Patents

Literature

53 results about "Solar dryer" patented technology

Efficacy Topic

Property

Owner

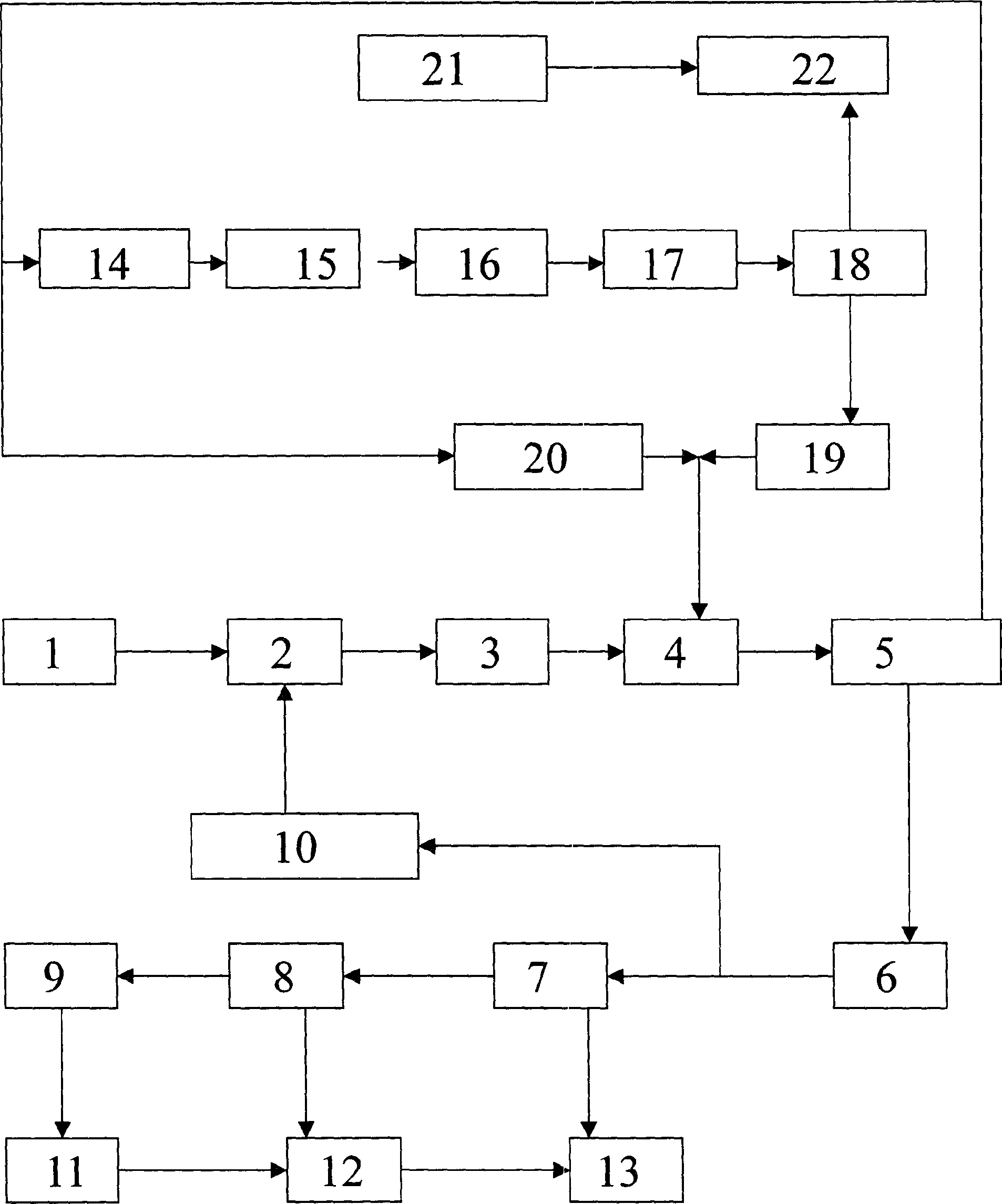

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solar dryers are devices that use solar energy to dry substances, especially food. There are two general types of solar dryers: Direct and indirect.

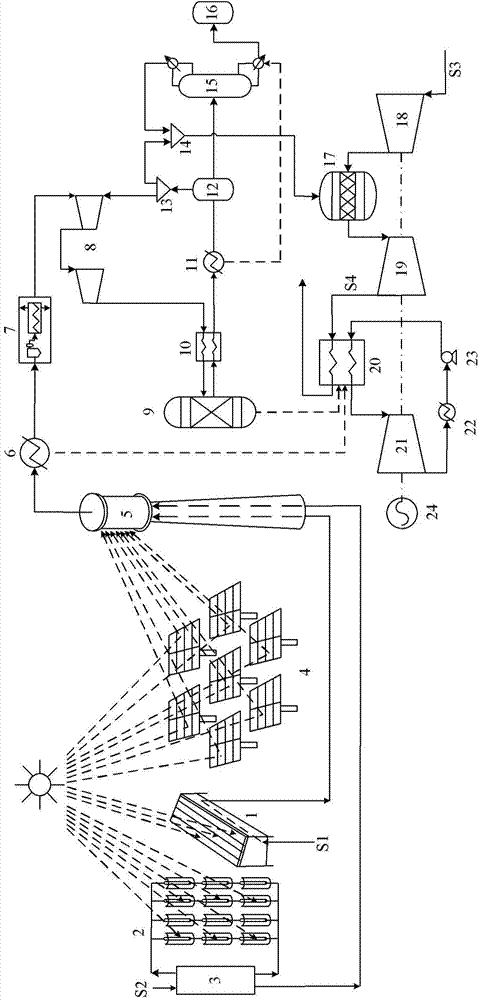

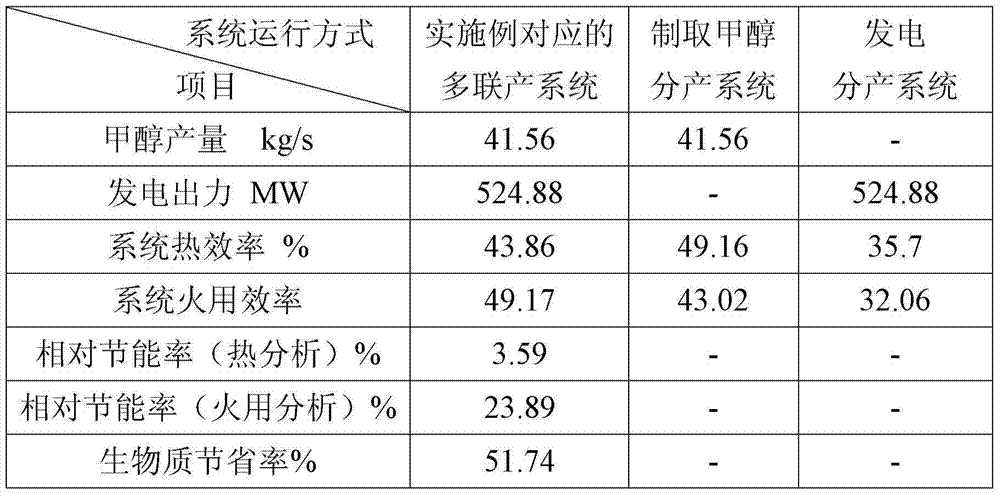

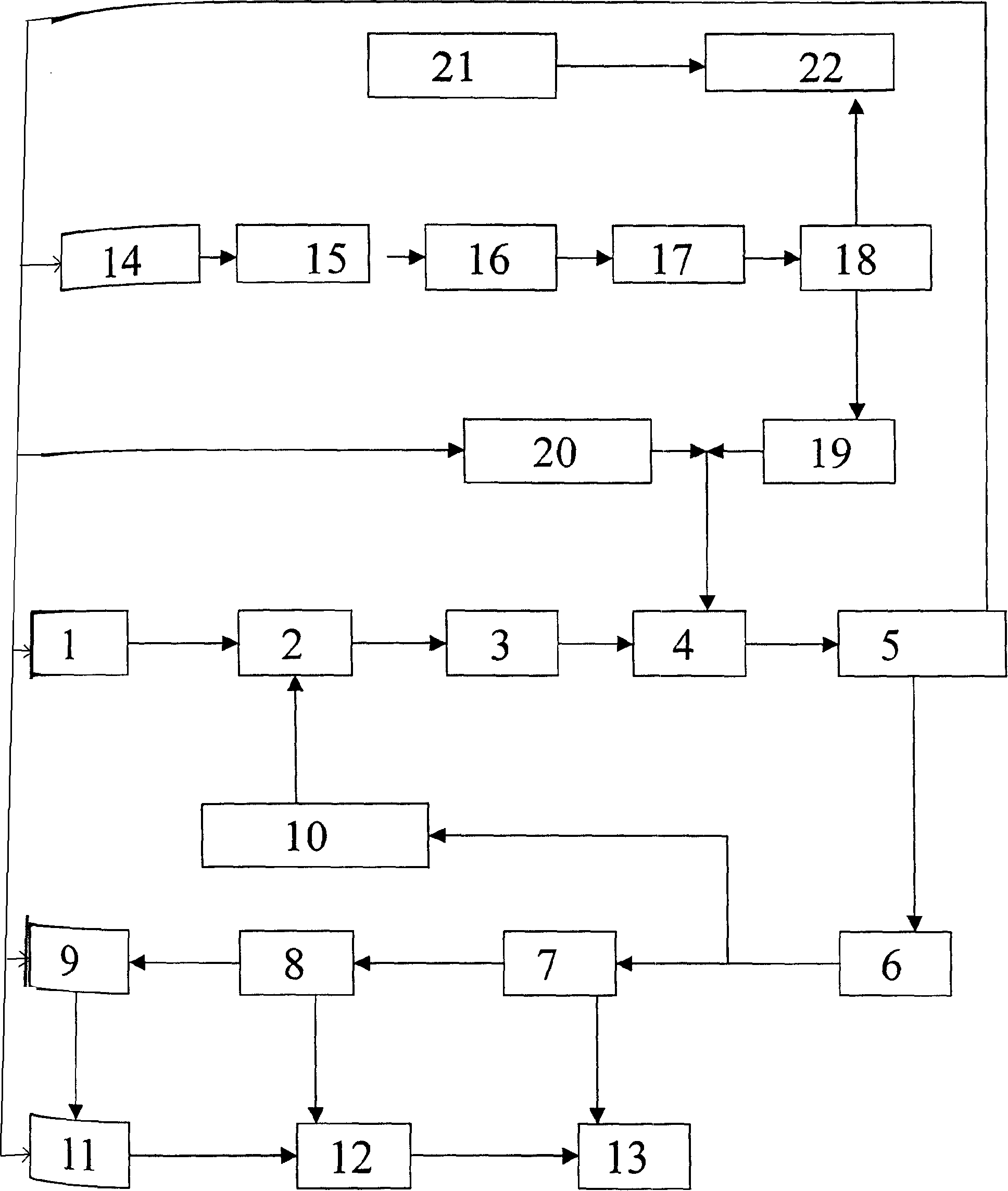

Poly-generation system using biomass and solar energy for making methyl alcohol and generating power

ActiveCN103899371AOptimize thermal energy utilizationHigh thermal efficiencyOrganic compound preparationSolar heat devicesCombustion chamberLiquid temperature

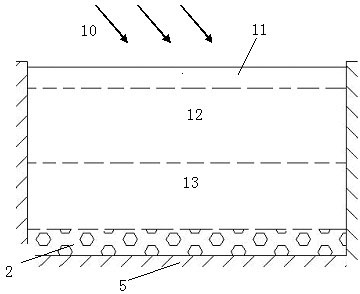

The invention discloses a poly-generation system using biomass and solar energy for making methyl alcohol and generating power. The poly-generation system comprises a solar energy heat collecting reaction subsystem, a biomass gasification subsystem, a methyl alcohol synthesis subsystem and a power generation subsystem. Main devices comprise a flat plate type solar energy drying device, a groove type solar thermal collector, a steam generator, a tower type solar energy reflection mirror field, a tower type high-temperature gasification reactor, a gas temperature reduction device, a gas condensation purifying device, a compressor set, a methyl alcohol synthesis tower, a heat exchanger, a gas-liquid temperature reduction device, a flash tank, a separator, a mixer, rectifying tower, a methyl alcohol, a combustion chamber, a compressor, a gas turbine, a waste heat boiler, a steam turbine, a condenser, a water feed pump and a power generator. By the utilization of the poly-generation system, solar energy is converted into chemical energy, the problems that the storage of solar energy is difficult, and stability of renewable energy source delivering is poor are solved, and meanwhile the effective utilization efficiency of the biomass is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

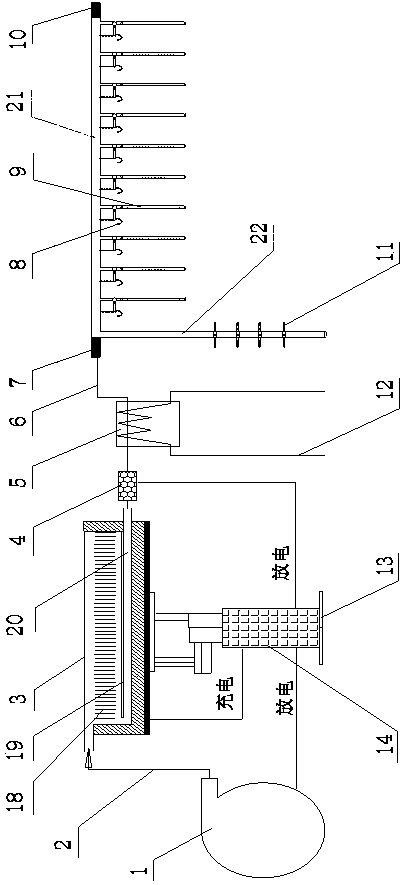

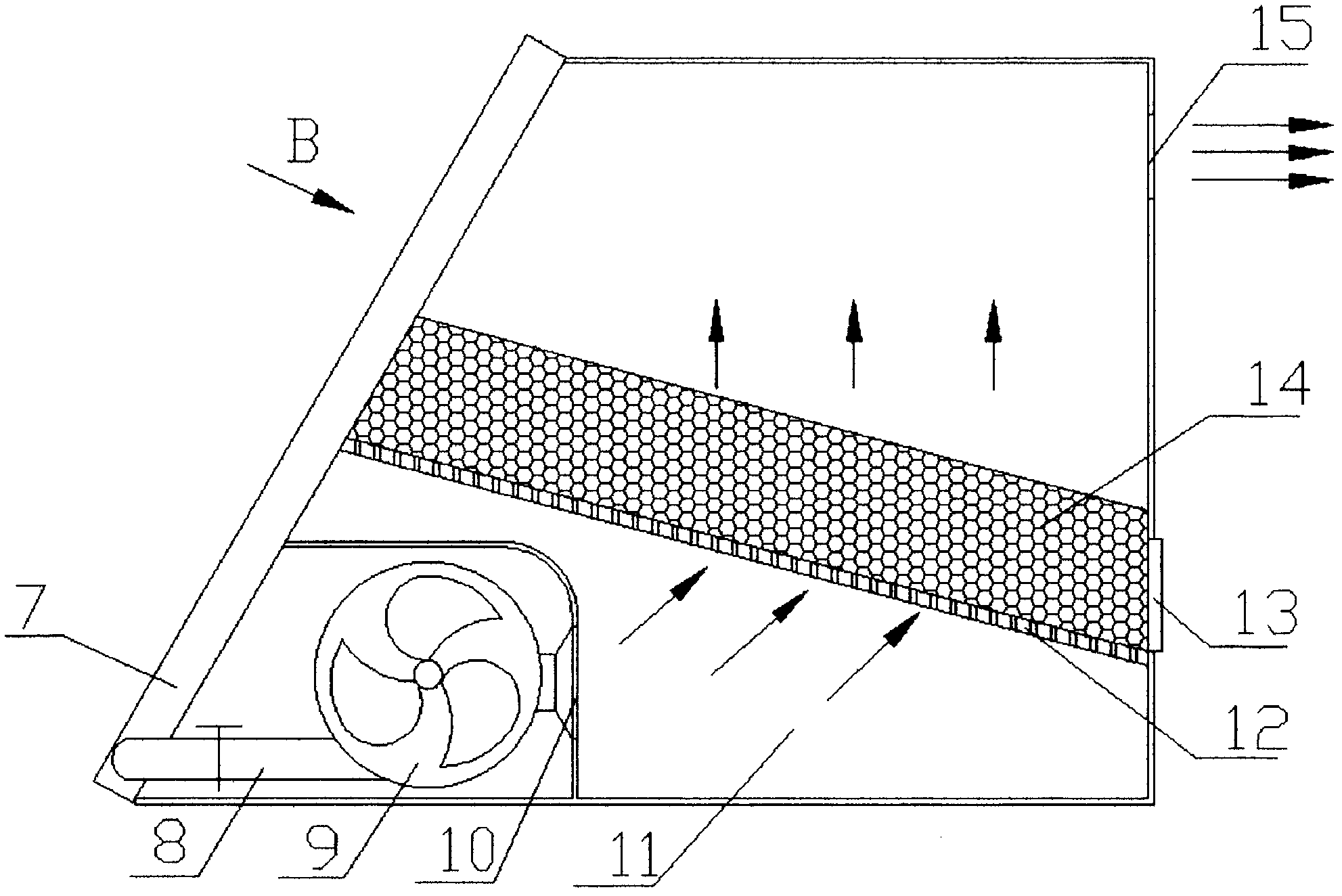

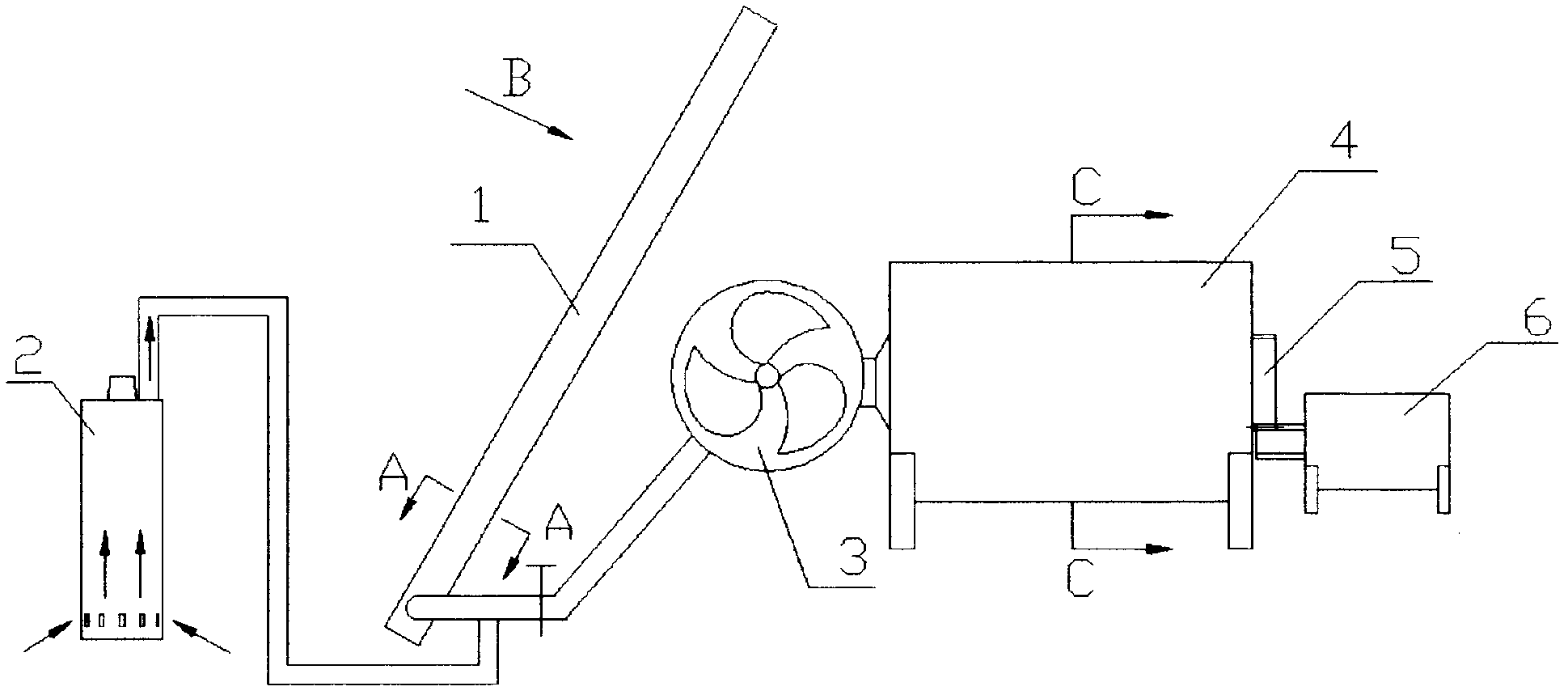

Intelligent effective and multifunctional solar air heat collection dryer

InactiveCN103898722ASimple structureImprove energy savingSolar heat devicesDrying gas arrangementsThermodynamicsControl system

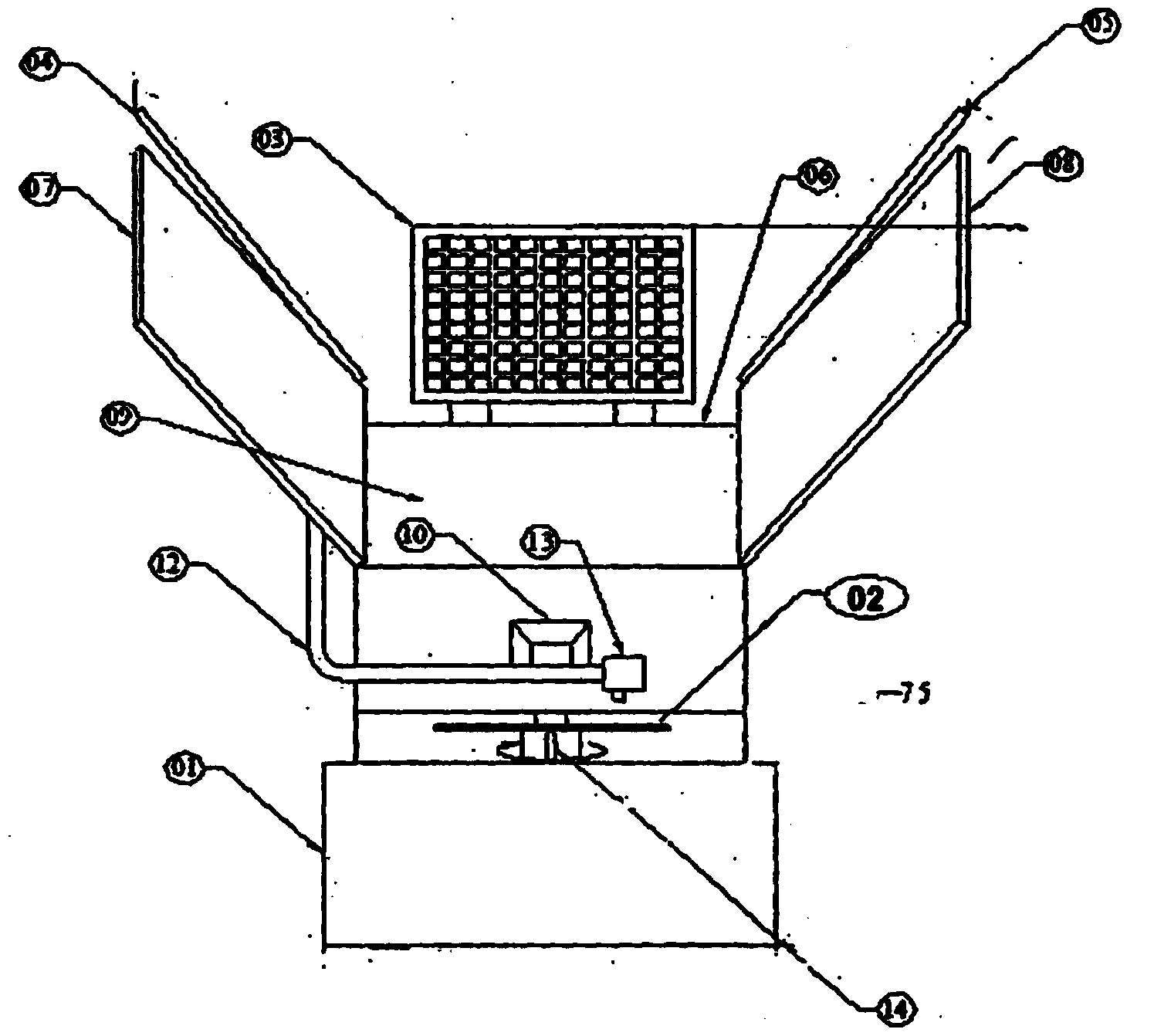

The invention relates to a solar dryer. An intelligent effective and multifunctional solar air heat collection dryer is characterized in that the dryer comprises a fan, an airflow pipeline, a solar air heat collector and a hanging rack, the solar air heat collector is formed by solar cell panels and an air heat collector, the solar cell panels are arranged on the two sides of the air heat collector respectively, the output ends of the solar cell panels are connected with the power input end of a storage battery of an electric energy control system, the output end of a pressure control switch of the electric energy control system is respectively connected with the fan and an auxiliary heating device, an air outlet of the fan is communicated with an air inlet of the air heat collector through the airflow pipeline, an air outlet of the air heat collector is communicated with a warm air inlet of the hanging rack, and the hanging rack is provided with a warm air outlet. The dryer has the advantages of being low in cost and good in energy-saving effect.

