Patents

Literature

133 results about "Alcohol synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthesis Of Alcohol. The first chemical synthesis of alcohol has generally been attributed to Berthelot, who, in 1854, obtained it from ole-fiant gas by absorbing this gas in sulphuric acid, diluting the product, and distilling it.

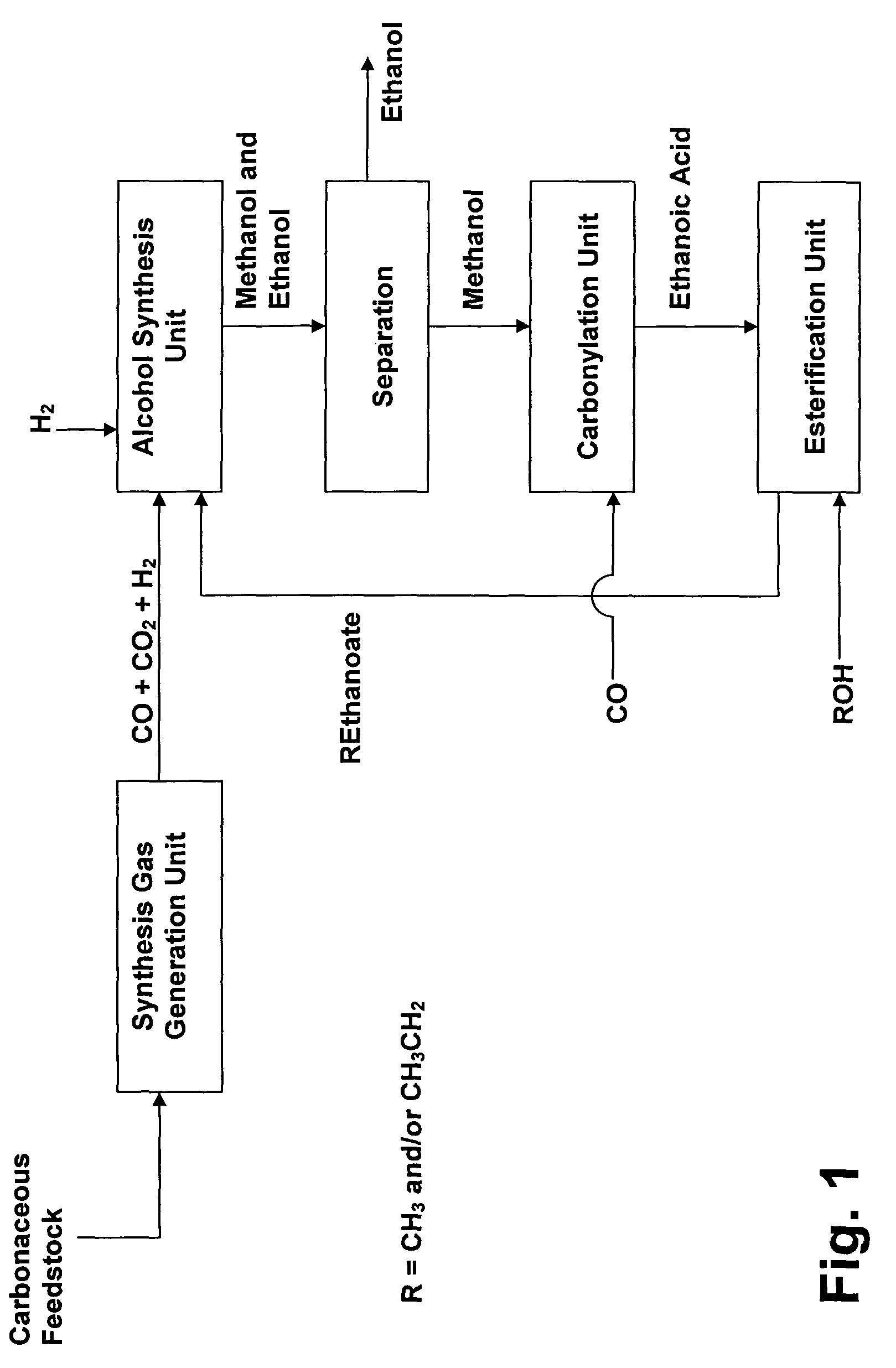

Process for the conversion of hydrocarbons into ethanol

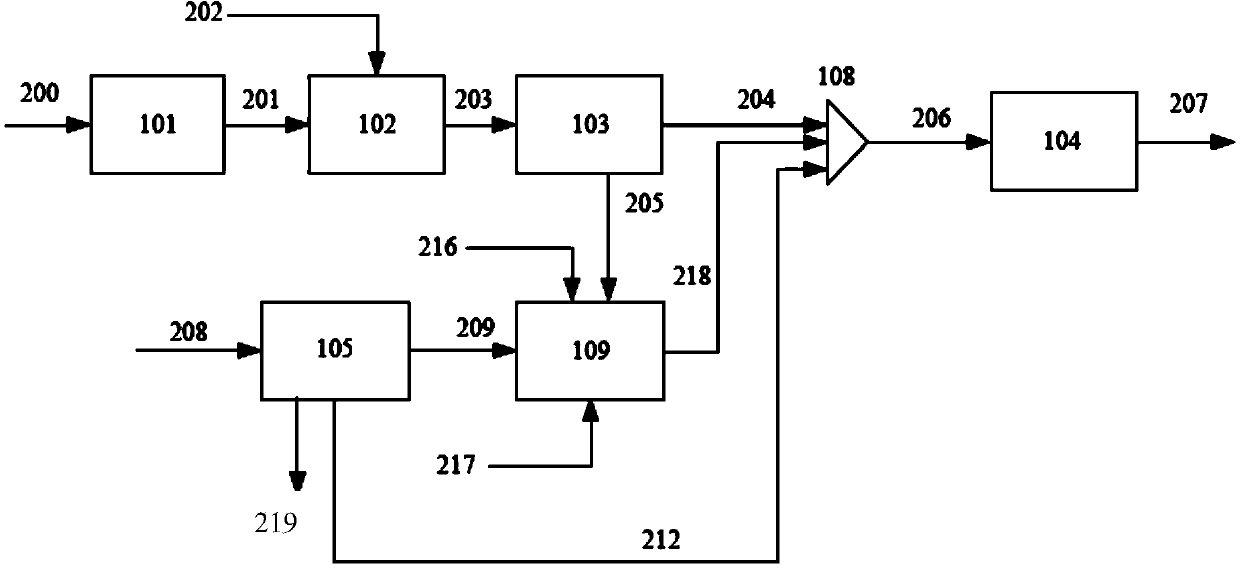

ActiveUS7947746B2Increased formationIncreased purge stepOrganic compound preparationOxygen compounds preparation by reductionAcetic acidAlcohol

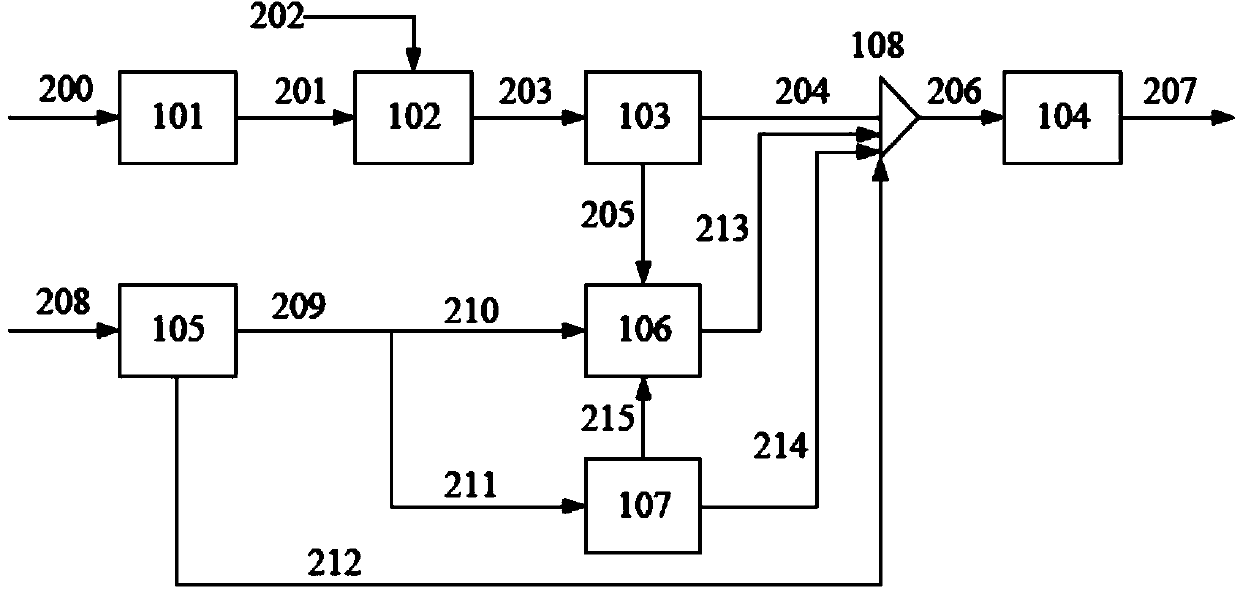

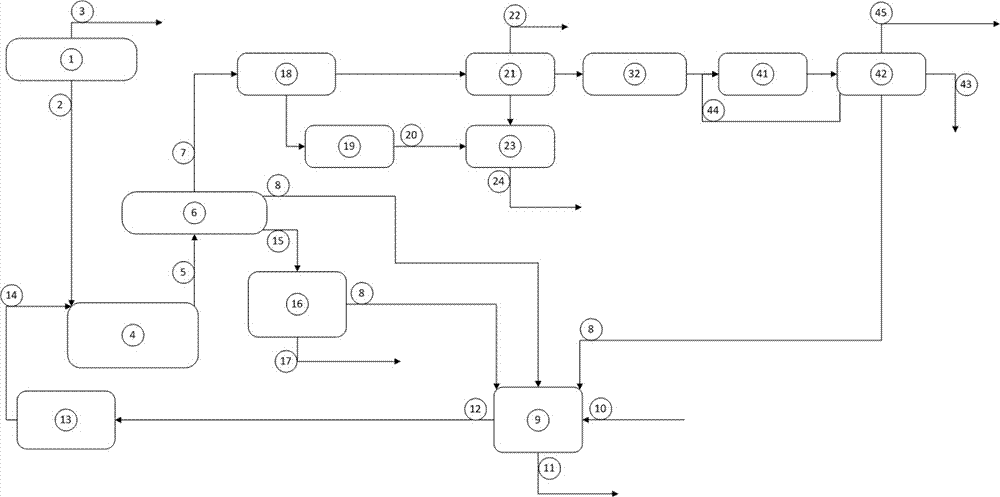

Process for converting synthesis gas to ethanol, including the steps of 1) introducing synthesis gas, together with methyl ethanoate and / or ethyl ethanoate, into an alcohol synthesis unit to produce methanol and ethanol, 2) separating the methanol from the ethanol of step 1, 3) introducing methanol, from step 2, together with CO, into a carbonylation unit in the presence of a methanol carbonylation catalyst, to produce ethanoic acid, and 4) introducing ethanoic acid, from step 3, together with methanol and / or ethanol, into an esterification unit to produce methyl ethanoate and / or ethyl ethanoate. In step 5), methyl ethanoate and / or ethyl ethanoate, produced in step 4, are fed into the alcohol synthesis unit of step 1, and in step 6) ethanol from step 2 is recovered.

Owner:INEOS ACETYLS UK LTD

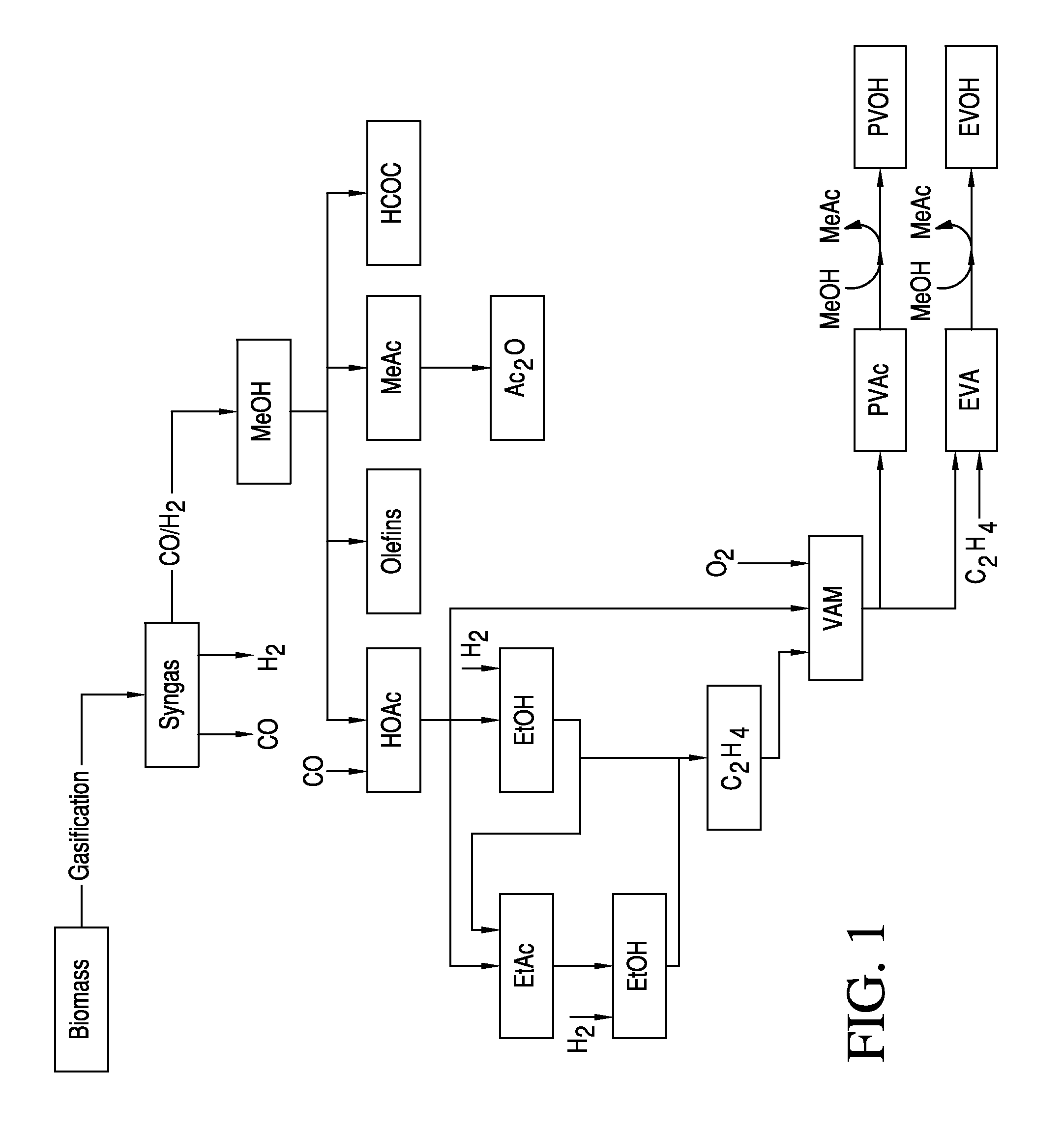

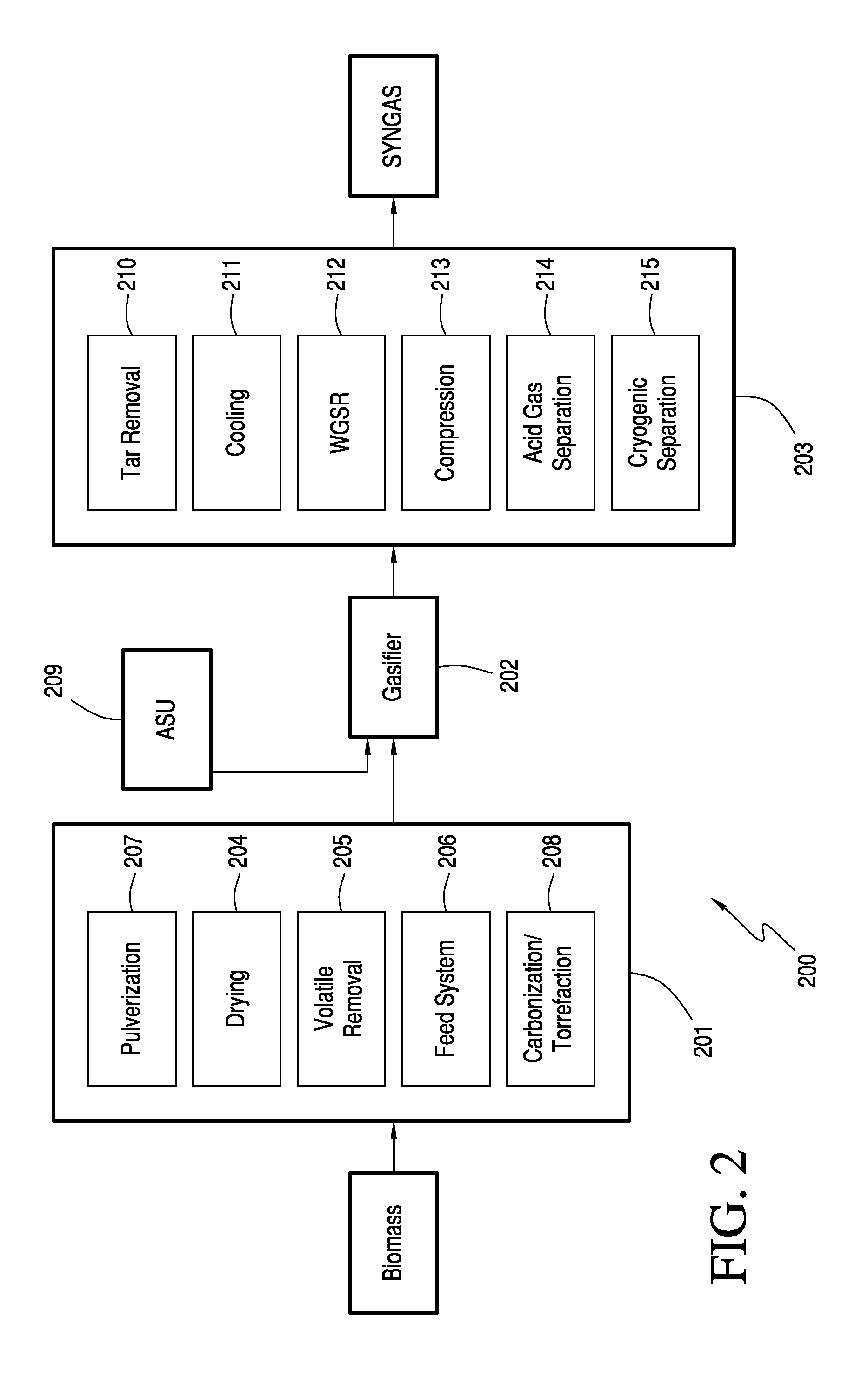

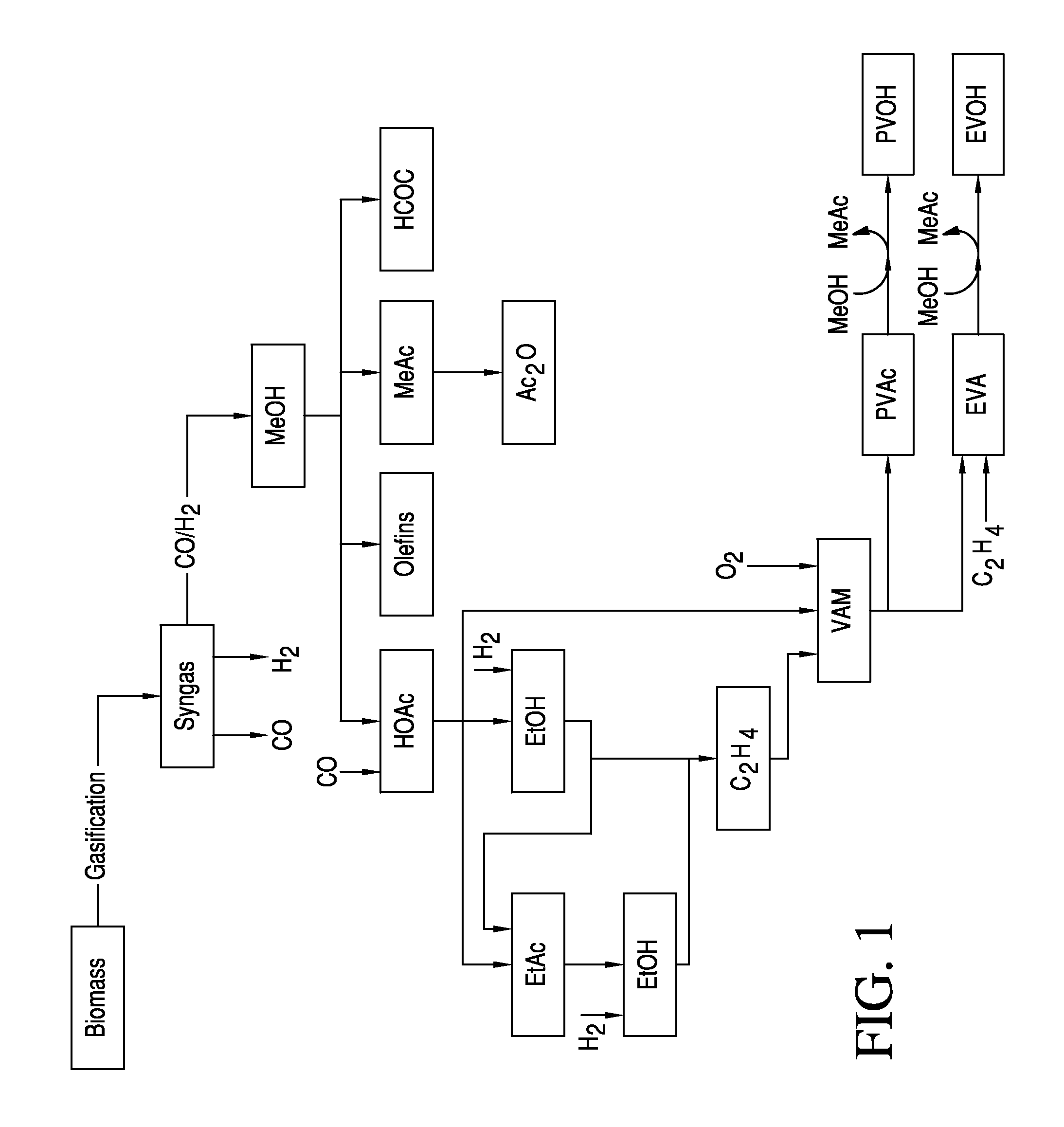

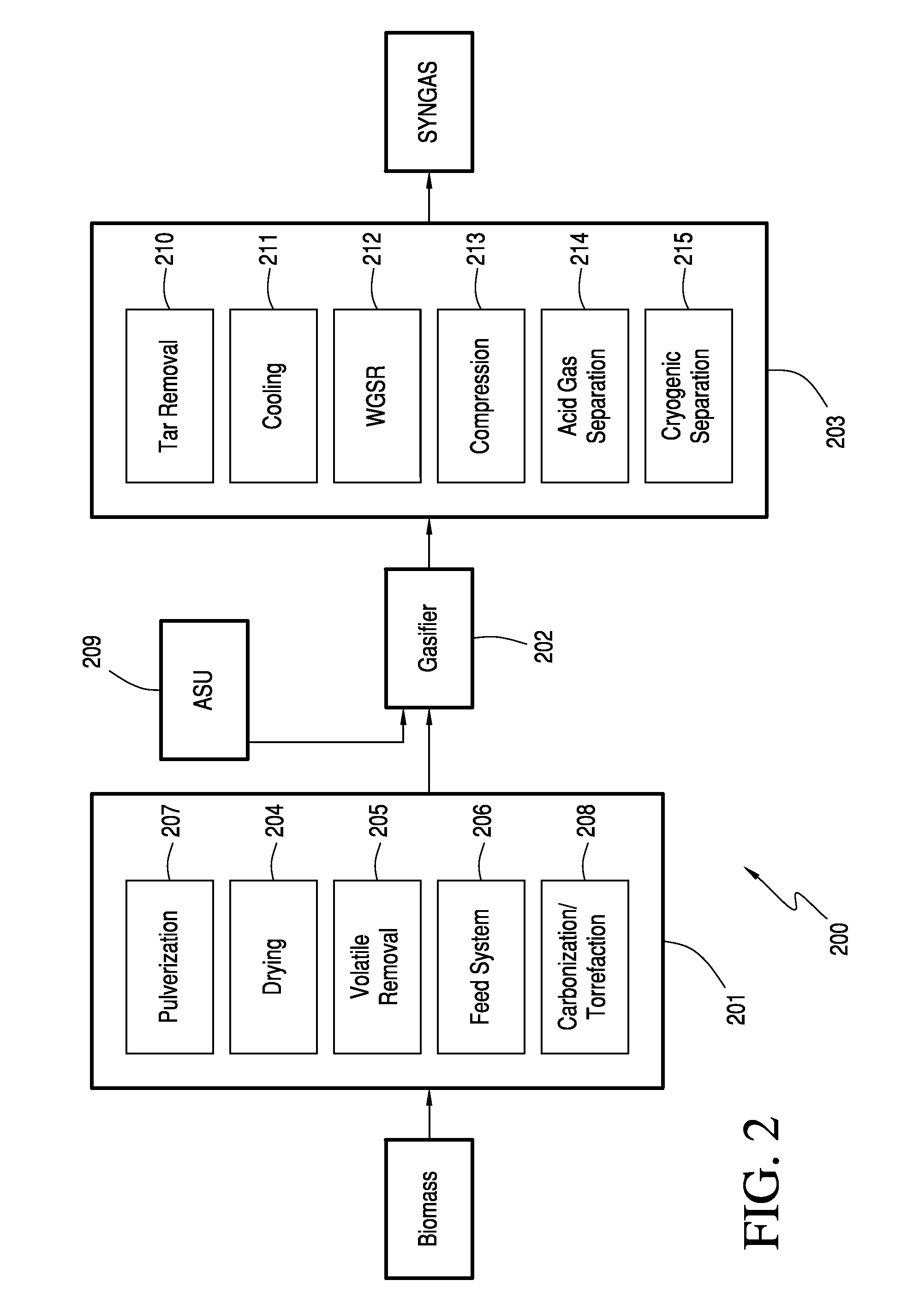

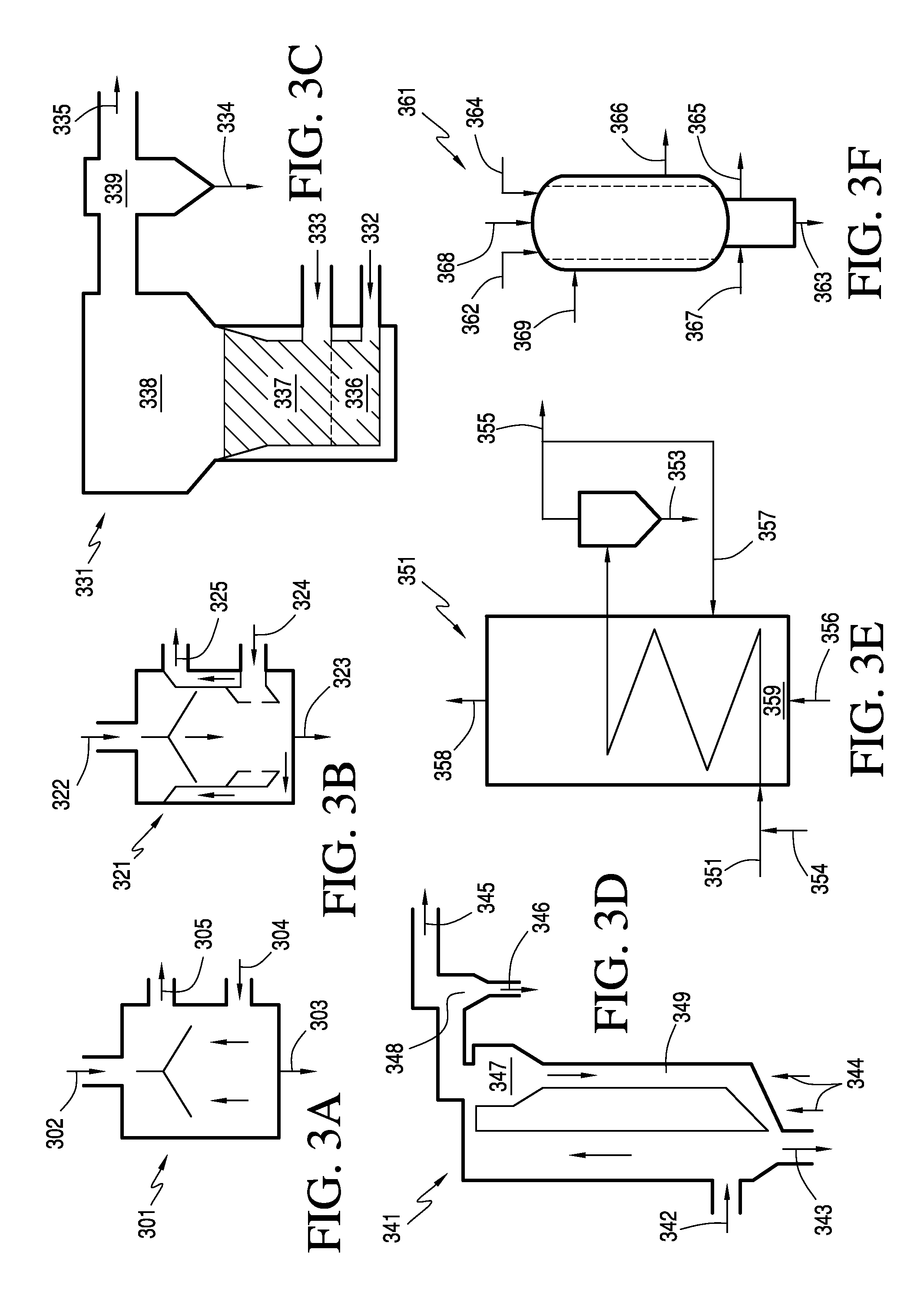

Biomass gasification and integrated processes for making industrial chemicals through an acetic acid intermediate

InactiveUS20130143972A1Raise the ratioCombustible gas catalytic treatmentBiofuelsCarboxylic acidOxygen

The invention relates to integrated processes for producing industrial chemicals, such as alcohols, carboxylic acids, esters, aldehydes, olefins and polymers from biomass. In one embodiment, the invention is to a process comprising the steps of (a) introducing biomass and an oxygen stream to a gasifier and converting the biomass into a product gas, wherein the gasifier is operated at a pressure of at least 10 bar; (b) compressing the product gas at a compression ratio that is less than 5:1 to form compressed product gas; (c) directing a first portion of the compressed product gas to an alcohol synthesis reactor to produce methanol; (d) directing a second portion of the compressed product gas to a gas separator to produce a hydrogen stream and a carbon monoxide stream; (e) reacting the carbon monoxide stream with the methanol to produce acetic acid; and (f) reacting the hydrogen stream with acetic acid to produce ethanol.

