Patents

Literature

140results about How to "Control the moving distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

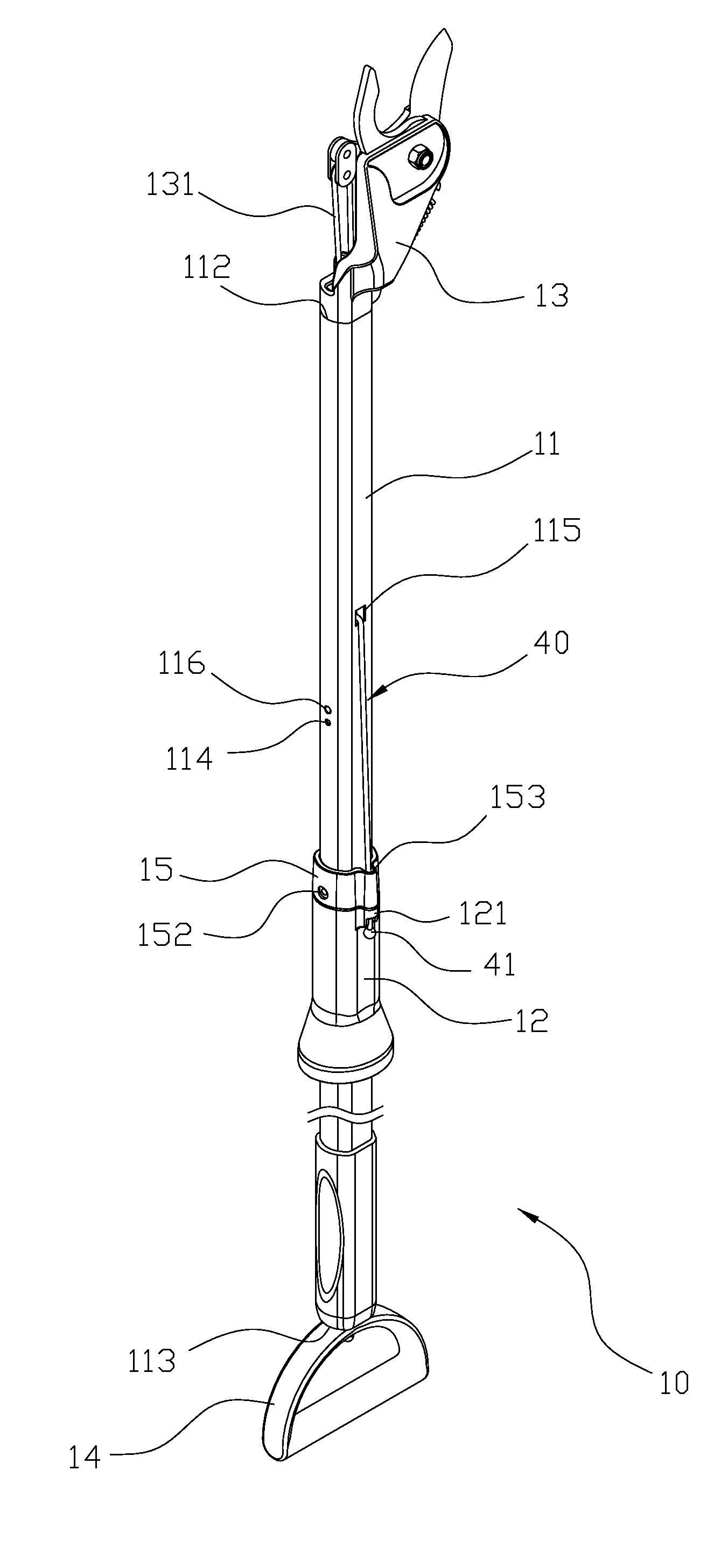

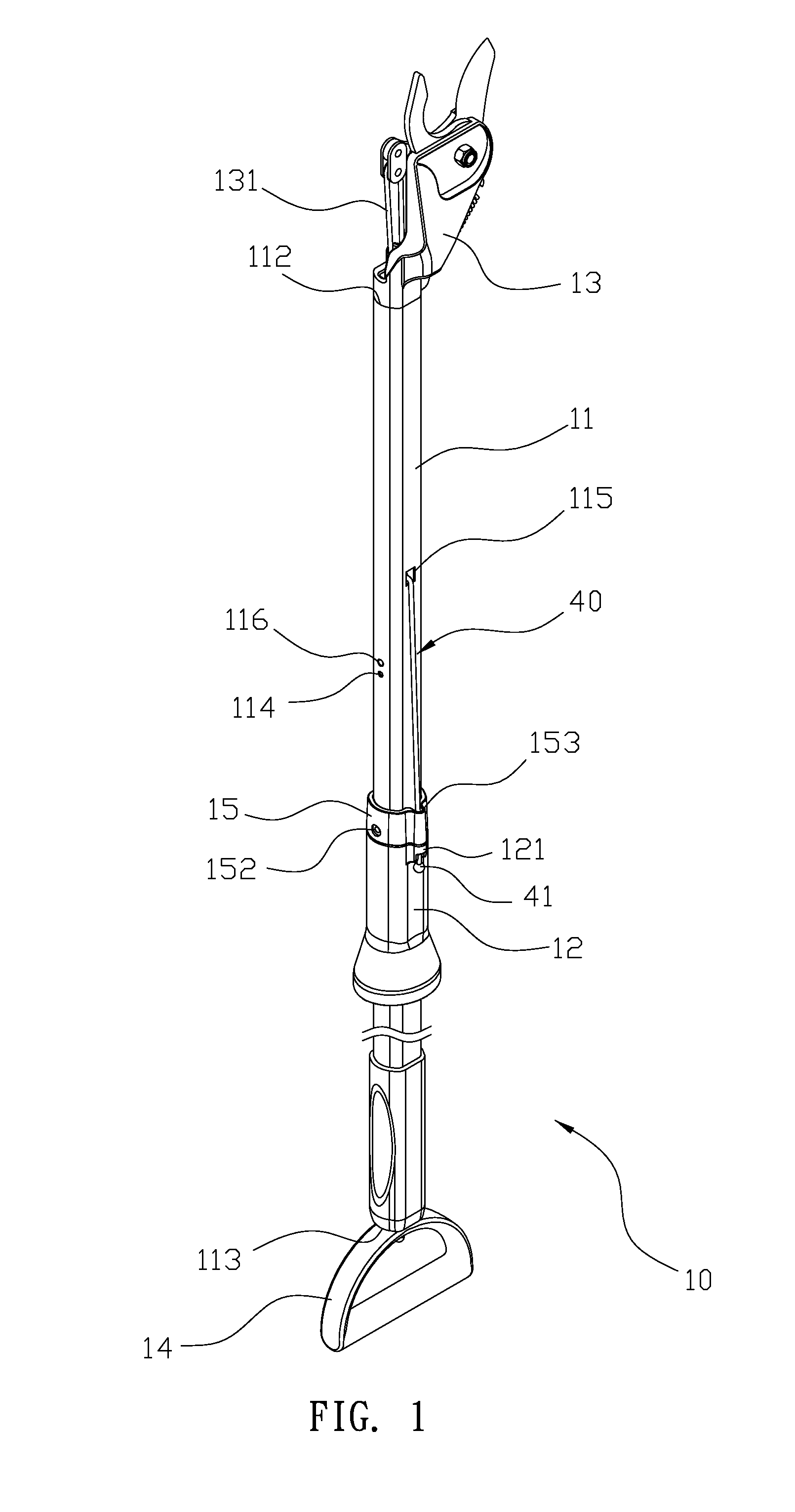

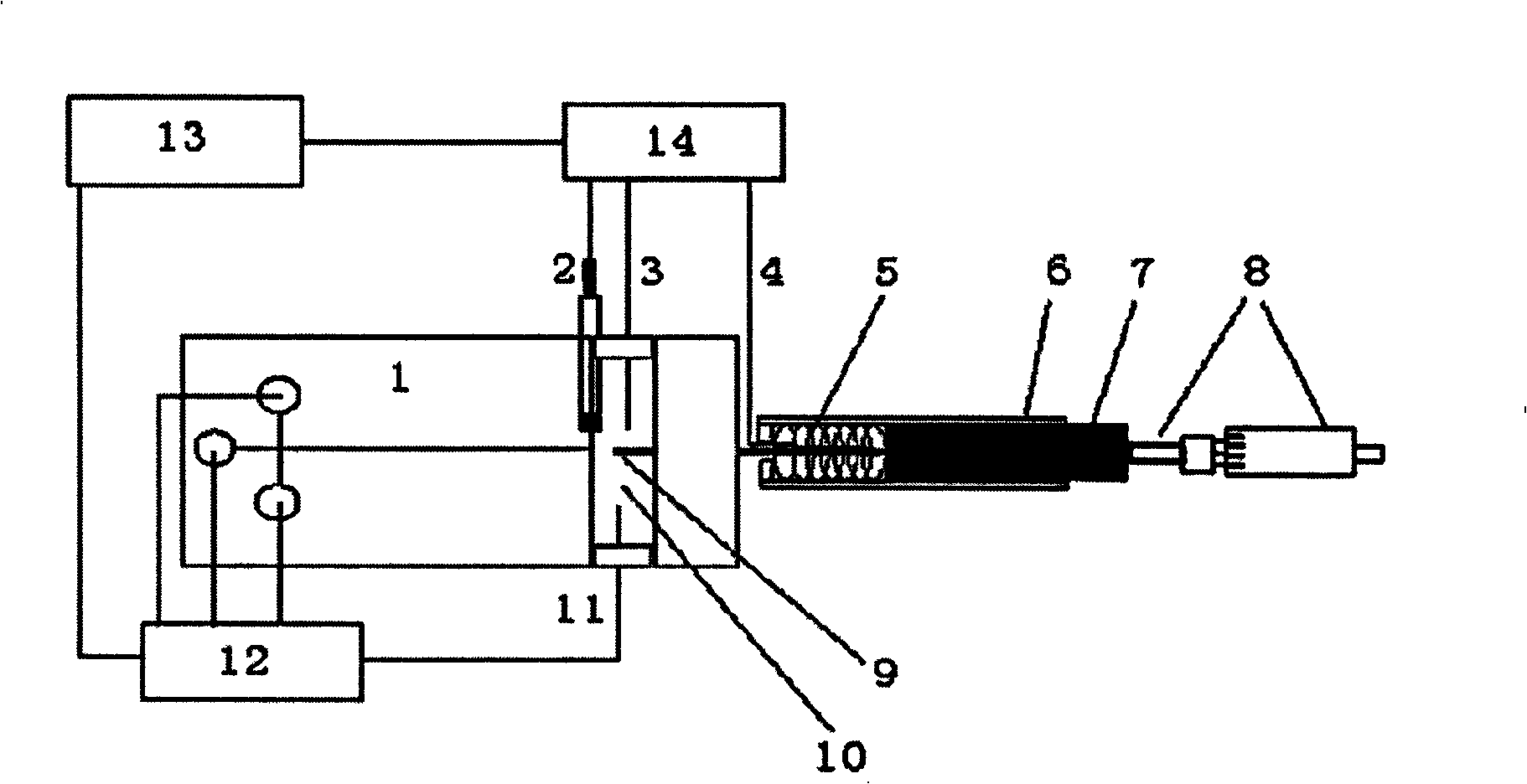

Rope-controlled structure for extended reach garden shears

InactiveUS20120167397A1Reduce actionSmooth movementCuttersCutting implementsEngineeringMechanical engineering

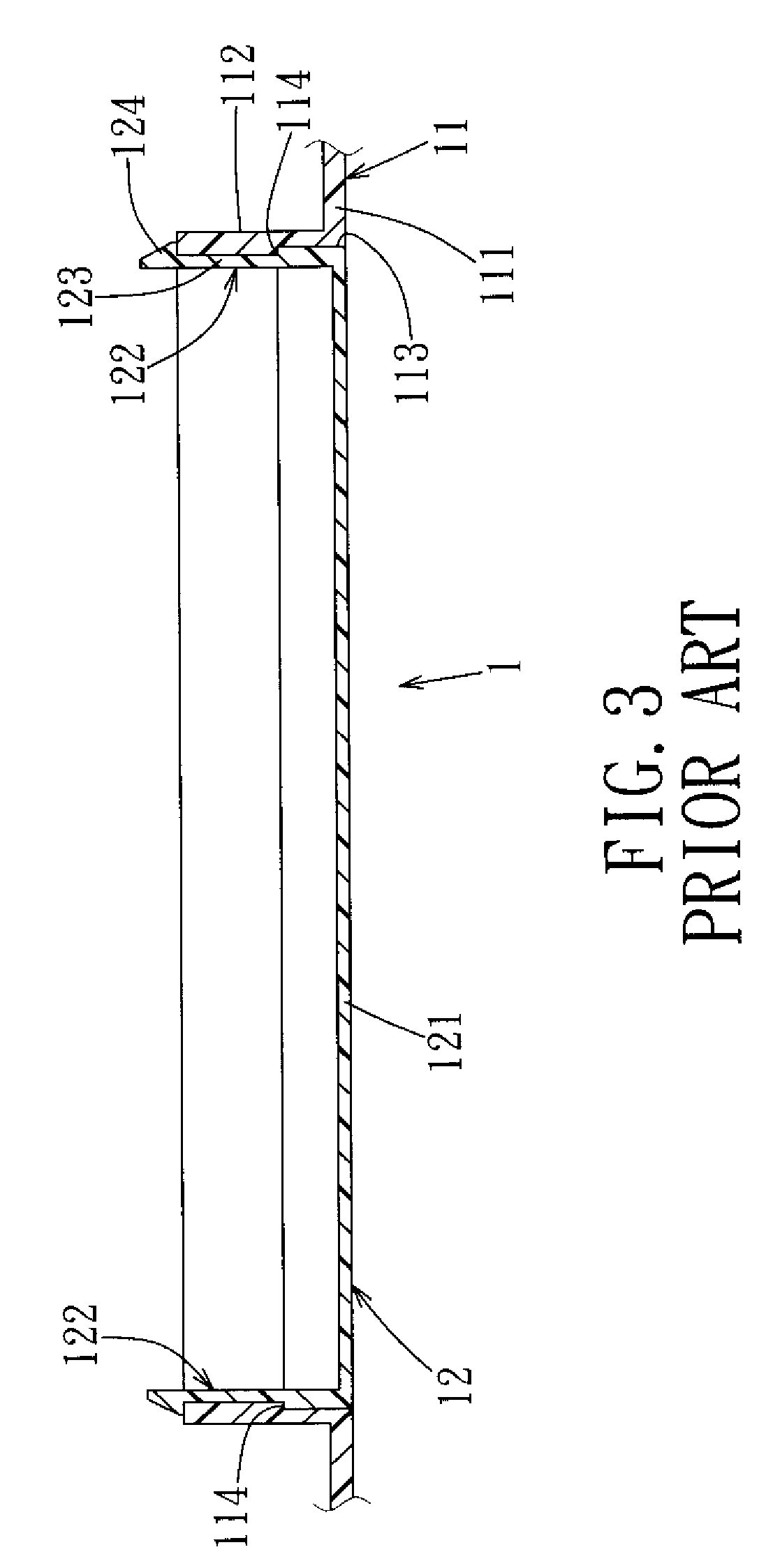

Extended reach garden shears include an extension rod, a handgrip, a cutting head and a pull handle. The extension rod is formed with an accommodating space, a front opening and a rear opening. The extension rod is provided with a pin hole and a rope-guiding hole. The handgrip is slidingly disposed on the extension rod. The cutting head is inserted into the front opening. The pull handle is inserted into the rear opening. A fixed base is fixed in the accommodating space. A movable base is slidingly disposed in the accommodating space and connected to the cutting head. A rope has a combining end, a connecting end and a wrapping section. The wrapping section wraps around the fixed base and the movable base. The combining end is connected to the pull handle. The connecting end is connected to the pull handle. The rope, the fixed base and the movable base enable the garden shears to achieve an efficient trimming action.

Owner:HO CHENG GARDEN TOOLS

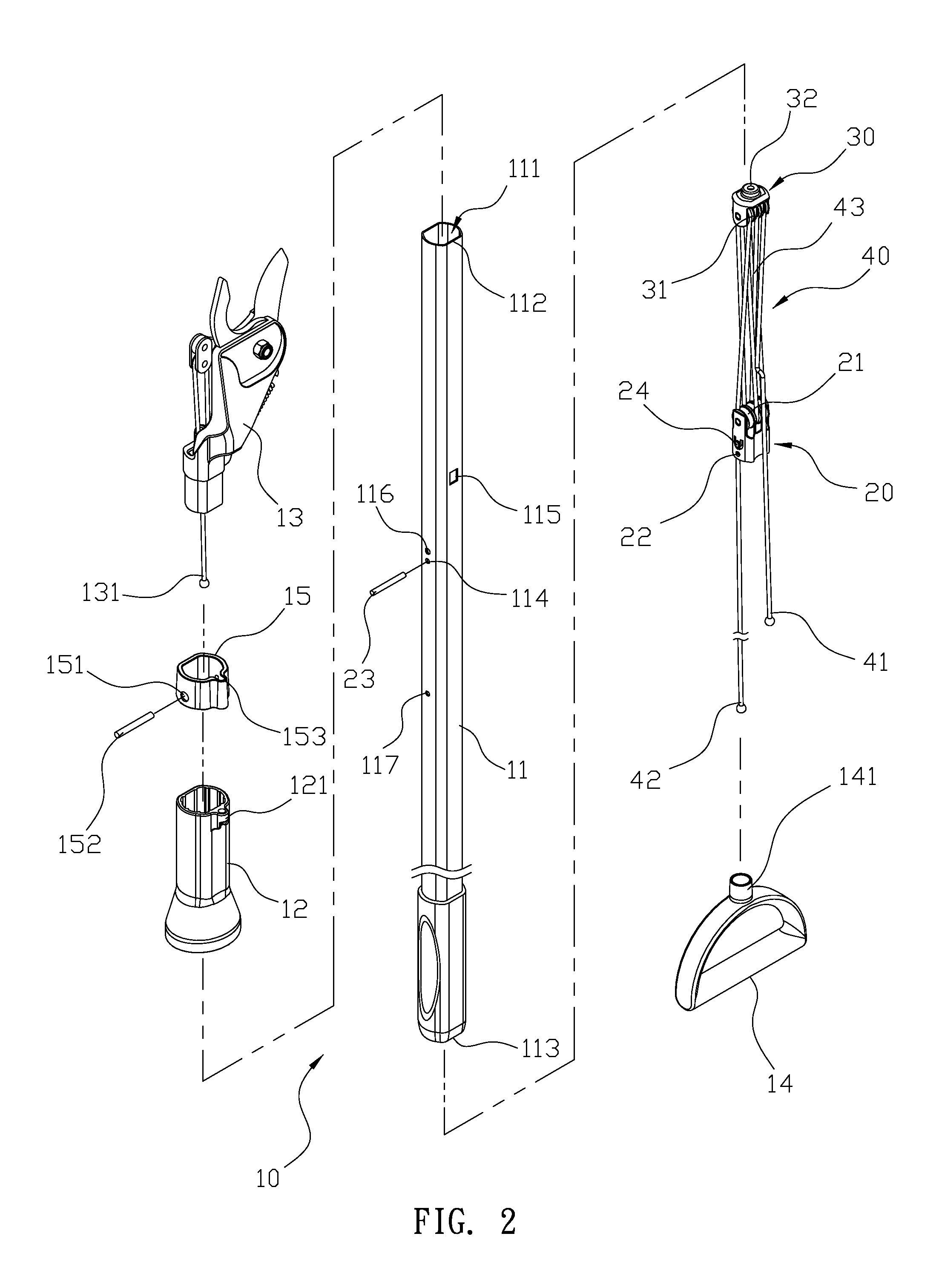

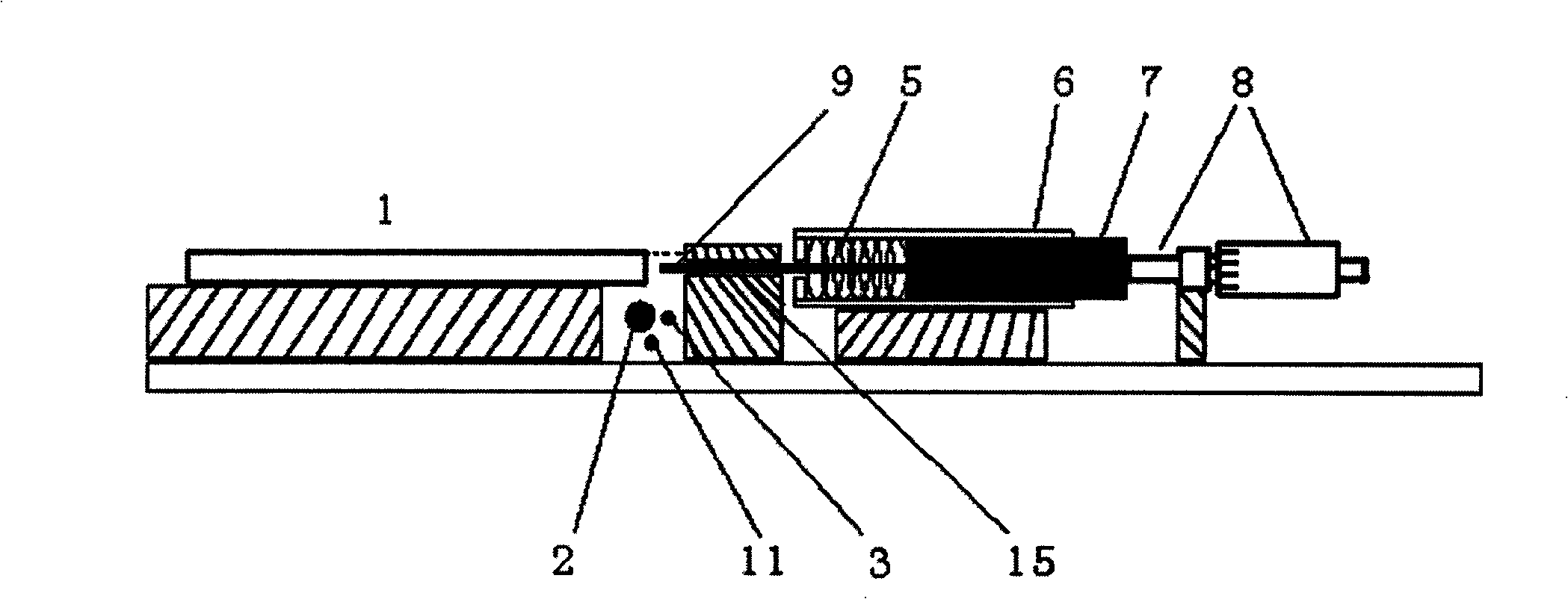

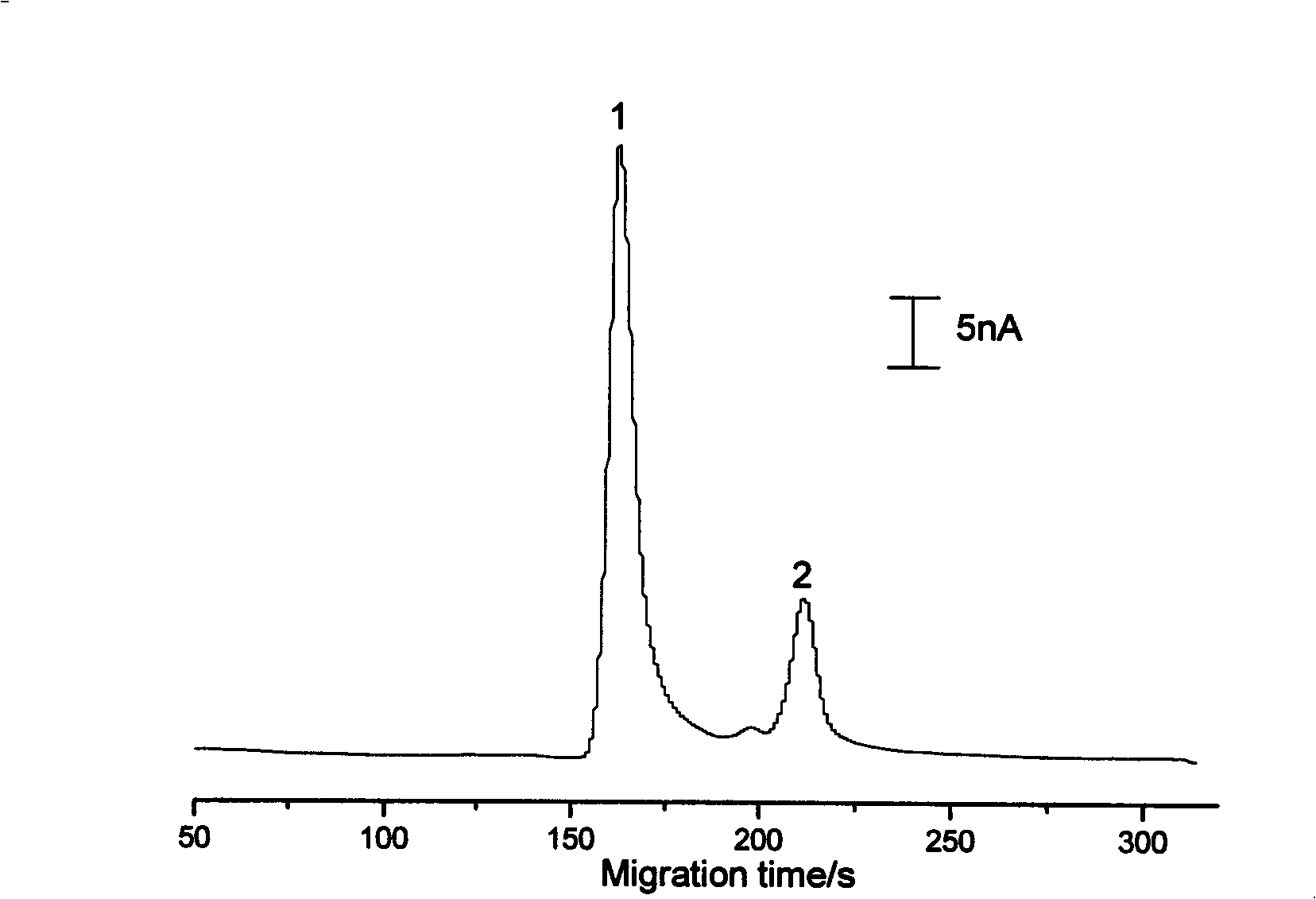

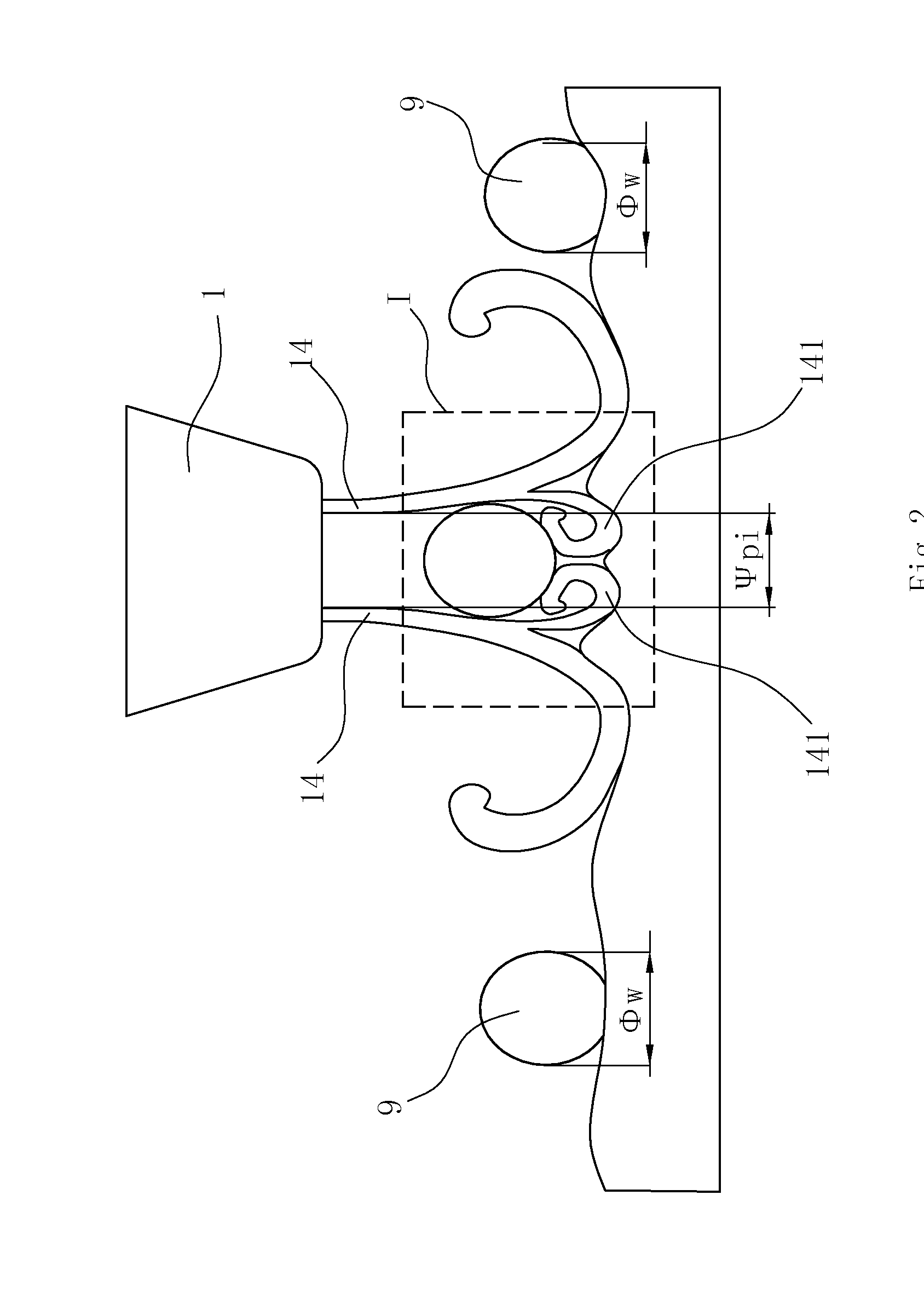

Microflow control chip electrochemical detection device capable of accurately controlling electrode distance

InactiveCN101349672AControl the moving distanceEasy to useMaterial electrochemical variablesFast measurementSample pool

The invention provides a micro-fluidic chip electrochemical detection device which can accurately control the distance between electrodes, which comprises a micro-fluidic chip which is provided with a detection pool and a micro-flow pipeline, wherein one end of the micro-flow pipeline is communicated with a sample pool, a buffer pool and a sample waste liquid pool, and the other end of the micro-flow pipeline is connected with the detection pool. The invention is characterized in that a three-electrode system is arranged in the detection pool, wherein the working electrode detection end in the three-electrode system is positively faced to the outlet end of the micro-flow pipeline, and the working electrode is mounted on an adjusting-driving mechanism which can move relative to the outlet end of the micro-flow pipeline. The special structure of the micro-fluidic chip electrochemical detection device can lead the working electrode to lightly aim at the outlet end of a chip separator pipeline and accurately control the movement distance of an electrode. The invention has the advantages of convenient employment, fast measurement, excellent reproducibility, simple manufacture, convenient installation and low production cost.

