Patents

Literature

51results about How to "Improve weaving effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

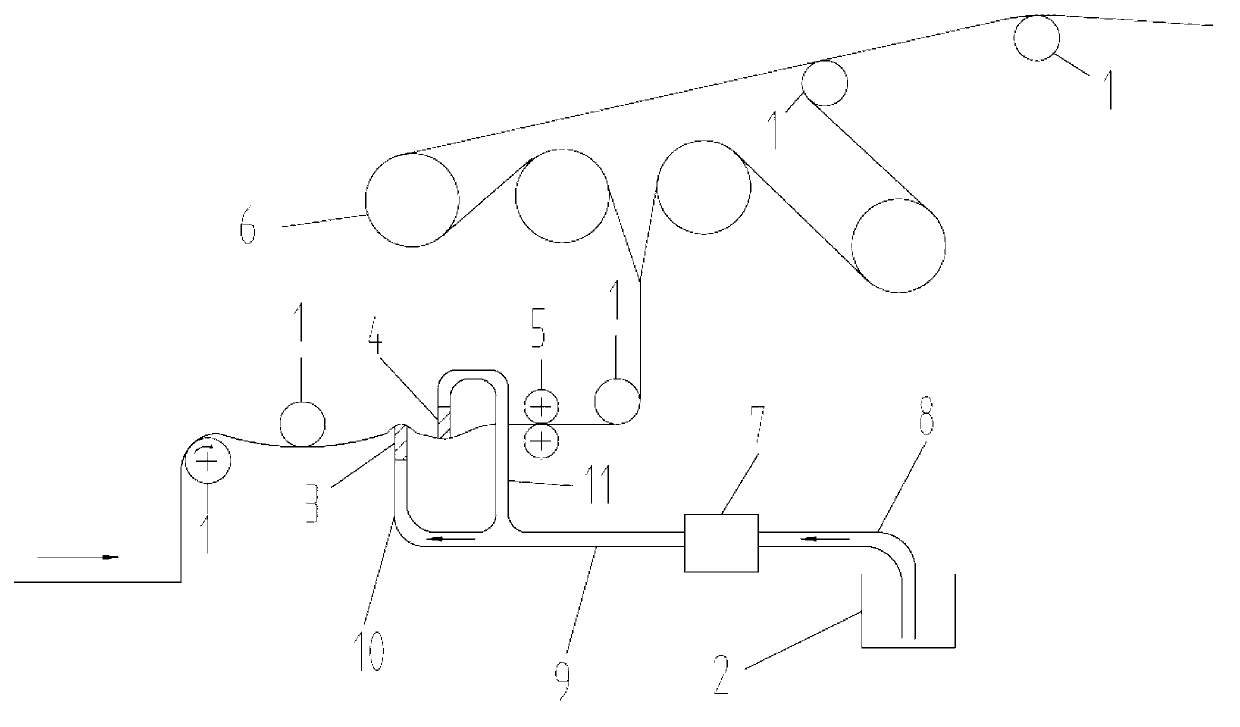

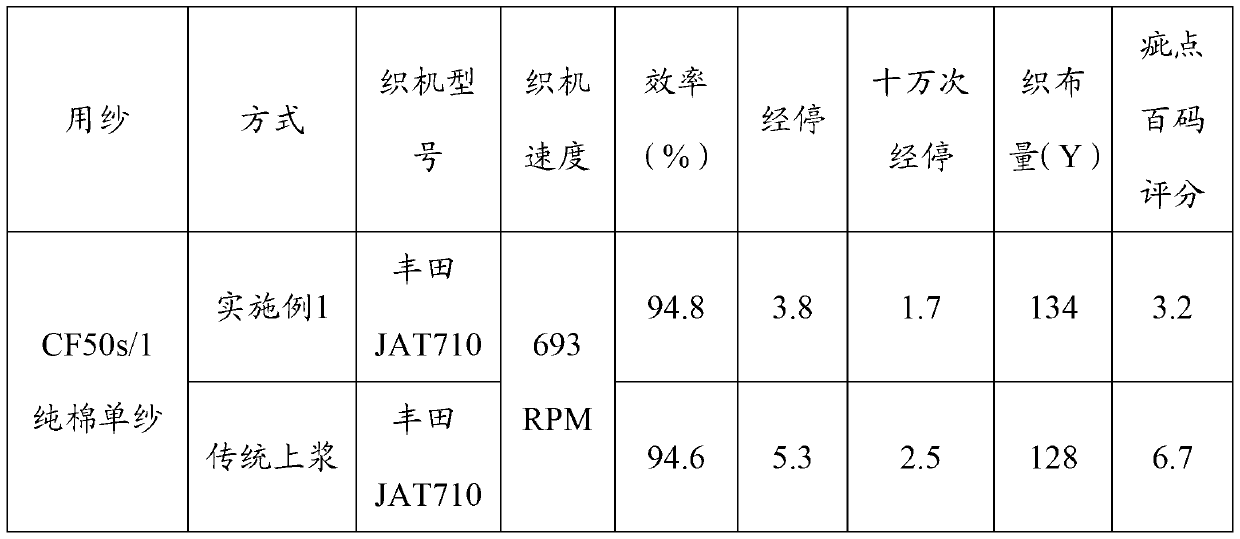

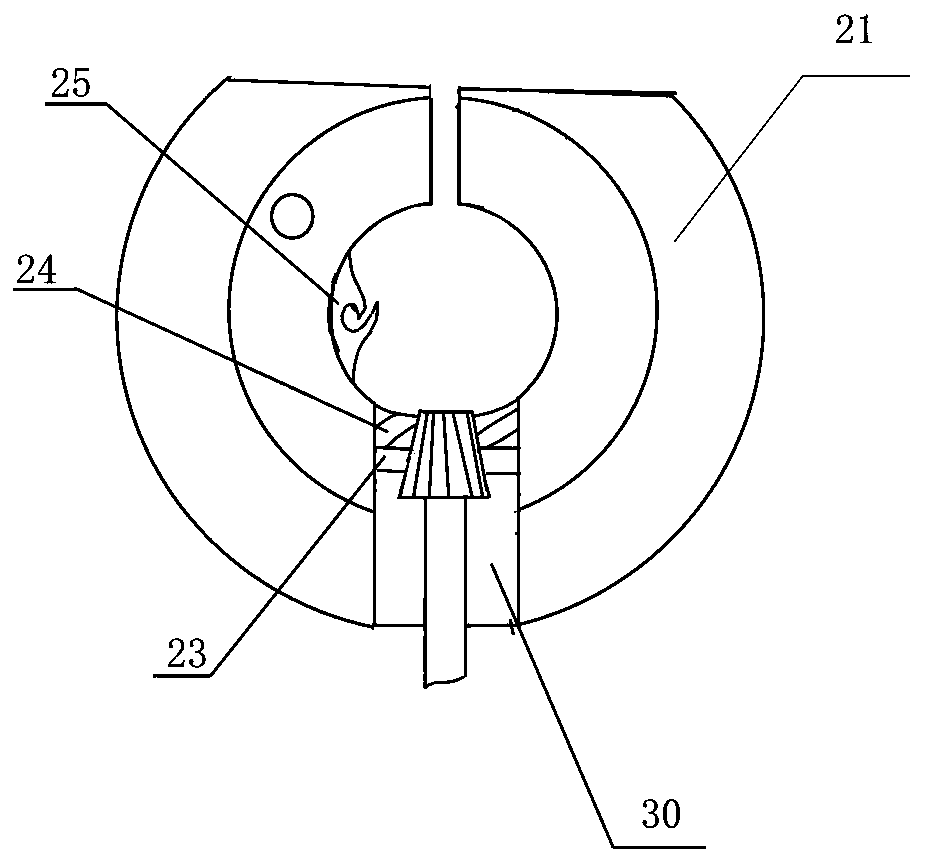

Warp sizing method and application thereof

ActiveCN103103710AEmission reductionReduce water consumptionFibre treatmentLiquid/gas/vapor textile treatmentYarnWastewater

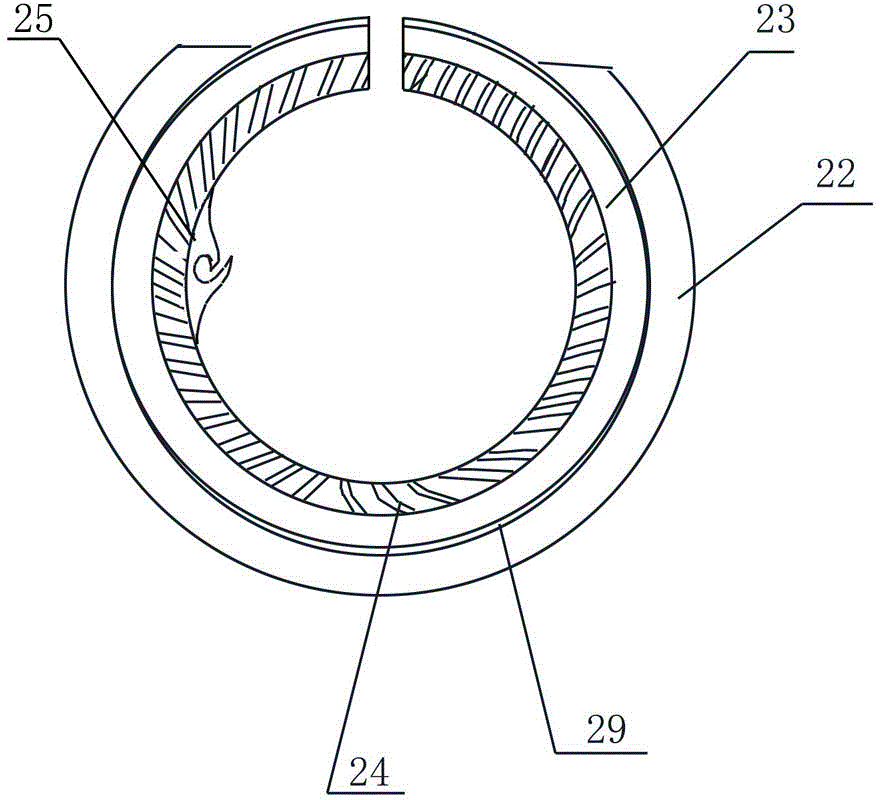

The invention discloses a warp sizing method and an application thereof. The warp sizing method includes the following steps: preparing sizing agents, boiling the sizing agents, foaming, conducting foam sizing, rolling the sizing agents, drying and leasing; foaming ratio and applying amount are controlled by a foam producer in the step of foaming; the foaming ratio is 1:3-30, and the applying amount is 10%-50%; foam formed by the foam producer is instantly and entirely applied to warp yarn through a foam applicator in the step of conducting foam sizing; and the foam applicator is divided into an upper applying head and a lower applying head. The warp sizing method has the advantages of being low in water consumption, little in chemical and wastewater discharge, little in sizing amount, easy to desize, short in yarn drying time, capable of saving energy consumption by 50%-60%, high in production speed, low in cost, continuous in foam applying mode, capable of ensuring uniformity and stability of the applied foam, low in product breakage rate, high in efficiency and good in weaving effect.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Anti-cracking treatment method for rattan

InactiveCN106393369APrevent peelingAvoid breakingElectric wood treatmentWood treatment detailsWarm waterLow temperature plasma

The invention discloses an anti-cracking treatment method for a rattan. The method comprises the following steps: treating the rattan in a dark environment of which the humidity is 65% to 68% and the temperature is 8 to 10 DEG C, and irradiating twice; subsequently soaking the rattan in warm water and putting in cold storage; dissolving chitosan in a saturated carbon dioxide water solution to prepare a solution for soaking the rattan; and treating the rattan by utilizing low-temperature plasma generated by dielectric barrier discharge at atmospheric pressure. In comparison with an existing rattan treatment method, the method disclosed by the invention has the advantages that a knitted product made from the rattan treated by the method disclosed by the invention is not deformed, free of cracks and very comfortable to skin in use; the bearing capacity is increased; the dimensional stability is good; decrustation of the rattan can be effectively prevented; after the rattan is knitted, the strength of the rattan is gradually restored and is increased by 2% to 3% in comparison with the original strength; the treated rattan is quite good in corrosion prevention effect, good in rattan softening effect and harder to mildew and damage in use; the knitted product prepared by the rattan treated by the method disclosed by the invention is free of mildew and worm damages and can be kept in the original color within at least 8 years.