Owner:CELANESE INT CORP

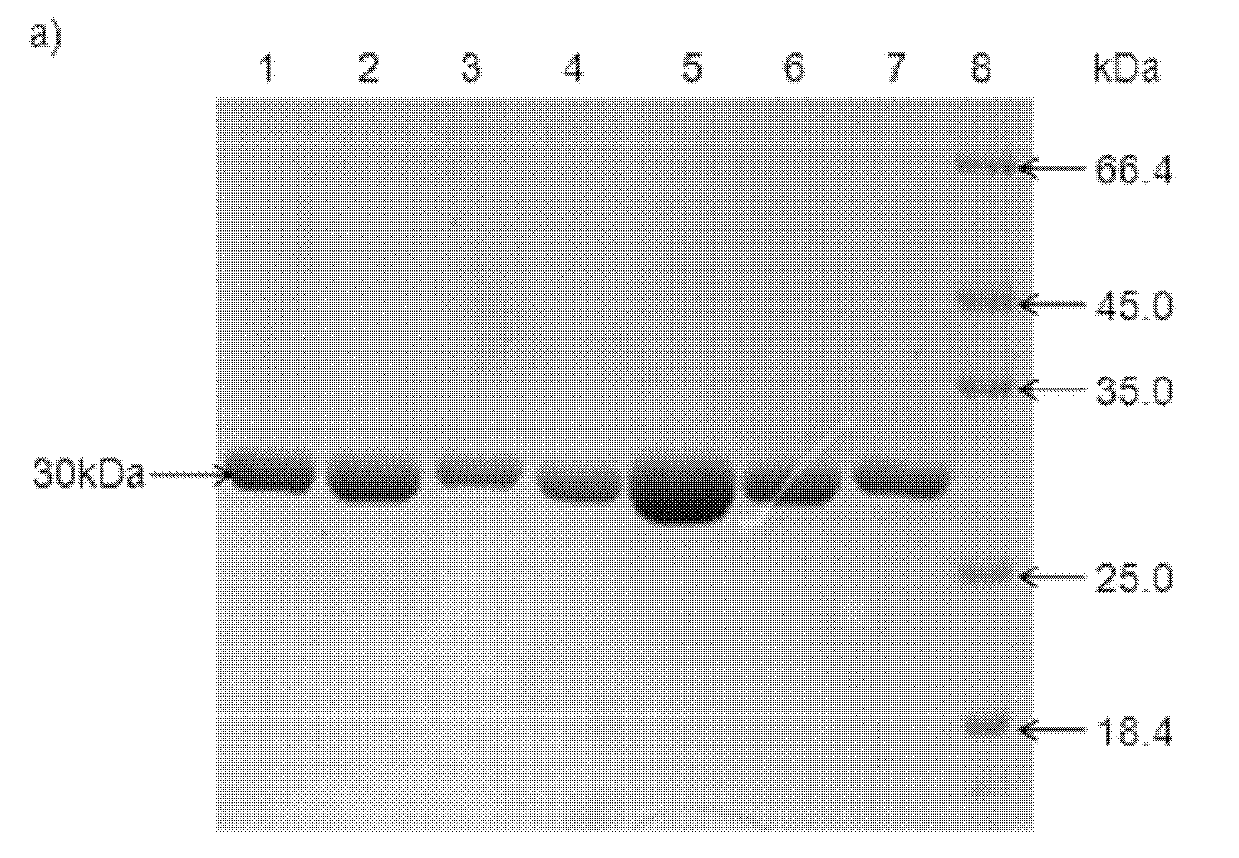

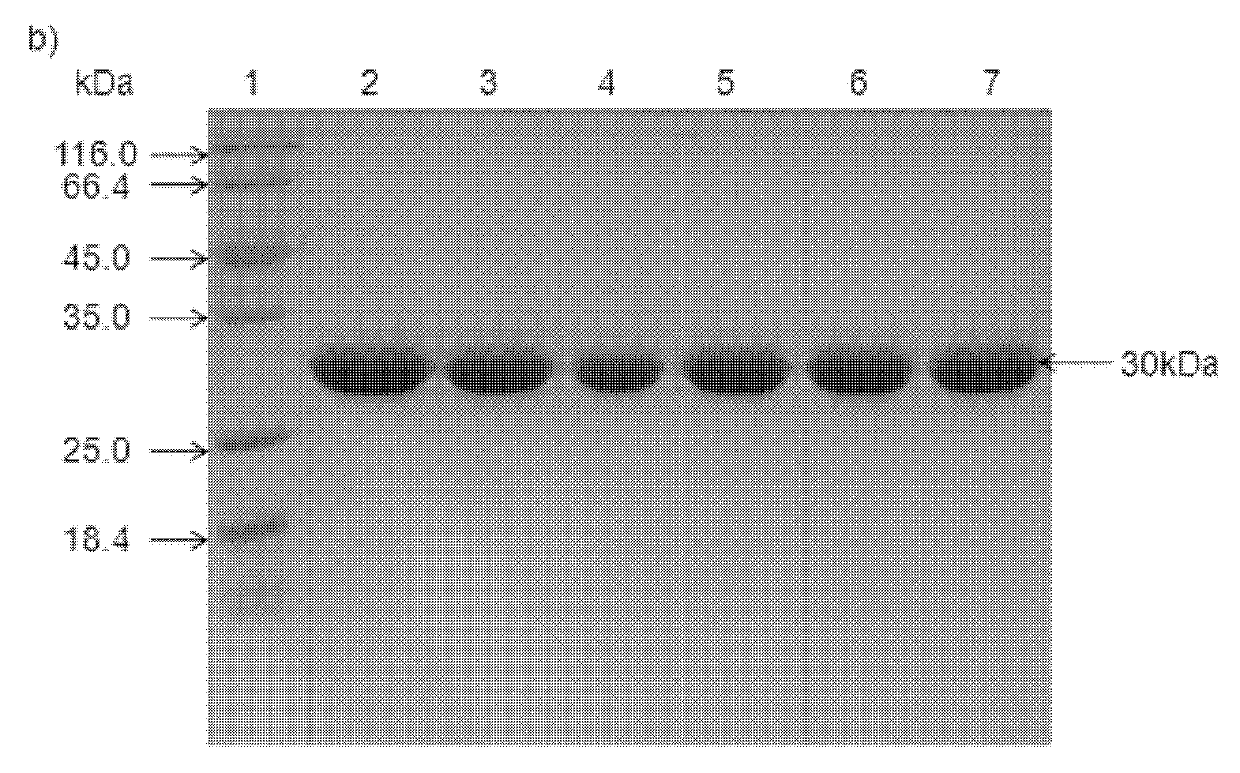

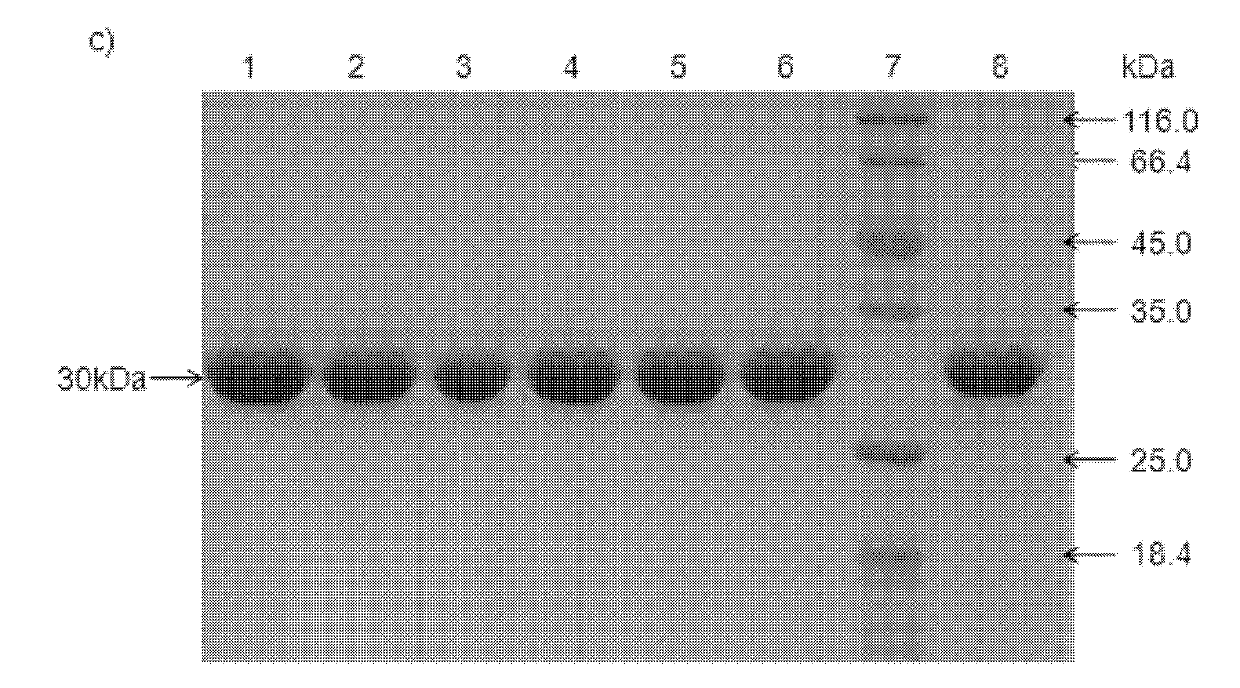

Double carbonyl reductase mutant and its application

InactiveCN102277338AEffective catalytic reduction reactionImprove conversion efficiencyBacteriaMicroorganism based processesCarbonyl ReductaseTransformation efficiency

The invention belongs to the field of biotechnology, and in particular relates to a mutant of diketoreductase (DKR) that can be used as a catalyst for chiral alcohol synthesis; the invention discloses a mutant of diketoreductase, the diketoreductase The amino acid sequence of the mutant has more than 80% homology with any amino acid sequence shown in SEQ ID NO.1-SEQ ID NO.20. Compared with the wild-type double carbonyl reductase, the double carbonyl reductase mutant of the present invention has higher transformation efficiency and higher stereoselectivity.

Owner:CHINA PHARM UNIV

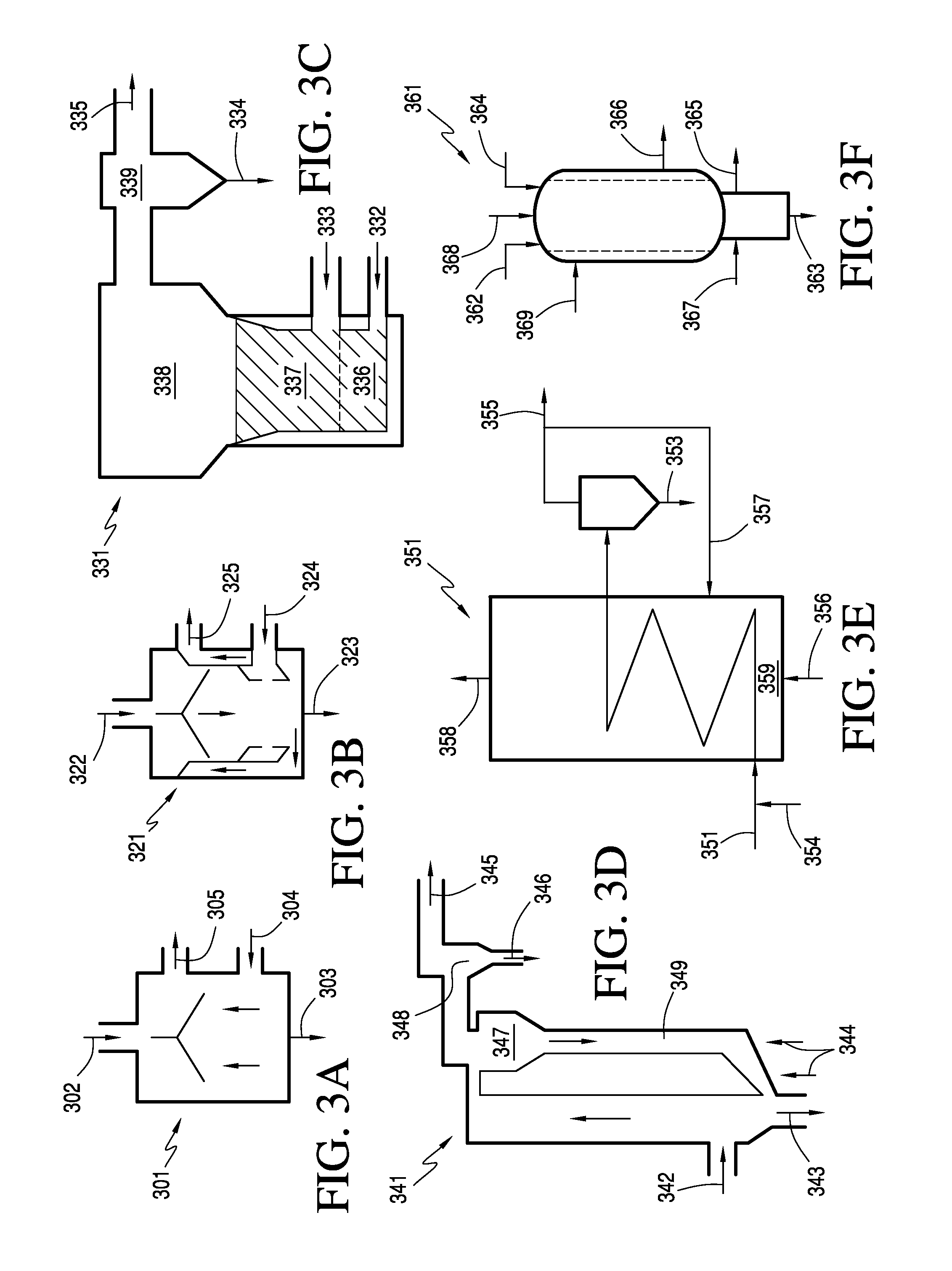

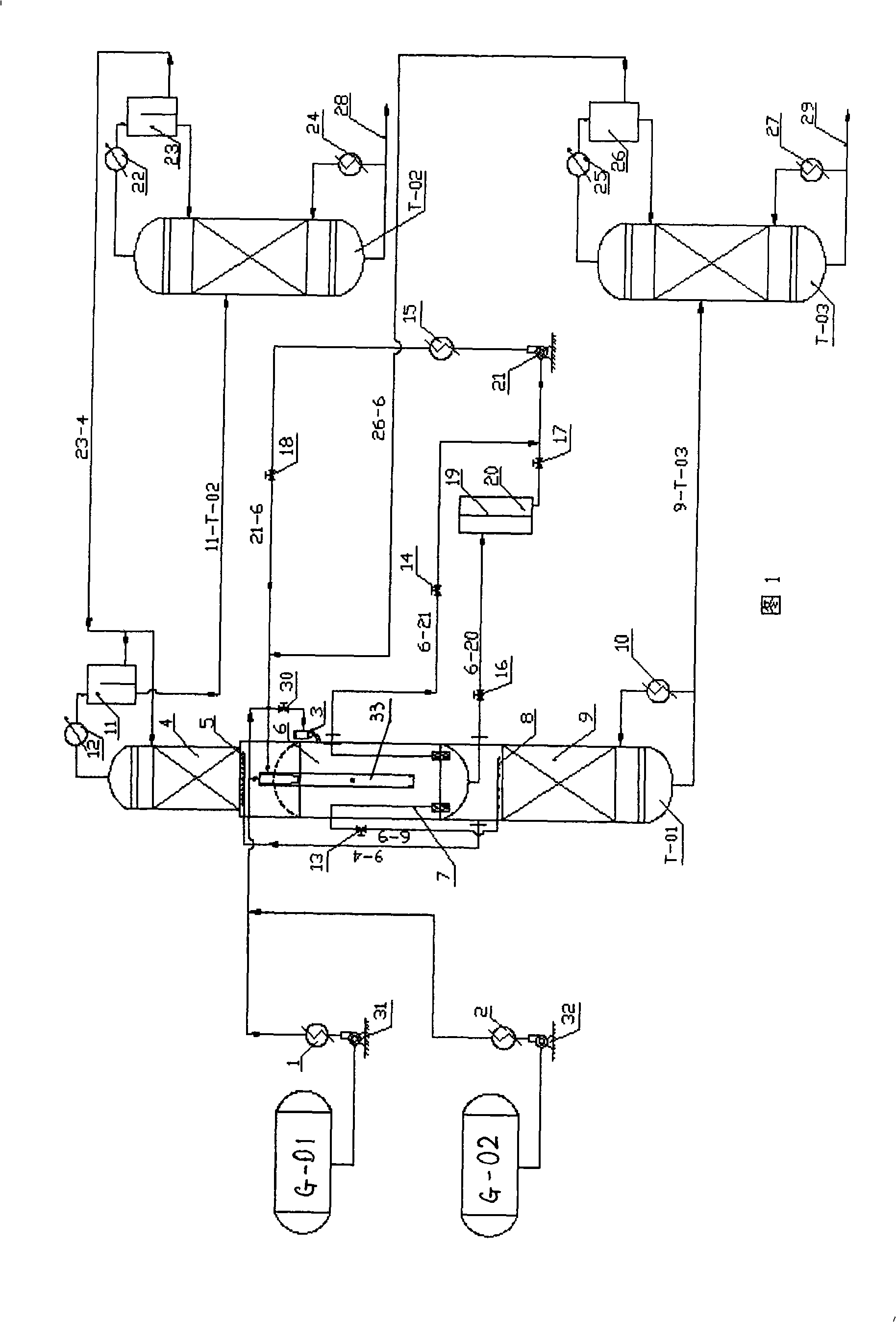

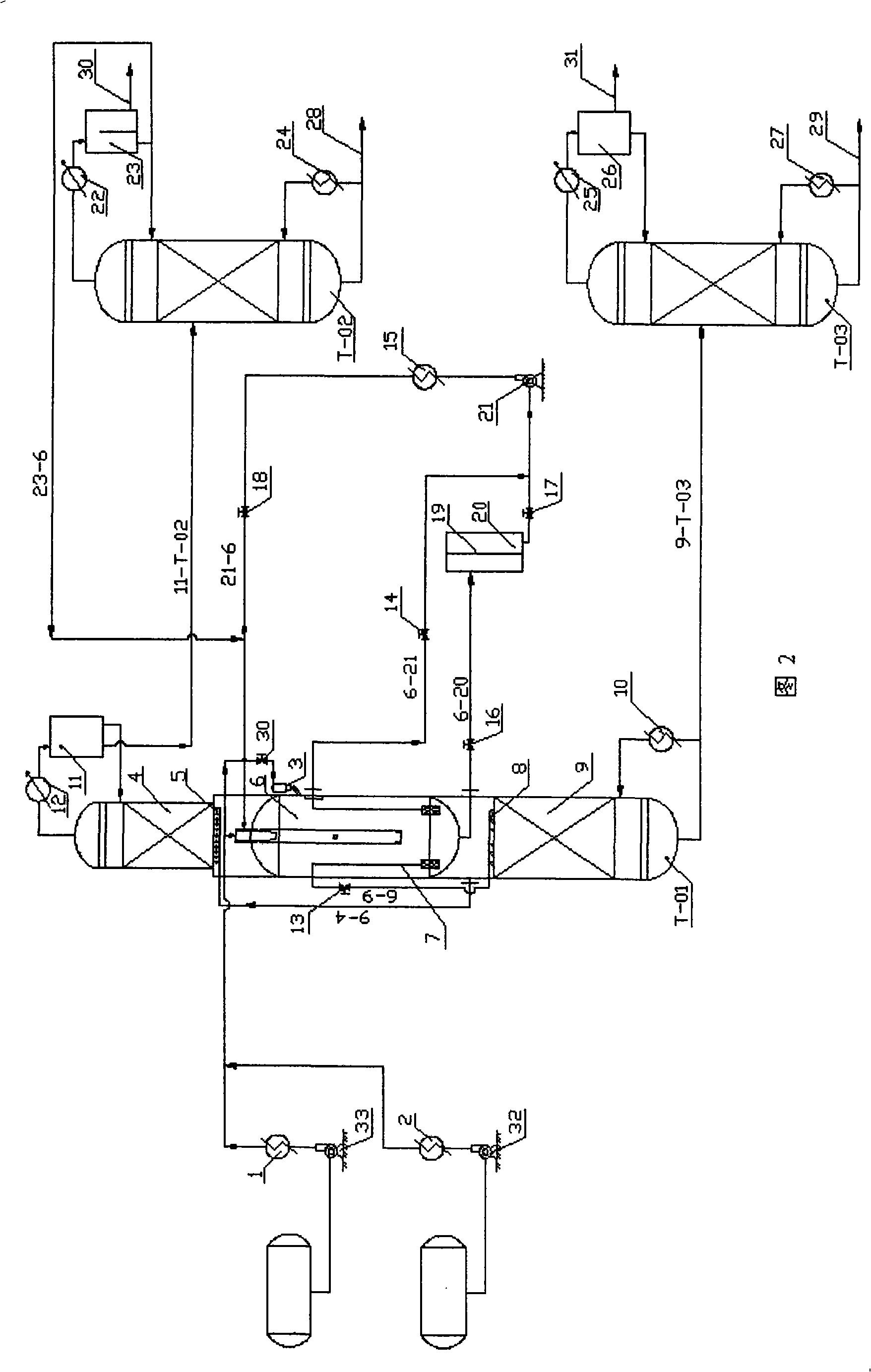

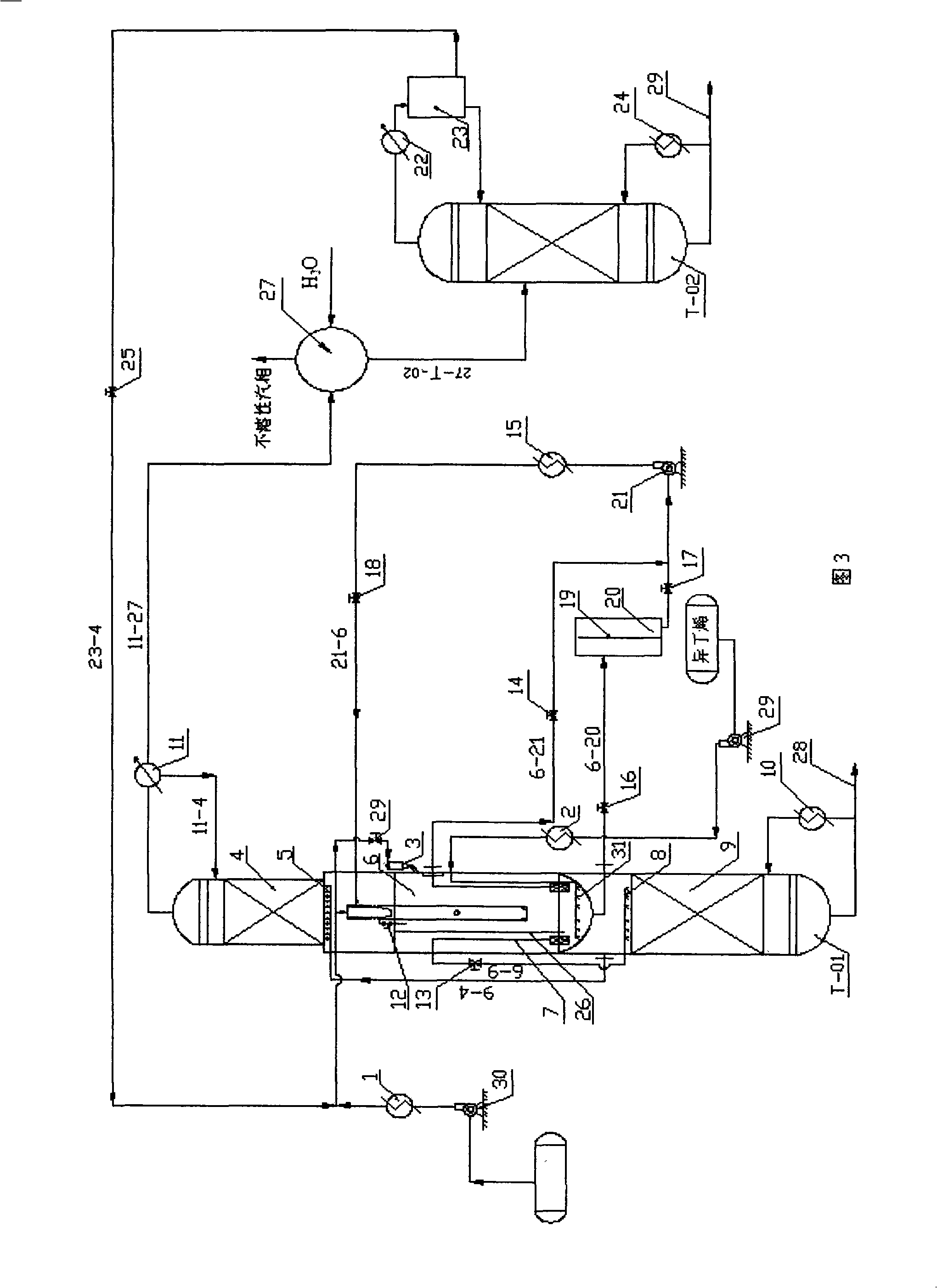

Catalytic reaction, rectification integrated technique and special-purpose equipment

InactiveCN101254444AIncrease production capacityHigh reaction conversion rateOrganic compound preparationCarboxylic acid esters preparationAlcoholEther

A catalytic reaction / rectification integrated process is provided, which includes: reaction raw materials are pre-heated and then mixed with catalysts; the resulting mixture is fed into a jet mixing reaction section 6 of a catalytic reaction / rectification integrated tower through a feed port, wherein the jet mixing reaction section 6 is a kettle-like reactor in the middle of the catalytic reaction / rectification integrated tower T-01; after the reaction raw materials are pressurized by a centrifugal pump, a subsonic or transonic jet mixer 33 inside the jet mixing reaction section 6 jets the reaction raw materials at a high speed into the jet mixing reaction section 6 and performs high-efficiency mixing of solid and liquid phases inside the jet mixing reaction section 6, thereby enhancing the heat and the mass transfer efficiencies during the process; the reaction mixture is directly separated and purified inside the catalytic reaction / rectification integrated tower. Therefore, the catalytic reaction / rectification integrated process has high conversion rate and production capacity and low energy consumption and production cost. The process is used for esterification, alcohol synthesis from alkenes and water, and the ether synthesis from alkenes and alcohols. A special catalytic reaction / rectification integrated tower is also provided.

