Sample surface coating sampling device

A technology of surface coating and sampling device, applied in sampling device, sampling, measuring device and other directions, can solve the problems of low work efficiency, operator injury, insufficient collection of coating sampling, etc., to control the coating thickness, The effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

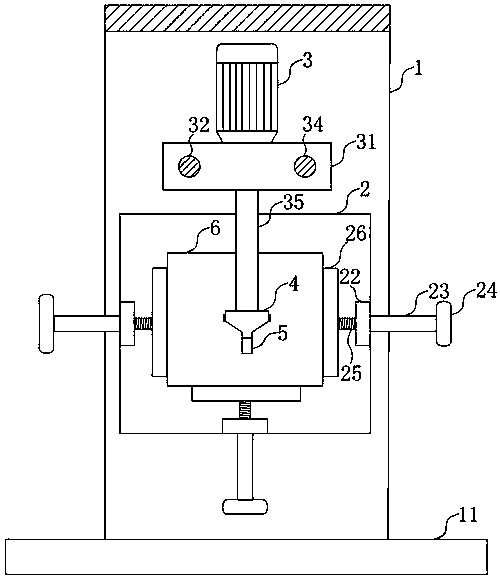

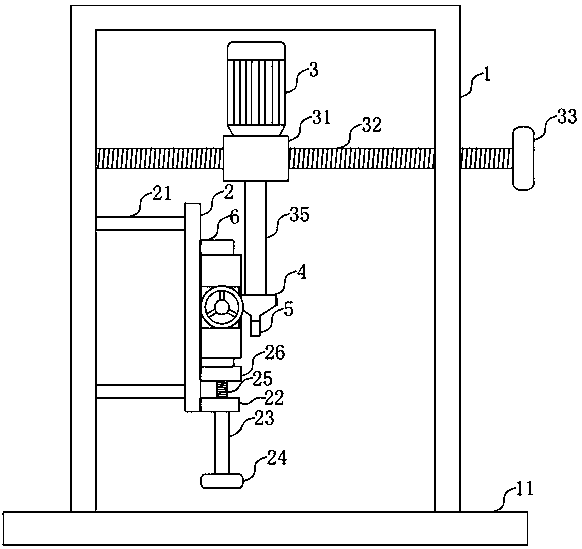

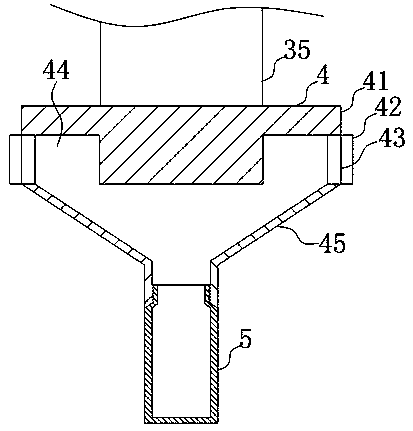

[0018] according to Figure 1-4 , a sample surface coating sampling device, comprising a frame 1, the bottom of the frame 1 is fixedly connected with a base 11, the top side of the rear side wall of the frame 1 is rotatably inserted with a second threaded rod 32 through a bearing, and the front side of the second threaded rod 32 passes through The bearing is rotated and interspersed on the top side of the front side wall of the frame 1, the front end of the second threaded rod 32 is fixedly connected with the second runner 33, the middle part of the second threaded rod 32 is connected with a slider 31 through a screw thread, and the right side of the slider 31 slides through There is a slide bar 34, the front and rear ends of the slide bar 34 are fixedly connected to the front and rear side walls of the frame 1, the top surface of the slide block 31 is fixedly connected to the motor 3, the driving end of the motor 3 is connected to the shaft rod 35 by transmission, and the shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com