Owner:WUHAN UNIV OF TECH

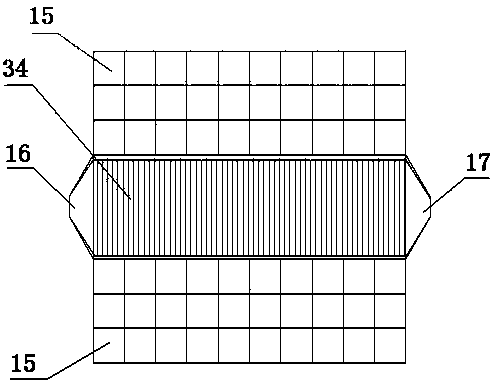

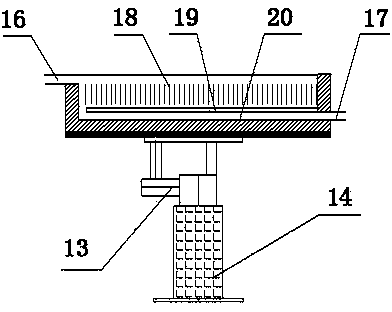

Low melting point alloy phase change heat storage device applied to solar dryer

InactiveCN102620534AMake up for low thermal conductivity, poor phase transition stability and other deficienciesNo pollutionHeat storage plantsEnergy storageHeat conductingHeat storage material

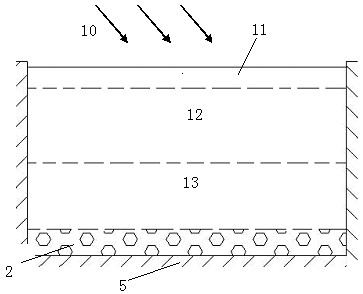

The invention relates to a low melting point alloy phase change heat storage device applied to a solar dryer, which is characterized by comprising a drying chamber box body, a drawing type material containing box, heat storage blocks and an upper and lower sliding type heat insulation door. Two to one hundred heat storage blocks are arranged in a drying space of the drying chamber box body, and the edge parts of the heat storage blocks are supported by the heat insulation blocks to be fixed with the drying chamber box body. The drawing type material containing box is located between an upper heat storage block and a lower heat storage block and is contacted with the lower heat storage bock, and drying samples are contained in the drawing type material containing box. Each heat storage block is composed of a heat storage material container, a heat storage material, a heat conducting pipe and heat conducting oil. The heat storage materials are encapsulated in the heat storage material containers, the heat conducting pipes are arranged in the heat storage material containers, the heat storage materials are encapsulated between the inner walls of the heat storage material containers and the outer walls of the heat conducting pipes, and the heat conducting oil serves as a heat conducting medium in the heat conducting pipes. The low melting point alloy phase change heat storage device applied to the solar dryer has the advantages of being convenient in feeding and discharging, reliable, safe and high in drying efficiency.

Owner:WUHAN UNIV OF TECH

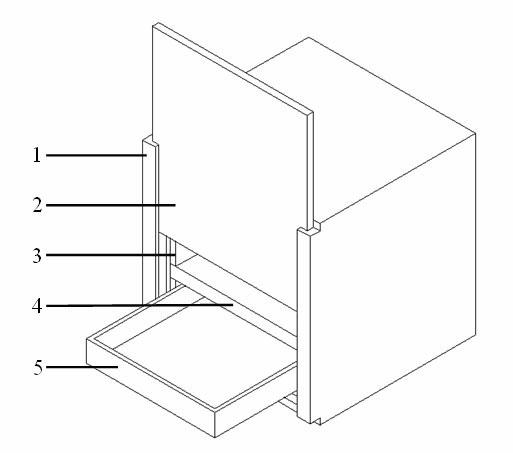

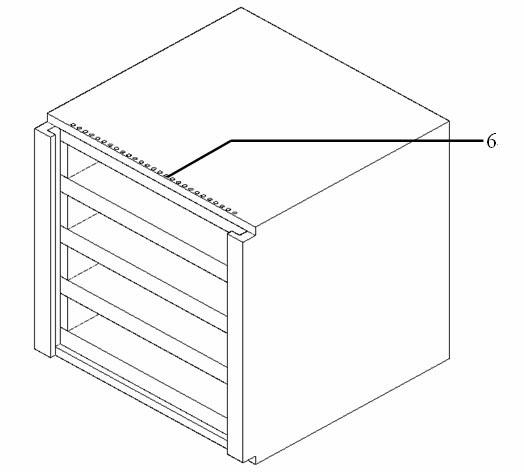

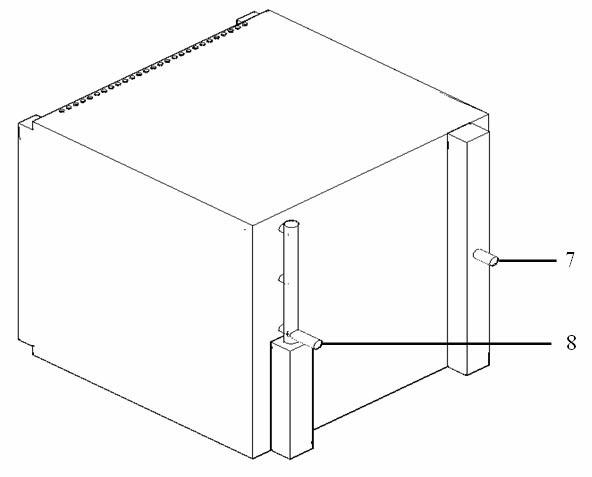

Solar dryer with enhanced efficiency of drying

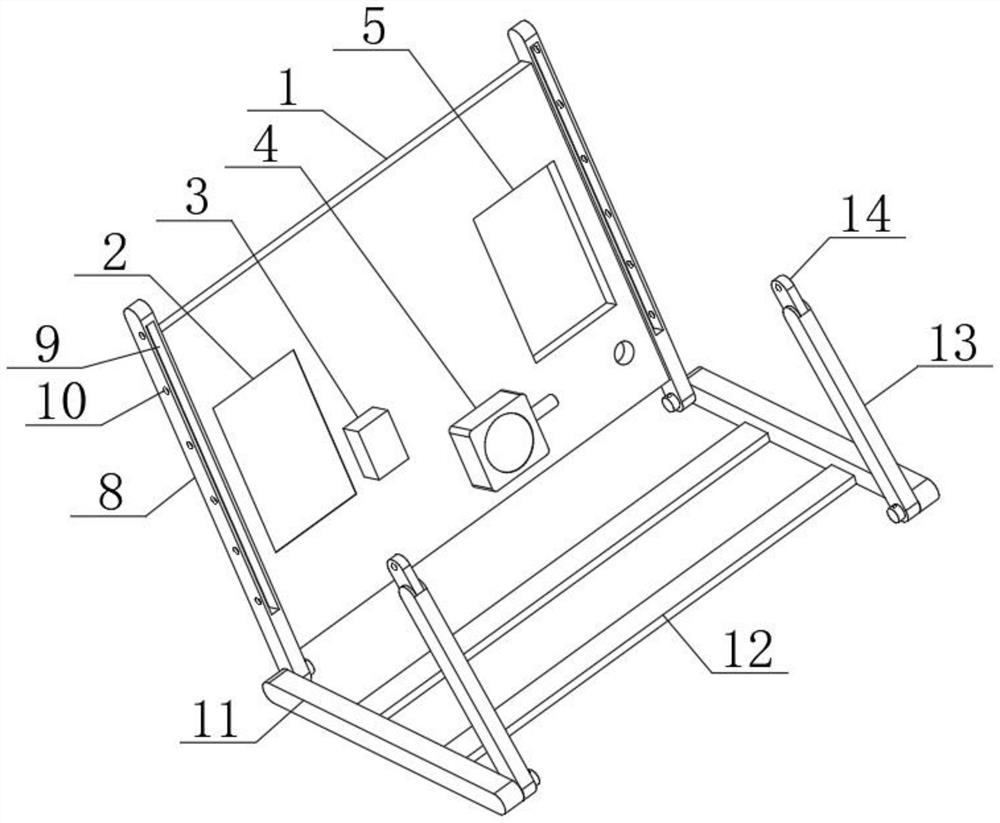

InactiveUS20140182158A1Improve drying efficiencyEnhance solar insolationSolar heating energyDrying solid materials with heatSolar dryerSolar absorber

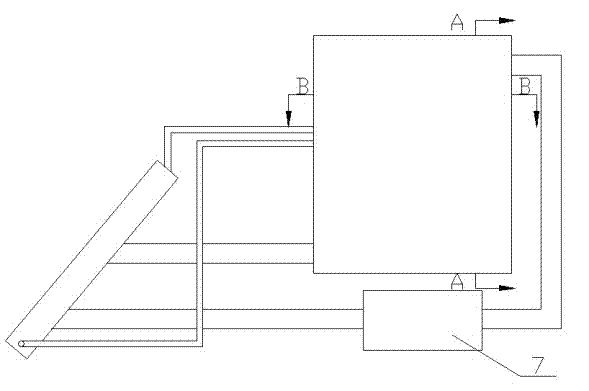

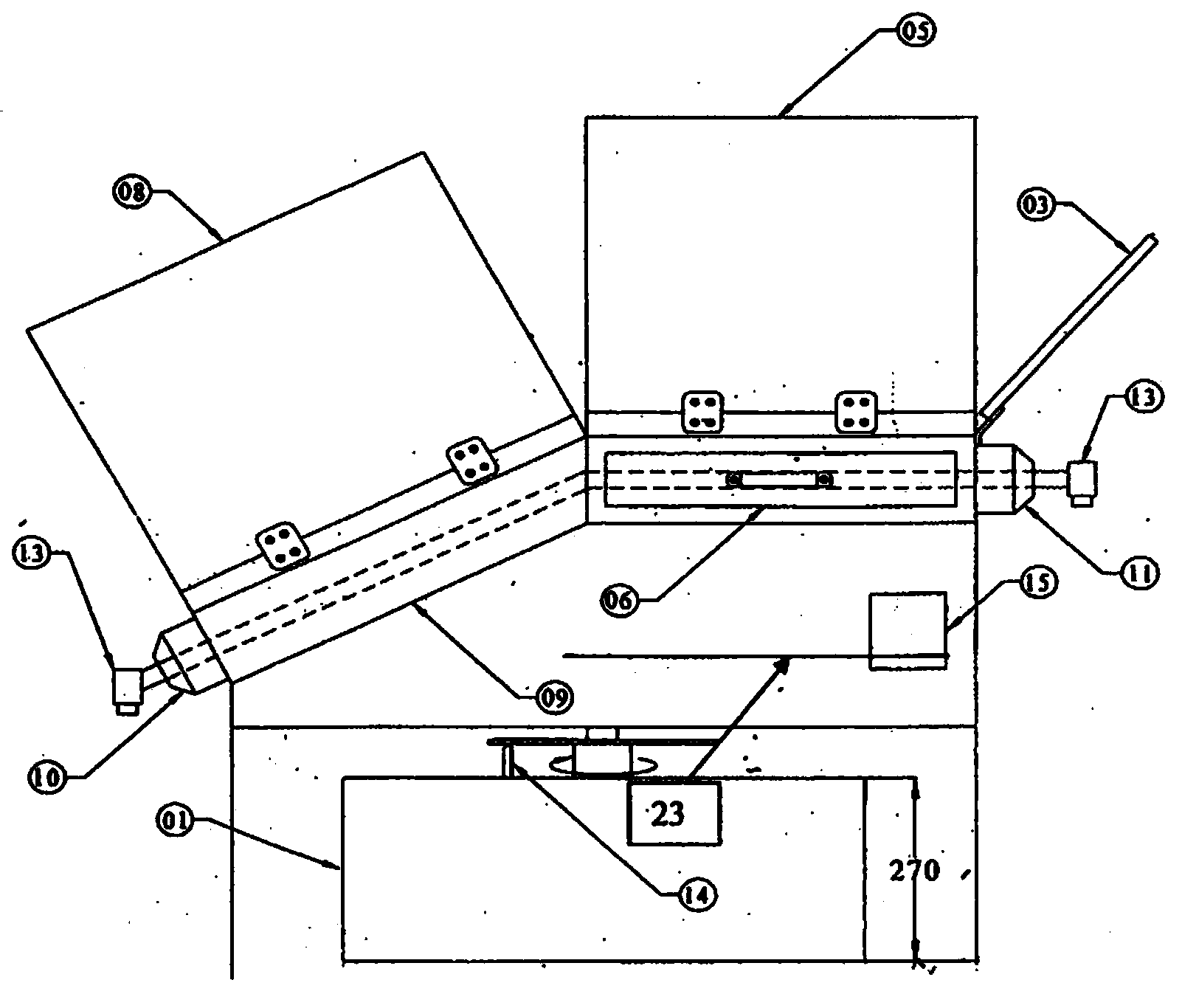

The present invention provides an improved solar dryer with improved. The dryer consists of a solar absorber / collector (9) and a drying chamber (6). One end of the collector is connected to a forced draft fan (10) and the other end connects the drying chamber. The drying chamber has a drawer in which the material to be dried is kept on a wire mesh. The dryer further has the provision for placing color indicative silica gel under the wire mesh when operated in recirculation mode. The other end of the drying chamber has an induced draft fan (11). Both the dc fans operate using a 10 watt photovoltaic panel (3). V-trough reflectors (4,5,7,8) made from anodized aluminum are fixed on the collector and optionally on the drying chamber. A tracking circuit is incorporated to auto-track the dryer. A locking mechanism (14) is also incorporated to help the unit withstand high wind load. The dryer further has the provision of programmable recirculation of the spent air from drying chamber once its humidity drops below a pre -set value which process helps to speed up the rate of drying.

Owner:COUNCIL OF SCI & IND RES

Solar pond composite drying system

InactiveCN102183096AImprove heat storage capacityTake advantage ofSolar heating energySolar heat devicesGreenhouseBoiler slag

The invention relates to a solar pond composite drying system. The system comprises a salt gradient solar pond, wherein an upper layer of the salt gradient solar pond is an upper convection layer which consists of clear water, a lower layer of the salt gradient solar pond is a lower convection layer, namely a heat storage layer, which consists of saturated salt solution, and a middle layer of the salt gradient solar pond is a non-convection layer, namely a gradient layer. A porous heat absorption dielectric layer is arranged in the heat storage layer of the salt gradient solar pond. Waste boiler slag is used as a heat absorption dielectric in the porous heat absorption dielectric layer. In order to enhance a heat absorption effect, the waste boiler slag is laid at the bottom of the solar pond to serve as the heat absorption dielectric. The solar pond has functions of a heat collector and a heat storage device; the system has a simple structure and is low in manufacturing cost; heat can be stored for a long time (extraseasonally); and a low-temperature heat source with stable performance can be provided all year around. Through the system, the problem of serious influence of changes of weather on a heat collector-greenhouse type solar dryer is solved, solar energy is fully utilized, and drying efficiency is increased.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Process for gradient treating organic wastes

InactiveCN1576246AMaximize utilizationHigh economic valueBio-organic fraction processingClimate change adaptationMarshFeces

The stepped pig and / or ox excrement treating process includes pre-treatment of the gathered excrement, conventional anaerobic digestion in marsh pool to prepare marsh gas, using marsh gas for generating electric power, precipitating dregs in the precipitation tank from the marsh pool, using marsh liquid from the precipitation tank in planting feed grass, drying the marsh dregs with solar energy for planting mushroom, raising earthworm with the leftover after gathering mushroom, and using earthworm excrement in planting feed grass. The present invention forms one positive circulation to realize the comprehensive utilization of wastes.

Owner:李益冉

Solar dryer

InactiveCN102889769AIncrease flow rateFast exchangeSolar heating energySolar heat devicesThermodynamicsCollector device

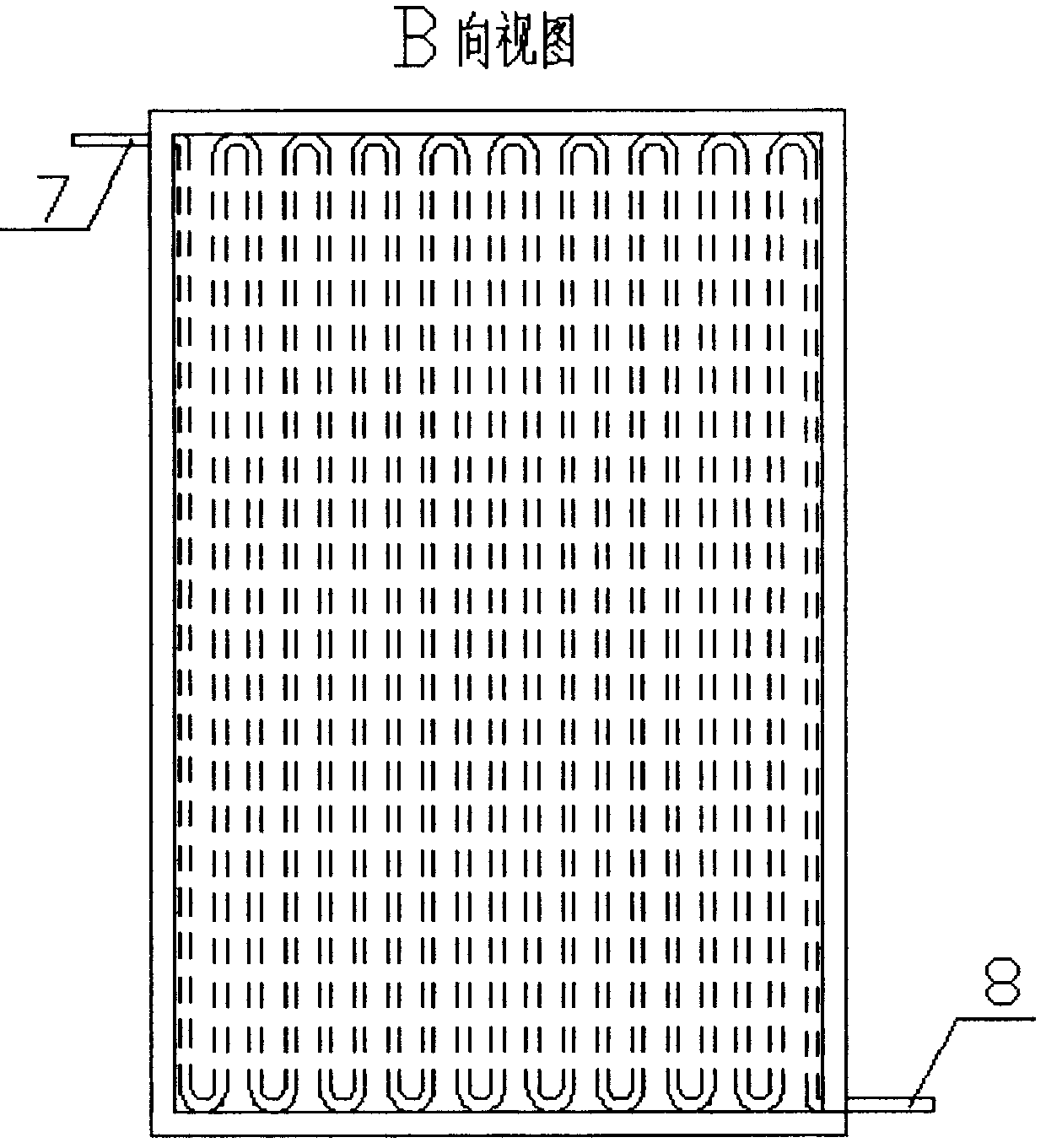

The invention discloses a solar dryer. The dryer comprises a solar collector, a medium pipeline, a ventilating pipeline and a drying cabin, wherein a heat absorber of the collector is formed by a porous heat absorbing plate with a snake bend welded on the back; the snake bend is filled with heat-conducting media with boiling points at about 30 DEG C; a heat release pipeline divided into a plurality of layers is designed on the upper layer of the drying cabin; and the heat release pipeline and the heat absorber are connected by a pipeline. The dryer has the beneficial effects that the heat-conducting media circularly flow between the heat absorbers and the heat release pipeline and transmit heat to the dried objects quickly, thus reducing the heat loss and increasing the drying speed; and the air passes through the porous heat absorbing plate, absorbs heat and becomes hot air, the hot air is sent into the drying cabin and takes away moisture, and the hot air can be recycled after being dried by the dryer.

Owner:JIANGSU QIZHENG NEW ENERGY

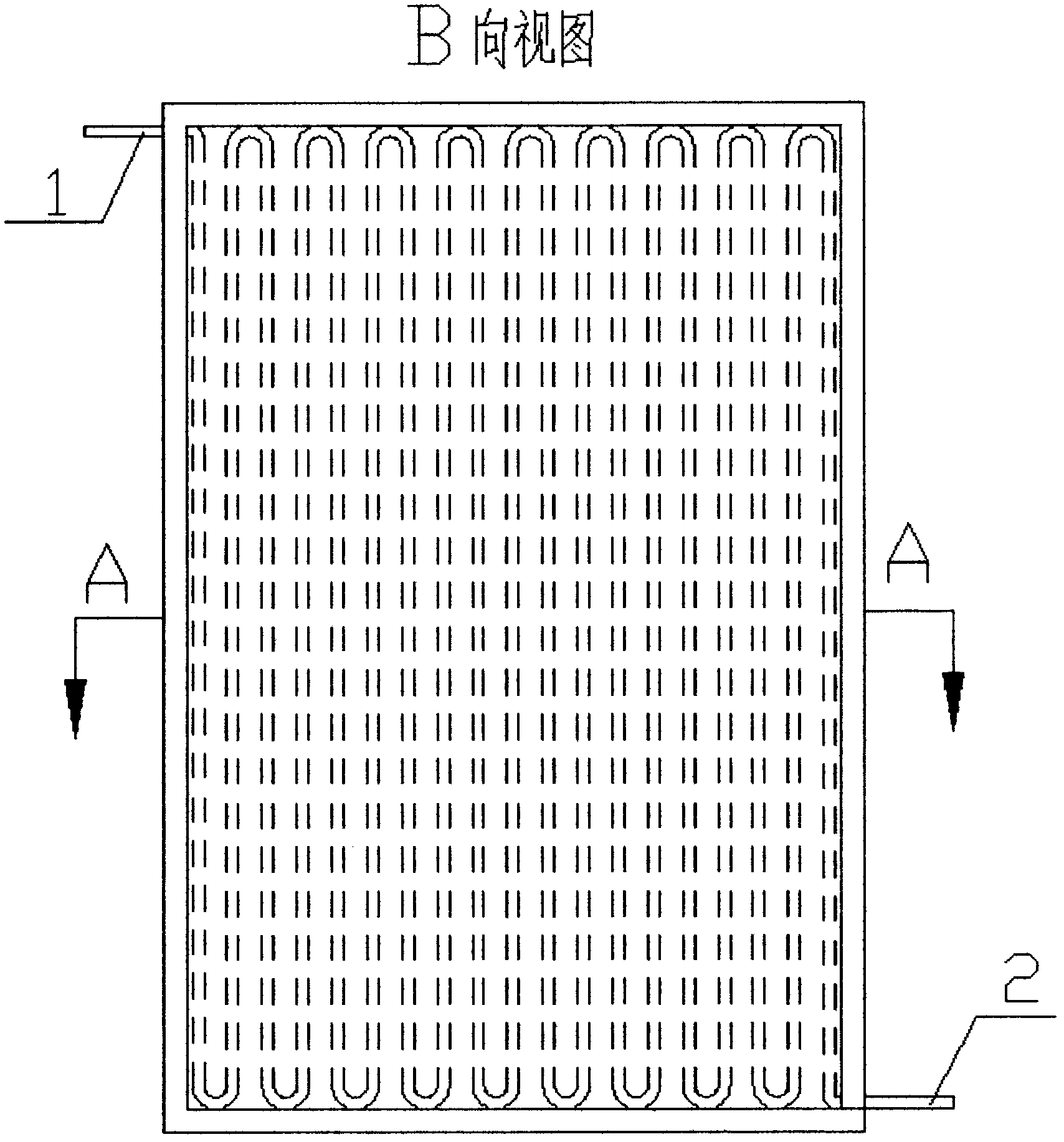

Solar dryer

InactiveCN102901330AIncrease flow rateFast exchangeSolar heating energySolar heat devicesThermodynamicsProcess engineering

The invention discloses a solar dryer. The solar dryer comprises a solar heat collector, a medium pipeline, a ventilating pipeline and a drying bin; a heat absorbing body of the heat collector is formed by a multi-pore heat absorbing plate which is provided with an S-shaped bend on the back surface; the S-shaped bend is filled by a heat-conducting medium with boiling point of about 30 DEG C; a heat releasing pipeline, which is divided into a plurality of layers, is arranged at the upper layer of the drying bin; and the heat releasing pipeline is integrally connected with the heat absorbing body through a pipeline. According to the solar dryer, the heat-conducting medium circularly flows between the heat absorbing body and the heat releasing pipeline, and the heat is quickly transmitted to a drying object, so that the heat loss is reduced, and the drying speed is raised; and the air absorbs heat during passing through the multi-pore heat absorbing plates, so that hot air can be generated, and the hot air is conveyed into the drying bin to remove the moisture.