Owner:NANJING UNIV

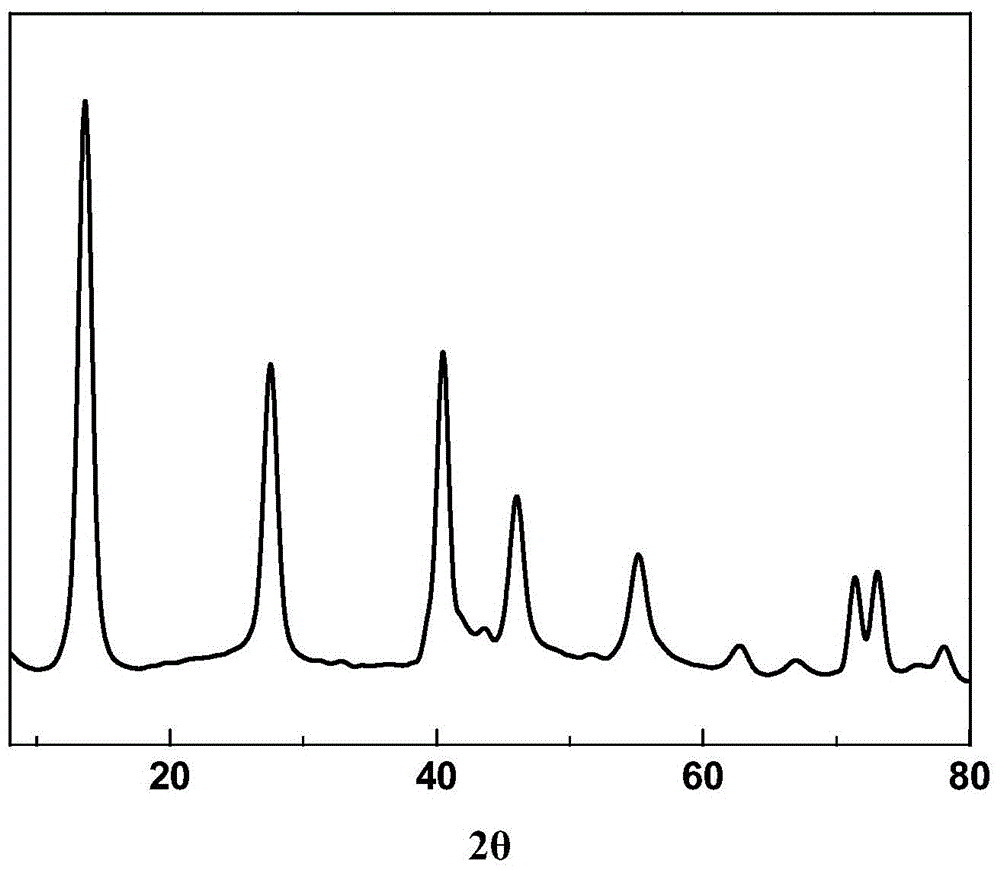

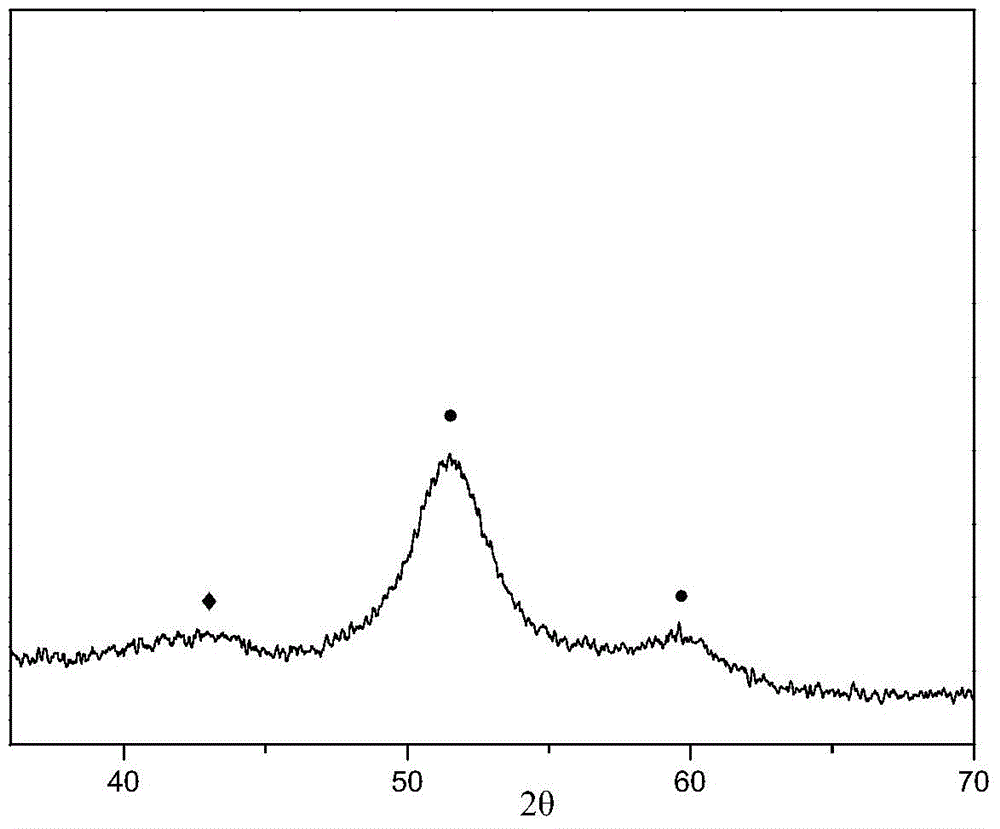

Methods of making improved cobalt-molybdenum-sulfide catalyst compositions for higher alcohol synthesis

InactiveUS20100331581A1Organic compound preparationHeterogenous catalyst chemical elementsAlcohol productionAlcohol synthesis

This invention improves prior methods of making cobalt-molybdenum-sulfide catalysts for alcohol production from syngas. In one aspect, improved methods are provided for making preferred cobalt-molybdenum-sulfide compositions. In another aspect, processes utilizing these catalysts for producing at least one C1-C4 alcohol, such as ethanol, from syngas are described.

Owner:ALBEMARLE CORP

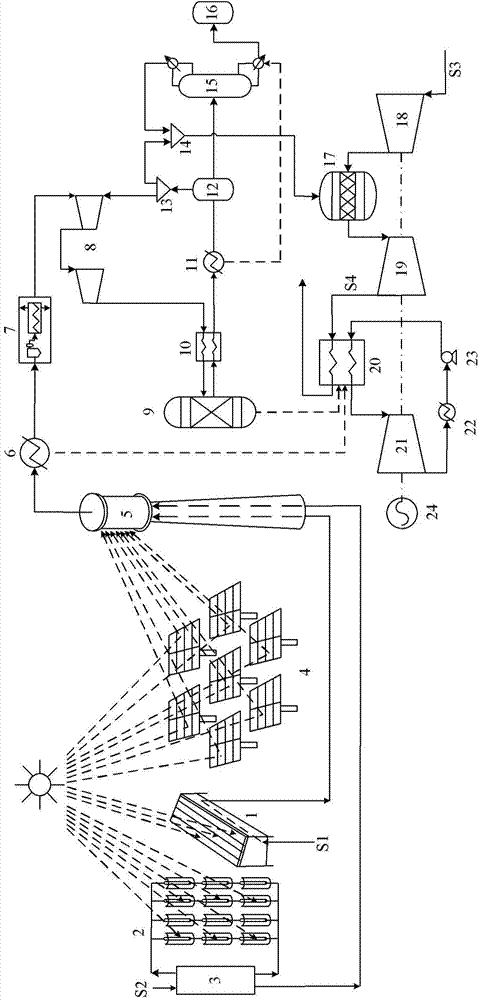

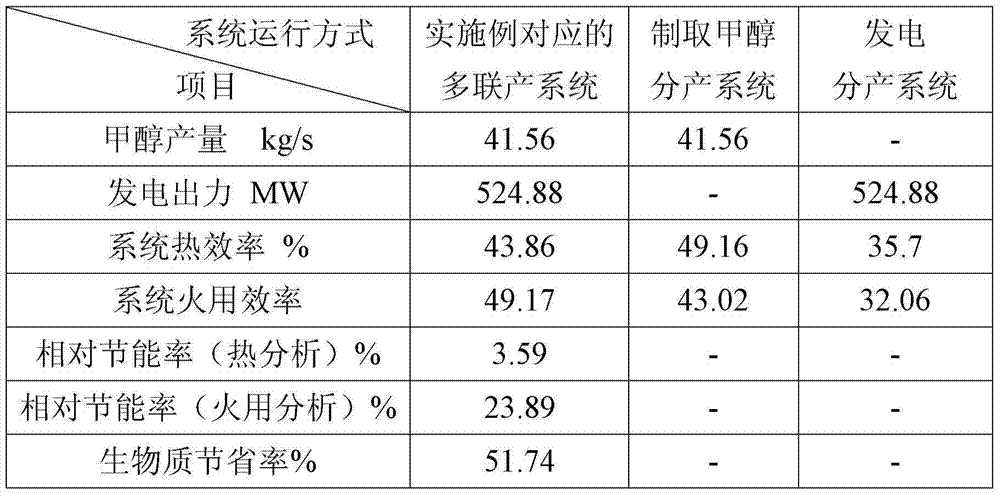

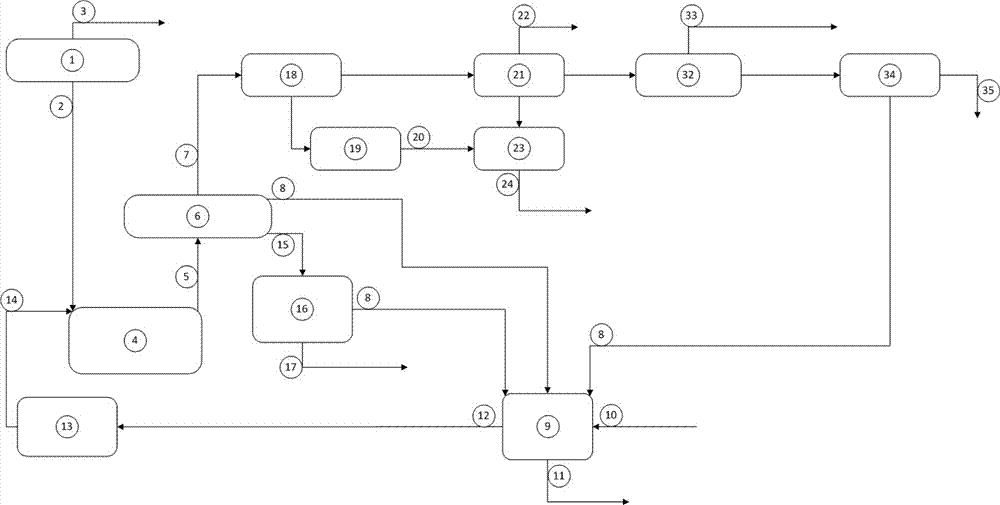

Poly-generation system using biomass and solar energy for making methyl alcohol and generating power

ActiveCN103899371AOptimize thermal energy utilizationHigh thermal efficiencyOrganic compound preparationSolar heat devicesCombustion chamberLiquid temperature

The invention discloses a poly-generation system using biomass and solar energy for making methyl alcohol and generating power. The poly-generation system comprises a solar energy heat collecting reaction subsystem, a biomass gasification subsystem, a methyl alcohol synthesis subsystem and a power generation subsystem. Main devices comprise a flat plate type solar energy drying device, a groove type solar thermal collector, a steam generator, a tower type solar energy reflection mirror field, a tower type high-temperature gasification reactor, a gas temperature reduction device, a gas condensation purifying device, a compressor set, a methyl alcohol synthesis tower, a heat exchanger, a gas-liquid temperature reduction device, a flash tank, a separator, a mixer, rectifying tower, a methyl alcohol, a combustion chamber, a compressor, a gas turbine, a waste heat boiler, a steam turbine, a condenser, a water feed pump and a power generator. By the utilization of the poly-generation system, solar energy is converted into chemical energy, the problems that the storage of solar energy is difficult, and stability of renewable energy source delivering is poor are solved, and meanwhile the effective utilization efficiency of the biomass is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

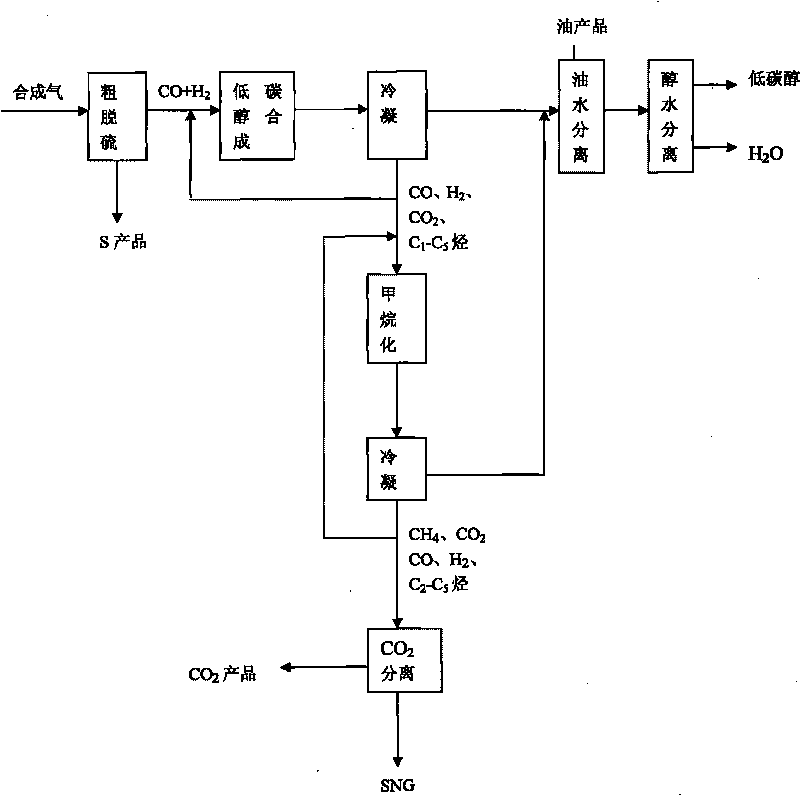

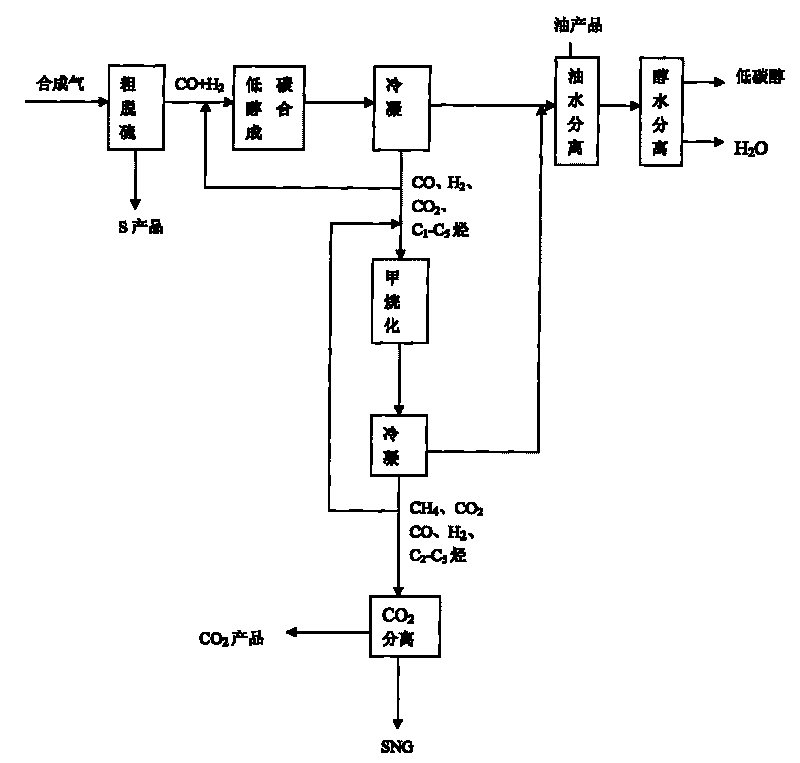

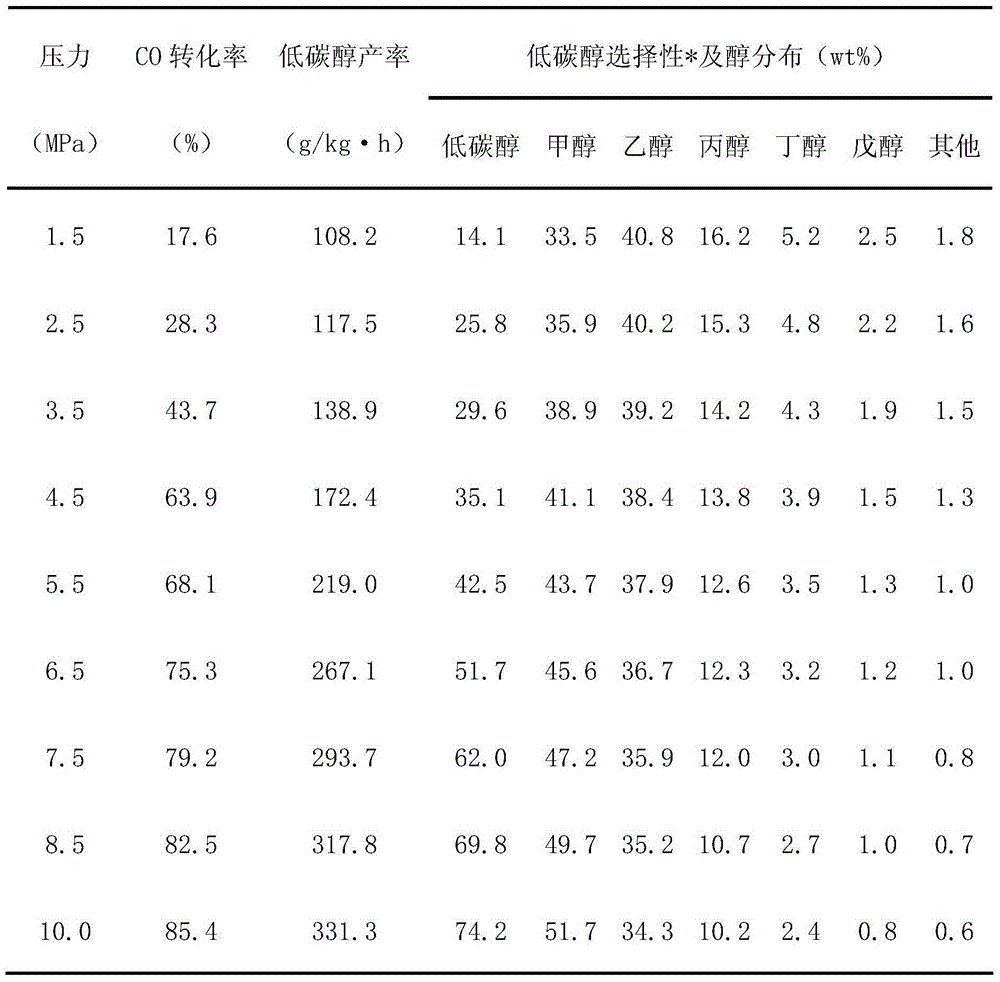

Sulfur tolerant catalyzing process for preparing low carbon alcohol from synthesis gas and co-producing natural gas

ActiveCN101735009APolygenerationAchieving Sulfur ResistanceOrganic compound preparationGaseous fuelsAlcoholMethanation

The invention relates to a sulfur tolerant catalyzing process for preparing low carbon alcohol from synthesis gas and co-producing natural gas, which comprises the following steps: performing a synthetic reaction by contacting the synthesis gas with a sulfur tolerant low carbon alcohol synthetic catalyst after the synthesis gas is subjected to coarse desulphurization; condensing the synthetic product to obtain a liquid phase of alcohol-water-oil and a tail gas mixture consisting of CO, H2, CO2, C1-C5 hydrocarbon, performing a low carbon alcohol synthesis reaction on a part of the tail gas mixture for recycling, and performing methanation on the other part of the tail gas mixture; separating oil from water in the liquid phase of the alcohol-water-oil to obtain an oil product and alcohol water, and separating alcohol from water in the alcohol-water mixture to obtain low carbon alcohol and water; performing methanation on the tail gas in the presence of the sulfur tolerant methanation catalyst and under the condition of methane conversion; condensing a methanation product to obtain a liquid phase of oil and alcohol water and a gas containing CH2, CO2, CO, H2, C2-C5 hydrocarbon, and performing the methanation on a part of the gas mixture of CH4, CO2, CO, H2, C2-C5 hydrocarbon for recycling; and sending the other part of the gas mixture to a CO2 separation device, and separating CO2 to obtain an SNG. The process has the advantages of having simple steps and low cost, organically coupling the low carbon alcohol synthesis process with the methanation process, improving the carbonutilization rate and realizing co-production and complementation of the low carbon alcohol and the natural gas.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Copper-iron core-shell catalyst for lower alcohol synthesis as well as preparation method and application thereof

ActiveCN103191741ANovel structureThe synthesis method is simpleOrganic compound preparationHydroxy compound preparationAlcohol synthesisCopper

The invention relates to a copper-iron core-shell catalyst for lower alcohol synthesis, comprising Fe2O3 and CuO. The catalyst is of a core-shell structure, the core of the catalyst is Fe2O3, and the shell of the catalyst is CuO; and the element mol ratio Cu:Fe of the catalyst is 1:8-8:1. The catalyst has the advantages of iron sintering prevention, high alcohol selectivity and good stability.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

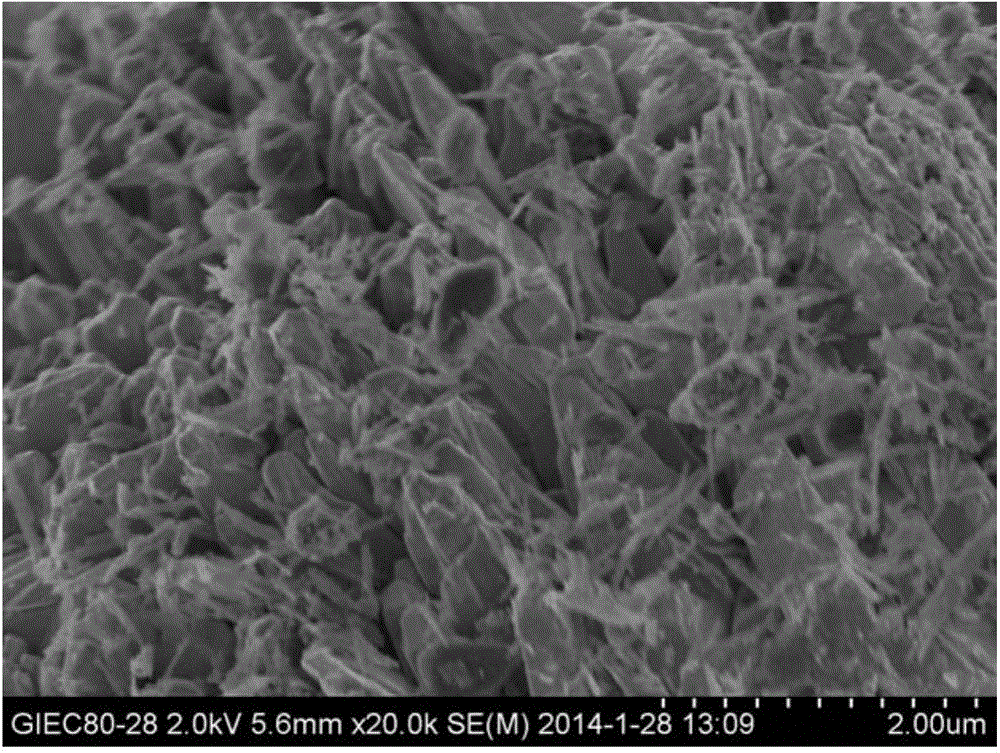

Cu-Fe-based multi-component catalyst loaded with natural nanometer material attapulgite, preparation method of multi-component catalyst and application of multi-component catalyst in lower alcohol synthesis

ActiveCN104084212AHigh activityGood choiceOrganic compound preparationHydroxy compound preparationRare-earth elementAlcohol

The invention provides a Cu-Fe-based multi-component catalyst loaded with natural nanometer material attapulgite, a preparation method of the multi-component catalyst and an application of the multi-component catalyst in low alcohol synthesis. The multi-component catalyst is characterized in that the expression formula is CuaFebMc / ATP, wherein an auxiliary agent M represents one or the combination of multiple elements, namely a transition metal element, alkali metal or a rare earth element; the total amounts of Cu, Fe and M loaded in the catalyst are respectively a, b and c, a is equal to 10-35%, b is equal to 10-25%, c is equal to 1-10%, and the rest is a catalyst carrier ATP. The preparation method comprises the steps of preparing acid-modified attapulgite with a larger specific surface area from an inorganic acid modified natural attapulgite raw material, carrying out loading in a metal salt mixed water solution including Cu, Fe and other components by taking the acid-modified attapulgite as a carrier by virtue of an impregnation method, so as to prepare the Cu-Fe-based multi-component catalyst. The Cu-Fe-based multi-component catalyst can be applied to a process for synthesizing low alcohol by virtue of synthesis gas. By taking the natural nanometer material attapulgite which is rich in resources and low in cost in China as the carrier, the cost is low, the preparation method is simple, the performance is stable, and the industrial large-scale production is easily realized.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

Biomass gasification and integrated processes for making industrial chemicals through an ester intermediate

InactiveUS20130143973A1Raise the ratioCombustible gas catalytic treatmentBiofuelsCarboxylic acidOxygen

The invention relates to integrated processes for producing industrial chemicals, such as alcohols, carboxylic acids, esters, aldehydes, olefins and polymers from biomass. In one embodiment, the invention is to a process comprising the steps of: introducing biomass and an oxygen stream to a gasifier and converting the biomass into a product gas, wherein the gasifier is operated at a pressure of at least 10 bar; compressing the product gas at a compression ratio that is less than 3:1 to form a compressed product gas; directing a first portion of the compressed product gas to an alcohol synthesis reactor to produce methanol; reacting carbon monoxide with the methanol to produce acetic acid; esterifying the acetic acid with ethanol to form ethyl acetate; and reducing the ethyl acetate with hydrogen in the presence of a catalyst to form ethanol.