Owner:FUZHOU UNIV

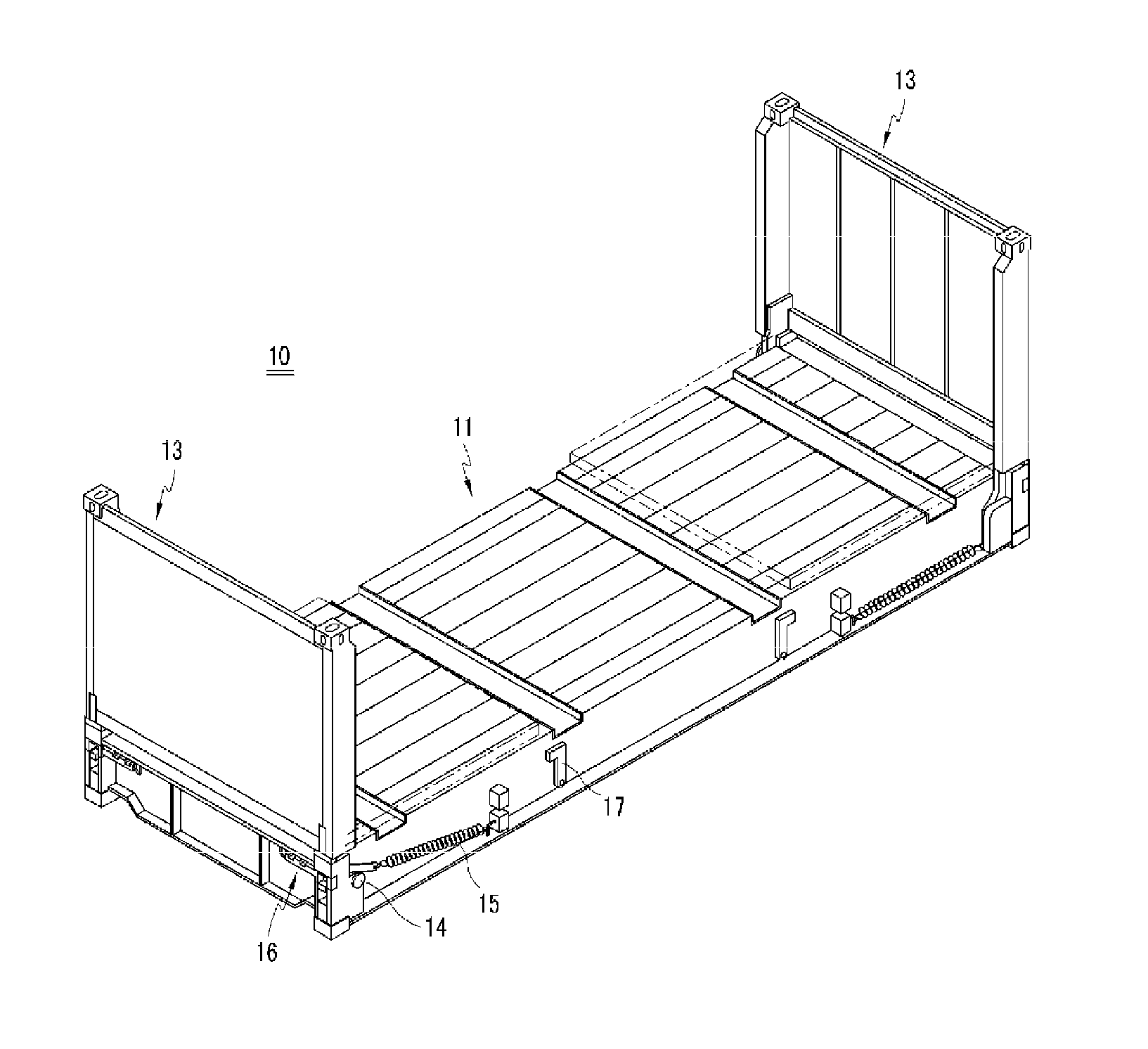

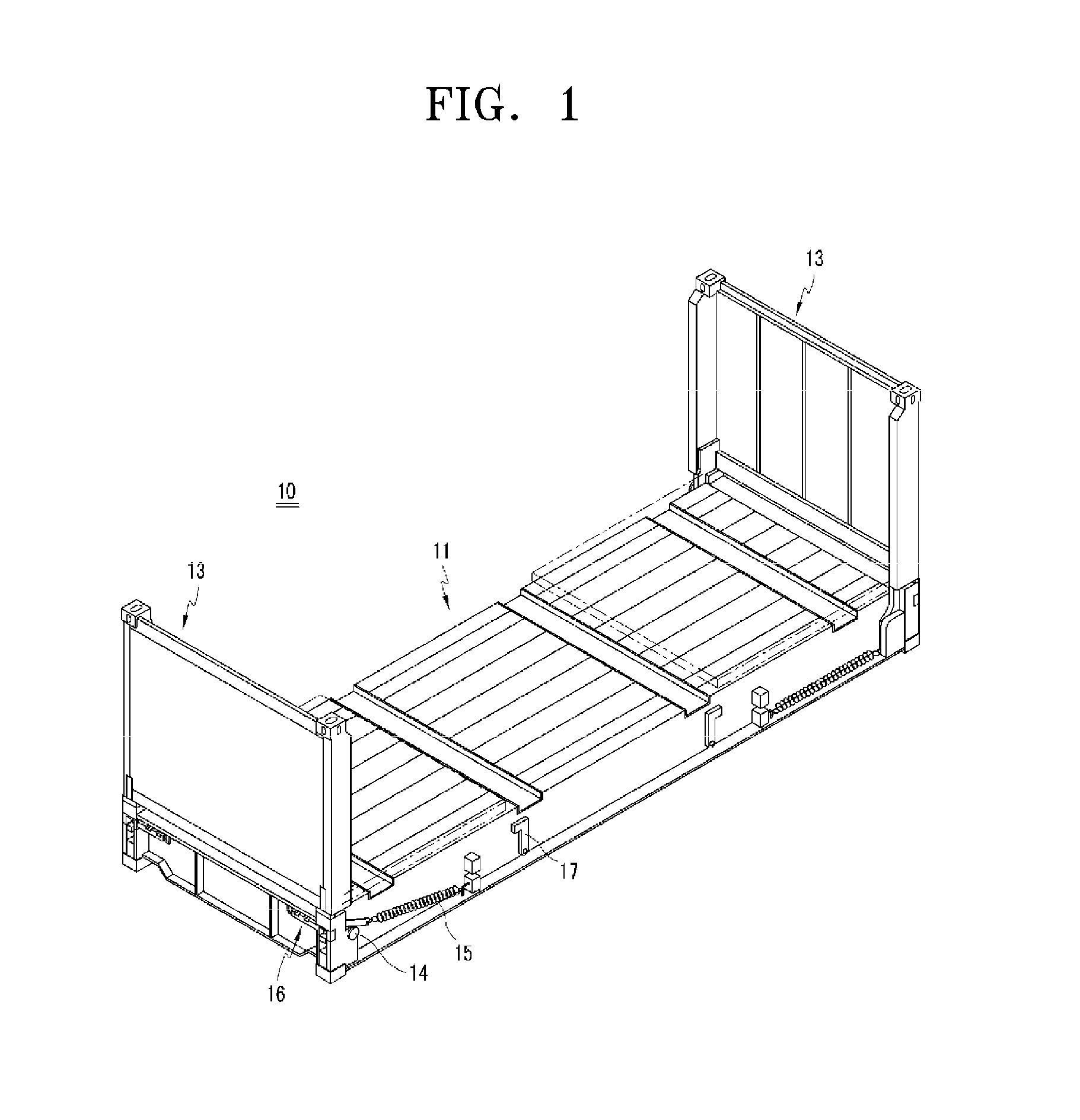

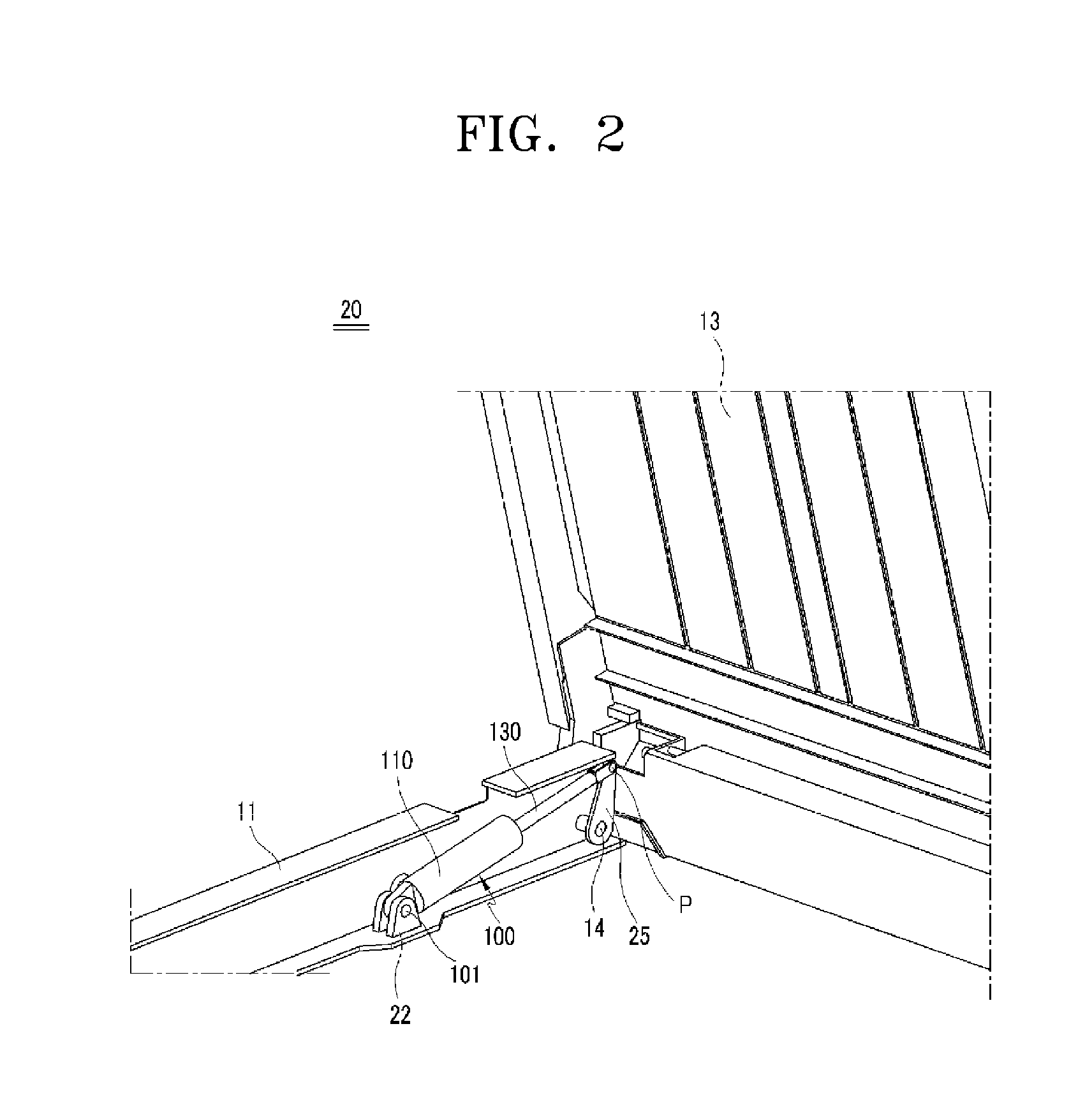

Integral buffering apparatus for automatically controlling flow rate of fluid and flat rack container including the integral buffering apparatus

ActiveUS20120048846A1Avoid damageEasy to implementSpringsLarge containersControl flowAutomatic control

The present invention relates to a flat rack container, and more particularly, to an integral buffering apparatus disposed between end walls and a base and for automatically controlling a flow rate of oil that flows in a cylinder housing through channels formed in a slider when the end walls are folded, to control a falling speed of the end walls, thereby absorbing an impact of the end walls, preventing damage of the end walls and the base, and ensuring safety of workers. The integral buffering apparatus includes a cylinder housing including a space for accommodating oil; a slider disposed in the space to be movable in a length direction of the cylinder housing and to divide the space into a first space and a second space; first oil channels and a second oil channel for connecting the first space and the second space to each other.

Owner:VANPLUS

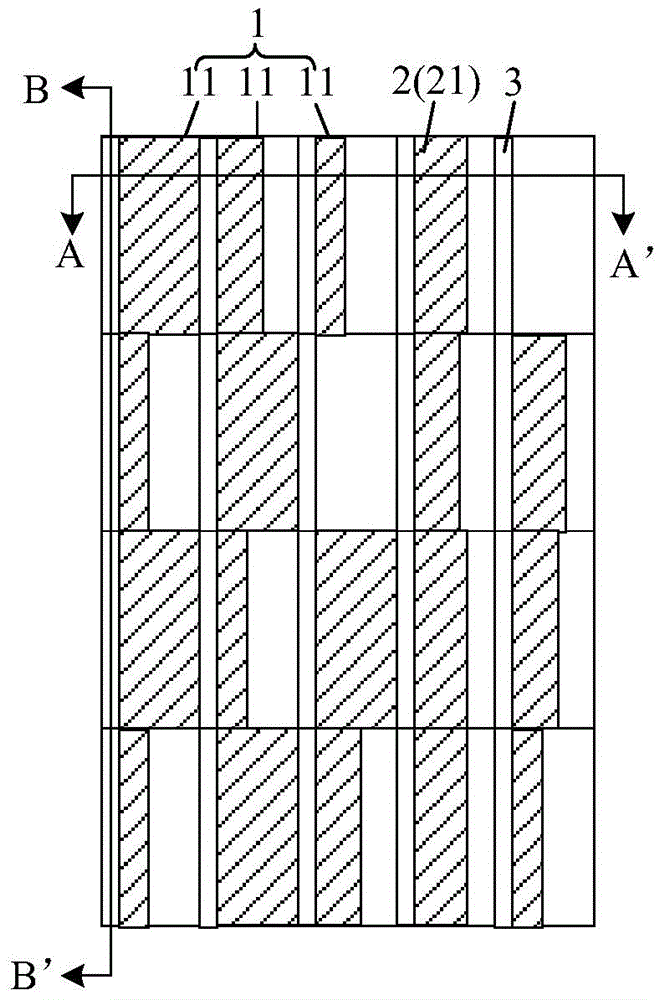

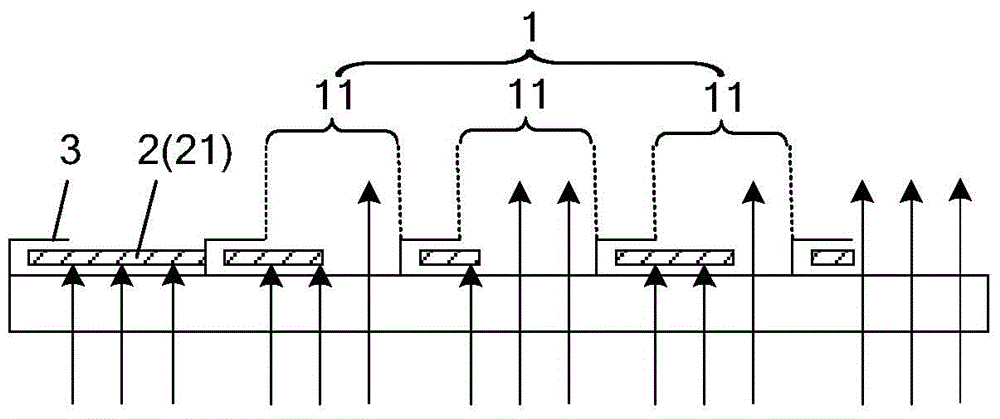

Display base plate and driving method and display device thereof

ActiveCN104795046AAdjust light transmittanceControl the moving distanceStatic indicating devicesNon-linear opticsComputer graphics (images)Display device

The invention discloses a display base plate and a driving method and a display device of the display base plate, relating to the technical field display and aiming at reducing the power consumption of the display device. The display base plate is provided with multiple first light-transmitting areas distributed into an array, each first area is used as a sub-pixel, at least two adjacent sub-pixels form one pixel, all sub-pixels in each pixel correspond to backlights with different colors respectively, the display base plate also comprises multiple light shading structures corresponding to the sub-pixels one by one, and each light shading structure is used for adjusting the light ray transmitting rate of one sub-pixel. The power consumption of the display device can be reduced.

Owner:BOE TECH GRP CO LTD +1

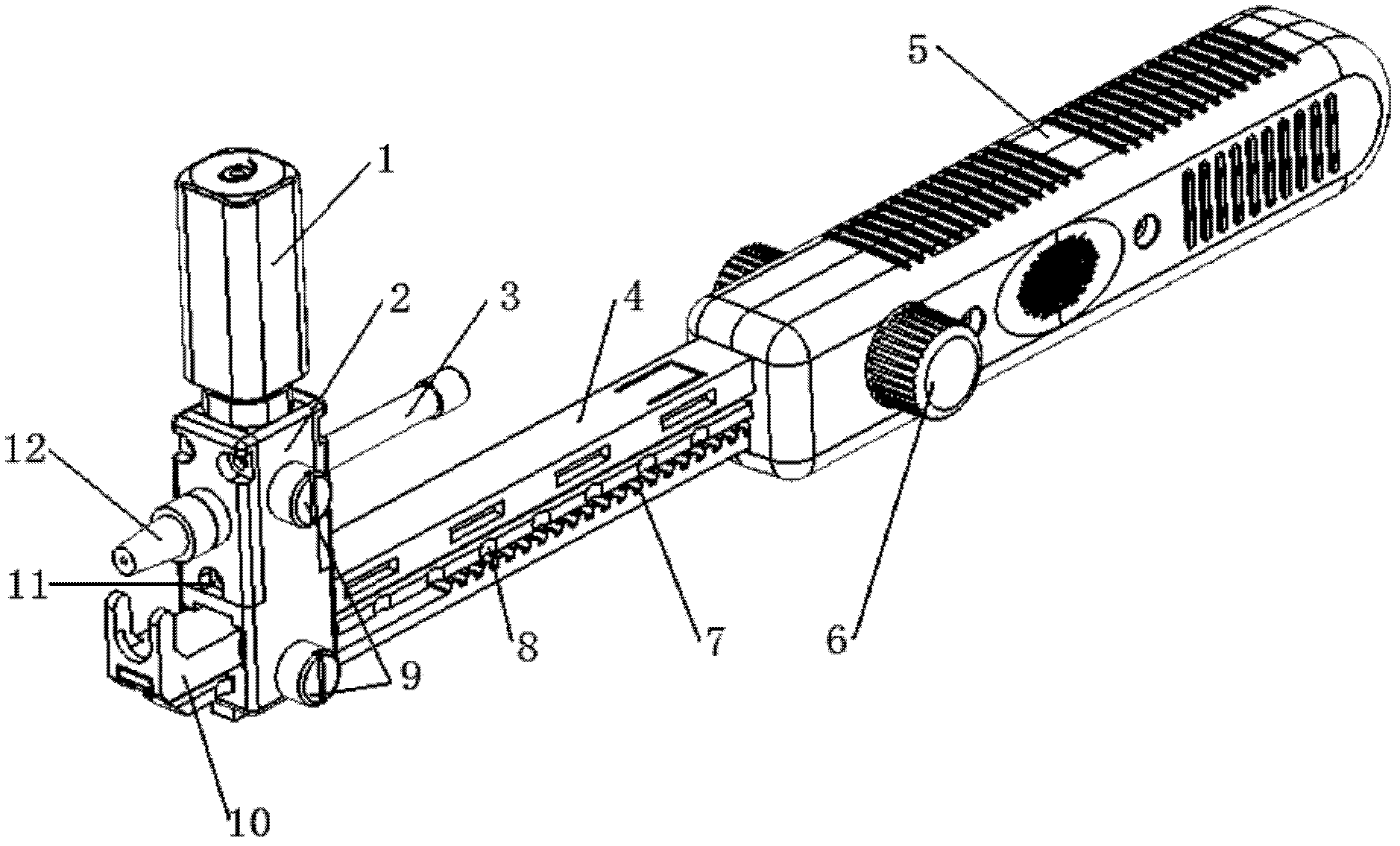

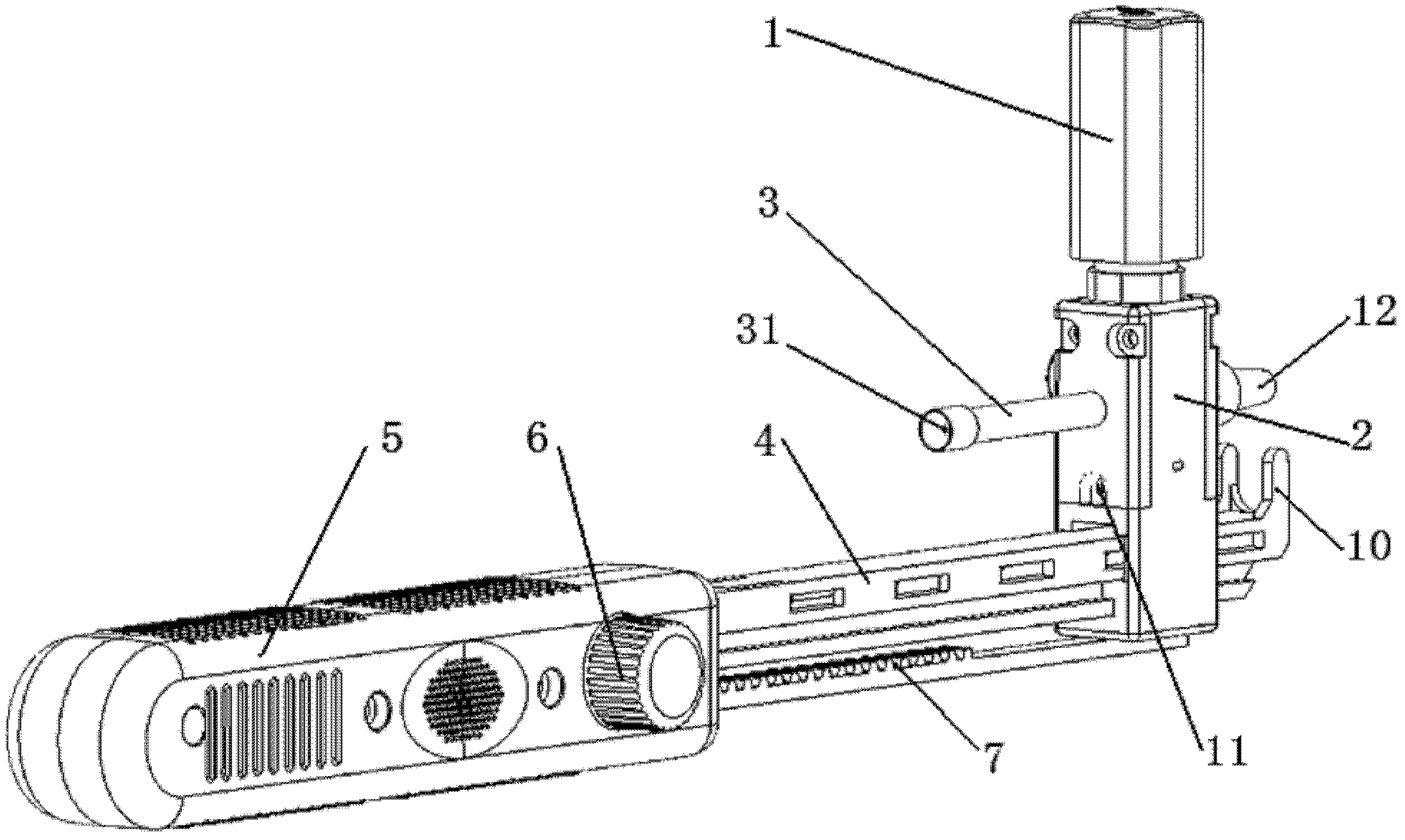

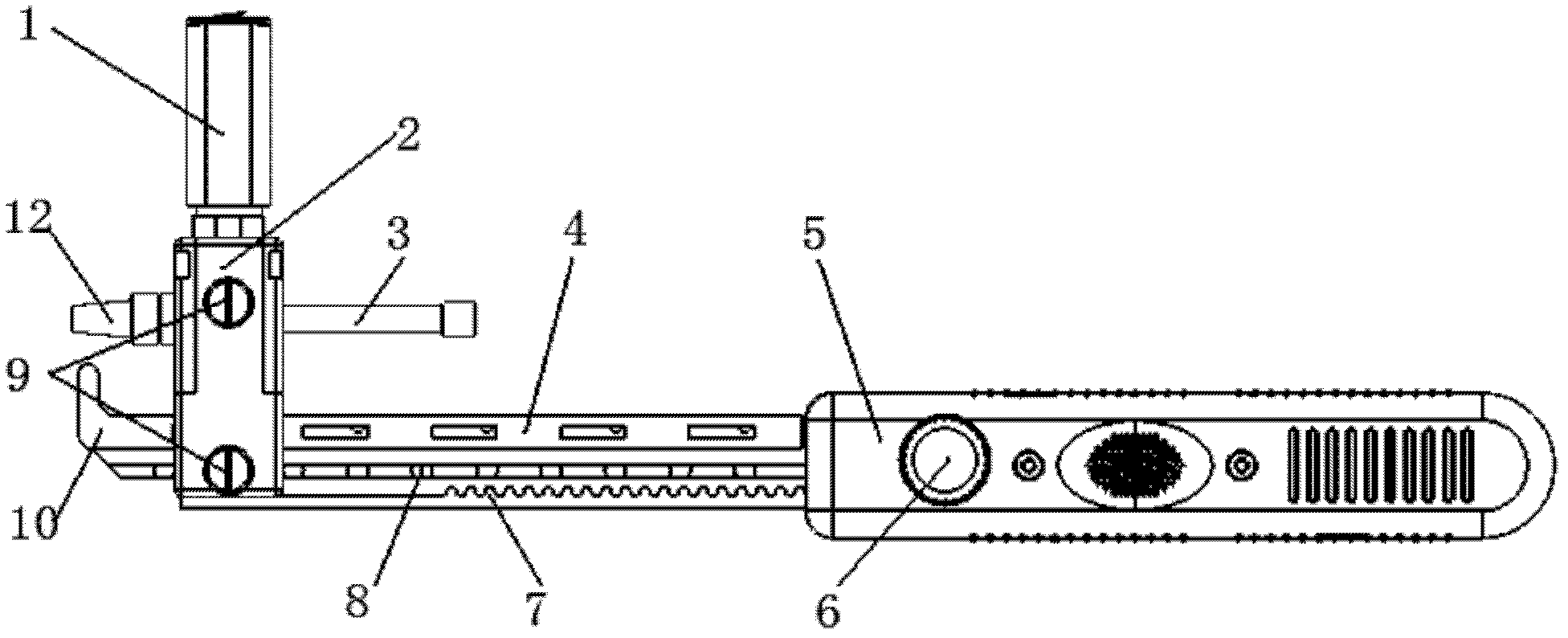

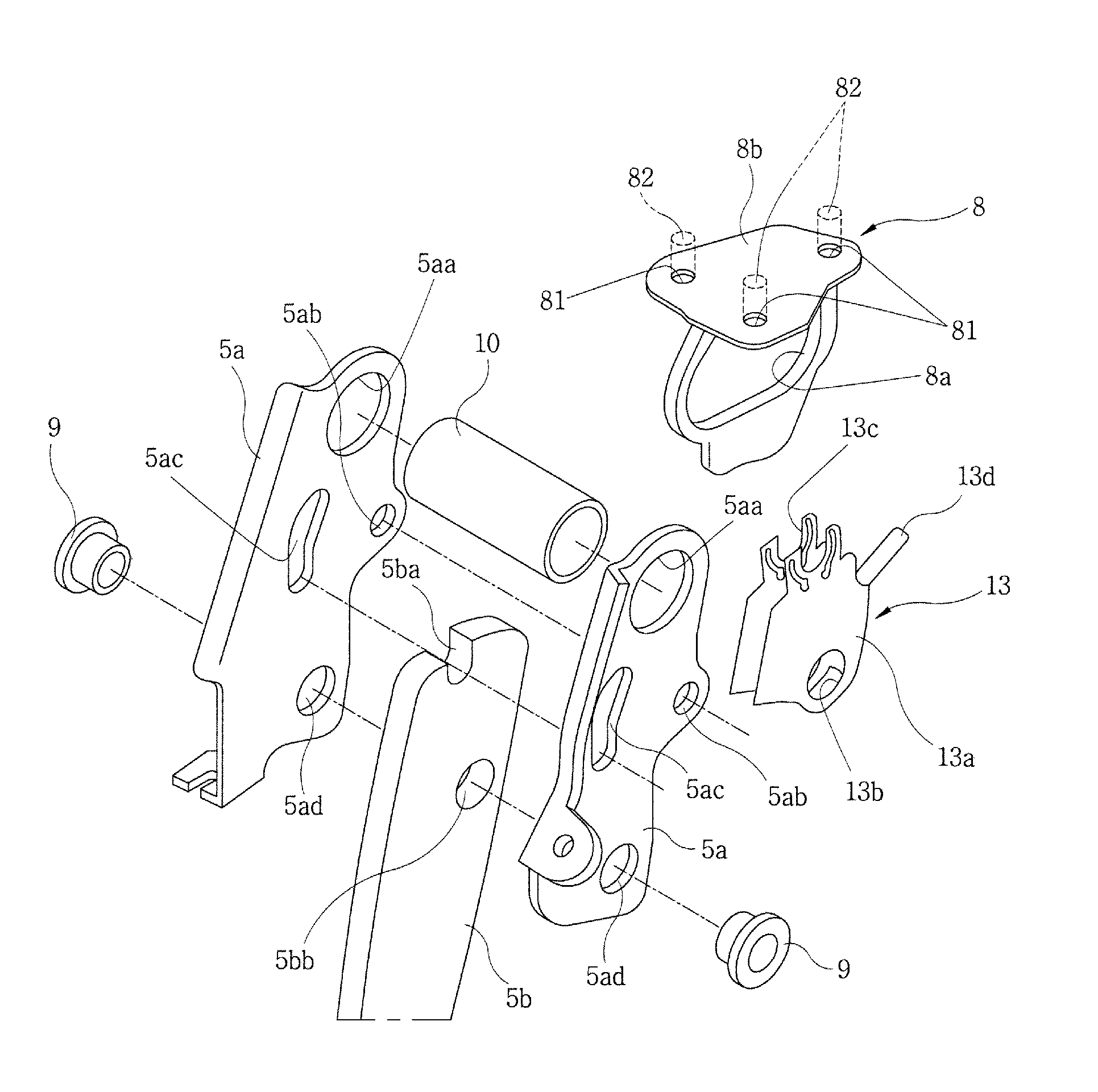

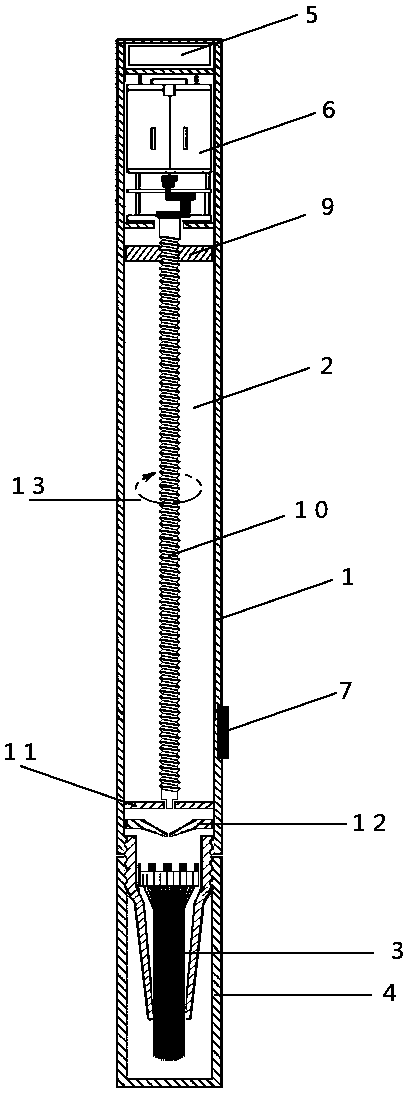

Pen type inner irradiation particle implanter

The invention discloses a pen type inner irradiation particle implanter. The pen type inner irradiation particle implanter comprises a handle, a particle magazine, a mobile device ensuring that the particle magazine moves along the axial direction of a pushing rod duct according to a certain distance and a paracentetic needle depth positioning device which is used to control the depth of a paracentetic needle in human body which is used in the operation. The particle magazine is provided with a through pushing rod pore, the top of the particle magazine is provided with a particle cartridge magazine, the front wall of the particle magazine is provided with a paracentetic needle universal interface and the back wall of the particle magazine is provided with the pushing rod duct. The bottom of the particle magazine is provided with a blood return releasing hole, a space which is a blood return collecting-releasing slot is arranged below the particle magazine and the blood return releasing hole is communicated with the blood return collecting-releasing slot. The pen type inner irradiation particle implanter is characterized in that the structure is simple, the weight is light and the magazine can be accurately moved; the particle implanter is suitable for all specifications of paracentetic needles of all manufacturers, the source blockage phenomenon and the reuse of the particle magazine are avoided, the cross-infection of the patient can be prevented; and the particle implanter is convenient in use. The pen type inner irradiation particle implanter is more suitable for clinical implantation for curing tumor.

Owner:UNION BIOTECH TIANJIN

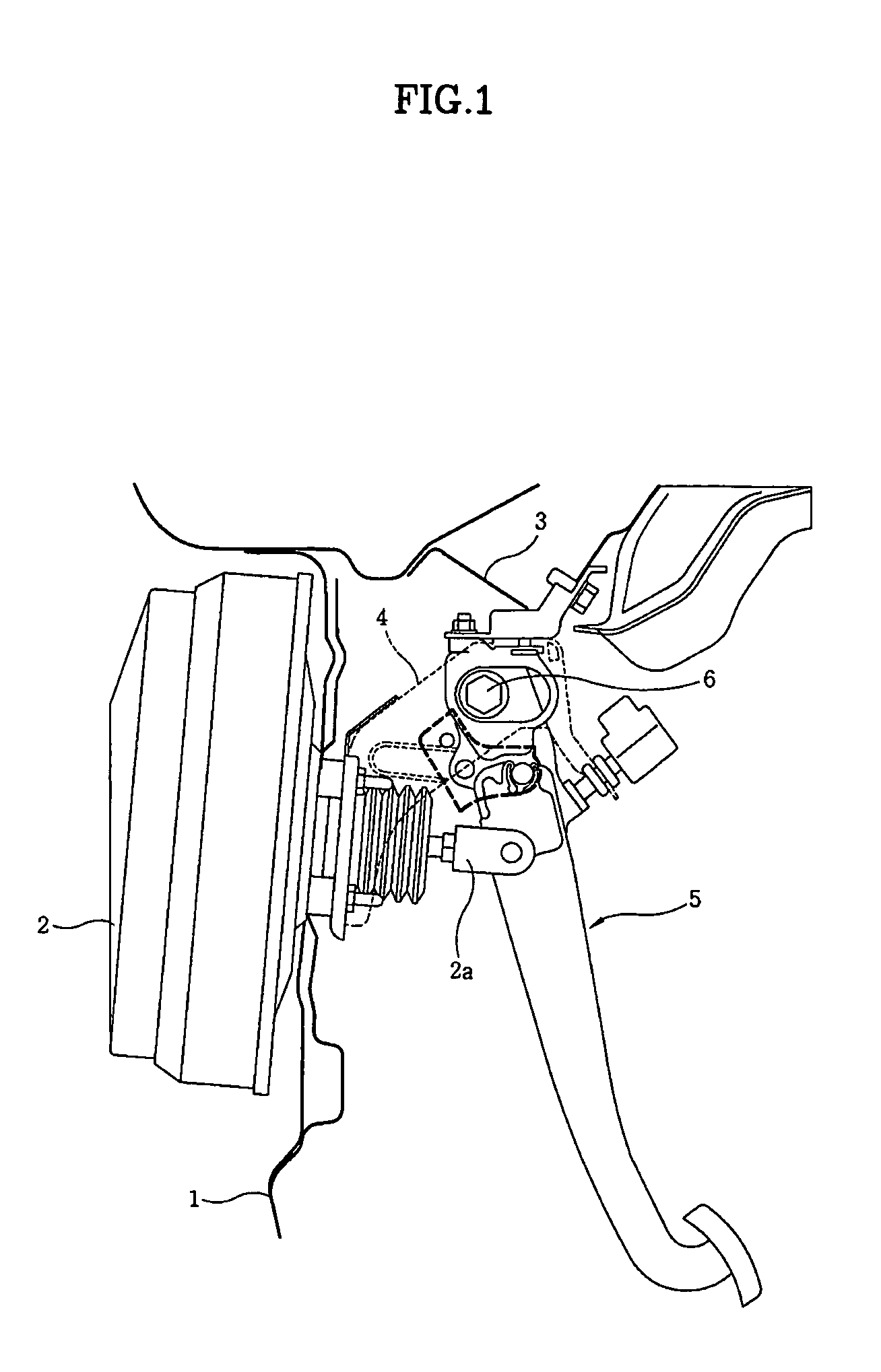

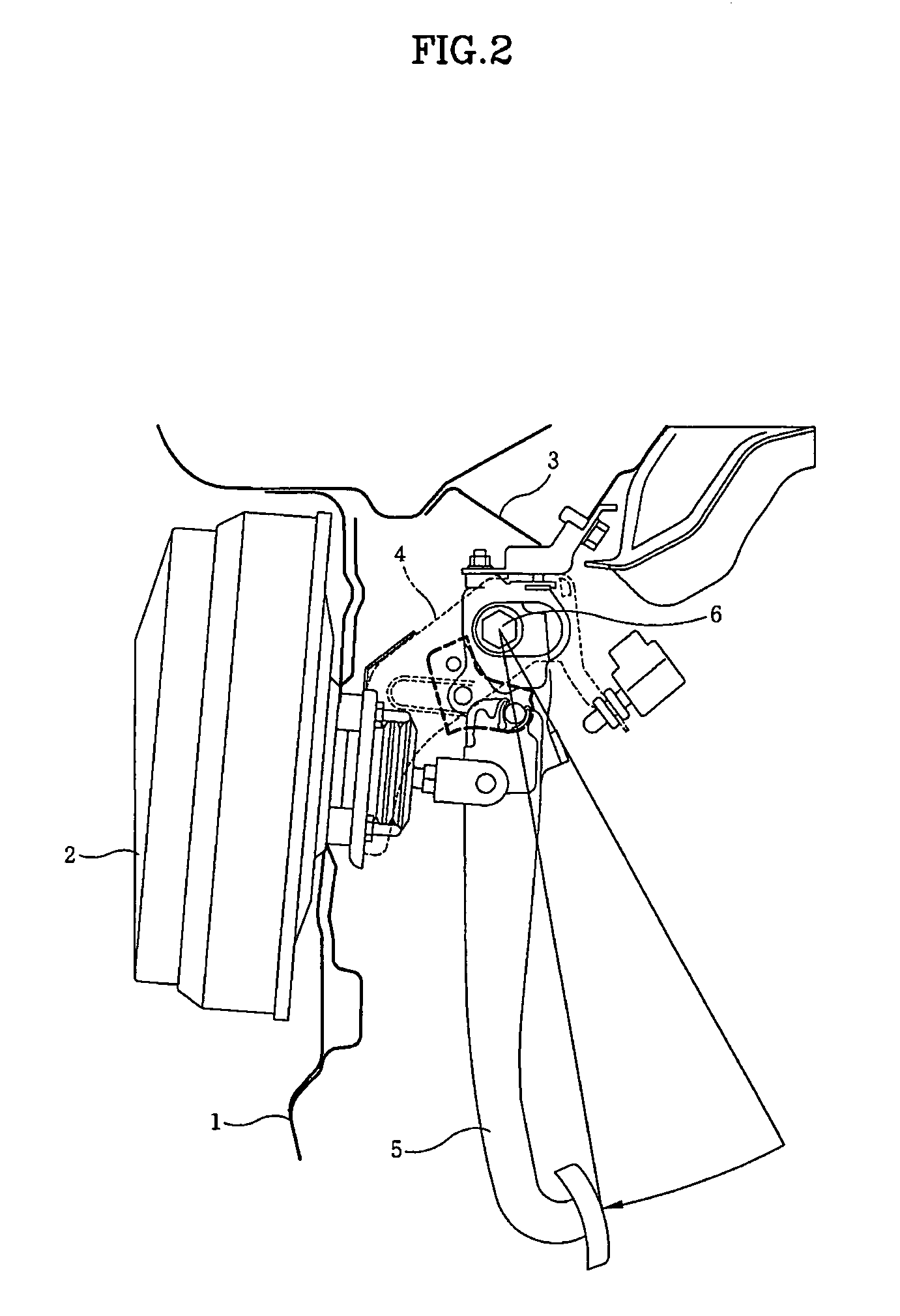

Shock absorbing device for brake pedals

ActiveUS7665387B2Reduce collision speedMinimize injuryControlling membersMechanical apparatusEngineeringFootplate