Owner:JIANGSU QIZHENG NEW ENERGY

Solar dryer

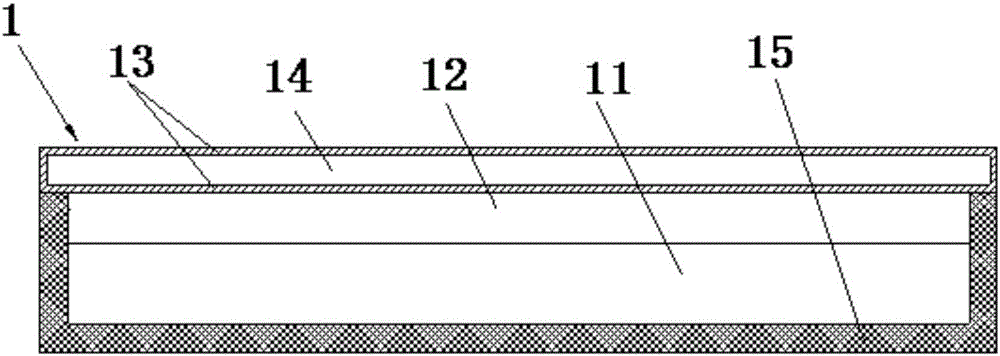

InactiveCN105222371AImprove thermal conductivityRapid heat storageSolar heating energySolar heat devicesPlate heat exchangerSolar light

The invention relates to a solar dryer which comprises an oil tank, an evacuated collector tube, circulating oil pumps, a drying system and a liquid-gas heat exchanger, wherein conduction oil is stored in the oil tank, the circulating oil pumps are arranged on oil outlets of the oil tank, and the oil outlets of the oil tank comprise two paths; reflective collecting mirrors are uniformly and fixedly arranged on the periphery of the evacuated collector tube and utilizes focused solar light to heat the conduction oil flowing through the evacuated collector tube; a temperature sensor for measuring the temperature of the conduction oil is arranged in the oil tank; the conduction oil achieving the temperature requirement flows through the liquid-gas heat exchanger and exchanges heat with process gas in the drying system, so that the process gas is dried. According to the solar dryer, after the high-temperature conduction oil exchanges heat with the process gas in the liquid-gas heat exchanger, the heated process gas is used for drying substances to be dried in a drying tube, for example drying tobaccos; thus, the utilization field of solar energy is widened.

Owner:山东新帅克能源科技有限公司

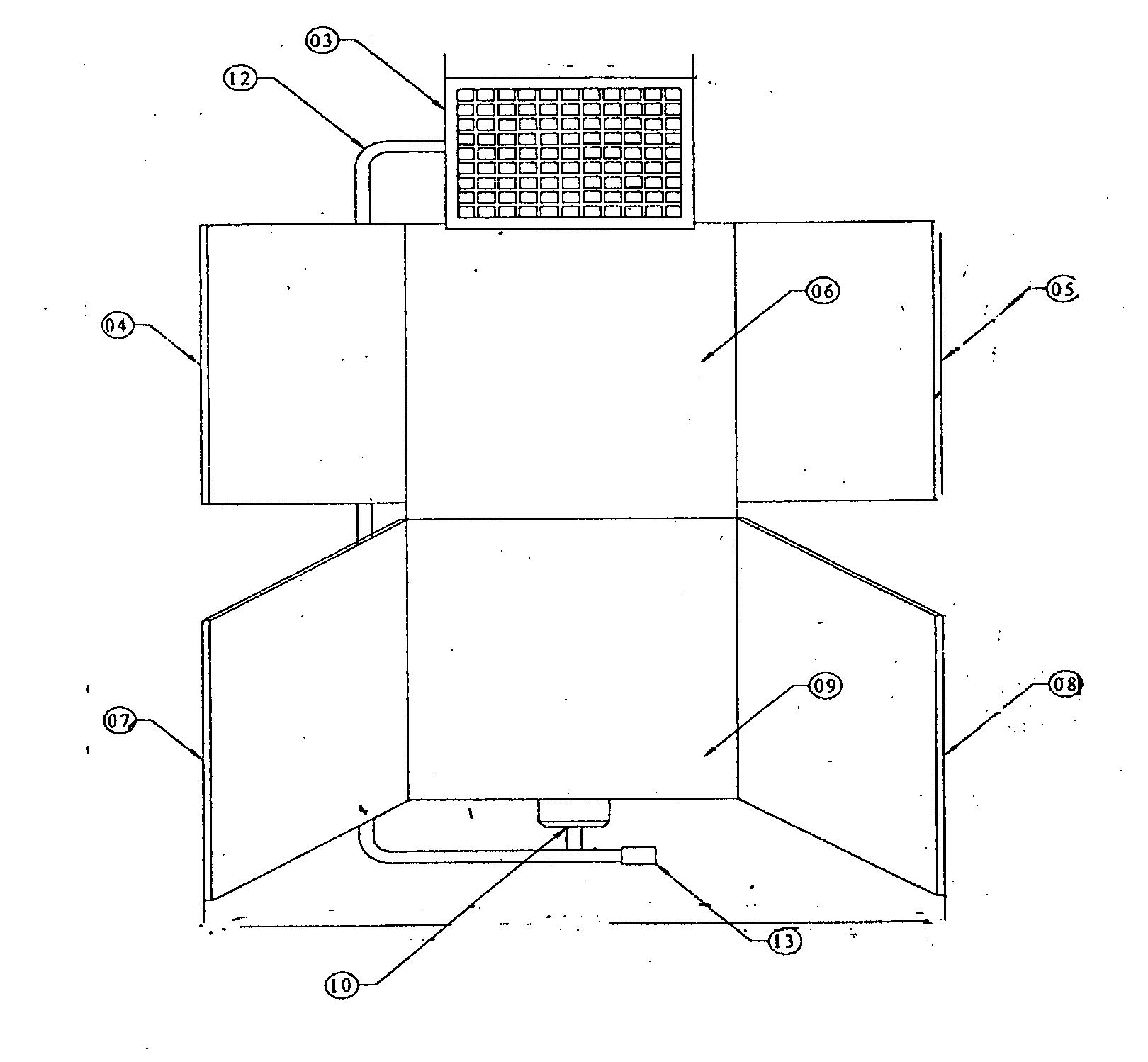

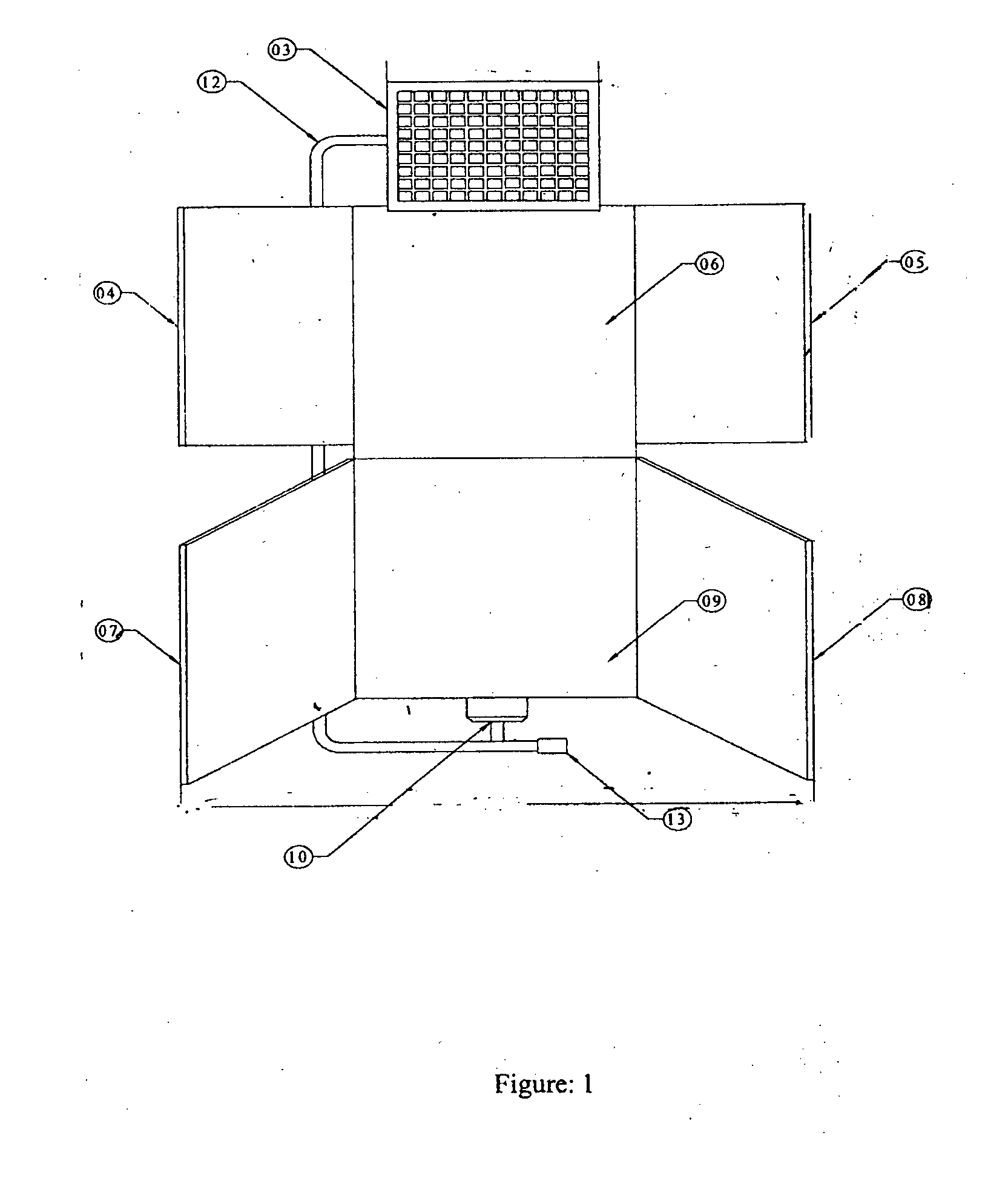

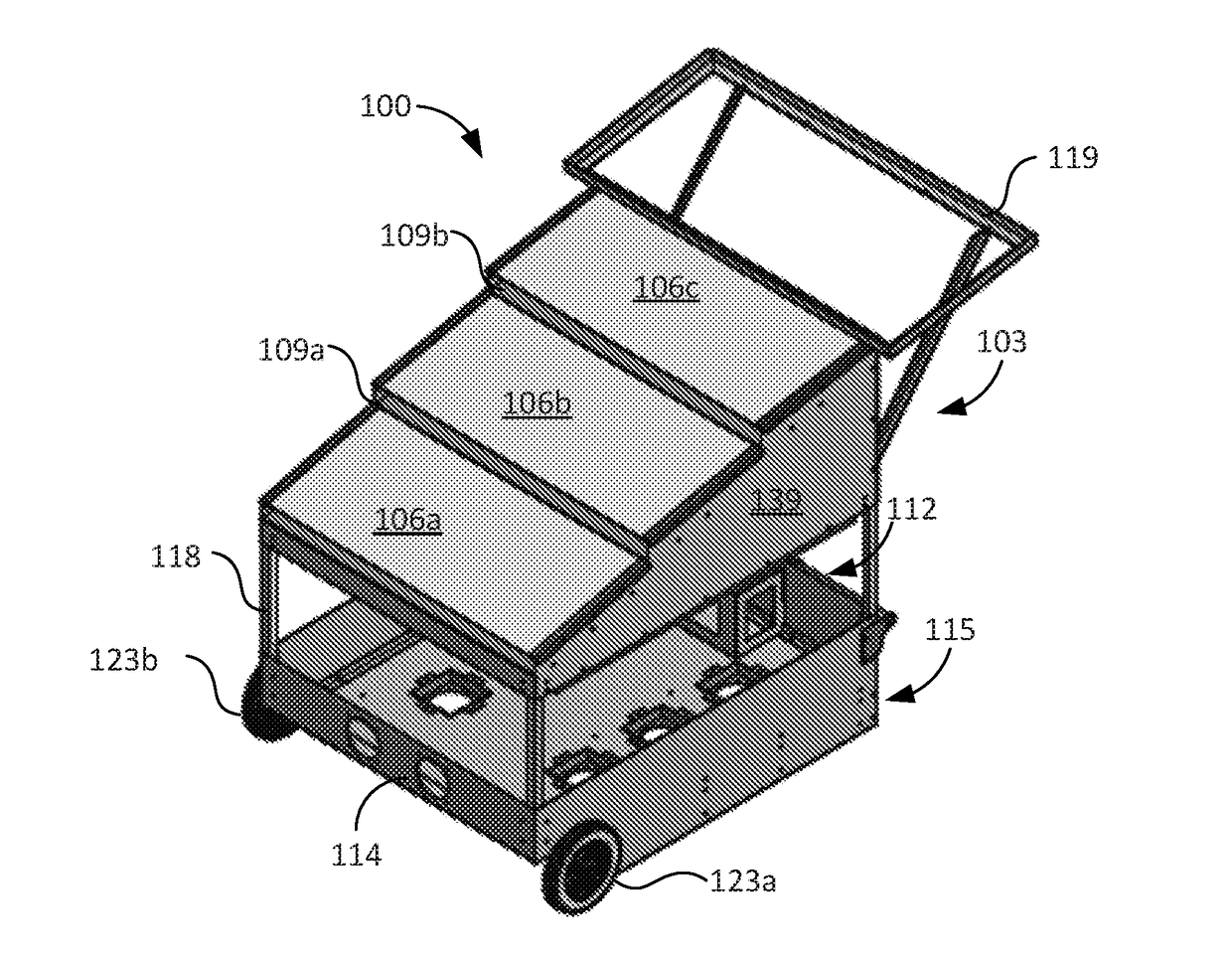

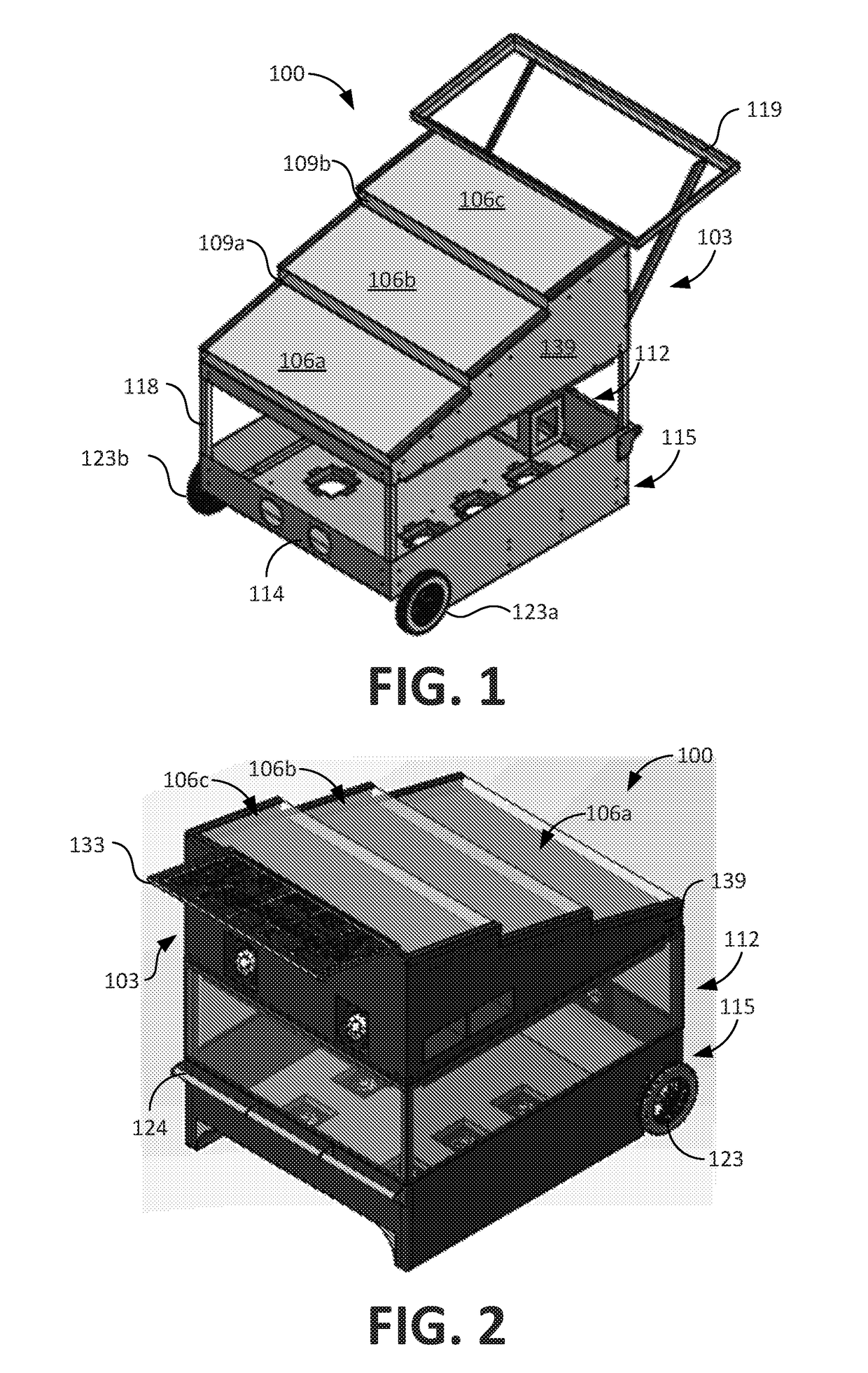

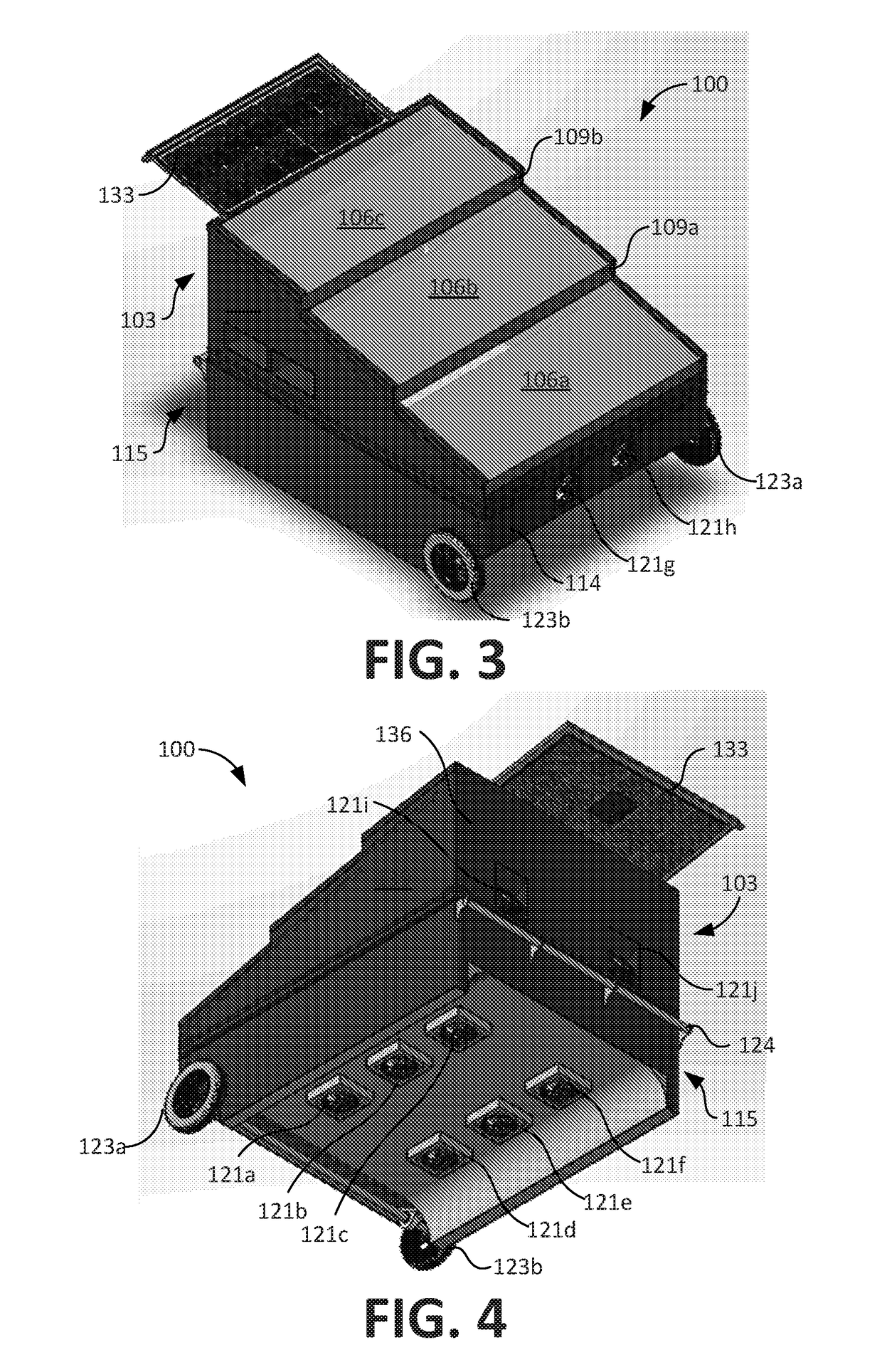

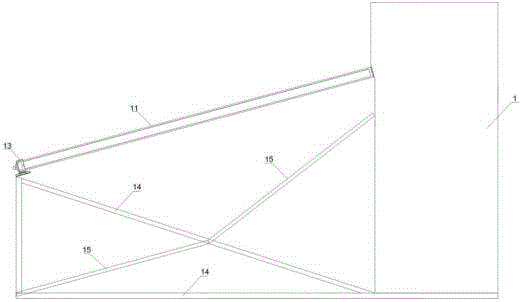

Modular collapsible solar dryer for multipurpose drying

ActiveUS20180231308A1Reduce air pressureIncrease airflowDrying solid materials with heatDrying gas arrangementsSolar dryingModularity

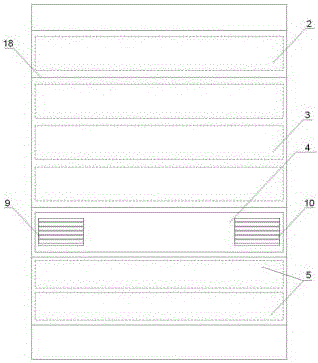

A solar dryer system, including an upper thermal collection unit including a plurality of tiers of thermal radiation collection panels, where a vent is disposed between adjacent ones of the tiers of the thermal radiation collection panels. The solar dryer system can include a chamber disposed between the upper thermal collection unit and a base, where the chamber is configured to receive an object for a drying process using the dryer system. The solar dryer system can also include at least one fan disposed within the chamber and coupled to the base to provide circulation for the drying process.