Owner:阜南县环宇柳木工艺制品有限公司

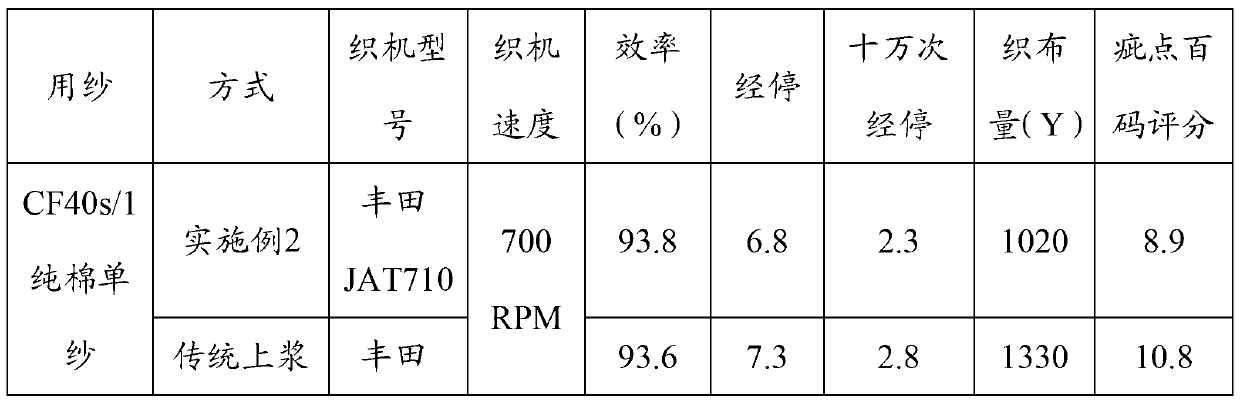

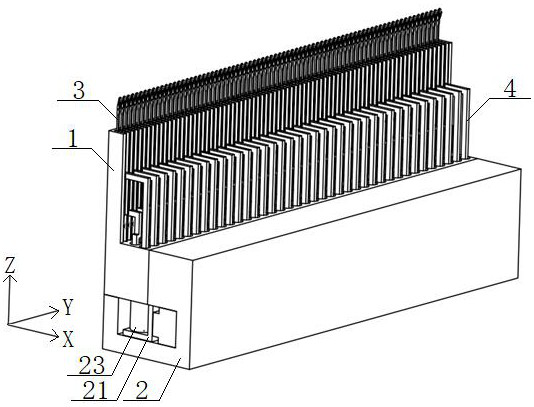

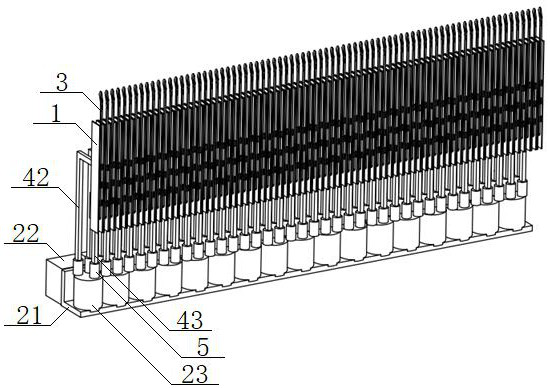

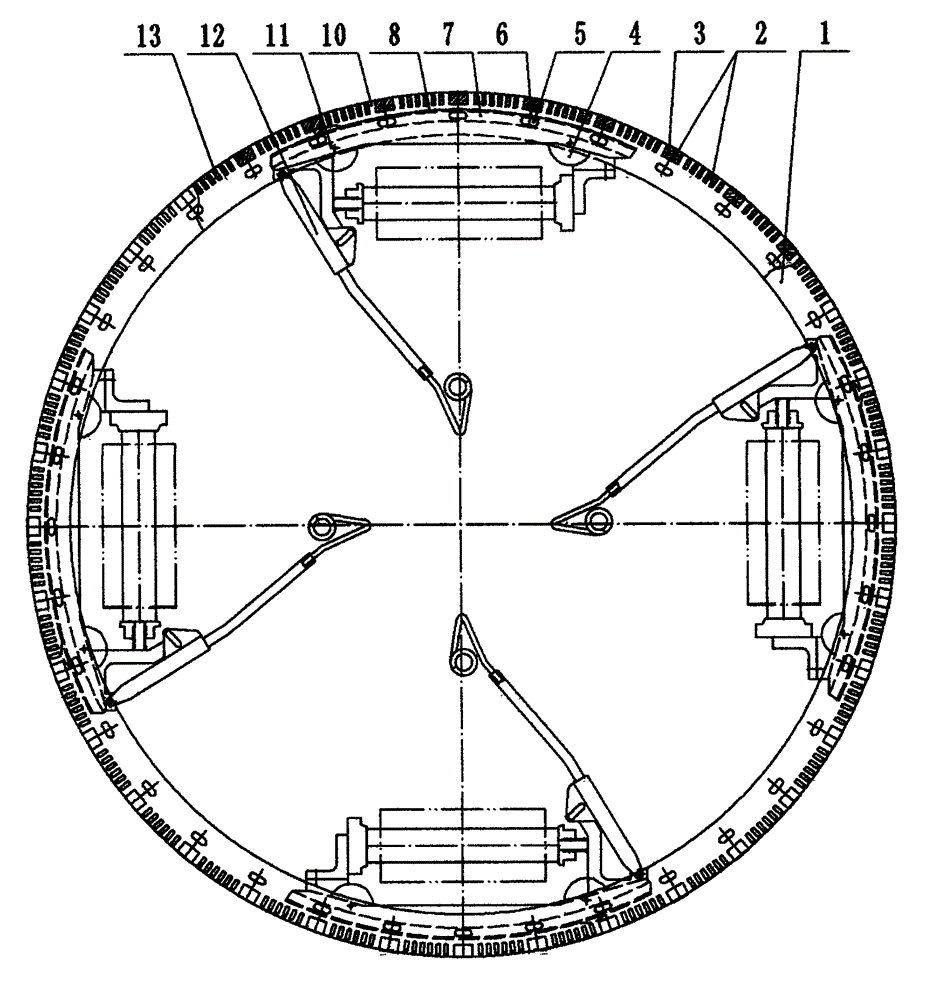

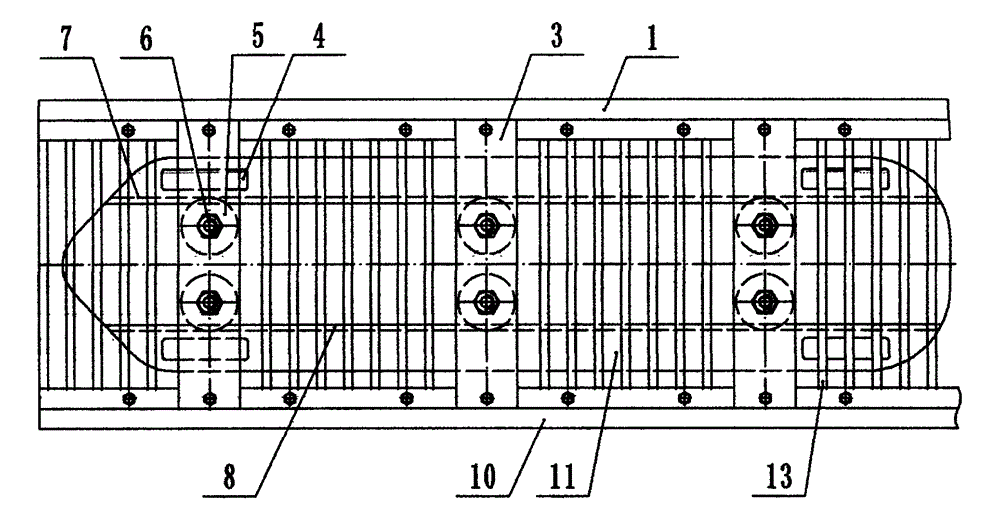

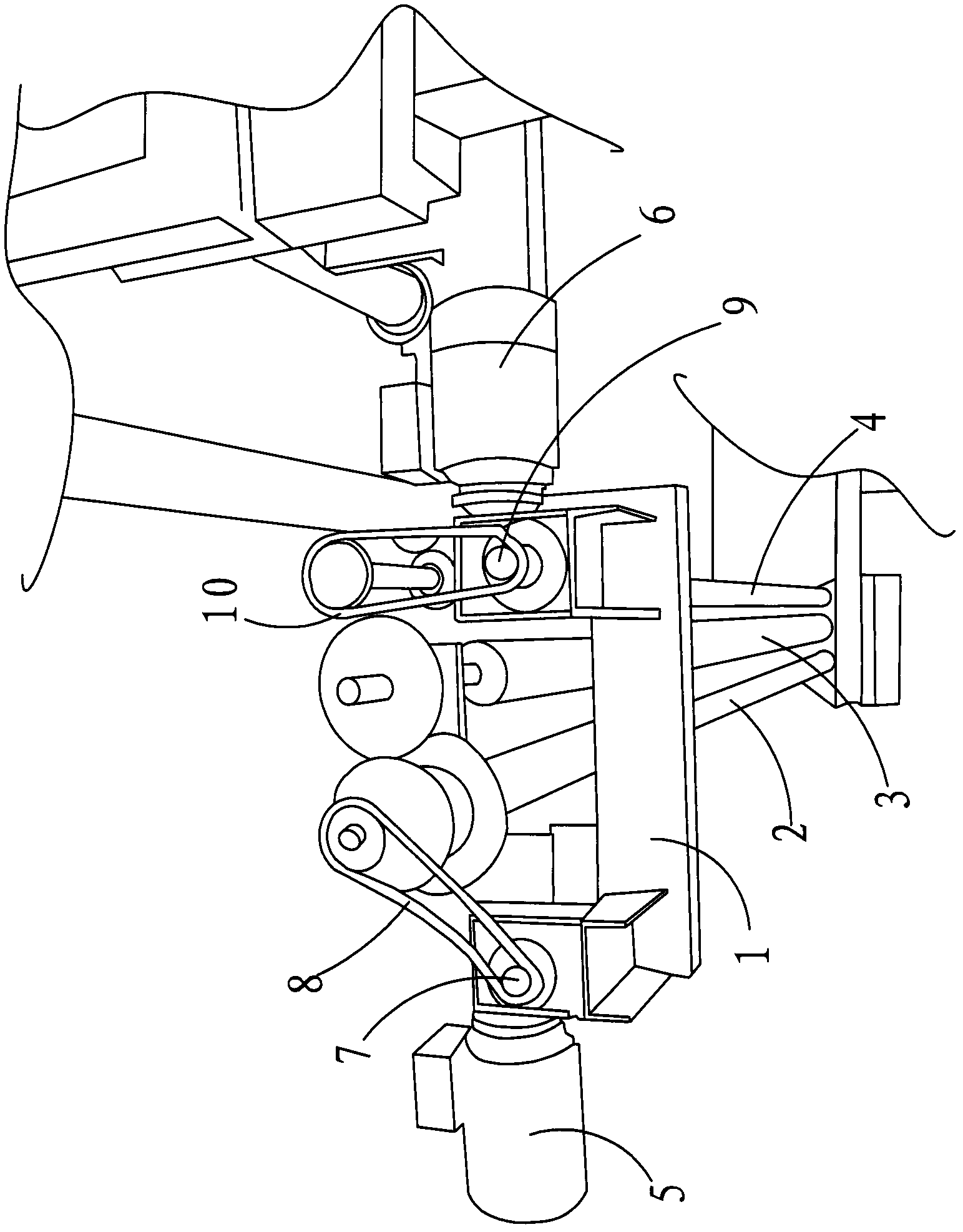

Electromagnetic array type driving device for knitting needle flat knitting machine and control method thereof

ActiveCN111691056AControl the moving distanceDifferent weaving effectWeft knittingElectric machineryEngineering

The invention discloses an electromagnetic array type driving device for a knitting needle flat knitting machine. The electromagnetic array type driving device for the knitting needle flat knitting machine comprises an upper machine frame and a lower machine frame; a plurality of needle slots are formed in a first inner side surface of the upper machine frame; No. 2 permanent magnets are mounted on both two inner side walls of each needle slot; a knitting needle is inserted into each needle slot; one or more rows of blind holes are formed in a second inner side surface of the upper machine frame; connecting rods are inserted into the blind holes; one end, positioned at the bottom of the blind hole, of each connecting rod is connected with a No. 1 permanent magnet; the other end of each connecting rod is connected to the corresponding knitting needle after extending into the corresponding needle slot, and No. 3 permanent magnets with the same polarity as the No. 2 permanent magnets aremounted on both sides of the end; a mounting seat and a motor module which are connected are arranged in the lower machine frame; the mounting seat can move reciprocally in a Y-axis direction; a plurality of mounting holes are formed in the mounting seat; electromagnets are mounted in the mounting holes; and the electromagnets are positioned below the plurality of the No. 1 permanent magnets. Through the design, the knitting efficiency and the knitting effect are improved, and the service lives of the knitting needles are prolonged.

