Unsaturated hydrocarbon hydrogenation catalyst and application thereof

A hydrogenation catalyst, unsaturated technology, used in molecular sieve catalysts, purification/separation of hydrocarbons, catalyst activation/preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

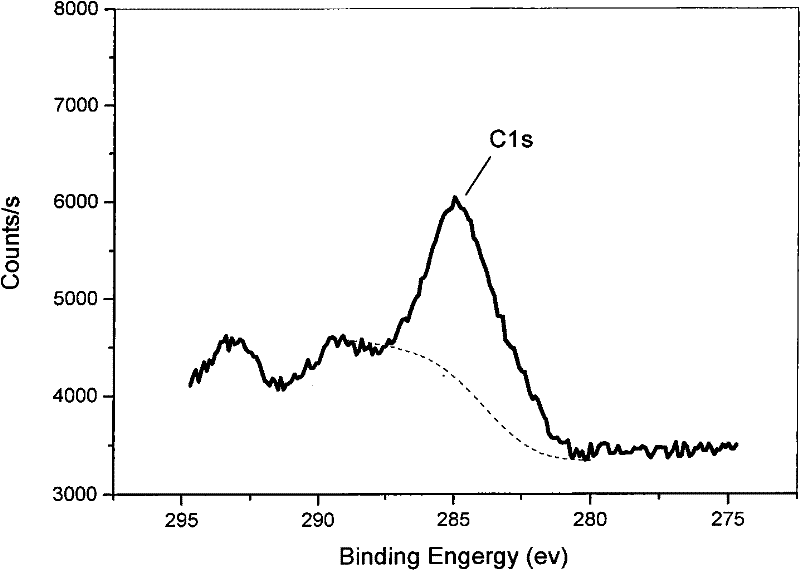

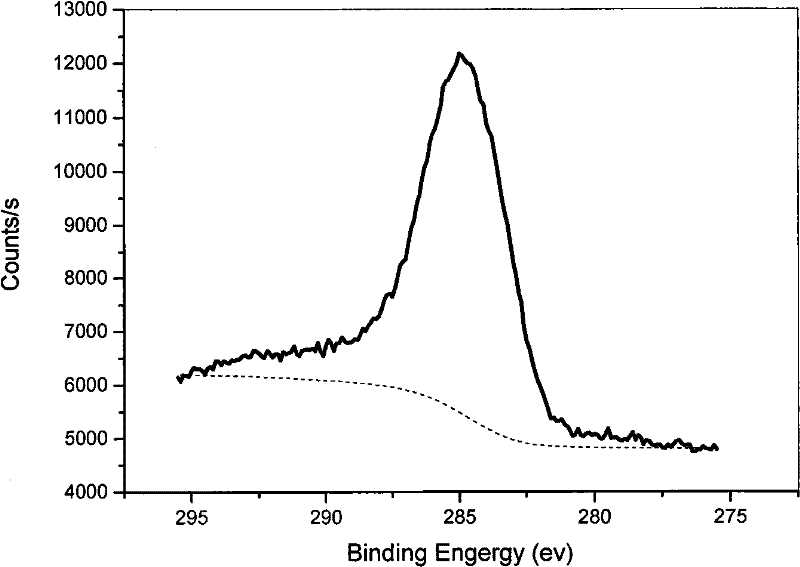

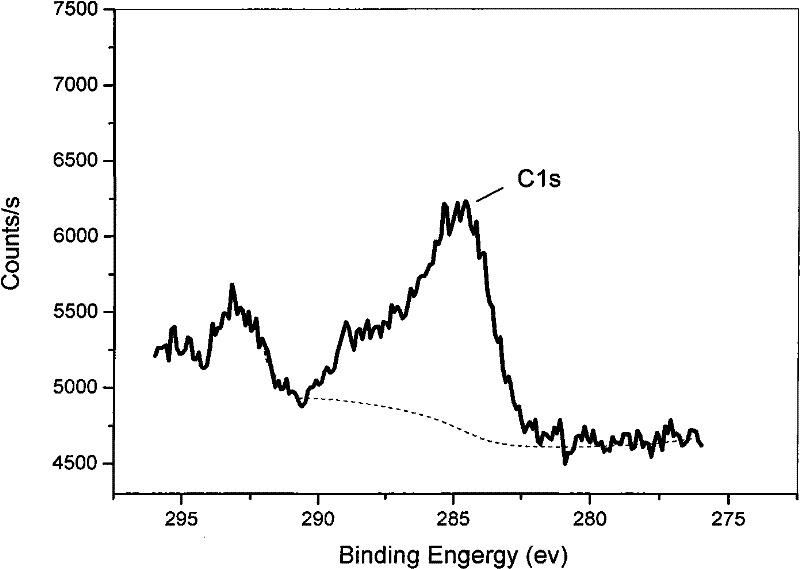

Image

Examples

Embodiment 1

[0063] Take a spherical Ni-Mg / Al with a diameter of 3mm 2 o 3 50 grams of catalyst (produced by Beijing Research Institute of Chemical Industry, volume 72ml, the mass percents of Ni and Mg are respectively 12% and 2.2%, and the balance is Al 2 o 3 ; When the temperature rises to 500°C on the thermogravimetric analyzer, the weight loss is 2.8wt%; the specific surface area is 113m 2 / g, pore volume 0.62ml / g, average pore diameter 11.8nm, wherein the pores greater than 9nm account for 69% of the pore volume, and the pores less than 5nm account for 10% of the pore volume), the catalyst is packed into a fixed bed reactor (diameter 15mm, length 400mm, with two temperature display control points). After the temperature of the reactor is stabilized at 80°C, the hydrogen containing 2vol% trimethylethoxyalkane is passed into the reactor, the flow rate is controlled at 300ml / min, 80°C is maintained for 2h, and then the temperature is raised to 120°C, and the temperature is stable Aft...

Embodiment 2

[0069] Take a strip-shaped Pd-Ca / Al with a diameter of 1.5mm and a length of 1.5-5.0mm 2 o 3 -SiO 2 30 grams of catalyst (produced by Beijing Research Institute of Chemical Industry, volume 35ml, the mass percentages of Pd and Ca are respectively 0.08% and 0.5%, and the balance is Al 2 o 3 -SiO 2 , when the temperature rises to 300°C on the thermogravimetric analyzer, the weight loss is 0.9wt%; the specific surface area is 56m 2 / g, pore volume 0.45ml / g, average pore diameter 20.7nm, wherein the pores greater than 9nm account for 83% of the pore volume, and the pores less than 5nm account for 2% of the pore volume), the catalyst is packed in a 500ml there-necked flask, One of the three-neck bottles is connected to the serpentine cooling, the other is connected to the temperature control display point, and the other is the feeding port. Put the three-necked flask into an oil bath at 110° C., pour 100 ml of p-xylene containing 1.0 wt % trimethylchlorosilane into it, keep the...

Embodiment 3

[0075] Take a strip of Pd-Ni-La-Mg / ZrO with a diameter of 3mm 2 -Al 2 o 3 25 grams of catalyst (produced by Beijing Research Institute of Chemical Industry, volume 41ml, the mass percentages of Pt, Ni, La and Mg are 0.02%, 5.0%, 0.8% and 2.8% respectively, and the balance is ZrO 2 -Al 2 o 3 , when the temperature rises to 500°C on the thermogravimetric analyzer, the weight loss is 1.8wt%; the specific surface area is 34m 2 / g, pore volume 0.51ml / g, average pore diameter 60.8nm, wherein the pores greater than 9nm account for 92% of the pore volume, and the pores less than 5nm account for 0.7% of the pore volume), the catalyst is packed in a 500ml three-necked bottle, three-necked The bottle is placed in an oil bath, and one port of the three-neck bottle is connected to a cooling coil, one port is connected to a thermometer, and the other port is connected to the feeding port. First, 150ml of p-xylene was poured into the three-necked flask, and after the temperature of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com