Owner:HYUNDAI MOTOR CO LTD

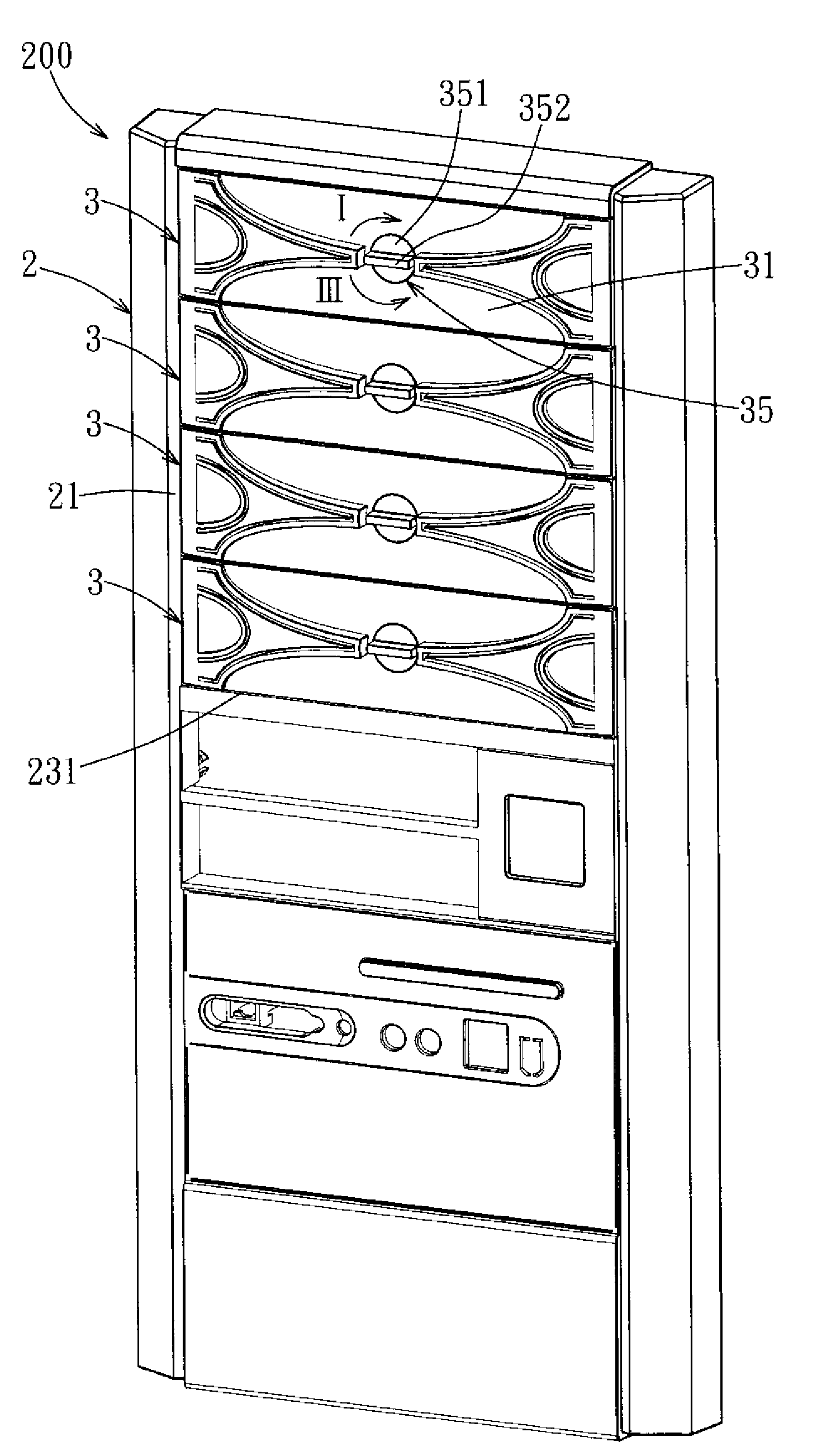

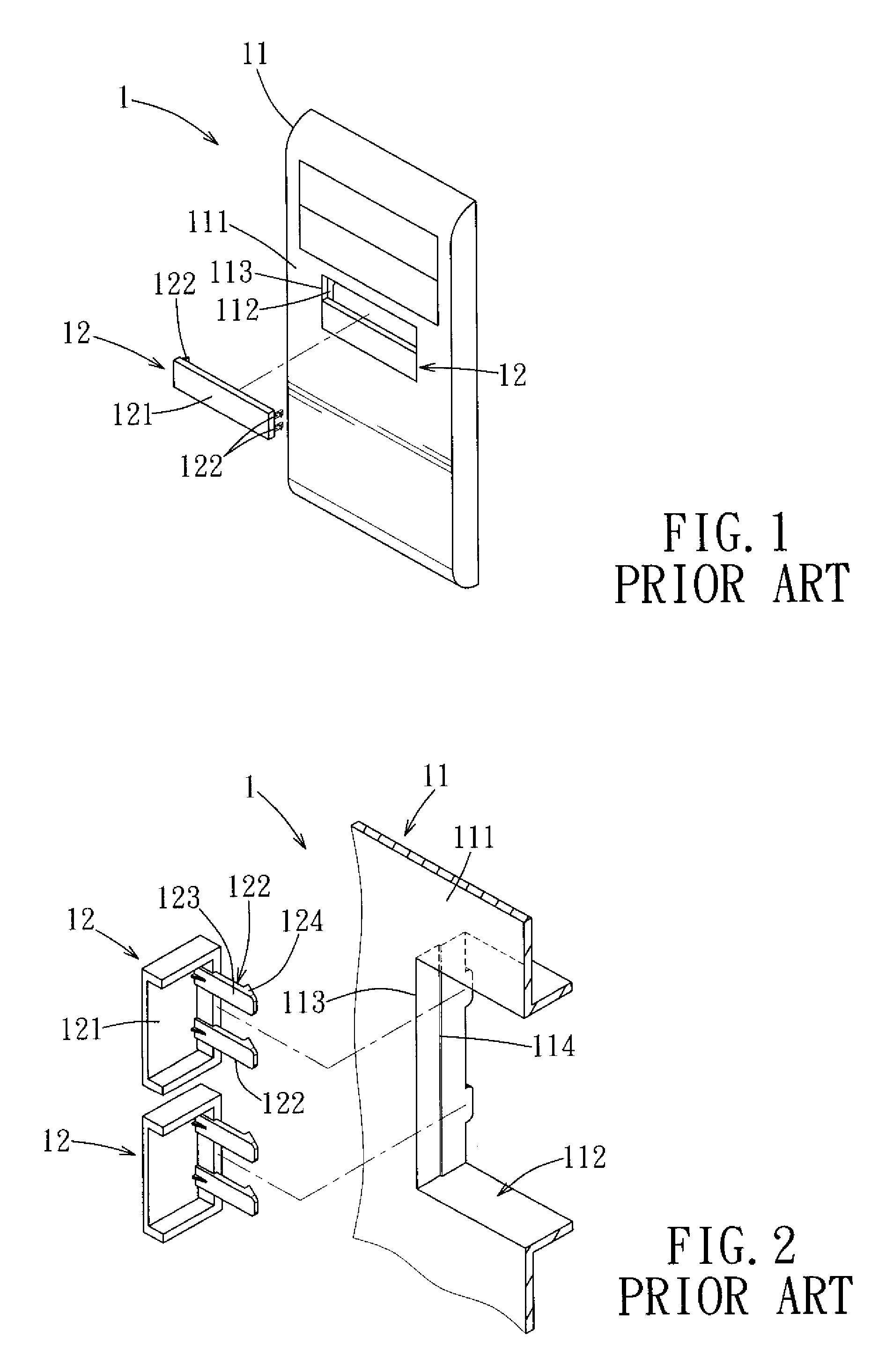

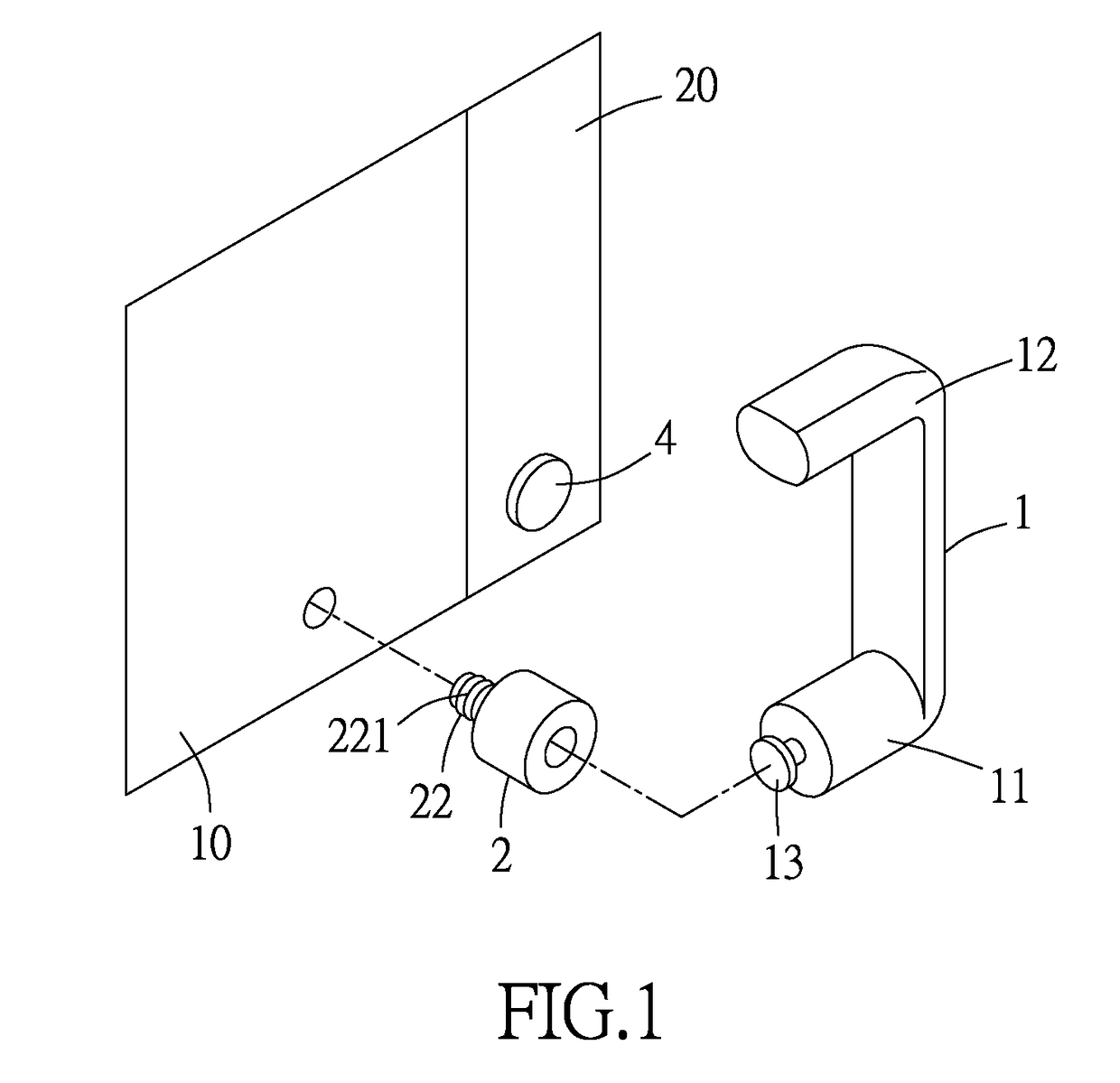

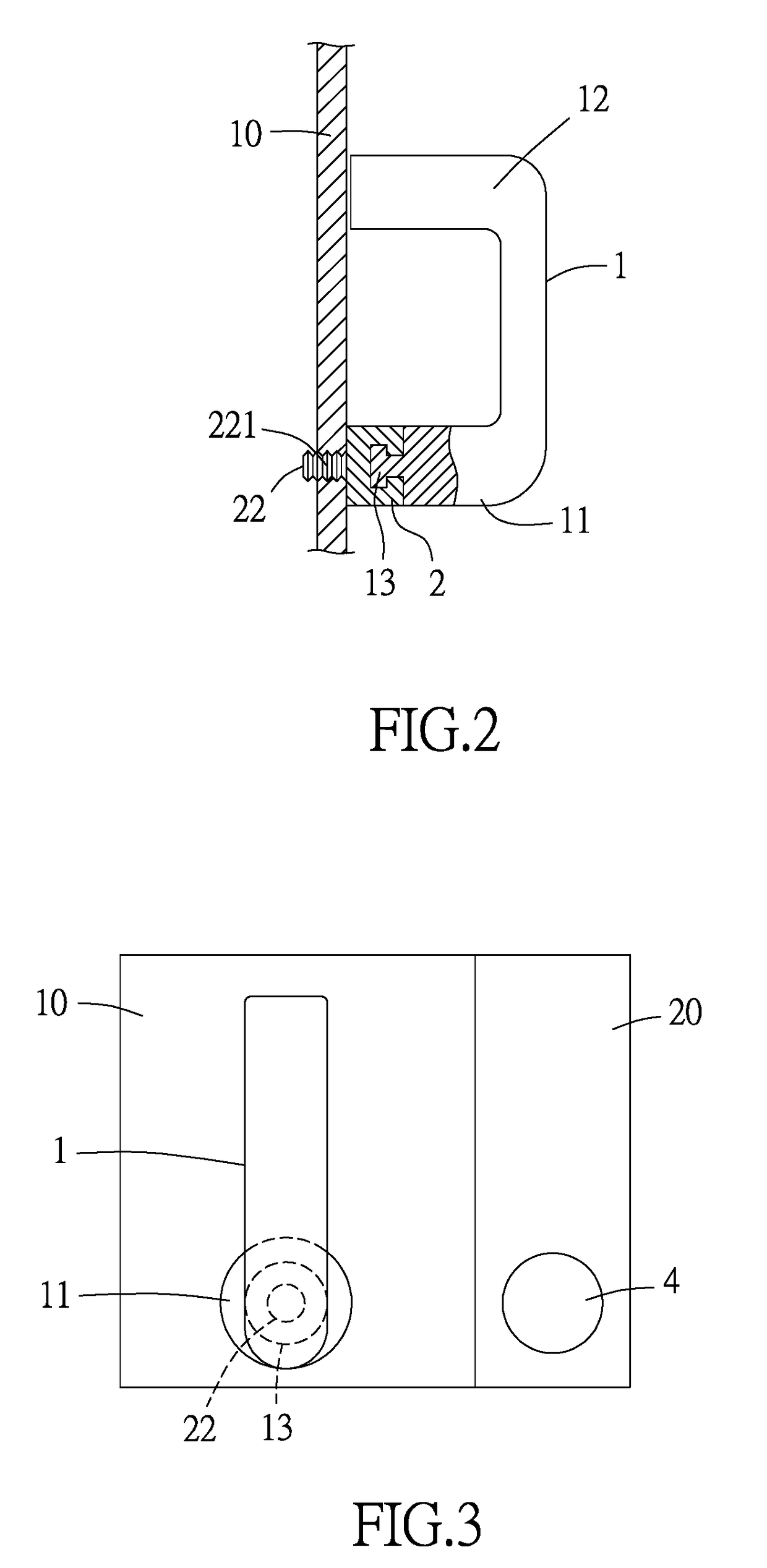

Face Panel for a Computer Housing

InactiveUS20100052484A1Quick disassemblyQuick and convenient mannerDigital data processing detailsWing fastenersEngineeringSurface plate

A face panel for a computer housing includes a face panel body and a cover plate assembly. The face panel body includes a surrounding wall and a mounting hole. The surrounding wall has first and second engaging grooves. The cover plate assembly includes a cover plate, a locking member, and an unlocking member. The cover plate has a first engaging hook for engaging the first engaging groove, and a guide groove. The locking member is assembled to the guide groove, and has a second engaging hook, a post, and a restoring resilient plate to apply a pressure to the cover plate so as to enable the second engaging hook to engage the second engaging groove. The unlocking member has an operating portion, and a contact portion movable with the operating portion so as to push the post for disengaging the second engaging hook from the second engaging groove.

Owner:AOPEN

Ultrasonic testing method for concentration of liquid-solid two-phase flow

InactiveCN1542447ASolve measurement problemsReduce volumeAnalysing fluids using sonic/ultrasonic/infrasonic wavesAttenuation coefficientSonification

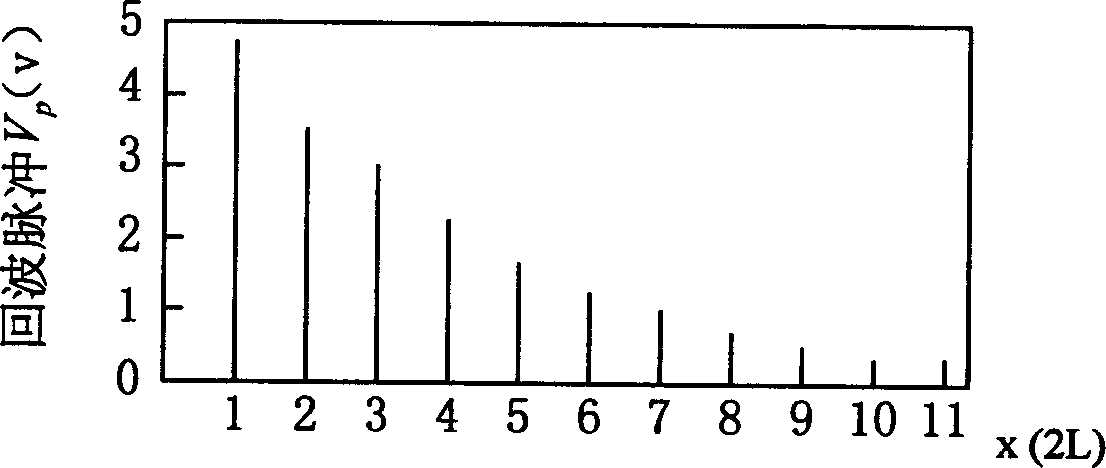

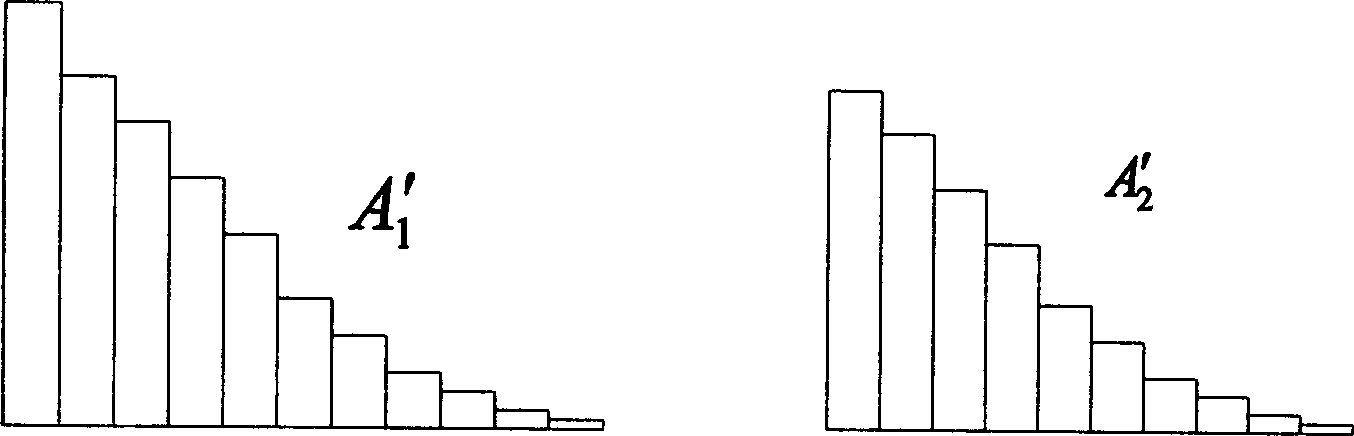

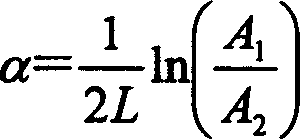

The ultrasonic testing method for the concentration for two-phase solid-liquid flow includes: adopting two parallel plates with fixed interval of L=100 mm with two-phase flow medium in between and setting the ultrasonic probe beside the parallel plates to make ultrasonic wave reflected between the parallel plates and obtain multiple echoes; measuring the first to the n-th echoes of the same emitted wave; calculating the envelope area A1 of the first to the n-th echoes and the envelope area A2 of the second to the n-th echoes separately; calculating the attenuation coefficient based on formula alpha=(1 / 2L)ln(A1 / A2), where L is the acoustic path of the sensor; and measuring different alpha values corresponding to different concentration sample compounded in lab so as to obtain the calibration curve of alpha value vs sample concentration.

Owner:NANJING NORMAL UNIVERSITY

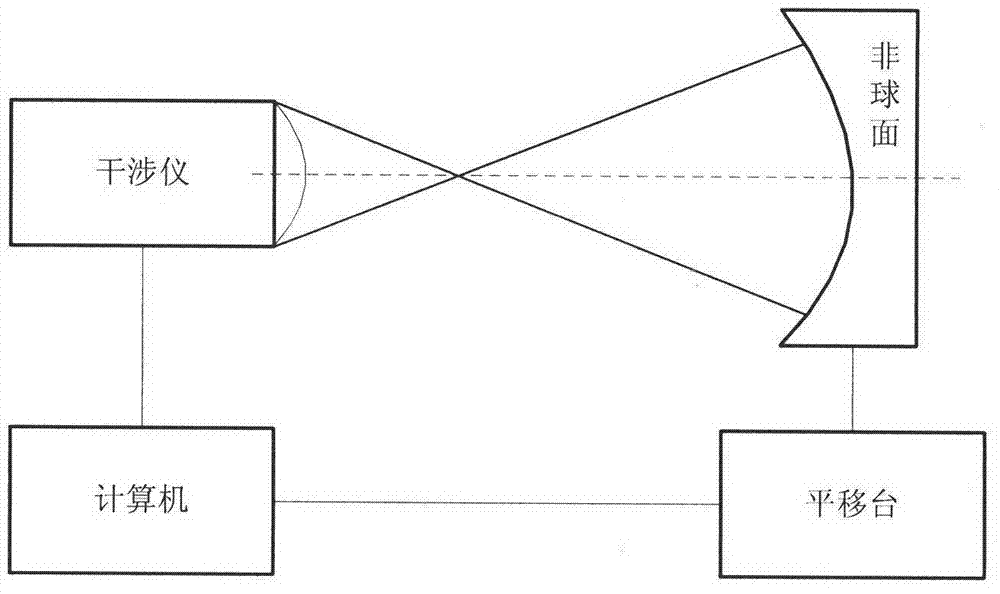

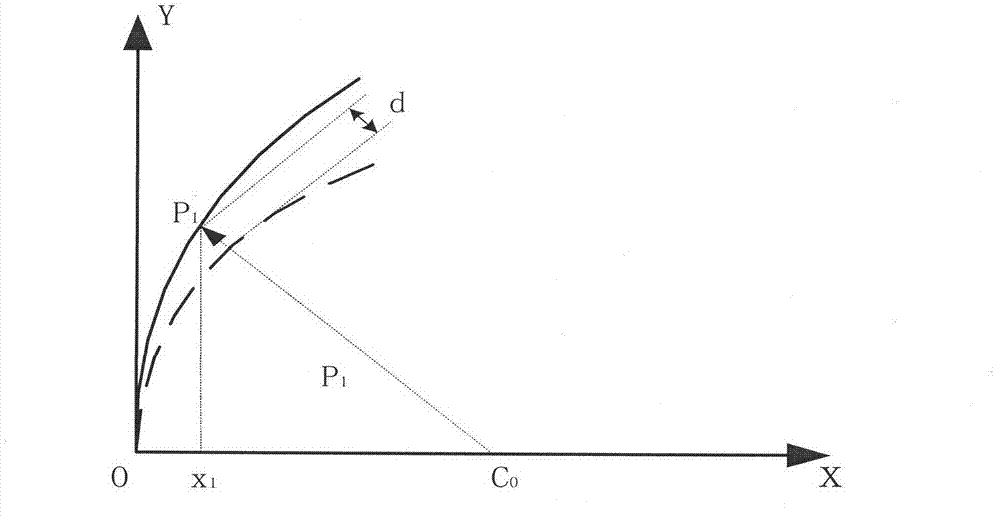

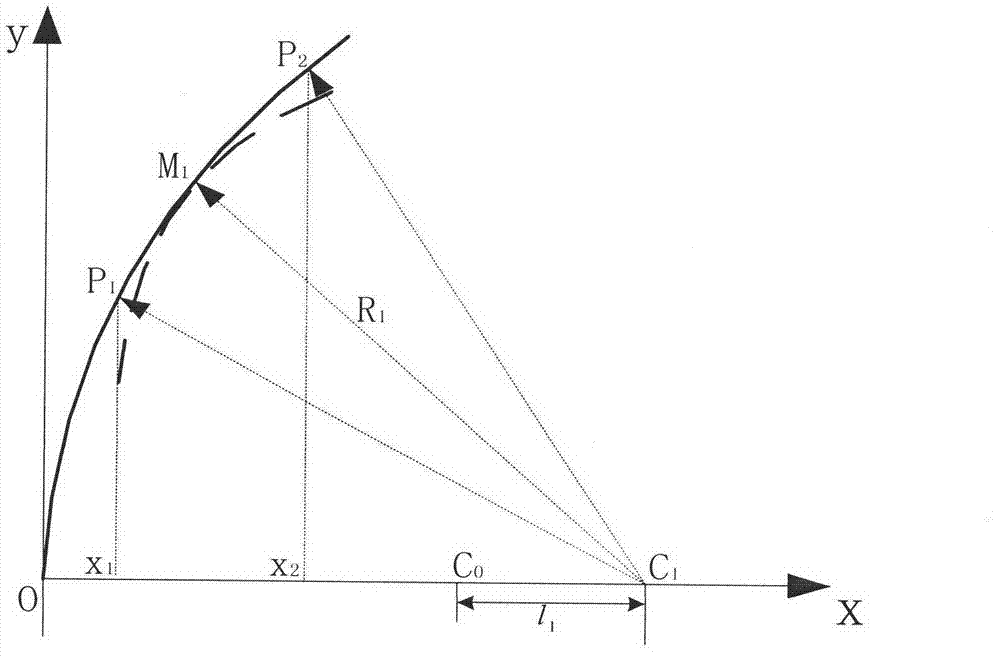

Searching method for annular sub-aperture boundary splicing

InactiveCN102735187AControl the moving distanceEasy to handleUsing optical meansSmall caliberComputer science

The invention discloses a searching method for annular sub-aperture boundary splicing. The moving distance of an interferometer and sub-aperture inner and outer boundaries in a splicing experiment are positioned; the method is mainly applied to an system for measuring heavy-caliber aspherical surface shapes by a small-caliber interferometer; the method determines the sub-aperture boundary condition of a clear interference fringe and the axial moving distance of the interferometer through the measured paraboloid mirror caliber, relative aperture and CCD (charge coupled device) sampling resolution of the interferometer, and the next boundary is obtained through the circulative calculation until the suspend condition is achieved, that is, the critical point coordinate exceeds the aspherical caliber. According to the method, a sub-aperture division model is established, and a particular solving method of the model is given, thus the detection process can be controlled, quantized and can be repeated, and convenience for the treatment of the subsequent experiment data is provided.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