Owner:WUHAN TEXTILE UNIV

Preparation method of anti-electrostatic linen fiber

The invention discloses a preparation method of anti-electrostatic linen fiber. The preparation method of the anti-electrostatic linen fiber comprises the following operating steps: (1) putting the woven formed linen fiber into hot water, performing soaking treatment for 40 to 50 minutes, putting into hot air and blow-drying until the water content is 40 to 55 percent; and (2) putting the linen fiber treated in the step (1) into anti-electrostatic modified liquid and soaking for 60 to 80 minutes, wherein the mass ratio of the linen fiber to the anti-electrostatic modified liquid is 1:(8-12). The preparation method of the anti-electrostatic linen fiber is simple in operation, three wastes are few in the preparation process, the cost is low, and the prepared anti-electrostatic linen fiber maintains the original excellent characteristics of the linen fiber and improves the anti-electrostatic property of the linen fiber so as to improve the weaving effect of the linen fiber.

Owner:JIESHOU SHUANGXIN TEXTILE

Anti-cracking processing method of osiers

InactiveCN106313237AImprove weaving effectReduce the probability of crackingWood treatment detailsPretreatment apparatusAmbient humidityWarm water

The invention discloses an anti-cracking processing method of osiers. The anti-cracking processing method of the osiers comprises the steps of processing the osiers in a dark environment with the ambient humidity being 70 to 75 percent and the temperature being 10 to 12 DEG C, and providing illumination for two times; then soaking in warm water and refrigerating; dissolving chitosan in a saturated carbon dioxide water solution to prepare into a solution for soaking the osiers; and utilizing a low-temperature plasma generated by atmospheric pressure dielectric barrier discharge to process the osiers. Compared with an existing osier processing method, the anti-cracking processing method of the osiers provided by the invention is simple, and the osiers can be effectively prevented from being cracked or deformed, so that the service time of an osier product can be further prolonged, the skin-friendly feeding is good, the bearing strength is increased, the size stability is good, the osiers can be effectively prevented from peeling, after the osiers are woven, the strength of the osiers is gradually recovered and is improved by 3 to 4 percent compared with the original strength, the processed osiers have a better preservative effect and an excellent osier softening effect, and the technological value and the economic value of the osier product are improved.

Owner:阜南县环宇柳木工艺制品有限公司

Preparation method of high-strength and high-water absorption craft woven paper

InactiveCN110016832AImprove writing effectImprove efficiencySpecial paperMicroorganism/enzyme additionPotato starchBran

The invention belongs to the technical field of art crafts, and particularly relates to a preparation method of high-strength and high-water absorption craft woven paper. The preparation method comprises the following specific steps: (1) weighing raw materials, (2) mixing cotton shells with soybean straw, performing crushing, performing steam treatment, freezing treatment and steam treatment, andconducting cooling to room temperature so as to obtain a straw-shell material, (3) soaking corn bran in an acetic acid aqueous solution, performing cold storage treatment, mixing the obtained corn bran with gumbo leaf fermentation broth, performing crushing and pulping, adding the straw-shell material, and performing even mixing so as to obtain a pulp material, (4) adding algal polysaccharides, Sargassum fusiforme polysaccharides, modified potato starch and modified lotus root starch to the pulp material, performing heating with gentle fire, adding aminomethylbenzoic acid, sodium sulfamate andnano zinc oxide, performing homogenizing treatment, and performing paper making and drying. The water absorption performance of the paper can be ensured effectively, the paper is flexible and elastic, and has high structural stability and resistance to cracking and tearing, and smooth printing and writing can also be maintained effectively, so that the efficiency and performance of application ofthe craft woven paper are improved greatly.

Owner:阜南县金源柳木工艺品有限公司

Drying anti-craking method of rattans

InactiveCN107263646AReduce breakageAvoid breakingWood treatment detailsReed/straw treatmentEngineeringBreakage rate

The invention mainly relates to the technical field of weaving handicrafts, and discloses a method for drying and preventing cracking of rattan, comprising: rattan fermentation, primary drying, and secondary drying; the method is simple, easy to operate, and reduces the fracture rate of rattan weaving by 8.5% %, drying and anti-cracking are treated at the same time, the treatment time is shortened to 17-18 days, the utilization rate of the rattan is improved, and the production cost is saved; after the fresh rattan bark is stacked, the fermentation liquid is sprayed and covered with a black plastic film, Promote the proliferation of Lactobacillus plantarum and yeast in the fermentation broth, slowly ferment the rattan, gradually reduce the pH to 4.6~4.8, and produce extracellular metabolites rich in polypeptides, polysaccharides and fats, which gradually penetrate into the rattan tissue and soften the rattan bark And the fiber structure of the rattan core, so that both the rattan bark and the rattan core can be used for weaving, which improves the weaving performance of the rattan and reduces breakage.

Owner:安徽宏润工艺品有限公司

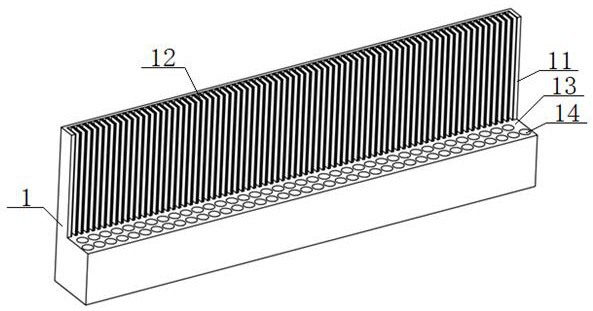

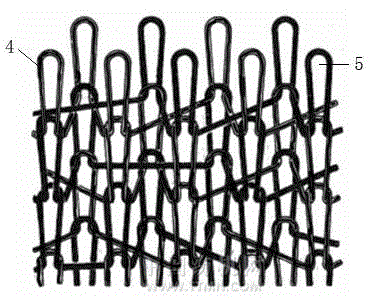

Alternate twill knitted net of blended yarn with multicolor jacquard

InactiveCN103952844ASolve count ratioSolve the uniformity of blendingWeft knittingFibre treatmentYarnFiber

An alternate twill knitted net of blended yarn with multicolor jacquard is composed of total yarn, which is formed by mutual intertwining of cotton yarn, cellulose yarn and modified wool yarn; part of the total yarn forms a yarn coil by weaving, wherein, the rest total yarn floats in front of the yarn coil and forms an embossing like floating thread, the embossing is intertwined and fixed with the yarn coil through the total yarn and forms a sesame pattern at the back of the yarn coil. The alternate twill knitted fabric of the blended yarn with the multicolor jacquard solves the problems in count ratio of three cellulose of the blended yarn, blending homogeneity and twist degree, improves the knitting property and physical properties of the product, has the distinct characteristics of hydrophilicity, softness, smoothness, air permeability, UV resistance, consistent color, soft luster and the like.

Owner:POLARGOOSE CLOTHING

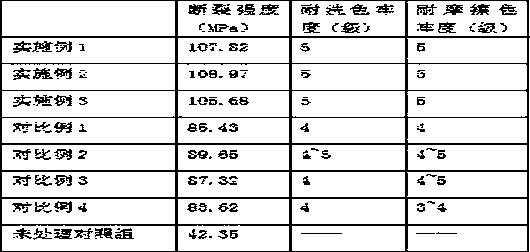

Method for softening and dyeing soybean straw

InactiveCN108748560AHigh strengthMake up for the defect of easy breakageRadiation/waves wood treatmentWood treatment detailsPetalAlkyl polyglycoside

The invention belongs to the technical field of straw dyeing treatment, and particularly relates to a method for softening and dyeing soybean straw. The method specifically comprises the following steps that (1) the soybean straw is immersed in a magnesium sulfate solution for heat preservation and immersing, then is taken out after the solution drains and until no water drops falls, the soybean straw is put into a freezing room for freezing treatment and then is taken out, and then the soybean straw is subjected to constant-temperature steam treatment and then is taken out, and the soybean straw is dried until the moisture content is 7-9%; (2) the soybean straw is immersed in a coloring agent for immersing and then is taken out after the coloring agent drains and until no water drops falls, and the soybean straw is put into an electric field for electric field treatment, wherein the coloring agent is prepared from the following raw materials of fresh cockscomb petals, carrots, fresh celery leaves, fresh ryegrass, natural phenol polyoxyethylene ether, alkyl polyglucoside, grifola polysaccharide, lycium barbarum polysaccharide and water; and (3) the soybean straw is dried until themoisture content is 15-17%. According to the method, the breaking strength of the soybean straw is greatly enhanced after softening and dyeing treatment, the color is bright, uniform and glossy, discoloring and color fading are avoided, and extremely high color fastness to washing and color fastness to rubbing are achieved.