Owner:CELANESE INT CORP

Water-Forming Hydrogenation Reactions Utilizing Enhanced Catalyst Supports and Methods of Use

ActiveUS20110230572A1High catalytic activityIncrease conversionsCarbon compoundsHydrocarbon purification/separationAlcoholMethanation

Improved reaction efficiencies are achieved by the incorporation of enhanced hydrothermally stable catalyst supports in various water-forming hydrogenation reactions or reactions having water-containing feeds. Examples of water-forming hydrogenation reactions that may incorporate the enhanced hydrothermally stable catalyst supports include alcohol synthesis reactions, dehydration reactions, hydrodeoxygenation reactions, methanation reactions, catalytic combustion reaction, hydrocondensation reactions, and sulfur dioxide hydrogenation reactions. Advantages of the methods disclosed herein include an improved resistance of the catalyst support to water poisoning and a consequent lower rate of catalyst attrition and deactivation due to hydrothermal instability. Accordingly, higher efficiencies and yields may be achieved by extension of the enhanced catalyst supports to one or more of the aforementioned reactions.

Owner:CLARIANT INT LTD

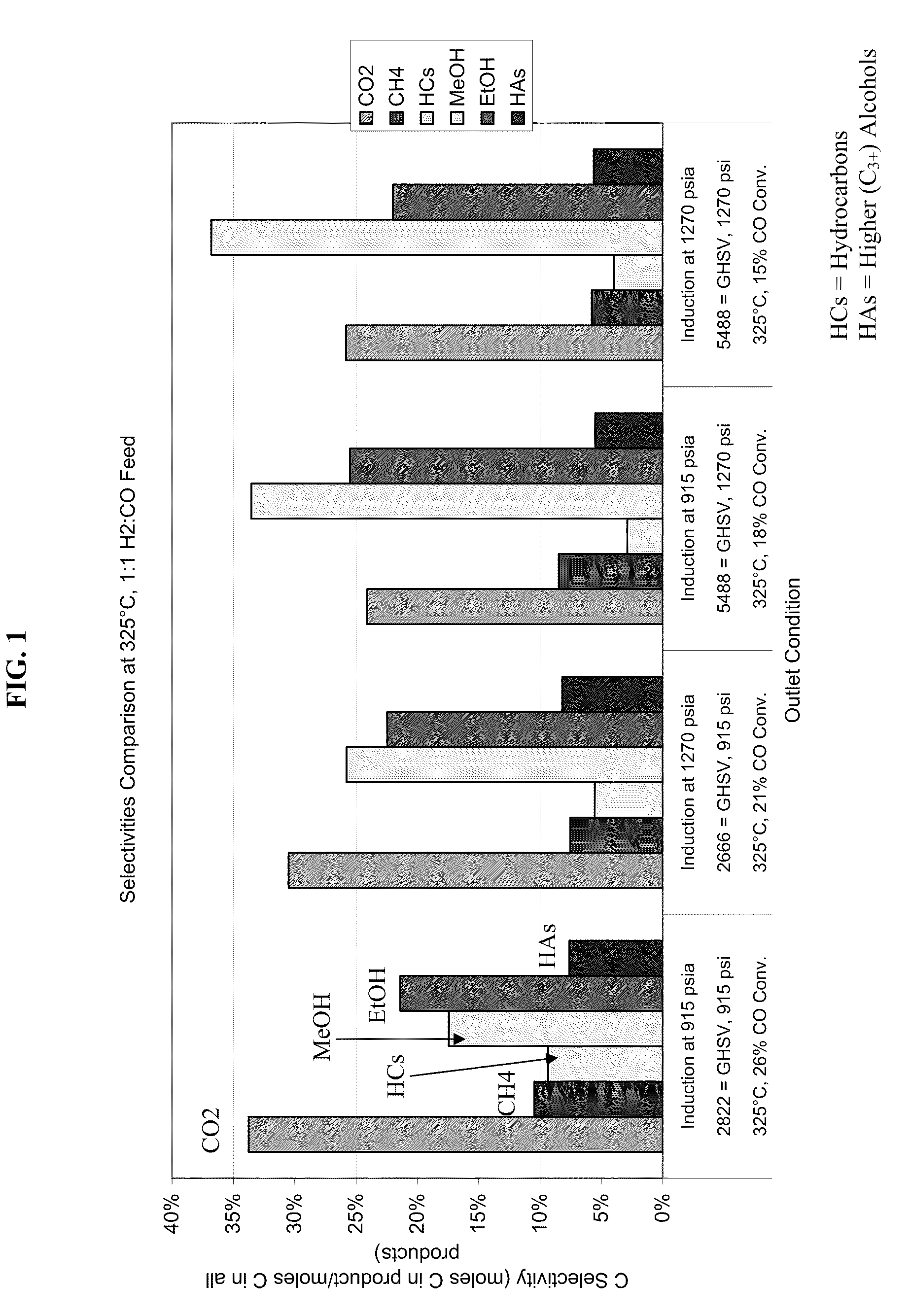

Methods for improving syngas-to-ethanol catalyst selectivity

InactiveUS20100152498A1High selectivity ratioOrganic compound preparationHydroxy compound preparationAlcoholAlcohol synthesis

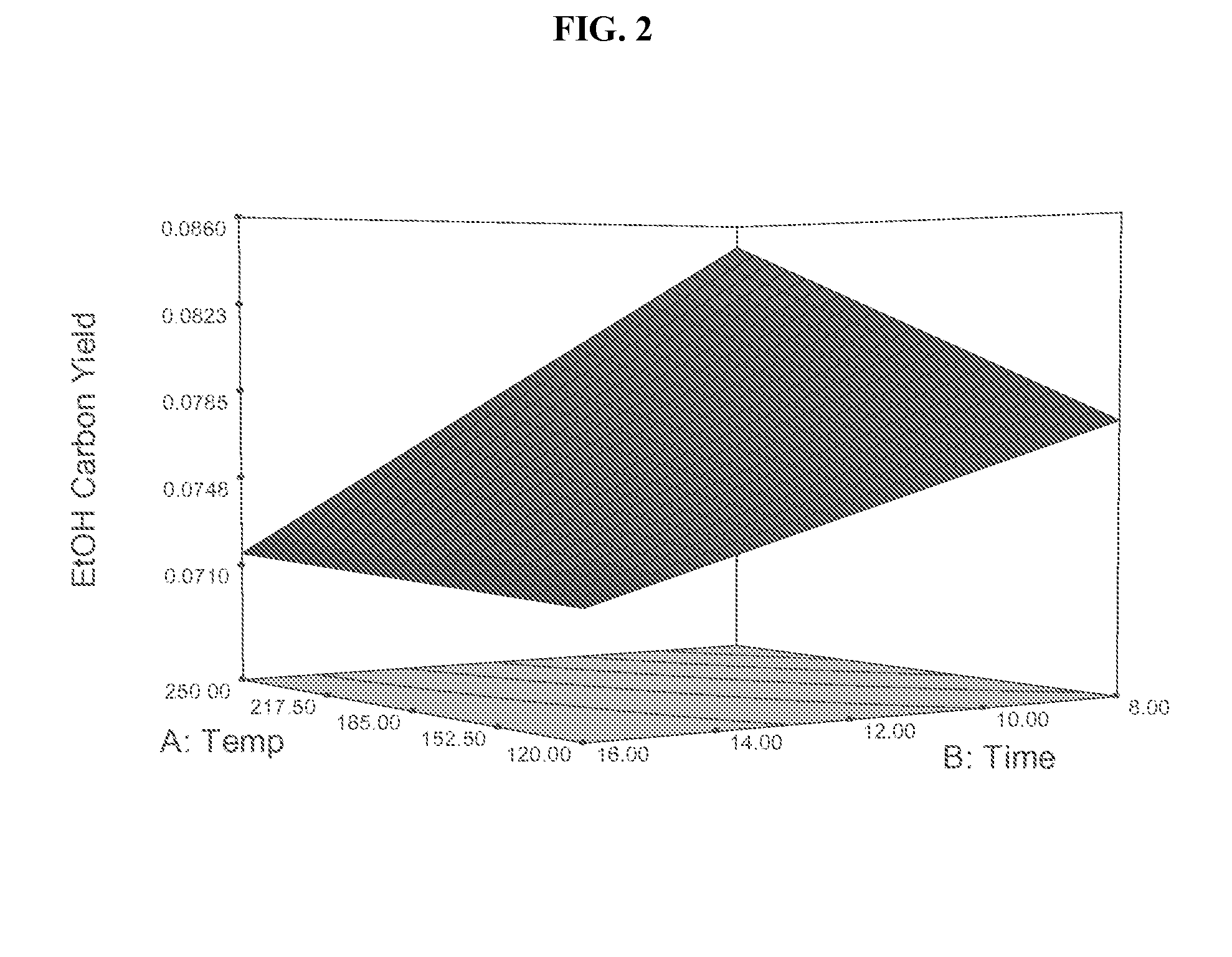

The present invention provides methods to increase yields and selectivities to particular alcohols, such as ethanol, during alcohol synthesis from syngas. In some embodiments, a starting catalyst can be activated by contacting with a gas stream under certain preferred activation temperatures, pressures, and compositions.

Owner:ALBEMARLE CORP

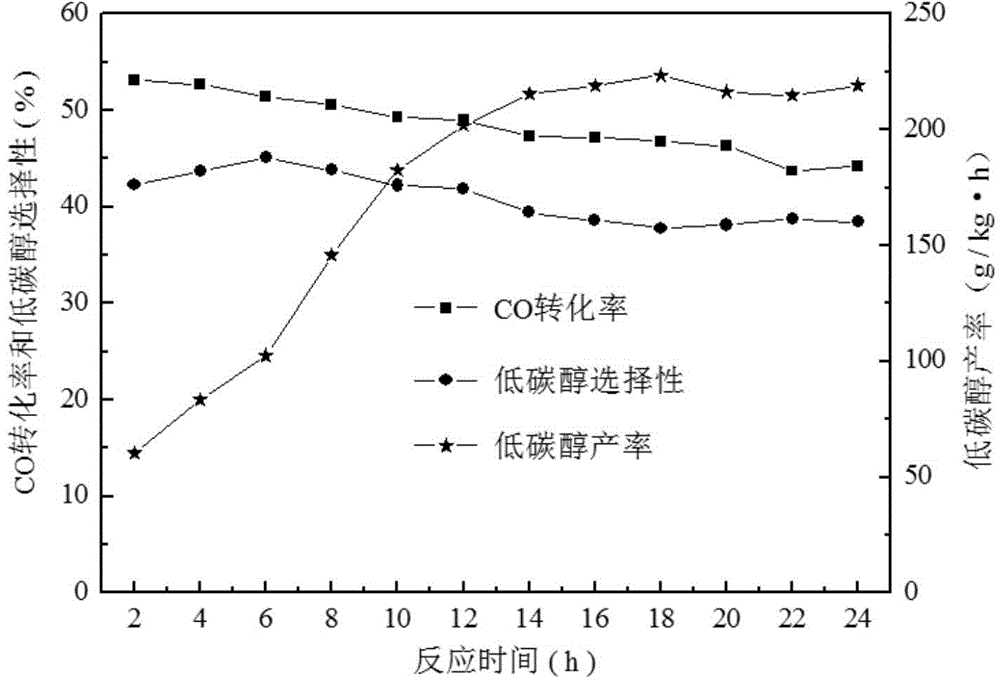

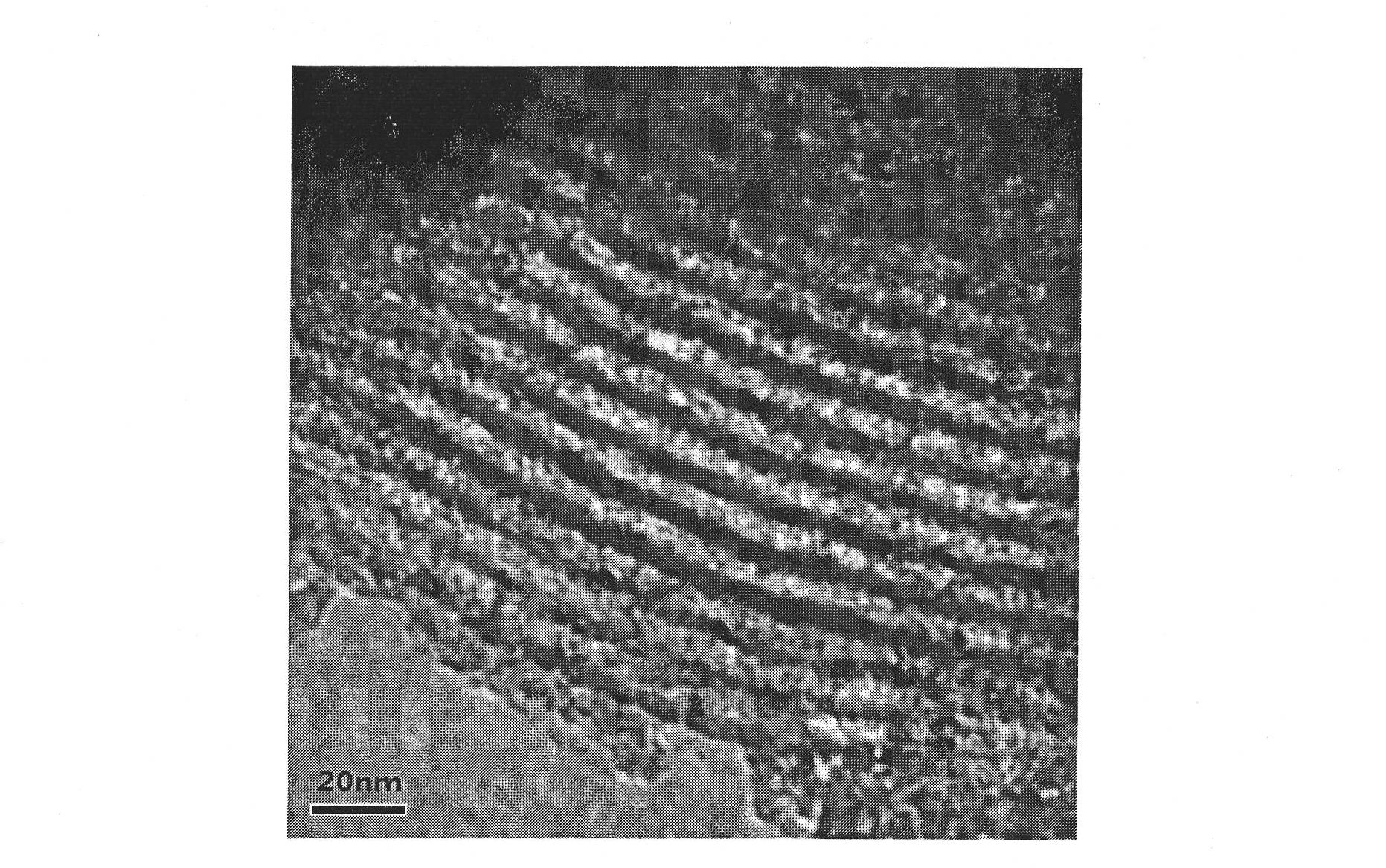

Carbon fiber compound nano copper cobalt alloy catalyst for low-carbon alcohol synthesis and preparation method of catalyst

The invention relates to a carbon fiber compound nano copper cobalt alloy catalyst for low-carbon alcohol synthesis and a preparation method of the catalyst. A hydrotalcite-like / carbon fiber precursor is prepared by virtue of a coprecipitation method and the precursor is reduced to obtain the nano copper cobalt alloy catalyst. Metal ions, particularly copper and cobalt ions in the catalyst precursor are uniformly mixed by controlling the precipitation condition. Due to strong interaction between metals and carbon fibers, after reduction, Cu-Co nanoalloy can be highly dispersed on the carbon fibers, so that particle sintering of the Cu-Co alloy caused by migration is effectively avoided. The prepared Cu-Co active component has a high active specific surface area. A carrier and an additive can be used for inhibiting sintering of the active component. The catalyst has the remarkable advantages that low-carbon alcohol selectivity and low-temperature activity are relatively high as well as the stability is relatively high; the CO conversion ratio at 260 DEG C can reach not less than 50%, the low-carbon alcohol selectivity can reach not less than 50%, and the active component hardly grows during sintering; the catalyst has an industrial application value.

Owner:TIANJIN UNIV

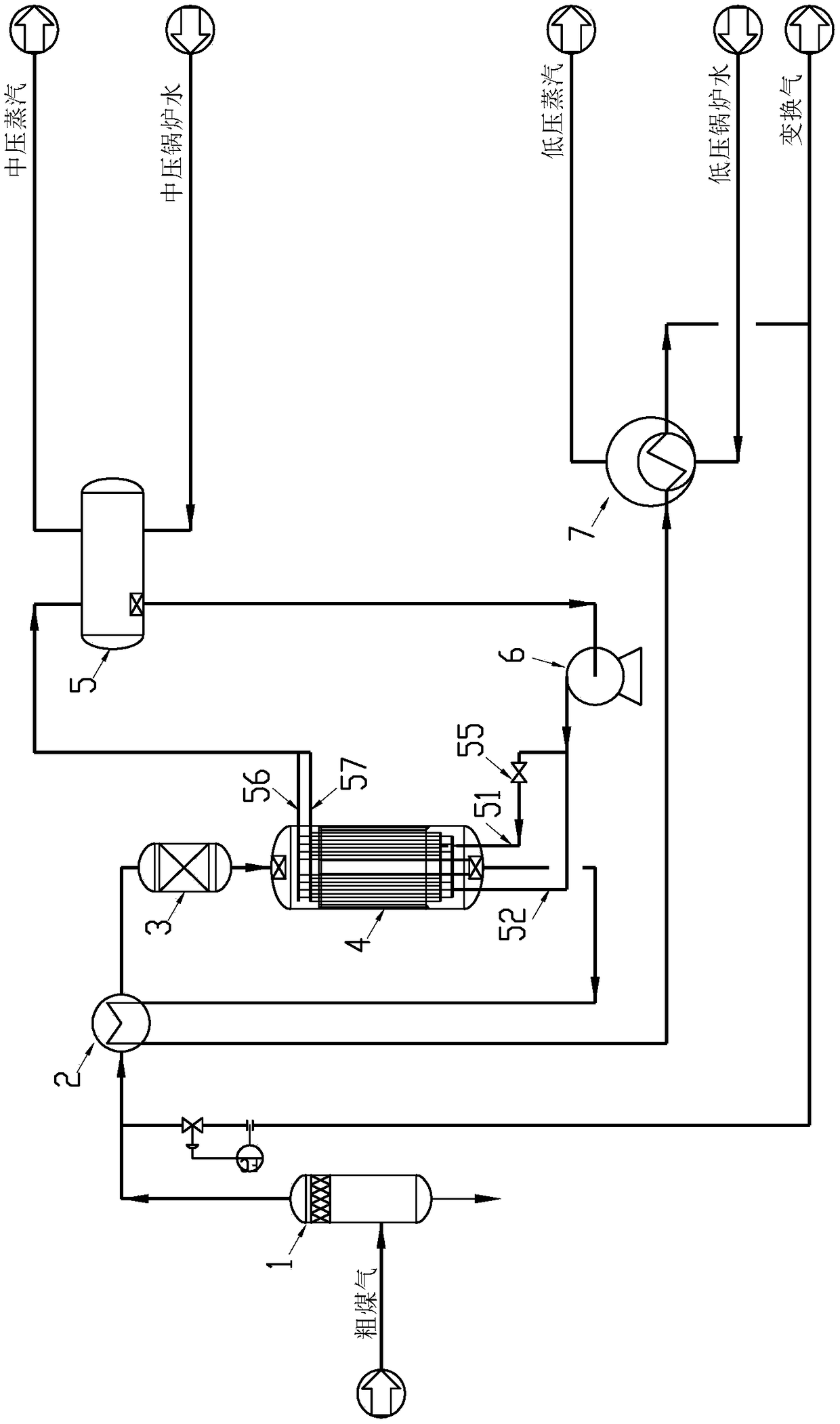

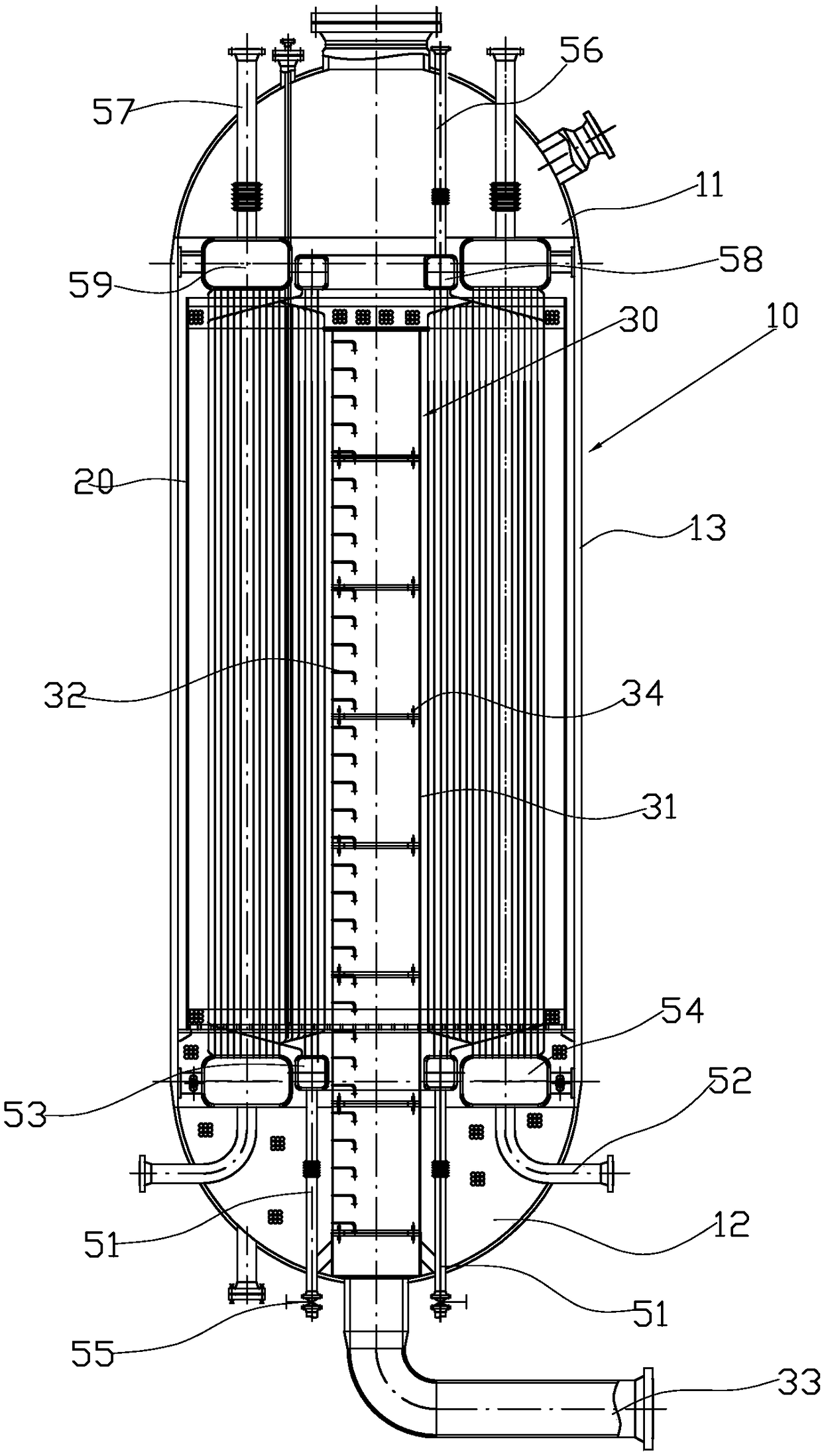

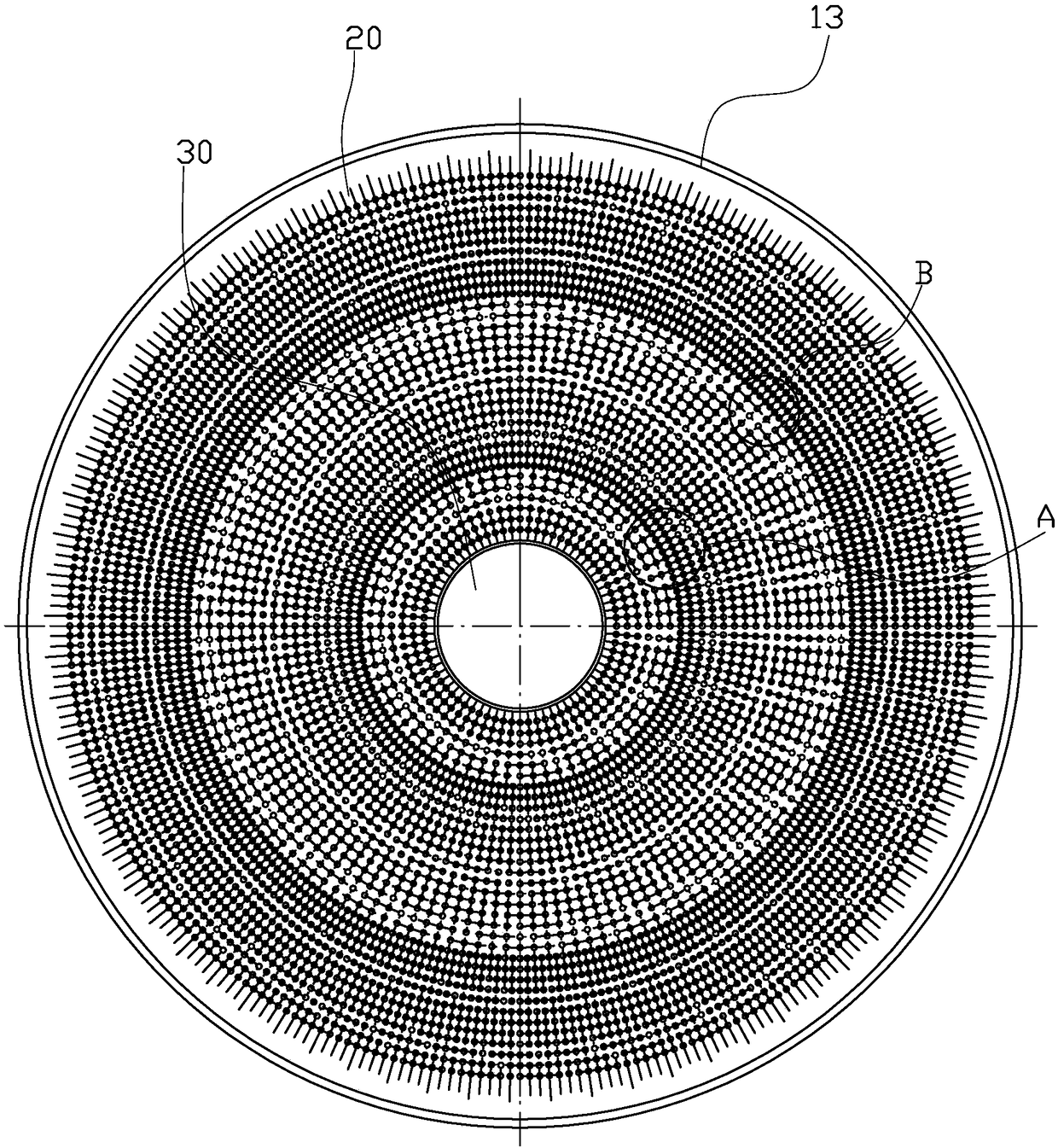

High-CO equal-temperature transformation process for matched methyl alcohol synthesis

