Patents

Literature

422results about How to "Easy industrial scale-up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

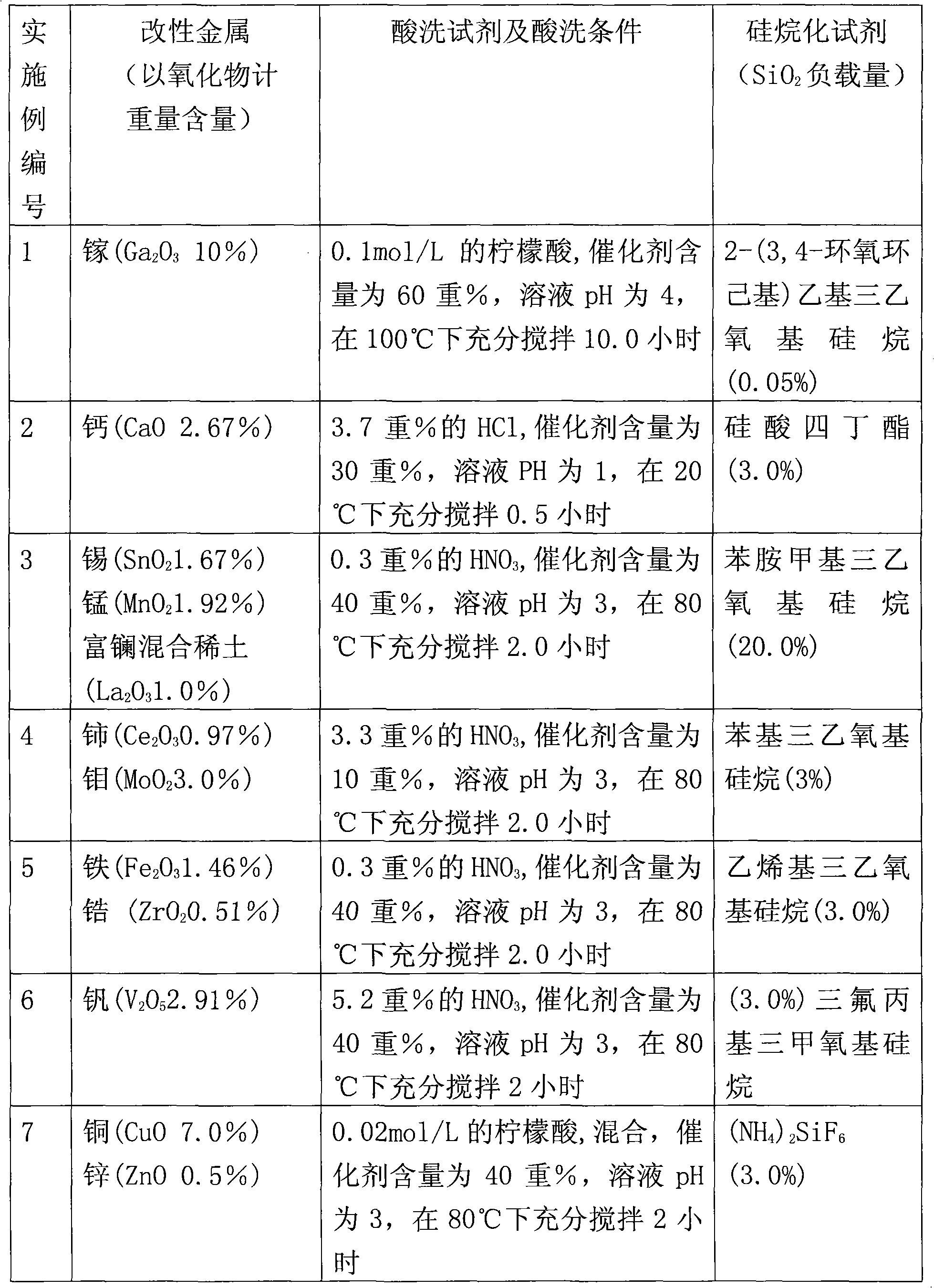

Method for preparing alcohols by selectively hydrogenating aldehydes

ActiveCN102408304AHigh selectivityHydrophobicOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSilanesReaction temperature

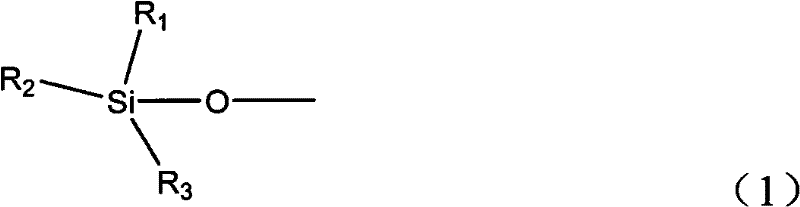

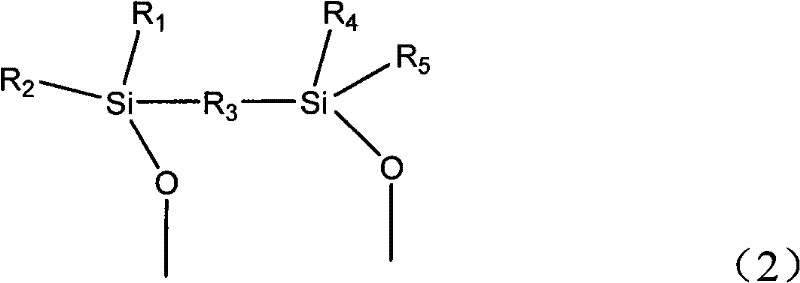

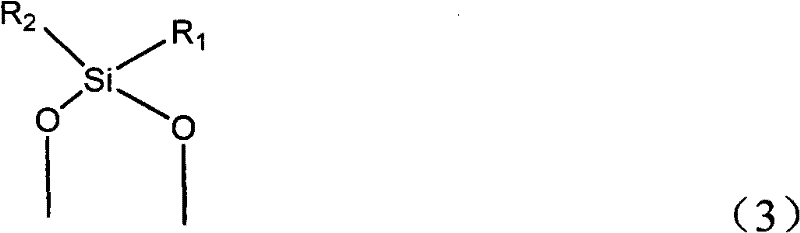

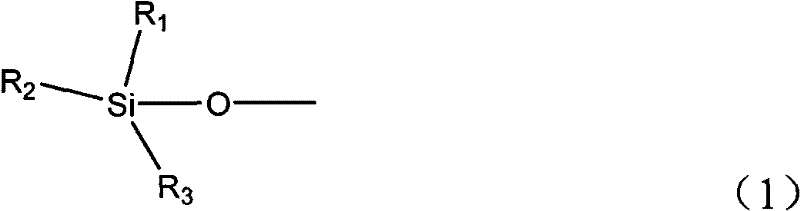

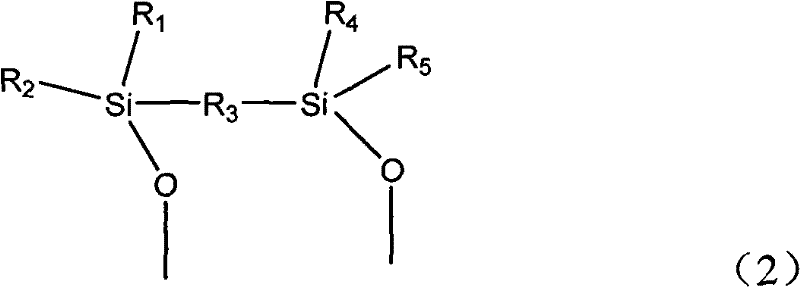

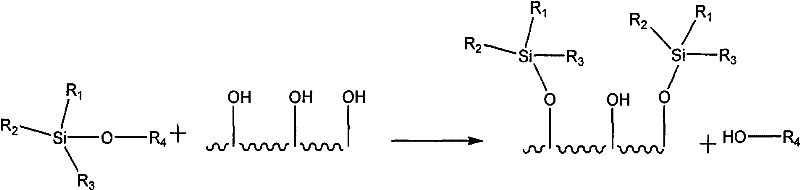

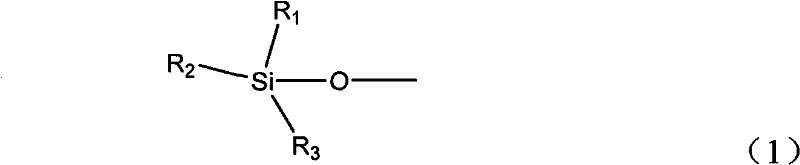

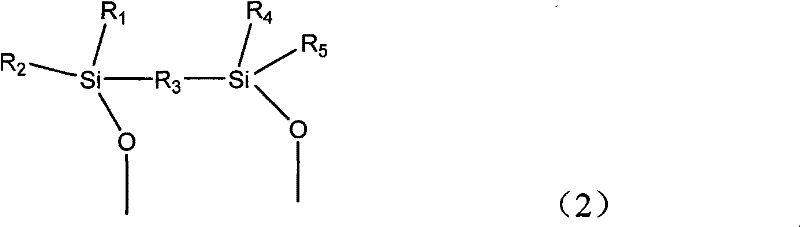

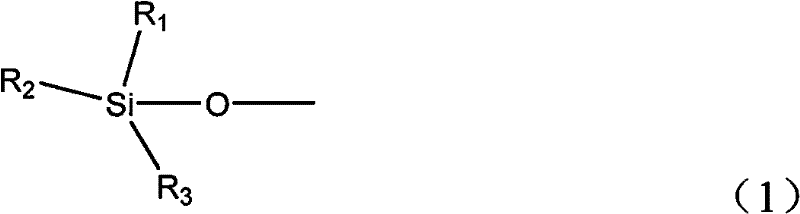

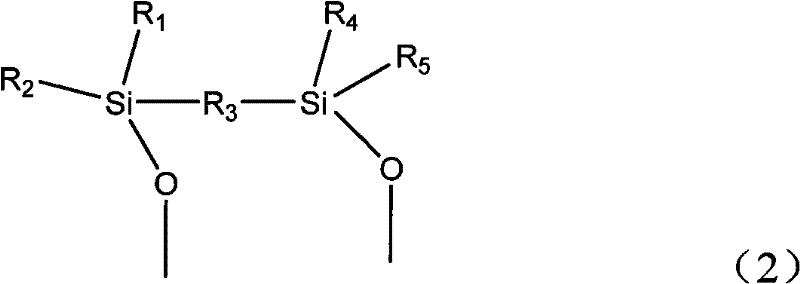

The invention relates to a method for preparing alcohols by selectively hydrogenating aldehydes, belonging to hydrogenation technologies. In order to meet the requirements of people on two aspects, i.e. the improving of the selectivity on preparing the alcohols by hydrogenating the aldehydes and the prolonging of the service life of a catalyst currently, the method proposes that: the aldehydes are taken as raw materials; the reaction temperature is 20-300 DEG C; the reaction pressure is 0.1-7.0 MPa; the weight space velocity of the aldehydes is 0.02-20 h<-1>; the aldehydes and hydrogen gas are in contact with a hydrogenation catalyst; and the aldehydes are produced into corresponding alcohols through selectively hydrogenating. In the method, the hydrogenation catalyst comprises a carrier, a metal active component and silane groups; the silane groups are grafted through a silylanizing treatment; and the content of the silane groups in the total weight of the catalyst is 0.05 wt% to 25 wt%. Compared with the existing method, with the adoption of the catalyst in the method provided by the invention, the selectivity is high, the amount of byproducts, such as ethers, esters and acetals is greatly lowered; and meanwhile, the generation amount of carbon deposit is little, so that the catalyst has longer service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis process of propylene carbonate or vinyl carbonate

InactiveCN1421431AImprove economyGood performance repeatabilityOrganic compound preparationCarbonic/haloformic acid esters preparationReaction temperatureNitrogen

The synthesis process of propylene carbonate or vinyl carbonate includes adding urea, propylene glycol or ethylene glycol in the molar amount of 1-100 times that of urea and solid alkali in the molaramount of 0.001-10 times that of urea into the reactor and reaction at the temperature of 100-200 deg.c and vacuum degree 50-600 mmHg or nitrogen blowing in the flow rate of 1-1000 ml / ml cat. min for0.5-20 hr. The present invention has the advantages of repeatable catalyst performance, material converting rate near the theoretical number, high product selectivity, less side product, etc.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

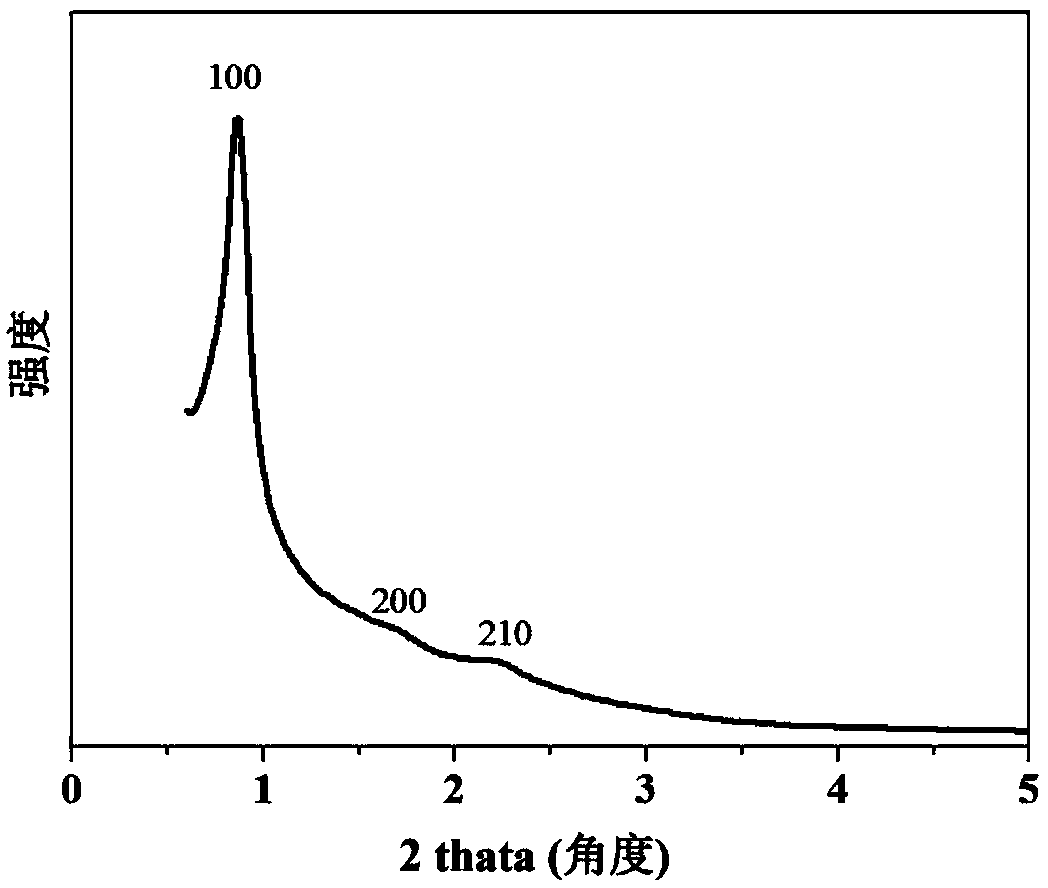

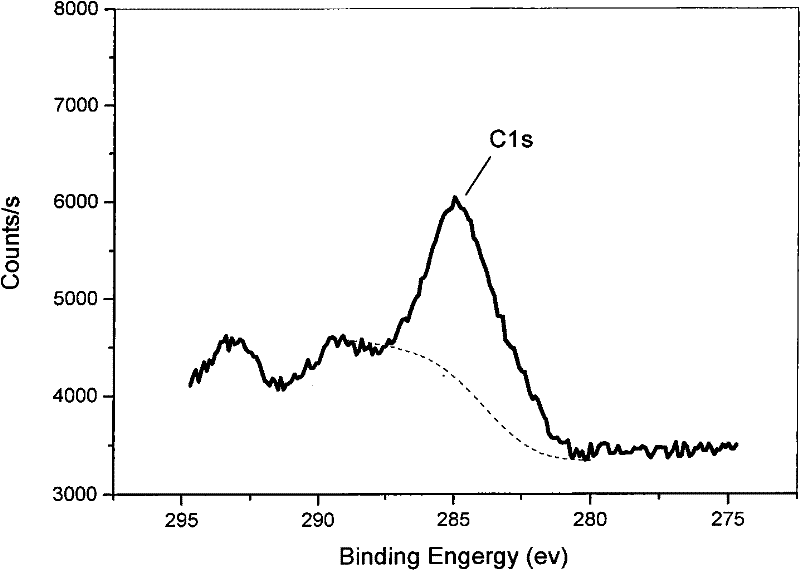

Solid-phase synthetic method of highly ordered mesoporous carbon material

InactiveCN103964414AIncrease the areaHigh pore volumeCarbon preparation/purificationPore diameterSelf-assembly

The invention discloses a solid-phase synthetic method of a highly ordered mesoporous carbon material. The solid-phase synthetic method comprises the following steps: 1) mixing a structure-directing agent with a high molecular monomer used as a carbon source, and grinding for 5-180 min at 10-100 DEG C; 2), heating for 0.5-120 h at 40-380 DEG C; 3) under the protection of inert gases, rising the temperature to 500-2,100 DEG C at the temperature rising speed of 1-40 DEG C / min, and roasting for 2-10 h at high temperature. The functionalization mesoporous carbon material is synthetized through the organic-organic self-assembly between the high molecular monomer and the structure-directing agent and between the low polymer of the high molecular monomer and the structure-directing agent, and the mechanical grinding. The solid-phase synthetic method is simple to operate, efficient, and low in cost, and the prepared mesoporous carbon material has a highly ordered mesoporous channel, high specific surface area (500-2,500 m<2> / g and large pore volume (pore diameter of 2.5-20 nm and pore volume of 0.1-2.5 cm <3> / g).