Owner:阜南县明强柳编工艺品有限公司

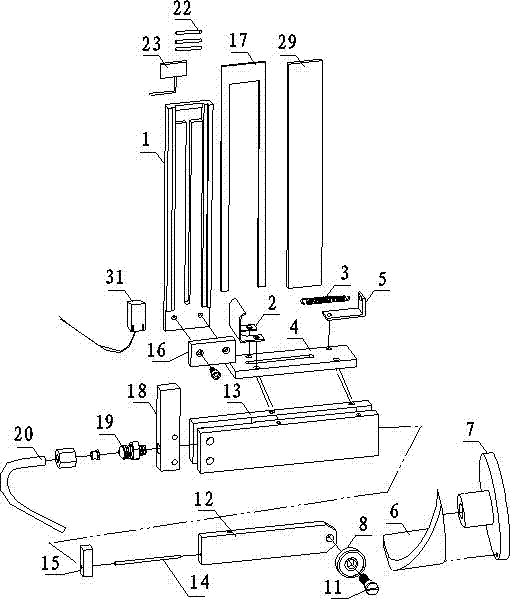

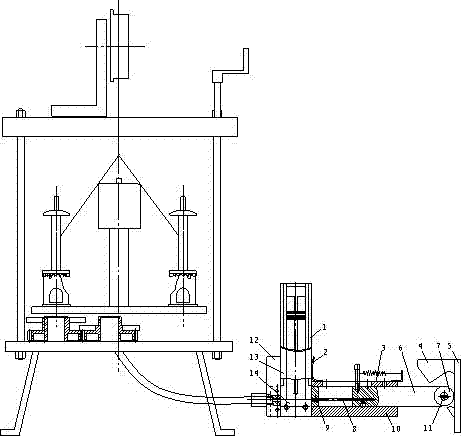

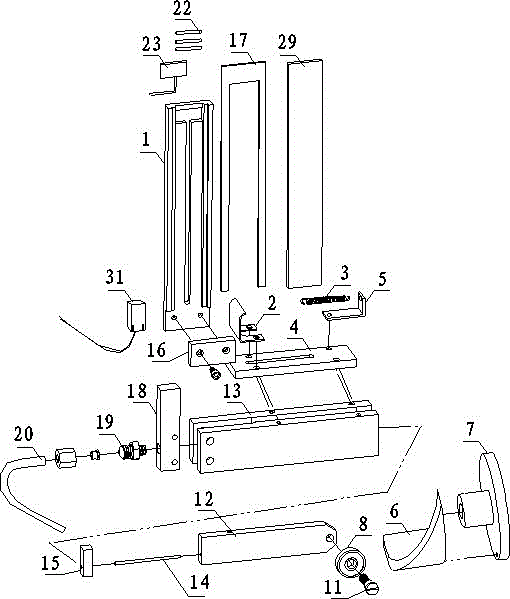

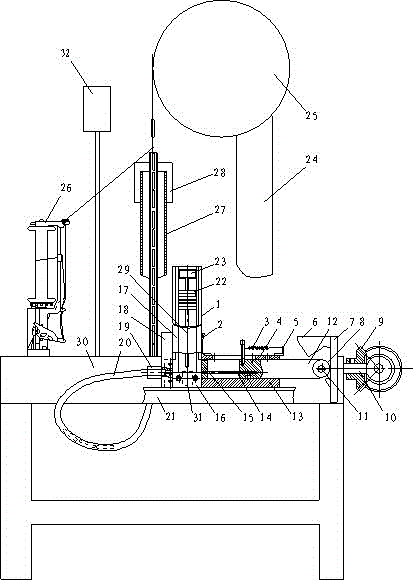

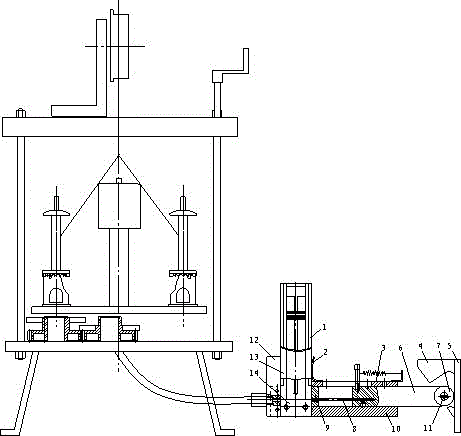

Automatic filling and feeding device of braiding machine

The invention provides an automatic filling and feeding device of a braiding machine, belonging to the braiding machine. A groove is arranged at the middle part of a base of the feeding device and an adjusting plate is connected with one end of the groove on the base; the adjusting plate is connected with a metal guide pipe through a pipe connector; the upper end of the base is connected with a cover plate and a long-strip-shaped hole is arranged at the middle part of the cover plate; one end of the cover plate is connected with a spring bracket and the other end of the cover plate is connected with a limiting spring; a tension spring is connected with the spring bracket; an embedding block is arranged in the groove on the base and is connected with a storage bin through the embedding block; the upper end of the storage bin is provided with a tracking block and the groove at the other end of the base is internally connected with a guide block and a push plate; one end of the push plate is sequentially connected with a bearing and a push plate shaft; a cam block and a cam sheet are connected into a whole body; and a sensor is arranged on one side of the storage bin and is connected with an alarm to form a material blanking alarming device. The automatic filling and feeding device of the braiding machine has the advantages of feeding material for a long time, saving manpower and time and improving the yield, and is simple and stable in a transmission structure; and the automatic feeding time period is accurate, the interval pitch precision is high and the automatic filling and feeding device is easy to control.

Owner:韩百峰

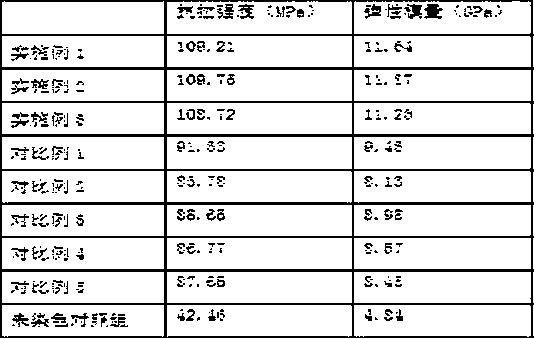

Dyeing method for enhancing mechanical performances of cotton stems

InactiveCN108772933AIncrease elasticityHigh strengthRadiation/waves wood treatmentWood treatment detailsAluminium sulfateEngineering

The invention belongs to the technical field of biological treatment of cotton stems, and especially relates to a dyeing method for enhancing the mechanical performances of cotton stems. The method concretely comprises the following steps: (1) carrying out constant-temperature steam treatment on the cotton stems, taking out the cotton stems, carrying out constant-temperature freezing treatment, taking out the cotton stems, carrying out constant-temperature steam treatment, and taking out and cooling the cotton stems; (2) immersing the cotton stems in an aqueous solution of aluminum sulfate ata kept temperature, removing the obtained leachate, and carrying out hot pressing drying; and (3) immersing the cotton stems in a coloring agent, applying ultrasonic waves to carry out ultrasonic treatment, taking out the obtained leachate, and airing the cotton stems to reach a constant weight. The method has the advantages of high coloring fastness, no color fading, no color change, bright color, great improvement of the utilization values and the utilization effect of the cotton stems, effective improvement of the tensile strength and the elastic modulus of the cotton stems, enhancement ofthe mechanical performances of the cotton stems, improvement of the braiding performance in the braiding process, improvement of the use performances in the use process, and great prolongation of theservice life.