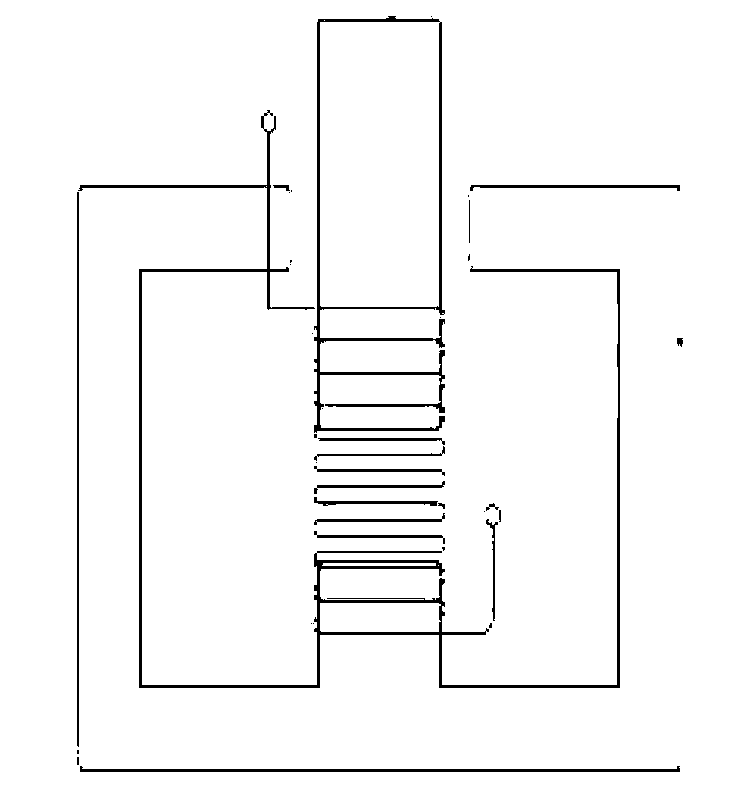

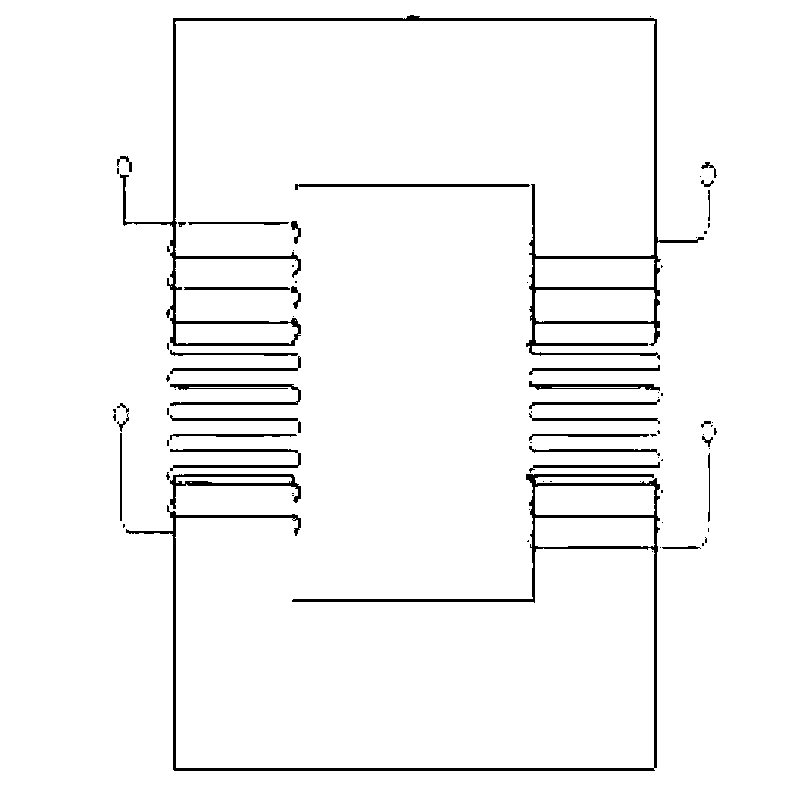

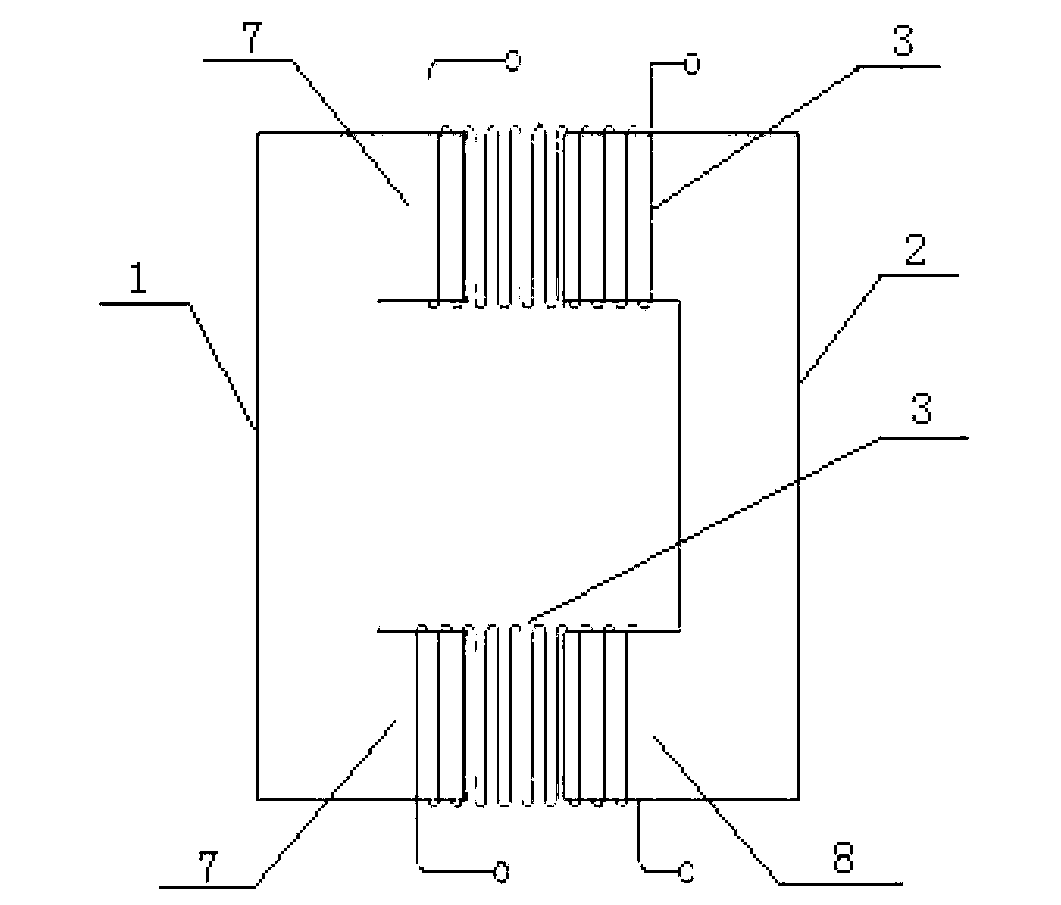

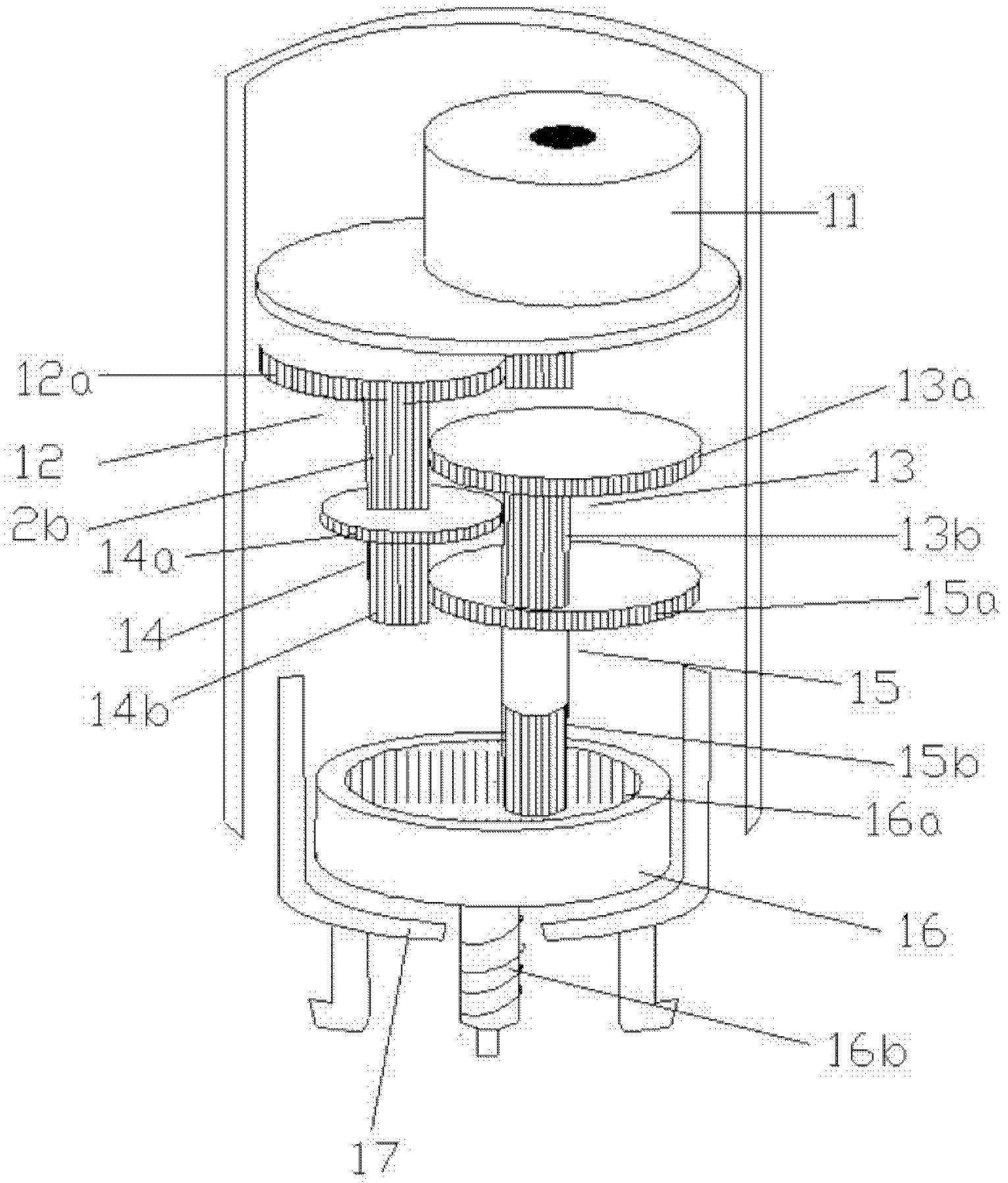

High-voltage adjustable reactor

ActiveCN103219138ALarge transmission ratioImprove carrying capacityVariable inductancesTransformers/inductances magnetic coresNuclear engineeringResonance

The invention relates to circuit induction adjustment equipment, in particular to a high-voltage adjustable reactor applied to resonance power-frequency high-voltage test devices. The high-voltage adjustable reactor comprises a reactor main body, a supporting frame and a transmission mechanism, wherein the reactor main body is composed of a movable iron core, a static iron core and a coil, the supporting frame performs fixing and supporting functions on the reactor main body, and the transmission mechanism is used for moving the movable iron core. The transmission mechanism comprises a first screw rod arranged inside the movable iron core, a first turbine sleeved on the end portion of the first screw rod, a first worm inserted into the movable iron core and meshed with the first turbine on the end portion of the first screw rod, and a drive device arranged on the end portion of the first worm. Compared with the prior art, the high-voltage adjustable reactor uses the high-precision turbine and the high-precision worm for transmission, and due to the fact that meshing faces of the turbine and the worm are in line contact, bearing capacity of the reactor is greatly higher than that of a common transmission mechanism.

Owner:SHANGHAI DIELEC ELECTROTECHNICS

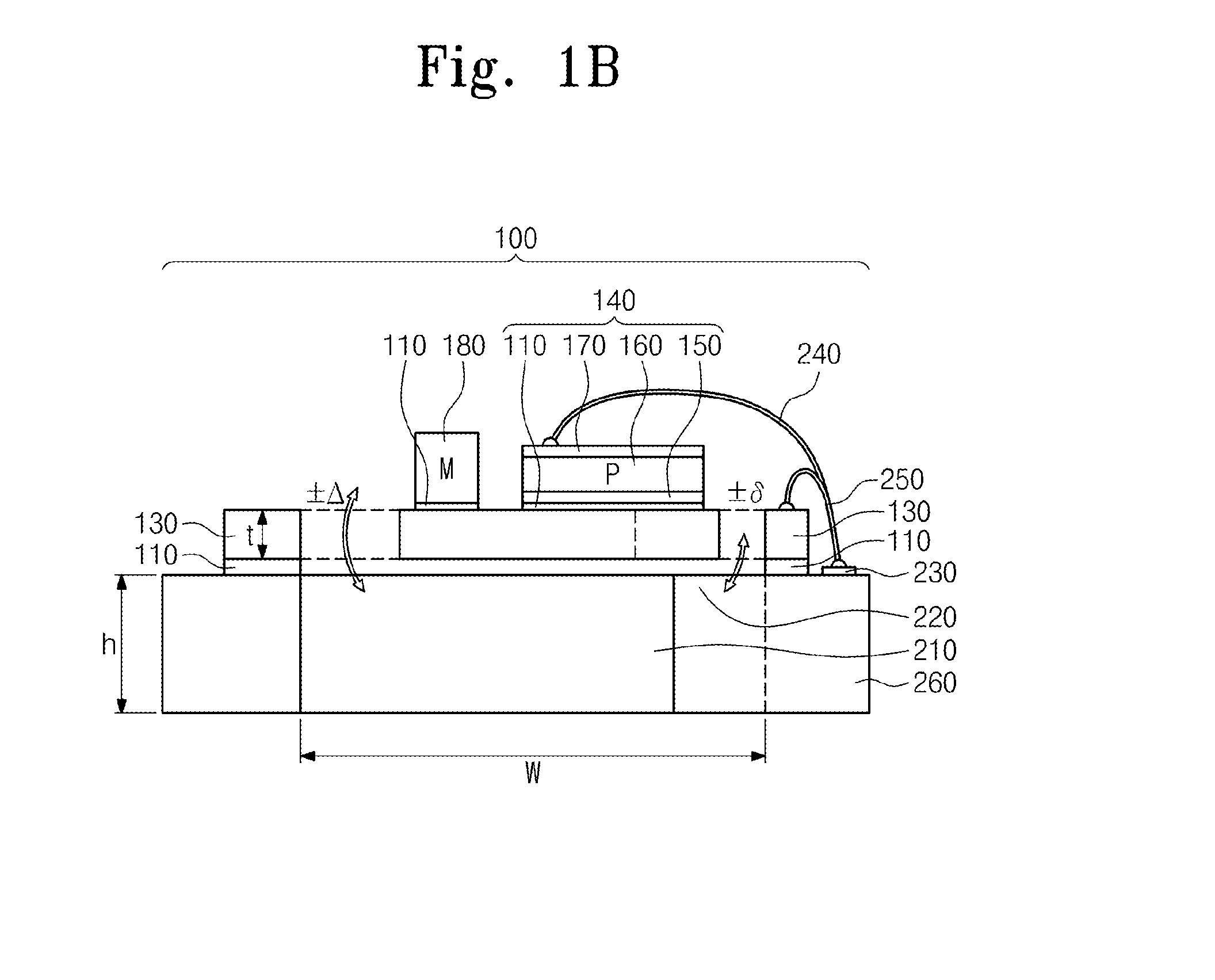

Impact-type piezoelectric micro power generator

InactiveUS20140159547A1Simple configurationEfficient powerPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesElectricityEngineering

The present inventive concept discloses an impact-type piezoelectric micro power generator. The impact-type piezoelectric micro power generator may comprise a base having a cavity and at least one stop area adjacent to the cavity; a frame fastened to the base; a vibrating body comprising a plurality of first vibrating beams extended from the frame toward a top of the cavity, an impact beam connected to between first tips of the plurality of first vibrating beams and extended onto the stop area, and a second vibrating beam extended from the impact beam to between the plurality of first vibrating beams, the second vibrating beam having a second tip; and a piezoelectric device disposed on one of a top and a bottom of the second vibrating beam and the impact beam, the piezoelectric device generating electric power according to impacts of the vibrating body to the stop area and bending of the impact beam and the second vibrating beam.

Owner:ELECTRONICS & TELECOMM RES INST

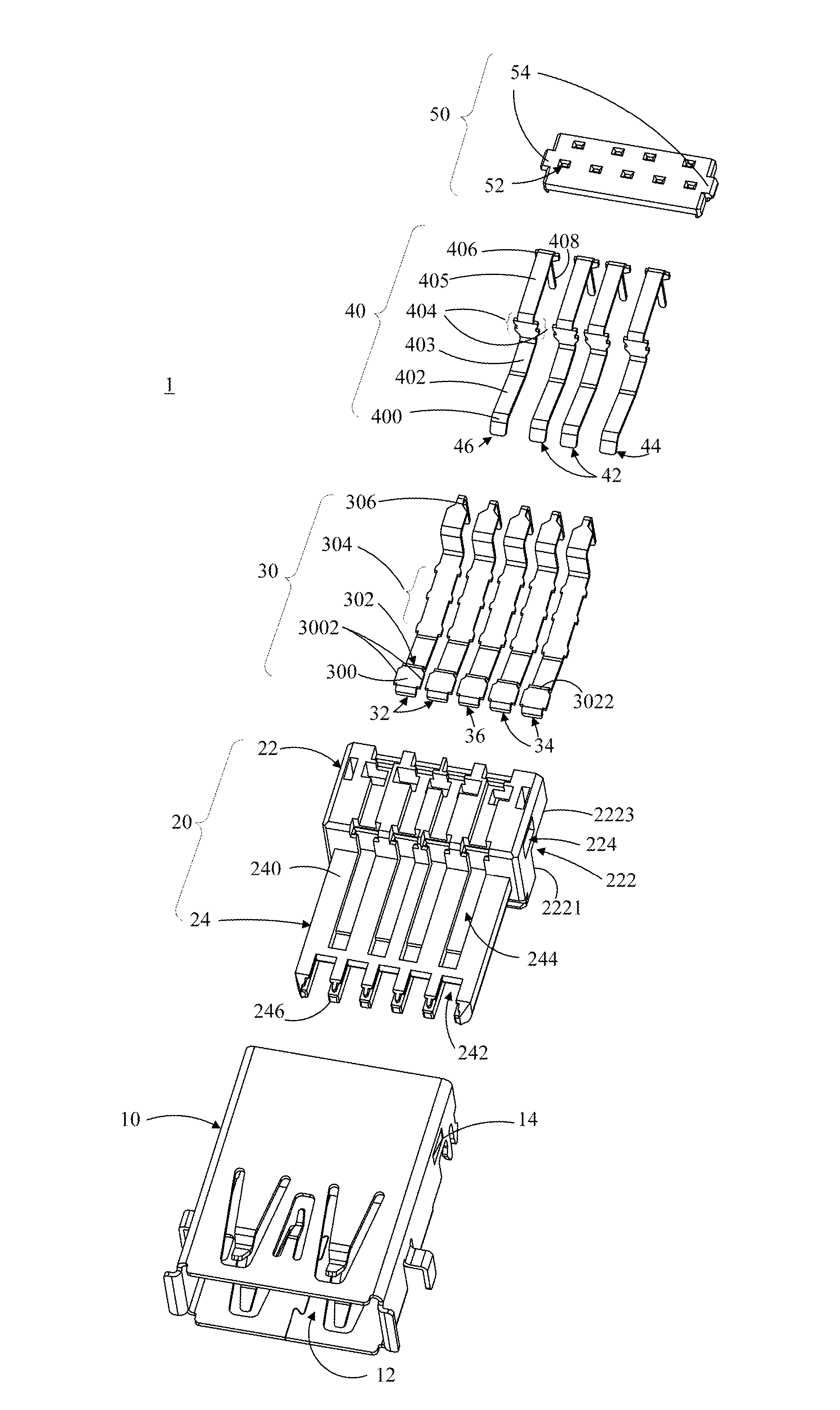

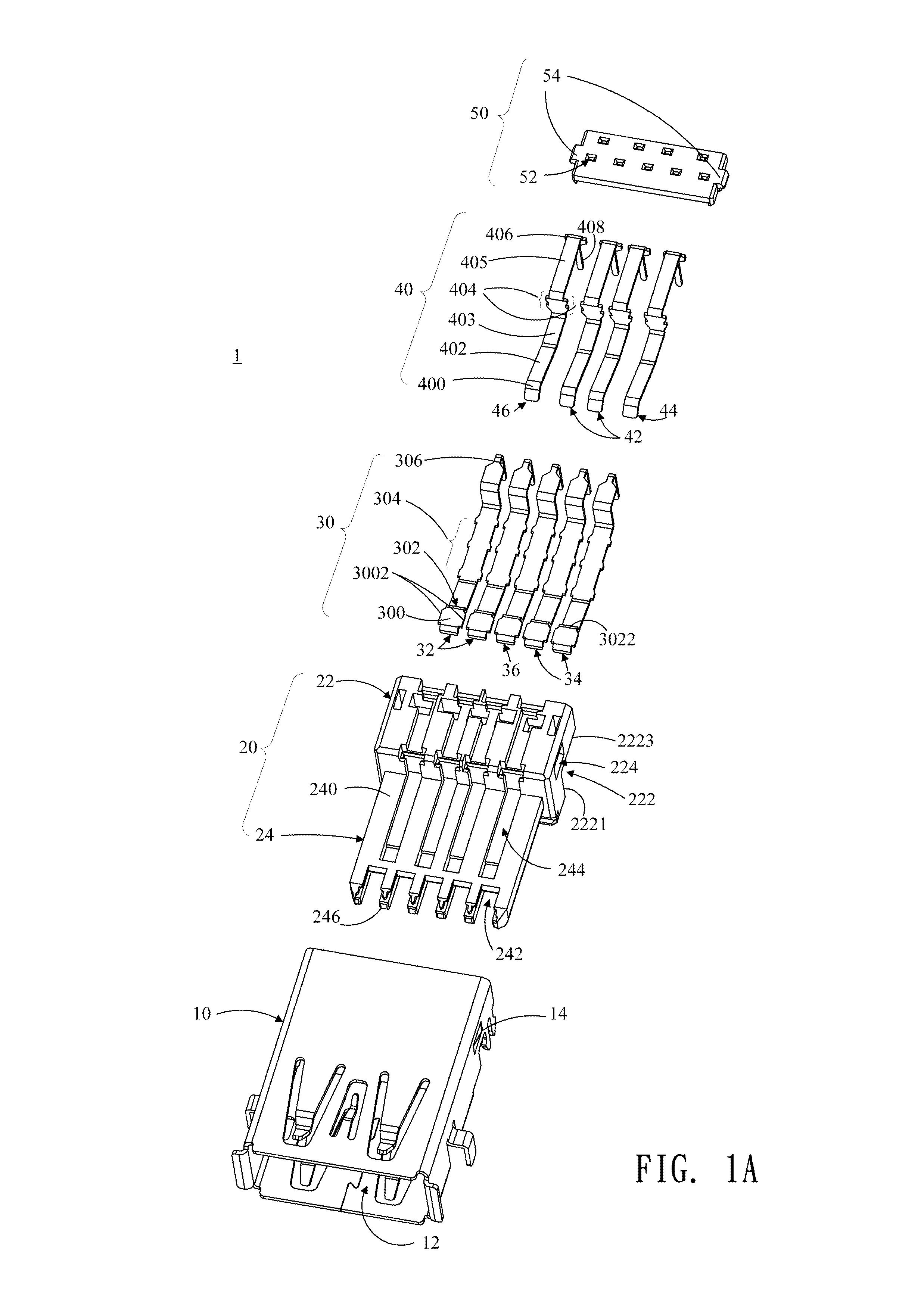

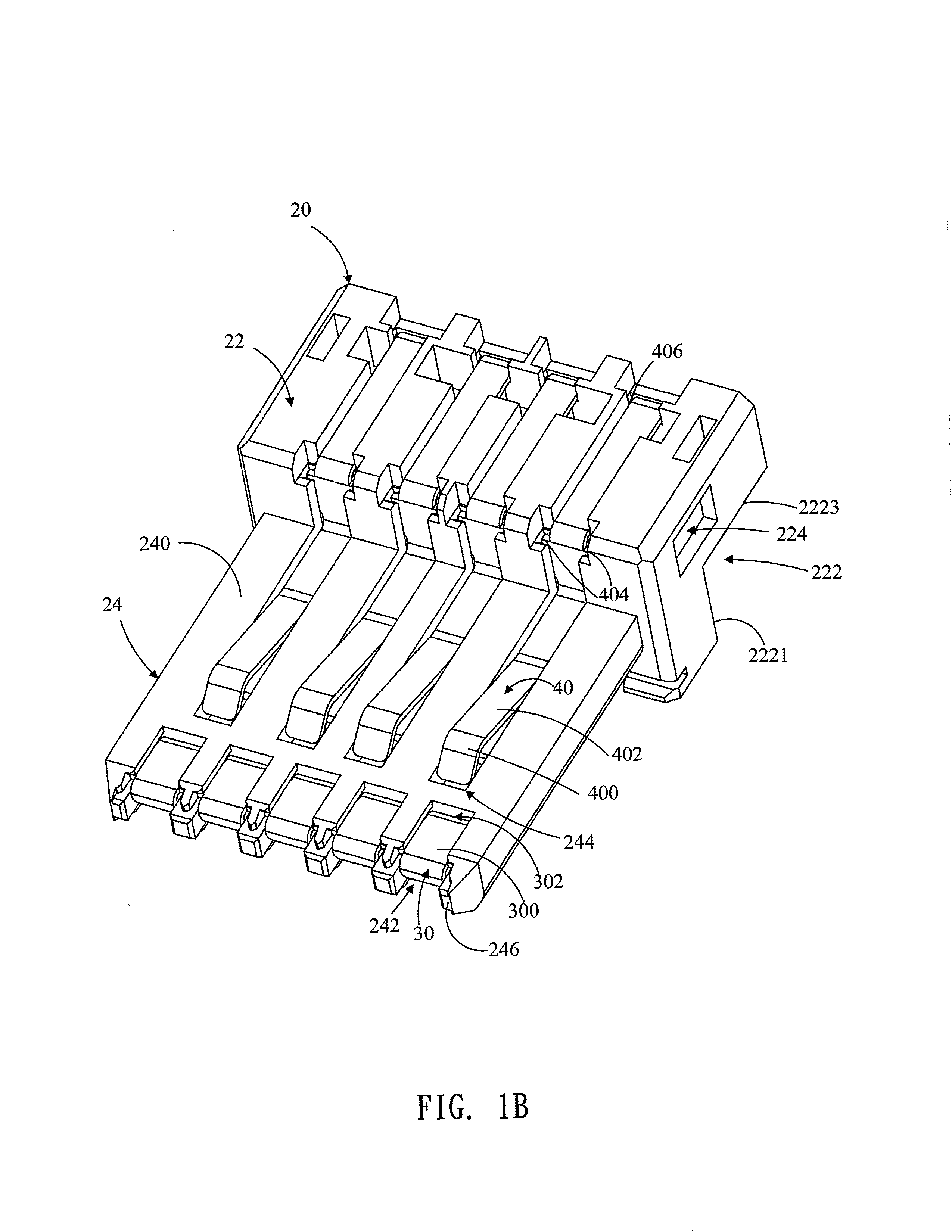

Electrical connector, electronic apparatus using the same, and assembling method of the electrical connector

InactiveUS20130183868A1Contact elasticityAvoid damageCoupling device detailsTwo-part coupling devicesElectricityComputer terminal

An electrical connector, an electronic apparatus using the same, and an assembling method of the electrical connector are introduced herein. The electrical connector includes first set terminals, second set terminals, and an insulated housing which has a plurality of first set terminal passages and second set terminal passages for respectively disposing said first and second terminals therein. When an elastic contact section of the respective first set terminal contacts with a complementary electrical connector, at least one elastic supporting section of the respective first set terminal provides flexibility required for the elastic contact section so that the elastic contact section can limitedly and elastically move within the corresponding first set terminal passage

Owner:ANT PRECISION IND CO LTD

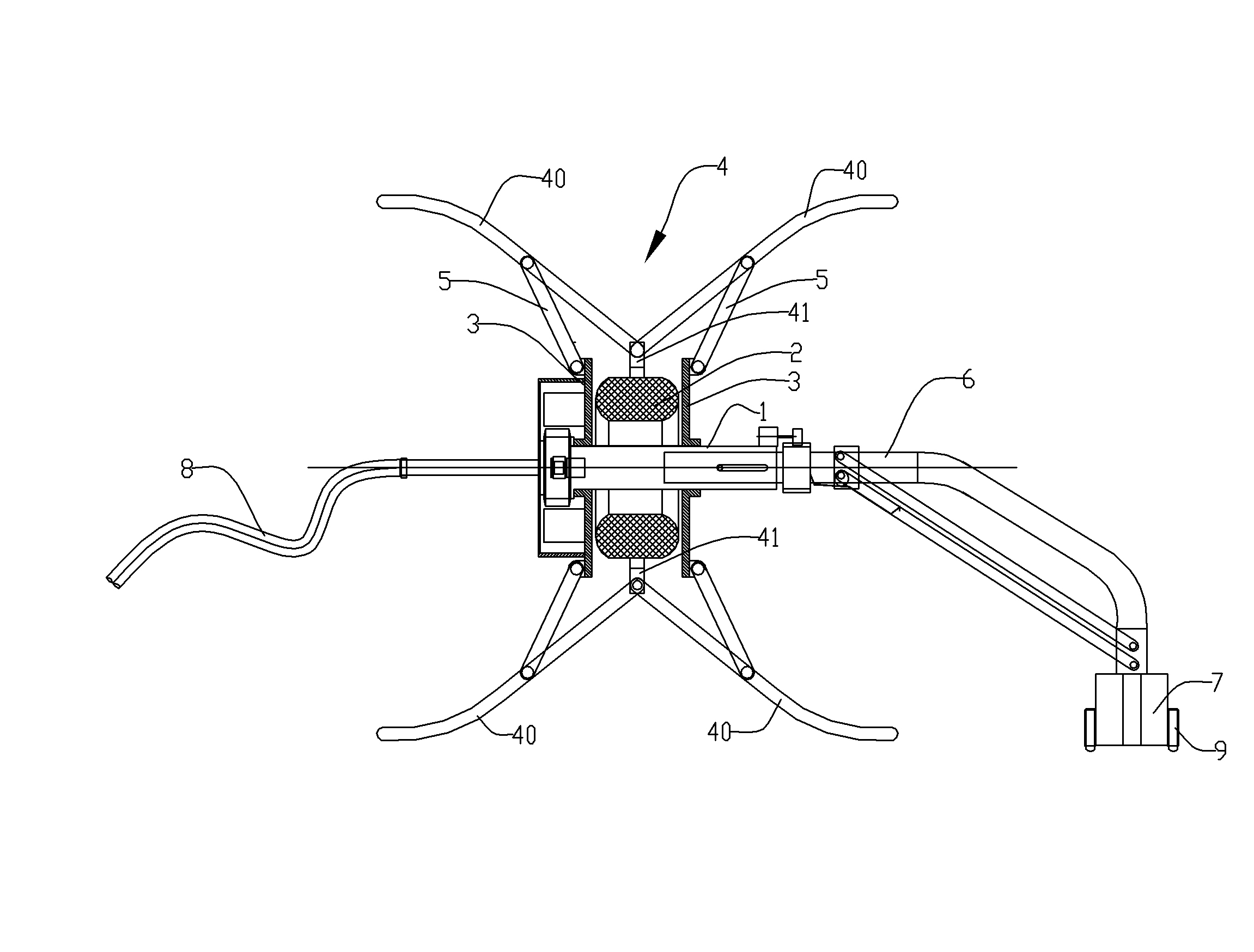

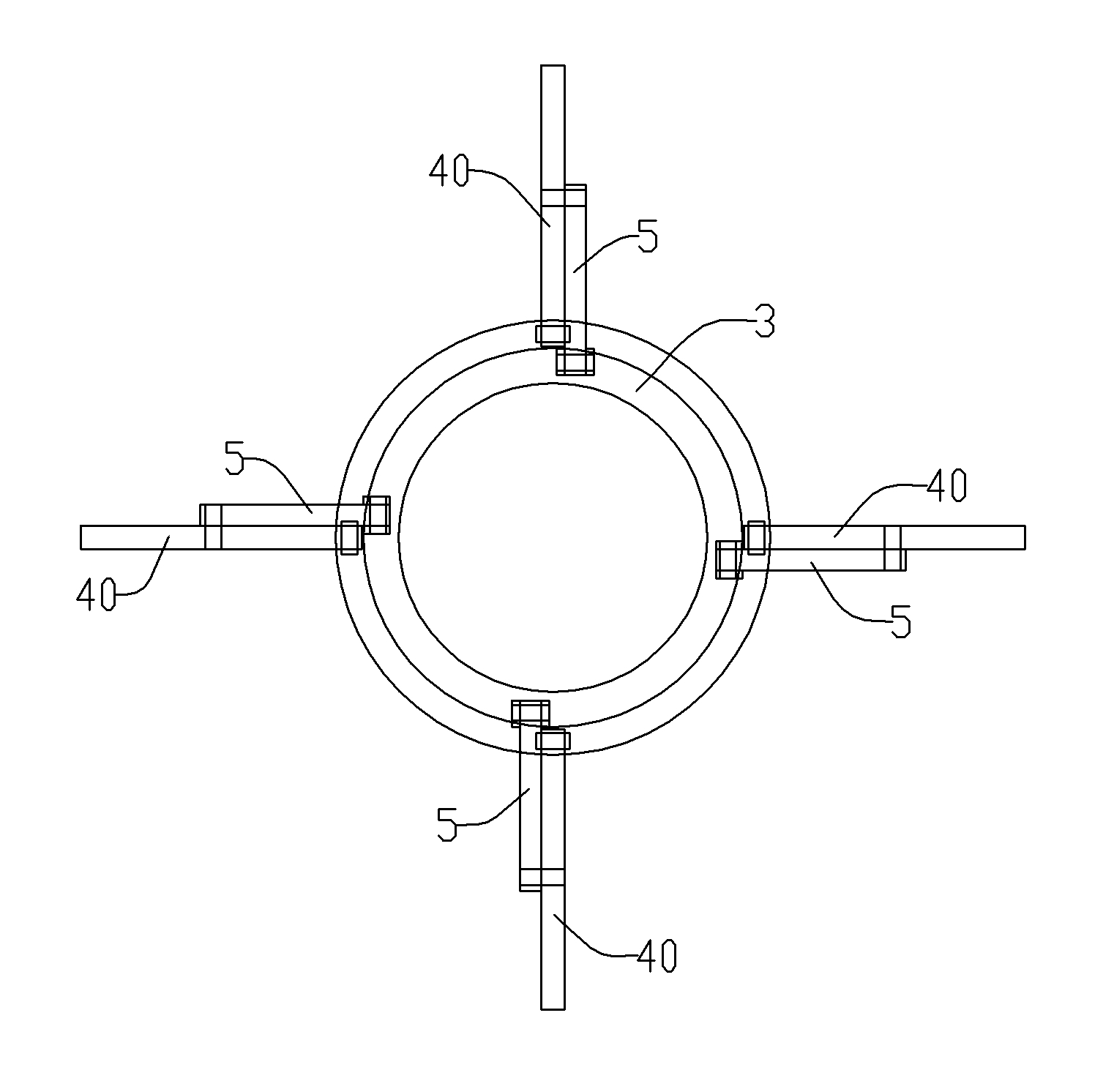

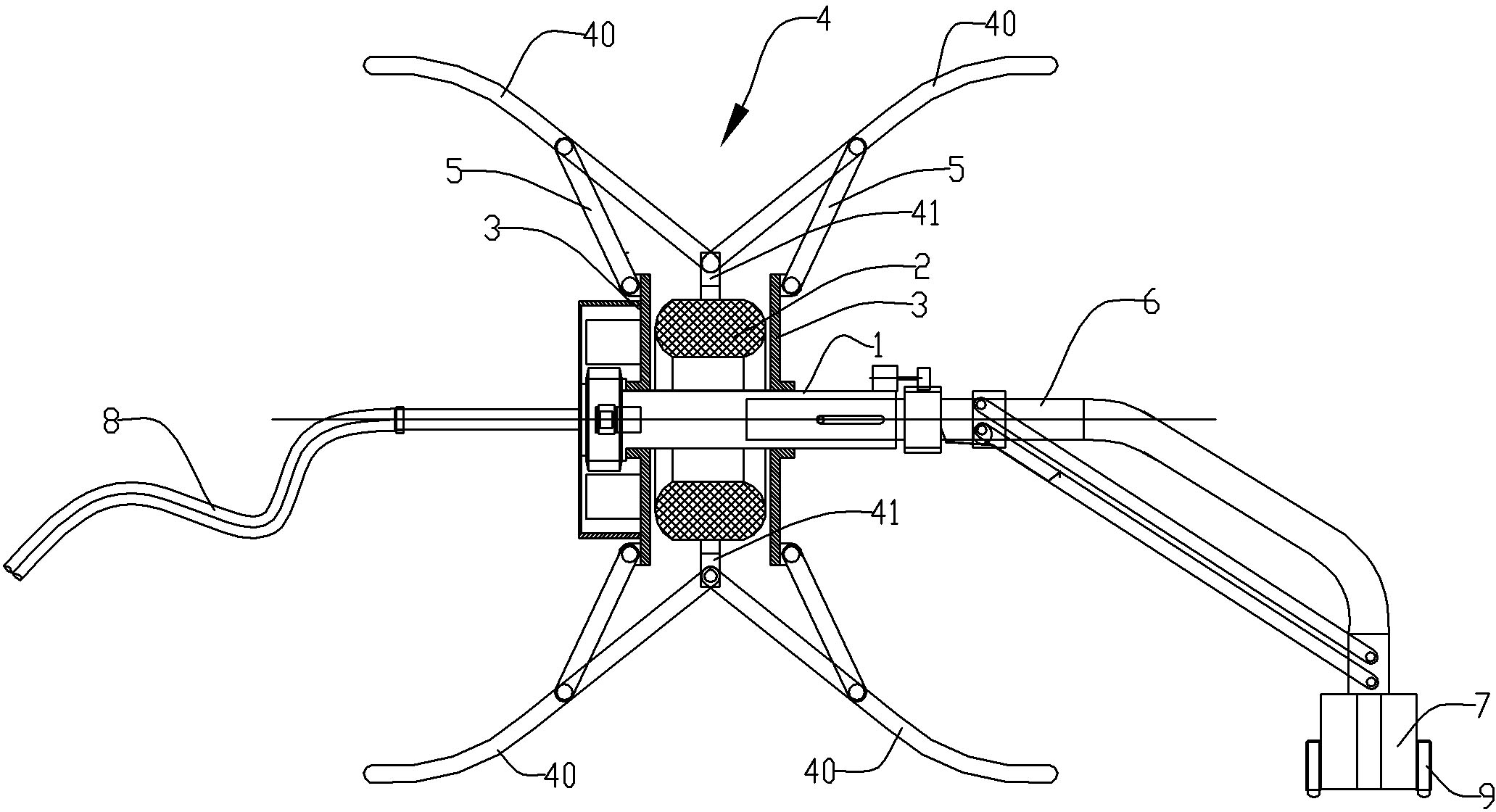

Inflation protection device and method for welding of pipe fitting

ActiveCN102126070AProvides protection against oxidationReduce dosageWelding accessoriesGas protectionNitrogen gas

The invention discloses an inflation protection device and method for welding of a pipe fitting, wherein the device is applied in gas protection of the inner wall of a weld joint when butting and welding the pipe fitting and comprises a middle shaft pipe, an expansion gasbag, a sliding plate, a support rod component capable of grasping and loosening the pipe wall, a spray head support extending from one end of the middle shaft pipe and a jet head arranged at the end part of the spray head support. A support rod can grasp and loosen the pipe wall through expansion and contraction of the expansion gasbag, a spray head can rotate directly, when in welding, the jet head can be controlled to aim at the welding part of the weld joint and move along with the welding part. The inflation protection device can pertinently provide gas protection according to the welding part, not only reliably provide anti-oxidation protection for the welding position and can be used for greatly reducing the amount of nitrogen, but also can be simultaneously used for shortening the primary preparation time of welding, and further can be used fro reducing the cost and improving the efficiency under the situation of improving the welding quality.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

