Patents

Literature

89results about How to "Achieve continuous separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wear-resistant super-hydrophobic super-lipophilic polyurethane sponge and preparation method and application thereof in oil-water continuous separation

ActiveCN105542221ASuperhydrophobicity unchangedLower surface energyNon-miscible liquid separationPolymer scienceOrganosolv

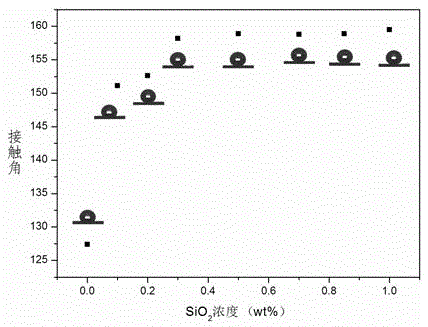

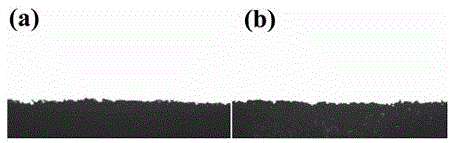

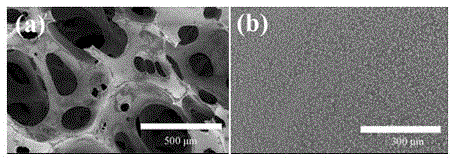

The present invention belongs to the technical field of functional materials, and in particular relates to a preparation method of a wear-resistant super-hydrophobic super-lipophilic polyurethane sponge, and the method comprises the following steps: 1) hydrophobic nano-silica and polydimethylsiloxane are uniformly dispersed in n-hexane or anhydrous ethanol to obtain a system A; 2) a cleaned polyurethane sponge is put into the system A obtained in the step 1) for soaking for 1-2h, then taken out, and put into a drying oven for drying to obtain the wear-resistant super-hydrophobic super-lipophilic polyurethane sponge. The preparation method is simple, through nano-silica / polydimethylsiloxane modifying, the surface energy of the polyurethane sponge can be reduced, the surface and bulk phase of the polyurethane sponge both can reach super-hydrophobic super-lipophilic functions. Surface contact angles of organic solvents such as paraffin oil, petrol, diesel oil, n-hexane, acetone and the like on the surface of the polyurethane sponge is 0 degree, and a surface contact angle of water on the polyurethane sponge is greater than 150 degree. The prepared polyurethane sponge has excellent wear resistance, is non-fluorinated and environmentally friendly, and can be used for continuous separation of an oil and water mixture.

Owner:HENAN UNIVERSITY

Device and method for refining and separating polyoxymethylene dimethyl ether containing formaldehyde

PendingCN107118083AReduce consumptionSolving Formaldehyde Polymerization ProblemsOrganic chemistryOrganic compound preparationPipingChemistry

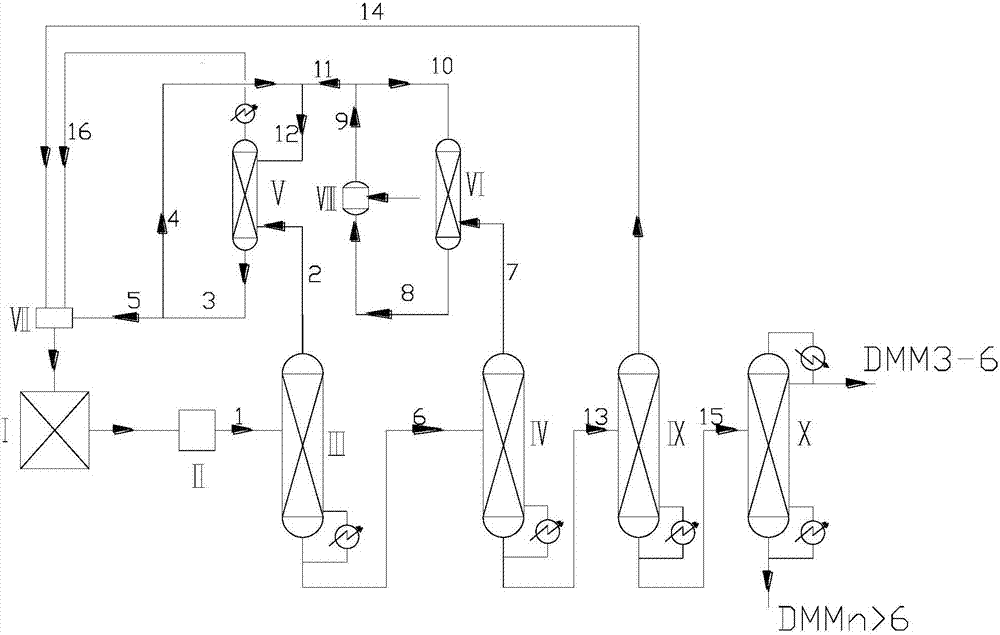

The invention relates to a device and a method for refining and separating polyoxymethylene dimethyl ether containing formaldehyde. The device mainly comprises a separation system and an elution and condensation circulating system. The separation system is mainly composed of a reaction unit (I), a deacidification device (II), a first normal-pressure fractionating column (III), a second normal-pressure fractionating column (IV), a vacuum distillation column (IX), a vacuum distillation column (X) and a dehydration device (VII); the elution and condensation circulating system comprises a first elution and absorption column (V), a second elution and absorption column (VI), an elution solution storage tank (III) and a related pipeline. According to the device and the method, provided by the invention, a separation-elution system is organically combined so that the problem that a condenser and a pipeline are blocked by formaldehyde polymerization in a process of separating a polyoxymethylene dimethyl ether product containing aldehyde is solved and the formaldehyde in the separated product can be 100 percent recycled; a continuous separation process, which takes DMM3-6 as a product, of the polyoxymethylene dimethyl ether product containing the formaldehyde is realized and energy saving and environment protection are saved.

