Automatic filling and feeding device of braiding machine

A feeding device and automatic filling technology, which is applied in the direction of braided fabrics, textiles and papermaking, etc., can solve the problems of inaccurate filling interval pitch, inconsistent feeding and filling directions, etc., and achieve manpower saving, accurate automatic feeding time cycle, and time saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

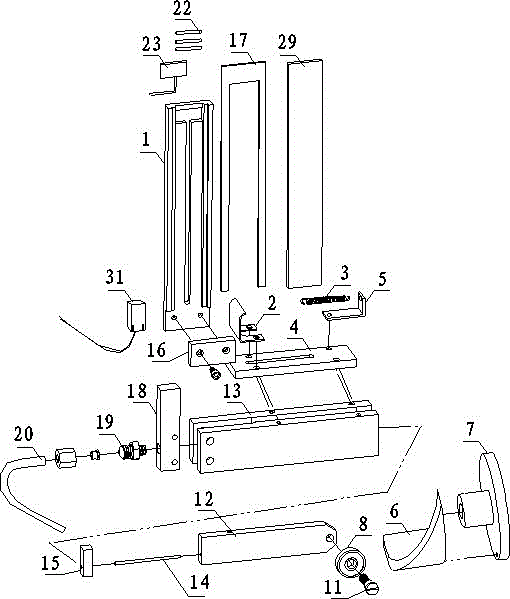

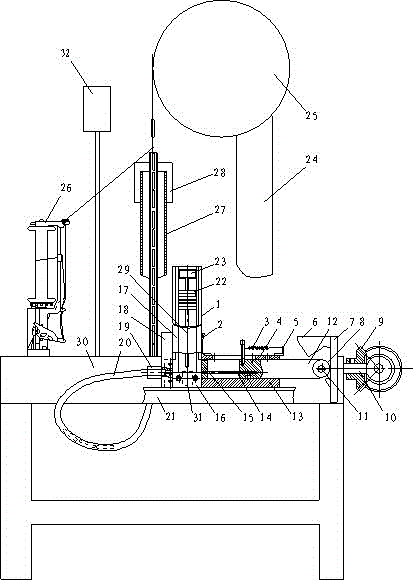

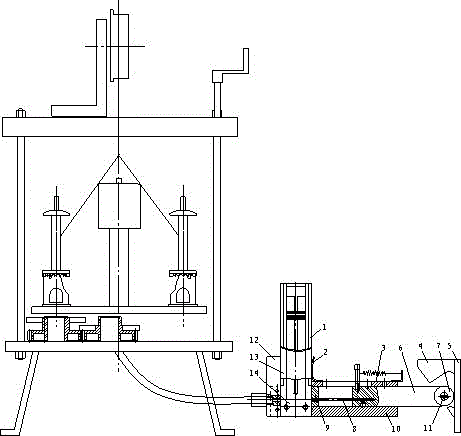

[0022] Embodiment 1: The feeding device includes: feed bin 1, limit spring 2, extension spring 3, cover plate 4, spring support 5, cam block 6, cam piece 7, bearing 8, first bevel tooth 9, second bevel Teeth 10, push plate shaft 11, push plate 12, base 13, thimble 14, guide block 15, insert block 16, bin cover 17, adjustment plate 18, pipe joint 19, metal conduit 20, base plate 21, material 22, tracking Block 23, pillar 24, traction wheel 25, spindle 26, threading pipe 27, wire pipe seat 28, transparent cover 29, lower plate 30, inductor 31 and alarm 32.

[0023] There is a groove in the middle of the base 13, an adjustment plate 18 is connected to one end of the groove of the base 13, and a metal conduit is connected to the adjustment plate 18 through a pipe joint 19; a cover plate 4 is connected to the upper end of the base 13, and in the middle of the cover plate 4 There is a strip hole in the position, a spring support 5 is connected to one end of the cover plate 4, a limi...

Embodiment 2

[0029] Embodiment 2: The cam body is a grooved cam, and the grooved cam has a cylinder with a groove on the cylinder. Others are the same as in Example 1.

Embodiment 3

[0030] Embodiment 3: the cam body is a disc cam, and the disc cam has an eccentric wheel, and a cylinder is located at the center of the eccentric wheel. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com