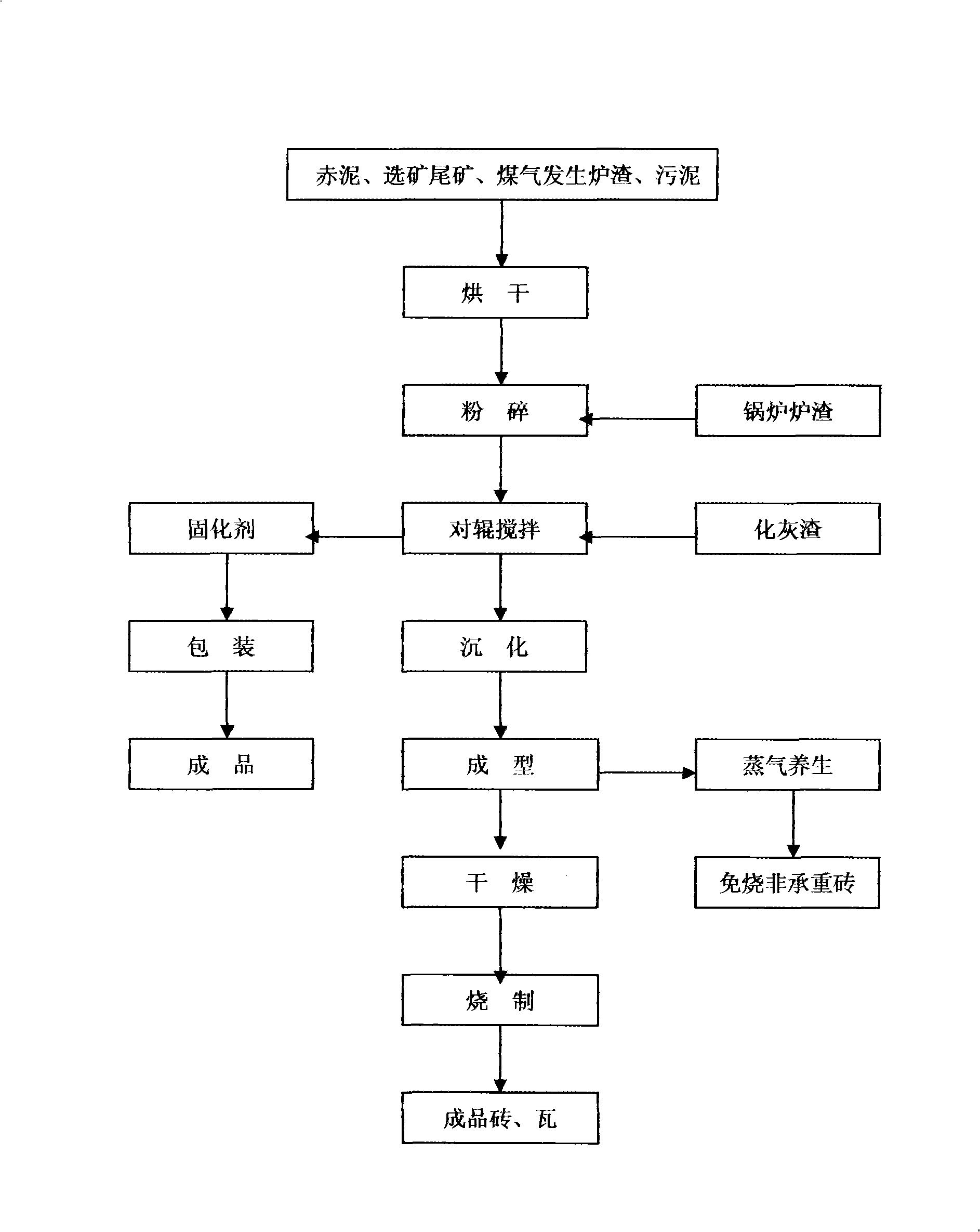

Process and method for converting waste slag wholly of aluminum industry into ecological building material

The invention belongs to a method for utilizing resources. The method utilizes the matter characteristics of solid wastes (six kinds of waste residues) such as red mud(the sintered method and the Bayer method), boiler slag, ore dressing tailings, ash and gas generation slag, which are generated during the manufacturing process in aluminum industry, and converts the solid wastes into a novel road material and construction walling material by the processes such as drying, crushing, reasonable proportioning, machine shaping(grinding and extrusion) and consolidation or sintering. The method is characterized in that the utilization ratio of the waste residues is 100 percent. The waste residues comprise the following compositions: (1) the produced road material-curing agent, which can be used to reinforce a highway subgrade and bases of road surface substrates(substrate and subbase) and buildings and completely replace cement, lime and sandstone materials, and the road material can meet prior national(industrial) standards and environmental protection standards in performance; and (2) the produced construction walling materials-non supporting brick, supporting brick, air brick, hollow building block, common tile, glazed roof tile and andorful tile, which are superior to the prior national standards in performance. The material obtained by the invention has the characteristics of energy conservation, thermal insulation, high strength, corrosion resistance, efflorescence resistance and no pollution.

Owner:王文举

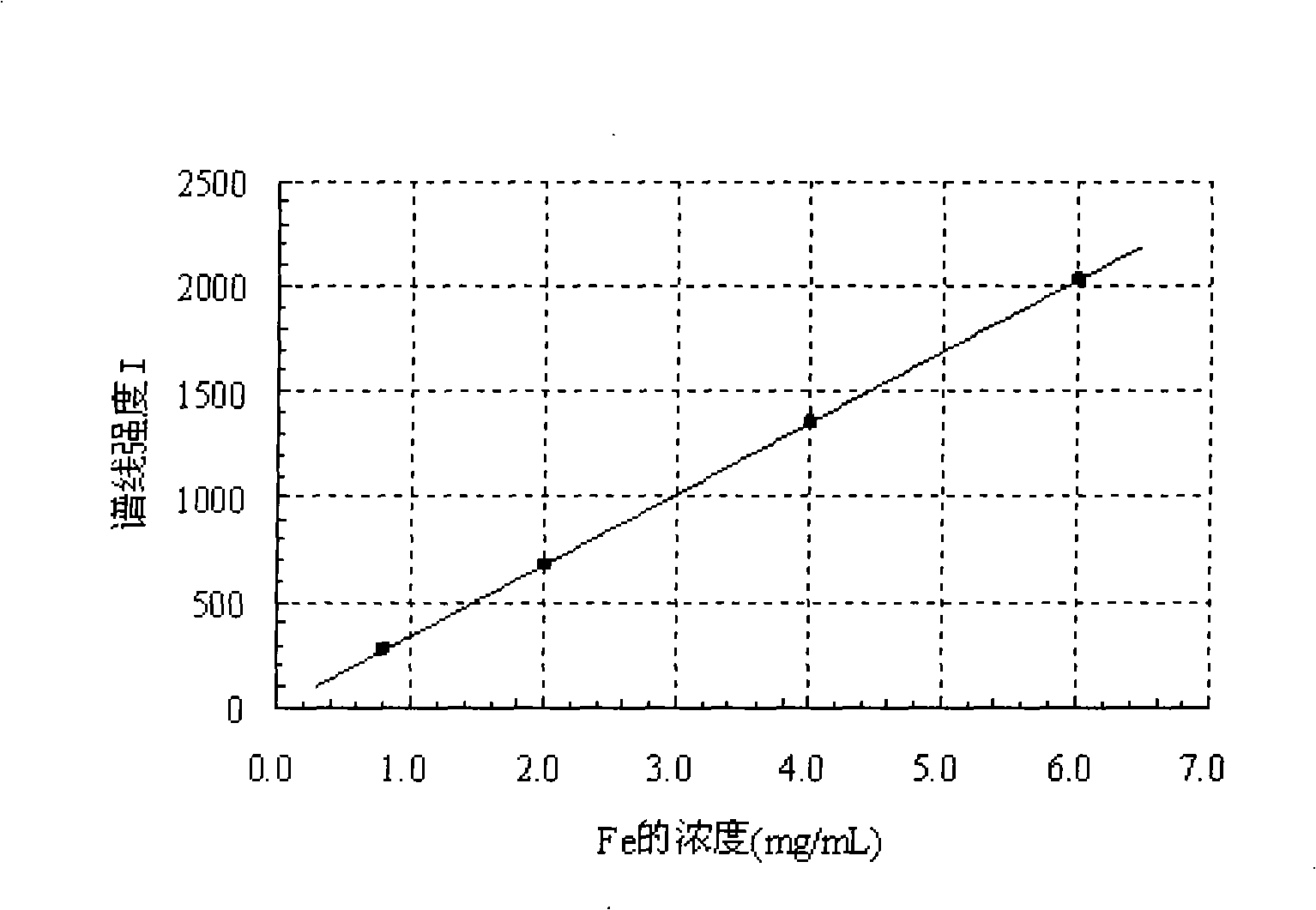

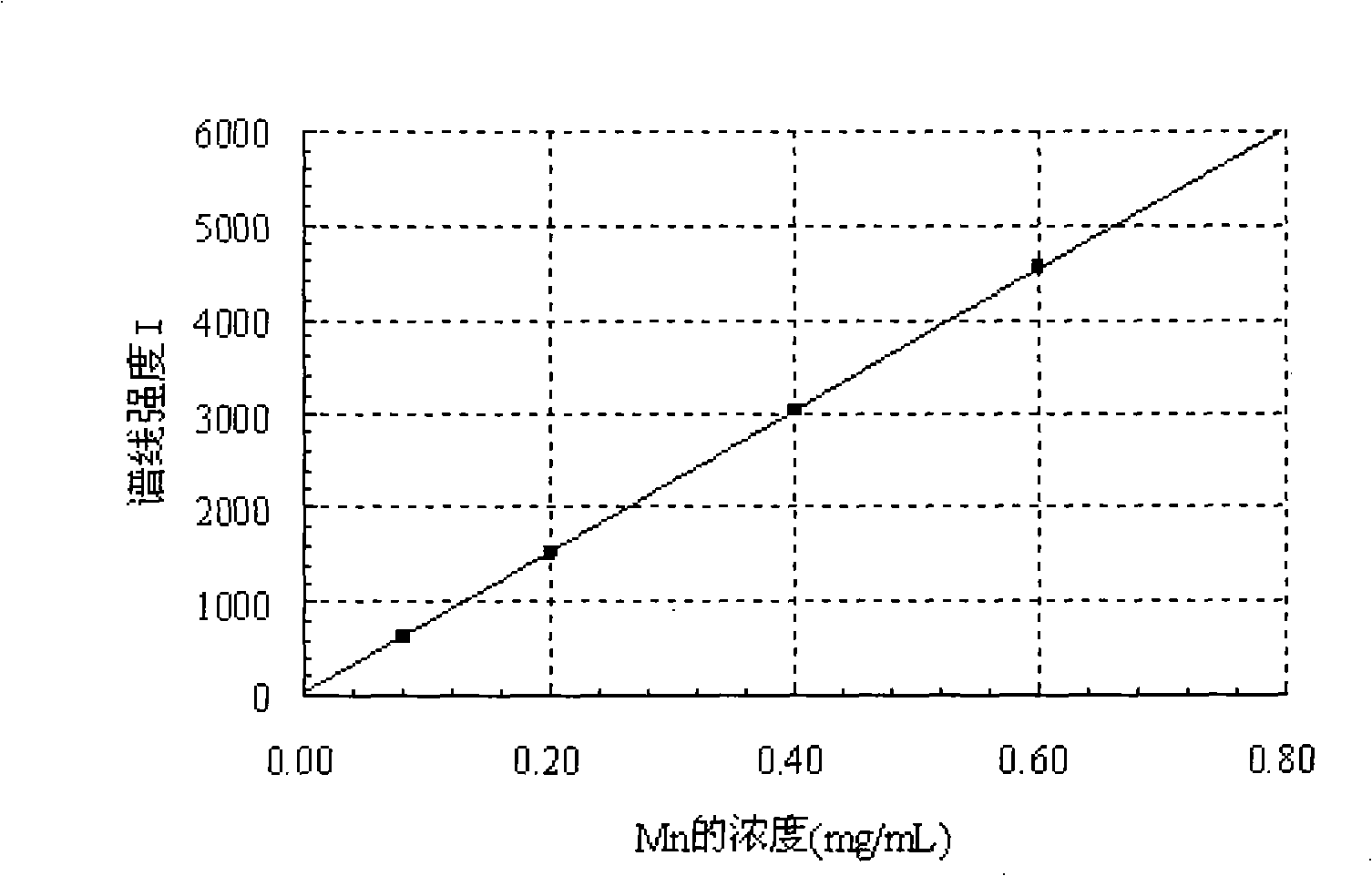

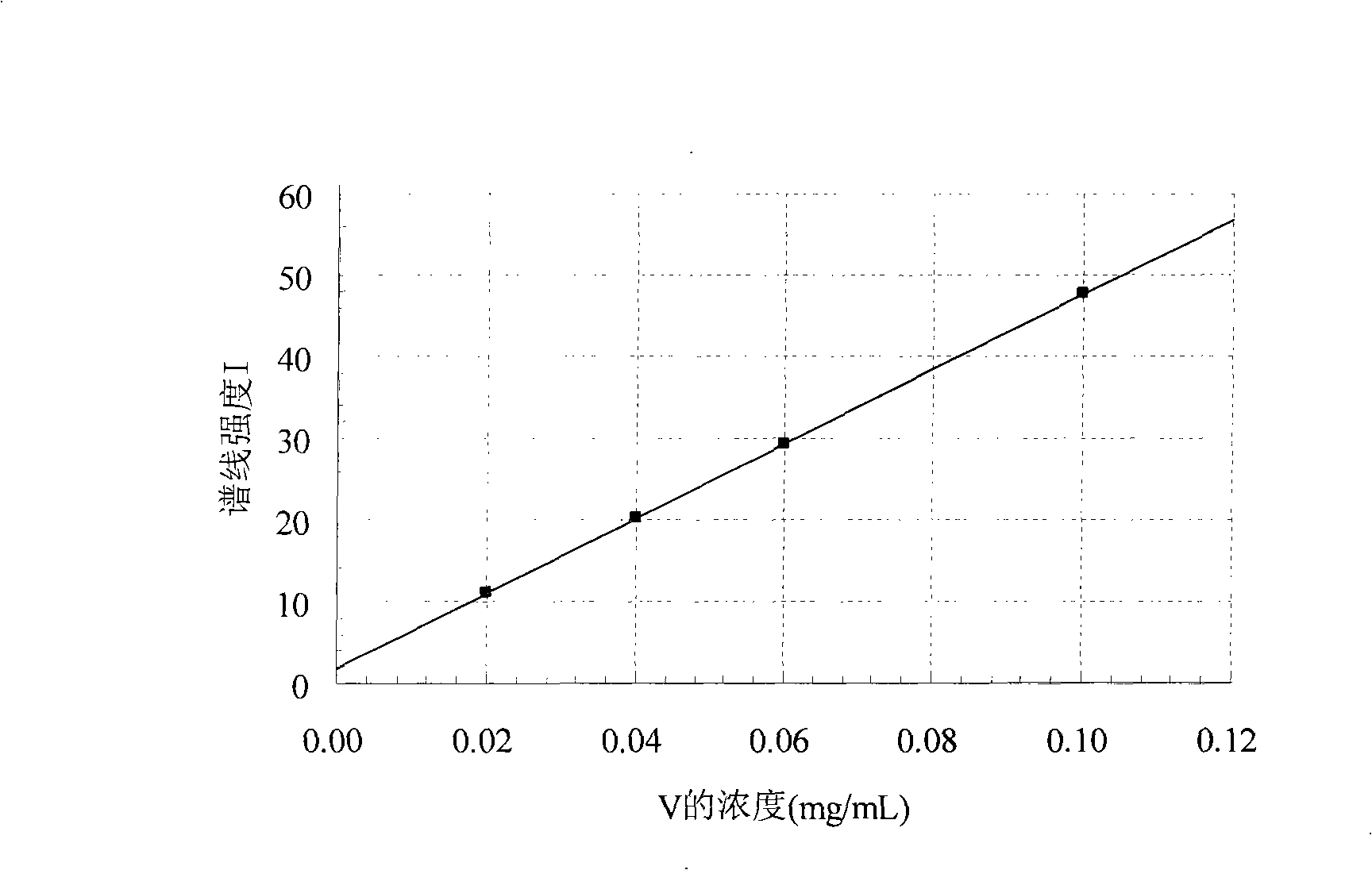

Method for measuring trace elements in high titanium high boiler slag

InactiveCN101349648ABreak down completelyShort processing timeAnalysis by thermal excitationTrace elementBoiler slag

The invention relates to a method for measuring microelements in high titanium blast furnace slag, which comprises the following steps: firstly, adopting an alkali fusion method to pre-process samples, and leading the samples to be totally conversed into soluble salt, and preparing into sample solution, secondly, preparing standard solution of iron, manganese, vanadium and phosphor with different concentrations, thirdly, respectively measuring the spectral line strength of calcium in the standard solution of iron, manganese, vanadium and phosphor with different concentrations, utilizing the concentration of elements to be the abscissa and the spectral line strength to be the longitudinal coordinate to draw a working curve, fourthly, measuring the intensity of the spectral lines of iron, manganese, vanadium and phosphor in sample solution under the condition which is the same to the step three, and calculating and assuring the content of the four elements in each sample solution according to the working curve. The invention has the advantages that the method is simple and fast, which has little dosage of agents and samples, and can simultaneously measure a plurality of elements. The method shortens analysis time, and lowers test cost.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Settable Building Material Composition Including Landfill Leachate

InactiveUS20110232532A1High compressive strengthReduce Shrinkage ProblemsSolid waste managementCement productionBottom ashLitter

A composition capable of setting to produce a building material is disclosed. The composition can include from 1% to 30% by weight of an activator, from 1% to 55% by weight of a pozzolan, such as fly ash; from 40% to 90% by weight of an aggregate; and liquid landfill leachate in a sufficient amount such that the composition sets to a building material having a compressive strength of at least 2 MPa, wherein all weight percentages are percent by weight of the total composition. The liquid landfill leachate replaces all or part of the tap water in a conventional composition for forming a building material. The liquid landfill leachate can be recovered after a liquid (typically water) percolates through a landfill and contacts at least one landfilled coal combustion product selected from fly ash, bottom ash, boiler slag, and flue gas desulfurization material. The building material can be a concrete, or a masonry unit.