ActiveCN109081346AAvoid large fluctuations in pressureConstant conversion rateOrganic compound preparationChemical industryAlcohol synthesisGas exchange

Owner:SINOPEC NINGBO ENG +2

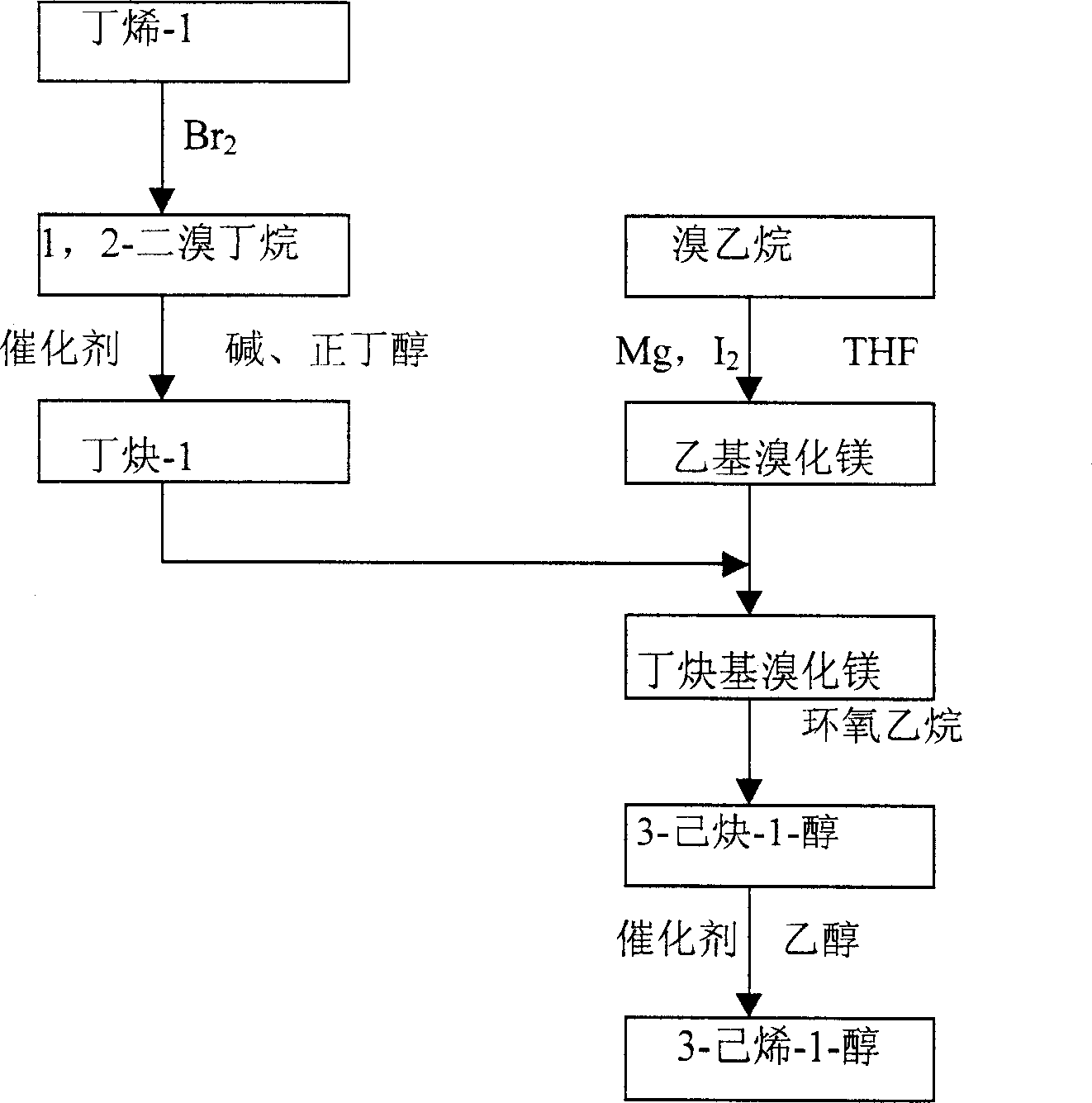

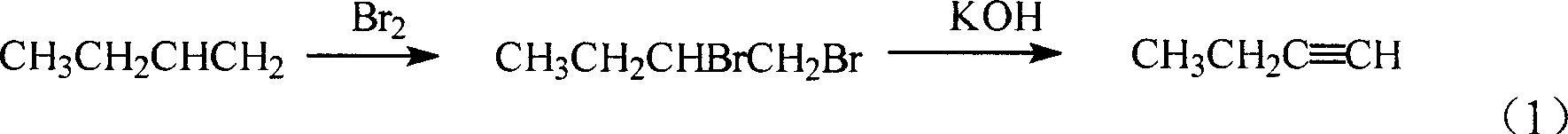

Leaf alcohol synthesis method

InactiveCN1762941ARaw materials are easy to getLow costOrganic compound preparationHydroxy compound preparationAlkaneGrignard reagent

The present invention relates to high grade perfume leaf alcohol named chemically as cis-3-hexenol and with molecular expression of C6H12O and molecular weight 100-16. Specifically, the present invention synthesizes cis-3-hexenol with butene-1 as material and through bromination, dedebromination under alkaline condition to obtain 1-butine, exchange reaction of 1-butine and alkane bromide under the action of Grignard reagent, reaction with ethylene epoxide, hydrolysis to obtain 3-hexyne-1-alcohol, and final imperfect hydrogenation at normal temperature and normal pressure. The present invention has product purity over 99 %, and has easy-to-obtain material and low cost.

Owner:大连圣迈化学有限公司 +1

Technique for recycling purge gas of device used for synthesizing methyl alcohol by utilizing synthesis gas

The invention relates to a technique for synthesizing methyl alcohol by utilizing synthesis gas in the field of chemical industry and in particular relates to a technique for recycling purge gas of device used for synthesizing methyl alcohol by utilizing synthesis gas. The technique comprises the following steps of: carrying out a water vapour transformation reaction on the purge gas of the methyl alcohol synthesizing device, wherein carbon oxide in the purge gas is converted into carbon dioxide and hydrogen, and methyl alcohol in the purge gas is reformed and decomposed into carbon dioxide and hydrogen; carrying out pressure swing adsorption separation purification on the purge gas after the transformation reaction, so as to obtain hydrogen with higher purity; and returning the hydrogen after pressure swing adsorption purification to a methyl alcohol synthesis process, so as to achieve higher feed gas utilization rate. According to the technique for recycling the purge gas of the device used for synthesizing methyl alcohol by utilizing the synthesis gas, content of hydrogen in the purge gas is increased, and discharge of carbon monoxide effective gas is also reduced; direct discharge of methyl alcohol is eliminated, and recycling of the methyl alcohol in the purge gas is realized; and the total consumption of the synthesis gas in methyl alcohol synthesis front processes such as low temperature transformation reaction and pressure swing adsorption decarbonisation is reduced, and direct discharge of carbon dioxide and methyl alcohol synthesis cost are reduced.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

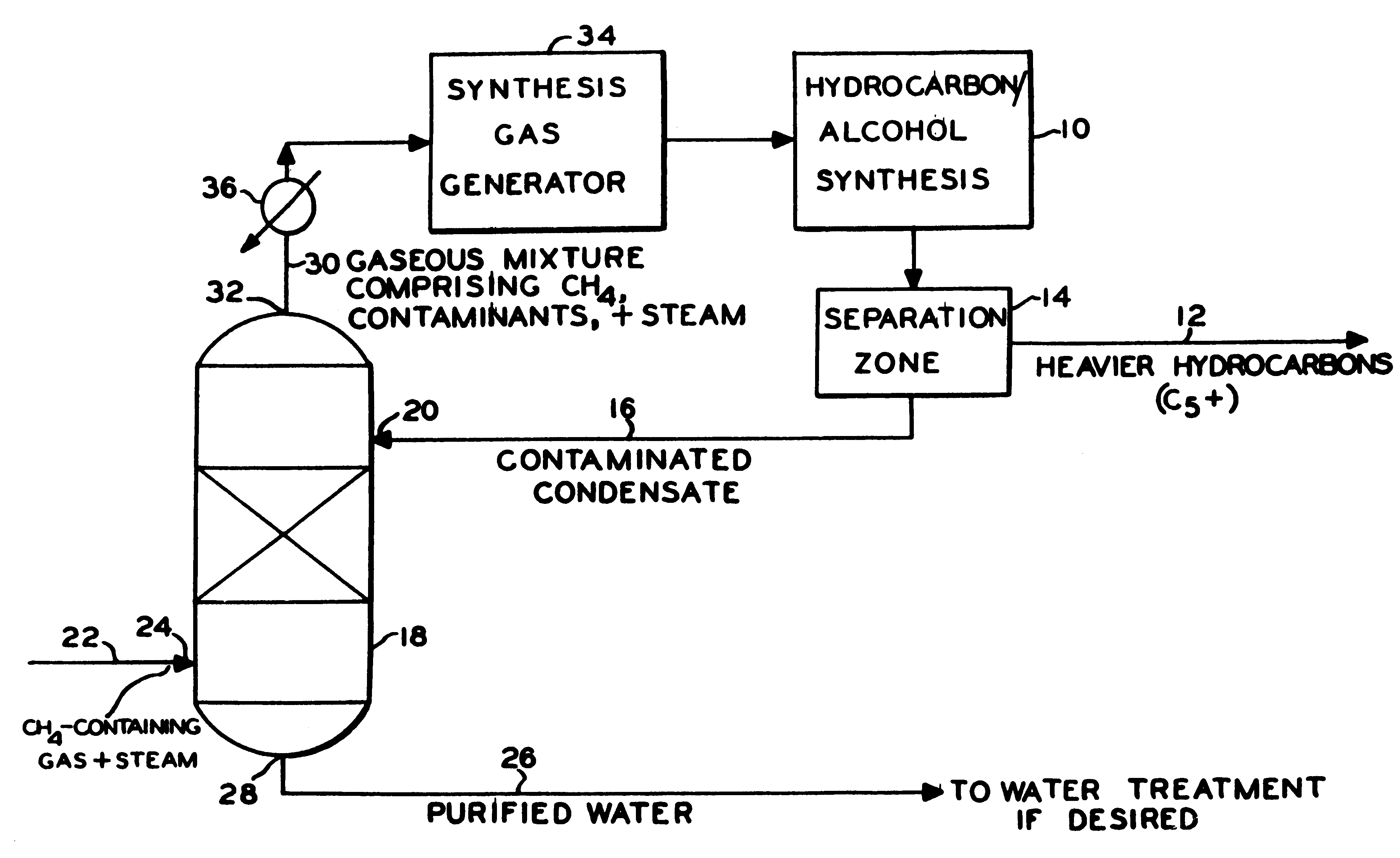

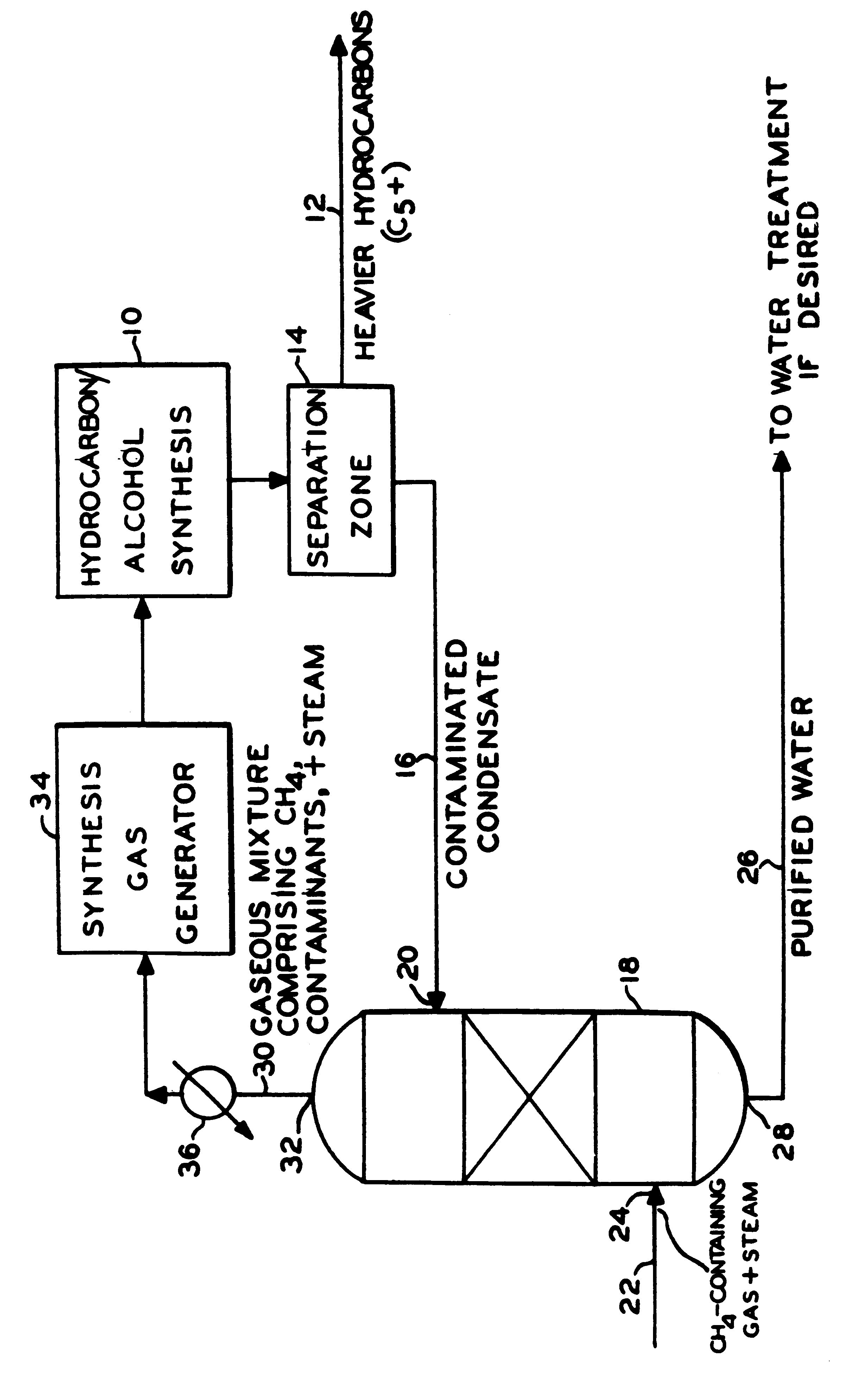

Process for recycling and purifying condensate from a hydrocarbon or alcohol synthesis process

InactiveUSRE37046E1Low costDewatering/demulsification with chemical meansHydrogenGeneration processAlcohol

This invention relates to a process of recycling condensate from a hydrocarbon or alcohol synthesis, wherein the condensate comprises water and contaminants such as lower molecular weight hydrocarbons, alcohols, and other oxygenates. A hot gaseous mixture comprising CH4 and steam contacts the condensate so as to strip the contaminants from the condensate. The stripped contaminants, CH4, and steam are separately recovered as a gaseous stream from the remaining purified water. The recovered CH4-containing gaseous stream may be used in synthesis gas (CO / H2) generation processes with the generated synthesis gas then being used in a hydrocarbon synthesis process to produce heavy hydrocarbons.

Owner:EXXON RES & ENG CO

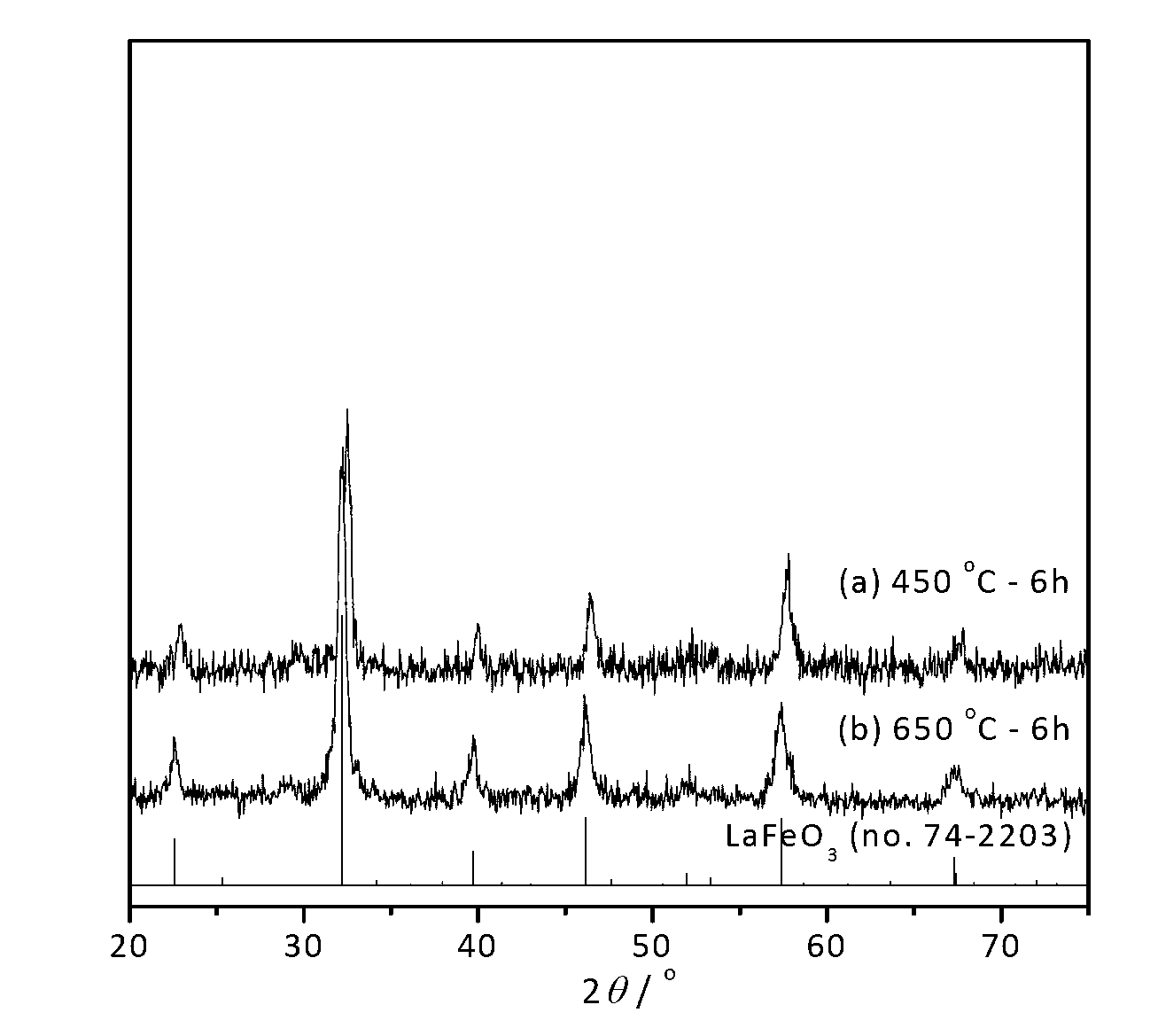

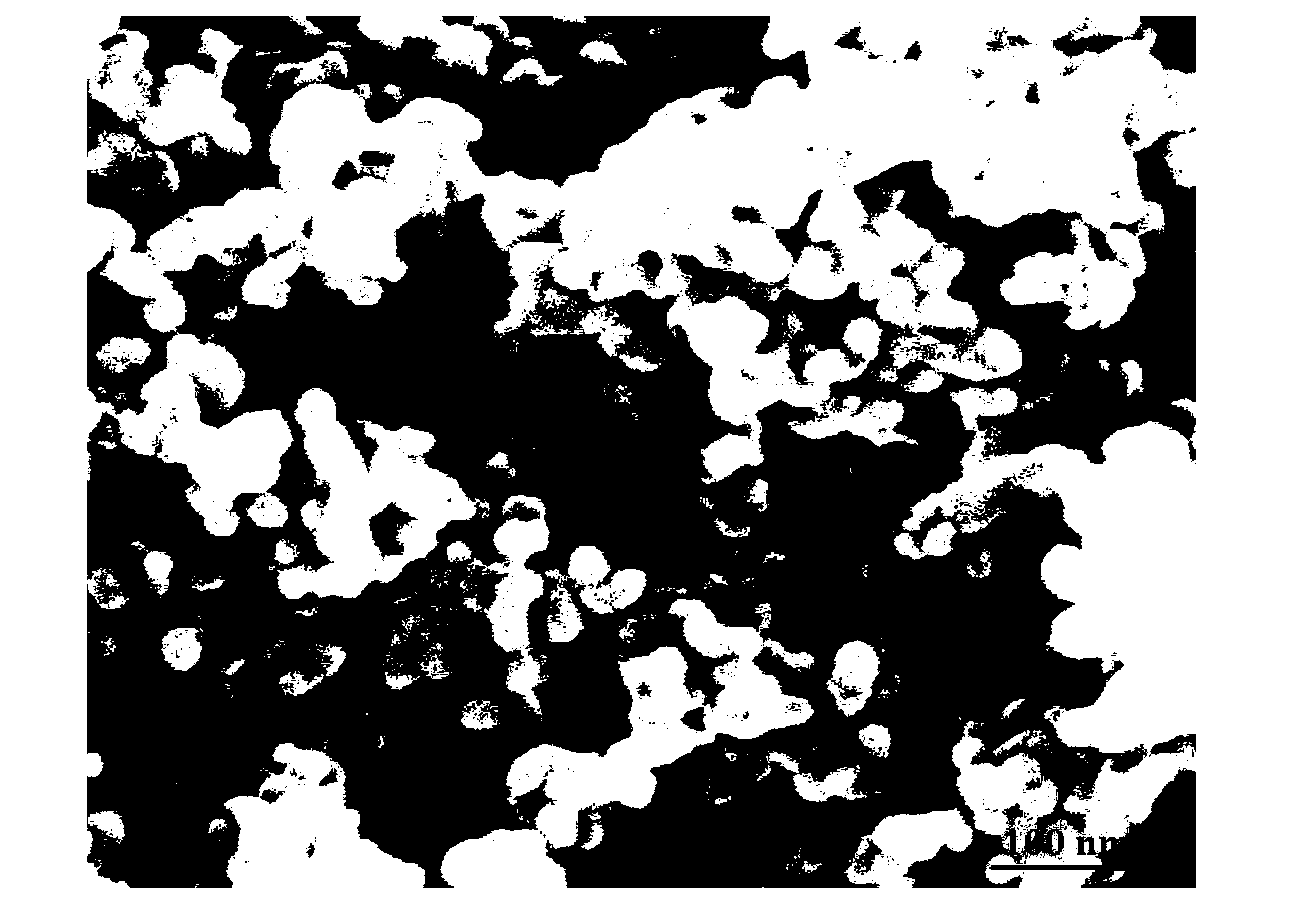

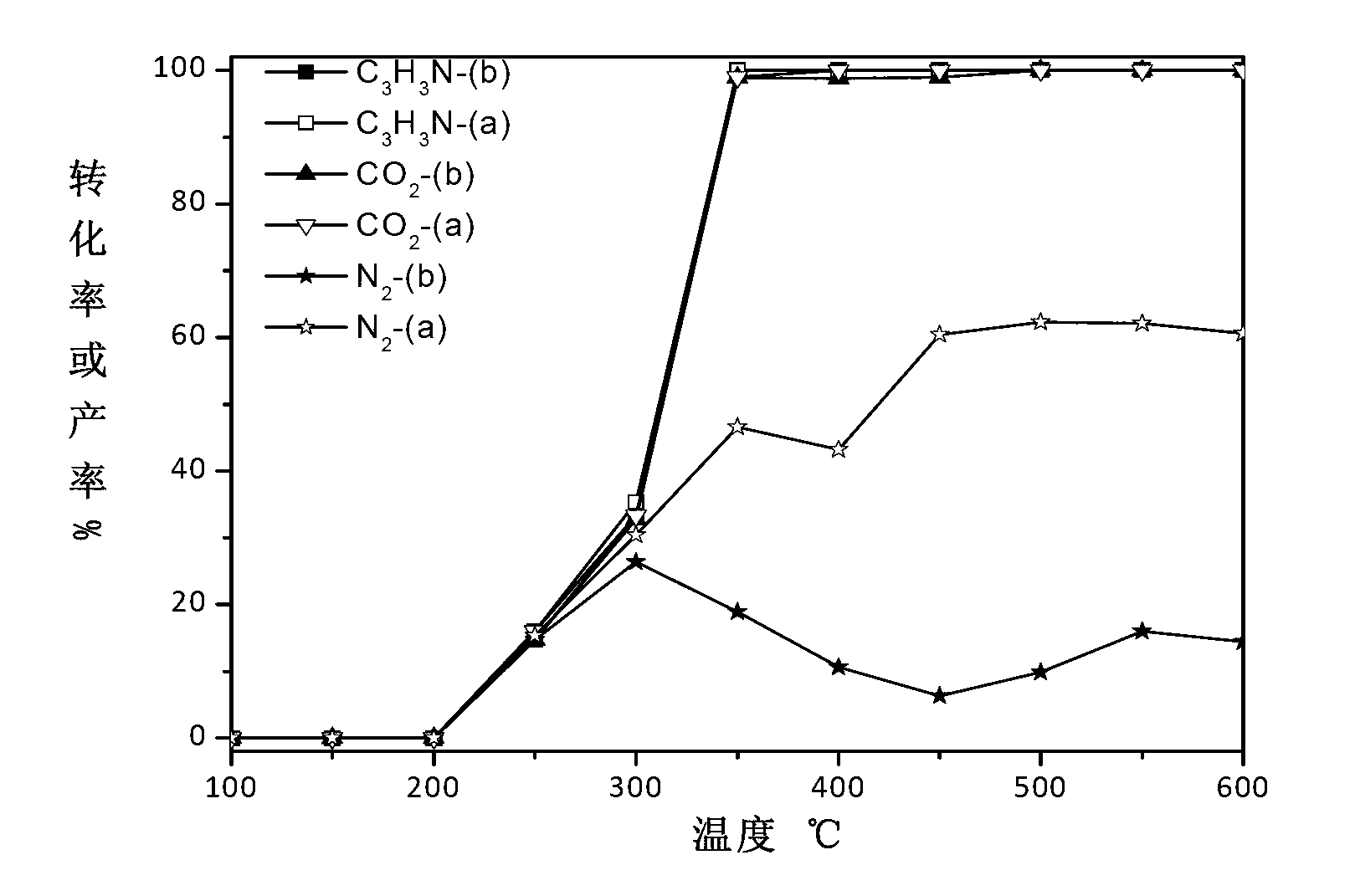

Preparation method and application of catalyst for treating acrylonitrile contained waste gas

ActiveCN103212419ALow ignition temperatureAvoid excessive oxidationIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCarbon fibers

The invention discloses a preparation method and application of a catalyst for treating acrylonitrile contained waste gas. The catalyst is characterized in that a metallic oxide with a perovskite crystal form (ABO3) is used as a catalyst, the catalyst suitable for removing the acrylonitrile contained waste gas is synthesized by using a benzoic alcohol synthesis method and through sieving and combining A-site and B-site metal ions, acrylonitrile is converted into nontoxic and harmless products including N2, H2O and CO2 through controlling catalytic combustion process conditions, and particularly, other nitrogen oxides such as NO2, NO and other secondary pollution gases can be prevented from being generated at a high-temperature stage. The catalyst can be applied to the treatment for the acrylonitrile contained waste gas discharged by an acrylonitrile factory and a carbon fiber factory.