Owner:FUNAN TENGBO ARTS & CRAFTS CO LTD

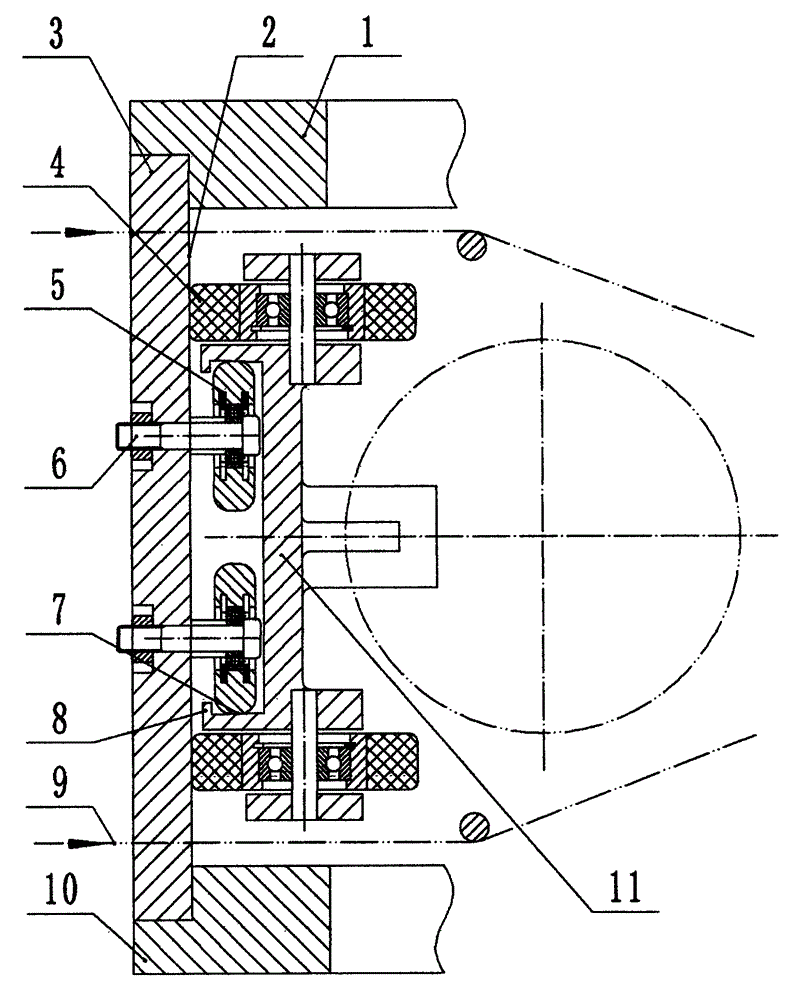

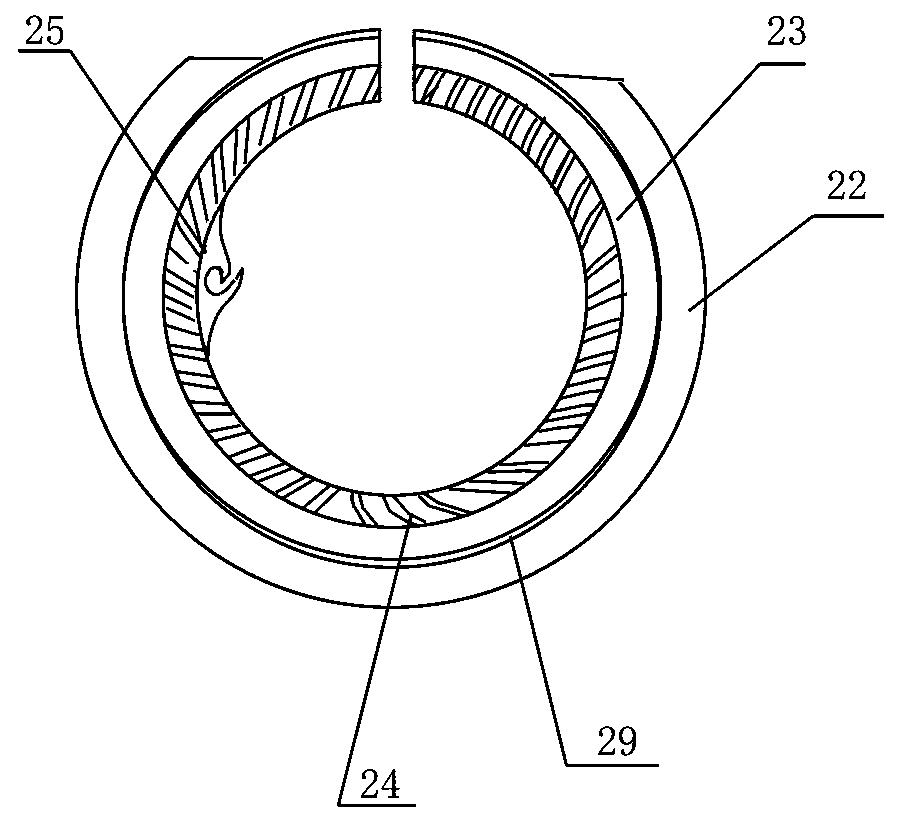

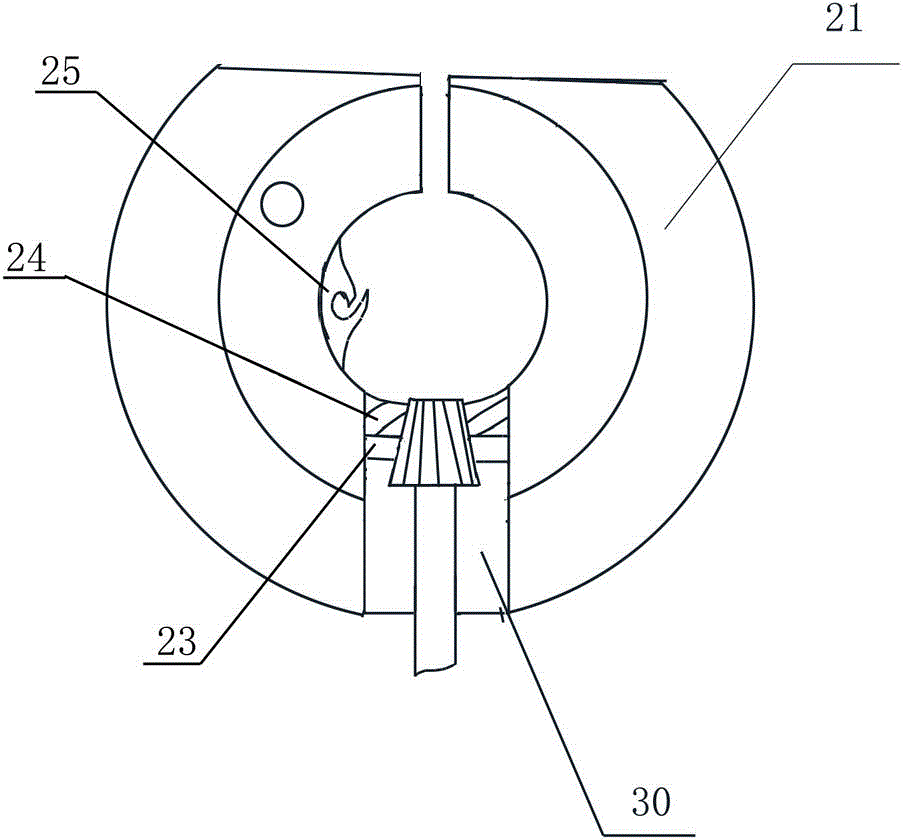

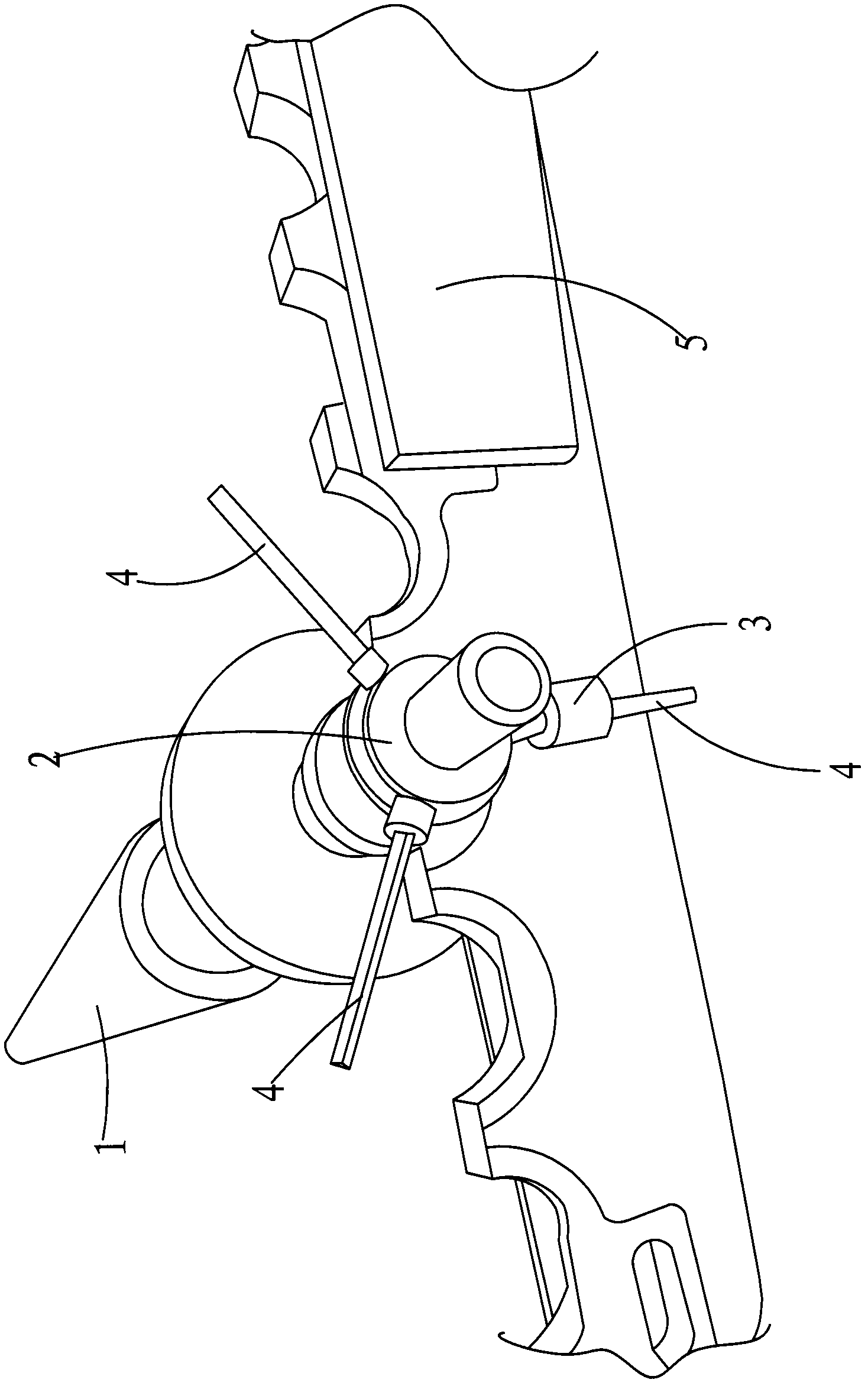

Reed door type shuttle rail pair

The invention relates to a plastic knitting machine and discloses a reed door type shuttle rail pair. The reed door type shuttle rail pair is characterized by comprising a reed door rail, an internal horizontal rail and a shuttle, the reed door rail comprises sheet inner side faces arranged between an upper door ring and a lower door ring and an inner side face of a stand column, the internal horizontal rail comprises the stand column and wheels arranged on the stand column, the shuttle comprises a shuttle body, shuttle wheels and seam allowances, the shuttle wheels are matched with the reed door rail in a rolling mode, the seam allowances are matched with the internal horizontal rail in a rolling mode, the wheels are paired in an up-and-down mode, the wheels are fixedly connected to the stand column, the outer diameter of the wheels is smaller than the width of the stand column, and warps penetrate through the part among the upper door ring, the lower door ring and the shuttle body. The reed door type shuttle rail pair has the advantages that the shuttle is suspended in the intersection of the warps all the time in the work process, the shuttle does not grind the warps, the faults of yarn scraping, yarn breading and the like caused by shuttle wheel grinding are thoroughly overcome, the knitting reliability is greatly improved, and the requirement for the strength of flat yarns of a knitting machine is lowered.

Owner:邳州市滨河中小企业管理服务有限公司

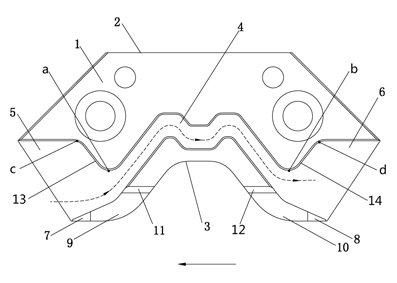

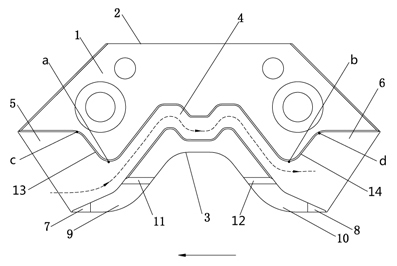

Stitch transfer cam of computer knitting machine

The present invention discloses a stitch transfer cam of computer knitting machine, comprising a body symmetrically left and right, wherein the body has a top edge in a shape of a straight line, and an U-shaped bottom edge concave inwardly; the middle part of the body is provided with an M-shaped groove; two ends of the M-shaped groove respectively extend to two sides of the body and intersect with two sides of the body to form an expanding horn mouth, therefore the groove penetrates through the body. Compared with the prior technology, a plurality of electromagnets, electric control devices and mechanical auxiliary devices can be saved; the structure of a handpiece is simplified, the weight of the handpiece is reduced, and phenomenon that the cam is blocked or is not flexible is avoided; the use of the equipment is more stable and energy is saved; the manufacture cost and use cost are reduced basically; furthermore, the knitting effect of the equipment is improved in a certain extent.

Owner:NINGBO CIXING

Preparation method for compound treating fluid for salix integra branches

InactiveCN108839171AReasonable collocationImprove mildew resistanceWood treatment detailsReed/straw treatmentMicrocrystalline waxAdditive ingredient

The invention discloses compound treating fluid for salix integra branches. The compound treating fluid comprises Chinese herbal extract, sodium tetraborate, epoxidized soybean oil, microcrystalline wax, ethylene glycol, sodium cetyl benzene sulfonate, sodium hexametaphosphate, nanometer titania and deionized water. The compound treating fluid is provided, all the raw material ingredients are matched reasonably, preparation and processing are convenient, the obtained compound treating fluid can significantly improve mildew resistance of the salix integra branches, the salix integra branches can be further softened, knitting performance is improved, finally service life of the salix integra branches can be prolonged by about 35%, and the compound treating fluid has great use and popularization value.