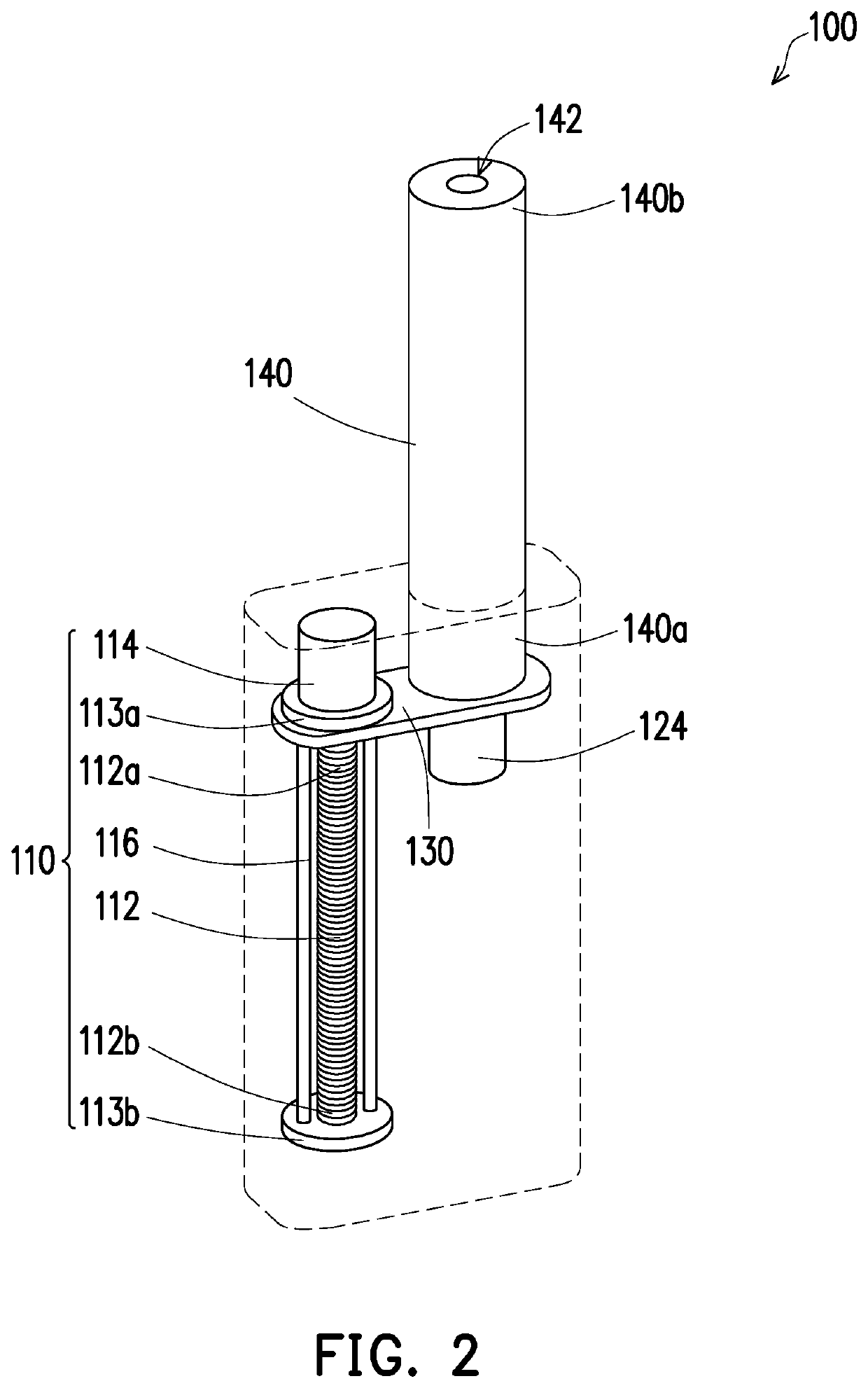

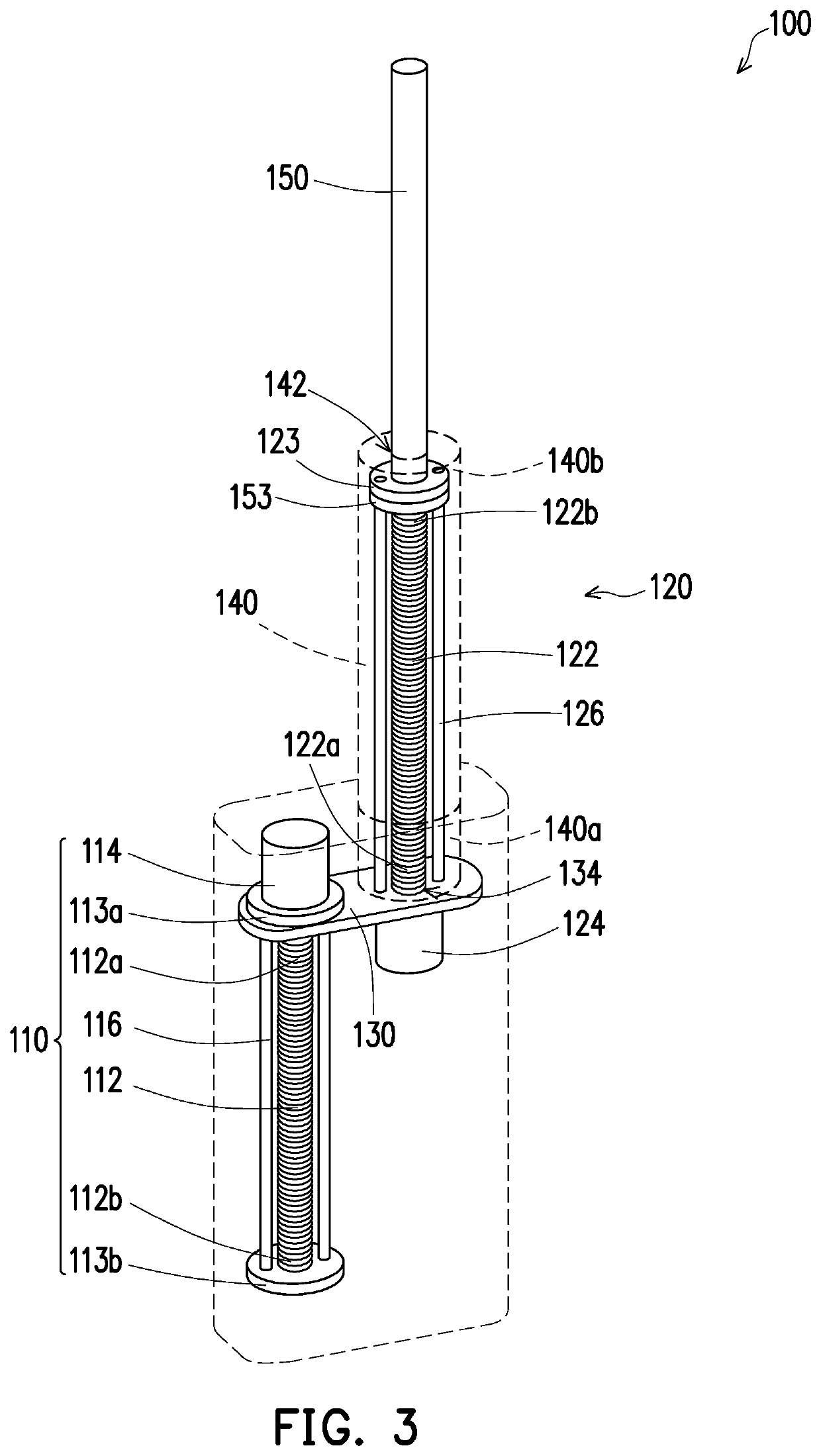

Telescopic adjuster

ActiveUS20190390752A1Effectively increasing a strokeControl the moving distanceGearingRod connectionsLinear actuatorControl theory

A telescopic adjuster including first and second linear actuators, a connecting platform and first and second telescopic levers is provided. The first linear actuator includes a first screw and a pair of first fixing rings. The first fixing rings are arranged at two respective ends of the first screw. The second linear actuator includes a second screw and a second fixing ring. The second fixing ring is arranged at the end of the second screw, relatively away from the connecting platform. The first and second linear actuators are arranged on the connecting platform in parallel. The first screw pushes the connecting platform to move along the first screw, and the first fixing rings limit a movement of the connecting platform. The first and second telescopic levers are coaxially arranged.

