Device and method of continuously separating solid-liquid phases in caprolactam distilled heavy residual liquid

A caprolactam, solid-liquid phase technology, applied in the chemical industry, can solve the problems of low filtration efficiency and poor weighing weight of filter cloth centrifuges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

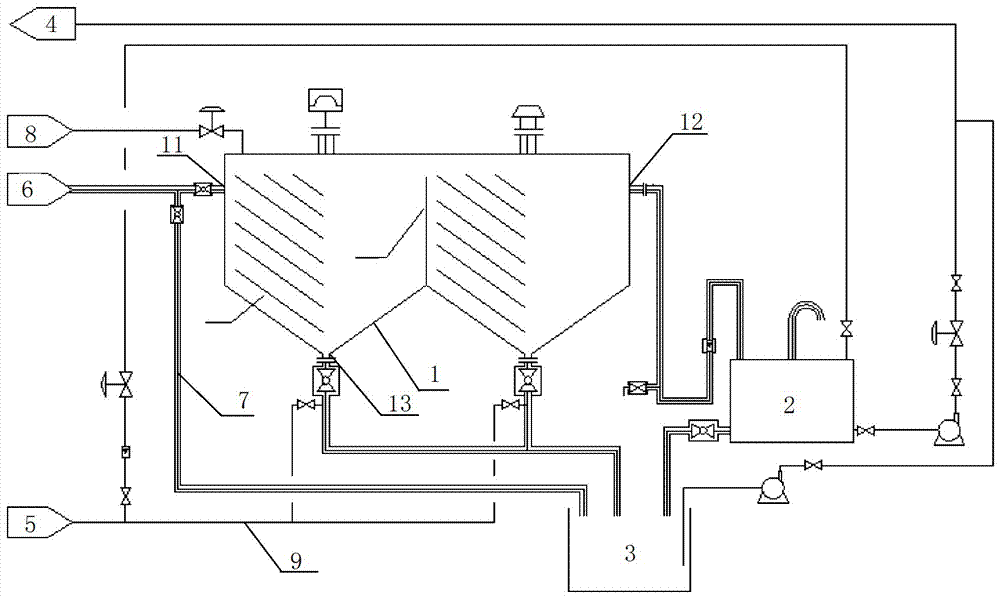

[0031] Such as figure 1 As shown, the present invention relates to a device for continuous solid-liquid phase separation in the heavy raffinate of caprolactam distillation, comprising a settler 1, one side of which is provided with a feed port 11, the other side is provided with an overflow port 12, and the bottom is provided with a The slag discharge port 13; the overflow port is connected to the clarified liquid intermediate tank 2, and the slag discharge port 13 is connected to the residue clarified tank 3; the clarified liquid intermediate tank 2 is connected to the caprolactam process 4 through pipelines and pumps, and the clarified liquid intermediate tank 2 is also connected to caprolactam Process water piping 5.

[0032] Further, the feed inlet 11 is connected to the caprolactam distillation heavy raffinate pipeline 6, a valve is installed near the feed inlet, and a branch pipe 7 is arranged between the caprolactam distillation heavy raffinate pipeline 6 and the valve,...

Embodiment 2

[0039] Embodiment 2: Use the above-mentioned device to separate the solid-liquid of the heavy residue of caprolactam distillation, control the evaporation of the caprolactam distillation tower, and make the flow rate of the heavy residue of distillation reach 1.5m 3 / h, analyze that its solid content is 0.8~1.2%wt, first introduce the heavy raffinate into the settler for sedimentation, control the temperature in the settler at 70~75°C, and the clear night after sedimentation enters the clarified liquid through the overflow port Further settle in the intermediate tank, and at the same time pass the process water in the caprolactam process water pipeline into the clarified liquid intermediate tank to dilute the clear night, and then transport the liquid in the clarified liquid intermediate tank to the caprolactam process.

[0040] During the operation, the volume ratio of the process water and the clear liquid in the middle tank of the clarified liquid is 1~5:1, so that the conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com