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

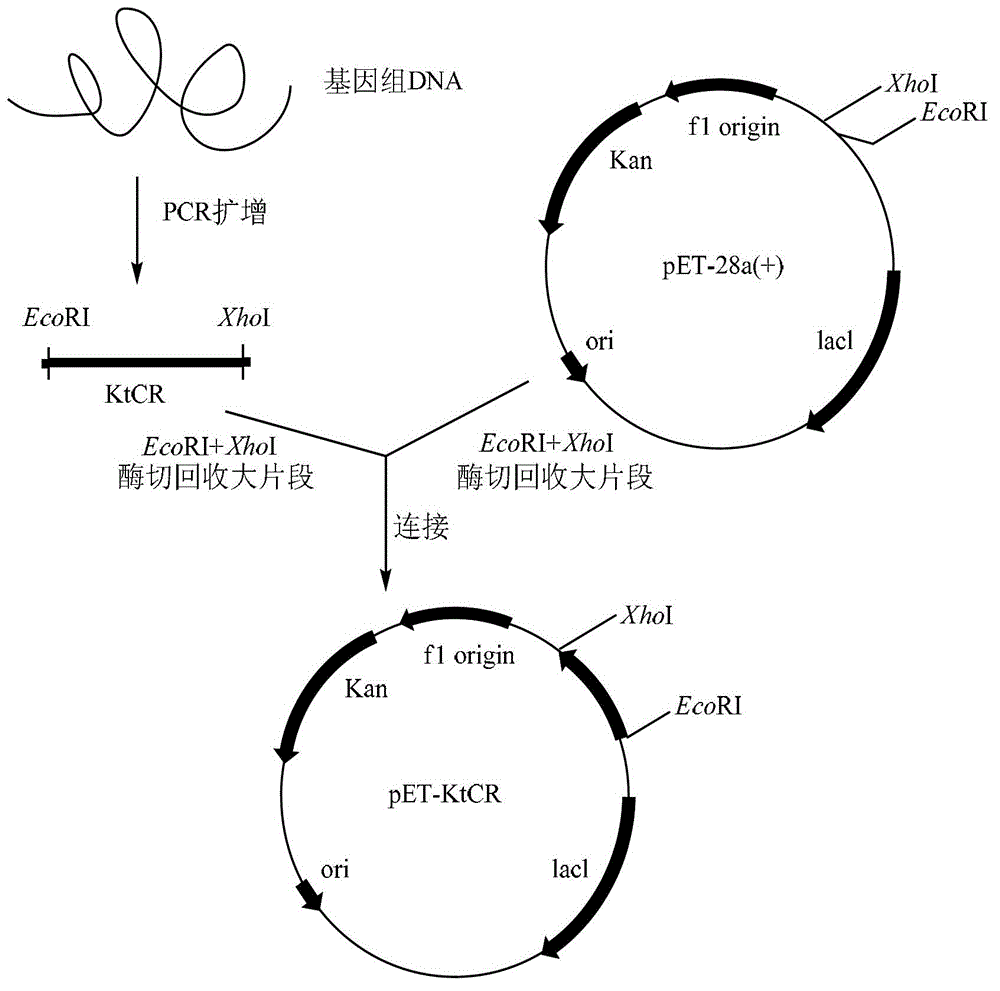

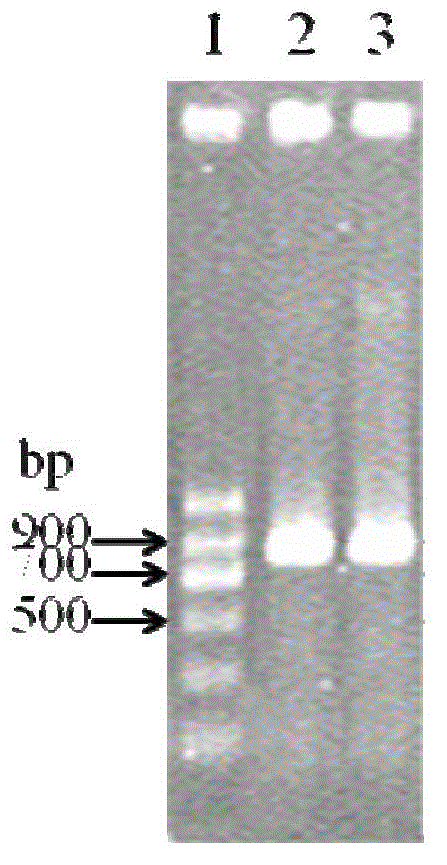

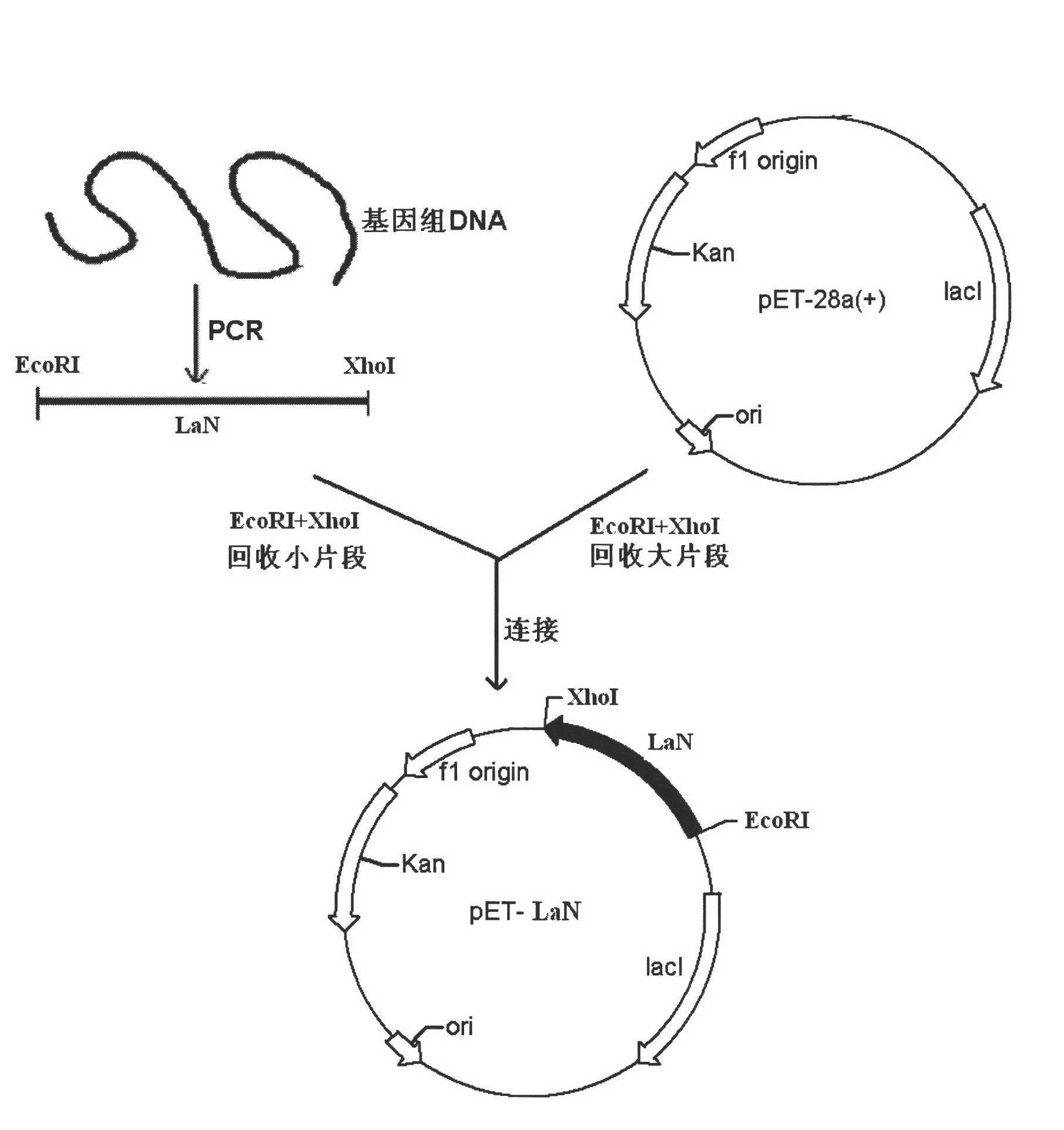

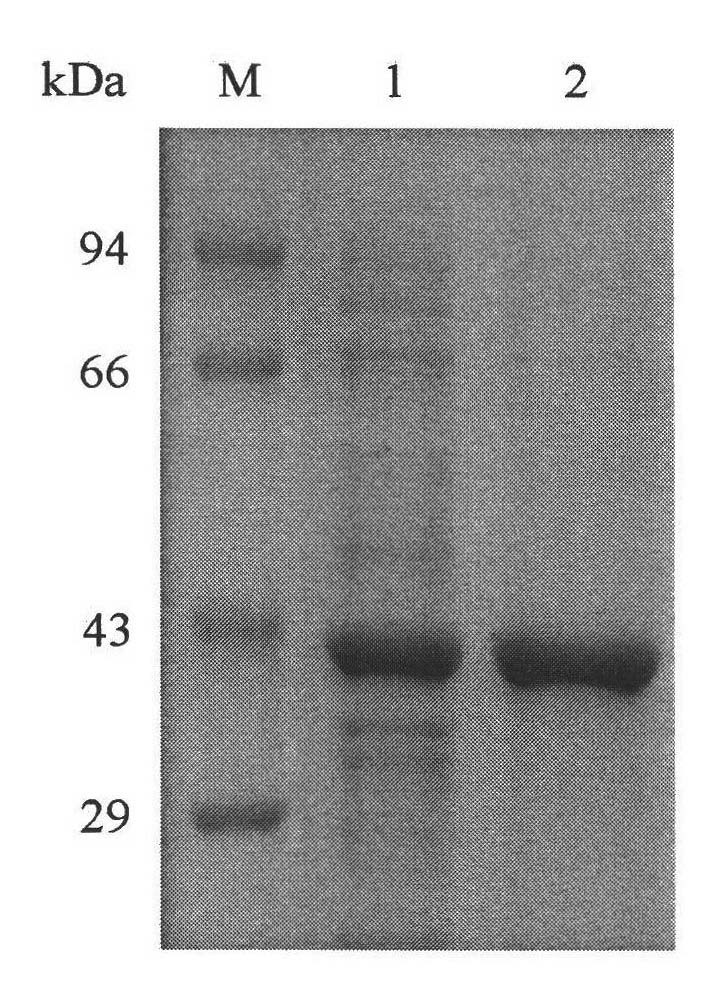

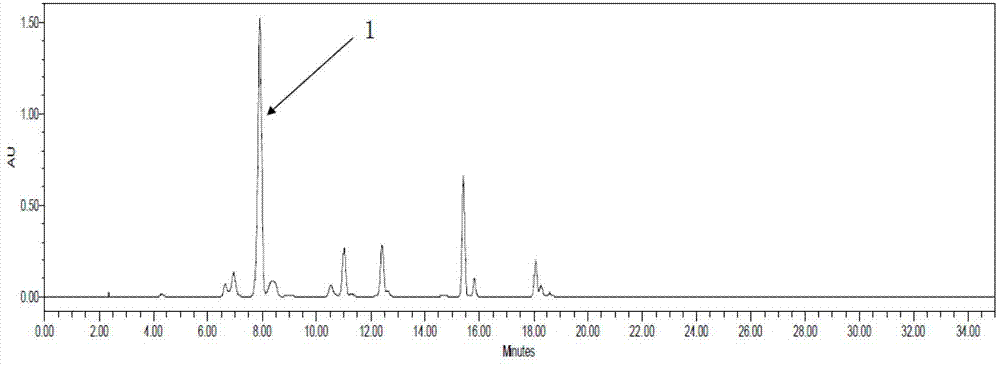

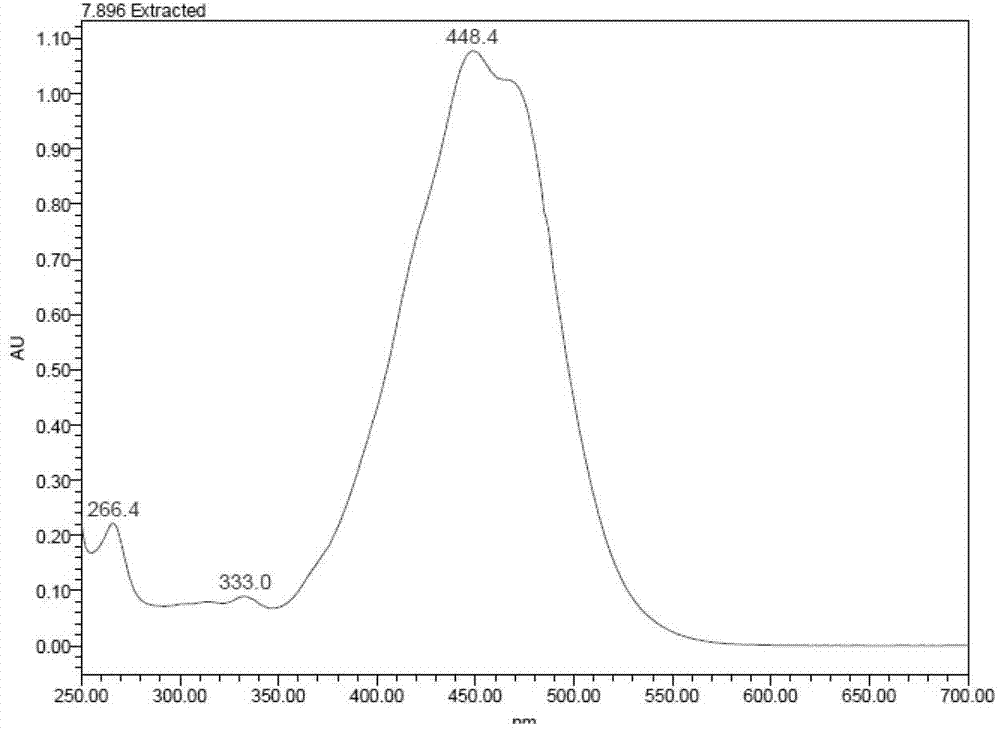

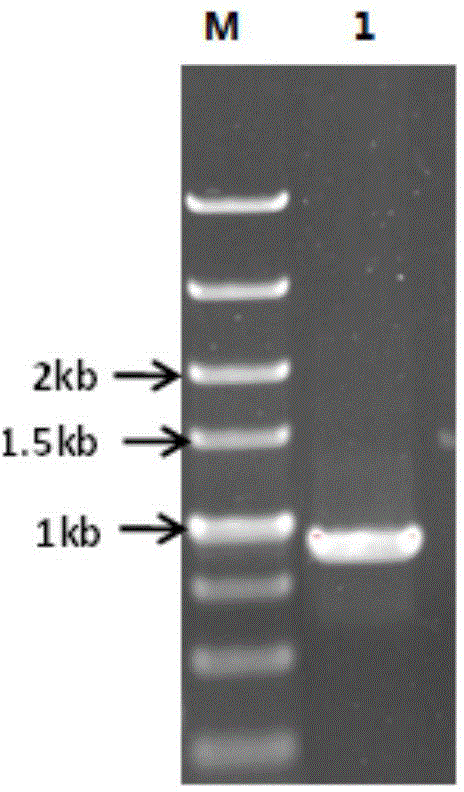

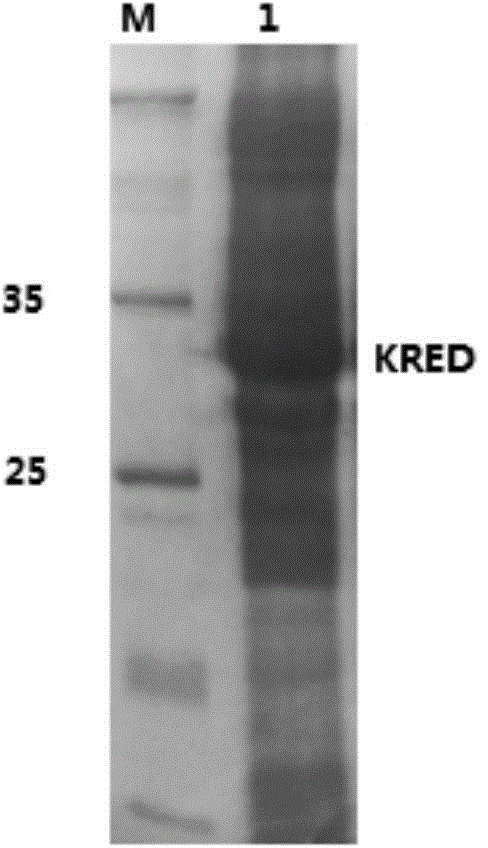

Carbonyl reductase, gene and mutant and application thereof to asymmetrical reduced carbonyl compound

ActiveCN102618513AHigh optical purityMild reaction conditionsBacteriaMicroorganism based processesHigh concentrationMethyl o-chloromandelate

The invention discloses a novel carbonyl reductase, a gene, a mutant thereof, a recombinant expression vector containing the gene and the mutant, a recombinant expression transformant, a recombinase preparation method, and applications of the carbonyl reductase and recombinase to preparation of active chiral alcohols with a chiral carbonyl compound before asymmetrical reduction. The carbonyl reductase is derived from candida glabrata, is applied to preparation of a plurality of optically-active chiral alcohols such as (R)-chloromandelic acid methyl ester, (R)-2-hydroxy-4-phenyl ethyl butyrate, (R)-4-chlorin-3-phenyl ethyl butyrate and the like. Compared with other preparation methods, a product prepared through the method has high concentration, does not require additionally or slightly adding any expensive coenzyme, has high optical purity, and has the advantages of mild reaction conditions, easiness and convenience for operating, easiness for amplifying and the like, and has a good industrial application prospect in the production of clopidogrel, L-carnitine and perindopril antihypertensive medicinal intermediates.