Owner:PEGATRON

Safety shredder with bin-full device and time delay

Owner:AURORA OFFICE EQUIP

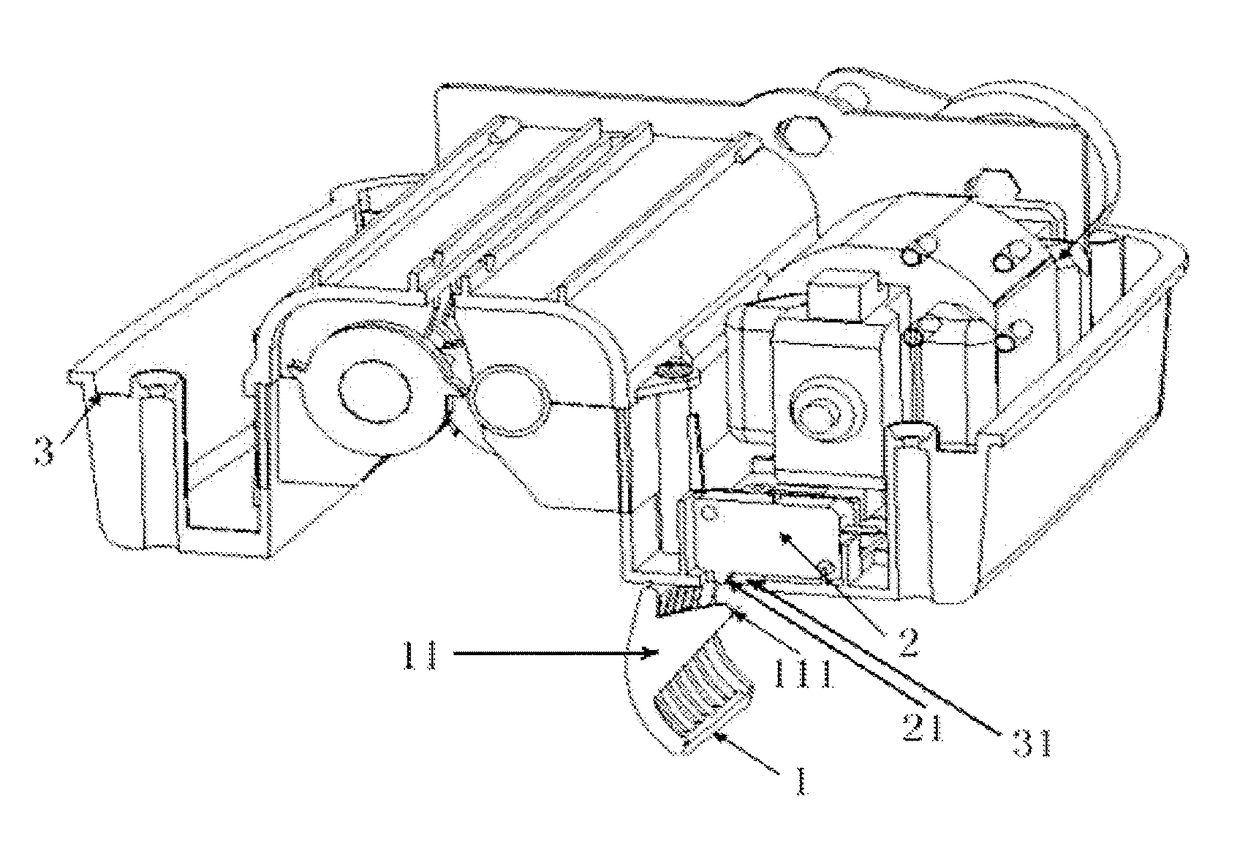

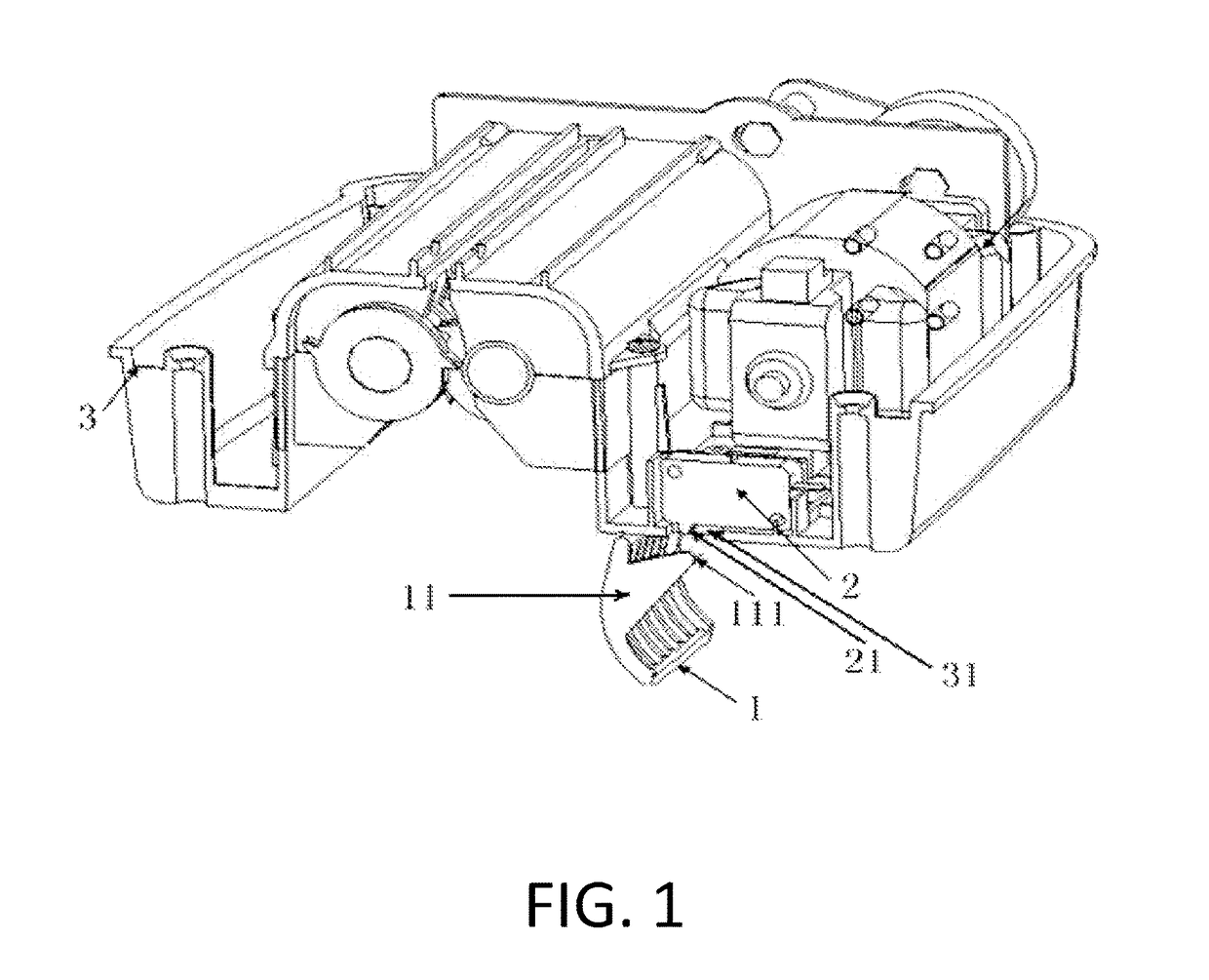

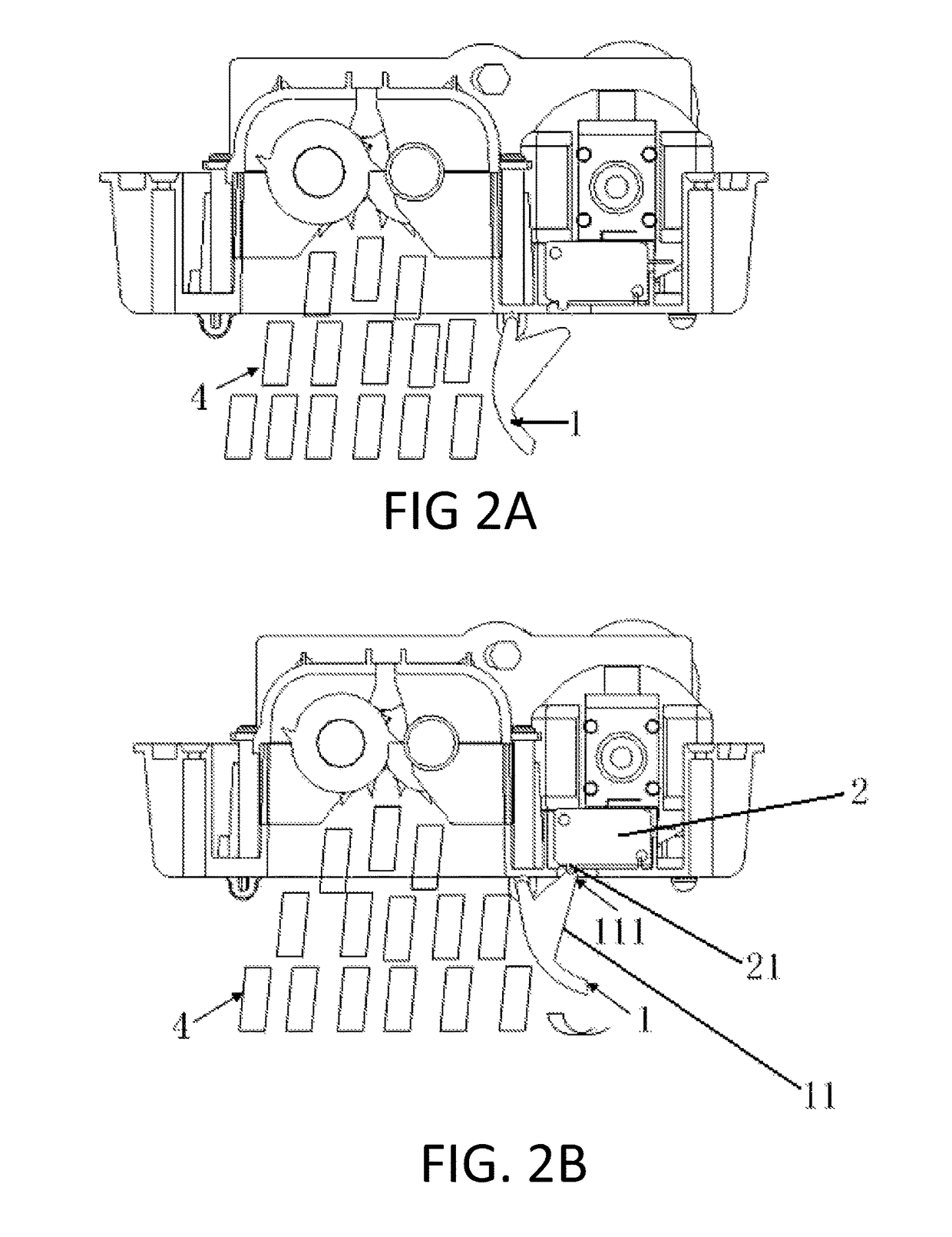

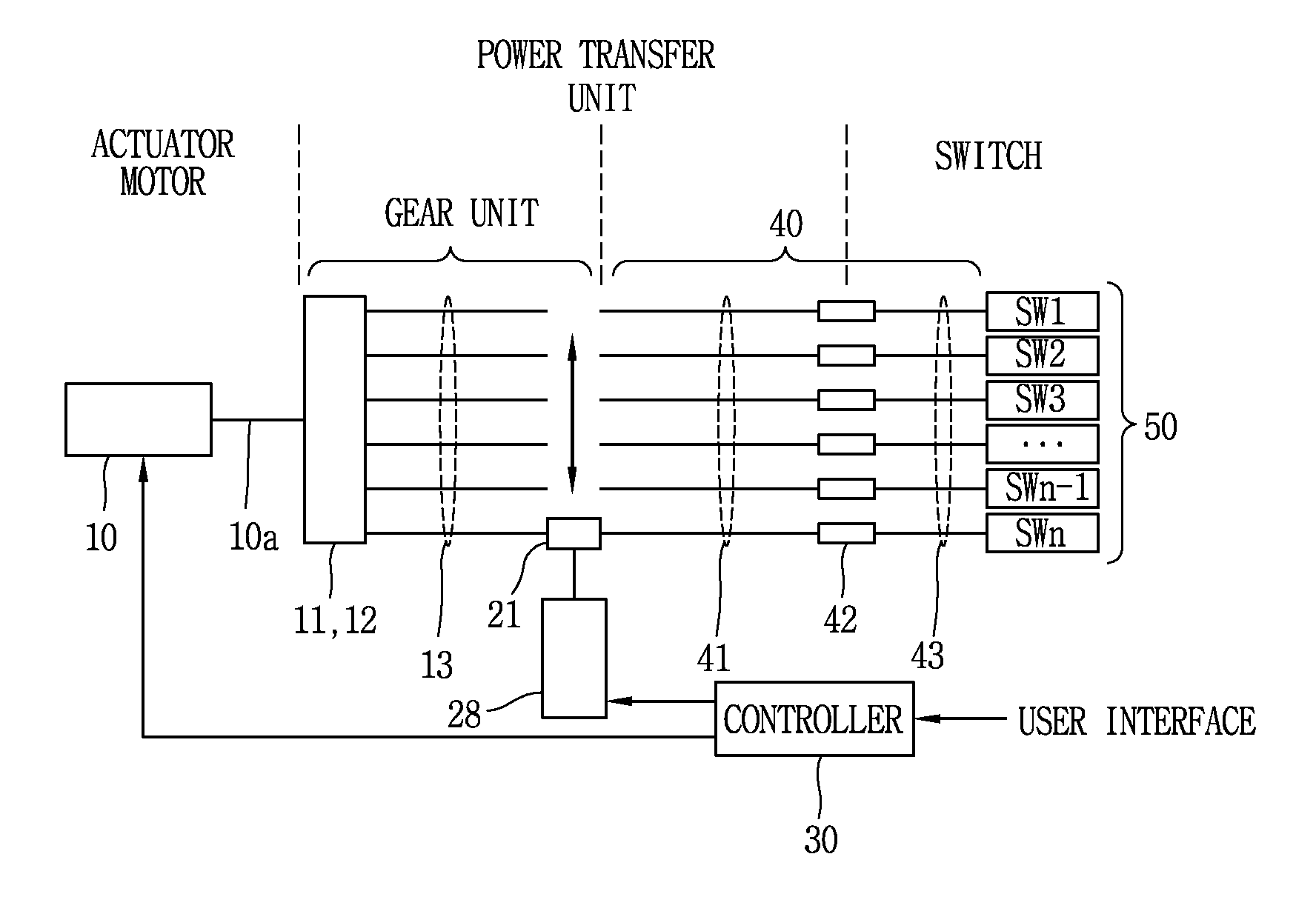

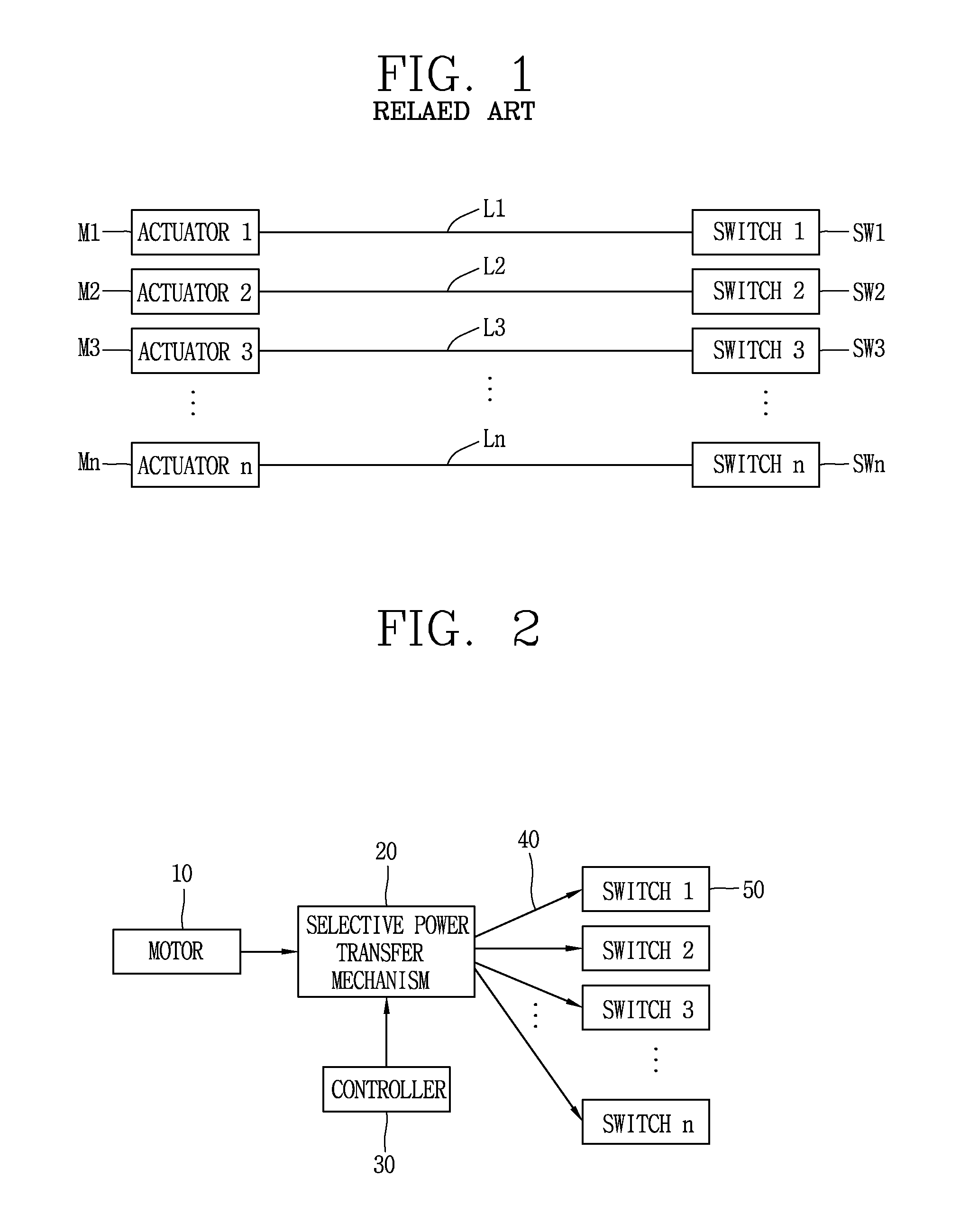

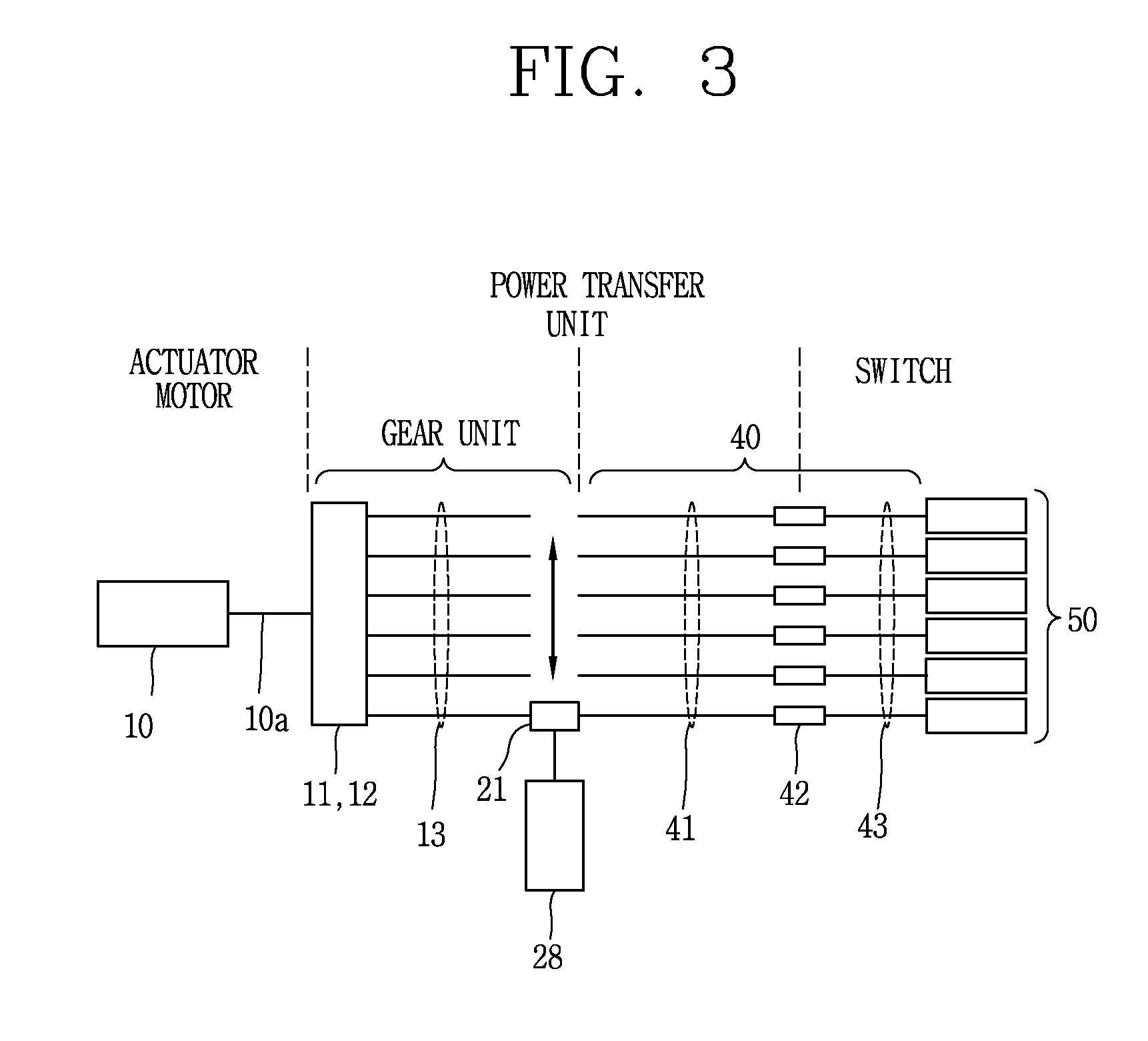

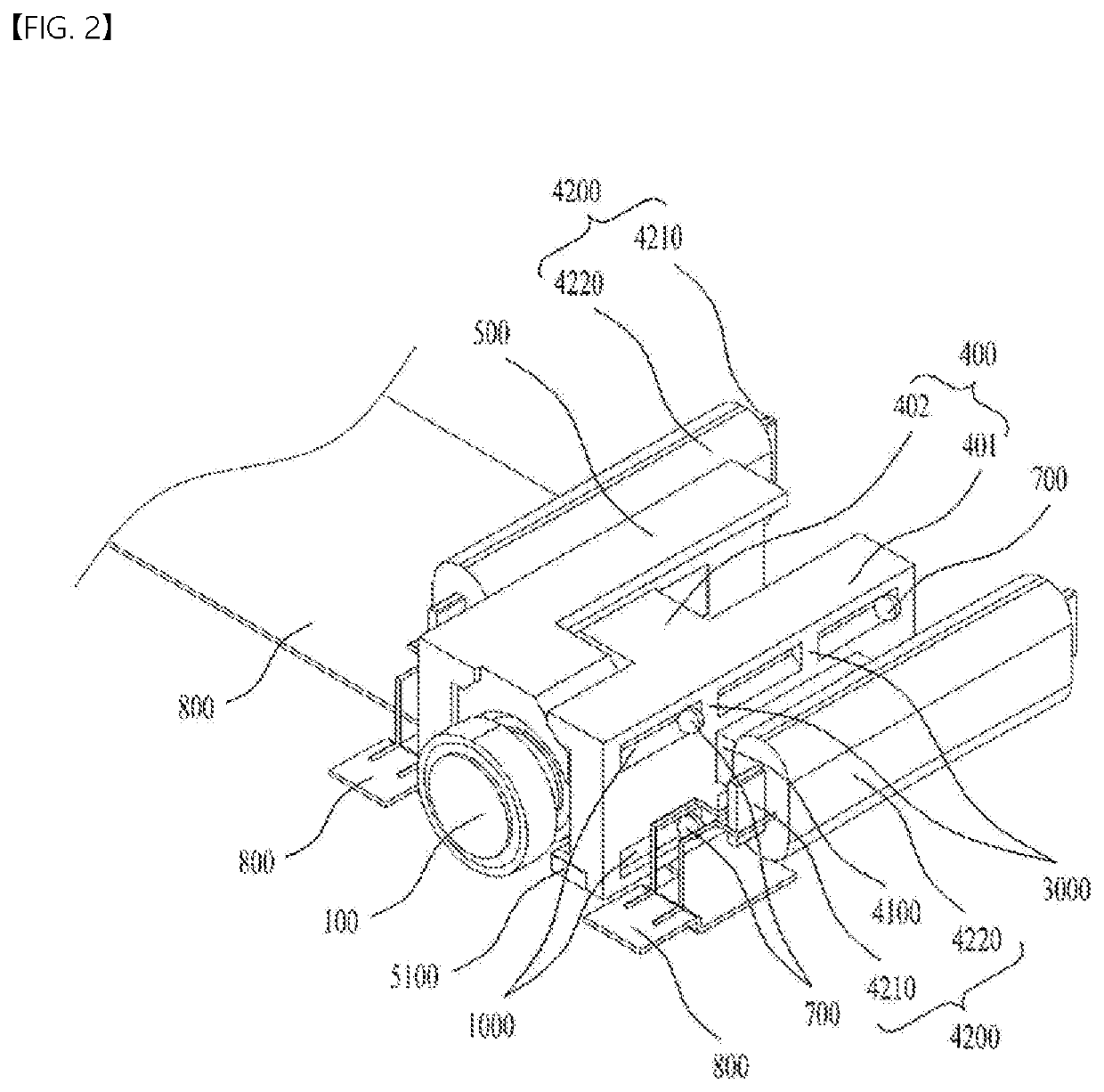

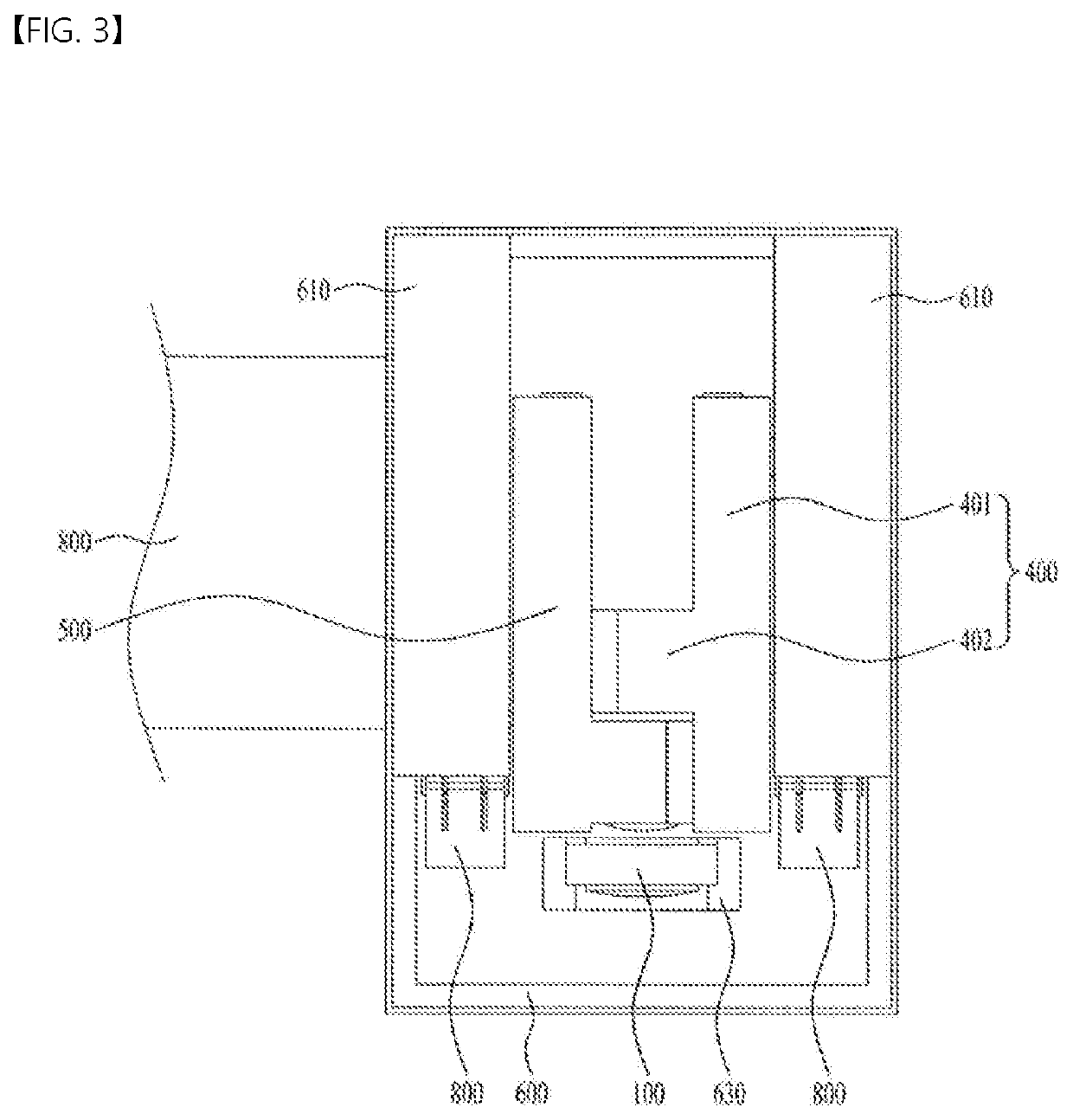

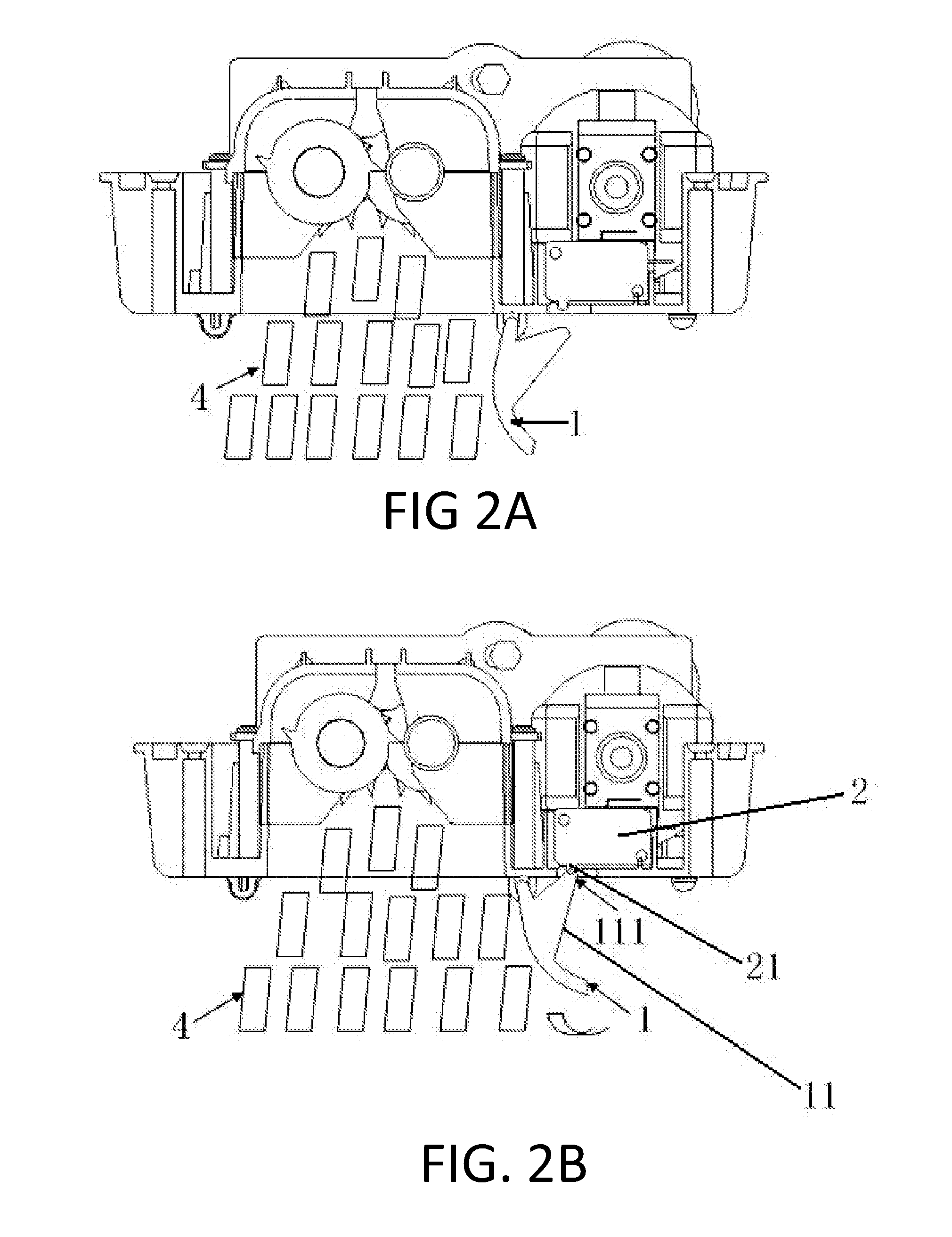

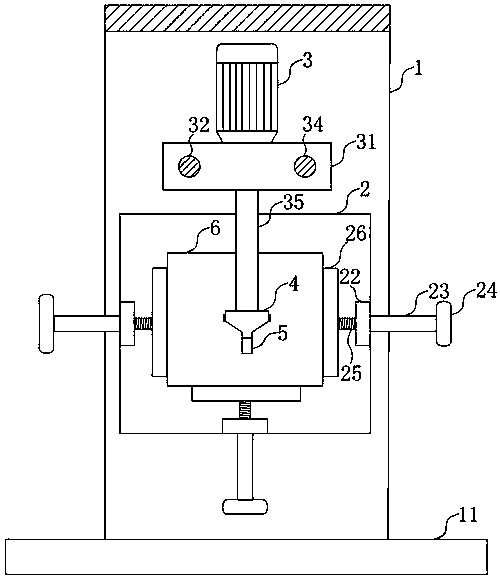

Common actuator system of multi switches for switchgear

InactiveUS20130228438A1Reduce manufacturing costControl the moving distanceSwitch power arrangementsTransfer mechanismActuator

A common actuator system of multi switches for a switchgear is capable of selectively opening or closing the plurality of switches using a single common actuator motor. The actuator system includes a single actuator motor providing a rotational force for commonly opening or closing the plurality of switches and having an output shaft, a plurality of link members provided to correspond to the plurality of switches, respectively, to transfer the rotational force of the actuator motor to the plurality of switches, a selective power transfer mechanism to selectively connect one of the plurality of link members to the actuator motor, and a rotational-linear force conversion mechanism to convert the rotational force of one of the plurality of link members into a linear force for opening or closing a corresponding switch and providing the linear force to the switch.

Owner:LSIS CO LTD

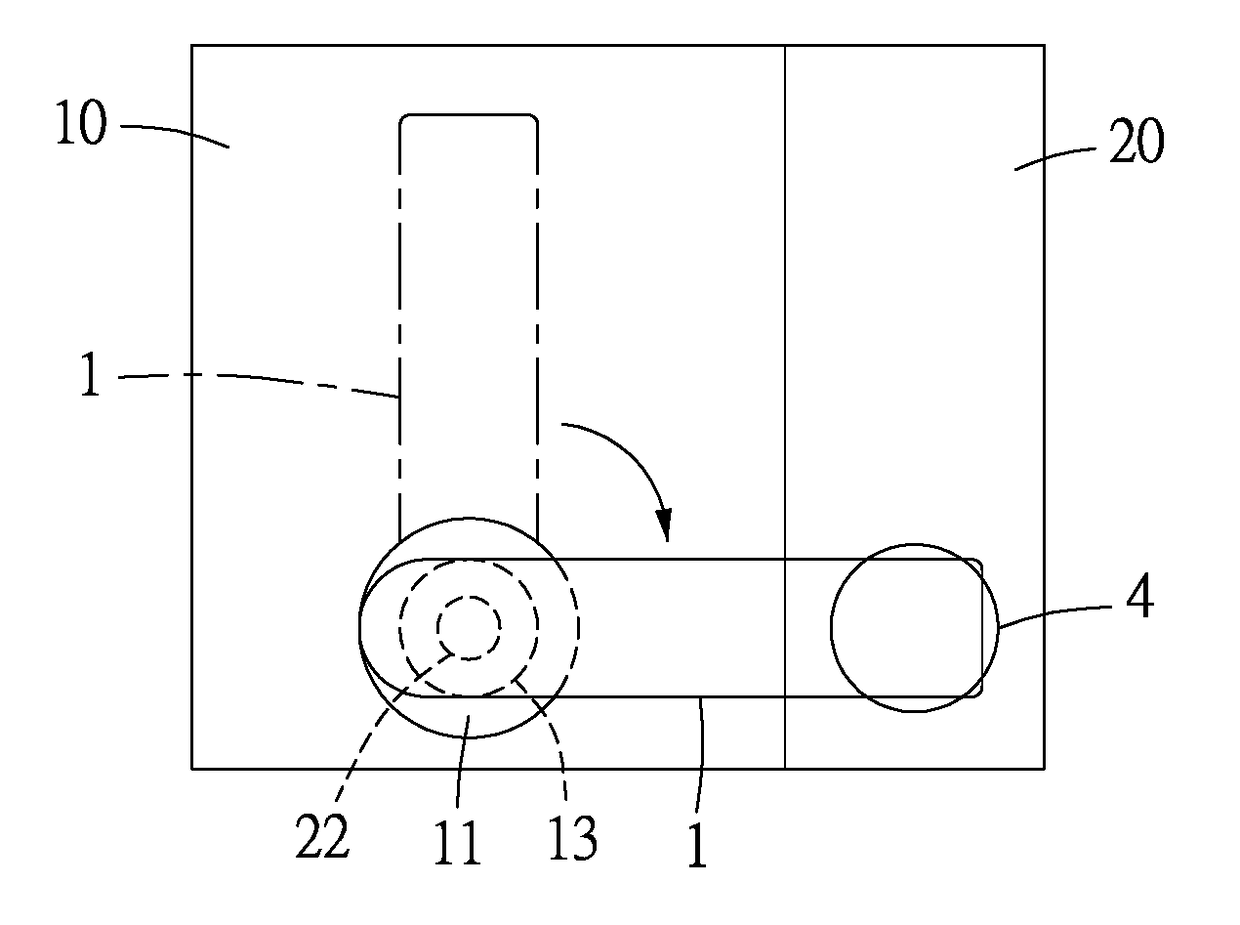

Roller device

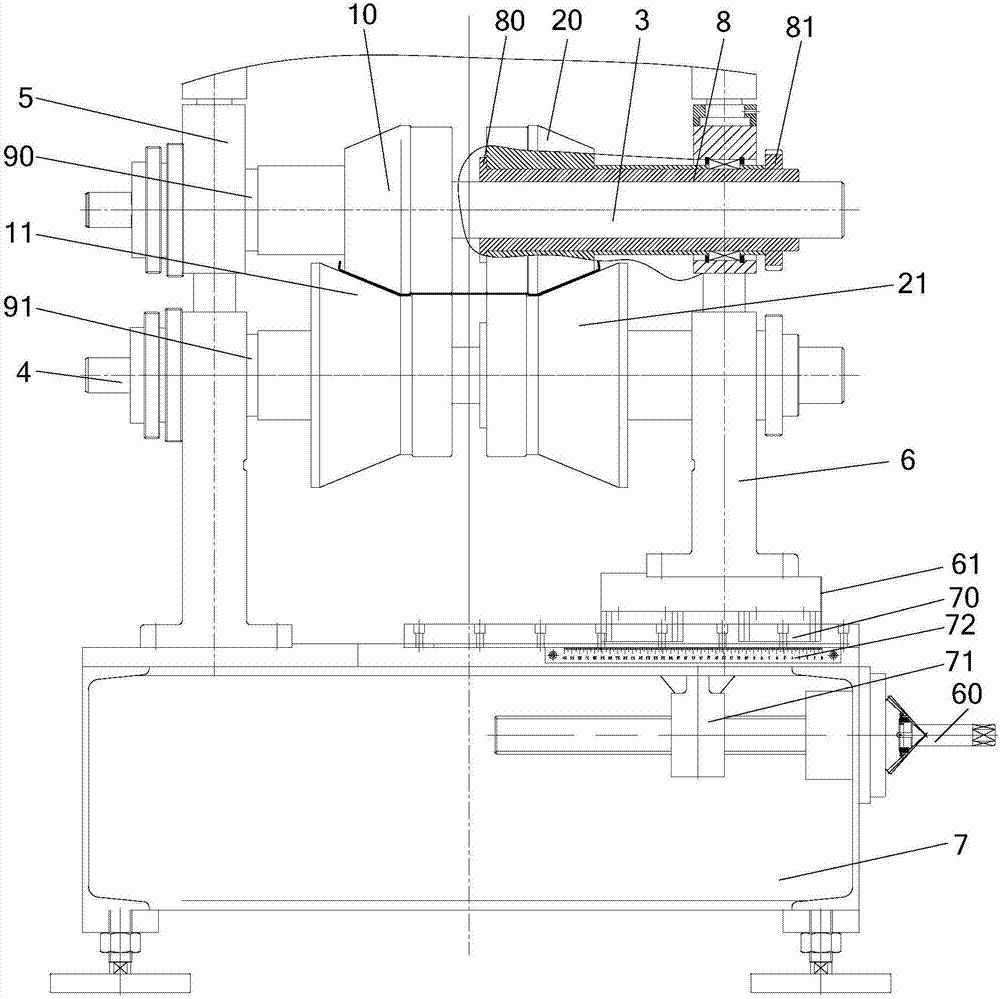

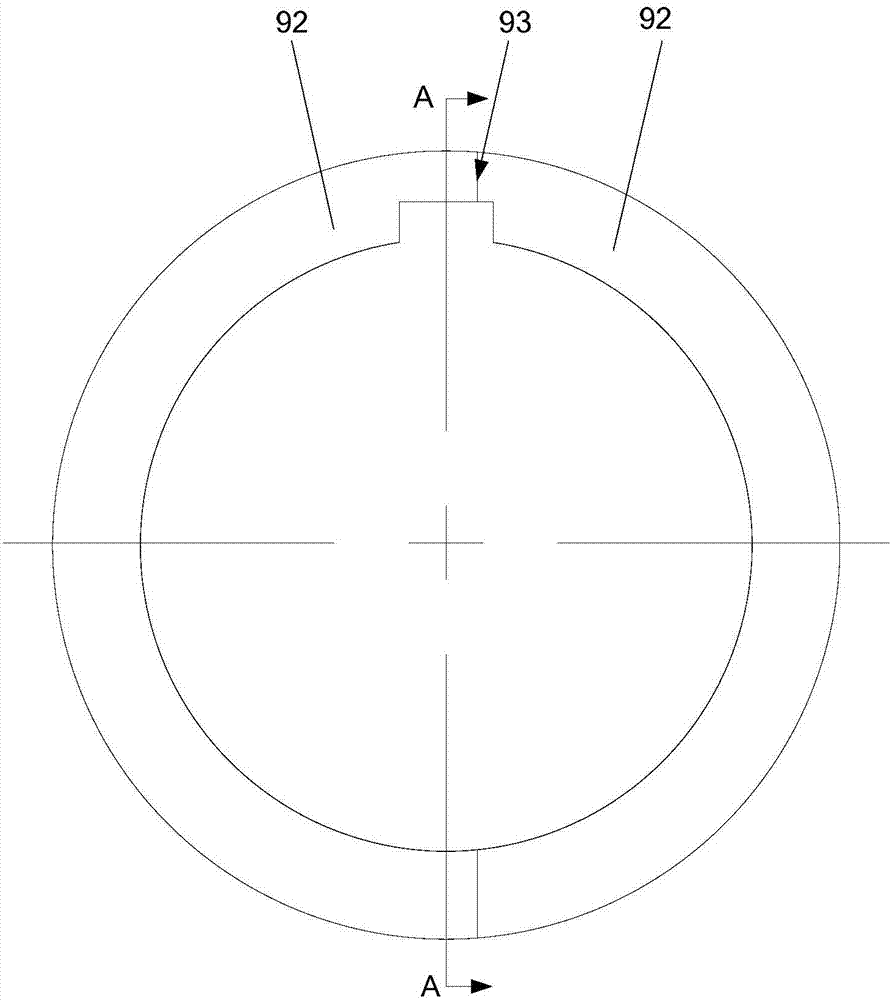

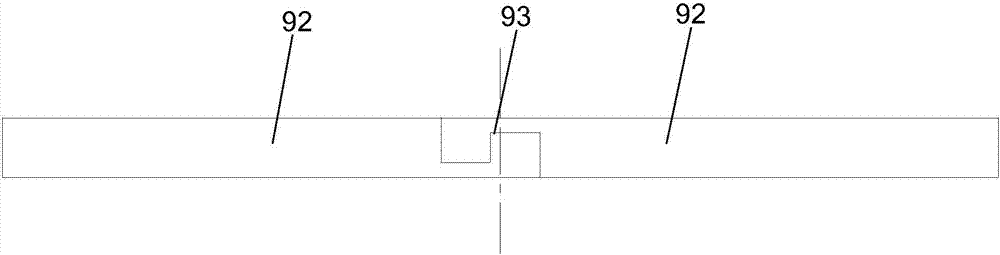

ActiveCN107350291ALow costEasy to move distanceMetal rolling stand detailsMetal rolling arrangementsEngineeringKeel

The invention discloses a roller device and is applied to the field of keel production. The roller device comprises a left forming roller, a right forming roller, an upper roller shaft, a lower roller shaft, a left forming rack, a right forming rack and a pedestal, wherein a left-upper roller and a left-lower roller of the left forming roller are respectively arranged on the left sides of the upper roller shaft and the lower roller shaft; the left ends of the upper roller shaft and the lower roller shaft are connected with the pedestal via the left forming rack; the right sides of the upper roller shaft and the lower roller shaft are both provided with adjusting sleeves; a right-upper roller and a right-lower roller of the right forming roller are respectively covered with the adjusting sleeves; the right ends of the upper roller shaft and the lower roller shaft are connected with the right forming rack via the adjusting sleeves; and the right forming rack is movably connected with the pedestal along an axial direction. Therefore, the right forming rack moves along an axial direction to drive the adjusting sleeves and the right forming roller thereon to axially move; and a distance between the left forming roller and the right forming roller can be changed, and the roller device can be suitable for manufacture of keels of various sizes; and production device cost can be reduced.

Owner:BEIJING NEW BUILDING MATERIAL

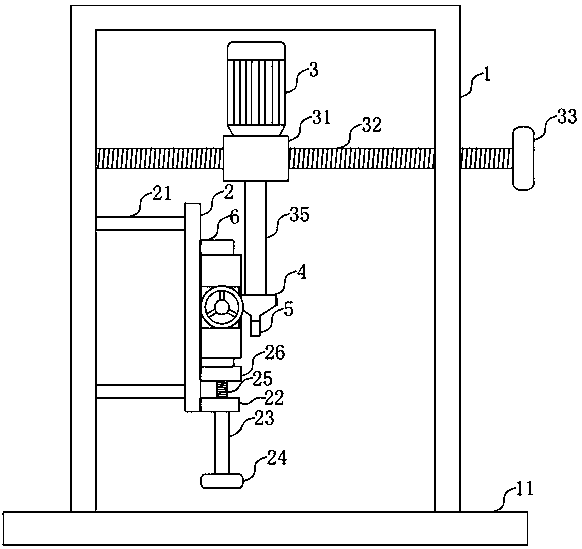

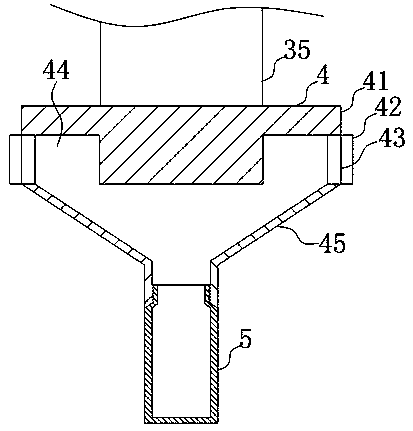

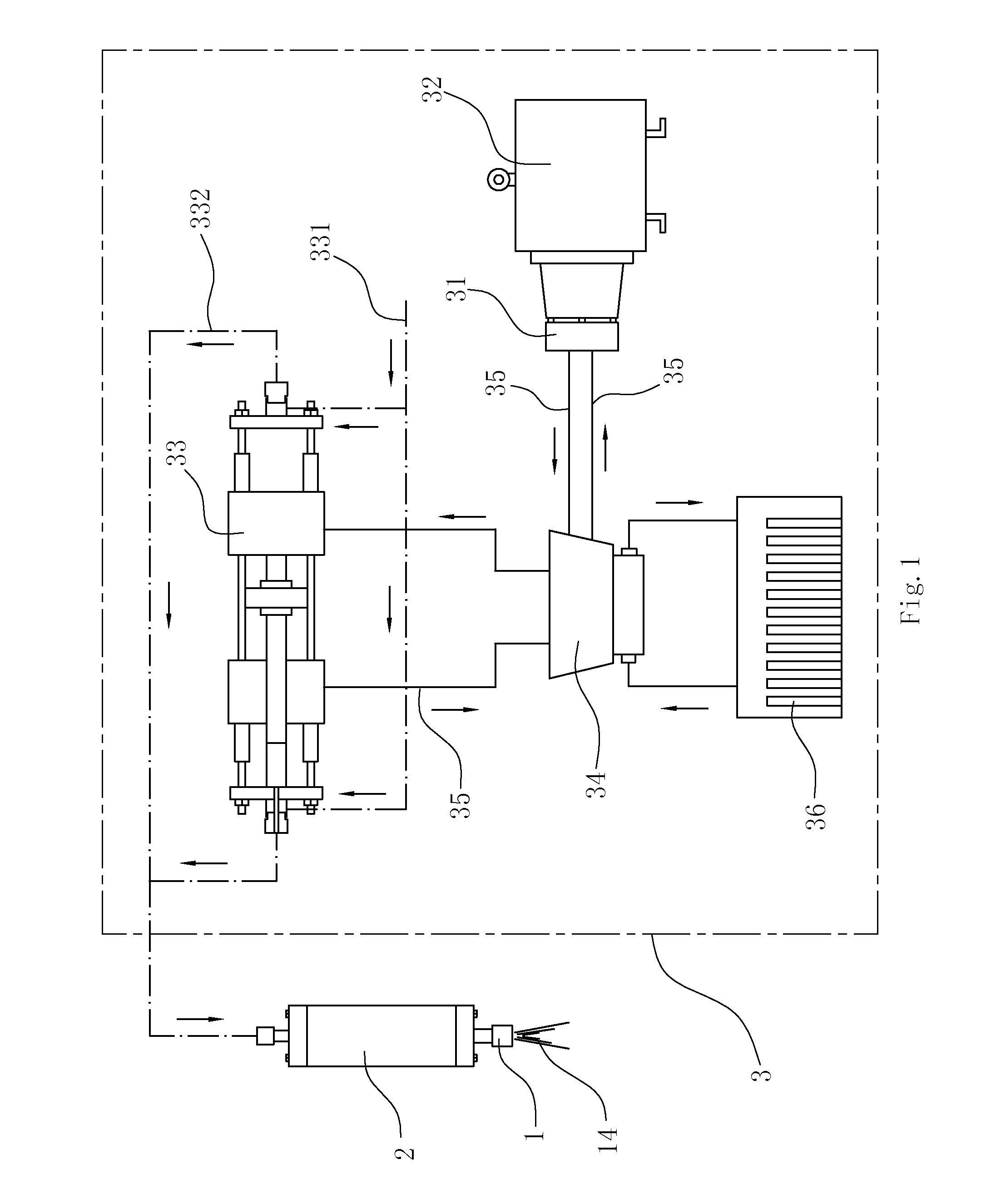

Automatic metal pipe cutting device

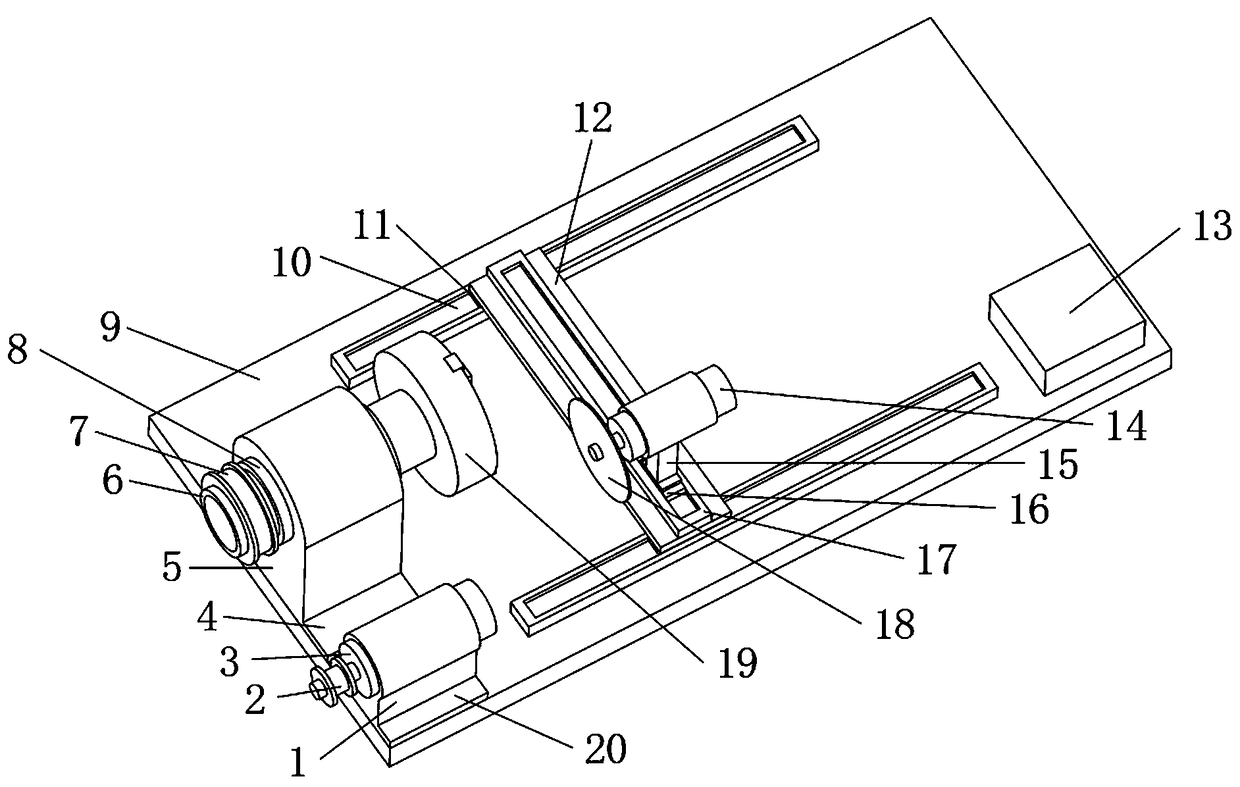

PendingCN109434182AControl the moving distanceControl movementTube shearing machinesShearing machine accessoriesBall bearingEngineering

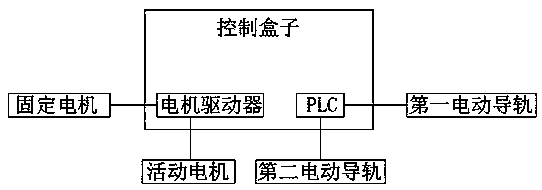

The invention discloses an automatic metal pipe cutting device which comprises an installation support plate, a rotary pipe, a fixed motor, a three-jaw chuck, a movable motor, a first electric guide rail and a second electric guide rail. The outer contour of the installation support plate is of a rectangular platy structure; a fixed motor base is arranged at the position, close to the edge, of oneside on the upper surface of the installation support plate; a motor bottom plate with a platy-structure contour is arranged on the bottom part of the fixed motor base; the fixed motor is arranged inthe upper end of the fixed motor base; a motor belt pulley sleeves an output shaft of the fixed motor; a ball bearing is arranged in the top end of an installation stand column on the installation support plate; the rotary pipe is arranged in the ball bearing; a pipeline belt pulley fixedly sleeves the position, on the same side of the output shaft of the fixed motor, of the rotary pipe; and thethree-jaw chuck is arranged at one end, far away from the pipeline belt pulley, of the rotary pipe. The automatic metal pipe cutting device has the advantage of smoothness in notches and convenience in adjusting the size, and is suitable for widely popularizing and using.

Owner:江苏众利达自动化设备有限公司

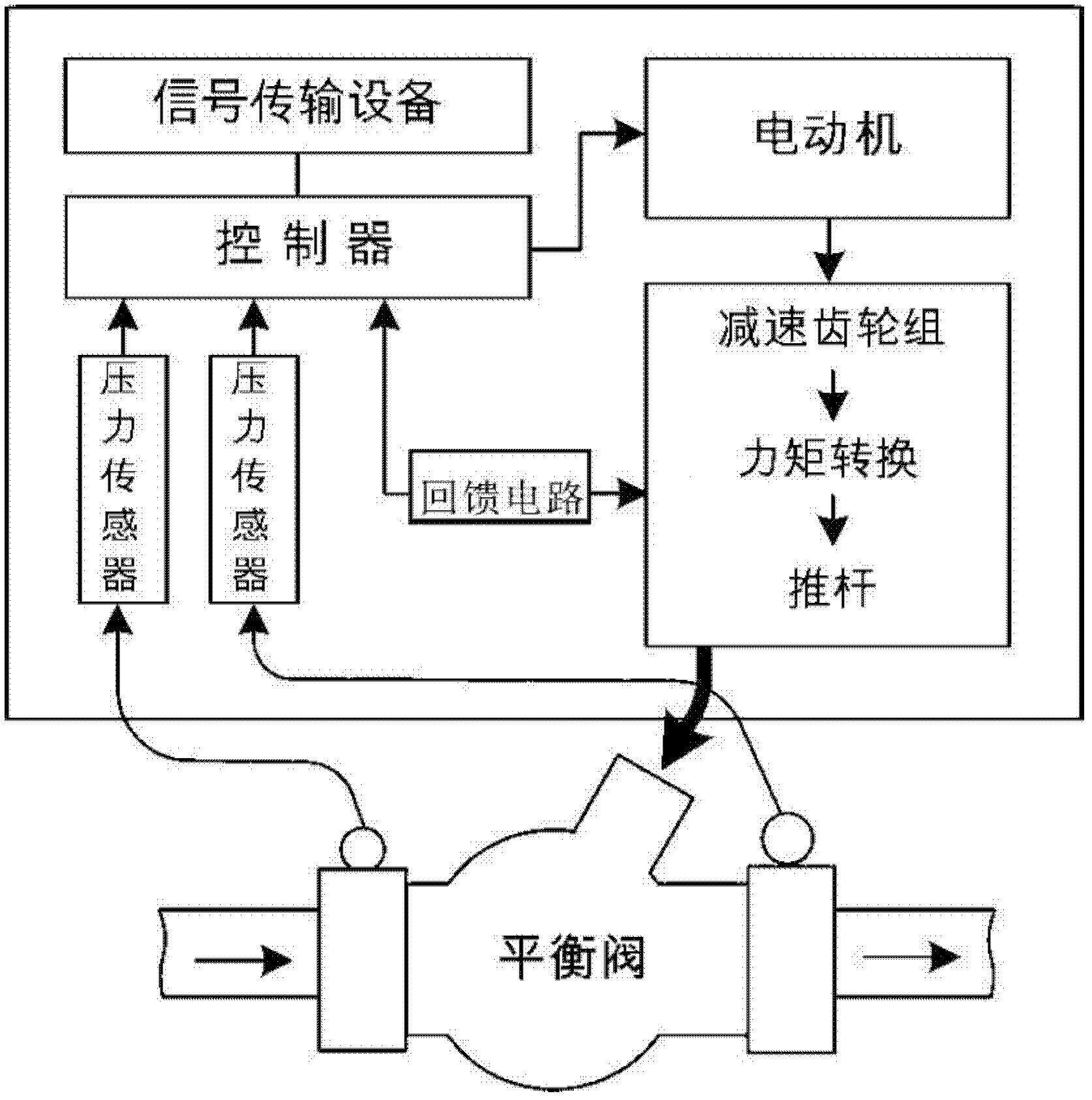

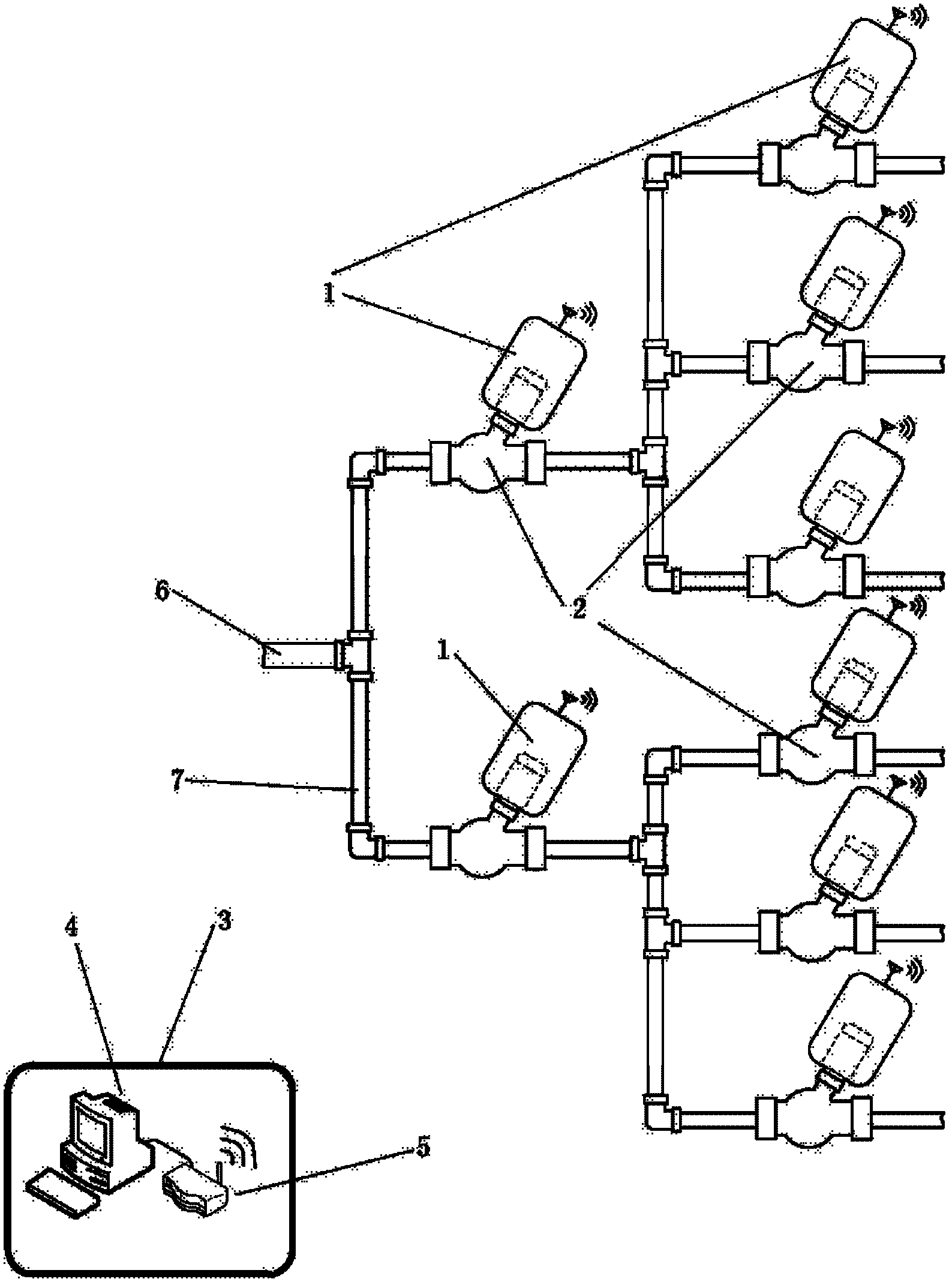

Balance valve adjuster, intelligent balance valve adjusting system composed of the same, and method

ActiveCN102661425AGuaranteed adjustment accuracyEasy to adjustOperating means/releasing devices for valvesControl systemEngineering

The invention relates to a balance valve adjuster, comprising a detection apparatus, a motor, a transmission mechanism, a feedback circuit, a controller and signal transmission equipment. The invention further relates to an intelligent balance valve adjusting system composed of the balance valve adjuster, comprising a balance valve, the balance valve adjuster and a central control system. Motions of the balance valve adjuster are controlled by the central control system, thereby opening degree of the balance valve is controlled and intelligent adjusting is realized. Provided are automatic intelligent adjusting equipment and a method, according to the invention, tedious working of the personnel on-site is not required, and update can be carried out momentarily. The equipment and the method solve the problem of expensive adjusting cost for the professional personnel and greatly reduce adjusting time, and that balancing adjustment can be carried out momentarily by managers according to system changes so as to save energy.