Owner:安徽宏润工艺品有限公司

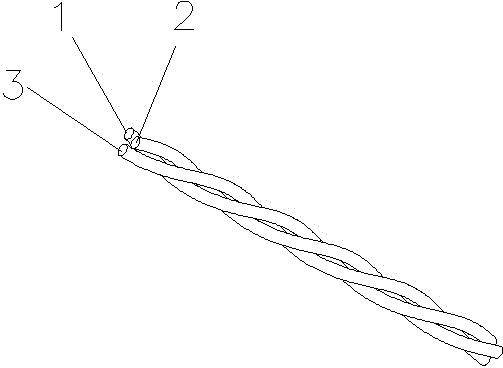

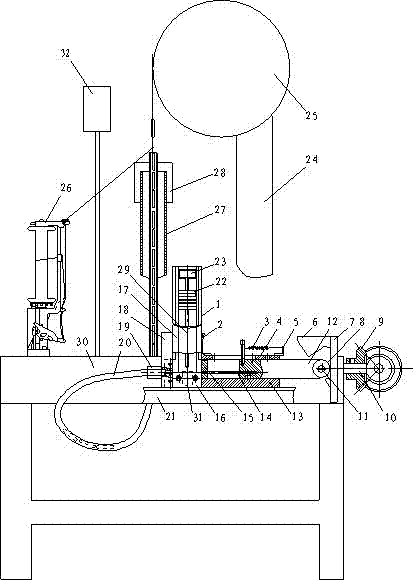

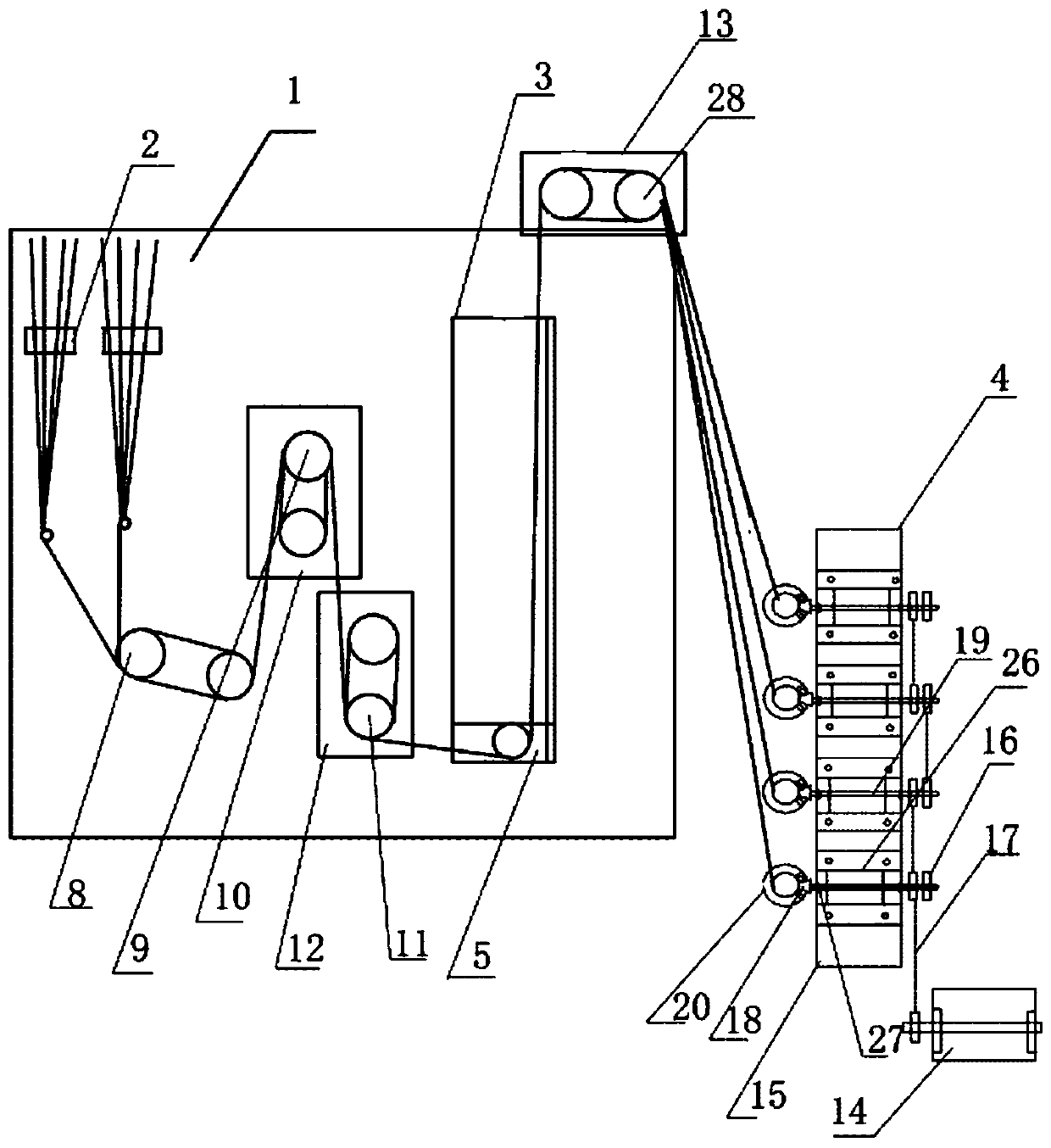

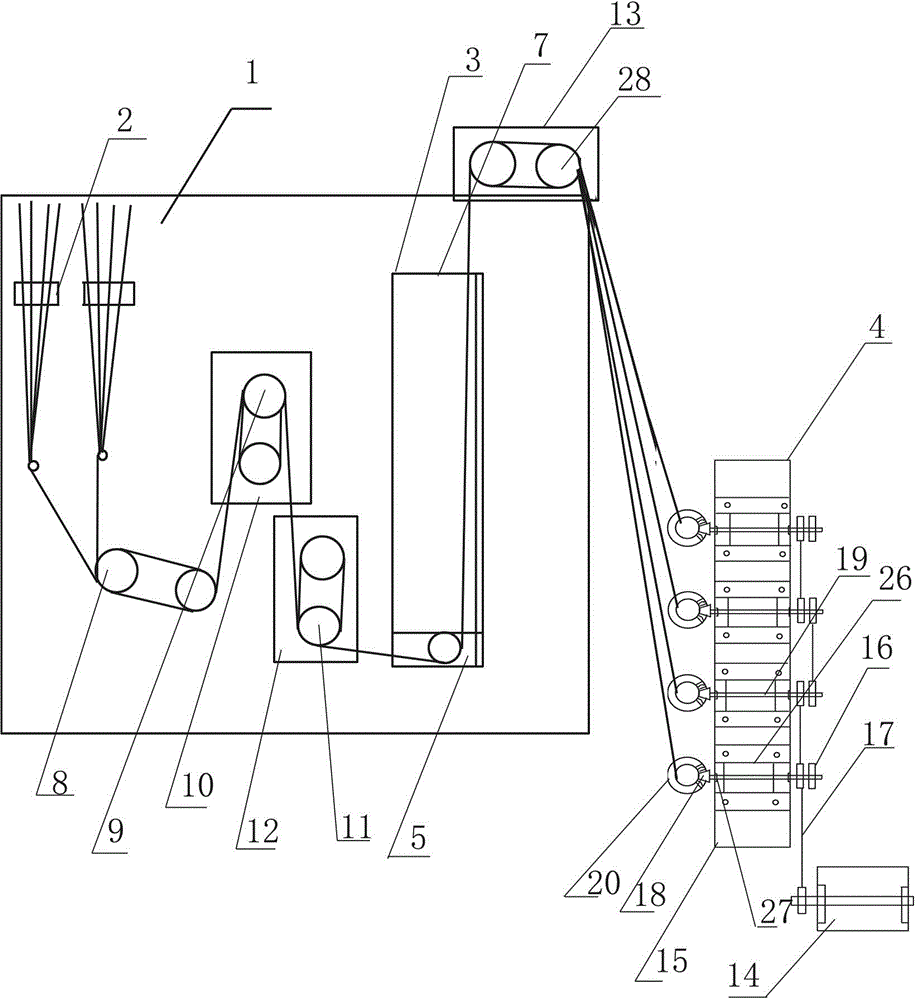

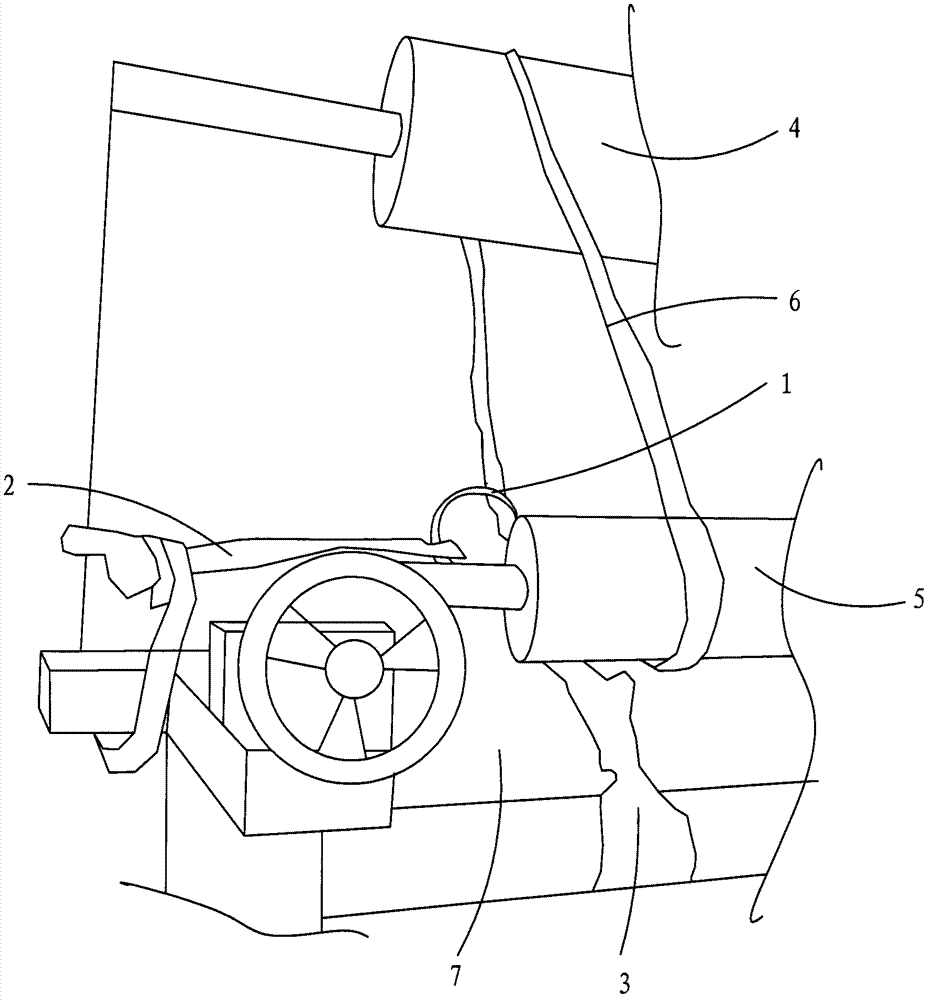

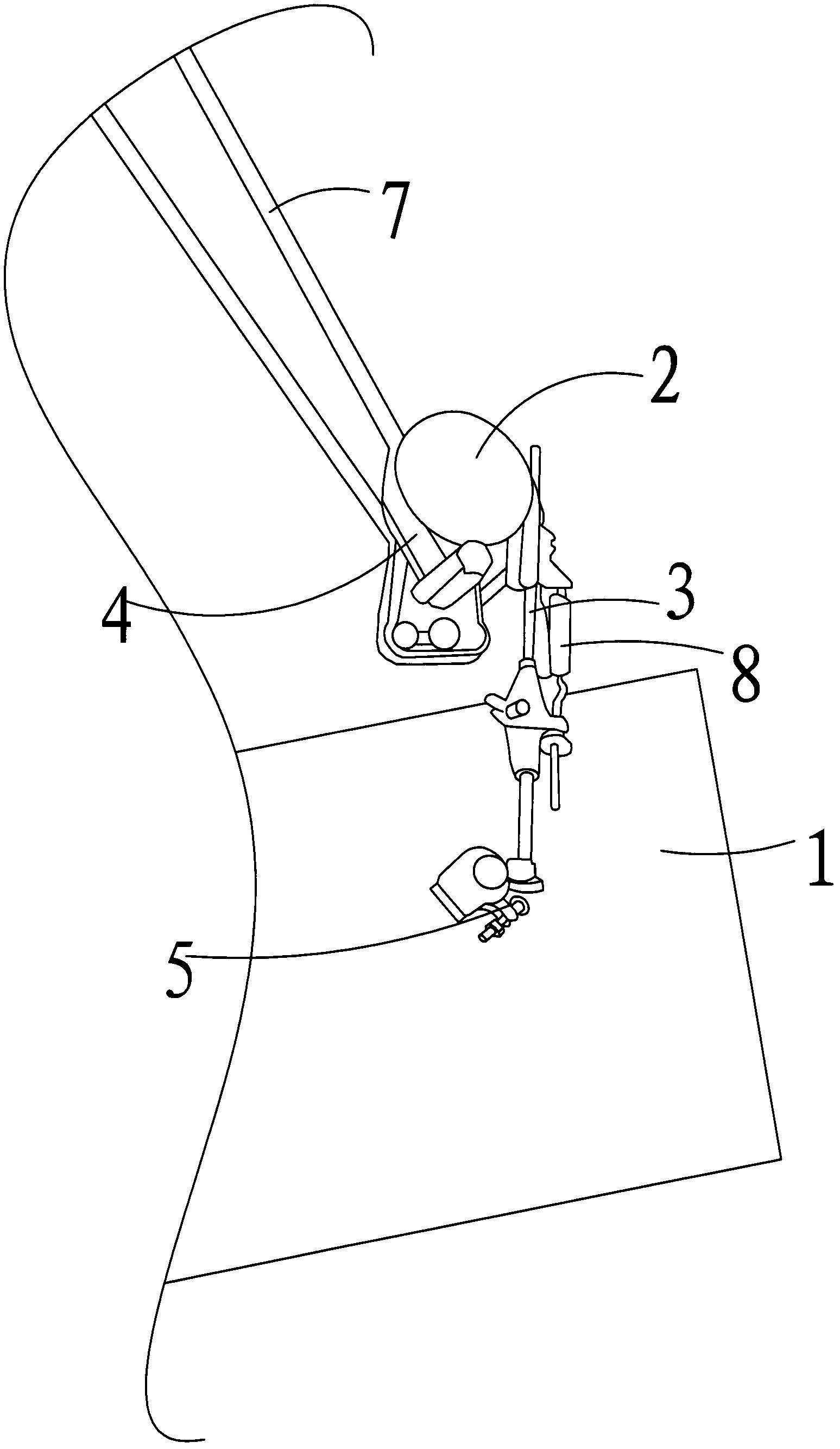

A stretching twisting machine

The invention discloses a drafting twisting machine. The drafting twisting machine comprises a supporting frame (1), wherein a plurality of thread inlet brackets (2) are arranged on one side of the surface of the supporting frame (1); a drafting roller assembly I, a drafting roller assembly II, a drafting roller assembly III and a heating tank (3) are arranged on the supporting frame (1); a drafting roller assembly IV is arranged at the top of the supporting frame (1); a twisting machine (4) is arranged on the other side of the supporting frame (1); threads enter from the thread inlet brackets (2), pass through the drafting roller assembly I, the drafting roller assembly II, the drafting roller assembly III, the heating tank (3) and the drafting roller assembly IV in sequence, and enter into the twisting machine (4).