Owner:TIANJIN UNIV

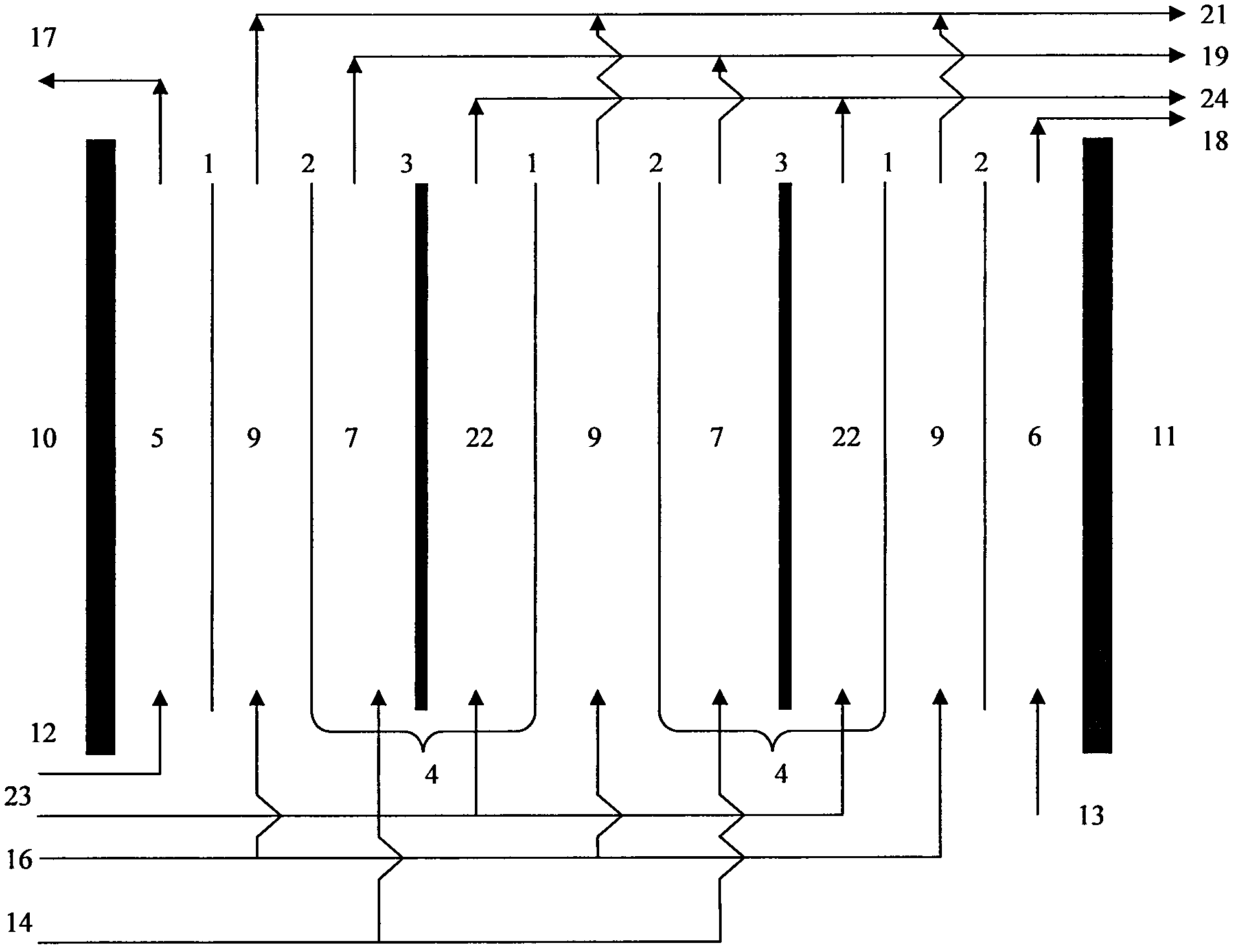

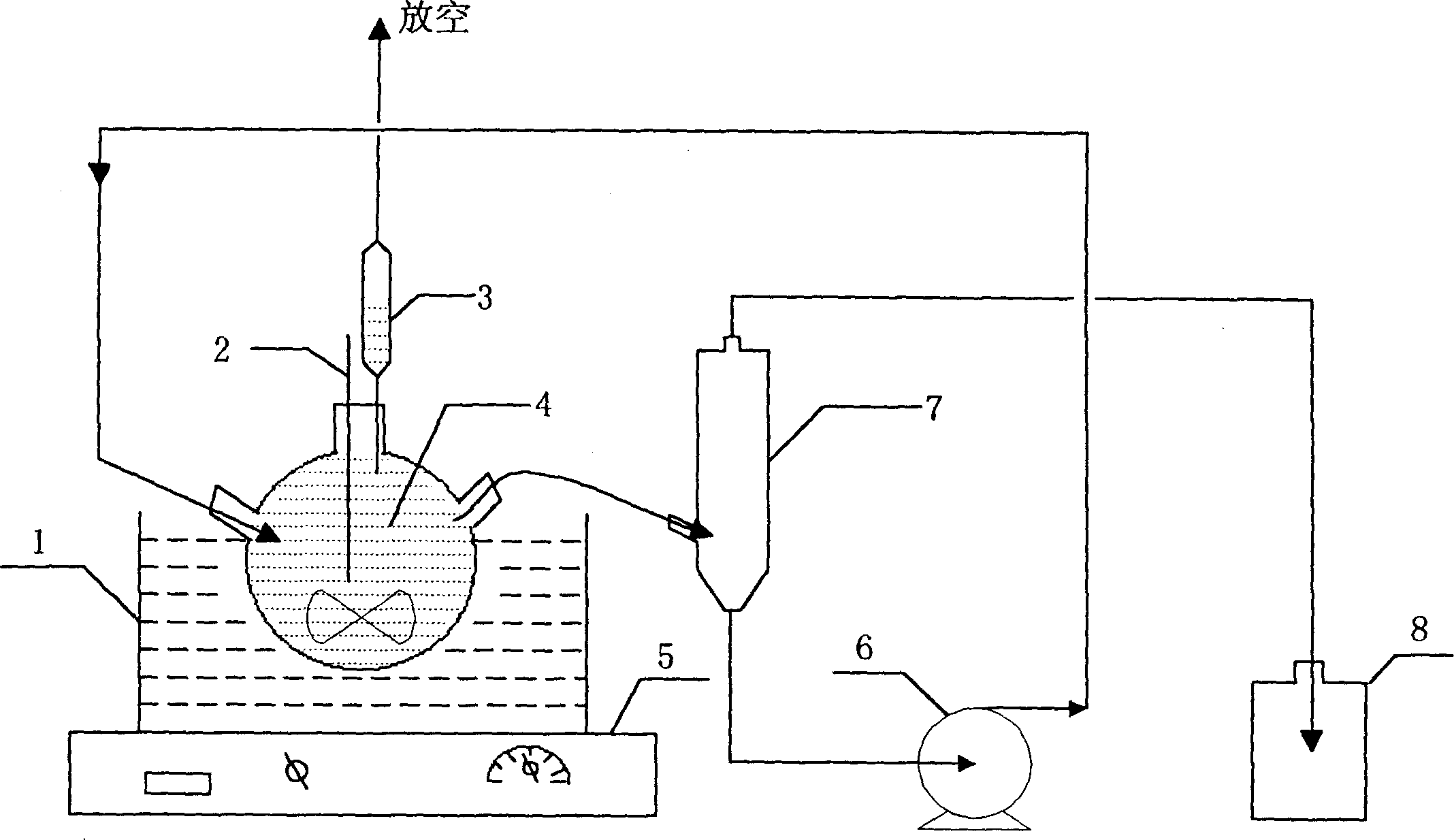

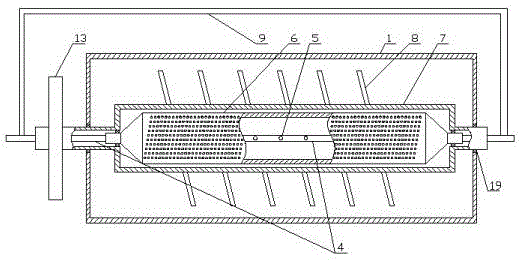

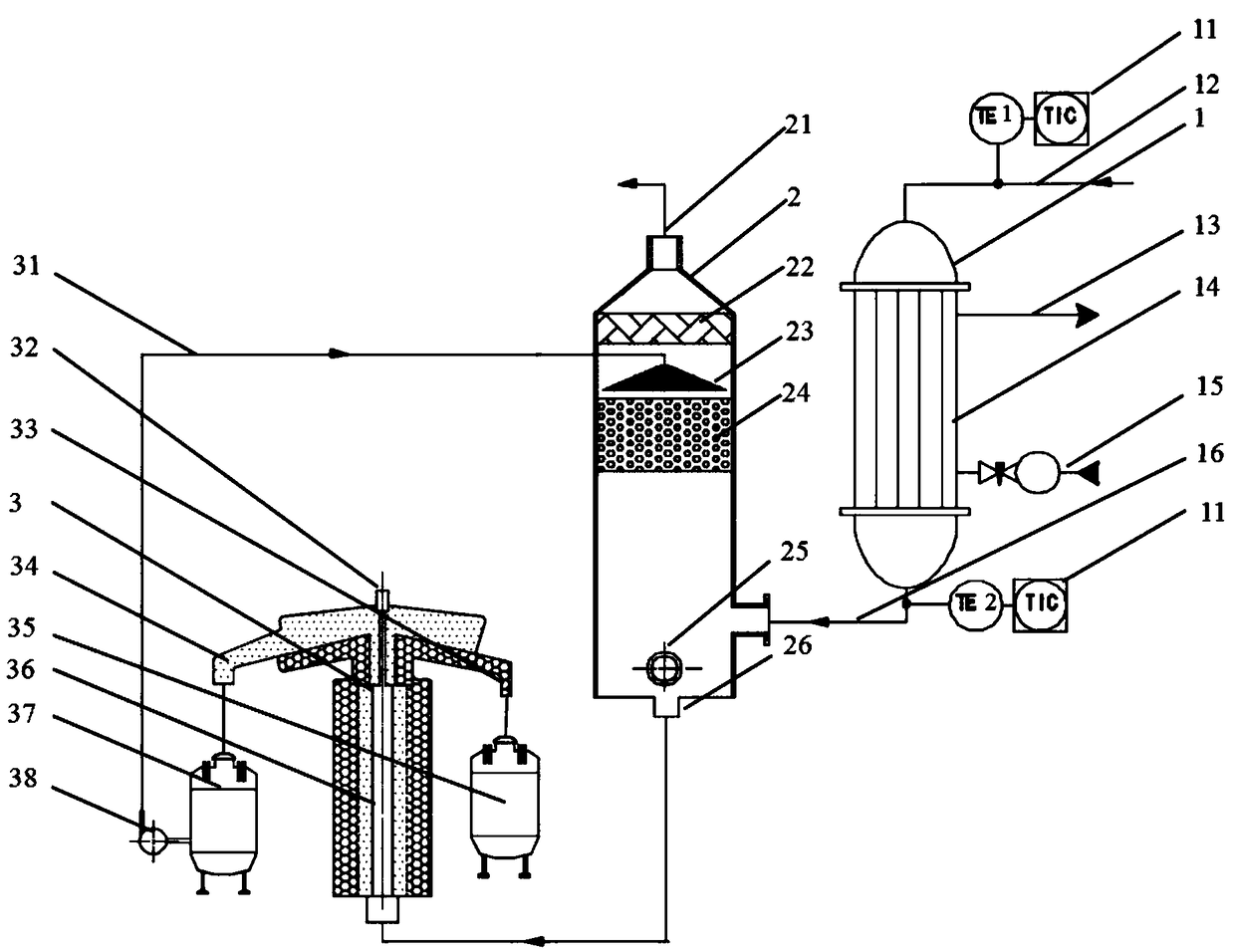

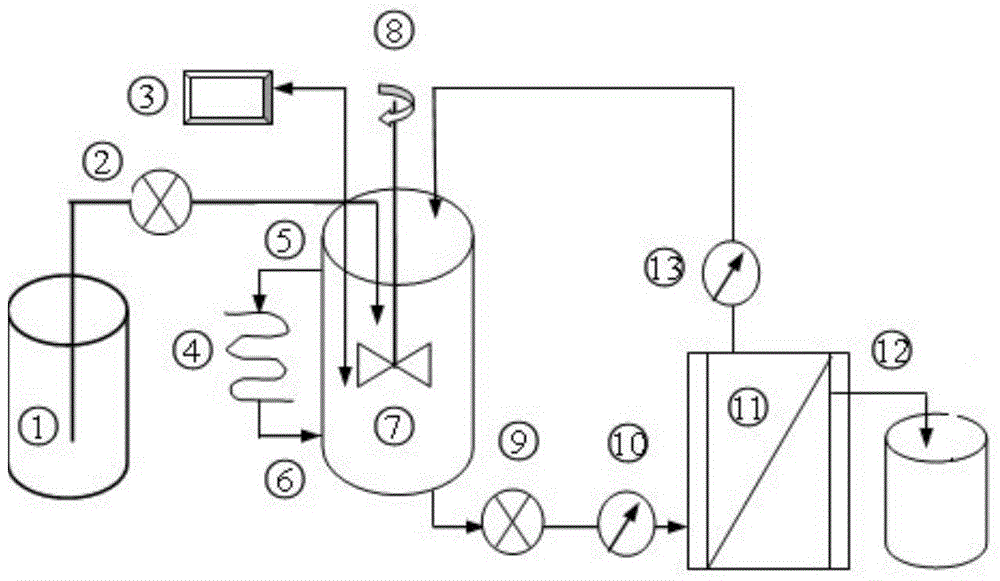

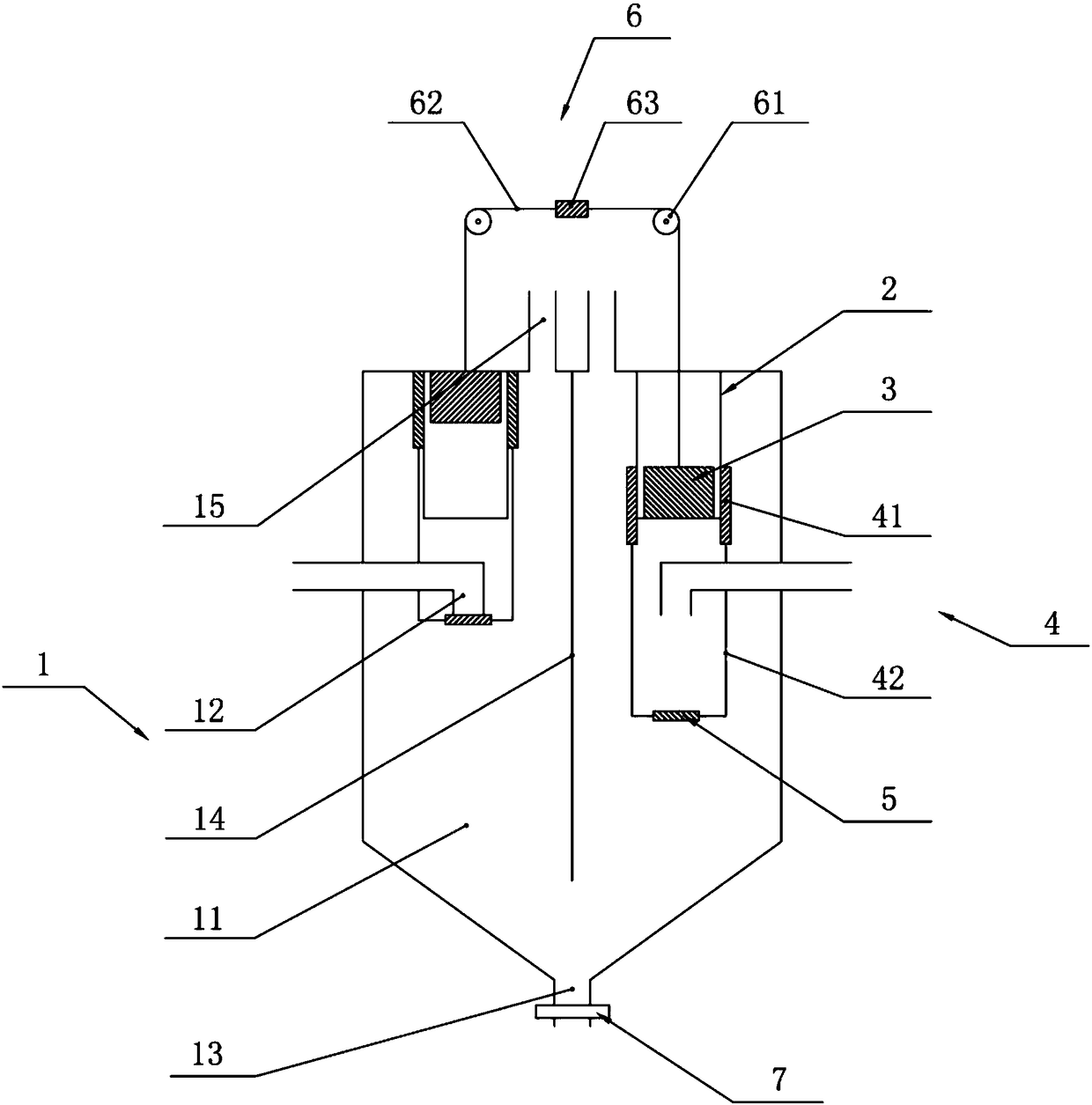

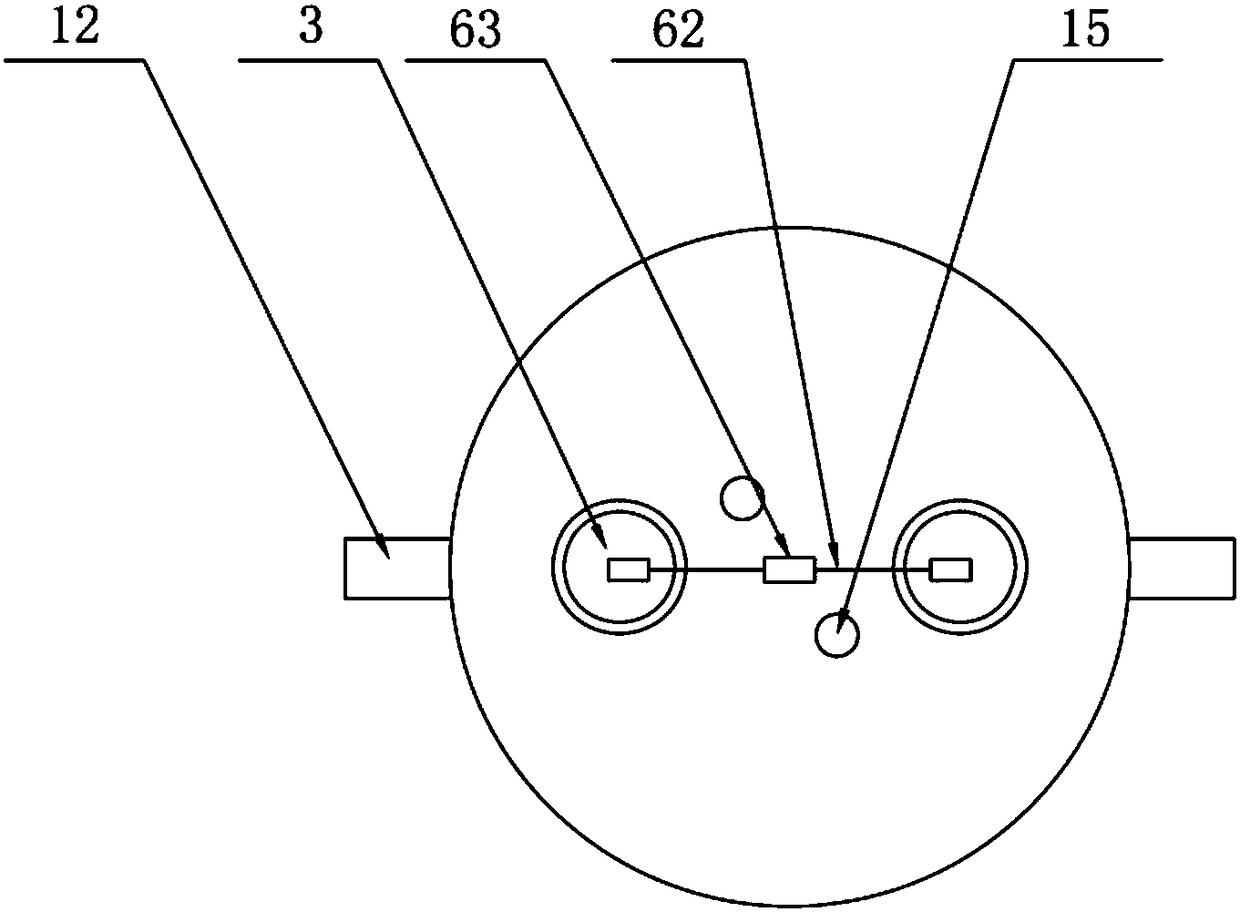

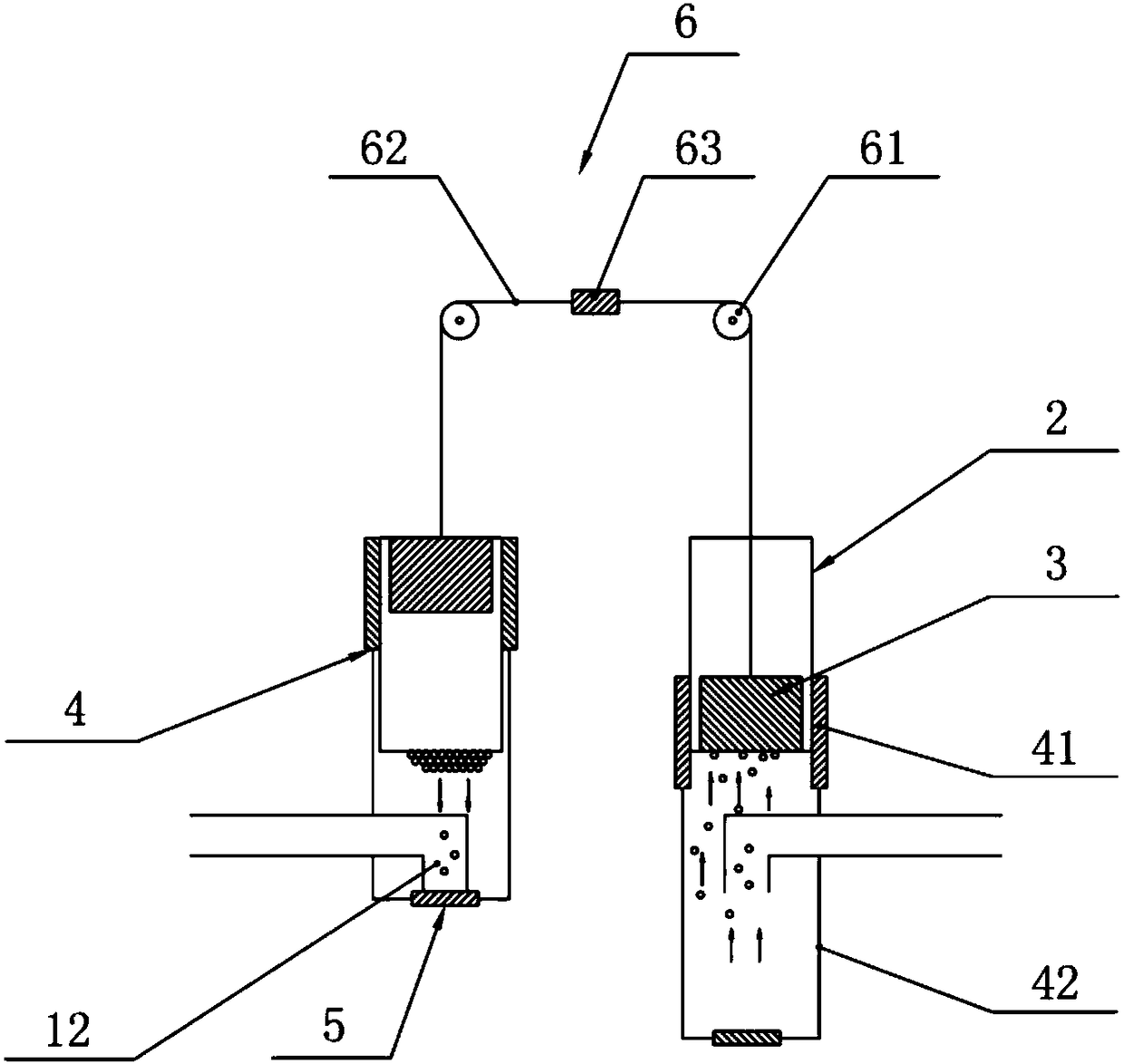

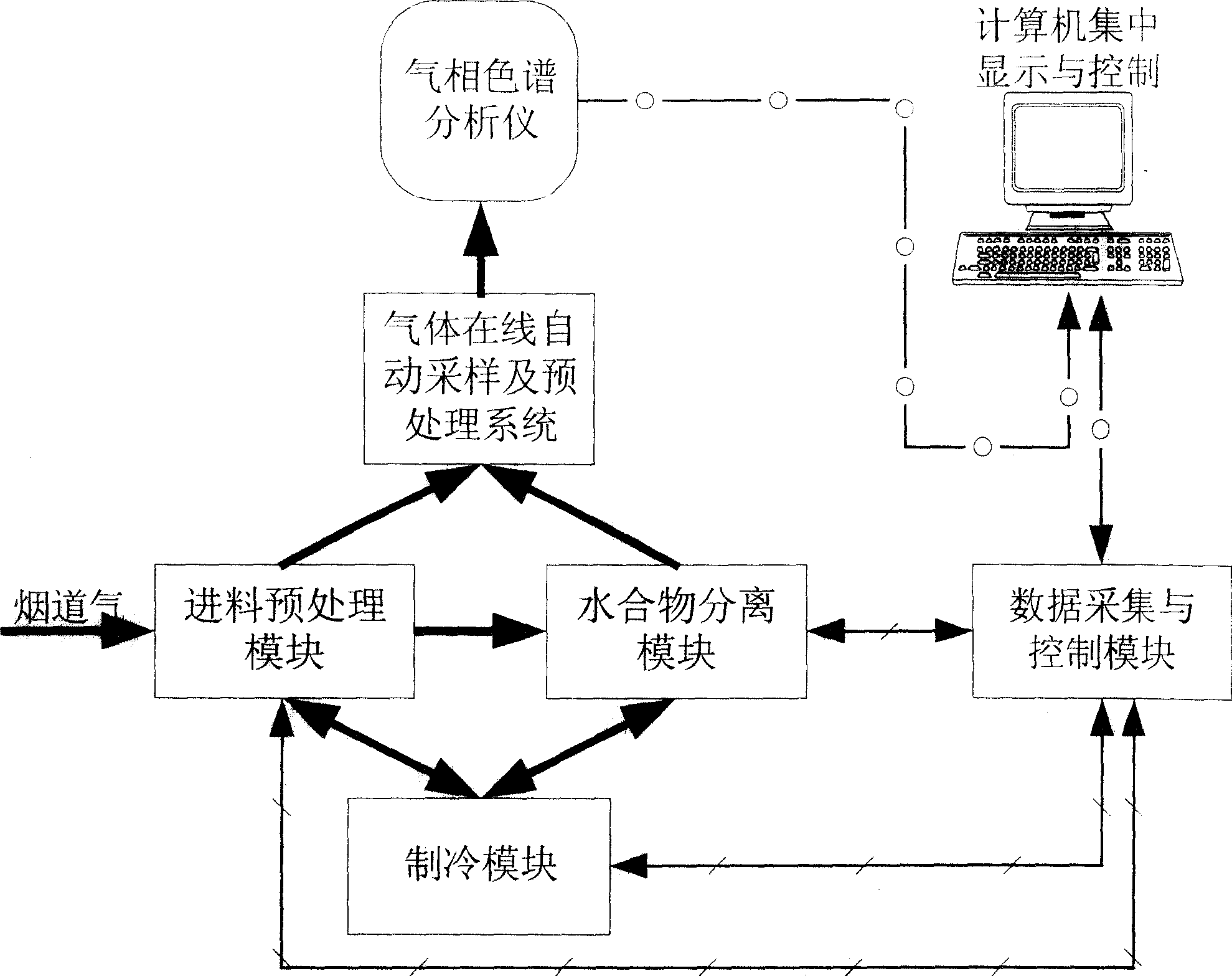

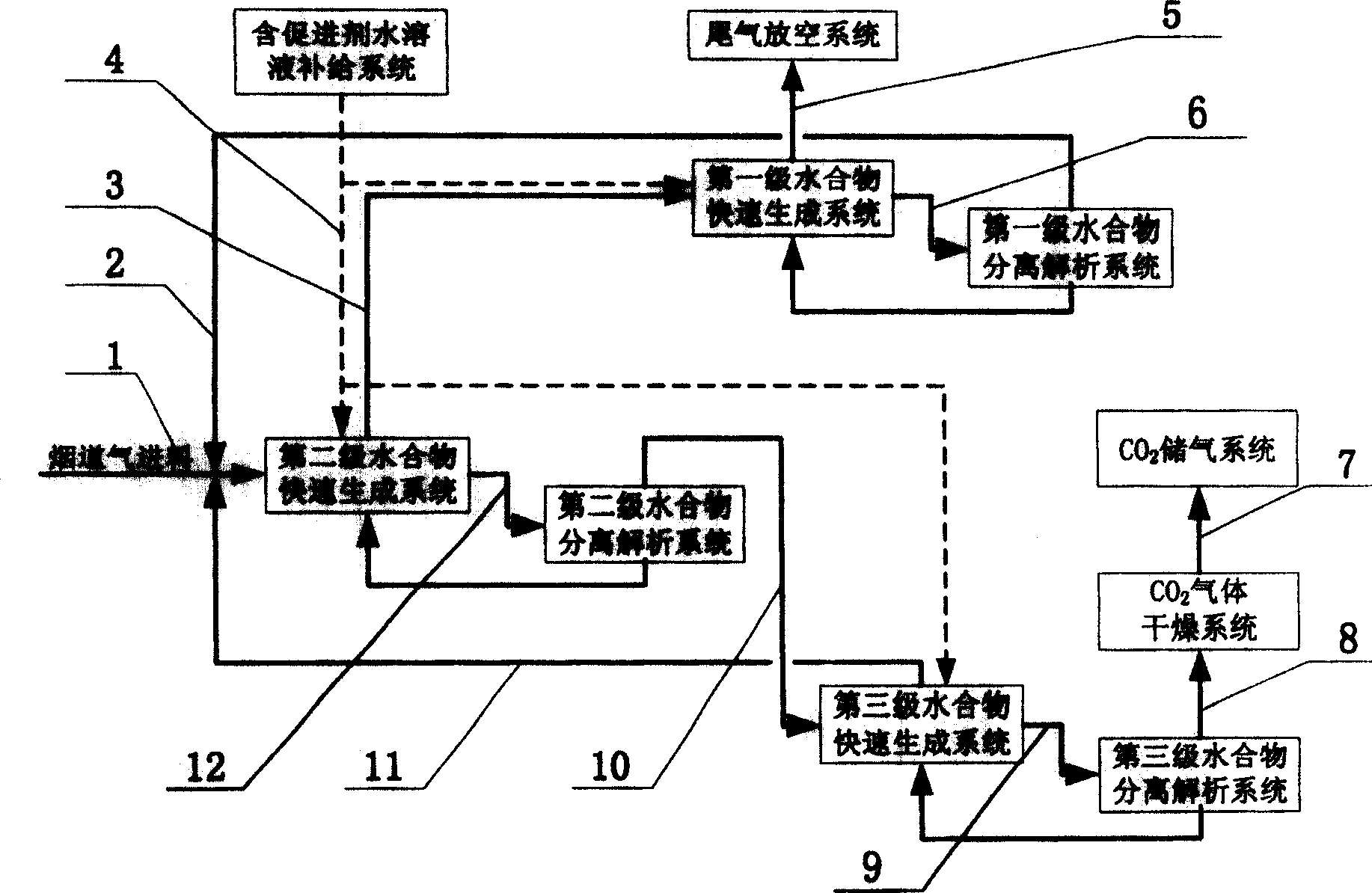

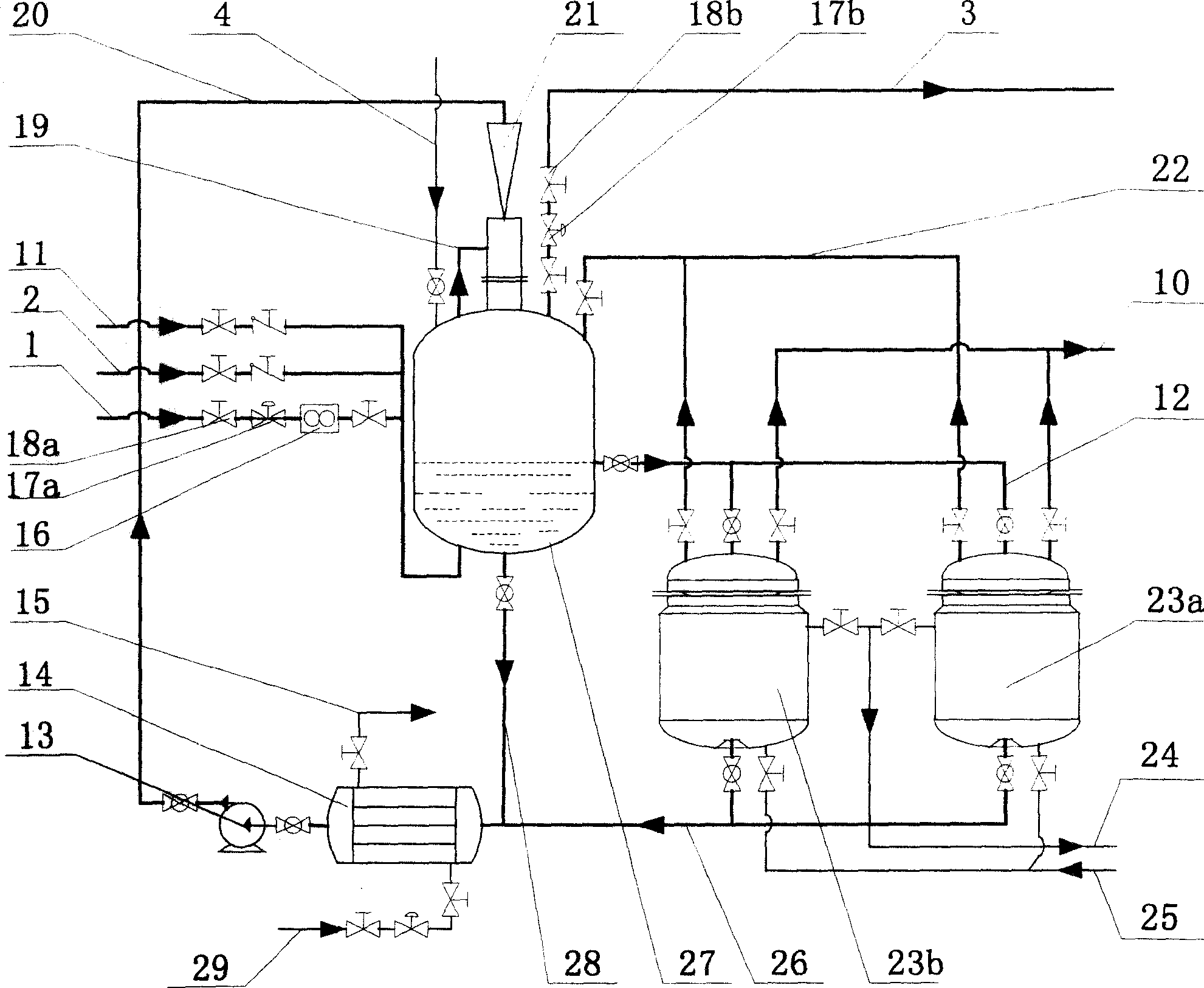

Hydrate process and apparatus for separating gas mixture continuously

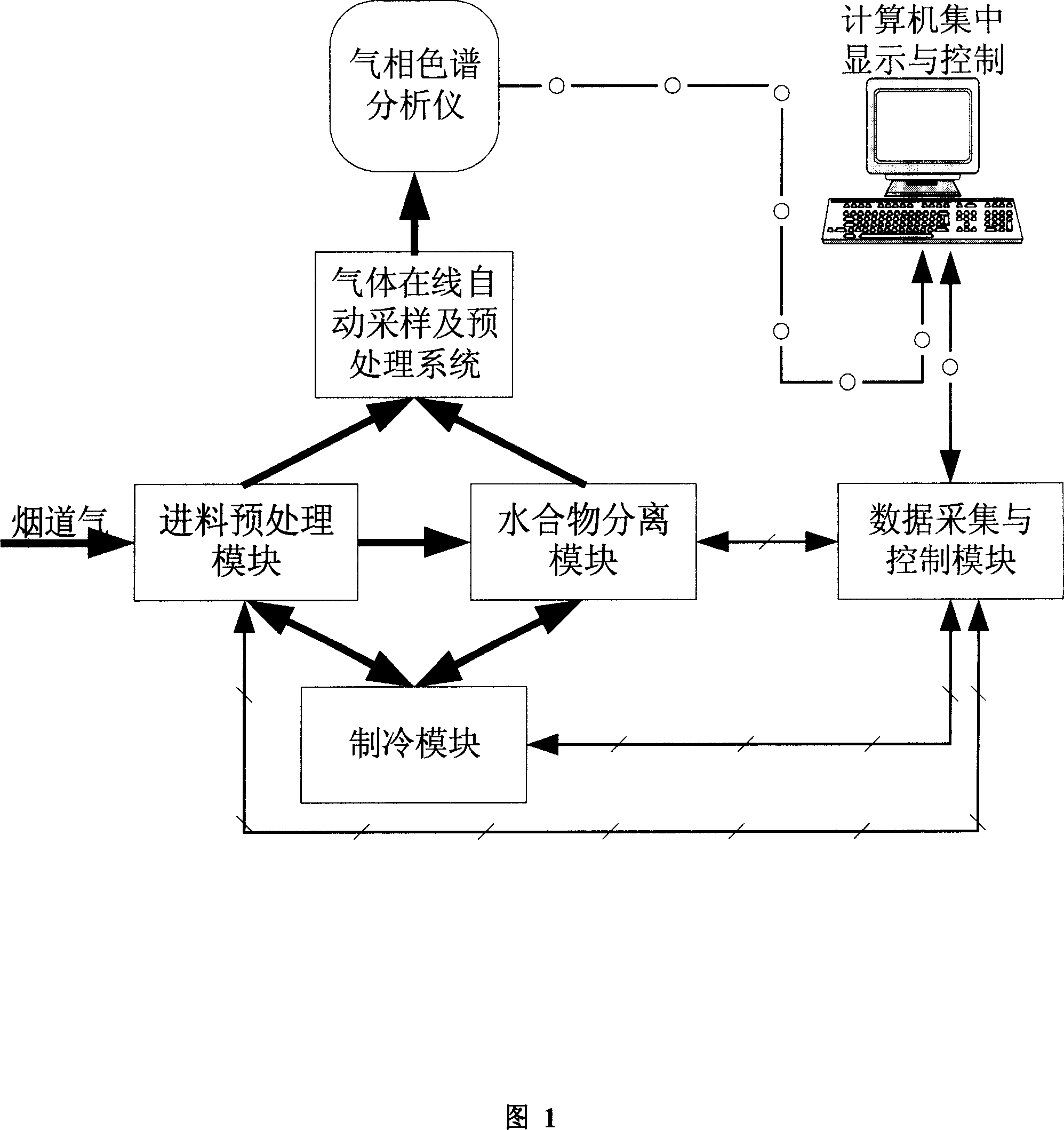

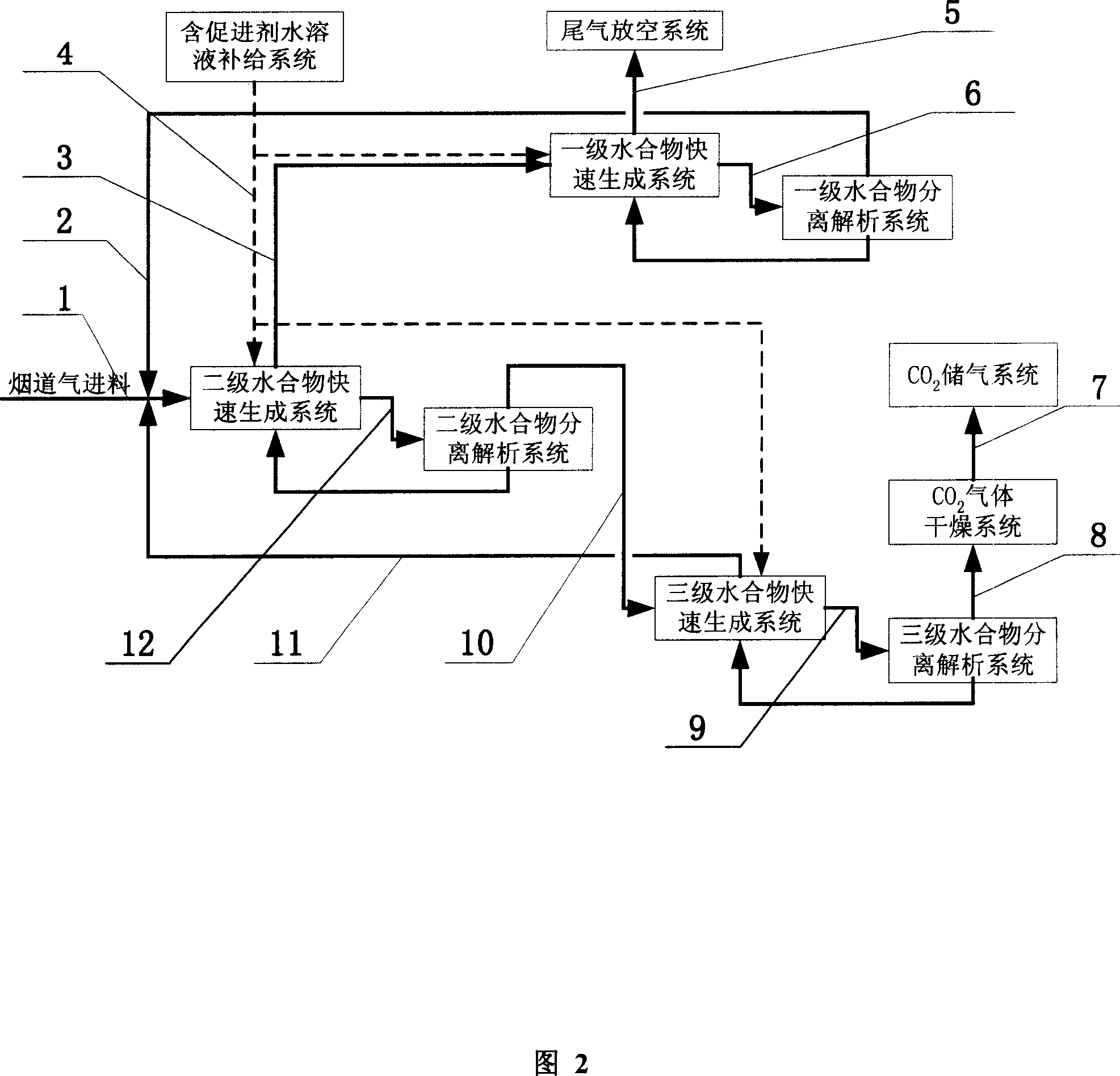

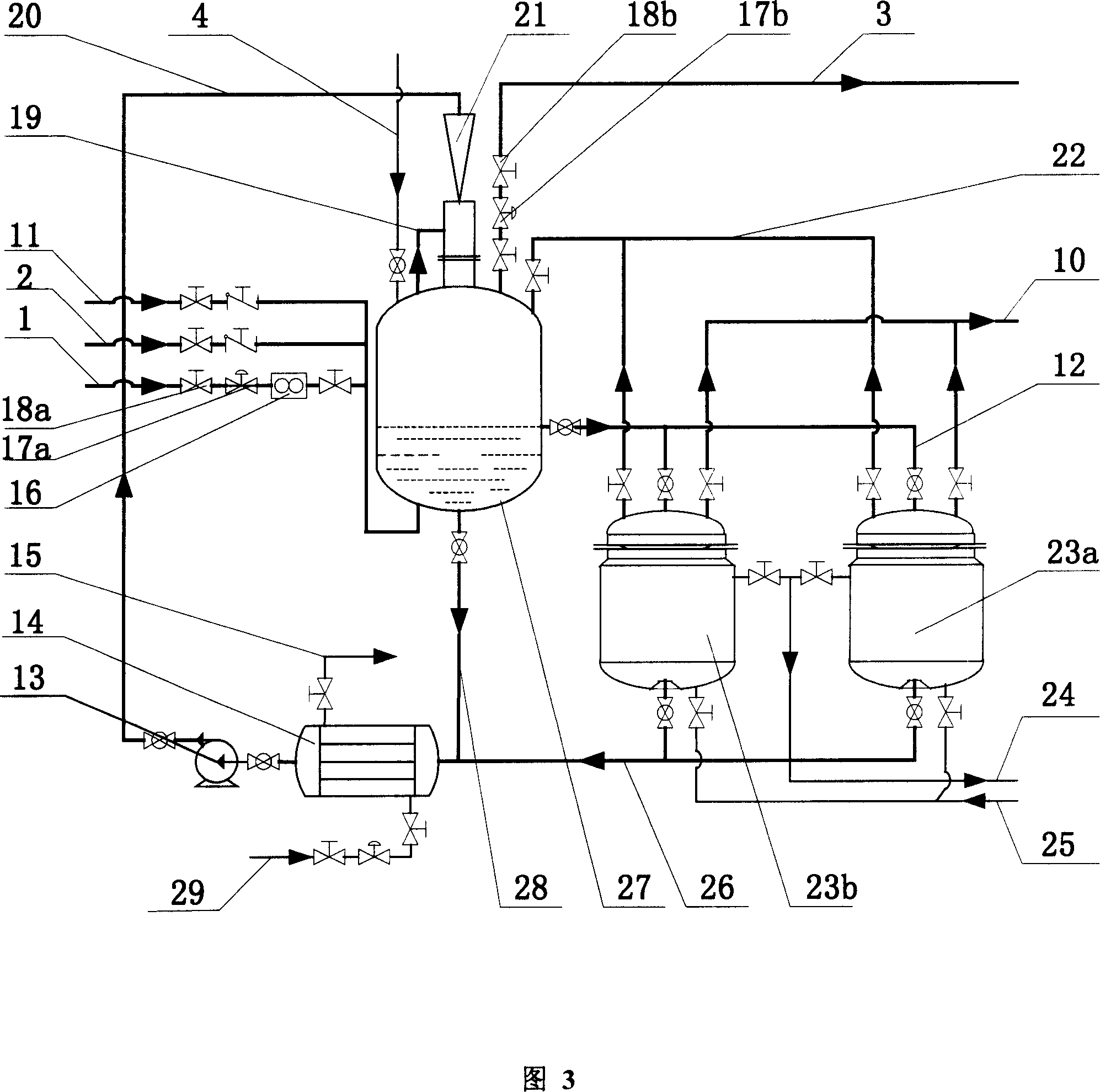

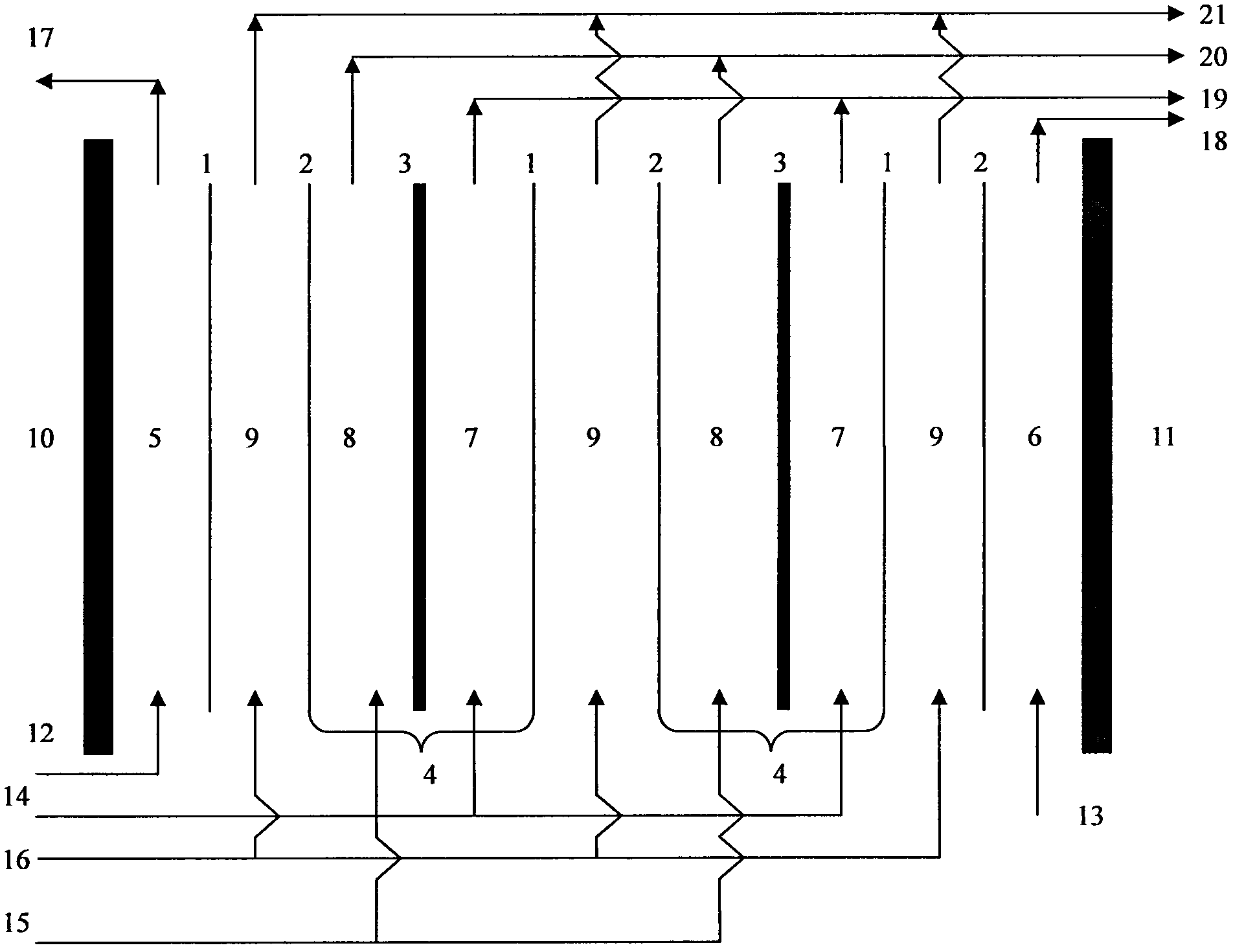

ActiveCN1973959AIncrease concentrationHigh recovery rateProductsCarbon compoundsChemical industryMicro bubble

The present invention proposes hydrate process and apparatus for separating gas mixture continuously. The countercurrent continuous separation process in three serially connected stages is adopted to raise the CO2 recovering rate from fume, the CO2 concentration in the product and the separation rate and efficiency. Each of the separating systems consists of a hydrate synthesizer, a hydrate decomposer, a circulating pump, a heat exchanger, and a micro bubble mixing and jetting reactor. The present invention is suitable for continuous separation and enrichment of CO2 in the fume of coal burning power plant, and may be also used in the continuous separation and enrichment of gas mixture containing CO2 in chemical industry, metallurgy, petroleum and other fields.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

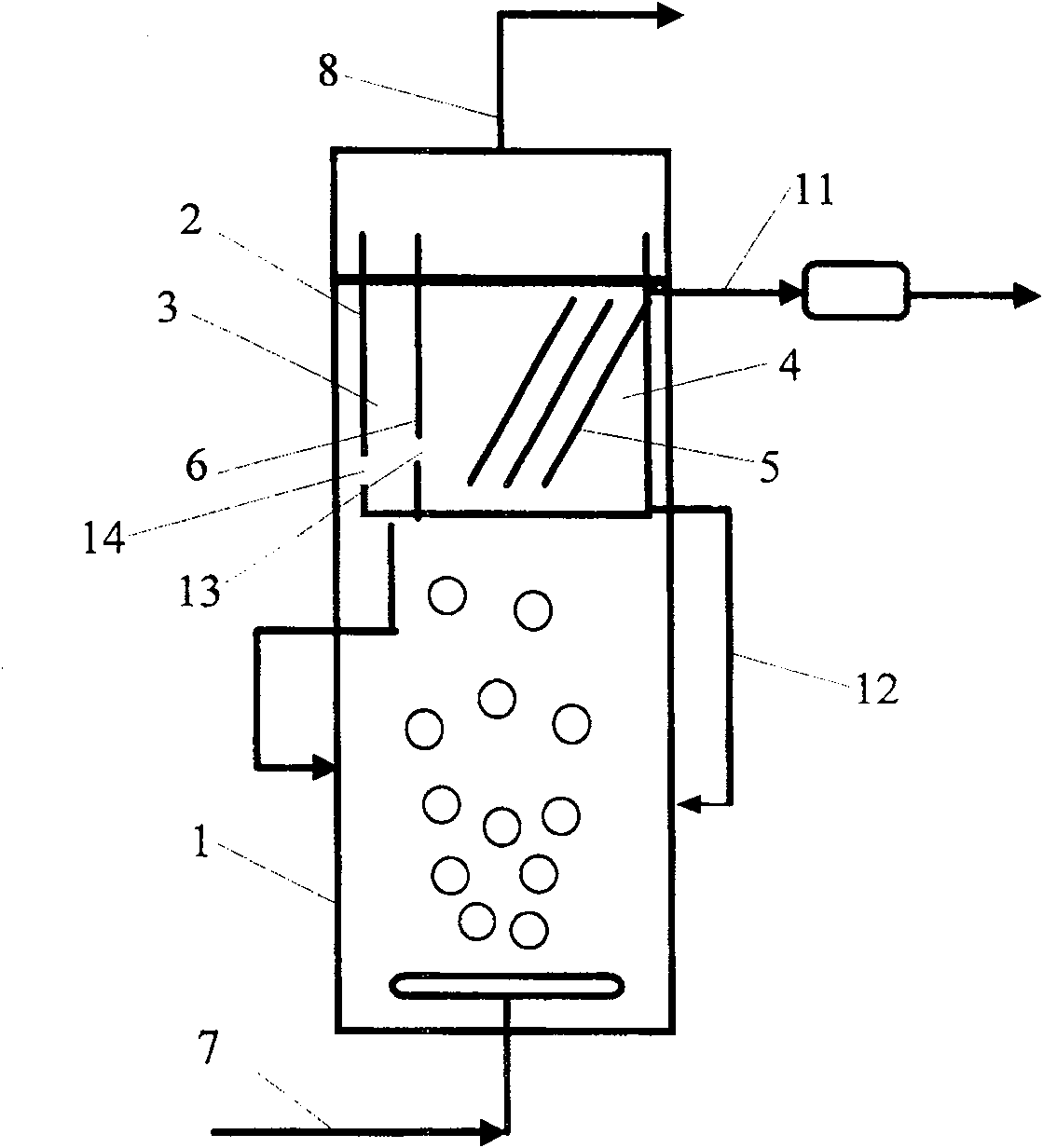

Antibiotic pharmaceutical wastewater processing method and device

ActiveCN103183403AAchieve continuous separationTo achieve resourceSemi-permeable membranesDispersed particle separationAntibiotic YMembrane reactor

The invention discloses an antibiotic pharmaceutical wastewater processing method and an antibiotic pharmaceutical wastewater processing device, and belongs to a wastewater processing technology. According to the invention, a porous filtering membrane is specifically arranged between an anion-exchange membrane and a cation-exchange membrane of an electrodialyzer membrane reactor, such that electrodialysis is intrinsically coupled with a membrane filtering process. Macromolecular substances such as mycelia, proteins, and colloidal are retained with