Owner:EAST CHINA UNIV OF SCI & TECH

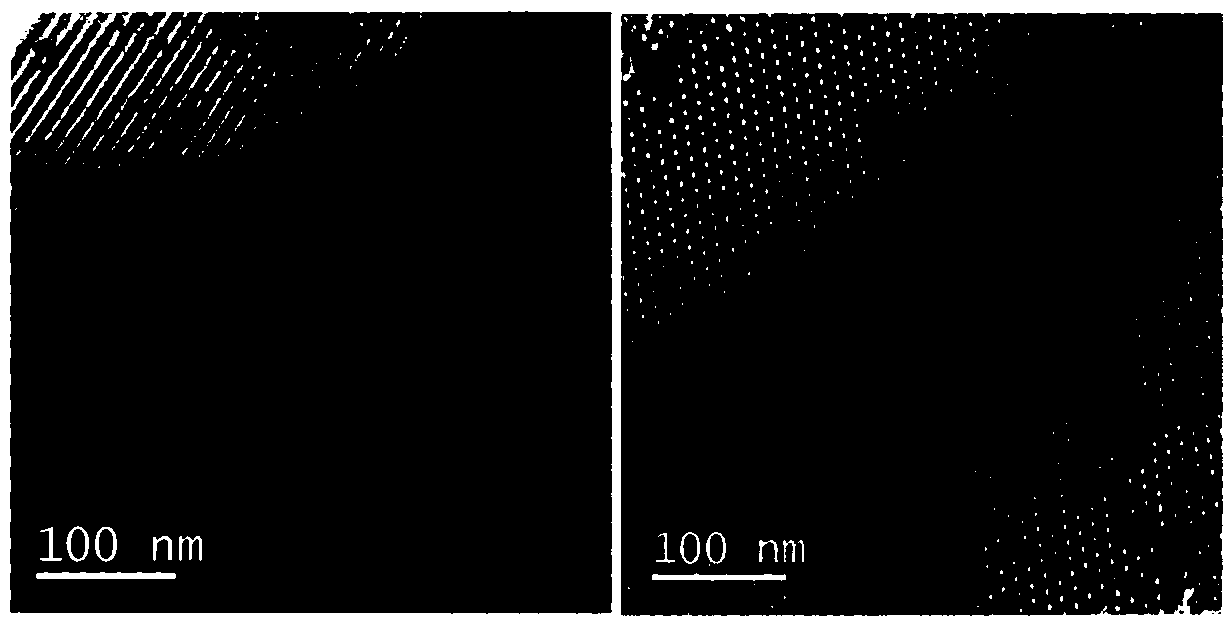

Method for preparing minor-diameter carbon nanotube array on surface of flaky material

The invention relates to a method for preparing a minor-diameter carbon nanotube array on the surface of a flaky material, which belongs to the technical fields of nanometer materials and the preparation process thereof. The method comprises the following steps: the nanoparticles including one or more of Fe, Co, Ni, Cu and Mo (active metals) are dispersed on various flaky materials such as a graphitic sheet, magnesia or layered double hydroxide according to the density (10<8>-10<12> grains / cm<2>), then the chemical vapor deposition is performed, and finally, the carbon nanotube array grows onthe flaky surface. The diameter of the nanotube is less than 20 nm in the array. The method is easy to operate, realizes the mass production of the carbon nanotube array and promotes the industrial application.

Owner:TSINGHUA UNIV

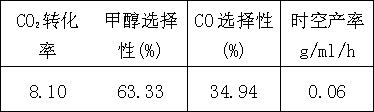

Copper based catalyst used for hydrogenating carbon dioxide to synthesize methanol, and preparation method and application thereof

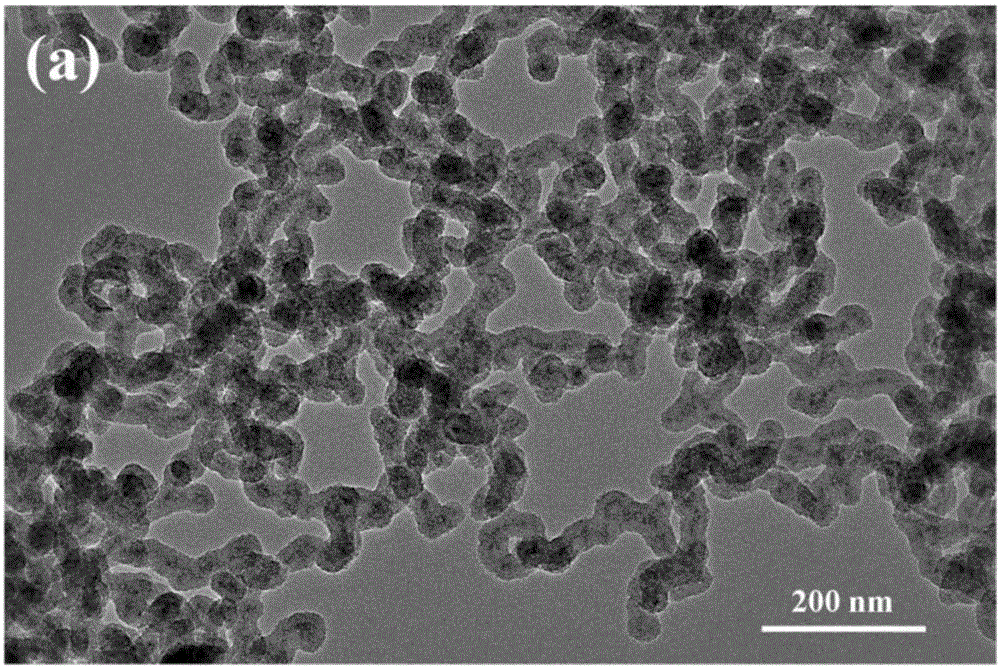

ActiveCN103272607AEvenly dispersedSmall particle sizeOrganic compound preparationHydroxy compound preparationCarbon dioxideCopper salt

The invention discloses a copper based catalyst used for hydrogenating carbon dioxide to synthesize methanol, and a preparation method and an application thereof. The preparation method of the catalyst comprises the following steps: 1, processing a zinc salt, an aluminum salt, a zirconium salt and a stabilizer to prepare a first solution, or processing the zinc salt, the aluminum salt and the zirconium salt to prepare a second solution; 2, processing carbonate and hydroxide to prepare a third solution; 3, processing a copper salt to prepare a fourth solution; 4, processing the first solution and the third solution to form a first precipitation solution, or processing the second solution and the third solution to form a second precipitation solution; 5, adding the fourth solution to the first precipitation solution to form a third precipitation solution or adding the fourth solution to the second precipitation solution to form a fourth precipitation solution, ageing after Cu in the precipitation solution precipitates, and washing; and 6, drying, and calcining. The catalyst contains 30-50% of Cu, 20-40% of Zn, 10-20% of Al, and 5-20% of Zr. The catalyst is used for a reaction for hydrogenating carbon dioxide to synthesize methanol.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Method for preparing carbon nano-tube array on particle interior surface

ActiveCN101348249AAvoid shape damageEasy to operateChemical vapor deposition coatingHigh volume manufacturingChemical separation

The invention provides a method for preparing carbon nano pipe arrays on the inner surface of a particle, belonging to the technical field of novel material and novel material preparation. In the method, the active metal components are loaded on the inner surface of the particle, and subjected to reduction or thermal decomposition to obtain a loaded type particle inner surface containing metal nano particles; the loaded type particle inner surface is subjected to chemical vapor deposition, and carbon nano pipe arrays grow up between the particle inner surfaces. By the physical or chemical separation, the carbon nano pipe arrays are separated from the particles, and the carbon nano pipe arrays with high purity are obtained, wherein in the method, the reaction speed and the operational conditions are controlled, the bed density of a reactor is kept between 10 and 1000kg / m<3>, and the carbon nano pipes / particles are in flowing / fluidized states. The method has the advantages of being easily operated, realizing the mass production of the carbon nano pipe arrays and promoting the industrialized application of the carbon nano pipe arrays.

Owner:TSINGHUA UNIV

Unsaturated hydrocarbon hydrogenation catalyst and application thereof

ActiveCN102407118AImprove water resistanceExtended service lifeMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsUnsaturated hydrocarbonSilanes

The invention discloses an unsaturated hydrocarbon hydrogenation catalyst, belonging to the technical field of hydrogenation catalysts. For meeting the requirements of water resistance and carbon deposition resistance on the unsaturated hydrocarbon hydrogenation catalyst, the catalyst contains a carrier, a metal active ingredient loaded on the carrier and a silane group, the silane group on the catalyst is grafted by performing silylanizing treatment, and the content of the silane group is 0.05-25 percent by weight; and the carrier is made of a porous material of which the specific surface area is 2-300 m<2> / g, the pore volume is 0.05-1.2 ml / g, the average pore diameter is 9-150 nanometers, over 50 percent of pore volume is included in pores with pore diameters being greater than 9 nanometers, and the pore volume of pores with pore diameters being smaller than 5 nanometers is less than 25 percent. Compared with the conventional catalyst, the catalyst disclosed by the invention has theadvantages of high water resistance, small amount of deposited carbon, longer service life and great reduction in the powder removal phenomenon of the catalyst when the catalyst is applied to unsaturated hydrocarbon hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

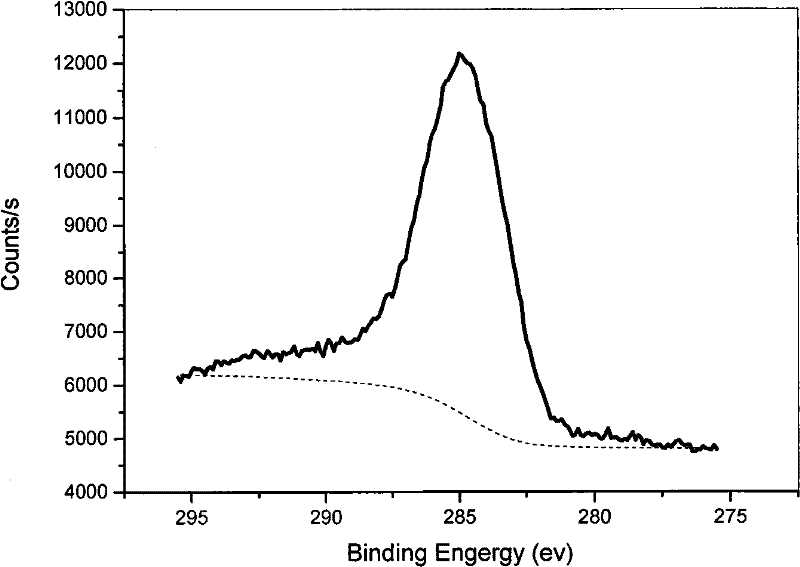

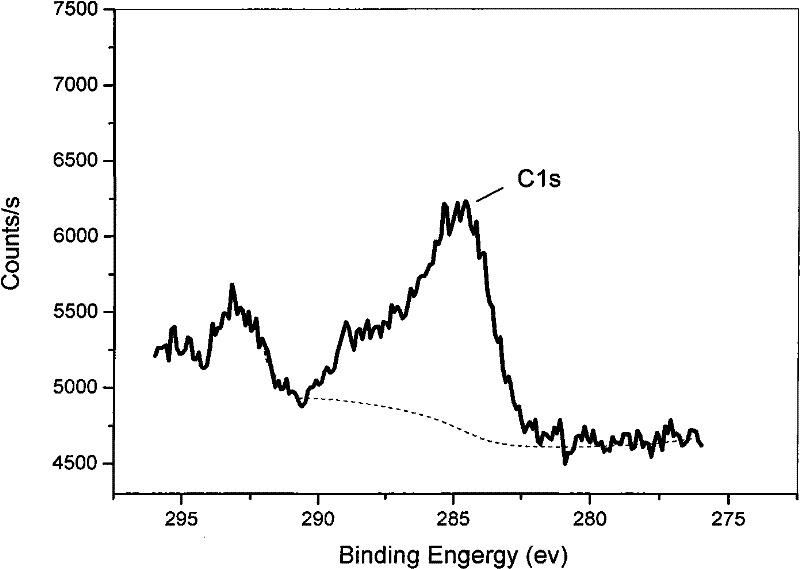

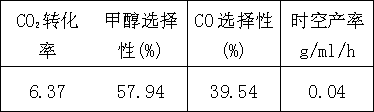

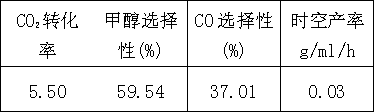

Catalyst for synthesising methanol by hydrogenation of carbon dioxide as well as preparation method and application thereof

ActiveCN103252241AEasy to prepareEasy to operateOrganic compound preparationHydroxy compound preparationMetalMethanol

The invention discloses a catalyst for synthesising methanol by hydrogenation of carbon dioxide. The catalyst is composed of oxides with the following molar ratio based on metal: 20-50% of La, 0-10% of M, 15-35% of Cu, and 2-15% of Zn, wherein M is one or more of Zr, Y, K, Ag, Ce, Pd, Mn, Mg, Fe, Co, Ni or Cr. The catalyst disclosed by the invention has the advantages that preparation is simple, operation is easy, catalyst performance repeatability is good, industrial amplification is easy to realize, and reaction conversion rate and reaction selectivity are high.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Antibiotic pharmaceutical wastewater processing method and device

ActiveCN103183403AAchieve continuous separationTo achieve resourceSemi-permeable membranesDispersed particle separationAntibiotic YMembrane reactor

The invention discloses an antibiotic pharmaceutical wastewater processing method and an antibiotic pharmaceutical wastewater processing device, and belongs to a wastewater processing technology. According to the invention, a porous filtering membrane is specifically arranged between an anion-exchange membrane and a cation-exchange membrane of an electrodialyzer membrane reactor, such that electrodialysis is intrinsically coupled with a membrane filtering process. Macromolecular substances such as mycelia, proteins, and colloidal are retained with a sieving effect of the porous filtering membrane, such that ion-exchange membrane surface pollution is reduced. Also, under an effect of a direct current electric field, with a selective permeability of the ion-exchange membranes upon charged ions, separation and concentration of anions and cations, and charged antibiotic ions are realized. With an adopted external direct current electric field, a specific solute can be effectively prevented from forming membrane pollution on the surface of the porous filtering membrane, such that the processing process can be safely and stably operated. With the method and the device, antibiotic wastewater processing system investment and operation cost can be greatly reduced; and salt ions and residual antibiotics can be highly efficiently recovered from pharmaceutical wastewater. The method and the device have important application values in antibiotic production and wastewater processing.

