Double-hole carrier iron/ copper low-carbon alcohol synthesis catalyst and preparation method thereof

A pore carrier and catalyst technology, applied in the field of iron/copper catalyst and its preparation, can solve the problems of harsh reaction conditions, low selectivity of higher alcohol products, poor activity and the like, and achieve the effects of good stability, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

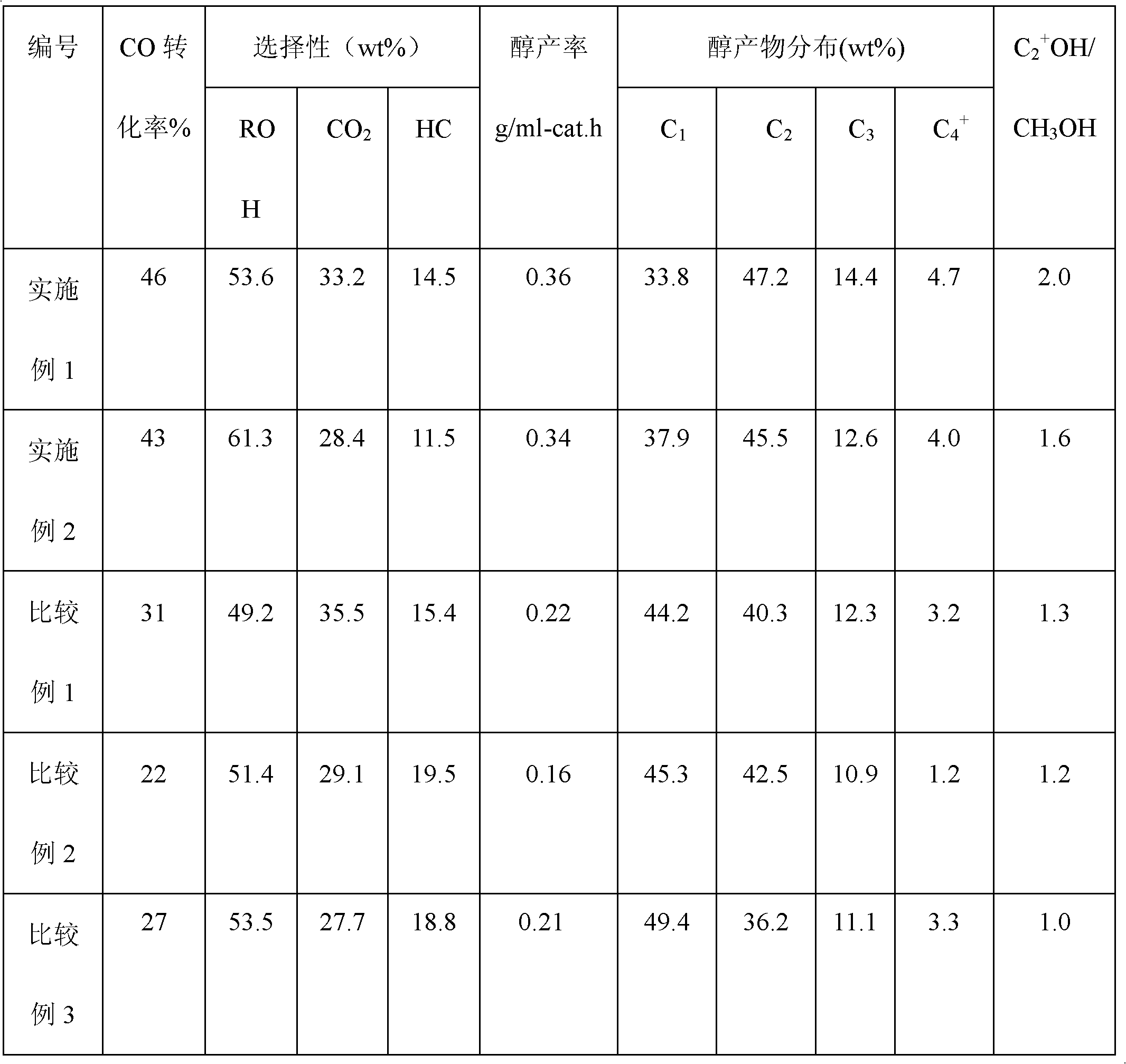

Examples

Embodiment 1

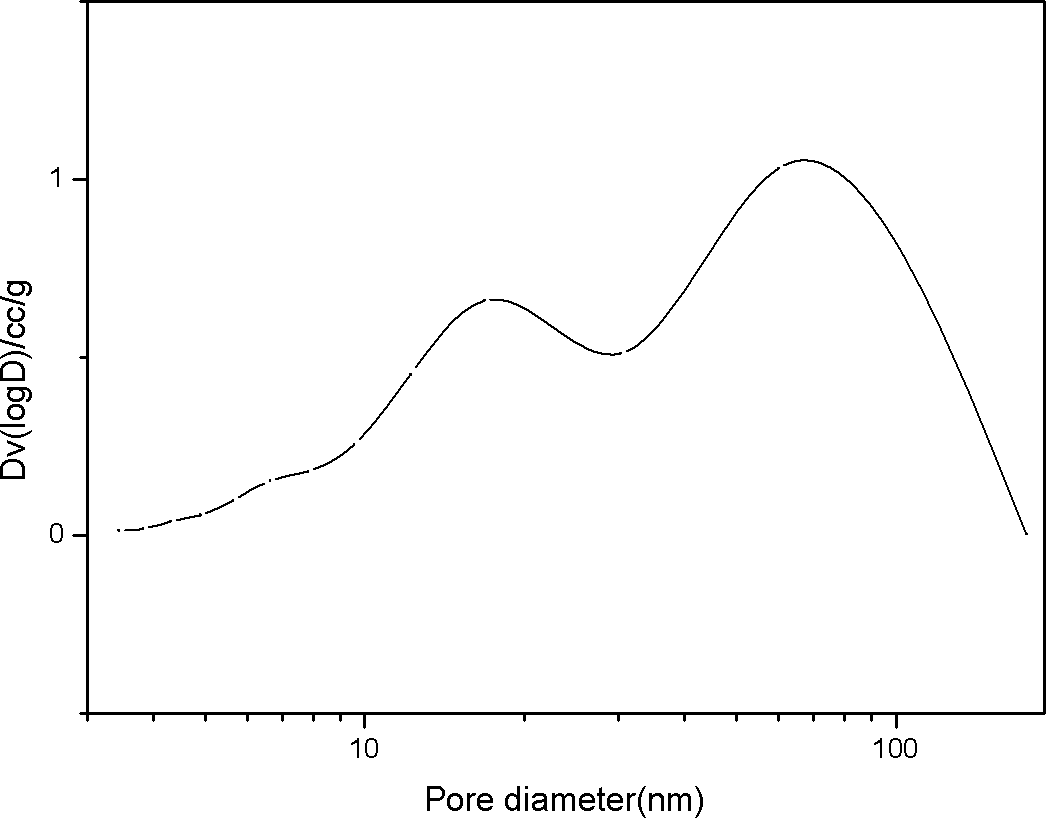

[0018] Select small-porous silica sol with a pore size range of 3-5 nm and macro-porous silica gel with a pore size range of 50-60 nm, and immerse an equal volume of small-porous silica sol in the macro-porous silica gel under ultrasonic conditions. The immersion process needs to be fully Stir. After the immersion was completed, it was left to stand for 1 h under ultrasonic conditions, and then placed in an oil bath and evacuated at 80° C. for 1 h. The obtained coagulum was crushed to 40-180 mesh and then calcined at 600° C. for 2 hours to obtain a double-porous carrier. For the texture properties of the double-porous carrier, see figure 1 , the weight percentage of the small-porous silica sol in the carrier relative to the macro-porous silica gel is 20%.

[0019] A mixed solution formed by dissolving 36 grams of ferric nitrate, 152 grams of copper nitrate and 1.3 grams of potassium nitrate in 100 ml of distilled water was immersed in a double-porous carrier by an equal volu...