Owner:WISCONSIN ELECTRIC POWER

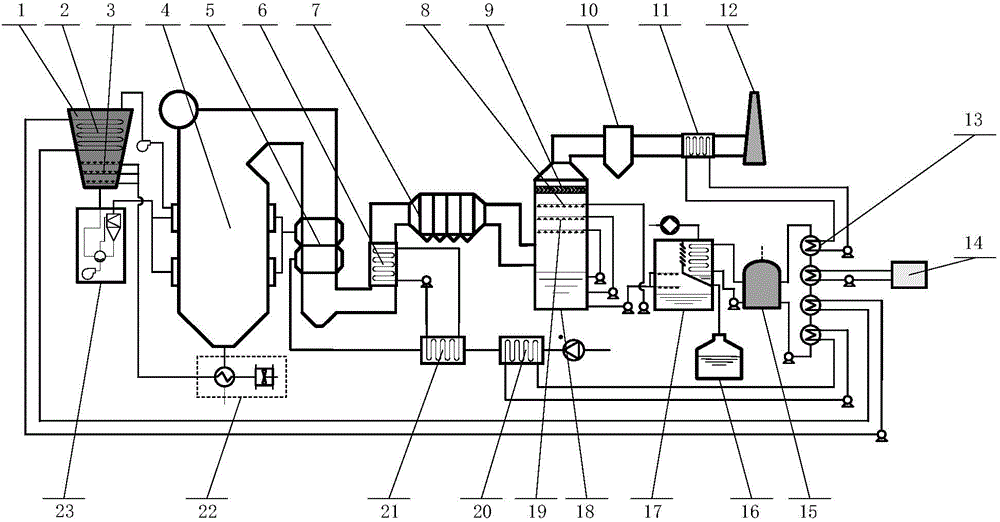

Coal-fired power plant flue gas heat regenerative system and energy-saving water-saving ultra-clean discharging method

ActiveCN104930539AImprove solubilityImprove desulfurization efficiencyIndirect carbon-dioxide mitigationLump/pulverulent fuel preparationSlurryWater vapor condensation

The invention discloses a coal-fired power plant flue gas heat regenerative system and an energy-saving water-saving ultra-clean discharging method. The temperature of the flue gas is reduced to about 90-110 DEG.C through a low-temperature coal economizer, and the recycled flue gas heat heats primary and secondary wind entering a boiler through a steam air heaters, so that the first stage of heat regenerative cycles is achieved. The temperature of the flue gas at the outlet of a desulfurization tower is reduced to 30-40 DEG.C through a vacuum flash evaporation and solidification device and a low-temperature heat pump heat exchange device, and a part of water vapor of the flue gas is condensed and collected, so that water is saved. The low-temperature heat pump heat exchange device absorbs the latent heat released in flue gas sensible heat and condensation processes, and dry as-fired coal and air are heated, so that the second stage of heat regenerative cycles is achieved. A boiler slag discharge system recycles the waste heat of heat slag, and the as-fired coal is heated, so that the third stage of heat regenerative cycles is achieved. When the waste heat is not used up, the remained waste heat can be utilized, so that energy is saved. Low-temperature desulphurization slurry led out from the vacuum flash evaporation and solidification device is injected into the desulfurization tower, so that the desulphurization efficiency is improved, and an ultra-clean discharging objective is achieved.

Owner:SHANDONG UNIV +2

Low-cost porous ceramic sound absorbing material and preparation process thereof

InactiveCN104671821AAchieving low-carbon productionReduce the formation temperatureSolid waste disposalCeramicwareRed mudPorous ceramics

The invention relates to a low-cost porous ceramic sound absorbing material and a preparation process thereof. The ceramic sound absorbing material is prepared from the following raw materials in percentage by weight: 23-28 percent of combination-process red mud, 23-28 percent of steel slags, 13-18 percent of coal gangue, 8-12 percent of carbide slag, 8-12 percent of boiler slags, 3-8 percent of quartz sand and 8-12 percent of a 10% sodium hydroxide solution. By taking the metallurgical industrial waste red mud and steel slags as main raw materials, the sound absorbing material disclosed by the invention can be used for solving the problem of noise pollution of subways, urban roads, expressways and railways.

Owner:HENAN UNIV OF SCI & TECH

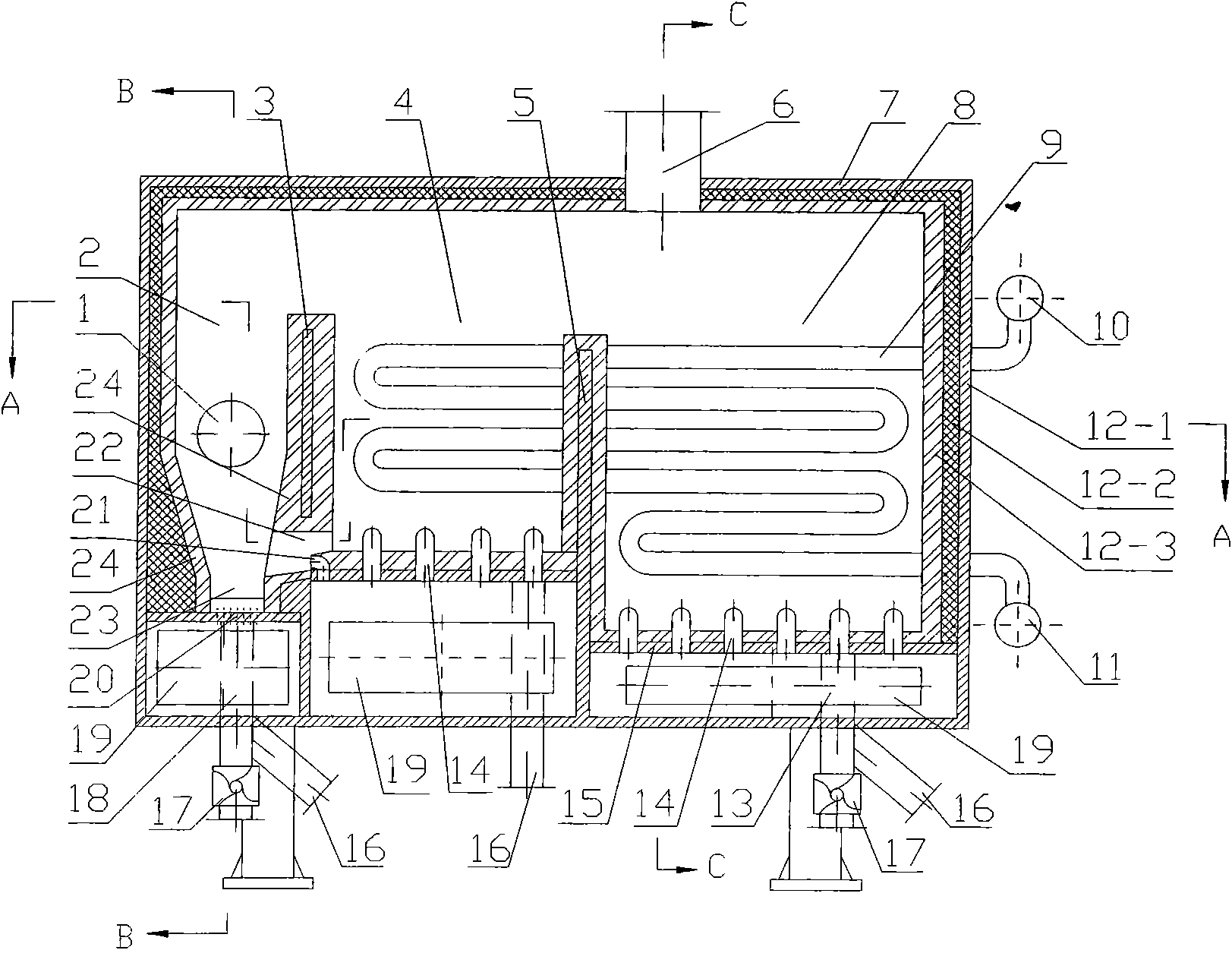

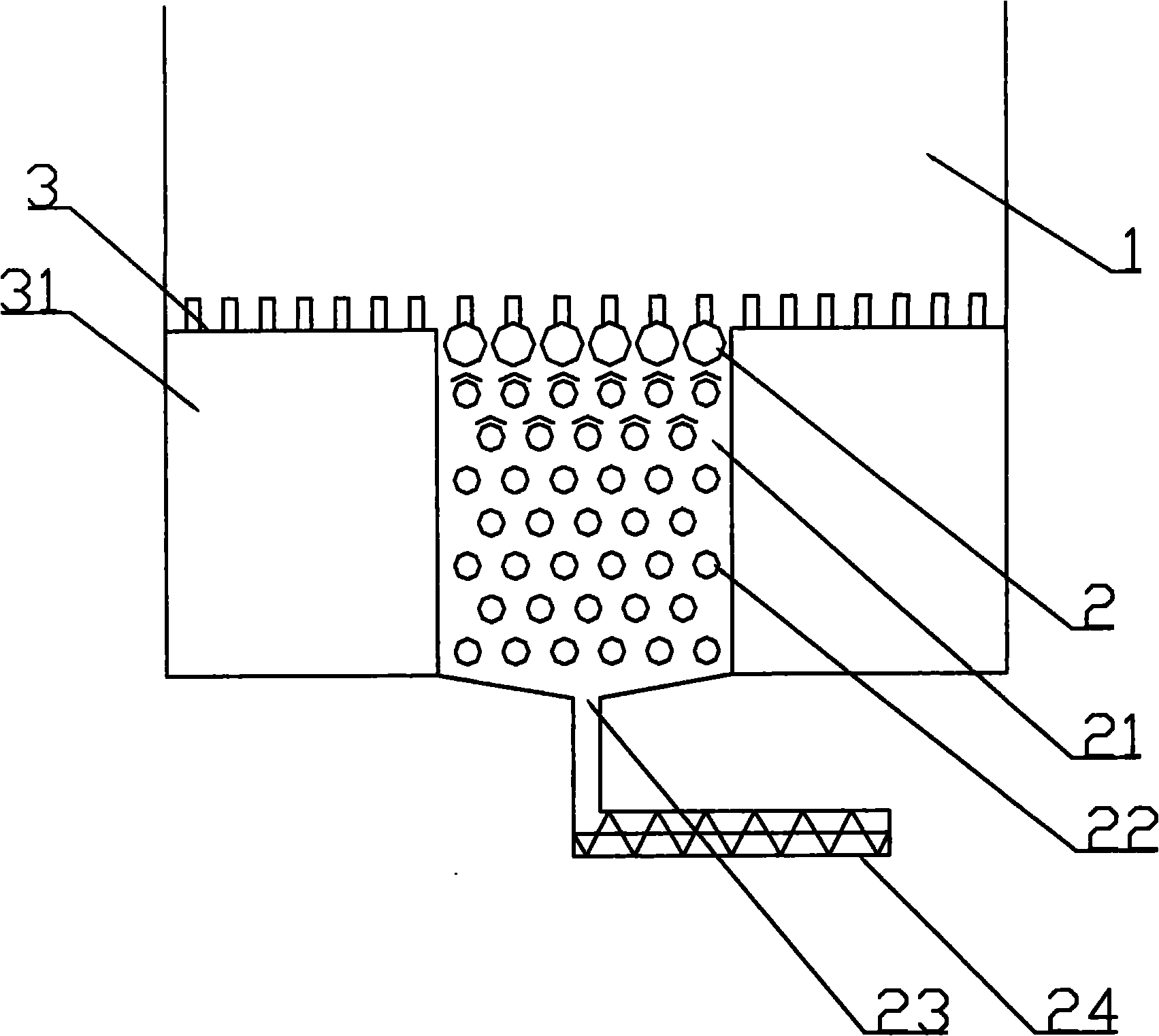

Double-separation type fluidized bed slag cooler

InactiveCN101943403AReduce the operating air volumeImprove operational safetyFluidized bed combustionApparatus for fluidised bed combustionFluidized bedBoiler slag

The invention relates to a double-separation type fluidized bed slag cooler which comprises a main body (7), an air chamber (19), a slag circulating channel (22) and the like, wherein a first separation wall (3) and a second separation wall (5) are arranged in the main body (7) of the slag cooler and separate the inner space of the main body (7) of the slag cooler into 3 cooling bins (a separation bin (2), a circulating bin (4) and a water cooling bin (8)) the upper parts of which are communicated with each other; the first separation wall (3) is arranged between the separation bin (2) and the circulating bin (4); the bottom of the first separation wall (3) is provided with the slag circulating channel (22); and the slag circulating channel (22) is in a cascade plate structure. By carrying out two-stage separation on the bottom slag and arranging a slag circulating cooling loop between the separation bin (2) and the circulating bin (4), the invention reduces the air quantity for operation, enhances the adaptability to the particle size distribution of the boiler slag, increases the water cooling proportion and enhances the operation safety and reliability of the slag cooler.

Owner:CHONGQING UNIV

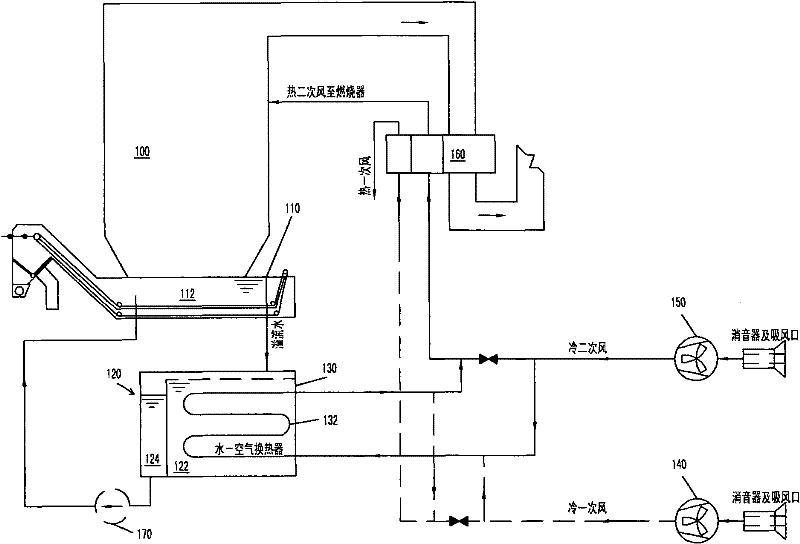

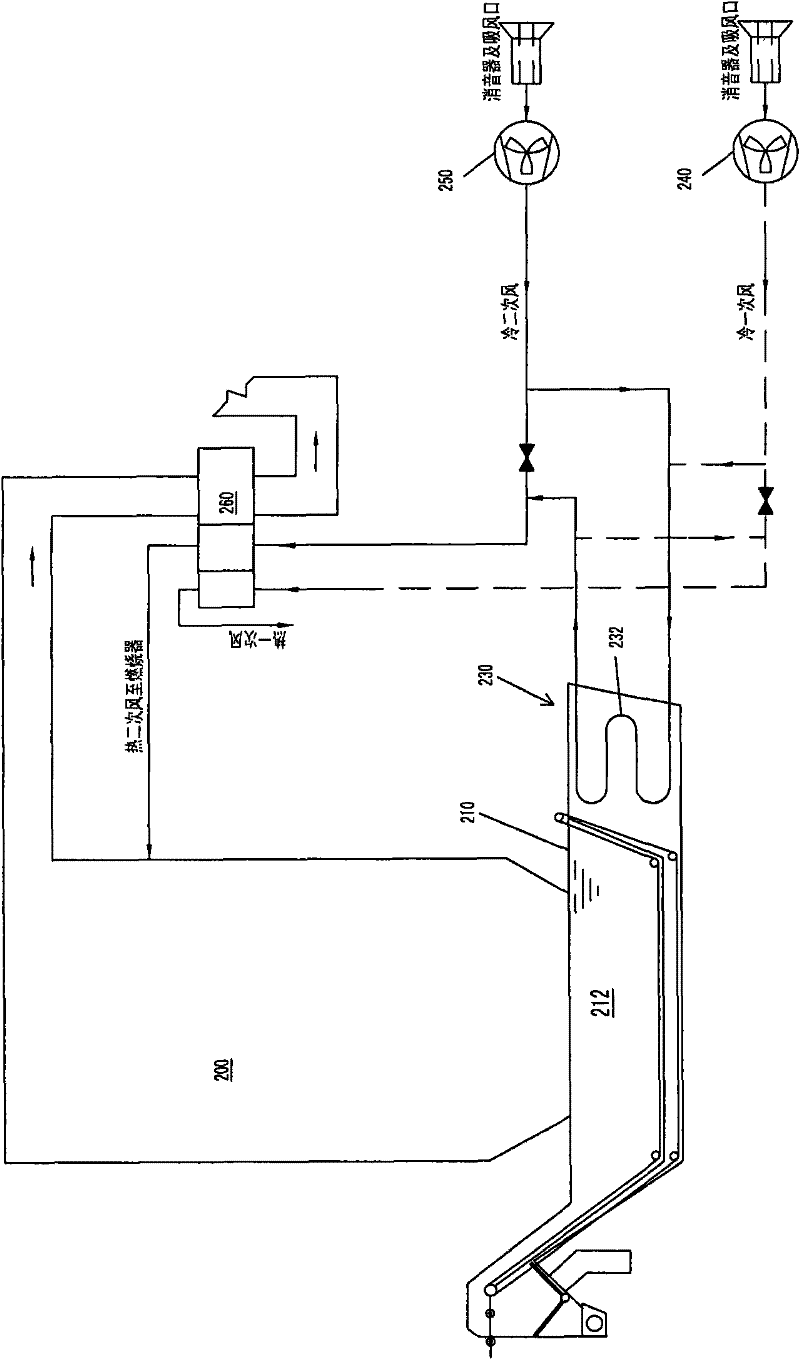

Boiler wet slag removal system

InactiveCN102287835AIncrease power generationReduce fuel consumptionCombustion processMachines/enginesAir preheaterBottom ash

The invention relates to a boiler wet slag removal system, which comprises a slag extractor and a heat exchanger. The slag extractor is located under the boiler and has a water tank for receiving boiler bottom slag. The heat exchanger includes a heat exchange surface, one side of the heat exchange surface introduces the water in the water tank as the first heat exchange medium, and the other side of the heat exchange surface is the flowing second heat exchange medium to absorb the water in the water tank energy. In one solution of the present invention, the second heat exchange medium can be air, which is provided by the blower or the primary blower of the boiler, and is sent to the air preheater for the boiler together with the cold air of the blower or the primary blower after being heated . In another solution of the present invention, the second heat exchange medium can be condensed water, which is provided by one or more low-pressure heaters of the steam turbine condensate system, and is heated and delivered to one or more low-pressure heaters . In this way, the waste heat of the slag can be recovered, which simplifies the structure of the wet slag removal system and reduces the water consumption.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

Aerated concrete building block and preparation method thereof

InactiveCN101845866ASolving activityAddress usability issuesSolid waste managementBuilding componentsAluminium powderBoiler slag

The invention discloses an aerated concrete building block which is prepared from the following raw materials in parts by weight: 45 to 55 parts of fly ash, 20 to 30 parts of boiler slag, 3 to 6 parts of phosphogypsum, 17 to 19 parts of quicklime, 1 to 3 parts of cement and 0.07 to 0.085 part of aluminium powder. The preparation method of the aerated concrete building block comprises the following steps of: (1) after mixing the raw materials of the boiler slag and the phosphogypsum fully, adding water, grinding, preparing mixed slurry, adding the water into the fly ash, preparing fly ash slurry, mixing the mixed slurry, the fly ash slurry, the quicklime, the cement and the aluminium powder fully and evenly and preparing a mixed material; (2) pouring the mixed material obtained in the step (1), molding and cutting into a building block blank after precuring at the temperature of 30 to 35 DEG C for 1.5 to 2.5 hours; and (3) steaming and curing the building block blank to obtain the aerated concrete building block.