Owner:天津大远科技有限公司

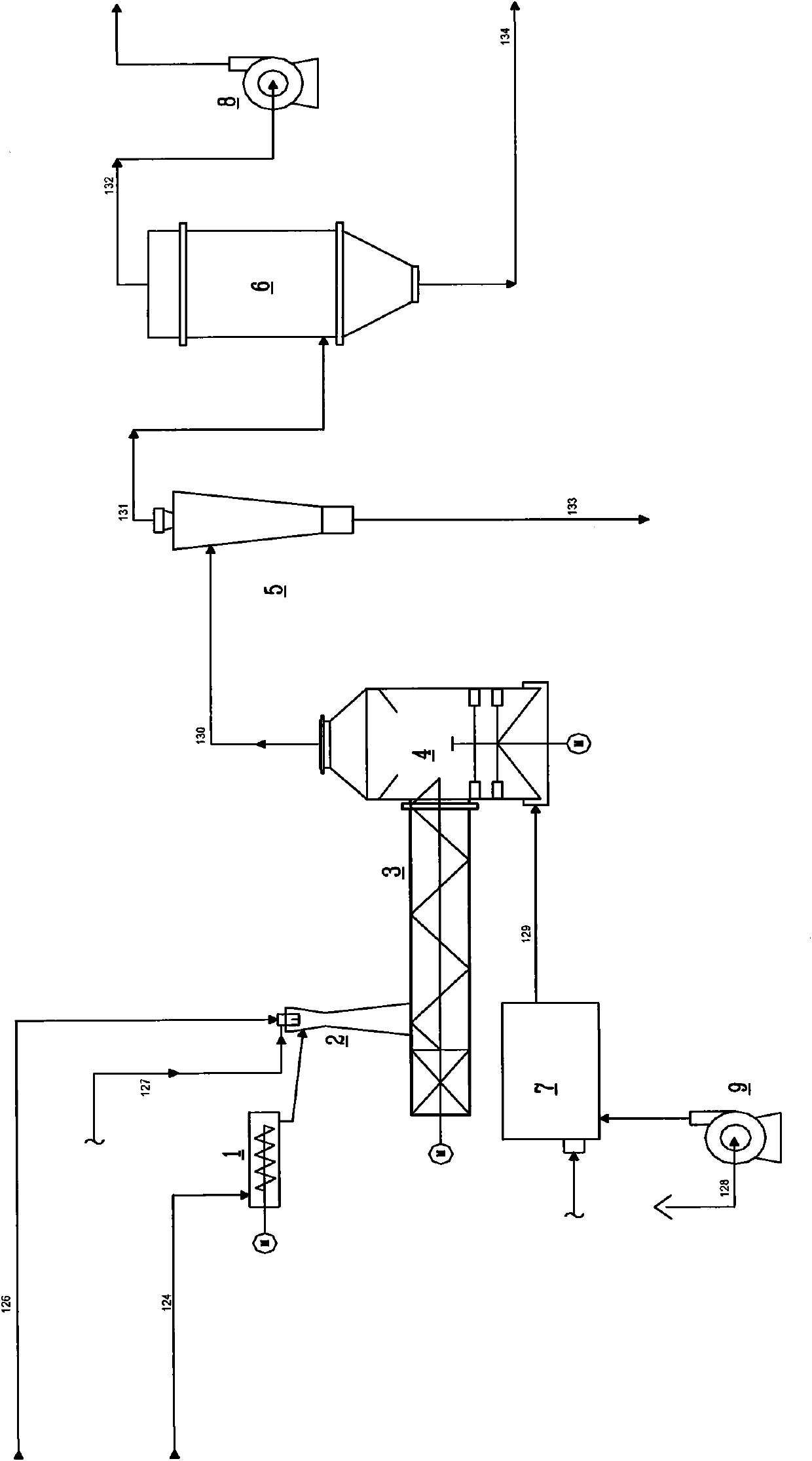

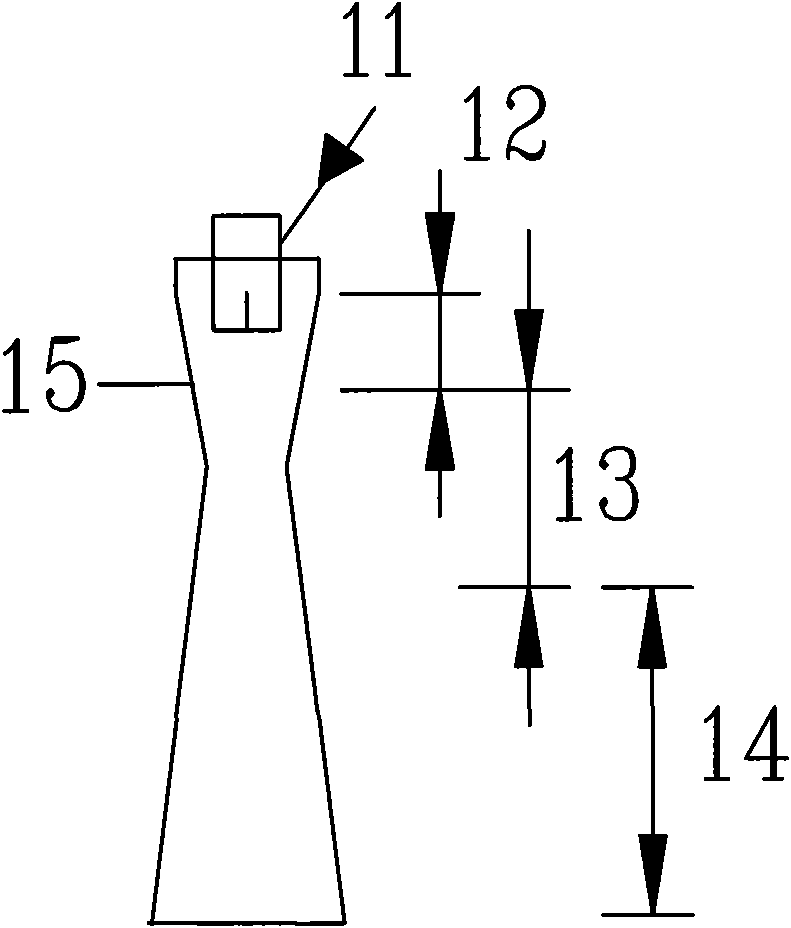

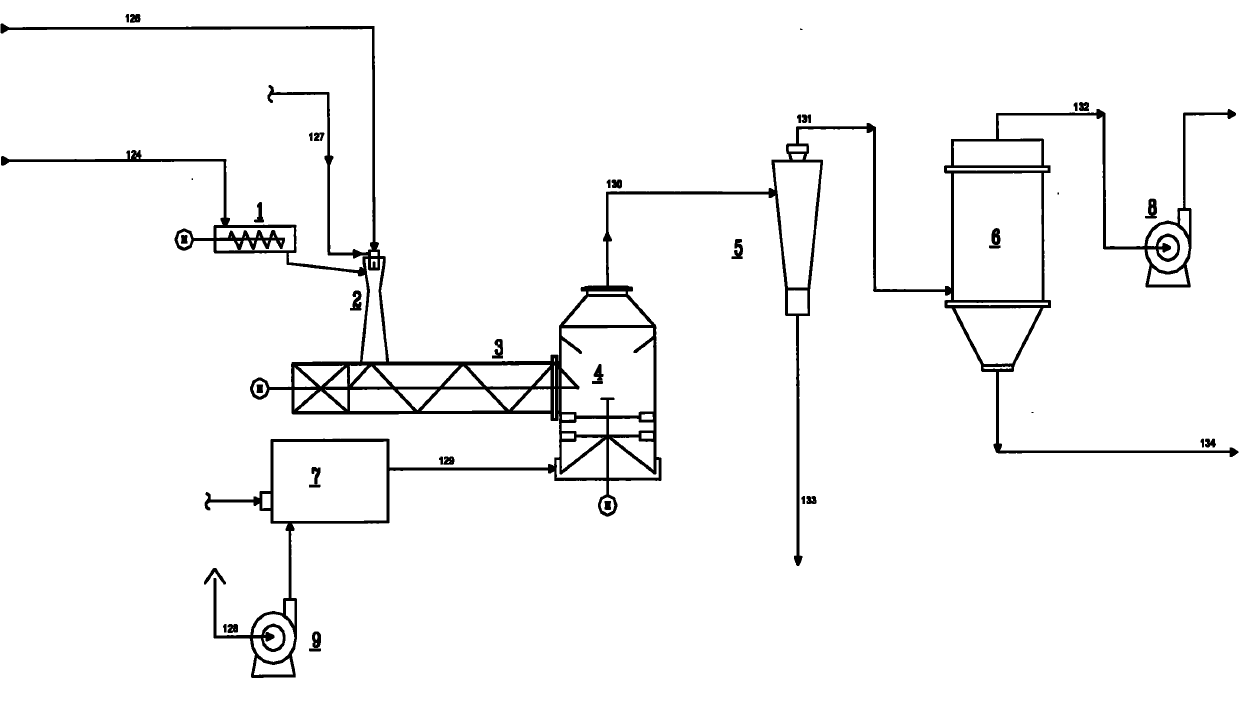

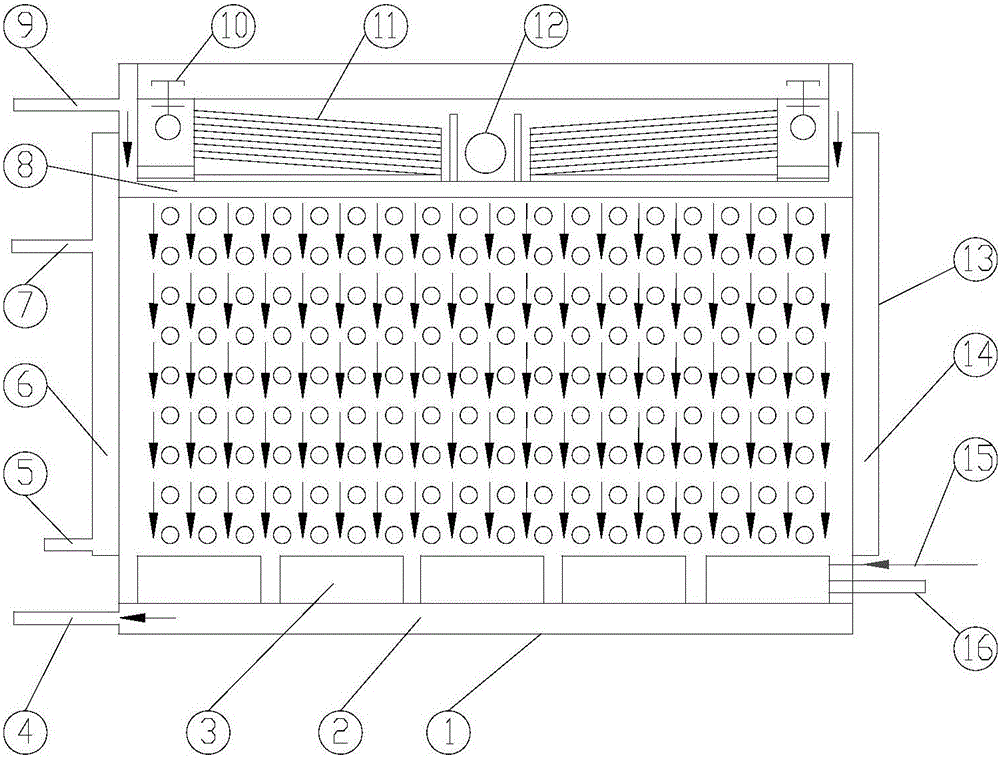

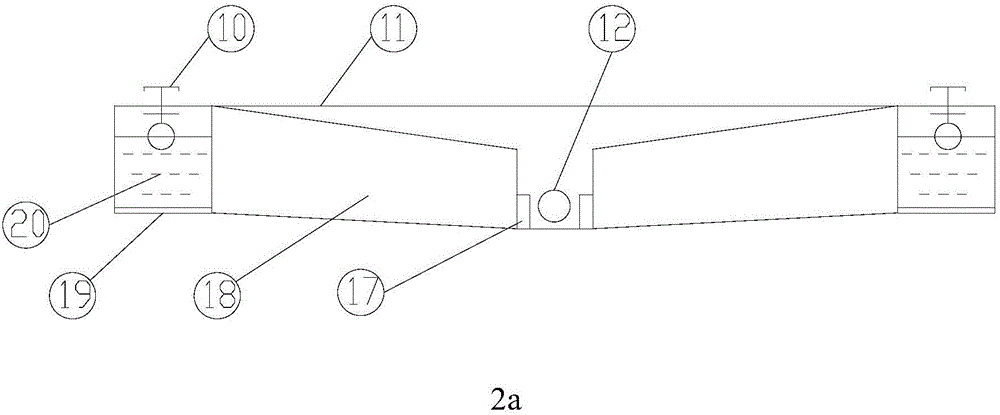

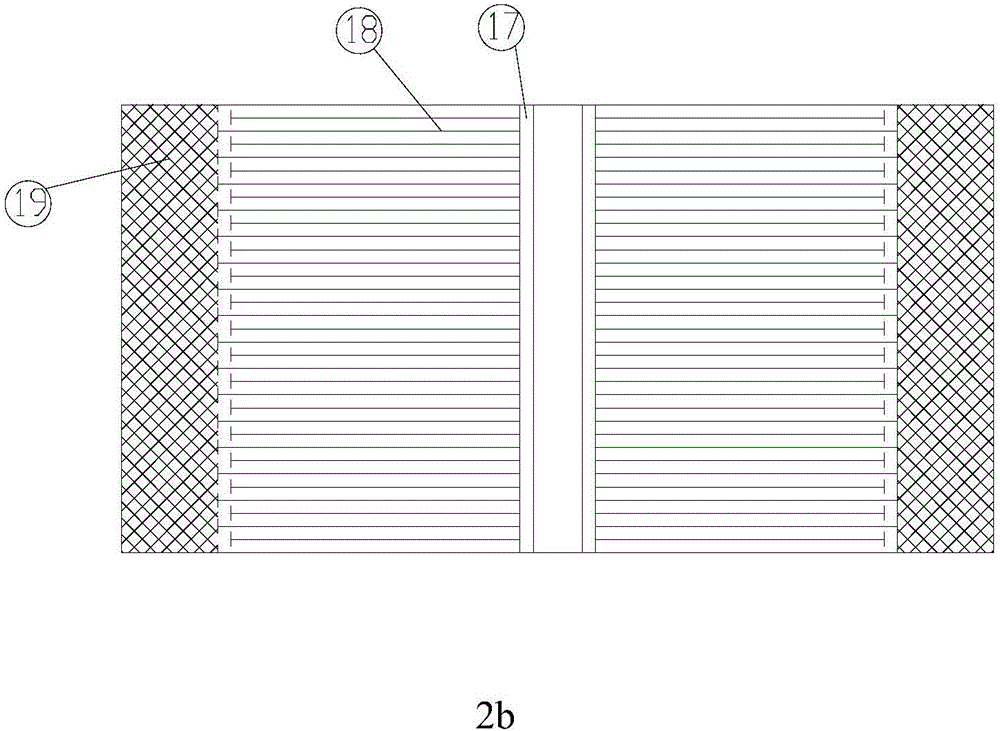

Continuous steeping method for grain carrier and equipment thereof

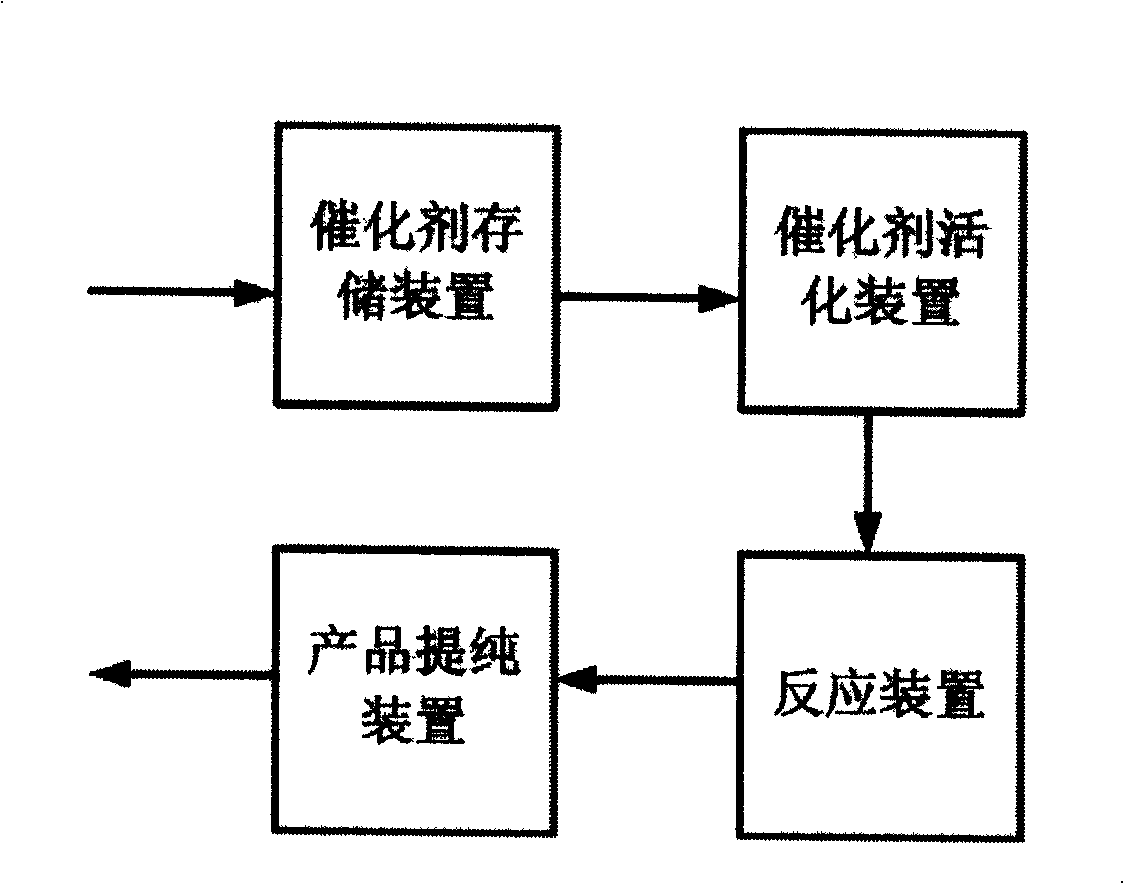

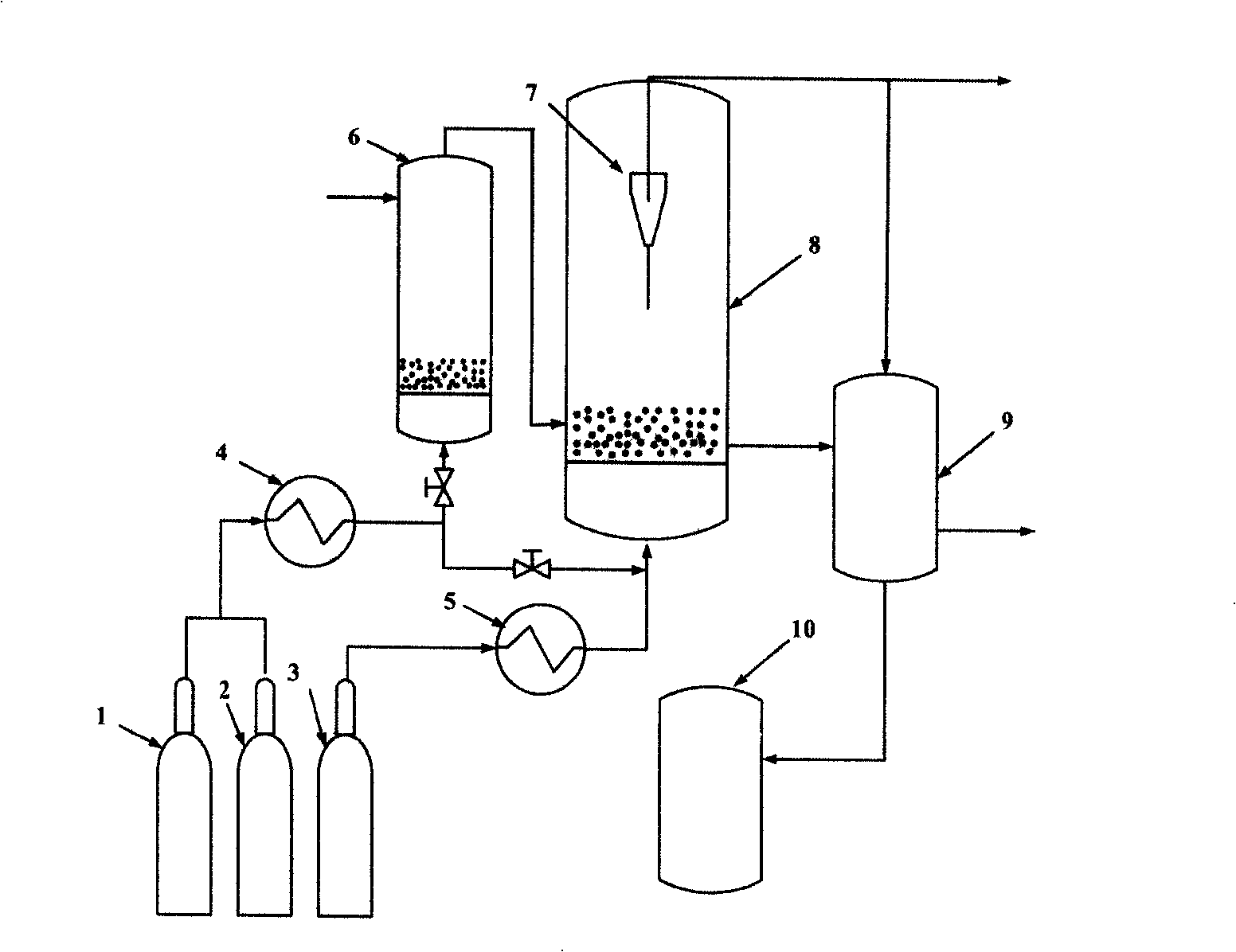

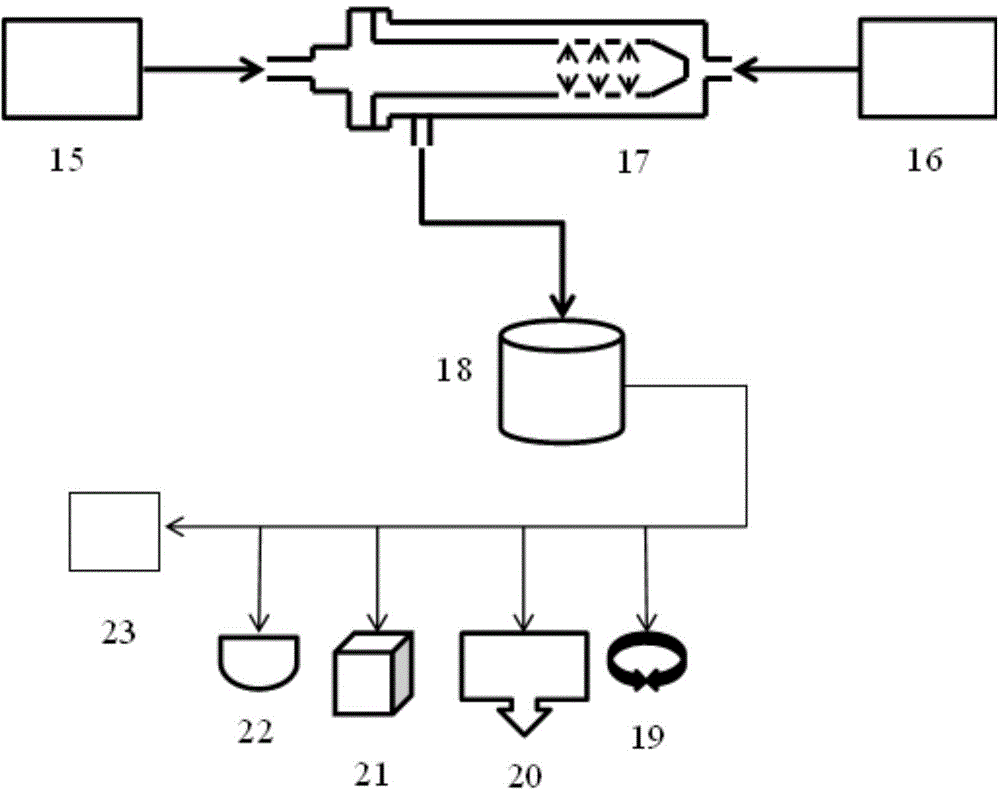

ActiveCN102019208AImprove impregnation efficiencyGuaranteed uptimeOther chemical processesCatalyst activation/preparationActive componentSorbent

The invention relates to a continuous steeping method for a grain carrier and equipment thereof. The continuous steeping method comprises the following steps that steeping liquor is atomized into drops through a nozzle and is jetted into an atomizer; carrier grains are led into the atomizer; the steeping liquor drops and the carrier grains are mixed in the atomizer to form a mixture; the mixture enters into a steeping mixer to carry out sufficient contact; the average grain diameters of the carrier grains are 40-90 microns; the average grain diameters of the steeping liquor drops are 0.5-1.0 time the average grain diameters of the carrier grains; and the ratio of the volume flow of the steeping liquor to the mass flow of the carrier is 0.30-0.60L / kg. The continuous steeping equipment comprises the atomizer and the steeping mixer which is connected with the outlet of the atomizer. The method can implement the continuous steeping process of the grain carrier and can make active component evenly distributed in the carrier, thereby ensuring the strength of an adsorbent finished product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Enzymatically hydrolyzed cereal beverage and method for preparing same

The invention relates to a comprehensive development and utilization technology of cereals, especially oats and particularly relates to a whole-oat dietary beverage and a method for preparing the whole-oat dietary beverage by virtue of an enzyme preparation. The whole-oat dietary beverage is a beverage prepared by mixing oat grains or oat powder with water to obtain oat pulp and hydrolyzing the oat pulp through amylase and protease. The process of hydrolyzing the oat pulp through the amylase and the protease is finished in one step. The beverage is good in flavor and the production method of the beverage is easy to implement industrially.

