A wear-resistant superhydrophobic superoleophilic polyurethane sponge, its preparation method and its application in the continuous separation of oil and water

A polyurethane sponge, super lipophilic technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of poor surface durability, inability to continuously separate, high cost, and achieve reduced surface energy, small specific gravity, and strong acid resistance. The effect of strong alkali corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of wear-resistant superhydrophobic superoleophilic polyurethane sponge, comprising the steps of:

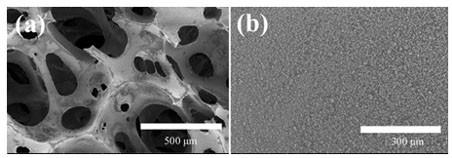

[0030] 1) The polyurethane sponge was ultrasonically cleaned with distilled water and absolute ethanol for 30 minutes, and dried naturally at room temperature;

[0031] 2) Evenly disperse hydrophobic DNS-2 nano-silica and polydimethylsiloxane in n-hexane with magnetic stirring, wherein the mass fraction of nano-silica is 0.1%, and the mass fraction of polydimethylsiloxane 0.01%;

[0032] 3) Soak the cleaned polyurethane sponge in the above solution for 1 hour, put the soaked polyurethane sponge in an oven and dry at 100°C for 0.5 hour to obtain the product.

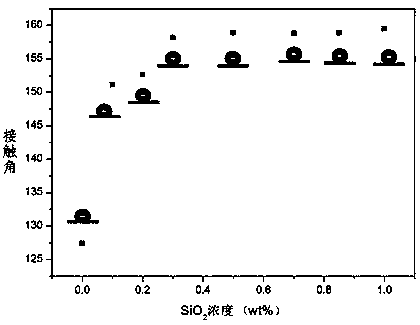

[0033] Adopt OCAH200 contact angle tester to test the wettability of gained polyurethane sponge, the result shows: the contact angle of polyurethane sponge and water is 152 °, shows superhydrophobic property; The contact angle with normal hexane, paraffin oil is 0 ° (see figure 2 ), exhibiting ...

Embodiment 2

[0040] A preparation method of wear-resistant superhydrophobic superoleophilic polyurethane sponge, comprising the steps of:

[0041] 1) The polyurethane sponge was ultrasonically cleaned with distilled water and absolute ethanol for 30 min, and dried naturally at room temperature;

[0042] 2) Evenly disperse hydrophobic DNS-2 nano-silica and polydimethylsiloxane in n-hexane with magnetic stirring, wherein the mass fraction of nano-silica is 0.3%, and the mass fraction of polydimethylsiloxane 0.03%;

[0043] 3) Soak the cleaned polyurethane sponge in the above solution for 1.5 hours, and dry the soaked polyurethane sponge in an oven at 100°C for 0.5 hours to obtain the product.

[0044] Insert one end of the catheter into the polyurethane sponge obtained in step 3), and connect the other end to a vacuum pump. Dye paraffin oil red with oil red, mix it with water 1:2, put the obtained polyurethane sponge into the oil-water mixture, turn on the vacuum pump, the red paraffin oil...

Embodiment 3

[0047] A preparation method of wear-resistant superhydrophobic superoleophilic polyurethane sponge, comprising the steps of:

[0048] 1) The polyurethane sponge was ultrasonically cleaned with distilled water and absolute ethanol for 30 min, and dried naturally at room temperature;

[0049] 2) Evenly disperse hydrophobic DNS-3 nano-silica and polydimethylsiloxane in absolute ethanol with magnetic stirring, wherein the mass fraction of nano-silica is 0.3%, vinyl polydimethylsiloxane Ratio 0.03%;

[0050] 3) Soak the cleaned polyurethane sponge in the above solution for 1.5h. The soaked polyurethane sponge is dried in an oven at 100°C for 1h.

[0051] Insert one end of the catheter into the polyurethane sponge obtained in step 3), and connect the other end to a vacuum pump. Dye paraffin oil red with oil red, mix it with water 1:2, put the obtained polyurethane sponge into the oil-water mixture, turn on the vacuum pump, the red paraffin oil is quickly sucked, and the water is b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com