Owner:BEIJING UNIV OF CHEM TECH

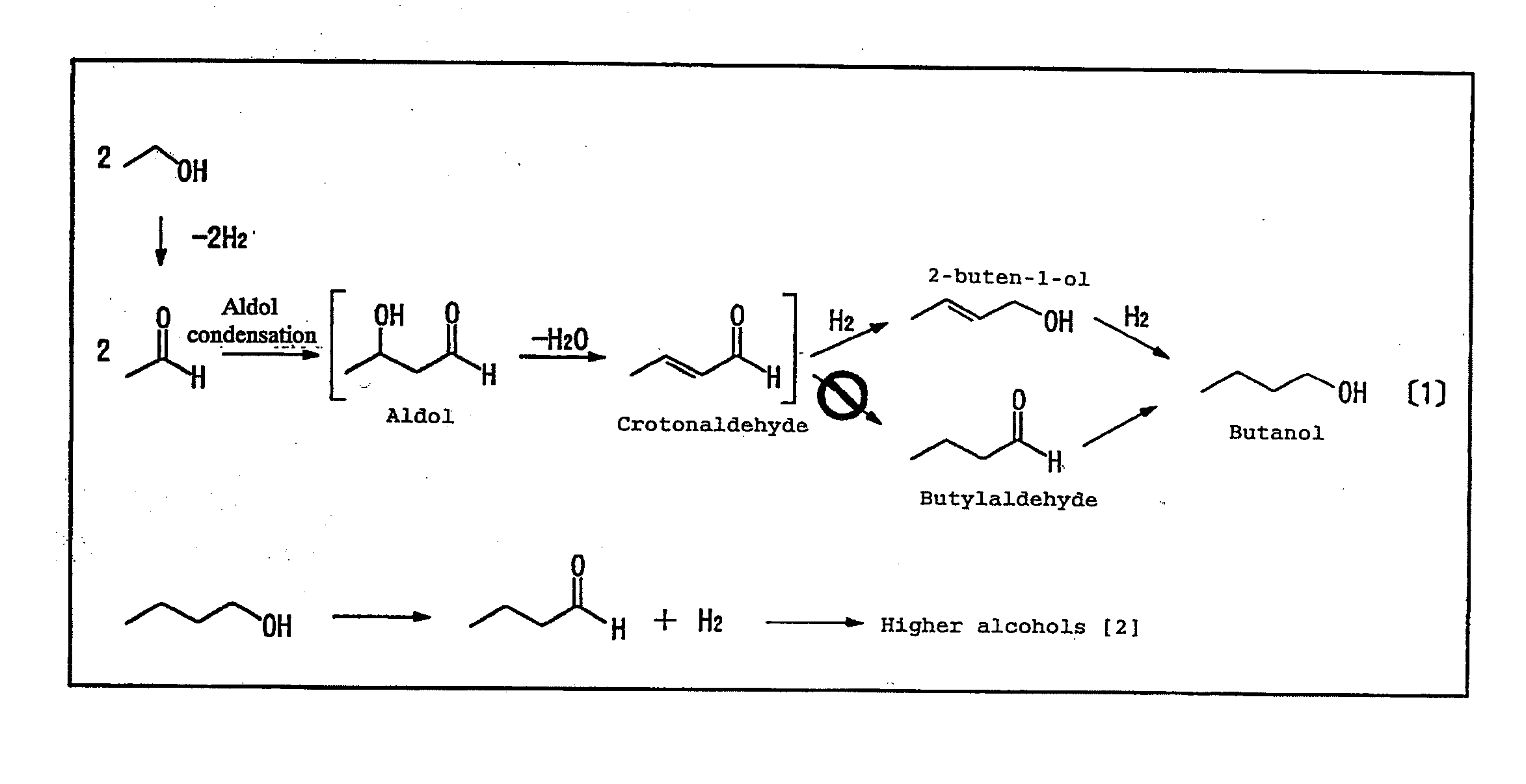

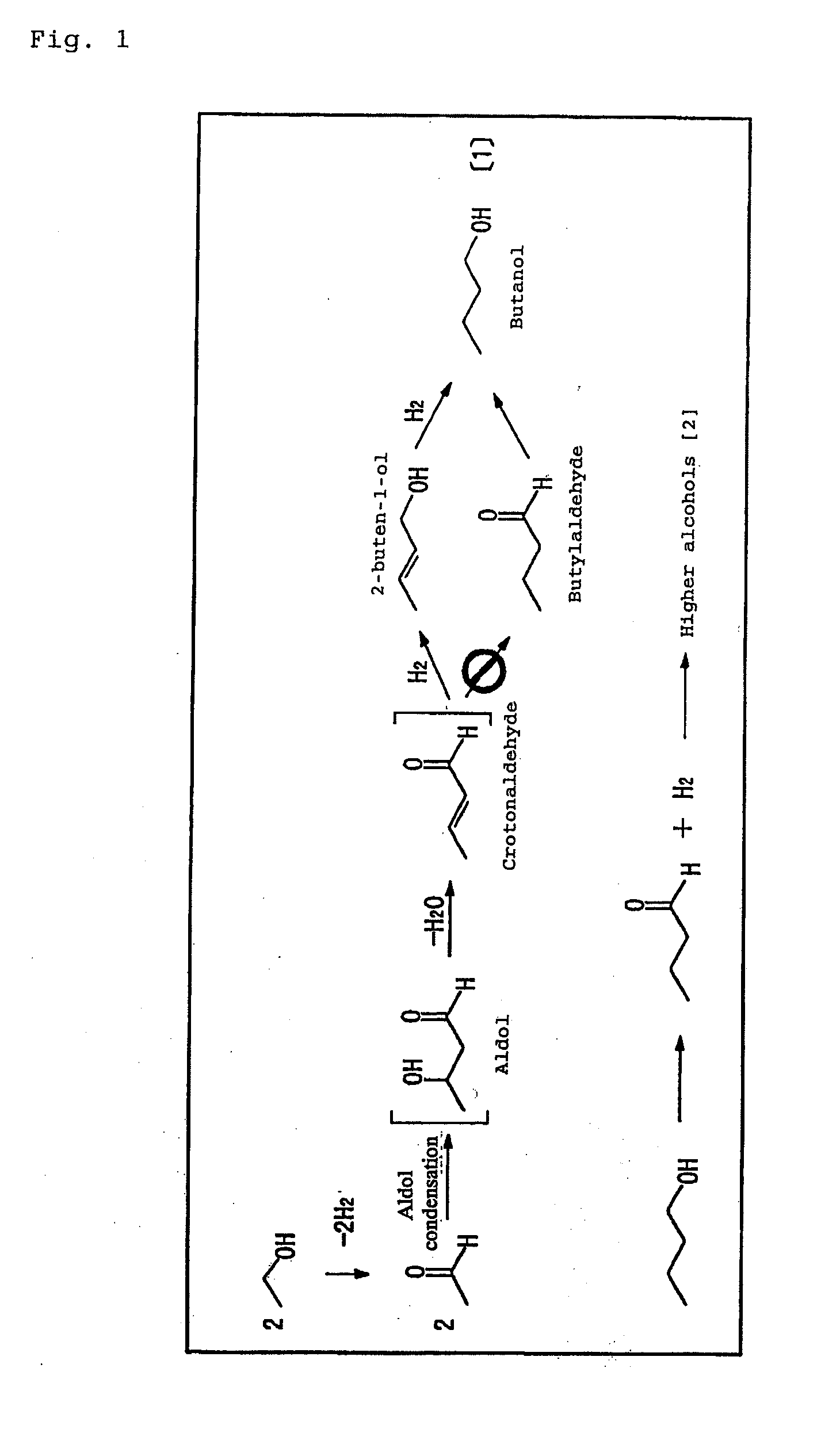

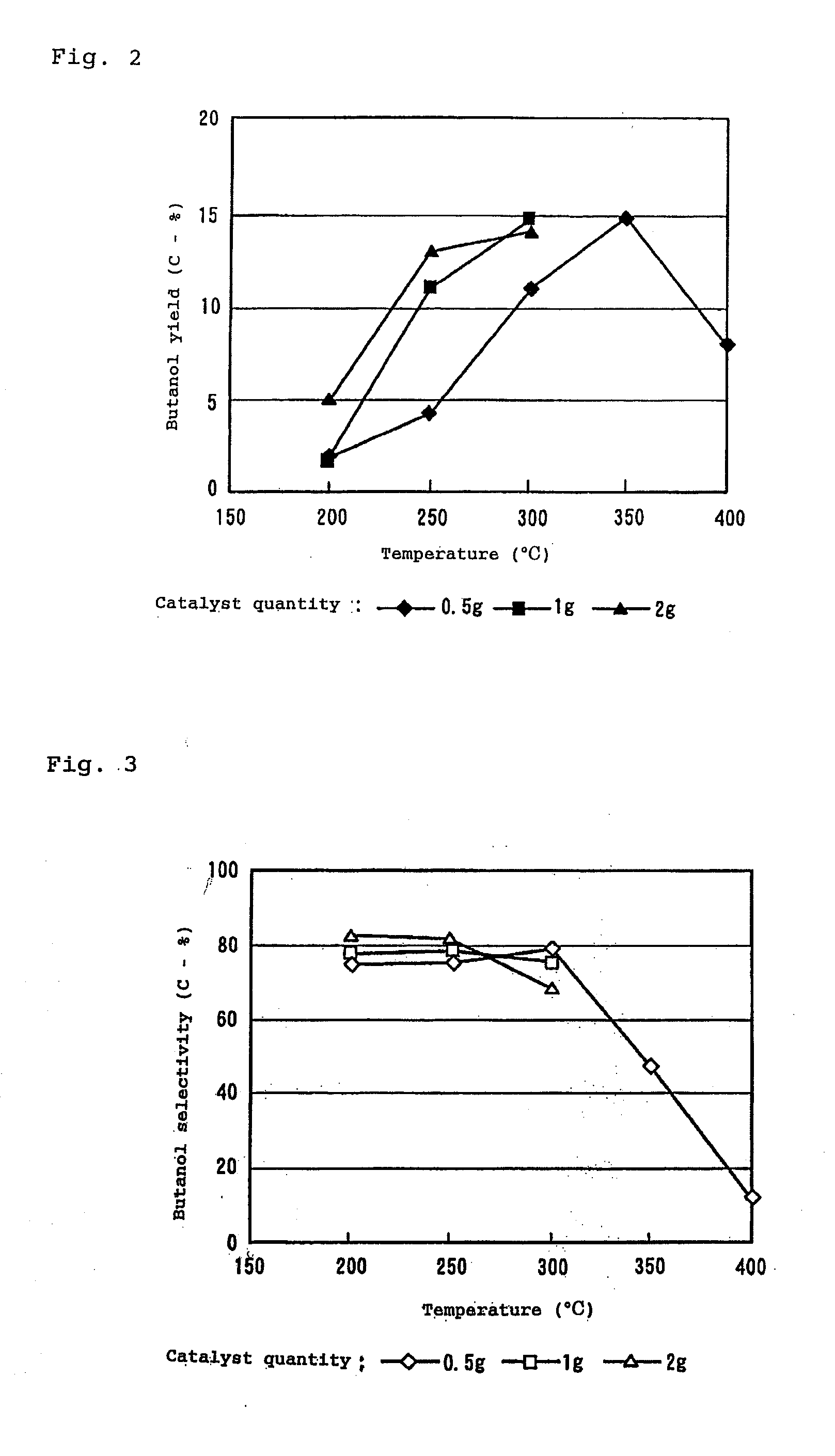

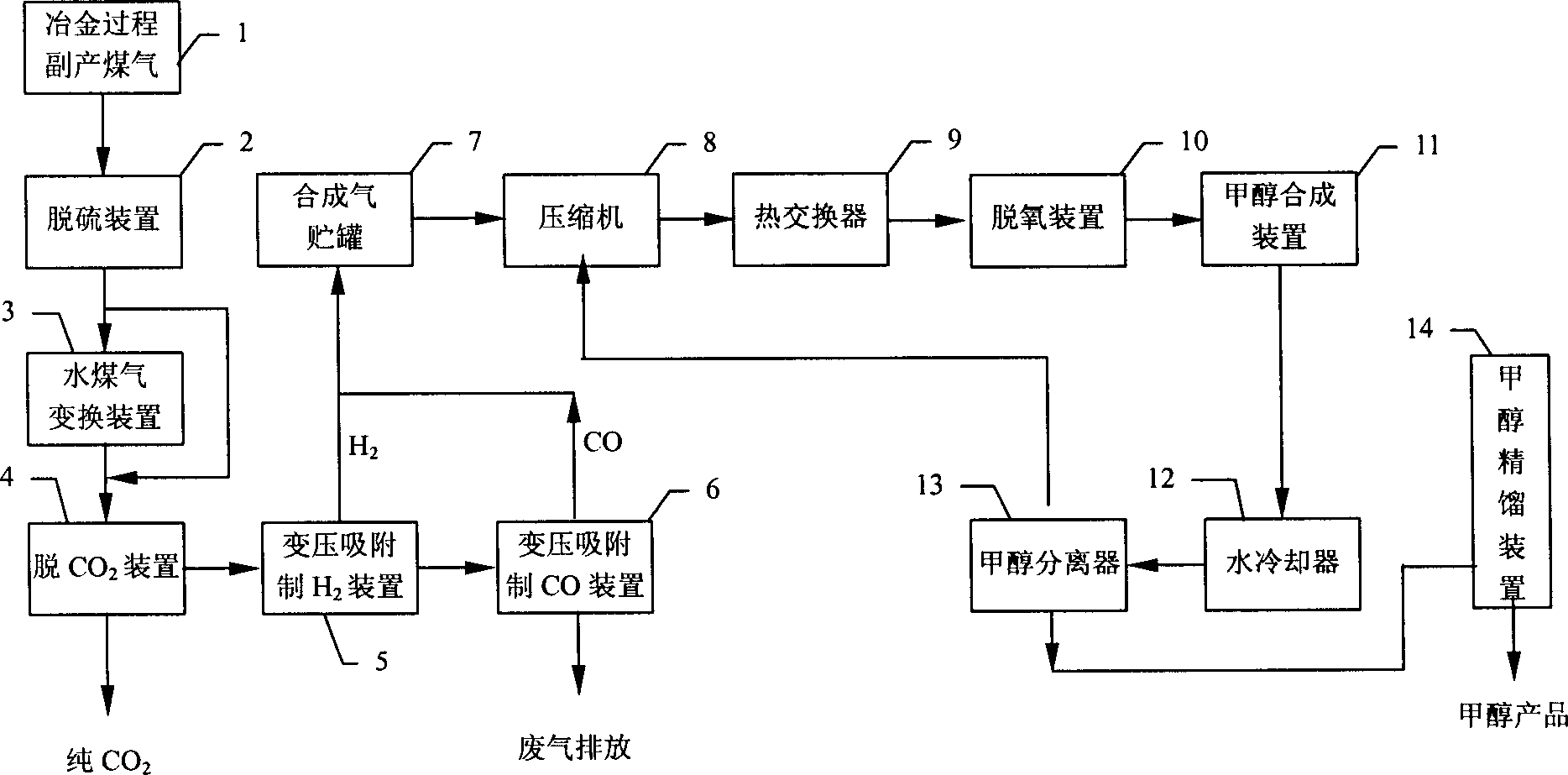

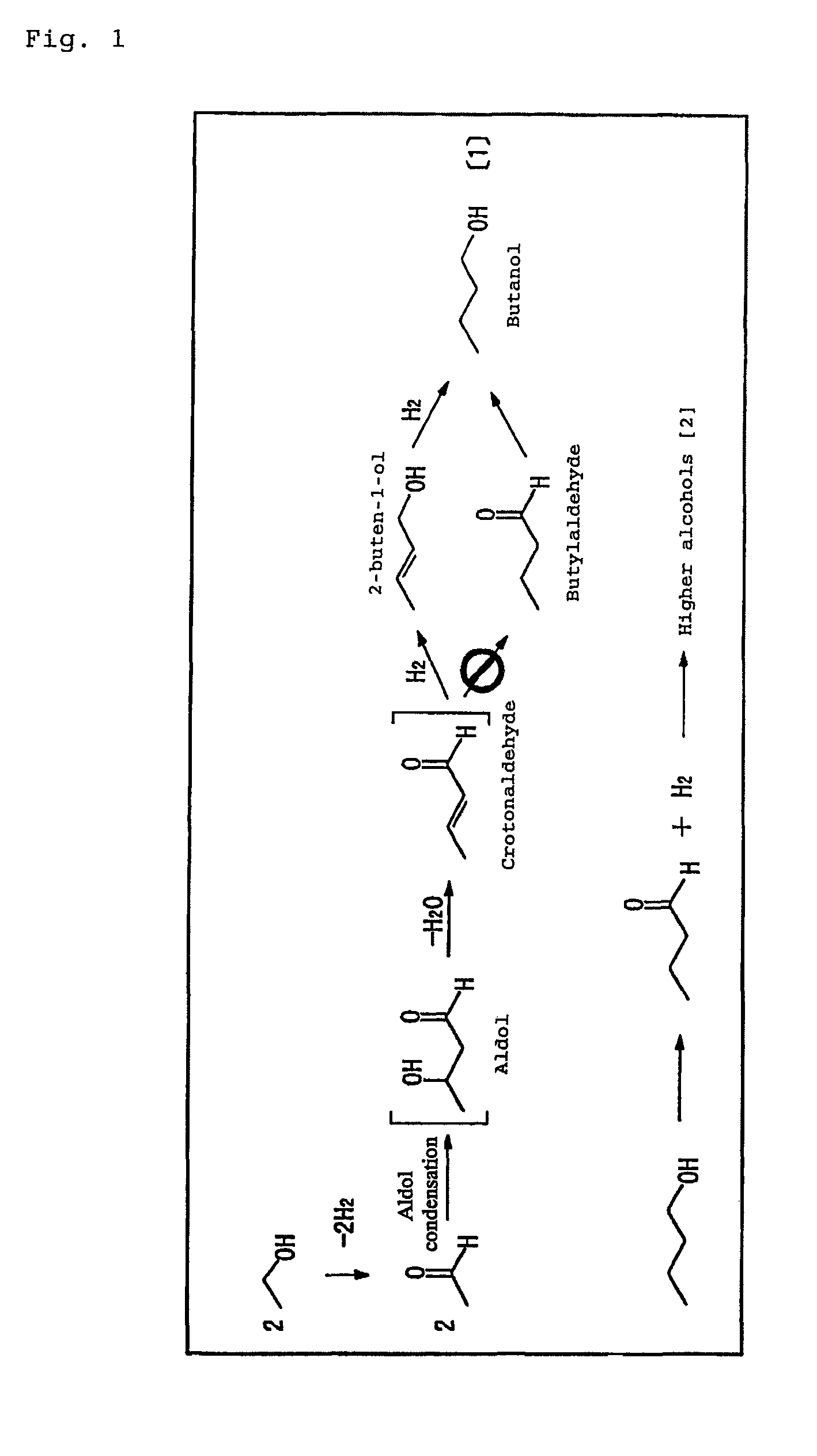

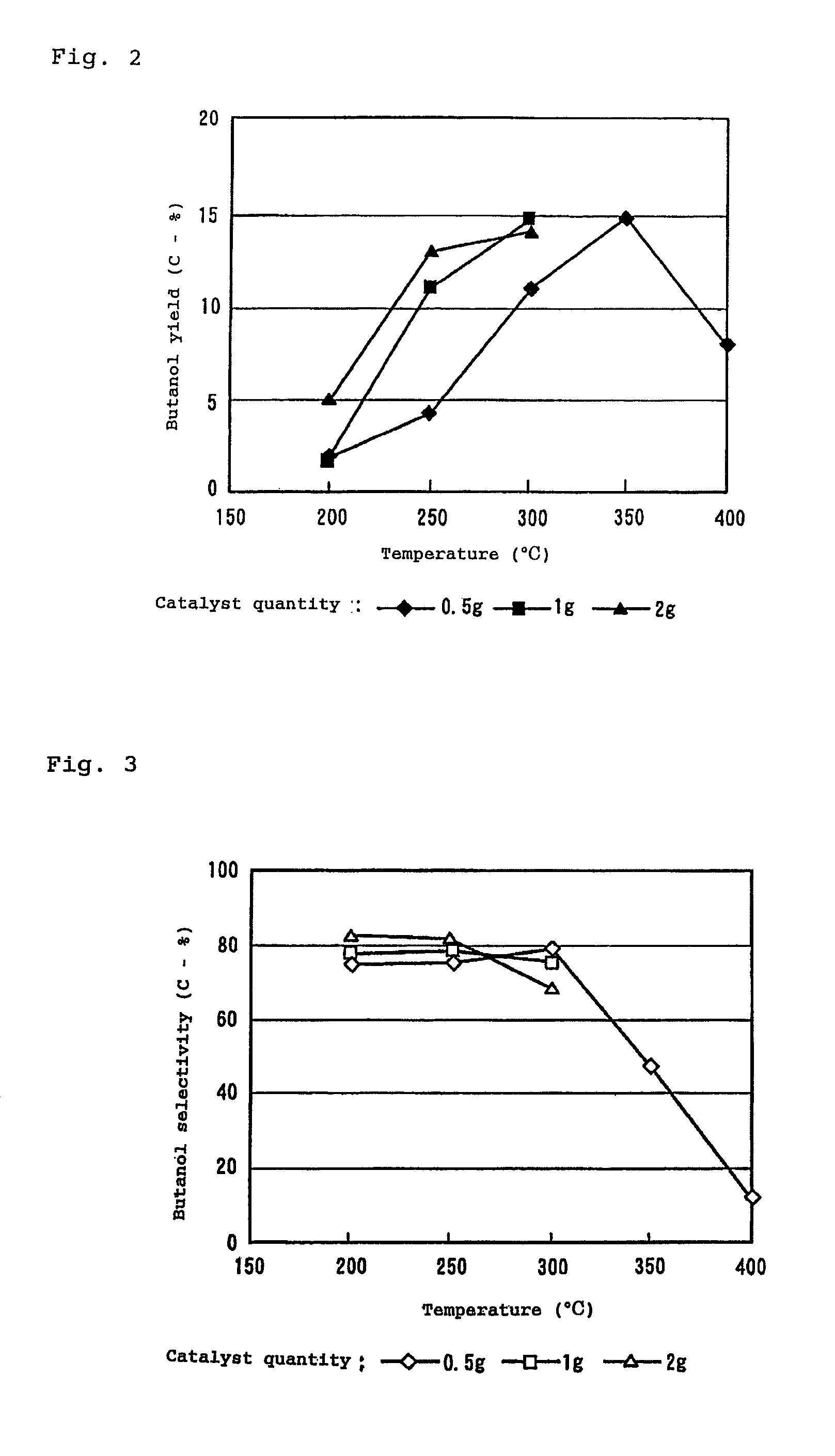

Catalyst And Alcohol Synthesis Method

ActiveUS20110190553A1High selectivityOxygen-containing compound preparationPhosphatesAlcoholSynthesis methods

The present invention is intended to provide a catalyst which is for synthesizing butanol from ethanol at a high selectivity and which comprises strontium phosphate apatite having the Sr / P atomic ratio of 1.5-2.0, and the synthesis method.

Owner:NAT UNIV CORP KOCHI UNIV +1

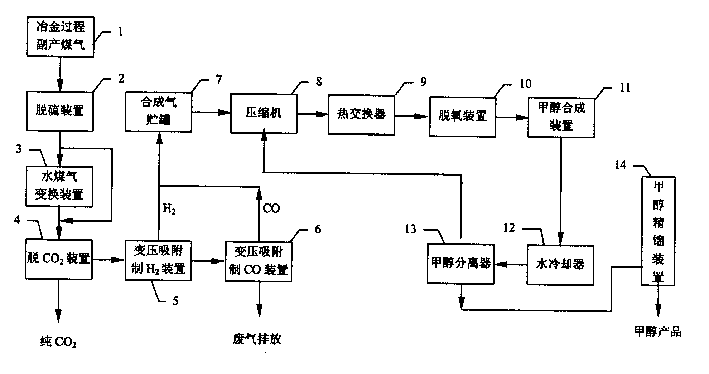

Process method and system for synthesizing methanel using by-product coal-gas during metallurgical process

InactiveCN1405132AEmission reductionLess investmentOrganic compound preparationHydroxy compound preparationAlcoholAlcohol synthesis

The invention uses the by-product gas product in the course of metallurgical process as raw material for synthesizing methyl alcohol, and adopts the following steps: desulfurizing, decarbonizing, pressure swing adsorption to prepare H2, pressure swing adsorption to prepare CO and after deoxidation making regulation to obtain synthetic gas suitable for synthesizing methyl alcohol, making methyl alcohol synthesis reaction in the methyl alcohol synthesis equipment, and making the gas obtained after reaction undergo the processes of cooling, gas-liquid separation and rectification to obtain reagent-grade methyl alcohol.