a sieving effect of the porous filtering membrane, such that ion-exchange membrane surface pollution is reduced. Also, under an effect of a direct current electric field, with a selective permeability of the ion-exchange membranes upon charged ions, separation and concentration of anions and cations, and charged antibiotic ions are realized. With an adopted external direct current electric field, a specific solute can be effectively prevented from forming membrane pollution on the surface of the porous filtering membrane, such that the processing process can be safely and stably operated. With the method and the device, antibiotic wastewater processing system investment and operation cost can be greatly reduced; and salt ions and residual antibiotics can be highly efficiently recovered from pharmaceutical wastewater. The method and the device have important application values in antibiotic production and wastewater processing.

Owner:天津大远科技有限公司

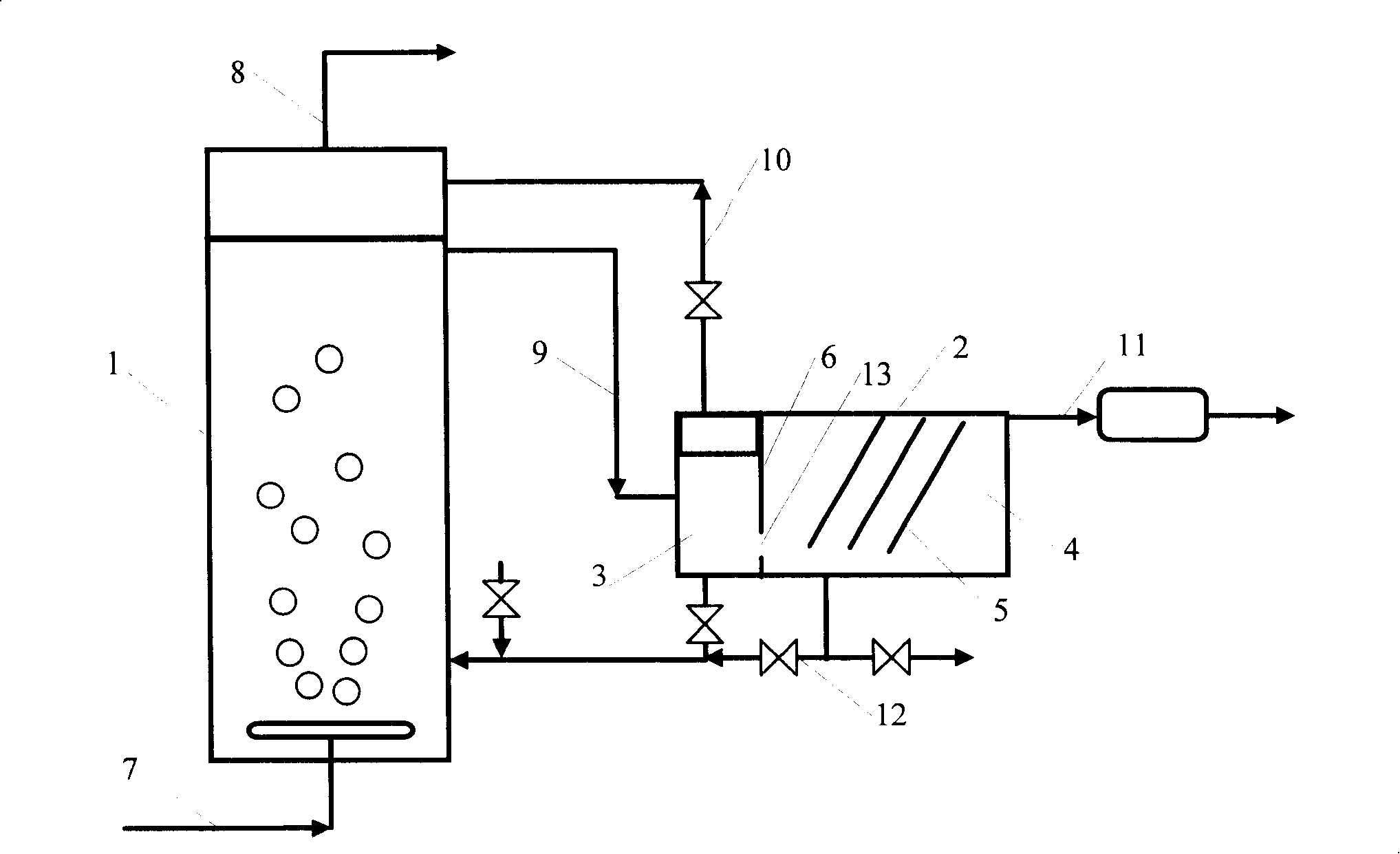

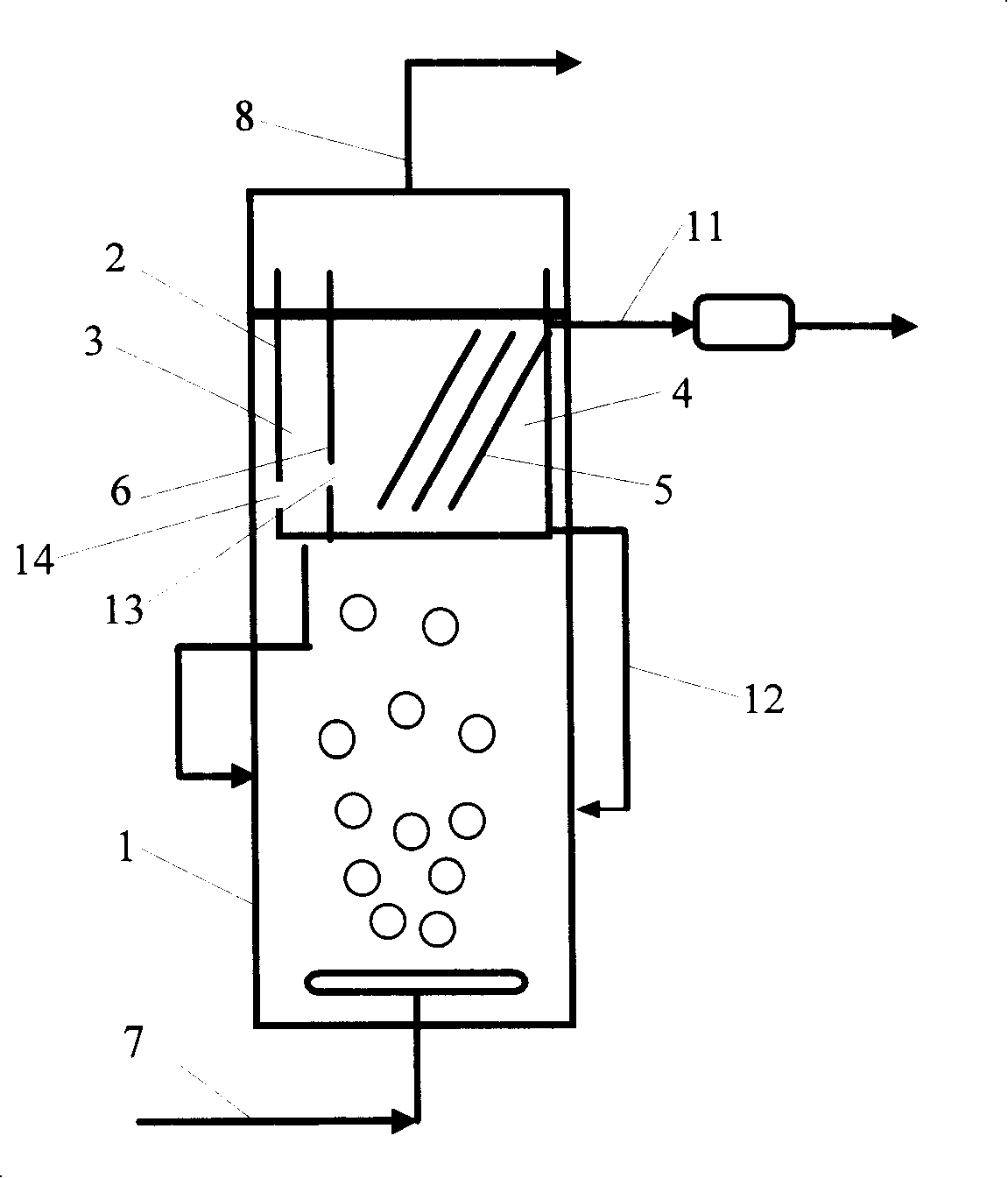

Method and equipment for liquid-solid continuously separation for slurry state bed reactor

ActiveCN101209403AAchieve continuous separationAchieve separationLiquid hydrocarbon mixture productionChemical/physical processesLiquid productLiquid viscosity

The invention discloses a method and a piece of equipment which are used for continuously separating liquid and solid of a serum-bed reactor. The contact reaction between materials and catalyst particles takes place in a serum-bed reactor, and suspension serum after the reaction is guided into a separation unit which comprises an inclined-plate settlement vessel and quickly separated into supernatant and concentrated serum in the inclined-plate settlement vessel, wherein, the concentrated serum returns to the reactor for continuing to participate in the reaction, and the supernatant flows upward into an upper part of the inclined-plate settlement vessel along gaps between the plates and is exhausted. The method provided by the invention implements the continuous separation and circular utilization of solid catalyst particles and liquid products in a smaller operation space and improves settlement efficiency. The equipment provided by the invention is applicable for separating suspension serum with smaller catalyst particles and larger liquid viscosity, occupies small space and has high separation efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

