Wear-resistant super-hydrophobic super-lipophilic polyurethane sponge and preparation method and application thereof in oil-water continuous separation

A technology of polyurethane sponge and super lipophilicity, applied in the direction of liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of non-continuous separation, poor surface durability, high cost, etc., achieve small specific gravity, reduce surface energy, and strong acid resistance The effect of strong alkali corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of wear-resistant superhydrophobic superoleophilic polyurethane sponge, comprising the steps of:

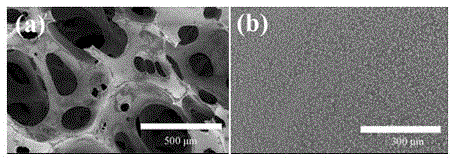

[0031] 1) The polyurethane sponge was ultrasonically cleaned with distilled water and absolute ethanol for 30 minutes, and dried naturally at room temperature;

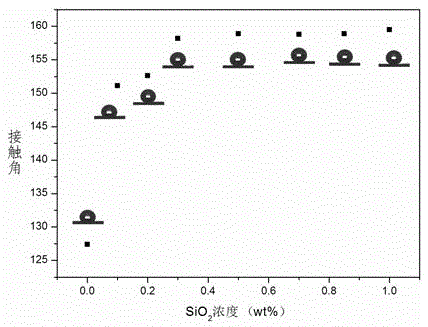

[0032] 2) Evenly disperse hydrophobic DNS-2 nano-silica and polydimethylsiloxane in n-hexane with magnetic stirring, wherein the mass fraction of nano-silica is 0.1%, and the mass fraction of polydimethylsiloxane 0.01%;

[0033] 3) Soak the cleaned polyurethane sponge in the above solution for 1 hour, put the soaked polyurethane sponge in an oven and dry at 100°C for 0.5 hour to obtain the product.

[0034] Adopt OCAH200 contact angle tester to test the wettability of gained polyurethane sponge, the result shows: the contact angle of polyurethane sponge and water is 152 °, shows superhydrophobic property; The contact angle with normal hexane, paraffin oil is 0 ° (see figure 2 ), exhibiting ...

Embodiment 2

[0041] A preparation method of wear-resistant superhydrophobic superoleophilic polyurethane sponge, comprising the steps of:

[0042] 1) The polyurethane sponge was ultrasonically cleaned with distilled water and absolute ethanol for 30 minutes, and dried naturally at room temperature;

[0043] 2) Evenly disperse hydrophobic DNS-2 nano-silica and polydimethylsiloxane in n-hexane with magnetic stirring, wherein the mass fraction of nano-silica is 0.3%, and the mass fraction of polydimethylsiloxane 0.03%;

[0044] 3) Soak the cleaned polyurethane sponge in the above solution for 1.5 hours, and dry the soaked polyurethane sponge in an oven at 100°C for 0.5 hours to obtain the product.

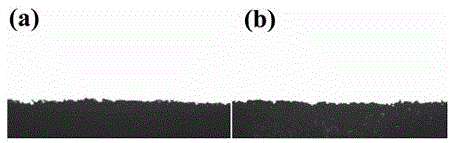

[0045]Insert one end of the catheter into the polyurethane sponge obtained in step 3), and connect the other end to a vacuum pump. Dye paraffin oil red with oil red, mix it with water 1:2, put the obtained polyurethane sponge into the oil-water mixture, turn on the vacuum pump, the red paraffin ...

Embodiment 3

[0048] A preparation method of wear-resistant superhydrophobic superoleophilic polyurethane sponge, comprising the steps of:

[0049] 1) The polyurethane sponge was ultrasonically cleaned with distilled water and absolute ethanol for 30 minutes, and dried naturally at room temperature;

[0050] 2) Evenly disperse hydrophobic DNS-3 nano-silica and polydimethylsiloxane in absolute ethanol with magnetic stirring, wherein the mass fraction of nano-silica is 0.3%, vinyl polydimethylsiloxane Ratio 0.03%;

[0051] 3) Soak the cleaned polyurethane sponge in the above solution for 1.5h. The soaked polyurethane sponge is dried in an oven at 100°C for 1h.

[0052] Insert one end of the catheter into the polyurethane sponge obtained in step 3), and connect the other end to a vacuum pump. Dye paraffin oil red with oil red, mix it with water 1:2, put the obtained polyurethane sponge into the oil-water mixture, turn on the vacuum pump, the red paraffin oil is quickly sucked, and the water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com