Owner:DSM IP ASSETS BV

Preparation method of molecular sieve catalyst

InactiveCN102049302AEasy to operateEasy industrial scale-upMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsChemistryMolecular sieve

The invention discloses a preparation method of a molecular sieve catalyst. The preparation method is characterized in that a molecular sieve with a crystallized aluminosilicate structure is subjected to acid pickling treatment and surface silanization treatment. With the method, the pore structure and the acid property of the molecular sieve can be effectively adjusted; and when used for converting methanol and dimethyl ether into gasoline components, the invention is favored to improve the selectivity of the gasoline components in the process of converting into hydrocarbon reactions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Carbonyl reductase, gene and applications of carbonyl reductase in asymmetric reduction of prochiral carbonyl compound

ActiveCN102876734AIncrease concentrationHigh optical purityMicroorganism based processesOxidoreductasesCarbonyl groupMutant

The invention discloses applications of carbonyl reductase being as a catalyst in the preparation of chiral alcohol by asymmetric reduction of a prochiral carbonyl compound, and a gene, protein and a mutant of the carbonyl reductase. The invention also provides a recombinant expression vector and a recombinant expression transformant containing the gene of the carbonyl reductase. When the carbonyl reductase disclosed by the invention is utilized for catalyzing the asymmetric reduction reaction of the prochiral carbonyl compound, the reaction conditions of the asymmetric reduction are moderate, the operation process is simple and convenient, and the amplification is easy; and the chiral alcohol product prepared by the asymmetric reduction reaction is high in concentration and optical purity. Therefore, the carbonyl reductase has a good industrial application and development prospect in the preparation of the optically pure chiral alcohol.

Owner:EAST CHINA UNIV OF SCI & TECH

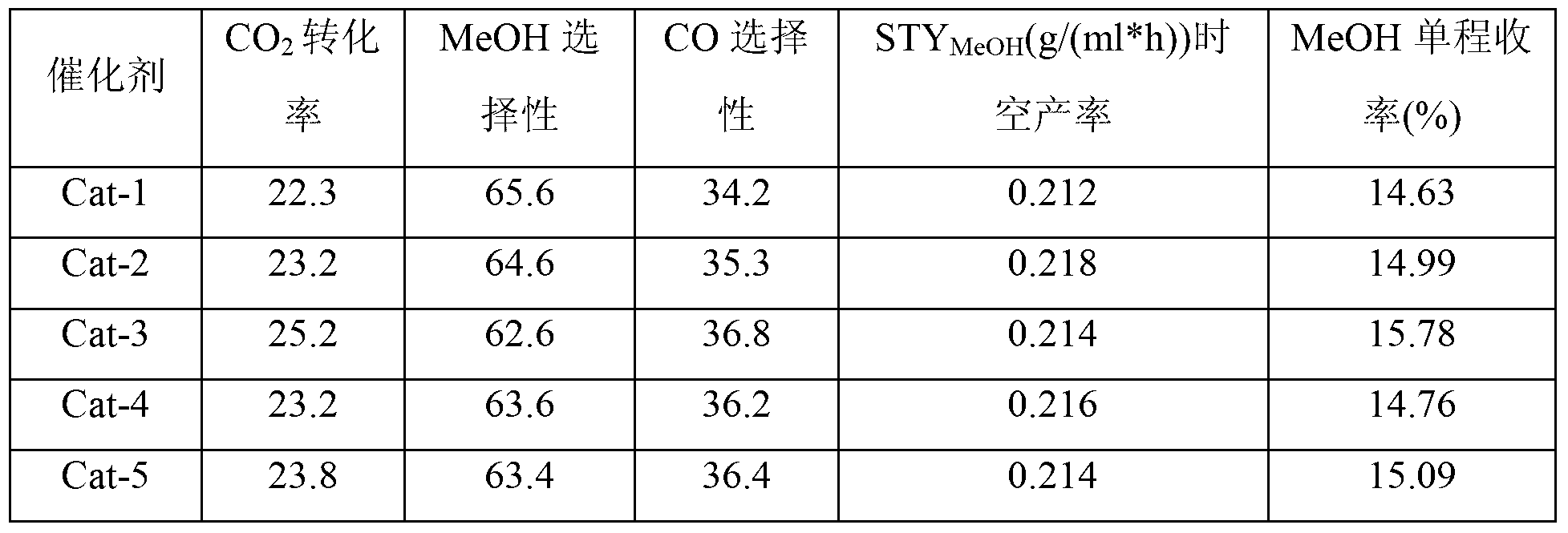

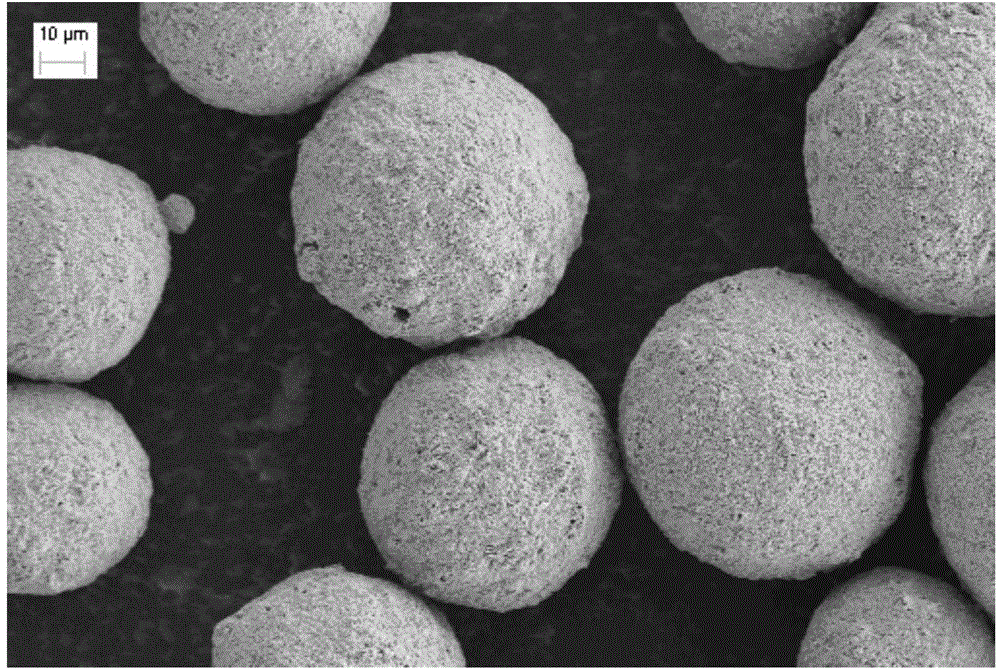

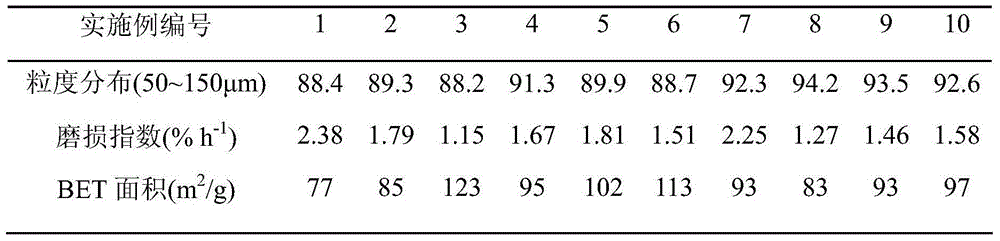

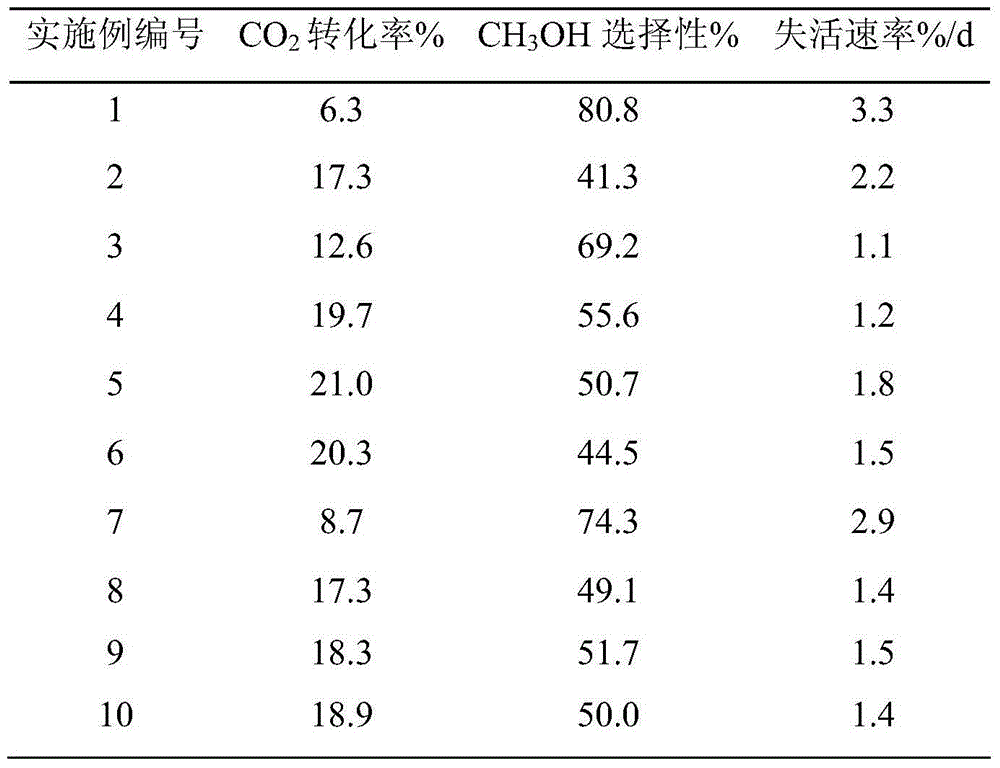

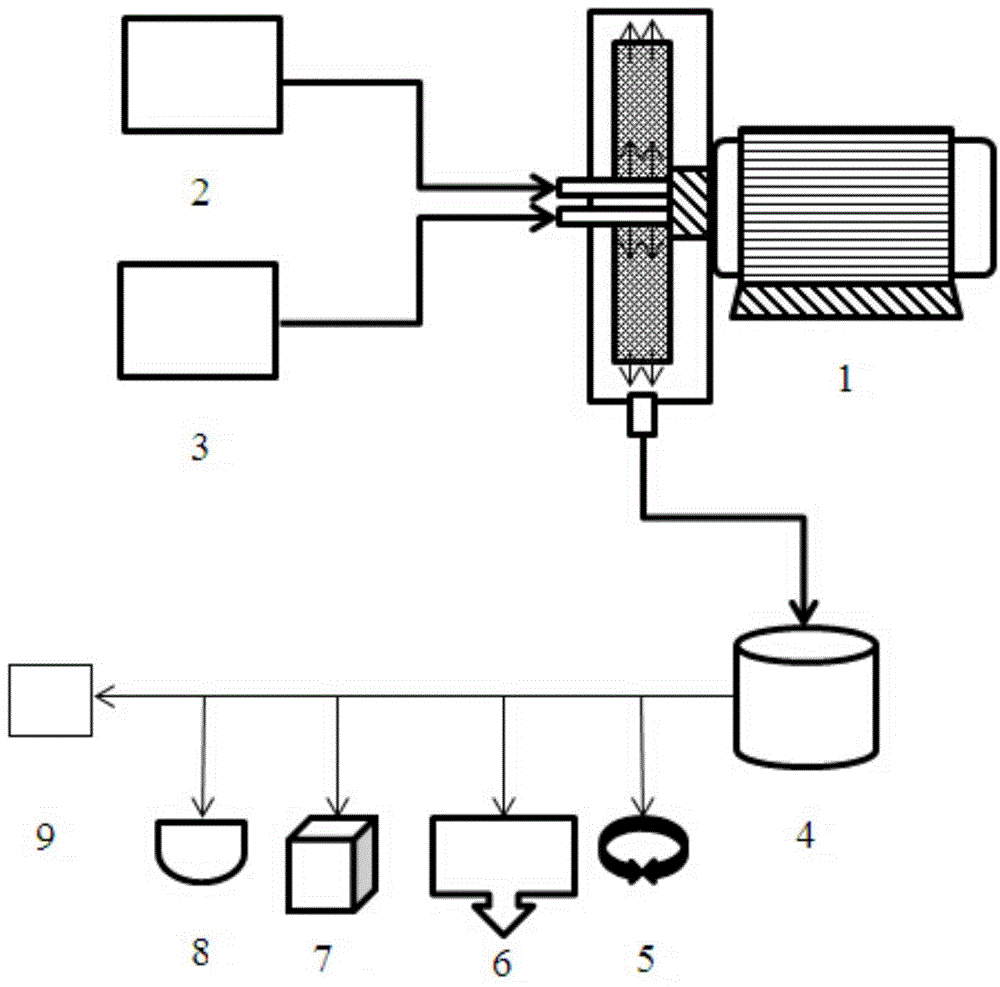

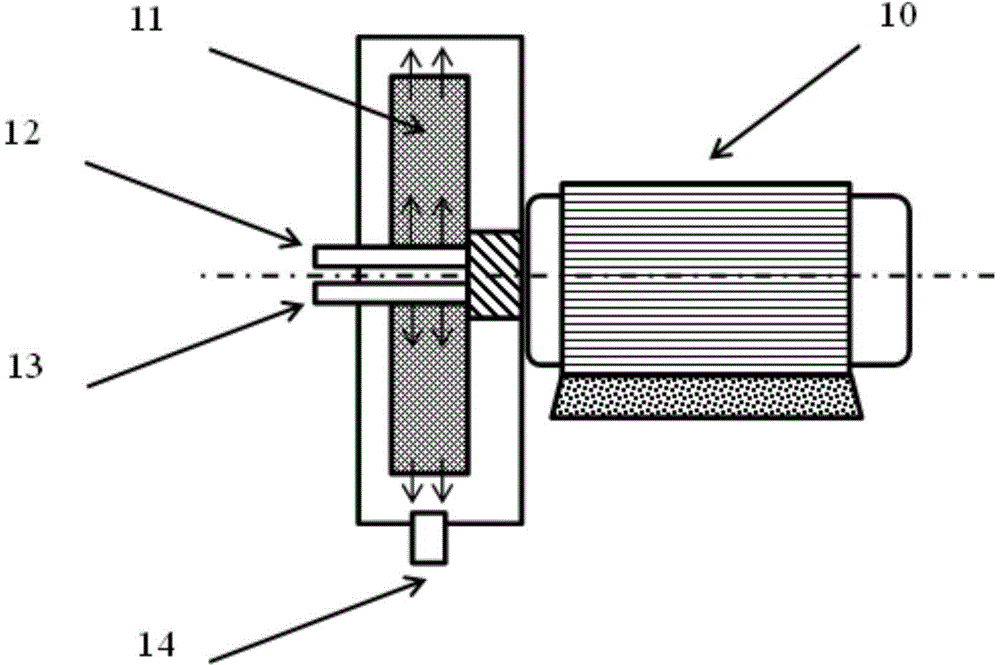

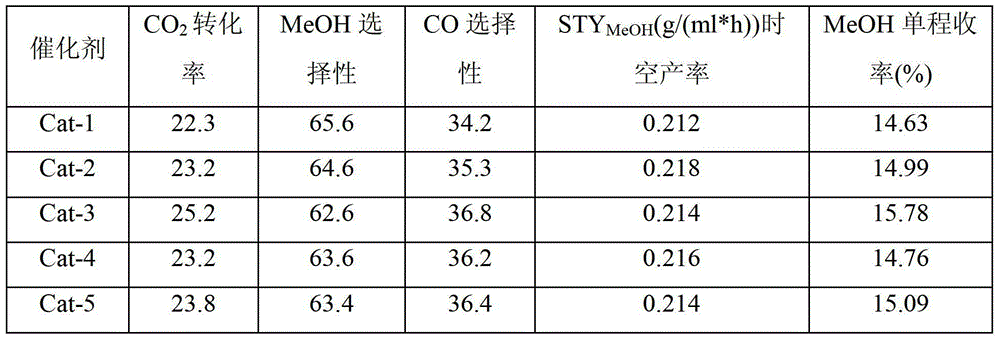

Catalyst for methanol synthesis via CO2 hydrogenation on slurry bed reactor, preparation method and application