Owner:PURDUE RES FOUND INC

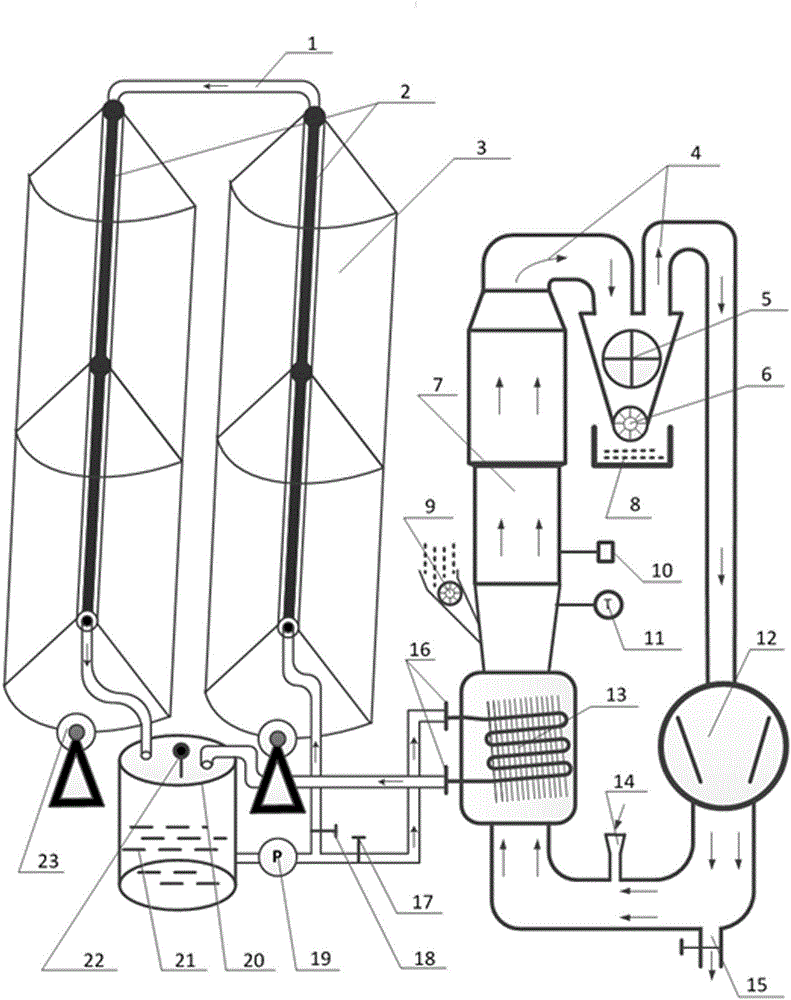

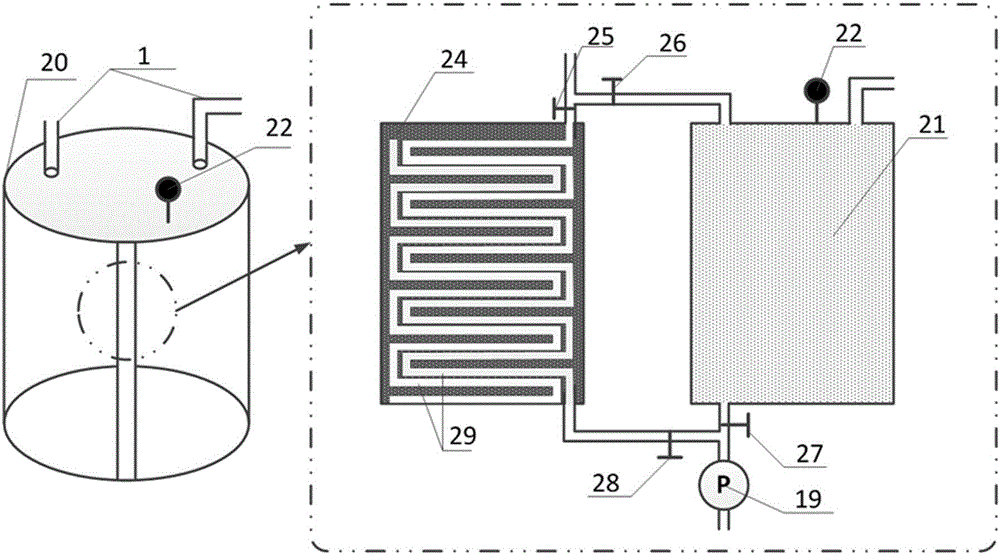

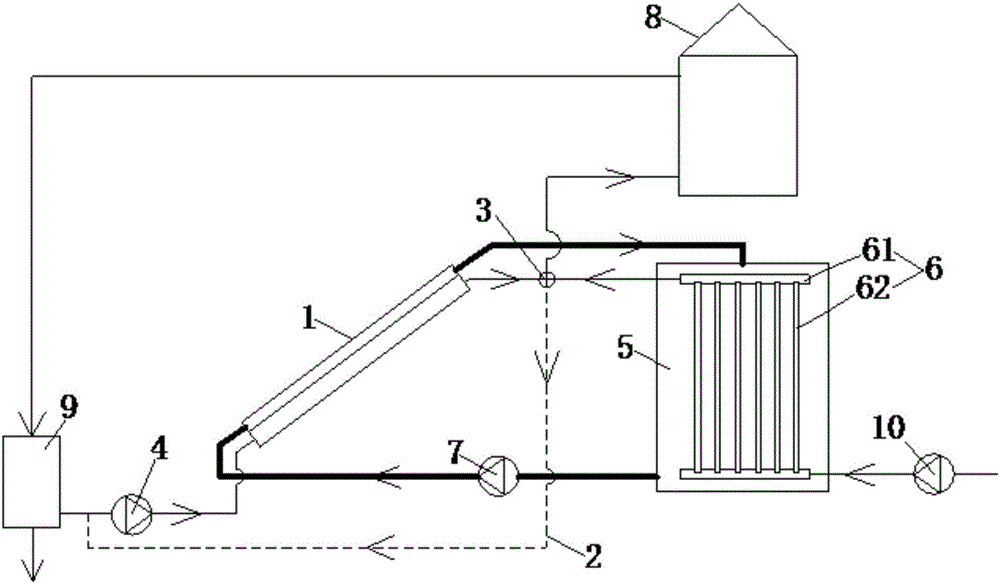

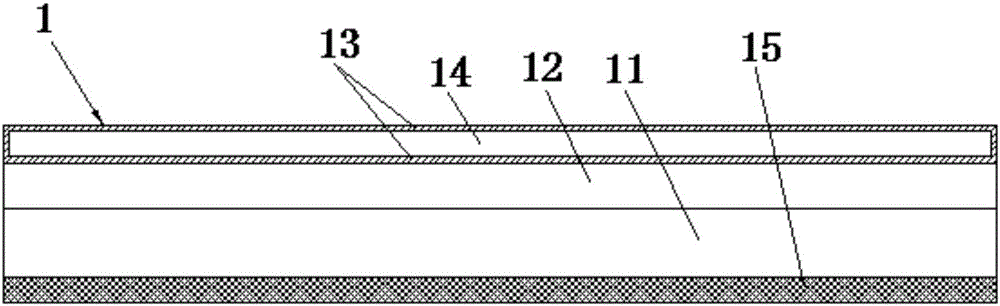

Two-medium solar drying boiler system

InactiveCN106382810AIncrease heating capacityAvoid the problem of frequent changes in thermal parametersSolar heating energySolar heat collector controllersSolar dryingIrradiation

The invention belongs to the technical field of solar utilization, and particularly relates to a double-medium solar drying boiler system which comprises a double-medium solar heat collector, a drying room, a salt heat storage tank, a salt / air heat exchanger, a salt pump, a first fan and a humidity-heat heat exchanger, wherein the double-medium solar heat collector comprises an air runner and a salt runner; one end of the air runner communicates with the drying room; one end of the salt runner communicates with one end of the salt heat storage tank; the other end of the salt heat storage tank communicates with the other end of the salt runner through the salt pump; the salt / air heat exchanger is arranged in the salt heat storage tank; and the drying room sequentially communicates with the other end of the air runner through the humidity-heat heat exchanger and the first fan. The double-medium solar drying boiler system can be used for solving the problem that temperature fluctuation of the solar dryer is relatively great in a crop drying process very well, can restrain damages, caused by rapid rise of the air temperature, on the dried materials when solar irradiation suddenly rises, and can enable the solar wheel to have more practical prospect in agriculture.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

Novel efficient solar dryer

PendingCN112344658AImprove drying efficiencySave electricityDrying solid materials with heatDrying chambers/containersThermodynamicsCollector device

The invention relates to the technical field of dryers, in particular to a novel efficient solar dryer. The novel efficient solar dryer comprises a mounting plate, wherein a photovoltaic panel is fixedly mounted on one side of the front face of the mounting plate, an inverter and an air blower are fixedly connected to the back face of the mounting plate, a hole groove is formed in one side of themounting plate, a trough type heat collector is fixedly mounted in the hole groove, and a drying box is fixedly mounted on the front face of the mounting plate. The novel efficient solar dryer has theadvantages that by arranging the photovoltaic panel, the trough type heat collector and the drying box on the mounting plate, heat collection and power generation are conducted at the same time, thedrying efficiency is improved, and a low cost is guaranteed; as the angle of the mounting plate can be adjusted at multiple angles, the solar energy utilization rate is increased; by arranging partition plates in a heat collection pipe, the heat absorption effect is enhanced; by arranging a heat conduction plate, materials can be uniformly heated; by arranging small boxes on a storage rack, the problem of material accumulation is avoided; by arranging supporting plates, the materials can be conveniently taken or placed; and a heat conduction plate fixing structure is simple, effective and convenient to manufacture.

Owner:INNER MONGOLIA UNIV OF TECH

Photoelectric thermal coupling solar drier with heat storage function

InactiveCN108895774AImprove heat utilizationImprove drying effectSolar heating energySolar heat storageFresnel lensEngineering

The invention discloses a photoelectric thermal coupling solar drier with a heat storage function. The driver comprises a heat storage chamber and a drying chamber, exhaust holes are formed in the topof the drying chamber, and an air inlet in the right side of the bottom of the drying chamber is communicated with the heat storage chamber; a materiel laying layer is installed in the drying chamber, a linear Fresnel lens is arranged at the top of the heat storage chamber, a heat storage copper pipe is installed in the heat storage chamber, and a fan is connected to the heat storage copper pipe.According to the photoelectric thermal coupling solar drier, sunlight is focused through the Fresnel lens, then the heat storage copper pipe is adopted for heat storage, hot airflow collected in theheat storage copper pipe is blown by the fan into the drying chamber, materials in the drying chamber are dried, the utilization rate of heat energy is high, the drying effect is good, the structure is relatively simplified, and the manufacturing cost is lowered.

Owner:GUIZHOU UNIV

All-weather solar dryer

The invention discloses an all-weather solar dryer. The part of an upper outlet of a solar heat collector is connected with the upper end of a water storage tank through a pipeline, a lower port of the solar heat collector is communicated with the lower end of the water storage tank via an auxiliary water pump, a furnace body is a cavity with one side open, a heat exchanger is arranged at the open position of one side of the furnace body, one end of the heat exchanger is communicated with the bottom of the water storage tank through a pipeline, the other end of the heat exchanger is communicated with the upper-end liquid level of the water storage tank through a main water pump, a main air blower is arranged in the furnace body and close to the inner side of the heat exchanger, a feed bin is arranged at the top end of the furnace body, a screen is arranged at the bottom of the feed bin, the feed bin and the furnace body are communicated via the screen, and the inlet end and the outlet end of an auxiliary air blower are communicated with an upper port of the feed bin and the bottom of the water storage tank respectively through pipelines. The all-weather solar dryer is an auxiliary electric heater, and can be ensured to be normally used in weather without sunshine.