Owner:沈居富

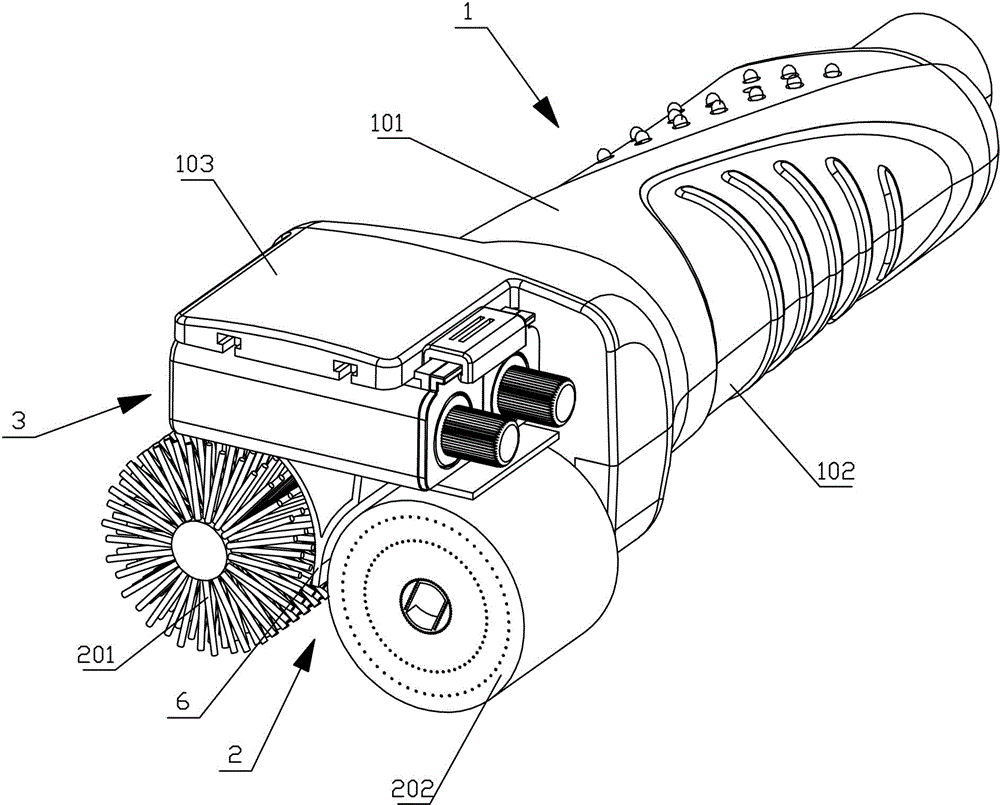

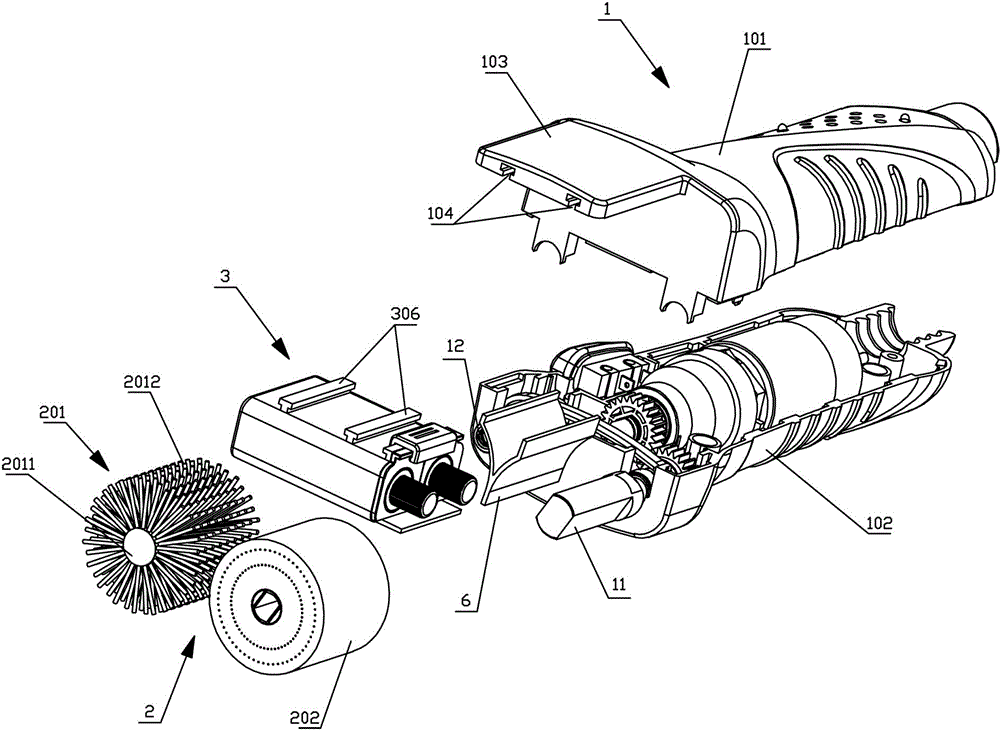

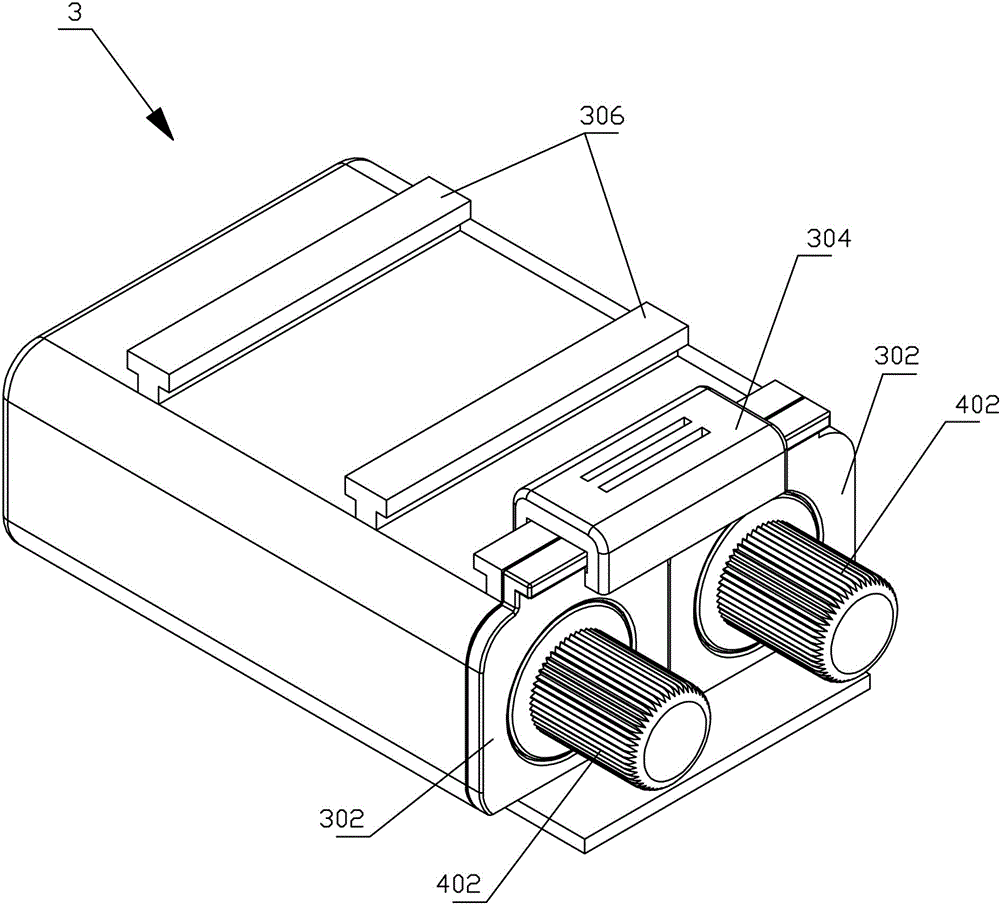

Electric shoe polisher

InactiveCN103815855AShorten the timeWon't splashFootwear cleanersElectrical and Electronics engineeringEngineering

The invention discloses an electric shoe polisher which comprises a handle, a brush and a cream storage device. The brush comprises a shoe cream brush roll and a polishing brush roll, the shoe cream brush roll, the polishing brush roll and the cream storage device are arranged at an end of the handle, the axis of the shoe cream brush roll is parallel to the axis of the polishing brush roll, a power device which is used for driving the shoe cream brush roll and the polishing brush roll to rotate synchronously is arranged in the handle, the cream storage device comprises at least one cavity and at least one squeezing mechanism, the cavities are used for accommodating shoe cream, and the shoe cream in the cavities can be squeezed onto the shoe cream brush roll by the squeezing mechanisms. The electric shoe polisher has the advantages that cream applying and polishing can be synchronously carried out on a leather shoe, accordingly, the electric shoe polisher is high in work efficiency, the shoe cream can be prevented from splashing out when applied to the shoe, and wastage of the shoe cream can be prevented.