Owner:GAOMI FURI BUILDING MATERIALS

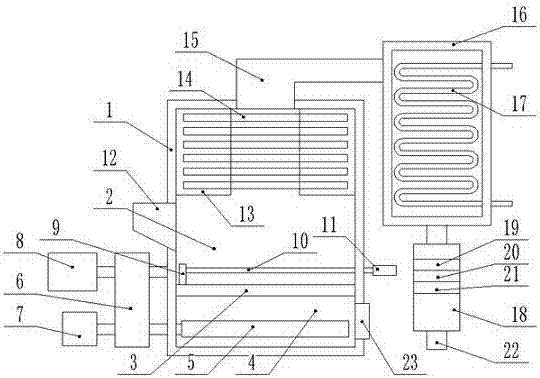

Energy-saving and environment-friendly boiler with preheating function

InactiveCN107421116AIncrease the burning areaBurn fullyCombustion processIndirect carbon-dioxide mitigationCombustionBoiler slag

The invention discloses an energy-saving and environment-friendly boiler with a preheating function. The energy-saving and environment-friendly boiler comprises a shell, a grate, a boiler slag collection trough, a circulating pump and a fan. A vertical material uniformization plate is arranged on the upper surface of the grate. A material passing opening penetrating the two sides is formed in the material uniformization plate. A heat absorption pipe is arranged in the boiler slag collection trough and is located at the bottom of the boiler slag collection trough, and the outer end of the heat absorption pipe communicates with a heat exchanger. Multiple heat conduction columns are horizontally inserted into a water jacket. The other end of a smoke discharging pipe communicates with a waste heat collection box. A heat exchange coiled pipe is mounted in the waste heat collection box. The bottom of the waste heat collection box communicates with a purification box. According to the energy-saving and environment-friendly boiler, the arranged material uniformization plate moves to uniformly pave dye, the combustion area of fuel is large, and contact of the fuel and air is sufficient; and heat in smoke is absorbed by the heat exchange coiled pipe and used for preheating inner heating water, the water temperature increase speed is increased, and the heating efficiency of hot water in the boiler is guaranteed.

Owner:YANCHENG CITY LONG XIANG MACHINERY MFG PLANT

Biomass gas and coal dust mixed combustion process

InactiveCN101881455ALower temperature levelReduce slaggingBurnersCombined combustion mitigationCoal dustSolid particle

The invention belongs to the technical field of biomass power generation, and particularly relates to a new biomass gas and coal dust mixed combustion process. The process adopts a biomass gasification system, a high-temperature dust removal system, a coal dust boiler and an auxiliary system thereof; and the biomass is gasified in a gasification furnace, the generated biomass gasification gas enters the high-temperature dust removal system, solid granules are removed, and then the high-temperature biomass gas is sprayed into the coal dust boiler and is combusted in the coal dust boiler. The process realizes efficient and reasonable utilization of fuels with low heat value, can avoid the problems of boiler slag formation and monitoring and the like produced in a direct mixed combustion process of the biomass, effectively reduce the discharge of pollutants such as NOX and the like and improve the combustion efficiency, and meanwhile can prevent the coal dust components from being affected, ensure later effective utilization and fulfill dual purposes of energy conservation and environmental protection.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

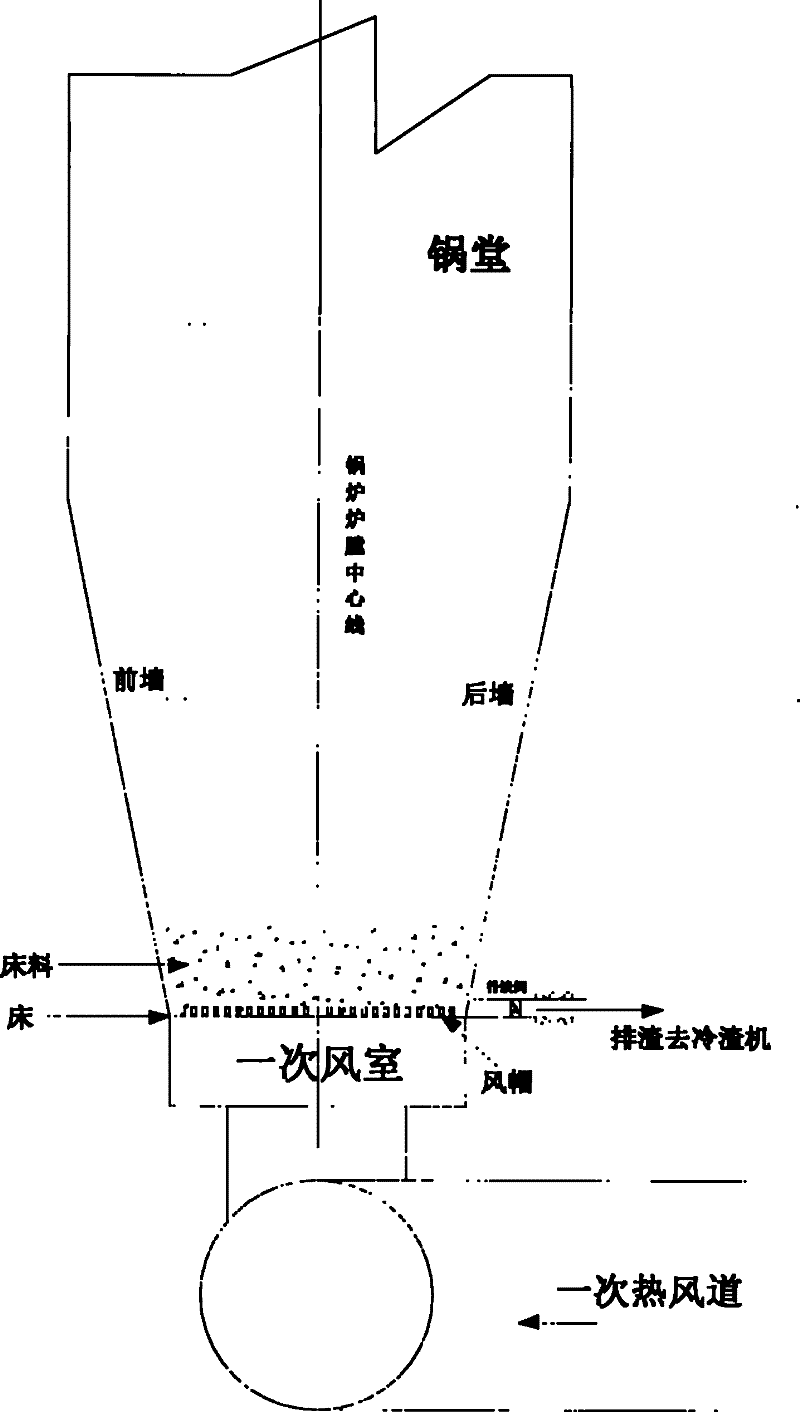

Circulating fluidized bed boiler bottom slag cooling system

ActiveCN101949537AImprove running stabilityReduce running power consumptionFluidized bed combustionApparatus for fluidised bed combustionAir preheaterFluidized bed

The invention discloses a circulating fluidized bed boiler bottom slag cooling system, and relates to combustion equipment bottom slag cooling technology. The system mainly comprises a slag cooler and a bottom slag thickness separator. The bottom slag thickness separator comprises a barrel, a bottom slag inlet, an air inlet, an air outlet and a bottom slag outlet. The bottom slag inlet is connected with a slag discharge port at the bottom of the circulating fluidized bed boiler through a boiler slag conveying pipe; the bottom slag outlet is connected with the inlet of the slag cooler; and the air inlet is connected with a secondary air pipe of the circulating fluidized bed boiler. Secondary air from an air pre-heater enters the bottom slag thickness separator through the air inlet to exchange heat with bottom slag before entering the hearth of the boiler and takes away fine granule materials in the bottom slag, finally the fine granule materials are returned to the hearth of the boiler through the air outlet to participate in material circulation, and the coarse granular slag falls to the slag cooler on the lower part for further cooling. The system can realize selective slag discharge, and solves the problems of local coking of the fluidized bed slag cooler and the like so as to further improve the running stability of the boiler.

Owner:TAIYUAN BOILER GROUP +1

Preparation method of insulating baking-free brick

The invention relates to a preparation method of an insulating baking-free brick. The preparation method comprises the following steps: (1) premixing: adding water into raw materials including gangue, steel slag, gasification slag and boiler slag according to a certain mass ratio and stirring until the materials are uniformly mixed; (2) aging; (3) moulding; (4) press-fitting; (5) steam curing; and premixing and adding CaO and Na2SO4 as excitant, and adding a binder into a heat-insulation layer. By the preparation method, strength of the insulating brick is greatly enhanced; and gangue and steel slag, etc. are changed from waste into valuable things so as to save resources and protect the environment. The preparation method of the invention is simple and feasible, and is easy to realize. Strength of the brick prepared by the method is 3 times higher than strength of a common brick. The brick of the invention has huge market potential and wide prospect.

Owner:岳佐星

Novel haydite concrete light-weight building block walling material and preparation method thereof

ActiveCN102108026ASufficient sourceSave resourcesSolid waste managementCeramicwareFoaming agentExpanded clay aggregate

The invention discloses a novel haydite concrete light-weight building block walling material and a preparation method thereof. The walling material is prepared from a cementing material, haydite, boiler slag, water and silica sand powder. The preparation method comprises the following steps: drying building sand of which the content of silicon dioxide is greater than 90%, or crushed quartzite, and grinding to obtain silica sand powder of which the specific area is 400-500m<2> / kg; weighing 0.11-0.43 part of silica sand powder, 1 part of cementing material, 1-2.6 parts of tailings, 1.3-3.4 parts of haydite, 1.5-3.5 parts of boiler slag, 0.30-0.50 part of water and 0.0021-0.0050 part of foaming agent; adding the silica sand powder, cementing material, tailings, haydite, boiler slag and water into a forced mixer, evenly mixing, quickly adding the foaming agent, and mixing for 30 seconds; and evenly filling the mixture in a die, carrying out extrusion forming, carrying out natural curing or atmospheric steam curing, and curing at 175-190 DEG C under high pressure for 2-6 hours, thereby obtaining the walling material.

Owner:中山建华墙体材料有限公司

Method for reducing contamination of high-sodium coal

InactiveCN105670732ASolve contaminationSolve slaggingSolid fuelsLump/pulverulent fuel preparationHigh sodiumSodium silicoaluminate

The invention relates to a method for reducing contamination of high-sodium coal. The method comprises the following steps: breaking the high-sodium coal and an ash fusion point regulating agent and screening, then mixing the high-sodium coal with the ash fusion point regulating agent so that the ash composition of the mixture meets certain conditions, then putting the mixture into a boiler for burning, and controlling the temperature and excess air coefficient of the burning boiler; and starting a boiler slag removing system for removing slag. The method has the advantages that the high-sodium coal is combined with the ash fusion point regulating agent in different ratios, so that the composition ratio of each ash of a mixed ash sample is changed, the ratio of contents of various elements is regulated, especially the ratio of silicon and aluminum elements is improved, an ash fusion point of the mixed ash sample rises, the sodium element migrates into sodium silicate and sodium silicoaluminate and is discharged outside along with coal residues, and thus the problems of contamination, scorification and corrosion of the high-sodium coal during burning in the boiler are solved; and meanwhile, the technology is simple, the operation is safe, and the investment is low.

Owner:TAIYUAN UNIV OF TECH

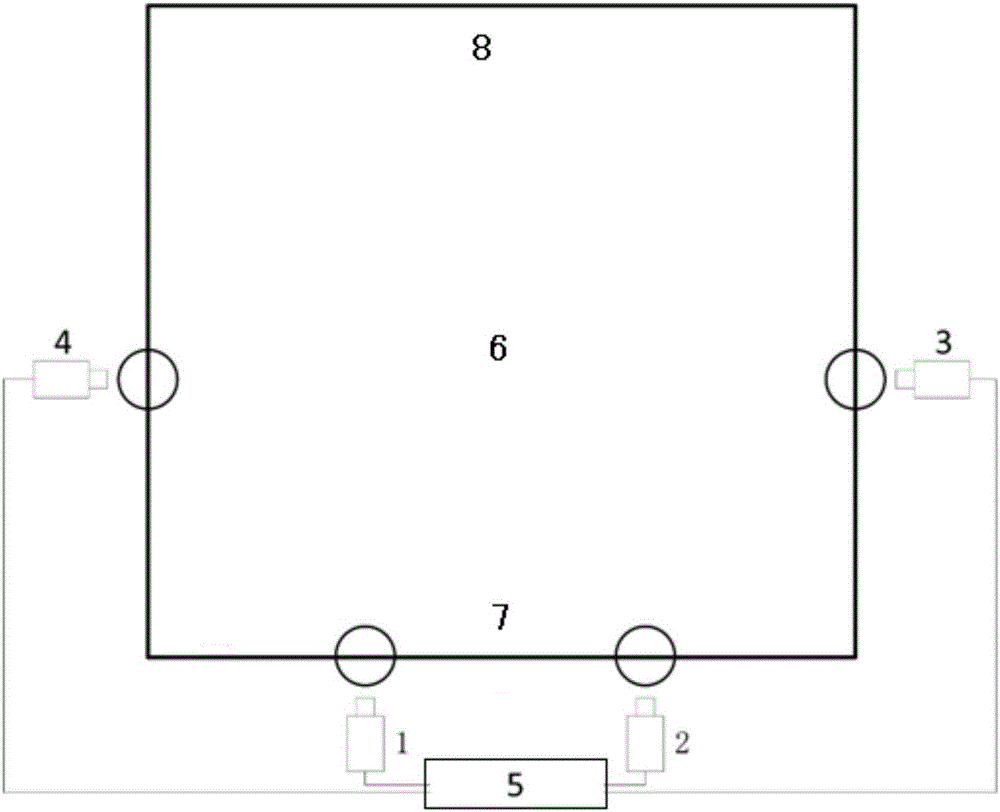

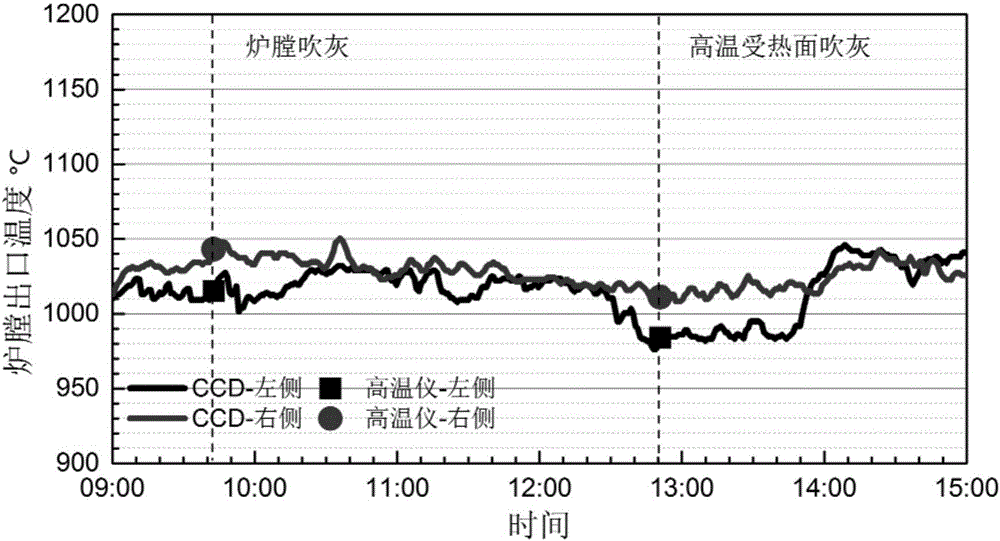

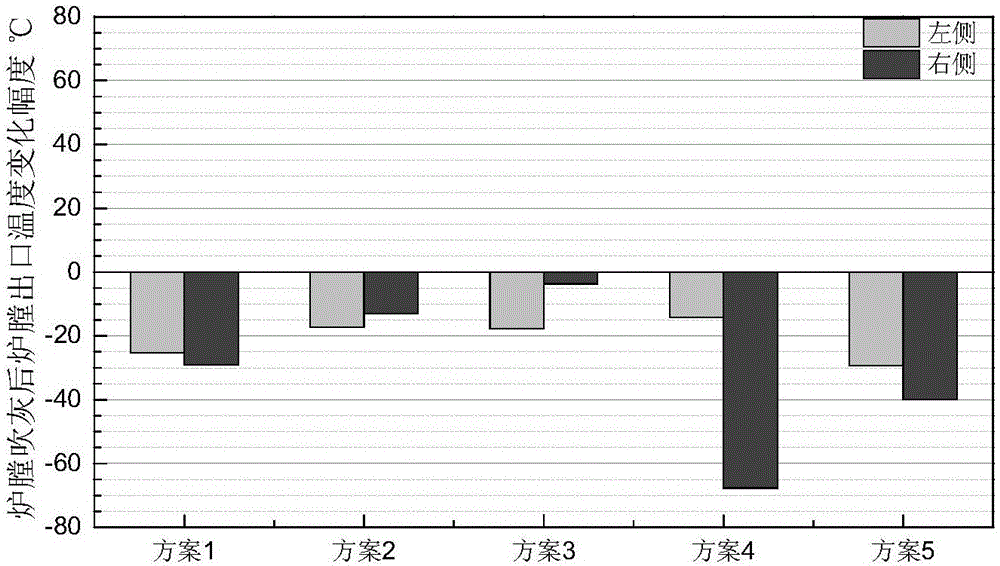

Boiler slagging condition monitoring and controlling methods based on outlet temperature of combustion chamber

ActiveCN106247308ACleanliness reflectsReflect slagging characteristicsBoiler indication operationsBoiler controlCombustion chamberBoiler slag

The invention discloses a boiler slagging condition monitoring method based on the outlet temperature of a combustion chamber. The monitoring method includes the steps of 1, detecting the outlet temperature of the combustion chamber; 2, calculating the temperature change before and after soot blowing and the temperature rising rate after soot blowing of an outlet of the combustion chamber according to detection in the step 1; and 3, judging that combusted coal tends to form slag when the temperature change is greater than 50 DEG C and the temperature rising rate is greater than 5 DEG / h, and judging that the combusted coal is not suitable for long-term combustion and adjusting the coal type when the temperature change is greater than 80 DEG C and the temperature rising rate is greater than 10 DEG / h. The invention further provides a boiler slagging condition controlling method based on the outlet temperature of the combustion chamber. According to the monitoring method and the controlling method, scientific use of a soot blower can be effectively guided, the outlet temperature of the combustion chamber can be continuously recorded, the temperature change before and after soot blowing and the temperature rising rate after soot blowing of the combustion chamber can be calculated, the use time of the soot blower can be further obtained, and the cleanliness degree of a water-cooled wall and the slagging characteristics of the coal type can be reflected.