Owner:XUZHOU BINGCHEN ELECTRONICS

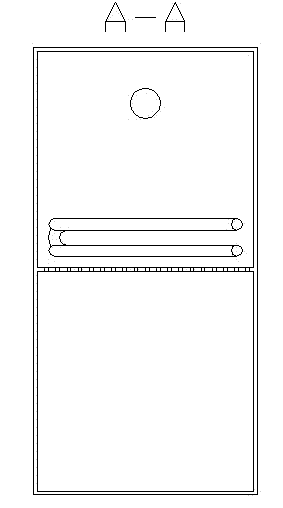

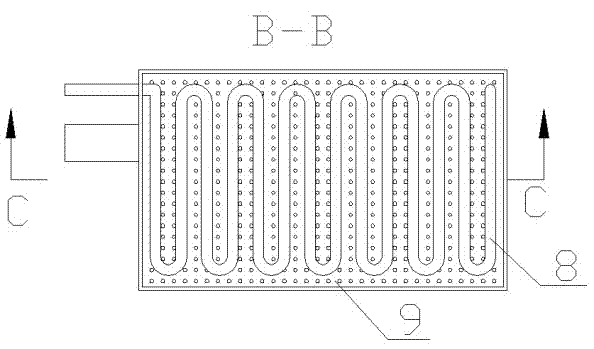

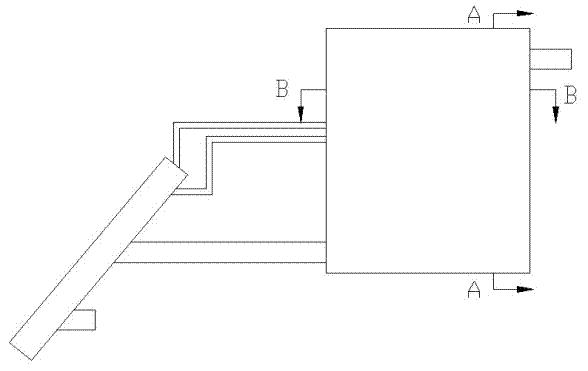

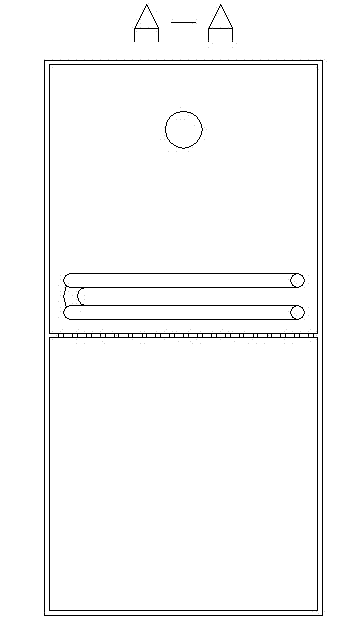

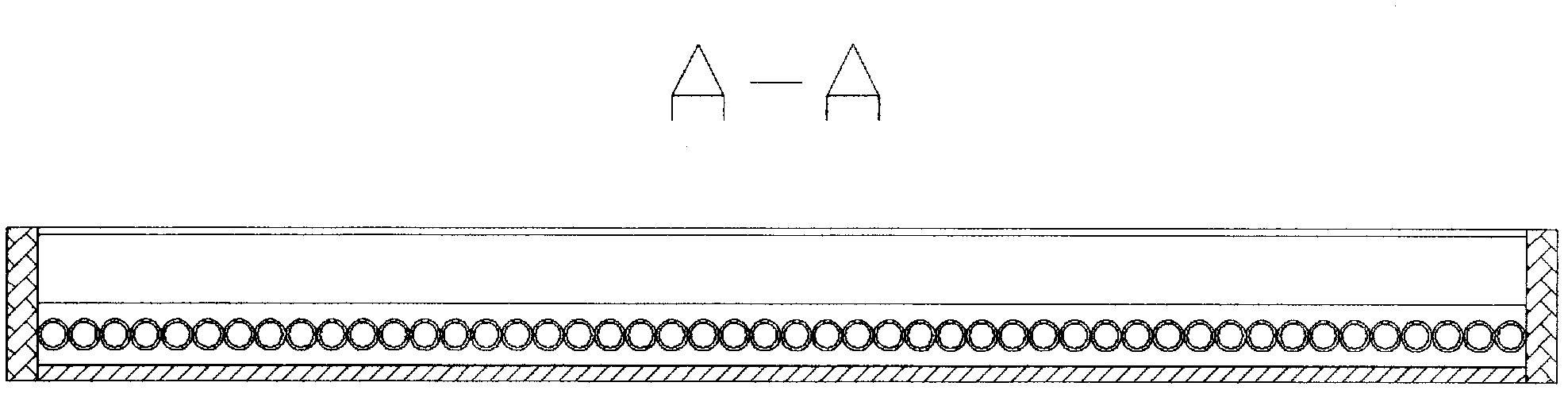

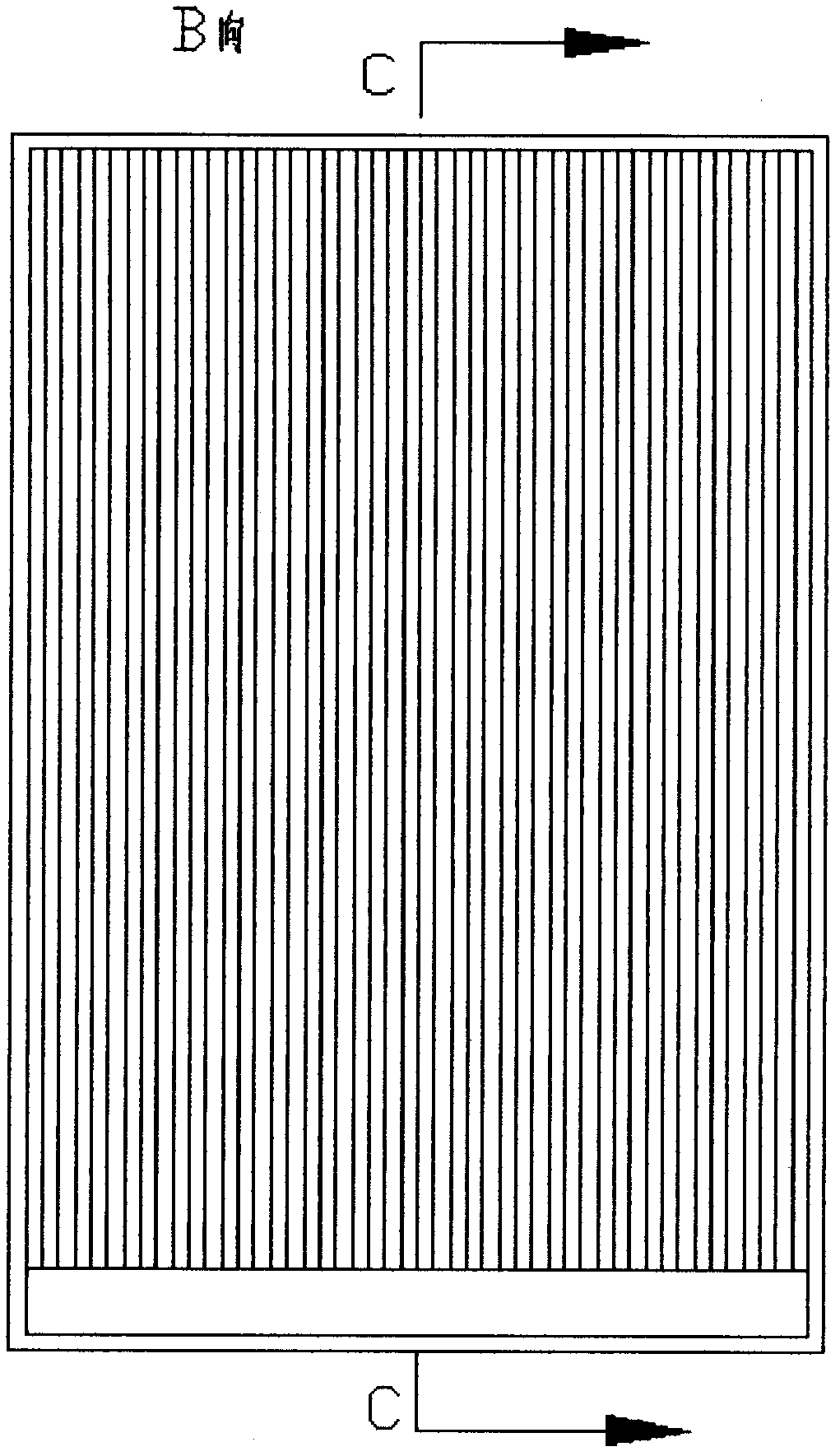

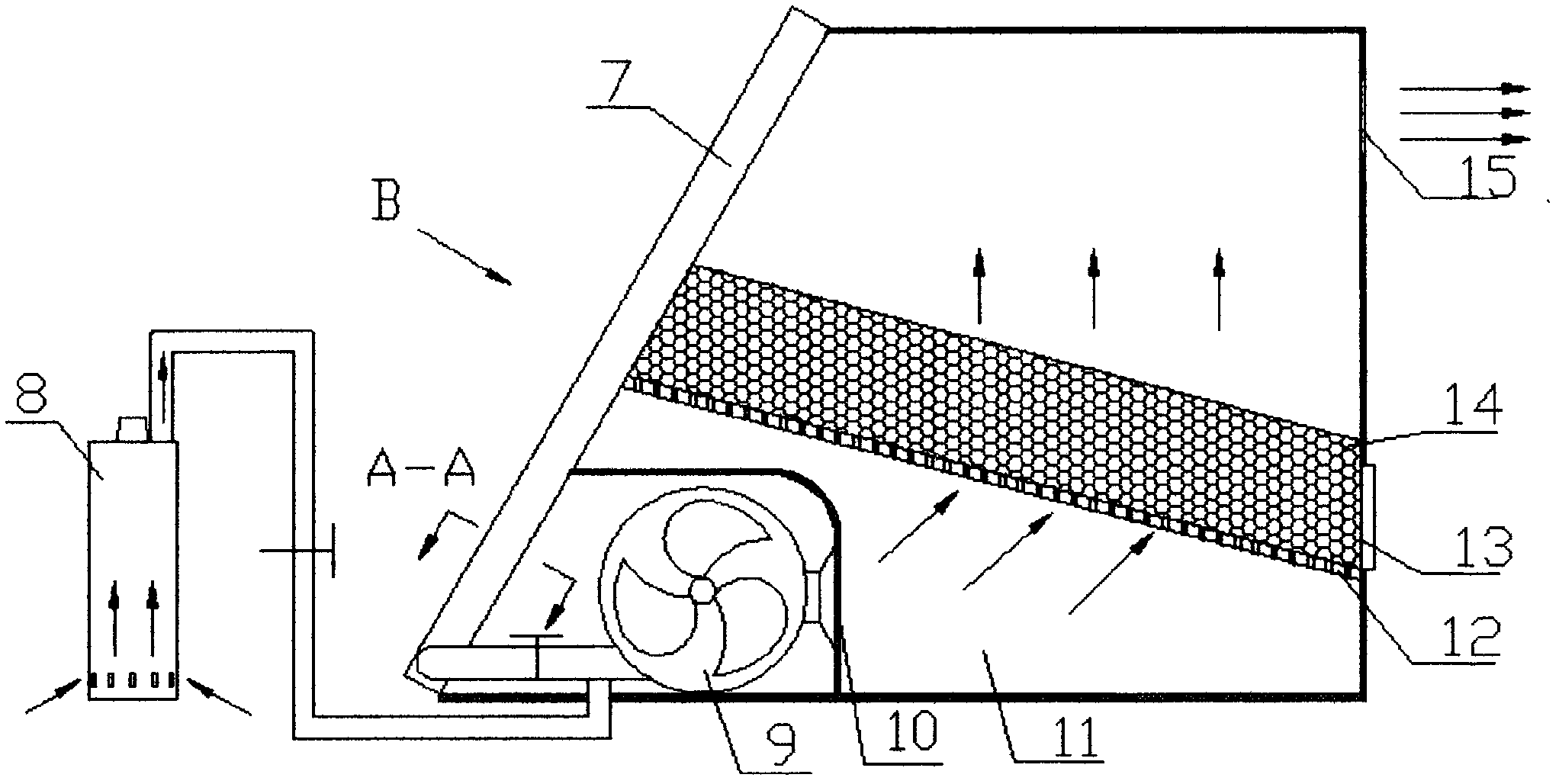

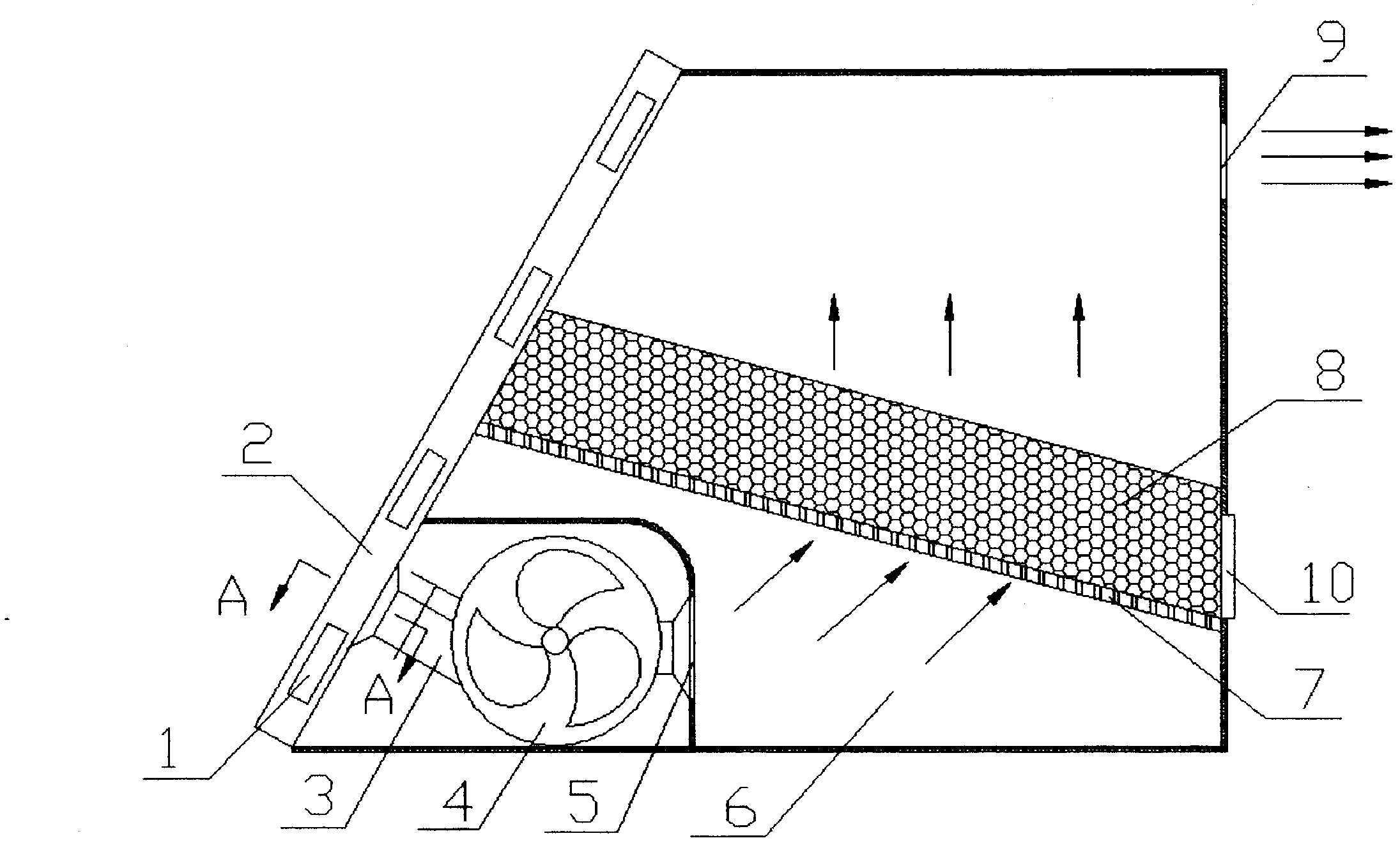

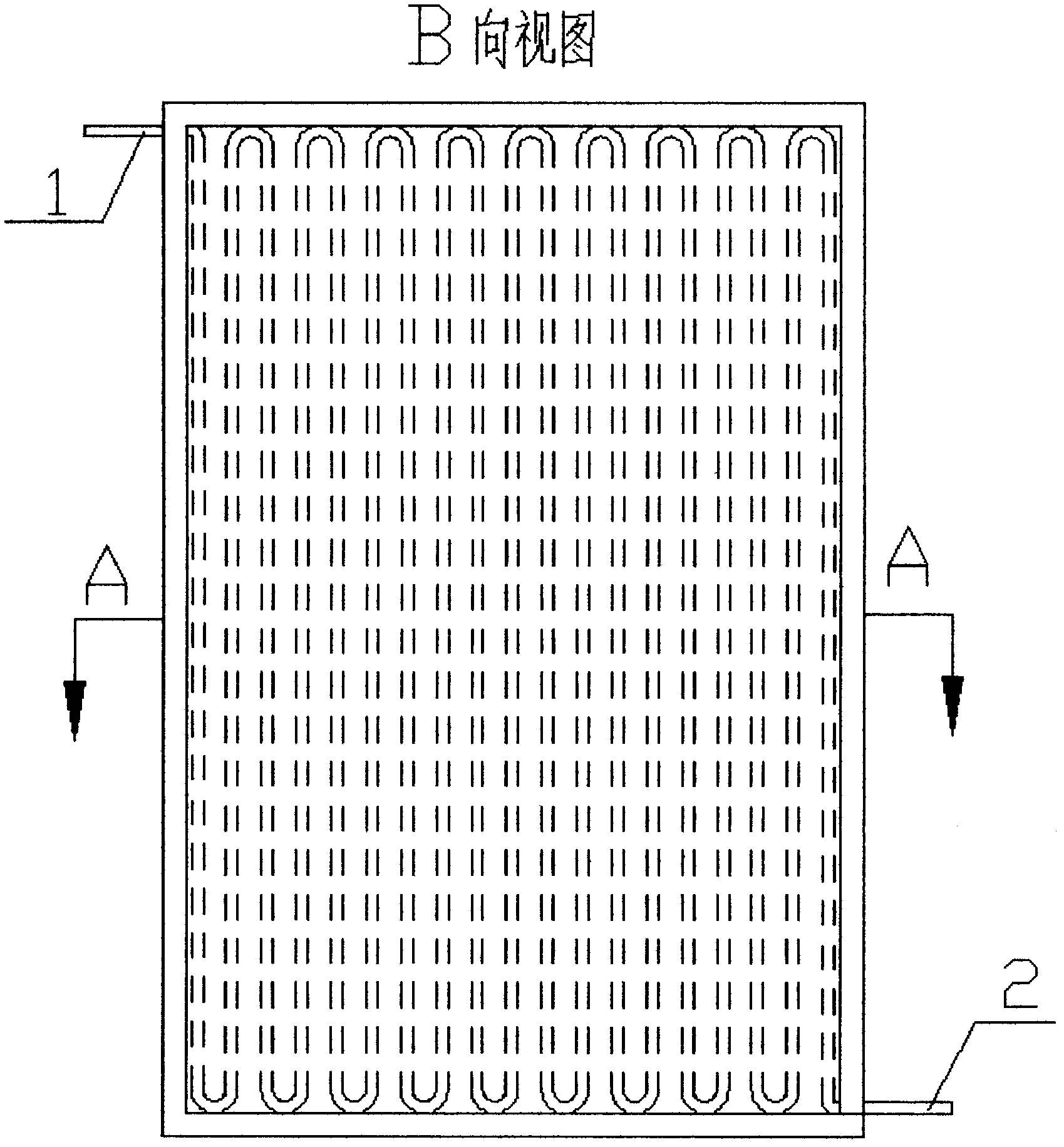

Tube type integrated solar dryer

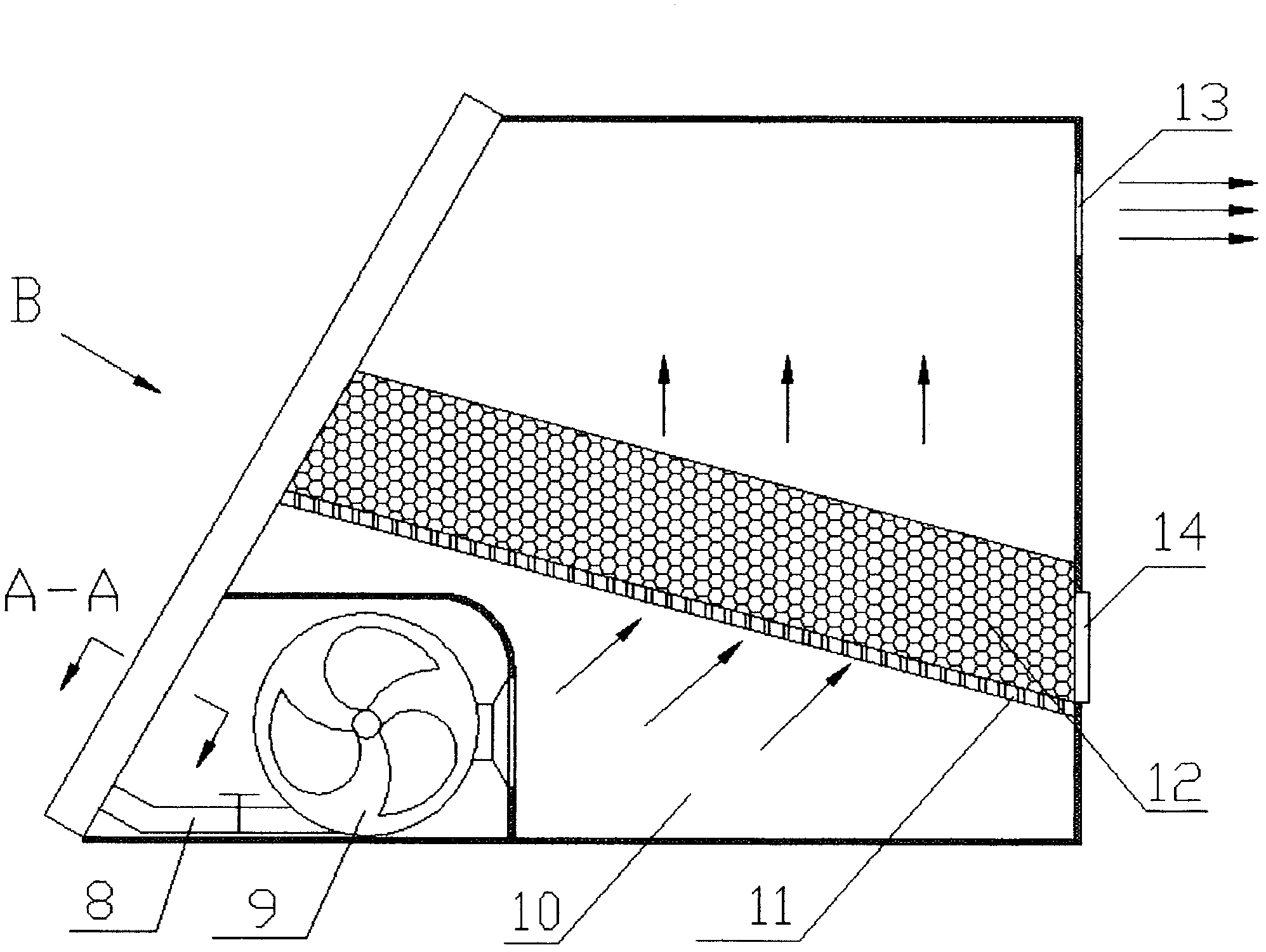

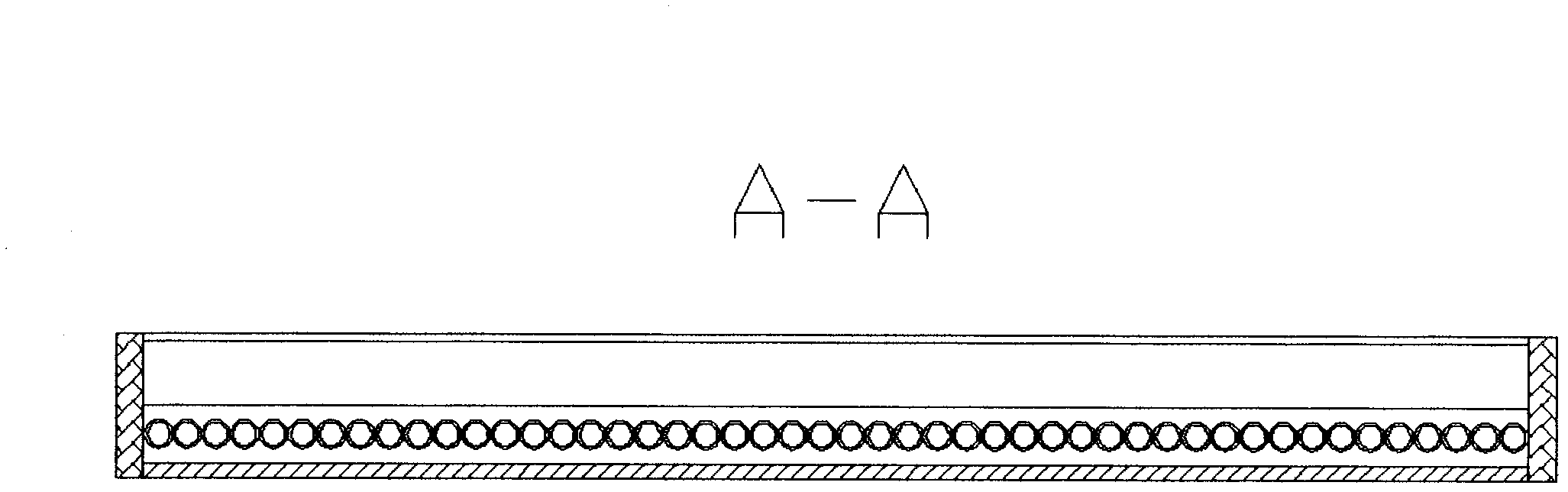

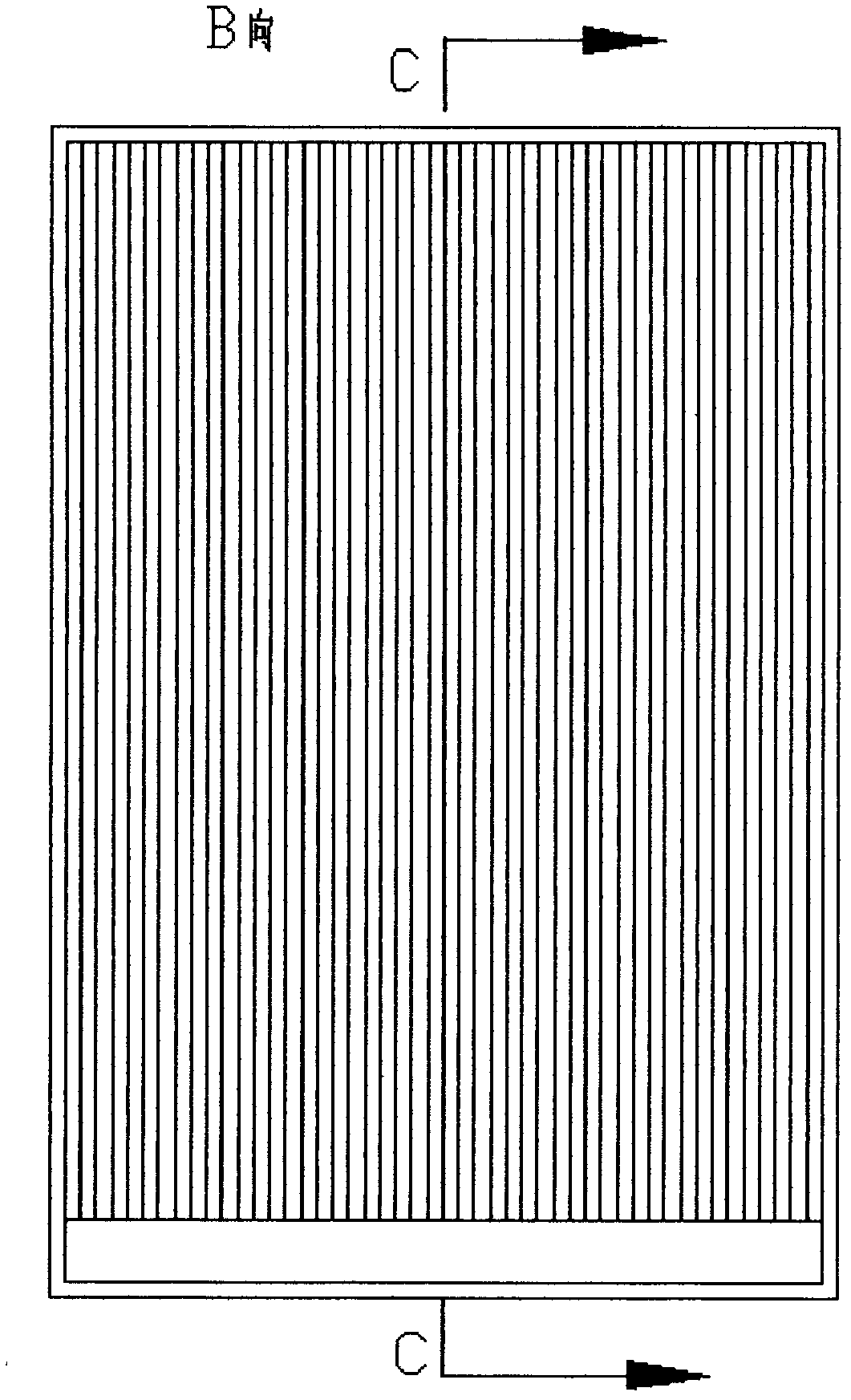

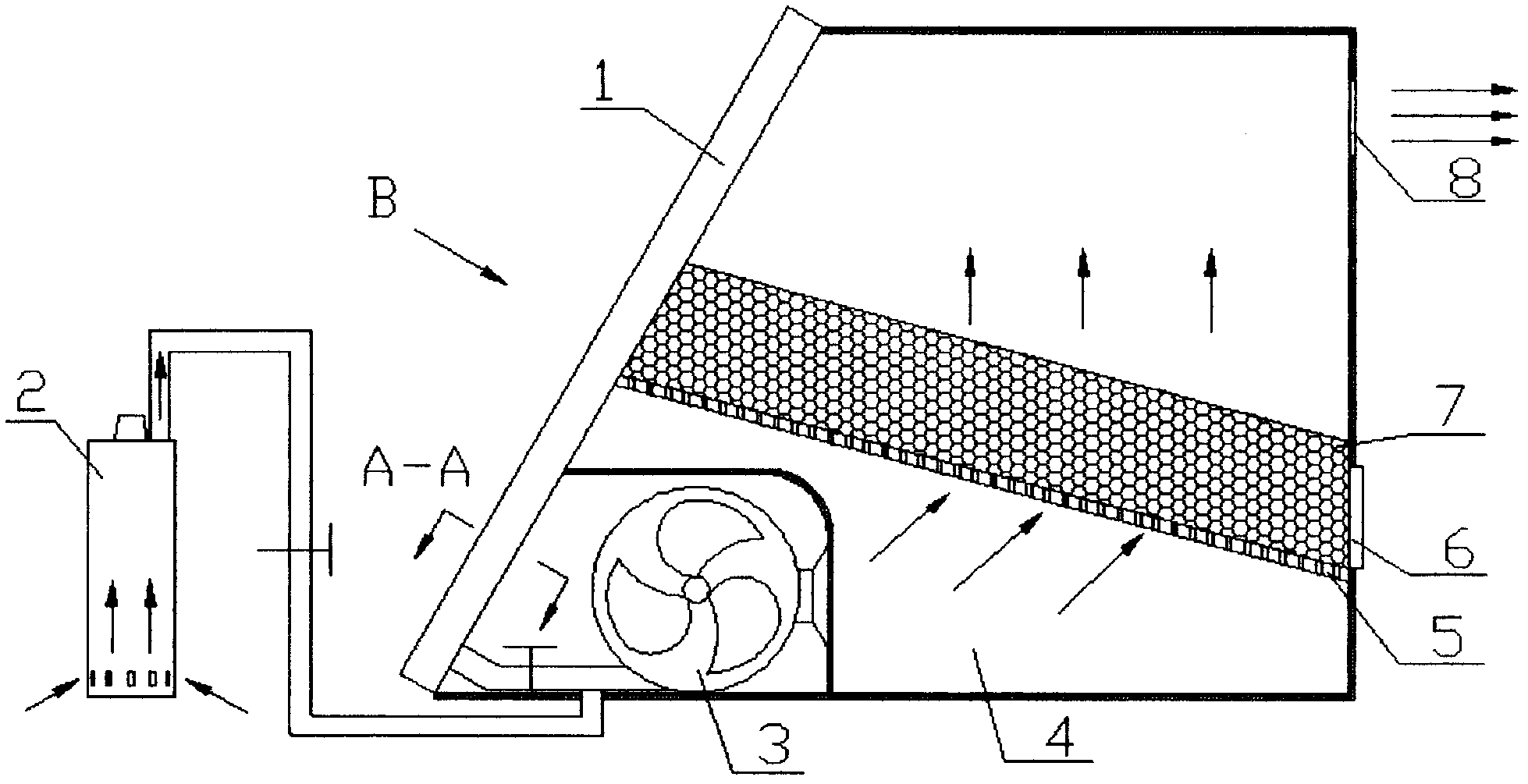

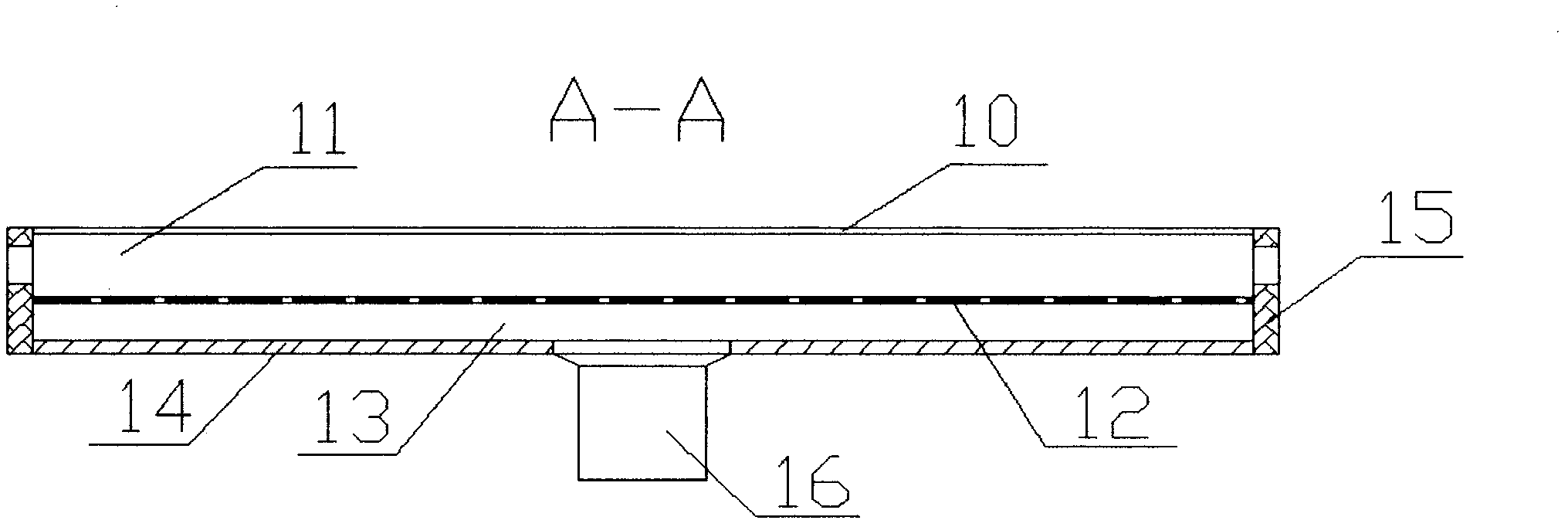

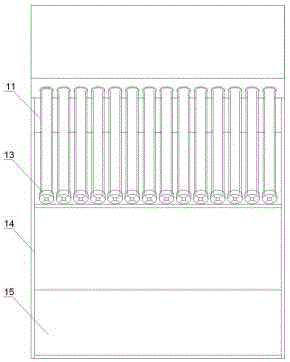

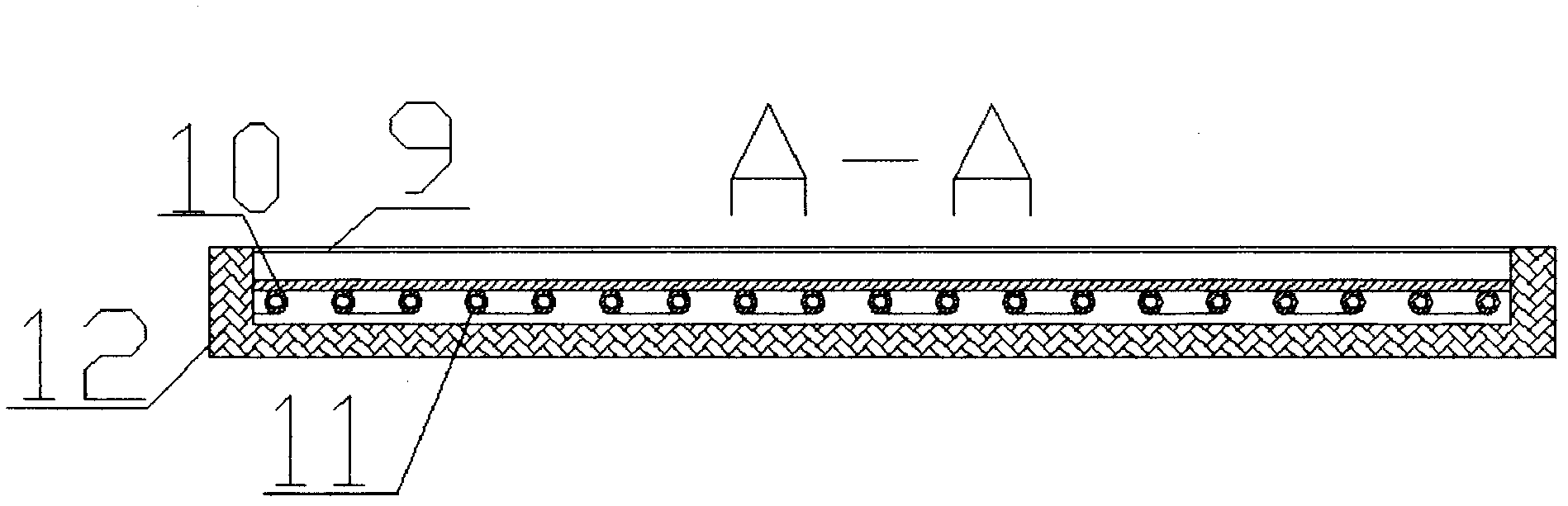

InactiveCN102607244AEasy to pour outEnsure parallelism without slippingSolar heating energySolar heat devicesSolar air collectorHeat losses

The invention discloses a tube type integrated solar dryer, which comprises a solar heat collector, a fan, a ventilating tube and a drying bin. The solar heat collector is a tube type solar air collector, and a porous screen in the drying chamber is arranged in an inclination angle of 20 degrees. The drying temperature of the tube type integrated solar dryer ranges from 30 DEGC to 50 DEG C, and accordingly quality of dried products is guaranteed. Besides, since the solar air collector is integrated with the drying bin, heat loss is reduced, and the tube type integrated solar dryer is applicable to drying crops of single rural family.

Owner:ZHENJIANG XINMENGXI ENERGY TECH

Auxiliary heating pipeline integral type solar drier

InactiveCN102620531AEasy to unloadEnsure parallelism without slippingSolar heating energyFood processingEngineeringHeating furnace

The invention discloses an auxiliary heating pipeline integral type solar drier, which comprises a pipeline solar air heat collector, a heating furnace, a blower, a pipeline and a drying chamber. A heat collection part of the heat collector comprises collection pipes and exhausting pipes, the perforated sieve of the drying chamber is placed at an inclination angle of 20 degrees, and the heating furnace uses crop straws as fuel. The entire system constitutes a compact whole, and the air heat collector and the drying chamber enclose to form a drying space. The drying temperature of the system is around 50 DEG C, so that the quality of dried products is ensured. Also, the system is compact in designed structure and high in heat efficiency, and is suitable for crop drying quantity demanded by a single rural family.