Owner:宁波清士洁电器科技有限公司

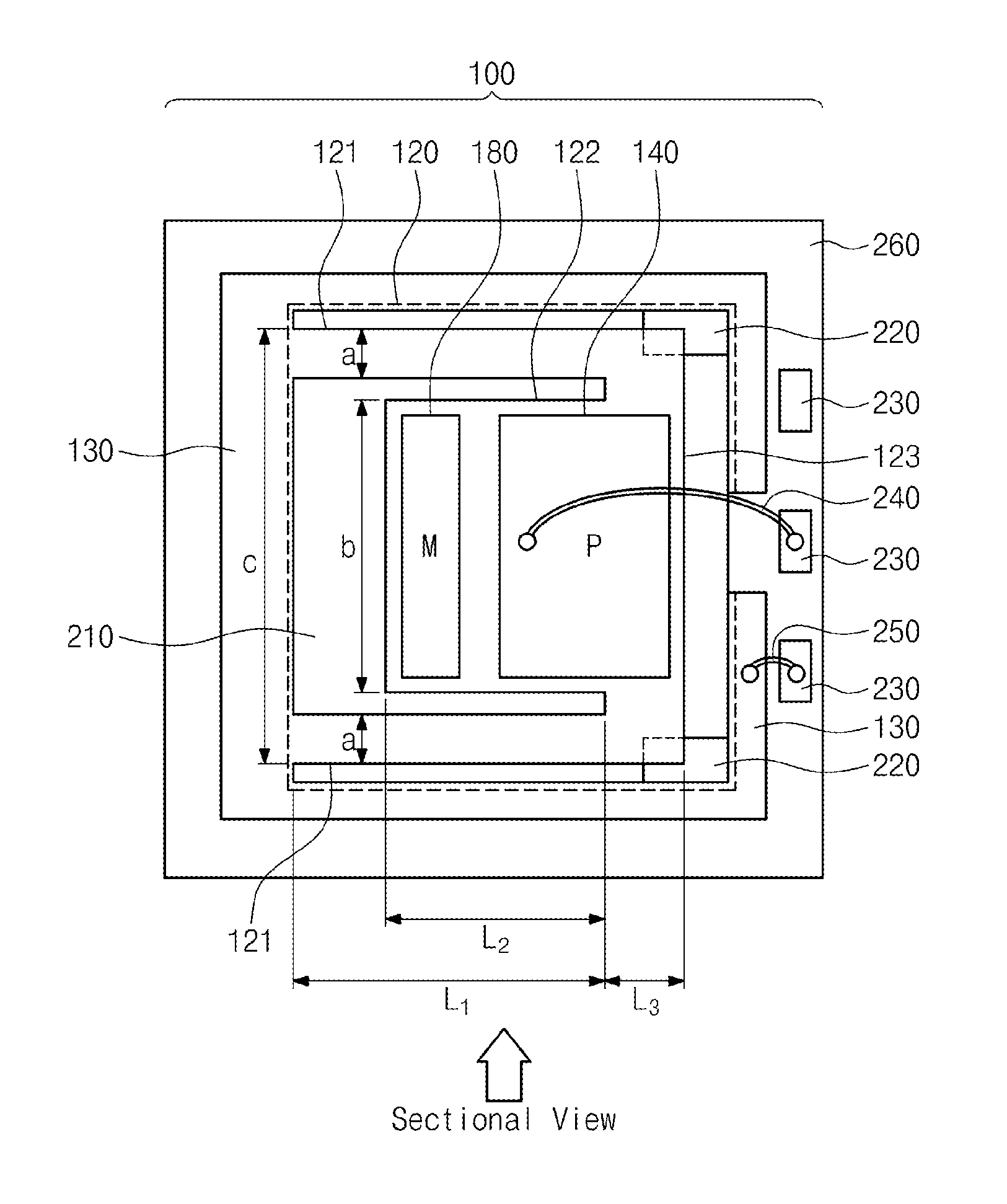

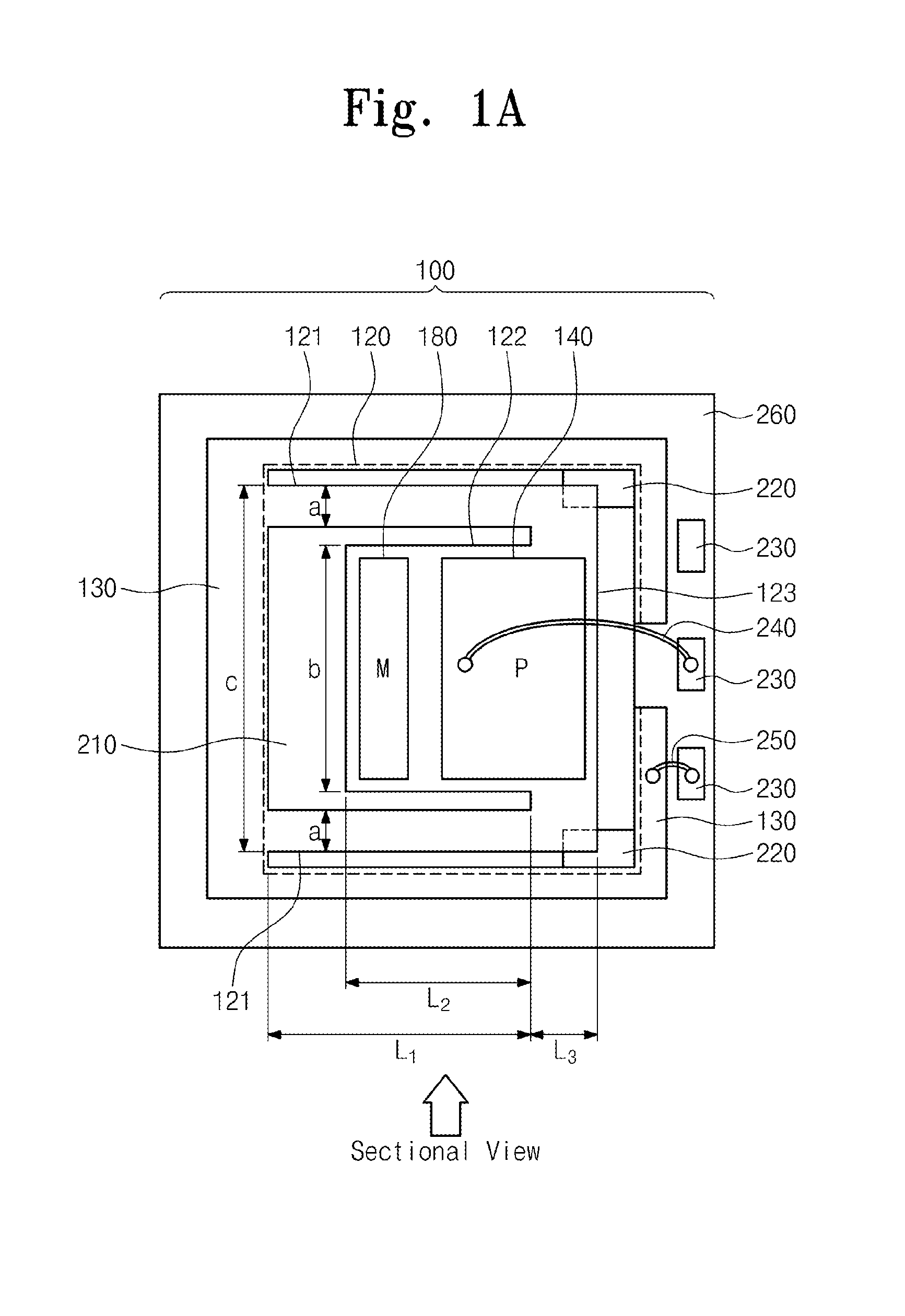

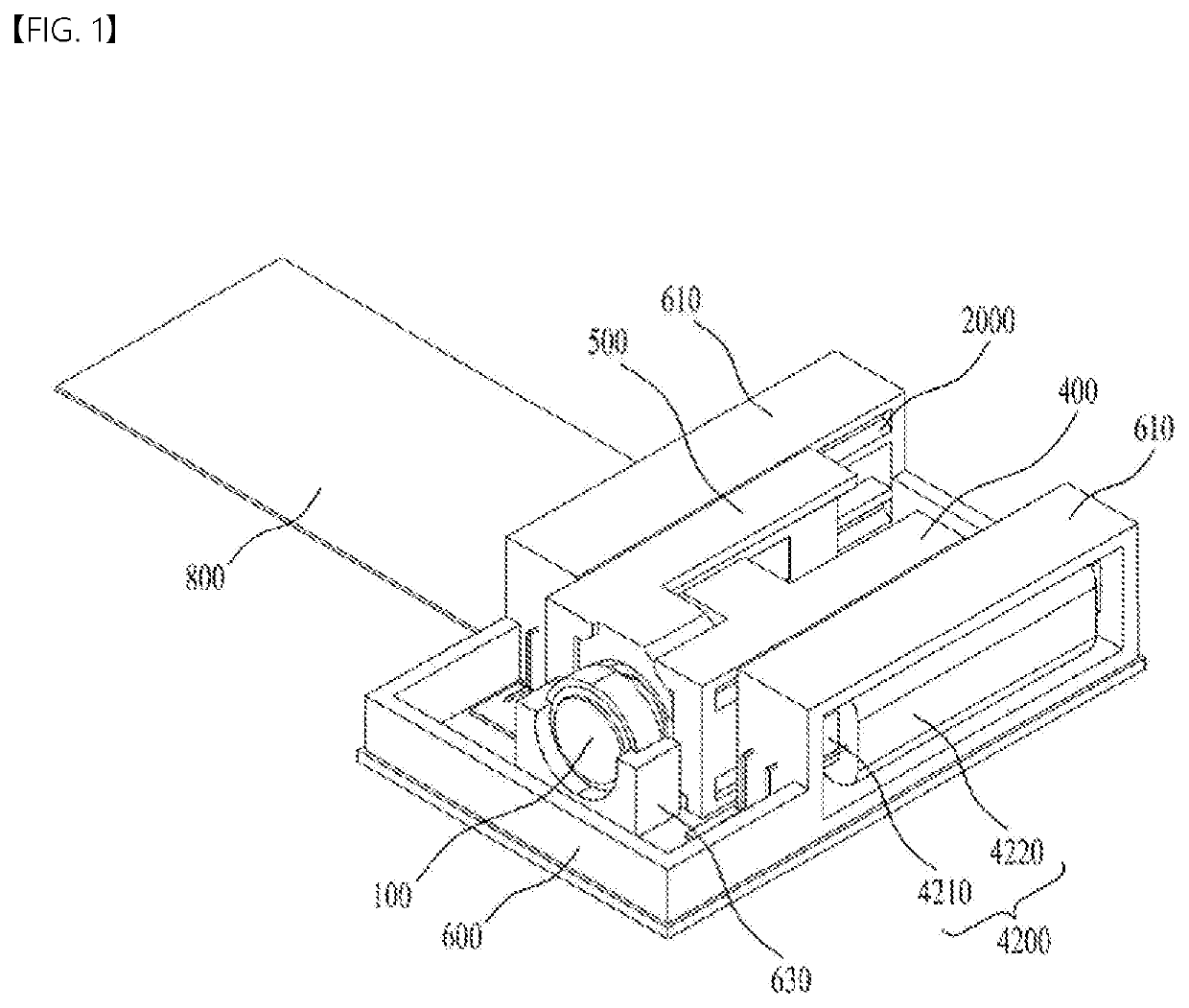

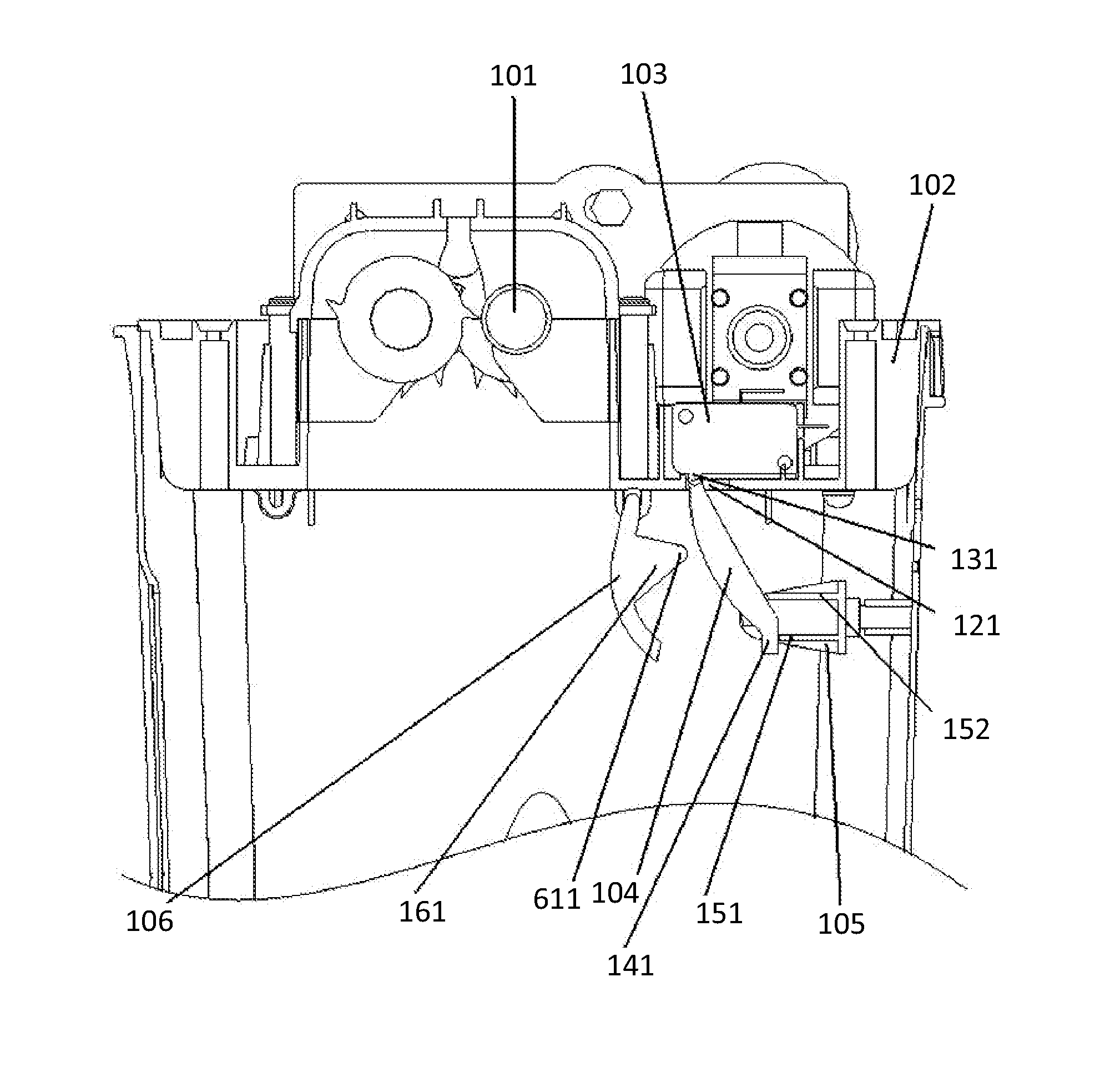

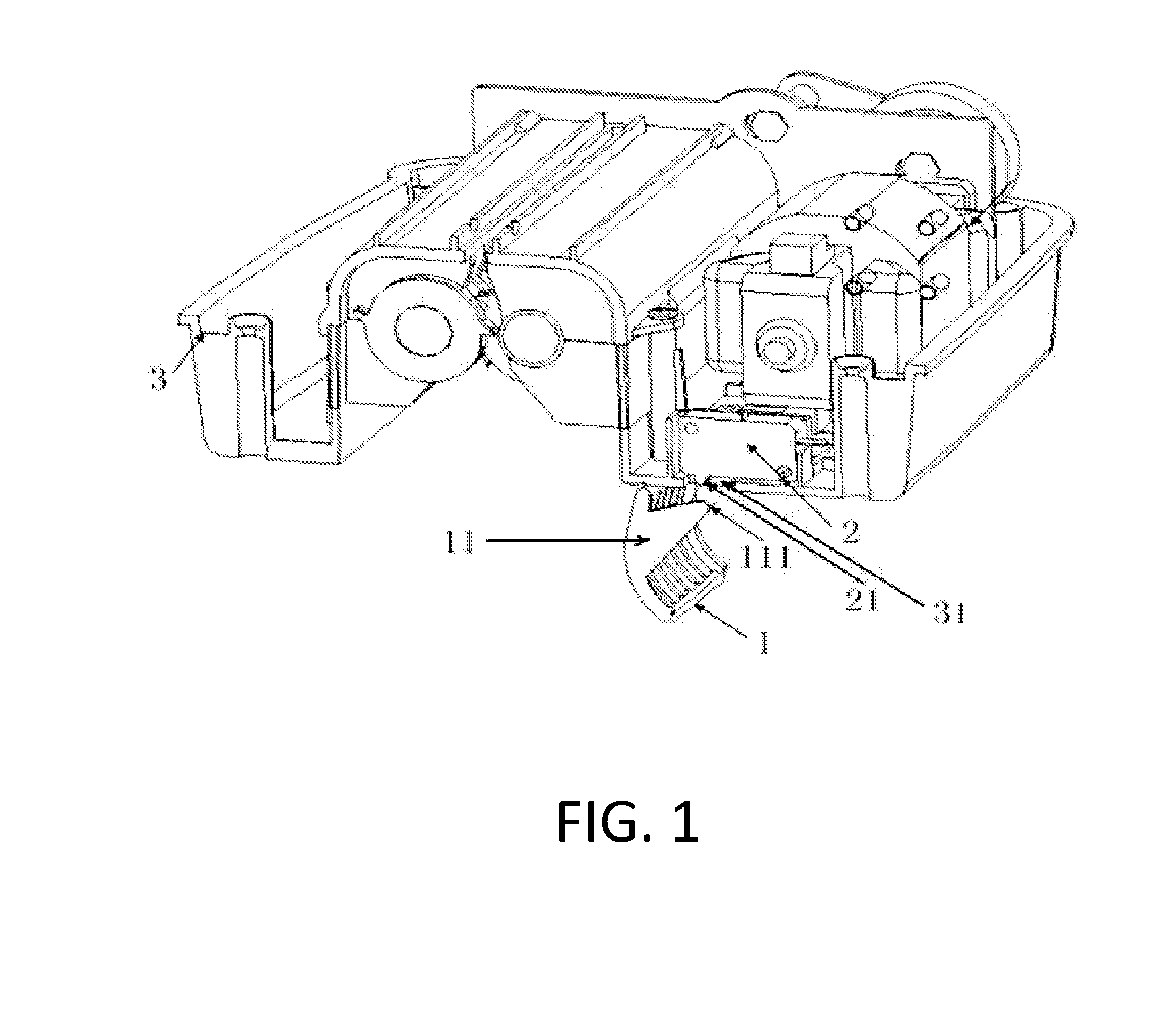

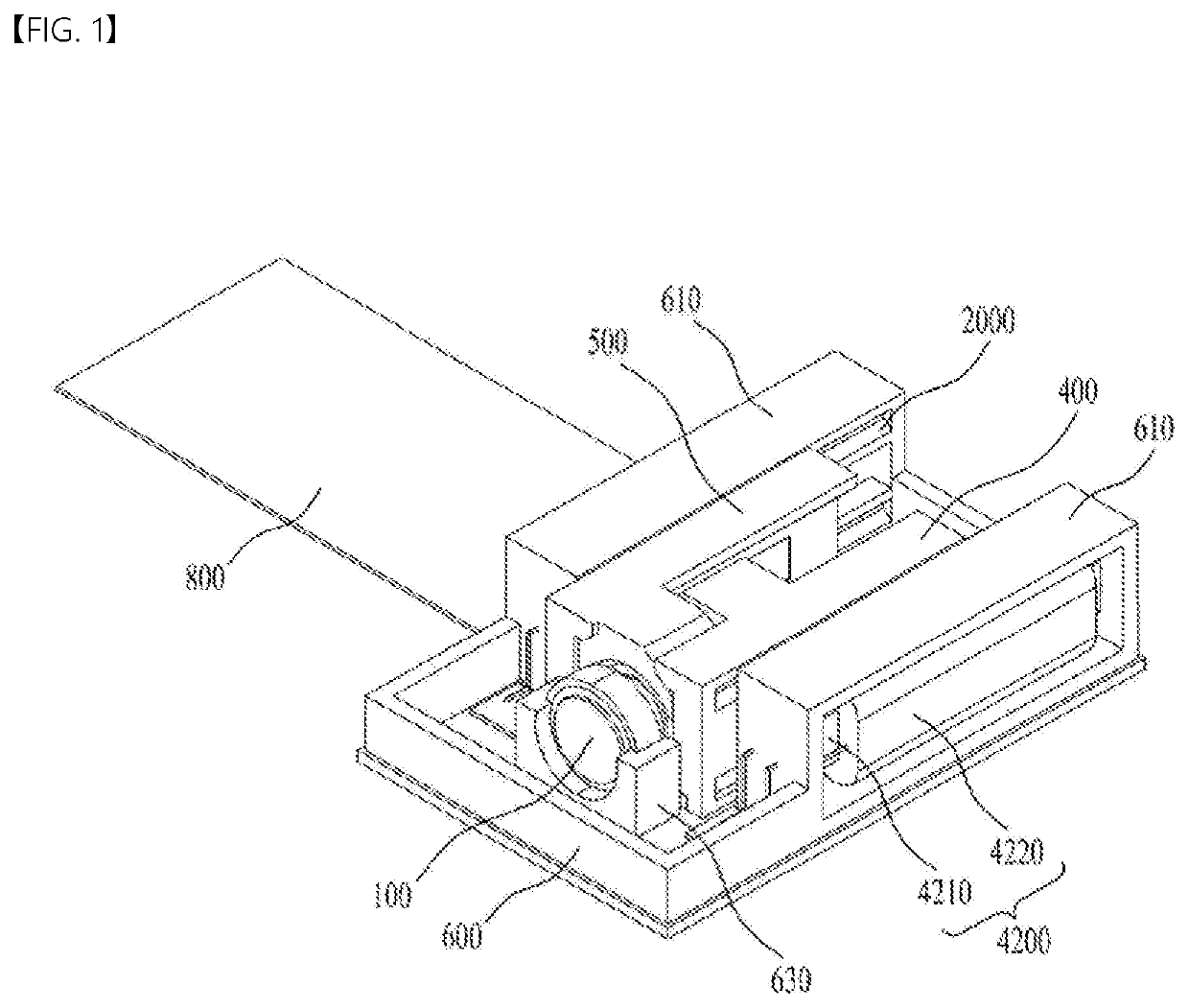

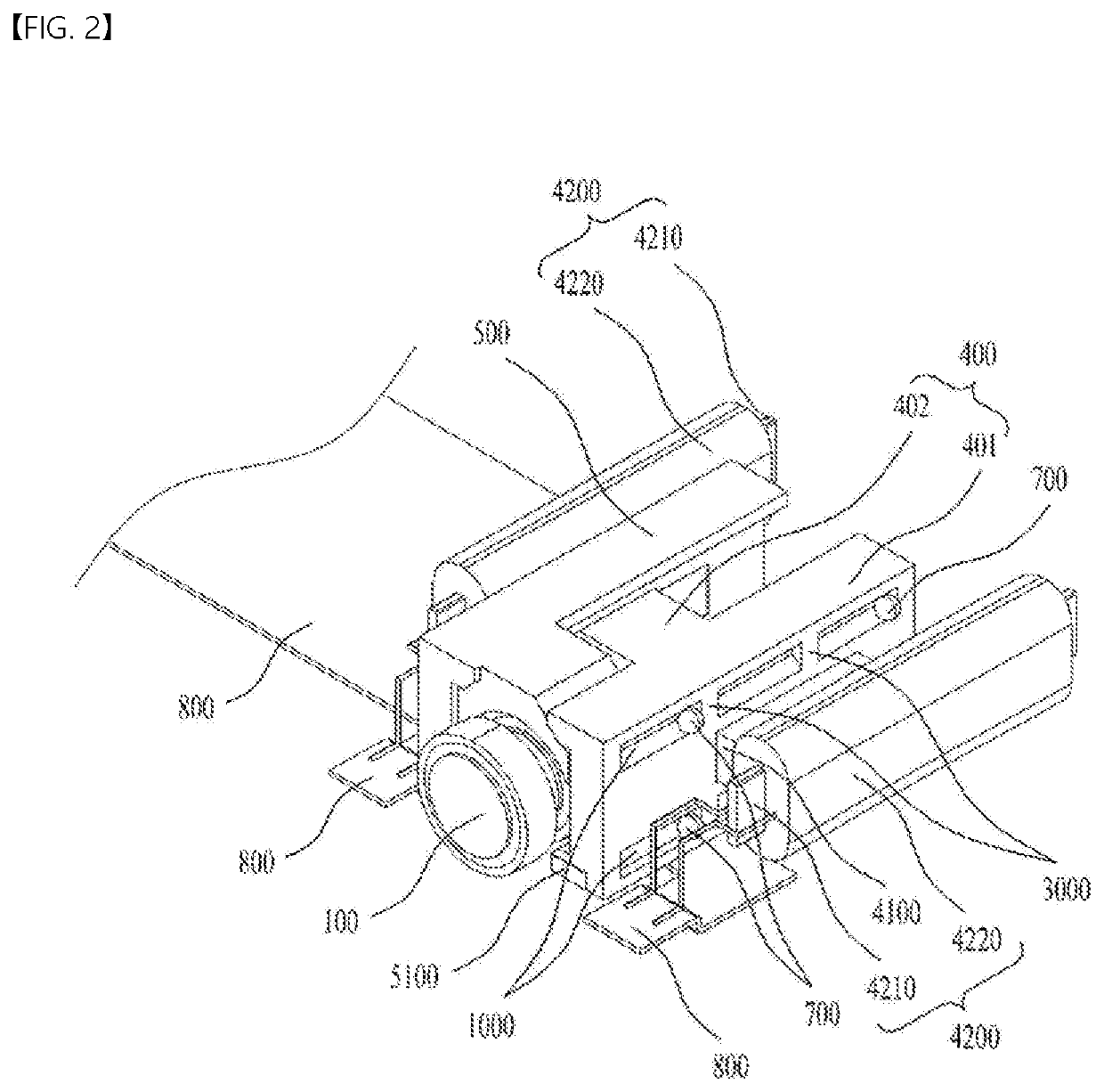

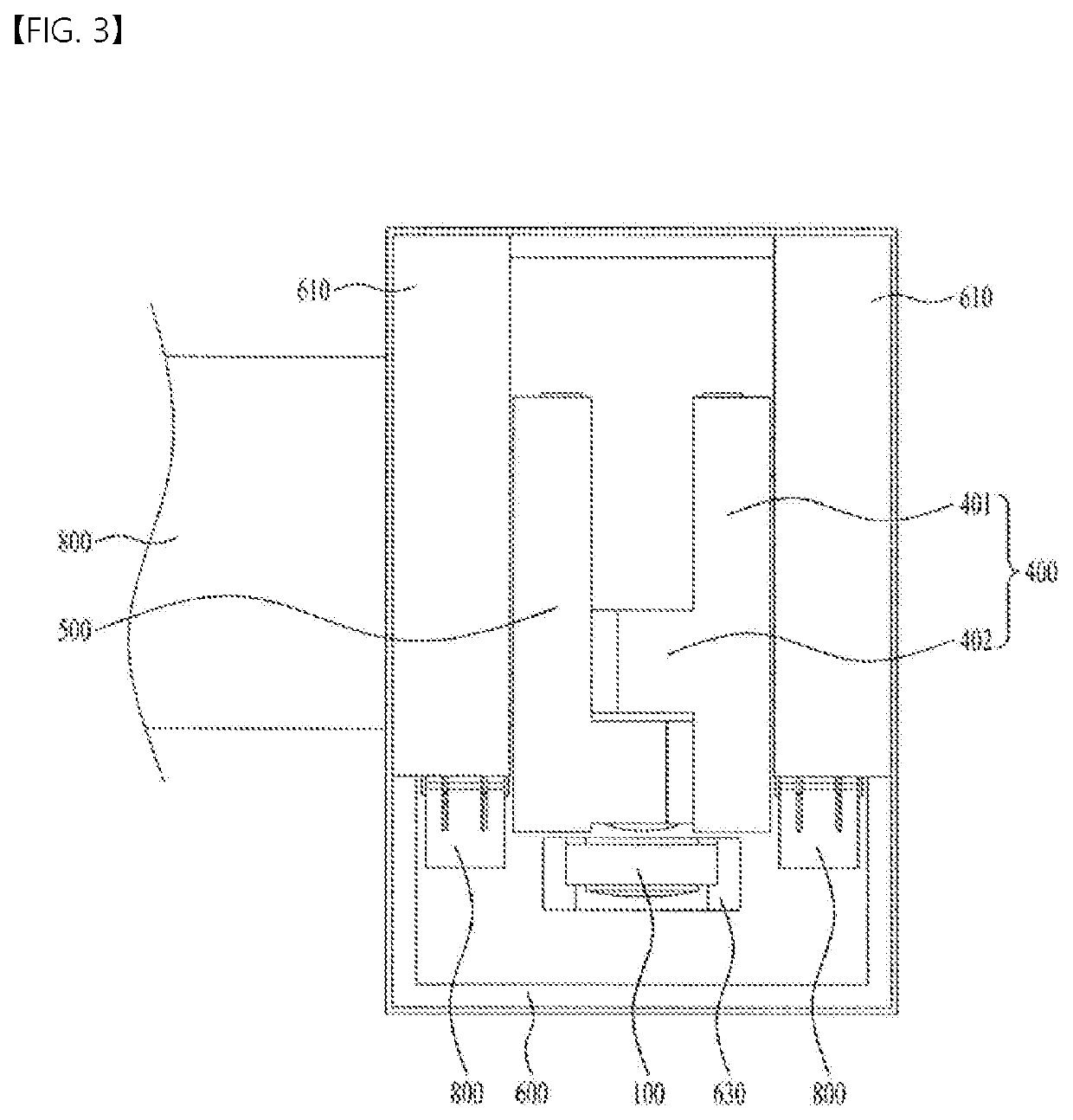

Camera module

ActiveUS20210092264A1Friction is generatedReduce generationTelevision system detailsProjector focusing arrangementOptical axisEngineering

A camera module includes first to third lens groups; a first mover configured to move the second lens group in the optical-axis direction; a second mover configured to move the third lens group in the optical-axis direction; a base accommodating the first mover and the second mover; a support ball disposed to be in rolling contact with the first mover, the second mover, and the base, the support ball supporting movement of the first mover and the second mover relative to the base; a driving magnet coupled to each of the first mover and the second mover; and a coil part coupled to the base, the coil part being disposed to face the driving magnet, and wherein an entirety of a surface of the driving magnet that faces the moving coil serves as a first pole.

Owner:LG INNOTEK CO LTD

Safety shredder with bin-full device and time delay

A mechanical bin-full device for a paper shredder with a pressing plate, a contact switch, and a touching part. The pressing plate is installed at an outside portion of the shredder mechanical parts under the lower housing. One end of the pressing plate is pivots on the lower housing and the other end is free. The contact switch is fixed on the lower housing and a contact point is provided on the contact switch. The touching part is provided on the pressing plate, away from the mechanical parts. The lower housing has a through-hole under the contact point of the contact switch enabling the touching part to contact the contact point. The waste paper drives the pressing plate to turn around the joint between it and the lower housing, making the touching part touch the contact point of the contact switch and making the shredder power off.

Owner:AURORA OFFICE EQUIP

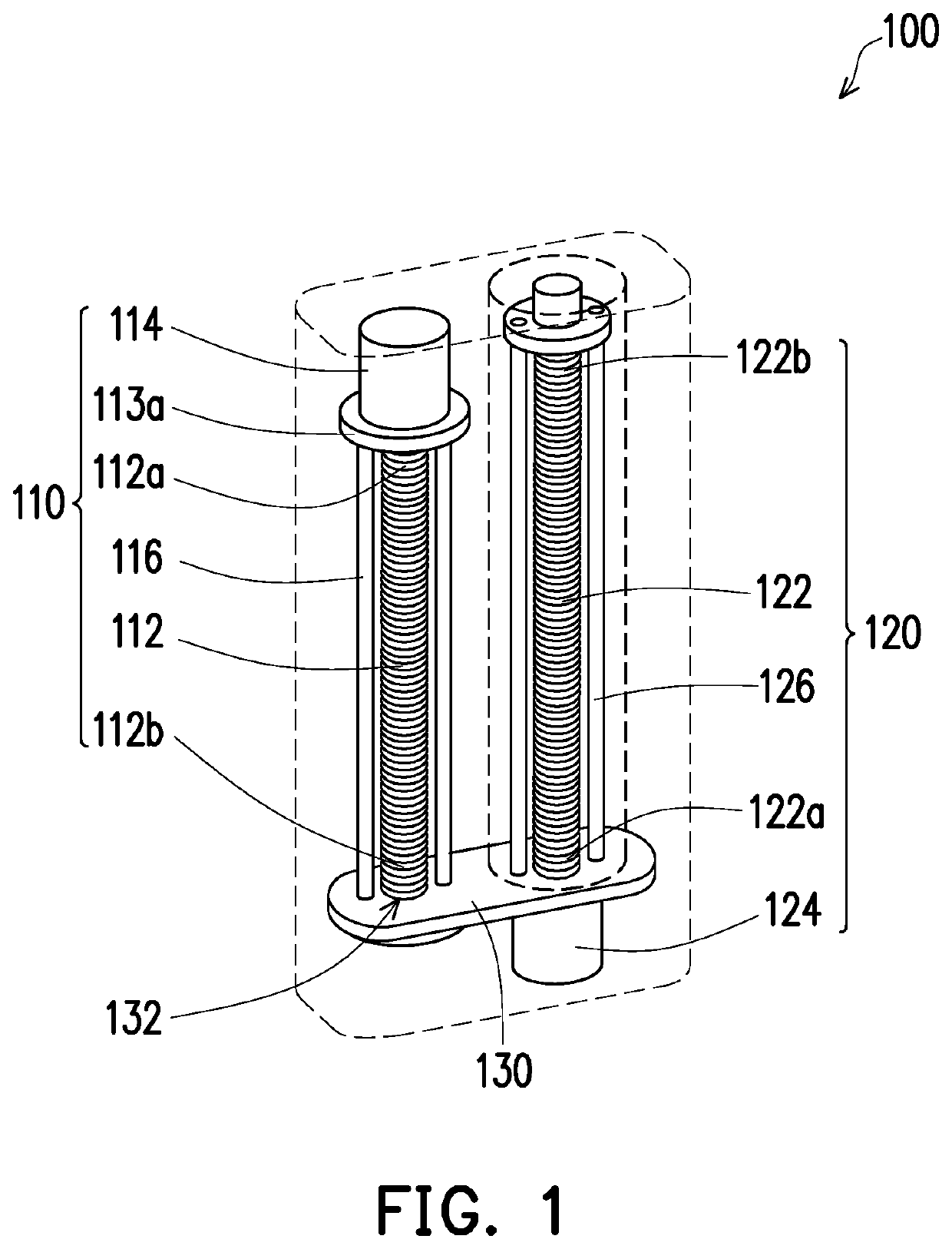

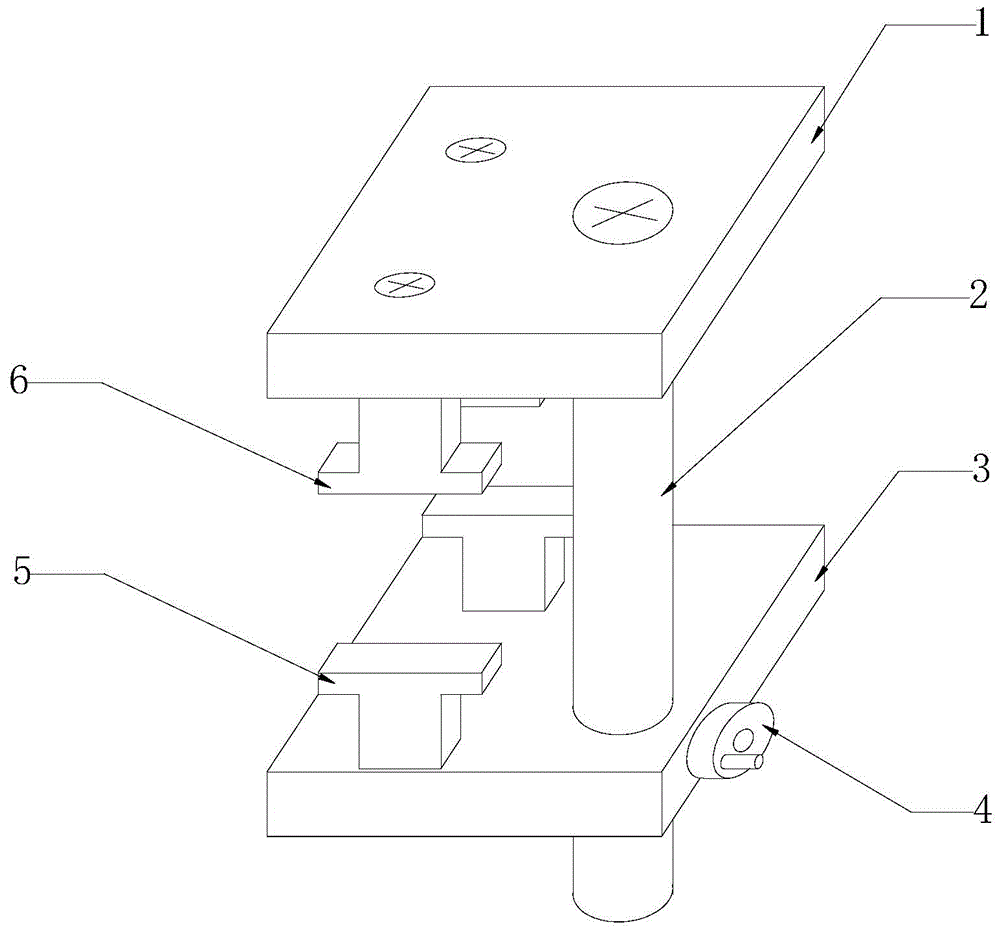

Dual cantilever adhesion sample thickness controller

InactiveCN104833561AControl the moving distanceControl thicknessPreparing sample for investigationAdhesiveSample length

The present invention discloses a dual cantilever adhesion sample thickness controller, which comprises a base, a guide rod, a moving block, a handle, a lower support block and an upper support block, wherein the base is fixed on one end of the guide rod, the other end penetrates through the moving block, the moving block is provided with the handle for driving the moving block to move along the guide rod, the upper end surface of the moving block is provided with the low support block, and the position on the base lower end surface and corresponding to the lower support block is provided with the upper support block. According to the present invention, the gear rack is used to drive the moving block to move up and down and has the fixed transmission ratio, such that the moving distance of the moving block can be accurately controlled so as to accurately control the adhesive thickness; and the two or more than two separate support blocks are used to form the controller, such that the self-weight can be reduced, the multi-point pre-tightening can be achieved along the sample length direction, and the thickness uniformity of the adhesive in the whole adhesion region can be controlled.

Owner:NANJING UNIV OF SCI & TECH

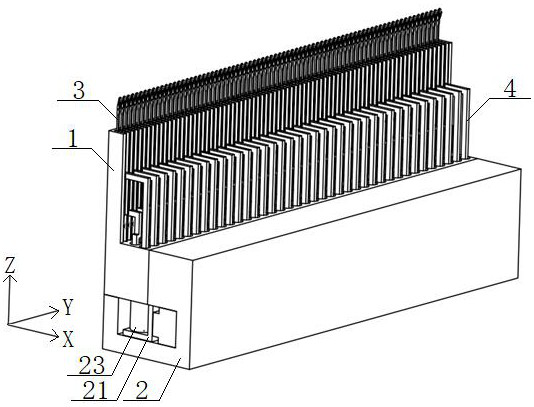

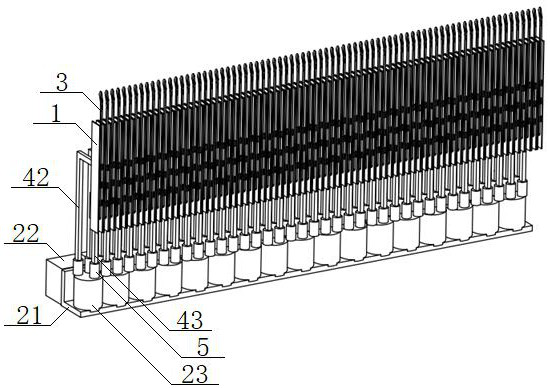

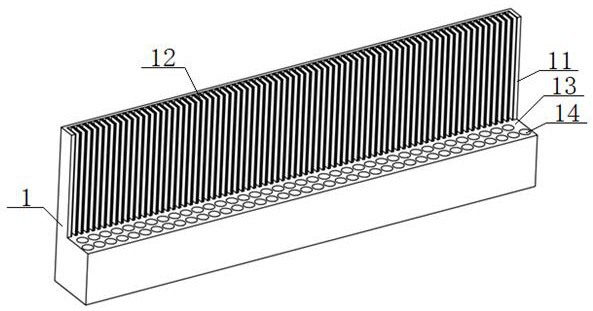

Electromagnetic array type driving device for knitting needle flat knitting machine and control method thereof

ActiveCN111691056AControl the moving distanceDifferent weaving effectWeft knittingElectric machineryEngineering

The invention discloses an electromagnetic array type driving device for a knitting needle flat knitting machine. The electromagnetic array type driving device for the knitting needle flat knitting machine comprises an upper machine frame and a lower machine frame; a plurality of needle slots are formed in a first inner side surface of the upper machine frame; No. 2 permanent magnets are mounted on both two inner side walls of each needle slot; a knitting needle is inserted into each needle slot; one or more rows of blind holes are formed in a second inner side surface of the upper machine frame; connecting rods are inserted into the blind holes; one end, positioned at the bottom of the blind hole, of each connecting rod is connected with a No. 1 permanent magnet; the other end of each connecting rod is connected to the corresponding knitting needle after extending into the corresponding needle slot, and No. 3 permanent magnets with the same polarity as the No. 2 permanent magnets aremounted on both sides of the end; a mounting seat and a motor module which are connected are arranged in the lower machine frame; the mounting seat can move reciprocally in a Y-axis direction; a plurality of mounting holes are formed in the mounting seat; electromagnets are mounted in the mounting holes; and the electromagnets are positioned below the plurality of the No. 1 permanent magnets. Through the design, the knitting efficiency and the knitting effect are improved, and the service lives of the knitting needles are prolonged.

Owner:WUHAN TEXTILE UNIV

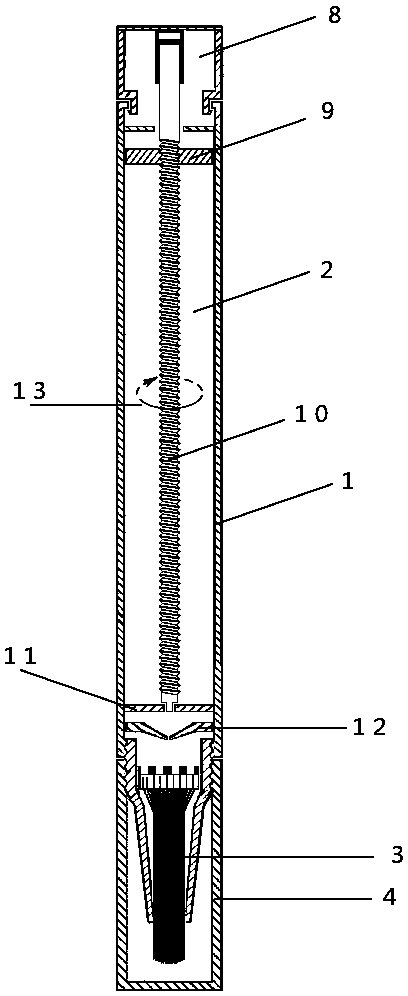

Beauty makeup pen capable of continuously supplying materials

PendingCN108338483AControl the moving distancePrevent volatilizationPackaging toiletriesPackaging cosmeticsMechanical engineeringPiston

The invention relates to the technical field of makeup equipment and provides a beauty makeup pen capable of continuously supplying materials. The beauty makeup pen is characterized in that the pen body comprises a driving component, a pushing component, a material body bin and a one-way valve; the pushing component mainly comprises a screw rod and a sealing piston, the screw rod passes through the sealing piston in a threaded manner and is driven to rotate by the driving component, and the rotating screw rod drives the sealing piston to move toward a discharge end so as to push a beauty makeup material body to press open the one-way valve, so that the beauty makeup material body can be continuously output, and the operation convenience is increased; and through the number of turns of rotation of the screw rod, the release amount of the beauty makeup material body is controlled to avoid waste.

Owner:胡通贵

Camera module

ActiveUS11258931B2Friction is generatedReduce the amount requiredTelevision system detailsProjector focusing arrangementOptical axisEngineering

A camera module includes first to third lens groups; a first mover configured to move the second lens group in the optical-axis direction; a second mover configured to move the third lens group in the optical-axis direction; a base accommodating the first mover and the second mover; a support ball disposed to be in rolling contact with the first mover, the second mover, and the base, the support ball supporting movement of the first mover and the second mover relative to the base; a driving magnet coupled to each of the first mover and the second mover; and a coil part coupled to the base, the coil part being disposed to face the driving magnet, and wherein an entirety of a surface of the driving magnet that faces the moving coil serves as a first pole.

Owner:LG INNOTEK CO LTD

Sample surface coating sampling device

PendingCN110864930AControl the moving distanceControl scraping thicknessWithdrawing sample devicesThreaded pipeScrew thread

The invention provides a sample surface coating sampling device. A scraper is driven by a motor to scrape a coating for sampling. The coating sample leaks into a sample storage bottle, so that the effects of effectively scraping and fully collecting the coating sample are achieved. The harm to an operator is avoided. A sliding block, a sliding rod, a second threaded rod and a second rotating wheelare arranged. The second threaded rod is used for pushing the sliding block to slowly move. The moving distance of the scraper can be effectively controlled, and the effect of effectively controllingthe coating scraping thickness is achieved. By arranging a lug plate, a threaded pipe, a first rotating wheel, a first threaded rod and a clamping plate, the position of the sample is flexibly adjusted. The scraper is enabled to sample a plurality of parts of the sample, and the effect of multi-position sampling is achieved.

Owner:JIANGSU SHENTONG VALVE

Movable handle

ActiveUS20170242452A1Control the moving distanceControlling membersClamping/extracting meansEngineeringMechanical engineering

A movable handle includes a movable member and a seat, both of which can be made of a plastic, a metal or a composite material. The movable member includes a main body and a bent portion. The main body can be bar-shaped, block-like, ball-shaped, wedge-shaped or in any other suitable shape, and the bent portion can be bent inward, outward or in any other direction relative to the main body. The main body of the movable member is movably assembled to the seat, and the seat is connected to a first object, such that the movable member is indirectly connected to the first object via the seat and can be turned or moved upward and downward or leftward and rightward on and relative to the first object.

Owner:FIVETECH TECH INC

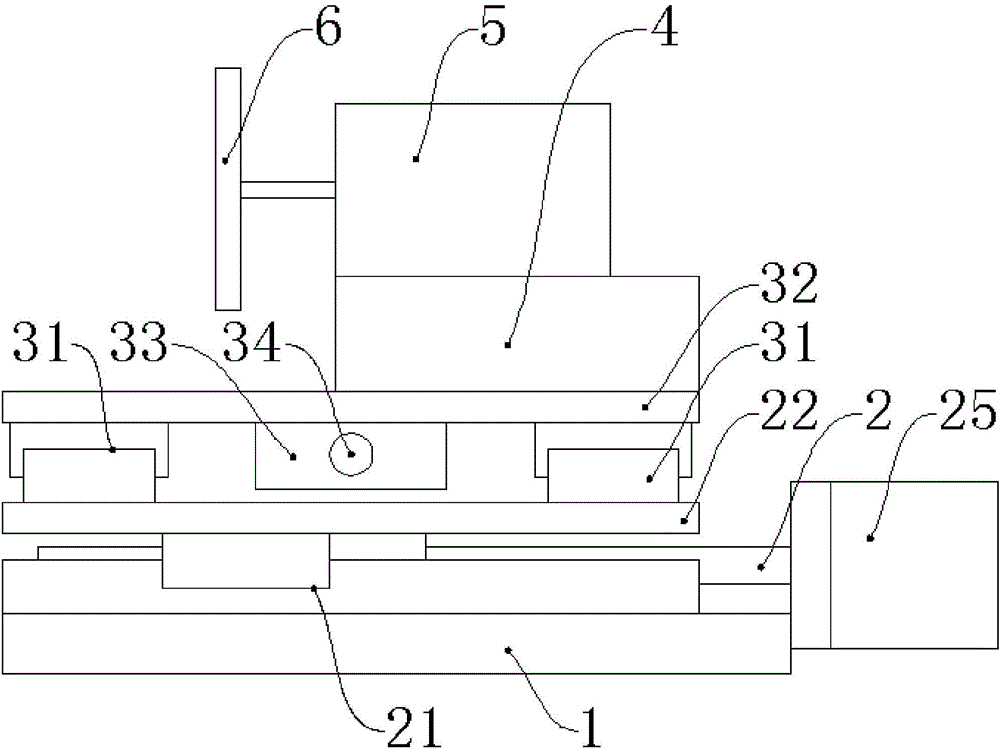

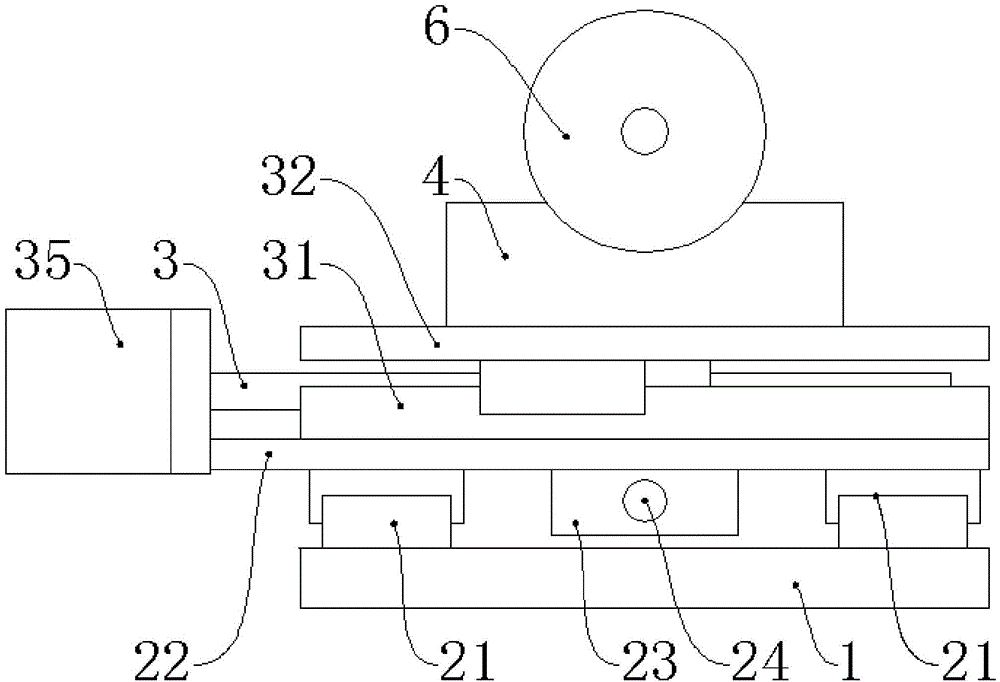

Automatic dressing mechanism of grinding wheel of numerical-control hob relieving grinding machine

InactiveCN104400651ASimple structureSmall sizeAbrasive surface conditioning devicesEngineeringMechanical engineering

The invention discloses an automatic dressing mechanism of a grinding wheel of a numerical-control hob relieving grinding machine. The automatic dressing mechanism is characterized by comprising a sliding table base, wherein the sliding table base is provided with an x-direction sliding device; the x-direction sliding device is provided with a y-direction sliding device; the x-direction sliding device is vertical to the y-direction sliding device; the y-direction sliding device is provided with a roller wheel motor by virtue of a motor mounting base; an output shaft of the roller wheel motor faces towards the x direction; the output shaft of the roller wheel motor is provided with a dressing diamond roller wheel. The technical scheme has the obvious effects that the movement distances of the dressing diamond roller wheel in the x direction and the y direction can be accurately controlled, the dressing diamond roller wheel can be accurately positioned at any position in a plane, and the dressing mechanism is simple and compact in structure, small in size and good in hob dressing effect.

Owner:CHONGQING XINGWANG TOOL MFG

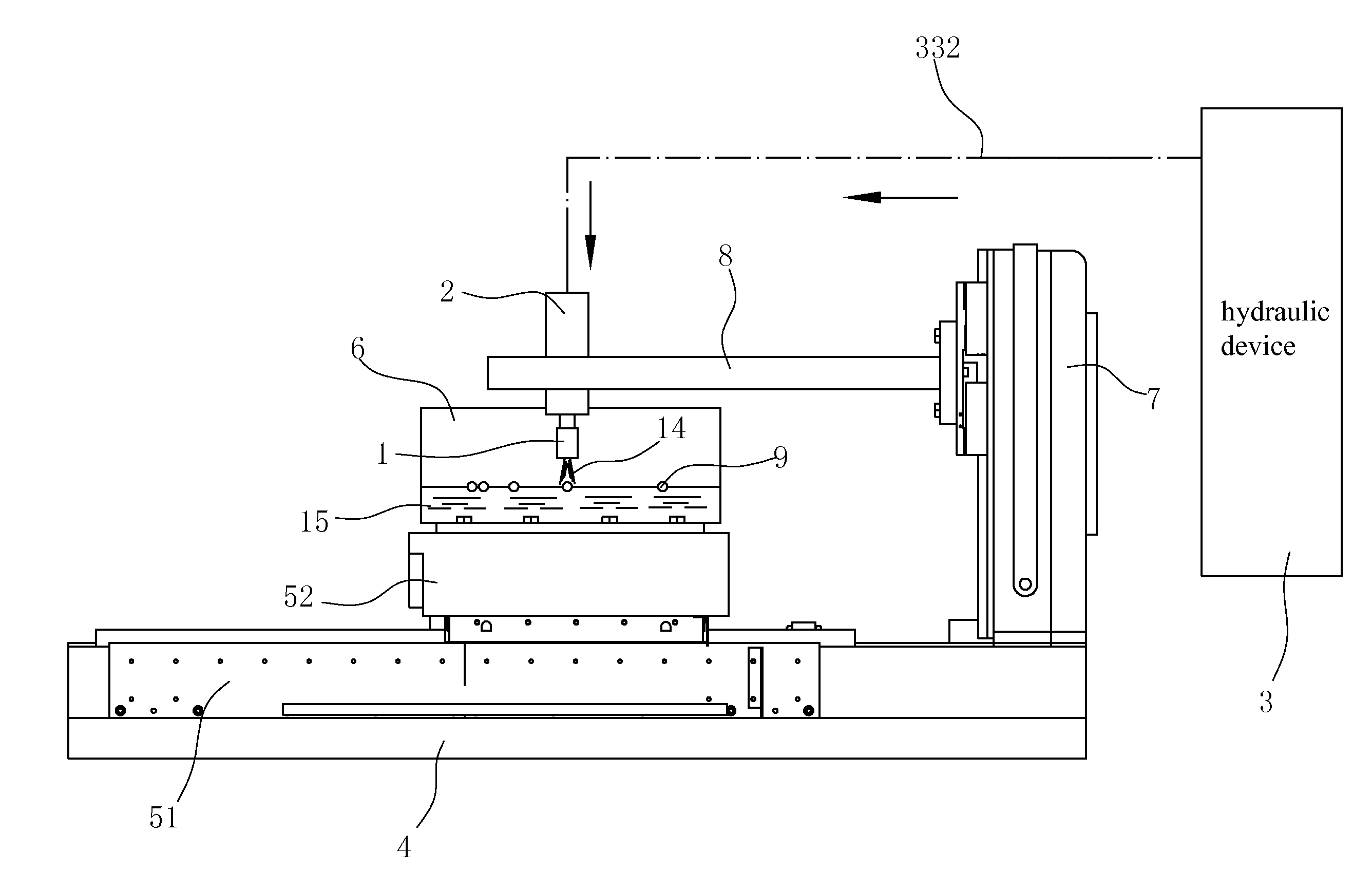

Device Used for Capturing Micro-Particles and a Micro-Particles Transporting Equipment Provided with the Device Thereof

ActiveUS20130101378A1Easy to manufactureEasy be realizedProgramme-controlled manipulatorGripping headsInjection portParticle transport

A device used for capturing micro-particles, which comprises a pressure regulator, a micro-jet nozzle, and a hydraulic device for providing injection liquid for the micro-jet nozzle; wherein the micro-jet nozzle is provided with an annular jet hole, the annular jet hole having a bottom end, a top end, an inner diameter, an entrance port located at the top end, and an injection port located at the bottom end, the output of the pressure regulator is connected to the entrance port of the micro-jet nozzle. Compared with the prior art, in the present invention, the liquid is taken as the medium, a kind of upward support on the micro-particles and a flow-around lift force perpendicular to the jet direction are generated by the micro-jet nozzle with the annular jet hole, which jointly act on the micro-particles, so as to achieve the micro-particle capture.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com