Owner:ZHEJIANG UNIV

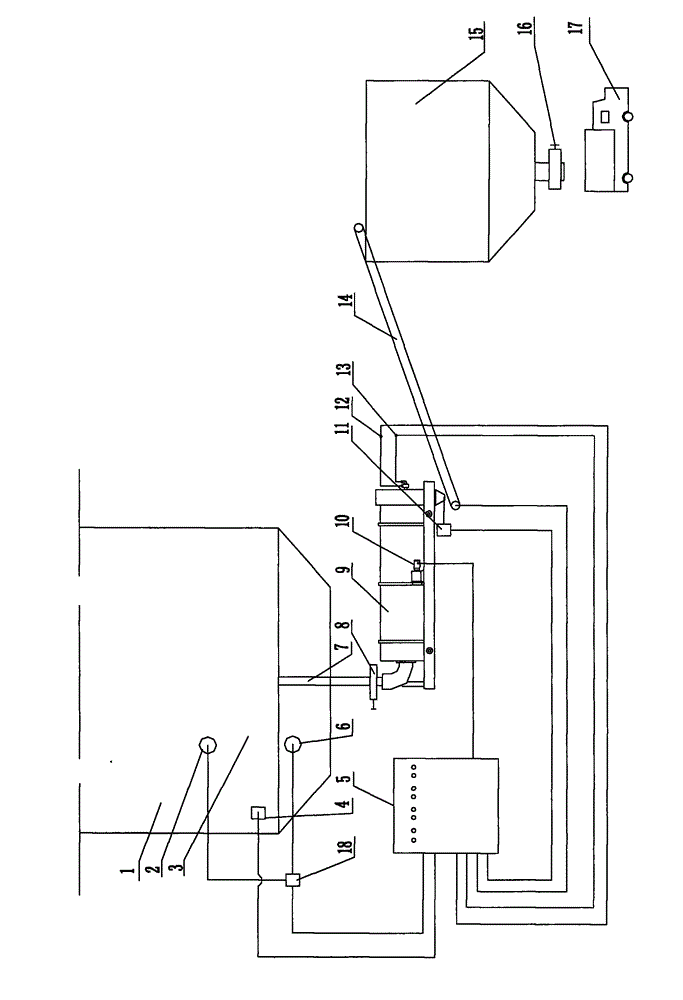

Control system and control method for material bed of circulating fluidized bed boiler

ActiveCN102944011ARealize chain controlReal-time control of cooling waterFluidized bed combustionApparatus for fluidised bed combustionAutomatic controlCompartment pressure

The invention discloses a control system and a control method for a material bed of a circulating fluidized bed boiler, and belongs to the technical field of boiler and automatic control. The control system comprises a hearth pressure gauge, an air compartment pressure gauge, a material bed thermometer, a slag cooler slagging thermometer, a slag cooler water outlet thermometer, a slag cooler water inlet thermometer, a slag cooler drive motor, and a PLC control system. The hearth pressure gauge and the air compartment pressure gauge are connected to a material bed differential pressure transmitter, which transmits electrical signals to the PLC control system; the slag cooler slagging thermometer, the slag cooler water outlet thermometer and the slag cooler water inlet thermometer send electrical signals to the PLC control system; and the PLC control system sends electrical signals to a slag conveying device and the slag cooler drive motor. The invention is safe, reliable and convenient for operation, and can improve utilization efficiency of boiler slag waste heat and production efficiency, and realize automatic control of slagging and real-time monitor for boiler material bed, so as to reduce production cost and labor intensity of operator, and facilitate control of the slag cooler to recover waste heat from high temperature slag.

Owner:德阳劲达节能科技有限责任公司

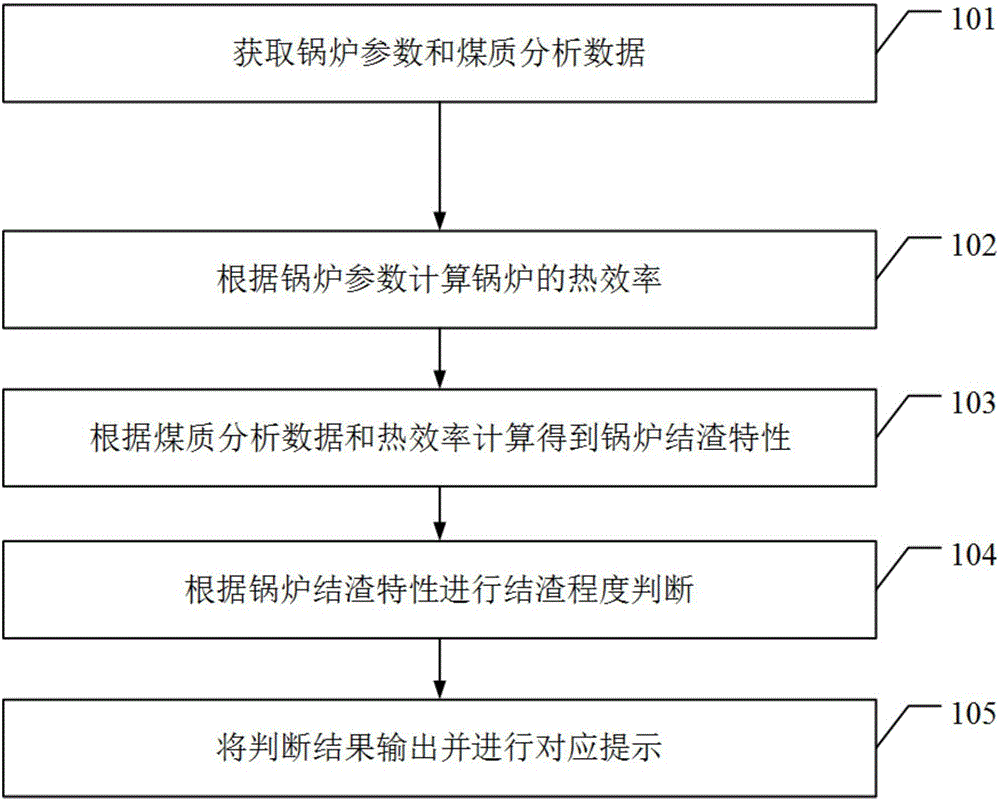

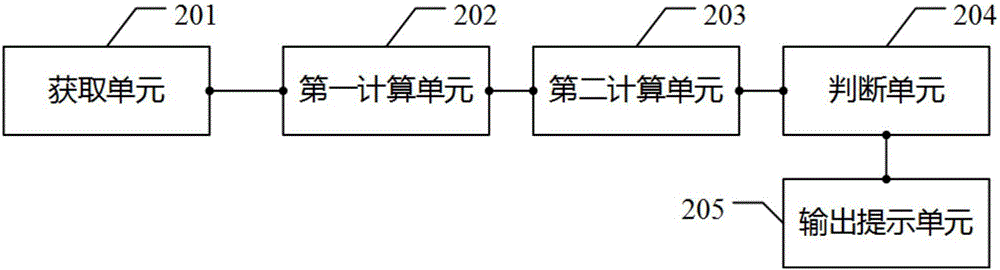

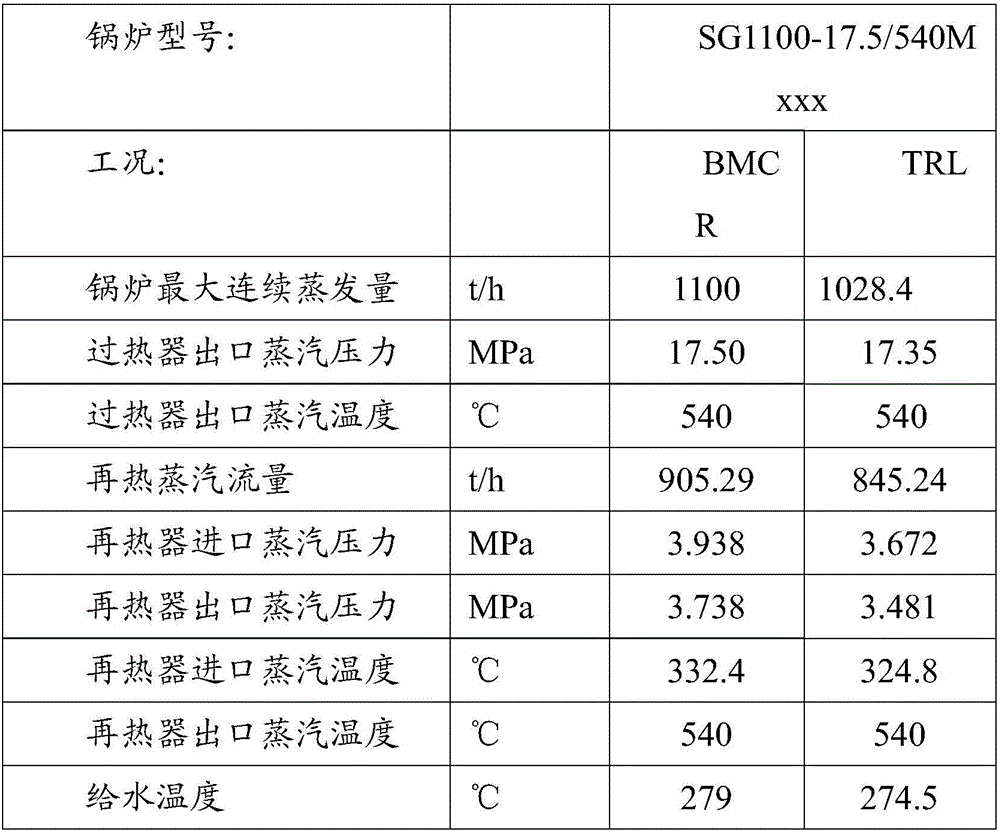

Slagging analysis method and device for power station boiler

The embodiment of the invention provides a slagging analysis method and device for a power station boiler. Boiler parameters and coal analysis data are obtained, the heat efficiency of the boiler are calculated according to the boiler parameters, the boiler slagging characteristic is obtained through calculation according to the coal analysis data and the heat efficiency, and the slagging degree is judged according to the boiler slagging characteristic. The technical problem that no complete analysis method for power station boiler slagging and characteristics exists at present, and consequently, how to analyze the power station boiler slagging becomes the issue is solved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