Owner:ZHENJIANG XINMENGXI ENERGY TECH

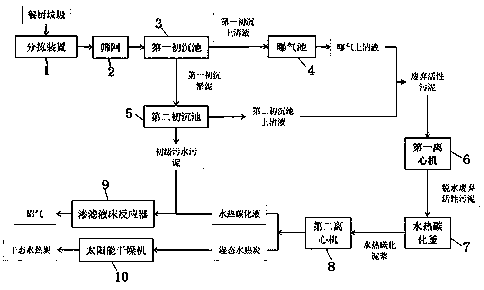

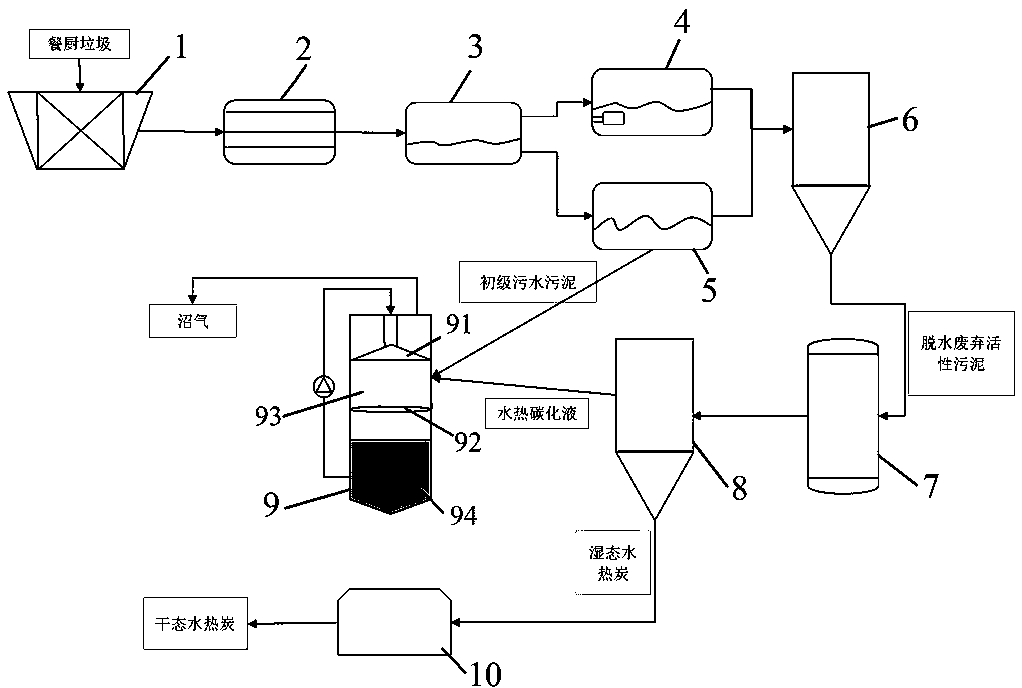

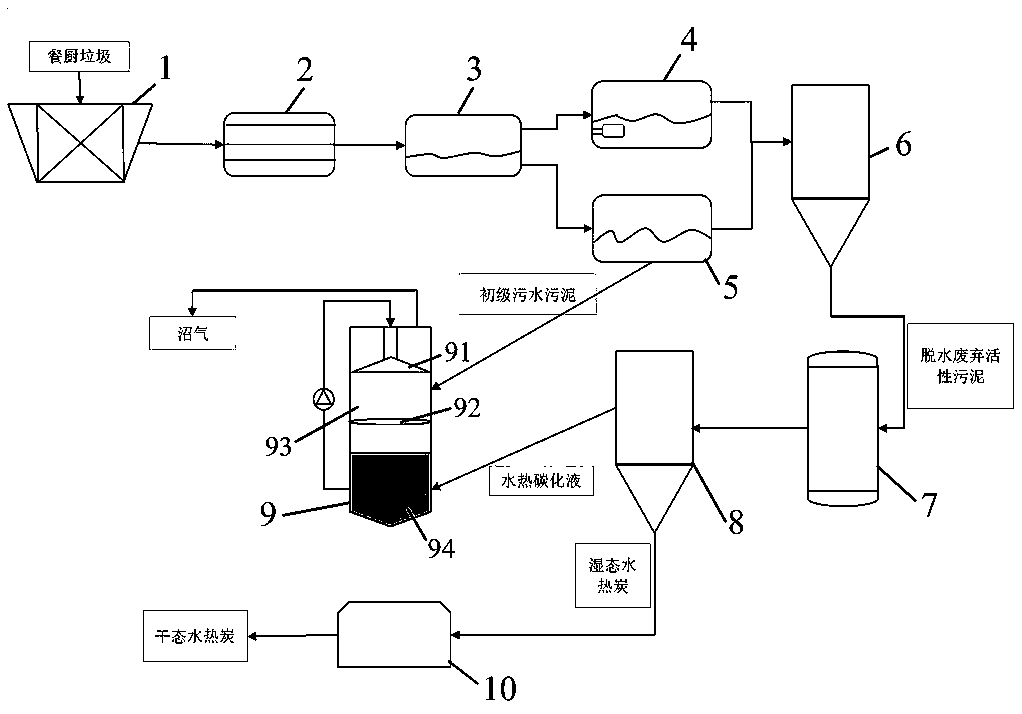

Innocent treatment method for kitchen waste

ActiveCN110745974AQuality improvementImprove abilitySludge treatment by pyrolysisWater aerationActivated sludgeSolar drying

The invention discloses an innocent treatment method for kitchen waste. The method comprises the steps of sorting and screening coarse solids and gravels from collected kitchen waste, carrying out sedimentation by a first primary sedimentation tank, aeration by an aeration tank and sedimentation by a second primary sedimentation tank so as to obtain waste activated sludge and primary sewage sludge, subjecting the waste activated sludge to centrifugation, then, carrying out hydrothermal carbonization, carrying out centrifugation so as to obtain wet state hydrothermal charcoal and hydrothermal carbonized liquid, transferring the hydrothermal carbonized liquid and the primary sewage sludge into a leachate bed reactor for an anaerobic digestion reaction so as to obtain biogas capable of serving as new energy, and drying the wet state hydrothermal charcoal by a solar dryer, so as to obtain a high-energy environment-friendly biofuel energy. According to the method provided by the invention,the hydrothermal charcoal with higher phosphorus content and yield is obtained, the digestibility of an anaerobic digestion process is improved, and thus, the residual amount of digested sediment is reduced; and after innocent treatment, the hydrothermal charcoal and the biogas as biofuel energy sources can be obtained, and thus, the recycling of energy is achieved.

Owner:湖南三五二环保科技有限公司 +1

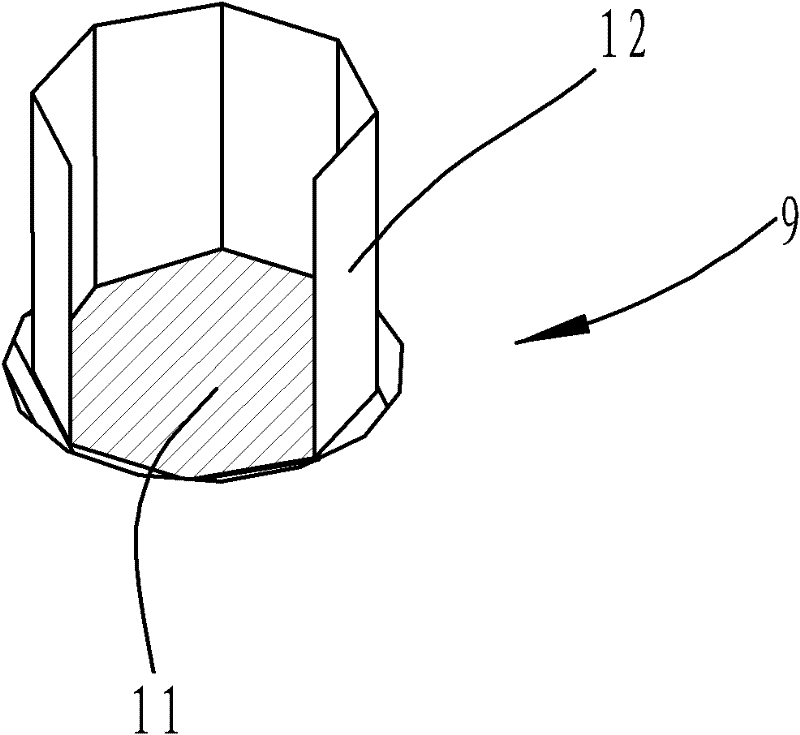

Concentrated solar device

ActiveCN102683461AGuaranteed efficiencyGuaranteed lifeSolar heating energyMirrorsSolar dryerOptoelectronics

Owner:BEIJING TERASOLAR PHOTOTHERMAL TECH CO LTD

Chemical color-retaining method for dried rose flowers

InactiveCN109497046AReduce pollutionSave conventional energyDead plant preservationSpecial ornamental structuresSaccharumSucrose

The invention relates to a chemical color-retaining method for dried rose flowers. The method comprises the specific preparation steps and the optimal soaking time that 20 g of magnesium chloride and20 g of citric acid are taken and dissolved in 160 mL of distilled water so as to prepare a magnesium chloride and citric acid mixed solution with the concentration of 20%, and fresh flowers are soaked in the mixed solution for 5 hours; 20 g of sucrose and 20 g of citric acid are taken and dissolved in 160 mL of distilled water so as to prepare a sucrose and citric acid mixed solution with the concentration of 20%, and the fresh flowers are soaked in the mixed solution for 4.5 hours; 30 mL of glycerol and 30 mL of a magnesium chloride solution with the concentration of 20% are taken and dissolved in 140 mL of distilled water so as to prepare a glycerol and magnesium chloride mixed solution with the concentration of 30%, and the fresh flowers are soaked in the mixed solution for 4 hours. According to the method, rose petals treated by three chemical color-retaining reagents can keep fadeless for a long time under natural conditions after being dried by a solar drier, the color of the rose petals is basically the same as the primary color or is very small in change, and therefore a very high utilization value is achieved.

Owner:YUNNAN NORMAL UNIV

Combined type solar dryer

InactiveCN103322779AConvenient cycle drying operationAchieve the purpose of dryingDrying chambers/containersDrying machines with progressive movementsEngineeringConveyor belt

The invention discloses a combined type solar dryer which comprises at least one dryer unit. According to the combined type solar dryer, a vacuum tube solar heat collector is utilized to absorb solar energy and heat a heat accumulation medium, and then the heat accumulation medium heats air in a drying chamber so as to achieve the purpose of drying materials in the drying chamber. The combined type solar dryer is flexible in usage mode, applicable to both low-temperature ranges and high-temperature ranges, and usable on powered or powerless occasions; and meanwhile, the combined type solar dryer can be used alone in the form of one single drying unit or can be used in a large-scale mode by combining and connecting a plurality of the drying units to form a large system, and conveyor belts can be used in upper and lower drying layers of the combined long drying system so as to facilitate circular operations of drying a large quantity of materials.

Owner:GUANGXI UNIV

Auxiliary heating flat plate integral type solar drier

InactiveCN102620530AEasy to pour outEnsure parallelism without slippingSolar heating energySolar heat devicesEngineeringHeating furnace

The invention discloses an auxiliary heating flat plate integral type solar drier, which comprises a flat plate solar air heat collector, a heating furnace, a blower, a pipeline and a drying chamber. Heat collection plates of the heat collector are multi-hole heat collection plates, a perforated sieve of the drying chamber is placed at an inclination angle of 20 degrees, and the heating furnace uses crop straws as fuel. The entire system constitutes a compact whole, and the air heat collector and the drying chamber enclose to form a drying space. The drying temperature of the system is around 50 DEG C, so that the quality of dried products is ensured. Also, the system is compact in designed structure and high in heat efficiency, and is suitable for crop drying quantity demanded by a single rural family.

Owner:ZHENJIANG XINMENGXI ENERGY TECH

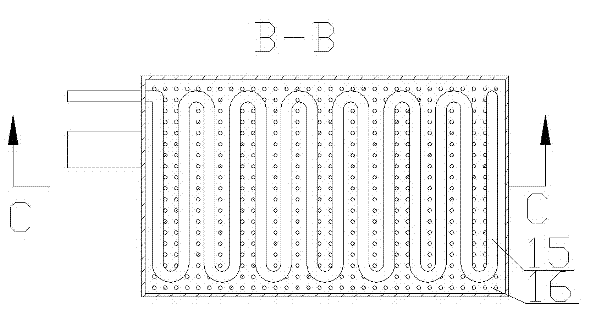

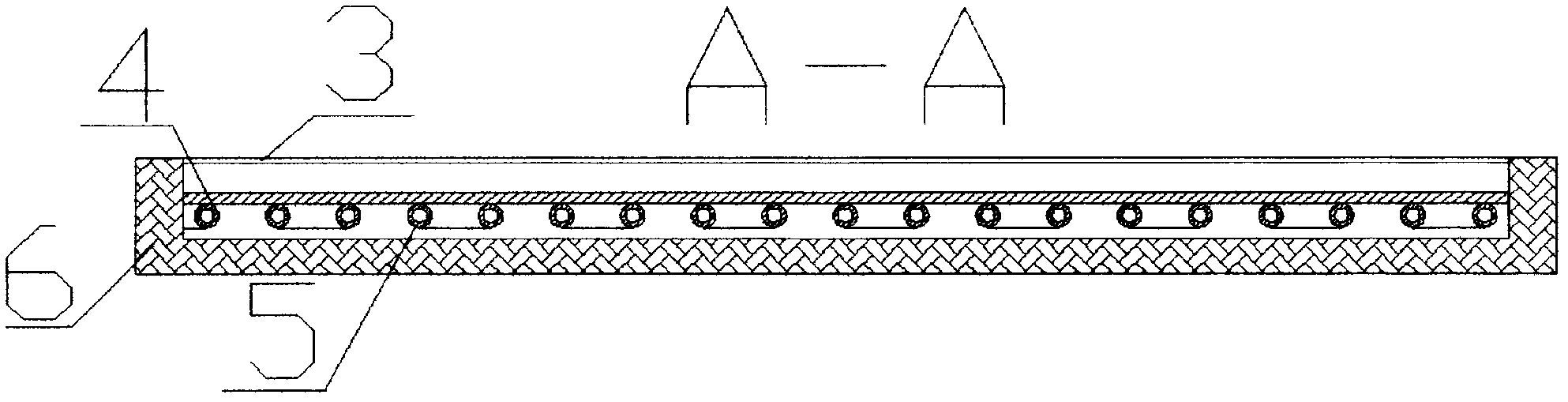

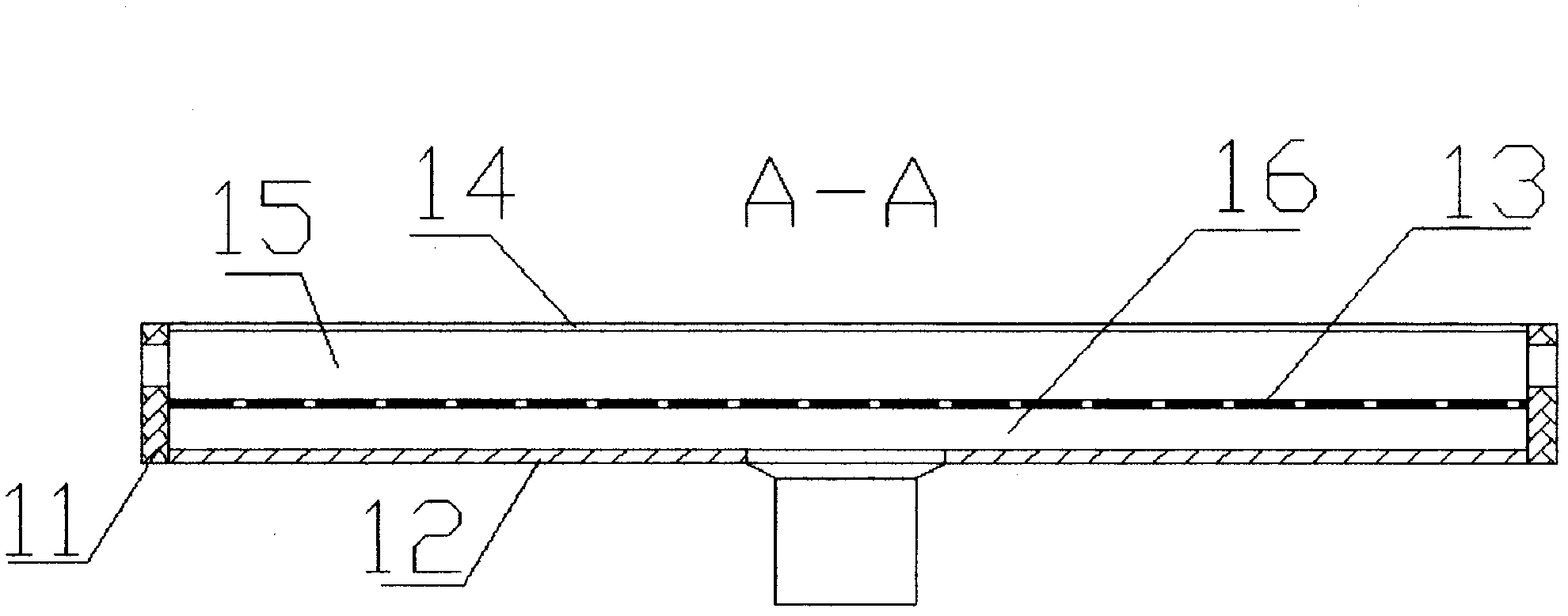

Coil integrated solar dryer with auxiliary heating

InactiveCN102620541AControl inflow directionEasy to passSolar heat devicesDrying gas arrangementsEngineeringHeating furnace

The invention discloses a coil integrated solar dryer with auxiliary heating, which comprises a coil type solar air heat collector, a heating furnace, a fan, pipelines and a drying bin. A heat collecting plate of the heat collector is a metal plate with the sunward side plated with selective absorbing coating, a coil is welded on the back of the heat collecting plate of the heat collector, a porous sieve of the drying bin is inclined by about 20 degrees, and the heating furnace utilizes crop straws as fuel. The whole solar dryer is closely integrated, and a drying space is enclosed by the air heat collector and the drying bin together. The drying temperature of the solar dryer is about 50 DEG C, so that the quality of dried products is guaranteed. The solar dryer is compact in structural design, high in heat efficiency and applicable to crop drying amount of single rural families.

Owner:ZHENJIANG XINMENGXI ENERGY TECH

Flat plate integral type solar drier

InactiveCN102620542AEasy to pour outEnsure parallelism without slippingSolar heat devicesDrying gas arrangementsSolar dryerEngineering

The invention discloses a flat pipe integral type solar drier, which comprises a solar heat collector, a blower, a ventilating pipeline and a drying chamber. Heat collection plates of the heat collector are multi-hole heat collection plates, and a perforated sieve of the drying chamber is placed at an inclination angle of 20 degrees. The drying temperature of the system is around 30-50 DEG C, so that the quality of dried products is ensured. In addition, the air heat collector and the drying chamber constitute a whole with a compact structure, and the flat pipe integral type solar drier reduces heat loss and is suitable for crop drying quantity demanded by a single rural family.