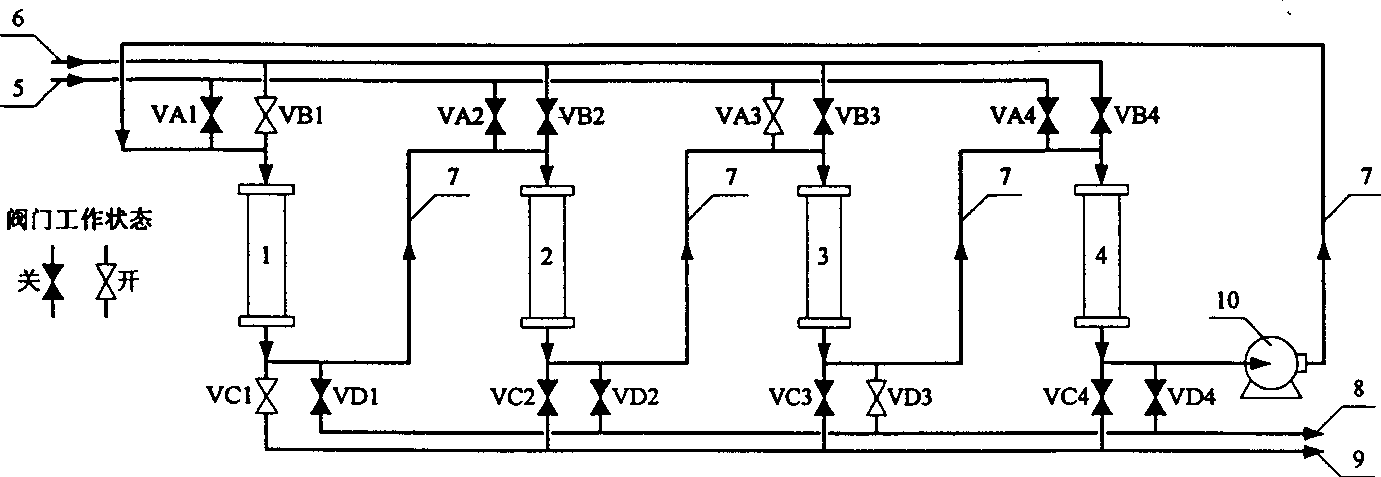

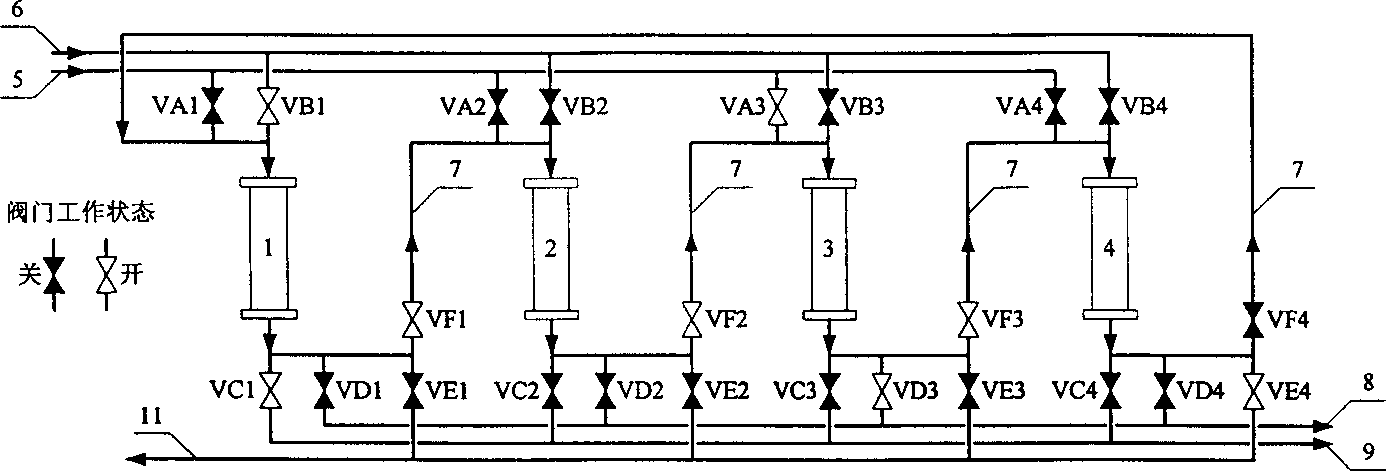

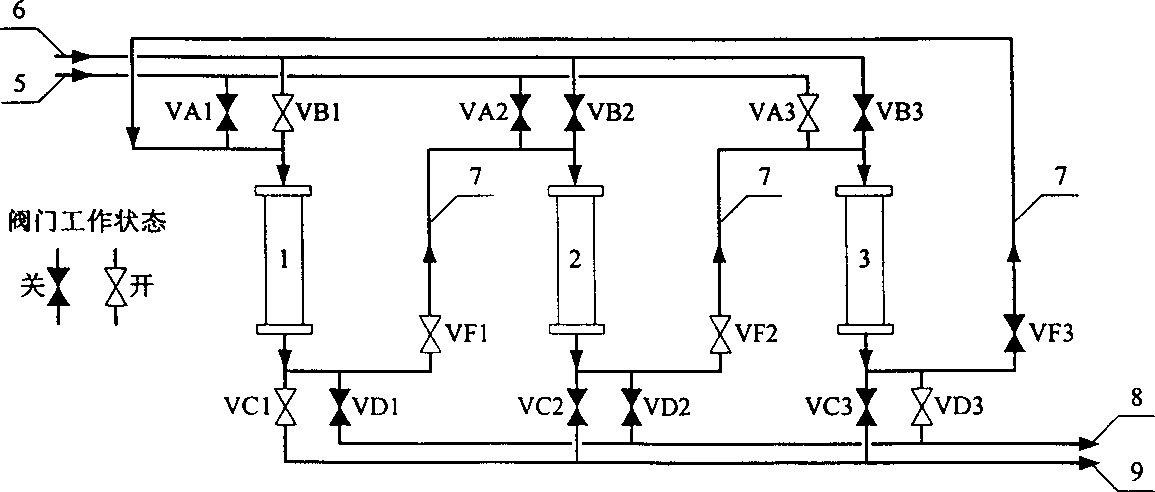

Analogue mobile bed chromatic reactor

InactiveCN1374146AAchieve continuous separationSpeed up chemical reactionsIon-exchange process apparatusIon-exchanger regenerationChromatographic separationSimulated moving bed

The chromatographic reactor includes three or more packed columns cascaded successively. The inlet end of each packed column is connected via a separated switch-type valve to the inlet pipe for material liquid to enter and the inlet pipe for eluting liquid to enter; and the outlet end of each packed column is connected via a separated switch-type valve to the outlet pipe for residual liquid with enriched weak sorptive component from reacted product to drain and the outlet pipe for extracting liquid with enriched strong sorptive component from reacted product to drain. By means of controlling the switch state of the valves, the present invention performs, chromatographic separation and reaction simultaneously, so that the reactor can run continuously with high reaction converting rate and high produce separating efficiency. The present invention is especially suitable for chromatographic separation course of different products and of product and reactant.

Owner:ZHEJIANG UNIV

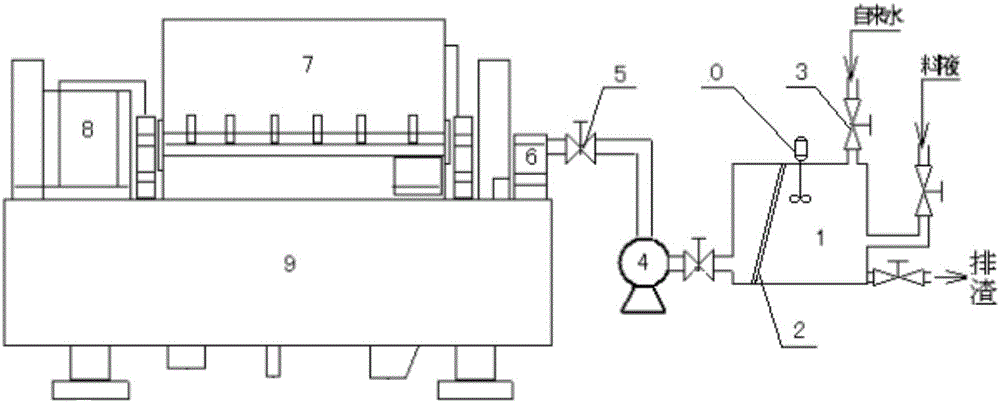

Fecal sewage solid-liquid separator

ActiveCN105174631AReduce difficultyFast degradationMultistage water/sewage treatmentAnimal fecesSewage

The invention relates to a fecal sewage solid-liquid separator. The fecal sewage solid-liquid separator comprises a solid-liquid separation device, a feeding pipe, a residue outlet device, a water pumping device and a control device, wherein the feeding pipe, the residue outlet device and the water pumping device are connected with the solid-liquid separation device, and the control device is used for controlling the solid-liquid separation device, the feeding pipe, the residue outlet device and the water pumping device. The solid-liquid separation device comprises a box and a sieve revolving drum arranged inside the box and capable of rotating, biological stuffing with microbial florae is borne inside the sieve revolving drum, and a liquid storage region used for collecting fecal sewage is arranged inside the box and located below the sieve revolving drum. The fecal sewage solid-liquid separator can effectively intercept and degrade fecal solid objects and facilitate follow-up treatment of the fecal solid objects and is suitable for small equipment.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Separation process of molecular sieve catalyst in ketone oxamidinating reaction system

InactiveCN1432432AContinuous separationGood separation effectMolecular sieve catalystsOximes preparationSal ammoniacWater content

In the ketone oxamidinating reaction system with water mutually soluble low-carbon alcohol of 30-50 wt% concentration and excessive ammonia water content, the material including titania-silica molecular sieve is deposited at 60-85 deg.c in deposition rate of 0.5-3 cm / min for at least 10 min. The present invention can realize the continuous separation of titania-silica molecular sieve from reaction liquid and is suitable for cyclohexanone oxamidinating reaction system with titania-silica molecular sieve catalyst of 0.1-0.3 micron size.

Owner:CHINA PETROLEUM & CHEM CORP +1

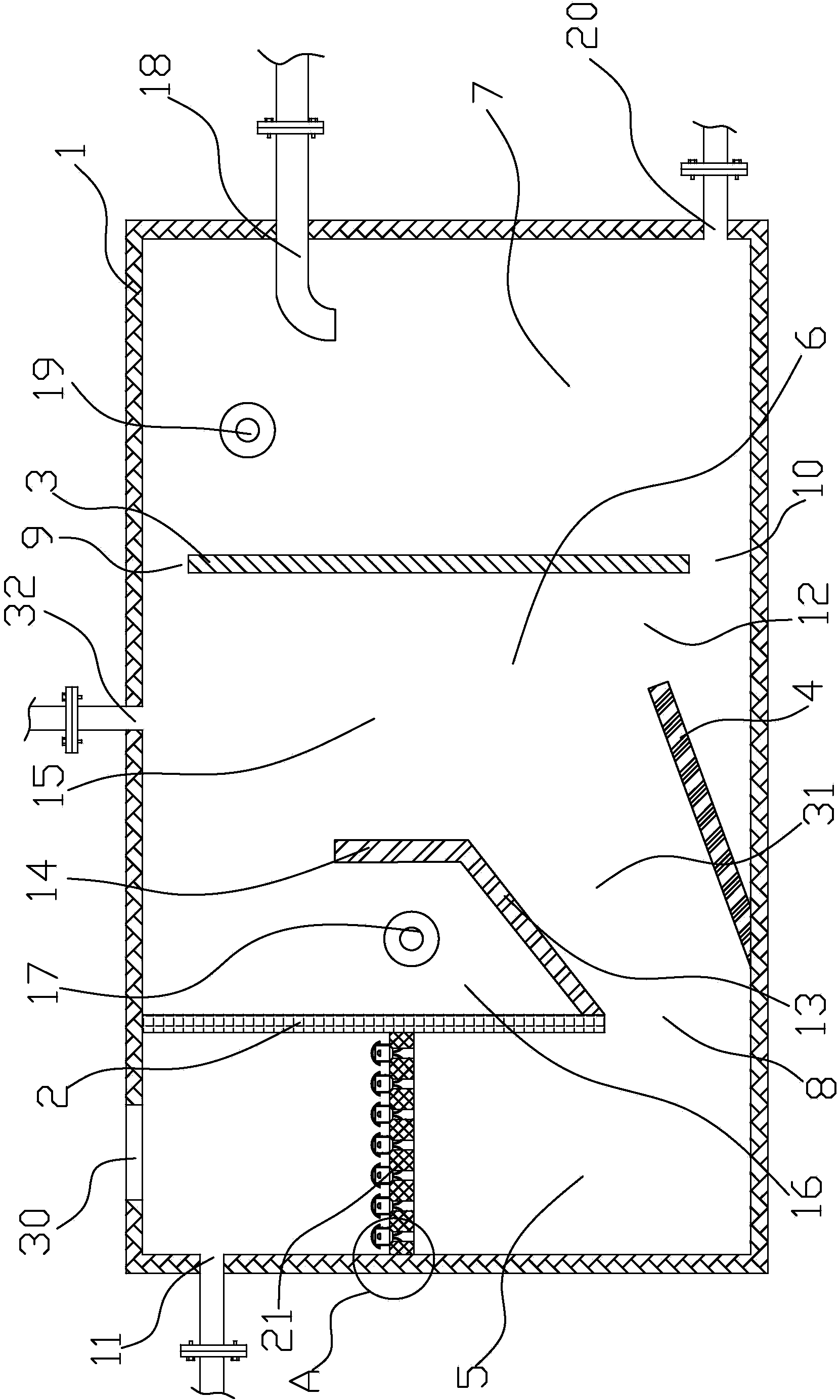

Multi-baffle type oil-and-water separator

ActiveCN104289010AThe amount of material is uniformSuppresses air bubbles and turbulenceLiquid separationFoam dispersion/preventionEmulsionInterior space

The invention discloses a multi-baffle type oil-and-water separator. The separator comprises a tank body, a first baffle, a second baffle and an oblique baffle, wherein the interior space of the tank body is divided into a subcritical flow defoaming area, a settling separation area and a water collection area by the first baffle and the second baffle; a feed port is formed in the subcritical flow defoaming area; a subcritical flow defoaming structure is arranged below the feed port; an air outlet is formed in the settling separation area; a bottom plate is arranged at the bottom of the first battle; a separation plate is arranged at the end part of the bottom plate; clearances are respectively reserved between the first baffle and the bottom surface of the tank body, the second baffle and the top surface of the tank body, the second baffle and the bottom surface of the tank body, the separation plate and the second baffle, the separation plate and the top of the tank body, and the oblique baffle and the second baffle; the space defined by the bottom plate, the separation plate, the first baffle and the tank body forms an oil collecting tank; an oil outlet is formed in the oil collecting tank; a water outlet and a discharge port are both formed at the upper part inside the water collecting area; the discharge port is higher than the water outlet; a sewage draining port is formed in the lower part of the water collecting area. The oil-and-water separator is simple in structure and low in operation cost, can effectively restrain emulsion and realize continuous oil-and-water separation and is high in separation efficiency and good in separation effect.

Owner:佛山市南海瑞泰机动车报废有限公司

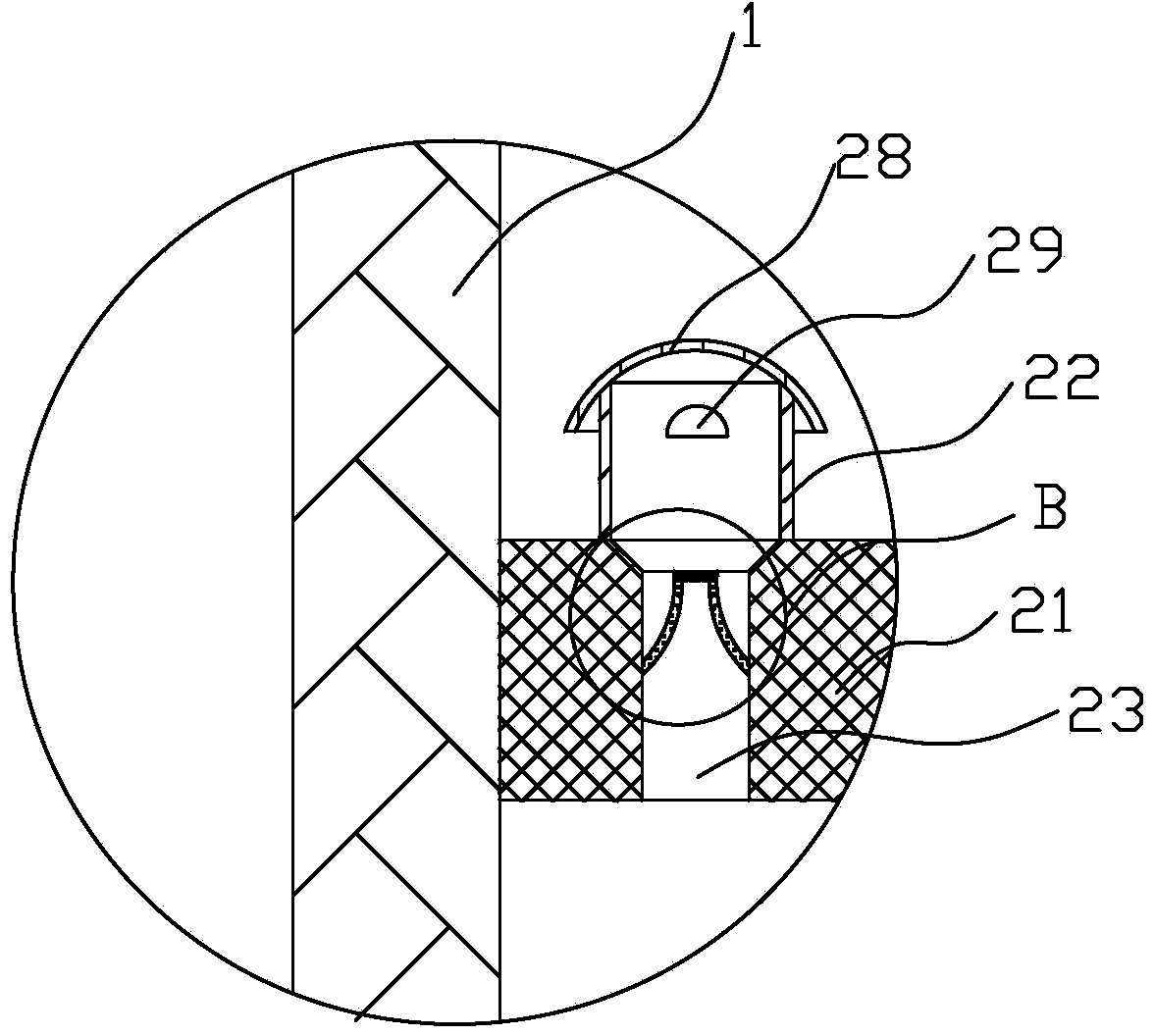

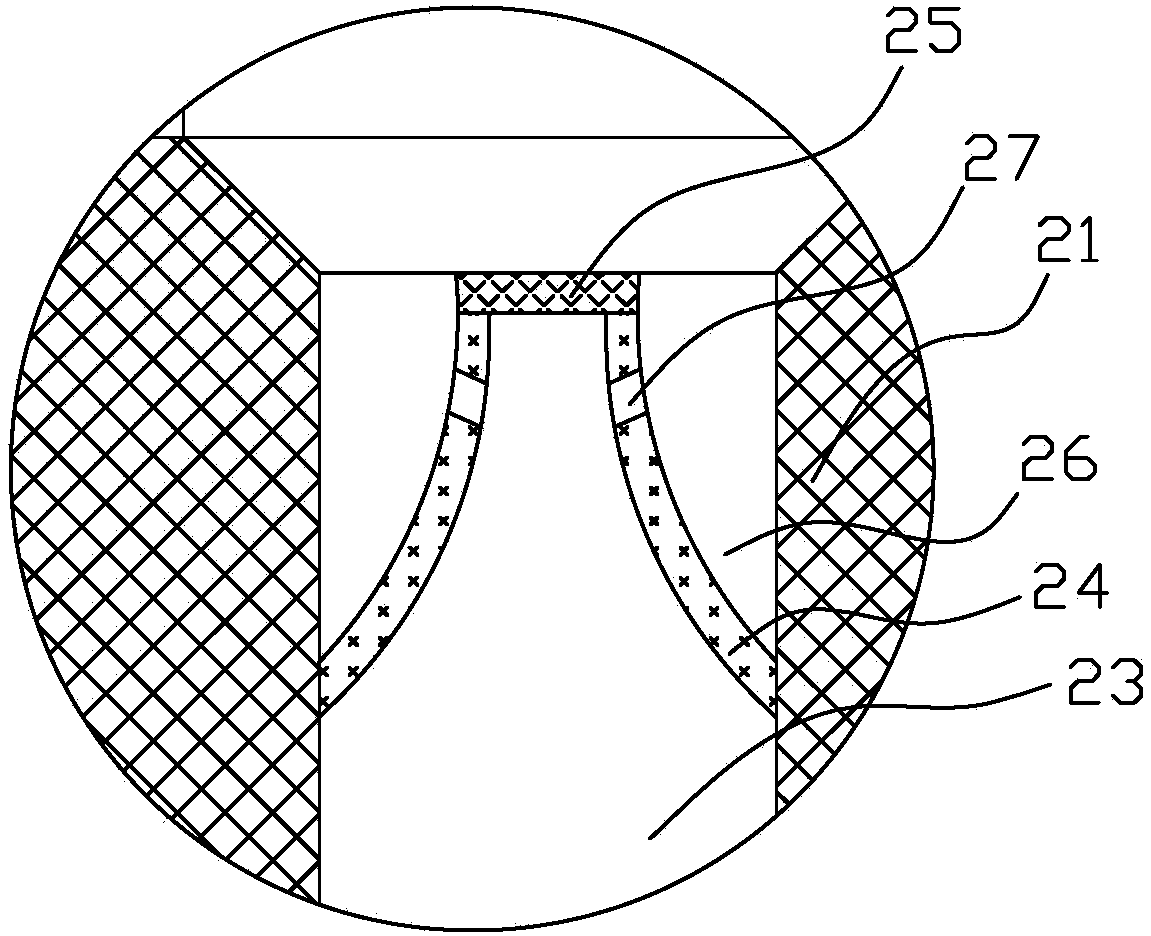

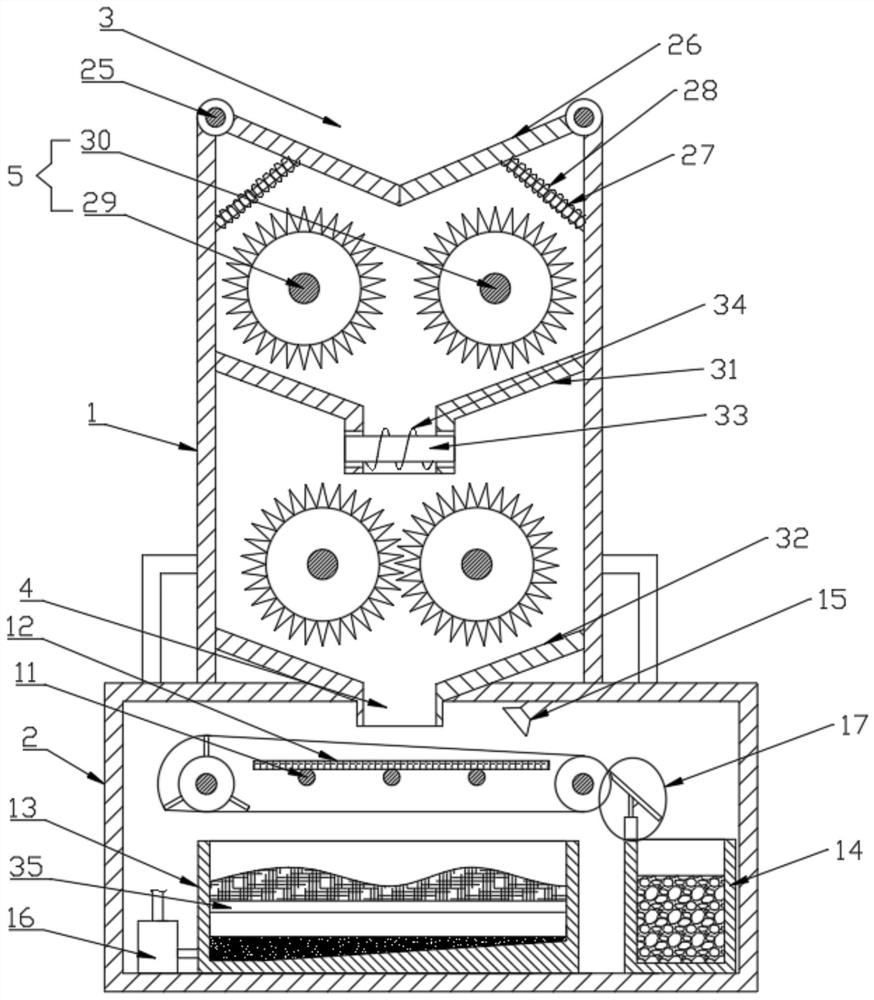

Crushing and recycling device for construction waste

InactiveCN112090559AAchieve separationAchieve recyclingSievingScreeningArchitectural engineeringEnvironmental engineering

The invention discloses a crushing and recycling device for construction waste. The crushing and recycling device for the construction waste comprises a crushing box and a recycling box, a plurality of crushing mechanisms are arranged in the crushing box from top to bottom, the crushing box communicates with the recycling box, a conveying device is arranged in the recycling box, a water tank and ametal collecting box are arranged at the lower end of the conveying device, and a scraping device is arranged on the metal collecting box. According to the crushing and recycling device for the construction waste, by arranging the recycling box, the construction waste crushed by the plurality of crushing mechanisms is guided into the conveying device, in cooperation with a permanent magnet arranged in the middle of the conveying device, separation of concrete and metal is achieved, through the scraping device arranged at the tail end of the conveying device, the metal on a conveying belt is guided into the metal collecting box, recycling and utilizing of the metal is achieved, meanwhile, through a high-pressure spray head arranged at the top of the recycling box, cleaning is carried out on screen holes in the conveying belt, and the screen holes are prevented from being blocked by the concrete, so that continuous separation of the crushed construction waste through the conveying device is achieved.