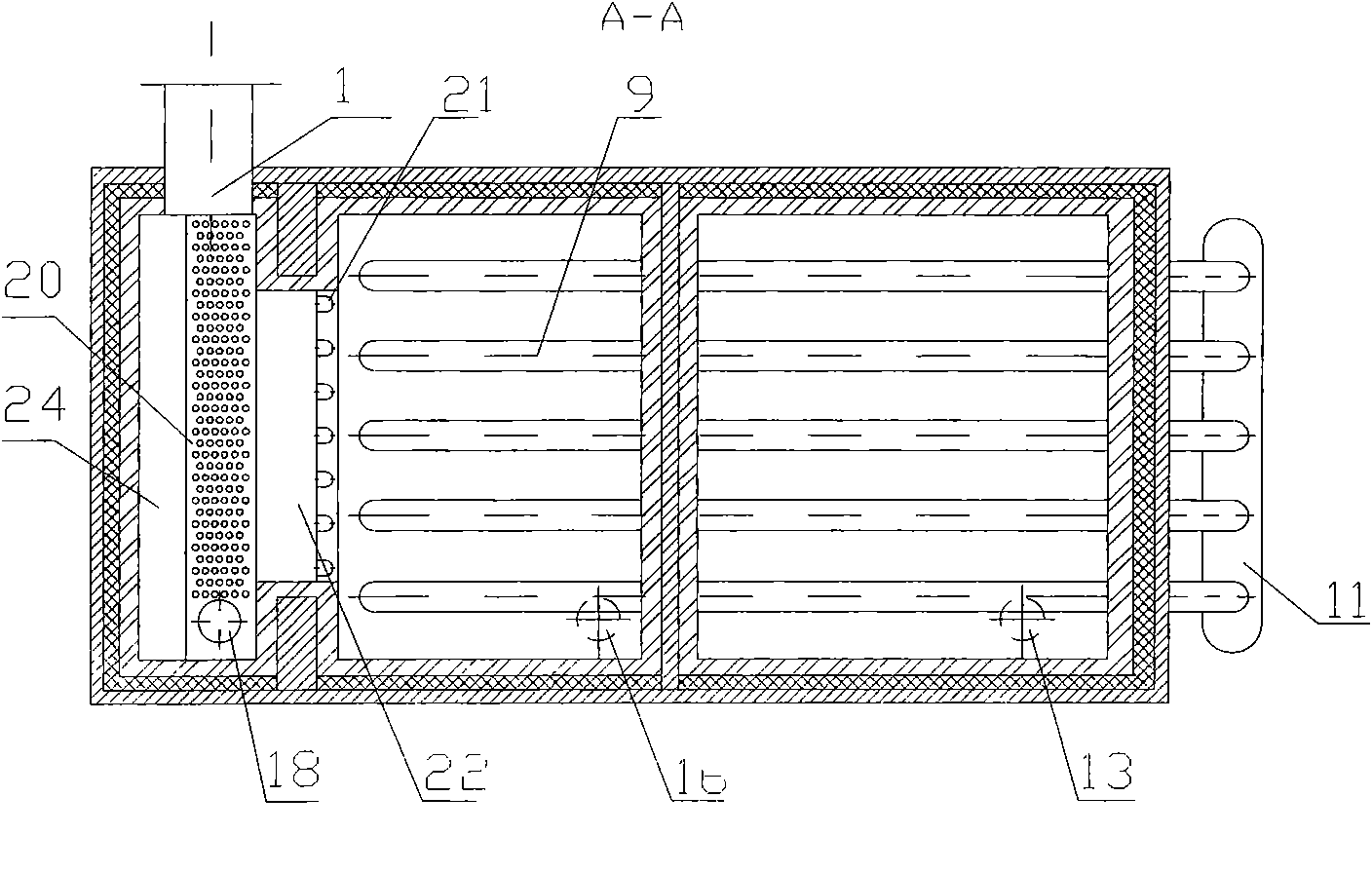

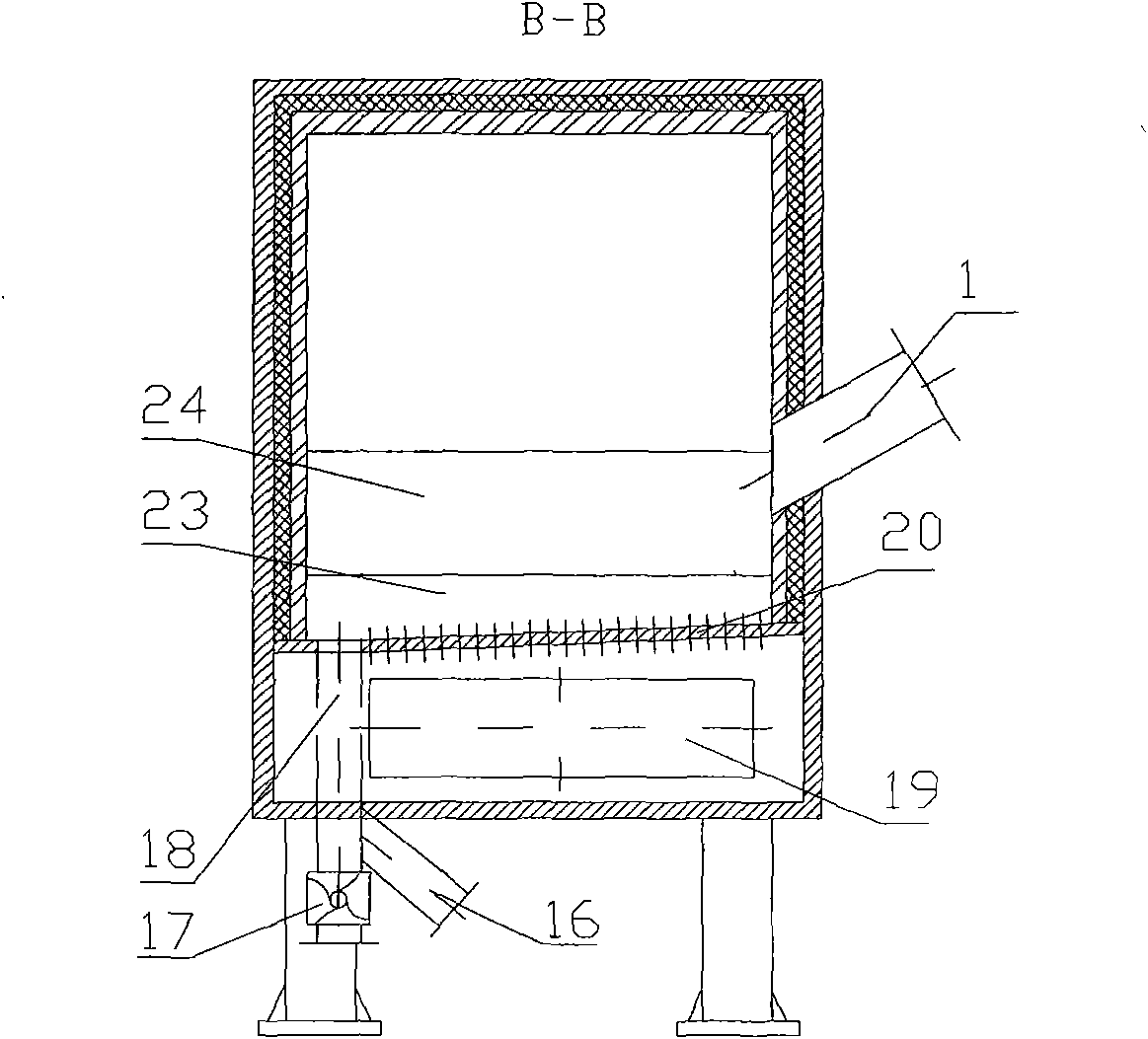

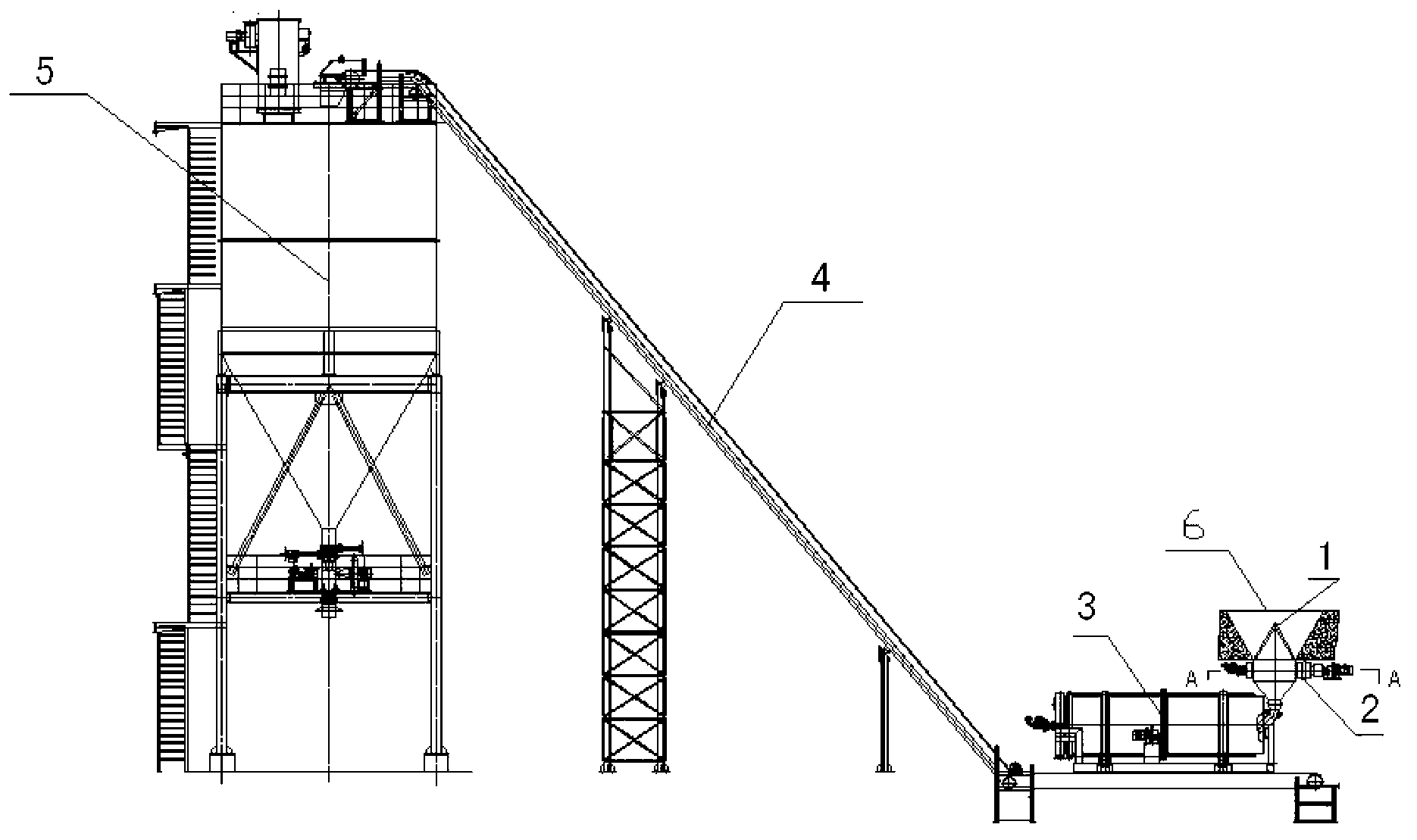

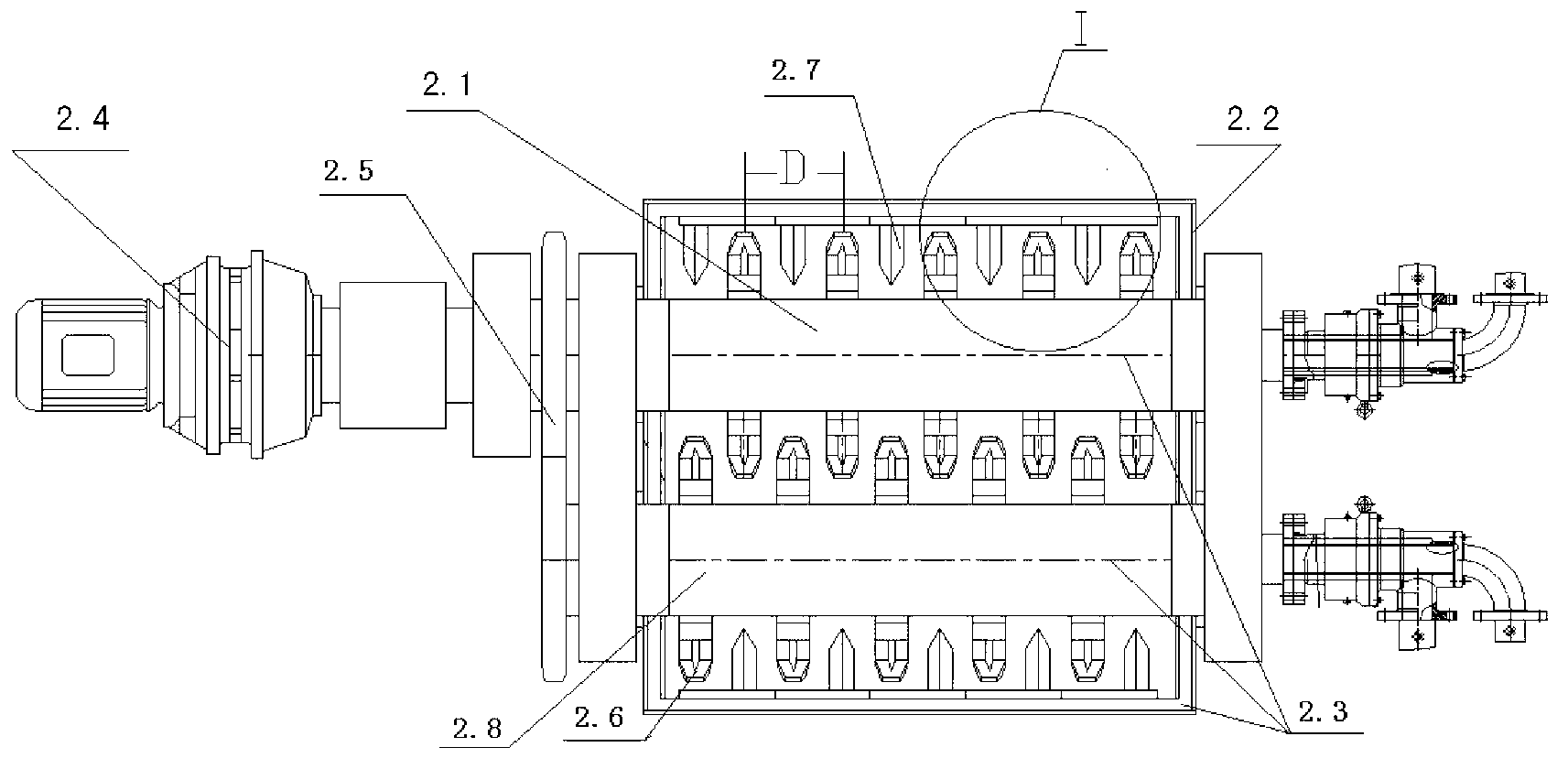

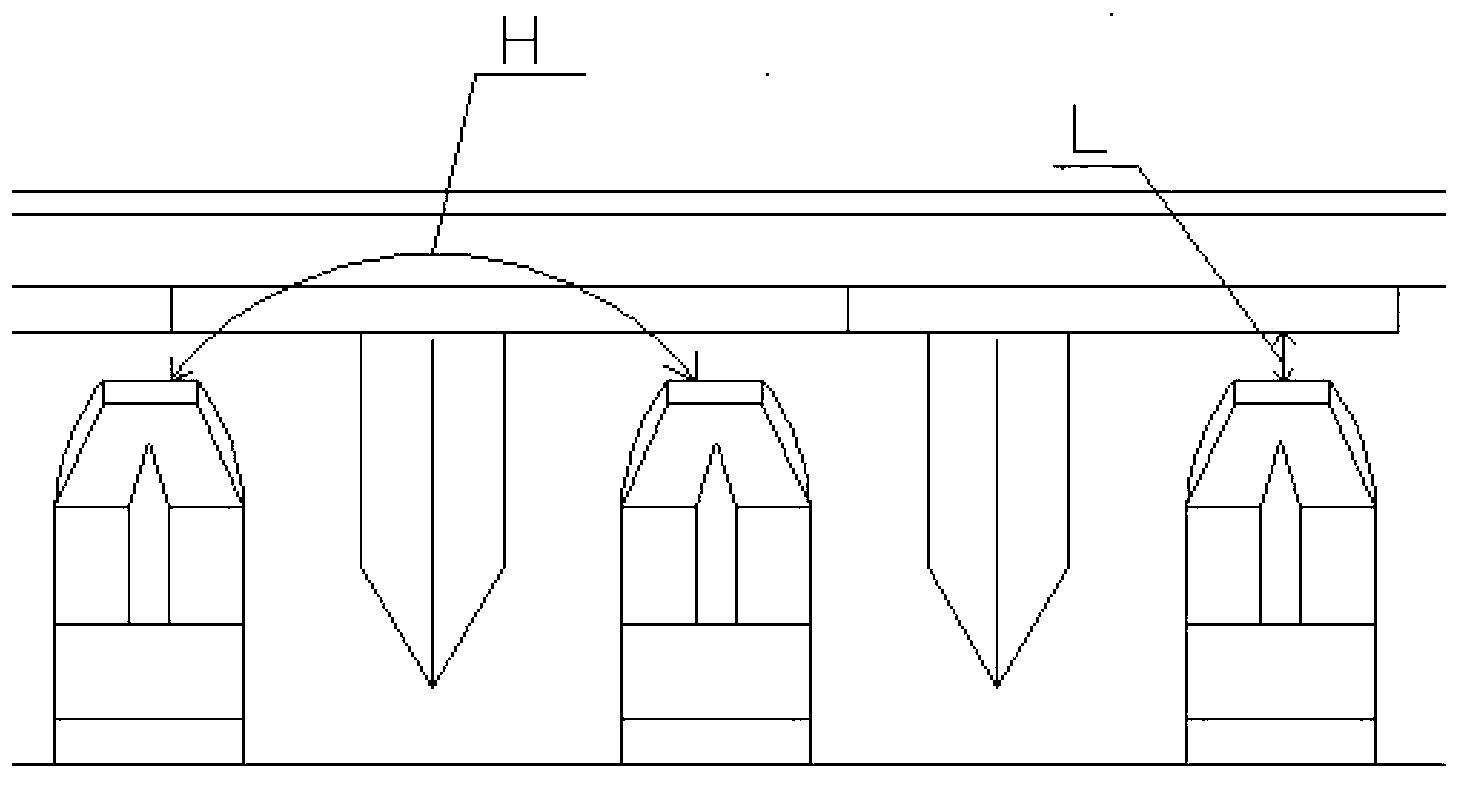

Water-cooling dry-type slag discharge device of pulverized coal boiler

ActiveCN103322580ALabor-intensiveReduce investmentLighting and heating apparatusBoiler slagCooling chamber

The invention provides a water-cooling dry-type slag discharge device of a pulverized coal boiler. The water-cooling dry-type slag discharge device comprises a drum slag cooler and a slag conveyor, a slag crushing device is arranged between a boiler slag well and the drum slag cooler, an outlet of the slag crushing device is communicated with a feed port of the drum slag cooler, a discharge port of the drum slag cooler is communicated with the slag conveyor, the slag crushing device is a high-temperature double-roll slag crusher which comprises two rotary rolls driven to rotate oppositely by a transmission mechanism a plurality of slag crushing teeth are distributed on the surface of each rotary roll along the axial direction of the rotary roll, the rotary rolls are arranged in a water jacket case, and auxiliary slag crushing teeth corresponding to the slag crushing teeth on the surfaces of the rotary rolls are distributed on the inner wall face of the water jacket case. A cooling chamber for supplying cooling water is formed in each of the rotary rolls and the water jacket case to cool parts in contact with slag blocks. The water-cooling dry-type slag discharge device of the pulverized coal boiler can crush coal slag to the required size and store the crushed slag as well as achieve heat recycling.

Owner:江苏靖隆合金钢机械制造有限公司

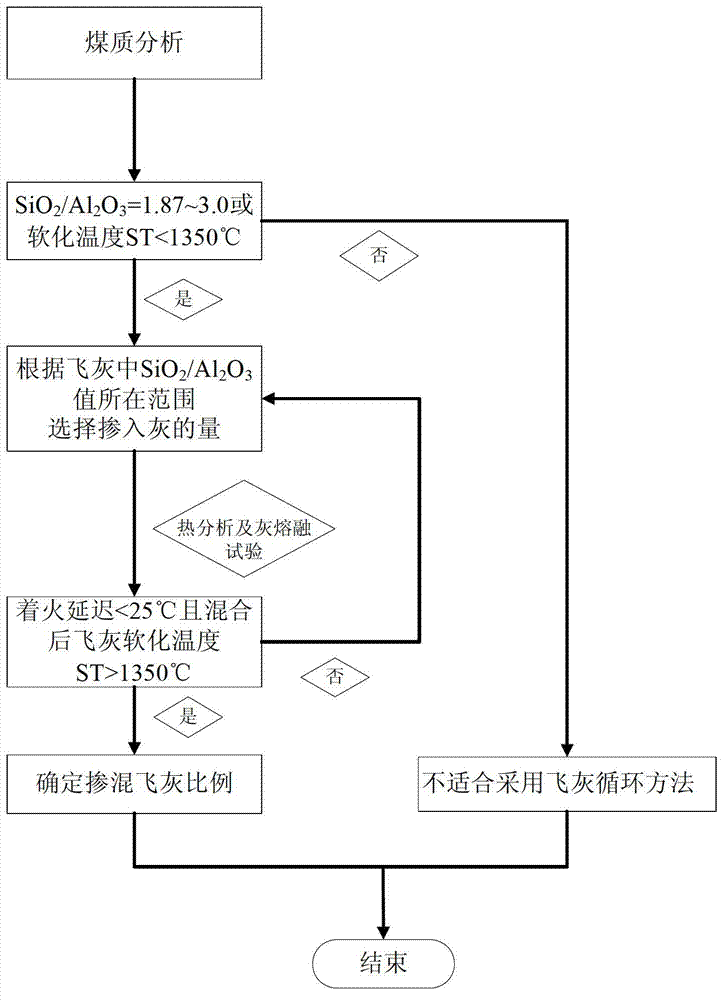

Method for relieving boiler slagging by using fly ash circulation

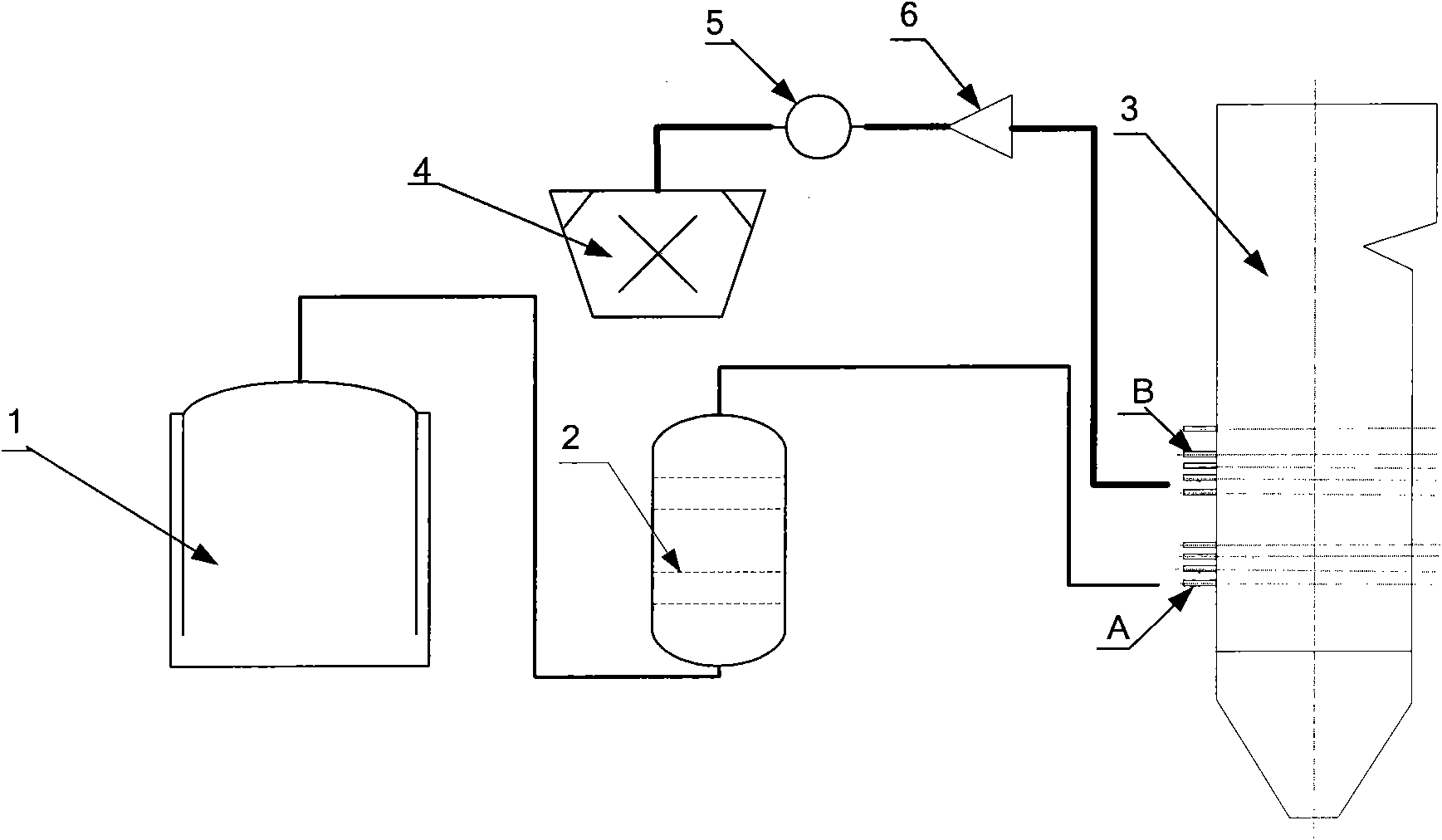

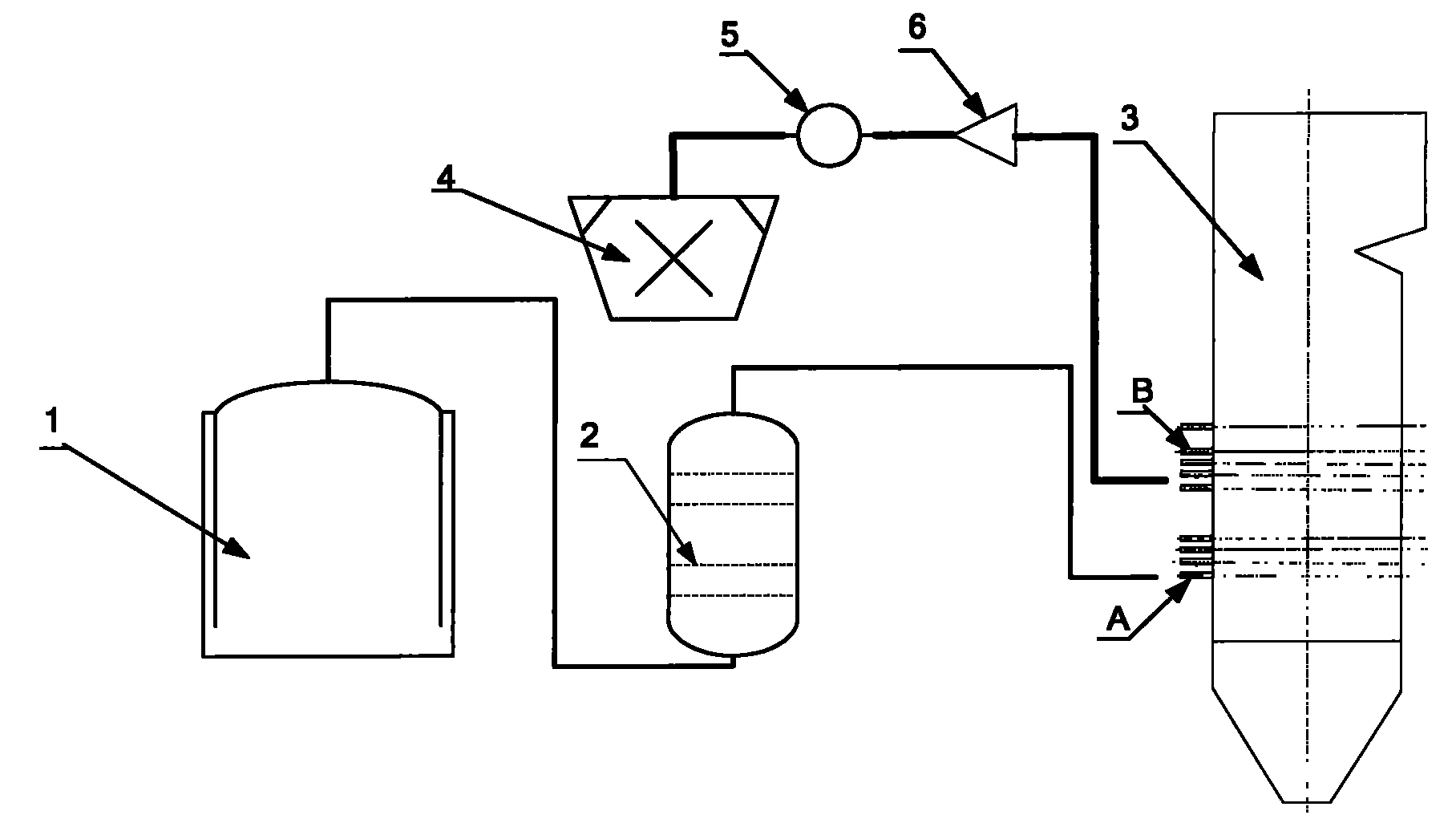

ActiveCN102759117AReduce slaggingFuel supply regulationLump/pulverulent fuel preparationPower stationBoiler slag

The invention relates to a method for relieving boiler slagging by using fly ash circulation, aiming at solving the problem of the traditional large power station boiler slagging, i.e. a certain amount of fly ash and coal dust being mixed and then sent to a hearth so as to achieve the purpose of relieving the boiler slagging. Researches find that the fly ash contains higher contents of SiO2 and Al2O3, and the fly ash and the coal dust are mixed in certain proportions to relieve the boiler slagging. Whether the method can be used or not is determined according to a value of the silica-alumina ratio of SiO2 to Al2O3 in the fly ash and the ash fusion softening temperature ST of the fly ash. In order to guarantee that the fly ash does not have a strong impact on fire-catching timeliness of the coal dust in the hearth and to relieve the slagging process at the same time, the amount of the mixed fly ash is determined according to the value of SiO2 to Al2O3 in the fly ash. The method can relieve the boiler slagging, and is economical and simple and convenient to operate.

