Electromagnetic array type driving device for knitting needle flat knitting machine and control method thereof

A technology of a driving device and a control method, applied in the directions of knitting, weft knitting, textile and papermaking, etc., can solve the problems of low knitting efficiency and poor knitting effect, and achieve the effect of improving knitting efficiency and knitting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

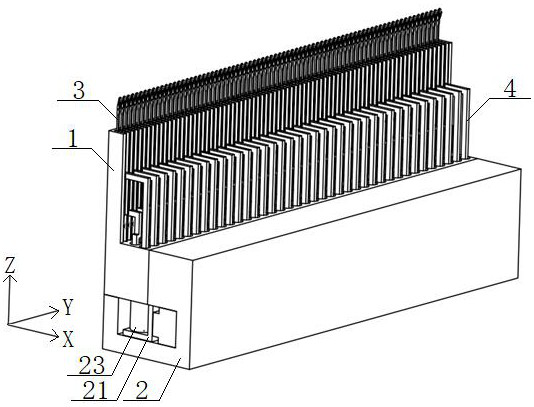

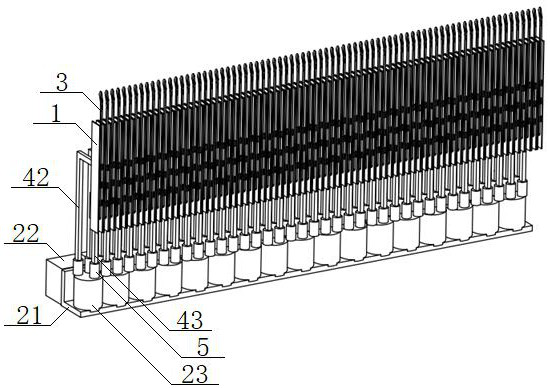

[0048] See figure 1 , An electromagnetic array drive device for a knitting needle flat knitting machine, comprising an upper frame 1, a lower frame 2 and a connecting rod 4, wherein the upper frame 1 is connected with the lower frame 2;

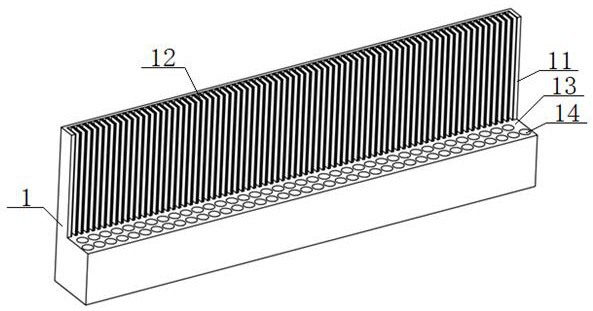

[0049] See Figure 2 to Figure 5 , The upper frame 1 has an L-shaped structure, and a plurality of needle grooves 12 are uniformly opened on the first inner side surface 11 of the upper frame 1 along the Y-axis direction, and two inner side walls of the needle groove 12 are both installed No. permanent magnet 6, the needle groove 12 is inserted with the knitting needle 3, and the second inner side surface 13 of the upper frame 1 is sequentially provided with a first row of blind holes 141 and a second row of blind holes 142 along the X-axis direction;

[0050] See Figure 8 to Figure 10 The connecting rod 4 includes a first connecting rod 42 and a second connecting rod 43, the first connecting rod 42 includes a first rod 421 and a second rod 422, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com