Owner:蔡先婷

Ion separation device and ion separation method formed by magnetic field and ion exchange membranes

InactiveCN102863113AAchieve separationSeparation efficiency can be controlledMembranesGeneral water supply conservationHigh concentrationDesorption

Owner:苏润西

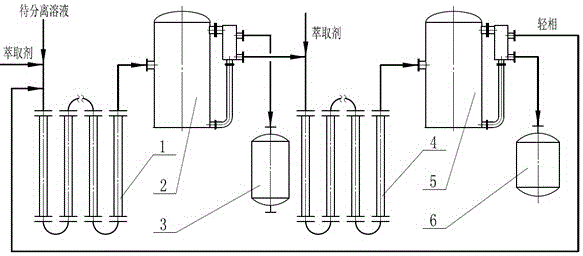

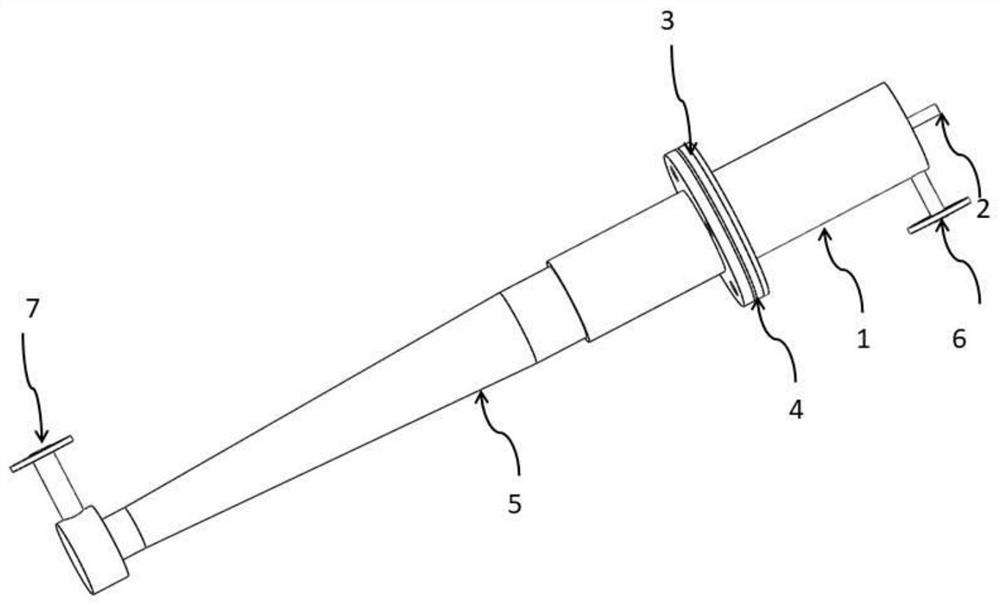

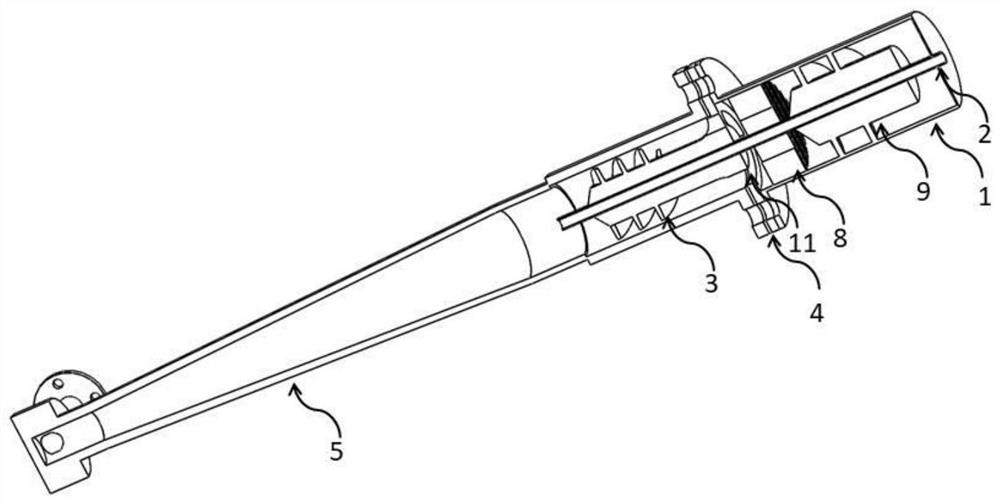

Tubular continuous liquid-liquid extraction device and operation method thereof

InactiveCN105727590AAchieve continuous separationLess investmentLiquid solutions solvent extractionChemistryLiquid–liquid extraction

The invention relates to a tubular continuous liquid-liquid extraction device and an operation method thereof. The tubular continuous liquid-liquid extraction device comprises continuous tubular extractors (1) and (4) and continuous extract phase and raffinate separators (2) and (5). The operation method comprises the following steps: mixing and extracting a flowing to-be-separated solution and a flowing extraction agent in the first-level tubular exactor (1); separating the extract phase from the raffinate of the material from the first-level tubular exactor (1) in the first-level extract phase and raffinate separator (2), feeding the extract phase into an extract phase storage tank (3) and mixing and extracting the flowing raffinate and another flowing extraction agent in the second-level tubular exactor (4); and separating the extract phase from the raffinate of the material from the second-level tubular exactor (4) in the second-level extract phase and raffinate separator (5) for the second time, feeding the raffinate into a raffinate storage tank (6) and returning the extract phase to the first-level tubular exactor (1). The tubular continuous liquid-liquid extraction device has the advantages of simple structure, less investment, high operating flexibility, low running cost and high extraction and separation efficiency.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY +1

Method for producing a series of phase change wax products

ActiveCN110628391AChemically stableNot corrosiveWax physical treatmentPetroleum wax refiningPhase change enthalpyCarbon number

The invention discloses a method for producing a series of phase change wax products. The method comprises: refining a Fischer-Tropsch synthetic wax raw material through a hydrogenation reaction to obtain a Fischer-Tropsch refined wax; carrying out pressure reducing distillation on the Fischer-Tropsch refined wax; and separating continuous distillates with distillation range of 5-30 DEG C by continuously increasing the operation temperature to obtain a series of phase change wax products, wherein the pressure of the pressure reducing distillation is 0-1000 pa, the tower top operation temperature is 120-260 DEG C, and the phase change enthalpy value of the series of phase change wax products is larger than or equal to 170 J / g. According to the method of the invention, various trademark phase change wax products with the melting points of 5-80 DEG C can be separated from the Fischer-Tropsch refined wax, the carbon number of the products is concentrated, the enthalpy value is high, and the process is high in flexibility, can achieve customization according to needs, is low in production cost, and is suitable for industrial production.

Owner:INNER MONGOLIA YITAI COAL BASED NEW MATERIALS RES INST CO LTD

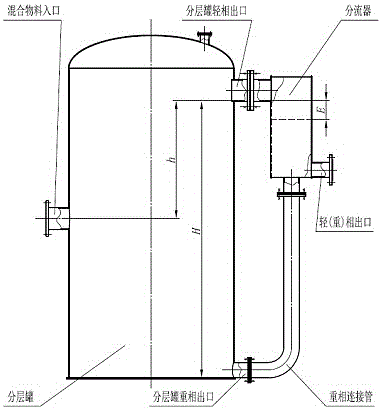

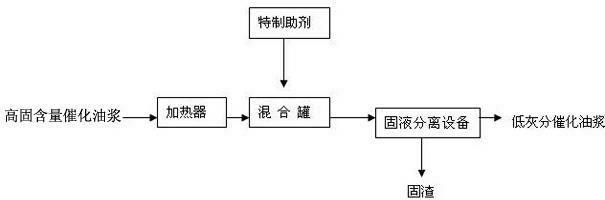

Separation method for solid particles in catalytic slurry oil

ActiveCN102585895ASimple solid-liquid separation processEasy to operateTreatment with plural serial refining stagesSlurryPetrochemical

The invention relates to a separation method for solid particles in catalytic slurry oil and belongs to the technical field of petrochemical complex. Special assistant is added into the high-solid-content catalytic slurry oil and is stirred and mixed reasonably; and then solid-liquid separation equipment is adopted to conduct separation effectively, so as to obtain lower-ash-content and good-quality catalytic slurry oil. The invention has the advantages that the process and the equipment are simple, the operation is easy, the production is continuous, and the solid-liquid separation is complete, so as to obtain the lower-ash-content and good-quality catalytic slurry oil and broaden the application range of the lower-ash-content and good-quality catalytic slurry oil.

Owner:李志英 +2

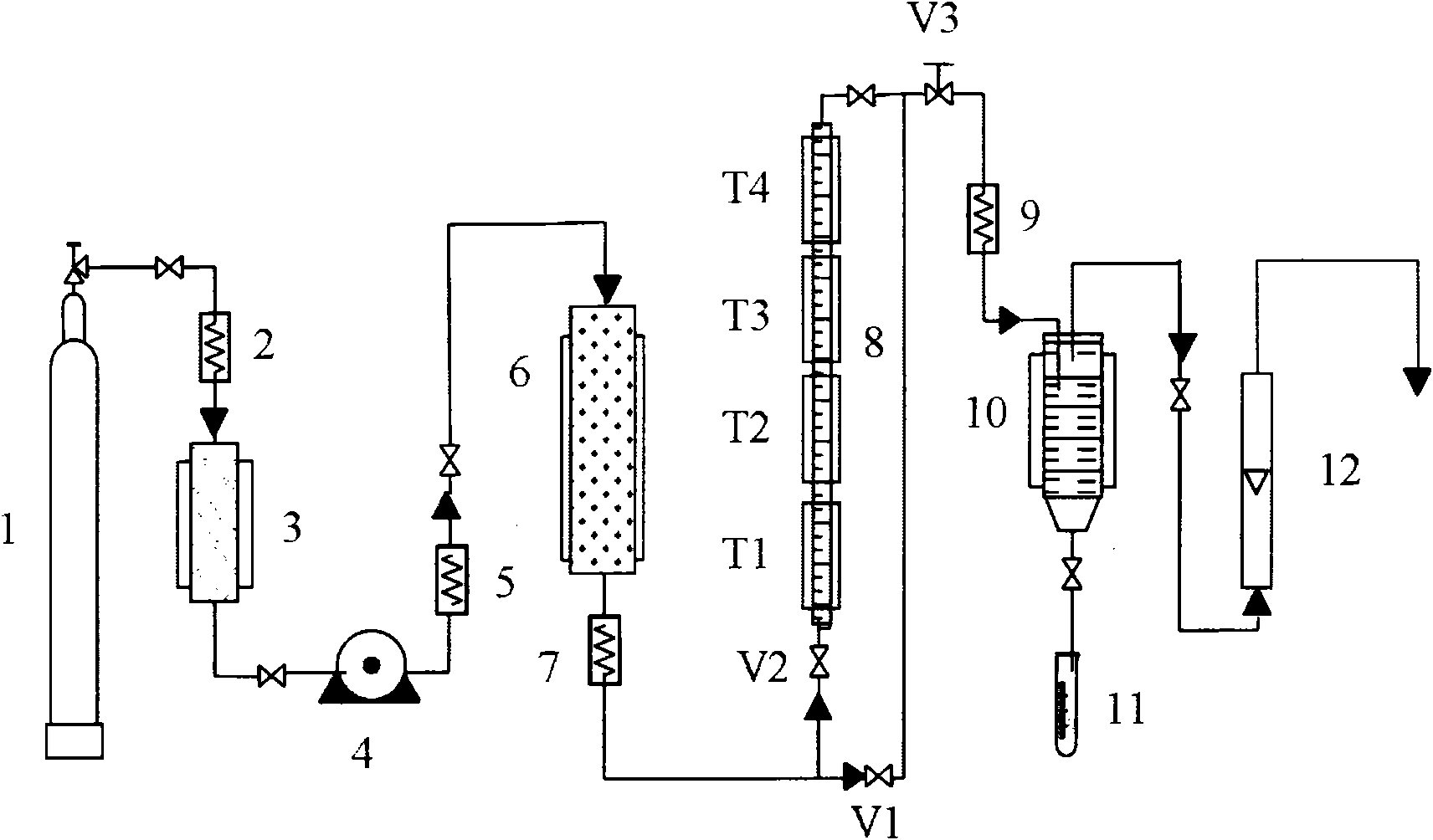

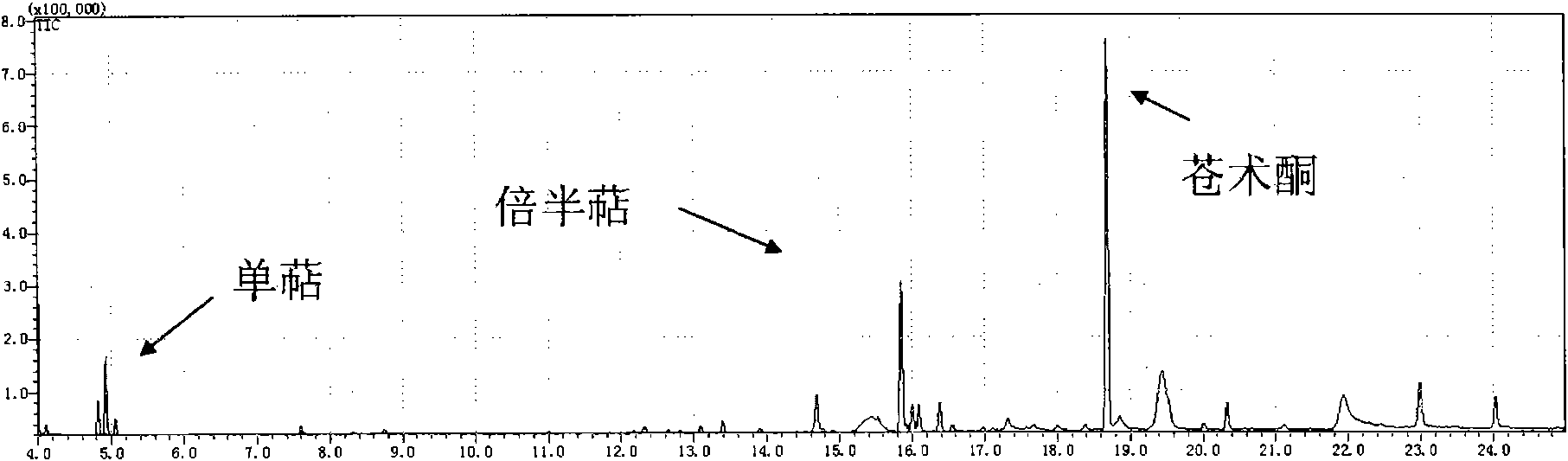

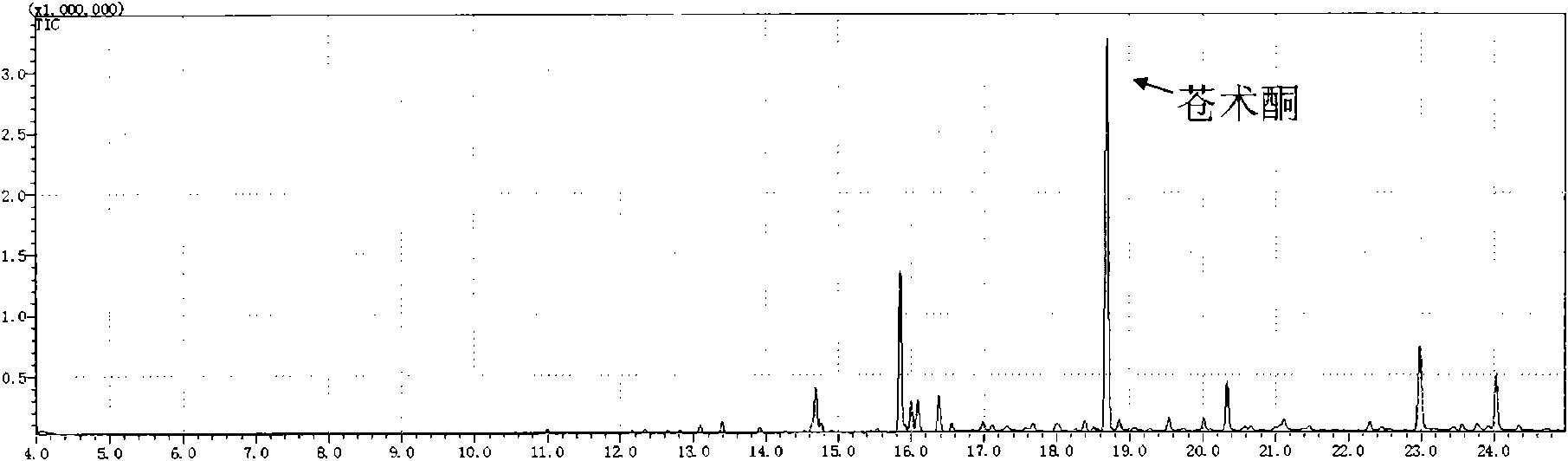

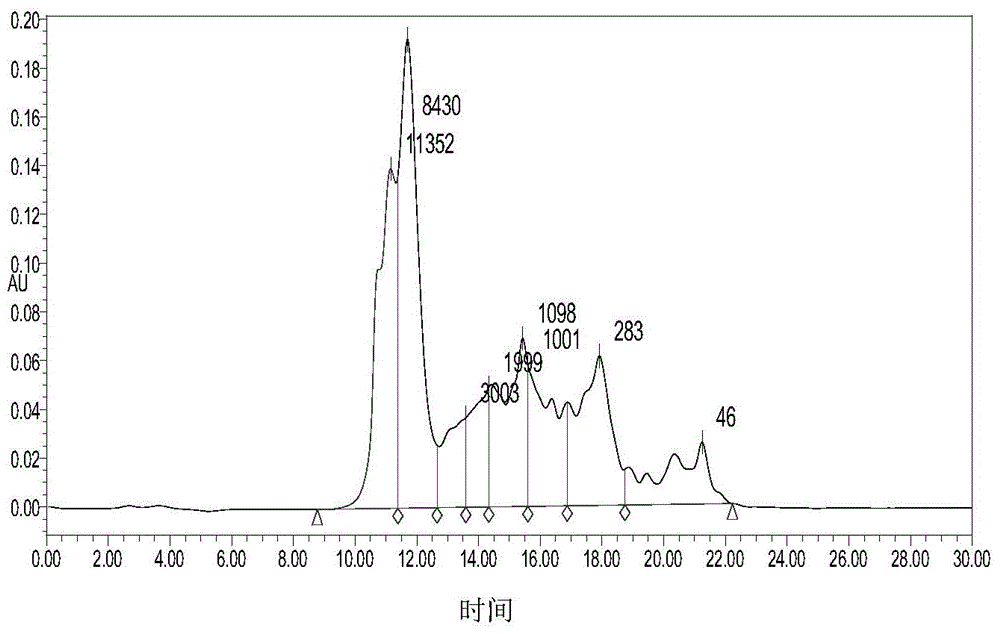

Method for preparing large-head atractylodes rhizome and sesquiterpene compound

InactiveCN101978984AAchieve continuous separationImprove quality scoreOrganic chemistryDigestive systemFractionationFractionating column

The invention discloses a method for preparing a large-head atractylodes rhizome and sesquiterpene compound. The method comprises the following steps of: 1) extracting a large-head atractylodes rhizome medicinal material at a set temperature and under a set pressure in a supercritical extractor, and feeding the extract into a fractionating column along with supercritical CO2 fluid; 2) applying a temperature gradient from low to high to the fractionating column under a certain fractionation pressure to ensure that the supercritical CO2 fluid sectionally fractionates volatile oil at a fixed flow rate; and 3) separating the volatile oil subjected to fractionation into two fractionation sections including a monoterpene component and a sesquiterpene compound, performing pressure reduction and feeding into a separator sequentially, collecting the fractionation section of the sesquiterpene compound, metering the CO2 by a rotor meter and emptying. By the method, the supercritical extraction is coupled to fractionation technology, so that the removal of the terpene from the volatile oil of the large-head atractylodes rhizome in the supercritical CO2 medium and the enrichment of the sesquiterpene are continuously finished, and a new way is provided for preparing the monoterpene-free large-head atractylodes rhizome and sesquiterpene compound.

Owner:SHENZHEN UNIV

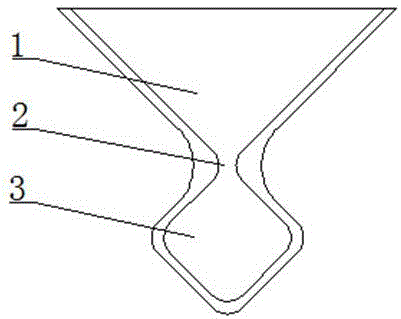

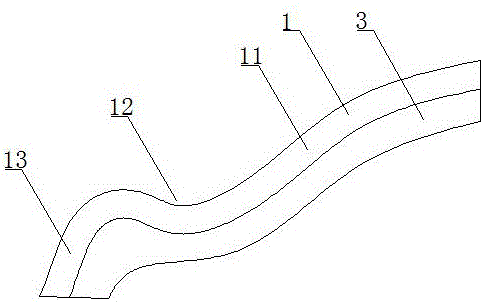

Egg white separator

The invention relates to a device for separating egg white of eggs, belongs to the field of separators, and particularly discloses an egg white separator, which comprises a first passage and a second passage, wherein the first and second passages are superposed, and are communicated through a gap; egg white in the first passage enters the second passage through the gap under the action of gravity. The gap is formed to implement separation of the egg white and reserve egg yolk in the first passage; by the structure, the egg white can be continuously separated, and multiple eggs can be placed on the first passage, so that the separation efficiency is improved; in addition, after the separator is inclined, the egg white can flow, thereby achieving an effect of continuous separation; the separator is simple in structure, convenient to use and applicable to batch separation, and can be conveniently used for individuals and families, the separation effectiveness is improved, rapid separation can be implemented, and the separation effect can be improved.

Owner:唐明

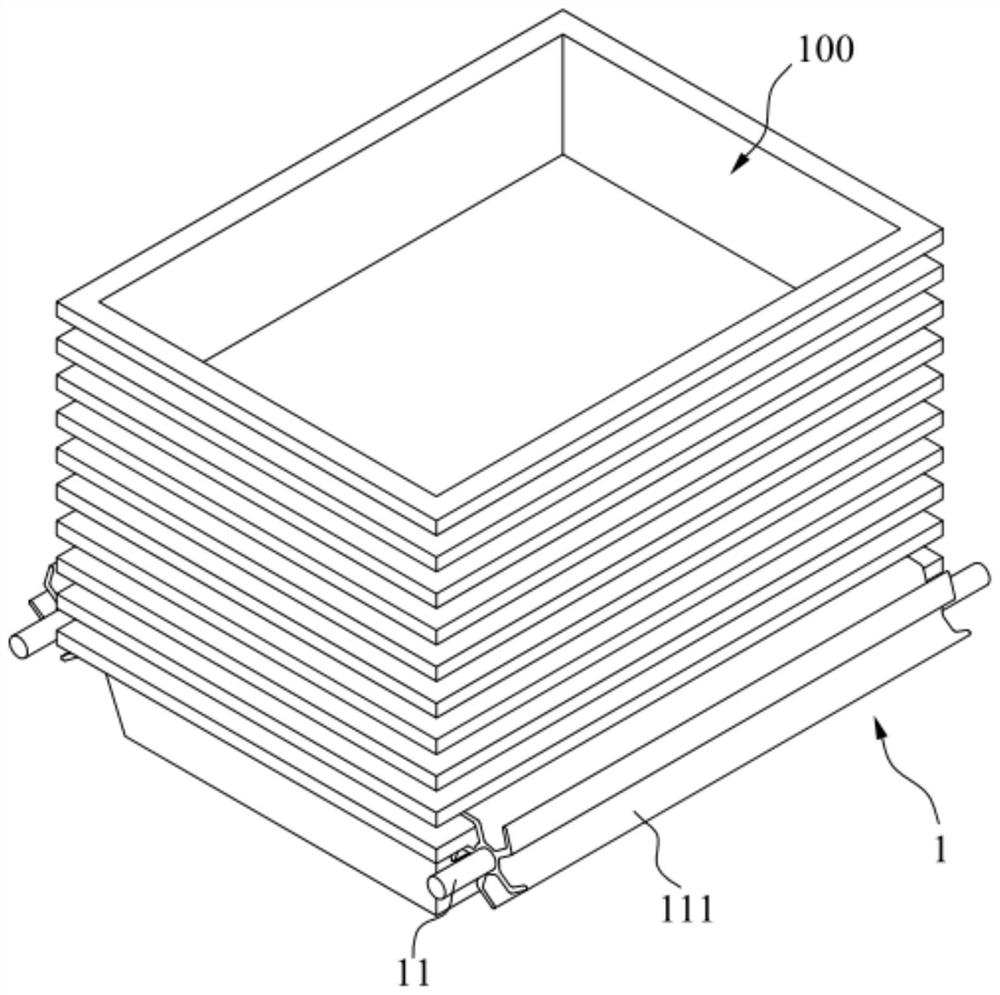

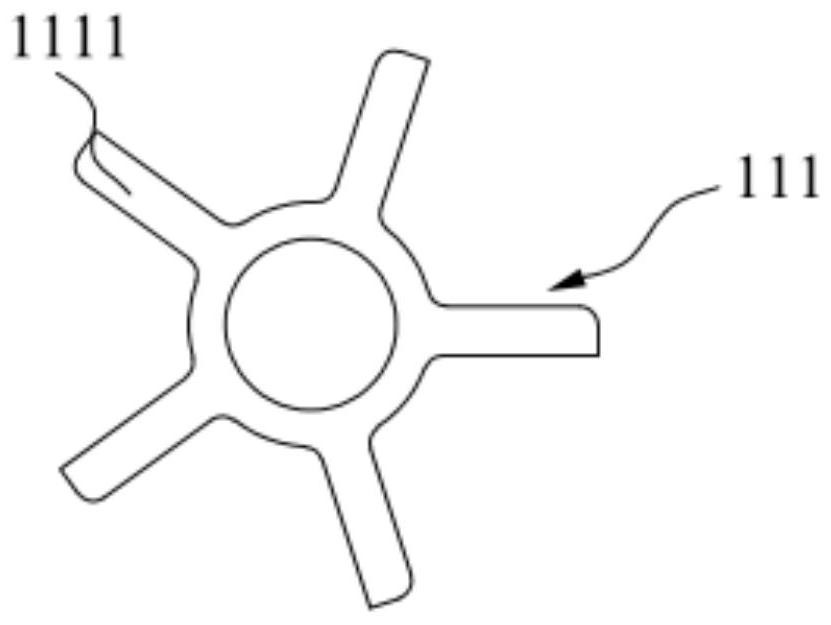

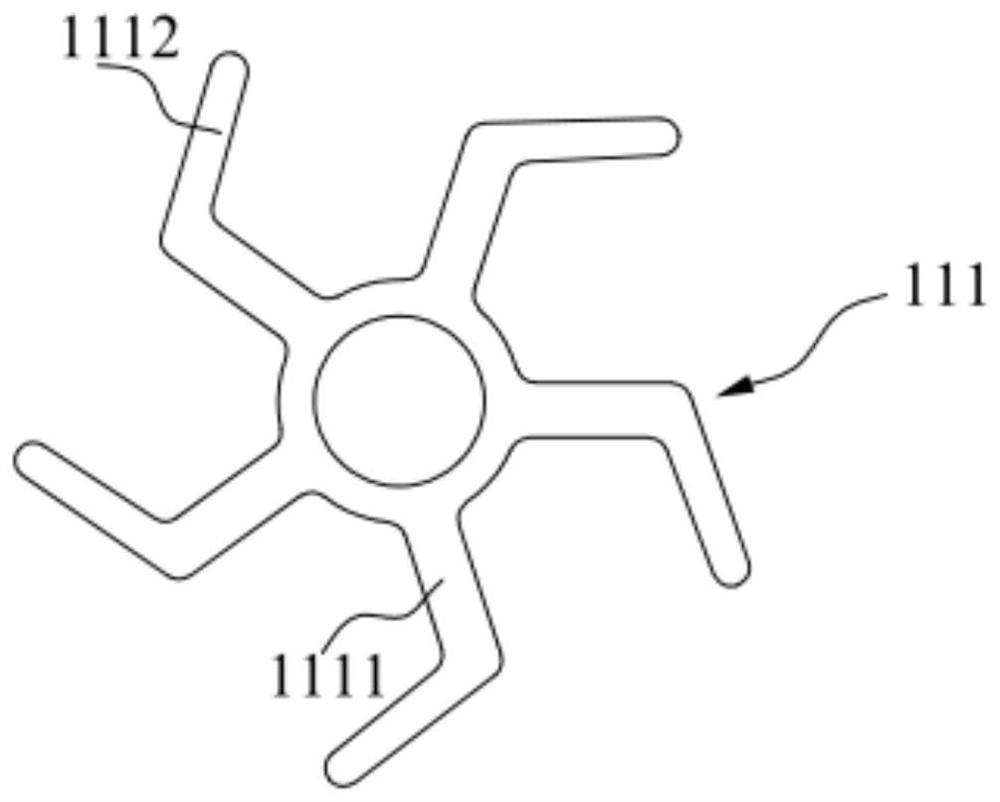

Continuous tray separation device, equipment and method

PendingCN112919145AReliable continuous separationAchieve continuous separationConveyorsDe-stacking articlesLogistics managementEngineering