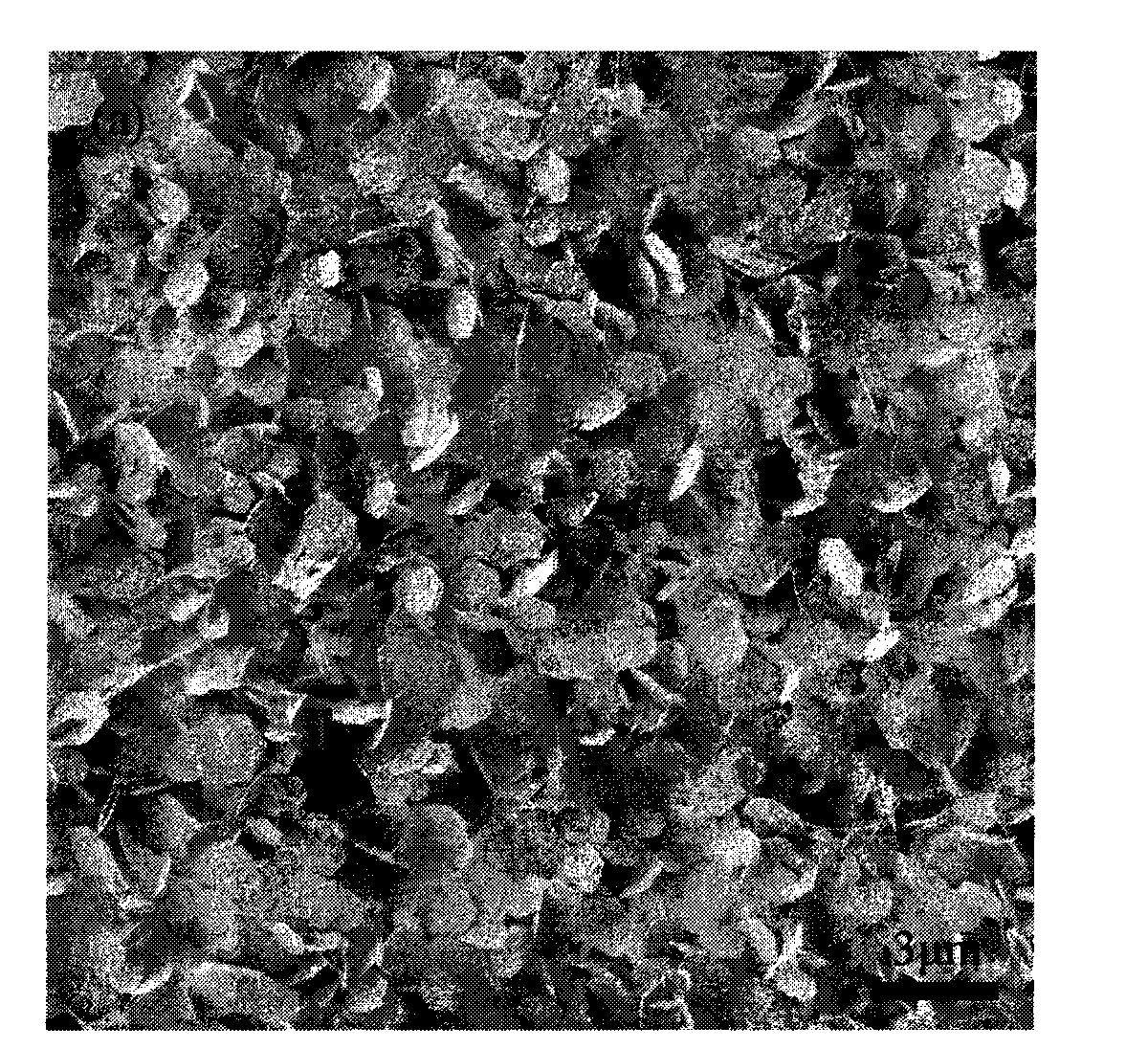

InactiveCN104959143AUniform particle size distributionLarge specific surface areaOrganic compound preparationHydroxy compound preparationHydrogenation reactionSlurry

The invention provides a catalyst for methanol synthesis via CO2 hydrogenation on a slurry bed reaction. The catalyst comprises the following components in percentage by weight: 30%-50% of CuO, 15%-30% of ZnO, 10%-25% of Al2O3, 2%-10% of transition metal oxides and 5%-40% of structural promoters. The catalyst has the advantages that the degree of sphericity of particles is high, the particles are distributed uniformly, the specific surface area is large, the wear resistance is high, the service life is long, the performance of the catalyst is stable in CO2 hydrogenation reaction, low-temperature activity, transformation activity and selectivity are high, the catalyst can be operated at low temperature ranging from 180-220 DEG C, the cost is low, and the catalyst is easy and convenient to prepare and can be industrially amplified easily. The CO2 single-pass conversion rate of the catalyst can be high at the temperature of 220 DEG C, and the wear resistance of the catalyst is quite high.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Method for preparing nanometer barium sulfate by using molecule mixing strengthening reactor

ActiveCN105329930ASmall particle sizeIncrease the nucleation rateMaterial nanotechnologyCalcium/strontium/barium sulfatesSulfateBarium salt

The invention discloses a method for preparing nanometer barium sulfate by using a molecule mixing strengthening reactor. A barium salt solution and dilute sulphuric acid or a sulphate solution are added into the molecule mixing strengthening reactor for reaction, after reaction, a barium sulfate suspending liquid is obtained; the molecule mixing strengthening reactor is a hypergravity rotating packed bed reactor or a tube-in-tube microchannel reactor; aftertreatment for the obtained barium sulfate suspending liquid is carried out, and nanometer barium sulfate powder is obtained. The hypergravity rotating packed bed reactor or the tube-in-tube microchannel reactor has the advantages of simultaneous control of reaction temperature, concentration of reaction solution, injection rate and injection speed ratio, and requirements of reaction product nanometer barium sulfate obtained finally, such as particle sizes (all smaller than 30nm) are smallest and distribution is narrowest, are met.

Owner:BEIJING UNIV OF CHEM TECH

Catalytic conversion method of ketone and alcohol

ActiveCN102408305AReduce generationHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlkaneHydrogen atmosphere

The invention discloses a method for producing an alcohol by hydrogenizing a ketone or producing a ketone by dehydrogenizing an alcohol. In order to meet the two requirements that the selectivity of the reaction for producing the alcohol by hydrogenizing the ketone or producing the ketone by dehydrogenizing the alcohol can be increased and the service life of a catalyst can be prolonged, the ketone or alcohol is used as a raw material to contact a hydrogenation catalyst in a hydrogen atmosphere, and catalytic conversion is performed to obtain the corresponding alcohol or ketone, wherein the catalyst comprises a carrier, a metal active component and a silane group, the metal active component is one or more of nickel, cobalt and copper, the silane group of the catalyst is grafted through silylation treatment and the silane group accounts for 0.05wt%-25wt% of the total weight of the catalyst. Compared with the existing catalyst, the catalyst has high selectivity; the yield of by-products, namely ether, olefin, alkane and ketal is greatly reduced; and the amount of deposited carbon is low and the catalyst has longer service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel hydrophilic hollow fiber membrane preparation method

The invention discloses a novel hydrophilic hollow fiber membrane preparation method, which comprises the following steps: firstly polyvinylpyrrolidone (PVP) is subjected to hydrolytic treatment to obtain partially hydrolyzed modified PVP; then the obtained modified PVP is blended with a polymer material, and the immersion and sedimentation method is adopted to prepare a hollow fiber membrane; finally a cross-linking agent is adopted to perform cross linking on the hollow fiber membrane after membrane forming so as to obtain a hydrophilic hollow fiber membrane with a cross-linking structure. According to the method, the reaction condition is mild and easy to control, and the operation is simple, convenient and safe; the modified raw materials are convenient and easy to obtain, and are low in cost; the stability of a hydrophilic modifier in the hollow fiber membrane is greatly improved after cross linking, and the hydrophilicity of the hollow fiber membrane is improved.

Owner:DALIAN TINSING TECH

Method of synthesizing methyl carbamate

InactiveCN1475481AGood performance repeatabilityHigh selectivityCarbamic acid derivatives preparationOrganic compound preparationMethyl carbamateAmmonia gas

A process for synthesizing methyl aminoformate includes the catalytic reaction between methanol, urea and catalyst at 120-200 deg.C, under 0.1-3 MPa for 0.5-20 hr and condensing and recovering ammonia gas. Its advantages are low cost and high selectivity to product.

Owner:PETROCHINA CO LTD +1

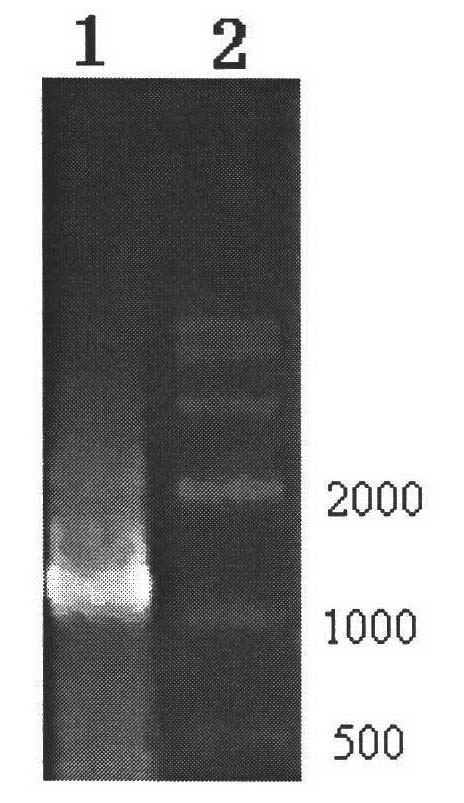

Nitrilase and gene and application thereof

The invention discloses a new nitrilase and gene thereof, a recombinant expression vector and a recombinant expression transformant containing the gene, a method for preparing the recombinant nitrilase or microbial cell containing the recombinant nitrilase by use of the recombinant expression transformant, and application of the microbial cell in dehydrating ortho-chlorine mandelonitrile or other analogues and producing chiral ortho-chlorine mandelonitrile or other analogues. The recombinant nitrilase disclosed by the invention comes from Labrenzia aggregate and can be used as a catalyst for dehydrating and splitting ortho-chlorine mandelonitrile or other analogues; and the recombinant nitrilase has the advantages of high catalysis efficiency, strong enantioselectivity, mild reaction conditions, environmental friendliness and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

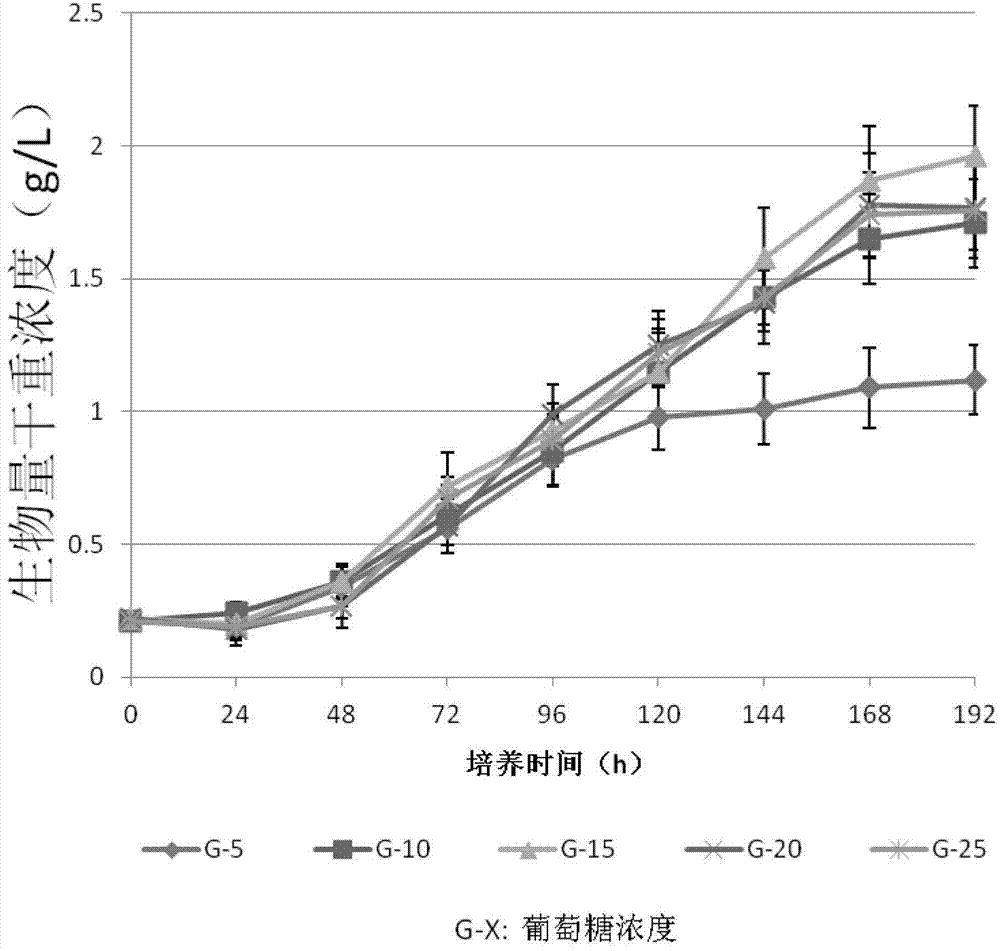

Culture method for increasing yield of fucoxanthin contained in diatom

ActiveCN103396979AIncrease productivityIncrease contentElectrical/wave energy microorganism treatmentElectrical/wave energy enzyme treatmentFucoxanthinCulture vessel

The invention provides a culture method for increasing the yield of fucoxanthin contained in diatom. The culture method comprises the following steps of: (1) heterotrophically culturing activated diatom for 3-8 days so that the diatom is in a logarithmic growth period; (2) inoculating a diatom culture solution obtained from the step (1) in the logarithmic growth period as a seed solution into a heterotrophic culture vessel which contains a heterotrophic culture medium (culture medium I) according to 5%-50% volume of inoculation amount to carry out heterotrophic culture for 4-12 days at the temperature of 20-34 DEG C, wherein tomato extractives are added to the heterotrophic culture medium (culture medium I) obtained from the step (2). The culture method provided by the invention can enhance the biomass concentration of the diatom and increase the fucoxanthin content of a stable diatom body, thereby increasing the yield of the fucoxanthin contained in the diatom.