Owner:ZHENJIANG XINMENGXI ENERGY TECH

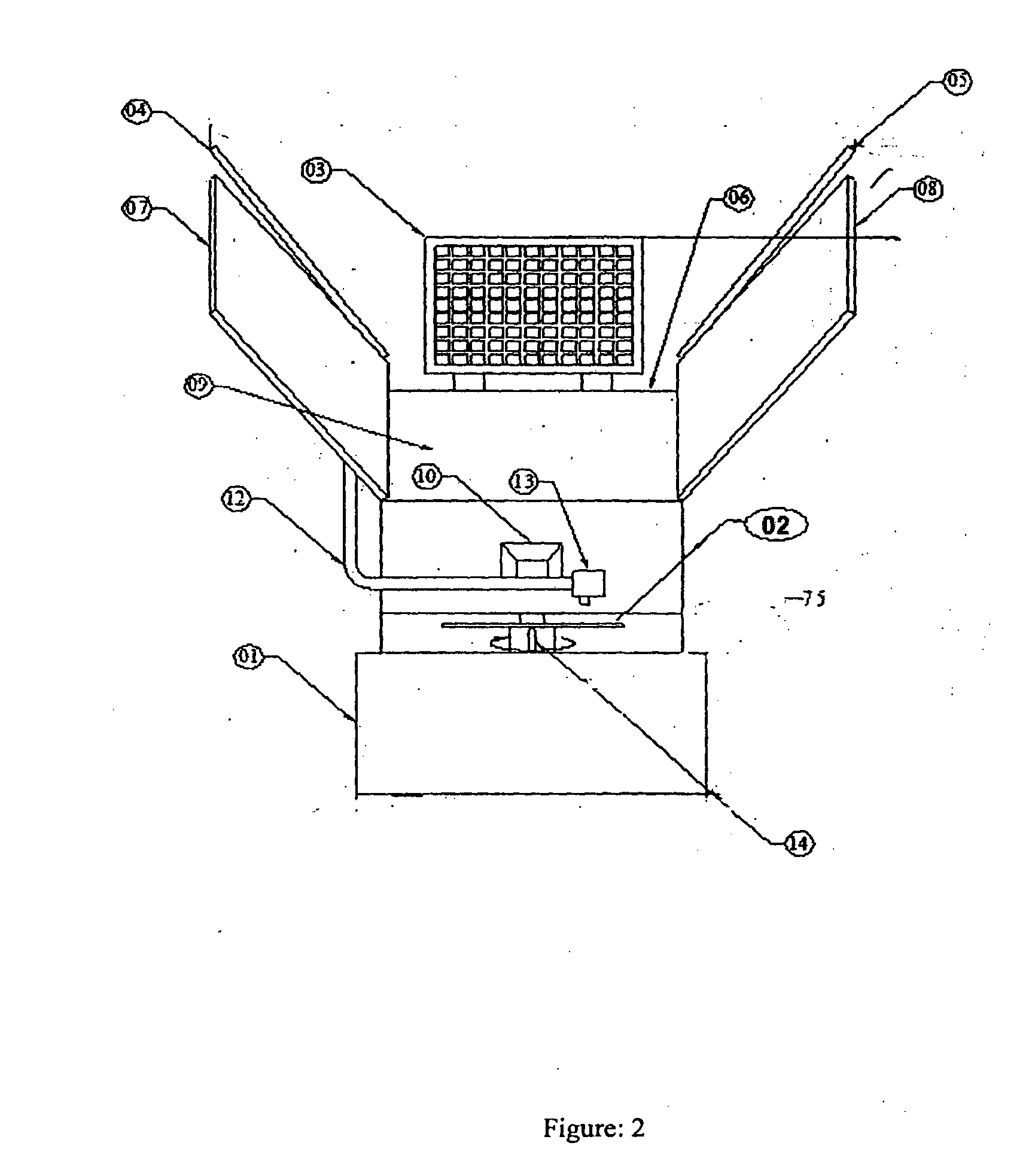

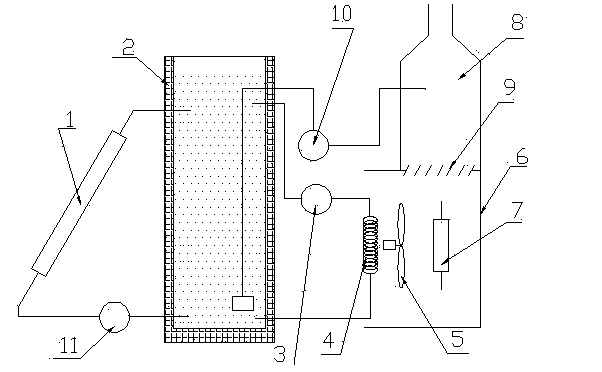

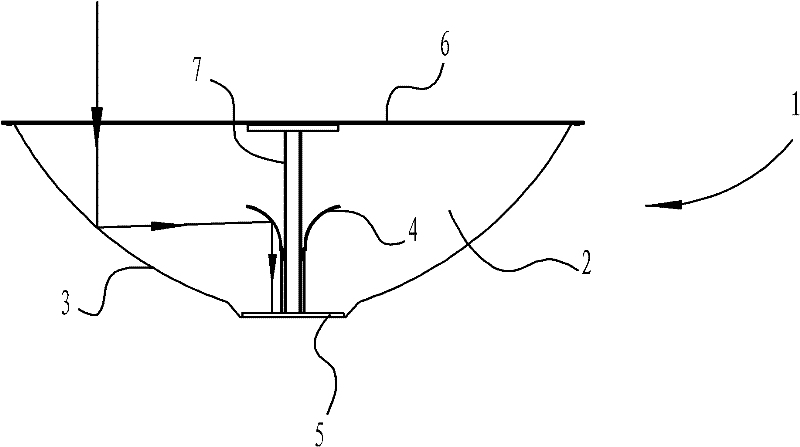

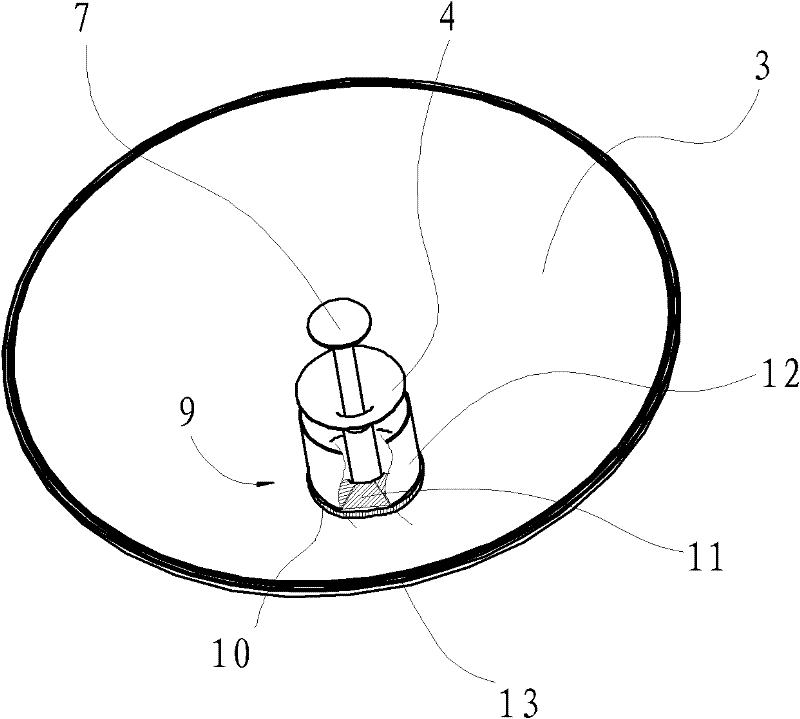

An improved solar dryer with enhanced efficiency of drying

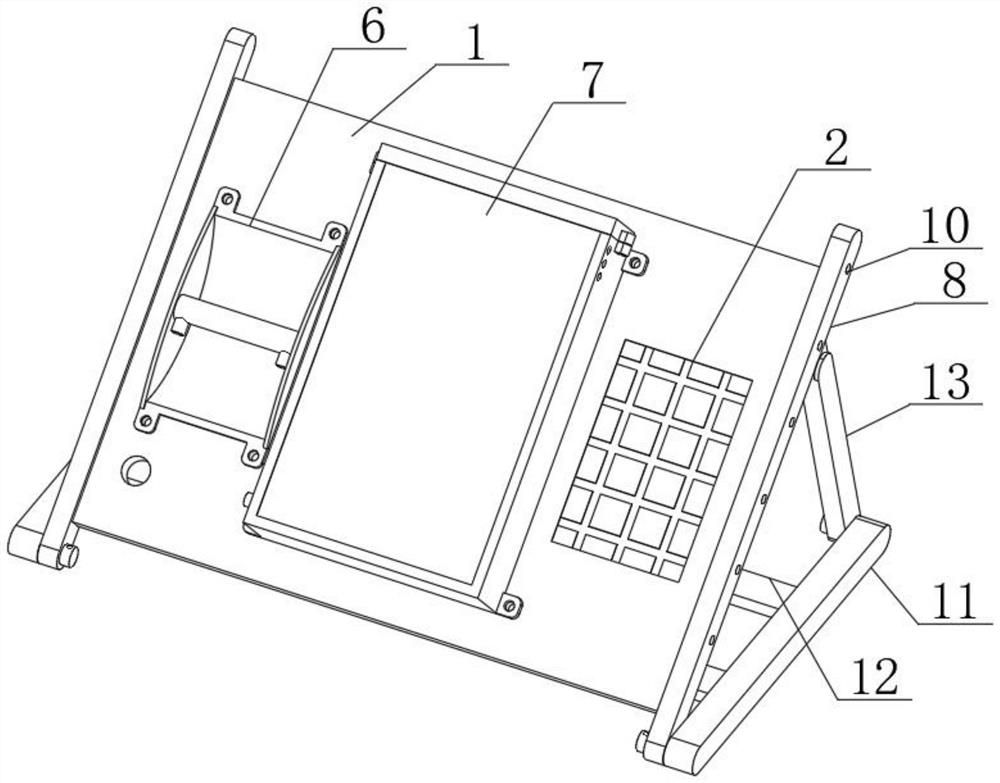

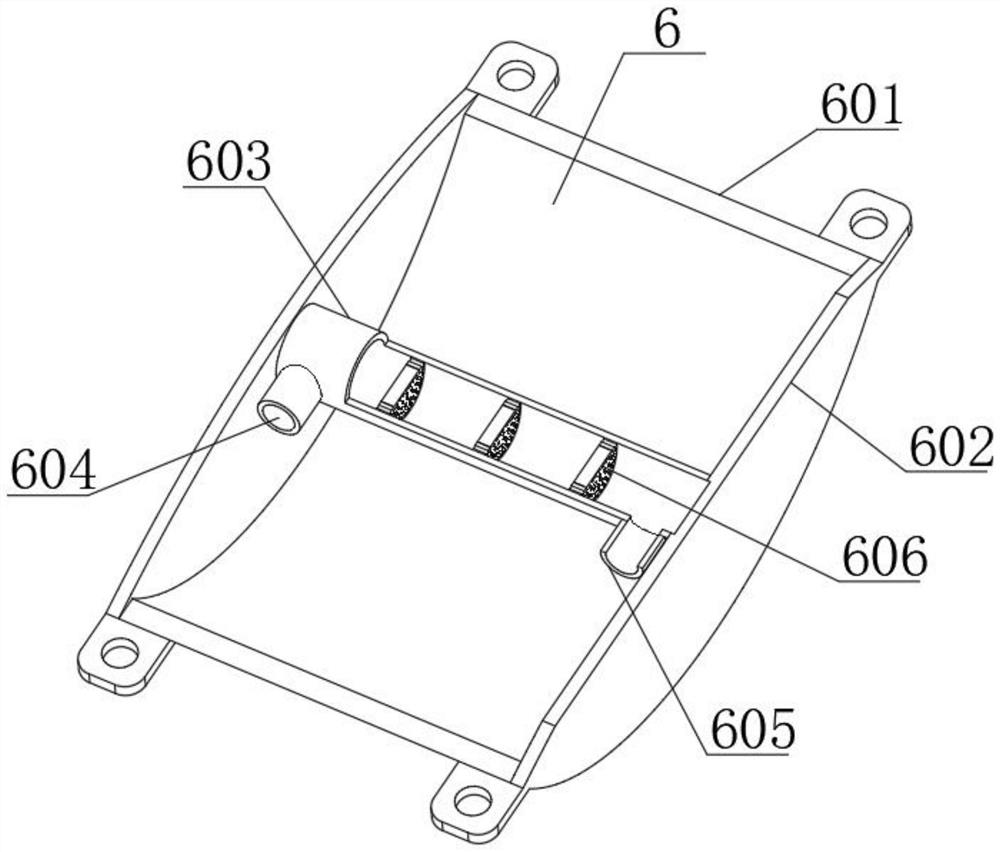

InactiveCN104011490AImprove drying efficiencyIncrease temperatureSolar heating energyDrying solid materials with heatLocking mechanismEngineering

The present invention provides an improved solar dryer with improved. The dryer consists of a solar absorber / collector (9) and a drying chamber (6). One end of the collector is connected to a forced draft fan (10) and the other end connects the drying chamber. The drying chamber has a drawer in which the material to be dried is kept on a wire mesh. The dryer further has the provision for placing color indicative silica gel under the wire mesh when operated in recirculation mode. The other end of the drying chamber has an induced draft fan (11). Both the dc fans operate using a 10 watt photovoltaic panel (3). V- trough reflectors (4,5,7,8) made from anodized aluminum are fixed on the collector and optionally on the drying chamber. A tracking circuit is incorporated to auto -track the dryer. A locking mechanism (14) is also incorporated to help the unit withstand high wind load. The dryer further has the provision of programmable recirculation of the spent air from drying chamber once its humidity drops below a pre -set value which process helps to speed up the rate of drying.

Owner:COUNCIL OF SCI & IND RES

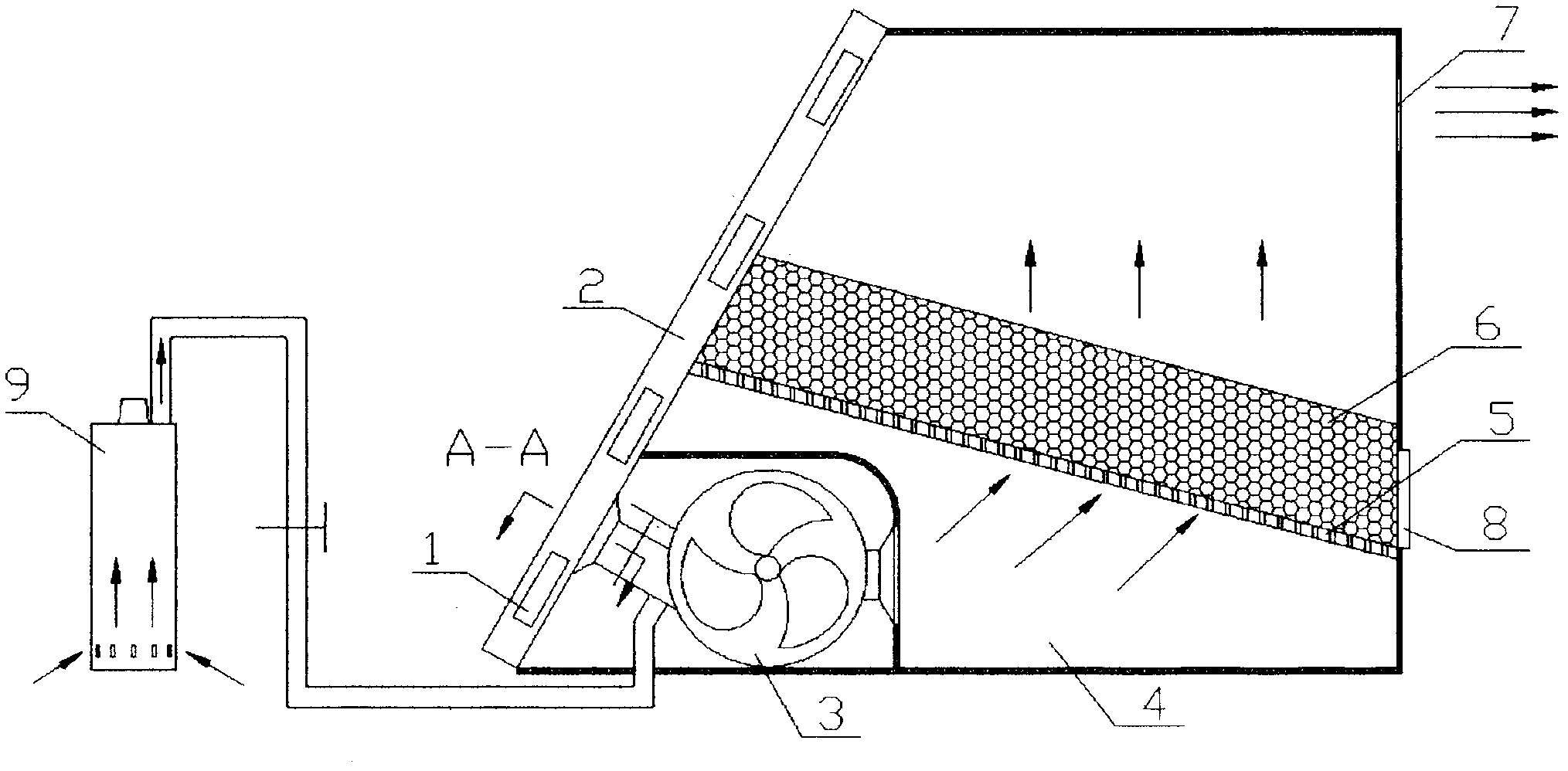

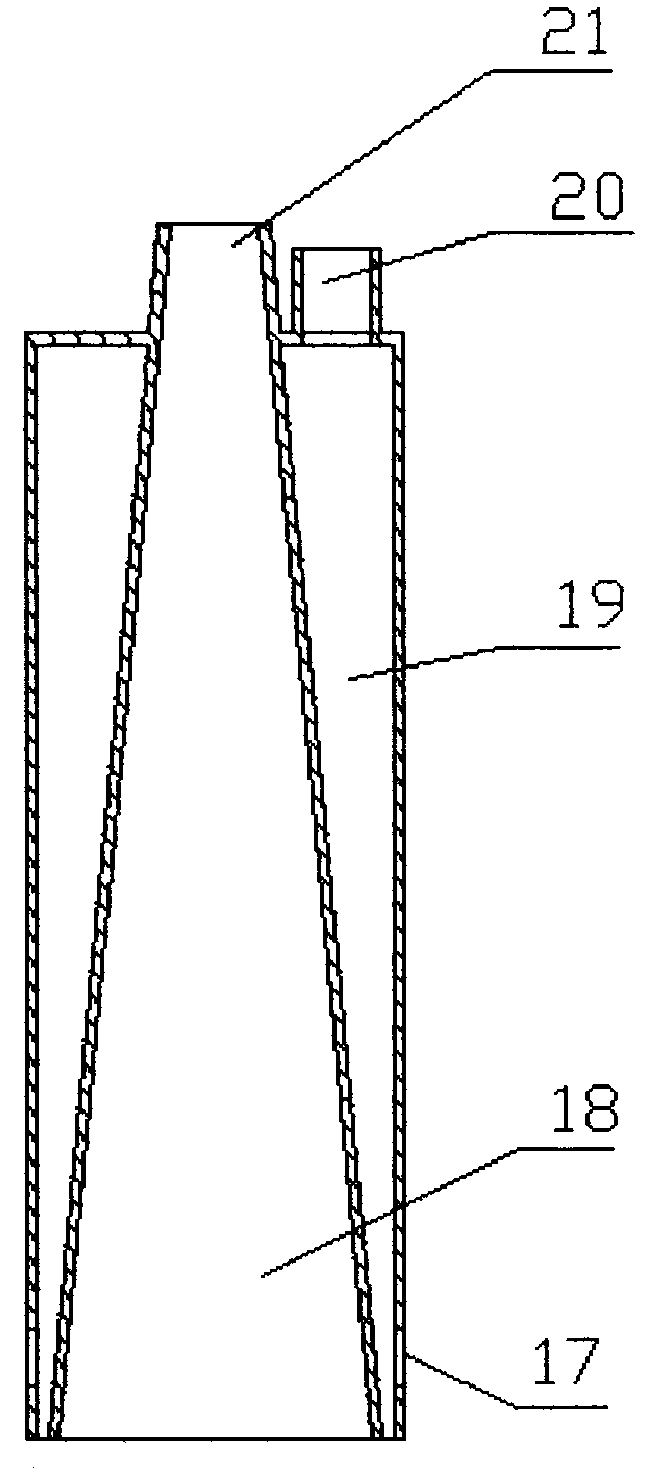

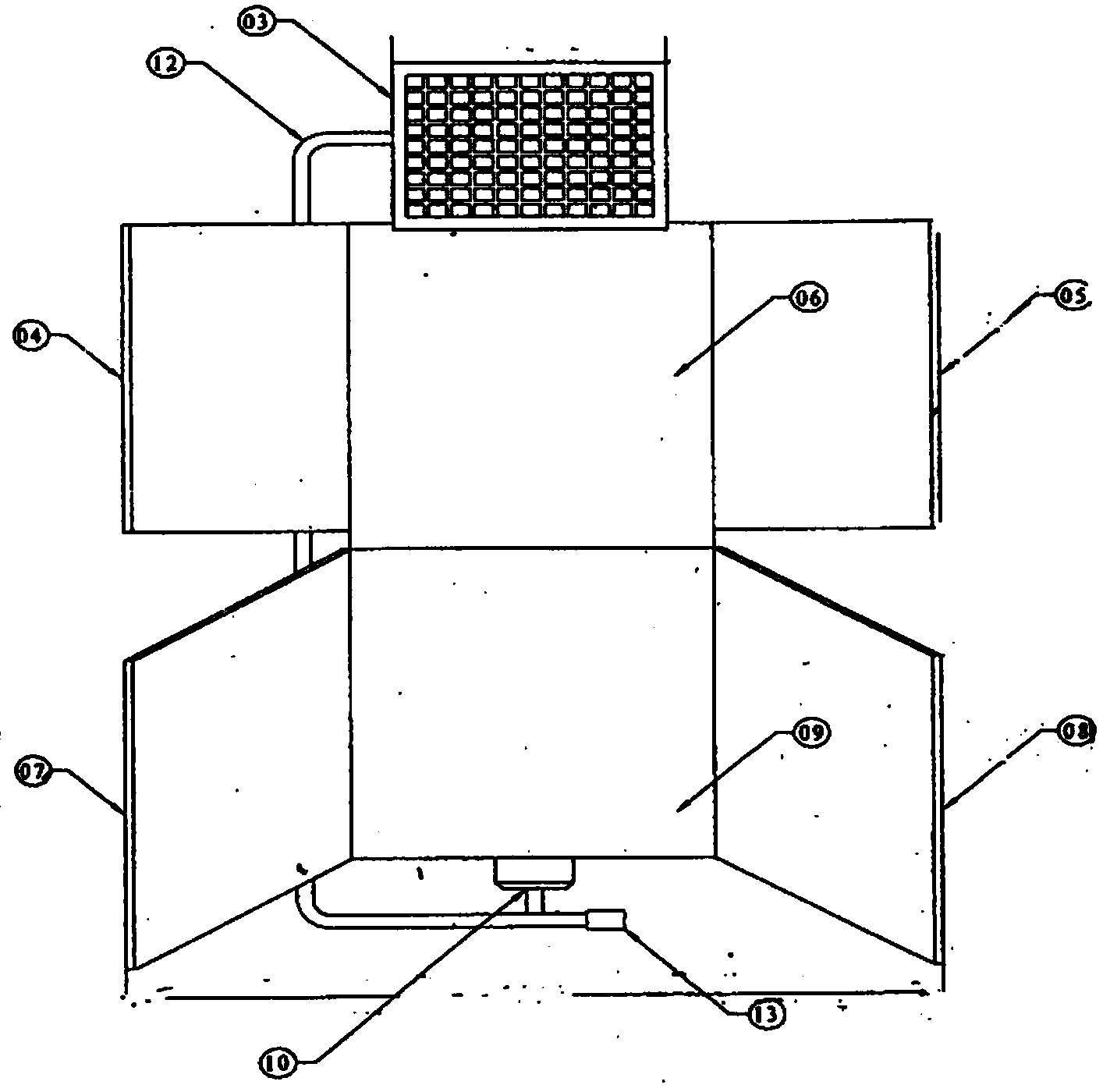

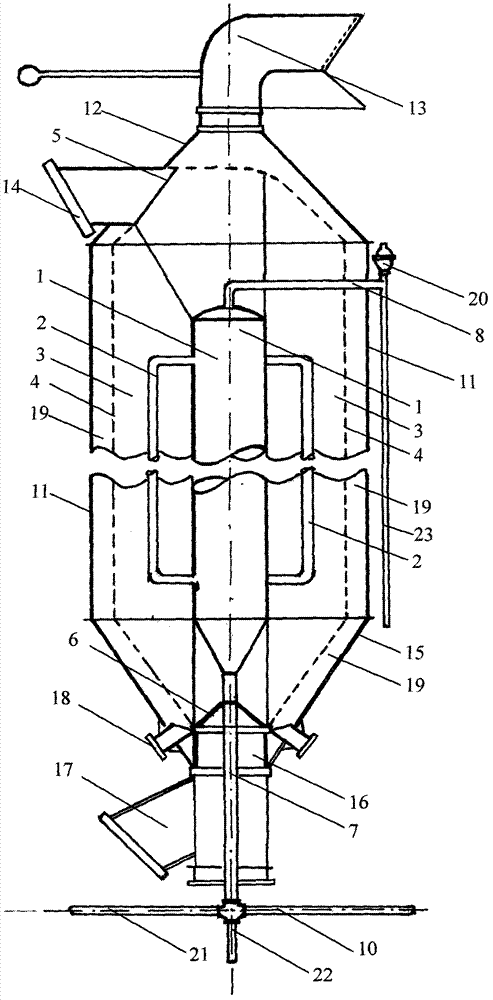

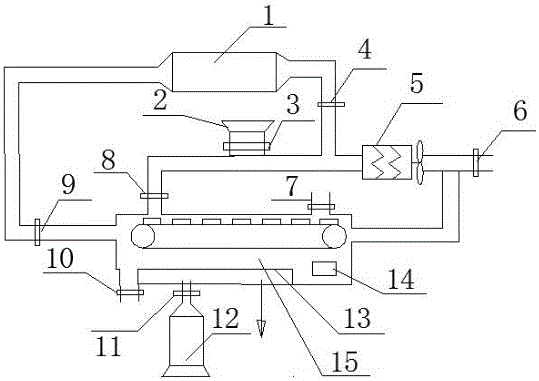

Internal absorption type solar drier

InactiveCN106643031AEffective control of drying temperatureIncrease profitDrying gas arrangementsDrying chambers/containersControl systemProcess engineering

The invention discloses an internal absorption type solar drier. The internal absorption type solar drier comprises a solar heat collecting device, a drying box and a control system, wherein phase change energy storage drawers, material drying drawers, a cross flow waste heat recovery exchanger and adsorption dehumidification drawers are sequentially arranged inside the drying box from top to bottom; a partition is arranged between the phase change energy storage drawers, the material drying drawers, the cross flow waste heat recovery exchanger and the adsorption dehumidification drawers and the back inner wall of the drying box; the partition and the back inner wall of the drying box define a preheated air flow channel; a circulating fan is arranged at the bottom of the drying box; the bottoms of the drawers are screen-shaped; a phase change energy storage material is placed in the phase change energy storage drawers; a to-be-dried material is placed in the material drying drawers; an adsorption dehumidification material is placed in the adsorption dehumidification drawers; the cross flow waste heat recovery exchanger is provided with an air inlet and an exhaust hole; heat superconducting finned tubes in the solar heat collecting device are positioned inside vacuum heat collecting pipes; the vacuum heat collecting pipes are obliquely arranged; the bottom ends of the vacuum heat collecting pipes are connected with pipe holders and are supported by a bracket; the top ends of the vacuum heat collecting pipes are hermetically connected with the upper part of the drying box; and the heat superconducting finned tubes stretch into the preheated air flow channel inside the drying box.