Owner:泰州市常沪线网有限公司

Wicker toughening and strengthening method

InactiveCN107253252AImprove binding abilityInhibits moisture return and yellowingWood treatment detailsReed/straw treatmentChemistryCellulose

The invention belongs to the technical field of willow weaving, in particular to a method for toughening and strengthening wicker. The specific method is as follows: (1) making primary wicker; (2) making secondary wicker; (3) making three-time wicker; (4) ) Put the willow sticks into boiling water for three times and boil them over medium heat, drain them out, wash the mud, and microwave dry; the present invention uses steam treatment to effectively promote the penetration of acetic acid molecules into the inside of the willow sticks, and combine closely with the components of the willow sticks to effectively soften the willow sticks structure; then treated with potassium fulvic acid solution and frozen, not only to further enhance the binding ability between the wicker cellulose molecules, but also effectively inhibit the moisture and yellowing of the wicker, and enhance its ability to resist moisture and moisture; use mud treatment to freeze and bake , using the alternating cold and hot mud to effectively enhance the crack resistance, bending resistance and compression resistance of the wicker, and make the surface of the wicker more colorful, bright, smooth and shiny, effectively enhance its weaving performance and use performance, and prolong its service life.

Owner:阜南县金威工艺品有限公司

Drafting twisting machine

The invention discloses a drafting twisting machine. The drafting twisting machine comprises a supporting frame (1), wherein a plurality of thread inlet brackets (2) are arranged on one side of the surface of the supporting frame (1); a drafting roller assembly I, a drafting roller assembly II, a drafting roller assembly III and a heating tank (3) are arranged on the supporting frame (1); a drafting roller assembly IV is arranged at the top of the supporting frame (1); a twisting machine (4) is arranged on the other side of the supporting frame (1); threads enter from the thread inlet brackets (2), pass through the drafting roller assembly I, the drafting roller assembly II, the drafting roller assembly III, the heating tank (3) and the drafting roller assembly IV in sequence, and enter into the twisting machine (4).

Owner:泰州市常沪线网有限公司

Weaving process of blended fabric

The invention provides a weaving process of a blended fabric and belongs to the technical field of weaving of kapok-blended woven fabrics. The process is characterized by comprising the following steps that warp yarn and weft yarn are subjected to beam-warping respectively; the mass ratio of kapok fibers in kapok-blended spinning yarn is 10-70%; sizing is conducted, wherein the warp yarn and weft yarn obtained after beam-warping are soaked in a sizing agent respectively for sizing, and the sizing agent used for sizing includes 72-77 g / L of starch, 8.7-10.8 g / L of acrylic acid, 23-27 g / L of polyvinyl alcohol, 1.8-2.3 g / L of urea, 8-12 g / L of glycerol and water serving as a solvent; weaving is conducted, wherein the warp yarn and weft yarn obtained after beam-warping are woven to obtain the kapok-blended fabric. According to the weaving method of the kapok-blended woven fabrics, by providing the sizing agent with specific components, the problem that kapok-blended spinning yarn is easy to knot and break in the weaving process can be well solved.

Owner:如皋市明德包装有限公司

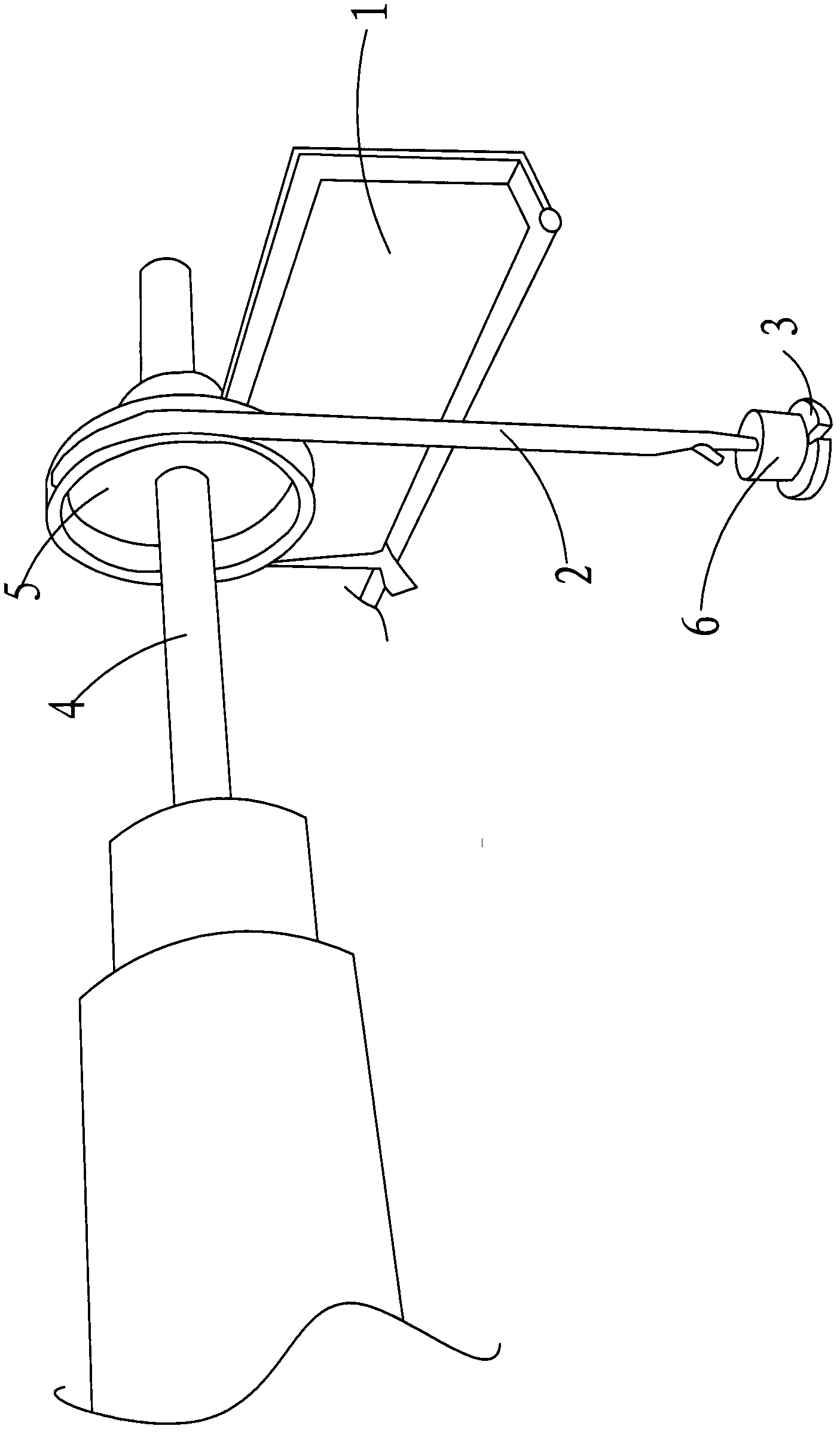

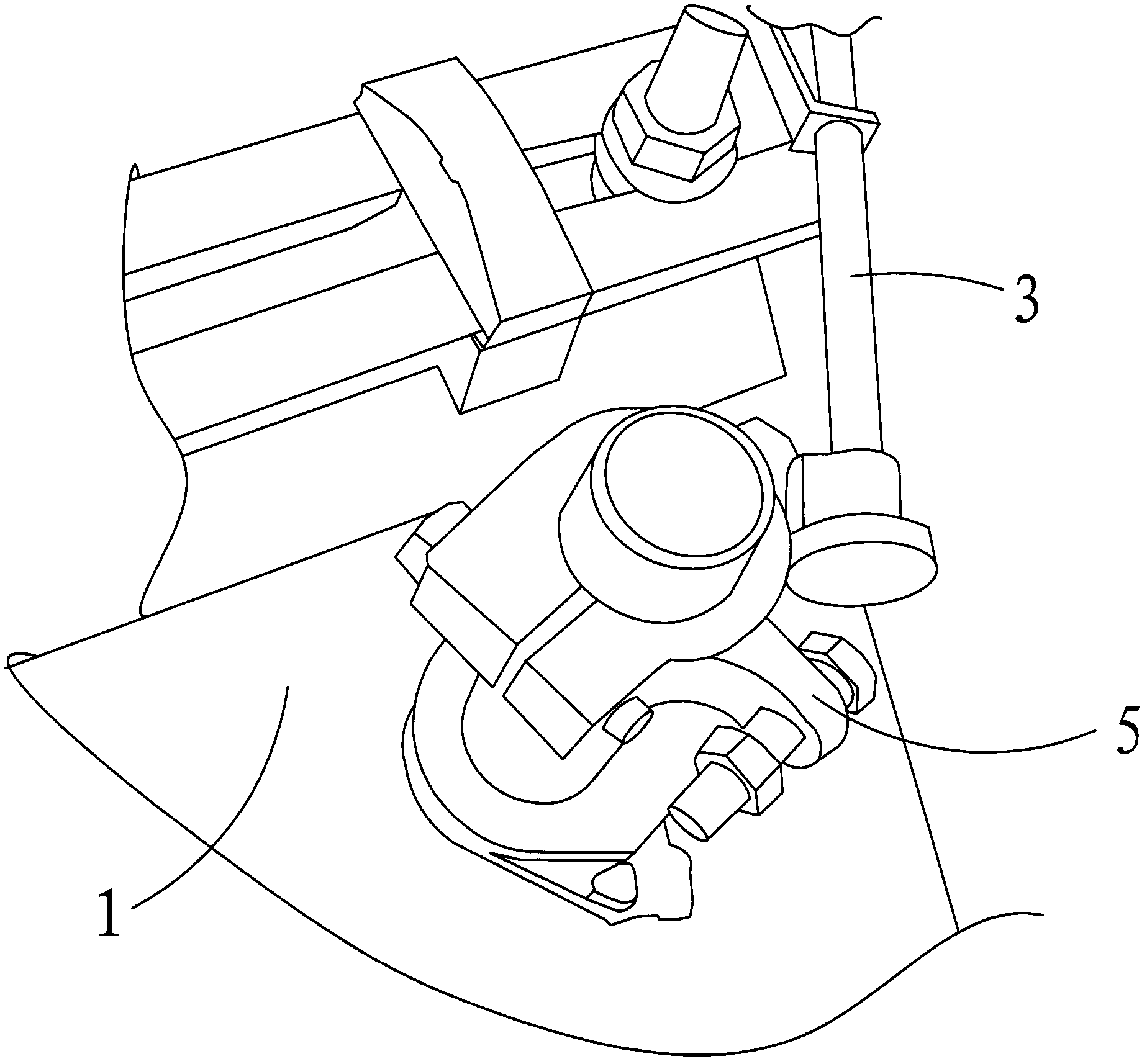

Tension adjusting mechanism of loom

The invention discloses a tension adjusting mechanism of a loom. The tension adjusting mechanism comprises an iron ring, a first pulling rope, a second pulling rope and a third pulling rope, wherein one end of the first pulling rope is connected with the iron ring; one end of the second pulling rope is connected with the iron ring; the third pulling rope is threaded through the iron ring and wound on an upper winding roller and a lower winding roller; the other end of the first pulling rope is fixedly connected with a rack; and the other end of the second pulling rope is fixedly connected with the rack. Through the tension adjusting mechanism, the weaving effect is better.

Owner:WUJIAN RUNFENG SILK FINISHING CO LTD

Controlled tension mechanism for looms

InactiveCN102943345AGood weaving effectImprove weaving effectWeft knittingWarp knittingYarnElectric machinery

Owner:SUZHOU HUALONG KNITTING TEXTILE

Tension control mechanism

A tension control mechanism comprises a traction band with one end fixedly connected with a machine frame and a connection frame fixedly connected with the other end of the traction band and used for weights to be placed on. The traction band winds around an installation shaft used for knitting lines to be wound on, and the installation shaft rotates relative to the machine frame. The tension control mechanism enables weaving effect to be good.