Owner:SOUTH CHINA UNIV OF TECH

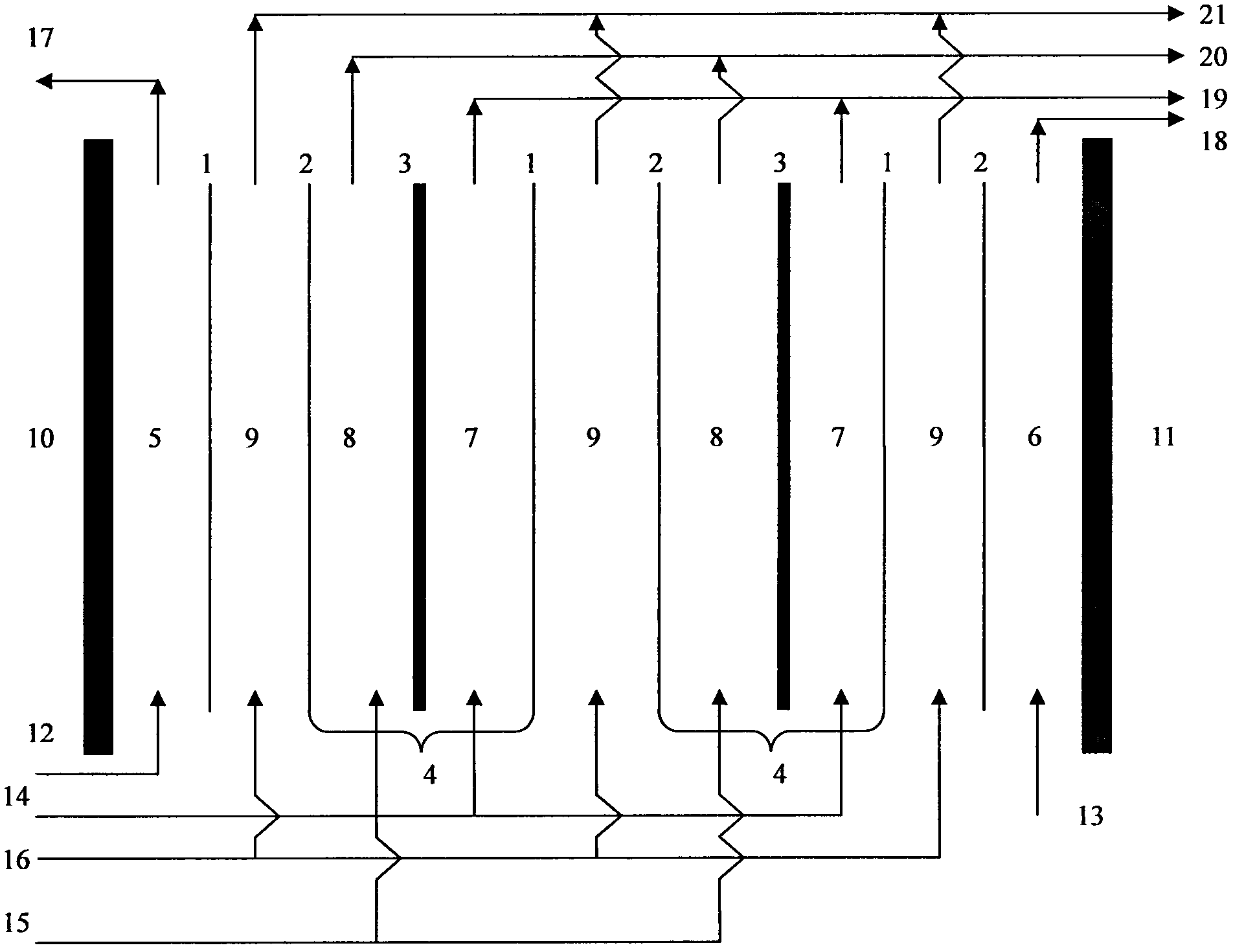

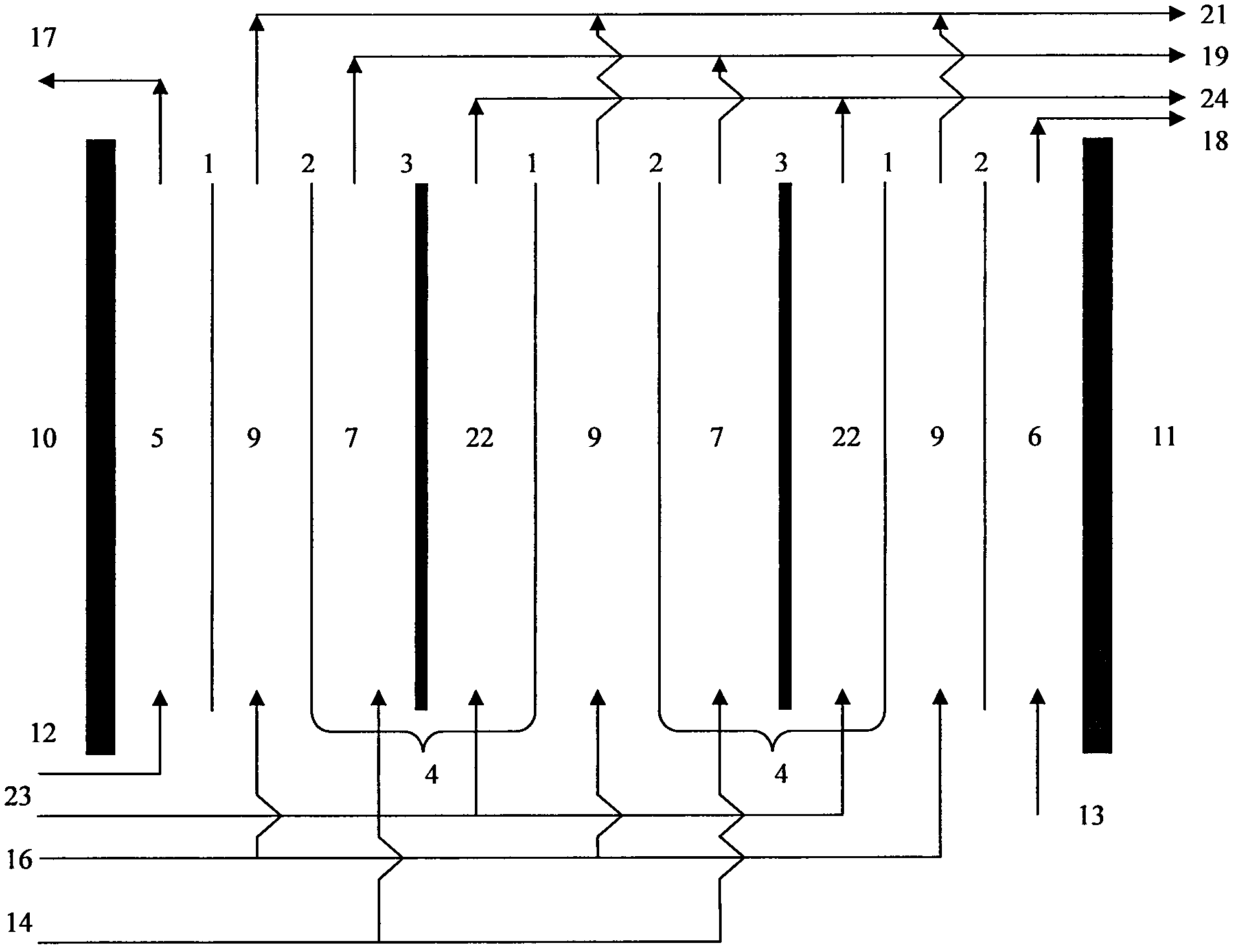

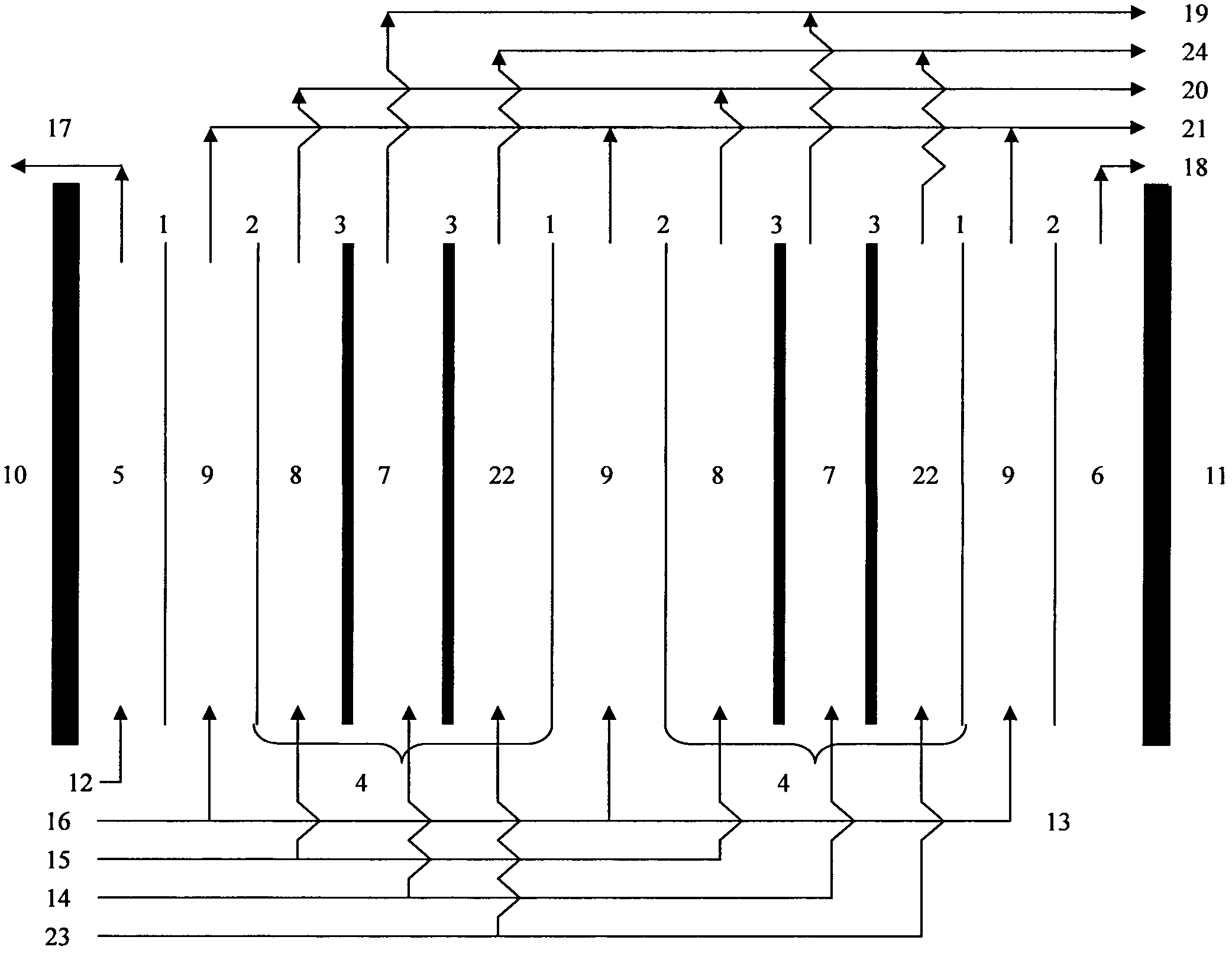

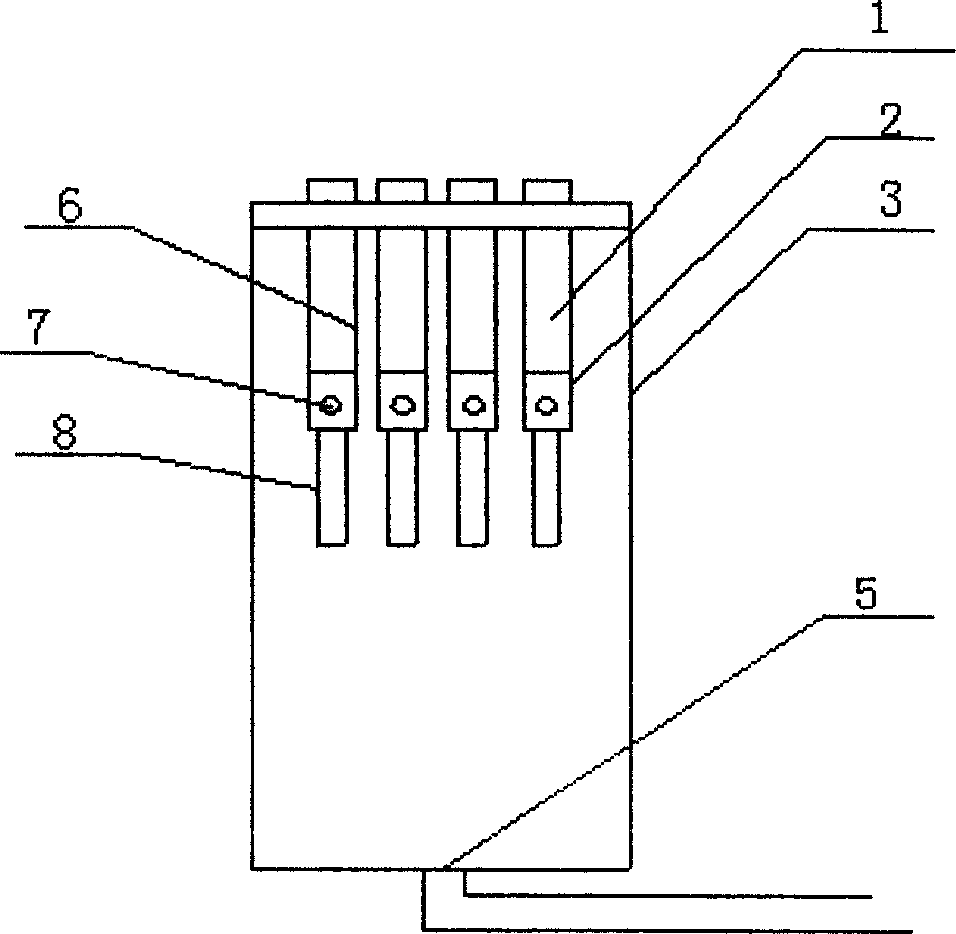

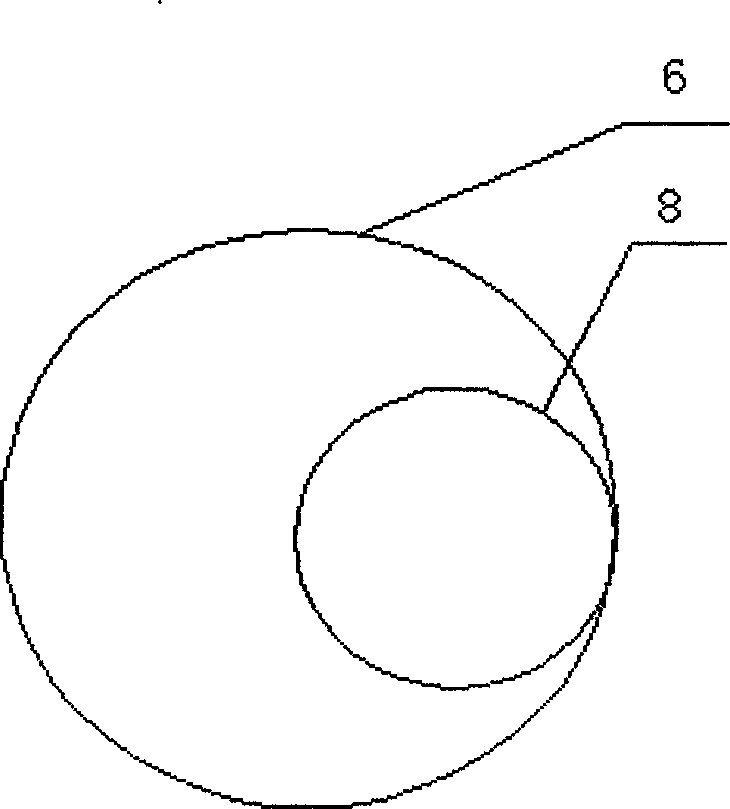

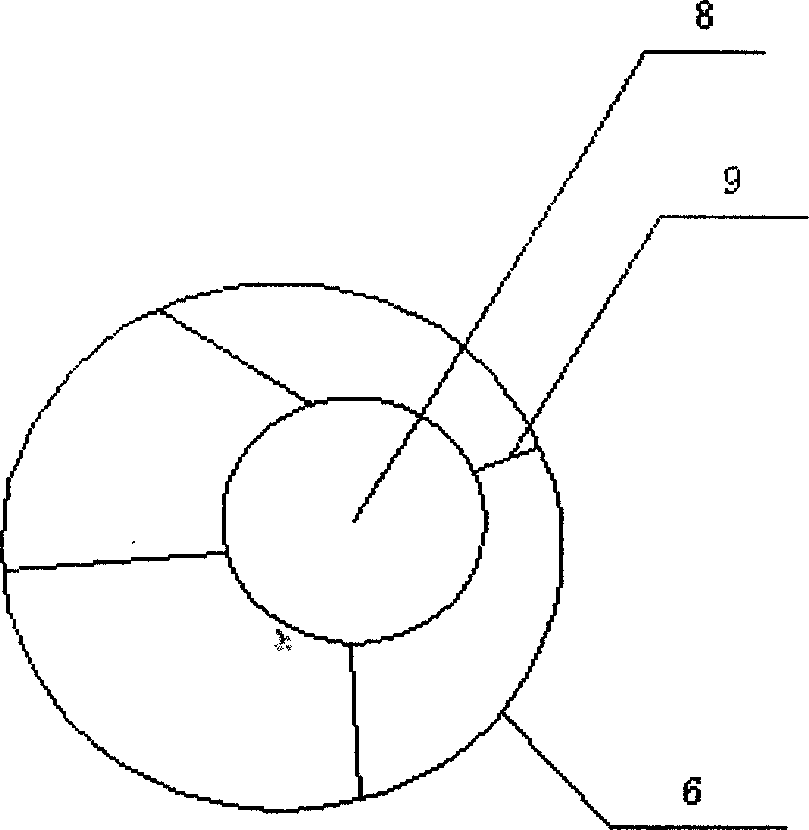

Uniform phase distribution device in liquid contained multiphase fluidized system

A uniform phase-distributing apparatus in the liquid-contained multi-phase fluidizing system where the density of solid phase is higher than that of liquid phase features that the material feeding inlet is arranged on the bottom of case, the sleeve pipe structure consisting of at least two nested pipes is arranged on the top of case, and the predistributor and master distributor are used. Its advantage is stable fluidizing state.

Owner:TIANJIN UNIV

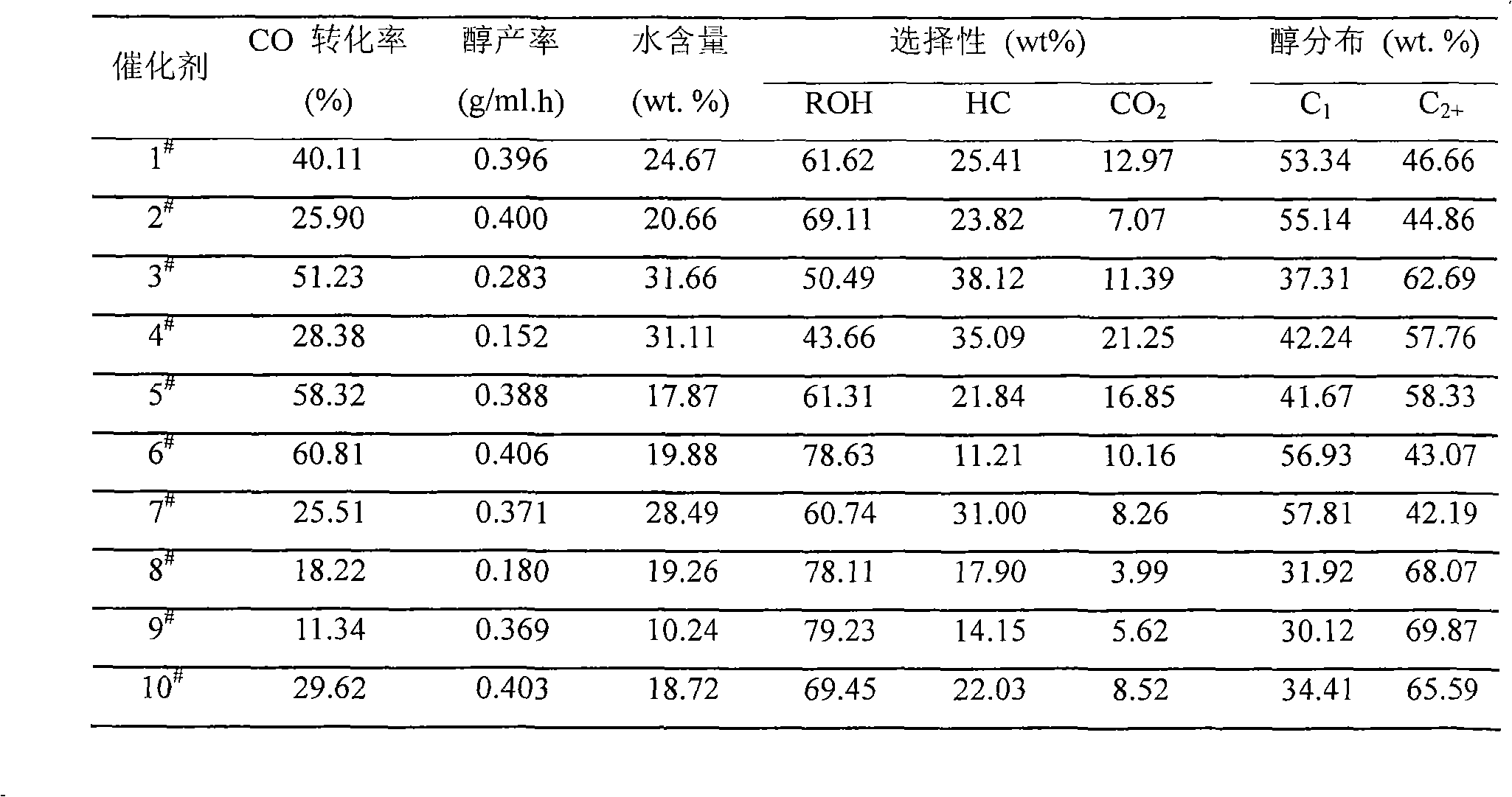

Iron-copper based catalyst for synthesizing low carbon mixed alcohol and production method and use

InactiveCN101327435AEasy to prepareEasy to operateOrganic compound preparationHydroxy compound preparationAlcoholCoprecipitation