The invention belongs to the technical field of logistics warehouse distribution automation equipment, and discloses a continuous tray separation device, equipment and method. The continuous tray separation device comprises a separation mechanism and a control module, the separation mechanism comprises two separation rollers rotationally installed on a rack, and the two separation rollers are symmetrically arranged at the two sides of trays; and a plurality of separation assemblies extending in the axial direction of the separation rollers are arranged at the periphery of the separation rollers and evenly distributed along the periphery of the separation rollers. The control module can control the two separation rollers to synchronously and reversely rotate with the axial direction as the center. The continuous tray separation equipment comprises a propelling device and the continuous tray separation device, the propelling device is used for pushing a tray pile onto the two separation rollers, and the control module can control starting and stopping of the propelling device. The continuous tray separation device can achieve continuous separation of the trays, and is high in separation efficiency, simple in overall structure and low in manufacturing cost. The continuous tray separation equipment can automatically replace a tray pile, the working efficiency is improved, and full automation of the equipment is achieved.

Owner:CHINA POST SCI & TECH

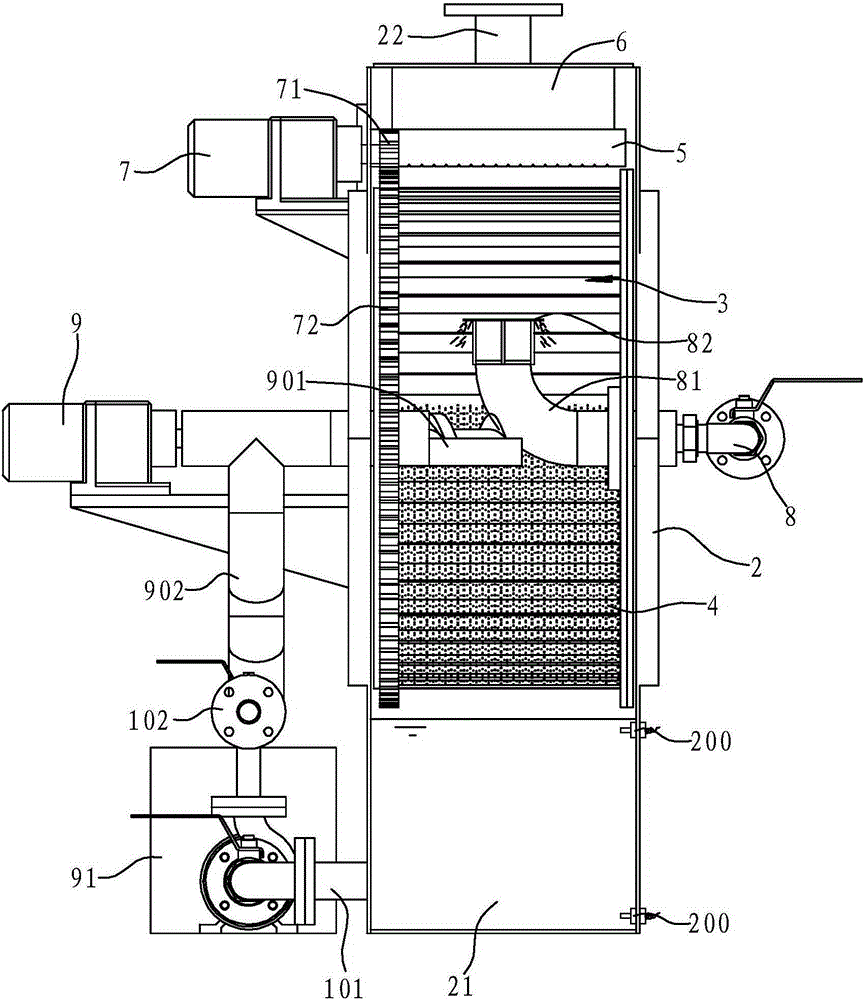

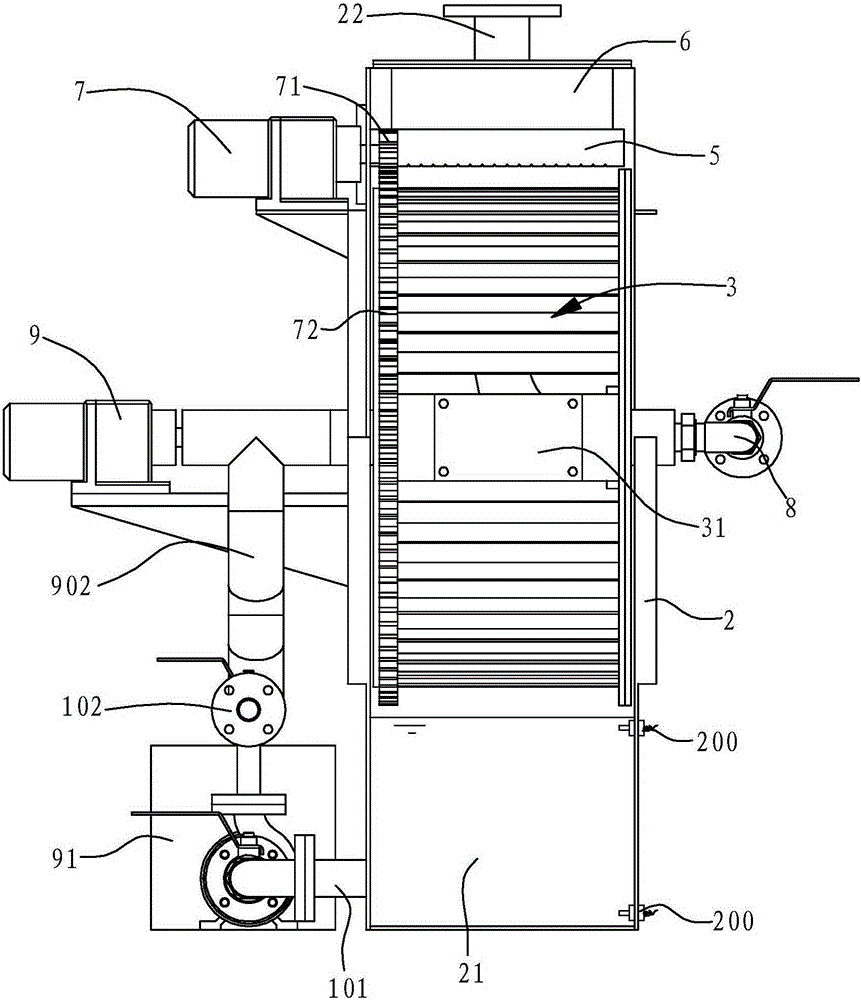

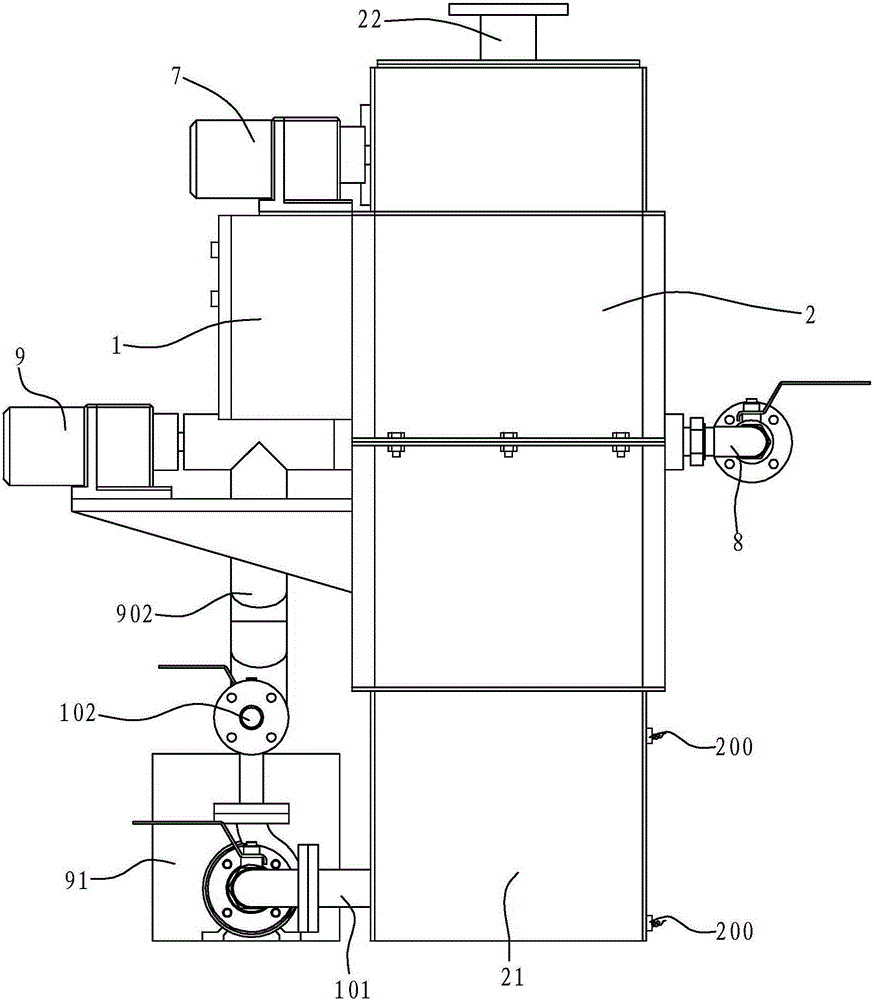

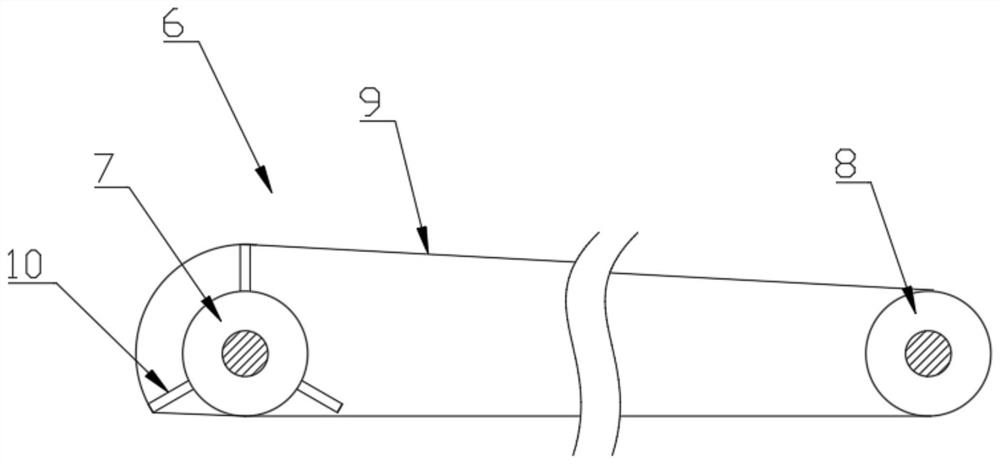

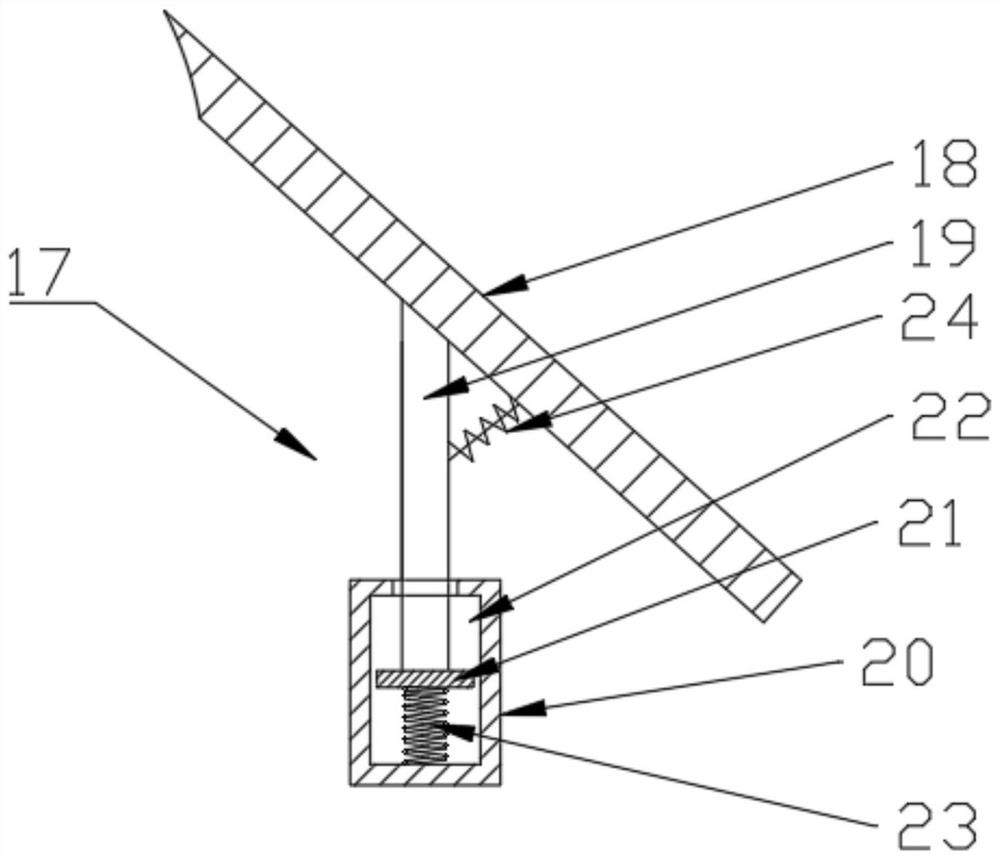

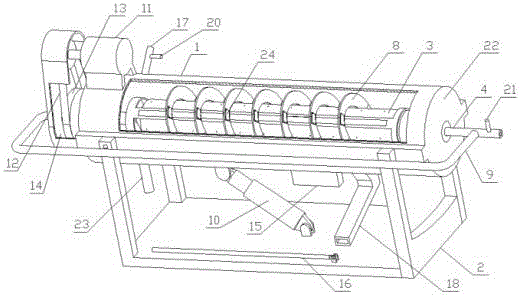

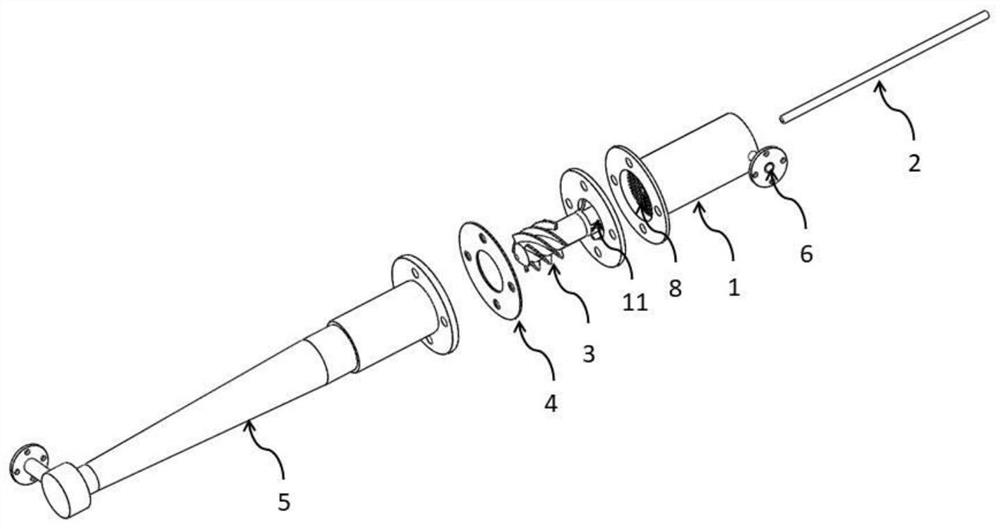

Dry discharging device for tailings of circular pipe through multiple force fields and use method

PendingCN106823519AAchieve continuous separationRealize solid-liquid separationStationary filtering element filtersPipeMechanical engineering

The invention discloses a dry discharging device for tailings of a circular pipe through multiple force fields and a use method. The device comprises a drum (1), wherein a spiral separating mechanism (3) is arranged in the drum (1); one end of the spiral separating mechanism (3) is connected with a driving mechanism; the spiral separating mechanism (3) comprises a suction filtration pipe (4); air vents (5) are distributed on the suction filtration pipe (4); a filter screen (6) and a filter element frame (7) are successively arranged outward along the radial direction of the suction filtration pipe (4); and spiral blades (8) are distributed on the filter element frame (7). The dry discharging device has the characteristics of high separating efficiency, simple structure and process, low failure rate, low maintenance cost and equipment cost and good solid-liquid separating effect.

Owner:GUIZHOU UNIV

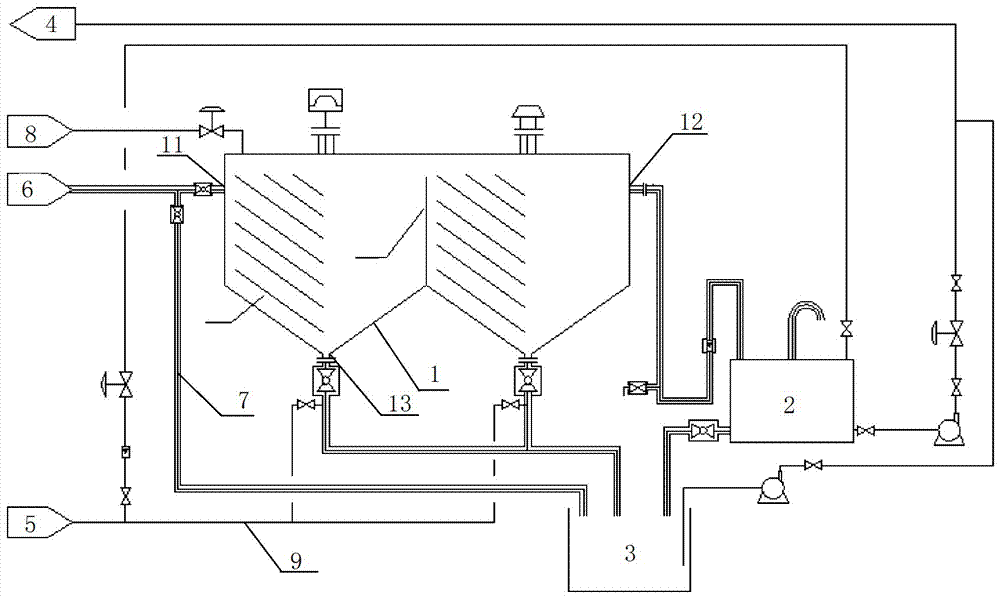

Device and method of continuously separating solid-liquid phases in caprolactam distilled heavy residual liquid

ActiveCN106943775AAchieve continuous separationAchieve recyclingSettling tanks heating/coolingSedimentation settling tanksPulp and paper industryCaprolactam

The invention discloses a device and a method of continuously separating solid-liquid phases in a caprolactam distilled heavy residual liquid. The device comprises a settler. A feed inlet is formed in one side of the settler while an overflow port is formed in the other side, and a slagging port is formed in bottom; the overflow port is connected to a clear liquor middle tank, and the slagging port is connected to a residual clear liquor tank; and the clear liquor middle tank is connected to a caprolactam step through a pipeline and a pump, and the clear liquor middle tank is connected to a caprolactam process water pipeline. By using caprolactam process water to clean and dilute the clear liquor and residues, continuous separation of caprolactam and low polymers in the caprolactam distilled heavy residual liquid and cyclic utilization of the caprolactam process water are realized.

Owner:HUBEI SANNING CHEM

Horizontal spiral settling centrifugal separation device of biological enzyme extracting solutions

The invention discloses a horizontal spiral settling centrifugal separation device of biological enzyme extracting solutions. The device comprises an adjusting solution tank arranged in the front, and the adjusting solution tank is provided with a feed port, a water inlet, a stirring device, a filtering net, a slag discharging port and a discharge port, wherein the feed port is formed in the front section of the adjusting solution tank, the water inlet is formed in the upper part of the adjusting solution tank, the stirring device is arranged on one side of a feed port of the filtering net, the filtering net is arranged to be inclined to the discharge port, and an acute angle of 70-80 degrees is formed between the filtering net and the bottom of the adjusting solution tank; and the adjusting solution tank is sequentially connected to a screw pump, a throttling valve and a feed port of a horizontal spiral settling centrifugal machine through a connecting pipe. According to the device, the solid-liquid concentration of the separated extracting solutions can reach 40-60%, slag removal is smooth and unblocked, separating solutions are clear, machine washing is not needed in the whole process, the halt operation is reduced, the problems that the horizontal spiral settling centrifugal machine cannot separate high-solid concentration solutions and halting and cleaning are needed because slag cannot be smoothly pushed are solved, and high-concentration continuous solid-liquid separation production is realized.