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

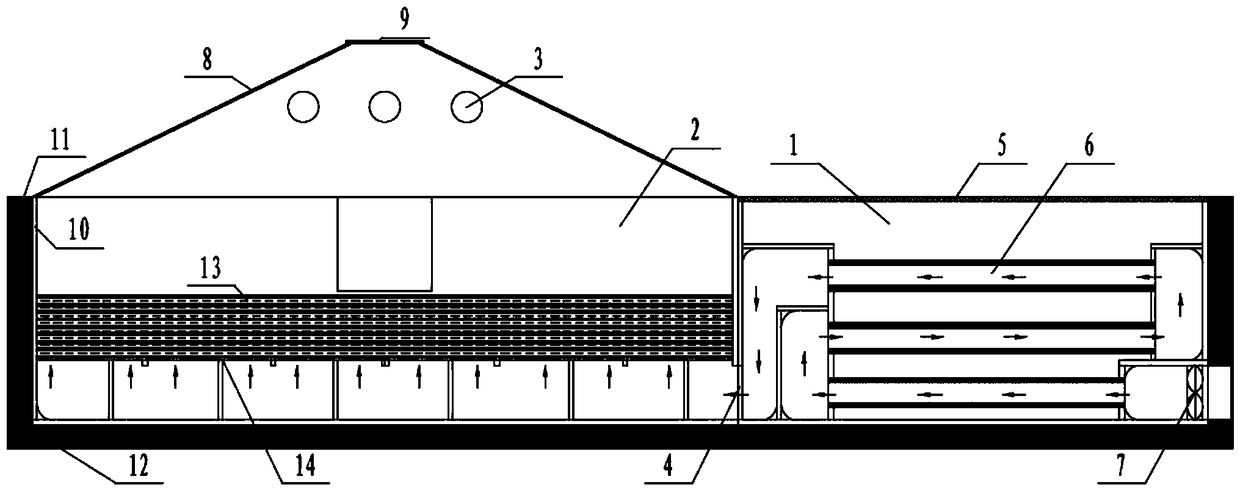

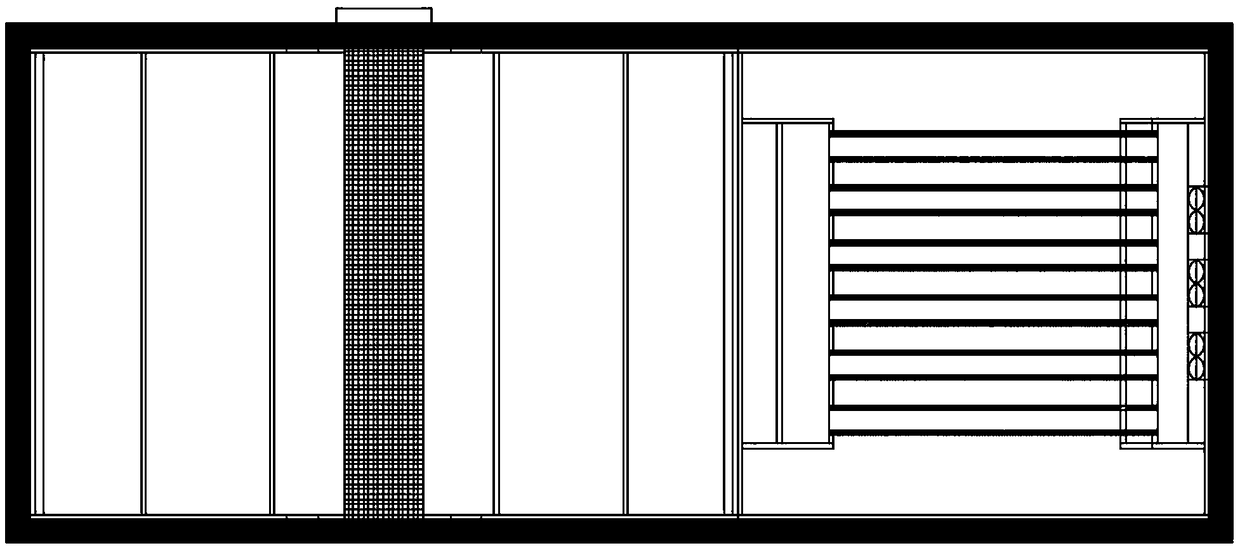

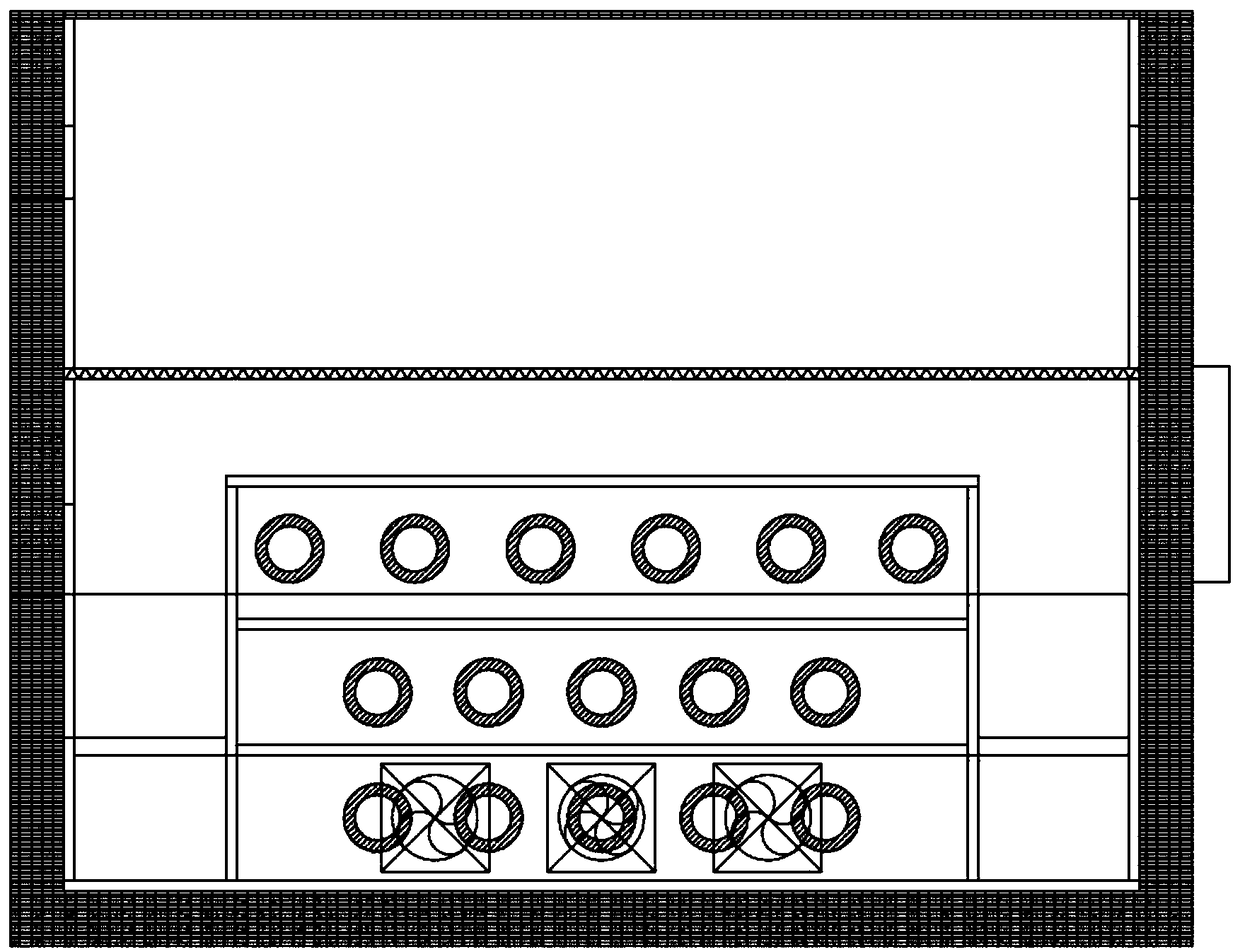

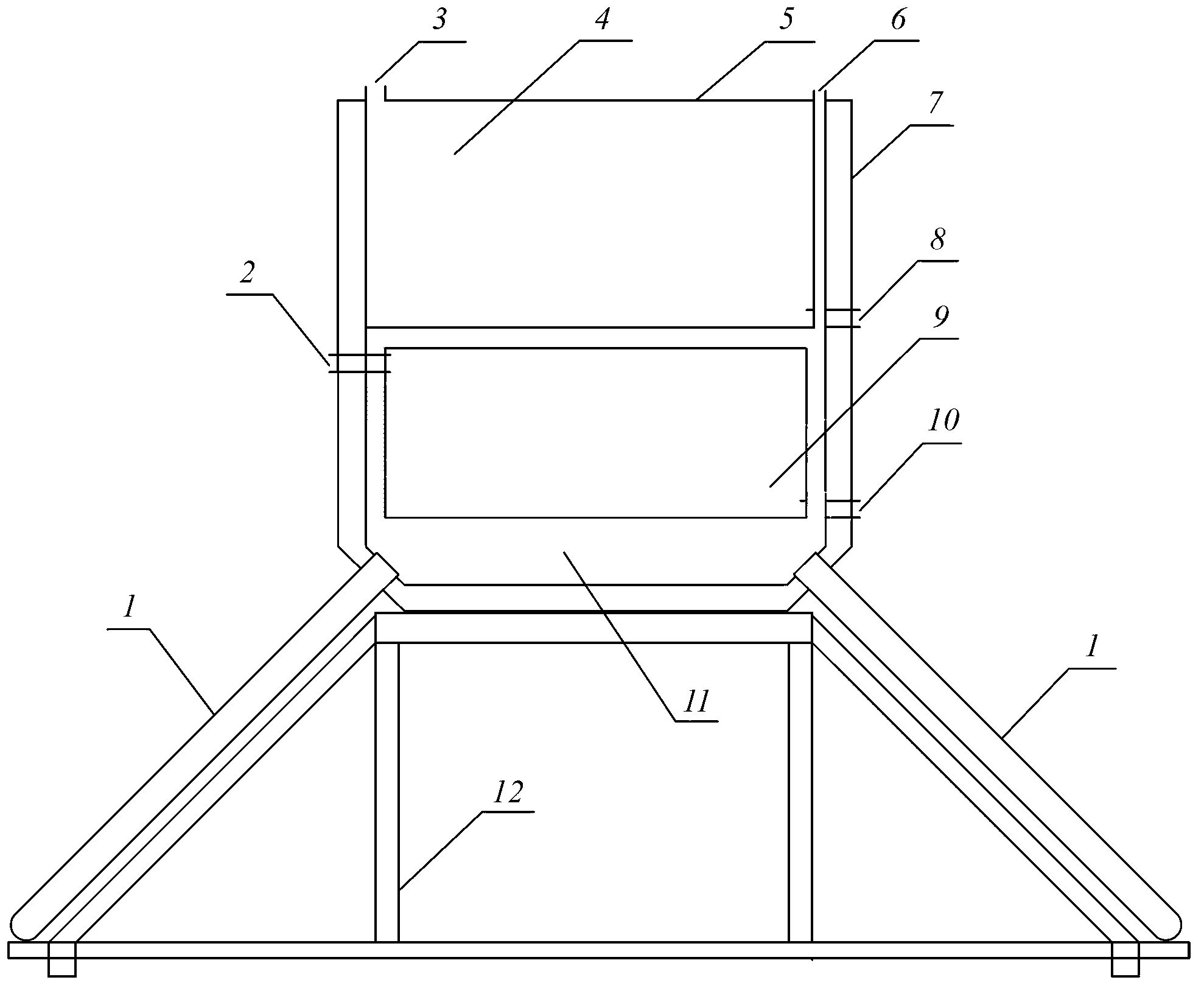

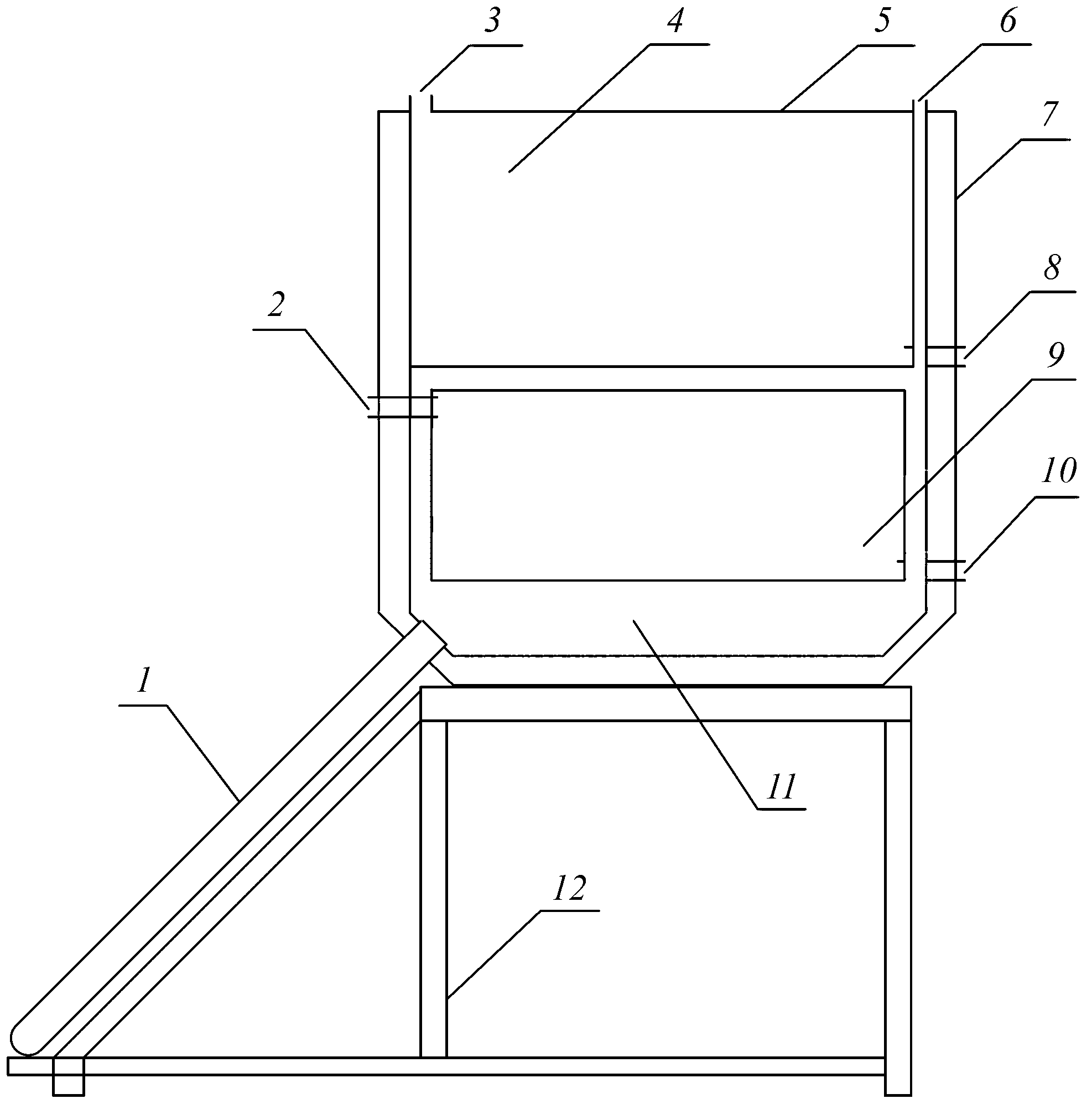

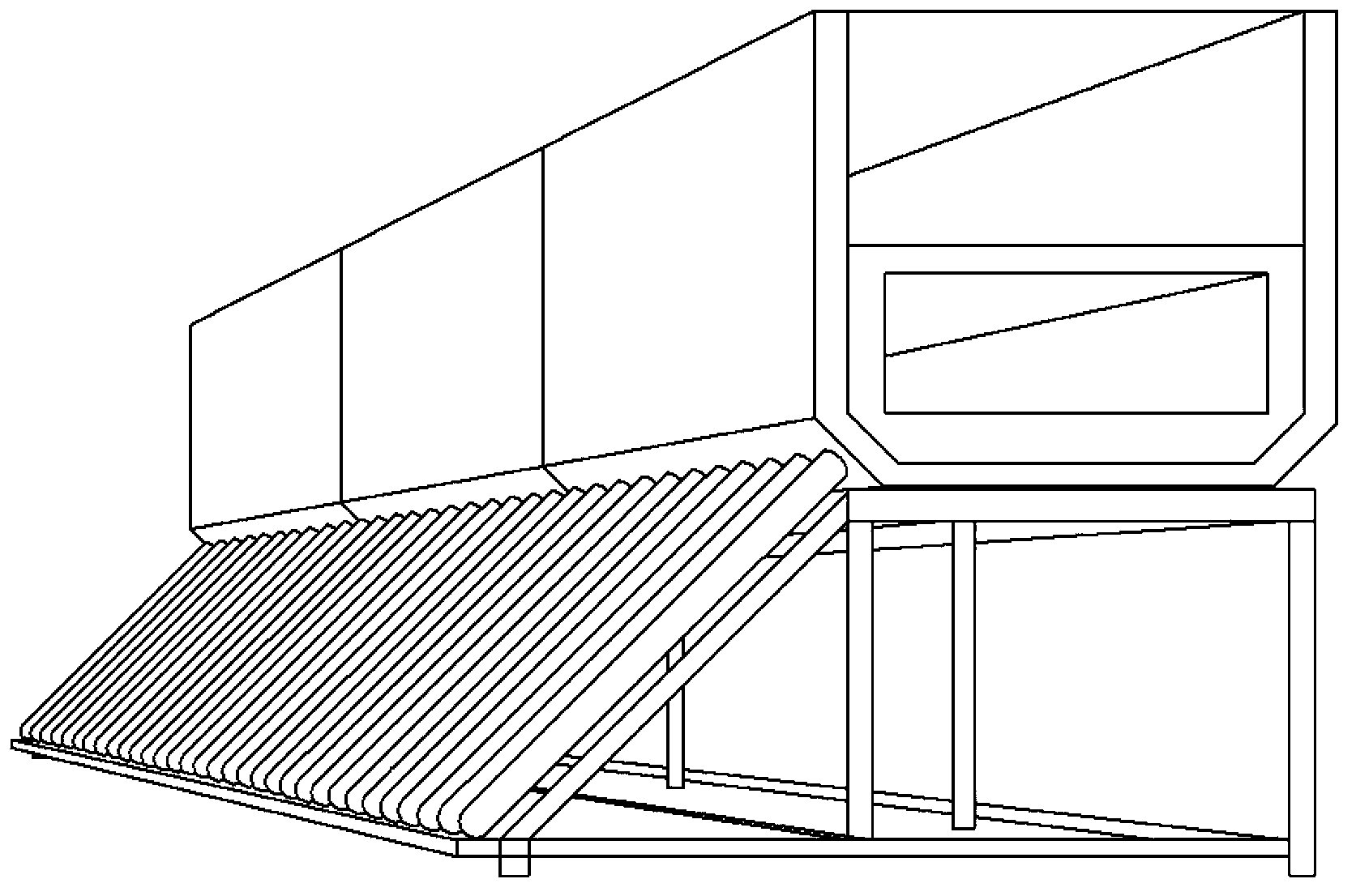

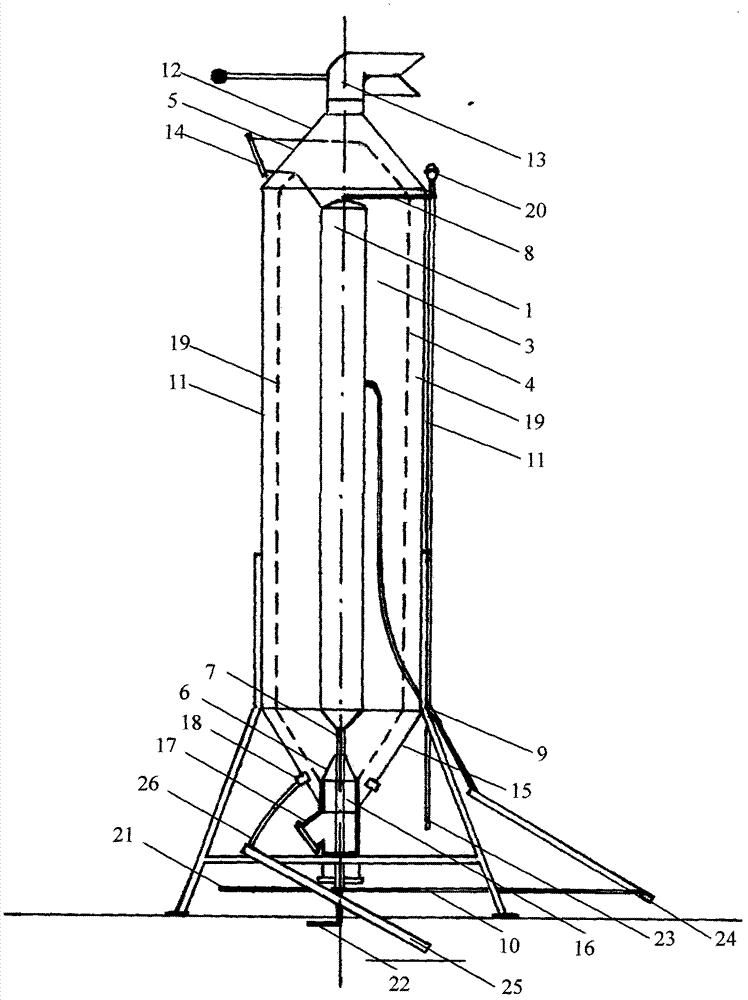

Double-working-media natural circulating bin type solar dryer

ActiveCN102818431AGood value for moneyExcellent yieldSolar heat devicesDrying machines with local agitationNatural ventilationEngineering

A double-working-media natural circulating bin type solar dryer can realize high-efficient heating and dewatering of things to be dried by controllable indirect heating and convection drying manner on the premise of no consumption of auxiliary energy and no power drive during dewatering, drying and long-term safety storage. Further, by temperature regulating and dehumidifying, the inside environment of a storage device can be kept dry by natural ventilation, and damage caused by insects, birds and rats and dust pollution are prevented; energy saving, emission reduction and low-carbon effect are achieved, production management cost is reduced, and safety, sanitation and long-term storage of storage things are guaranteed. The double-working-media natural circulating bin type solar dryer is widely applicable to rural households and massive production and application in the fields of the industry and the agriculture.

Owner:涂济民 +1

Coil pipe integral type solar drier

InactiveCN102620540AEasy to passEasy to pour outSolar heating energySolar heat devicesEngineeringHeat losses

The invention discloses a coil pipe integral type solar drier, which comprises a solar heat collector, a blower, a ventilating pipeline and a drying chamber. Heat collection plates of the heat collector are metal plates, the sunny sides of the metal plates are coated with selective absorption coatings, and snake bends are welded on the back sides of the metal plates, and a perforated sieve of the drying chamber is placed at an inclination angle of 20 degrees. The drying temperature of the system is around 30-50 DEG C, so that the quality of dried products is ensured. In addition, the air heat collector and the drying chamber constitute a whole with a compact structure, and the coil pipe integral type solar drier reduces heat loss and is suitable for crop drying quantity demanded by a single rural family.

Owner:ZHENJIANG XINMENGXI ENERGY TECH

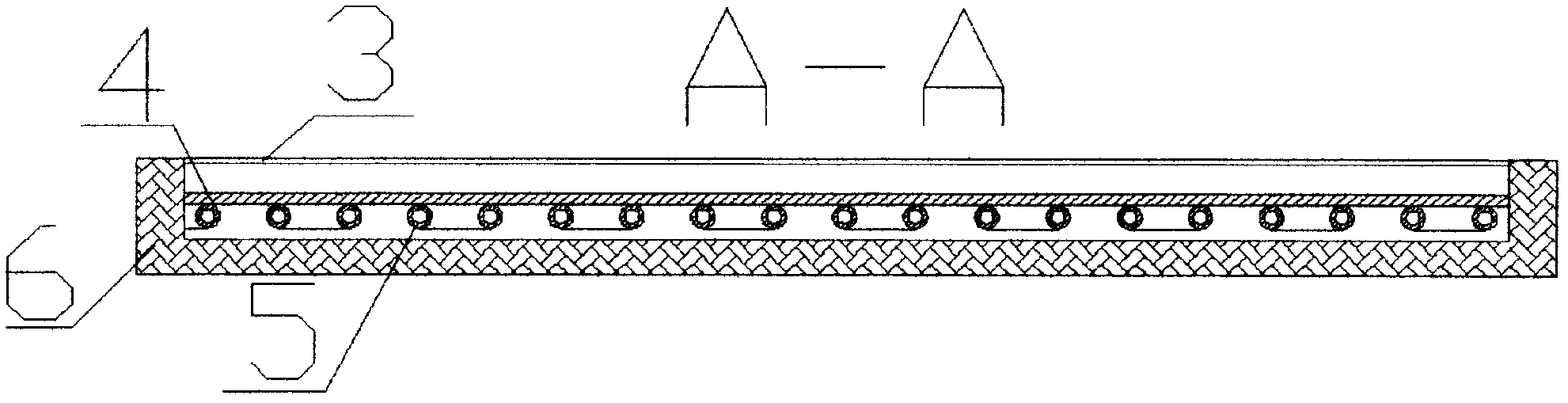

Mixed-type sludge solar dryer

InactiveCN105776800AThe drying process went smoothlyProcess stabilitySludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSolar air collectorSludge

The invention discloses a mixed-type sludge solar dryer which mainly consists of seven parts such as solar air collector, an air valve, a fan, a conveying belt, an air pipe, a drying chamber, a gas stove and the like. The mixed-type sludge solar dryer utilizes solar energy as a main heat source and methane generated in a sewage treatment process as an auxiliary heat source, so that continuous drying in different time and different seasons can be realized, not only can energy conservation and environmental friendliness be realized, but also the operating cost is relatively lower than those of other drying devices.

Owner:YUNNAN NORMAL UNIV

Coil tumbling solar dryer with auxiliary heating

InactiveCN102620539APrevent take outHeating fastSolar heat devicesDrying gas arrangementsEngineeringHeating furnace

The invention discloses a coil tumbling solar dryer with auxiliary heating, which comprises a solar heat collector, a fan, pipelines, a tumbling drying bin, an air heating furnace and a motor. A coil is welded on the back of a heat collecting plate of the heat collector, rollers are arranged on a holder of the drying bin, and the drying bin is connected with the motor through a gear structure and can roll under drive of the motor. Teeth are uniformly and circumferentially distributed inside the drying bin and can drive the dried articles to tumble, and the air heating furnace serving as an auxiliary heat source can guarantee all-weather operation of the dryer. The drying temperature of the solar dryer is about 30-50 DEG C, so that the quality of dried products is guaranteed.

Owner:ZHENJIANG XINMENGXI ENERGY TECH

Process for gradient treating organic wastes

InactiveCN1244506CGuaranteed outputQuality assuranceBio-organic fraction processingClimate change adaptationMarshFeces

The stepped pig and / or ox excrement treating process includes pre-treatment of the gathered excrement, conventional anaerobic digestion in marsh pool to prepare marsh gas, using marsh gas for generating electric power, precipitating dregs in the precipitation tank from the marsh pool, using marsh liquid from the precipitation tank in planting feed grass, drying the marsh dregs with solar energy for planting mushroom, raising earthworm with the leftover after gathering mushroom, and using earthworm excrement in planting feed grass. The present invention forms one positive circulation to realize the comprehensive utilization of wastes.

Owner:李益冉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com