Owner:XI AN JIAOTONG UNIV

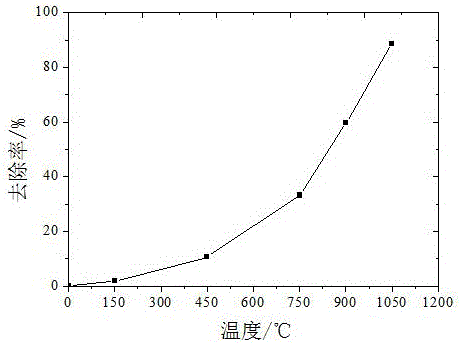

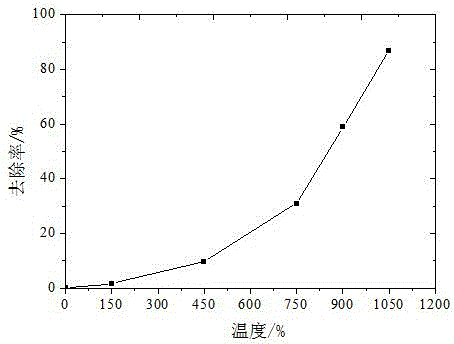

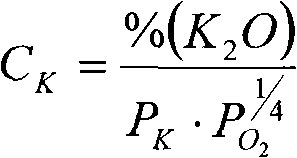

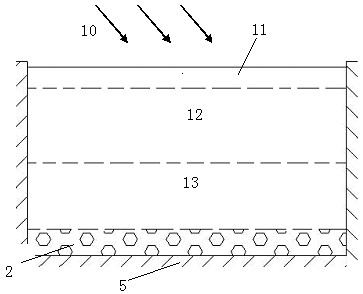

Method for measuring capacity of alkalis boiler slag potassium contained in blast furnace using gas-slag balancing technique

InactiveCN101275937AAccurate measurementThe experimental method is simplePreparing sample for investigationChemical methods analysisPotassiumPotassium carbonate

A method for measuring the potassium content of the alkali-containing slag with a gas-slag balancing technique belongs to a technique field of a physical and chemical experiment. The method is used for settling the problem that the complexity and difficulty of the potassium capability high-temperature experiment is increased because of the specificity of K2O in the slag. The technical scheme is composed of the procedures of preparing slag specimen, setting the arranging position of slag specimen and potassium carbonate agent in the corundum tube of the high temperature furnace, balanced reacting, measuring the content of potassium and the like. The invention adopts the gas-slag balancing technique. A platinum crucible is used as a gas-slag reaction vessel. A corundum crucible is used as a generation container of the potassium steam. The mixed gas of CO-CO2-Ar is used for control a certain partial pressure of oxygen in the system. The potassium carbonate decomposes to control the partial pressure of potassium in the system. The potassium capability of furnace slag CaO-SiO2-Al2O3-ZnO-TiO2 under different conditions is measured in MoSi2 high-temperature resistor furnace. The invention has the advantages of easy method, good repeatability, accurate measurement to the potassium content of alkali-containing furnace slag, and accurate data provided to the content of base metal in the furnace.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

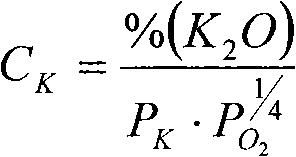

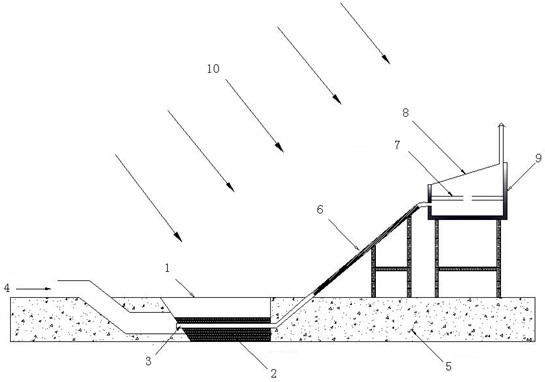

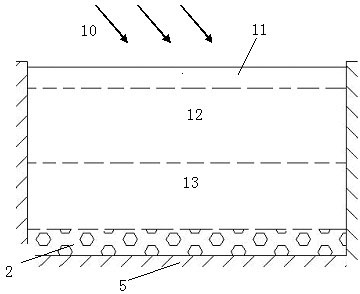

Solar pond composite drying system

InactiveCN102183096AImprove heat storage capacityTake advantage ofSolar heating energySolar heat devicesGreenhouseBoiler slag

The invention relates to a solar pond composite drying system. The system comprises a salt gradient solar pond, wherein an upper layer of the salt gradient solar pond is an upper convection layer which consists of clear water, a lower layer of the salt gradient solar pond is a lower convection layer, namely a heat storage layer, which consists of saturated salt solution, and a middle layer of the salt gradient solar pond is a non-convection layer, namely a gradient layer. A porous heat absorption dielectric layer is arranged in the heat storage layer of the salt gradient solar pond. Waste boiler slag is used as a heat absorption dielectric in the porous heat absorption dielectric layer. In order to enhance a heat absorption effect, the waste boiler slag is laid at the bottom of the solar pond to serve as the heat absorption dielectric. The solar pond has functions of a heat collector and a heat storage device; the system has a simple structure and is low in manufacturing cost; heat can be stored for a long time (extraseasonally); and a low-temperature heat source with stable performance can be provided all year around. Through the system, the problem of serious influence of changes of weather on a heat collector-greenhouse type solar dryer is solved, solar energy is fully utilized, and drying efficiency is increased.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

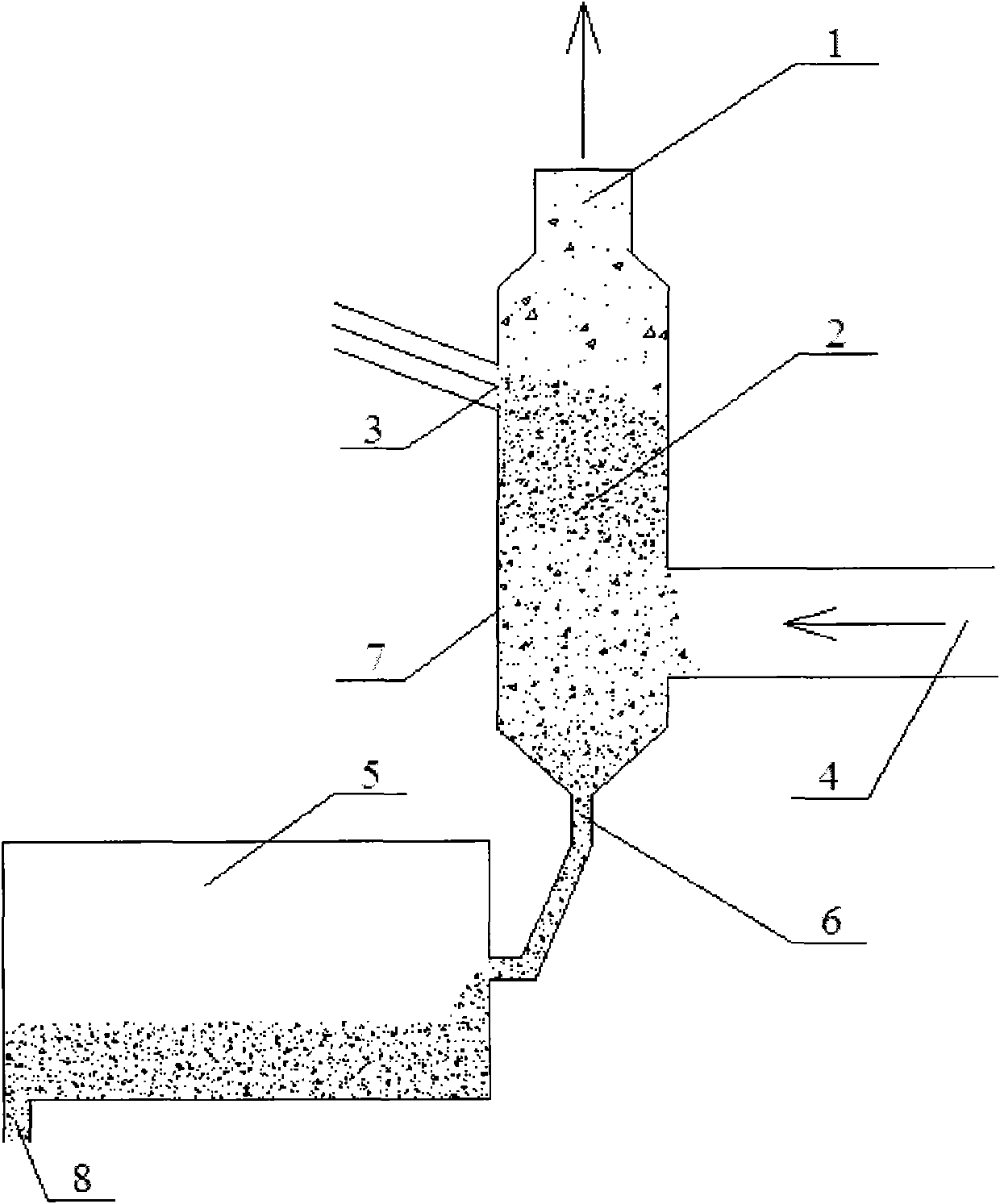

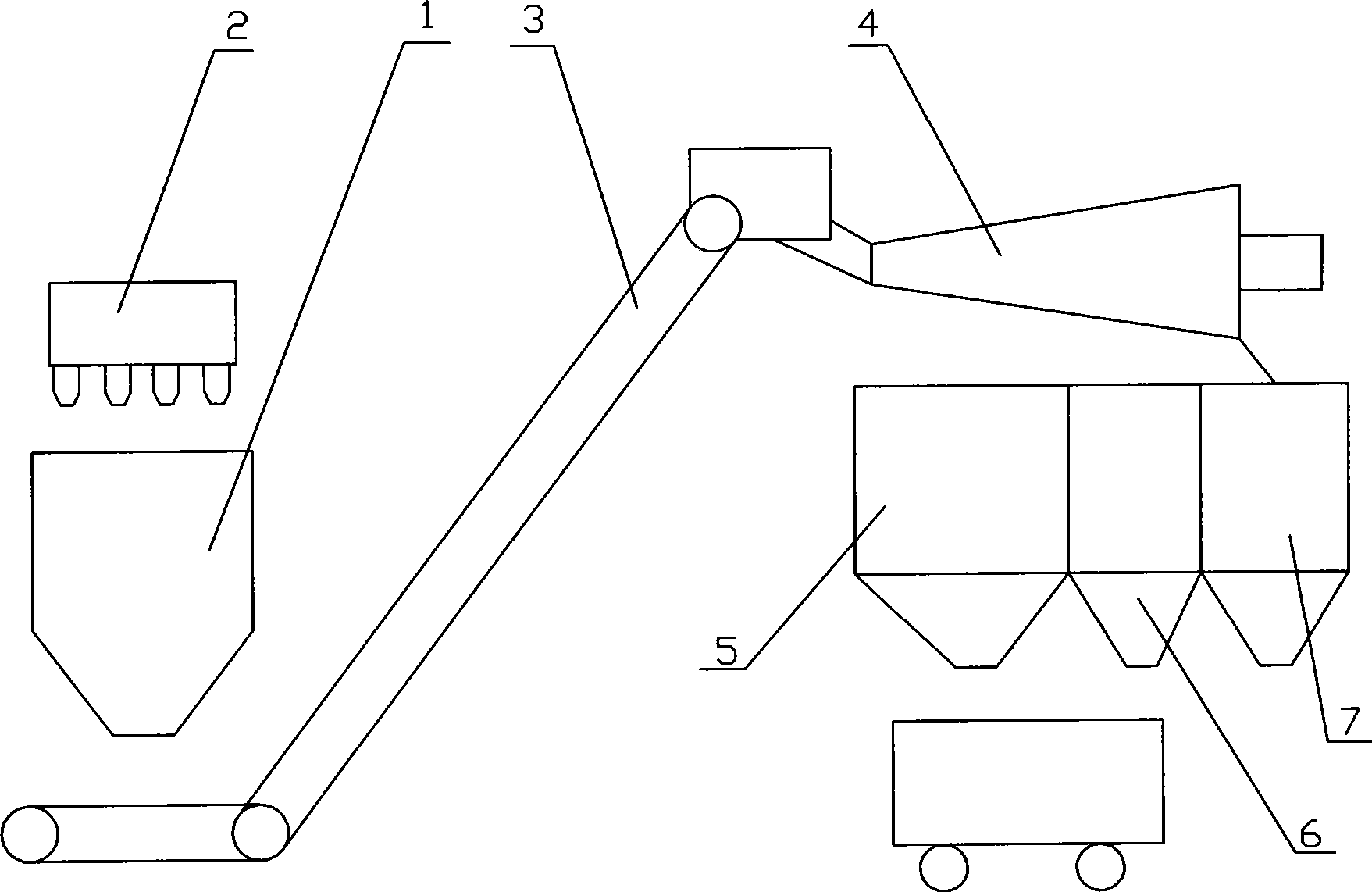

Method for automatically recycling and treating carbon residue from boiler slag of coal gasification

ActiveCN101480659ARealize automatic recyclingEliminate pollutionSolid waste disposalSolid fuelsRecovery methodBoiler slag

The invention relates to an automatic carbon residue recovery method for coal gasification slag treatment, which belongs to the technical field of coal gasification slag treatment and is characterized in that mixed slag is filled in a storage hopper, the top of the storage hopper is provided with a spraying device, the mixed slag is adjusted by adding water and stands in the storage hopper for 1-2 hours, and slag and carbon residue are separated from the mixed slag by schizolysis and then sieved; the sieve pore diameters of the front section and the rear section of a sievemesh are different, the slag is sieved out from the front section of the sievemesh, the carbon residue with a grain diameter between 10 mm and 15 mm is sieved out from the rear section of the sievemesh, and original carbon residue contained in the sieved carbon residue and mixed slag enters a second-stage carbon residue storage hopper from the tail part of a revolving screen. The invention utilizes the schizolysis to split the slag by adopting a principle that the stability of two substances with different structures are different because of the difference of the structures, thereby enabling the slag with complex grain diameters to become two materials which are easy to sieve so as to be recycled, such as fine slag with a small grain diameter and carbon residue coalballs which can not be split by the schizolysis but can be recycled, and realizing the automatic recycling of gasification slag carbon residue and the close type treatment.