Owner:TSINGHUA UNIV

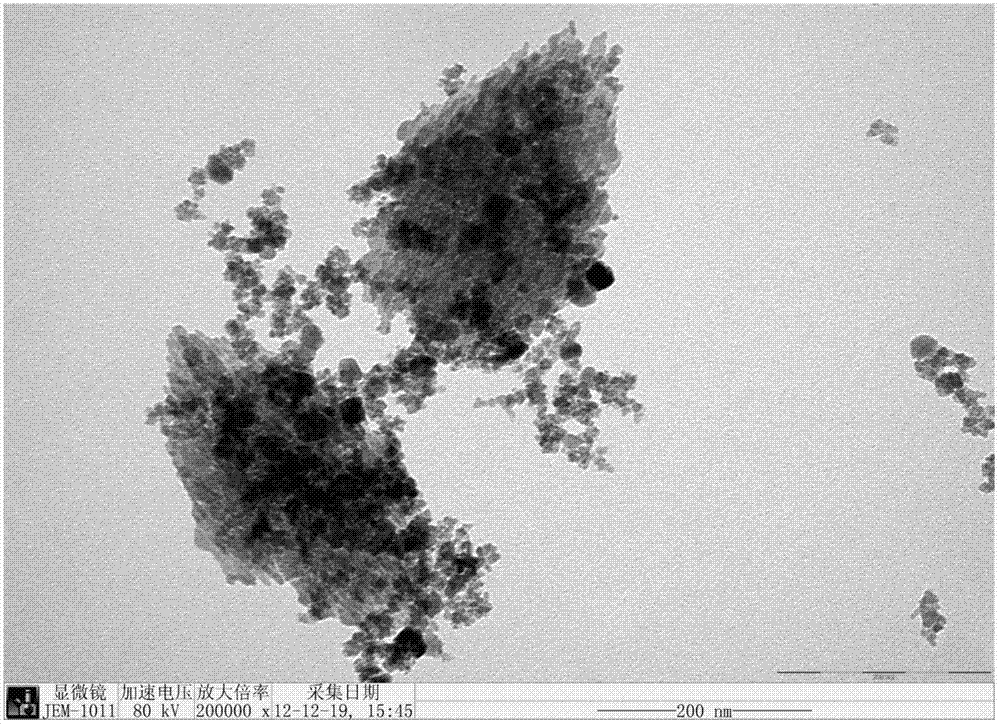

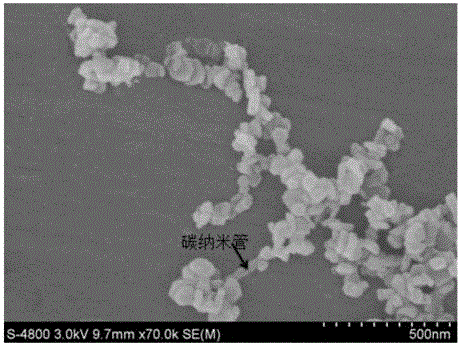

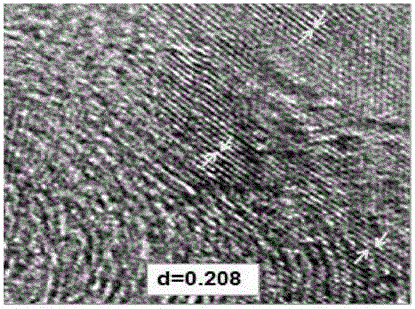

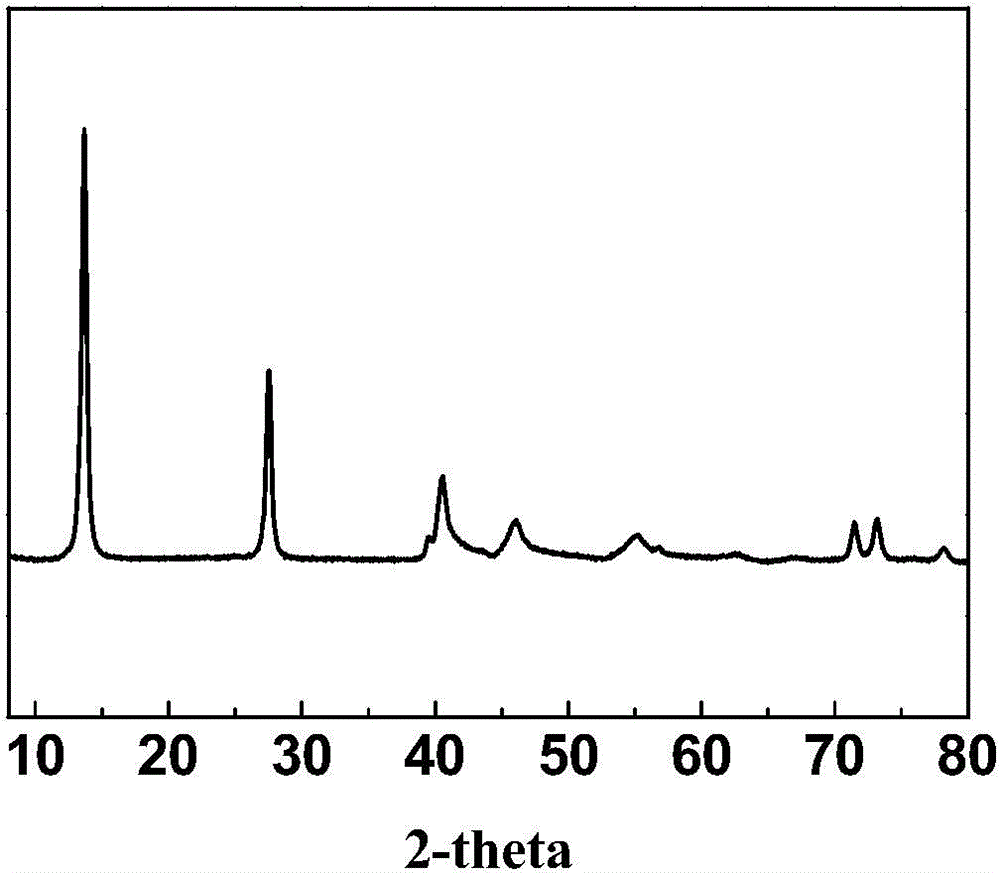

Carbon nano tube composite nanometer cobalt-copper alloy catalyst for low-carbon alcohol synthesis and preparation method of carbon nano tube composite nanometer cobalt-copper alloy catalyst

InactiveCN104475106AWell mixedHigh active specific surface areaOrganic compound preparationHydroxy compound preparationActive componentCarbon nanotube

The invention relates to a carbon nano tube composite nanometer cobalt-copper alloy catalyst for low-carbon alcohol synthesis and a preparation method of the carbon nano tube composite nanometer cobalt-copper alloy catalyst. According to the preparation method, firstly Co, Cu, Al and other additives are prepared into hydrotalcite-like structural substances to realize the uniform mixing of Co and Cu; CNTs and a hydrotalcite-like compound are compounded as a precursor of the catalyst, wherein a carbon nano tube is used as a diluent and the CNTs is used as a dispersing agent to prepare the nanometer cobalt-copper alloy catalyst used for preparing low-carbon alcohol from a synthetic gas; the uniform mixing of various metal ions contained in the precursor of the catalyst and copper ions and cobalt ions especially can be realized by controlling a deposition condition; because strong interaction exists between metal and the carbon nano tube, a Cu-Co nanometer alloy can be highly dispersed on the carbon nano tube after reduction, so that the granule sintering, which is caused by migration, of the Cu-Co nanometer alloy is effectively prevented. The prepared Cu-Co active component has the large active specific surface area, and the sintering of the Cu-Co active component can be inhibited by a carrier and the additives.

Owner:TIANJIN UNIV

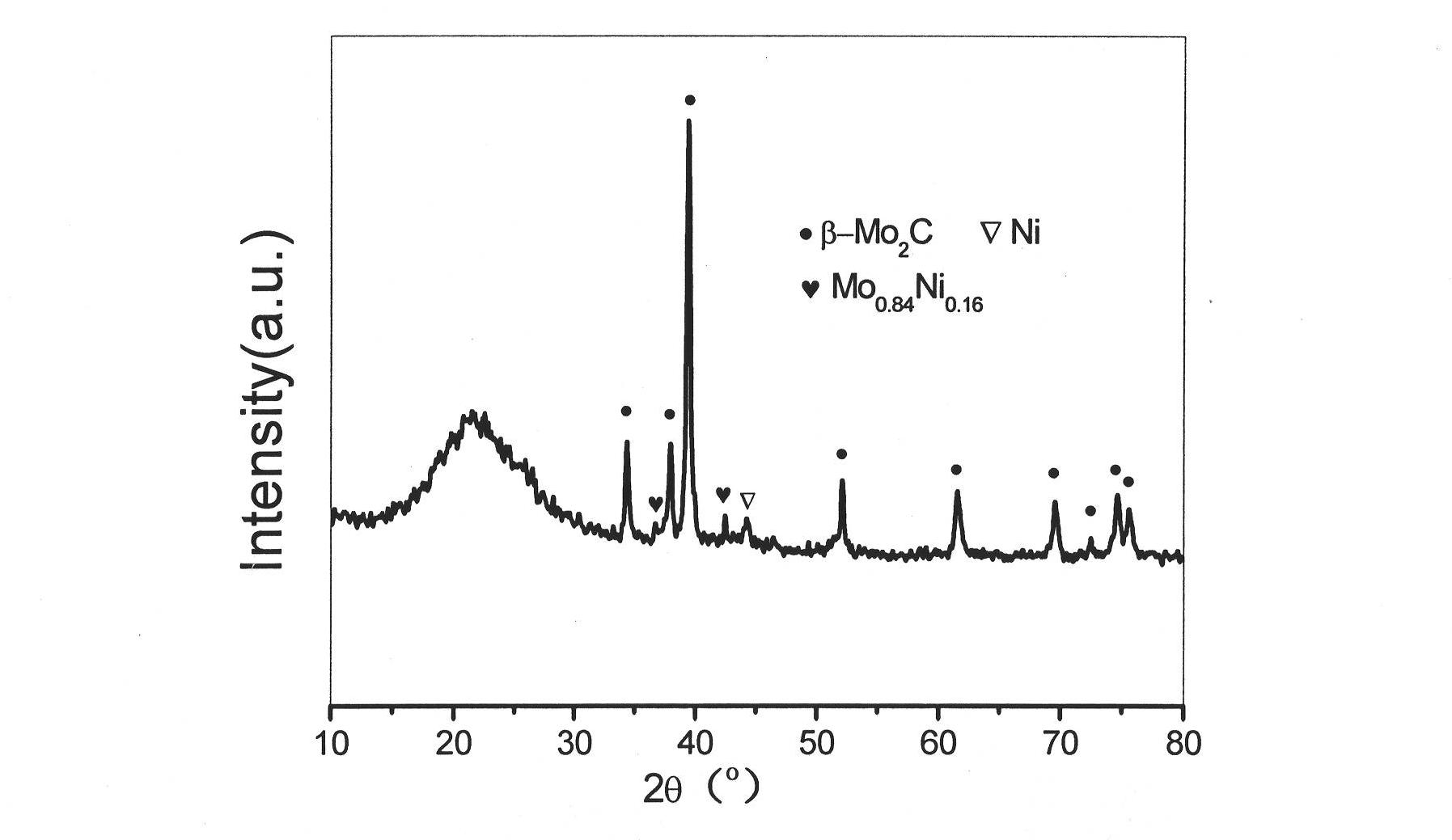

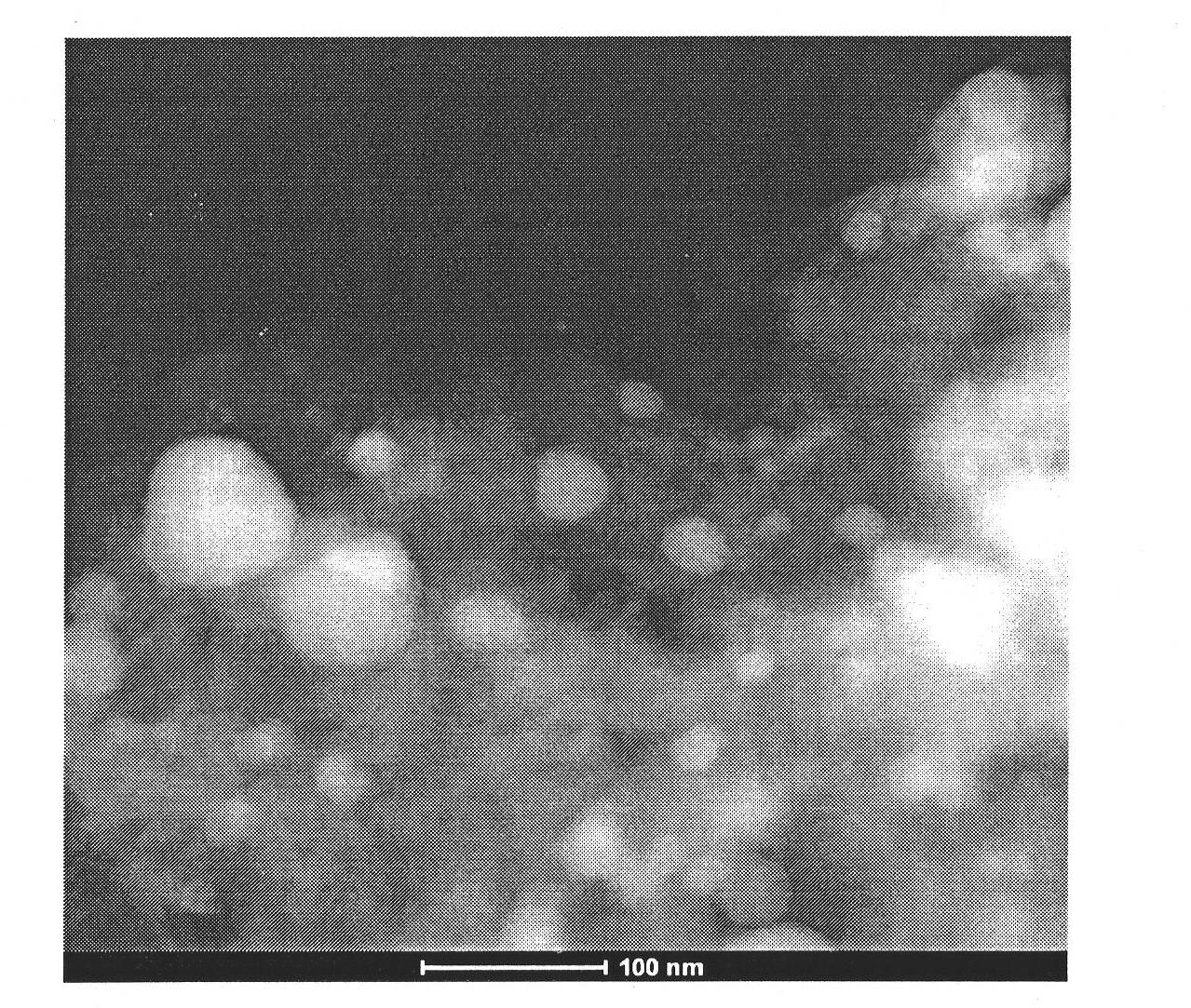

Catalyst for low-carbon mixed alcohol synthesis from syngas, and preparation method and application thereof

InactiveCN102417437ALarge specific surface areaGood dispersionMolecular sieve catalystsOrganic compound preparationCarbonizationMesoporous material

The invention provides a molybdenum carbide-based catalyst for low-carbon alcohol synthesis from syngas, and a preparation method and reaction conditions thereof. The catalyst uses surface carbon-modified SBA-15 as the carrier. The surface carbon-modified SBA-15 mesoporous material is prepared by using low-cost ethyl orthosilicate as the silicon source and saccharide as the carbon source, and is used as the carrier; and by using the carbon on the surface as the reducer and carbonizer, the molybdenum carbide-based catalyst for alcohol synthesis from syngas is prepared through high-temperature carbonization under inert gas atmosphere. The introduction of the carrier improves the dispersion degree of active components of the catalyst; and the prepared catalyst has the characteristics of high total alcohol selectivity, high C2+ alcohol selectivity and good reaction stability.

Owner:INNER MONGOLIA UNIVERSITY

Catalyst and alcohol synthesis method

ActiveUS8232433B2High selectivityOxygen-containing compound preparationOrganic compound preparationSynthesis methodsApatite

The present invention is intended to provide a catalyst which is for synthesizing butanol from ethanol at a high selectivity and which comprises strontium phosphate apatite having the Sr / P atomic ratio of 1.5-2.0, and the synthesis method.

Owner:NAT UNIV CORP KOCHI UNIV +1

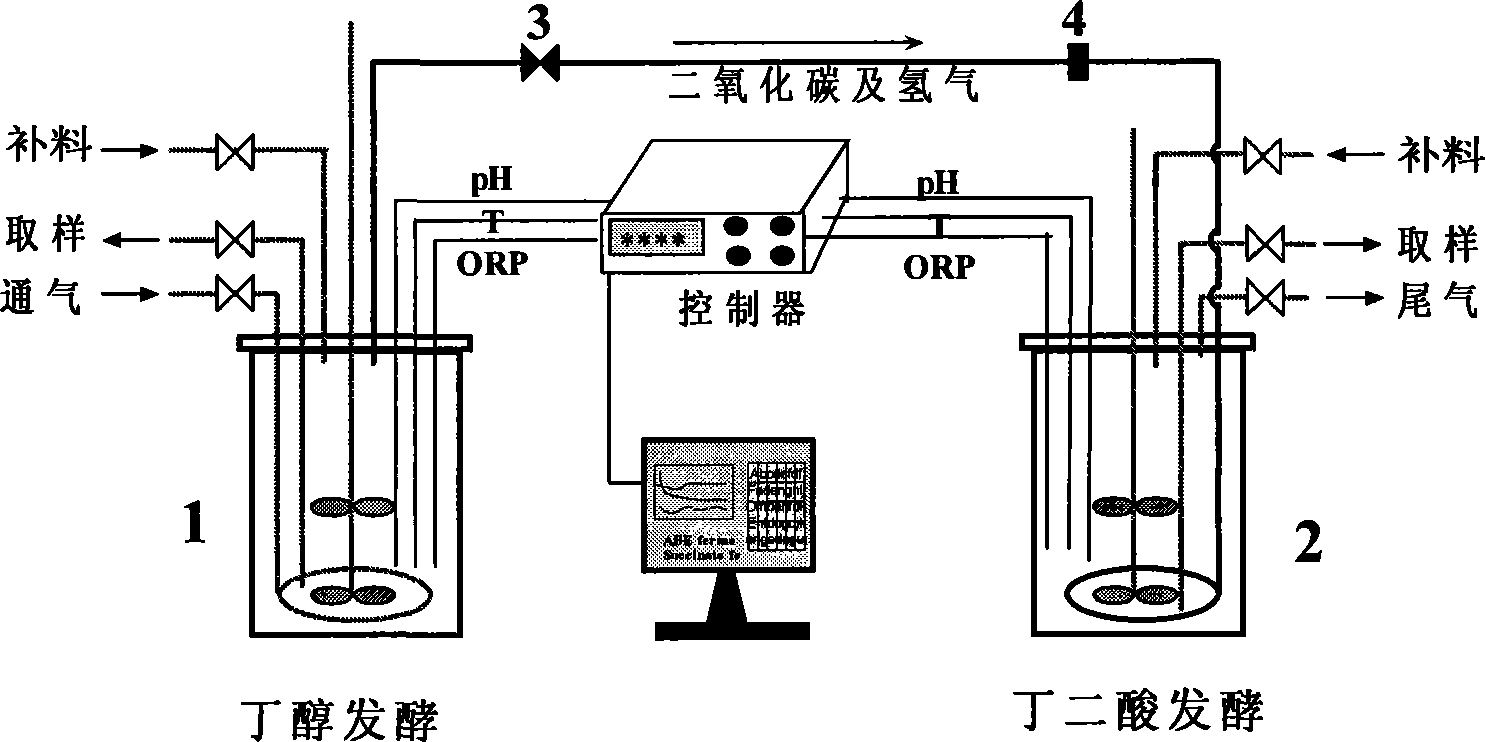

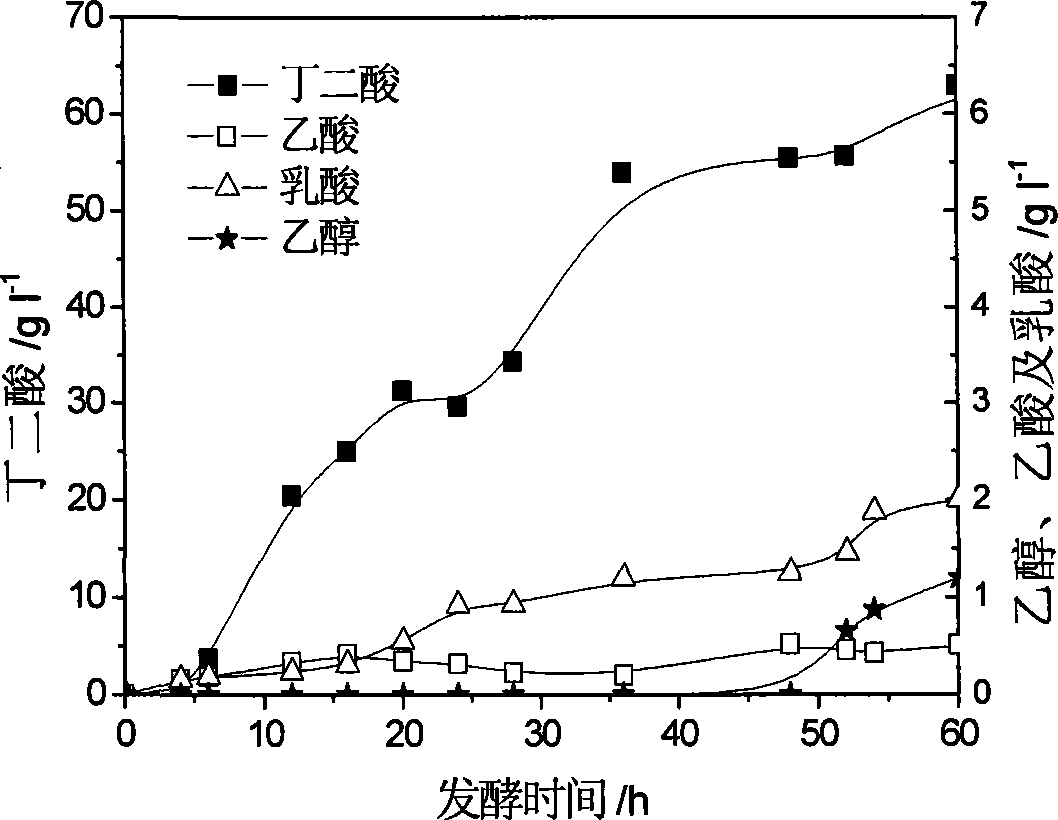

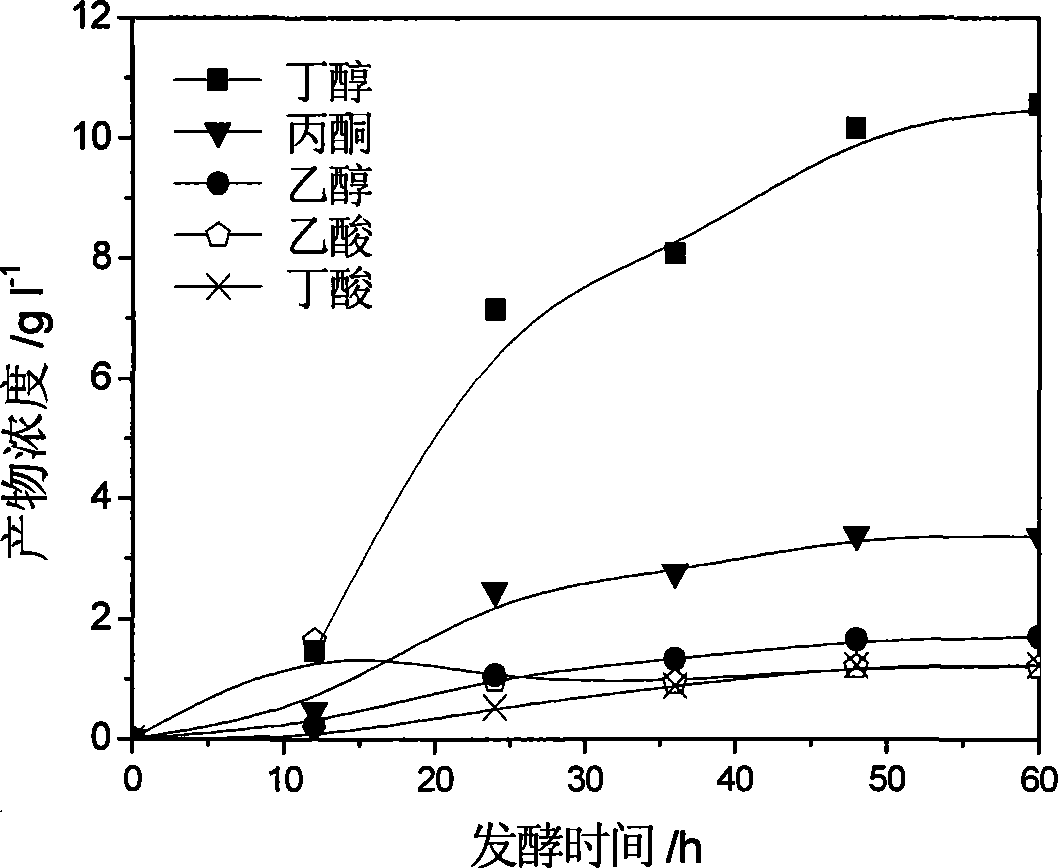

Method for producing butanol and butanedioic acid by fermentation

InactiveCN101250561AHigh yieldFermentation process efficiency is not affectedMicroorganism based processesFermentationButanedioic acidSuccinic acid

The invention discloses a method for producing butyl alcohol and succinic acid through fermentation. The method which is the method for producing the butyl alcohol and the succinic acid produces the butyl alcohol and the succinic acid simultaneously through fermenting microbe in different systems and gas which is produced in producing the butyl alcohol through the fermentation is inputted in a system for producing the succinic acid through the fermentation. The method connects a butyl alcohol fermentation system and a succinic acid fermentation system in series, CO2 and H2 which are produced through fermenting the butyl alcohol are utilized to promote succinic acid synthesis, which not only realizes the comprehensive use of the CO2, reduces the discharge of greenhouse gas, but also reduces the using amount of carbonate in the succinic acid producing process. The method does not need reforming complex devices and only needs adding a filtrating and removing bacteria device and then connecting with an air intake duct of a succinic acid fermentor. Experiments show that the method of the invention can keep or even increase the synthesis concentration of the succinic acid under the condition that the carbonate is not additionally added and simultaneously butyl alcohol synthesis is not affected.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

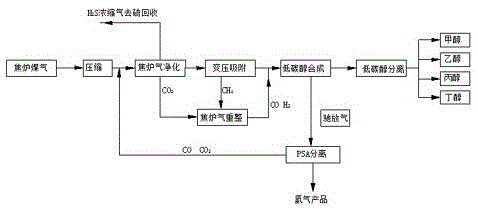

Technology for synthesizing low carbon alcohol and hydrogen as byproduct from coke oven gas

ActiveCN105061142AZero emissionAdjust the ratio of hydrogen to carbonHydrogen separation by selective and reversible uptakeOrganic compound preparationPropanolAlcohol

A technology for synthesizing low carbon alcohol and hydrogen as byproduct from coke oven gas comprises the following steps: compressing the coke oven gas, carrying out desulphurization and decarburization treatment to obtain purified coke oven gas with the H2S content being smaller than 1ppm, allowing the purified coke oven gas to enter a pressure swing adsorption unit in order to remove CH4, allowing removed CH4 and CO2 obtained after purification to enter a coke oven gas reforming unit, reforming, mixing the obtained reformed gas with the coke oven gas obtained after pressure swing adsorption to obtain synthetic gas meeting low carbon alcohol synthesis requirements, carrying out low carbon alcohol synthesis, allowing the obtained low carbon alcohol mixture to enter a low carbon alcohol separation unit, and separating to obtain methanol, ethanol, propanol and butanol products. The technology comprises the advantages of reasonable utilization of the coke oven gas, promotion of energy saving and emission reduction, energy structure adjustment, and obvious improvement of the economic and environmental benefits.