Owner:SUZHOU HUALONG KNITTING TEXTILE

Pressure relief device

Owner:SUZHOU HUALONG KNITTING TEXTILE

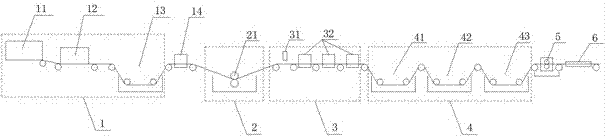

Automatic production line of uvioresistant tarpaulin roller

InactiveCN107217425AWith anti-ultraviolet effectReduce processing stepsSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersProduction lineUltraviolet

The invention relates to an automatic production line for an anti-ultraviolet tarpaulin idler, which belongs to the field of tarpaulin production; the technical problem to be solved is to provide an automatic production line for an anti-ultraviolet tarpaulin idler, which utilizes a rolling car added with an ultraviolet absorber to process common grey fabrics. Processing, so that the tarpaulin has the effect of anti-ultraviolet; the technical solution adopted to solve this technical problem is: the automatic production line of anti-ultraviolet tarpaulin idler, including the weaving area, dyeing area, baking area and cleaning area, and the weaving area is provided with The raw material moisture regaining machine, knitting machine, grey cloth washing machine and grey cloth drying machine. The grey cloth washing machine is connected with the grey cloth drying machine. A paddle car is arranged in the dyeing area. The baking area is provided with a pre-baking machine and a drying machine, the cleaning area is connected with a baking machine, and the baking machine is connected with a setting machine. Each area transmits the processing materials through the idler, and the controller controls the operation of the idler in each area. .

Owner:杨连桂

Tension adjusting mechanism

Owner:SUZHOU HUALONG KNITTING TEXTILE

A kind of processing technology of willow branches for willow weaving

InactiveCN104400857BImprove anti-corrosion performanceImprove weaving effectReed/straw treatmentAtmospheric pressureReagent

The invention relates to a processing technology of willow branch for willow artworks. The processing technology comprises the following steps: (1) putting fresh willow in a ventilation position for 5-7 days for airing; (2) performing heat treatment on willow, namely process willow at 75-90 DEG C for 30 min; (3) using steam to fumigate at 100-110 DEG C under 0.75-0.8 standard atmospheric pressure for 1-1.5 h; and (4) performing heat treatment on the above processed willow for 0.3-1 h by using circulated hot air with the temperature of 90-100 DEG C, and naturally cooling to normal temperature. The provided willow processing technology does not use reagents, improves the anticorrosion performance and stability of willows through heat treatment, improves the braiding performance of willow, enables the water content of willow to be substantially reduced, and shortens the willow processing time.

Owner:阜南县诚信工艺品有限公司

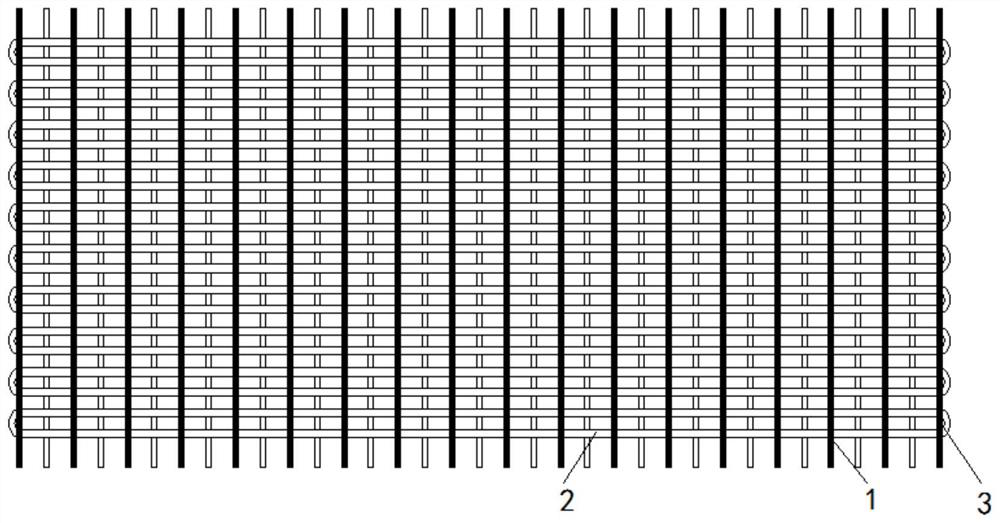

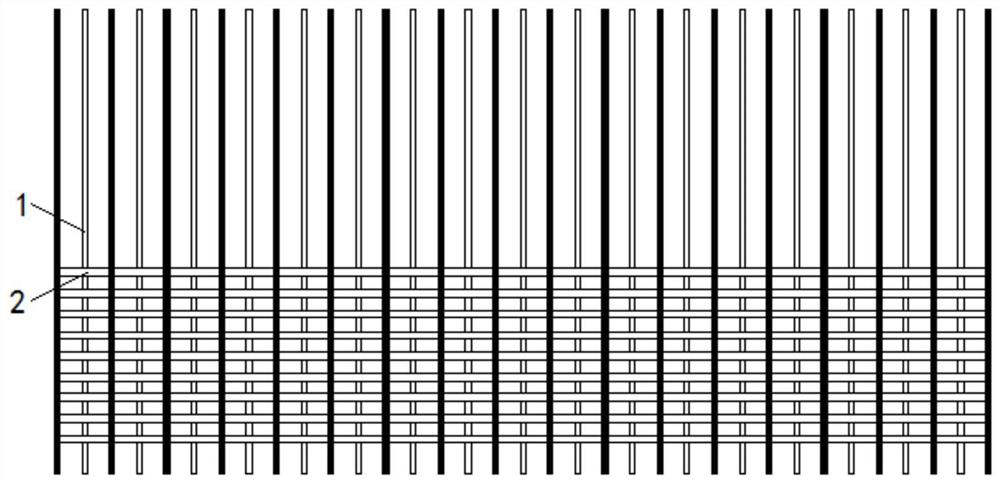

Composite lead wire shuttleless continuous weft woven grid

PendingCN113644278AReduce manufacturing costImprove consistencyElectrode carriers/collectorsGlass fiberManufacturing technology

The invention relates to a composite lead wire shuttleless continuous weft woven grid which comprises at least two warps. Wefts are fixedly connected to the front surfaces and the back surfaces of the warps, and hot melting wires are fixedly connected to the left ends and the right ends of the wefts. According to the composite lead wire shuttleless continuous weft woven grid, lead-coated glass fibers are made into composite lead wires by adopting a solid extrusion process, then the composite lead wires are woven by utilizing shuttleless spinning equipment, and when the wefts are quantitatively sent out, the wefts penetrate through the warp groups which are staggered up and down; and compared with an original horizontal battery grid manufacturing technology, the efficiency can be improved by more than five times, waste materials are basically not generated so that the production cost of the grid is greatly reduced, and meanwhile, due to the fact that continuous wefts are achieved on the positive grid, the phenomenon of grid corrosion acceleration caused by acid absorption of a single lead wire glass fiber inner core in the original horizontal battery lead net grid manufacturing process is avoided. Therefore, the horizontal battery consistency and the battery life can be greatly improved and prolonged.

Owner:江苏超威电源有限公司

Method for weaving kapok blended fabrics

InactiveCN106498736ACooperate wellImprove weaving effectGrip property fibresWoven fabricsPolyvinyl alcoholKapok fiber

The invention discloses a method for weaving kapok blended fabrics and belongs to the technical field of weaving of kapok blended fabrics. The method is characterized by comprising the following steps: respectively beaming warp yarns and weft yarns, wherein the mass of kapok fibers in kapok blended yarns account for 10-70%; slashing, namely respectively immersing the beamed warp yarns and weft yarns into a sizing agent for slashing, wherein the sizing agent used in slashing comprises 72-77g / L of starch, 8.7-10.8g / L of acrylic acid, 23-27g / L of polyvinyl alcohol, 1.8-2.3g / L of urea, 8-12g / L of glycerin and water serving as a solvent; and weaving, namely weaving the warp yarns and weft yarns subjected to slashing, thereby obtaining the kapok blended fabrics. According to the method for weaving kapok blended fabrics, disclosed by the invention, the sizing agent with specific components is given for slashing, so that the problems of knotting and breaking of the kapok blended yarns during weaving can be well solved.

Owner:ZIBO DARANFANG SILK GRP

Automatic filling and feeding device of braiding machine

The invention provides an automatic filling and feeding device of a braiding machine, belonging to the braiding machine. A groove is arranged at the middle part of a base of the feeding device and an adjusting plate is connected with one end of the groove on the base; the adjusting plate is connected with a metal guide pipe through a pipe connector; the upper end of the base is connected with a cover plate and a long-strip-shaped hole is arranged at the middle part of the cover plate; one end of the cover plate is connected with a spring bracket and the other end of the cover plate is connected with a limiting spring; a tension spring is connected with the spring bracket; an embedding block is arranged in the groove on the base and is connected with a storage bin through the embedding block; the upper end of the storage bin is provided with a tracking block and the groove at the other end of the base is internally connected with a guide block and a push plate; one end of the push plate is sequentially connected with a bearing and a push plate shaft; a cam block and a cam sheet are connected into a whole body; and a sensor is arranged on one side of the storage bin and is connected with an alarm to form a material blanking alarming device. The automatic filling and feeding device of the braiding machine has the advantages of feeding material for a long time, saving manpower and time and improving the yield, and is simple and stable in a transmission structure; and the automatic feeding time period is accurate, the interval pitch precision is high and the automatic filling and feeding device is easy to control.

Owner:韩百峰

Weaving paper spray flame retardant

InactiveCN108797203AHigh heat resistanceImprove cooling effectPaper coatingPaper/cardboardFiberPolyethylene glycol

The invention mainly relates to the technical field of weaving article processing, and discloses a weaving paper spray flame retardant which is prepared from silicone modified phenolic resin, modifiedhigh density polyethylene, sodium silicate, sodium selenite, magnesium hydroxide, nano-graphene fibers, phytic acid and polyethylene glycol. The weaving paper spray flame retardant is green, healthy,safe and environmentally friendly, the heat resistance of paper can be increased, heat dissipation of the paper is accelerated, the carbonization time of the paper is prolonged, paper water absorption and toxic gas generation are avoided, the structures of the paper and a woven product are kept complete, and loss generated by combustion is avoided. The silicone modified phenolic resin is rapidlyheated and molten, slow heating and stirring are continued after the magnesium hydroxide is added, melt polymerization of the silicone modified phenolic resin and the magnesium hydroxide is promoted,the flexibility and flame resistance of the silicone modified phenolic resin are improved, excessive paper hardness caused by the flame retardant is avoided, and folding and weaving performances of the paper are kept.

Owner:阜南县猛发工艺品有限公司

Plectocomia kerrana toughening and fire retardant treatment method

InactiveCN108748557AGood fire performanceReduce flammabilityMagnetic wood treatmentWood treatment detailsWater contentFreezing chamber

The invention belongs to the technical field of artware, and particularly relates to a plectocomia kerrana toughening and fire retardant treatment method. The plectocomia kerrana toughening and fire retardant treatment method comprises the specific steps that (1) harvested plectocomia kerrana is subjected to leaf removing treatment to be placed into a freezing chamber for freezing treatment, the plectocomia kerrana is taken out to be immersed into a sodium lactate aqueous solution for heat preservation and soaking, filter liquor is taken out, and drying is carried out until the water content is 7%-9%; and (2) the plectocomia kerrana is immersed into a treating agent to be soaked, a filtering agent is taken out, magnetization treatment is carried out, and drying is carried out until the water content is 7%-9%. The treating agent is prepared from the following raw materials including sodium benzoate, phenolic resin, polyethylene glycol, green bean starch, calcium sulfate, cupric fluoborate, magnesium chloride and water. The fire resistance and the hydrophobicity of the plectocomia kerrana are effectively improved, the extremely good fireproof performance is achieved, the network structure of the plectocomia kerrana is strengthened, the tenacity is greatly improved, the weaving performance is greatly improved, and the breakage and cracking phenomena generated in the weaving and using process are reduced.

Owner:阜南县海源工艺品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com