Owner:ZHISHENG CHEM

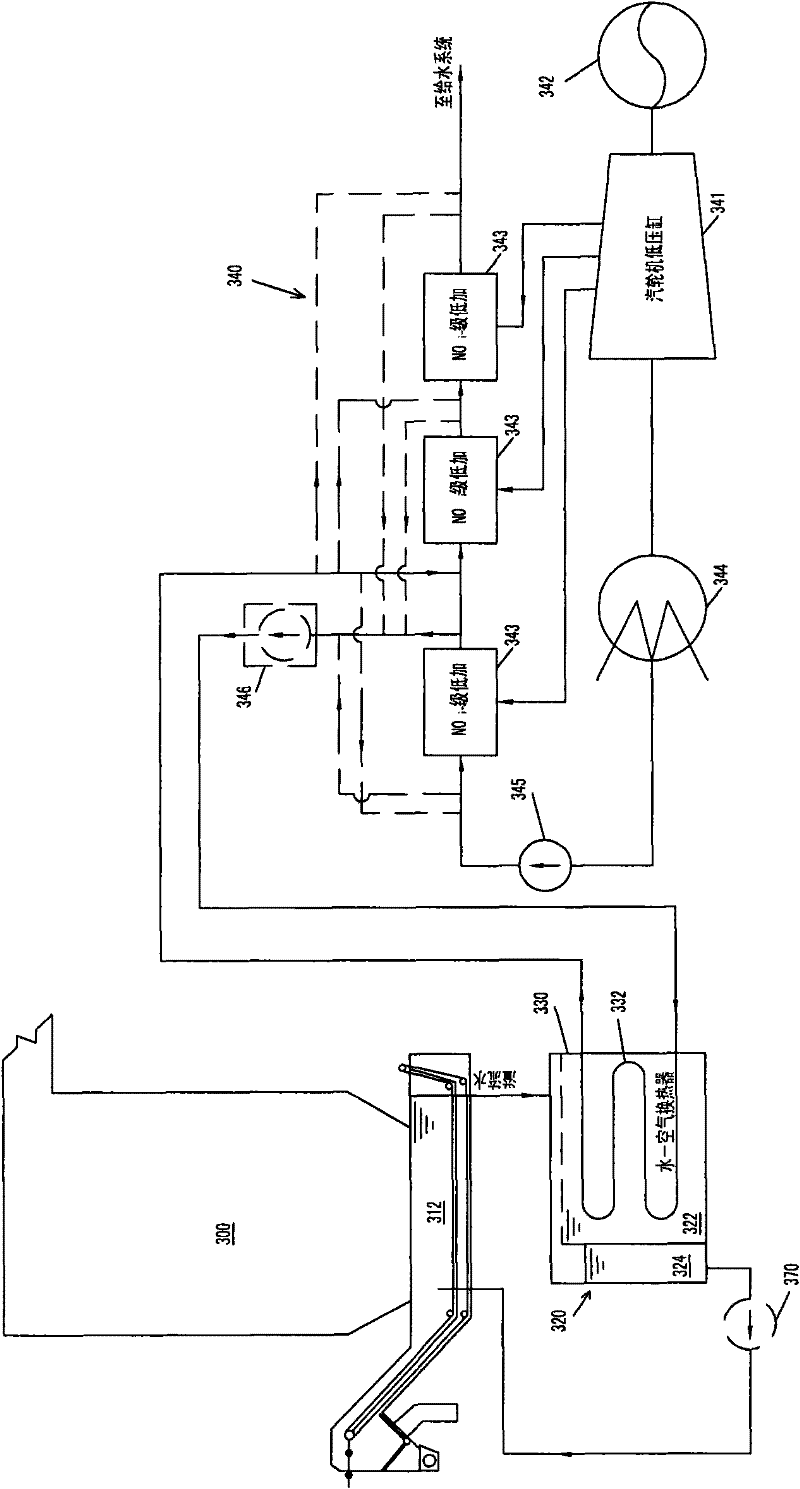

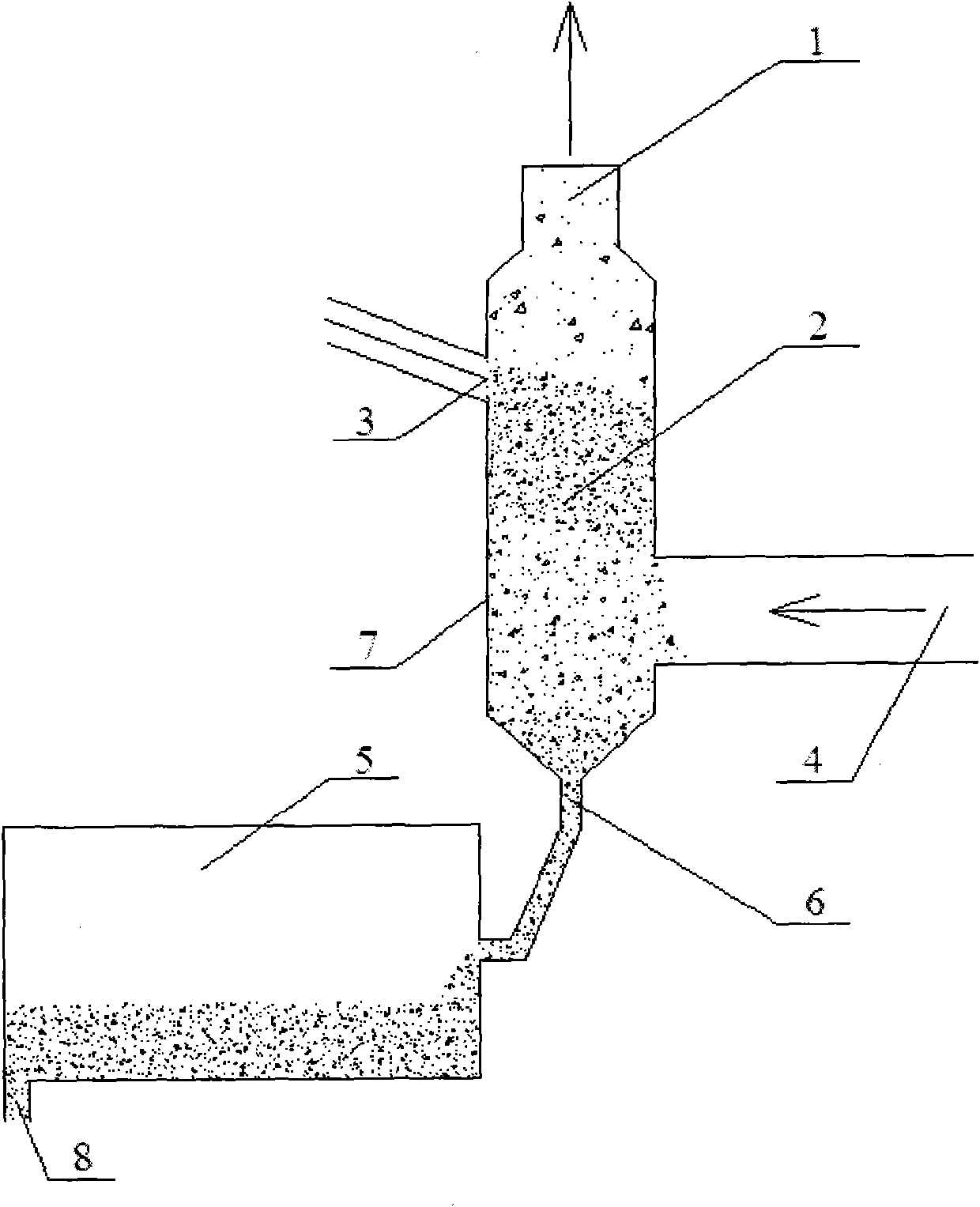

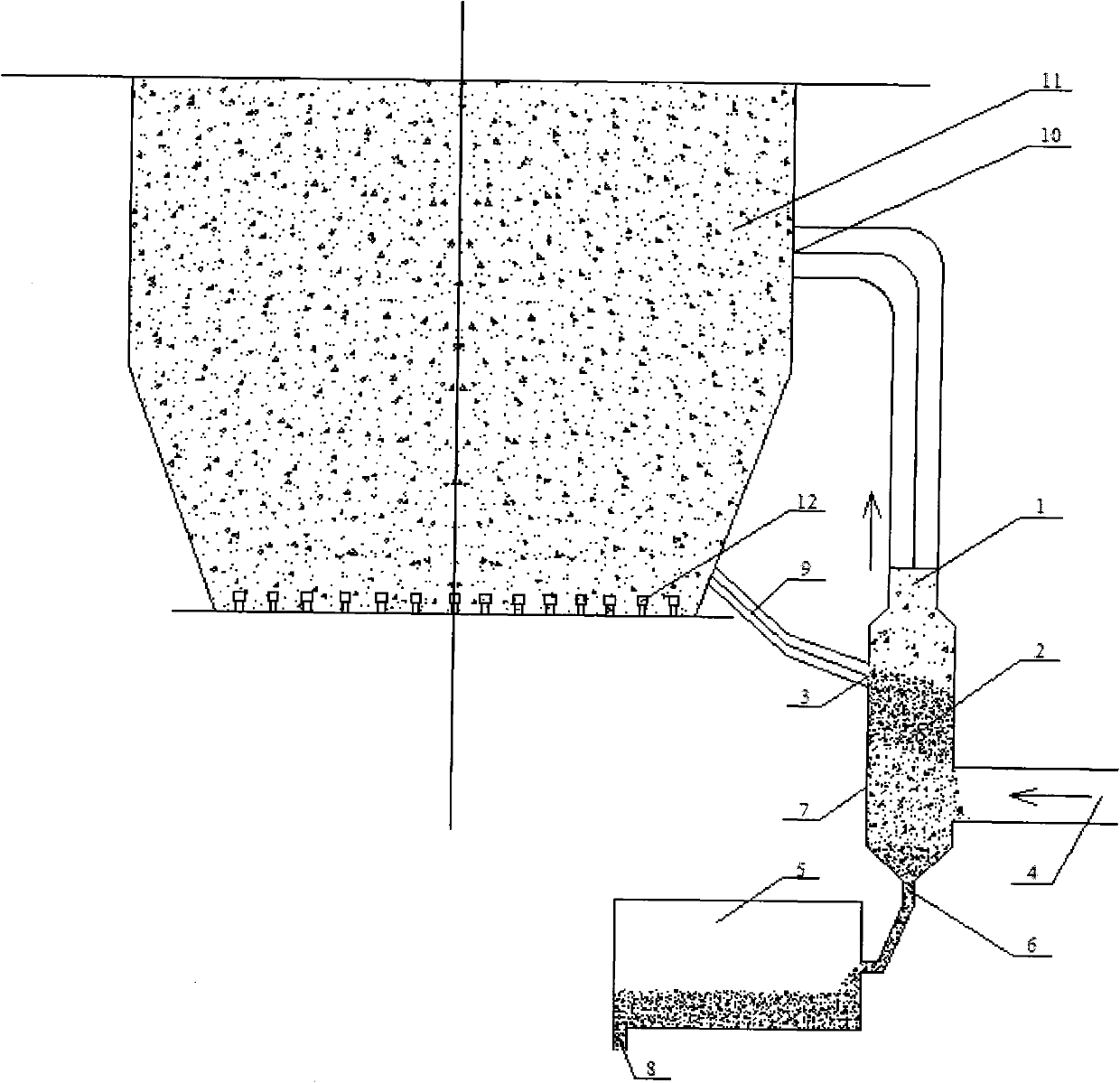

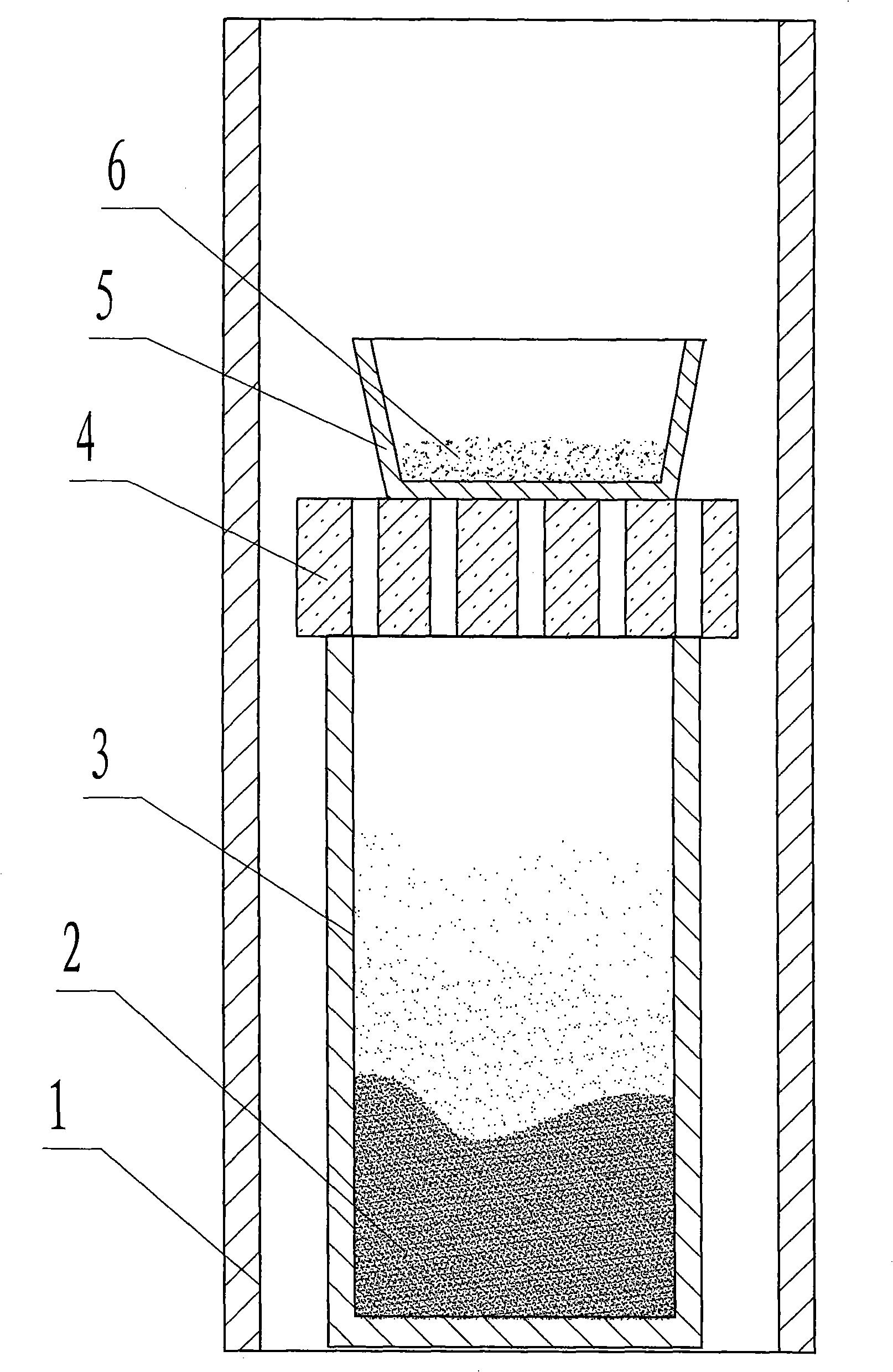

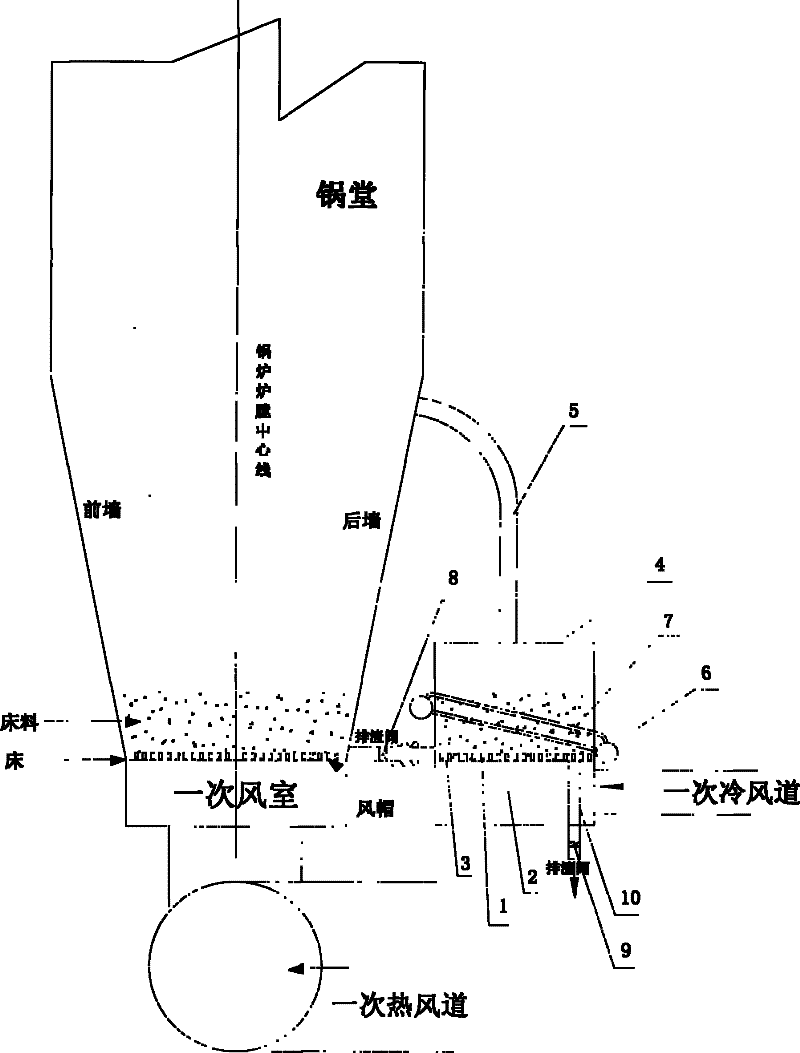

Device and method for recovering bottom slag heat of circulating fluidized bed boiler

ActiveCN102116471AHigh thermal efficiencyReduce physical heat lossFluidized bed combustionApparatus for fluidised bed combustionFluidized bedBoiler slag

The invention discloses a device and a method for recovering bottom slag heat of a circulating fluidized bed boiler and relates to a circulating fluidized bed boiler technology. A bottom slag heat recovering chamber is formed below the hearth of the circulating fluidized bed boiler and is directly communicated with the hearth through gaps among air distribution pipes of the hearth; and the bottom slag falls into the bottom slag heat recovering chamber from the gaps among the air distribution pipes and exchange heat with a cold slag heat exchange surface formed in the bottom slag heat recovering chamber; and after being cooled, the bottom slag is discharged out of the boiler from the bottom of the bottom slag heat recovering chamber, and a cooling medium in the cold slag heat exchange surface is heated. The working medium of the circulating fluidized bed boiler is used as the bottom slag cooling medium, the heat brought out of the hearth by the bottom slag is recovered, and the physical heat loss of the boiler slag is reduced, so that the heat efficiency of the boiler is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Settable building material composition including landfill leachate

InactiveUS8236098B2High compressive strengthReduce Shrinkage ProblemsSolid waste managementCement productionBottom ashBoiler slag

A composition capable of setting to produce a building material is disclosed. The composition can include from 1% to 30% by weight of an activator, from 1% to 55% by weight of a pozzolan, such as fly ash; from 40% to 90% by weight of an aggregate; and liquid landfill leachate in a sufficient amount such that the composition sets to a building material having a compressive strength of at least 2 MPa, wherein all weight percentages are percent by weight of the total composition. The liquid landfill leachate replaces all or part of the tap water in a conventional composition for forming a building material. The liquid landfill leachate can be recovered after a liquid (typically water) percolates through a landfill and contacts at least one landfilled coal combustion product selected from fly ash, bottom ash, boiler slag, and flue gas desulfurization material. The building material can be a concrete, or a masonry unit.

Owner:WISCONSIN ELECTRIC POWER

Lignin-graphene oxide composite modified polycarboxylic acid efficient water reducing agent

The invention discloses a lignin-graphene oxide composite modified polycarboxylic acid efficient water reducing agent. The water reducing agent is prepared by, by weight, 240-250 parts of TPEG, 25.2-26.0 parts of acrylic acid, 1.6-1.65 parts of ammonium persulfate, 0.53-0.55 part of thioglycolic acid, 13-14 parts of lignin, an appropriate amount of sodium hydroxide solution with the concentration being 10wt%, an appropriate amount of deionized water, 26-28 parts of graphene oxide, 20-23 parts of boiler slag, 5-7 parts of sorbitol, 2-3 parts of sodium nitrite, 2-3 parts of dodecyl dimethyl benzyl ammonium chloride, 4-5 parts of carbon black and 3-4 parts of microcrystalline wax. The lignin-graphene oxide composite modified polycarboxylic acid efficient water reducing agent has the advantages that components such as the carbon black and the dodecyl dimethyl benzyl ammonium chloride are added into the preparation of the water reducing agent, so that the dispersity of the water reducing agent in concrete can be increased; the industrial waste boiler slag is added into the water reducing agent, so that production cost is lowered; the sodium nitrite is added into the water reducing agent, and accordingly the early strength and later strength of the concrete are further increased.