Owner:SEDIN ENG

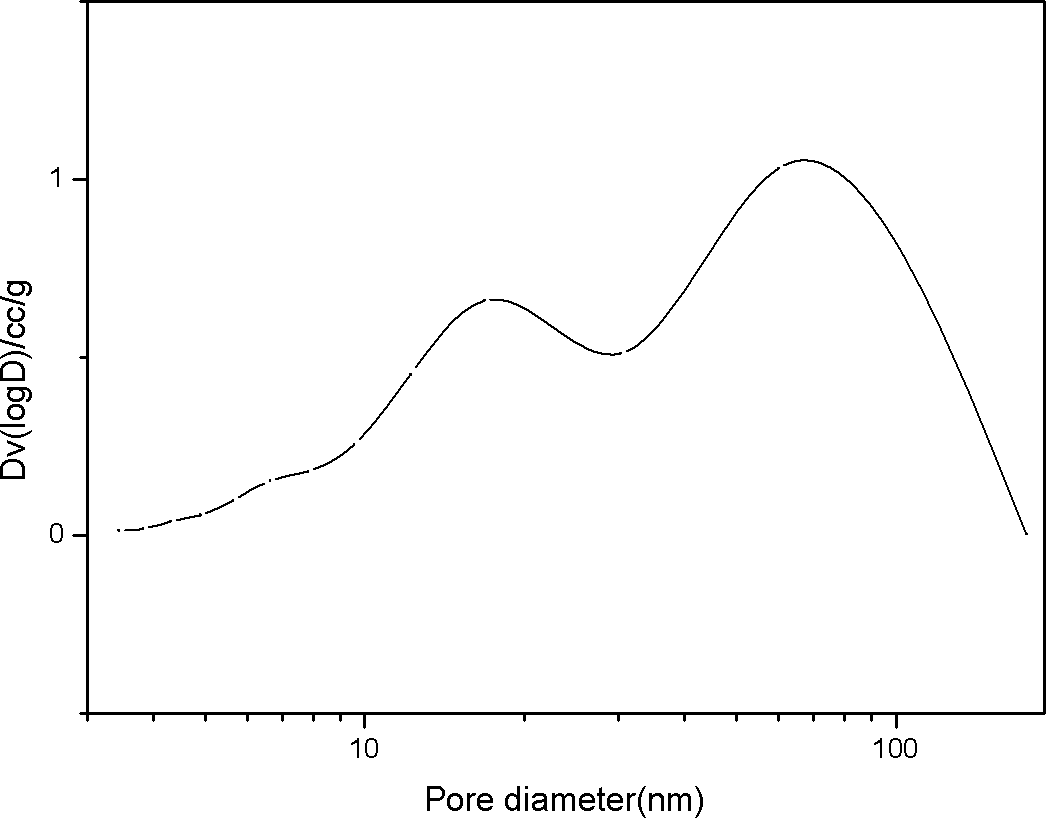

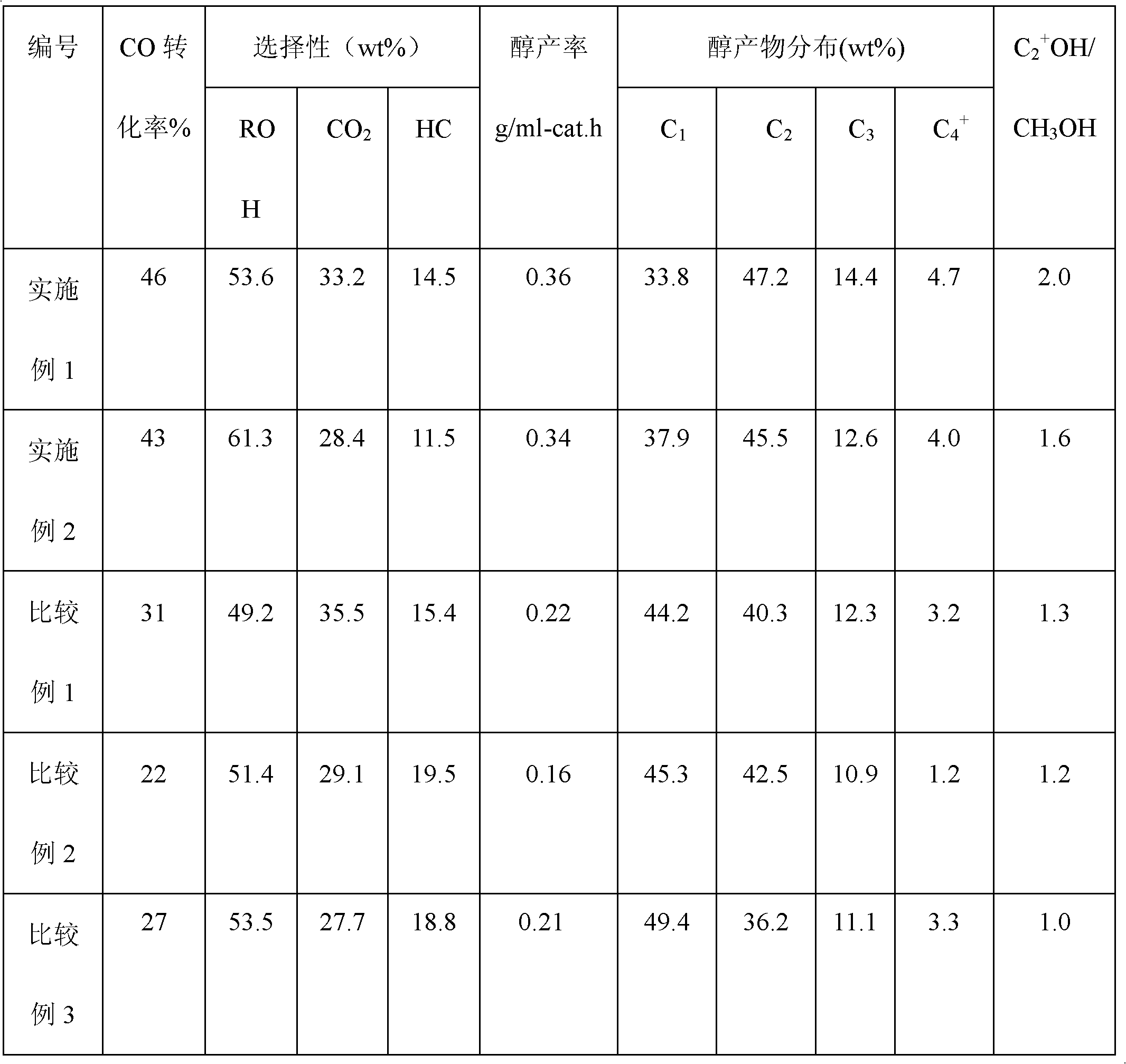

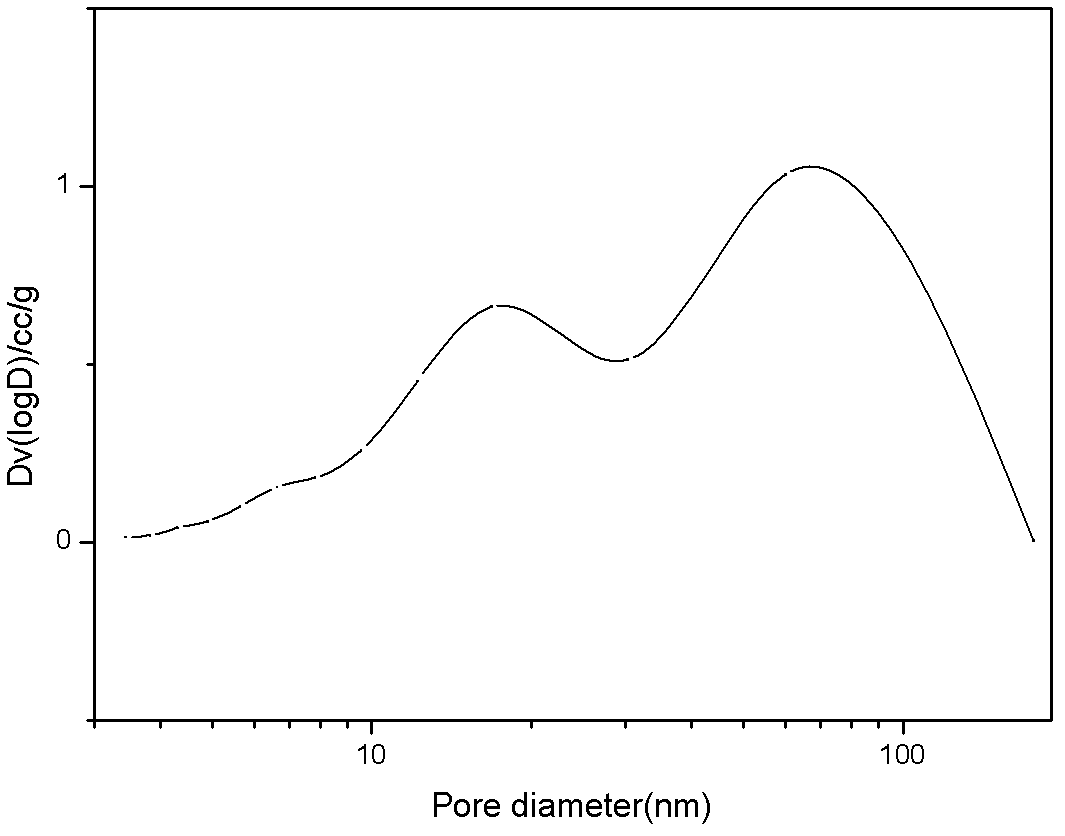

Double-hole carrier iron/ copper low-carbon alcohol synthesis catalyst and preparation method thereof

ActiveCN102631927AWide variety of sourcesLow costOrganic compound preparationHydroxy compound preparationColloidal silicaAlcohol

The invention provides a double-hole carrier iron / copper low-carbon alcohol synthesis catalyst with high activity and C<2+> alcohol selectivity, and a preparation method of the double-hole carrier iron / copper low-carbon alcohol synthesis catalyst. The double-hole carrier iron / copper low-carbon alcohol synthesis catalyst comprises Cu, Fe, K and M by weight percentage: 10-40% of Cu, 1-10% of Fe, 0.5-10% of K and 40-80% of M, wherein M is a double-hole carrier prepared from macroporous silica gel and ostiole colloidal silica. The preparation method comprises the steps of: dipping the ostiole colloidal silica in the macroporous silica gel in an isopyknic way, and preparing the double-hole carrier; then, dissolving metal in distilled water in a form of nitrate, and forming a mixed solution; and dipping the double-hole carrier in the mixed solution in an isopyknic way, and preparing the catalyst. The double-hole carrier iron / copper low-carbon alcohol synthesis catalyst prepared by the invention can be applied to the reaction for preparing low-carbon alcohol by synthesis gas, is simple in preparation technology, easy to operate, high in strength of the prepared catalyst and good in stability, and has high activity and C<2+> alcohol selectivity.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

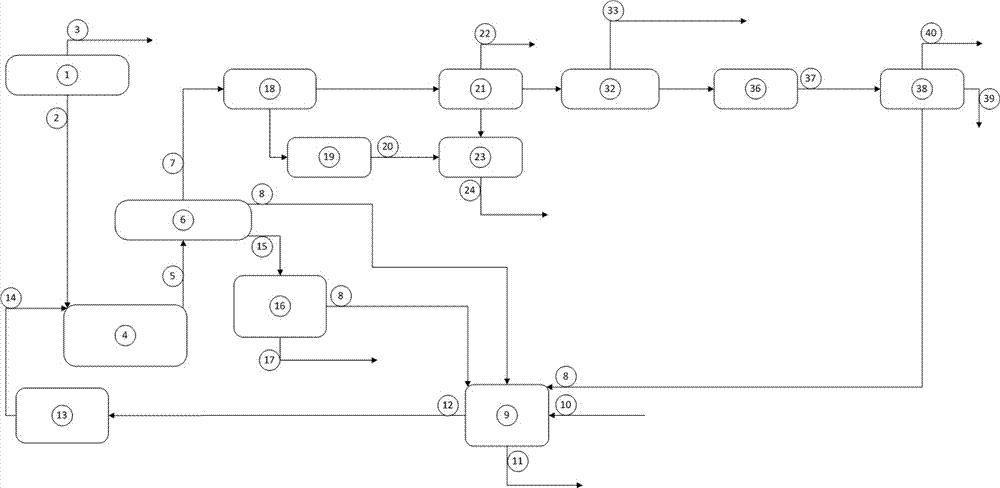

System and process for preparing methyl alcohol through coke-oven gas-assisted coal gasification

InactiveCN104193585ASimplified operating unitLess investmentOrganic compound preparationHydroxy compound preparationAlcoholAlcohol synthesis

The invention discloses a system and a process for preparing methyl alcohol through coke-oven gas-assisted coal gasification. The system comprises a water-coal-slurry preparation unit, a coal gasification unit, a synthesis gas purification unit, a methyl alcohol synthesis unit, a coke-oven gas purification and separation unit, a triple reforming reaction unit and a gas mixer, wherein the water-coal-slurry preparation unit, the coal gasification unit, the synthesis gas purification unit and the methyl alcohol synthesis unit are sequentially connected with one another. According to the system and the process, effective utilization of coal resources is achieved by complementary utilization of elements of coal and the coke-oven gas and the waste of active elements and energy consumption, caused by a component adjustment operation, can be avoided; and since carbon dioxide and coke-oven gas are used by integration of the triple reforming reaction unit, the operation units are relatively simple, the reaction process is relatively strong in flexibility, and the equipment investment is relatively low.

Owner:SOUTH CHINA UNIV OF TECH

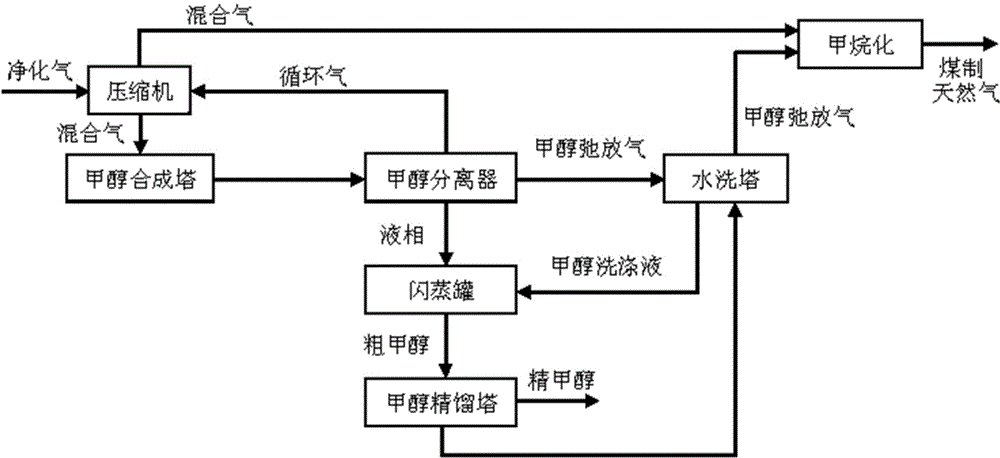

Preparation method for peak regulation of coal-based natural gas through methyl alcohol synthesis

ActiveCN102977958AEnable selective productionOrganic compound preparationGaseous fuelsFluid phaseMethanation

The invention discloses a preparation method for peak regulation of coal-based natural gas through methyl alcohol synthesis. The preparation method comprises the steps of: 1, gasifying coal to obtain purified gas; 2, pressurizing recycle gas and then carrying out heat exchange; 3, mixing the purified gas with the recycle gas and then sending the mixed gas to a methanation reaction system to generate the coal-based natural gas, or sending the mixed gas to a methyl alcohol synthetic reactor for preparing methyl alcohol; 4, synthesizing a reaction mixture in the methyl alcohol synthetic reactor; 5, sending the reaction mixture to a methyl alcohol separator for separating a liquid phase, methyl alcohol purge gas and the recycle gas; 6, sending the liquid phase and a methyl alcohol washing solution derived from a water scrubber to a flash tank to generate crude methyl alcohol, and sending the crude methyl alcohol to a methyl alcohol rectifying tower; and 7, producing a methyl alcohol product by the methyl alcohol rectifying tower, or separating the crude methyl alcohol into the methyl alcohol purge gas, scrubbing the methyl alcohol purge gas by the water scrubber and then sending into the methanation reaction system for generating the coal-based natural gas. According to the invention, a methyl alcohol synthesis section is set on a coal-based natural gas device, and the coal-based natural gas is subjected to peak regulation through methyl alcohol synthesis to ensure that the coal-based natural gas device plays a better role.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for producing methyl alcohol and derivatives of methyl alcohol by coal underground gasification product gases

InactiveCN107032954AIncrease productionIncrease sales revenueOrganic compound preparationHydroxy compound preparationAlcoholAlcohol synthesis

The invention relates to a method for producing methyl alcohol and derivatives of the methyl alcohol by coal underground gasification product gases. The method includes the steps: (1) producing coarse synthesis gases of proper economic scales by the aid of coal underground gasification; (2) acquiring dry synthesis gases; (3) conveying the dry synthesis gases to an acidic water gas conversion and cooling unit, and adjusting carbon hydrogen ratio expected by downstream methyl alcohol synthesis reaction; (4) conveying the cooled synthesis gases to an acidic gas removing unit for desulfurization; (5) performing decarburization on the synthesis gases; (6) performing synthesis reaction on the synthesis gases by a methyl alcohol synthesis unit to obtain the methyl alcohol. According to the method for producing the methyl alcohol and the derivatives of the methyl alcohol by the coal underground gasification product gases, downstream finished product ranges are widened by the aid of main by-products in a coal underground gasification process, and later processing and discharging cost is reduced.

Owner:ZHONGWEI SHANGHAI ENERGY TECH CO LTD

Method and device for synthesizing isobutanol through hydrogenation of carbon monoxide

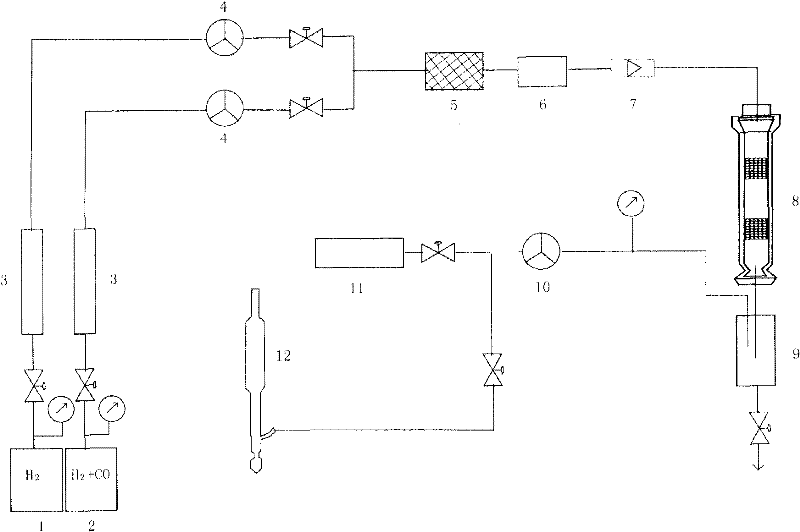

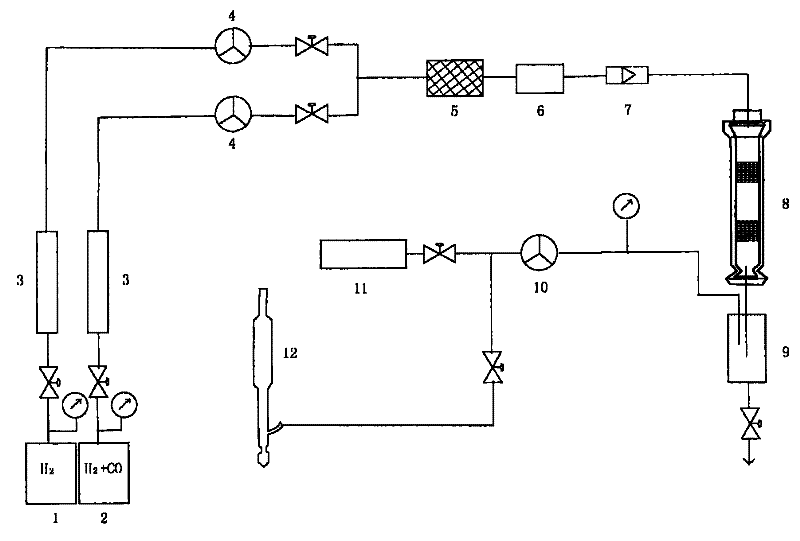

InactiveCN102190561ASimple processEasy to operateOrganic compound preparationHydroxy compound preparationIsobutanolHydrogen

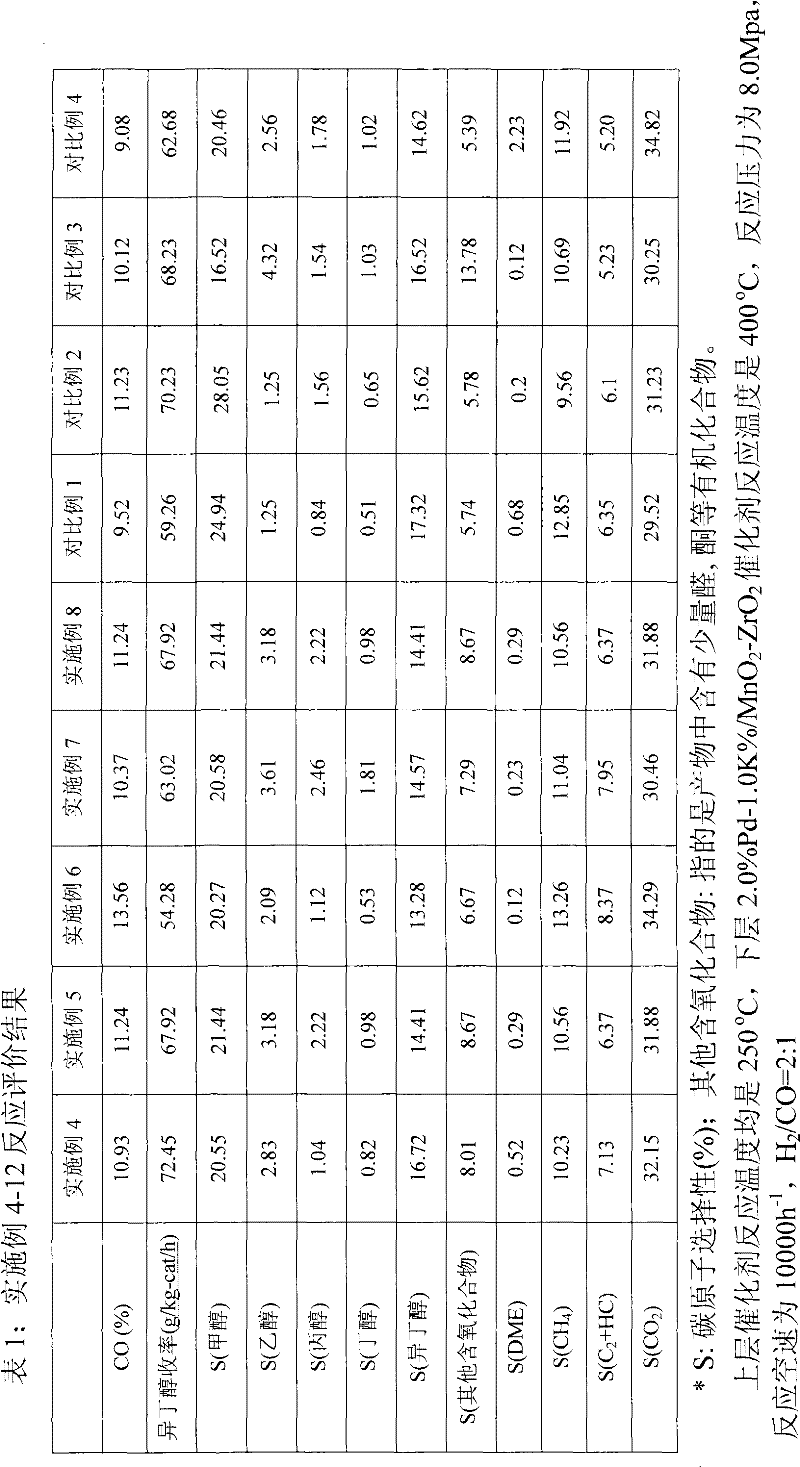

The invention discloses a method for synthesizing isobutanol through hydrogenation of carbon monoxide. A dual catalyst bed reactor is adopted; and the method comprises the following steps of: 1) reducing an upper-layer catalyst and a lower-layer catalyst in the reactor in hydrogen, wherein the upper-layer reduction temperature is 200-400DEG C, the lower-layer reduction temperature is 300-500DEG C, the reduction pressure is 0.5-2.0Mpa, the reduction space velocity is 1,000-20,000h<-1>, the reduction time is 1-6 hours, the upper-layer catalyst is a methanol catalyst or a mixed alcohols synthesis catalyst, and the lower-layer catalyst is a Pd-K / MnO2-ZrO2 catalyst; 2) introducing a feed gas of H2 / CO into the dual catalyst bed reactor, wherein the upper-layer reaction temperature is 200-300DEG C, the lower-layer reaction temperature is 300-500DEG C, the reaction pressure is 5-15Mpa, and the reaction space velocity is 1,000-20,000h<-1>; and 3) cooling and collecting a reaction product.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com