Automatic dressing mechanism of grinding wheel of numerical-control hob relieving grinding machine

A shovel grinder and grinding technology, which is applied in the field of automatic grinding wheel shaping mechanism of CNC hob shovel grinder, can solve the problems of complex structure of the grinding wheel shaper, large space occupied by the grinding machine, poor shape modification effect, etc., and achieve structural The effect of compactness, small size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

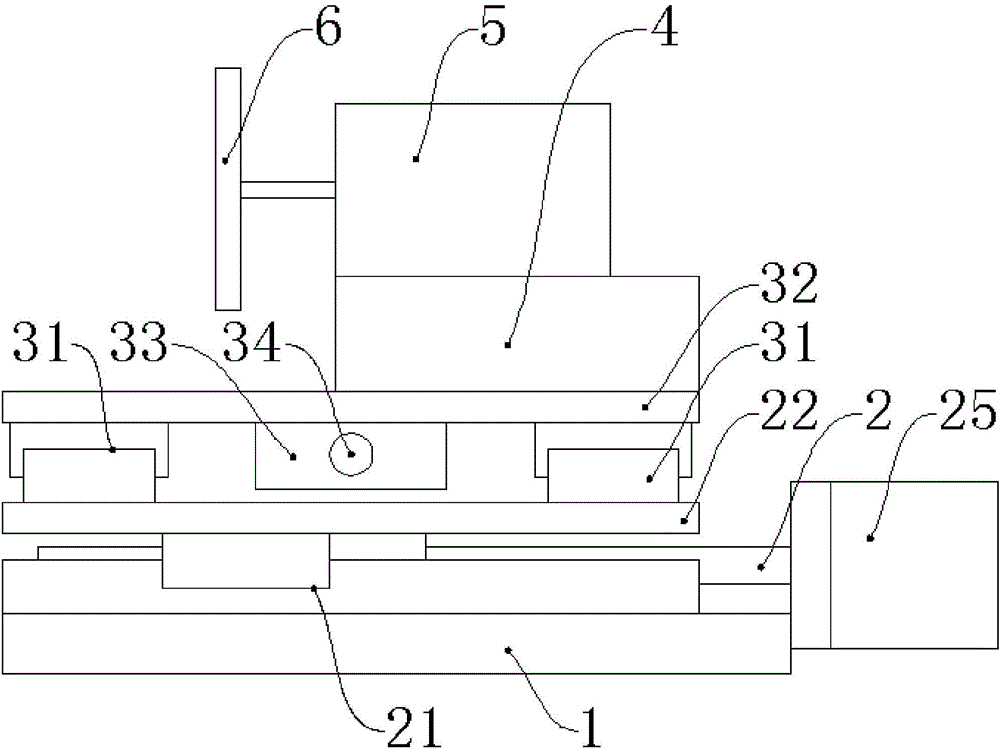

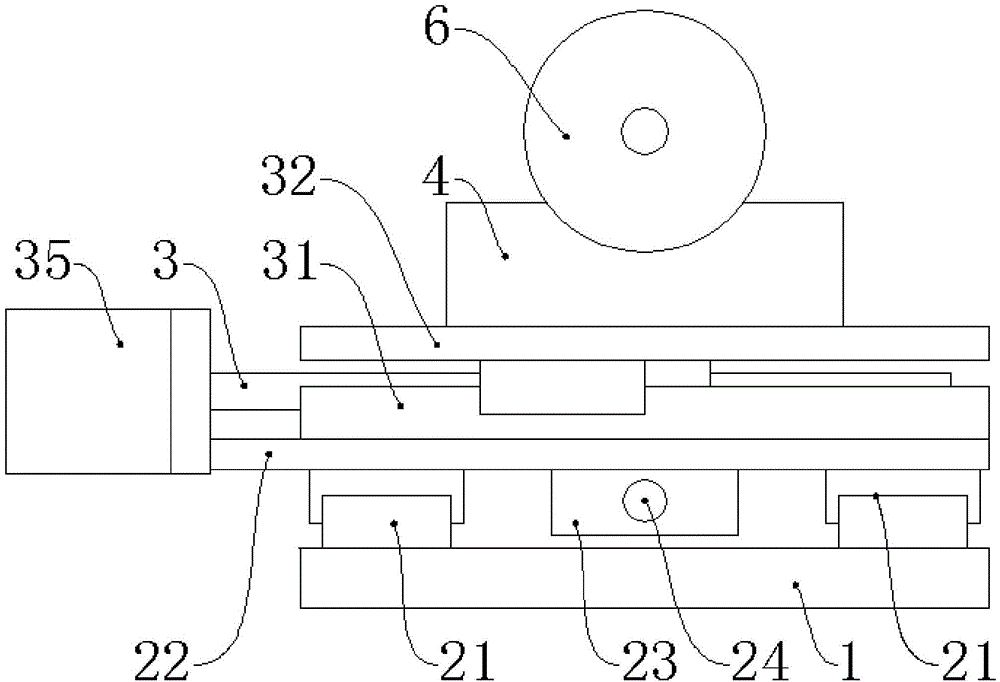

[0016] Such as figure 1 and figure 2 As shown, a CNC hob shovel grinder grinding wheel automatic modification mechanism, including a slide table base 1, on which slide table base 1 is provided with an x-direction sliding device 2, on which x-axis slide device 2 is provided with The y-direction sliding device 3, the x-direction sliding device 2 and the y-direction sliding device 3 are perpendicular to each other, the roller motor 5 is installed on the y-direction sliding device 3 through the motor mounting base 4, and the orientation of the output shaft of the roller motor 5 is It is the x direction, on the output shaft of the roller motor 5, a diamond roller 6 is installed; the x direction sliding device 2 includes two first linear guides 21 parallel to each other, the first linear guides 21 The slide rail is fixedly installed on the upper surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com