Owner:ANHUI XINRUN NEW MATERIALS

Autoclaved fly ash brick for construction and manufacturing method thereof

The invention discloses an autoclaved fly ash brick for construction, which is prepared from the following raw materials by weight in mixture ratio: 13 to 17 of boiler slag, 13 to 17 of fly ash, 8 to 12 of granolithic, 18 to 22 of carbide slag and 38 to 42 of mountain flour. When the fly ash brick is prepared, the boiler slag, the fly ash, the granolithic, the carbide slag and the mountain flour which are ground into a powder shape are mixed evenly according to the mixture ratio by weight of 13 to 17:13 to 17:8 to 12:18 to 22:38 to 42, water is added, and a mixed material with the water content of 10 to 15wt% is prepared and is autoclaved and cured to prepare a finished product after the mixed material is pressed and molded. The invention has simple technological formula, easy control of the technological operation and stable product quality and is a novel energy-saving environment-friendly process.

Owner:GAOMI FURI BUILDING MATERIALS

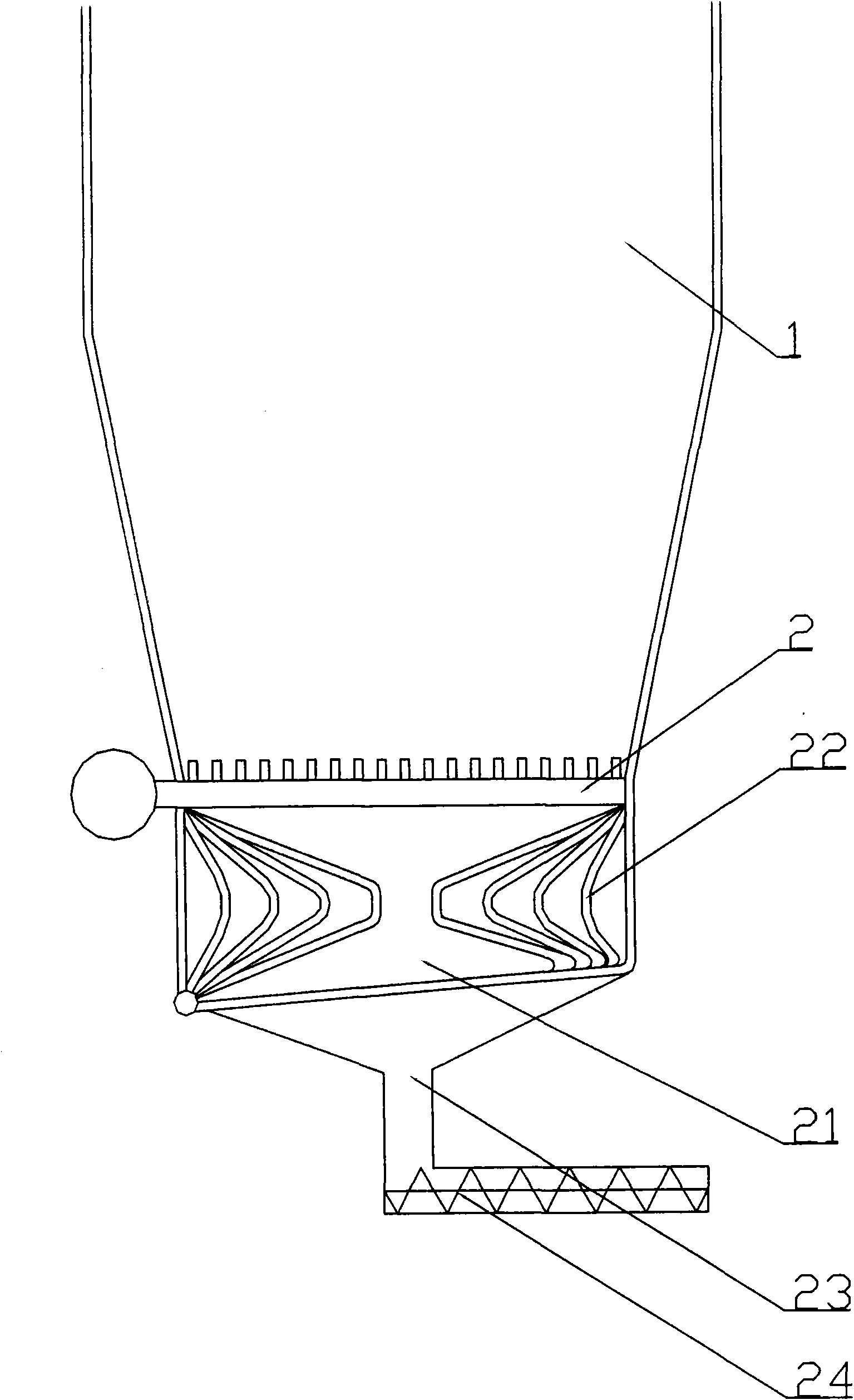

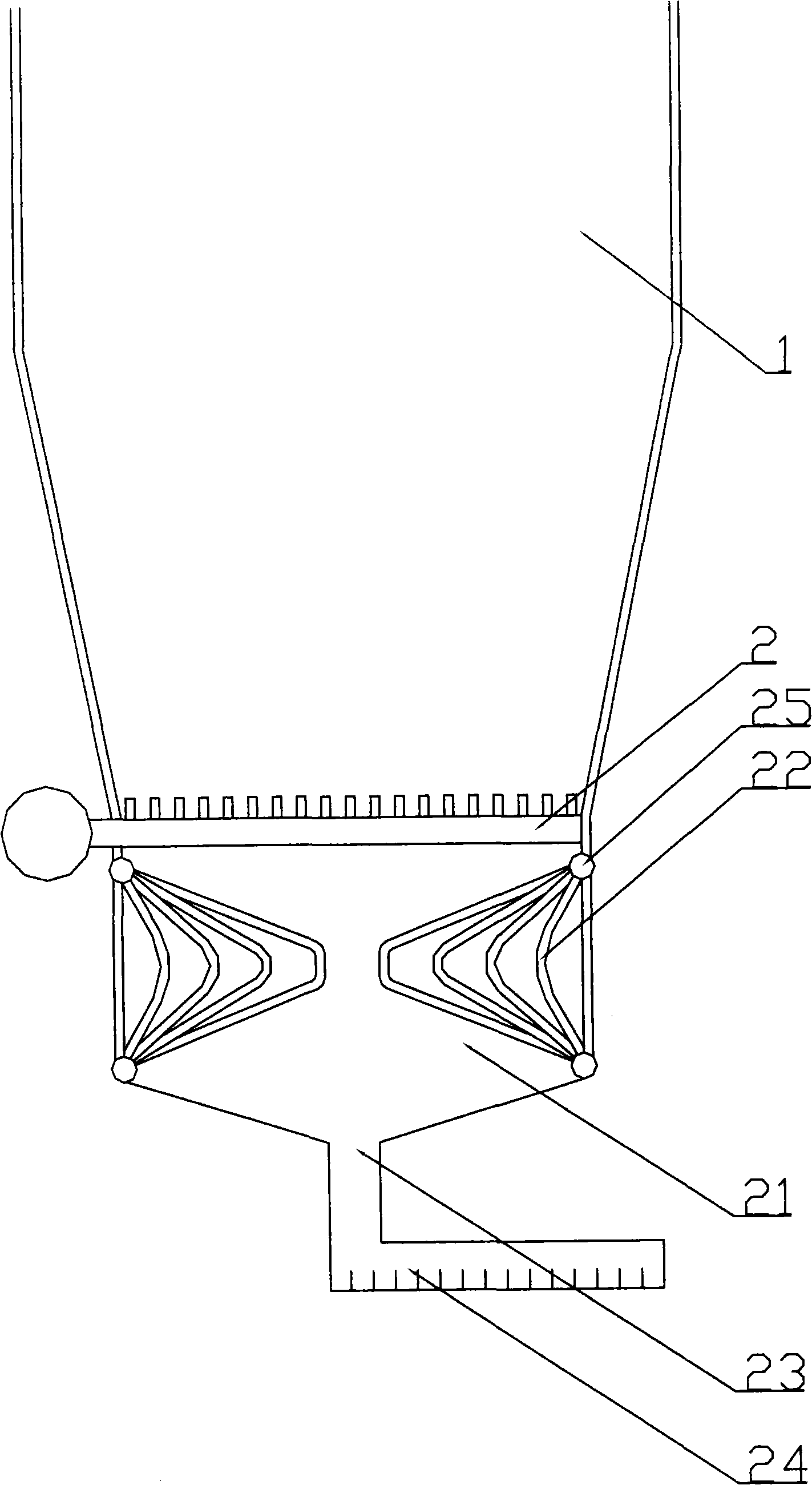

Biomass boiler slag separating machine

InactiveCN104162510AMake up for the shortcomings that cannot be comprehensively utilizedEasy to installGas current separationPotassiumBoiler slag

The invention discloses a biomass boiler slag separating machine which is composed of a tilted string vibration sieve, a ratchet wheel rolling sieve, a fine slag hopper, a coke button hopper, a large biomass block hopper and a protection plate. The string vibration sieve is composed of a flow guide plate, a plurality of tension nuts, a plurality of tension bolts and a plurality of strings. The ratchet wheel rolling sieve is composed of a plurality of ratchet wheels. The fine slag hopper is arranged below the string vibration sieve. The coke button hopper is arranged below the ratchet wheel rolling sieve. The large biomass block hopper is arranged on the lower portion of an outlet of the ratchet wheel rolling sieve. The string vibration sieve is fixed to the ratchet wheel rolling sieve through the protection plate. The biomass boiler slag separating machine has the advantages that fine boiler slag rich in potassium and coke buttons in biomass boiler slag are separated from large biomass blocks and stored in the different hoppers, concentrated landfill processing is carried out on the coke buttons, the landfill cost and landfill conveying cost are saved, large biomass blocks which are insufficiently burned can be fed into a boiler to be burned again, fuel is saved, boiler efficiency is improved, and the fine boiler slag rich in potassium can be used as farmland fertilizer.

Owner:SHENYANG INST OF ENG

Chromium-based boiler slag-removing ash-removal coal-saving composition and preparation method thereof

ActiveCN104910996AHigh active specific surface areaHigh hydrogen contentSolid fuelsFuel additivesPetroleumElectric power

The present invention relates to an additive product suitable for coal-fired boilers of electric power, thermal power, petroleum, chemical and metallurgical industries, and particularly relates to a chromium-based boiler slag-removing ash-removal coal-saving composition, and the chromium-based boiler slag-removing ash-removal coal-saving composition consists of the following components in parts by weight: 50 to 65 parts of chromium oxide, 8 to 15 parts of copper oxide, 5 to 9 parts of cerium oxide, 5 to 9 parts of barium molybdate, 7 to 14 parts of cobaltous oxide, 12 to 17 parts of potassium permanganate, 10 to 16 parts of manganese carbonate, 12 to 17 parts of barium carbonate, 8 to 15 parts of titanium dioxide, zinc oxide, 15 to 20 parts of zinc oxide, 6 to 10 parts of potassium chlorate, 6 to 10 parts of potassium perchlorate, 20 to 28 parts of sodium carbonate, 25 to 35 parts of active attapulgite carclazyte and 0.1 to 0.3 part of alkyl glycerol ether sulfonate. The chromium-based boiler slag-removing ash-removal coal-saving composition is an environmentally-friendly product which is efficient in combustion helping, and high in coal saving ratio, can reduce pollution, improve combustion efficiency, and extend the boiler service life, and is convenient to use and stable in performance, and when in use, only the chromium-based boiler slag-removing ash-removal coal-saving composition is added into a fuel to participate in the combustion without equipment transformation.

Owner:GANSU HEIMA PETROCHEM ENG

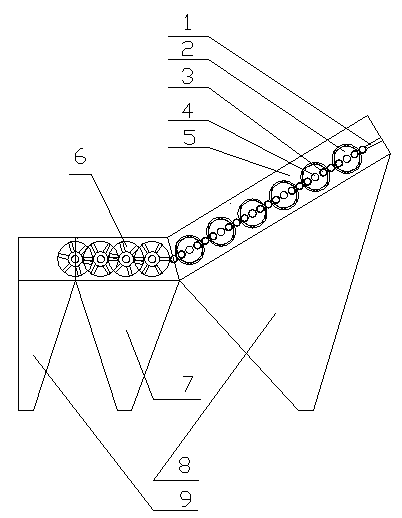

Equal-bed pressure cold slag fluidized bed of circulating fluidized bed boiler and operation method thereof

InactiveCN102221201AImprove wear resistanceAvoid accumulationFluidized bed combustionApparatus for fluidised bed combustionCold airDifferential pressure

The invention discloses an equal-bed pressure cold slag fluidized bed of a circulating fluidized bed boiler and an operation method thereof. The equal-bed pressure cold slag fluidized bed comprises a directional hood 1, a primary cold air chamber 2, a bed 3, a rectangular shell 4, a warm air pipe 5, a water cooling header 6, water cooled tube bundles 7, a boiler reject valve 8, a cold slag fluidized bed reject valve 9 and a cold slag fluidized bed reject tube 10. In the installation of the equal-bed pressure cold slag fluidized bed, the cold slag fluidized bed 3 is lower than a boiler fluidized bed by 150mm, and a plurality of rows of the water cooled tube bundles 7 are embedded in a material layer on the cold slag fluidized bed, so that the full heat exchange between water and boiler slag can be realized, and the slag can be cooled to be at a temperature below 100 DEG C. The water cooling header 6 uniformly supplies water to the water cooled tube bundles 7. The operation method is as follows: firstly, before the boiler is started, bed material is matted as thick as 350mm on the cold slag fluidized bed, and particle size of the bed material is smaller than 8mm; and secondly, as a slag discharging method at fixed period with higher frequentness is adopted, when the slag on the cold slag fluidized bed is cooled to be at the temperature of 100 DEG C, the slag can be discharged, and when differential pressure of the material layer of the clod slag fluidized bed reaches 3500Pa, the slag discharging door of the cold slag fluidized bed is closed, and then a boiler slag discharging door is opened.

Owner:张全胜

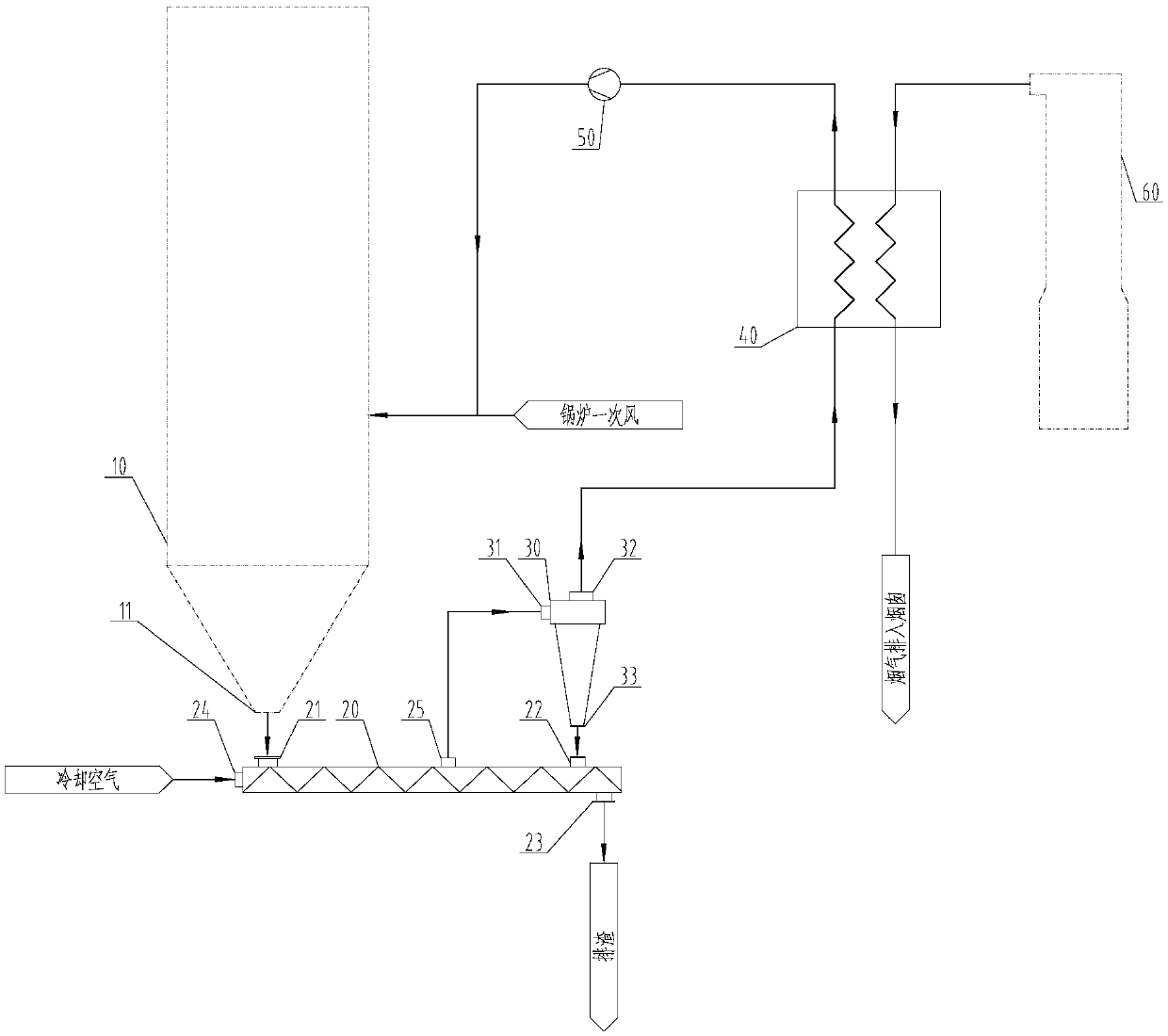

Boiler furnace slag waste heat utilization system and process

ActiveCN109539290AAvoid pollutionAvoid emission non-complianceAir/fuel supply for combustionBoiler furnaceFlue gas

The invention discloses a boiler furnace slag waste heat utilization system and a process. The boiler furnace slag waste heat utilization system is composed of a dry type slag discharging machine, a cyclone separator and a heat exchanger. An air inlet and first slag inlet of the dry type slag discharging machine are formed in the front end of the dry type slag discharging machine. A slag outlet ofthe dry type slag discharging machine is arranged at the rear end of the dry type slag discharging machine. A gas outlet of the dry type slag discharging machine is arranged on the rear portion of the dry type slag discharging machine. The first slag inlet of the dry type slag discharging machine is connected with an outlet of a boiler slag bucket. A gas outlet of the dry type slag discharging machine is connected with a gas inlet of the cyclone separator. A gas outlet of the cyclone separator is connected with an air channel inlet of the heat exchanger. An air channel outlet of the heat exchanger is connected with a primary air inlet of a boiler. A flue gas channel inlet of the heat exchanger is connected with a flue gas outlet of a wet desulfurization tower. A flue gas channel outlet ofthe heat exchanger is connected with an inlet of a chimney. By means of the boiler furnace slag waste heat utilization system and the process, furnace slag waste heat can be used for reheating post-wet-desulfurization cooled flue gas, residual waste heat can be recycled, and the gradient application of energy of the whole waste heat recycling system is realized.

Owner:SHANDONG WEIZHEN TEST & ANALYSIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com