Embodiment 2

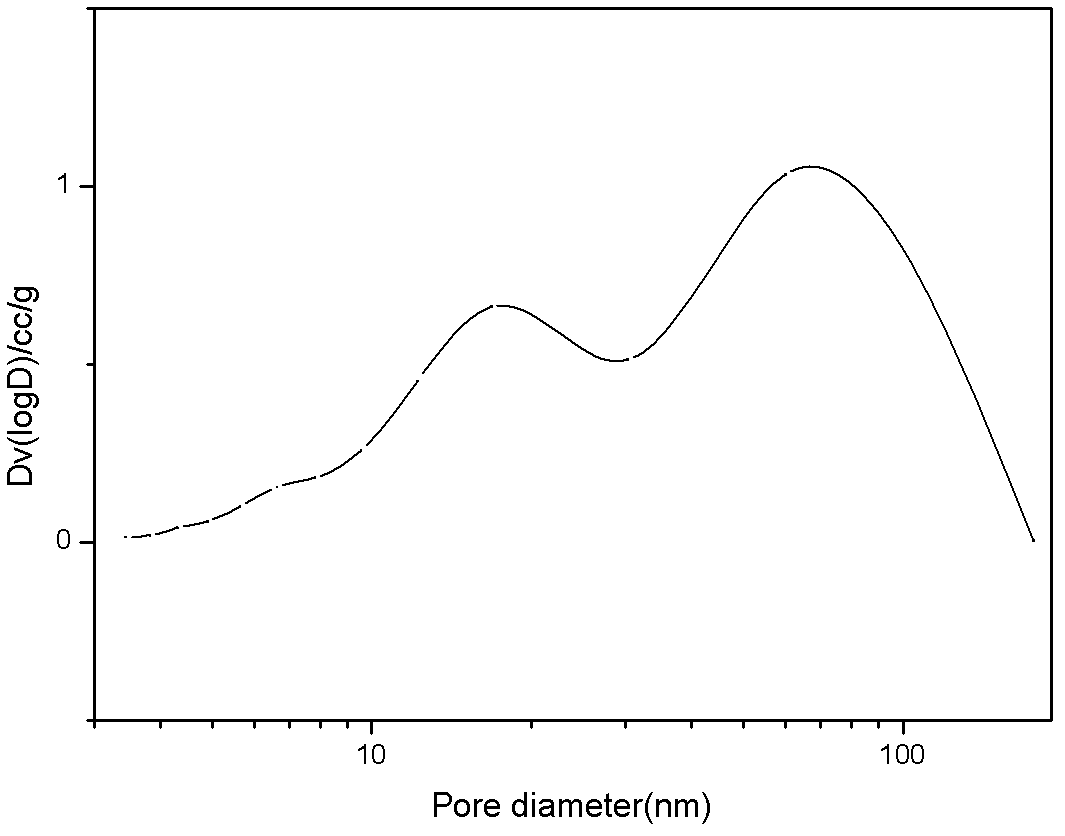

[0022] Select small-porous silica sol with a pore size range of 5-8 nm and macro-porous silica gel with a pore size range of 60-70 nm, and immerse an equal volume of small-porous silica sol in the macro-porous silica gel under ultrasonic conditions. The impregnation process needs to be fully Stir. After the immersion was completed, it was left to stand for 3 hours under ultrasonic conditions, and then placed in an oil bath and evacuated at 60 °C for 2 hours. The obtained coagulum was crushed to 40-180 mesh and then calcined at 500° C. for 4 hours to obtain a double-porous carrier. The weight percentage of the small porous silica sol relative to the macroporous silica gel in the carrier is 10%.

[0023] A mixed solution formed by dissolving 15 grams of ferric nitrate, 57 grams of copper nitrate and 15 grams of potassium nitrate in 100 ml of distilled water was immersed in a double-porous carrier by an equal volume impregnation method under ultrasonic conditions. The carrier d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com