Process for gradient treating organic wastes

An organic waste, cascade technology, applied in the field of cascade treatment of pig and/or cattle manure, which can solve problems such as power supply shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

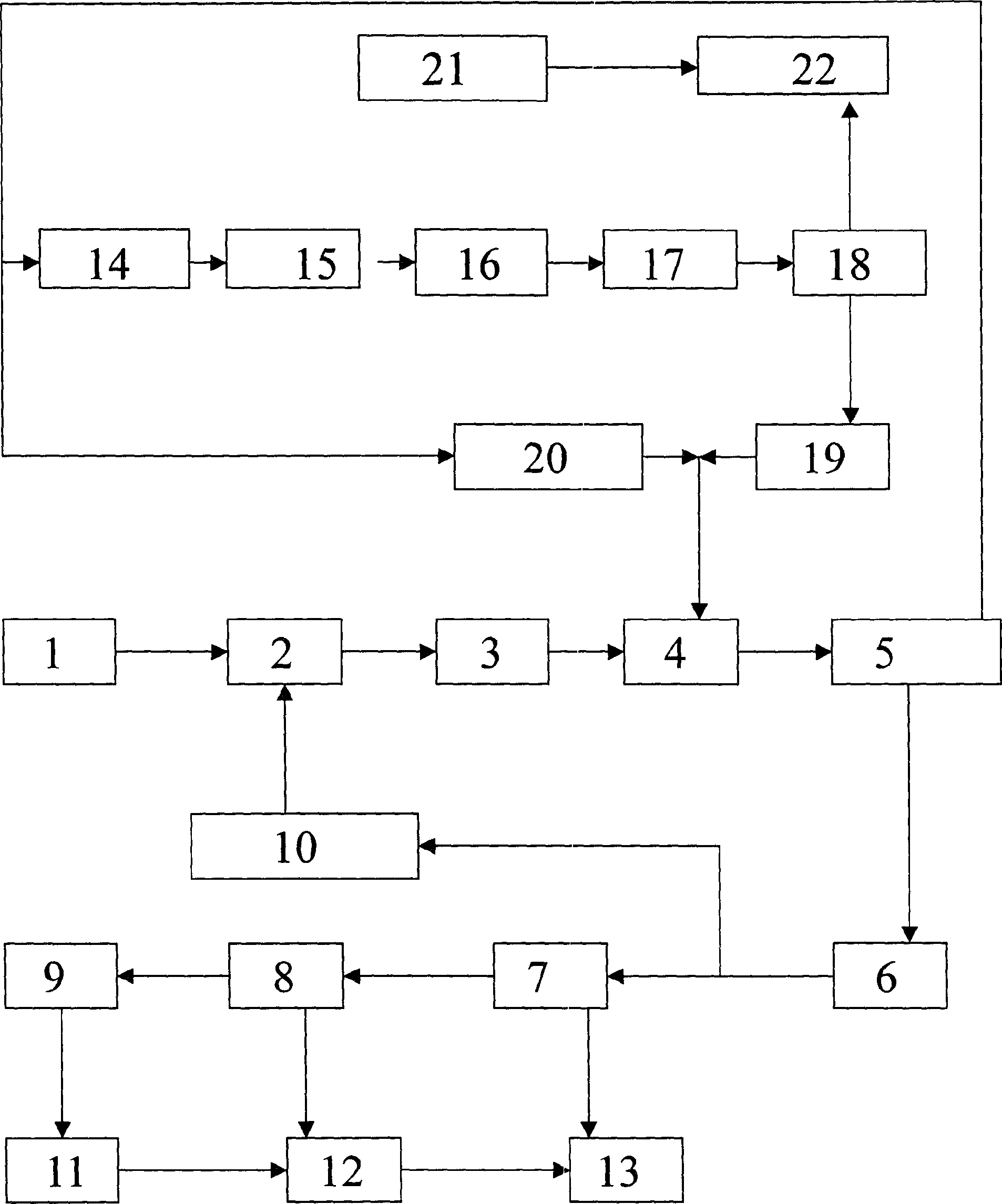

Image

Examples

Embodiment Construction

[0027] The collected cow manure is pretreated to meet the needs of conventional anaerobic digestion to prepare biogas. The produced biogas is used for power generation, and the rest of the biogas digester is discharged into the sedimentation tank for sedimentation. The obtained liquid is biogas slurry, part of which is used For planting forage grass. The slag is biogas residue, which is used to plant mushrooms after drying with the help of solar dryers, and the leftovers after harvesting mushrooms are used to breed earthworms, and vermicompost is used to plant forage grass.

[0028] The method provided by the invention forms a benign ecological cycle, realizes the maximum comprehensive utilization of waste resources, and is the most economical and practical treatment method for solving livestock and poultry manure pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com