Owner:南宁庞博生物工程有限公司

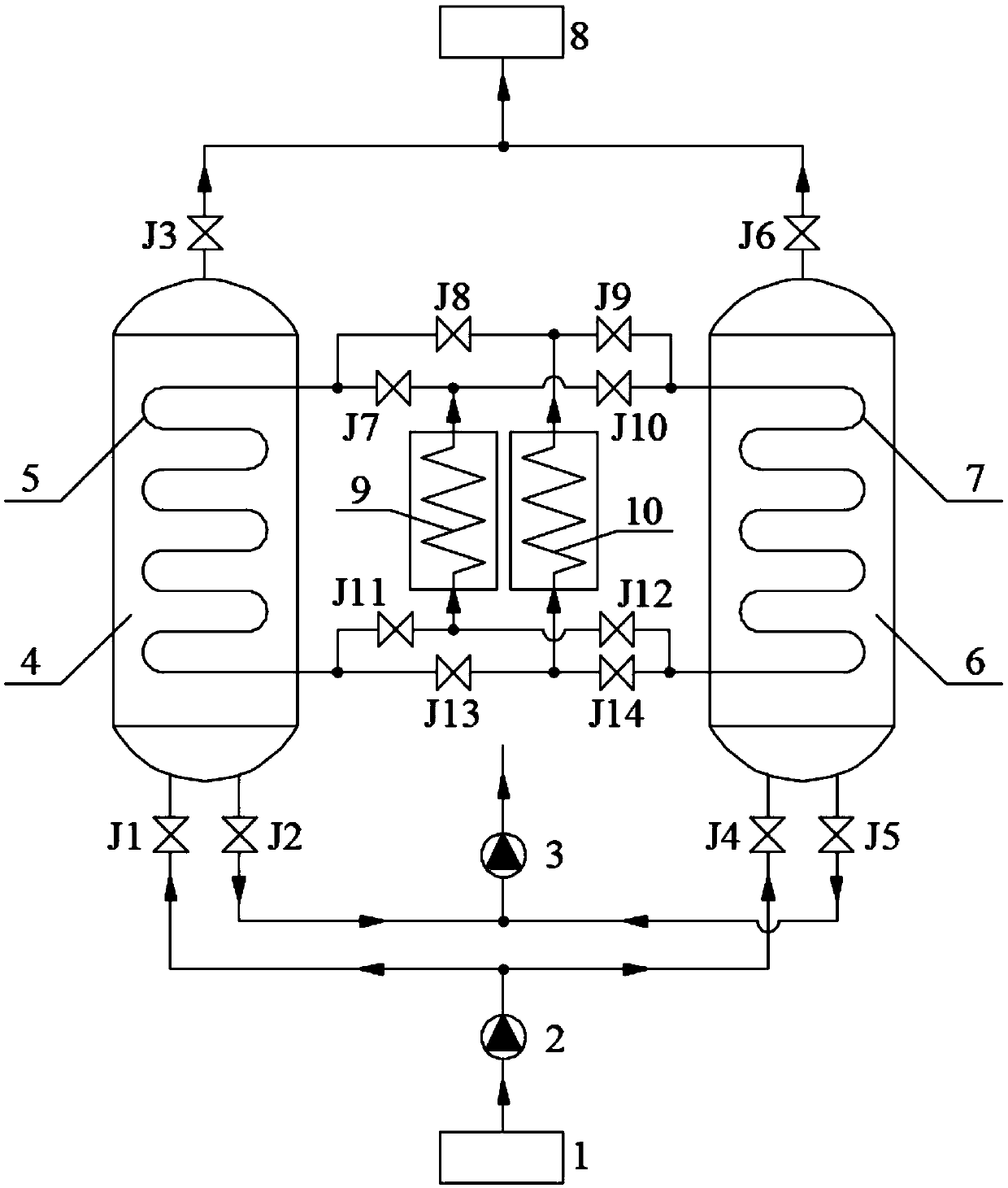

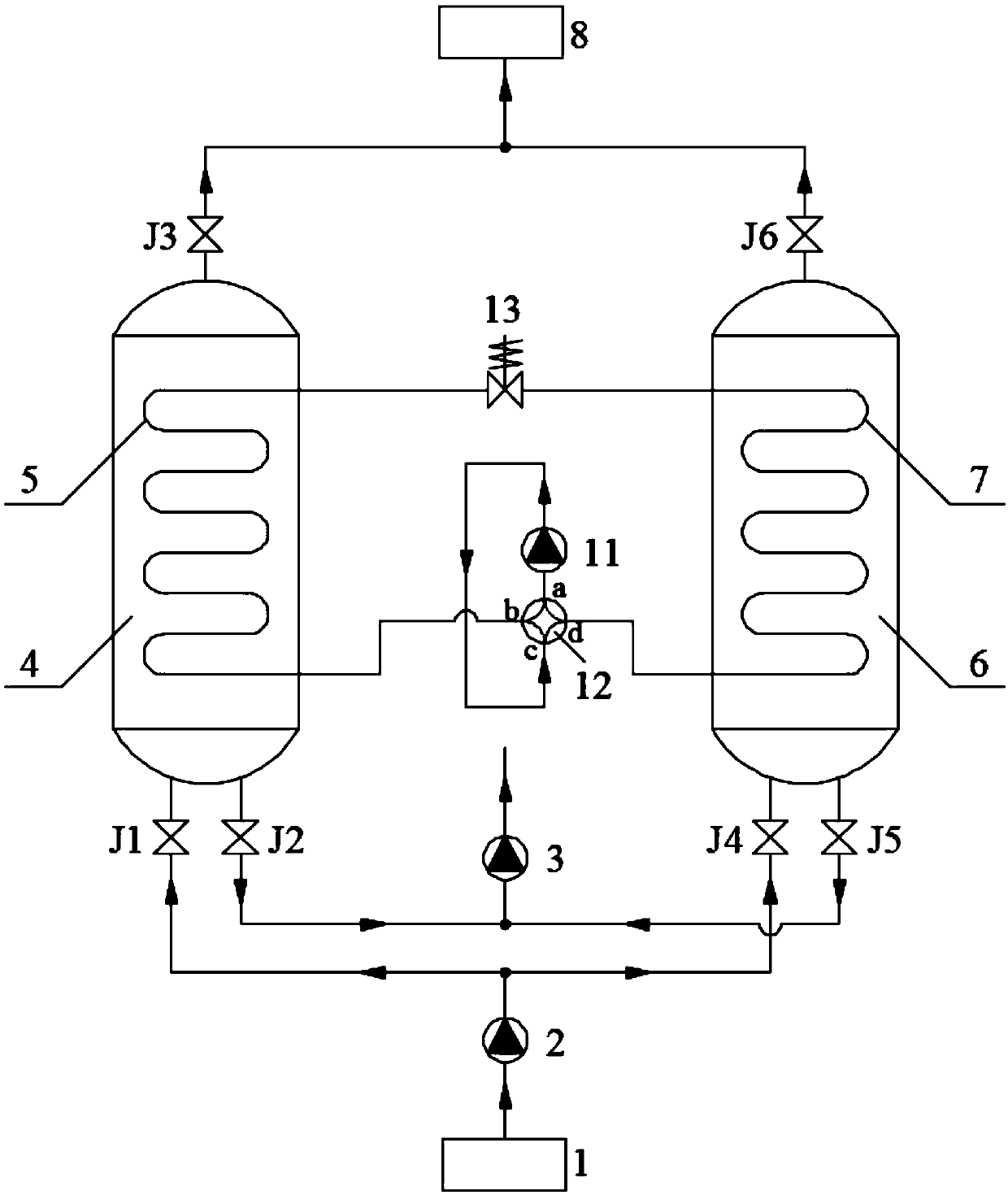

Temperature and pressure synergistic gas adsorption, separation and purification system

PendingCN109569182AEfficient separationAchieve continuous separationDispersed particle separationTemperature controlHigh energy

The invention discloses a temperature and pressure synergistic gas adsorption, separation and purification system which comprises a gas inlet unit, a gas exhaust unit, an adsorption and separation unit and a temperature control unit. The adsorption and separation unit comprises an air compressor I, a vacuum pump, an adsorption tower I and an adsorption tower II, the gas inlet unit is communicatedwith gas inlets in the bottoms of the adsorption tower I and the adsorption tower II via the air compressor I, gas outlets in the tops of the adsorption tower I and the adsorption tower II are communicated with the gas exhaust unit, gas return openings in the bottoms of the adsorption tower I and the adsorption tower II are communicated with the vacuum pump, the temperature control unit comprisesa heat exchanger I, a heat exchanger II and a cold and heat exchange device, the heat exchanger I is arranged inside the adsorption tower I, the heat exchanger II is arranged inside the adsorption tower II, and the cold and heat exchange device is connected with the heat exchanger I and the heat exchanger II. The temperature and pressure synergistic gas adsorption, separation and purification system has the advantages that the temperature and pressure synergistic gas adsorption, separation and purification system is easy and convenient to operate, and the problems of high energy consumption ofseparation procedures in existing gas pressure swing adsorption and purification procedures, low yield of products, incapability of sufficiently utilizing energy of systems and the like can be solvedby the aid of the temperature and pressure synergistic gas adsorption, separation and purification system.

Owner:CHINA UNIV OF MINING & TECH

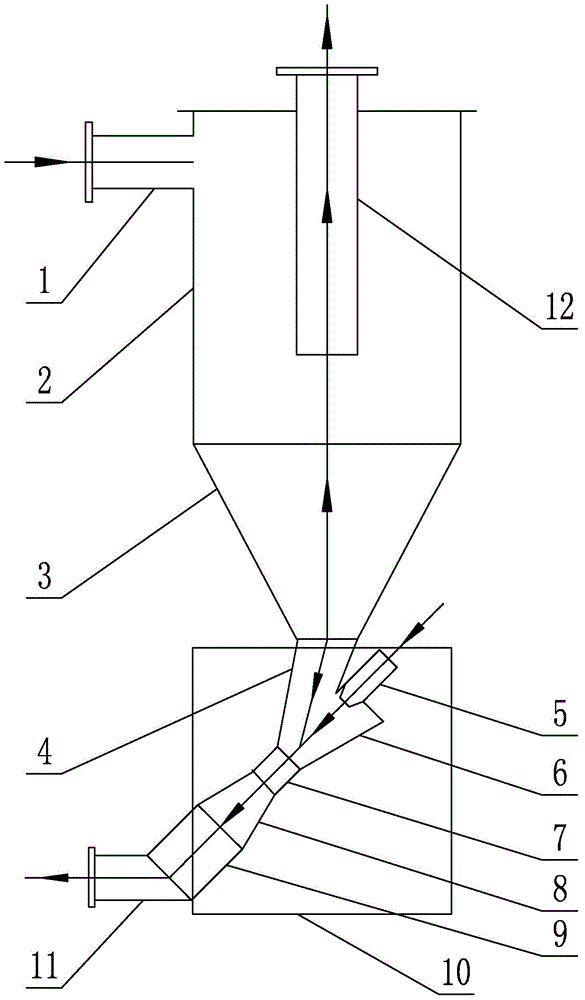

Injection type rotational flow continuous separator

InactiveCN104607325AReduce the amount of waterRealize water saving and energy savingWater/sewage treatment by centrifugal separationReversed direction vortexRefluxSewage

The invention discloses an injection type rotational flow continuous separator, relates to a rotational flow continuous separator and solves the problems that an existing rotational flow continuous separator adopts reflux waste water to inject dirty sundries, so that the water consumption is large, water cannot be taken on the spot, a pipeline is overlong, and the consumption of pipe materials is too high. The lower end of a cylinder is mutually communicated with the large end of a cone barrel, a waste water inlet pipe is tangentially arranged on the outer side wall of the cylinder, the waste water inlet pipe is communicated with the upper part of the cylinder, and an overflow pipe is vertically arranged on the axis of the cylinder; a mixing chamber, a throat part, a diffuser pipe and a mixed water outlet pipe are successively arranged in the direction of the axis in an inclined manner from top to bottom, and the mixing chamber, the throat part, the diffuser pipe and the mixed water outlet pipe are successively communicated; the lower end of the cone barrel is communicated with the mixing chamber through a blowdown pipe, a spray nozzle is arranged at the upper end of the mixing chamber, the inner diameter of the mixing chamber is arranged in an gradual constriction manner from top to bottom, the inner diameter of the diffuser pipe is arranged in an gradual extension manner from top to bottom, and a waste water outlet pipe is communicated with the lower end of the mixed water outlet pipe. The injection type rotational flow continuous separator disclosed by the invention is used for treating urban original waste water.

Owner:HARBIN INST OF TECH

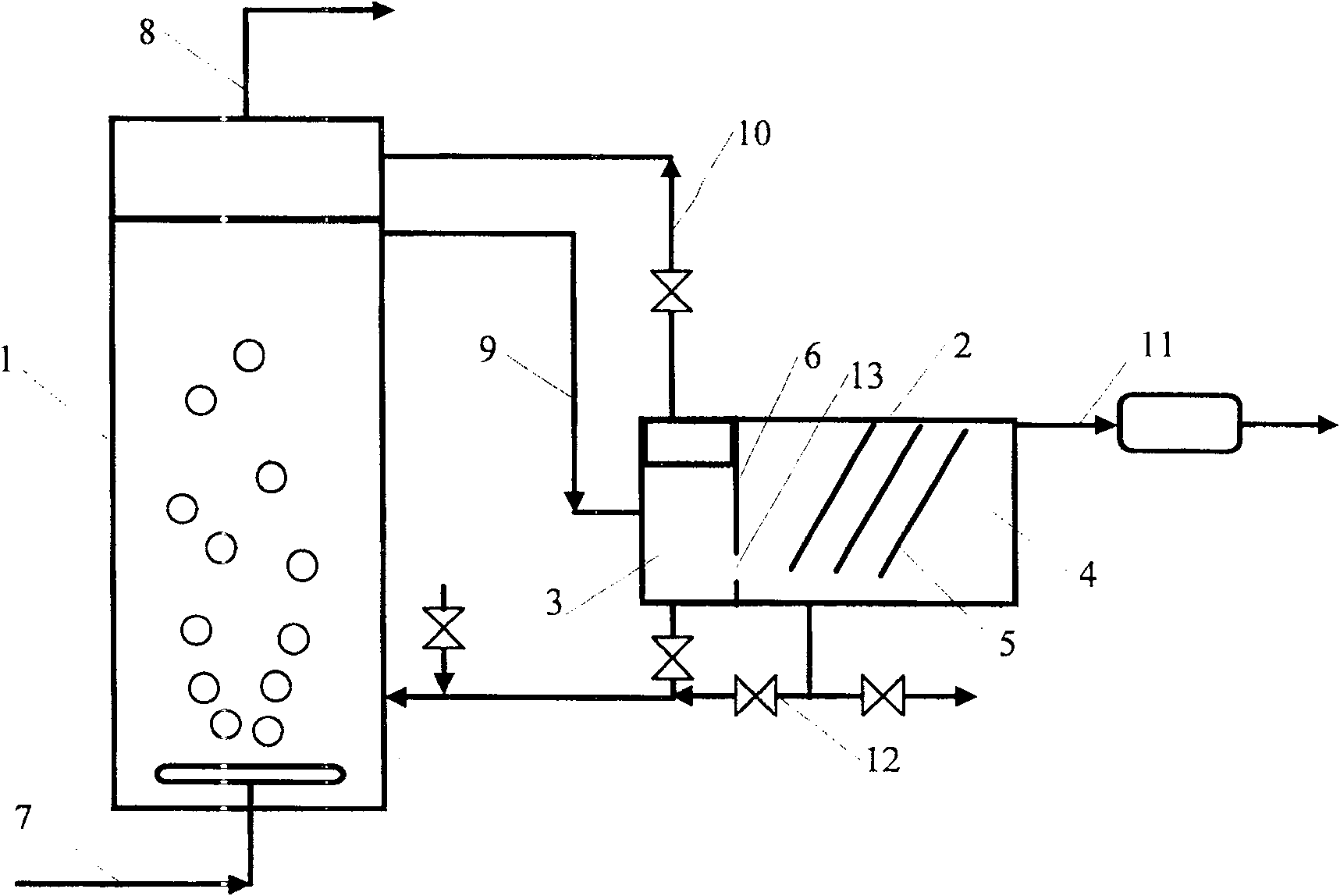

Continuous separation device for oil and water in pyrolysis gas

InactiveCN108707481AAchieve continuous separationAchieve recyclingBiofuelsPyroligneous acid productionShell and tube heat exchangerTar

The invention discloses a continuous separation device for oil and water in pyrolysis gas. The continuous separation device comprises a shell-and-tube heat exchanger, a spraying device and a centrifugal separation device which are connected in sequence, wherein the shell-and-tube heat exchanger is provided with an inner-layer tube and a shell; the inner-layer tube is provided with a pyrolysis gasinlet and a pyrolysis gas outlet; the shell is provided with a cooling medium inlet and a cooling medium outlet; the sprinkling device is connected with the pyrolysis gas outlet; the spraying device is provided with a condensing device, a pyrolysis gas purifying outlet and an oil outlet; the pyrolysis gas can be upwards discharged through the pyrolysis gas purifying outlet after passing through the condensing device; a liquid matter generated after condensation of the pyrolysis gas can downwards flow in the centrifugal separation device through the oil outlet; the centrifugal separation deviceis provided with a centrifugal shell, a rotor, a pyroligneous liquid outlet and a tar outlet; the rotor drives the centrifugal shell to rotate; the inner side of the upper end of the centrifugal shell is connected with the pyroligneous liquid outlet, and the outer side is connected with the tar outlet. According to the continuous separation device disclosed by the invention, continuous separationon tar and pyroligneous liquid in the pyrolysis gas can be realized by adopting a physical method, high-temperature pyrolysis is not required, and the requirements on the technology are reduced.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

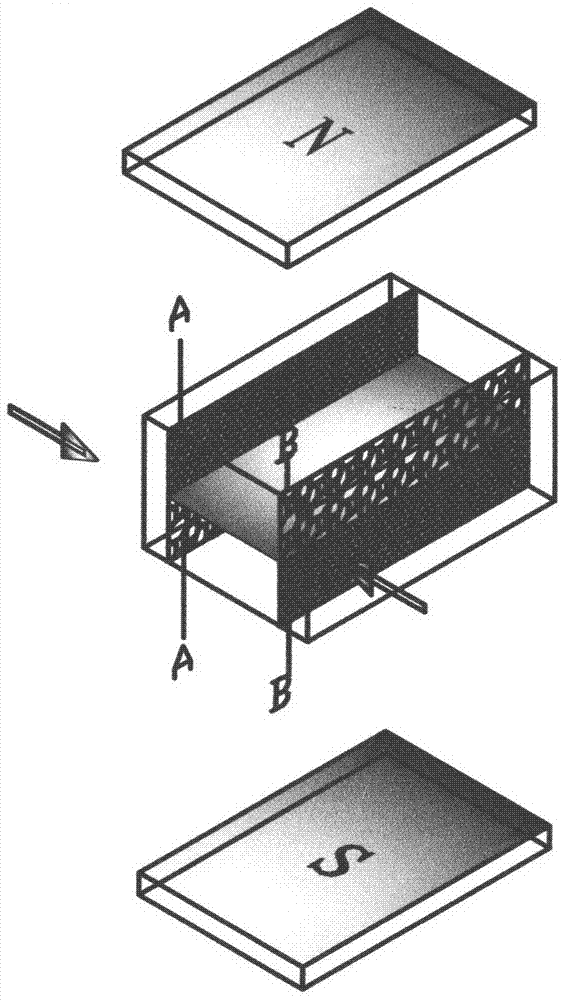

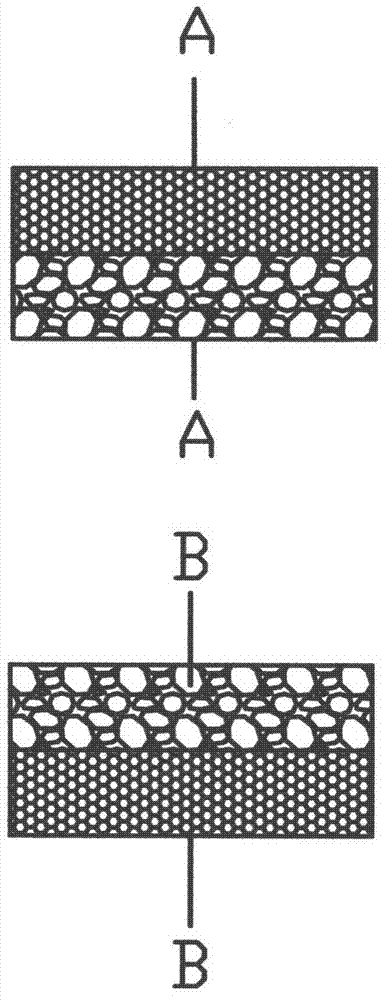

Method and equipment for liquid-solid continuously separation for slurry state bed reactor

ActiveCN100586550CAchieve continuous separationAchieve separationLiquid hydrocarbon mixture productionChemical/physical processesLiquid productLiquid viscosity

The invention discloses a method and a piece of equipment which are used for continuously separating liquid and solid of a serum-bed reactor. The contact reaction between materials and catalyst particles takes place in a serum-bed reactor, and suspension serum after the reaction is guided into a separation unit which comprises an inclined-plate settlement vessel and quickly separated into supernatant and concentrated serum in the inclined-plate settlement vessel, wherein, the concentrated serum returns to the reactor for continuing to participate in the reaction, and the supernatant flows upward into an upper part of the inclined-plate settlement vessel along gaps between the plates and is exhausted. The method provided by the invention implements the continuous separation and circular utilization of solid catalyst particles and liquid products in a smaller operation space and improves settlement efficiency. The equipment provided by the invention is applicable for separating suspension serum with smaller catalyst particles and larger liquid viscosity, occupies small space and has high separation efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

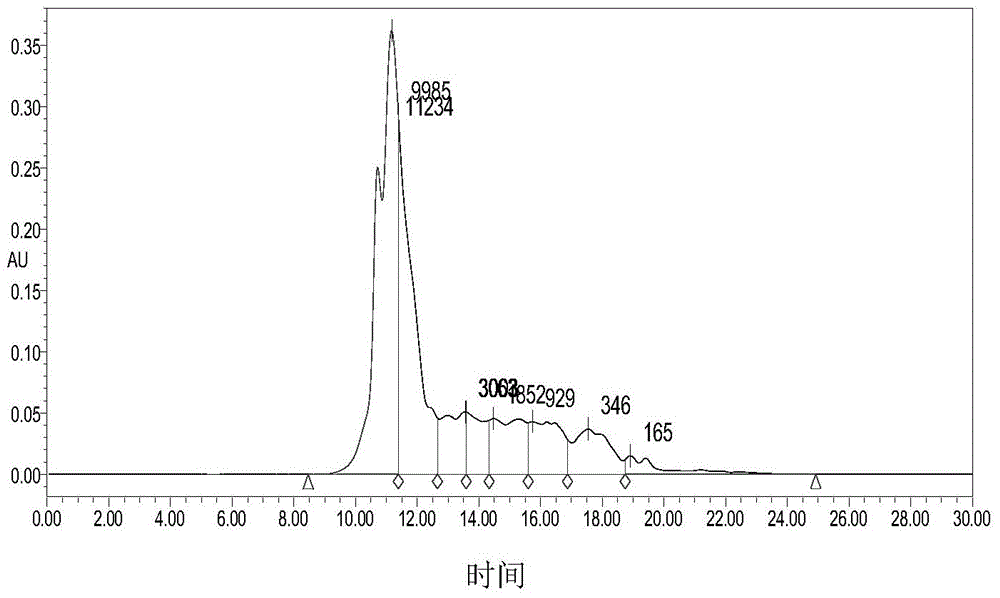

Method for preparing peptide-enriched product with high content of glutamine-bound peptide

ActiveCN104531815AAchieve continuous separationReduce inhibitionBioreactor/fermenter combinationsBiological substance pretreatmentsSolubilityEnzyme membrane

The invention discloses a method for preparing a peptide-enriched product with high content of glutamine-bound peptide, and belongs to the technical field of processing of medicines, foods, agricultural products. According to the method, wheat protein serving as a raw material is firstly sized and mixed, and then is subjected to compound protease enzymolysis in an enzyme membrane reactor which is formed by coupling vibration membrane equipment and an enzyme reactor, so that continuous separation of small-molecular-weight hydrolysate can be realized, macro-molecular substrate and enzyme can be trapped, substrate inhibiting effect can be reduced, the content of free amino acid can be reduced, and the defect of a traditional intermittent enzymolysis method can be overcome. The prepared peptide-enriched product with high content of glutamine-bound peptide has water solubility of more than 99 percent, polypeptide content of more than 90 percent, content of glutamine-bound peptide of more than 30 percent and ash content of less than 1 percent.