The present invention relates to an iron-copper base catalyst synthesizing mixture of lower alcohols. In weight percentage, the iron-copper base catalyst consists of 20 percent to 60 percent of Cu, 15 percent to 60 percent of Fe, 0.4 percent to 20 percent of Mn, 0.4 percent to 30 percent of Zn and 0 percent to 5 percent of MA. The catalyst is prepared by a coprecipitation method. The iron-copper base catalyst has the advantages of simple preparation, easy operation, good reaction performance repeatability of the catalyst, realizing industrial amplification easily, good stability and high total alcohol selectivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Extraction device and method

ActiveCN106139638AReduce backmixingSolve the problem of strong stirring and mixing extractionLiquid solutions solvent extractionProcess efficiency improvementGas phaseEngineering

The invention provides an extraction device and method. A mixed settler extractor comprises a mixing chamber, an organic liquid film generator, a gas-liquid separation device and a liquid-liquid coalescence separation device. The mixing chamber is provided with a heavy phase input port and a first heavy phase discharge port. The organic liquid film generator is connected with the mixing chamber and provided with a light phase input port and a gas inlet. The gas-liquid separation device is connected with the mixing chamber. The liquid-liquid coalescence separation device is connected with the gas-liquid separation device and provided with a liquid inlet, a first light phase discharge port and a second heavy phase discharge port. The extraction device can be provided with no clarifying chamber, the integrated structure of the mixing chamber and the clarifying chamber is well achieved, the problem of heavy phase liquid distribution uniformity of a mixing chamber and the problem about light phase, heavy phase and gas phase separation of the mixing chamber are solved, the occupied area is small, energy consumption is low, a high-flow water solution containing a to-be-separated target object can be treated, and back-mixing of a high-position extraction tower can be relieved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Regeneration method of copper, ruthenium, cobalt, nickel, palladium and platinum-based metal catalysts

ActiveCN102407169AHigh yieldSuppress generationMolecular sieve catalystsOrganic compound preparationPlatinumRuthenium

The invention relates to a regeneration method of copper, ruthenium, cobalt, nickel, palladium and platinum-based metal catalysts. In order to reduce the carbon deposition rate of a regenerated catalyst and prolong the service life of the regenerated catalyst, the invention provides a method. The method comprises the following steps: removing deposited carbon of the catalyst, activating and carrying out silanization treatment. Compared with the existing catalyst regeneration method, the method has the advantages that the yield of target products (the obtained catalyst) is high, and the amountof byproducts generated due to nonmetal catalysis is greatly reduced; the amount of carbon generated on the surface of the catalyst is low, and the catalyst has longer service life; and the influenceof the water content on the catalyst is reduced. The regeneration method is simple to operate, and has lower cost increase compared with that in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

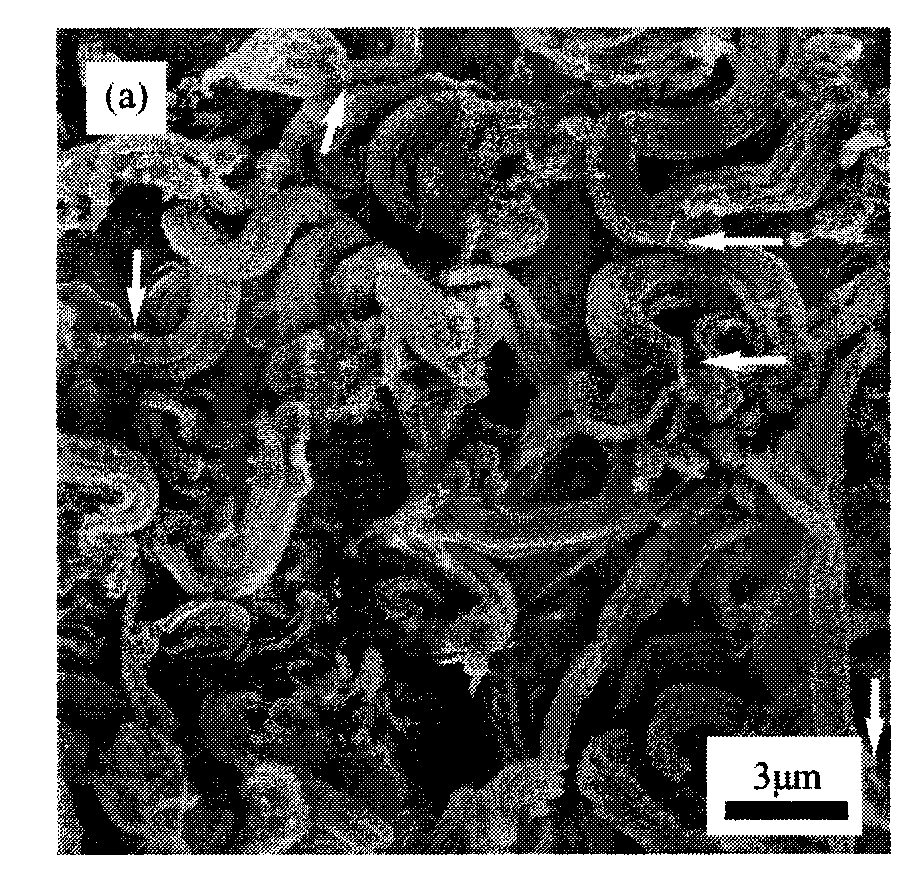

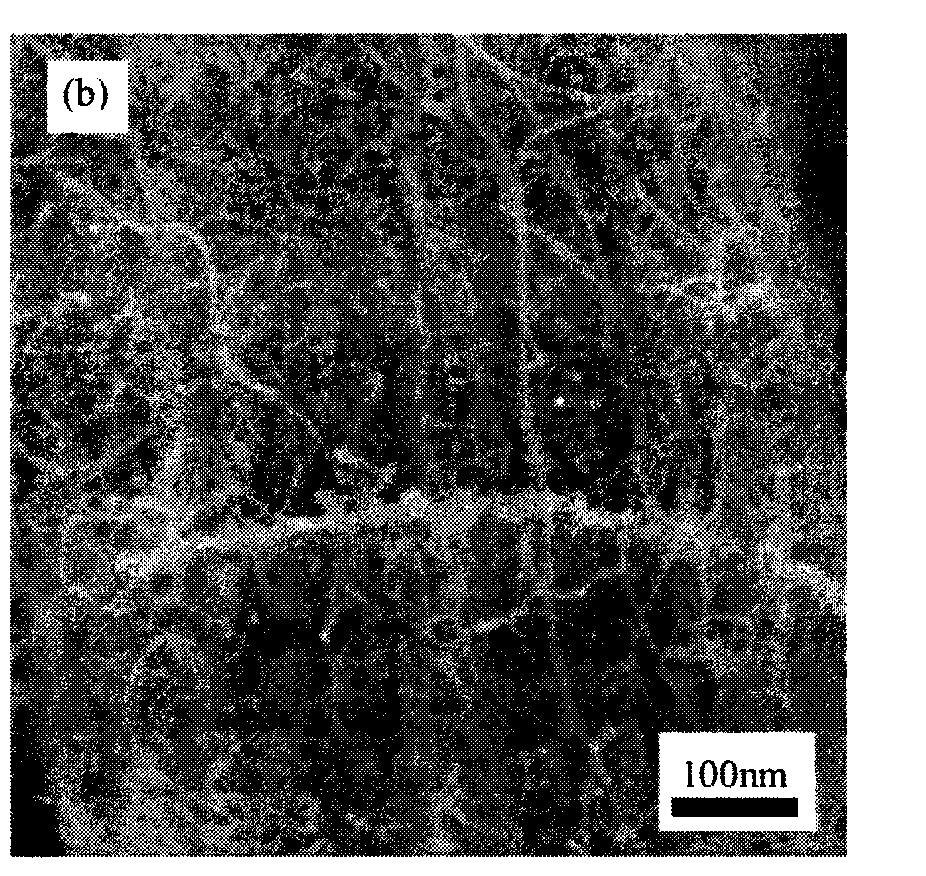

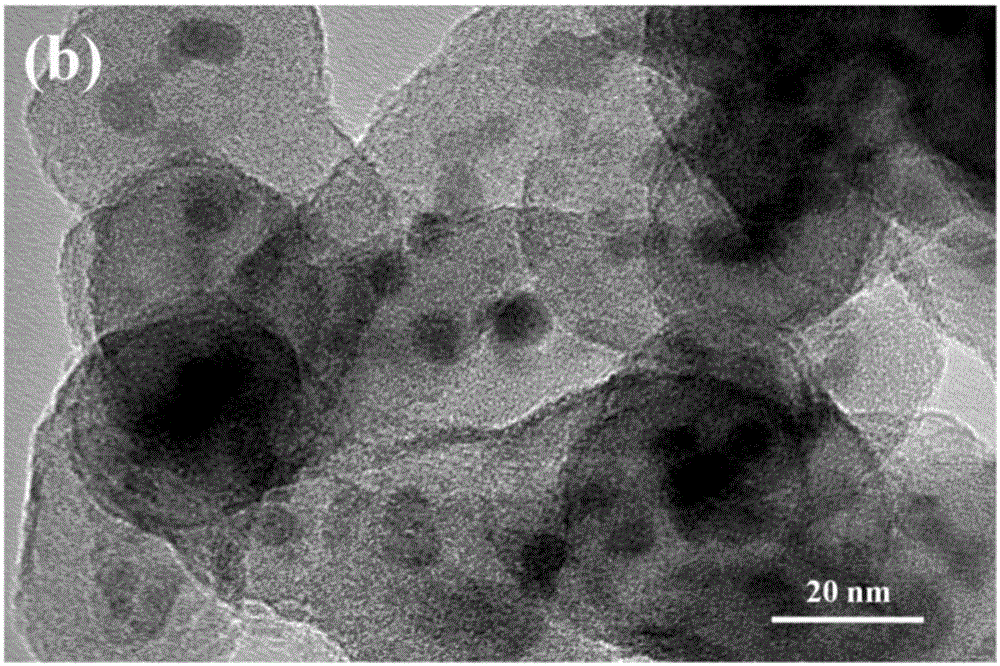

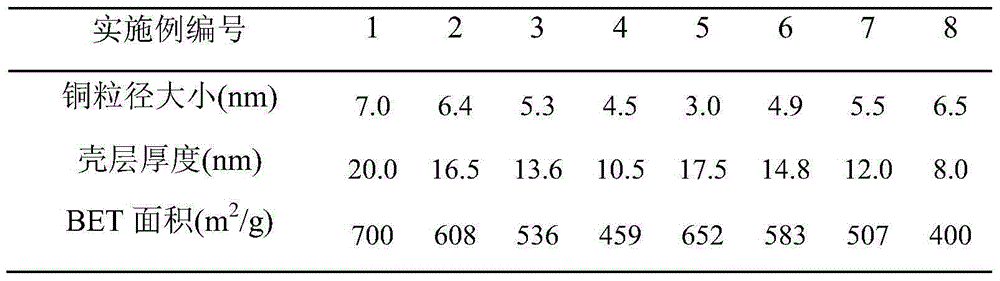

Core-shell structure type copper-based catalyst as well as preparation method and application thereof

ActiveCN105170151AUniform particle size distributionGood dispersionOrganic compound preparationHydroxy compound preparationHydrogenation reactionCopper

The invention provides a core-shell structure type copper-based catalyst as well as a preparation method and application thereof. The catalyst takes Cu as a core and takes mesoporous SiO2 as a shell layer material, the weight percentage of Cu is 8-25%, and the weight percentage of SiO2 is 75-92%. The core-shell structure type nano-composite catalyst material is uniform in grain distribution, adjustable in size, good in dispersibility, small in inner core copper grain, large in specific surface area, good in stability performance, and long in service life; in CO2 hydrogenation reaction operation, the catalyst is stable in performance, and high in activity, and can be operated at a high temperature (240-300 DEG C); the high CO2 conversion per pass can be still kept after long period evaluation, and the core-shell structure type copper-based catalyst has the advantages of being low in cost, easy to operate, easy to enlarge in industry and the like.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

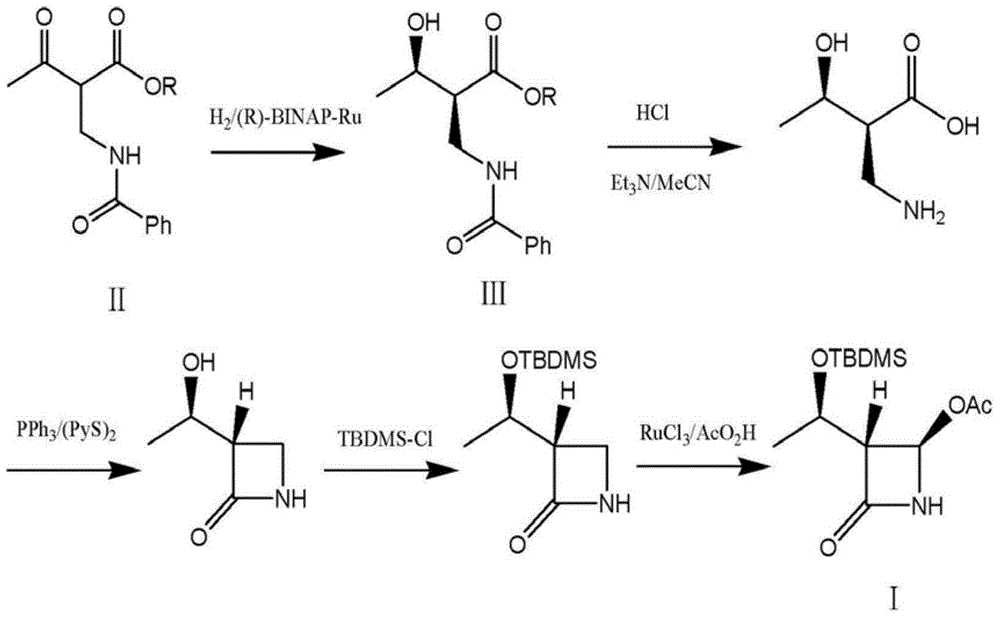

Aldo-keto reductase and application thereof in synthesis of (2S,3R)-2-benzoylaminomethyl-3-hydroxybutyrate

ActiveCN105624125AHigh optical purityMild reaction conditionsBacteriaMicroorganism based processesHigh concentrationMethyl palmoxirate

The invention provides a new aldo-keto reductase mutant and a method using the recombinant aldo-keto reductase mutant or a lyophilized powder thereof to carry out asymmetric reduction. When the new aldo-keto reductase is used to catalyze a substrate with the concentration reaching up to 1000g / L, the optical purity of products still reaches up to 98% or above, and extra addition of an expensive coenzyme is avoided. Compared with other asymmetric reduction preparation methods, a method using the aldo-keto reductase has the advantages of high concentration of the products, high optical purity of the products, mild reaction conditions, environmental protection, simple operation and easy industrial amplification, so the aldo-keto reductase has very good industrial application prospect.

Owner:弈柯莱生物科技(集团)股份有限公司

Solid phase extraction method for extracting total astaxanthin from haematococcus pluvialis

InactiveCN102659652AReduce consumptionReduce pollutionOrganic chemistryNatural dyesDistillationOrganosolv

The invention provides a solid phase extraction method for extracting total astaxanthin from haematococcus pluvialis, comprising the following steps of: (1) solid extraction: uniformly mixing haematococcus pluvialis with silica gel at the weight ratio of 1:1-5:1, adding 1-5mL of methanol, 10-20mL of petroleum ether and 1-5mL of methylene chloride into 10g of haematococcus pluvialis, stirring and extracting for 0.1-1h, and putting the extracted mixture into a chromatography column; (2) elution: carrying out elution by the use of methanol and collecting a red eluant part; and (3) condensation: carrying out underpressure distillation on the red eluant part to obtain a dark red astaxanthin oily liquid. The solid extraction method provided by the invention has advantages of simple operation step, short time, high recovery rate, low consumption of the organic solvent, little environmental pollution and low production cost, and is easy for industrial scale-up.

Owner:NORTHWEST A & F UNIV

Method for removing alkine and dialkene from pyrolysis gas through selective hydrogenation

ActiveCN102408916AImprove applicabilityReduced responseOrganic-compounds/hydrides/coordination-complexes catalystsGaseous mixture working upSilanesSilylation

The invention discloses a method for removing dialkene and alkine from pyrolysis gas through selective hydrogenation, belonging to the hydrogenation field. In order to satisfy the adaptability of catalyst performance to small water content or fluctuant water content in raw material in the selective hydrogenation reaction process of the pyrolysis gas and the inhibition on the generation of carbon deposition, the invention is characterized in that the pyrolysis gas used as the raw material is in contact with a hydrogenation catalyst under the conditions that the temperature is 15-150 DEG C, the pressure is 0.1-5.0 Mpa and the gas hourly space velocity of the pyrolysis gas is 500-20000h<-1>; and alkine and dialkene are changed into alkene through selective hydrogenation, wherein the hydrogenation catalyst contains a carrier, a metal active component palladium and a silane group, and the silane group is subjected to silylation and grafting and has a content of 0.05-25wt%. Compared with the existing method, the method disclosed by the invention ensures that the reaction performance can not be changed obviously when the hydrogenated raw material contains small water content and the reaction performance can be kept basically stable when the hydrogenated raw material contains fluctuant water content; and meanwhile, only a small amount of carbon deposition is generated on the catalyst, thereby ensuring that the catalyst has a longer service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Copper based catalyst used for hydrogenating carbon dioxide to synthesize methanol, and preparation method and application thereof

ActiveCN103272607BEvenly dispersedSmall particle sizeOrganic compound preparationHydroxy compound preparationZinc saltsCarbonate

The invention discloses a copper based catalyst used for hydrogenating carbon dioxide to synthesize methanol, and a preparation method and an application thereof. The preparation method of the catalyst comprises the following steps: 1, processing a zinc salt, an aluminum salt, a zirconium salt and a stabilizer to prepare a first solution, or processing the zinc salt, the aluminum salt and the zirconium salt to prepare a second solution; 2, processing carbonate and hydroxide to prepare a third solution; 3, processing a copper salt to prepare a fourth solution; 4, processing the first solution and the third solution to form a first precipitation solution, or processing the second solution and the third solution to form a second precipitation solution; 5, adding the fourth solution to the first precipitation solution to form a third precipitation solution or adding the fourth solution to the second precipitation solution to form a fourth precipitation solution, ageing after Cu in the precipitation solution precipitates, and washing; and 6, drying, and calcining. The catalyst contains 30-50% of Cu, 20-40% of Zn, 10-20% of Al, and 5-20% of Zr. The catalyst is used for a reaction for hydrogenating carbon dioxide to synthesize methanol.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com