Owner:苏州朗邦营养科技有限公司

Spiral shearing viscosity-reducing cyclone separation device

ActiveCN112588460AContinuous separationEfficient separationWater/sewage treatment by centrifugal separationReversed direction vortexOil viscosityOil water

The invention discloses a spiral shearing viscosity-reducing cyclone separation device. The problem that in the oil-water separation process, the oil viscosity is too high, and the oil-water separation performance is greatly influenced is solved. The device is characterized by further comprising a flange type viscosity-reducing spiral flow channel (1), an oil flow pipe (2), a secondary spiral flowchannel (3) and a large gasket (4). The flange type viscosity-reducing spiral flow channel (1), the secondary spiral flow channel (3), the large gasket (4) and a cyclone separation device shell (5) are combined and fixed through bolts and nuts, and the oil flow pipe (2) is inserted into a cavity of the flange type viscosity-reducing spiral flow channel (1) and a cavity of the secondary spiral flow channel (3). The flange type viscosity-reducing spiral flow channel (1) is matched with the secondary spiral flow channel (3) through a flange (10). According to the device, a spiral shearing viscosity-reducing cyclone separation structure is provided, the oil-water viscosity can be reduced through spiral separation of a primary spiral flow channel and the shearing effect of a viscosity-reducingbaffle before oil-water separation, oil and water are efficiently separated in the secondary spiral flow channel, and the applicability of the separation device is enhanced.

Owner:NORTHEAST GASOLINEEUM UNIV

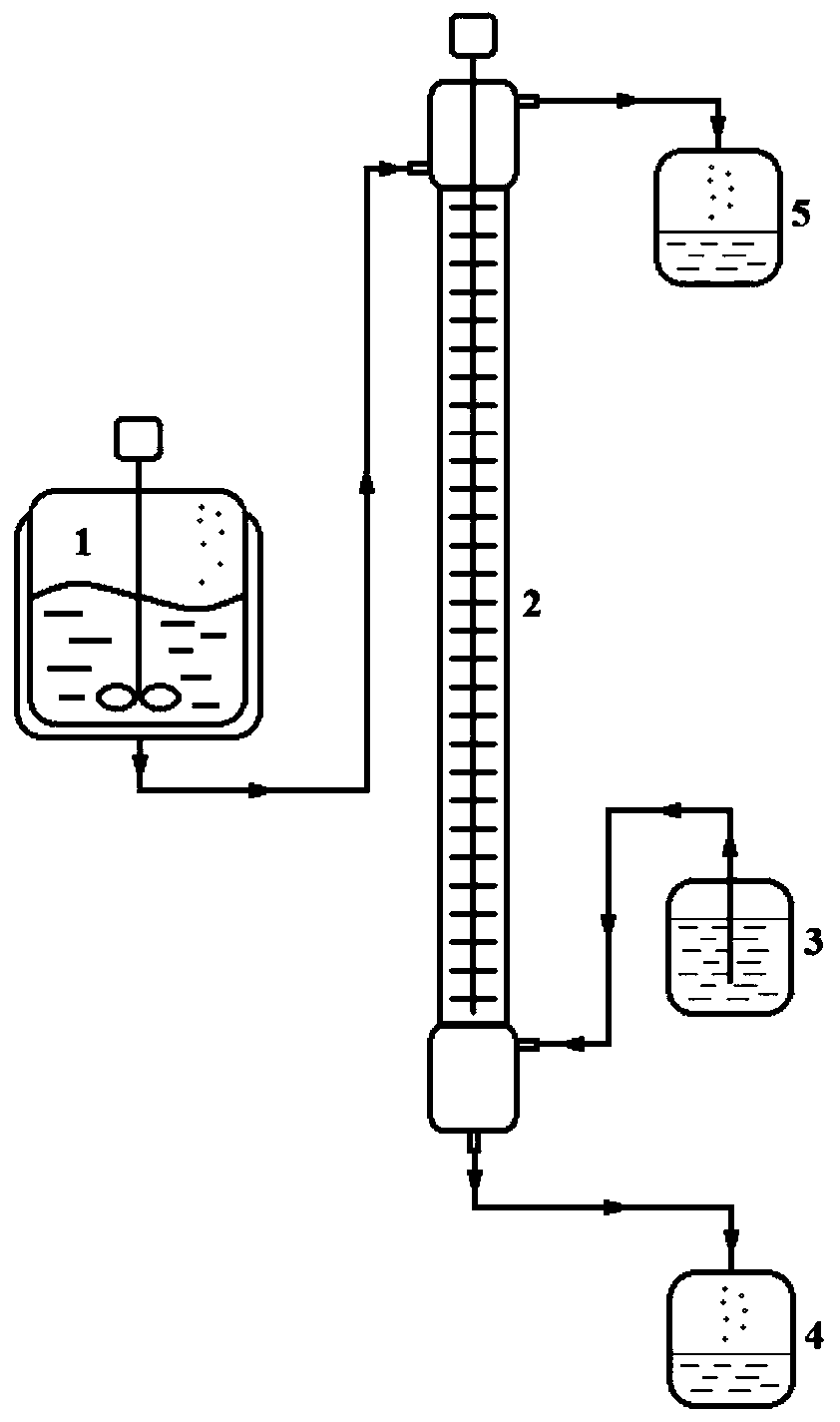

Green production method for continuously preparing nitrominocycline

ActiveCN110922339AReduce pollutionAchieve continuous separationOrganic compound preparationCarboxylic acid amides preparationNitrationEthyl acetate

The invention relates to a green production method for continuously preparing nitrominocycline. The preparation method comprises the following steps of: feeding minocycline, sodium nitrite and sulfuric acid into a reaction kettle for reaction; then feeding the reaction liquid into the top of a turntable extraction tower from the bottom of the reaction kettle, at the same time, feeding an ethyl acetate solution of organic amine from the bottom of the turntable extraction tower for countercurrent extraction; and adjusting the rotating speed of a turntable in the turntable extraction tower to mixthe two phases, discharging the reaction liquid from the bottom of the turntable extraction tower, discharging the extracted ethyl acetate phase from the top of the turntable extraction tower, concentrating the ethyl acetate phase under reduced pressure, and performing cooling, crystallizing and filtering to obtain the nitrominocycline. The continuous production process of nitration reaction of minocycline and sodium nitrite and separation of nitro minocycline is achieved by adopting the reaction kettle coupled with the turntable tower, so that the reaction product can be timely and continuously separated from the reaction system, low-energy-consumption, simple, rapid and continuous production is achieved, and the yield of the obtained reaction product nitrominocycline is greater than 90%.

Owner:南京恒道医药科技股份有限公司

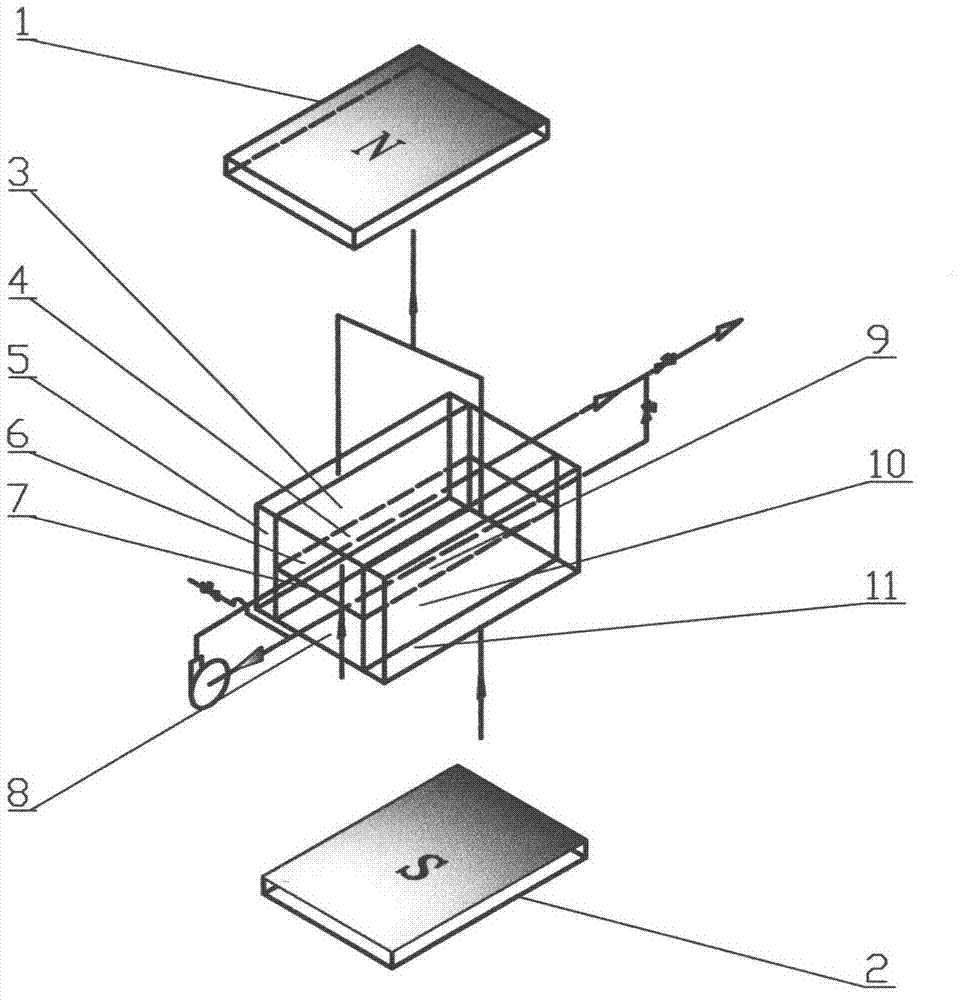

Magnetic separation device

ActiveCN108067350ALow costControl the moving distanceMagnetic separationParticle separationAtomic physics

The invention belongs to the technical field of catalyst particle separation and recovery and discloses a magnetic separation device. The magnetic separation device comprises a separation chamber, circular tubes and magnets, wherein the separation chamber is internally provided with two separation cavities, the separation cavities are provided with material liquid inlets and a magnetic particle recovery mouth, the circular tubes are arranged on the tops of the separation cavities in a sealed manner, and the magnets are located inside the corresponding circular tubes and capable of moving up and down in the axial direction of the corresponding circular tubes. According to the magnetic separation device, by means of the arrangements of the circular tubes inside the separation cavities and the magnets moving up and down inside the corresponding circular tubes, separation of magnetic particle catalyst can be realized, and by means of the arrangements of the two separation cavities, the continuous separation of the magnetic particle catalyst can be realized, and the separation efficiency is improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

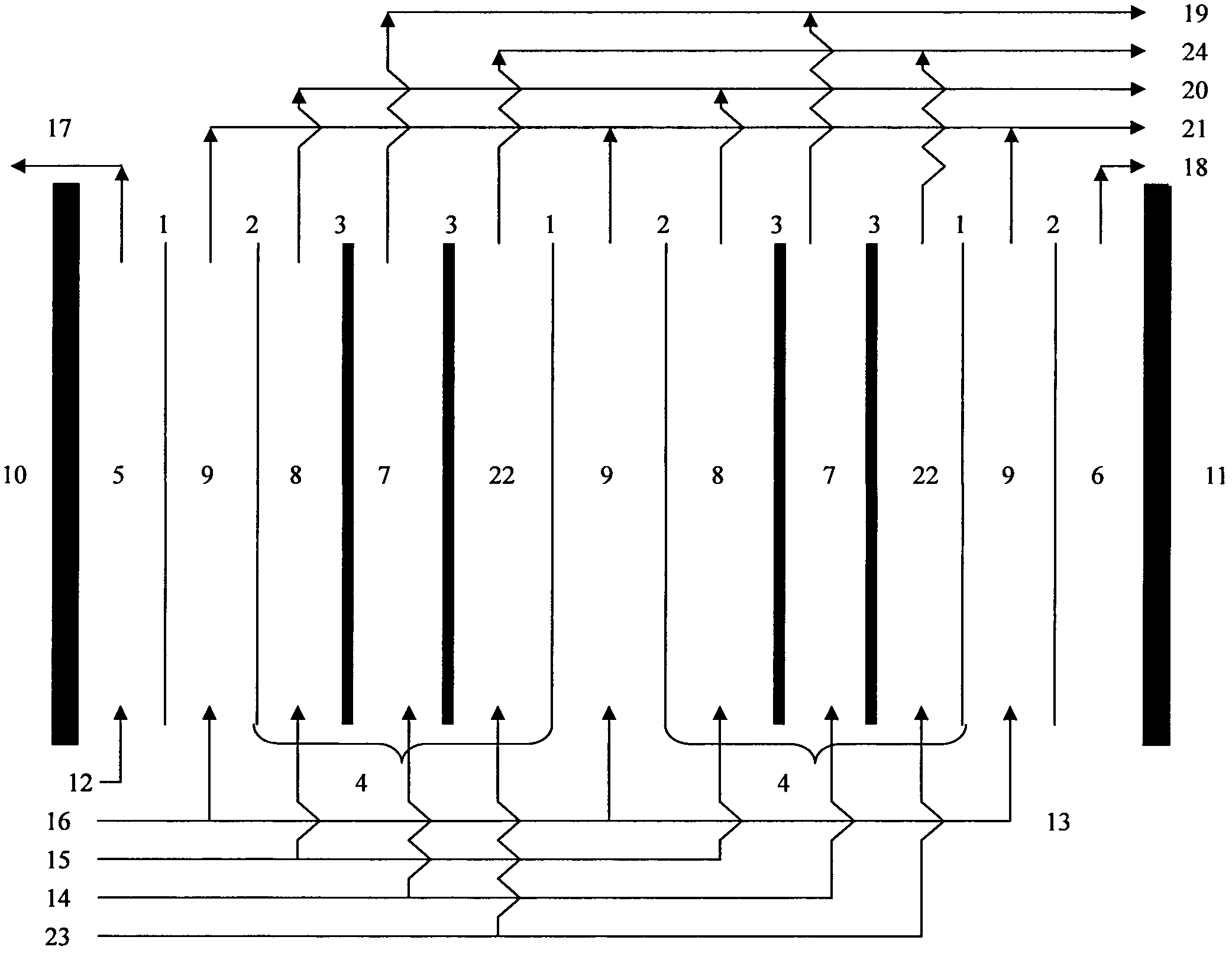

Hydrate process and apparatus for separating gas mixture continuously

ActiveCN100493672CIncrease concentrationHigh recovery rateProductsCarbon compoundsChemical industryMicro bubble

The present invention proposes hydrate process and apparatus for separating gas mixture continuously. The countercurrent continuous separation process in three serially connected stages is adopted to raise the CO2 recovering rate from fume, the CO2 concentration in the product and the separation rate and efficiency. Each of the separating systems consists of a hydrate synthesizer, a hydrate decomposer, a circulating pump, a heat exchanger, and a micro bubble mixing and jetting reactor. The present invention is suitable for continuous separation and enrichment of CO2 in the fume of coal burning power plant, and may be also used in the continuous separation and enrichment of gas mixture containing CO2 in chemical industry, metallurgy, petroleum and other fields.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

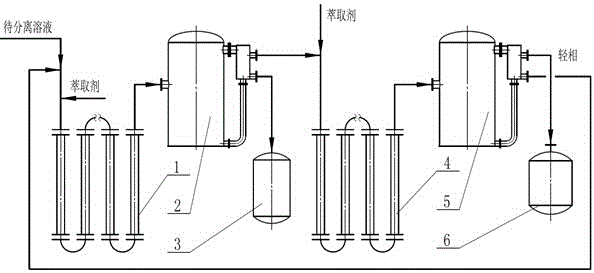

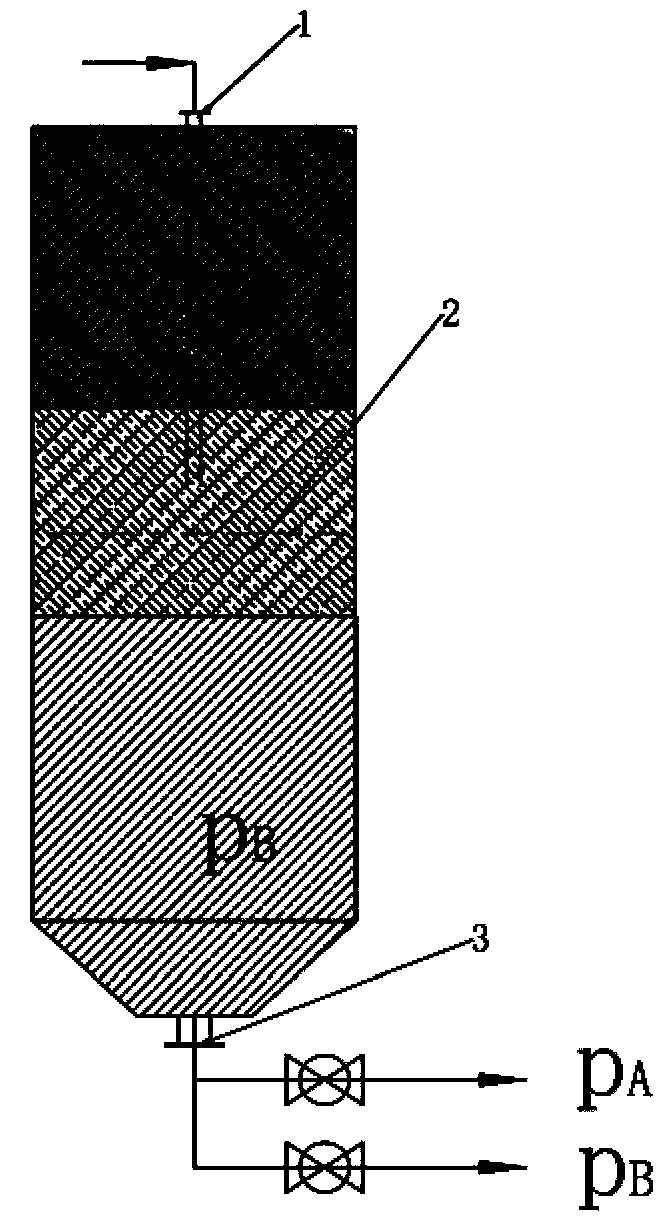

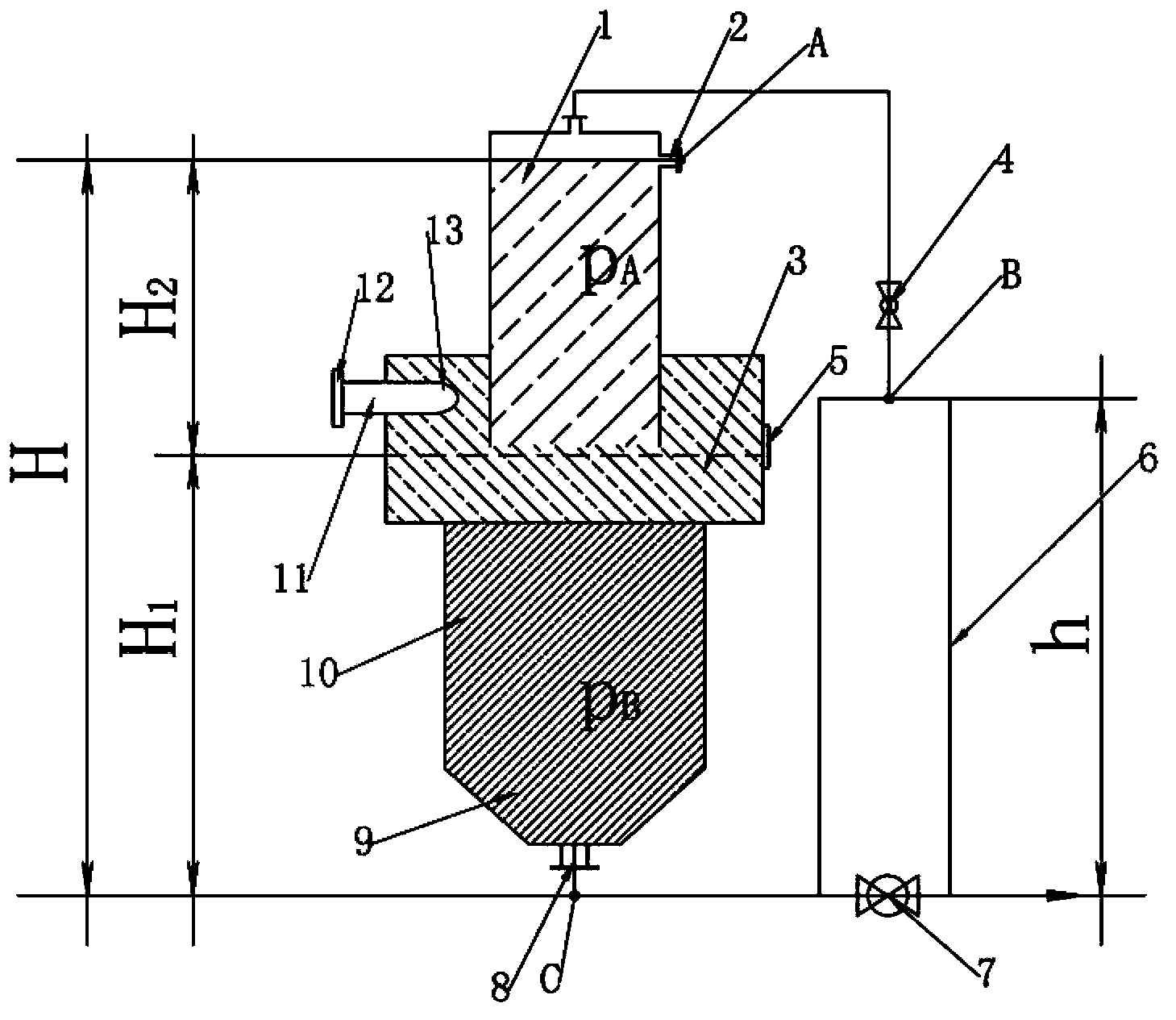

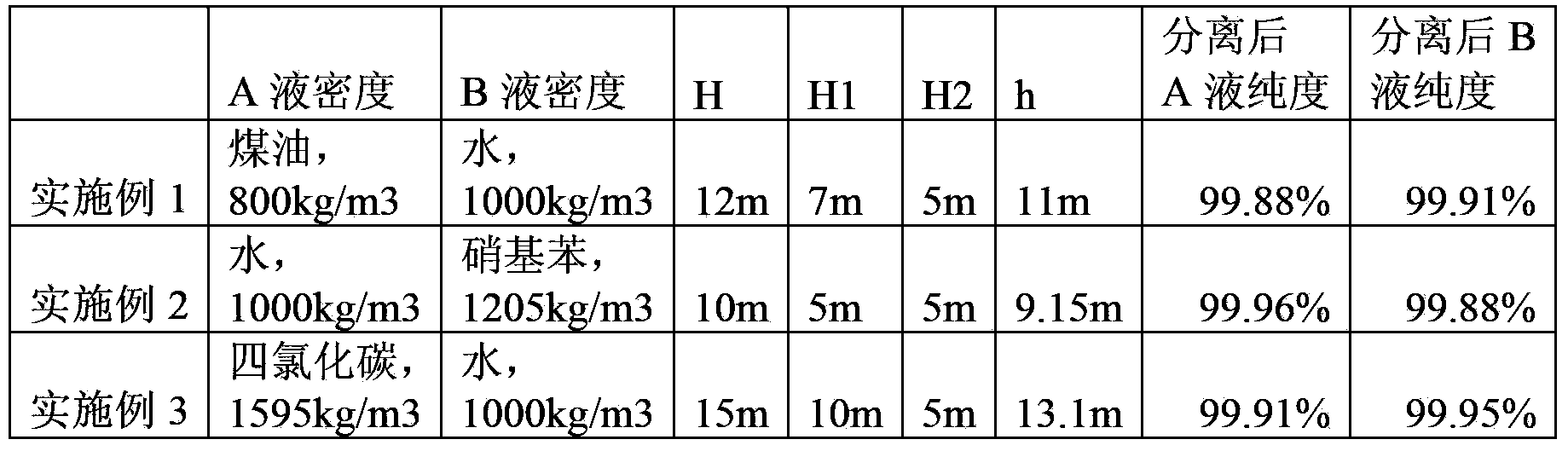

Equipment for continuously and automatically separating mutually insoluble liquid mixture

InactiveCN103357197AOvercome the disadvantage of being difficult to respond continuouslyRealize continuous automatic separationLiquid separationEngineeringPressure balance

The invention relates to equipment for continuously and automatically separating a mutually insoluble liquid mixture. The equipment comprises a barrel with sealed upper and lower ends, and an inverted U-type pipe, wherein the upper end of the barrel is provided with a light liquid outlet; the bottom end of the barrel is provided with a heavy liquid outlet; the middle upper part of the barrel is provided with a mixed liquid inlet pipe; the top end of the inverted U-type pipe is communicated with the top end of the barrel through a pipeline; a pressure balance valve is arranged on the pipeline for connecting the top end of the inverted U-type pipe and the top end of the barrel; two ports of the inverted U-type pipe are communicated with the heavy liquid outlet through a pipeline; a heavy liquid outlet valve is arranged on the pipeline for connecting the two ports of the inverted U-type pipe. The separation equipment can be used for collecting purified products by continuous and automatic separation and is stable and simple to run and free of long-time manual site operation, and the purity of the separated products is more than 99.8%.

Owner:内乡县乌克生物化学制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com